Gree KF-20x2GW/NA12, KFR-20x2GW/A12, KF-25x2GW/NA12, KF-32x2GW/NA12, KFR-25x2GW/A12 User Manual

...

Summary and features

25

1

Bird Dual-Split Type

Models Remarks

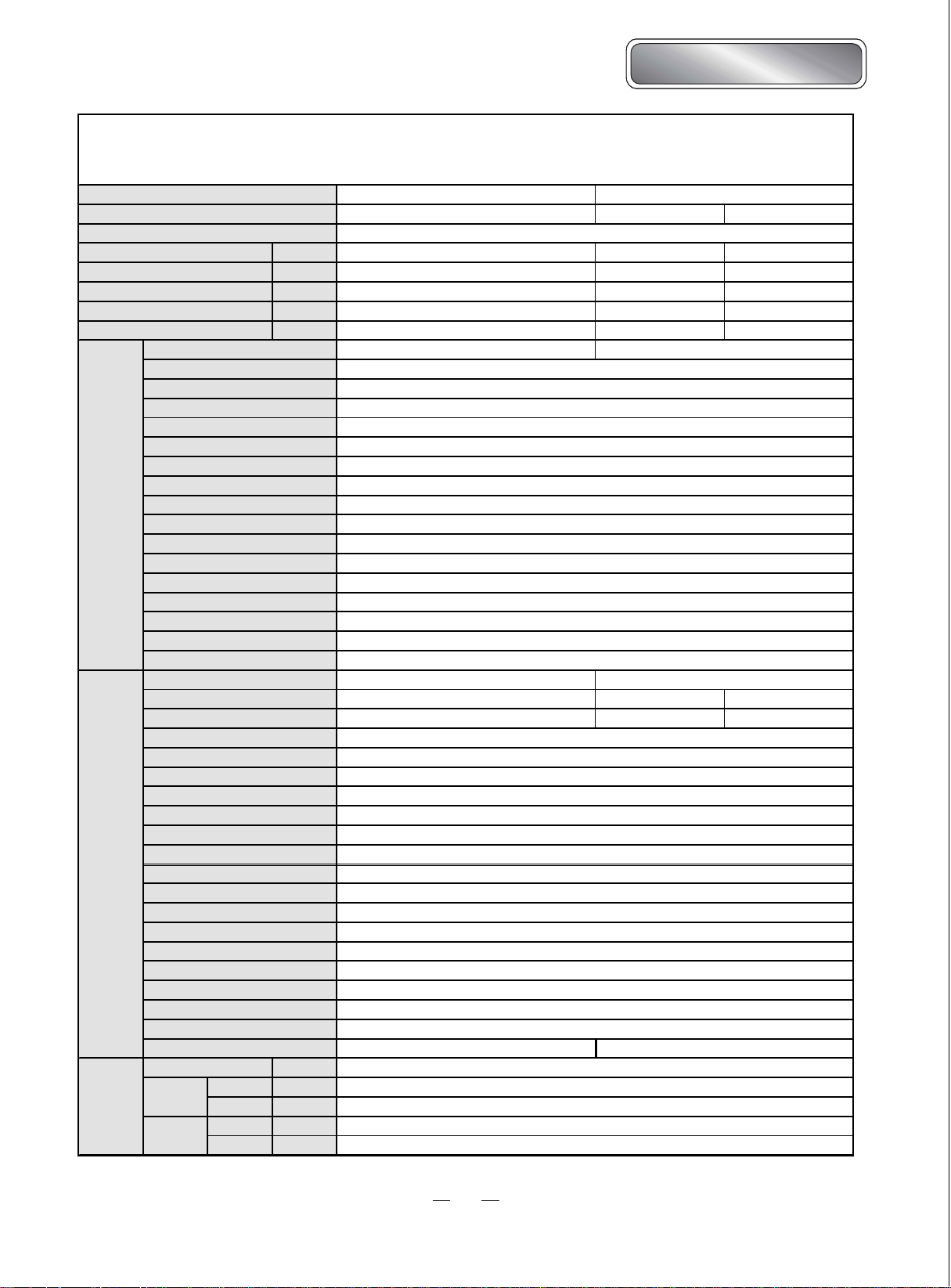

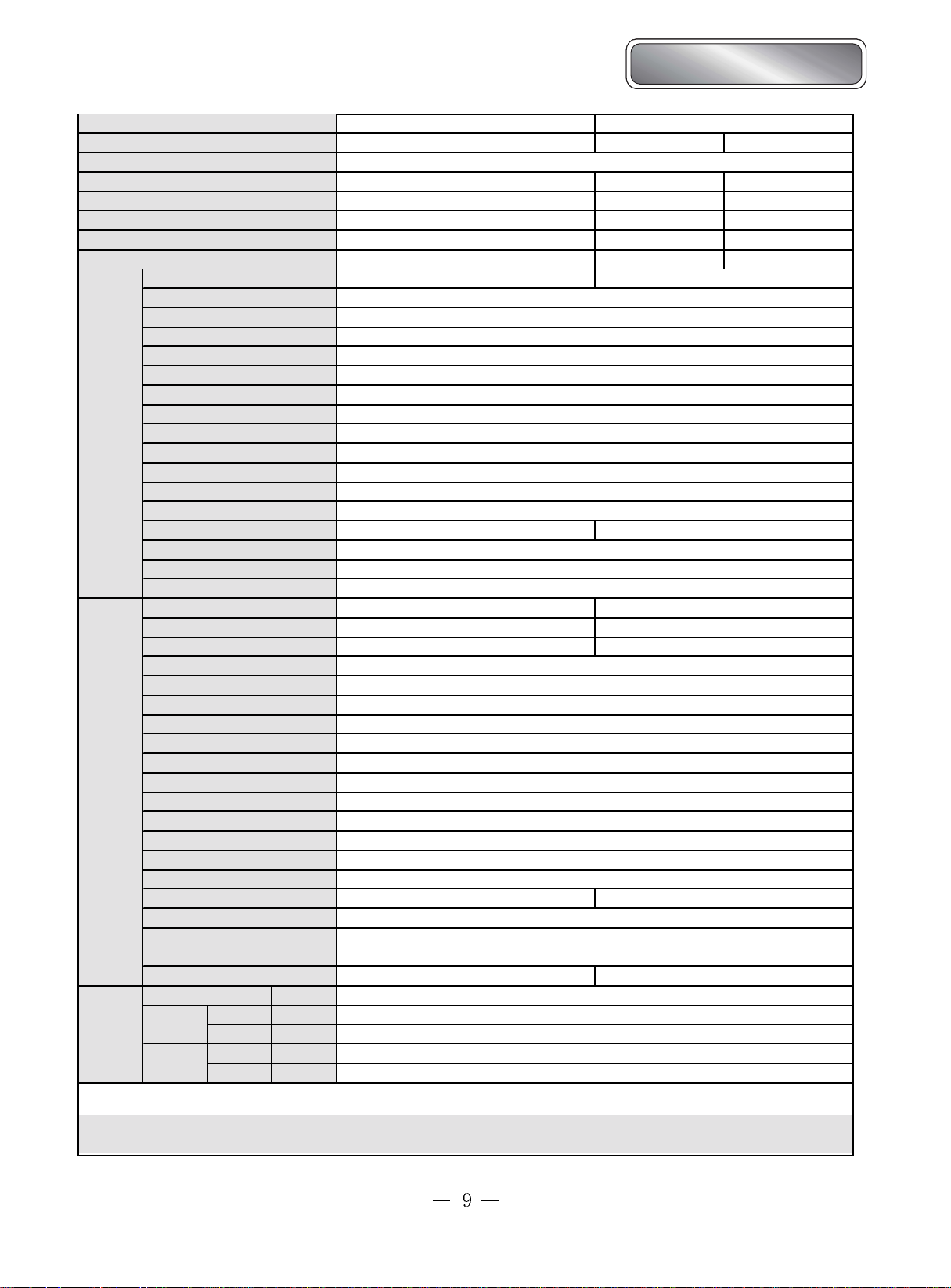

Technical and specifications

2

Model

KF-20×2GW/A12 KFR-20×2GW/A12

Function Cooling

Power supply(Phase-Frequency-Voltage)

Capaicty

Rated power

R ated current

Dehumidify volume

C.O.P/EER

Model

Fan speed

(r/min)(H/M/L)

Output power

F an type-piece C ross flow fan

Diameter-length(mm)

Evaporator

Pipe diameter

Indoor unit

Row- fin distance(mm)

Working area (m2)

Stepping motor

Motor power (W)

Control method/Fuse(A)

Running capacity

Noise

Outline dimension

Package dimension

Net weight/Gross weight(kg)

Model

Rated power

dB(A)

(W)

Rated current

(W)

(W)

(A)

(L/h)

(W/W)

) 8

(W

(μF)

(W/D/H)(mm)

(W/D/H)(mm)

(A)

Throttling method

Outdoor unit

Compressor type

Starting method

Working temperature

Condensor

Pipe diameter

Row- fin distance(mm)

Working area (m2)

(℃)

Fan motor power (W)/ speed (rpm)

Fan type-piece

Fan blade diameter

(mm)

Defrost method

Noise

Outline dimension

Package dimension

Net weight/Gross weight(kg)

dB(A)

(W/D/H)(mm)

(W/D/H)(mm)

Refrigerant/refrigerant charge(kg)

Connection

pipe

Length

Outer

diameter

Max.

distance

Liquid pipe

Gas pipe

Height

Length

(m)

(mm)

(mm)

(m)

(m)

1Ph 230V 50Hz

2000×2

770×2

3.4×2

0.7

2.6

KF-20×2G/A12 KFR-20×2G/A12

KF-20×2W/A12 KFR-20×2W/A12

R22/0.65×2 R22/0.9×2

2000×2 2300×2

770×2 750×2

3.4×2 3.33×2

0.76 -

2.8 3.07

960/900/850

1

—

97×585

φ

Aluminum fin-copper tube

7×0.41

φ

2-1.6

0.14

MP24GA

2

Controller 3.15A Transformer 0.2A

1

36

770×250×180

855×366×272

8.5/-

760

3.2

760 740

3.2 2.87

Capillary

-

Capacity

2-43

Aluminum fin-copper tube

9.52

φ

1-1.8

0.4

25/780

1

Axial flow fan

—

450

Auto defrost

57

950×710×412

-

65/-

4

6(1/4")

φ

9.52(3/8")

φ

5

10

HeatingCooling

℃

Bird Dual-Split Type

Bird Dual-Split type

Model

Function

Power supply(Phase-Frequency-Voltage)

Capaicty

Rated power

R ated current

Dehumidify volume

C.O.P/EER

Model

Fan speed

O utput power

Fan type-piece

Diameter-length(mm)

Evaporator

I ndoor unit

Outdoor unit

Connection

pipe

Pipe diameter

Row- fin distance(mm)

Working area (m2)

Stepping motor

Motor power (W)

Control method/Fuse(A)

Running capacity

Noise

dB(A)

Outline dimension

Package dimension

Net weight/Gross weight(kg)

Model

Rated power

Rated current

Throttling method

Compressor type

Starting method

Working temperature

Condensor

Pipe diameter

Row- fin distance(mm)

Working area (m2)

Fan motor power (W)/ speed (rpm)

Fan type-piece

Fan blade diameter

Defrost method

Noise

dB(A)

Outline dimension

Package dimension

Net weight/Gross weight(kg)

Refrigerant/refrigerant charge(kg)

Length

Outer

diameter

Max.

distance

Liquid pipe

Gas pipe

Height

Le ngth

(W)

(W)

(A)

(L/h)

(W/W)

(r/min)(H/M/L)

(W)

(μF)

(W/D/H)(mm)

(W/D/H)(mm)

(W)

(A)

(℃)

(mm)

(W/D/H)(mm)

(W/D/H)(mm)

(m)

(mm)

(mm)

(m)

(m)

KF-25×2GW/A12 KFR-25×2GW/A12

Heating

1060/990/910

97×583

2-1.6

0.14

2

38

≤

770×250×180

8.5/-

Cooling

2500×2 2900×2

990×2 1040×2

4.3×2 4.55×2

1.2 -

2.53 2.79

13

1

—

1

-

975 1025

4.15 4.35

Cooling

1Ph 230V 50Hz

2500×2

790×2

4.3×2

1.2

2.53

KF-20×2G/A12 KFR-20×2G/A12

Cross flow fan

φ

Aluminum fin-copper tube

7×0.41

φ

MP24GA

Controller 3.15A Transformer 0.2A

KF-20×2W/A12 KFR-20×2W/A12

975

4.165

Capillary

855×366×272

Capacity

2-43

℃

Aluminum fin-copper tube

9.52

φ

1-2.0 1-1.6

0.4

38/700 60/780

Axial flow fan

—

1

450

Auto defrost

58

920×710×412

-

65/-

R22/0.8×2 R22/0.9×2

4

6(1/4")

φ

9.52(3/8")

φ

5

10

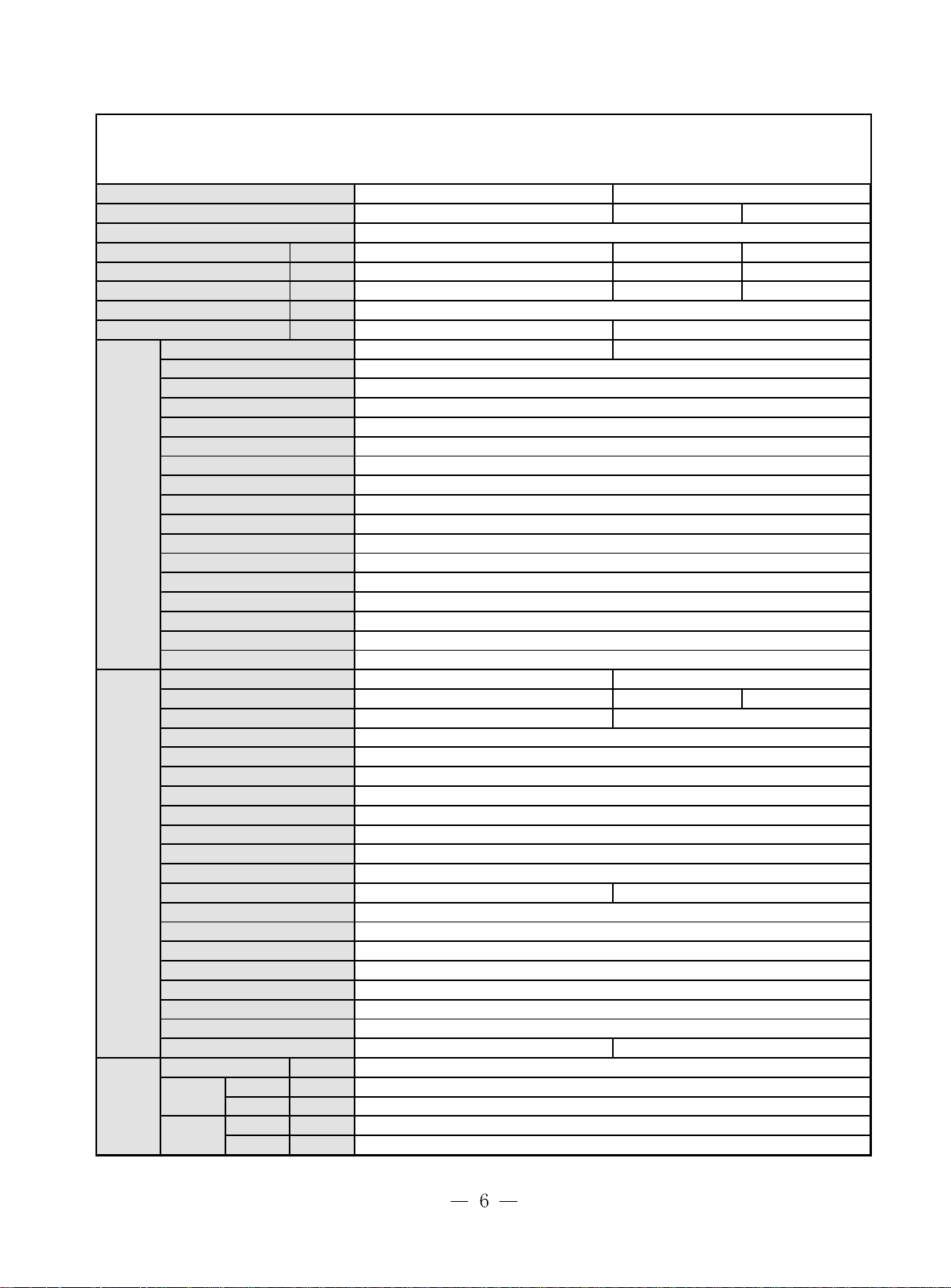

Model

Function

Power supply(Phase-Frequency-Voltage)

Capaicty

Rated power

R ated current

Dehumidify volume

C.O.P/EER

Model

Fan speed

O utput power

Fan type-piece

Diameter-length(mm)

Evaporator

I ndoor unit

Outdoor unit

Connection

pipe

Pipe diameter

Row- fin distance(mm)

Working area (m2)

Stepping motor

Motor power (W)

Control method/Fuse(A)

Running capacity

Noise

dB(A)

Outline dimension

Package dimension

Net weight/Gross weight(kg)

Model

Rated power

Rated current

Throttling method

Compressor type

Starting method

Working temperature

Condensor

Pipe diameter

Row- fin distance(mm)

Working area (m2)

Fan motor power (W)/ speed (rpm)

Fan type-piece

Fan blade diameter

Defrost method

Noise

dB(A)

Outline dimension

Package dimension

Net weight/Gross weight(kg)

Refrigerant/refrigerant charge(kg)

Length

Outer

diameter

Max.

distance

Liquid pipe

Gas pipe

Height

Le ngth

(W)

(W)

(A)

(L/h)

(W/W)

(r/min)(H/M/L)

(W)

(μF)

(W/D/H)(mm)

(W/D/H)(mm)

(W)

(A)

(℃)

(mm)

(W/D/H)(mm)

(W/D/H)(mm)

(m)

(mm)

(mm)

(m)

(m)

KF-32×2GW/A12 KFR-32×2GW/A12

Cooling

3200

×2

1360x2

1Ph 230V 50Hz

Cooling Heating

3200x2

1339x2

6.27x2 8.2x2 7.3x2

1.2

1.2 -

2.35 2.31

KF-32×2G/A12 KFR-32×2G/A12

1190/1090/990

14

Cross flow fan

97×583

φ

Aluminum fin-copper tube

7×0.41

φ

0.14

MP24GA

Transformer 0.2A

Controller 3.15A

KF-20×2W/A12 KFR-20×2W/A12

1344

6.07 8

≤

1

—

2-1.6

2

1

42

770×250×180

855x366x272

8.5/-

1323

Capillary

-

Capacity

≤T15℃

Aluminum fin-copper tube

9.52

φ

2-1.8

0.4

60/780

Axial flow fan

—

1

450

Auto defrost

60

840×412

950×

-

72/-

1.2×2 R22/1.25×2

R22/

4

6(1/4")

φ

12(1/2")

φ

5

10

3600x2

1426x2

2.76

1410

7.1

4

Bird Dual-Split Type

Bird Dual-Split type

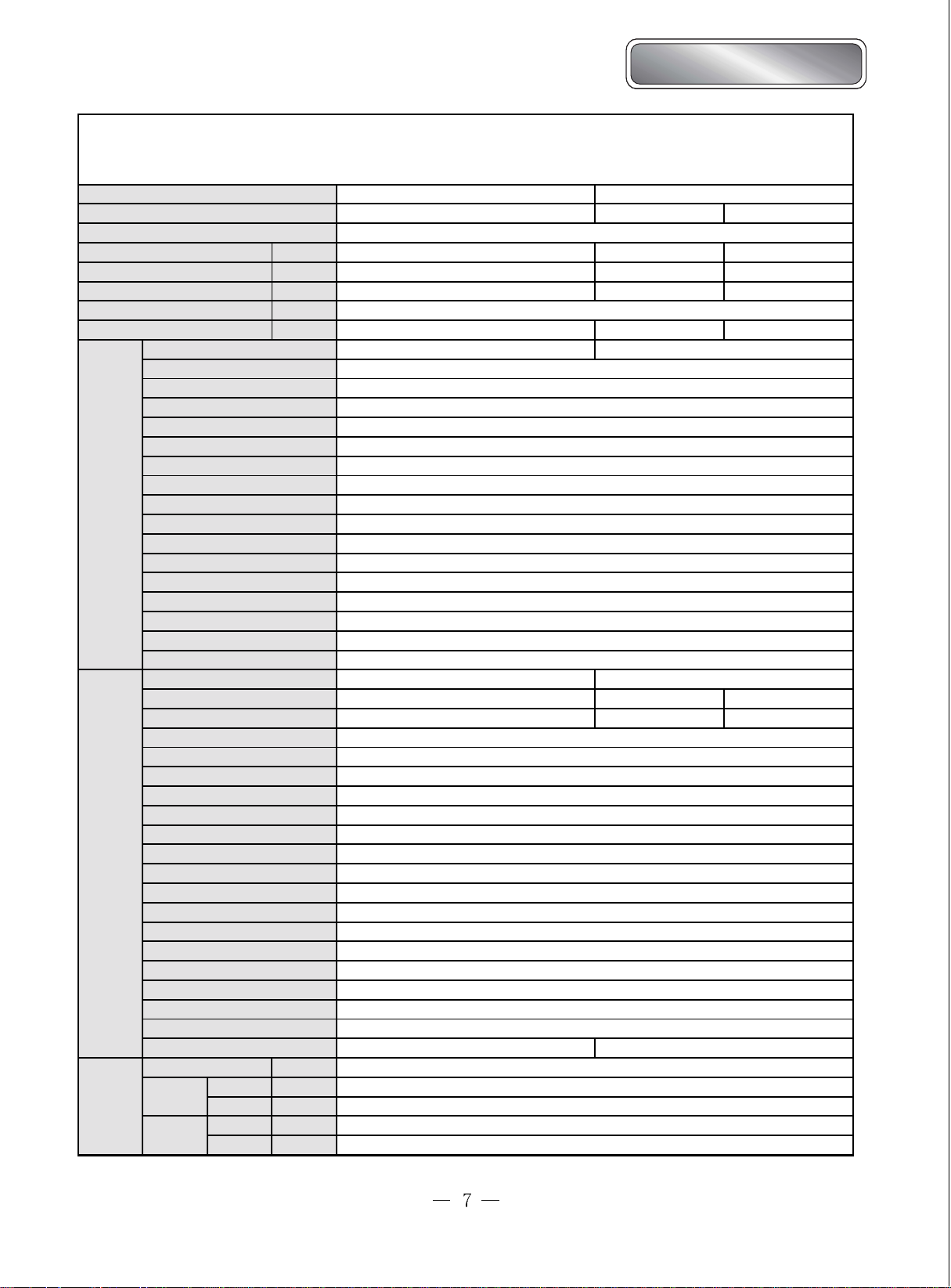

Model

Function

Power supply(Phase-Frequency-Voltage)

Capaicty

Rated power

R ated current

Dehumidify volume

C.O.P/EER

Model

Fan speed

O utput power

Fan type-piece

Diameter-length(mm)

Evaporator

I ndoor unit

Pipe diameter

Row- fin distance(mm)

Working area (m2)

Stepping motor

Motor power (W)

Control method/Fuse(A)

Running capacity

Noise

dB(A)

Outline dimension

Package dimension

Net weight/Gross weight(kg)

Model

Rated power

Rated current

(W)

(W)

(A)

(L/h)

(W/W)

(r/min)(H/M/L)

(W)

(μF)

(W/D/H)(mm)

(W/D/H)(mm)

(W)

(A)

KF-20×2GW/NA12 KFR-20×2GW/NA12

Cooling

KF-

KF-20×2W/NA12 KFR-20×2W/NA12

Throttling method

Outdoor unit

Compressor type

Starting method

Working temperature

Condensor

Pipe diameter

Row- fin distance(mm)

Working area (m2)

(℃)

Fan motor power (W)/ speed (rpm)

Fan type-piece

Fan blade diameter

(mm)

Defrost method

Noise

dB(A)

Connection

pipe

Outline dimension

Package dimension

Net weight/Gross weight(kg)

Refrigerant/refrigerant charge(kg)

Outer

Max.

distance

Length

Liquid pipe

Gas pipe

Height

Le ngth

diameter

(W/D/H)(mm)

(W/D/H)(mm)

(m)

(mm)

(mm)

(m)

(m)

R407C/0.7×2 R407C/0.82×2

1Ph 220V-230V 50Hz

2000x2

850x2

3.7x2

0.7

2.5

20×2G/NA12 KFR-20×2G/NA12

1060/900/910

Cross flow fan

φ

Aluminum fin-copper tube

7×0.41

φ

MP24GA

Controller 3.15A

810

3.53 3.53

Transformer 0.2A

Cooling Heating

2000x2 2400x2

850x2 920x2

3.7x2

0.7 0.7

2.8

13

1

—

97×583

2-1.6

0.14

1.5

1

38

770×250×180

855x366x272

8.5/-

810

4.0x2

860

3.41

Capillary

-

Capacity

2-43

℃

Aluminum fin-copper tube

9.52

φ

1-1.8

0.4

80/790

450

—

1

Axial flow fan

Auto defrost

58

710×412

950×

-

65/-

4

6(1/4")

φ

9.52(3/8")

φ

5

10

2.8

5

Model

Function

Power supply(Phase-Frequency-Voltage)

Capaicty

Rated power

Rated current

Dehumidify volume

C.O.P/EER

Model

Fan speed

(r/min)(H/M/L)

(W)

(W)

(A)

(L/h)

(W/W)

KF-25×2GW/NA12 KFR-25×2GW/NA12

Cooling

1Ph 230V 50Hz

2500×2

1100×2

4.78×2

2.5 2.8

KF-25×2G/NA12 KFR-25×2G/NA12

Output power(W)

Fan type-piece

Diameter-length(mm)

Evaporator Aluminum fin-copper tube

Pipe diameter

Indoor unit

Outdoor unit

Connection

pipe

Row- fin distance(mm)

Working area (m2)

Stepping motor

Motor power (W)

Control method/Fuse(A)

Running capacity

Noise

dB(A)

Outline dimension

Package dimension

Net weight/Gross weight(kg)

Model

Rated power

Rated current

Throttling method Capillary

Compressor type

Starting method Capacity

Working temperature

Condensor Aluminum fin-copper tube

Pipe diameter

Row- fin distance(mm)

Working area (m2)

Fan motor power (W)/ speed (rpm)

Fan type-piece Axial flow fan

Fan blade diameter

Defrost method Auto defrost

Noise

dB(A)

Outline dimension

Package dimension

Net weight/Gross weight(kg)

Refrigerant/refrigerant charge(kg)

Length

Outer

diameter

Max

distance

(μF)

(W/D/H)(mm)

(W/D/H)(mm)

(W)

(A)

(℃)

(mm)

(W/D/H)(mm)

(W/D/H)(mm)

(m)

Liquid pipe

Gas pipe

Height

Length

(mm)

(mm)

(m)

(m)

KF-25×2W/NA12 KFR-25×2W/NA12

R407C/0.85×2 R407C/0.92×2

Controller 3.15A Transformer 0.2A

38/700 60/780

Cross flow fan

1030

4.2

1.2

1060/900/910

13

97×583

φ

7×0.41

φ

2-1.6

0.14

MP24GA

2

38

770×250×180

855×360×272

8.5/-

-

9.52

φ

1-1.8

0.4

—

58

65/-

4

6(1/4")

φ

9.52(3/8")

φ

5

10

Cooling

2500×2 2900×2

1080×2 1100×2

4.70×2 4.78×2

1

—

1

1030 1020

4.4

2-43

℃

1

400

950×710×412

-

Heating

Bird Dual-Split Type

Bird Dual-Split type

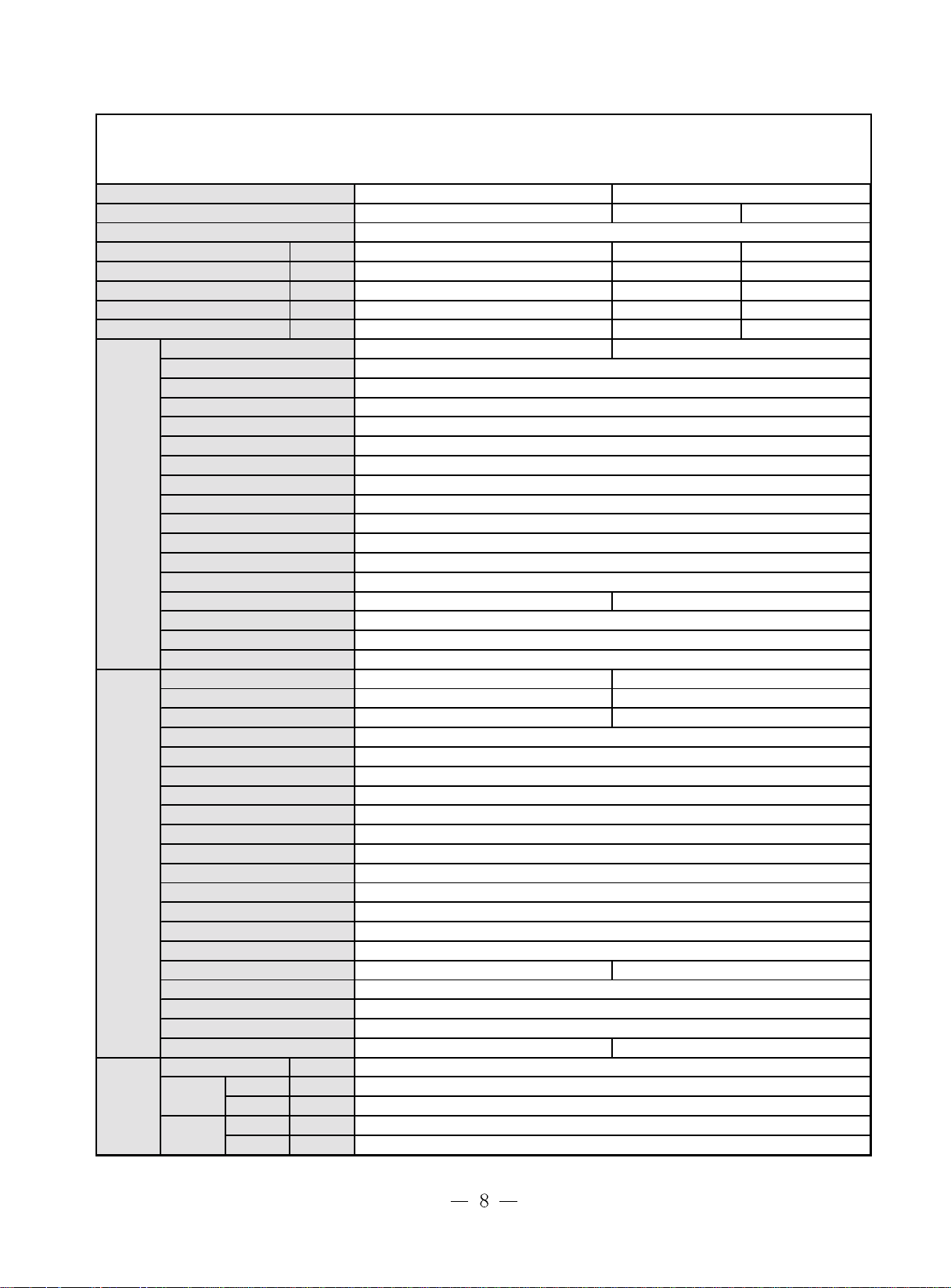

Model

Function

KF-32×2GW/NA12 KFR-32×2GW/NA12

Cooling Heating

Power supply(Phase-Frequency-Voltage)

Capaicty

Rated power

Rated current

Dehumidify volume

C.O.P/EER

(W)

(W)

(A)

(L/h)

(W/W)

Model

Fan speed

Output power

(r/min)(H/M/L)

(W)

3200×2

1390×2

13.5

2.3

KF-32×2G/NA12 KFR-32×2G/NA12

Fan type-piece Cross flow fan

Diameter-length(mm)

Evaporator

Pipe diameter

Indoor unit

Row- fin distance(mm)

Working area (m2)

Stepping motor

Motor power (W)

Control method/Fuse(A)

Running capacity

Noise

Outline dimension

Package dimension

(μF)

dB(A)

(W/D/H)(mm)

(W/D/H)(mm)

Net weight/Gross weight(kg)

Model

Rated power

Rated current

(W)

(A)

KF-32×2W/NA12 KFR-32×2W/NA12

1440

6

Throttling method

Outdoor unit

Connection

pipe

Compressor type

Starting method

Working temperature

Condensor

Pipe diameter

Row- fin distance(mm)

Working area (m2)

Fan motor power (W)/ speed (rpm)

Fan type-piece Axial flow fan

Fan blade diameter

Defrost method

Noise

Outline dimension

Package dimension

Net weight/Gross weight(kg)

Refrigerant/refrigerant charge(kg)

Length

Outer

diameter

Max.

distance

(℃)

(mm)

dB(A)

(W/D/H)(mm)

(W/D/H)(mm)

Liquid pipe

Gas pipe

Height

Length

(m)

(mm)

(mm)

(m)

(m)

R407C/1.20×2 R407C/1.25×2

Cooling

1Ph 230V 50Hz

3200×2 3800×2

1390×2 1490×2

13.5 14

/

2.3

1190/1090/990

8W

1

—

97×583

φ

Aluminum fin-copper tube

0.7×0.41

φ

2-1.4

/

MP24GA

2

—/3.15A

1

40

770×250×180

855×362×272

8.5/-

1280 1420

5.8 6.3

Capillary

-

Capacity

2-43

Aluminum fin-copper tube

9.52

φ

1-1.6

0.4

60/780

1

—

400

Auto defrost

62

950×710×412

-

70/-

4

6(1/4")

φ

12(1/2")

φ

5

10

2.55

℃

-

Model

Function

Power supply(Phase-Frequency-Voltage)

Capaicty

Rated power

Rated current

Dehumidify volume

C.O.P/EER

Indoor unit

Outdoor unit

Model

Fan speed

Output power(W)

Fan type-piece

Diameter-length(mm)

Evaporator

Pipe diameter

Row- fin distance(mm)

Working area (m2)

Stepping motor

Motor power (W)

Control method/Fuse(A)

Running capacity

Noise

Outline dimension

Package dimension

Net weight/Gross weight(kg)

Model

Rated power

Rated current

Throttling method

Compressor type

Starting method

Working temperature

Condensor

Pipe diameter

Row- fin distance(mm)

Working area (m2)

Fan motor power (W)/ speed (rpm)

Fan type-piece Axial flow fan

Fan blade diameter

Defrost method

Noise

Outline dimension

Package dimension

Net weight/Gross weight(kg)

Refrigerant/refrigerant charge(kg)

Length

Connection

pipe

Outer

diameter

Max. distance

(W)

(W)

(A)

(L/h)

(W/W)

(r/min)(H/M/L)

(μF)

dB(A)≤

(W/D/H)(mm)

(W/D/H)(mm)

(W)

(A)

(℃)

(mm)

(mm)

dB(A)

(W/D/H)(mm)

(W/D/H)(mm)

(m)

Liquid pipe

Gas pipe

Height

Length

(mm)

mm)

(m)

(m)

GSW(9×2)-22L/A GSW(9×2)-22R/A

Cooling HeatingCooling

1Ph 220V 50Hz

2500×2

870×2

4.03×2

1.2

2.78

GSW(9×2)-22L/A GSW(9×2)-22R/A

1050/960/900

20

Cross flow fan

97×583

φ

Aluminum fin-copper tube

7×0.41

φ

2-1.6

MP24GA

Controller 3.15A Transformer 0.2A

36 ≤37

8.5/-

GSW(9×2)-22L/A GSW(9×2)-22R/A

908 919

4.17 4.18

Capillary

Capacity

Aluminum fin-copper tube

9.52

φ

60/780

Auto defrost

56 58

65/-

R22/0.85×2 R22/0.95×2

6(1/4")

φ

9.52(3/8")

φ

10

2500×2 2900×2

970×2 1050×2

4.2×2 4.3×2

1.2

2.9 3.3

1

—

0.14

2

1

770×250×180

855×362×272

-

2-43

℃

2-1.8

0.4

1

—

450

950×710×412

-

4

5

-

Bird Dual-Split Type

Bird Dual-Split type

Model

GSW(12X2)-22L/A

Function Cooling

Power supply(Phase-Frequency-Voltage)

Capaicty

Rated power

Rated current

Dehumidify volume

C.O.P/EER

Indoor unit

Model

Fan speed

Output power(W)

Fan type-piece Cross flow fan

Diameter-length(mm)

Evaporator

Pipe diameter

Row- fin distance(mm)

Working area (m2)

Stepping motor

Motor power (W)

Control method/Fuse(A)

Running capacity

Noise

Outline dimension

Package dimension

Net weight/Gross weight(kg)

Model

Rated power

Rated current (A)

(W)

(W)

(A)

(L/h)

(W/W)

(r/min)(H/M/L)

(μF)

dB(A)

(W/D/H)(mm)

(W/D/H)(mm)

(W)

32000×2

1555.5

8.015

GSW(12×2)-22L/A

GSW(12×2)-22L/A GSW(9×2)-22R/A

Throttling method Capillary

Outdoor unit

Compressor type

Starting method

Working temperature

Condensor Aluminum fin-copper tube

Pipe diameter

Row- fin distance(mm)

Working area (m2)

Fan motor power (W)/ speed (rpm)

(℃)

2

)

(m

Fan type-piece Axial flow fan

Fan blade diameter

(mm)

Defrost method

Noise

dB(A)

Connection

pipe

Outline dimension

Package dimension

Net weight/Gross weight(kg)

Refrigerant/refrigerant charge(kg)

Length

Outer diamete r

Liquid pipe

Gas pipe

Max.

distance

(W/D/H)(mm)

(W/D/H)(mm)

(m)

(mm)

(mm)

Height

Length

(m)

(m)

R22/0.85×2

1Ph 220V 50Hz

2500×2 2900×2

970×2 1050×2

4.2×2 4.3×2

1.2

2.6

1200/1100/1000

14

—

97×538

φ

Aluminum fin-copper tube

7

φ

2-1.4

0.14

MP24GA

2

PCB 3.15A Transformer 0.2A

41/36(H/L)

855×362×272

8.5/12.5

- 919

-4

-

Capacity

9.52

φ

2-1.8

38/720

—

56

1100×450×775

65/70

4

6(1/4")

φ

12(1/2")

φ

5

10

1.2

2.9 3.3

1

1

770×180×250

2~43

℃

0.482

1

450

950×412×710

.18

The technical data are subject to change without notice. Please refer to the nameplate of the unit.

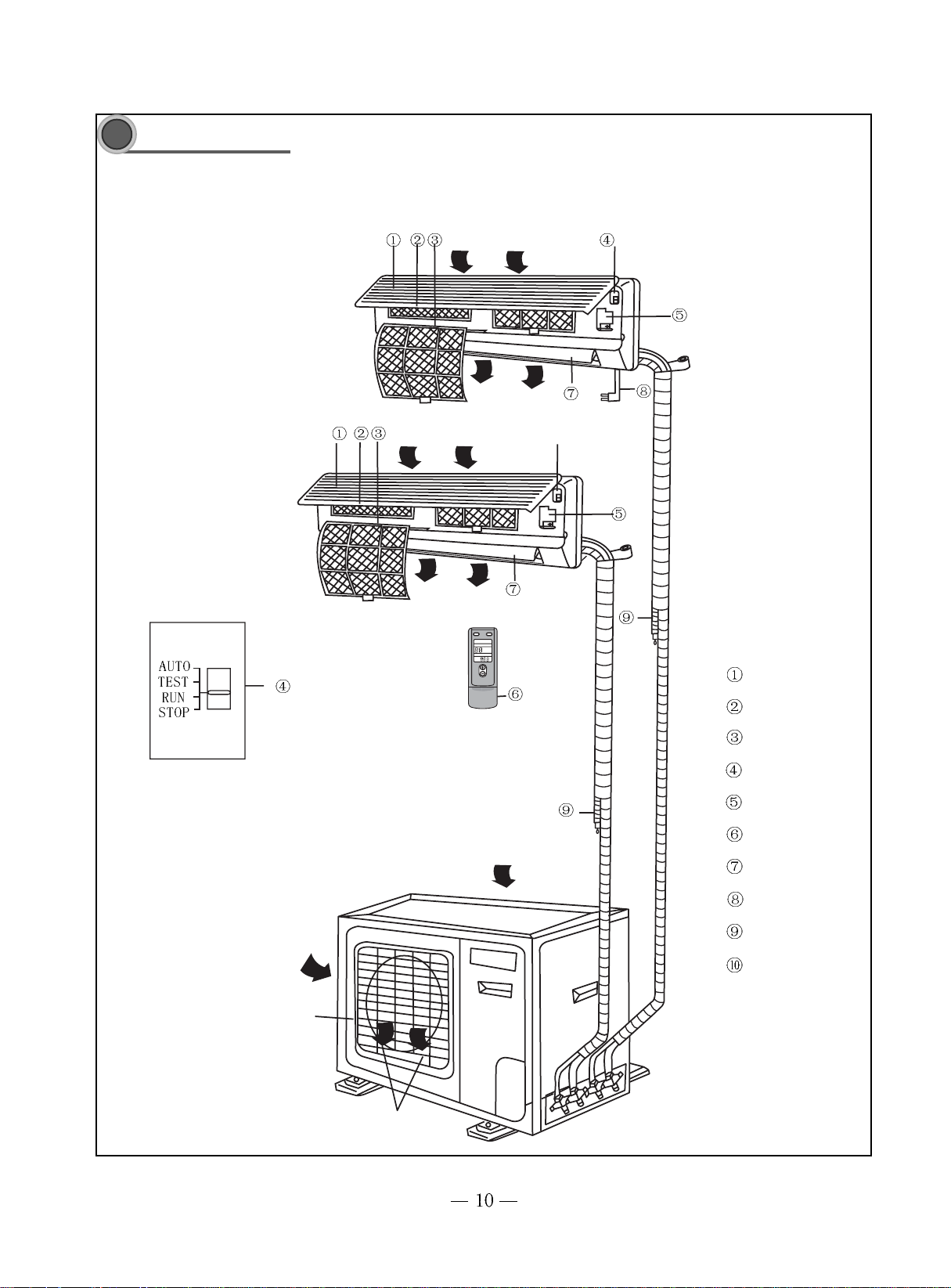

Spare part name

3

U nit B

Air in

Unit A

Air out

Air in

Air out

Front panel

Air cleaner

Filter

Manual switch

Covering plate

Wireless remote control

Air in

Guide louver

Power plug

Water drainage pipe

Air outlet grille

Air out

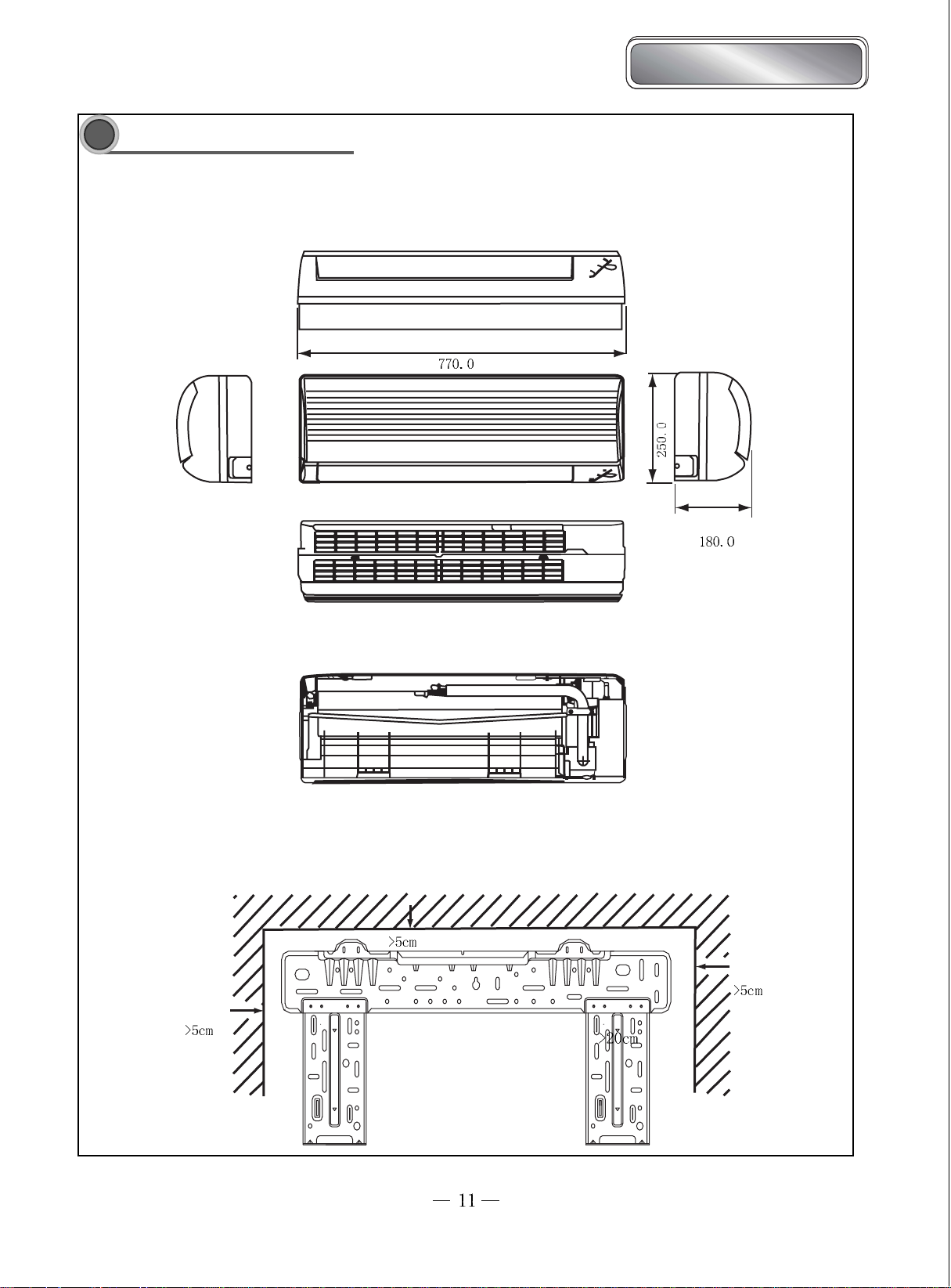

Outline and installation dimension

4

Bird Dual-Split Type

Bird Dual-Split type

Ceiling

Installation dimension

mm

Unit:

above

above

above

above

Screw

Nut

Spanner

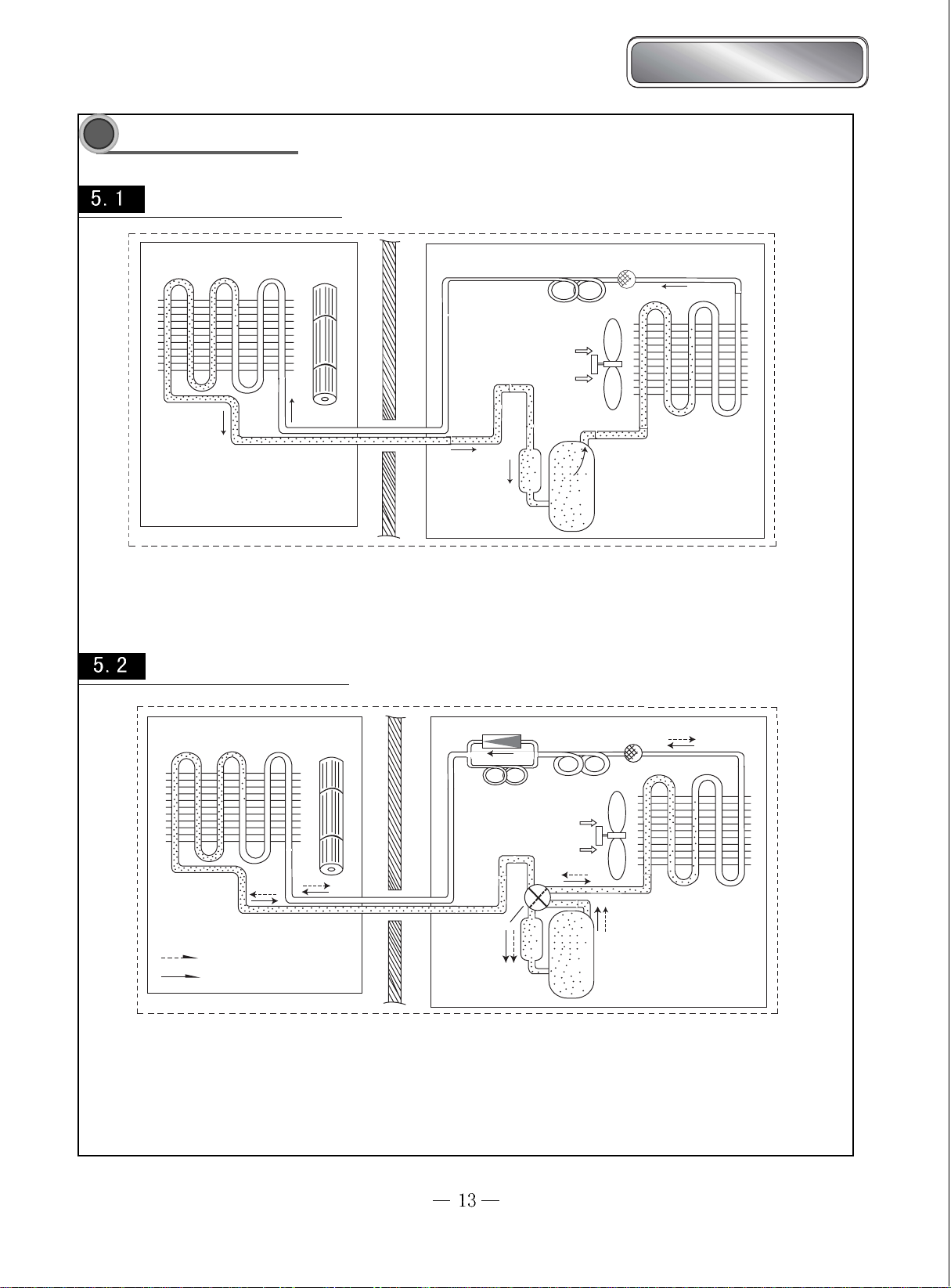

Cooling system diagram

5

Cooling system diagram for cooling only type

Bird Dual-Split type

Bird Dual-Split Type

Evaporator

Cross flow fan

Capillary

Filter

Axial flow fan

Condenser

Gas-liquid separator

Compressor

When the power is on, indoor and outdoor units will start to run. The compressor sucks low-pressure refrigerant gas from the evaporator

indoor unit and then discharges high-temperature, high-pressure refrigerant gas into outdoor condenser. Then air exchanges the heat with outdoor air

and becomes refrigerant liquid. The liquid is throttled by the capillary and changes into low-temperature and low-pressure liquid and then flows

into indoor evaporator. Then liquid exchanges the heat with the required air and changes into low-temperature and low-pressure refrigerant gas.

The cycle introduced above goes on and on, and the demanded low temperature environment is maintained.

of

Cooling system diagram for cooling/heating type

Evaporator

Heating

Cooling

When the power is on, indoor and outdoor units will start to run. When the system operates in cool mode, the compressor sucks low-temperature, lowpressure refrigerant gas from indoor evaporator and then discharges high-temperature, high-pressure refrigerant gas into outdoor heat exchanger. With

the help of axial flow fan, the gas transfers its latent heat into outdoor air and becomes high-pressure refrigerant liquid. The liquid is throttled by the

capillary and changes into low-temperature and low-pressure liquid and then flows into indoor heat exchanger. With the help of centrifugal fan, the

liquid evaporates into low-temperature refrigerant gas and indoor air is cooled down. The refrigerant gas is sucked into the compressor and the cycle

introduced above goes on and on, and the demanded low temperature environment is maintained.

When the system operates in heat mode, 4-way valve changes its way and the refrigerant flows into the reversible cycle as the cool mode. The

r

e frigerant discharges its latent heat in the indoor heat exchanger, and sucks heat from outdoor heat exchanger and forms the heat pump cycle.

T his cycle goes on and on, and the demanded high temperature environment is maintained.

Cross flow fan

One-way valve

Main capillary

Auxillary capillary

Axial flow fan

E lectromagnetic

4-way valve

Gas-liquid separator

Filter

Condenser

Compressor

6

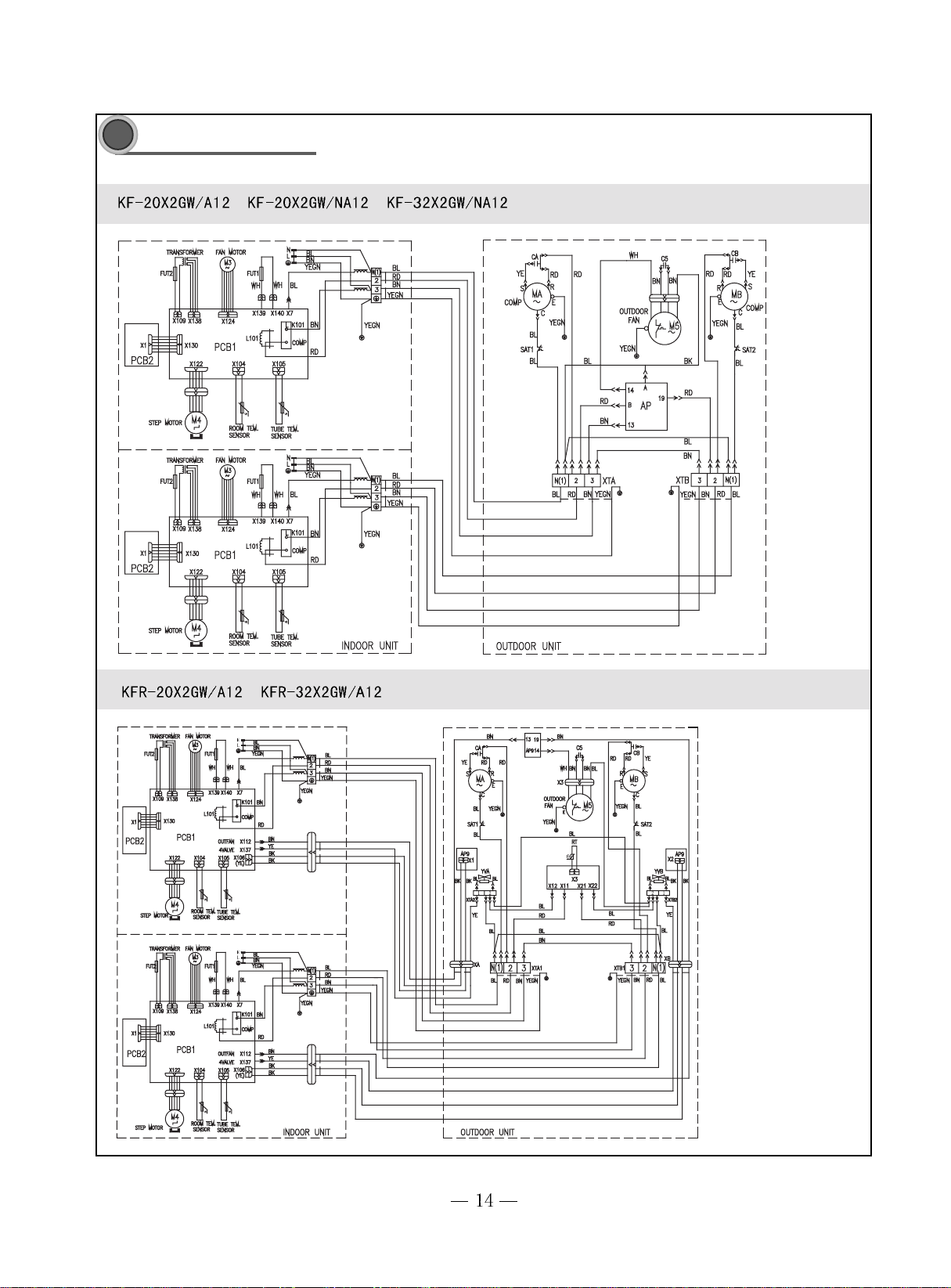

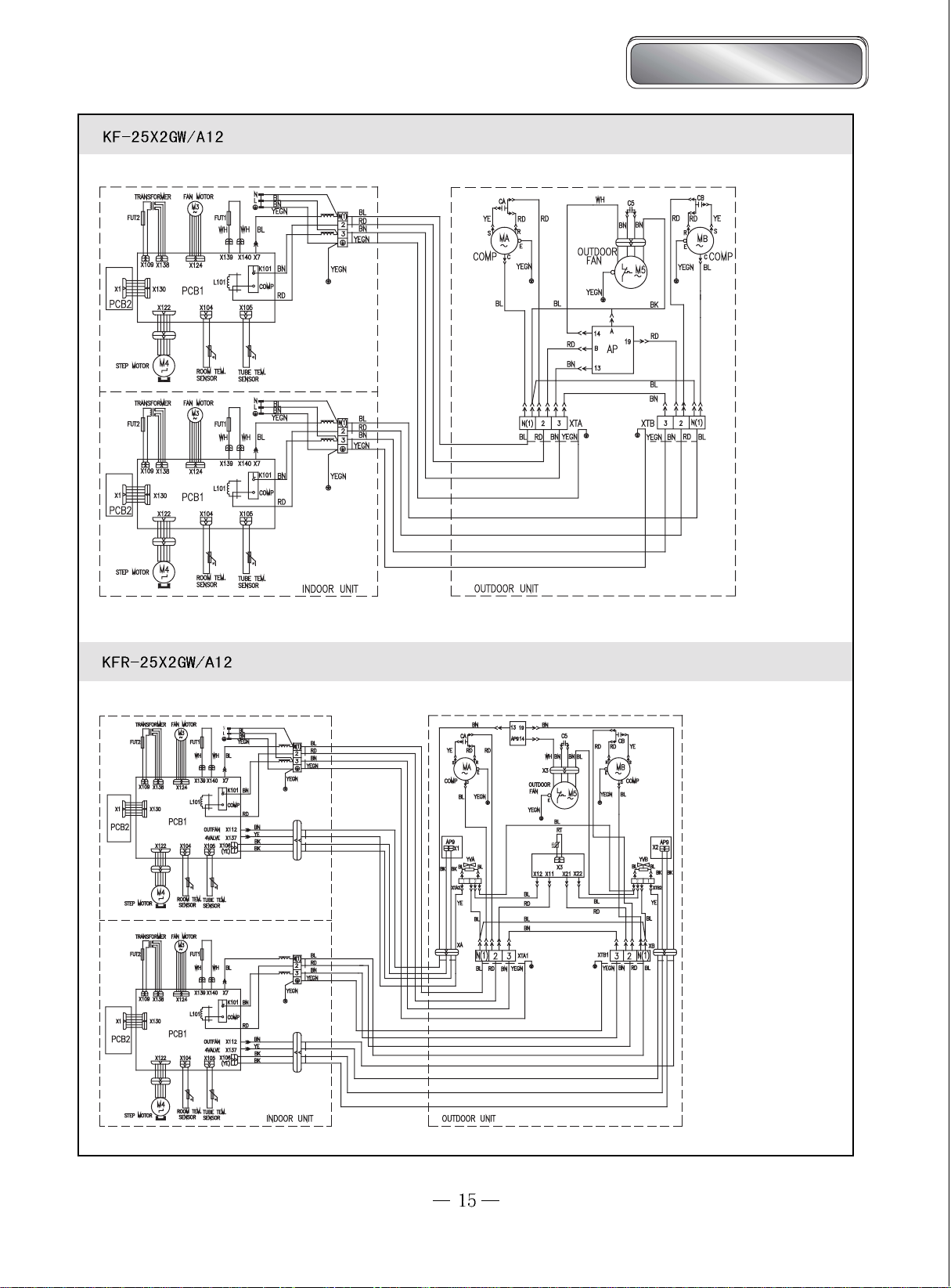

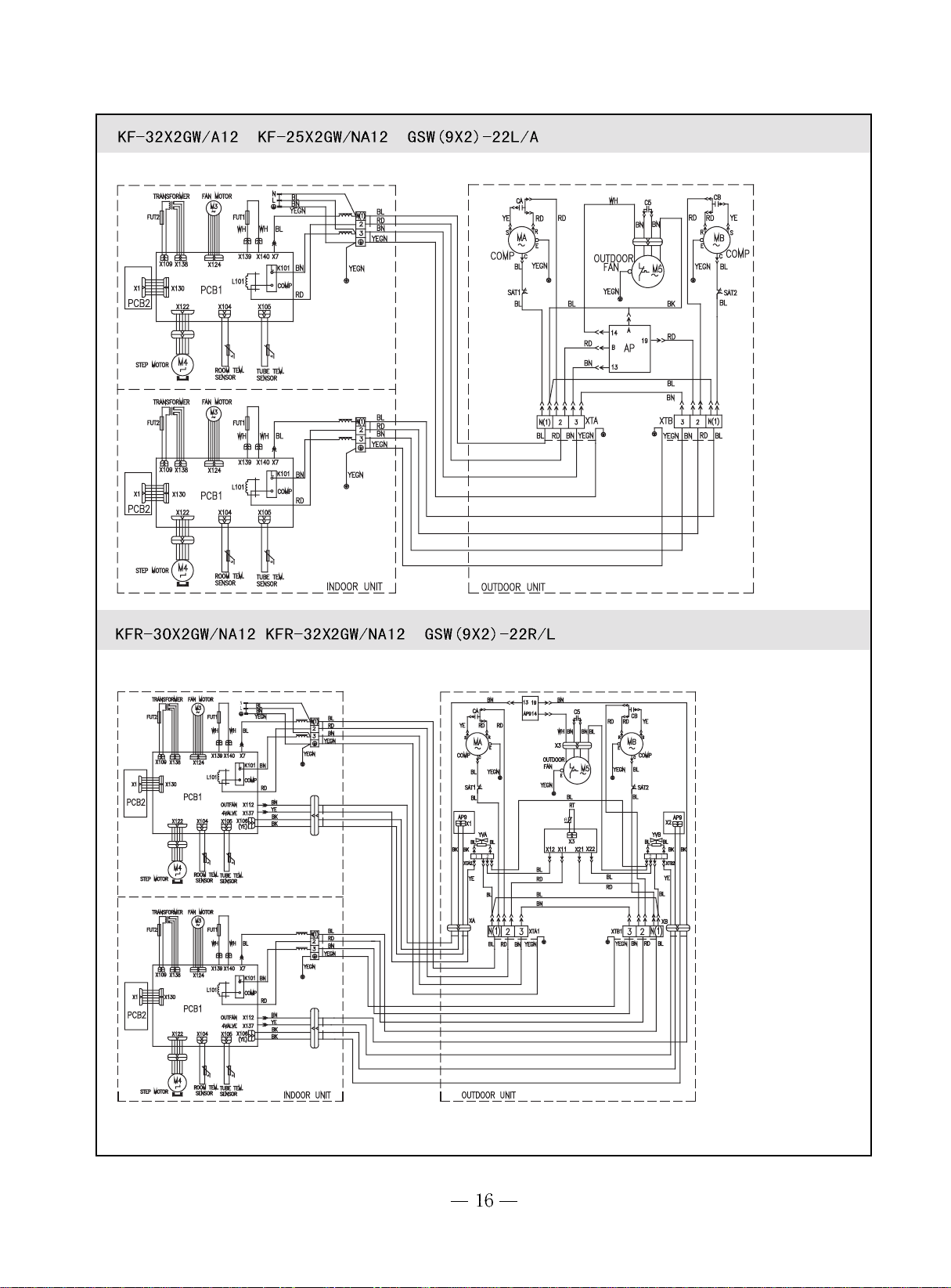

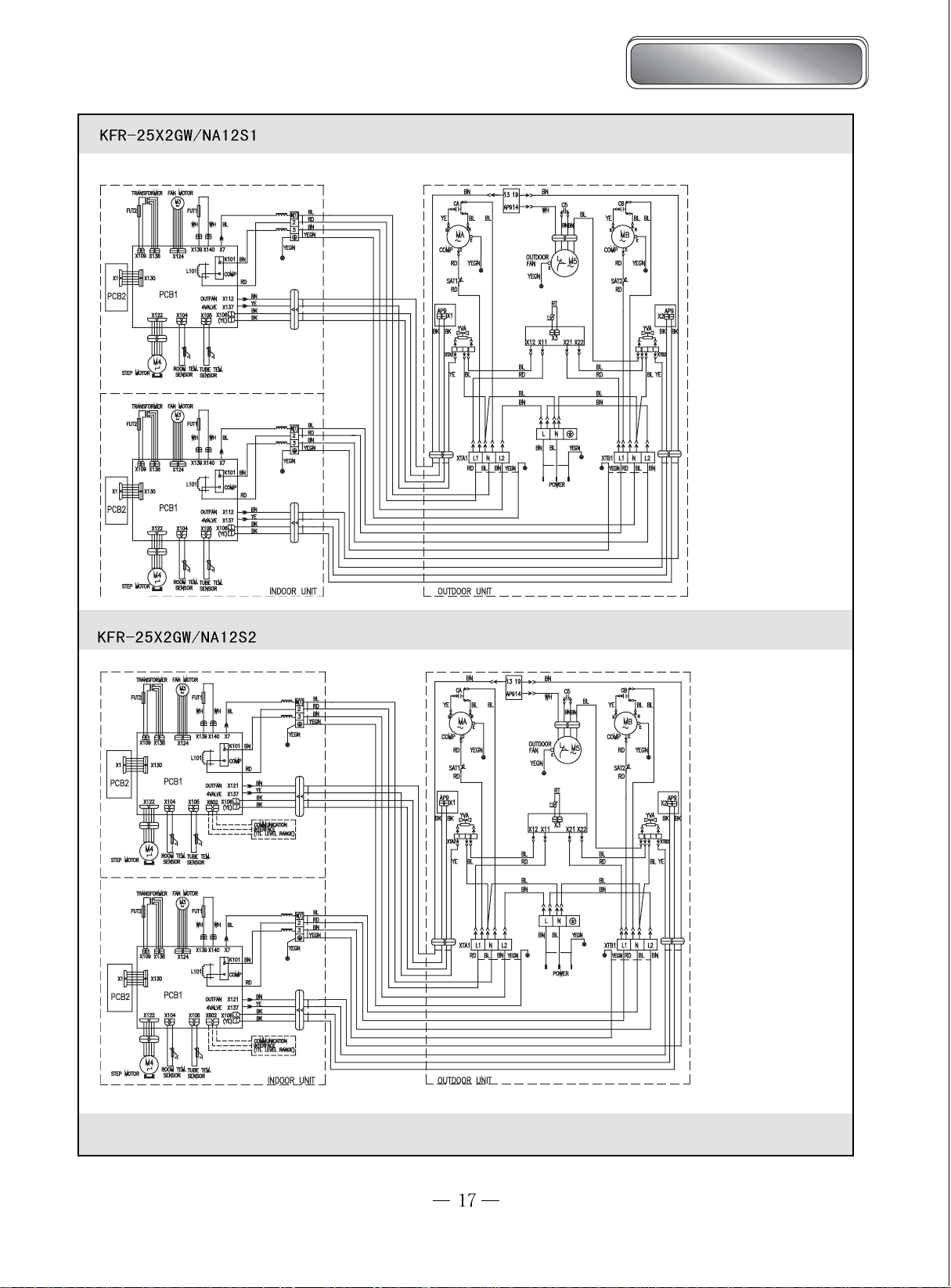

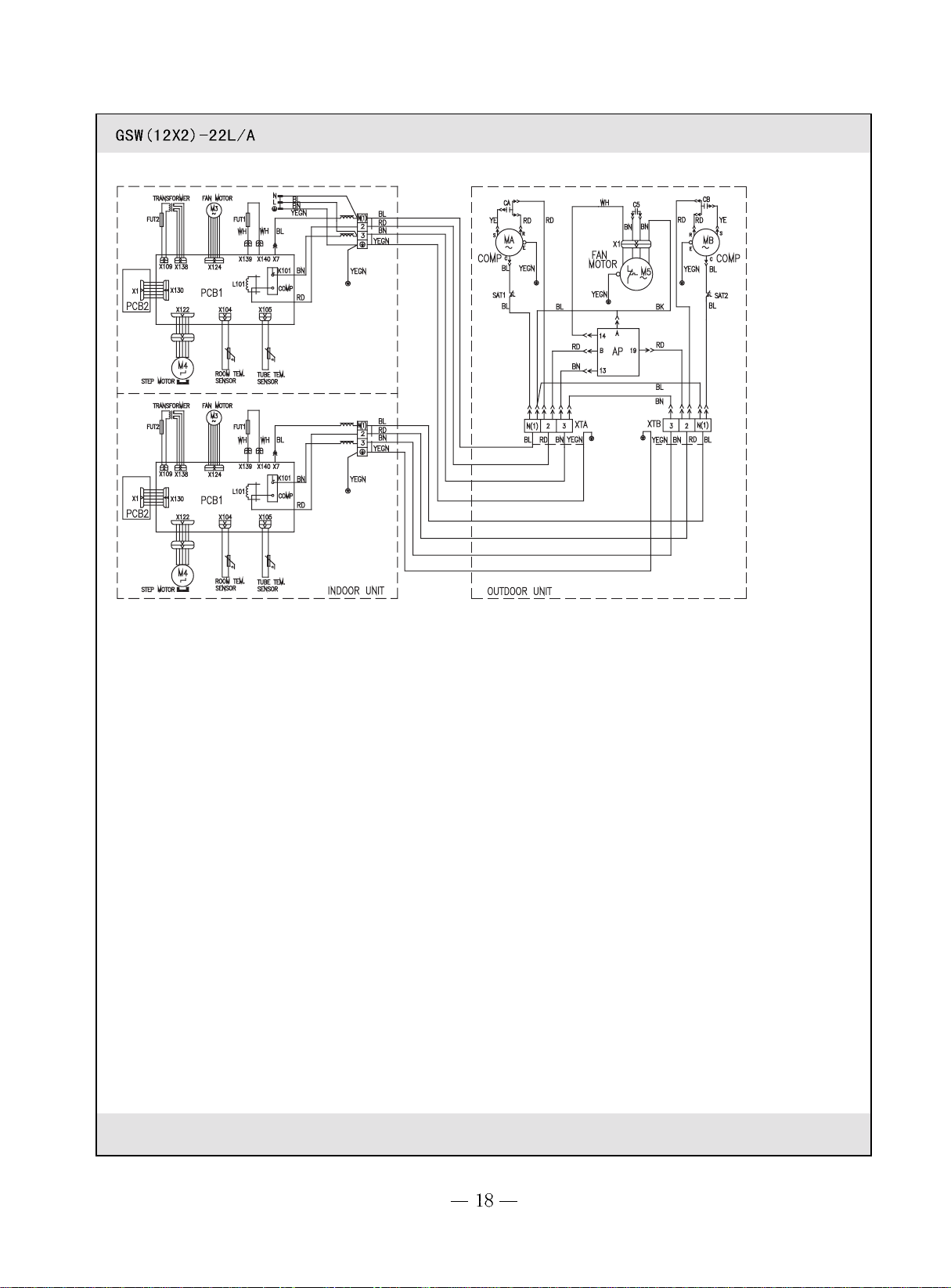

Circuit diagram

Bird Dual-Split type

Bird Dual-Split Type

Bird Dual-Split Type

Bird Dual-Split type

These circuit diagrams are subject to change without notice. Please refer to the ones stuck on the machines.

These circuit diagrams are subject to change without notice. Please refer to the ones stuck on the machines.

Bird Dual-Split Type

Tset

Tset

Ambient set

temp.Tamb

Start the cooling

Keep running in the old mode

Stopping the cooling

3Min

Run at the set speed

Run at the set speed

Running

Stop

Compressor

Outdoor fan

Indoor fan

Current

3Min

Running

Stop

Compressor

Outdoor fan

Indoor fan

Bird Dual-Split type

PCB function manual and operation method

77

7

77

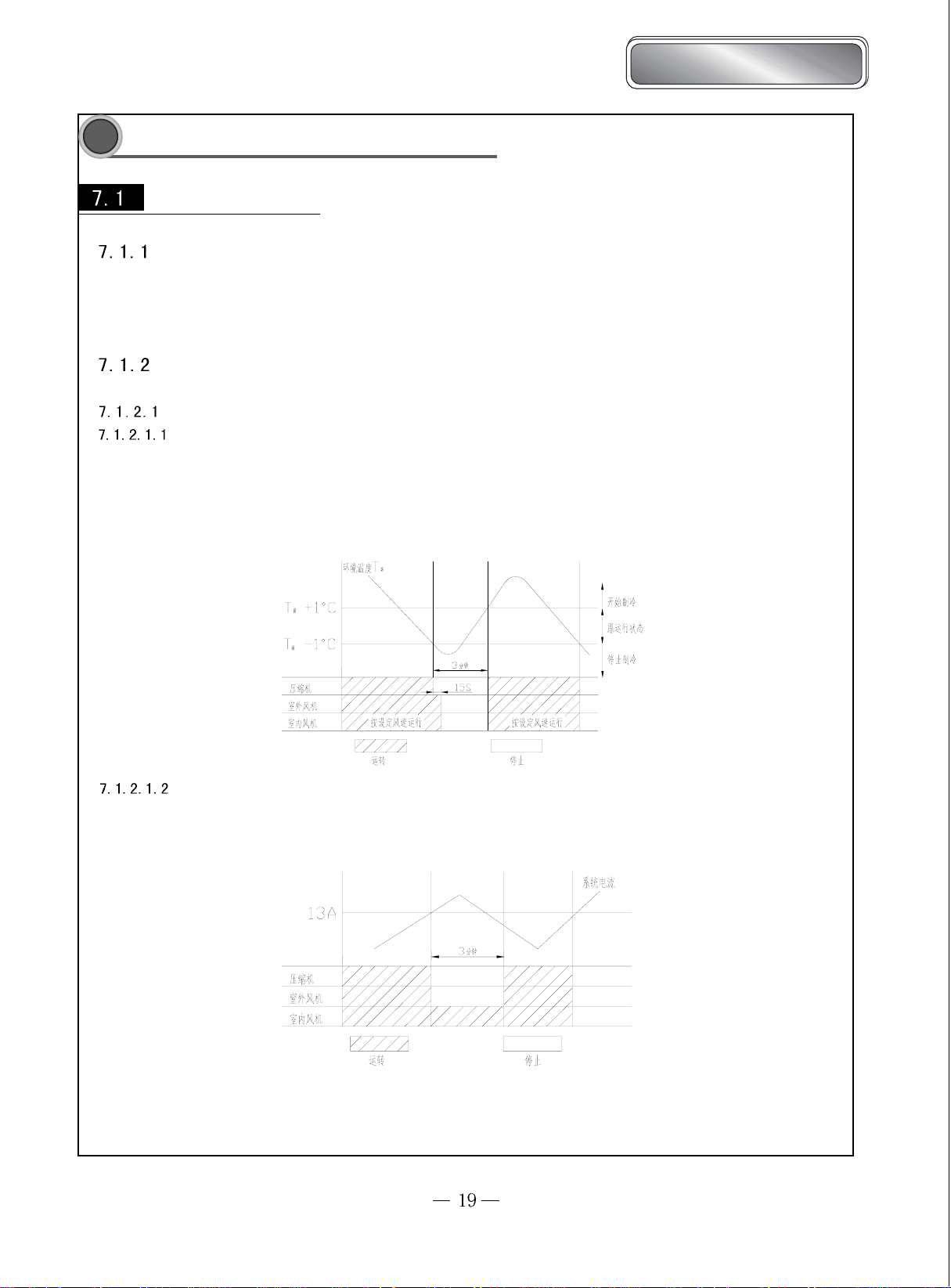

PCB function manual

Temperature parameter

The room set temperature: (Tset)

The room ambient temperature:(Tamb)

The evaporator tube temperature: (Ttube)

The condenser tube temperature: (Tdefrost)

Foundamental functions

After power is on, no matter when compressor is started, the time span between the startups cannot be less than 3 minutes.

COOL mode

Cooling condition

If Tamb≥Tset+1℃, COOL mode will act, compressor and outdoor fan will run, indoor fan will run at the set speed.

If Tamb≤Tset-1℃,tunit will stop , compressor will stop and then outdoor fan will delay 15sec and stop.

If Tset-1℃<Tamb<Tset+1℃, the unit will keep running in the old mode.

In this mode, the reversal valve will not power on, the setting temp. range:16℃~30℃

Protection Functions

Overcurrent Portection

When the system current is tested higher than 13A, only fan will run. After 3 minutes, the whole unit will run in the old

mode, if the overcurrent cannot be eliminated, the whole unit will stop, and can be restarted by the wireless remote control.

Antifreezing Protection

When the system is tested, the compressor and outdoor fan will stop, indoor fan will run at the set speed; when the antifreezing protection is

and the compressor has stopped for 3min, the unit will return to the old mode.

During the antifreezing protection

Compressor

Outdoor fan

Indoor fan

Running

Stop

3Min

Run at the set speed

Compressor

Outdoor fan

Indoor fan

Running

Stop

Start the cooling

Dehumidifying operation

Stop the cooling

Fan speed could

be adjusted

Low speed

Low speed

Min

Min

Min

Min

Tset

Tset

Ambient temp.Tamb

During the antifreezing protection

Compressor

Outdoor fan

Indoor fan

Running

Stop

Low speed

3Min

Tset

Tset

Compressor

Outdoor fan

Indoor fan

Reversal valve

Running

Stop

Low speed

Ambient temp. Tamb

Stop the heating

Keep running in the old mode

Start the heating

Min

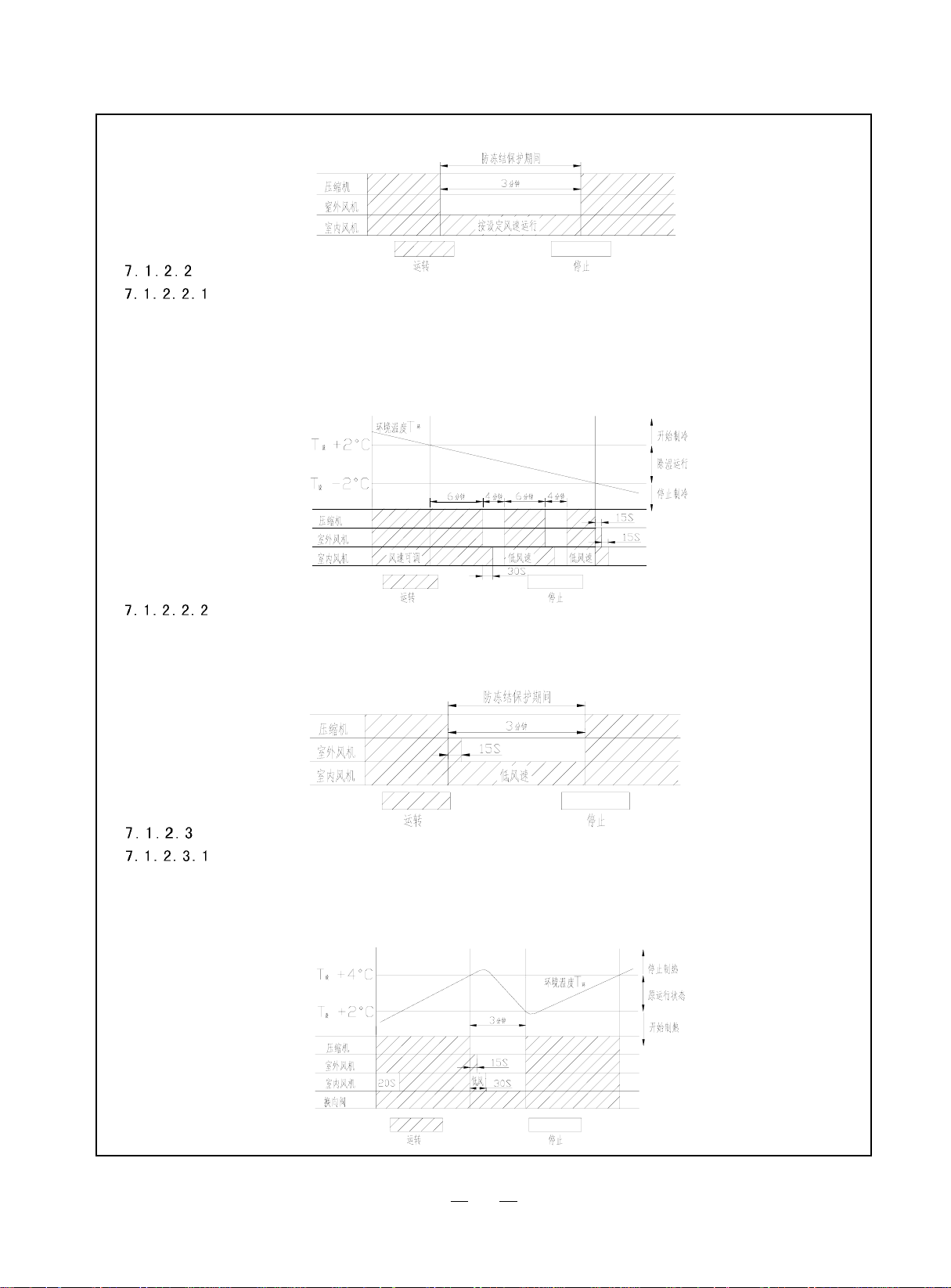

DRY Mode

The conditions and processes of dehumidifying:

If T

amb>Tset

If Tset -2℃≤Troom≤Tset+2℃,DRY mode will act, the indoor fan will run at the low speed.after running for 6mins, outdoor fan and compressor will stop, but

indoor fan will delay 30secs and stop, after 3.5mins, compressor and outdoor fan will run, and indoor fan will run at the low low speed. The processes of dehumidifying

a re shown as the above cycle.

If T

amb

+2℃, the cooling mode will act, indoor fan speed could be adjusted, outdoor fan will run.

< T

-2℃, the unit will stop, the compressor will stop, after 15sec latter, outdoor fan will stop, after another 15sec, indoor fan will stop.

set

In this mode, the reversal valve will not power on, the setting temp. range:16℃~30℃.

Protection Functions

Antifreezing Protection

When running in COOL mode, antifreezing protection is the same as the cooling. The DRY mode act, when the antifreezing protection is detected,

the compressor will stop, but outdoor fan will delay 15secs and stop, indoor fan will run at low speed; when antifreezing protection is eliminated and

compressor has stopped for 3min, the whole unit will run at the original status.

HEAT Mode

The conditions and processes of heating

If Tamb ≤Tset+2℃, HEAT mode will act, compressor, outdoor fan and reversing valve will run, but indoor fan will after 20sec delayed and run.

If Tamb≥Tset+4℃, Compressor will stop first, outdoor fan will delay 15s and stop, reversing valve will keep working, after 30secs indoor fan will blow

the surplus heat, after 30secs it will stop.

If Tset+2℃<T set<T set +4℃,the unit will keep running in the old mode.

In this mode, the reversal valve will not power on, the setting temp. range:16℃~30℃.

20

Loading...

Loading...