Gree GRS-CQ16Pd/NaB-K, GRS-CQ14Pd/NaB-K, GRS-CQ14Pd/NaB-M, GRS-CQ12Pd/NaB-M, GRS-CQ12Pd/NaB-K Owner's Manual

...

Change for life

Thank you for choosing Commercial Air Conditioners ,please read this

owner’s manual carefully before operation and retain it for future reference.

Air-to-water Heat Pump

Commercial Air Conditioners

Owner's Manual

Contents

1 Instruction to Users..................................................................................1

2 Safety Considerations .............................................................................2

3 Diagram of the Operating Principle .........................................................4

4 Operating Principle of the Unit.................................................................4

5 Nomenclature ..........................................................................................6

6 Installation Example .............................................................................7

7 Main Components ..................................................................................9

7.1 Indoor unit .................................................................................................. 9

7.2 Outdoor unit ........................................................................................... 10

8 Installation Guideline of the Unit ............................................................ 11

8.1 Instruction to installation ...........................................................................11

8.2 Installation of outdoor unit ........................................................................11

9 Installation of Indoor Unit ....................................................................... 12

9.1 Select installation location of indoor unit ................................................ 12

9.2 Install process of indoor unit .................................................................... 13

9.3 Outline dimension of indoor unit ............................................................ 14

9.4 Space requirements for installation ......................................................... 15

9.5 Precautions on installation of indoor unit ................................................. 15

9.6 Water volume and pump capacity (with pump)........................................ 15

9.7 Water volume and expansion vessel pressure ........................................ 16

9.8 The method of calculating the charging pressure of expansion vessel ... 16

9.9 Selection of expansion vessel ................................................................. 17

10 Connection of Pipeline ........................................................................18

10.1 Connection of outlet pipe for indoor & outdoor unit .............................. 18

10.2 Installation of protective layer on connection pipe ................................ 18

11 Remote Air Temperature Sensor .........................................................20

12 Thermostat ..........................................................................................21

13 2-Ways Valve .......................................................................................21

14 3-Way Valve.........................................................................................22

15 Other Auxiliary Heat Sources .............................................................23

16 Gate-controller ................................................................................... 23

17 Filling of Refrigerant ............................................................................23

18 Installation of Insulated Water Tank .................................................... 24

18.1 Installation measure .............................................................................. 24

18.2 Outline dimension and parameter of water tank .................................... 25

18.3 Connection of waterway system ............................................................ 26

18.4 Electric wiring work ............................................................................... 27

19 Wring Diagram .....................................................................................29

19.1 PCB outline ............................................................................................ 29

19.2 Electric wiring work ................................................................................ 33

20 Debugging Operation of Unit .............................................................. 40

20.1 Check before startup ............................................................................. 40

20.2 Test run .................................................................................................. 41

21 Daily Operation and Maintenance ......................................................42

22 Operation Range .................................................................................44

Air-to-water Heat Pump

1

1 Instruction to Users

Thank you for choosing our Air to water Heat Pump. Please read this manual carefully before

installation and use the unit correctly according to the following procedure.

◆

After receipt of the unit, check it for appearance, unit model compared with your desire and

attachments.

◆

For proper installation and future maintenance please read this Instruction and keep it

carefully.

◆

Design and installation work of the unit must be performed by authorized personnel according

to applicable laws and regulations and this Instruction.

◆

After installation work, the unit can not be energized unless there is not any problem in check.

◆

Ensure periodical clean and maintenance of the unit after normal operation of the unit for

longer life and reliable operation.

◆

For improvement of products, there should be not additional notice of amendment of the

contents.

◆

This appliance is not intended for use by persons (including children) with reduced physical,

sensory or mental capabilities, or lack of experience and knowledge, unless they have been

given supervision or instruction concerning use of the appliance by a person responsible for

their safety.

◆

Children should be supervised to ensure that they do not play with the appliance.

Notice!

This product must not be disposed together with the domestic waste. This product has to be

disposed at an authorized place for recycling of electrical and electronic appliances.

Air-to-water Heat Pump

2

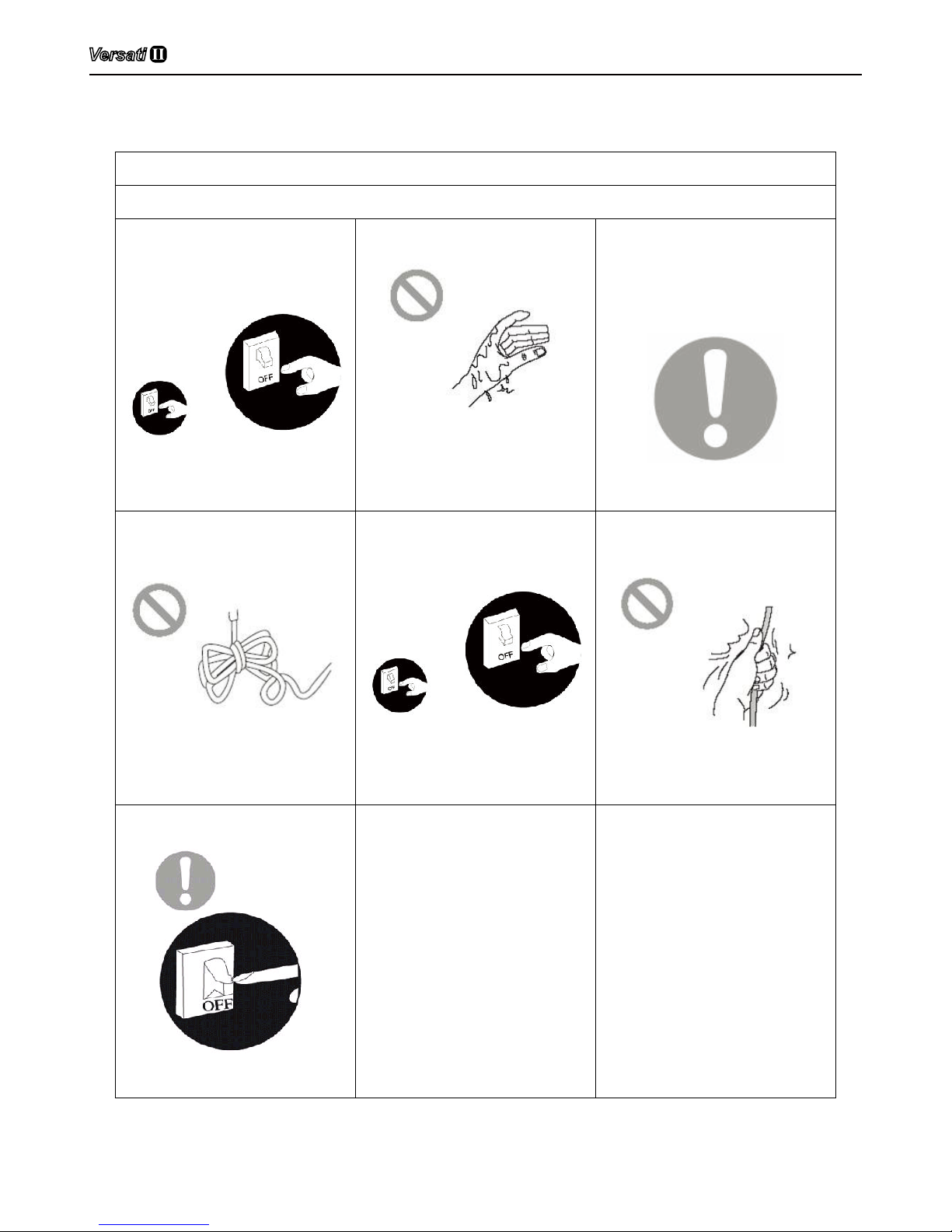

2 Safety Considerations

Please read the following contents carefully before operating.

WARNING

■ Once abnormality like burning

smell occurs, please cut off

the power supply immediately

and then contact with service

center.

If the abnormality still exists, the

unit may be damaged and

electric shock or re may result.

■ Don't operate the unit with wet

hand.

Otherwise, it may cause electric

shock.

■ Before installation,please

see if the voltage of local

place accords with that on

nameplate of unit and capacity

of power supply, power cord

or socket is suitable for input

power of this unit.

■ Special circuit must be

adopted for power supply to

prevent re.

Do not use octopus multipurpose

plug or mobile terminal board for

wire connection.

■ Be sure to pull out the power

plug and drain the indoor unit

and water tank when unit is

not in use for a long time.

Otherwise, the accumulated dust

may cause overheating,fire or

freeze of water tank or coaxial

heater exchanger in winter.

■ Never damage the electric

wire or use the one which is

not specied.

Otherwise, it may cause

overheating or re.

■ Before cleaning please cut off

the power supply.

Otherwise, it may cause electric

shock or damage.

■ The power supply must adopt

special circuit with leakage

switch and enough capacity.

■ User can not change power

cord socket without prior

consent. Wiring working must

be done by professionals.

Ensure good earthing and

don't change earthing mode

of unit.

Air-to-water Heat Pump

3

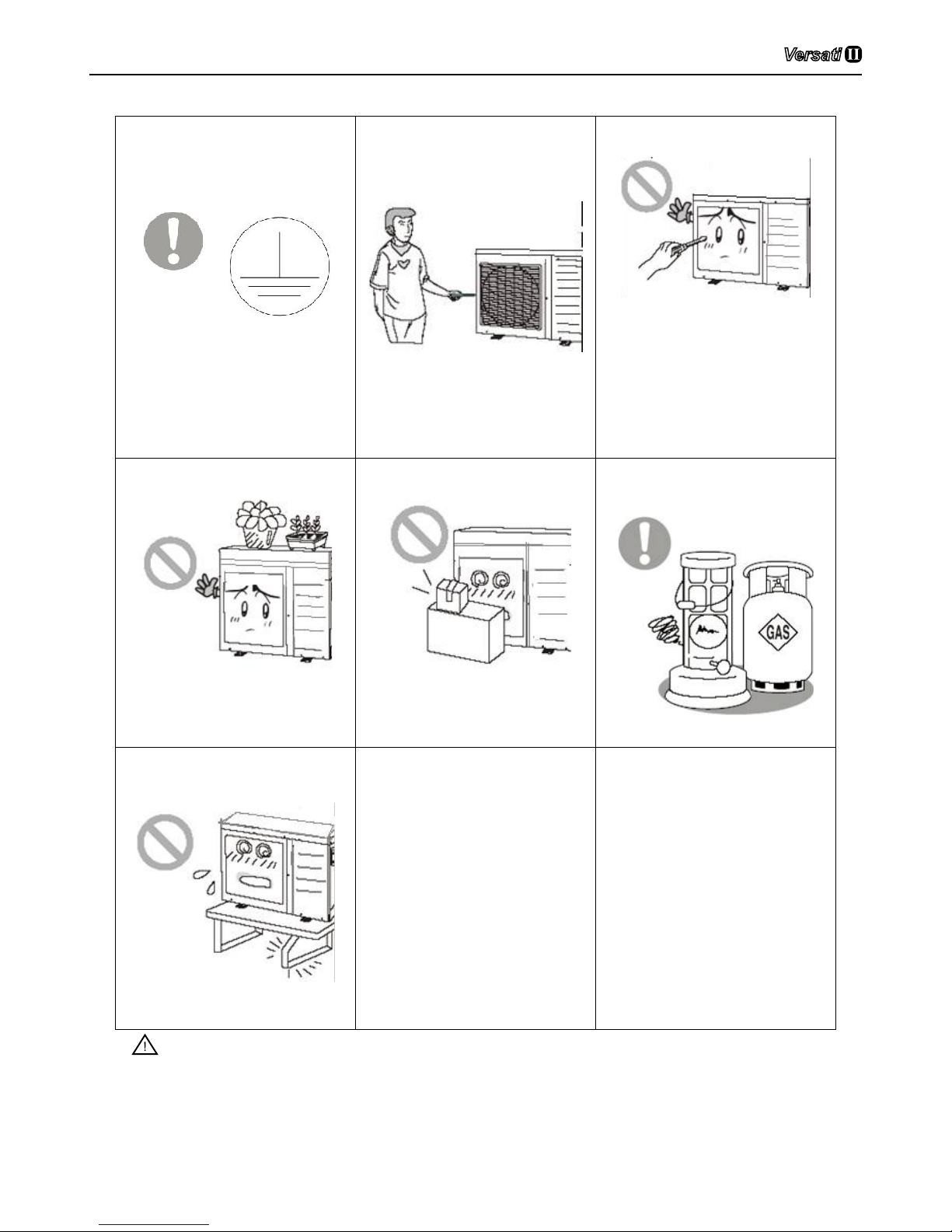

■ Earthing: the unit must be

earthed reliably ! The earthing

wire should connect with

special device of buildings.

If not, please ask the qualified

personnel to install.

Furthermore, don't connect

earth wire to gas pipe, water

pipe, drainage pipe or any

other improper places which

professional does not recognize.

■ Never insert any foreign

matter into uint to avoid

damage . And never insert

your hands into the air outlet

of outdoor unit.

■ Don't attempt to repair the unit

by yourself.

Improper repair may cause electric

shock or fire, so you should

contact the service center to

repair.

■ Don't step on the top of the

unit or place anything on it.

There is the danger of fall of

things or people.

■ Never block the air inlet and

outlet of unit.

It may reduce efficiency or cause

stop of the unit and even re.

■ Keep pressurized spray, gas

holder and so on away from

the unit above 1m .

It may cause re or explosion.

■ Please note whether the

installation stand is firm

enough or not.

If damaged, it may cause fall of

the unit and injury of people.

■ Unit should be installed at the

place with good ventilation to

save energy.

■ When there is not water in

water tank, never power the

unit on to run.

Notice!

(1) Before installation, please check if the adopted power is accordance with that listed on

nameplate, and check the safety of power.

(2) Before using, please check and conrm if wires and water pipes are connected correctly to

avid water leakage, electric shock or re etc.

Air-to-water Heat Pump

4

(3) Don’t operate the unit with wet hand, and don’t allow children to operate the unit.

(4) The On/off in the instruction is for the operation to on and off button of PCB for users; cut off

power means to stop supplying power to the unit.

(5) Don’t directly expose the unit under the corrosive ambient with water or dampness.

(6) Don’t operate the unit without water in water tank .The air outlet/inlet of unit can not be

blocked by other objects.

(7) The water in unit and pipeline should be discharged if the unit is not in use, to prevent the

water tank, pipe line and water pump from frost-cracking.

(8) Never press the button with sharp objects to protect manual controller. Never use other wires

instead of special communication line of the unit to protect control elements. Never clean

the manual controller with benzene, thinner or chemical cloth to avoid fading of surface and

failure of elements. Clean the unit with the cloth soaked in neutral eradicator .Slightly clean

the display screen and connecting parts to avoid fading.

(9) The power cord must be separated with the communication line.

If there is any question, please contact with local dealer, authorized service center, agencies

or our company directly.

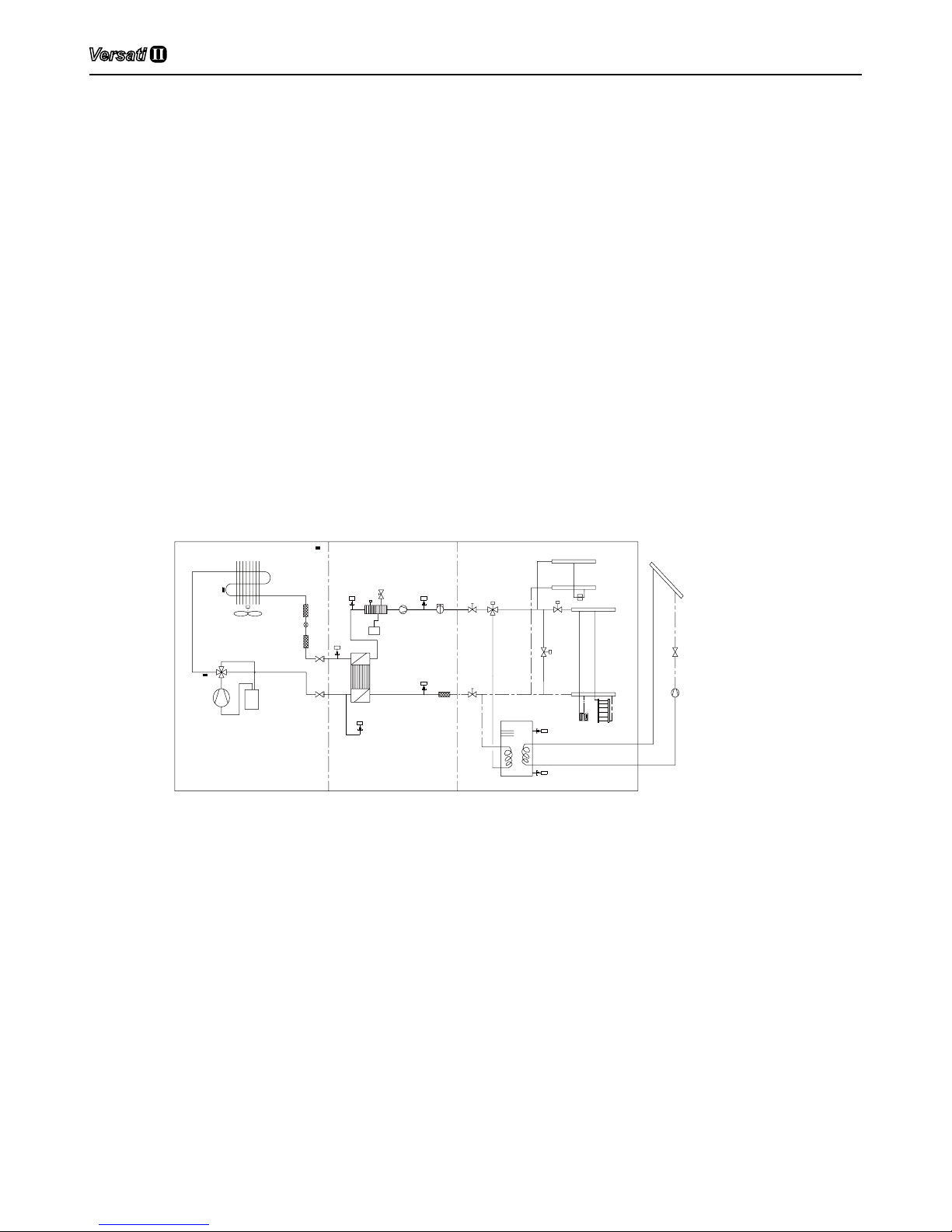

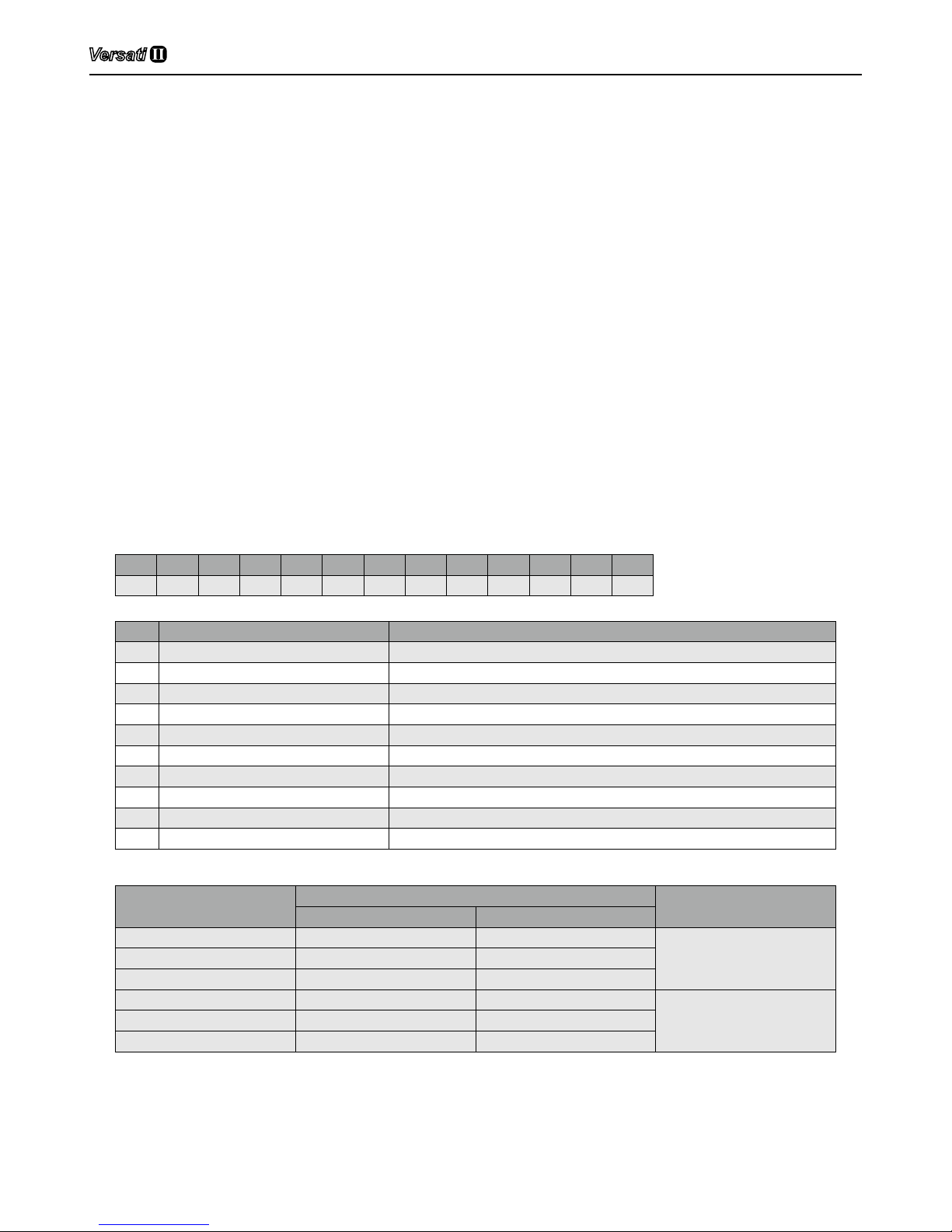

3 Diagram of the Operating Principle

R3T gas line temperature sensor

17

15

16

INDOOR UINTOUTDOOR UINT

M

M

M

M

1

2

3

4

5

6

7

8

10

11

20

19

5

18

12

1 compressor

2 four-way valve

3 finned coil exchanger

4 fan motor

5 filter

6 electronic expansion valve

7 plate heat exchanger

11 flow switch

10 electric heater

9 air-vent valve

8 pump

18 water tank

12 3-way valve

17 other thermal system

16 radiator

15 under-floor heating

R6T water tank temperature sensor 1

R4T returning water temperature sensor

R1T plate outlet temperature sensor

t

R1T

R3T

t

R5T

t

R4T

t

t

R6T

t

R2T

9

19 expansion tank

20 safety valve

R2T Liquid line temperature sensor

R5T leaving water temperature sensor

t

R7T

R7T water tank temperature sensor 2

13

14

13 2-way valve

14 by-pass valve

4 Operating Principle of the Unit

DC Inverter Air to Water Heat Pump is composed of outdoor unit, indoor unit and internal-fan coil

water tank. Operation functions:

(1) Cooling;

(2) Heating;

(3) Water heating;

(4) Cooling +water heating;

(5) Heating+ water heating;

Air-to-water Heat Pump

5

(6) Emergency mode;

(7) Quick water heating;

(8) Holiday mode;

(9) Forced Operation Mode;

(10) Silent mode;

(11) Disinfection mode;

(12) Weather-dependent Operation;

(13) Floor debugging

(14) Air removal of the water system

Cooling: in cooling mode, the refrigerant is condensed in the outdoor unit and evaporated in the

indoor unit. Via the heat exchange with water in the indoor unit, the temperature of water decrease

and it releases heat while the refrigerant absorbs heat and evaporates. With the help of wired

controller, the outow temperature can meet the user’s requirement. Through the control of valve,

the low-temperature water in the system is connected with indoor fan coil and underground pipe, and

exchanges heat with the indoor air so that the indoor temperature decreases to the required range.

Heating: in heating mode,the refrigerant evaporates in the outdoor unit and is condensed in

the indoor unit. Via the heat exchange with water in the indoor unit, the water absorbs heat and its

temperature increase while the refrigerant releases heat and is condensed. With the help of wired

controller, the outow temperature can meet the user’s requirement. Through the control of valve, the

high-temperature water in the system is connected with indoor fan coil and underground pipe, and

exchanges heat with the indoor air so that the indoor temperature increases to the required range.

Water heating: in water heating mode: the refrigerant evaporates in the outdoor unit and is

condensed in the indoor unit. Via the heat exchange with water in the indoor unit, the water absorbs

heat and its temperature increase while the refrigerant releases heat and is condensed. With the help

of wired controller, the outow temperature can meet the user’s requirement. Through the control of

valve, the high-temperature water in the system is connected with the coil pipe of bearing water tank,

and exchanges heat with the water in the water tank so that the temperature of water tank increases

to the required range.

Cooling + water heating: when cooling mode exists together with the water heating mode, the

user can set the priority of these two modes based on the needs. The default priority is heat pump.

That is under the default setting, if cooling mode exists together with the water heating mode, the

heat pump gives priority to cooling. In that case, water heating can only realized with e-heater of

the water tank. Inversely, the heat pump gives priority to water heating and switches to cooling after

nishing water heating.

Heating+ water heating: when heating mode exists together with the water heating mode, the

user can set the priority of these two modes based on the needs. The default priority is heat pump.

That is under the default setting, if heating mode exists together with the water heating mode, the

heat pump gives priority to heating. In that case, water heating can only realized with e-heater of

the water tank. Inversely, the heat pump gives priority to water heating and switches to heating after

nishing water heating.

Emergency mode: this mode is only available for heating and water heating. When the outdoor

unit stops due to malfunction, enter the corresponding emergency mode; as to heating mode, after

entering the emergency mode, heating can only be realized through e-heater of the indoor unit. When

the setting outow temperature or indoor temperature is reached, the e-heater of indoor unit will stop

running; as to water heating mode, the e-heater of indoor unit stops while the e-heater of water tank

runs. When the setting temperature or water tank is reached, the e-heater will stop running.

Quick water heating: in quick water heating mode, the unit runs according to the water heating

Air-to-water Heat Pump

6

control of heat pump and the e-heater of water tank runs at the same time.

Forced Operation Mode: this mode is only used for refrigerant recovery and debugging for the

unit.

Holiday mode: this mode is only available for heating mode. This mode is set to keep indoor

temperature or leaving water temperature in a certain range, so as to prevent water system of the unit

from freezing or protect certain indoor articles from freezing damage. When the outdoor unit stops

due to malfunction, the two e-heaters of the unit will run.

Disinfection mode: in this mode, the water heating system can be disinfected. When starting up

the disinfection function and setting corresponding time to meet the requirement of disinfection mode,

the function will start. After the setting temperature is reached, this mode will terminate.

Weather-dependent Operation: this mode is only available for space heating. In Weatherdependent mode, the setting value (remote room air temperature or leaving water temperature) is

detected and controlled automatically when the outdoor air temperature is changed.

Silent mode: Silent mode is available in cooling, heating and water heating mode. In silent mode,

the outdoor unit will reduce the running noise via automatic control.

Floor commissioning: this function is intended to preheat the oor periodically for the initial use.

Air removal of the water system: this function is intended to replenish water and remove air in

the water system to make the equipment run at the stabilized water pressure.

5 Nomenclature

G RS - C Q 16 Pd / Na B - K (O)

1 2 3 4 5 6 7 8 9 10

NO. Description Options

1 GREE G-GREE Air to water heat pump

2 Heat Pump Water Heater RS

3 Heating Mode S= Static; C=Circulating

4 Function Q=Multi-function; Omit=Single-function

5 Nominal Heating Capacity 6=6.0kW; 8=8.0kW;10=10kW; 12=12kW; 14=14kW; 16=16kW

6 Compressor Style Pd=DC Inverter; Omit=On/Off

7 Refrigerant Na=R410A

8 Design Serial Number B,C,D......

9 Power Supply K=220-240V,~,50Hz; M=380-415V,3N~,50Hz; H=380V,3N~,60Hz

10 Indoor and Outdoor Unit Code I=Indoor unit; O=Outdoor unit

Model Line-Up

Model Name

Capacity

Power supply

Heating

1

,kW Cooling2,kW

GRS-CQ16Pd/NaB-K 15.5 14.5

220-240V,~,50HzGRS-CQ14Pd/NaB-K 13.5 13.5

GRS-CQ12Pd/NaB-K 12.5 12.5

GRS-CQ16Pd/NaB-M 15.5 15.0

380-415V,3N~,50HzGRS-CQ14Pd/NaB-M 14.2 14.5

GRS-CQ12Pd/NaB-M 12.5 13.5

Note:

1

Capacities and power inputs are based on the following conditions:

Indoor Water Temperature 30°C/35°C,Outdoor Air Temperature 7°C DB/6°C WB;

2

Capacities and power inputs are based on the following conditions:

Indoor Water Temperature 23°C/18°C,Outdoor Air Temperature 35°C DB/24°C WB.

Air-to-water Heat Pump

7

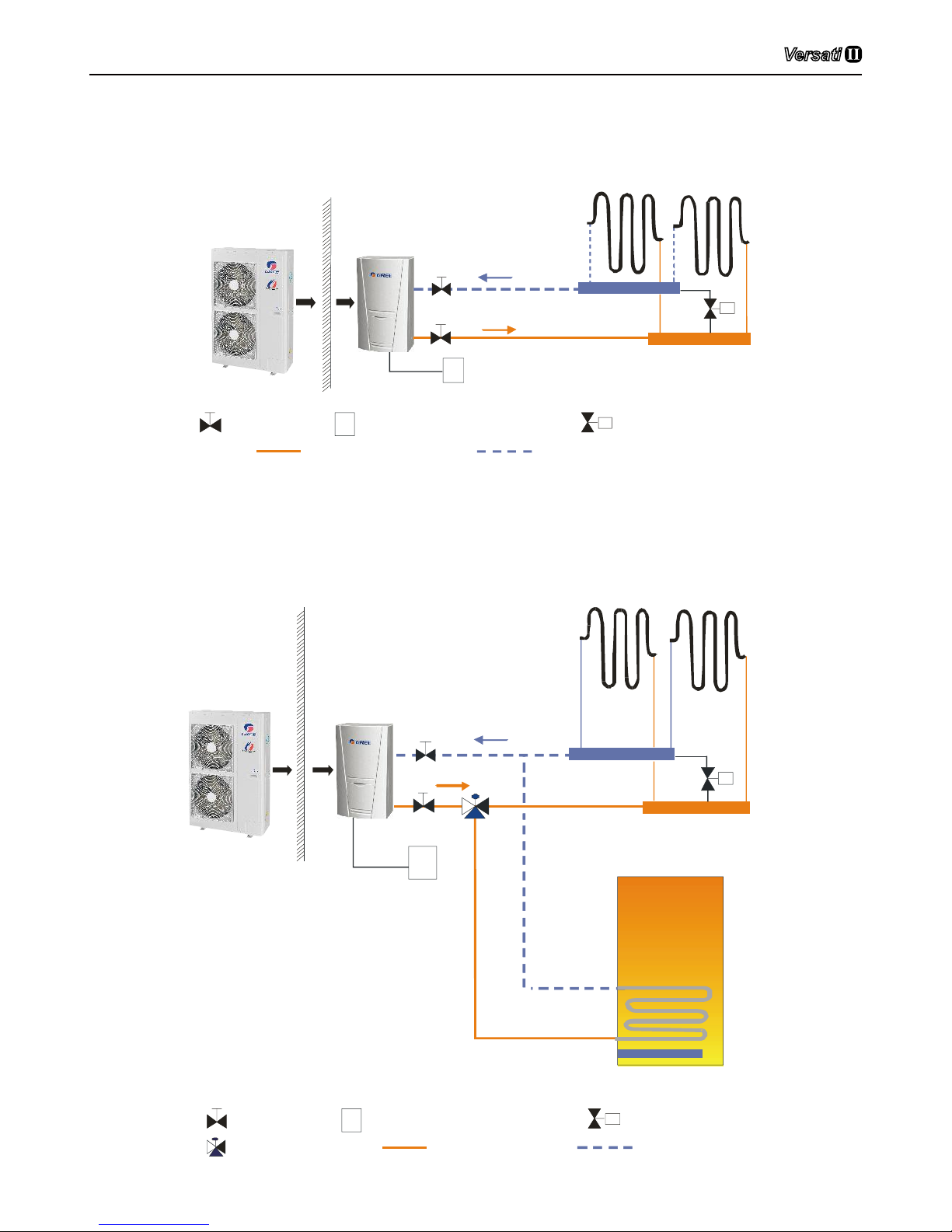

6 Installation Example

CASE 1: Connecting Under-oor Coil for Heating and Cooling

B

Under- floo r coil

Outdoo r

Indoor

T

Shut o ff value

By-pass value(Field supply)

Remote room Thermo stat(Field supply)

High temperature line

Low temperature line

T

B

Note:

①

Type of thermostat and specication should be complied with installation of this manual;

②

By pass valve must be installed to secure enough water ow rate,and by pass valve should be

installed at the collector;

CASE 2: Connecting Sanitary Water Tank

Shut off value

By-pass value(Field supply)

Remote room Thermo stat(Field suppl y)

High temperature line

Low temperature line

T

B

3-way value(Field supply)

B

T

IndoorOutdoor

Booster heater

Sanitary water tank

Under-floor coil

Air-to-water Heat Pump

8

Note:

①

In this case, three-way valve should be installed and should be complied with installation of this

manual;

②

Sanitary water tank should be equipped with internal electric heater to to secure enough heat

energy in the very cold days;

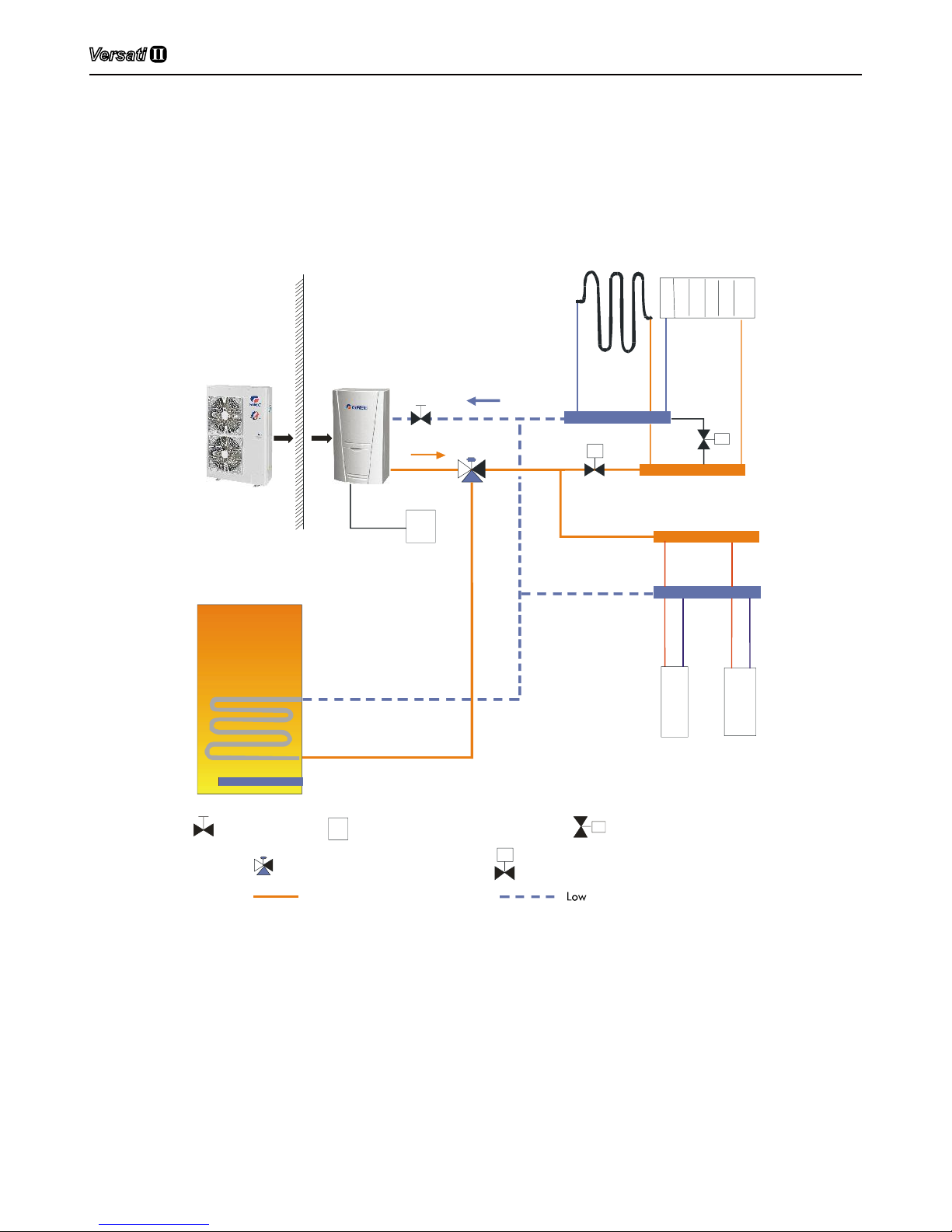

CASE 3 : Connecting Sanitary Water Tank and Heat Emitters for Heating and Cooling

IndoorOutdoor

Booster heater

Sanitary water tank

Under-floor coil Radiator

Shut off value

By-pass value(Field supply)

Remote room Thermo stat(Field suppl y)

High tempe rature temperature line

line

T

B

3-way value (Field supply)

B

FCU 1

FCU2

M

T

M

2-way value(Field supply)

Two-way valve is very important to prevent dew condensation on the floor and Radiator while

cooling mode.

Air-to-water Heat Pump

9

7 Main Components

7.1 Indoor unit

GRS-CQ12Pd/NaB-K(I), GRS-CQ14Pd/NaB-K(I), GRS-CQ16Pd/NaB-K(I), GRS-CQ12Pd/NaB-M(I),

GRS-CQ14Pd/NaB-M(I), GRS-CQ16Pd/NaB-M(I)

External

Air Vent

Electric Heater

Plate Heat Exchanger

Control Box

Control Panel

Water Pressure Gage

Flow Switch

Water Pum

p

Expansion Tank

Safety Valve

Internal

Air-to-water Heat Pump

10

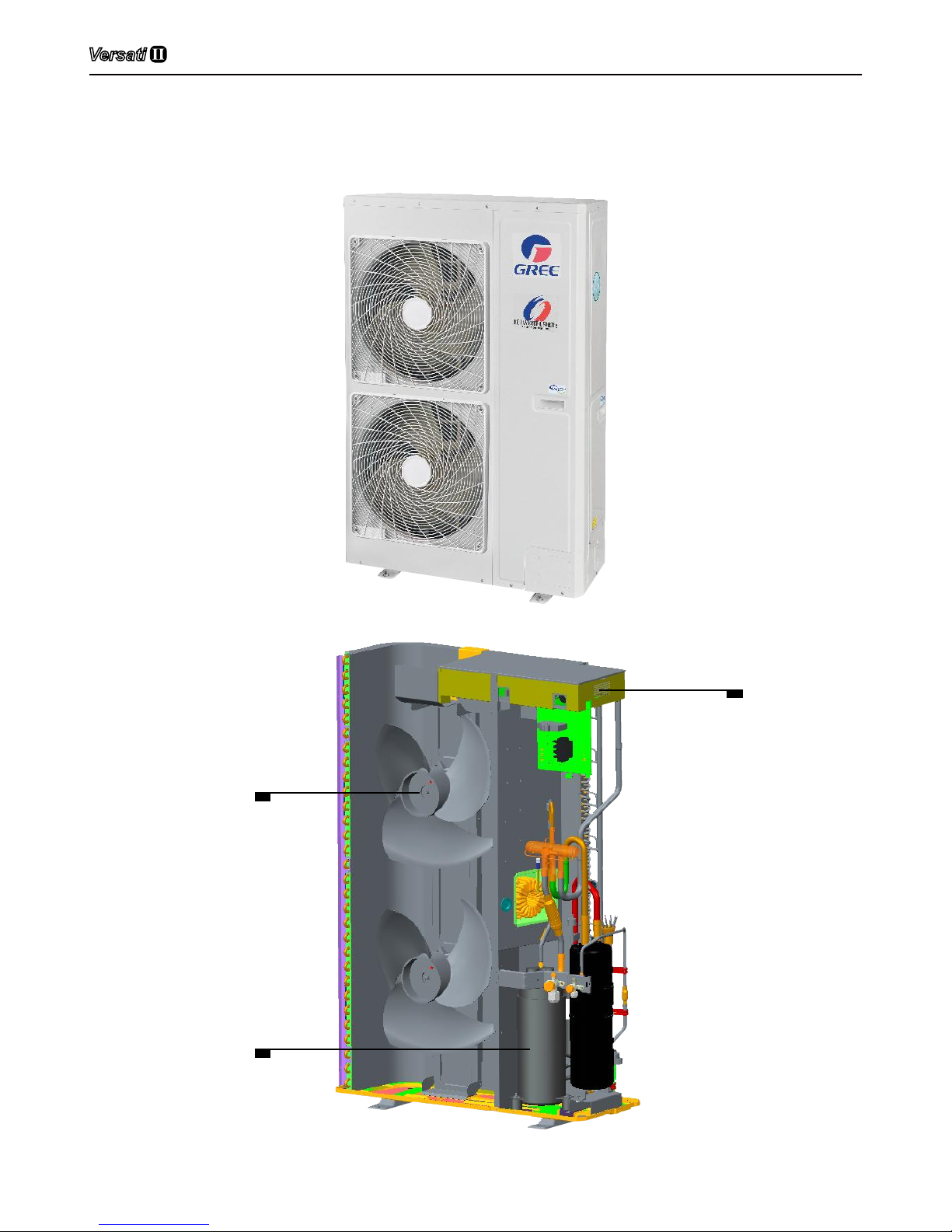

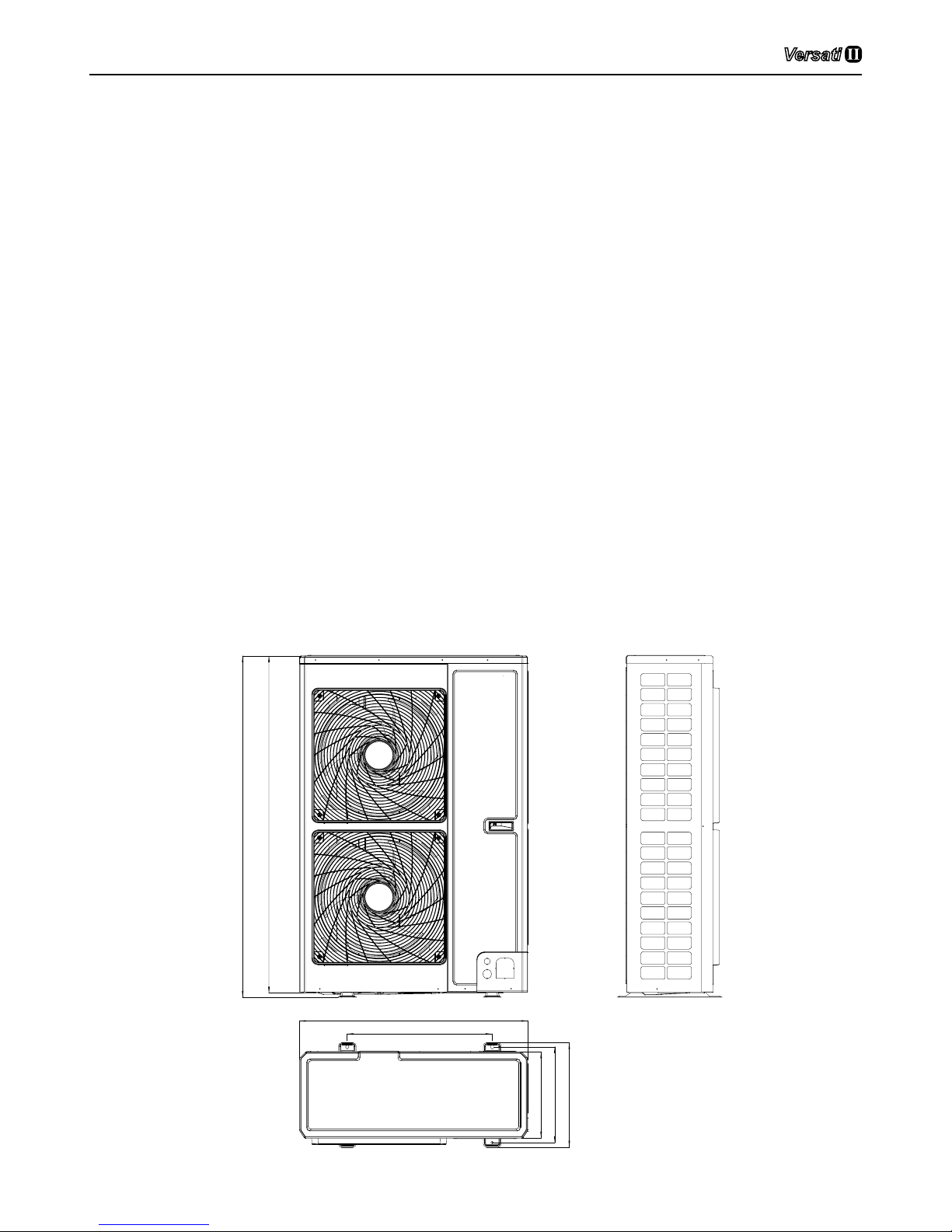

7.2 Outdoor unit

GRS-CQ12Pd/NaB-K(O), GRS-CQ14Pd/NaB-K(O), GRS-CQ16Pd/NaB-K(O), GRS-CQ12Pd/NaB-M(O),

GRS-CQ14Pd/NaB-M(O), GRS-CQ16Pd/NaB-M(O)

External

Compressor

Control Box

DC Fan Motor

Internal

Air-to-water Heat Pump

11

8 Installation Guideline of the Unit

8.1 Instruction to installation

(1) The installation of unit must be in accordance with national and local safety codes.

(2) Installation quality will directly affect the normal use of air conditioner unit. The user is

prohibited from installation by himself. Please contact your dealer after buying this machine.

Professional installation workers will provide installation and test services according to

installation manual.

(3) Do not connect to power until all installation work is completed.

8.2 Installation of outdoor unit

8.2.1 Select installation location of outdoor unit

(1) Outdoor unit must be installed on a rm and solid support.

(2) Outdoor unit shall be installed close to the indoor unit, hence to minimize the length and

bends of cooling pipe.

(3) Avoid placing the outdoor unit under window or between two constructions, hence to prevent

normal operating noise from entering the room.

(4) Air ow at inlet and outlet shall not be blocked.

(5) Install at a well-ventilated place, so that the machine can absorb and discharge sufcient air.

(6) Do not install at a place where flammable or explosive goods exist or a place subject to

severe dust, salty fog and polluted air.

8.2.2 Outline dimension of outdoor unit

GRS-CQ12Pd/NaB-K(O), GRS-CQ14Pd/NaB-K(O), GRS-CQ16Pd/NaB-K(O),GRS-CQ12Pd/NaBM(O), GRS-CQ14Pd/NaB-M(O), GRS-CQ16Pd/NaB-M(O)

900

572

412

378

1345

1326

340

Air-to-water Heat Pump

12

Description:

Unit: inch

No Name Remarks

1 Liquid-side Service Valve 3/8 GRS-CQ12/14/16Pd/NaB-K,GRS-CQ12/14/16Pd/NaB-M

2 Gas-side Service Valve 5/8 GRS-CQ12/14/16Pd/NaB-K,GRS-CQ12/14/16Pd/NaB-M

3 Handle Used to cover or uncover the front case

4 Air discharge Grill /

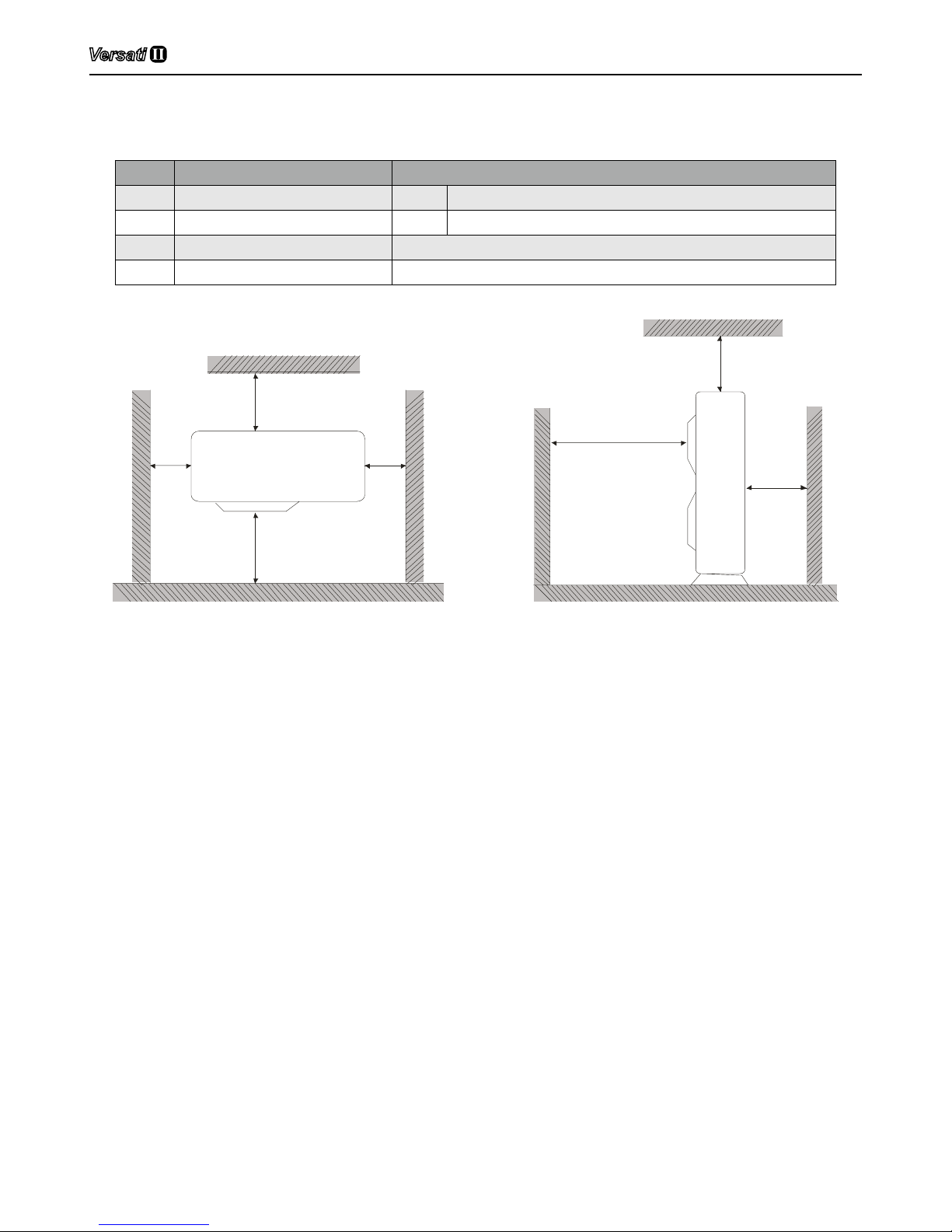

8.2.2 Space requirements for installation

>1000

>

2000

>

500

>

500

>

500

>

500

>

2000

8.2.3 Precautions on installation of outdoor unit

(1) When moving outdoor unit, it is necessary to adopt 2 pieces of long enough rope to hand the

unit from 4 directions. Included angle between the rope when hanging and moving must be

40°below to prevent center of the unit from moving.

(2) Adopt M12 bolts components to tighten feet and under frame when installing.

(3) Outdoor unit should be installed on concrete base that is 10cm height.

(4) Requirements on installation space dimension of unit’s bodies are shown in following

drawing.

(5) Outdoor unit must be lifted by using designated lifting hole. Take care to protect the unit

during lift. To avoid rusting, do not knock the metal parts.

9 Installation of Indoor Unit

9.1 Select installation location of indoor unit

(1) Avoid direct sunshine.

(2) Ensure the hanger rod, ceiling and building structure have sufcient strength to support the

weight of air conditioner unit.

(3) Drainage pipe is easy to connect out.

(4) Indoor and outdoor connection pipes are easy to go outdoors

(5) Do not install at a place where ammable or explosive goods exist or ammable or explosive

gas might leak.

(6) Do not install at a place subject to corrosive gas, severe dust, salty fog, smoke or heavy

moisture.

(7) Air ow at inlet and outlet air is not blocked.

Loading...

Loading...