Gree GMV-Pdhm224W/Na-M, GMV-Pdhm335W/Na-M, GMV-Pdhm400W/Na-M, GMV-Pdhm450W/Na-M, GMV-Pdhm504W2/Na-M Installation And Operating Instruction Manual

...

HEAT RECOVERY D.C INVERTER MULTI VRF

Installation and Operating Instruction Manual

This Manual is applicable to following outdoor units:

Basic Model:

GMV-Pdhm224W/Na-M GMV-Pdhm280W/Na-M

GMV-Pdhm335W/Na-M GMV-Pdhm400W/Na-M

GMV-Pdhm450W/Na-M

Combined Model:

GMV-Pdhm504W2/Na-M ~ GMV-Pdhm1800W4/Na-M

Please read this Manual carefully before

installation and use.

Thanks for your selection of Gree Air Conditioner Unit. Before use, please read this instruction

manual carefully and keep it properly to ensure correct use of this machine.

Instruction to Users 1

Safety Considerations 3

Selection of Installation Location and Precautions 8

Installation of Outdoor Unit 14

Connection of Indoor and Outdoor Units 25

Communication of the System 44

Notice for Project Installation 64

Installation Guideline for Air

Conditioner Unit

Filling of Refrigerants and Test Run 66

Operating Principle of Muti-split and Heat-recovered Air-Conditioning

Units

68

Types of Indoor Units to Be Integrated 70

Maintenance Measures 71

Reclaim refrigerants 72

Troubleshooting 75

Operating Temperature Range and Rated Work Conditions of the Unit

80

Performance Parameters of the Unit

81

1

Instruction to Users

☆ During using the unit under only-cooling /heating mode, the total capacity of indoor

units which are running simultaneously shouldn’t be more than that of outdoor unit,

or else poor cooling/heating capacity of each indoor unit will be resulted in. Under

principal-cooling /heating mode, the total capacity of indoor units as principal part

which are running simultaneously shouldn’t be more than that of outdoor units,or

else poor cooling /heating capacity of each indoor unit will be resulted in.

☆ According to capacity of each indoor unit, an air switch (or fuse) to each indoor unit

and a master switch to all indoor units should be installed. Each air switch, which is

usually shut off, is used for short circuit protection and abnormal overload of

corresponding indoor unit。The master switch is used for unified power supply for

all indoor units or shut-off of power supply.

☆ For smooth start of air conditioner unit, the main power switch shall be put to “ON”

position 8 hours before start.

☆ Upon receiving STOP signal from each indoor unit, the fan of related indoor unit will

continue to work for 20~70 seconds for purpose of utilizing the remaining cold air

or heats in heat exchanger and also make preparations for next use. This is normal.

☆ During installation, do not mix communication lines with power cables. Be sure to

separate them at minimum spacing over 20cm; otherwise it might result in

communication problem.

☆ If switch between cooling / dry mode and heating mode of indoor unit occurs or if

indoor unit is off under heating mode, brief flowing sound of refrigerants of cooling

and heating mode exchanger may occur ,which is normal.

☆ Install the cooling and heating mode exchanger in the place like corridor where

noise requirement is correspondingly lenient, furthermore, it should be installed in

ceiling with good sound insulation. Avoid installing it in the place like bedroom,

ward or office where low noise is required.

☆ An all-pole disconnection switch having a contact separation of at least 3mm in all

poles should be connected in fixed wiring

2

☆electric supply tolerances: (220-240V)±10%, (50±1)Hz

☆humidity :30-95%

☆installation altitude :max 1000m

☆transport/storage temperature : -25-55°C.

☆ Main switch provided by end user: main switch handle should be black or gray and it

can be locked in “OFF” position with padlock

☆ The main disconnection device should be explained in user manual and the height

should be recommended as 0.6-1.7m. Over current protection is required (EN

60947-3, EN 60947-2)

3

Safety Considerations

1. Please read this manual carefully before use and operate correctly as instructed in the manual.

2. You are specially warned to note the two symbols below.

WARNING!: A symbol indicates that improper operation might cause human death or severe

injuries.

CAUTIONS!: A symbol indicates that improper operation might cause human injury or

property damage.

WARNING!

z Please seek an authorized repair station for installation work. Improper installation might cause water

leakage, electric shock or fire.

z Please install at a place strong enough to support the weight of air conditioner unit. If not, the air

conditioner unit might fall down and cause human injury or death.

z To ensure proper drainage, the drainage pipe shall be correctly installed according to installation

instructions. Take proper measures for heat preservation to prevent condensing. Improper installation of

pipes might cause leakage and wet the articles in the room.

Do not use or store flammable, explosive, poisonous or other dangerous substances beside the air

conditioner.

z In case of trouble (e.g. burnt smell), please immediately cut off the main power of air conditioner unit.

z Keep air flow to avoid shortage of oxygen in the room.

z Never insert your finger or any objects into air outlet and inlet grill.

z Please take constant care to check if the mounting rack is damaged after long use.

z Never modify the air conditioner. Please contact the dealer or professional installation workers for repair

or relocation of the air conditioner.

4

Safety Considerations

Cautions!

z CAUTION FOR REFRIGERANT LEAKS

(Point to note connection with refrigerant leaks)

Introduction

The installer and system specialist shall safety against leakage according to local regulations or standards.

The following standards may be applicable if local regulations are not available. The GMV-Pdhm System

like other air conditioning system uses R410A as refrigerants.R410A itself is an entirely safe non-toxic,

non-combustible refrigerants. Nevertheless care must be taken to ensure that air conditioning facilities are

installed in a room which is sufficiently large. This assures that the maximum concentration level of

refrigerant gas is not exceeded, in the unlikely event of major leak in the system and this in accordance

with the local applicable regulations and standards.

Maximum concentration level

The maximum charge of refrigerants and the calculation of the maximum concentration of refrigerants is

directly related to the humanly occupied space in which it could leak.

The unit of measurement of the concentration is 1b/ft³(the weight in 1b of the refrigerant gas in 1 ft³

volume of the occupied space).

Compliance to the local applicable regulations and standards for the maximum allowable concentration

level is required.

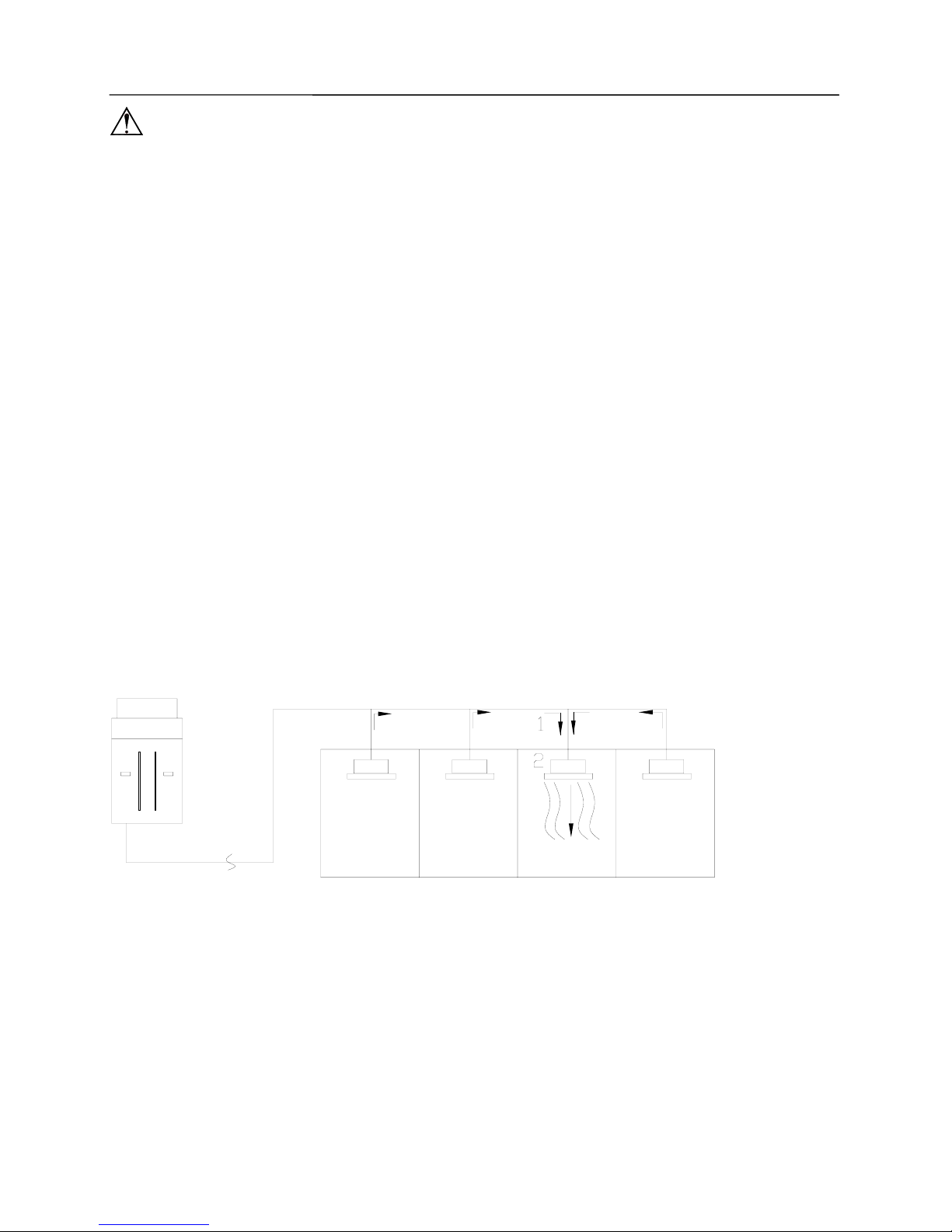

1).Direction of the refrigerant flow

2).Room where refrigerants leak has occurred (outflow of the entire refrigerants from the system).

Pay a special attention to the place, such as a basement, etc. where refrigerant can stay, since refrigerant

is heavier than air.

Procedure for checking maximum concentration .Check the maximum concentration level in accordance

with steps 11 to 4 below and take whatever action is necessary to comply.

5

Safety Considerations

1. Calculate the amount of refrigerants (1b) charged to each system separately.

Amount of refrigerants in a single unit system (amount of refrigerant with which the system is charged

before leaving the factory)

+

Additional charging amount (amount of refrigerant added locally in accordance with the length or

diameter of the refrigerant piping)

=total amount of refrigerants (1b) in the system.

NOTE

Where a single refrigerant facility is divided into 2 entirely independent refrigerant systems then use

the amount of refrigerants with which each separate system is charged.

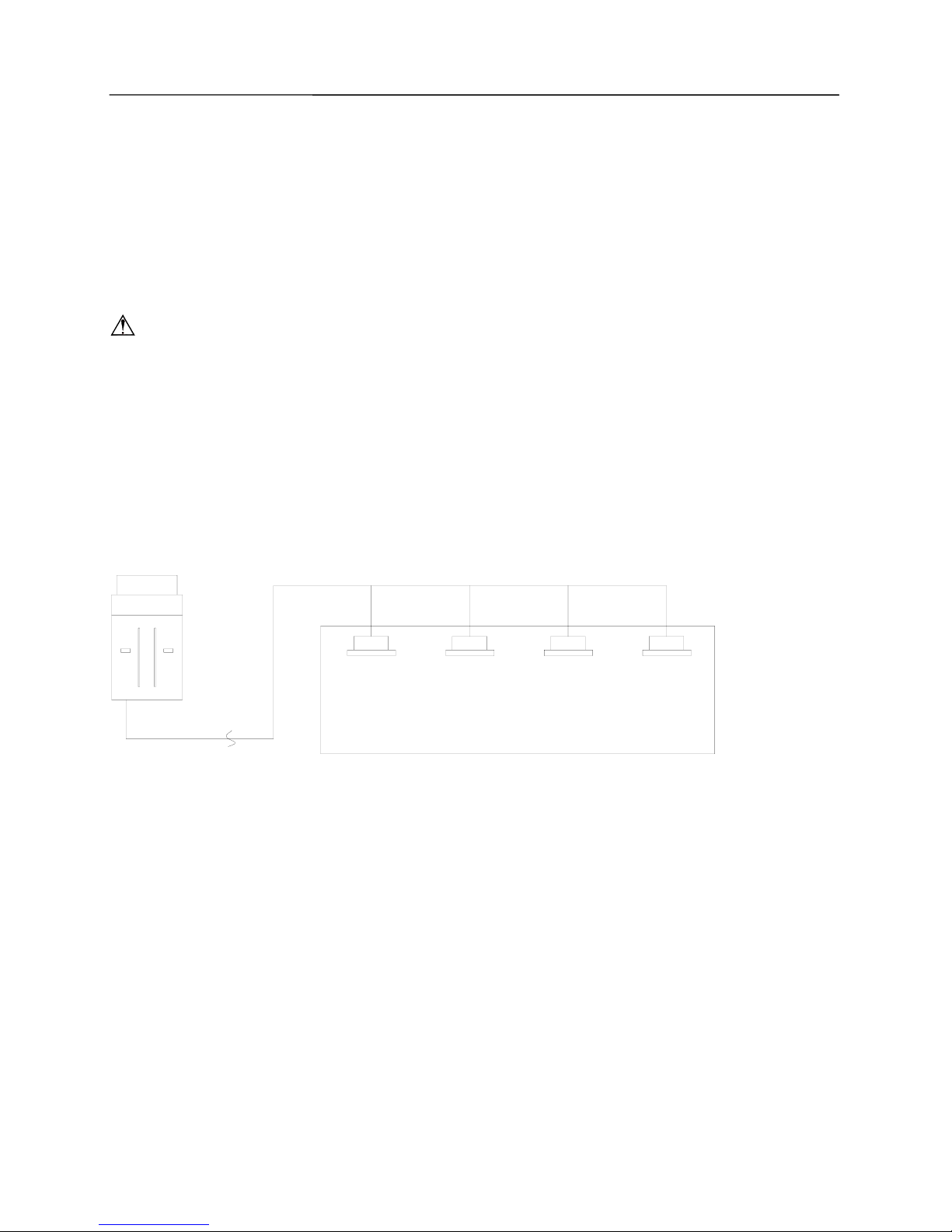

2. Calculate the smallest room volume(ft³)

Incase like the following, calculate the volume of (A), (B) as a single room or as the smallest room.

A. Where there are no smaller room divisions

B. Where there is a room division but there is an opening between the rooms sufficiently large to

permit a free flow of air back and forth.

6

Safety Considerations

1).opening between rooms.

2).partition.

(Where there is an opening without a door or where there are openings above and below the door which

are each equivalent in size to 0.15% or more of the floor area.)

3).Calculate the refrigerant density using the results of the calculations in steps 1 and 2 above.

Total volume of refrigerants in the refrigerant system ≤ maximum concentration level(1b/ ft³)

Size (ft³) of smallest room in which there is an indoor unit installed. If the result of the above

calculation exceeds the maximum concentration level then make similar calculations for the second

then third smallest room and so unit the result falls short of the second then third smallest room and

so until result falls short of the maximum concentration.

4).Dealing with the situations where the result exceeds the maximum concentration level and where the

installation of a facility encounters problem then it will be necessary to revise the system. Please consult

your GREE supplier.

z Before installation, please check the power supply for compliance with the ratings on nameplate. Check

the power safety as well. (it shall be done by professionals)

z Before use, please check and confirm if the cables, drainage pipes and pipelines are correctly

connected, hence to eliminate the risk of water leakage, refrigerants leakage, electric shock or fire(it

shall be done by professionals)

z Main power must be securely earthed to ensure effective grounding of air conditioner unit and avoid the

risk of electric shock. Please do not connect the earthing cable to coal gas pipe, water pipe, lightning

rod or telephone line.

z Once started, the air conditioner shall not be stopped at least after 10 minutes or longer; otherwise

service life of the unit will be affected.

7

Safety Considerations

z Do not let the child to operate the air conditioner unit.

z Do not operate the air conditioner unit with wet hands.

z Please disconnect the main power before cleaning the air conditioner or replacing the air filter.

z Please disconnect the main power if the air conditioner unit is out of use for a long period.

z This appliance is not intended for use by persons (including children) with reduced physical, sensory or

mental capabilities, or lack of experience and knowledge, unless they have been given supervision or

instruction concerning use of the appliance by a person responsible for their safety.

z Children should be supervised so that they can not play with the appliance.

z Please do not expose the air conditioner unit directly under corrosive environment with water or

moisture.

z Please do not put on or place any goods on air conditioner unit.

z After electrical installation, the air conditioner unit shall be energized for electrical leakage test. (it shall

be done by professionals)

8

Selection of Installation Location and Precautions

● Selection of Installation Location for Air Conditioner Unit

The installation of air conditioner unit must be in accordance with national and local safety

codes.

Installation quality will directly affect the normal use of air conditioner unit. The user is

prohibited from installation himself. Please contact your dealer after buying this machine.

Professional installation workers will provide installation and test services according to

installation manual.

Do not power on until all installation work is completed.

●

Selection of Installation Location for Indoor Unit

Avoid ☆ exposing in sunshine.

Ensure the hanger rod, ceiling and building structure have sufficient strength to support the weight of air ☆

conditioner unit.

☆ Drainage pipe is easy to connect out.

☆ Air inlet and outlet is not blocked.

Indoor and outdoor connection pipes are easy to go outdoors.☆

Do not install at a place where flammable or explosive goods exist or flammable or explosive gas might ☆

leak.

Do not install at a place☆ where there are corrosive gas, severe dust, salty fog, smoke or heavy moisture.

Select Installation Location of Outdoor Unit

Outdoor unit must be installed on a firm and solid support.☆

Outdoor unit shall be installed close to the indoor unit, hence to minimize the length ☆ and bends of cooling

pipe.

Avoid placing the outdoor unit under window or between two constructions, hence to prevent normal ☆

operating noise from entering the room.

Air flow at inlet and outlet shall not be blocked.☆

Install at a well☆ -ventilated place, so that the machine can absorb and discharge sufficient air.

Do not install at a place where flammable or explosive goods exist or a place ☆ where there are severe dust,

salty fog and polluted air.

Do not install induced draught pipe at the inlet and outlet of the outdoor unit. When the air

conditioner unit is generating heats indoors, the condensate water may flow from the base

of outdoor unit. When outdoor air is below 0 (32 ), the condensate water will be frozen. ℃℉

Take care that the installation of outdoor unit shall not affect the heat radiation of the unit.

9

Selection of Installation Location and Precautions

Caution!

Installation at following positions might cause trouble to the air conditioner unit. If unavoidable, please

contact Authorized Service Center.

A place full of machine oil; A region with saline①②-sodic soil near the sea;; A place with sulphide ③

gases (such as sulphur spring); A place with high frequency facilities, such as radio equipment, electric ④

welder or medical equipment;; An environment wi⑤ th special conditions.

● Cable Layout

Carry out installation in accordance with the state line layout rules. ☆

The power supply must be of rated voltage of the unit and special electrical line for air☆ -conditioning.

Please do not pull the ☆ power cord violently.

All electrical installation shall be carried out by professional technicians in accordance with the local laws ☆

and regulations.

The diameter of flexible power cable must be large enough; damaged flexible power cable and ☆

connection cable must be replaced by flexible cables for such special purpose.

☆ Ensure that safe grounding and the grounding wire shall be connected with the special grounding

equipment of the building and must be installed by professional technicians. In the fixed line there must

be an electrical leakage protection switch and an air switch with sufficient capacity (refer to the following

table). The air switch shall also have the magnetic tripping and thermal tripping functions to achieve

protection of both short-circuit and overload.

10

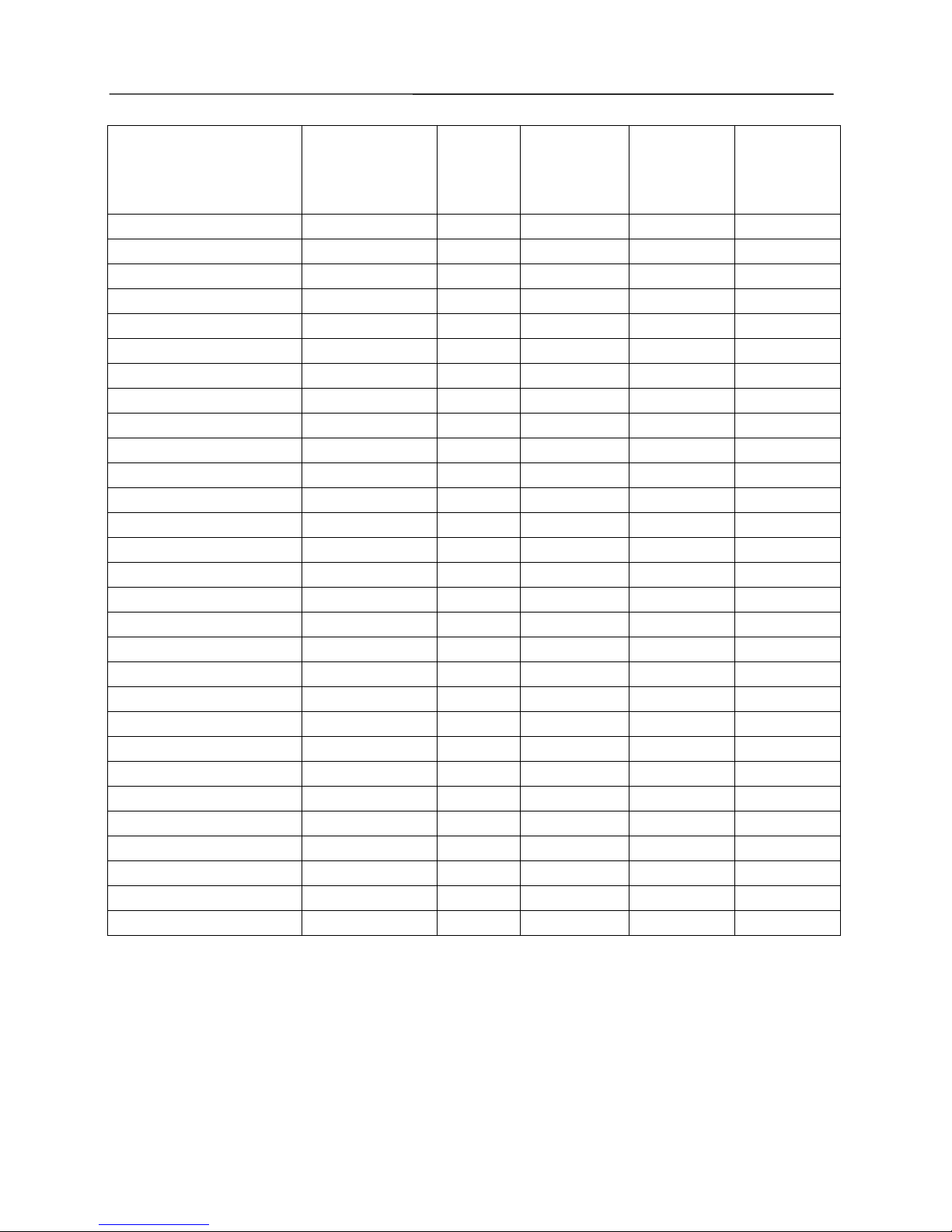

Selection of Installation Location and Precautions

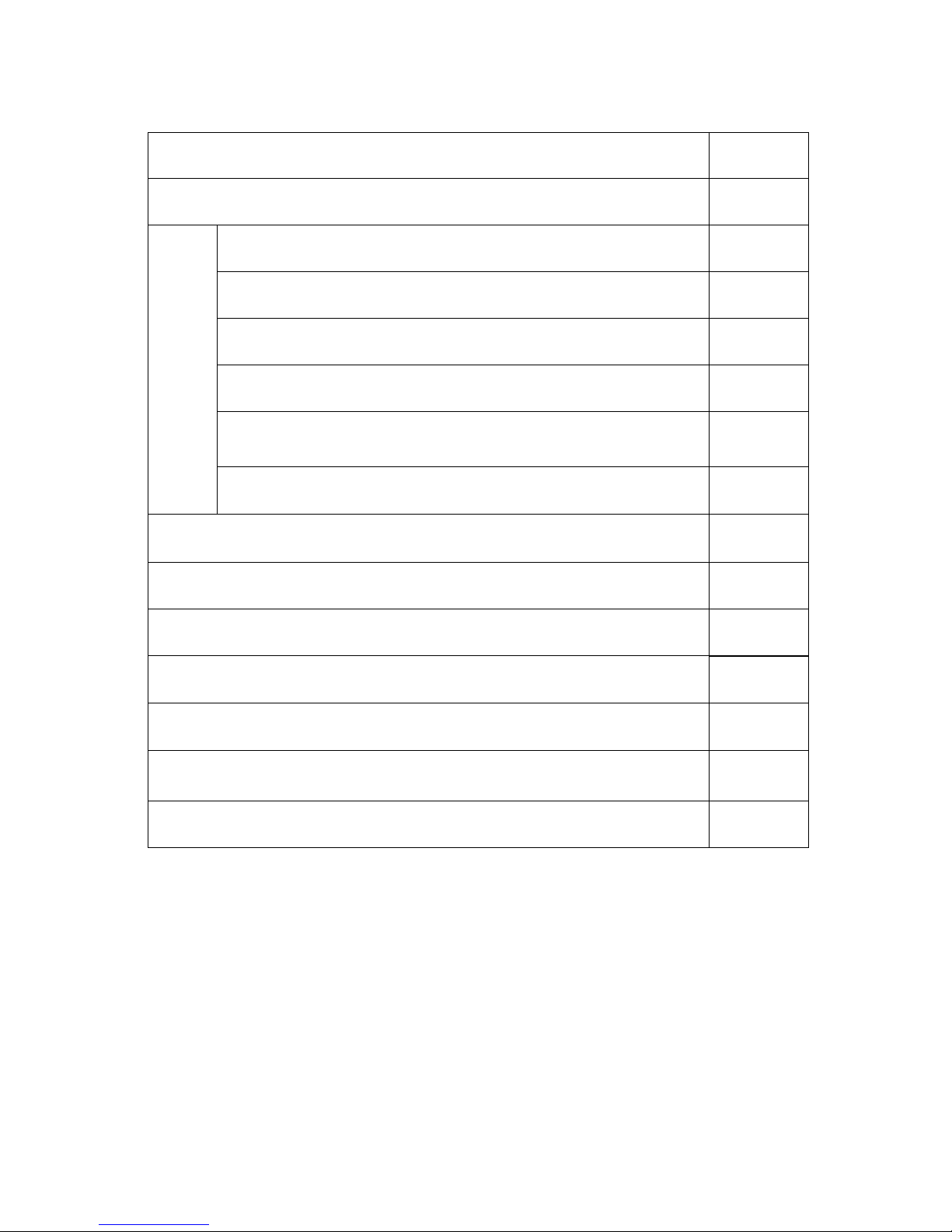

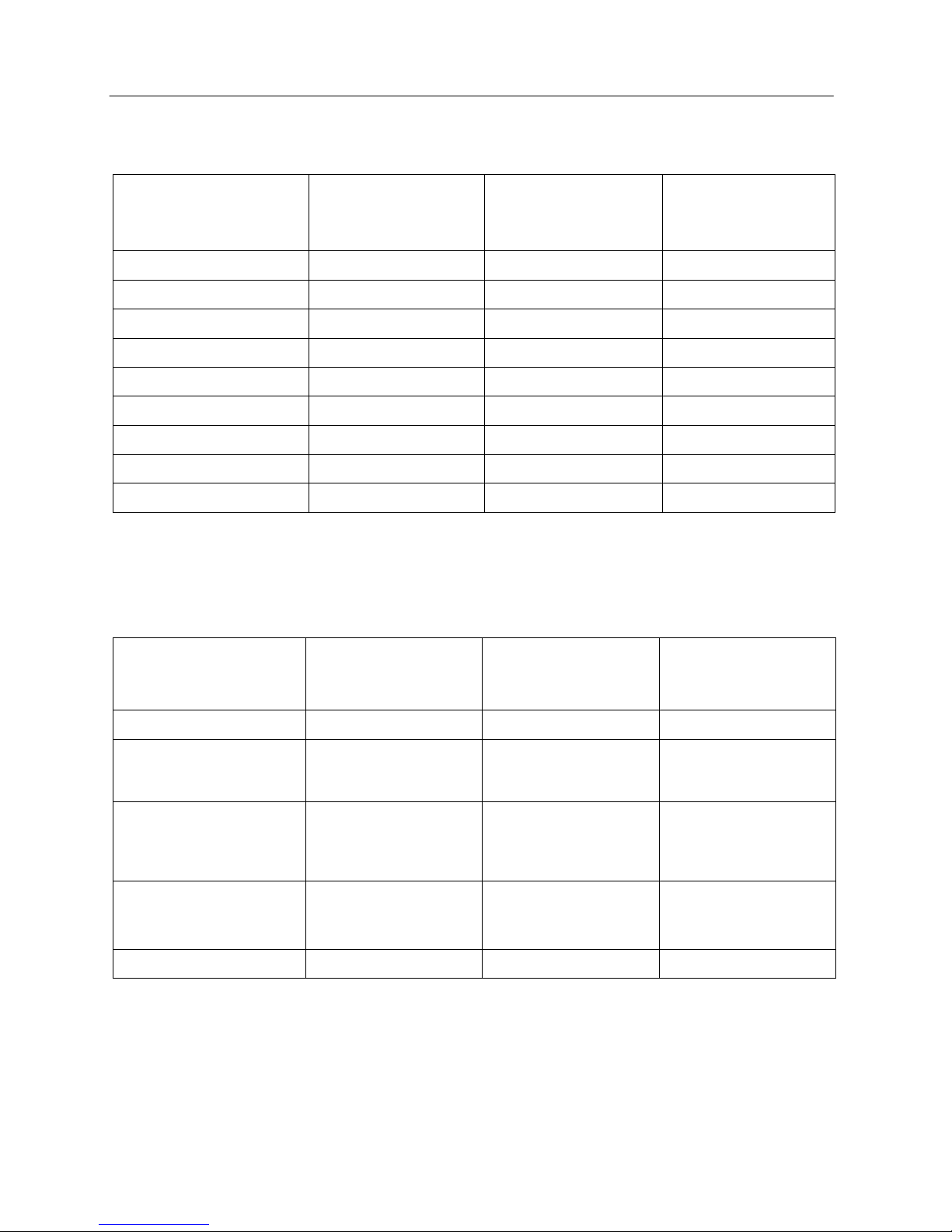

Model

Power supply

(V,Ph,Hz)

Capability

of circuit

breaker

(A)

Min.

sectional

area of earth

lead (mm

2

)

Min.

sectional

area of

power cord

(mm

2

)

The number

of the

cord(N)

GMV-Pdhm224W/Na-M 380~415,3 ,50 32 6.0 6.0

5

GMV-Pdhm280W/Na-M 380~415,3 ,50 32 6.0 6.0

5

GMV-Pdhm335W/Na-M 380~415,3 ,50 40 10.0 10.0

5

GMV-Pdhm400W/Na-M 380~415,3 ,50 40 10.0 10.0

5

GMV-Pdhm450W/Na-M 380~415,3 ,50 40 10.0 10.0

5

GMV-Pdhm504W2/Na-M 380~415,3 ,50 63 25.0 25.0

5

GMV-Pdhm560W2/Na-M 380~415,3 ,50 63 25.0 25.0

5

GMV-Pdhm615W2/Na-M 380~415,3 ,50 80 35.0 35.0

5

GMV-Pdhm680W2/Na-M 380~415,3 ,50 80 35.0 35.0

5

GMV-Pdhm730W2/Na-M 380~415,3 ,50 80 35.0 35.0

5

GMV-Pdhm800W2/Na-M 380~415,3 ,50 80 35.0 35.0

5

GMV-Pdhm850W2/Na-M 380~415,3 ,50 80 35.0 35.0

5

GMV-Pdhm900W2/Na-M 380~415,3 ,50 80 35.0 35.0

5

GMV-Pdhm960W3/Na-M 380~415,3 ,50 100 50.0 50.0

5

GMV-Pdhm1010W3/Na-M 380~415,3 ,50 100 50.0 50.0

5

GMV-Pdhm1065W3/Na-M 380~415,3 ,50 125 70.0 70.0

5

GMV-Pdhm1130W3/Na-M 380~415,3 ,50 125 70.0 70.0

5

GMV-Pdhm1180W3/Na-M 380~415,3 ,50 125 70.0 70.0

5

GMV-Pdhm1250W3/Na-M 380~415,3 ,50 125 70.0 70.0

5

GMV-Pdhm1300W3/Na-M 380~415,3 ,50 125 70.0 70.0

5

GMV-Pdhm1350W3/Na-M 380~415,3 ,50 125 70.0 70.0

5

GMV-Pdhm1410W4/Na-M 380~415,3 ,50 160 95.0 95.0

5

GMV-Pdhm1460W4/Na-M 380~415,3 ,50 160 95.0 95.0

5

GMV-Pdhm1515W4/Na-M 380~415,3 ,50 160 95.0 95.0

5

GMV-Pdhm1580W4/Na-M 380~415,3 ,50 160 95.0 95.0

5

GMV-Pdhm1630W4/Na-M 380~415,3 ,50 160 95.0 95.0

5

GMV-Pdhm1700W4/Na-M 380~415,3 ,50 160 95.0 95.0

5

GMV-Pdhm1750W4/Na-M 380~415,3 ,50 160 95.0 95.0

5

GMV-Pdhm1800W4/Na-M 380~415,3 ,50 160 95.0 95.0

5

Note:The specification of power cord mentioned hereby is defined as the required specification when wiring

with BV single core cable (2 ~ 4 pieces) under the cover of PVC pipe, and environment temperature shall be

at 40℃; Air switch shall be selected according to 40℃ temperature condition, and shall in “D” type. if the

installation conditions on site change, please consider the modification on the required specification of

Power cord and Air switch, according to the specification manual provided by manufacture.

● Grounding Requirement

As air☆ -conditioning unit is of Class 1 electrical appliance, reliable grounding measures must be taken for

11

Selection of Installation Location and Precautions

it.

☆ The double color (yellow and green) cable inside the unit is specially used for grounding, so it shall not

be used for other purposes nor can it be cut. Do not tighten with tapping screws; otherwise it might cause

risk of electric shock.

Installation of earth resistance should be in accordance with local ☆ standards.

The user power supply shall have reliable grounding terminal. It is prohibited to connect the grounding wire

to the following items:

① Water Supply Pipe Gas Pipe Sewage Pipe L②③ ④ightning Rod or Earth Line of Phone Other ⑤

positions that are considered to be unreliable by professionals.

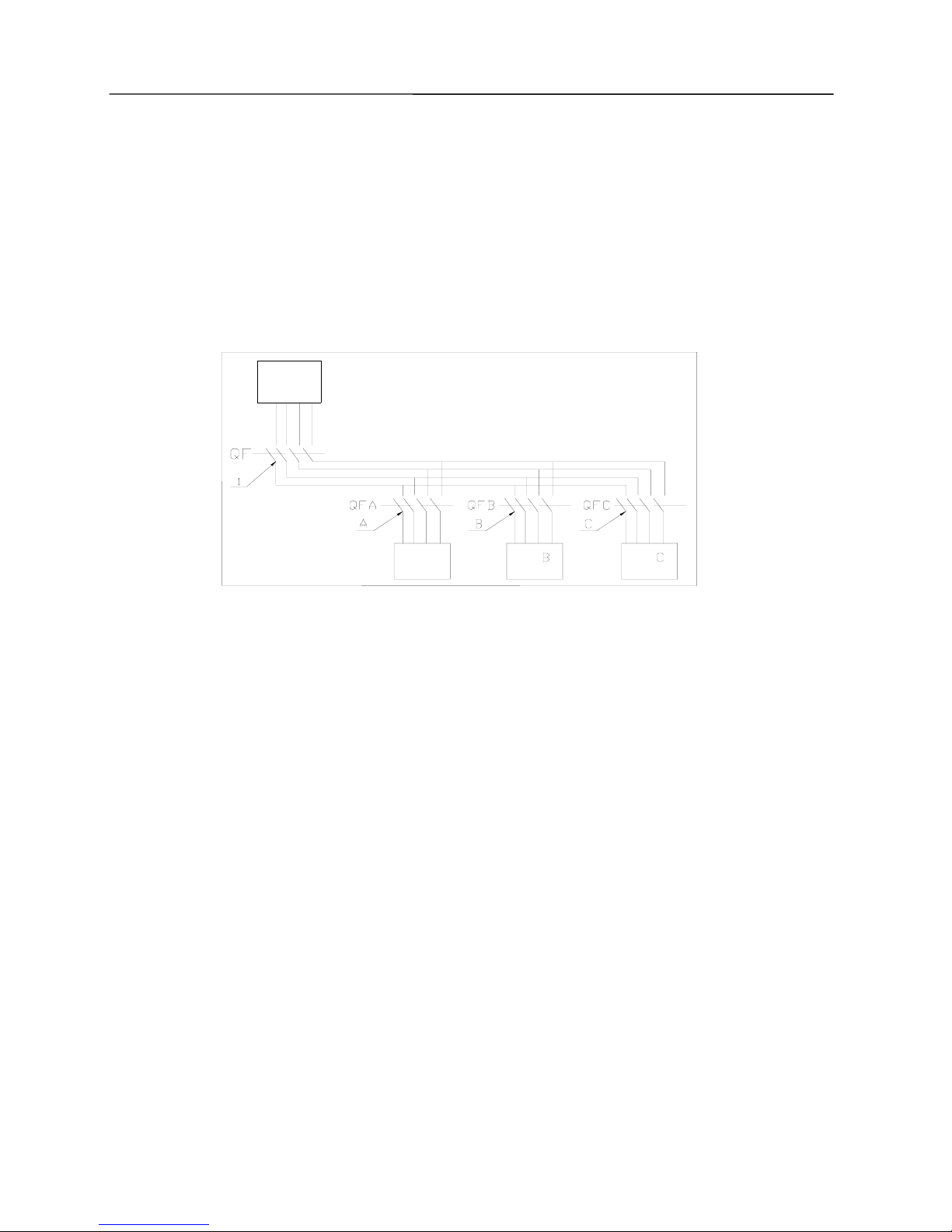

z Connection of power cord

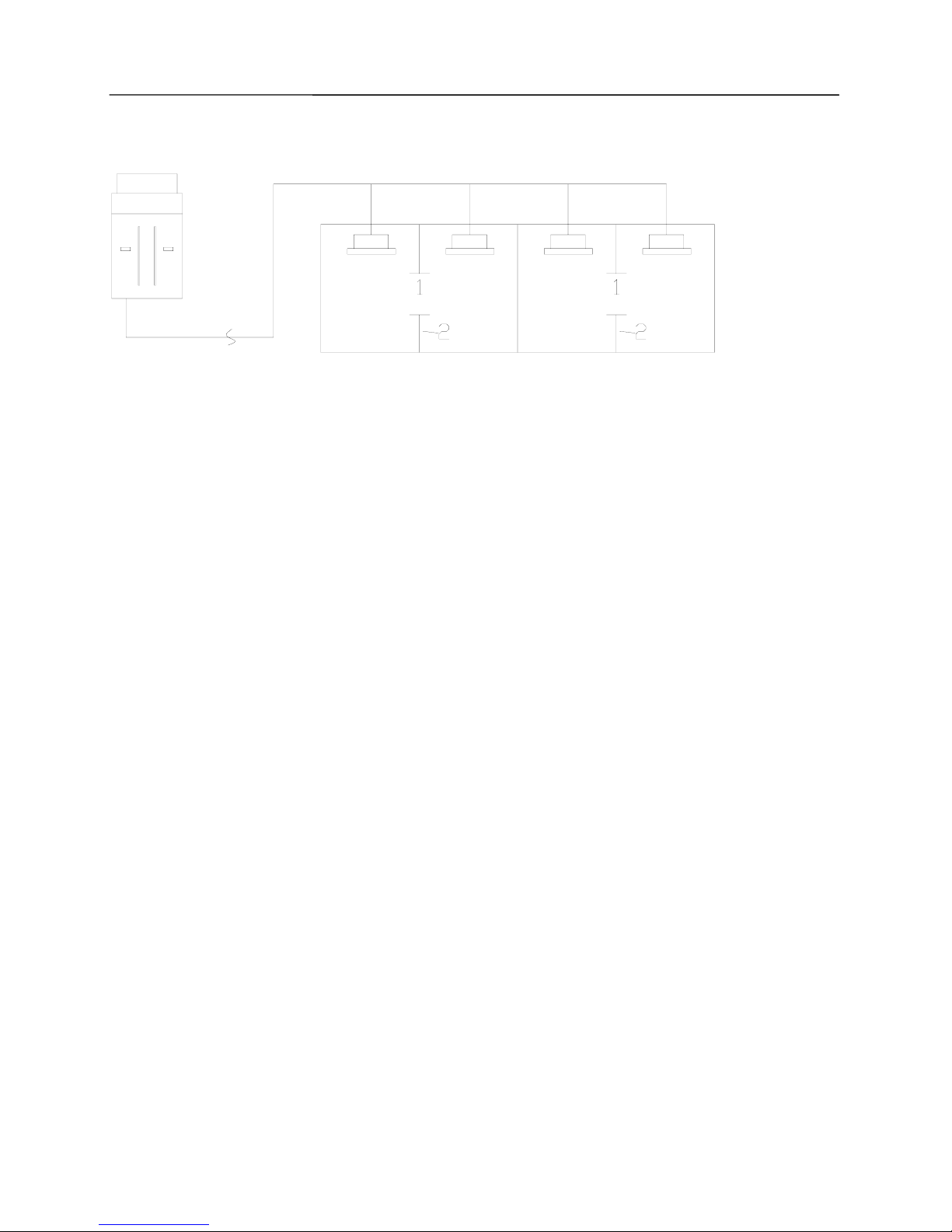

Unit A

Power

Cabinet

Unit Unit

12

Selection of Installation Location and Precautions

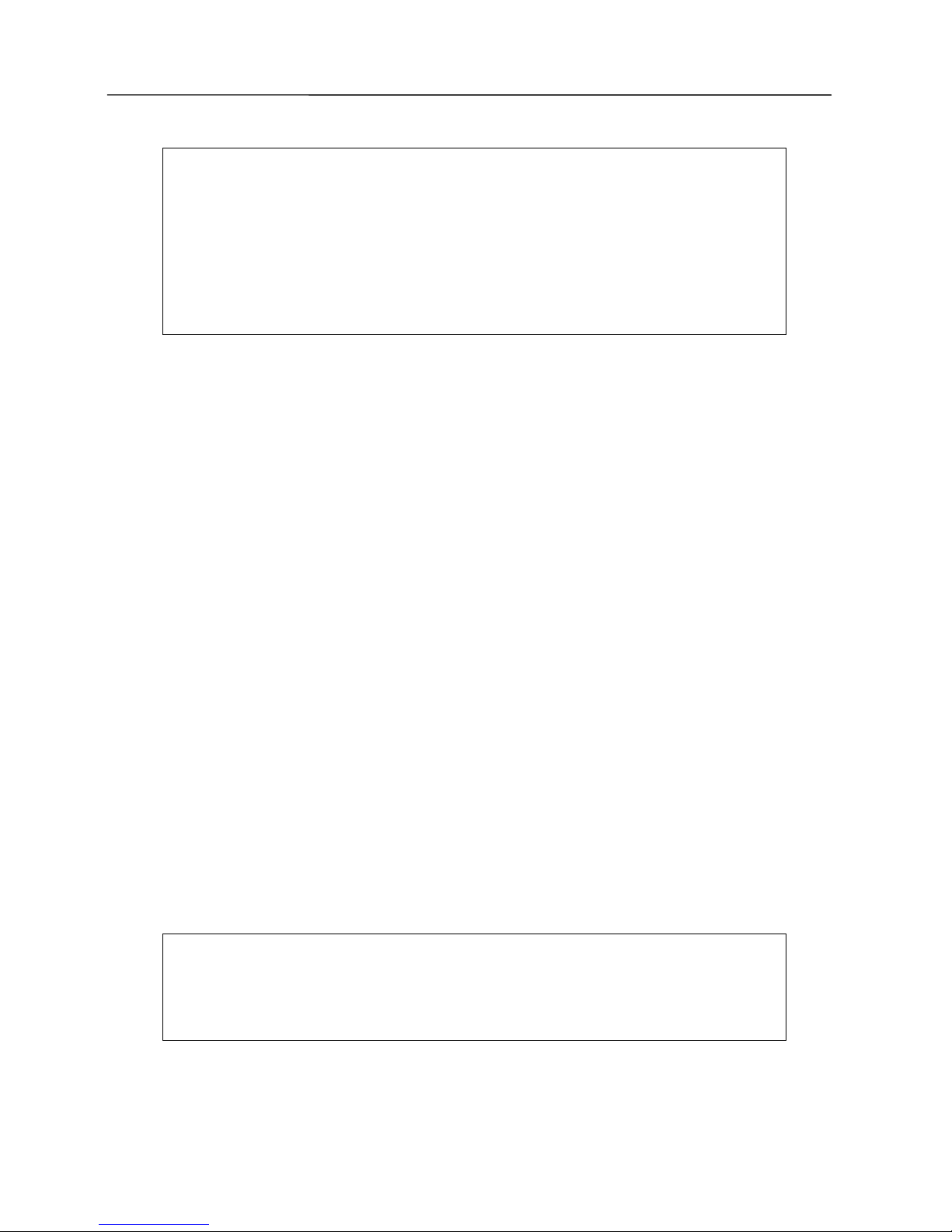

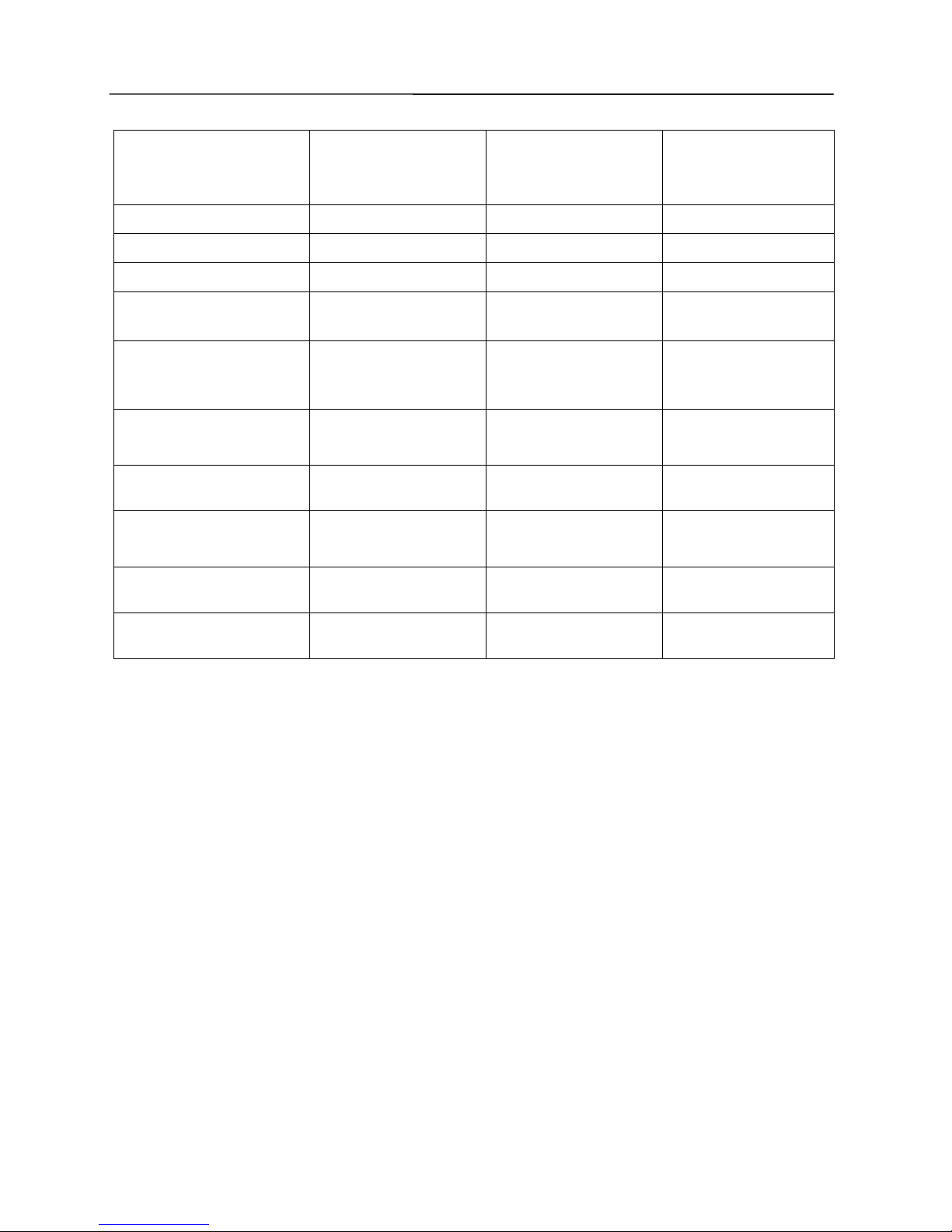

Power Supply Specification of Indoor Units

Sheet A: Circuit breakers below indicate total capacity of circuit breakers which are corresponding to indoor

units connecting general supply in the same system.

Total Capacity of the indoor

unit

Capacity of the Circuit

breaker

Min. Sectional Area of

Power Cord (mm

2

)

Min. Sectional Area of

Earth lead (mm

2

)

10A 以下

10 1.5 1.5

20~10A

20 4.0 4.0

32~20A

32 6.0 6.0

40~32A 40 10.0 10.0

50~40A 50 16.0 16.0

63~50A 63 35.0 16.0

80~63A 80 35.0 16.0

100~80A 100 50.0 25.0

125~100A 125 70.0 35.0

Note: Specific parameters can be revised according to conditions and laws of users’ country

Circuit breakers are closed in normal condition,which are for the purpose of short circuit protection for

indoor units and abnormal overload. All terminals of circuit breakers should be connected to a same

general supply switch for cutting power supply of all indoor units.

Indoor Unit Model

Capacity of the Circuit

breaker

Min. Sectional Area of

Earth lead (mm

2

)

Min. Sectional Area of

Power Cord (mm

2

)

Wall-mounted Units 10 1.0 1.0

Duct Type Units 10 1.0 1.0

Cassette Type Units( Heat

Pump or Cooling Only)

10 1.0 1.0

One-way Cassette Type units 10 1.0 1.0

Floor-standing Units 10 1.0 1.0

13

Selection of Installation Location and Precautions

If choose the indoor unit with auxiliary electric heater which decides the capacity of circuit breaker. Below is

the circuit breaker models which should be specially configured.

Model of Indoor Units(with

auxiliary electric)

Capacity of Circuit Breaker

Min. Sectional Area of

Earth lead (mm

2

)

Min. Sectional Area of

Power Cord (mm

2

)

22、28、32、36 duct type units

10 1.0 1.0

40、45、50duct type units

13 1.5 1.5

56、63、71、80duct type units

20 2.5 2.5

90、100、112、125、140 duct

type units

13 1.5 1.5

28、36、45、50 cassette type

units

10 1.0 1.0

56、63、71 cassette type units

13 1.5 1.5

80、90、112、125 cassette type

units

13 1.5 1.5

22、25、28、32、36 ultra-thin

duct units

10 1.0 1.0

40、45、50 ultra-thin duct units

13 1.5 1.5

56、63、71 ultra-thin duct units

16 2.5 2.5

●

Noise Control

Install ☆ the unit at a well-ventilated place; otherwise it might result in decreased working capacity or higher

noise.

Install ☆ the unit securely on a base that can fully support its weight; otherwise vibration and noise might be

caused.

Install the outdoor unit so that the hot air or noise will not disturb your neighb☆ ors.

Do not place any obstacle close the outlet of outdoor unit; otherwise it might result in decreased working ☆

capacity or higher noise.

If the air conditioner gives out abnormal noise during use, please immediately contact your dealer.☆

● Accessories for Installation Use

For the accessories for installation of indoor units and outdoor units, please see the Packing List in the

package.

14

Installation of Outdoor Unit

●

Precautions on Installation of Outdoor Unit

To ensure the unit in proper function, selection of installation location must be in accordance with following

principles:

Outdoor unit shall be installed so that the air discharged by outdoor unit will not return and that sufficient ☆

space for repair shall be provided around the machine.

Pla☆ ce of installation must be well ventilated so that the machine can absorb and discharge sufficient air.

Ensure the air inlet and outlet of the machine are not blocked. If blocked, please clear off the obstacles

blocking the air inlet or outlet.

Place of ☆ installation shall be strong enough to support the weight of outdoor unit, and it shall be able to

insulate noise and prevent vibration. Ensure that the wind and noise from the unit will not affect your

neighbors.

Outdoor unit must be lifted by using des☆ ignated lifting hole. Take care to protect the unit during lift. To

avoid rusting, do not knock the metal parts.

Try best to avoid direct sunshine.☆

Place of installation must be able to drain the rainwater and defrosting water.☆

Place of installation ☆ must ensure that the machine will not be buried under snow or subject to the

influence of rubbish or oil fog.

To meet the noise and vibration requirements, the outdoor unit shall be installed with rubber damper or ☆

spring damper.

☆

Installation dimension shall be in accordance with the installation requirements in this

manual. Outdoor unit must be securely fixed to the position.

The unit shall be installed by professional technicians.☆

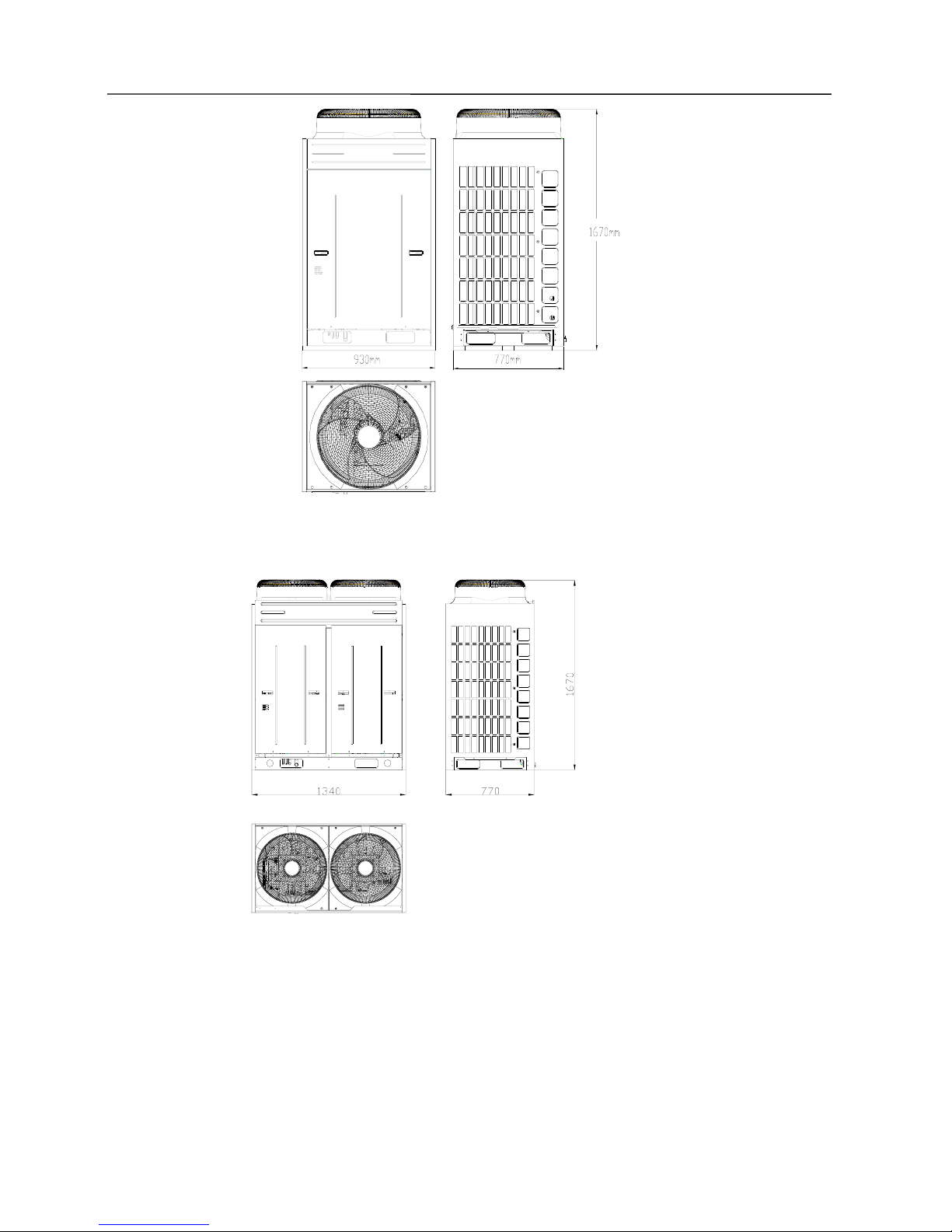

● Installation of Outdoor Unit

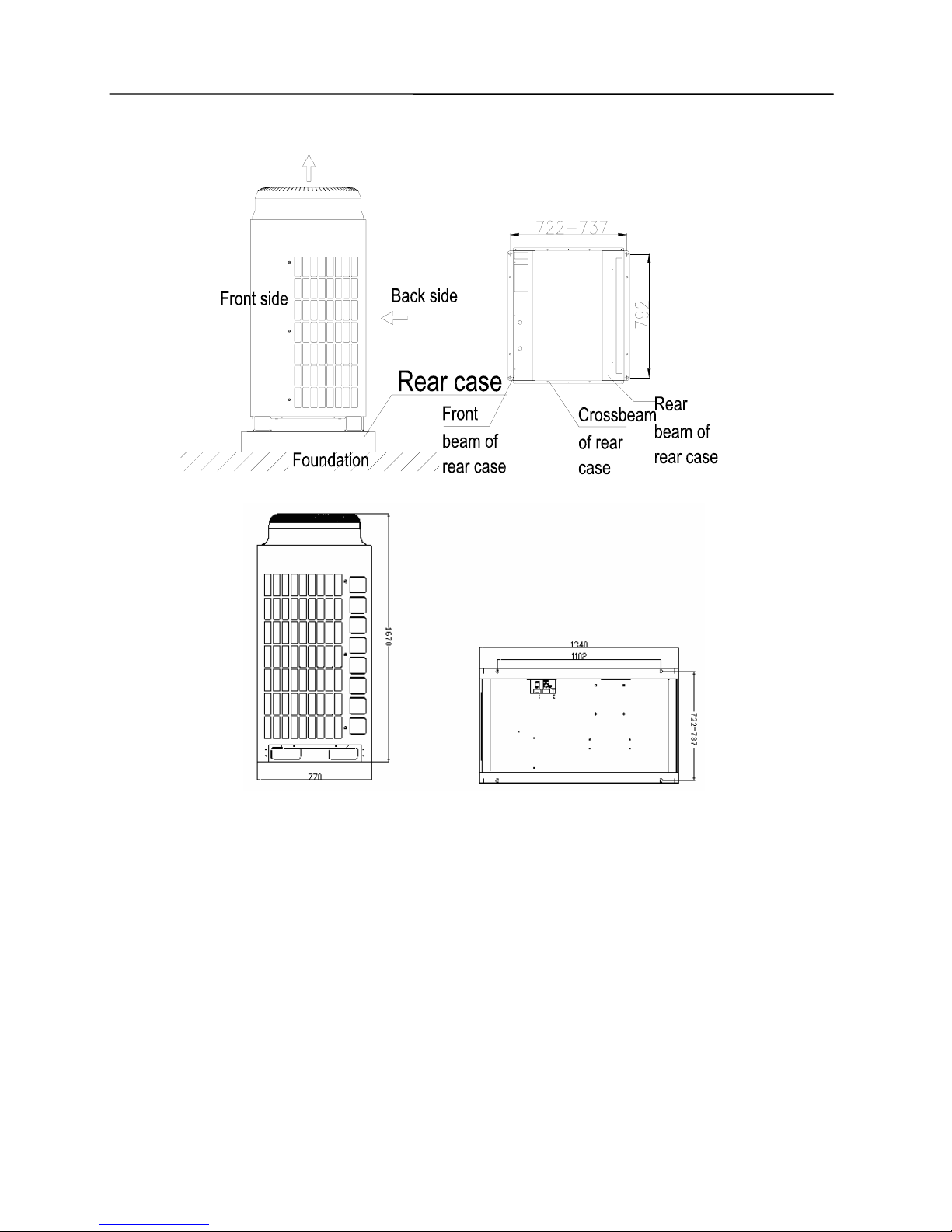

1. Outline Dimension of GMV-Pdhm224W/Na-M、GMV-Pdhm280W/Na-M

15

Installation of Outdoor Unit

Outline Dimension of GMV-Pdhm335W/Na-M、GMV-Pdhm400W/Na-M、GMV-Pdhm450W/Na-M

unit:mm

16

Installation of Outdoor Unit

2. Outdoor Unit Installation Holes of GMV-Pdhm224W/Na-M、GMV-Pdhm280W/Na-M

Outdoor Unit Installation Holes of GMV-Pdhm335W/Na-M、GMV-Pdhm400W/Na-M、GMV-Pdhm450W/Na-M

unit:mm

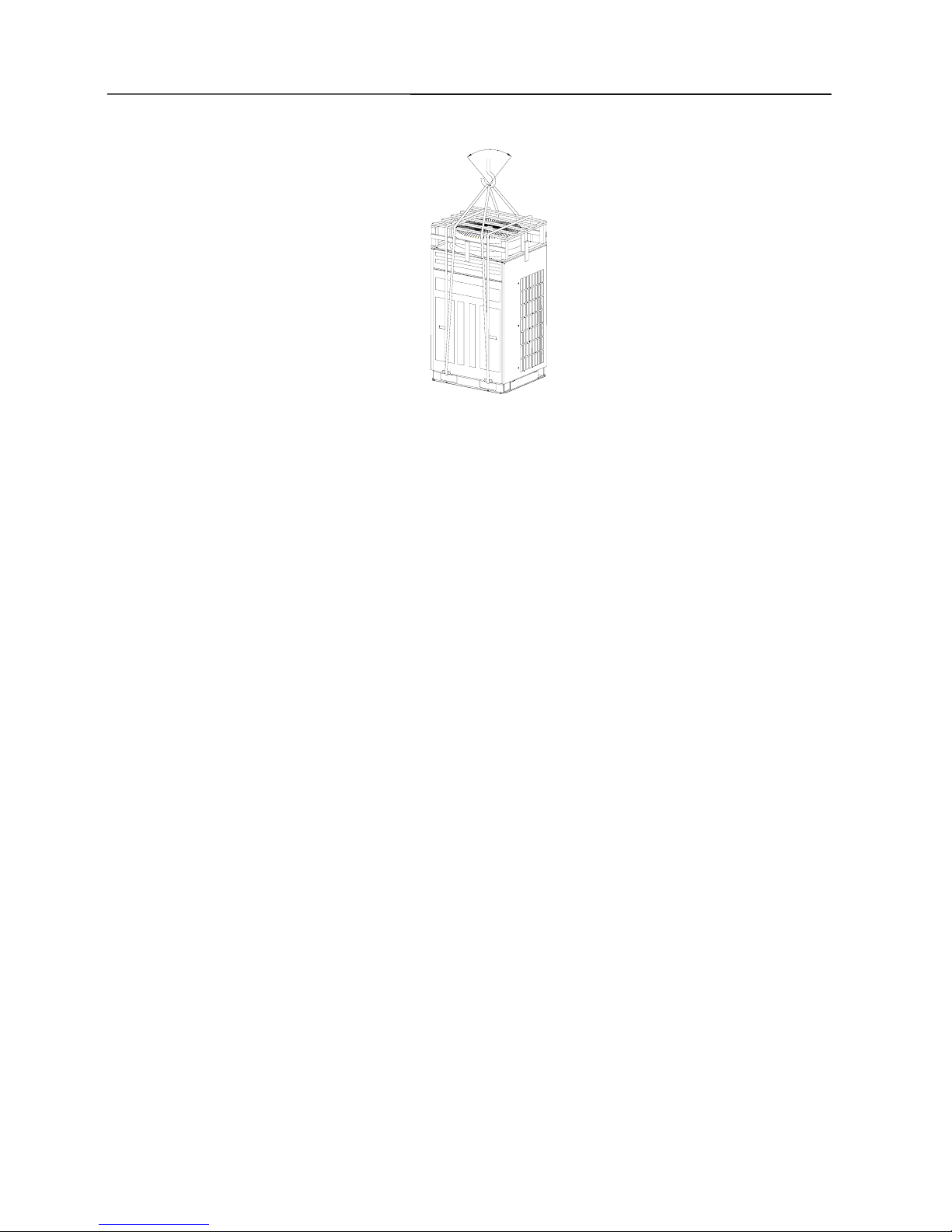

3.To handle the outdoor unit, enough length of two ropes must be used on four directions. To avoid

displacement of unit center, the angle of the ropes must be kept lower than 40

°

during lift and movement.

The below is illustration for lifting of GMV-Pdhm280W/Na-M outdoor unit, with which other outdoor unit

series with outlet on top is similar.

17

Installation of Outdoor Unit

<40°

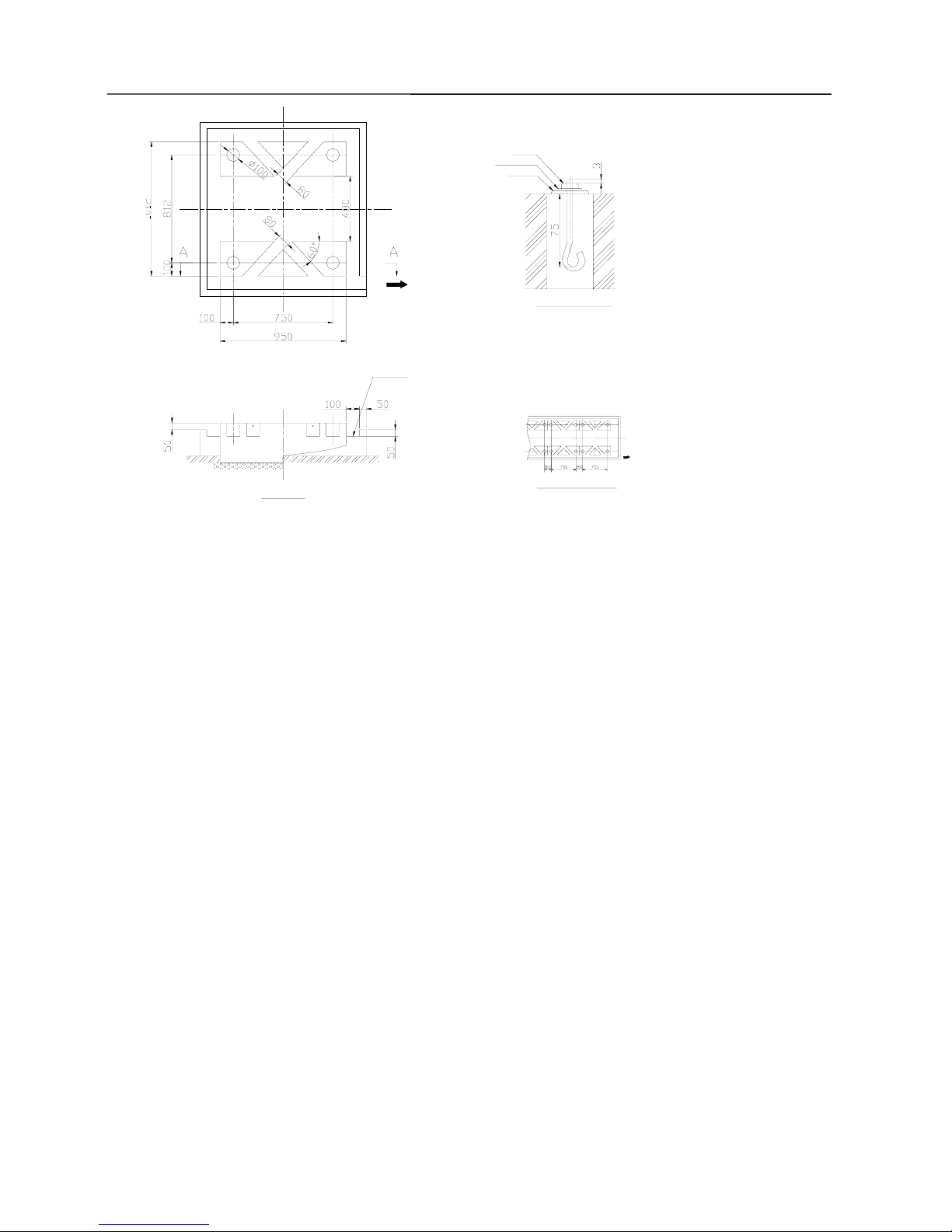

4. During installation, tighten the support and base of the unit by using M12 screws.

18

Installation of Outdoor Unit

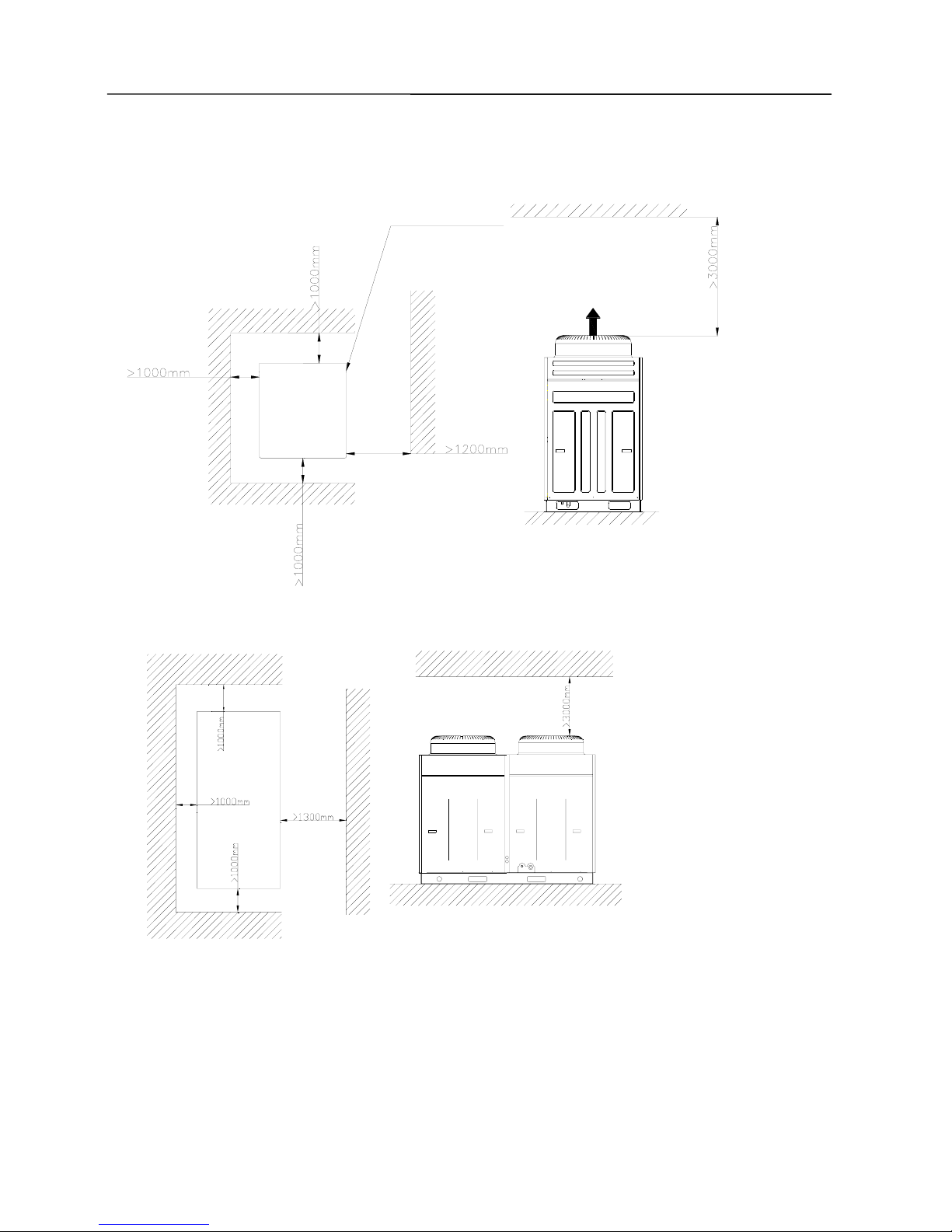

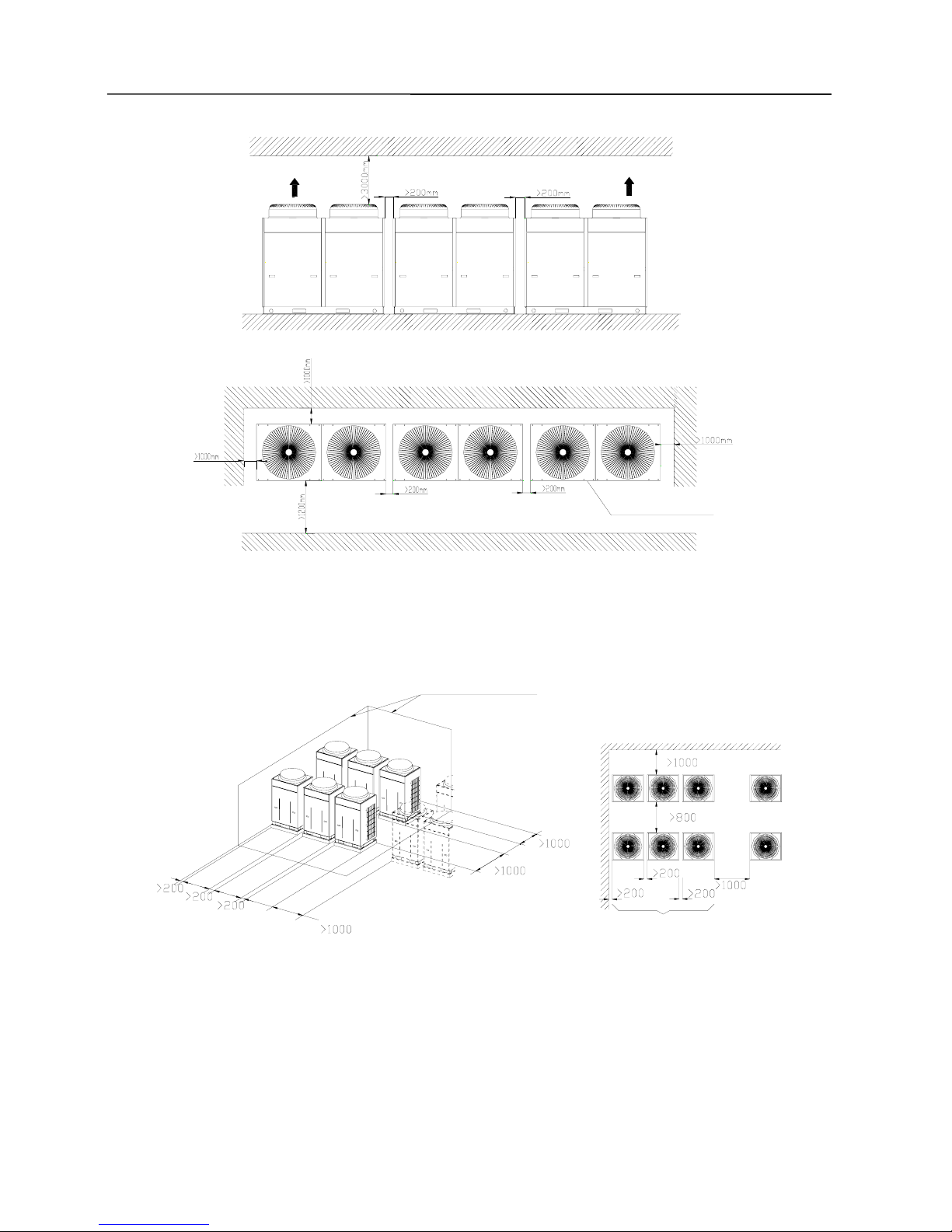

5. Space dimension for installation of the unit is shown below.

1) Clearance data of single unit

GMV-Pdhm224W/Na-M、GMV-Pdhm280W/Na-M

Outdoor

Unit

Electric box and exit are on this side

Air Outlet

GMV-Pdhm335W/Na-M、GMV-Pdhm400W/Na-M、GMV-Pdhm450W/Na-M

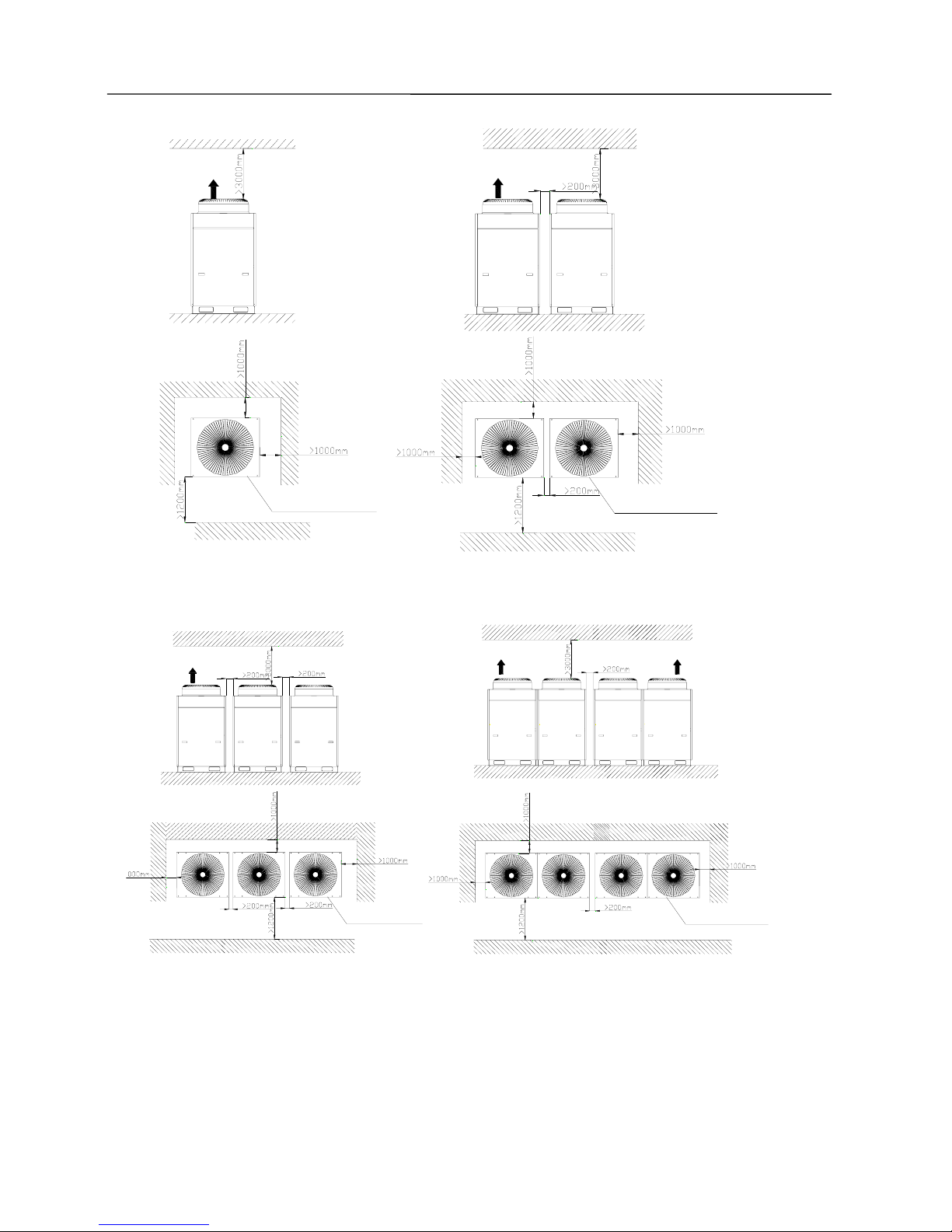

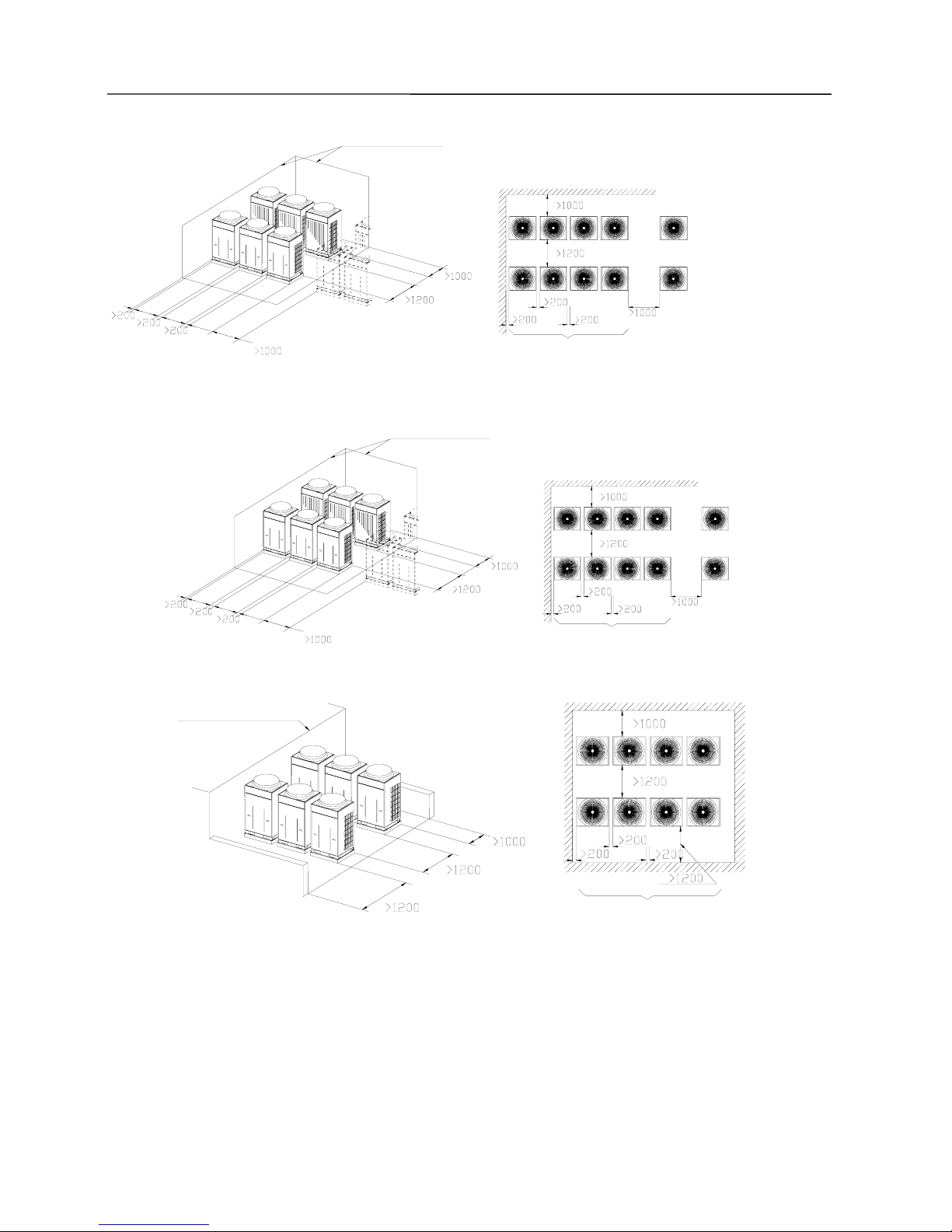

2) Clearance data of multiple unit

¾ Requirements for mounting space dimensions of single-fan and single-fan double-module outdoor units

19

Installation of Outdoor Unit

Air Outlet

Air Outlet

Electric box and exit are on this side

Electric box and exit are on this side

¾ Requirements for mounting space dimensions of single-fan three-module and double-fan double-module

outdoor units

出风口

Air Outlet

Air Outlet

Electric box and exit are on this side

Electric box and exit are on this side

¾ Requirements for mounting space dimensions of double-fan three-module outdoor units

20

Installation of Outdoor Unit

Air Outlet

Air outlet

Electric box and exit are on this side

3).Take Monsoons and Snow into Consideration

To ensure good ventilation, the top of unit shall be kept open and free of any obstructions. In case that the

front side and left side (or right side) of the outdoor unit is open space, the unit shall be installed in the same

direction.

No restriction to wall height

ce to another outdoor unit beside

Max. three machines in line

Back side

Front side

Back side

Front side

Dimension of installation space for back-to-back installation is as below.

21

Installation of Outdoor Unit

Front side

Front side

Back side

Back side

No restriction to wall height

another outdoor unit beside

Max. four machines in line

In case there are walls on four sides of the outdoor unit,

it is suggested to install the unit in the same direction.

No restriction to wall height

to another outdoor unit beside

Max. Four machines in line

Front side

Back side

Back side

Front side

In case there are walls on four sides of the outdoor unit,

it is suggested to install the unit in the same direction.

前侧

后侧

前侧

后侧

Max. four machines in line

No restriction to wall height

4). The monsoon shall be taken into consideration when installing the outdoor unit.

22

Installation of Outdoor Unit

Correct

Fresh air suction side (back side)

Fresh air

suction side

(back side)

Protective

cover

Fresh air

suction side

(back side)

Fresh air

suction side

(back side)

Correct

Incorrect

The defrost time will be extended under this condition.

5). The snow shall be taken into consideration when installing the outdoor unit.

To prevent the snow from covering air supply outlet and air return inlet, it is required to use protective

covers on them, and use a higher foundation base.

Air supply

outlet protective

cover (to be

provided on

installation site)

)

Monsoon

Return air

protective cover

(to be provided

on installation

site)

The base height shall consider the snow.

Correct

Monsoon

Incorrect

6.Outdoor unit shall be installed on a concrete base with10cm height

23

Installation of Outdoor Unit

型槽 型槽

Drainage ditch

Incline smoothly downward for 1/50 approx.

Construction method for anchoring bolt

Nut

Spring washer

Support

Screws protruding out

Type of anchoring bolt:JA

Size M12

4 bolts required

ilt on ground

When foundation is built on floor

Drainage ditch

A Viewa

Centralized Installation of Multiple Units

Notes:

1) Concrete proportioning: Cement: sand: stone = 1: 2: 4. Meanwhile, 10 pieces of φ10mm reinforced

steel bars shall be placed every 30mm.

2) Level the foundation surface with mortar and chamfer the sharp edge.

3) It is not needed to use gravel stone when the foundation is built on concrete floor, but the foundation

surface must be deburred.

4) Drainage ditch shall be built around the foundation, so that the condensate from the equipment can be

fully discharged.

5) To install the air conditioner on roof, please check the strength of building and take waterproof

measures.

24

Installation of Outdoor Unit

●Electrical Cable Connection

Cautions:

☆ Outdoor unit and indoor unit may be of unified power supply or separate power supply. But the

indoor units must be of unified power supply.

☆ Be sure install a circuit breaker that can cut off the power of complete system.

● Power Cable Connection:

1. Pass the cable though rubber ring.

2. Connect the power cable

with the terminal marked “L1, L2, L3 & N” and earthing screws.

3. Fix the cables with cable clamp.

● Connection of Distribution (Communication) Line:

1. Open the electric box on outdoor unit.

2. Pass the distribution (communication) line into the base and through the rubber ring of electrical box.

3. Insert the distribution (communication) line into 4-pin terminal CN11 on outdoor unit circuit board.

4. Fix the distribution (communication) lines properly.

5. Put back the junction cover plate and tighten the screws. Cover up the panel.

25

Connection of Indoor and Outdoor Unit

●Installation requirements of refrigerant piping

1. Specification of Connecting Pipes

R410A refrigerant system

External

Diameter(mm/inch)

Thickness(mm) Type

Φ6.35(1/4)

≥0.8

0

Φ9.52(3/8)

≥0.8

0

Φ12.70(1/2)

≥0.8

0

Φ15.88(5/8)

≥1

0

Φ19.05(3/4)

≥1

1/2H

Φ22.2(7/8)

≥1.5

1/2H

Φ25.40(1/1)

≥1.5

1/2H

Φ28.60(9/8)

≥1.5

1/2H

Φ34.90(11/8)

≥1.5

1/2H

Φ38.10(12/8)

≥1.5

1/2H

Φ41.30(13/8)

≥1.5

1/2H

Φ44.45(7/4)

≥1.5

1/2H

Φ54.1(17/8)

≥1.5

1/2H

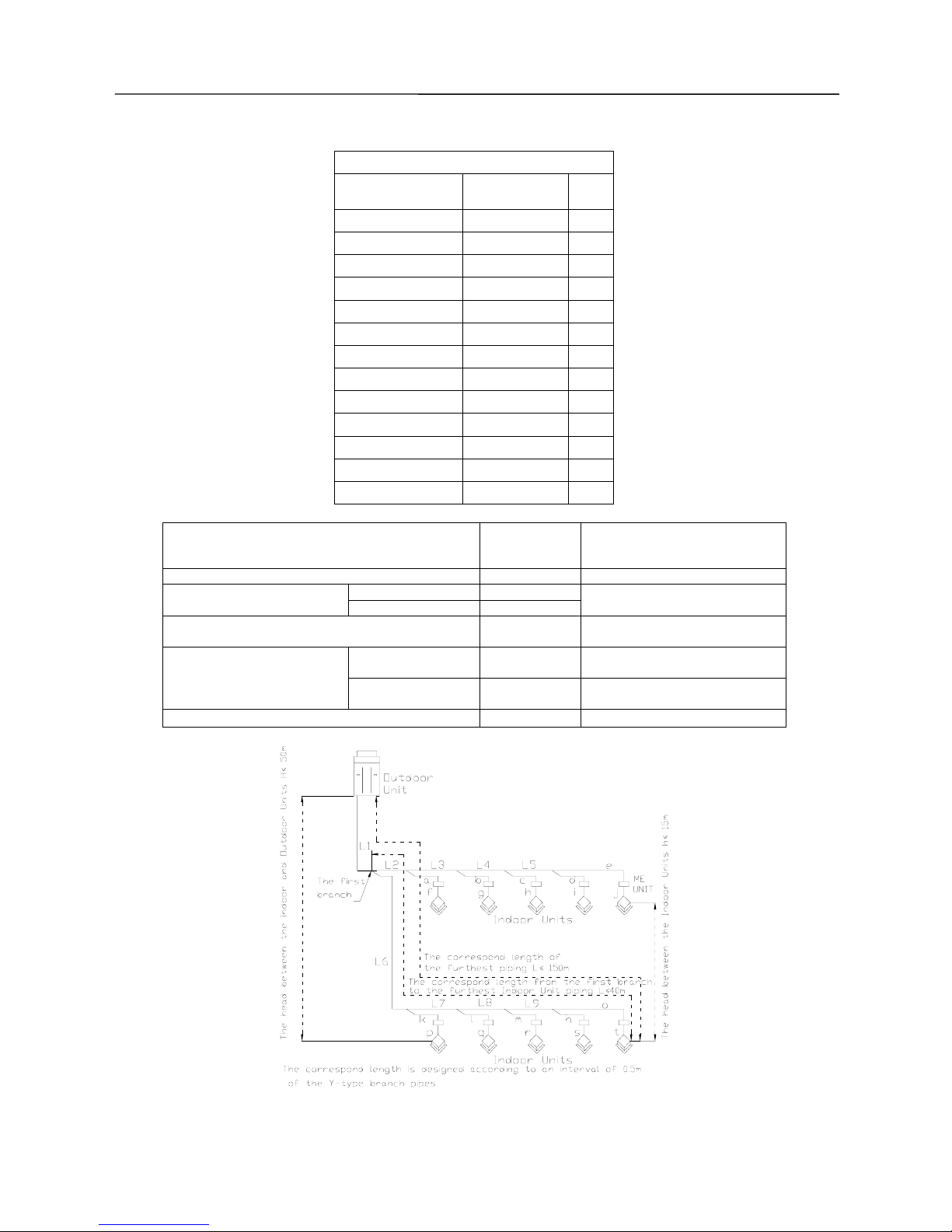

2. Allowable Length and Height Differences of the Connecting pipes between the Indoor and Outdoor Units

R410A refrigerant system

Allowable

(m/ft)

value

Fitting pipe

Total length (actual length) of fitting pipe 500/1640 L1+L2+L3+L4+…+L9+a+b+…+s+t

Actual length 150/492 Length of the furthest fitting

pipe

Equivalent length 175/574

L

1+L6+L7+L8+L9

+o+t

Equivalent length of fitting pipe

from the 1

st

branch joint to farthest indoor unit

40/131.2 L

1+L6+L7+L8+L9

+o+t

Outdoor unit at

upper

50/164

——

Height differences between

indoor unit and outdoor unit

Outdoor unit at

lower

40/131.2

——

Height differences between indoor units 15/49.2 ——

26

Connection of Indoor and Outdoor Unit

3. Selection of Diameter of Branch Pipe and Connection Pipe

System Piping Schematics:

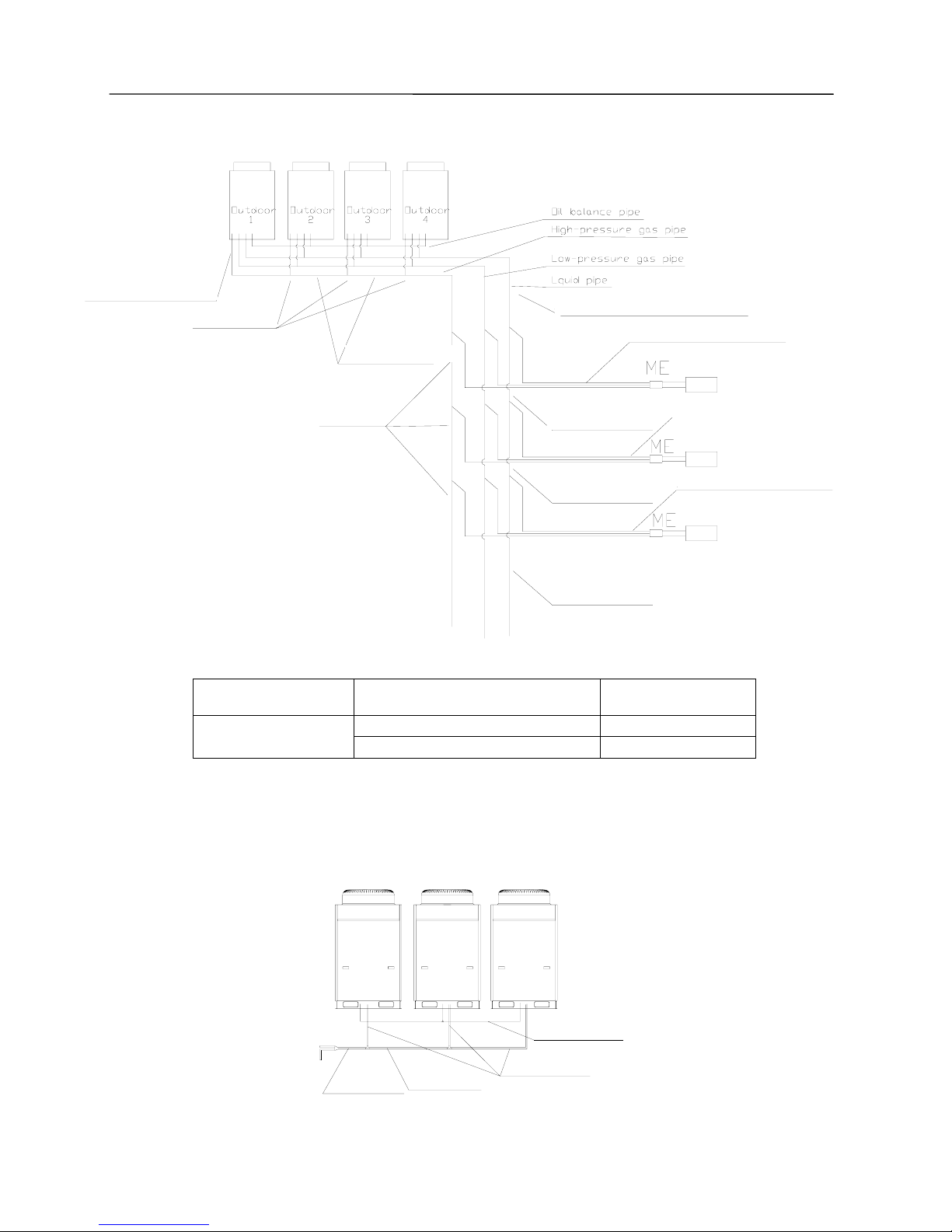

1). Selection of the branch piping between outdoor units

R410A refrigerant

system

Total Capacity of the Outdoor Unit

(C)

Model

224≤C≤960

ML01R

Y-Type Branch Pipe

960<C

ML02R

Piping between connection sub-assys of module

Piping between outdoor unit and indoor unit

Piping between outdoor unit and connection sub-assy

Piping between outdoor unit and connection sub-assy

Connection pipes between the branch

piping of outdoor unit and indoor unit

Connection branch piping

between outdoor units

Connection piping between

branch

pip

es of outdoor units

Branch piping

between indoor units

Connection pipe between the branch piping of outdoor

unit and the first branch pipe on the indoor side

Connecting pipe between the branch piping

of indoor unit and mode exchange

r

Indoor Unit 1

Connecting pipe between the

branch pipes of outdoor unit

Connecting pipe between the branch

piping

of indoor unit and mode converte

r

Indoor Unit 2

Connecting pipe between the branch

piping

of indoor unit and mode converte

r

Connecting pipe between the

branch pipes of outdoor unit

Indoor Unit 3

Connecting pipe between the

branch pipes of outdoor unit

27

Connection of Indoor and Outdoor Unit

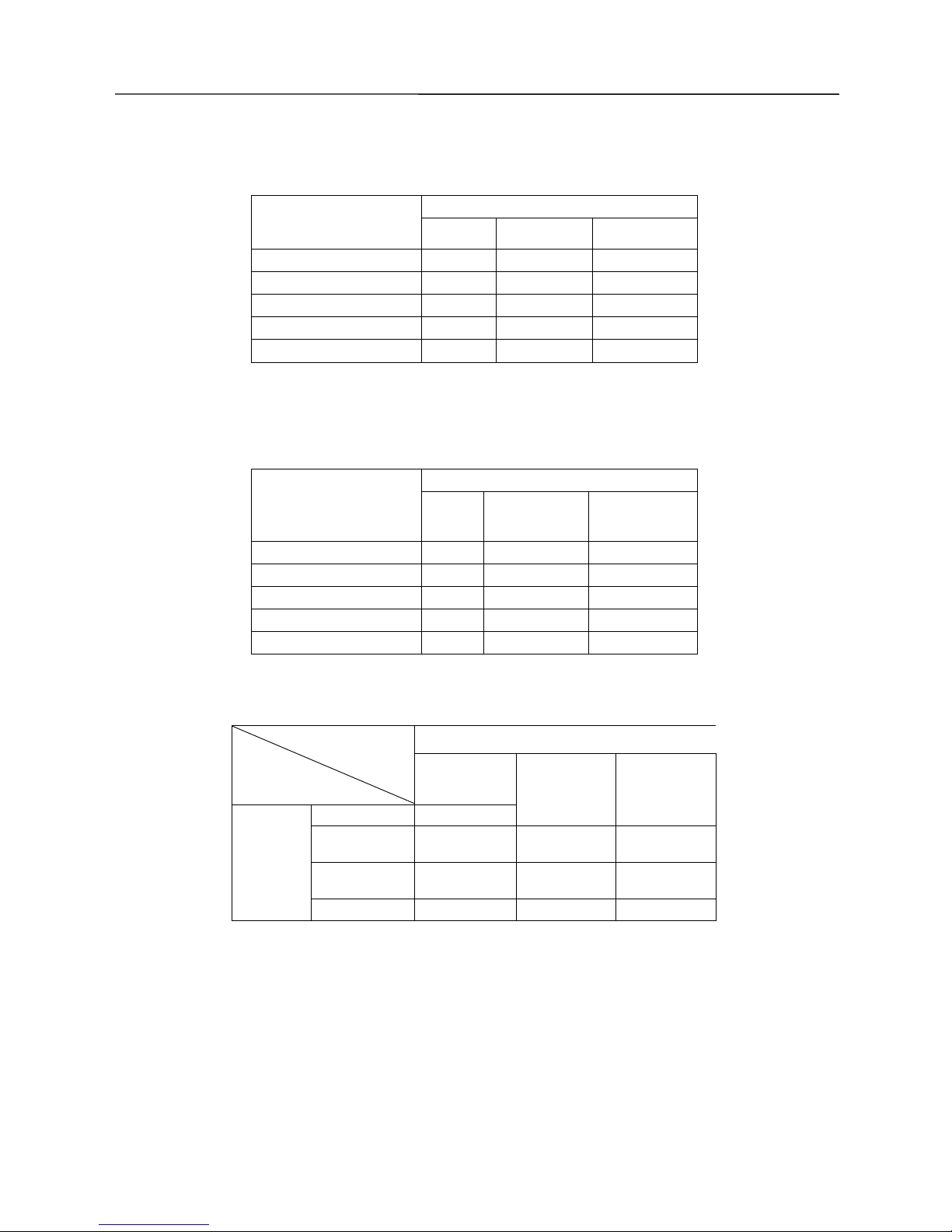

The diameter of the piping (the main pipe) from the Outdoor Unit to the first branch joint

A. For a single-module system, the diameter of the piping from the Outdoor Unit to the first branch joint shall

be selected according to the diameter of refrigerant piping for outdoor unit. The diameter of connection pipes

for basic module outdoor unit is as below:

Piping Connections

Basic Model

Liquid

(mm)

Suction Gas

(mm)

Discharge Gas

(mm)

GMV-Pdhm224W/Na-M

Φ9.5 Φ22.2 Φ19.1

GMV-Pdhm280W/Na-M

Φ9.5 Φ22.2 Φ19.1

GMV-Pdhm335W/Na-M

Φ12.7 Φ28.6 Φ19.1

GMV-Pdhm400W/Na-M Φ12.7 Φ28.6 Φ22.2

GMV-Pdhm450W/Na-M Φ12.7 Φ28.6 Φ22.2

B. If it is multi-module system,

The diameter of the branch piping between modules and outdoor unit shall be selected based on the

diameter of the connection pipe of basic module outdoor unit. The diameter of the connection pipe of basic

module outdoor unit is as below:

Piping Connections

Basic Model

Lquid

pipe

(mm)

Low-pressure

gas pipe

(mm)

High-pressure

gas pipe

(mm)

GMV-Pdhm224W/Na-M

Φ9.5 Φ22.2 Φ19.1

GMV-Pdhm280W/Na-M

Φ9.5 Φ22.2 Φ19.1

GMV-Pdhm335W/Na-M

Φ12.7 Φ28.6 Φ19.1

GMV-Pdhm400W/Na-M Φ12.7 Φ28.6 Φ22.2

GMV-Pdhm450W/Na-M Φ12.7 Φ28.6 Φ22.2

The diameter of the connection pipe between the branch pipes of basic module outdoor unit is as follows:

Diameter of the refrigerant piping between the branch

pipes of outdoor unit

Lquid pipe

(mm)

High-pressur

e gas pipe

(mm)

Low-pressur

e gas pipe

(mm)

450≥Q Φ12.7 Φ28.6 Φ28.6

960≥Q>

450

Φ19.1 Φ34.9 Φ34.9

1580≥Q>

960

Φ22.2 Φ41.3 Φ41.3

Total rated

capacity Q

of upstream

outdoor unit

Q>1580 Φ25.4 Φ41.3 Φ54.1

Loading...

Loading...