Gree GMV-36WL/A-T(U), GMV-60WL/A-T(U), GMV-48WL/A-T(U) User Manual

DC INVERTER SIDE DISCHARGE VRF Ⅱ

FOR NORTH AMERICA

CONTENTS

PRODUCT ..................................................................................................................................................... 2

1 PRODUCT LIST ................................................................................................................................................ 2

2 PRODUCT FEATURES ................................................................................................................................... 2

3 SPECIFICATIONS ............................................................................................................................................ 3

4 PRODUCT CAPACITY CORRECTION ......................................................................................................... 4

5 PRINCIPAL OF OPERATION ......................................................................................................................... 6

CONTROL ..................................................................................................................................................... 9

1 UNITS’ CONTROL ............................................................................................................................................ 9

2 WIRED CONTROLLER ................................................................................................................................. 12

3 REMOTE CONTROLLER ............................................................................................................................. 18

4 MONITORING SOFTWARE .......................................................................................................................... 20

INSTALLATION ...................................................................................................................................... 65

1 ENGINEERING INSTALLATION PREPARATION AND NOTICE ........................................................... 65

2 INSTALLATION MATERIALS SELECTION ............................................................................................... 66

3 INSTALLATION OF OUTDOOR UNIT ........................................................................................................ 68

4 INSTALLATION OF ELECTRONIC EXPANSION VALVE ASSY (UNIT WITH EXTERNAL EXV) .... 71

5 INSTALLATION OF REFRIGERANT PIPELINE ....................................................................................... 71

6 INSTALLATION OF CONNECTION PIPE .................................................................................................. 75

7 ELECTRIC WIRING ....................................................................................................................................... 83

8 DEBUGGING OF UNIT .................................................................................................................................. 85

MAINTENANCE ..................................................................................................................................... 92

1 MALFUNCTION LIST .................................................................................................................................... 93

2 TROUBLESHOOTING ................................................................................................................................... 95

3 POWER DISTRIBUTION OF UNIT ............................................................................................................ 105

4 REMOVAL OF PARTS ................................................................................................................................. 108

5 COMMON MAINTENANCE ........................................................................................................................ 121

6 EXPLODED VIEW OF UNIT AND PARTS’ LIST ..................................................................................... 126

DC Inverter Side Discharge VRF Ⅱ for North America

PRODUCT

1

DC Inverter Side Discharge VRF Ⅱ for North America

Model

Product

Code

Cooling

Capacity

Heating

Capacity

Power

Supply

Refrigerant

Appearance

Kw(Btu/h))

Kw(Btu/h

GMV-36WL/A-T(U)

CN850W

0230

11

(37500)

12.3

(42000)

208/230V

~

60Hz

R410A

GMV-48WL/A-T(U)

CN850W

0220

14.1

(48000)

15.8

(54000)

GMV-60WL/A-T(U)

CN850W

0270

17.6

(60000)

18.7

(64000))

PRODUCT

1 Product List

2 Product Features

2.1 General introduction

Gree DC Inverter Multi VRF System II is the latest generation of DC inverter units.

One set of air-cooled outdoor unit can be connected with multiple direct evaporation

indoor units that are of the same or different forms and capacity. This refrigerating system

can directly provide air conditioning for one or more areas, and is applicable for residential

and light commercial uses. It features high energy efficiency, strong anti-interference

capability, long connectable pipe, wide operation range, good sound quality, intelligent

capacity regulation, complete protection, etc.

2.1.1 Features

(1)

complete direct current and upgrade the energy efficiency. SEER is up to 16; HSPF of

GMV-36WL/A-T(U) and GMV-48WL/A-T(U) is up to 9; HSPF of GMV-60WL/A-T(U) is up

to 8.2.

(2)

anti-interference capability is stronger and the control on indoor units is more accurate,

Super high energy efficiency

The 2nd generation of DC Inverter Multi VRF System adopts DC motor to realize

New generation CAN bus communication

Due to the latest communication method—CAN Bus Communication, system’s

with higher reliability. Specialized shield wire is no more needed and ordinary

communication wire can be applied in the construction, which has increased the

installation flexibility.

(3)

Long connection pipe

2

DC Inverter Side Discharge VRF Ⅱ for North America

Model

GMV-36WL/A-T(U)

GMV-48WL/A-T(U)

GMV-60WL/A-T(U)

Cooling capacity

kW

11

14.1

17.6

Btu/h

37500

48000

60000

Heating capacity

kW

12.3

15.8

18.7

Btu/h

42000

54000

64000

Circulating air

volume

m3/h

6000

6300

7800

CFM

3532

3708

4601

Noise

dB(A

)

55

56

63

Refrigerant charge

volume

Kg

5 5 6.5

oz

176

176

229

Power supply

208/230V~60Hz

208/230V~60Hz

208/230V~60Hz

Rated

power

input

Coolin

g

kW

3.25

4.47

6.45

Heatin

g

kW

3.72

3.93

5.60

Unit Dimensions

(WxDxH)

mm

900×340×1345

940×320×1430

inch

35_7/16×13_3/8×53

37×12_9/16×56_1/4

Dimensions

mm

998×458×1515

1033×433×1580

The maximum length of connection pipe is 300m(984ft) (in total) and the farthest

connection pipe between indoor and outdoor units can be 120(394ft)m’s long, which has

extended the installation condition and reduced the limit of installation distance.

(4)

Wide operation range

Units can operate reliably in a wide temperature range (cooling: -5~48℃(23~118°F),

heating: -20~27

(5)

Fine sound quality

-4~81°F))

℃(

Through a series of optimized measures, system has reduced the throttle noise and

oil return noise of indoor units, gas bypass noise, etc. so that units are more comfortable

regarding sound quality.

(6)

Intelligent PID capacity regulation

With the independently developed PID capacity regulation technology, units are able

to control the indoor ambient temperature more quickly and reduce the fluctuation of room

temperature.

(7)

Complete protection

Units are equipped with a series of protection to accurately identify errors and protect

the units, which has ensured reliable and safe operation.

3 Specifications

3.1Outdoor Unit

3

DC Inverter Side Discharge VRF Ⅱ for North America

Model

GMV-36WL/A-T(U)

GMV-48WL/A-T(U)

GMV-60WL/A-T(U)

(WxDxH)

inch

39_5/16×18×59_5/8

40_5/8×17×62_3/16

Compressor

QXAS-F428zX050A

LNB53FCFMC

Water-proof level

IPX4

IPX4

IPX4

Suitable climite

T1

T1

T1

Connectio

n pipe

Gas

mm

Φ15.9

Φ15.9

Φ19.05

inch

Φ5/8

Φ5/8

Φ3/4

Liquid

mm

Φ9.52

Φ9.52

Φ9.52

inch

Φ3/8

Φ3/8

Φ3/8

Connection

Method

Bell mouth connection

Bell mouth connection

Bell mouth connection

Net weight

Kg

110

110

124

oz

3880

3880

4375

Cooling

Outdoor temperature: -5~48℃ (23~118°F)

Heating

Outdoor temperature: -20℃~27℃(-4~81°F)

Note:

① Units conform to design standard: ARI 210/240.

② Specifications may be changed due to product improvement. Please refer to

nameplates of the units.

③ Noise data are collected from a semi-anechoic room. Decibels may be slightly higher

in actual operation due to environmental change.

④ Refrigerant charge volume listed in the table is based on the condition where indoor

and outdoor units are at a same level and with no connection pipe. Supplementary

refrigerant needs to be charged according to actual circumstance.

3.2 Operation range

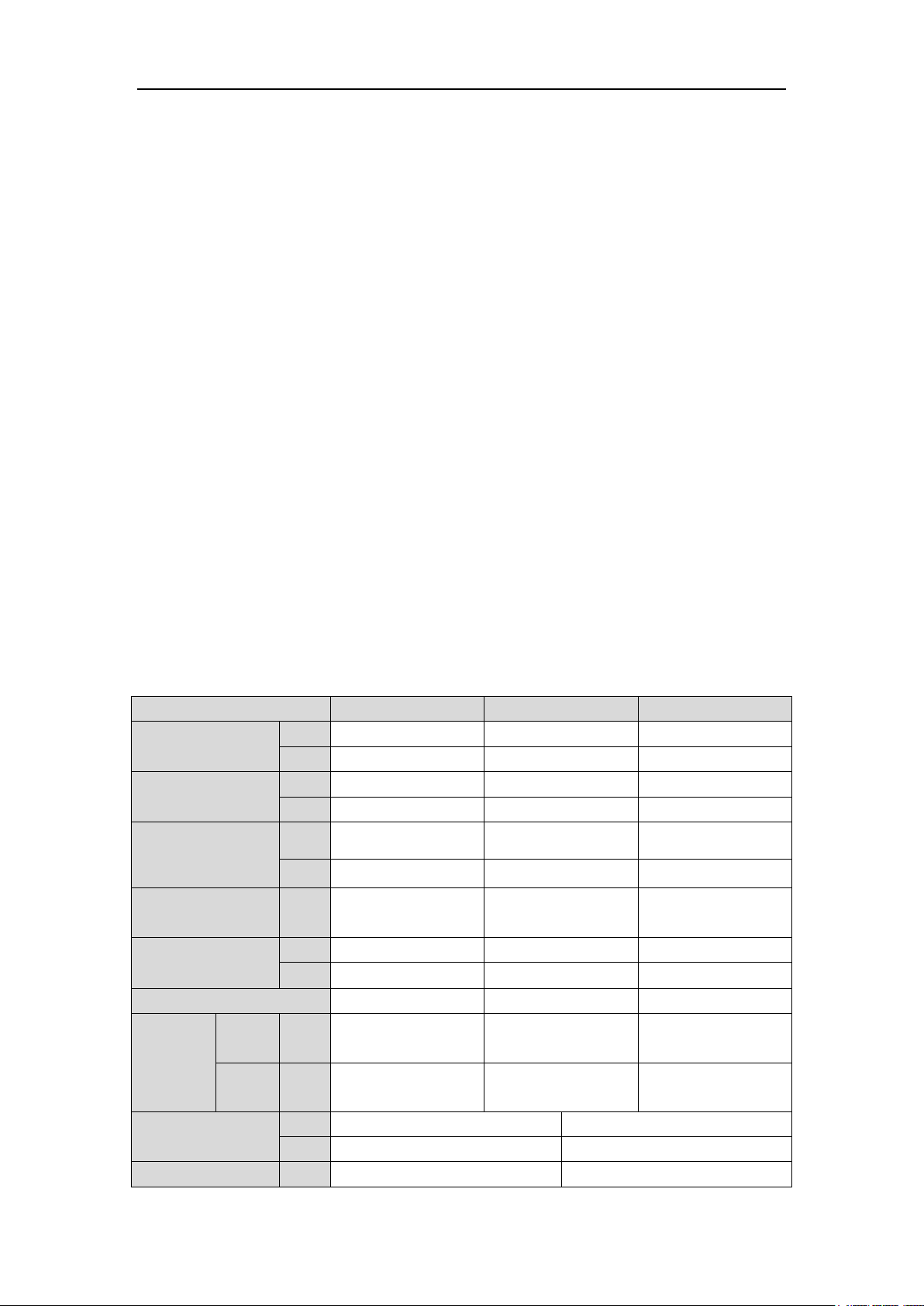

4 Product Capacity Correction

4.1 Instruction of Product Capacity Correction

Nominal cooling capacity and nominal heating capacity are tested under given

conditions:

(1)

(2)

(3)

Rated cooling or heating condition

No height difference between indoor unit and outdoor unit

Short connection pipe

If the three conditions above have changed, the cooling and heating capacity will

change correspondingly and correction is needed.

4.2 Capacity Code

Instruction of capacity code

GMV-36WL/A-T(U) 、GMV-48WL/A-T(U) and GMV-60WL/A-T(U) are identical in

4

DC Inverter Side Discharge VRF Ⅱ for North America

Sheet of DIP Switch (5-bit DIP switch)

Model

Bit 1

Bit 2

Bit 3

Bit 4

Bit 5

GMV-36WL/A-T(U)

0 0 1 0 0

GMV-48WL/A-T(U)

0 0 1 0 1

GMV-60WL/A-T(U)

0 1 0 0 0

Model

GMV-36WL/A-T(U)

GMV-48WL/A-T(U)

GMV-60WL/A-T(U)

Rated cooling

capacity

kW

11

14.1

17.6

Btu/h

37500

48000

60000

Rated heating

capacity

kW

12.3

15.8

18.7

Btu/h

42000

54000

64000

components, systems and structure, etc. While the required capacity is set through the

capacity DIP switch.

4.3Capacity Correction Formula

4.3.1Rated capacity of outdoor unit

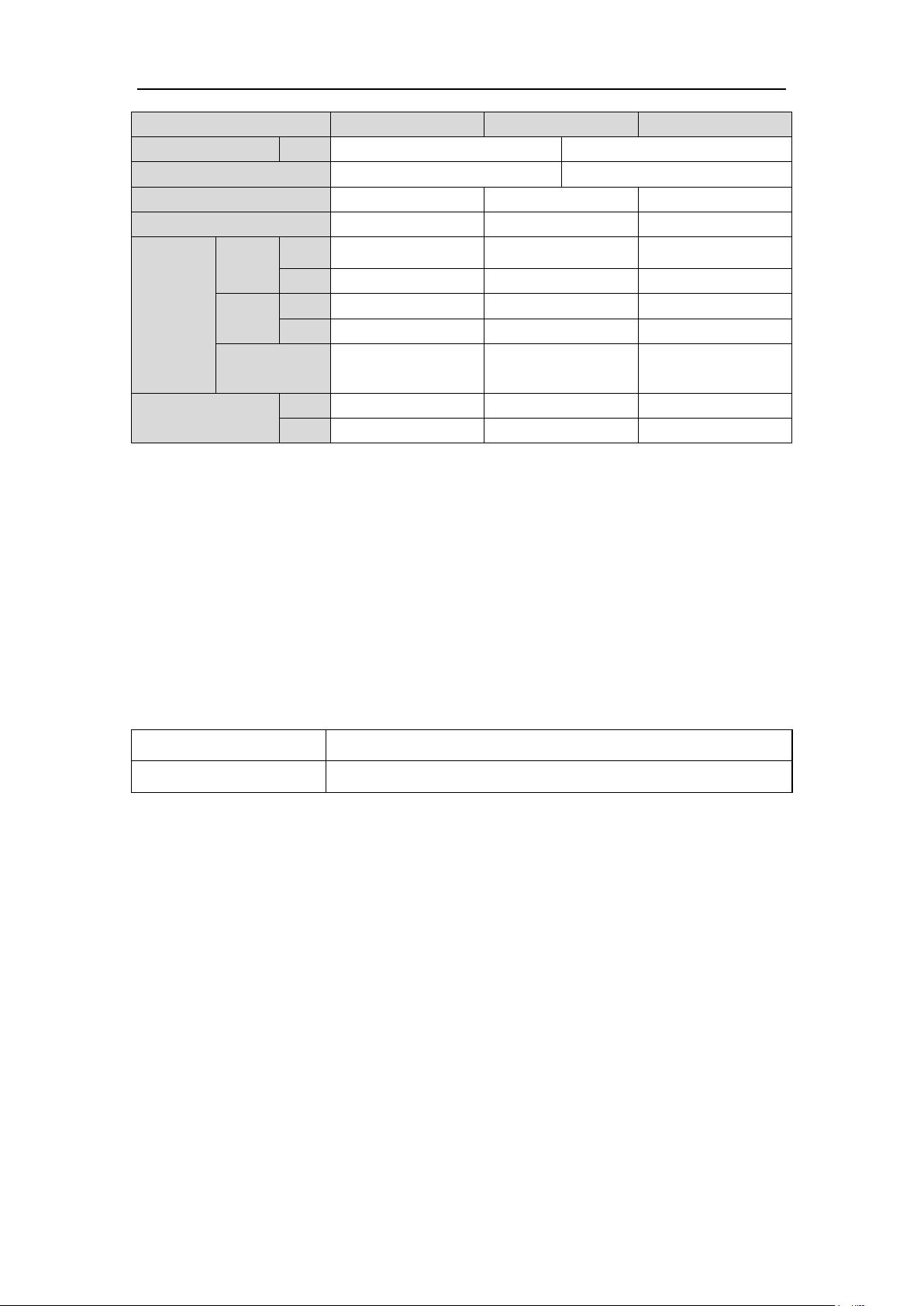

4.3.2 Correction factor of indoor and outdoor temperature

(1)

(2)

Correction factor of cooling capacity

Correction factor of heating capacity

5

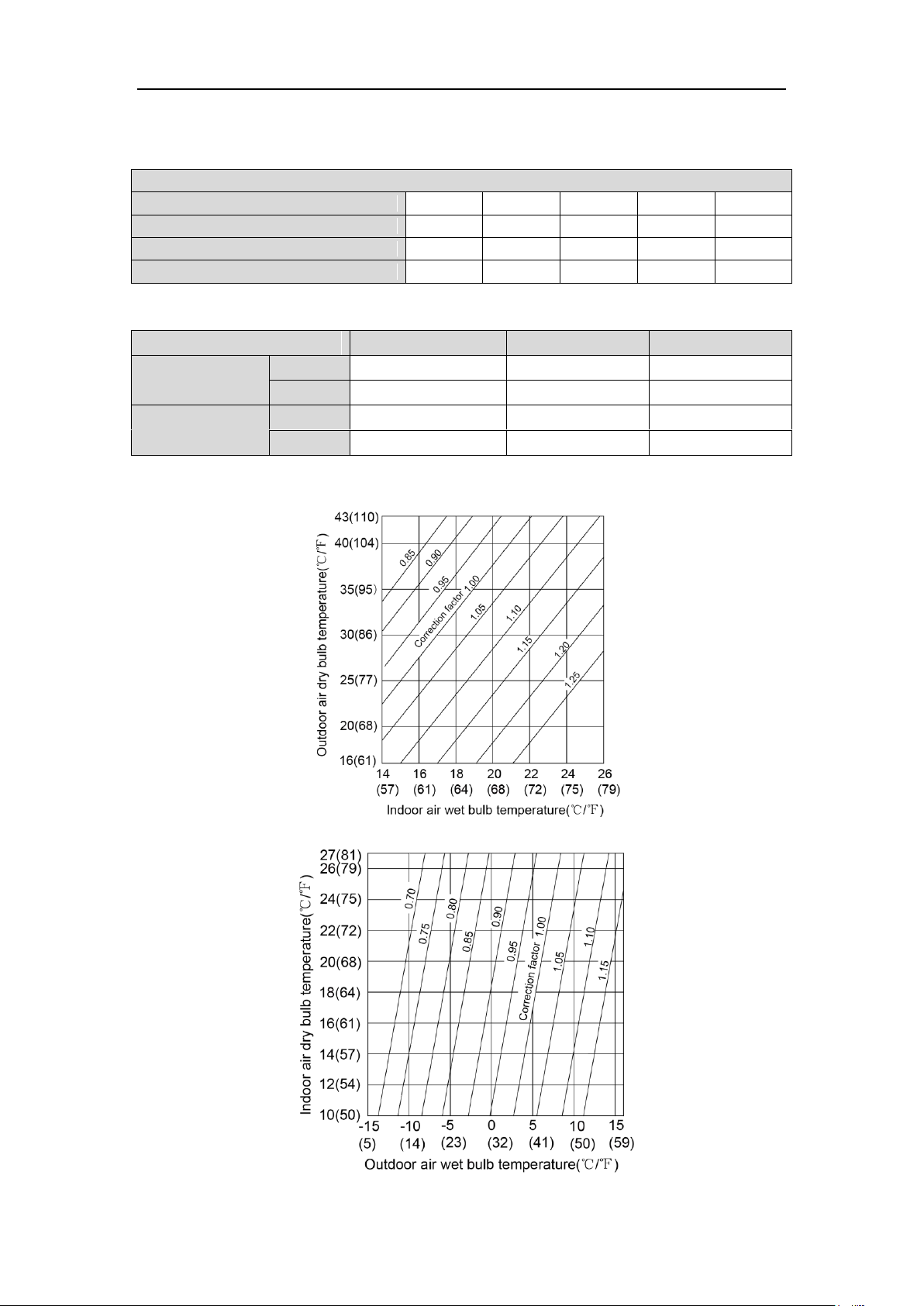

DC Inverter Side Discharge VRF Ⅱ for North America

m 0 10

20

30

40

50

60

70

80

90

100

110

120

130

140

150

ft 0 33

66

98

131

164

197

230

262

295

328

361

394

427

459

492

Name

Compressor

4-way valve

Cut-off

valve

One-way valve

Capillary tube

Symbol

Name

Gas-liquid

separator

Pressure

switch

Pressure

sensor

Axial-flow finned heat

exchanger

Electronic expansion valve

Symbol

4.3.3 Correction factor of pipe length and height difference

Symbol description:

Hp:Height difference in case indoor unit is below outdoor unit(m/feet);

Hm: Height difference in case indoor unit is above outdoor unit (m/feet);

L: Length of one-way equivalent pipe

Below table shows the capacity variance ratio for 100% full load in standard working

condition (thermostat setting is 16℃(61℉) for cooling and 30℃(86℉) for heating).

Variance ratio of heating capacity

NOTE:

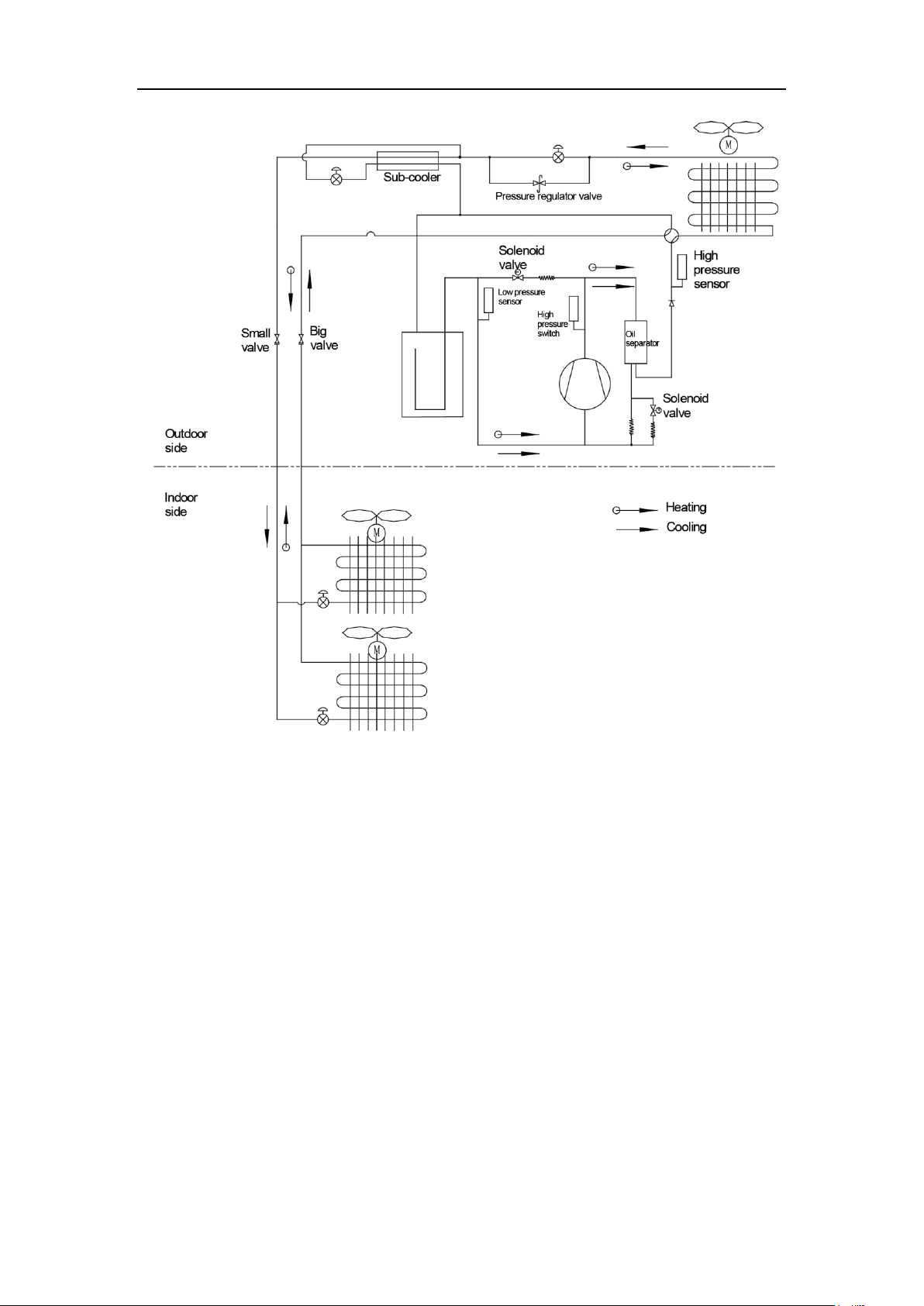

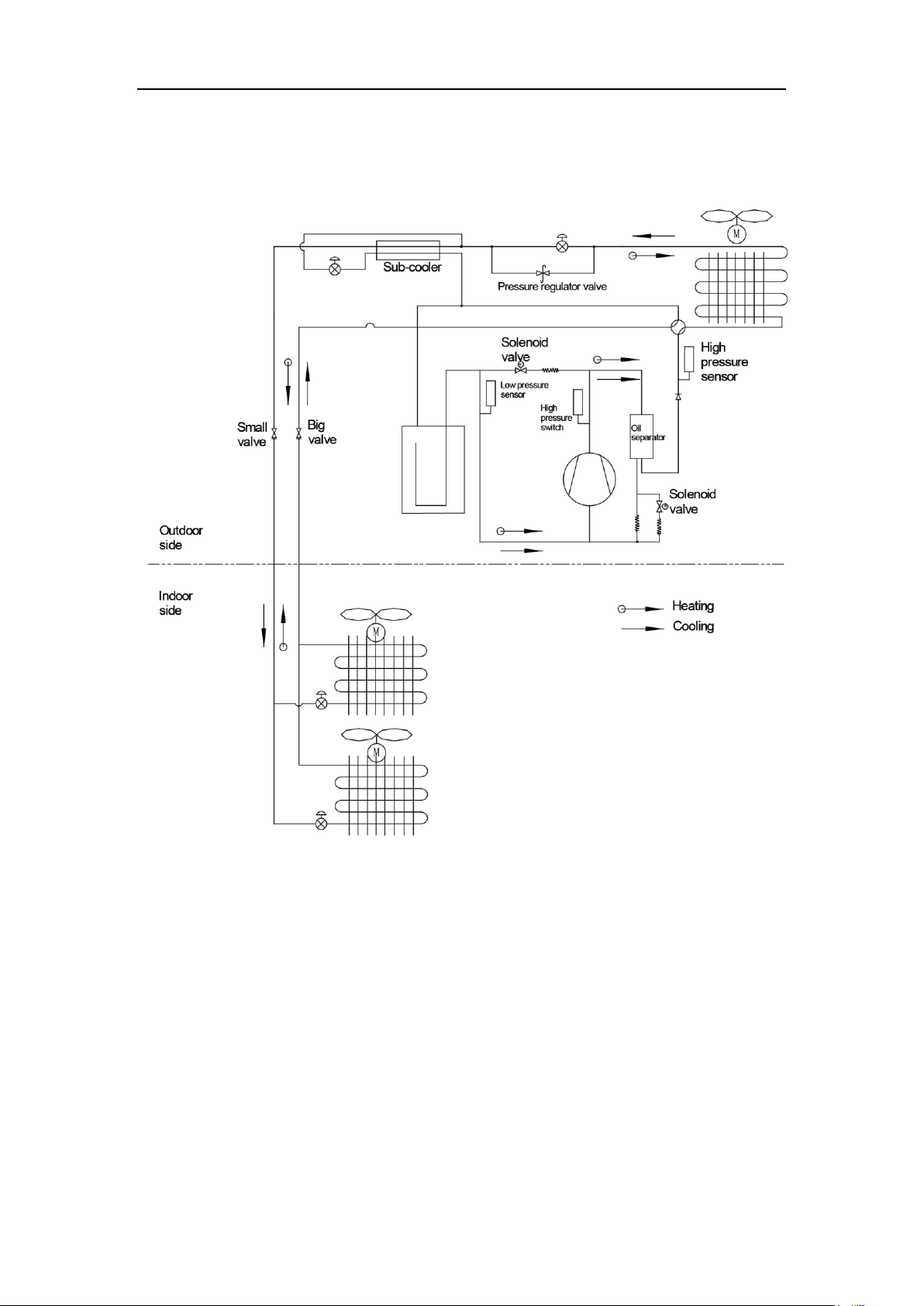

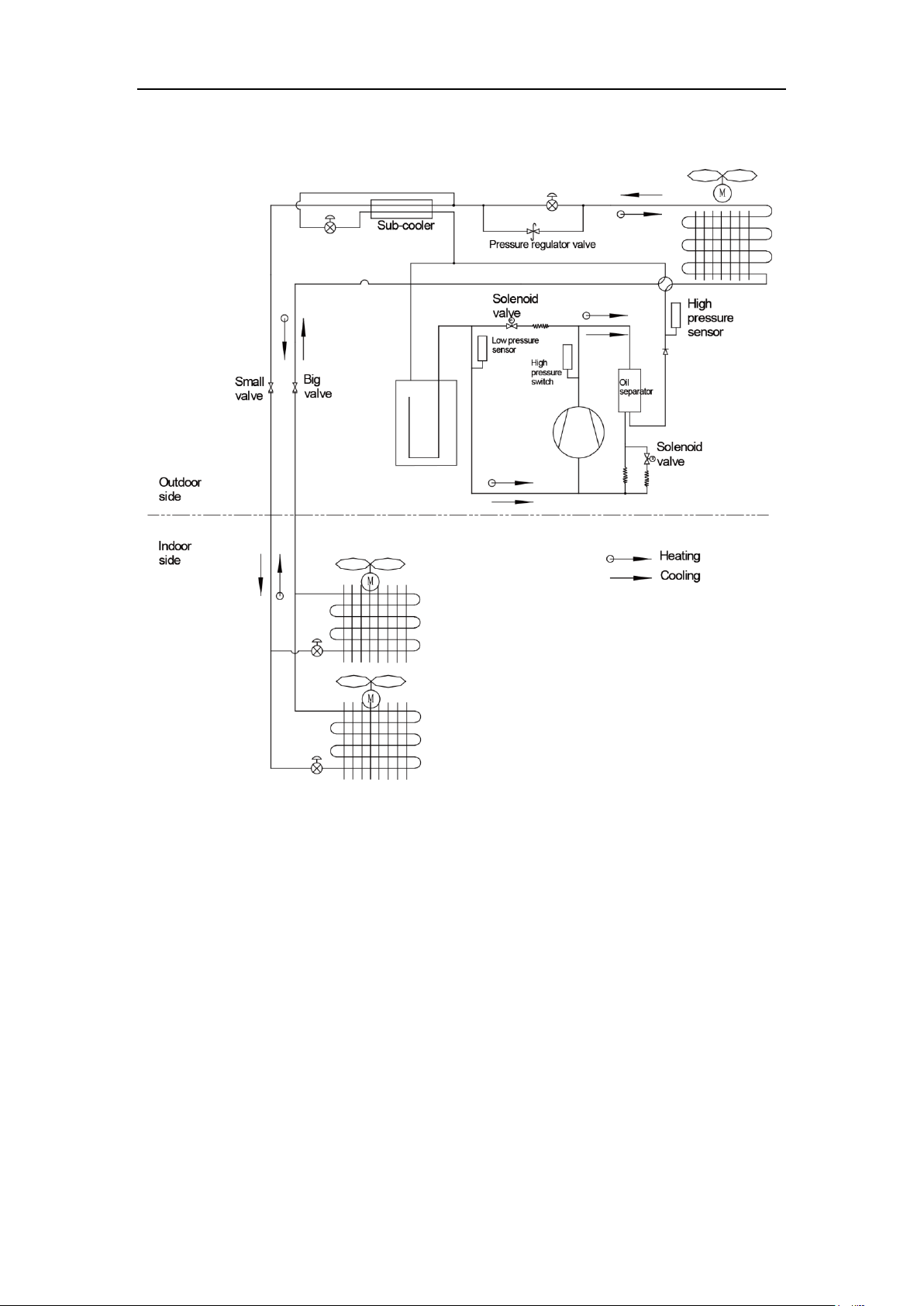

5 Principal of Operation

Components in flowcharts are presented according to the following table:

6

DC Inverter Side Discharge VRF Ⅱ for North America

In cooling, the low-temperature and low-pressure refrigerant gas from each indoor

heat exchanger will be merged and inhaled by the compressor and then become

high-temperature and high-pressure gas, which will later be discharged into outdoor heat

exchangers. By exchanging heat with outdoor air, refrigerant will turn to liquid and flow to

each indoor unit via Y-type branch or manifold. Pressure and temperature of the

refrigerant will then be lowered by throttle elements before it flows into indoor heat

exchangers. After exchanging heat with indoor air, refrigerant wil become low-temperature

and low-pressure gas again and repeat the circulation so as to realize the cooling effect.

In heating, 4-way valve will be energized to make refrigerant circulate in a reverse

direction of cooling. Refrigerant will release heat in indoor heat exchangers (electric

heating elements will also work under certain circumstance and release heat) and absorb

heat in outdoor heat exchangers circularly so as to realize the heating effect.

7

DC Inverter Side Discharge VRF Ⅱ for North America

CONTROL

8

DC Inverter Side Discharge VRF Ⅱ for North America

CONTROL

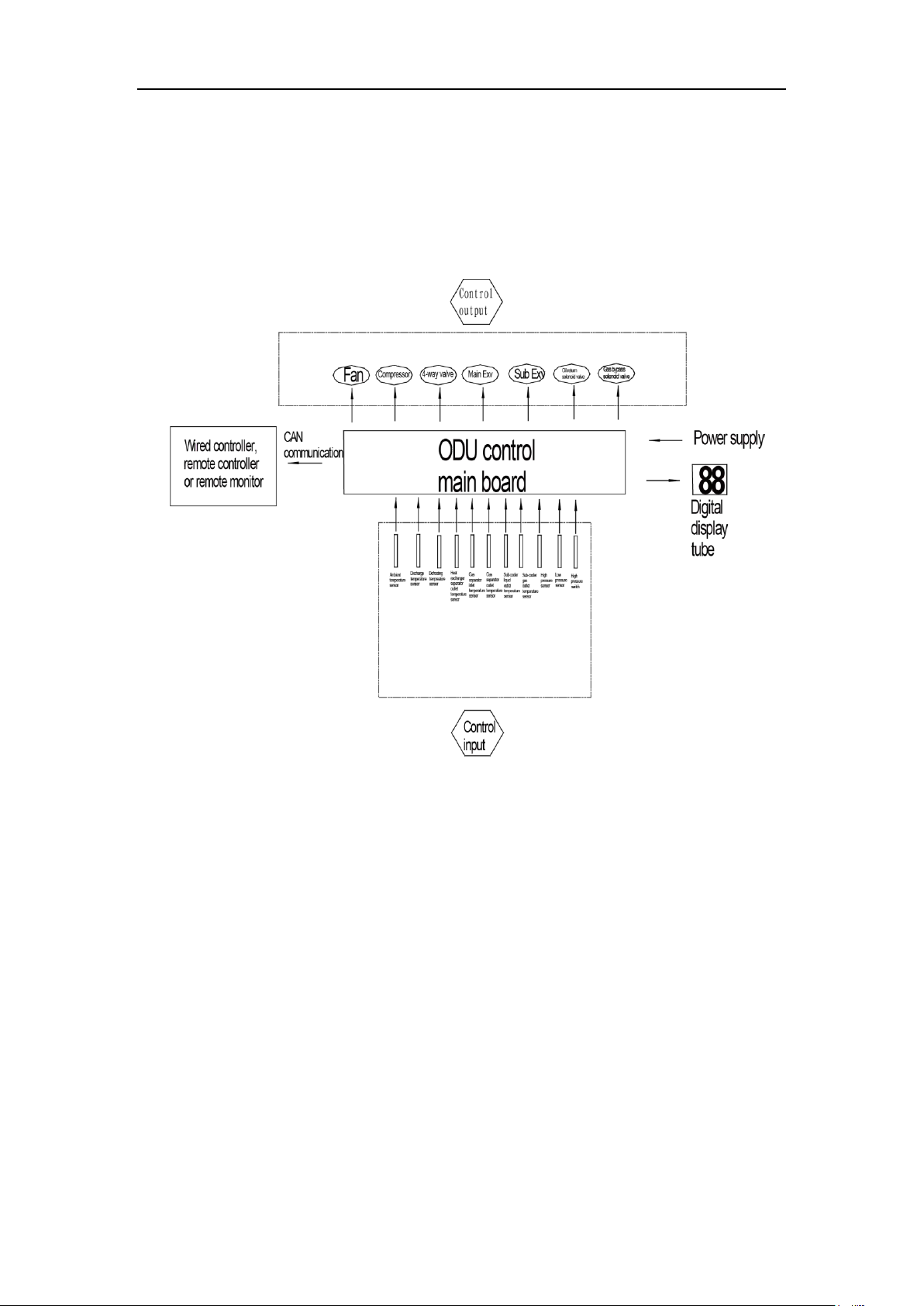

1 Units’ Control

1.1 Schematic diagram of units’ control

(1) Interpretation on the schematic diagram

1) High pressure switch is used to identify system’s high and low pressure. When

pressure is too high, the switch will break off and send a signal to main board.

Main board will pass this signal to controller, where the error will be displayed, and

stop unit from working.

2) High/low pressure sensor is used to test unit’s high/low pressure and send

real-time data to controller, which will control each unit’s output according to the

control logic.

3) Temperature sensors are used to test the tube temperature of the unit and send

data to the controller, which will control each unit’s output according to the control

logic.

9

DC Inverter Side Discharge VRF Ⅱ for North America

1.2 Operation Flow Chart

1.2.1 Operation Flow Chart of Indoor Unit

1) Cooling operation

2) Heating operation

3) Drying operation

4) Operation procedure is the same as that of cooling operation

5) Fan operation

6) The EXV of the indoor unit closes in fan mode, so that there is no refrigerant flow

in the refrigerant pipe of that indoor unit. But the fan of that indoor unit operates.

10

DC Inverter Side Discharge VRF Ⅱ for North America

1.2.2 Operation Flow Chart of Outdoor Unit

1) Cooling operation

2) Heating operation

1.3 Unit Control Functions

1.3.1Control functions of outdoor unit

1) Include the following contents.

2) Compressor capacity output.

3) Compressor start-up control.

4) Outdoor fan control.

5) Defrosting control.

6) Heating EXV control.

7) Subcooling valve control.

8) Refrigerant lacking control.

1.3.2Control functions of indoor unit

1) Include the following contents

2) Cool

11

DC Inverter Side Discharge VRF Ⅱ for North America

3) Dry

4) Heat

5) Fan

6) Heating temperature compensation

7) Anti-freezing

8) Air swing

9) Drainage pump

10) IDU EXV

11) Static pressure level

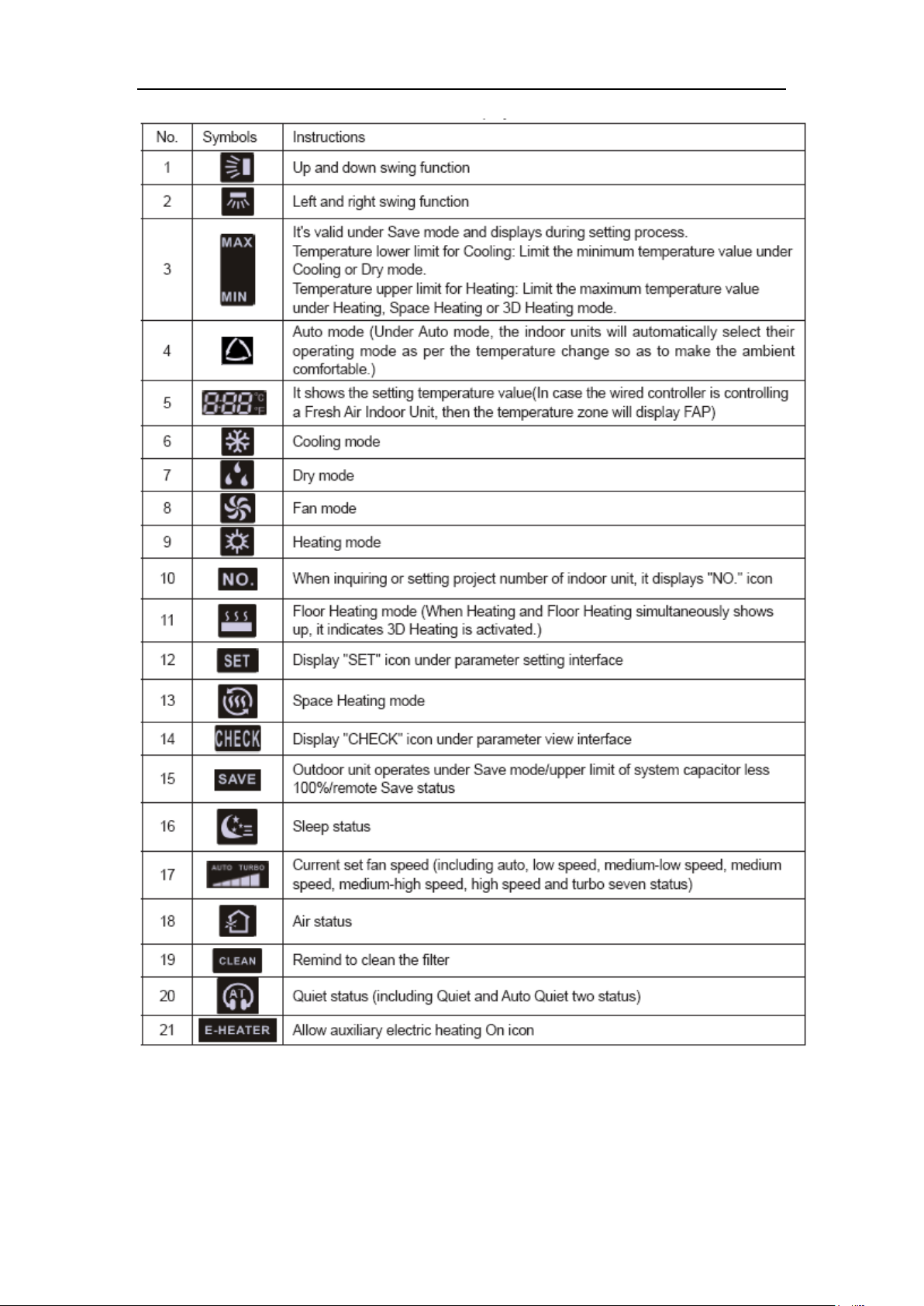

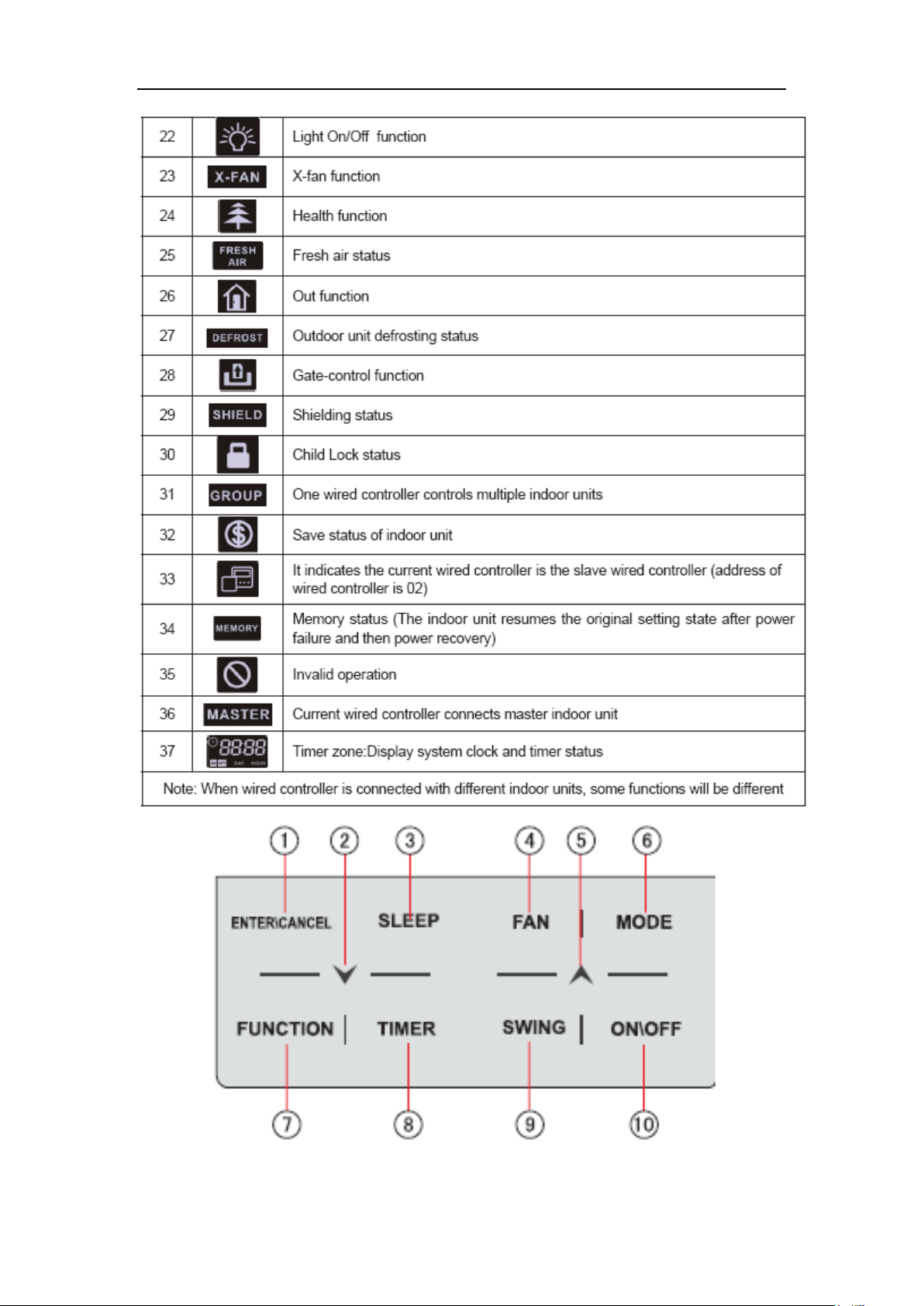

2 Wired Controller

2.1 Control panel

12

DC Inverter Side Discharge VRF Ⅱ for North America

13

DC Inverter Side Discharge VRF Ⅱ for North America

Button Graphics

14

DC Inverter Side Discharge VRF Ⅱ for North America

mm

112

22

2.7

3.3 5 42.5

40

82.5

inch

4.41

0.87

0.11

0.13

0.20

1.67

1.57

3.25

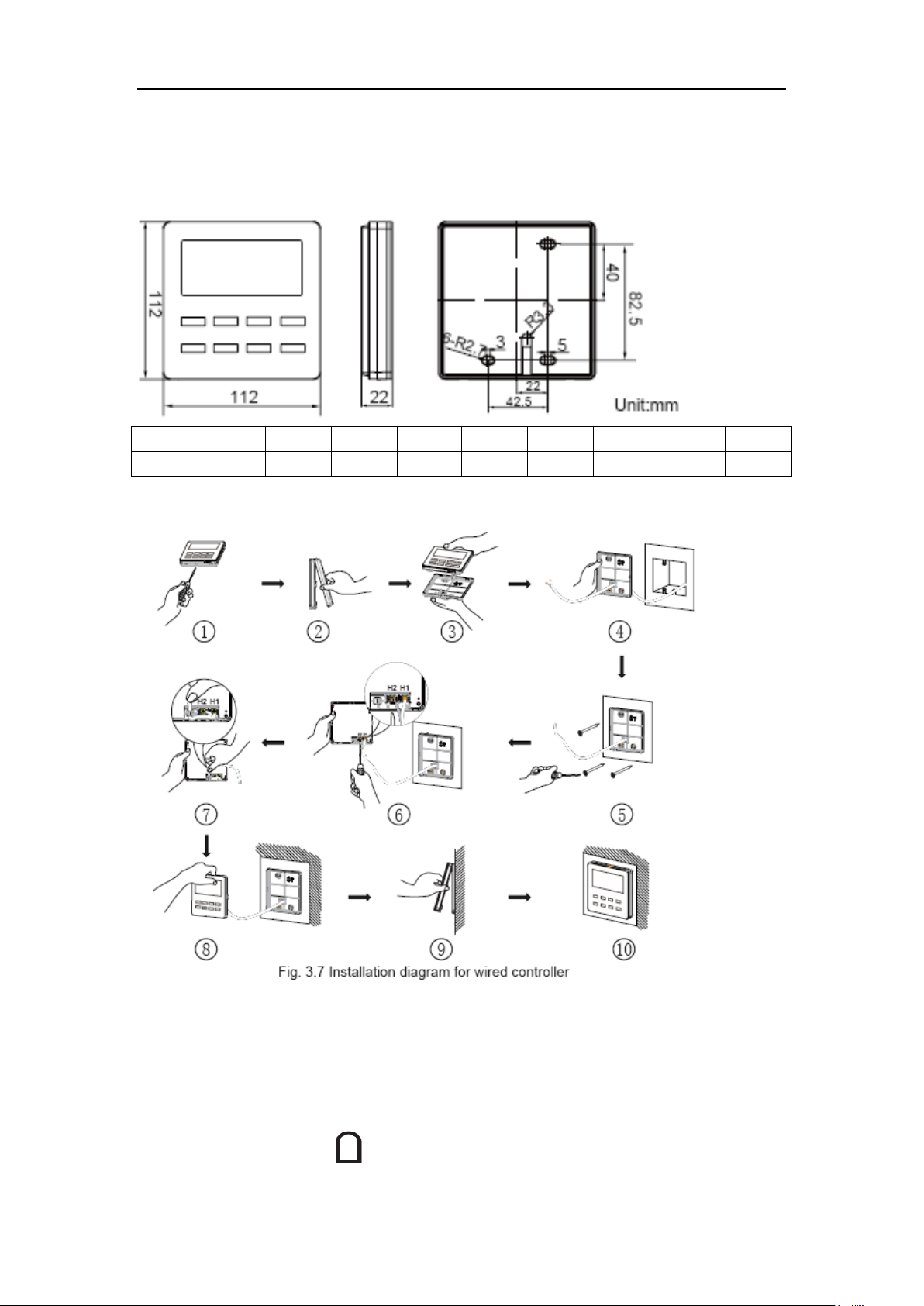

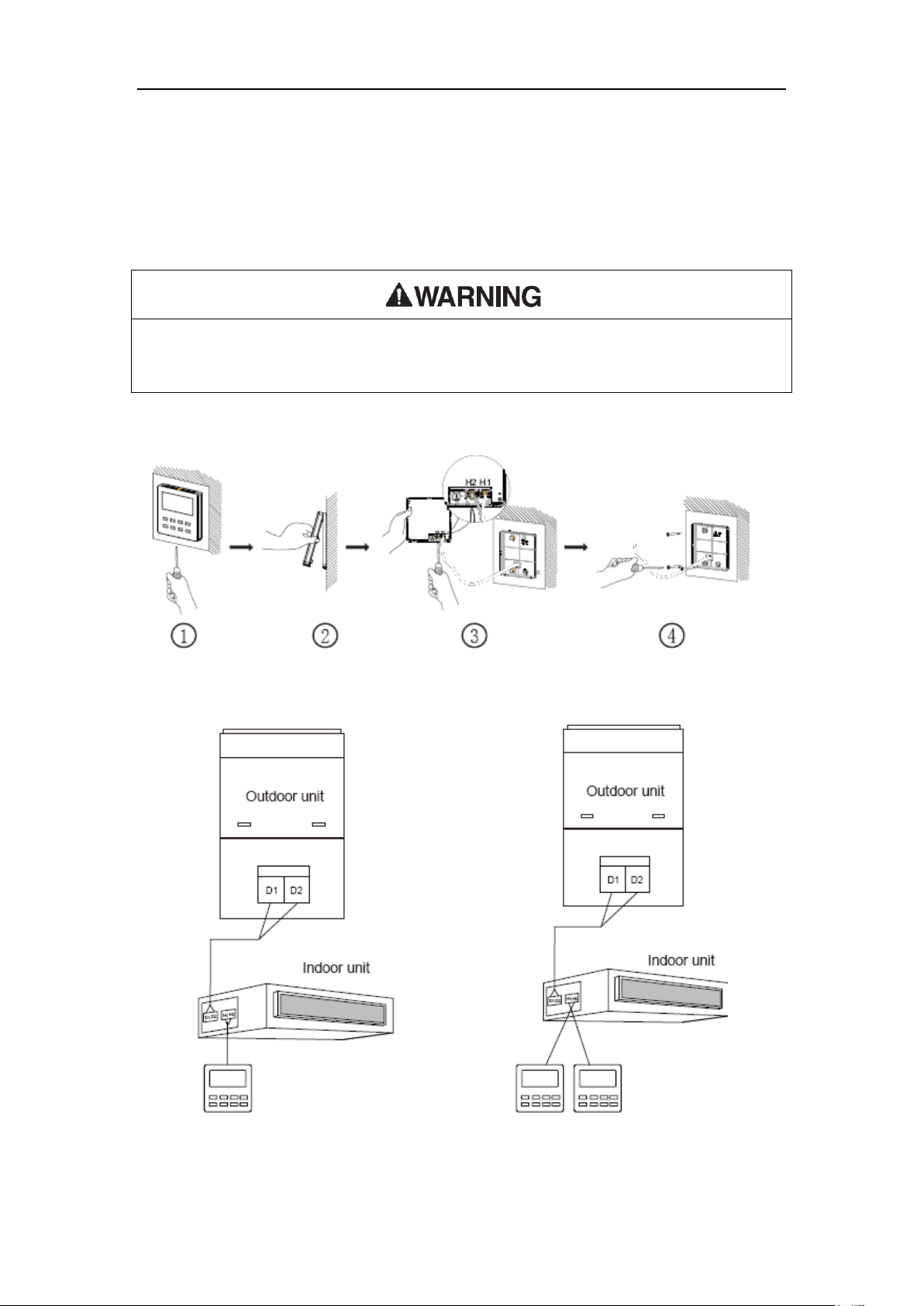

2.2 Installation and removal

2.2.1 Installation dimensions

2.2.2 Installation method

Above is a simple installation method of wired controller. Please pay attention to the

following:

1) Before installation, disconnect power of the indoor unit. Do not operate when

power is connected.

2) Pull out the 2-core twisted pair cable from the installation hole on the wall and lead

it through the hole on the back plate of wired controller.

15

DC Inverter Side Discharge VRF Ⅱ for North America

If caliber of the communication cord is too large, which causes difficulty in leading or sticking the cord

according to above point 2 and point 5, strip some of the sheath of the communication cable to meet the

installation requirement.

3) Place the wired controller on wall and secure its back plate on wall with screw

M4X25.

4) Connect the 2-core twisted pair cable to terminal H1 and terminal H2. Tighten up

the screws.

5) Stick the cable in the slot that is left of the terminals and buckle the wired

controller’s panel with its back plate.

2.2.3 Removal method

Fig.2.1.3 Removal of Wired Controller

2.2.4 Connection of communication cord

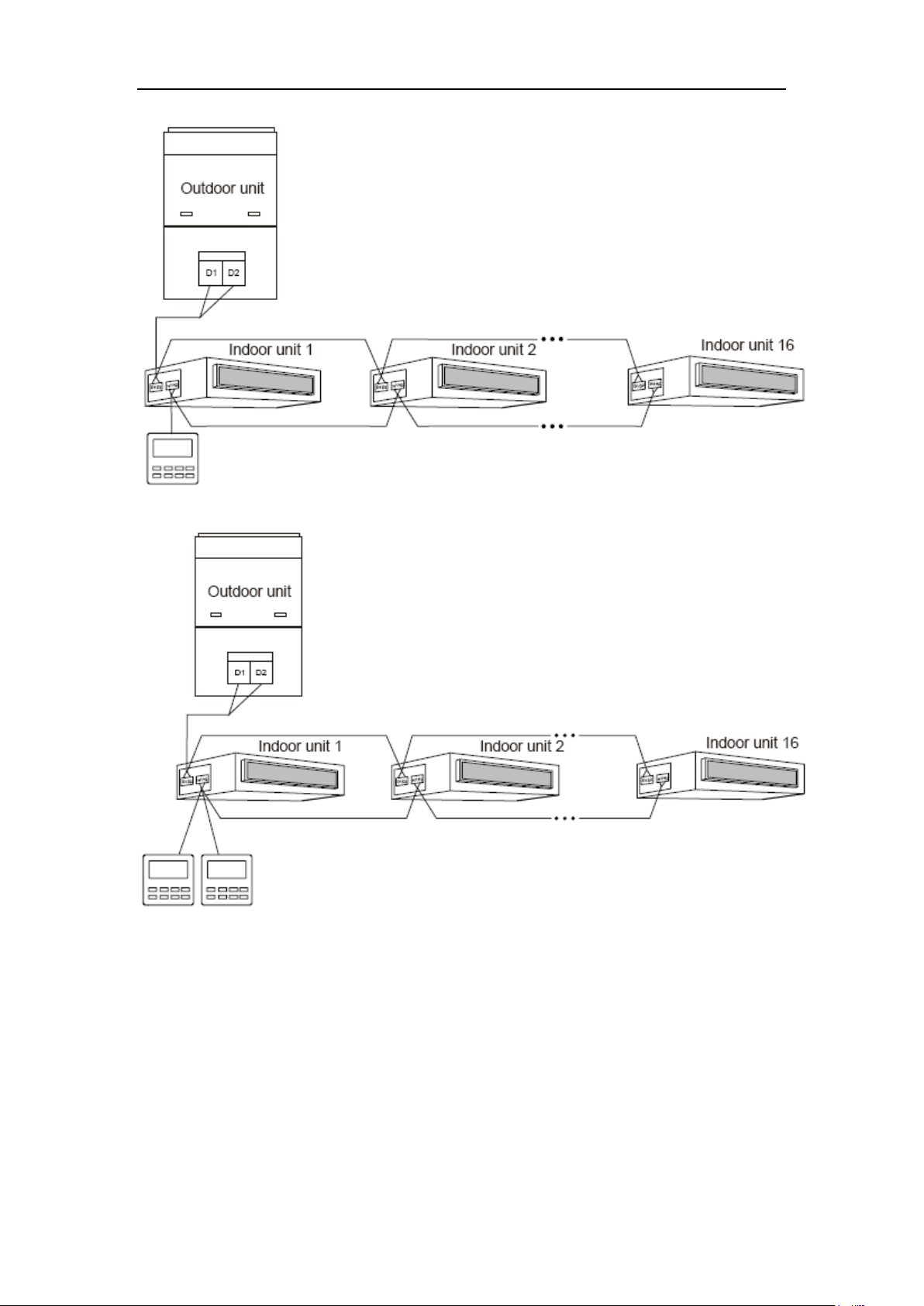

There are 4 ways to connect wired controller with indoor units’ network:

Fig. 2.2.4.1 One wired controller Fig. 2.2.4.2 Two wired controllers

control one indoor unit controls one indoor unit

16

DC Inverter Side Discharge VRF Ⅱ for North America

Fig. 2.2.4.3 One wired controller controls multiple indoor units simultaneously.

Fig. 3.6Two wired controllers control multiple indoor units simultaneously.

17

DC Inverter Side Discharge VRF Ⅱ for North America

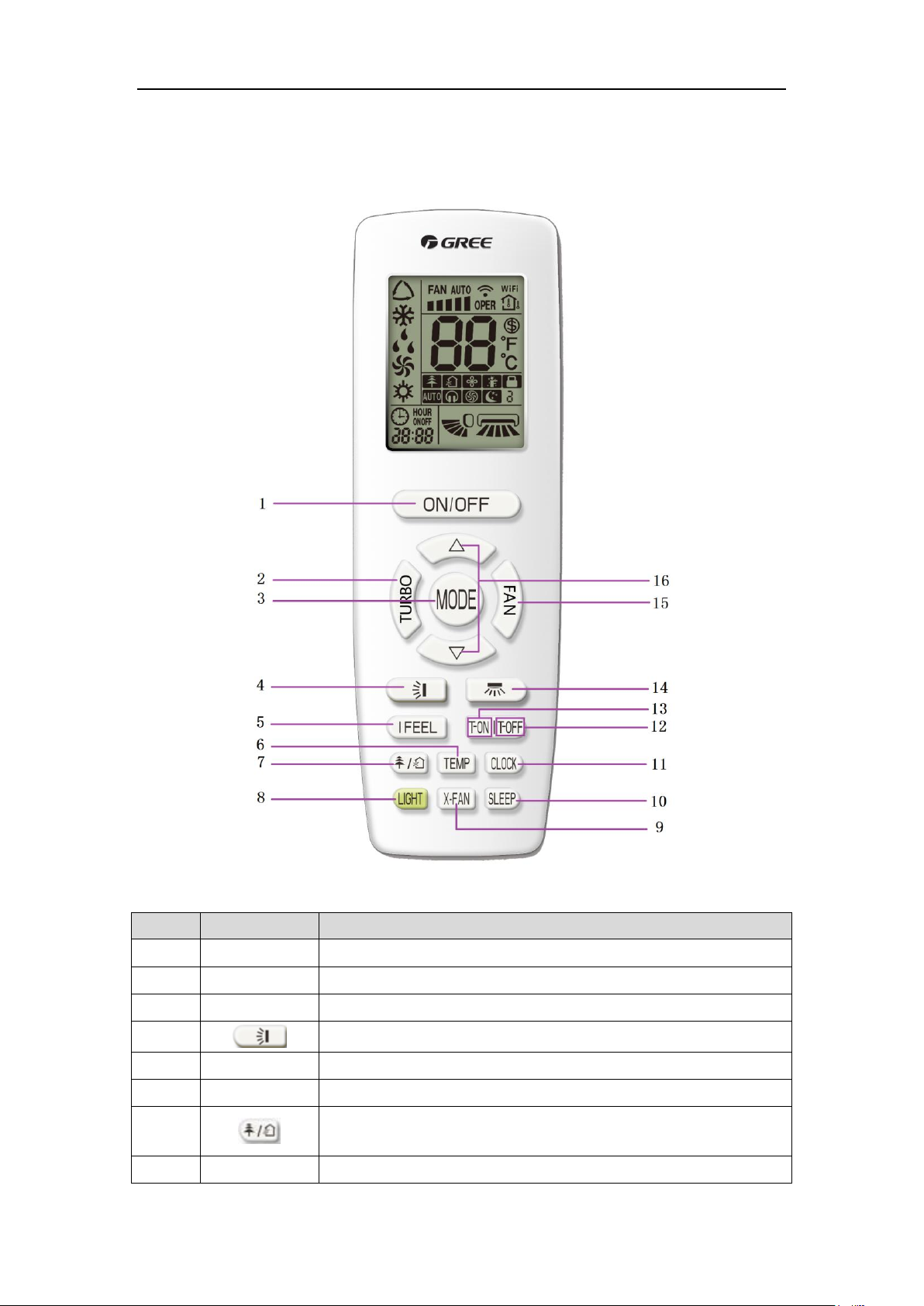

No.

Button name

Function

1

ON/OFF

Turn on or turn off the unit

2

TURBO

Set turbo function

3

MODE

Set operation mode

4

Set up&down swing status

5

I FEEL

Set I FEEL function

6

TEMP

Switch temperature displaying type on the unit’s display

7

Set health function and air function

8

LIGHT

Set light function

3 Remote Controller

(1) Remote controller YAP1F

Button name and function introduction

18

DC Inverter Side Discharge VRF Ⅱ for North America

9

X-FAN

Set X-FAN function

10

SLEEP

Set sleep function

11

CLOCK

Set clock of the system

12

TOFF

Set timer off function

13

TON

Set timer on function

14

Set left&right swing status

15

FAN

Set fan speed

16

/

Set temperature and time

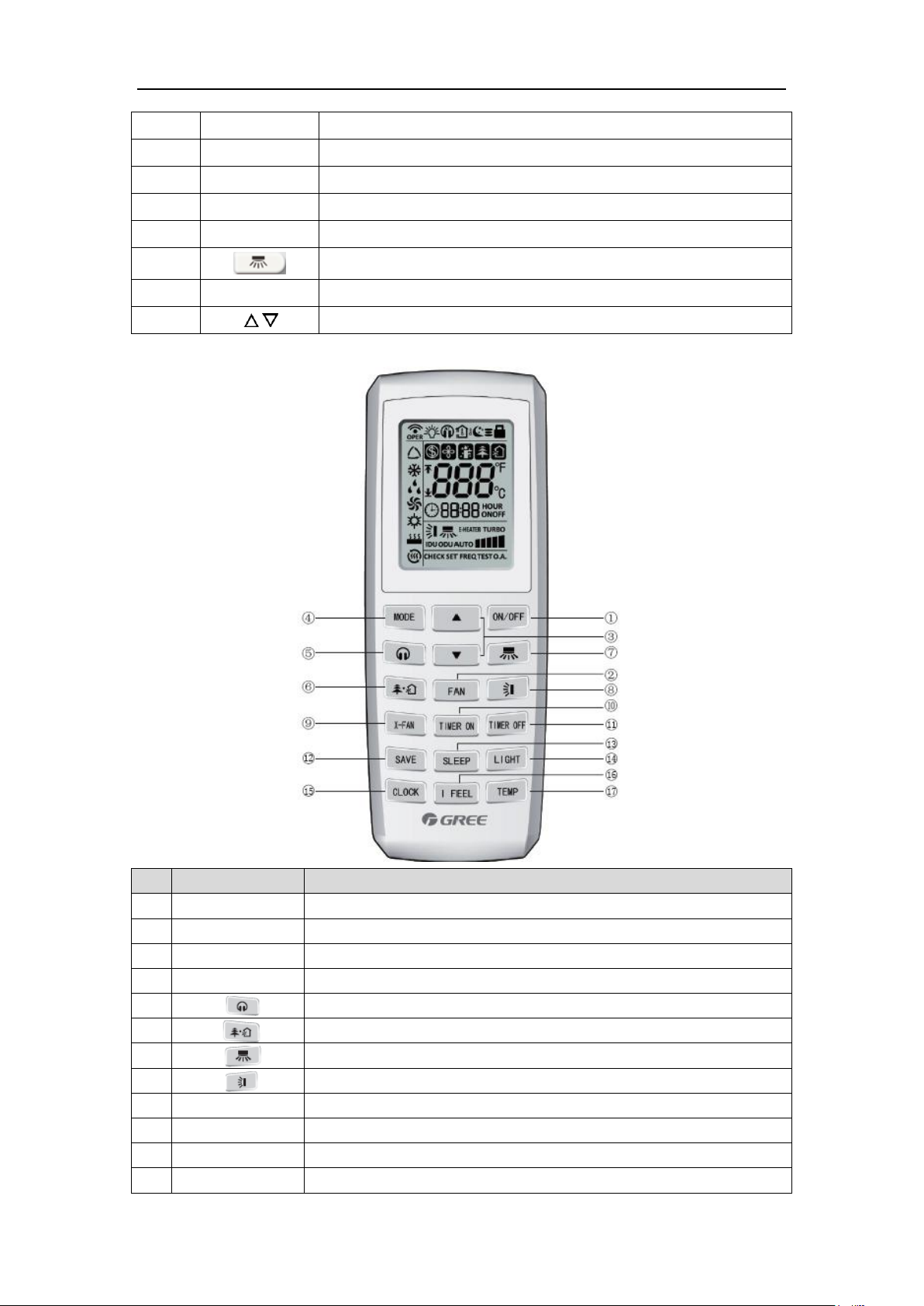

No.

Button name

Function

1

ON/OFF

Turn on or turn off the unit

2

FAN

Set fan speed

3

▲/▼

Set temperature and time

4

MODE

Set operation mode

5 Set quiet function

6

Set health function and air function

7 Set left&right swing status

8 Set up&down swing status

9

X-FAN

Set X-FAN function

10

TIMER ON

Set timer on function

11

TIMER OFF

Set timer off function

12

SAVE

Set energy-saving function

(2) Remote controller YV1L1

19

DC Inverter Side Discharge VRF Ⅱ for North America

13

SLEEP

Set sleep function

14

LIGHT

Set light function

15

CLOCK

Set clock of the system

16

I FEEL

Set I FEEL function

17

TEMP

Switch temperature displaying type on the unit’s display

4 Monitoring Software

4.1 Function introduction

With the rapid development of building complex, more and more central air

conditioners in various models are used in different places, resulting in inconvenience for

the management of air conditioners. Integrating with telecommunication technology and

computing software, Gree Commissioning Tool Kits can realize the comprehensive

monitor, control and commissioning on central air conditioners. It is an efficient solution for

the management of central air conditioners that are separated in different parts of a

building. Administrator doesn’t need to control every unit on site, but rather controls the

units by just sitting in front of a computer. This will not only improve the productivity, but

also reduce cost on human resources, property and management.

Gree Commissioning Tool Kits can monitor and control the 2nd generation of Gree

Multi VRF. User can monitor and control units by monitoring the computer. This software is

an efficient tool for the intelligent air conditioning management as well as installation and

after-sales service and commissioning. It can debug units and control units’ operation

status quickly and conveniently. It will not only improve the productivity but also reduce the

difficulty and cost of commissioning and maintenance, providing better and faster service

to customers.

4.2 Connection of computer and units

It can be connected with single-system network or multi-system network. In the

single-system network, indoor units or outdoor units are connectable, while in the

multi-system network, only the master outdoor unit can be connected.

Seen from the diagram, Gree commissioing network is made up of 3 parts:

20

DC Inverter Side Discharge VRF Ⅱ for North America

Name

Model

Material no.

Remark

Gree USB data converter

MC40-00/B

30118027

Convert the air conditioning

communication into computing

communication

Gree Commissioning Tool

Kits (CD-ROM)

DG40-33/A(C)

36400000003

Include Gree debugger, monitoring

software, USB driver and USB

converter configuring software.

USB wire

\

40020082

Wire connecting computer’s USB

interface and converter

Communicaiton board

\

30118015

This board can be used when units

are far from the computer.

Board connection wire (1m)

\

4001023229

4-core wire connecting units and

converter

Board connection wire

(5.5m)

\

4001023214

4-core wire connecting units and

converter

Instruction manual

\

64134100023

Instruction manual

The 1st part is the monitoring computer, including Gree debugger and Gree USB

converter driver that are installed in the computer.

The 2nd part is Gree USB converter, which is to convert the air conditioning

communication into computing communication. This part is made up of Gree USB data

converter and USB data wire.

The 3rd part is air conditioners, including outdoor units, indoor units and the

connection wires. If connection wire is not long enough, it’s OK to connect via the patching

board of the commissioning tool kits. In a single-system network, both indoor units and

outdoor units can be connected, while in a multi-system network, only the master outdoor

unit can be connected.

4.3 Parts introduction

4.3.1 List of parts

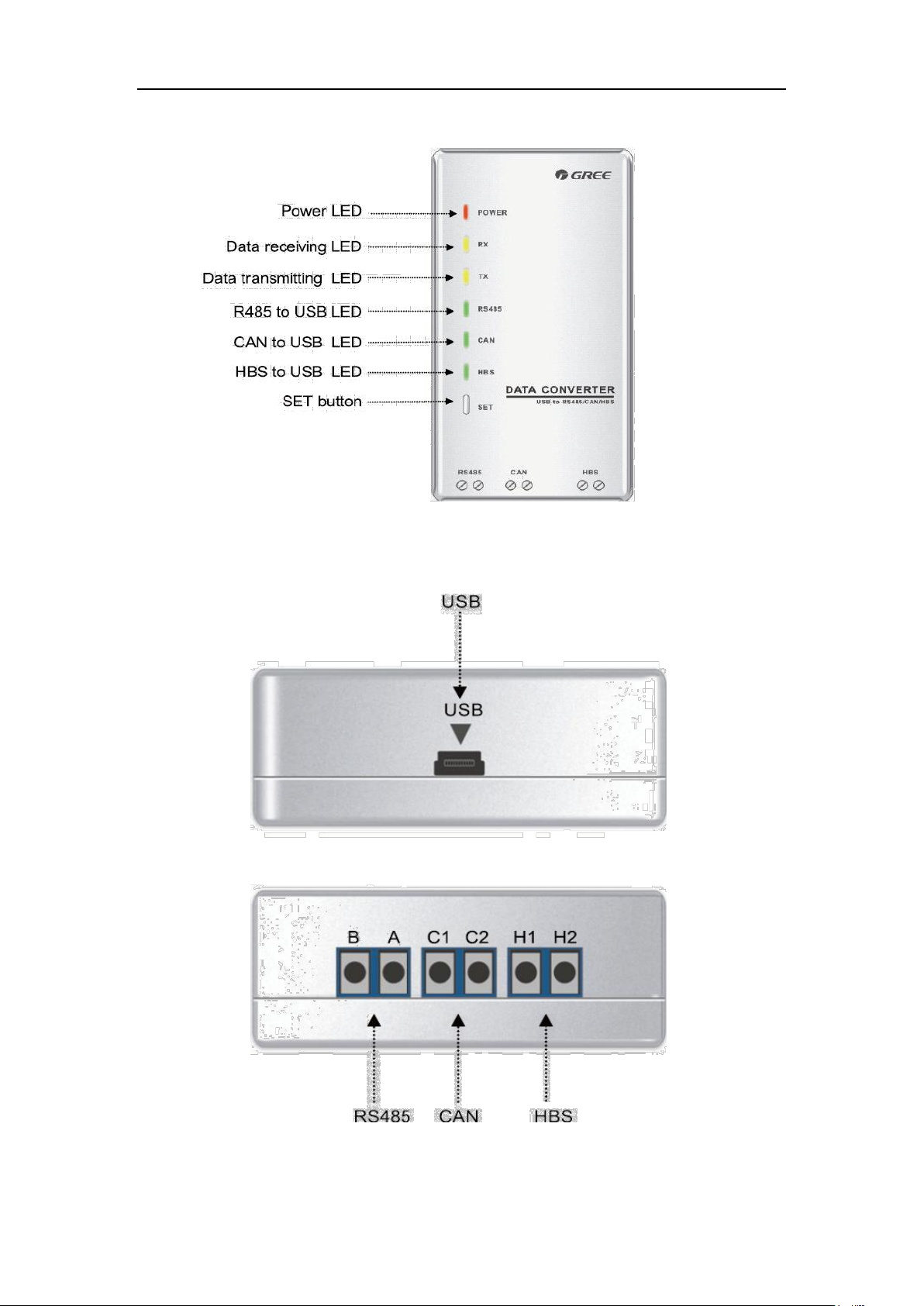

4.3.2 Gree USB data converter

4.3.2.1 Functions introduction

Gree USB data converter will convert the RS485, HBS and CAN commucation within

the air conditioners into the communication that is recognizable by computer’s USB

interface.

21

DC Inverter Side Discharge VRF Ⅱ for North America

4.3.2.2 Appearance

22

DC Inverter Side Discharge VRF Ⅱ for North America

4.3.2.3 Operation instruction

(1) Power LED: a red light. If the red light is on, it indicates normal power supply. If the

red light is off, it indicates the power supply of converter is not normal.

(2) Communication LEDs: yellow lights. When converter is working and the computer is

transmitting data, the TX data transmitting light will be flickering. When units are

uploading data to the computer, the RX data receiving light will be flickering.

(3) When converter is under RS485 data transferring mode, the function LED of RS485

to USB will be on.

(4) When converter is under CAN data transferring mode, the function LED of CAN to

USB will be on.

(5) When converter is under HBS data transferring mode, the function LED of HBS to

USB will be on.

(6) USB interface: connect USB data wire.

(7) CAN interface: When converter is under CAN communication mode, connect air

conditioner’s CAN data interface. CAN interface exhibits no polarity (A and B are

equal).

(8) HBS interface: When HBS converter is under HBS communication mode, connect air

conditioner’s HBS data interface. HBS interface exhibits no polarity (This interface is

not yet available for Gree debugger and the monitoring software).

(9) RS485 interface: When RS485 converter is under RS485 communication mode,

connect air conditioner’s RS485 data interface. RS485 interface exhibits polarity and

terminal A and B are different.

4.3.2.4 Installation notice

(1) Install indoors. To avoid collision, it is suggested to place it in the monitoring room

together with the computer.

(2) No need of power supply. Power is supplied through computer’s USB interface.

4.3.3 Communication board

Communication board is mainly used for transferring data. It functions similar with a

patching board. Provided that units are far away from the monitoring computer,

communication board can be used for connection.

4.3.4 Communication cord

4.3.4.1 USB wire

(1) Connect USB wire with computer’s USB interface at one end and with the USB

interface of USB data converter at the other end, as indicated below:

23

DC Inverter Side Discharge VRF Ⅱ for North America

USB Wire

Board Connection Wire

4.3.4.2 Board Connection Wire

(1) There are 2 board connection wires supplied for the commissioning tool kits. One is 1

meter’s long and the other is 5.5 meters’ long. They are only different in length. One

end of the wire shall connect with air conditioner’s communication interface and the

other end shall connect with CAN interface of Gree USB converter. As shown below,

the wire can be connected to the communication interface of outdoor unit or the

communication interface of indoor unit:

4.4 Software introduction

(1) One-button commissioning

Personnel responsible for the commissioning of air conditioners can start

commissioning by pressing one button according to the commissioning logic of

software, which will give the commissioning order to units. Then commissioning will

be started up automatically step by step. During the commissioning, the

corresponding process will be ticked in green on the software interface. If any

commissioning process is not normal, it will be displayed in red.

(2) Comprehensive monitoring

The software can monitor every part of the air conditioning system, including

functions, equipment and components operating status. The monitoring results will be

displayed in text or curve so that user can acquire the operating status of the entire

system conveniently and straightforwardly.

(3) Real-time control

24

DC Inverter Side Discharge VRF Ⅱ for North America

Memory

1 GB at least

2 GB or above is preferred

Hard Disc

10 GB available

CPU

Core 2 or higher

1 GHz at least

2 GHz or above is preferred

Operation System

Windows Server 2003 SP3 or higher

Windows XP SP3 or higher

Windows Vista

Windows 7

Air conditioner’s operating time and requirements may be different based on areas

and functions. User can set units’ parameters on computer according to actual needs,

such as the on/off, temperature, fan speed, mode, etc. Meanwhile, the software can

also set or view the function parameters of outdoor units, gateway and other

equipment. In this way, the mangement of central air conditioners is realized.

(4) Replay history

Software can replay and save the historical monitoring information in the data base.

The replay speed can be selected and the information will be shown in text or curve.

This function has greatly saved the time to track problem cause and resolved the

difficulty of problem reproduction.

(5) Applicable to multiple series, models and users

Gree Commissioning Tool Kits is applicable to air conditioning system that comsists

of multiple series and models. Later, it will be developed to cover all series of Gree

central air conditioners, such as multi VRF, centrifugal chiller, screw type chiller,

ground source heat pump units, modular units, fan coiled units, close control units,

etc. It can be used by system and controller designers to develop and monitor units,

or used for maintenance and commissioning.

(6) Other functions

For the convenience of users, the software has added functions like connection guide,

printing screen, opening database folder, rebuilding database, changing database

saving path, etc.

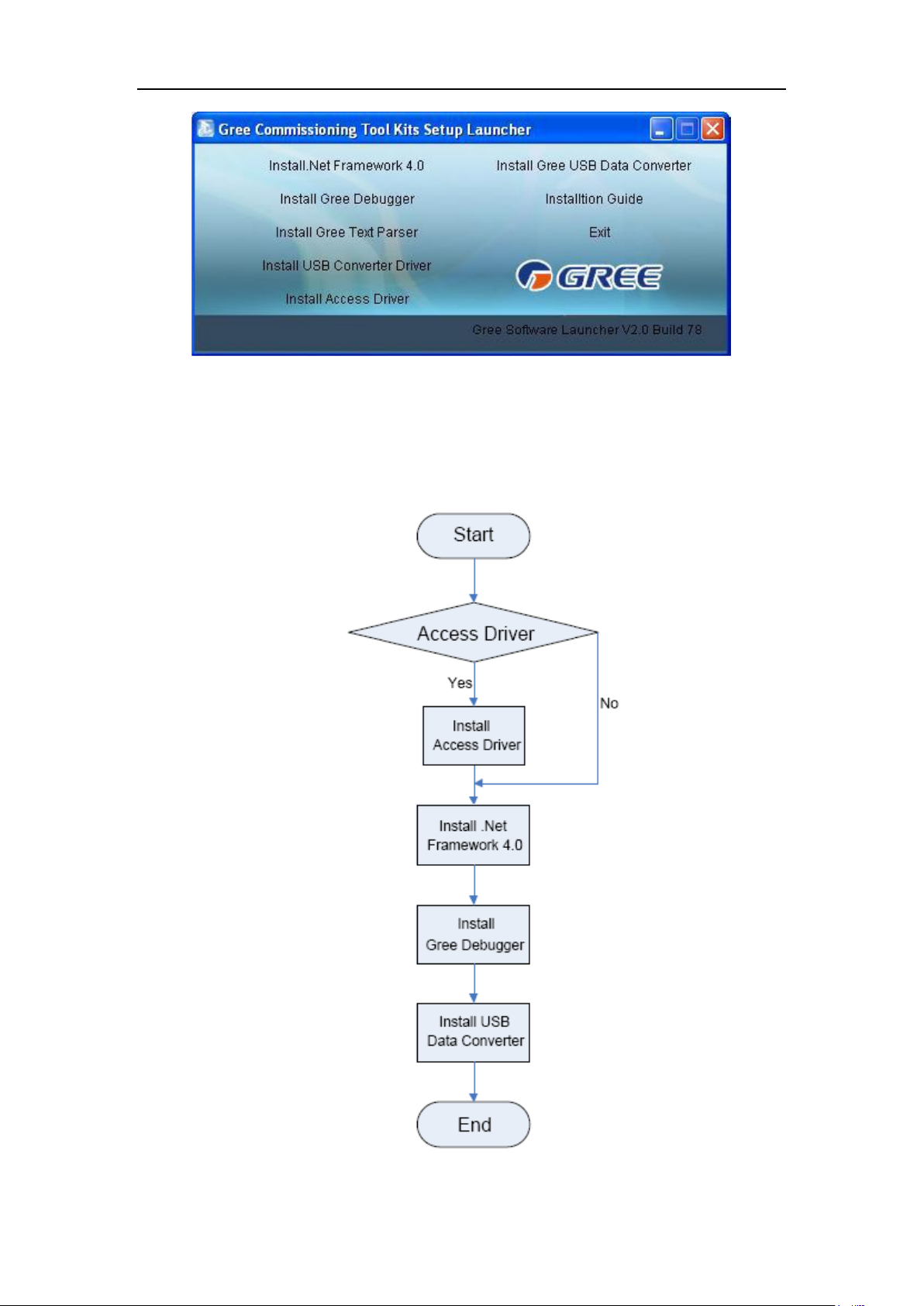

4.4.1 Software installation

4.4.1.1 Installation requirements

(1) Computer Configuration

(2) CD Playing

Make sure you have administrator access to the computer and there is a CD-ROM in

the computer. Put the CD into the CD-ROM. If it’s automically running, then the

following display will be shown. Or double-click the file “Launcher.exe”.

25

DC Inverter Side Discharge VRF Ⅱ for North America

For the first time to use Gree Commissioning Tool Kits, install these

programmes: .Net Framework 4.0, USB Data Converter, Access Driver (necessary for

versions below OFFICE 2007), Gree Debugger.

4.4.1.2 Installation flowchart

(1) Button Graphics

This flowchart describes basically the software installation process. See below for details.

26

DC Inverter Side Discharge VRF Ⅱ for North America

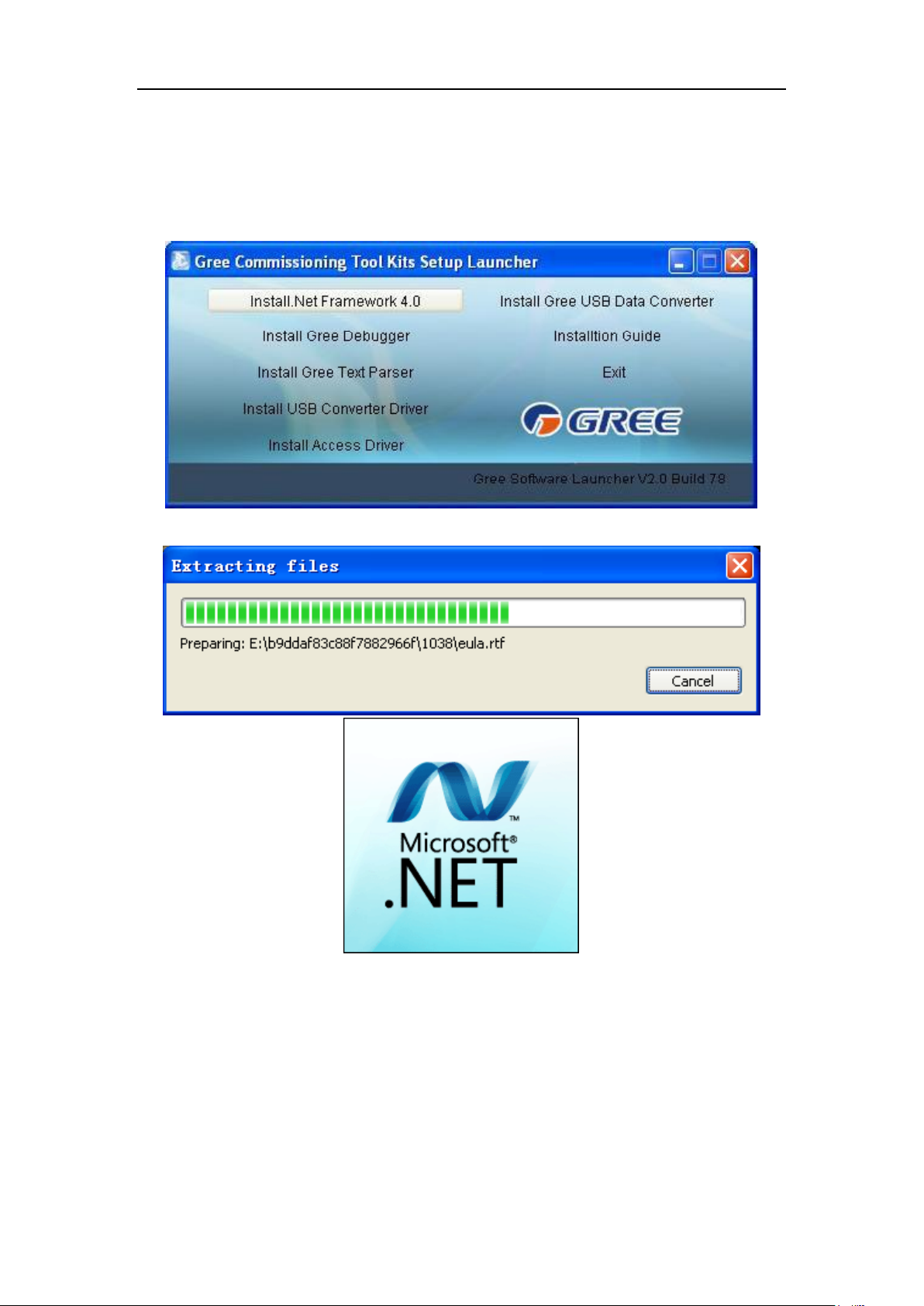

4.4.1.3 Installation process

(1) Install .Net Framework 4.0

If your computer has installed .Net Framework 4.0 or versions above, there’s no need

to install again. Otherwise, click “Install .Net Framework 4.0”.

Extracting files

Click and select “I have read and accept the license terms”. Then click “Install”.

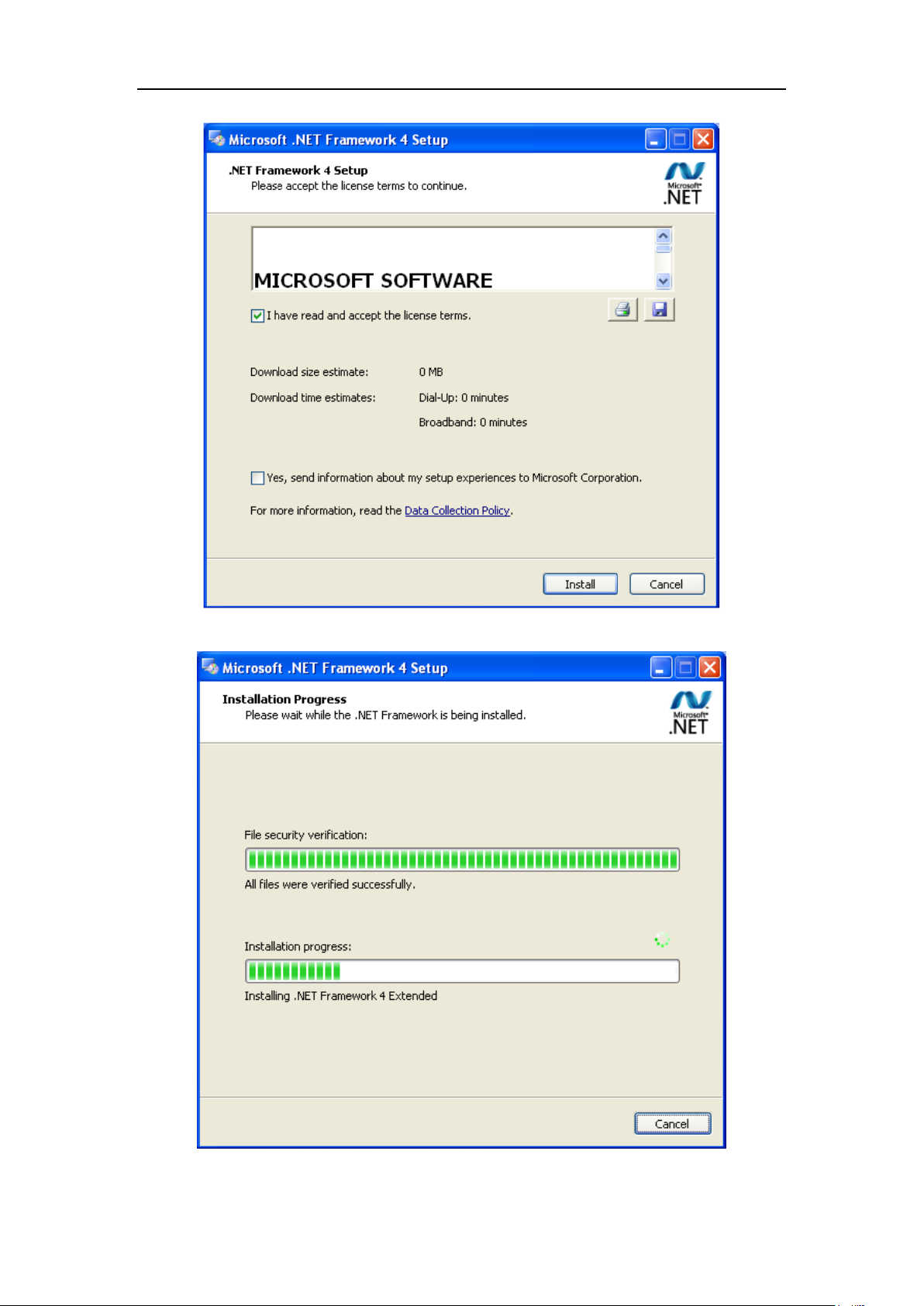

27

DC Inverter Side Discharge VRF Ⅱ for North America

Installation is in progress.

28

Loading...

Loading...