Gree GMV-72WM/B-FU, GMV-144WM/B-F, GMV-120WM/B-F, GMV-120WM/B-FU, GMV-72WM/B-F Service Manual

...

GMV5 DC Inverter VRF Units SERVICE

MANUAL (For North America)

T1/R410A/60Hz

(GC201601-Π)

Contents

PREFACE ............................................................................................................................ 1

SAFTY PRECAUTIONS ...................................................................................................... 2

CHAPTER 1 INTRODUCTION TO BASIC FEATURES OF UNITS .................................... 7

1 MODELS LIST .......................................................................................................................................................... 7

2 BASIC OPERATING PRINCIPLE .......................................................................................................................... 7

3 INTERNAL PIPING DESIGN OF THE UNITS ...................................................................................................... 8

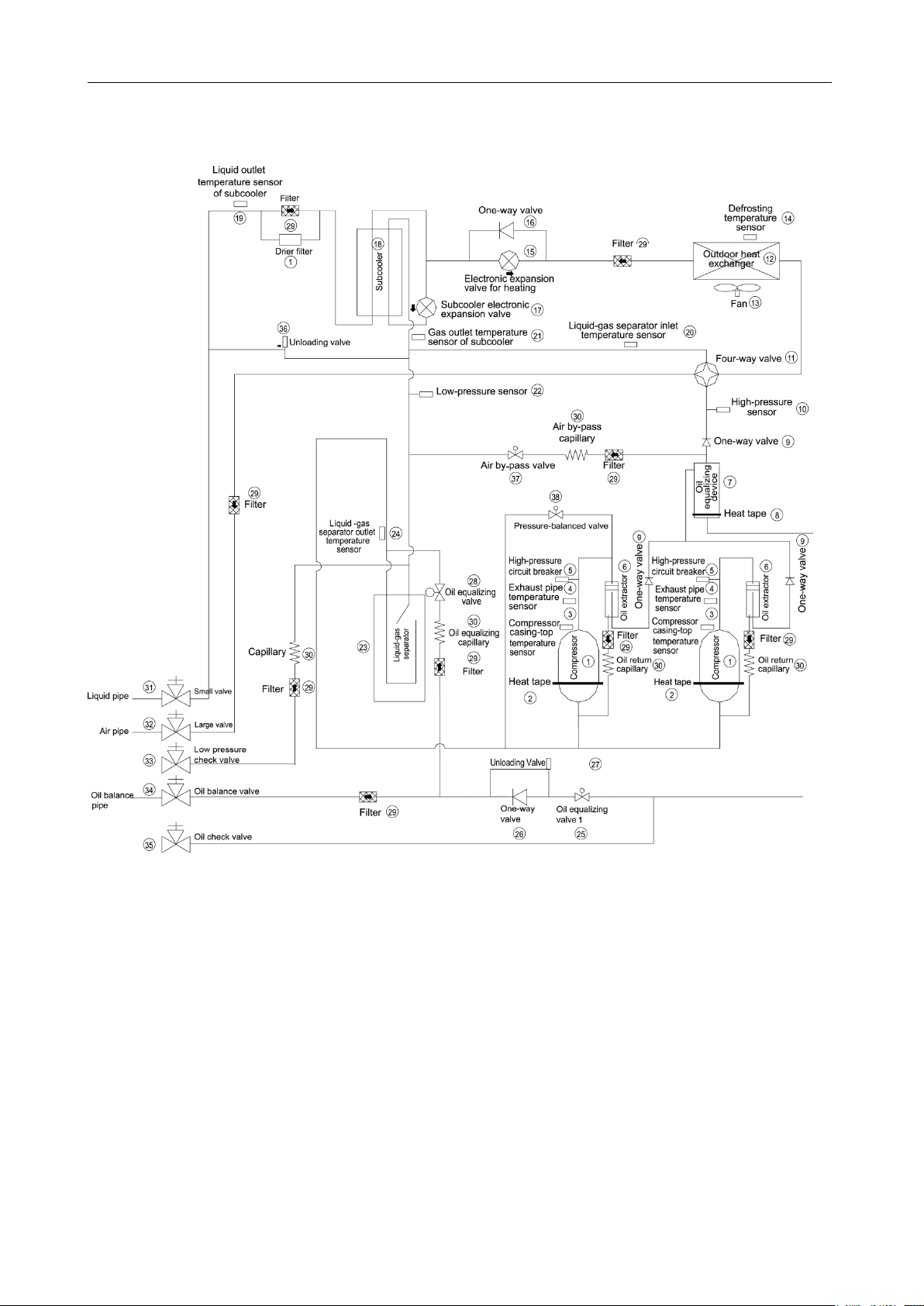

3.1 Piping Diagram of GMV-72WM/B-F(U) and GMV-96WM/B-F(U) ........................................................... 8

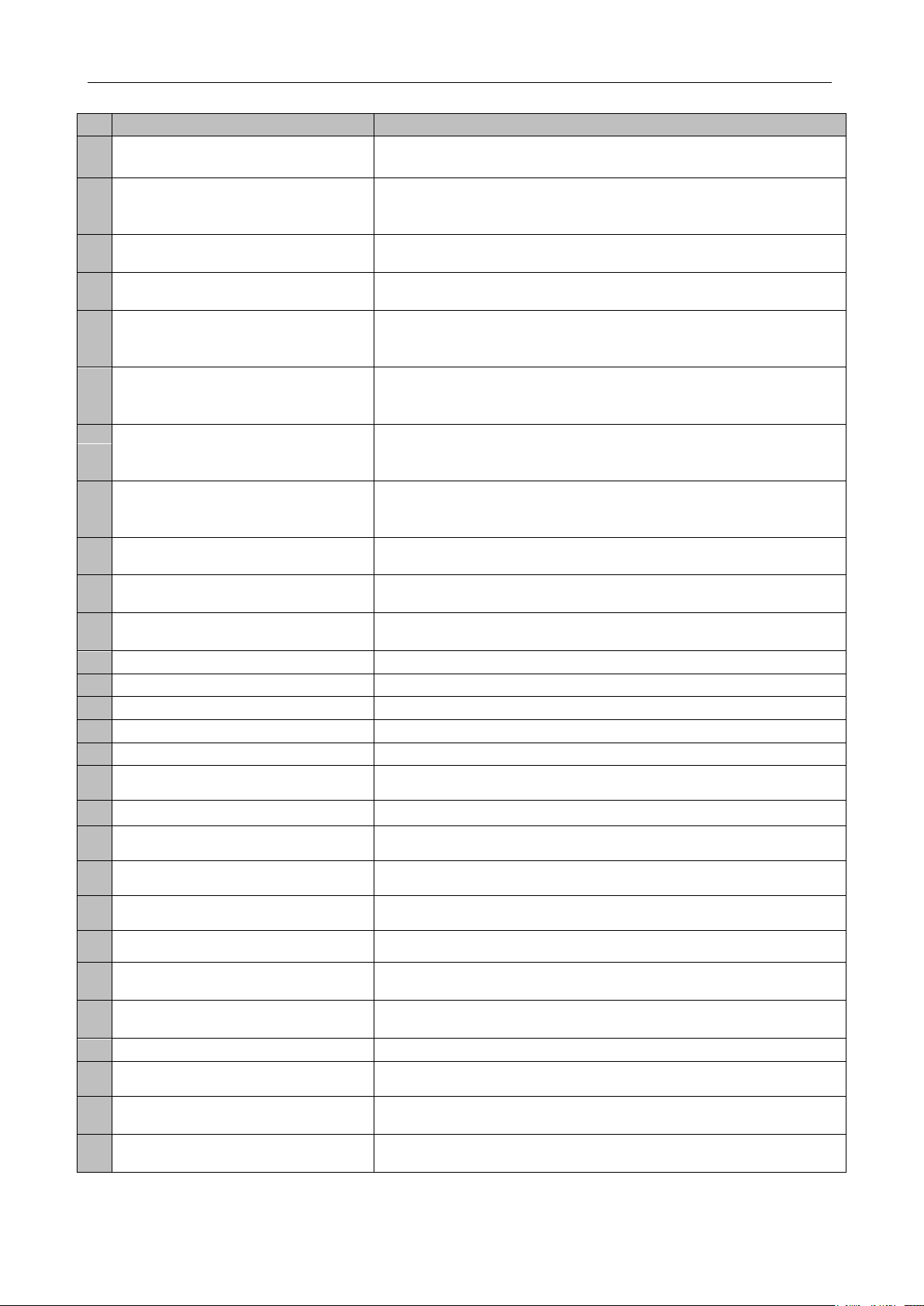

3.2 Piping Diagram of GMV-120WM/B-F(U) ..................................................................................................... 9

3.3 Names and Main Functions of Components.......................................................................................... 10

4 BASIC PARAMETERS OF UNIT.......................................................................................................................... 12

5 ELECTRICAL PARAMETERS ............................................................................................................................. 15

6 OPTIONAL ACCESSORIES ................................................................................................................................. 18

7 BASIC REQUIREMENT FOR PIPE CONNECTION ......................................................................................... 18

8 PRECAUTIONS ON REFRIGERANT LEAKAGE ............................................................................................. 21

9 UNIT OPERATING TEMPERATURE................................................................................................................... 23

CHAPTER 2 INSTALLATION ........................................................................................... 25

1 ENGINEERING INSTALLATION PREPARATION ............................................................................................ 25

1.1 INSTALLATION SAFETY .............................................................................................................................. 25

1.2 IMPORTANCE OF INSTALLATION ENGINEERING ................................................................................ 25

1.3 COOPERATION BETWEEN DIFFERENT PROFESSIONS .................................................................... 26

1.4 ONSITE REVIEW OF DESIGN DRAWING ................................................................................................ 29

1.5 CONSTRUCTION ORGANIZATION PROCESS ....................................................................................... 30

2 MATERIAL SELECTION ....................................................................................................................................... 31

2.1 REQUIREMENT FOR SELECTING CONSTRUCTION MATERIALS ................................................... 31

2.2 REQUIREMENT FOR SELECTING MAJOR MATERIALS ..................................................................... 31

3 INSTALLATION SPACE REQUIREMENT .......................................................................................................... 32

3.1 PLACE SELECTION FOR INSTALLING ODU .......................................................................................... 33

3.2 ODU DIMENSIONS AND INSTALLATION HOLE SIZE ........................................................................... 33

3.3 INSTALLATION SPACE REQUIREMENT FOR ODU .............................................................................. 35

4 REQUIREMENTS ON FOUNDATION INSTALLATION.................................................................................... 43

4.1 ODU FOUNDATION ....................................................................................................................................... 43

4.2 ODU FIXING .................................................................................................................................................... 44

4.3 VIBRATION REDUCTION FOR ODU ......................................................................................................... 44

5 PIPING CONNECTION .......................................................................................................................................... 45

5.1 Schematic Diagram of Piping Connection ............................................................................................. 45

5.2 Schematic Diagram of Piping Sequence ................................................................................................ 46

5.3 Allowable pipe length and drop height among indoor and outdoor units ..................................... 47

5.4 Connection Pipe among Outdoor Modules ............................................................................................ 49

5.5 Fitting pipe between Outdoor Unit and the First Manifold ................................................................. 51

6 PIPE INSTALLATION AND INSULATION .......................................................................................................... 57

6.1 PIPE INSTALLATION FOR THE COOLING SYSTEM ............................................................................. 57

6.2 PIPE INSTALLATION FOR THE CONDENSATE WATER SYSTEM ..................................................... 65

6.3 INSULATION SYSTEM .................................................................................................................................. 70

7 ELECTRIC AND CONTROLLER INSTALLATION ............................................................................................ 72

7.1 PRECAUTIONS .............................................................................................................................................. 72

7.2 INSTALLATION OF THE POWER CABLE ................................................................................................ 74

7.3 INSTALLATION OF THE COMMUNICATION SYSTEM .......................................................................... 78

8 VACUUMIZATION AND DESICCATION FOR THE REFRIGERANT SYSTEM ............................................ 86

8.1 AIR-TIGHTNESS TEST ................................................................................................................................. 86

8.2 VACUUMIZATION AND DESICCATION FOR THE SYSTEM ................................................................. 87

9 REFRIGERANT PERFUSION .............................................................................................................................. 89

9.1 CALCULATION METHOD FOR PERFUSING REFRIGERANT .......................................................... 89

9.2 METHOD FOR PERFUSING REFRIGERANT .......................................................................................... 91

CHAPTER 3 COMMISSIONING OPERATION ................................................................. 95

1 SECURITY REQUIREMENTS .............................................................................................................................. 95

1.1PRECAUTIONS FOR CONSTRUCTION ..................................................................................................... 95

1.2 PRECAUTIONS FOR THE USE OF REFRIGERANTS ........................................................................... 95

1.3 FUNCTION SETTINGS OF ODUS .............................................................................................................. 95

2 COMMISSIONING PROCESS ........................................................................................................................... 121

2.1 NECESSITY OF VRF ENGINEERING COMMISSIONING .................................................................... 121

2.2 REQUIRED FILES AND TOOLS FOR ENGINEERING COMMISSIONING ....................................... 121

2.3 ENGINEERING COMMISSIONING PROCEDURES .............................................................................. 122

2.4 REFERENCES FOR PROPER UNIT OPERATION PARAMETERS ................................................... 147

CHAPTER 4 MAINTENANCE ......................................................................................... 150

1 FAILURE CODE TABLE ...................................................................................................................................... 150

1.1 System Failure Code Table ...................................................................................................................... 150

2 EXCEPTION AND TROUBLESHOOTING ....................................................................................................... 156

2.1 How to locate a faulty IDU promptly ...................................................................................................... 156

2.2 Exception Analyzing and Troubleshooting .......................................................................................... 157

3 KEY PARTS MAINTENANCE ............................................................................................................................ 198

3.1 CAUTIONS ON CONTROLLER AP1 REPLACEMENT ......................................................................... 198

3.2 COMPRESSOR REPLACEMENT AND CAUTIONS .............................................................................. 204

3.3 CAUTIONS ON COMPRESSOR DRIVE REPLACEMENT ................................................................... 229

3.4 ASSEMBLING AND DISASSEMBLING KEY PARTS OF ODUS ........................................................ 233

3.5 UNIT MAINTENANCE ................................................................................................................................. 245

4 APPENDIXES ....................................................................................................................................................... 246

4.1 MINUTES ABOUT A DEBUG SOLUTION CONFIRMATION MEETING ............................................. 246

4.2 VISUAL INSPECTION CHECKLIST OF THE DEBUG SYSTEM ......................................................... 246

4.3 DEBUG PARAMETER RECORD LIST ..................................................................................................... 247

4.4 COMMON PARAMETER LISTS ................................................................................................................ 248

4.5 EXPLODED VIEWS AND SPARE PART LIST ........................................................................................ 258

CHAPTER 5 REMOTE CONTROL.................................................................................. 267

1 ENGINEERING DEBUGGER ............................................................................................................................. 267

1.1 Overview ....................................................................................................................................................... 267

1.2 System Networking .................................................................................................................................... 268

1.3 Hardware ....................................................................................................................................................... 269

1.4 Software Setup ............................................................................................................................................ 272

1.5. Using Debugger ......................................................................................................................................... 284

1.6 Software Debug ........................................................................................................................................... 302

2 REMOTE CONTROL ........................................................................................................................................... 303

2.1 MODBUS GATEWAY REMOTE MONITORING SYSTE ........................................................................ 303

2.2 BACnet GATEWAY REMOTE MONITORING SYSTE ........................................................................... 370

GMV5 D.C INVERTER MULTI VRF SERVICE MANUAL

PREFACE

This manual specifies safe operation requirements for GMV5 series VRF units from perspectives of

engineering and installation, commissioning and maintenance, as well as basic principles and

implementation methods. Professional operators must abide by relevant national (local) safety

requirements and technical specifications set forth in this manual during operations; otherwise, the air

conditioning system may fail or be damaged, and personnel safety accident may also occur.

1

GMV5 D.C INVERTER MULTI VRF SERVICE MANUAL

This is the safety alert symbol. It is used to alert you to potential personal injury hazards.

Obey all safety messages that follow this symbol to avoid possibleinjury or death.

WARNING

This mark indicates procedures which, if improperly performed, might lead to the death or

serious injury of the user.

CAUTION

This mark indicates procedures which, if improperly performed, might possibly result in

personal harm to the user, or damage to property.

NOTICE is used to address practices not related to personal injury.

SAFTY PRECAUTIONS

To prevent injury to the user or other people and property damage, the following instructions must

be followed.

Incorrect operation due to ignoring instruction will cause harm or damage. The seriousness is

classified by the following indications.

■Installation

Have all electric work done by a licensed electrician according to "Electric Facility

Engineering

Standard" and "Interior Wire Regulations" and the instructions given in this manual and

always use a special circuit.

• If the power source capacity is inadequate or electric work is performed improperly, electric shock

or fire may result.

Ask the dealer or an authorized technician to install the air conditioner.

• Improper installation by the user may result in water leakage, electric shock, or fire.

Always ground the product.

• There is risk of fire or electric shock.

Always install a dedicated circuit and breaker.

• Improper wiring or installation may cause fire or electric shock.

For re-installation of the installed product, always contact a dealer or an Authorized Service

Center.

• There is risk of fire, electric shock, explosion, or injury.

Do not install, remove, or re-install the unit by yourself (customer).

• There is risk of fire, electric shock, explosion, or injury.

Do not store or use flammable gas or combustibles near the air conditioner.

• There is risk of fire or failure of product.

Use the correctly rated breaker or fuse.

• There is risk of fire or electric shock.

2

GMV5 D.C INVERTER MULTI VRF SERVICE MANUAL

Prepare for strong wind or earthquake and install the unit at the specified place.

• Improper installation may cause the unit to topple and result in injury.

Do not install the product on a defective installation stand.

• It may cause injury, accident, or damage to the product.

When installing and moving the air conditioner to another site, do not charge it with a

different refrigerant from the refrigerant specified on the unit.

• If a different refrigerant or air is mixed with the original refrigerant, the refrigerant cycle may

malfunction and the unit may be damaged.

Do not reconstruct to change the settings of the protection devices.

• If the pressure switch, thermal switch, or other protection device is shorted and operated forcibly,

or parts other than those specified by GREE are used, fire or explosion may result.

Ventilate before operating air conditioner when gas leaked out.

• It may cause explosion, fire, and burn.

Securely install the cover of control box and the panel.

• If the cover and panel are not installed securely, dust or water may enter the outdoor unit and fire

or electric shock may result.

If the air conditioner is installed in a small room, measures must be taken to prevent the

refrigerant concentration from exceeding the safety limit when the refrigerant leaks.

• Consult the dealer regarding the appropriate measures to prevent the safety limit from being

exceeded.Should the refrigerant leak and cause the safety limit to be exceeded, hazards due to

lack of oxygen in the room could result.

■Operation

Do not damage or use an unspecified power cord.

• There is risk of fire, electric shock, explosion, or injury.

Use a dedicated outlet for this appliance.

• There is risk of fire or electrical shock.

Be cautious that water could not enter the product.

• There is risk of fire, electric shock, or product damage.

Do not touch the power switch with wet hands.

• There is risk of fire, electric shock, explosion, or injury.

When the product is soaked (flooded or submerged), contact an Authorized Service

Center.

• There is risk of fire or electric shock.

Be cautious not to touch the sharp edges when installing.

• It may cause injury.

Take care to ensure that nobody could step on or fall onto the outdoor unit.

3

GMV5 D.C INVERTER MULTI VRF SERVICE MANUAL

• This could result in personal injury and product damage.

Do not open the inlet grille of the product uring operation. (Do not touch the electrostatic

filter, if the unit is so equipped.)

• There is risk of physical injury, electric shock, or product failure.

■Installation

Always check for gas (refrigerant) leakage after installation or repair of product.

• Low refrigerant levels may cause failure of product.

Do not install the product where the noise or hot air from the outdoor unit could damage

the neighborhoods.

• It may cause a problem for your neighbors.

Keep level even when installing the product.

• To avoid vibration or water leakage.

Do not install the unit where combustible gas may leak.

• If the gas leaks and accumulates around the unit, an explosion may result.

Use power cables of sufficient current carrying capacity and rating.

• Cables that are too small may leak, generate heat, and cause a fire.

Do not use the product for special purposes, such as preserving foods, works of art, etc. It is

a consumer air conditioner, not a precision refrigeration system.

• There is risk of damage or loss of property.

Keep the unit away from children. The heat exchanger is very sharp.

• It can cause the injury, such as cutting the finger. Also the damaged fin may result in degradation

of capacity.

When installing the unit in a hospital, communication station, or similar place, provide

sufficient protection against noise.

• The inverter equipment, private power generator, high-frequency medical equipment, or radio

communication equipment may cause the air conditioner to operate erroneously, or fail to operate.

On the other hand, the air conditioner may affect such equipment by creating noise that disturbs

medical treatment or image broadcasting.

Do not install the product where it is exposed to sea wind (salt spray) directly.

• It may cause corrosion on the product. Corrosion, particularly on the condenser and evaporator

fins, could cause product malfunction or inefficient operation.

4

GMV5 D.C INVERTER MULTI VRF SERVICE MANUAL

■Operation

Do not use the air conditioner in specialenvironments.

• Oil, steam, sulfuric smoke, etc. can significantly reduce the performance of the air conditioner or

damage its parts.

Do not block the inlet or outlet.

• It may cause failure of appliance or accident.

Make the connections securely so that the outside force of the cable may not be applied

to the terminals.

• Inadequate connection and fastening may generate heat and cause a fire.

Be sure the installation area does not deteriorate with age.

• If the base collapses, the air conditioner could fall with it, causing property damage, product failure,

or personal injury.

Install and insulate the drain hose to ensure that water is drained away properly based on

the installation manual.

• A bad connection may cause water leakage.

Safely dispose of the packing materials.

• Packing materials, such as nails and other metal or wooden parts, may cause stabs or other

injuries. • Tear apart and throw away plastic packaging bags so that children may not play with

them. If children play with a plastic bag which was not torn apart, they face the risk of suffocation.

Turn on the power at least 6 hours before starting operation.

• Starting operation immediately after turning on the main power switch can result in severe damage

to internal parts. Keep the power switch turned on during the operational season.

Be very careful about product transportation.

• Only one person should not carry the product if it weighs more than 44lbs (20kg).

• Some products use PP bands for packaging. Do not use any PP bands for a means of

transportation. It is dangerous.

• Do not touch the heat exchanger fins. Doing so may cut your fingers.

• When transporting the outdoor unit, suspending it at the specified positions on the unit base. Also

support the outdoor unit at four points so that it cannot slip sideways.

Do not touch any of the refrigerant piping during and after operation.

• It can cause a burn or frostbite.

Do not operate the air conditioner with the panels or guards removed.

• Rotating, hot, or high-voltage parts can cause injuries.

Do not directly turn off the main power switch after stopping operation.

• Wait at least 5 minutes before turning off the main power switch. Otherwise it may result in water

leakage or other problems.

Auto-addressing should be done in condition of connecting the power of all indoor and

5

GMV5 D.C INVERTER MULTI VRF SERVICE MANUAL

outdoor units. Auto-addressing should also be done in case of changing the indoor unit PCB.

Use a firm stool or ladder when cleaning or maintaining the air conditioner.

• Be careful and avoid personal injury.

Do not insert hands or other objects through the air inlet or outlet while the air conditioner is

plugged in.

• There are sharp and moving parts that could cause personal injury.

6

GMV5 D.C INVERTER MULTI VRF SERVICE MANUAL

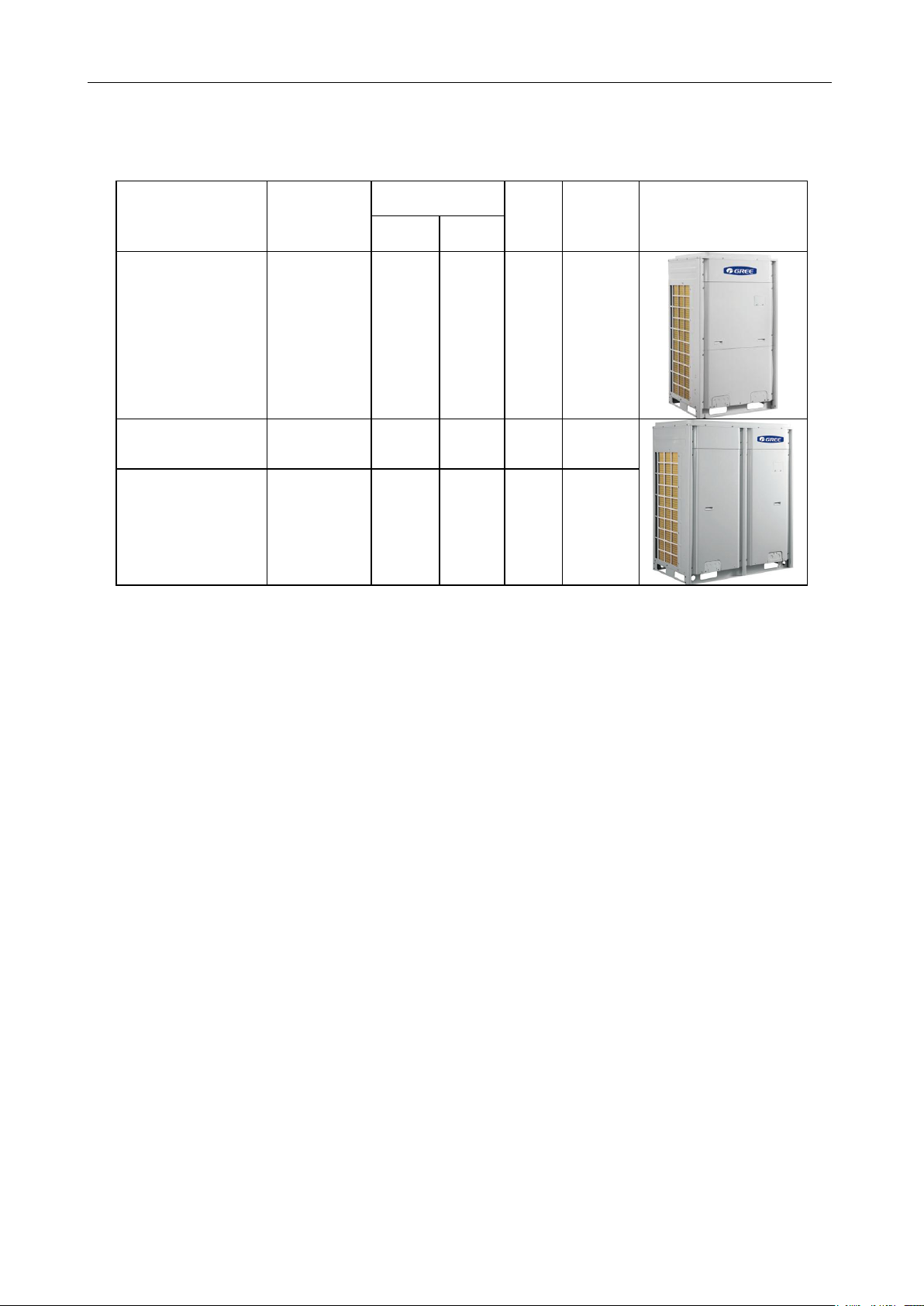

Model

Product Code

Capacity

Ref.

Power

Supply

Appearance

Cooling

(Btu/h)

Heating

(Btu/h)

GMV-72WM/B-F(U)

CN851W1380

CN851W1381

72000

81000

R410a

208/230V

3~60Hz

GMV-96WM/B-F(U)

CN851W1390

CN851W1391

96000

108000

R410a

208/230V

3~60Hz

GMV-120WM/B-F(U)

CN851W1420

CN851W1421

120000

135000

R410a

208/230V

3~60Hz

CHAPTER 1 INTRODUCTION TO BASIC FEATURES OF UNITS

1 MODELS LIST

2 BASIC OPERATING PRINCIPLE

Outdoor units of GMV5 VRF air conditioner can be implemented by combining multiple modules in

parallel. Similarly, indoor units (IDUs) consist of multiple units connecting in parallel. The operating

principle is as follows: When an IDU is operating in cooling mode, the outdoor unit (ODU) can

correspondingly enable the outdoor module based on the operating load requirement of the IDU. The

outdoor heat exchanger serves as a system condenser, and the heat exchangers of cooling IDUs are

connected in parallel to serve as a system evaporator. The circulation of air supply and air return of the

IDU is performed to adjust the indoor temperature and humidity. When an IDU is operating in heating

mode, all four-way valves in the ODU module are switched into energized status. The outdoor heat

exchange serves as the system evaporator, and the heat exchanger of the IDU serves as the system

condenser. The circulation of air supply and air return of the IDU is performed to adjust the indoor

temperature and humidity.

7

GMV5 D.C INVERTER MULTI VRF SERVICE MANUAL

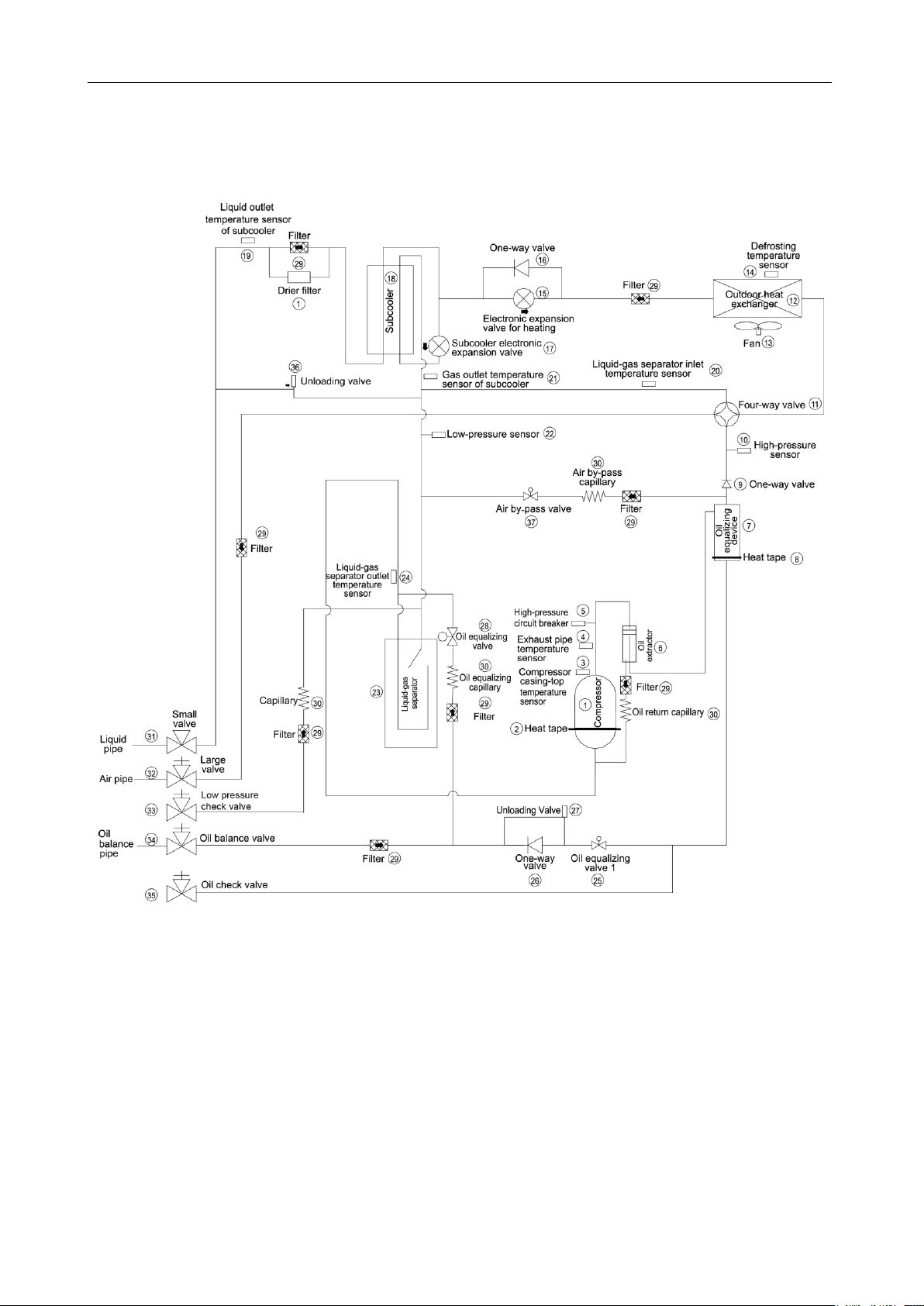

3 INTERNAL PIPING DESIGN OF THE UNITS

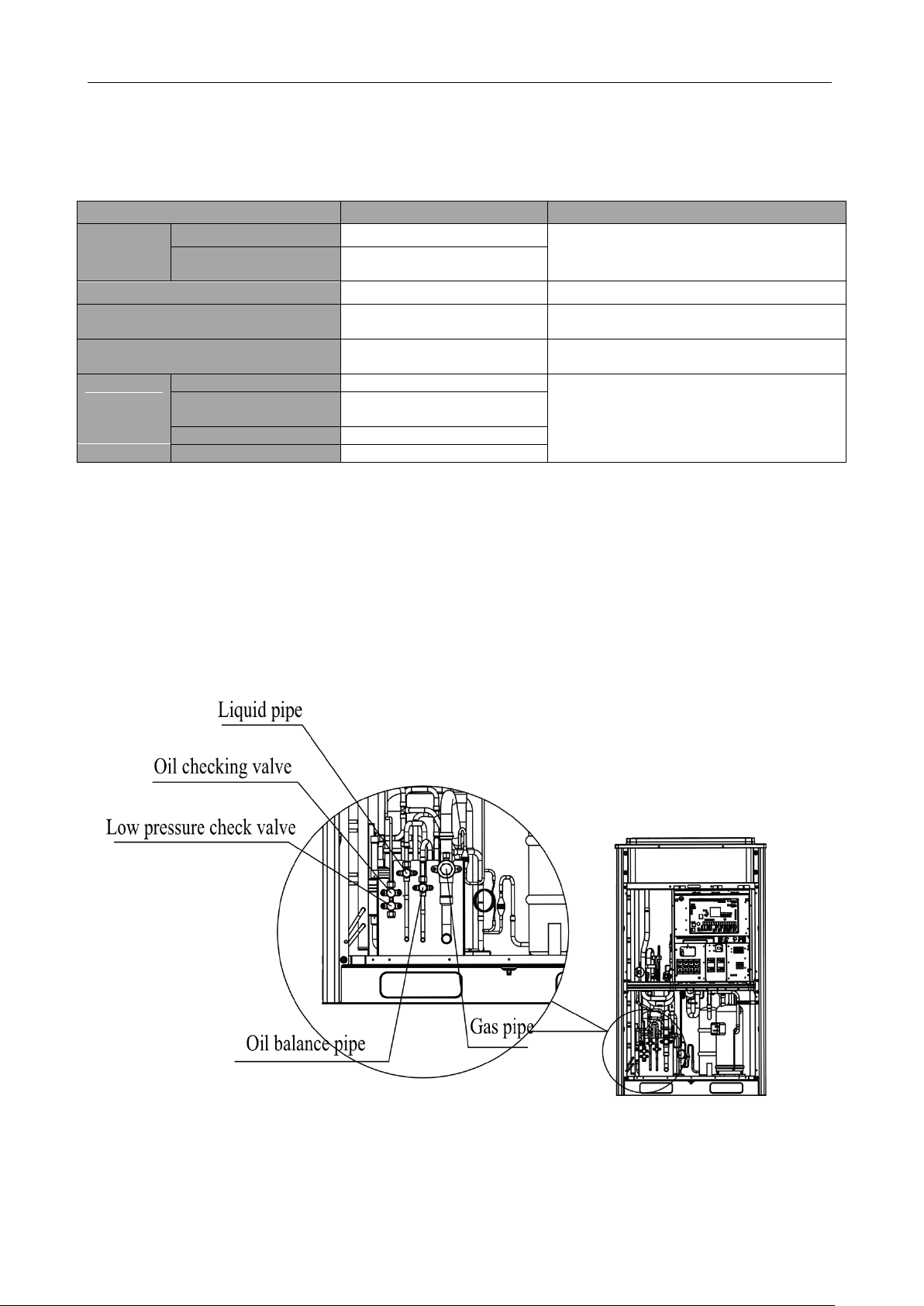

3.1 Piping Diagram of GMV-72WM/B-F(U) and GMV-96WM/B-F(U)

8

GMV5 D.C INVERTER MULTI VRF SERVICE MANUAL

3.2 Piping Diagram of GMV-120WM/B-F(U)

9

GMV5 D.C INVERTER MULTI VRF SERVICE MANUAL

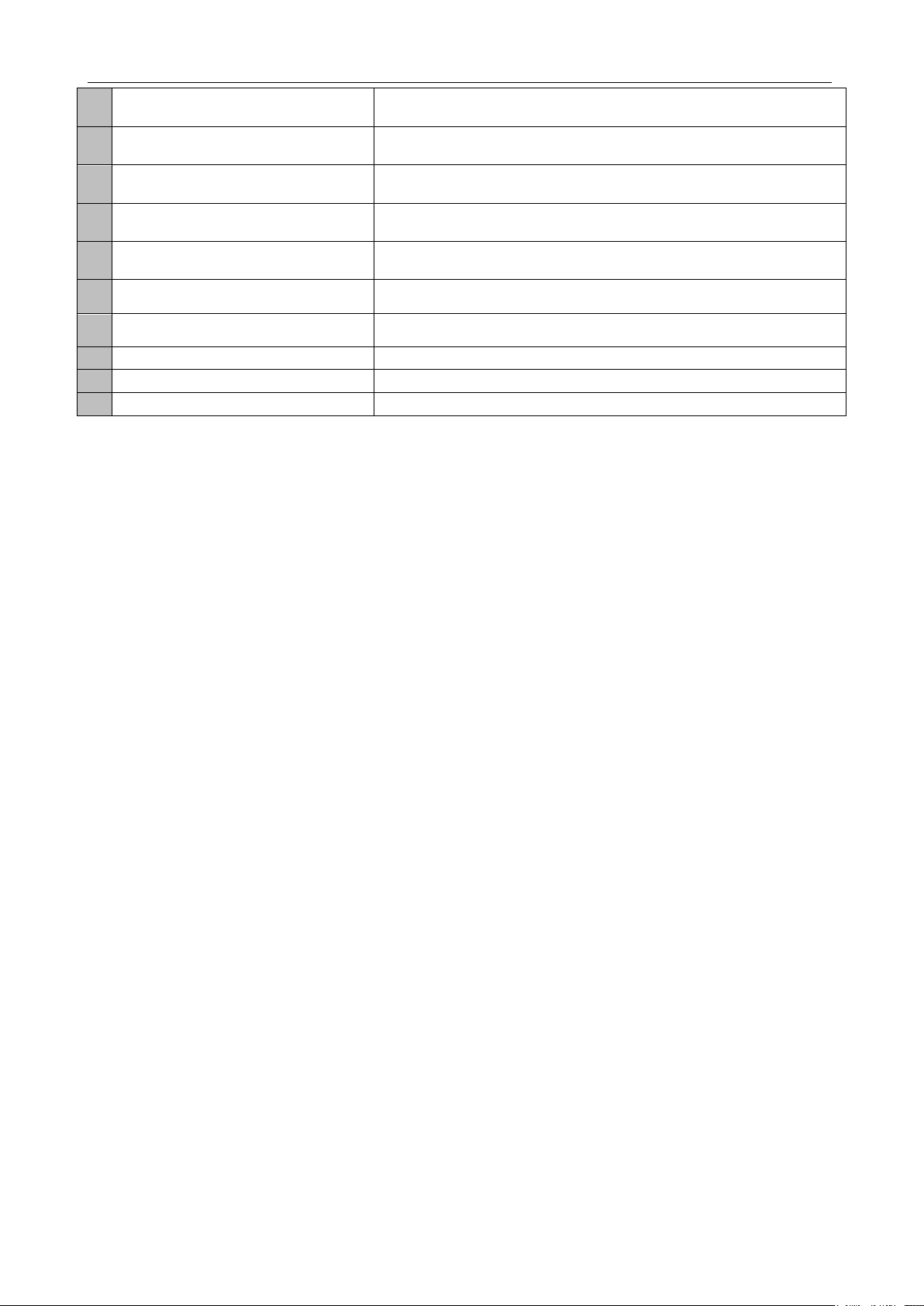

No

Name

Main Function

1

Compressor

Adjusts its own rotational speed based on the actual requirement of the

system to implement capacity control.

2

Compressor heat tape

Maintains a proper oil temperature in the compressor when the

compressor is in standby status, ensuring the reliability during

compressor startup.

3

Compressor casing-top temperature

sensor

Detects a compressor's exhaust gas temperature for compressor

control and protection.

4

Exhaust pipe temperature sensor of

compressor

Detects a compressor's exhaust gas temperature for compressor

control and protection.

5

High-pressure circuit breaker

Protects a compressor by sending feedback signal to stop the system

when the compressor's discharge temperature exceeds the operating

value of high-pressure circuit breaker.

6

Oil extractor

Separates the gas and oil in the system to ensure compressor

reliability.

7

Oil balance device

Equalizes the oil for all modules in the case of excess oil in the current

module when multiple modules are arranged in parallel, thus ensuring

the system reliability.

8

Heat tape of oil balance device

Maintains a proper oil temperature in the compressor when the

compressor is in standby status, ensuring the reliability of compressor

startup.

9

One-way valve

Prevents high-pressure gas from entering the compressor and fast

balances the suction pressure and discharge pressure in a compressor.

10

High-pressure sensor

Detects the high pressure value in the system in real time mode for

compressor protection and other control functions.

11

Four-way valve

Used for the switching between the cooling and heating functions of

system IDU.

12

Heat exchanger

Used for outdoor heat exchange.

13

Fan

Strengthens heat exchanging.

14

Defrosting temperature sensor

Used for defrosting detection.

15

Electronic expansion valve for heating

Controls refrigerant adjustment in heating mode.

16

One-way valve

Controls refrigerant flow direction.

17

Subcooler electronic expansion valve

Controls the degree of subcooling of tube refrigerant when the system

is running in cooling mode, and reduces the capacity loss on pipes.

18

Subcooler

Controls the degree of subcooling of tube.

19

Liquid outlet temperature sensor of

subcooler

Detects tube temperature.

20

Inlet temperature sensor of gas-liquid

separator

Detects the inlet temperature of gas-liquid separator to prevent the

system from running when the refrigerant flows back to the compressor.

21

Gas outlet temperature sensor of

subcooler

Detects gas temperature of subcooler.

22

Low-pressure sensor

Detects system low pressure to avoid extra-low operating pressure.

23

Gas-liquid separator

Separate gas and liquid to prevent the system from running when the

refrigerant flows back to the compressor.

24

Outlet temperature sensor of

gas-liquid separator

Detects internal status of gas-liquid separator to further control the

compressor suction performance.

25

Oil balance valve 1

Used for oil balance control among modules.

26

One-way valve

Used for oil balance control among modules and avoid reverse flow of

oil.

27

Unloading valve

Avoids over-high pressure caused by pipeline blind spot.

28

Oil balance valve 2

Used for oil balance control among modules.

3.3 Names and Main Functions of Components

10

GMV5 D.C INVERTER MULTI VRF SERVICE MANUAL

29

Filter

Prevents impurities from entering components and parts.

30

Capillary tube

Supports flow regulating and pressure reduction.

31

Liquid valve

Stop valve, closed when the unit is delivered from the factory and will

be opened after installation.

32

Gas valve

Stop valve, closed when the unit is delivered from the factory and will

be opened after installation.

33

Low-pressure measurement valve

Detects the low pressure value or charges refrigerant during system

running.

34

Oil balance valve

Stop valve, closed when the unit is delivered from the factory and will

be opened after installation.

35

Oil check valve

Checks the quality of refrigerating machine oil of compressor during

maintenance.

36

Unloading valve

Avoid over-high pressure caused by pipeline blind spot.

37

Air by-pass valve

Avoids extra-high or low operating pressure.

38

Pressure-balanced valve

Ensures success startup of compressor.

11

GMV5 D.C INVERTER MULTI VRF SERVICE MANUAL

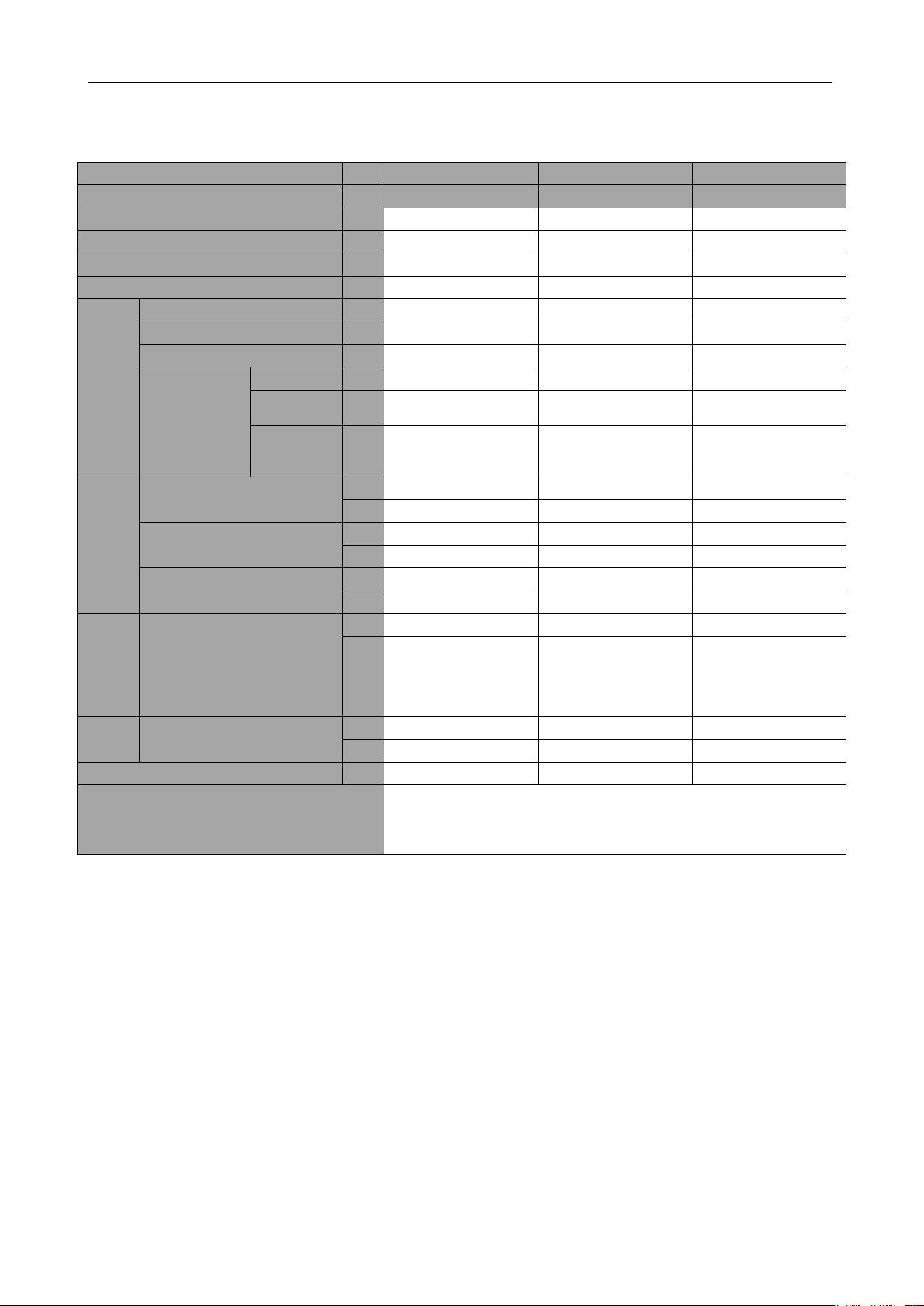

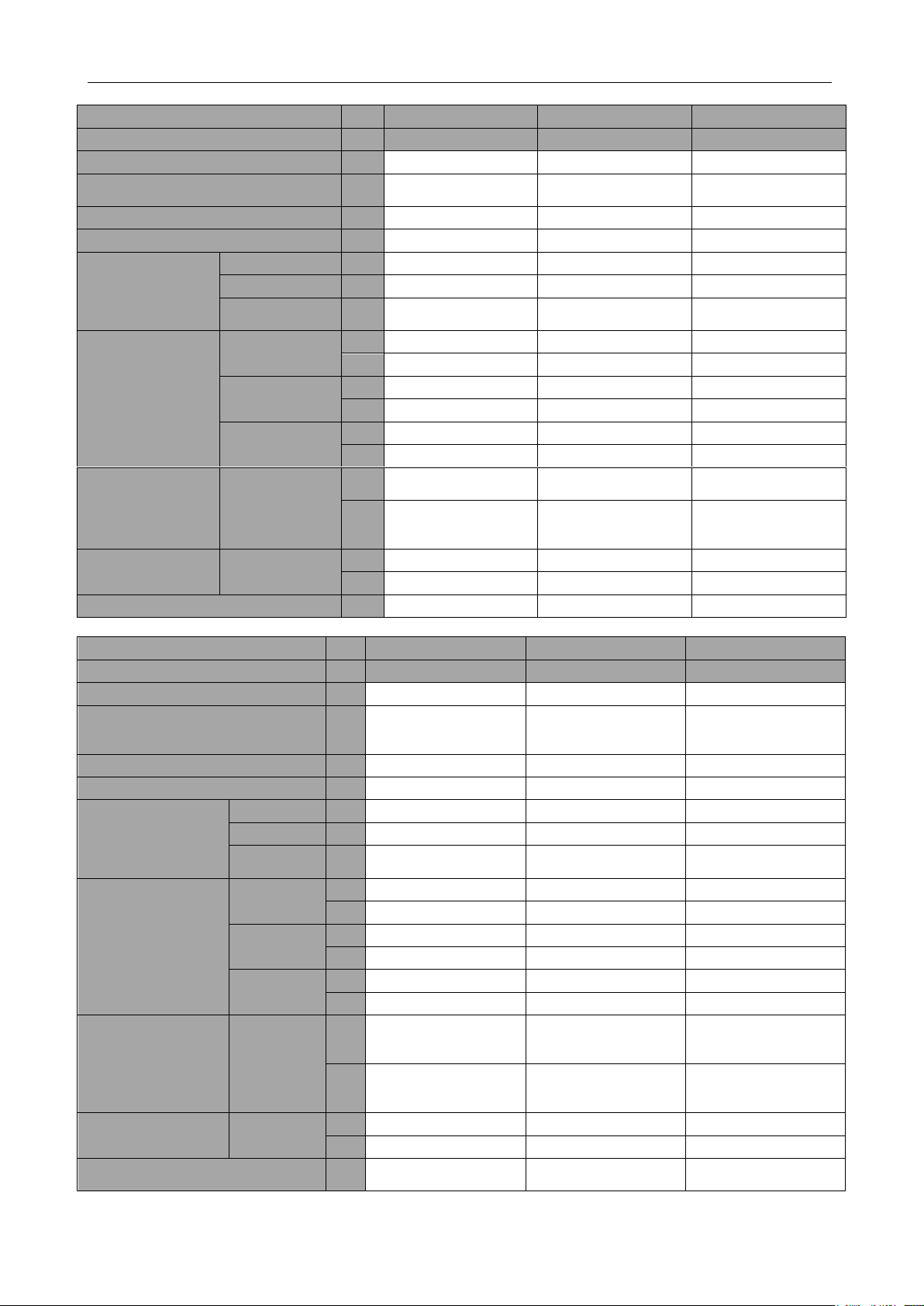

Outdoor Units_Heat Pump

-

6Ton

8Ton

10Ton

Horse Power

HP

8

10

12

Model

-

GMV-72WM/B-F(U)

GMV-96WM/B-F(U)

GMV-120WM/B-F(U)

Module combination

-

GMV-72WM/B-F(U)

GMV-96WM/B-F(U)

GMV-120WM/B-F(U)

Power Supply

-

208/230V 3~60Hz

208/230V 3~60Hz

208/230V 3~60Hz

Code

-

CN851W1380

CN851W1390

CN851W1420

Compr

essor

Type

-

Inverter scroll type

Inverter scroll type

Inverter scroll type

Number

N

1 1 2

Refrigeration Oil Brand

-

FVC68D or FV-68H

FVC68D or FV-68H

FVC68D or FV-68H

Oil Charge①

Total L 4 4 5.5

Compresso

r

L

1 1 1×2

Oil

Banlance

Tank

L

3 3 3.5

Pipe

Conne

ction

Gas Pipe Size

mm

19.05

22.2

28.6

in.

3/4

7/8

1 1/8

Liquid Pipe Size

mm

9.52

9.52

12.7

in.

3/8

3/8

1/2

Oil Balance Pipe Size

mm

9.52

9.52

9.52

in.

3/8

3/8

3/8

Dimen

sions

(width

×depth

×heigh

t)

External Dimension

mm

930×765×1605

1340×765×1605

1340×765×1605

in.

36-3/5×30-1/8×63-1/

5

52-3/4×30-1/8×63-1/

5

52-3/4×30-1/8×63-1/

5

Weight

Net Weight

kg

225

300

360

lbs.

496

661

794

Maximum qty of connected indoor units

unit

12

16

20

Remark

Oil charge includes the total oil amount of outdoor units, residual

oil amount of compressor and oil balance tank. When replacing the

compressor or oil balance tank, only the corresponding required oil

amount shall be charged

4 BASIC PARAMETERS OF UNIT

12

GMV5 D.C INVERTER MULTI VRF SERVICE MANUAL

Outdoor Units_Heat Pump

-

12Ton

14Ton

16Ton

Horse Power

HP

14

18

20

Model

-

GMV-144WM/B-F(U)

GMV-168WM/B-F(U)

GMV-192WM/B-F(U)

Module combination

-

GMV-72WM/B-F(U)+

GMV-72WM/B-F(U)

GMV-72WM/B-F(U)+

GMV-96WM/B-F(U)

GMV-96WM/B-F(U)+

GMV-96WM/B-F(U)

Code

- - -

Power Supply

-

208/230V 3~60Hz

208/230V 3~60Hz

208/230V 3~60Hz

Compressor

Type

-

Inverter scroll type

Inverter scroll type

Inverter scroll type

Number N 1+1

1+1

1+1

Refrigeration Oil

Brand

-

FVC68D or FV-68H

FVC68D or FV-68H

FVC68D or FV-68H

Pipe Connection

Gas Pipe Size

mm

28.6

28.6

28.6

in.

1 1/8

1 1/8

1 1/8

Liquid Pipe Size

mm

12.7

15.9

15.9

in.

1/2

5/8

5/8

Oil Balance Pipe

Size

mm

9.52

9.52

9.52

in.

3/8

3/8

3/8

Dimensions

(width×depth×height

)

External

Dimension

mm

930×765×1605+

930×765×1605

930×765×1605+

1340×765×1605

1340×765×1605+

1340×765×1605

in.

36-3/5×30-1/8×63-1/5

+

36-3/5×30-1/8×63-1/5

36-3/5×30-1/8×63-1/5

+

52-3/4×30-1/8×63-1/5

52-3/4×30-1/8×63-1/5

+

52-3/4×30-1/8×63-1/5

Weight

Net Weight

kg

225+225

225+300

300+300

lbs.

496+496

496+661

661+661

Maximum qty of connected indoor units

unit

25

29

33

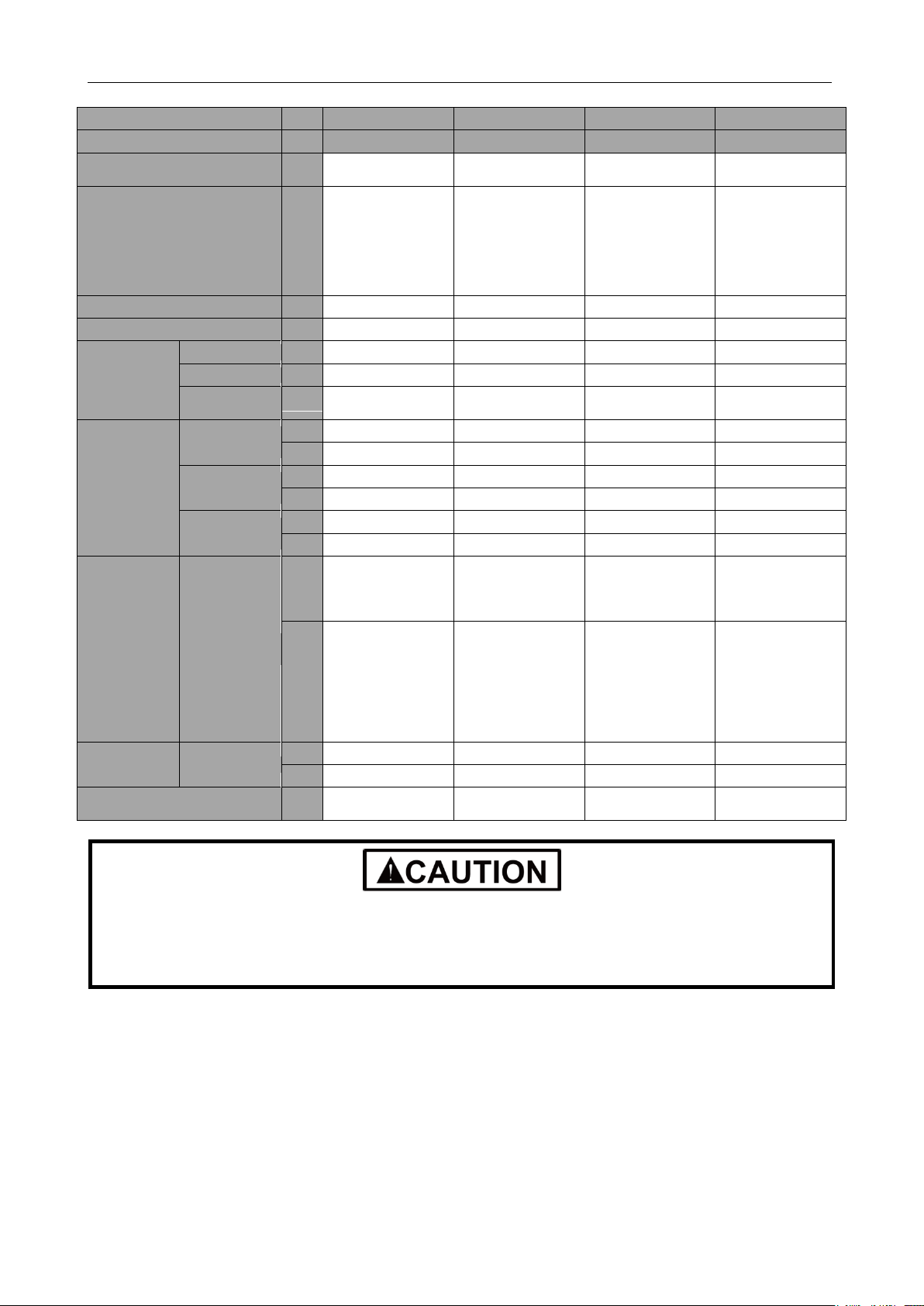

Outdoor Units_Heat Pump

-

18Ton

20Ton

22Ton

Horse Power

HP

22

24

26

Model

-

GMV-216WM/B-F(U)

GMV-240WM/B-F(U)

GMV-264WM/B-F(U)

Module combination

-

GMV-96WM/B-F(U)+

GMV-120WM/B-F(U)

GMV-120WM/B-F(U)+

GMV-120WM/B-F(U)

GMV-72WM/B-F(U)+

GMV-96WM/B-F(U)+

GMV-96WM/B-F(U)

Code

- - -

Power Supply

-

208/230V 3~60Hz

208/230V 3~60Hz

208/230V 3~60Hz

Compressor

Type

-

Inverter scroll type

Inverter scroll type

Inverter scroll type

Number N 1+2

2+2

1+1+1

Refrigeration

Oil Brand

-

FVC68D or FV-68H

FVC68D or FV-68H

FVC68D or FV-68H

Pipe Connection

Gas Pipe

Size

mm

28.6

34.9

34.9

in.

1 1/8

1 3/8

1 3/8

Liquid Pipe

Size

mm

15.9

15.9

19.05

in.

5/8

5/8

3/4

Oil Balance

Pipe Size

mm

9.52

9.52

9.52

in.

3/8

3/8

3/8

Dimensions

(width×depth×height)

External

Dimension

mm

1340×765×1605+

1340×765×1605

1340×765×1605+

1340×765×1605

930×765×1605+

1340×765×1605+

1340×765×1605

in.

52-3/4×30-1/8×63-1/5+

52-3/4×30-1/8×63-1/5

52-3/4×30-1/8×63-1/5+

52-3/4×30-1/8×63-1/5

36-3/5×30-1/8×63-1/5+

52-3/4×30-1/8×63-1/5+

52-3/4×30-1/8×63-1/5

Weight

Net Weight

kg

300+360

360+360

225+300+300

lbs.

661+749

749+749

496+661+661

Maximum qty of connected indoor

units

unit

37

41

45

13

GMV5 D.C INVERTER MULTI VRF SERVICE MANUAL

Outdoor Units_Heat Pump

-

24Ton

26Ton

28Ton

30Ton

Horse Power

HP

28

32

34

36

Model

-

GMV-288WM/B-F

(U)

GMV-312WM/B-F

(U)

GMV-336WM/B-F

(U)

GMV-360WM/B-F

(U)

Module combination

-

GMV-96WM/B-F(

U)+

GMV-96WM/B-F(

U)+

GMV-90WM/B-F(

U)

GMV-96WM/B-F(

U)+

GMV-96WM/B-F(

U)+

GMV-120WM/B-F

(U)

GMV-96WM/B-F(

U)+

GMV-120WM/B-F

(U)+

GMV-120WM/B-F

(U)

GMV-120WM/B-F

(U)+

GMV-120WM/B-F

(U)+

GMV-120WM/B-F

(U)

Code

- - -

Code

Power Supply

-

208/230V 3~60Hz

208/230V 3~60Hz

208/230V 3~60Hz

208/230V 3~60Hz

Compressor

Type

-

Inverter scroll type

Inverter scroll type

Inverter scroll type

Inverter scroll type

Number

N

1+1+1

1+1+2

1+2+2

2+2+2

Refrigeration

Oil Brand

-

FVC68D or

FV-68H

FVC68D or

FV-68H

FVC68D or

FV-68H

FVC68D or

FV-68H

Pipe

Connection

Gas Pipe

Size

mm

34.9

34.9

41.3

41.3

in.

1 3/8

1 3/8

1 5/8

1 5/8

Liquid Pipe

Size

mm

19.05

19.05

19.05

19.05

in.

3/4

3/4

3/4

3/4

Oil Balance

Pipe Size

mm

9.52

9.52

9.52

9.52

in.

3/8

3/8

3/8

3/8

Dimensions

(width×depth

×height)

External

Dimension

mm

1340×765×1605+

1340×765×1605+

1340×765×1605

1340×765×1605+

1340×765×1605+

1340×765×1605

1340×765×1605+

1340×765×1605+

1340×765×1605

1340×765×1605+

1340×765×1605+

1340×765×1605

in.

52-3/4×30-1/8×63

-1/5+

52-3/4×30-1/8×63

-1/5+

52-3/4×30-1/8×63

-1/5

52-3/4×30-1/8×63

-1/5+

52-3/4×30-1/8×63

-1/5+

52-3/4×30-1/8×63

-1/5

52-3/4×30-1/8×63

-1/5+

52-3/4×30-1/8×63

-1/5+

52-3/4×30-1/8×63

-1/5

52-3/4×30-1/8×63

-1/5+

52-3/4×30-1/8×63

-1/5+

52-3/4×30-1/8×63

-1/5

Weight

Net Weight

kg

225+300+360

225+360+360

300+360+360

360+360+360

lbs.

496+661+749

496+749+749

661+749+749

749+749+749

Maximum qty of connected

indoor units

unit

49

53

58

61

No matter how many outdoor units there are, the total rated capacity of indoor units must not

exceed 135% of the total rated capacity of outdoor units. Stable and safe operation can only be

guaranteed in a range of 50%~135%.

14

GMV5 D.C INVERTER MULTI VRF SERVICE MANUAL

Model

Power Supply

Fuse Capacity

Minimum Circuit

Ampacity

Maximum Overcurrent

Protection

V/Ph/Hz

A A A

GMV-72WM/B-F(U)

208V/230V 3~ 60Hz

45

30

45

GMV-96WM/B-F(U)

208V/230V 3~ 60Hz

70

45

70

GMV-120WM/B-F(U)

208V/230V 3~ 60Hz

100

74

100

GMV-144WM/B-F(U)

208V/230V 3~ 60Hz

70

55

70

GMV-168WM/B-F(U)

208V/230V 3~ 60Hz

90

70

90

GMV-192WM/B-F(U)

208V/230V 3~ 60Hz

125

99

125

GMV-216WM/B-F(U)

208V/230V 3~ 60Hz

125

111

125

GMV-240WM/B-F(U)

208V/230V 3~ 60Hz

150

140

150

GMV-264WM/B-F(U)

208V/230V 3~ 60Hz

150

123

150

GMV-288WM/B-F(U)

208V/230V 3~ 60Hz

150

136

150

GMV-312WM/B-F(U)

208V/230V 3~ 60Hz

175

164

175

GMV-336WM/B-F(U)

208V/230V 3~ 60Hz

200

177

200

GMV-360WM/B-F(U)

208V/230V 3~ 60Hz

225

205

225

Power cable wire gauge and circuit breaker must be selected based on the above parameters

and in compliance with local safety requirements. If there is conflict between above parameters and

national requirements, please contact the manufacture promptly.

If power cable wire gauge and circuit breaker is out of the above design range, fire hazard may

occur.

5 ELECTRICAL PARAMETERS

15

GMV5 D.C INVERTER MULTI VRF SERVICE MANUAL

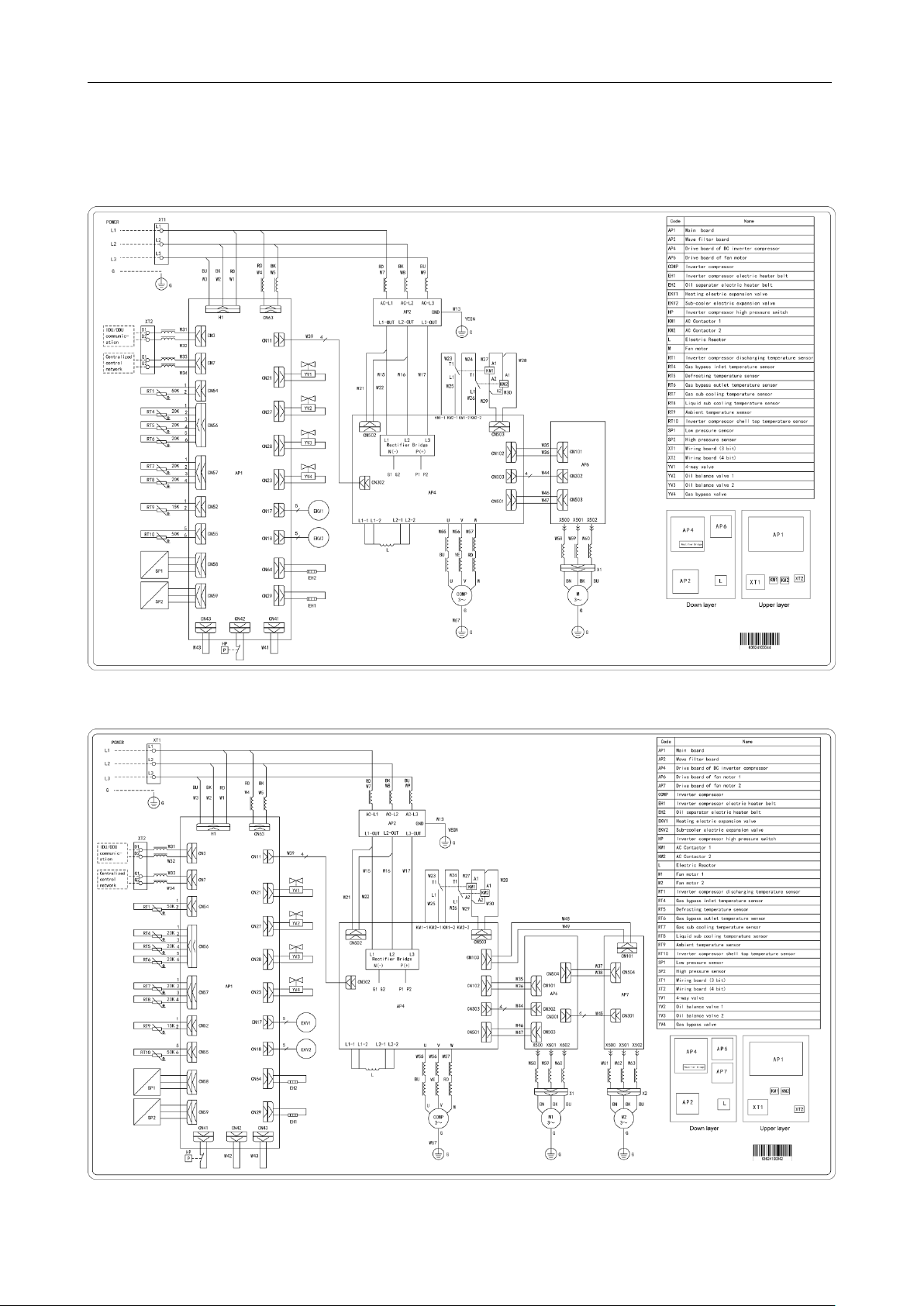

2. Circuit Diagram

2.1 Circuit Diagram of ODU

2.1.1 Circuit diagram of GMV-72WM/B-F(U)

2.1.2 Circuit diagram of GMV-96WM/B-F(U)

16

GMV5 D.C INVERTER MULTI VRF SERVICE MANUAL

When conducting maintenance based on above circuit diagrams, units must be power-off. Please

strictly following the circuit diagrams when reconnecting the wires, otherwise, electric shock may occur.

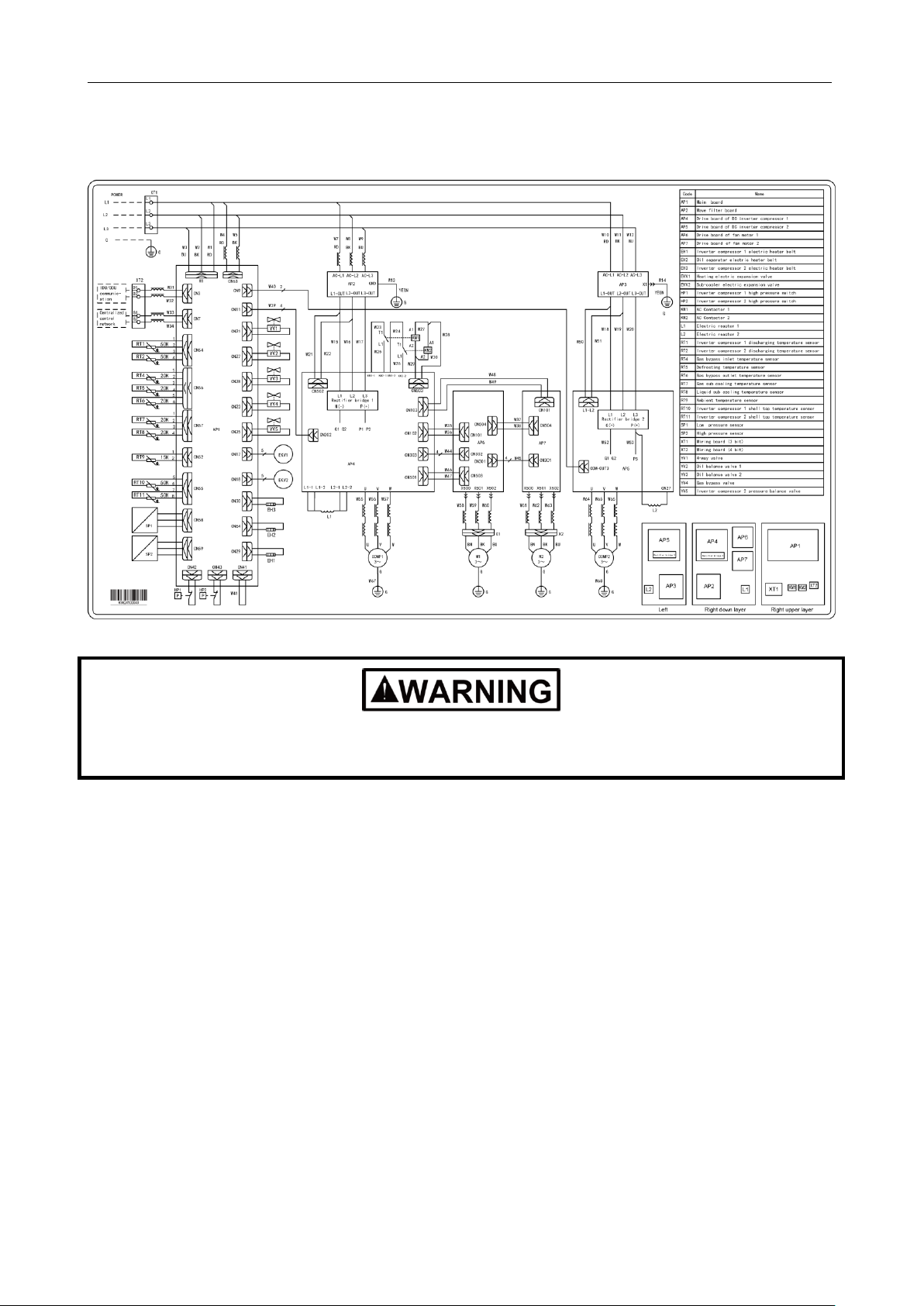

2.1.3Circuit diagram of GMV-120WM/B-F(U)

17

GMV5 D.C INVERTER MULTI VRF SERVICE MANUAL

Export Model

Remark

Manifold

ODU

ML01/A

For model selection, refer to Pipe Selection.

IDU

FQ01A/A, FQ01B/A, FQ02/A,

FQ03/A

Remote-control Receiver Board

JS03

Applicable for air-duct-type IDUs.

Commissioning Remote Controller

YV1L1

Provides the commissioning functions for

function settings of IDUs.

Commissioning Software

DE40-33/A(C)

Applicable for units that support CAN bus

communication technology.

Remote

Monitoring

System

Software

FE31-00/AD(BM)

Applicable for units that support CAN bus

communication technology.

Optoelectronic Isolation

Converter

GD02

Modbus Gateway

ME30-24/E4(M)

BACnet Gateway

MG30-24/D2(B)

6 OPTIONAL ACCESSORIES

GMV5 series VRF units support the following optional accessories:

NOTICE! Contact local sales company for optional accessories.

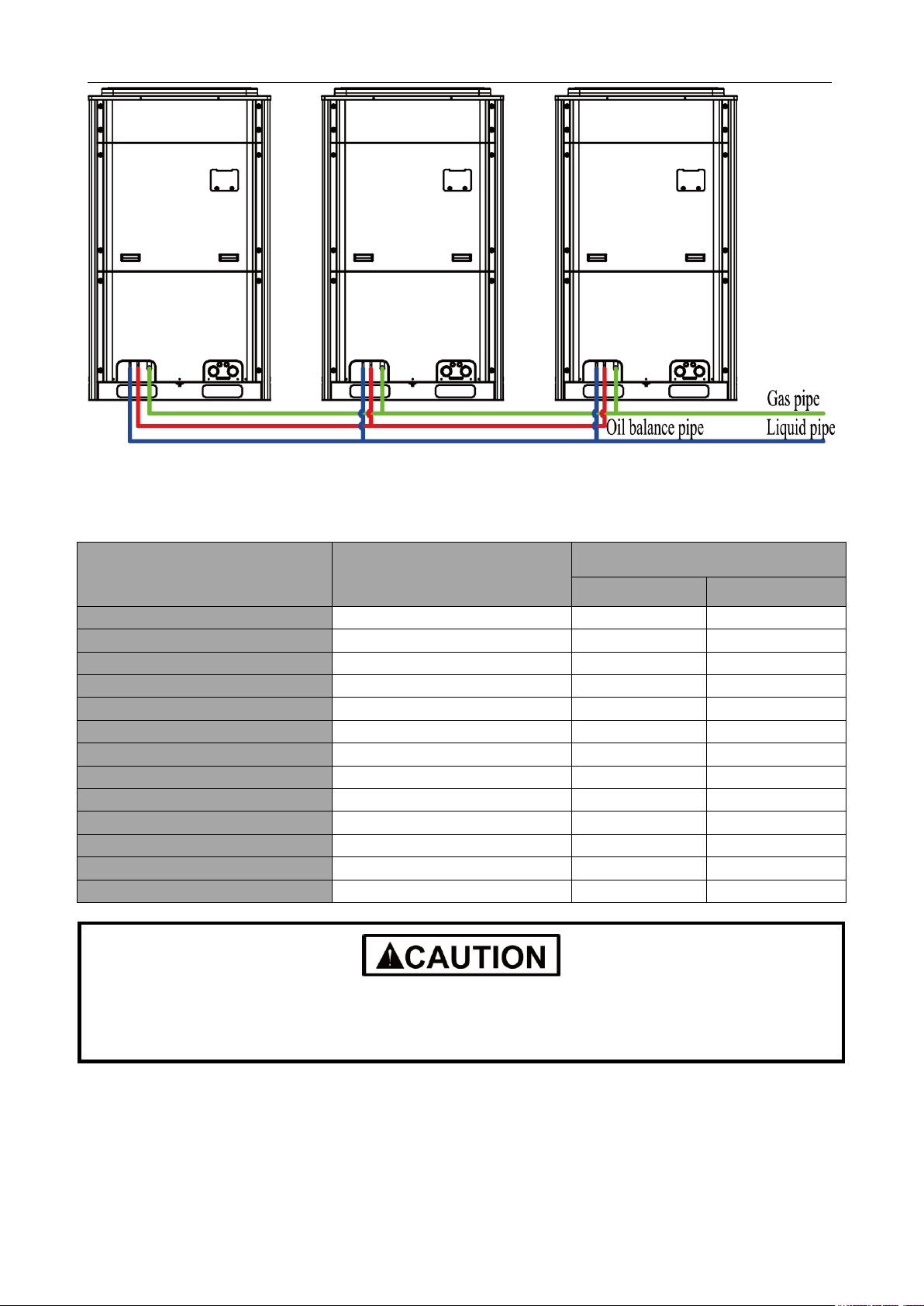

7 BASIC REQUIREMENT FOR PIPE CONNECTION

7.1 Outdoor units adopt the modular combination design of individual

cooling system, that is, units are connected by using pipes in parallel

during installation. The tubing system used among modules includes air

pipes, liquid pipes and oil balance pipes.

18

GMV5 D.C INVERTER MULTI VRF SERVICE MANUAL

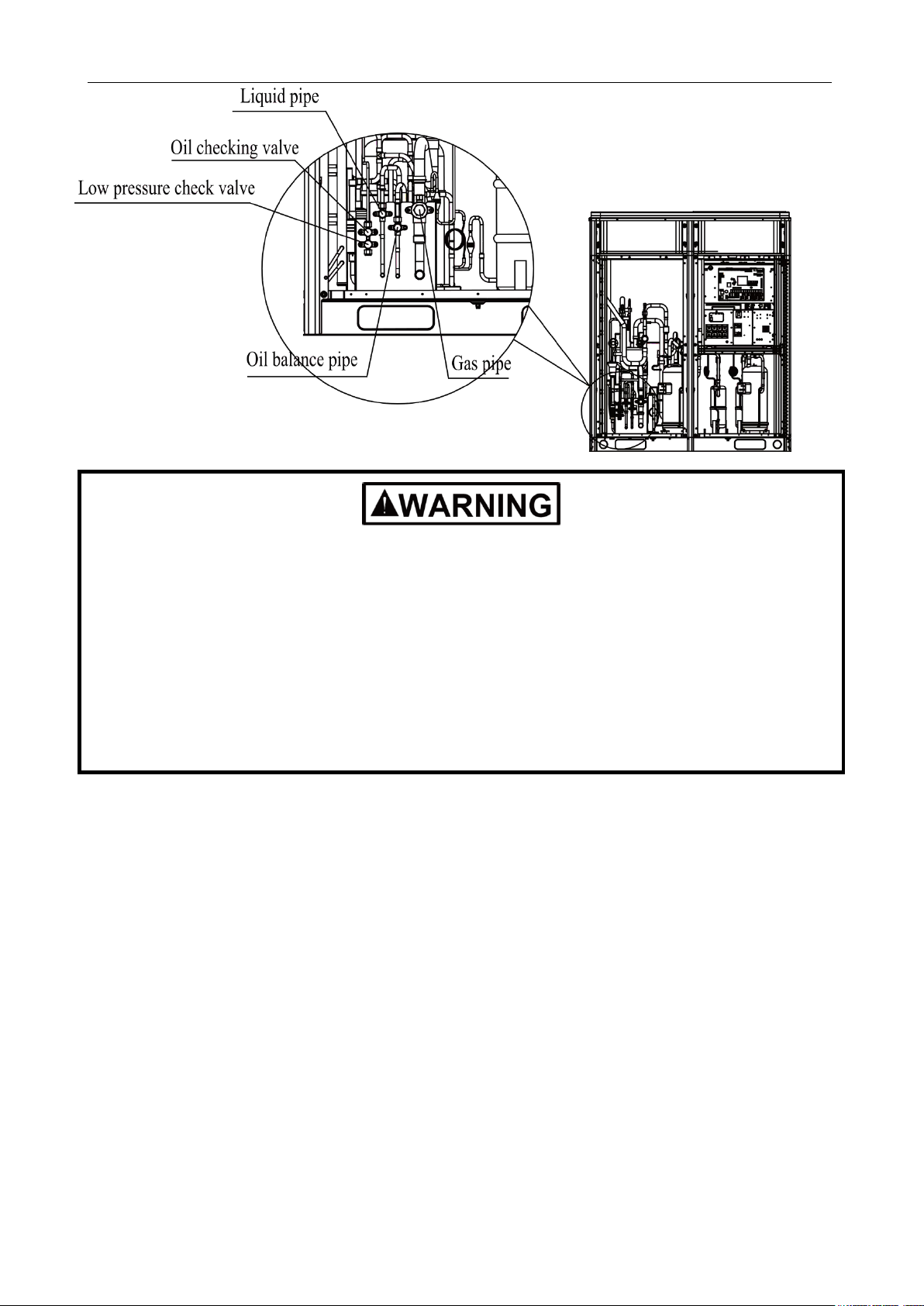

Functions of oil check valve: During after-sale maintenance, the oil check valve can be used to

extract lubricating oil samples, which are further detected to analyze the oil quality in the system.

The oil check valve can also serve as the inlet for lubricating oil charging. Before extracting

lubricating oil from the system, stop the system for at least 12 hours and release refrigerant. Do not

extract oil until system‘s pressure drops to 0.05MPa (7.25psi) or below; otherwise, overheat oil may

burn the operator.

Functions of low-pressure check valve: It is mainly used for low pressure detection of the system

and refrigerant charging during after-sale maintenance.

Pipe connection diagram of outdoor modules

19

GMV5 D.C INVERTER MULTI VRF SERVICE MANUAL

Model

Maximum Number of

Connected IDUs (units)

Capacity Range of Connected IDU

(kBtu/h)

Minimum Capacity

Maximum Capacity

GMV-72WM/B-F(U)

12

36.0

97.2

GMV-96WM/B-F(U)

16

48.0

129.6

GMV-120WM/B-F(U)

20

60.0

162.0

GMV-144WM/B-F(U)

25

72.0

194.4

GMV-168WM/B-F(U)

29

84.0

226.8

GMV-192WM/B-F(U)

33

96.0

259.2

GMV-216WM/B-F(U)

37

108.0

291.6

GMV-240WM/B-F(U)

41

120.0

324.0

GMV-264WM/B-F(U)

45

132.0

356.4

GMV-288WM/B-F(U)

49

144.0

388.8

GMV-312WM/B-F(U)

53

156.0

421.2

GMV-336WM/B-F(U)

58

168.0

453.6

GMV-360WM/B-F(U)

61

180.0

486.0

During installation, please strictly follow the above capacity range and number to construct,

otherwise, units may work abnormally and compressors may even be damaged

7.2 Each ODU system can be connected to multiple IDUs. Detailed information about the number of units to be connected and capacity ranges is shown in the following table:

20

GMV5 D.C INVERTER MULTI VRF SERVICE MANUAL

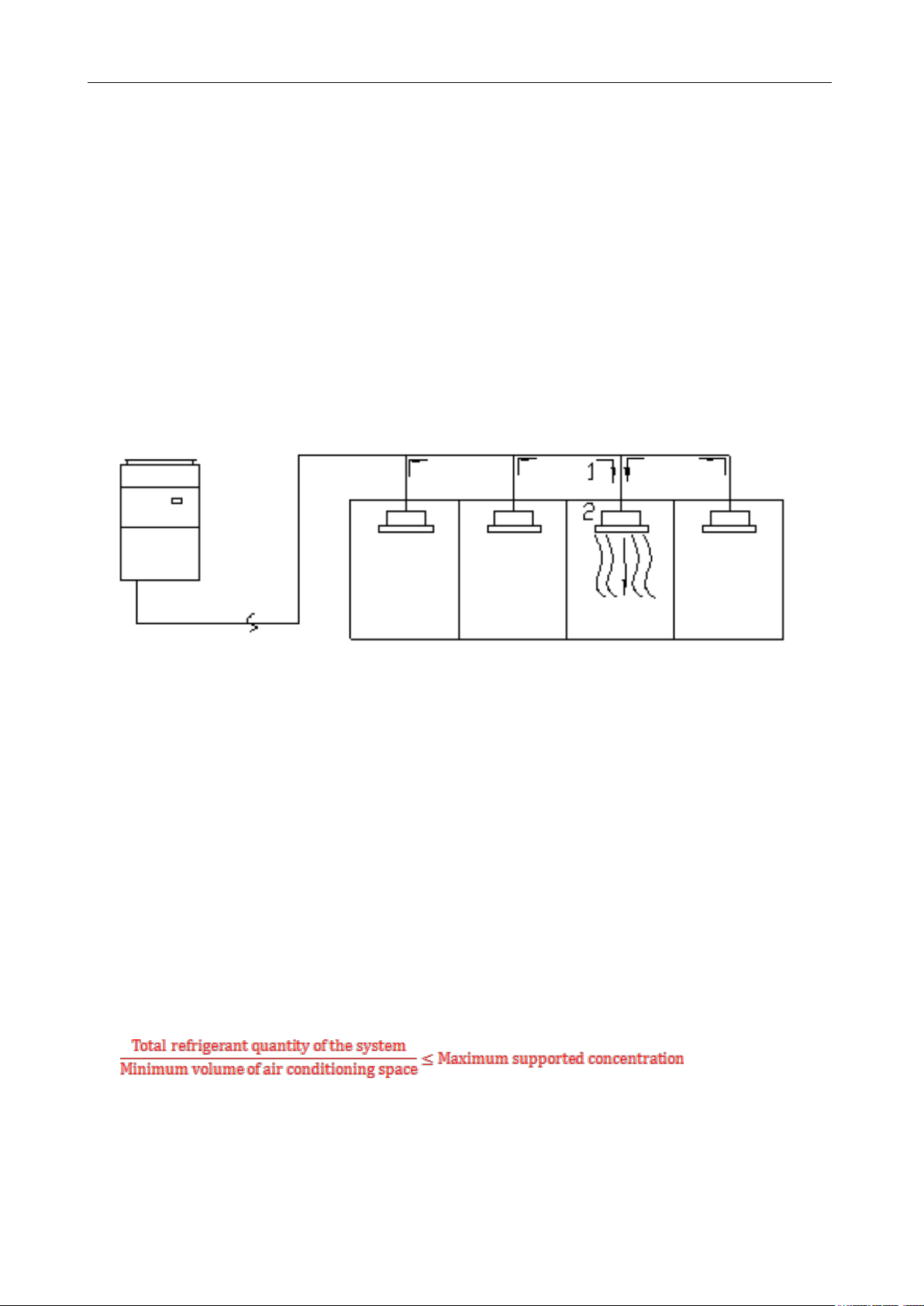

8 PRECAUTIONS ON REFRIGERANT LEAKAGE

Personnel related to air conditioning engineering design and installation operators must abide by

the safety requirement for preventing refrigerant leakage specified in local laws and regulations. If such

safety requirement is unavailable in local documents, the design and operation must be implemented

based on the following principles: GMV5 series VRF units adopt the R410A refrigerant, which is

nonflammable and nontoxic. However, the space for refrigerant leakage must be sufficient to ensure that

the refrigerant concentration does not exceed that specified in the safety requirement; otherwise, people

involved can be stifled by the refrigerant.

The maximum refrigerant charge and maximum refrigerant concentration in the system are

calculated directly based on the size of the air conditioning space. The unit of refrigerant concentration is

1 kg/m³ or 1lb/m³.

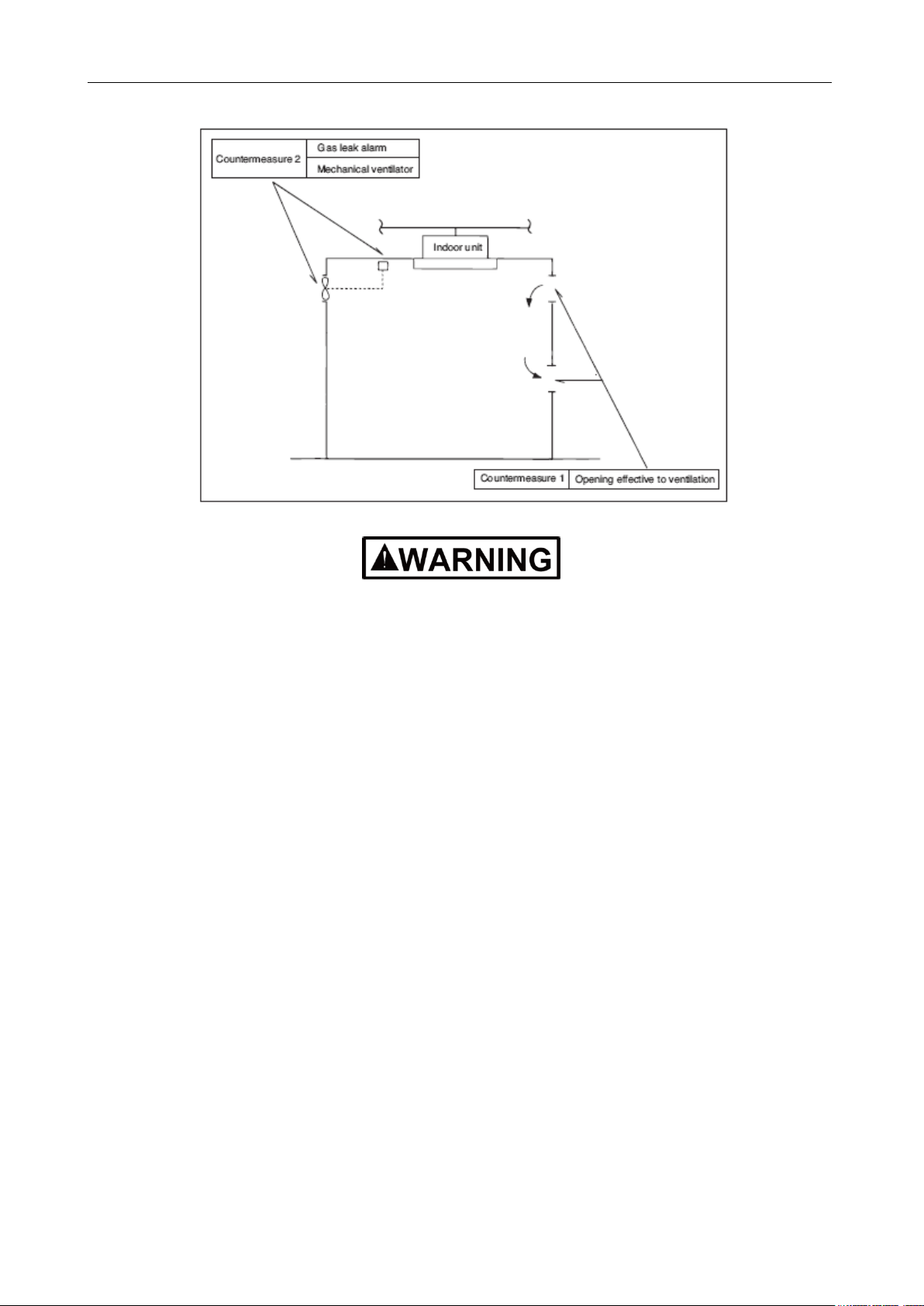

1) Flow direction of refrigerant leakage.

2) Room for refrigerant leakage. Since the concentration of refrigerant is greater than that of air, pay

attention to the spaces where the refrigerant may residue, for example, the basement.

Method for calculating the maximum concentration of refrigerant:

(1) Calculate the refrigerant charge quantity of each system.

Charge quantity of an ODU upon delivery (for the system consisting of multiple modules in parallel,

the accumulative charge quantity of modules upon delivery is used) + Onsite charge quantity = Total

refrigerant charge quantity in the system (kg)

(2) Calculate the volume of maximum air conditioning space (m³).

Volume of air conditioning space (m³) = Length x Width x Height

Note: The length, width and height here refer to the effective length, width and height of the indoor

space.

(3) Calculate the maximum refrigerant concentration of the refrigeration system.

Note: If the maximum supported refrigerant concentration is not available in relevant local standard,

use 0.3kg /m³ (0.66lbs/m³)as the maximum supported refrigerant concentration.

(4) If the maximum refrigerant concentration exceeds the allowed threshold, the refrigeration system

must be redesigned. In this case, separate the refrigeration system into multiple small-capacity

21

GMV5 D.C INVERTER MULTI VRF SERVICE MANUAL

refrigeration systems, or contact local Gree sales company.

If the above equation can not be satisfied, then follow the following steps.

Selection of air conditioning system: select one of the next

1). Installation of effective opening part

2). Reconfirmation of Outdoor Unit capacity and piping length

3). Reduction of the amount of refrigerant

4). Installation of 2 or more security device (alarm for gas leakage)

Change Indoor Unit type

: installation position should be over 6.6ft from the floor (Wall mounted type → Cassette type)

Adoption of ventilation system

: choose ordinary ventilation system or building ventilation system

Limitation in piping work

: Prepare for earthquake and thermal stress

22

GMV5 D.C INVERTER MULTI VRF SERVICE MANUAL

Cooling

Ambient temperature: -5ºC(23ºF)~52ºC(125.6ºF)

Heating

Ambient temperature: -20ºC (-4ºF)~24ºC (75.2ºF)

Cooling

Ambient temperature: 16ºC(60.8ºF)~45ºC(113ºF)

Heating

Ambient temperature: -7ºC (19.4ºF)~16ºC (60.8ºF)

If unit operates out of the above range, it may not work stably and components may even be

damaged.

9 UNIT OPERATING TEMPERATURE

In the case of a full fresh air conditioning IDU, the unit operating temperature is as follows:

23

GMV5 D.C INVERTER MULTI VRF SERVICE MANUAL

CHAPTER 2 INSTALLATION

24

GMV5 D.C INVERTER MULTI VRF SERVICE MANUAL

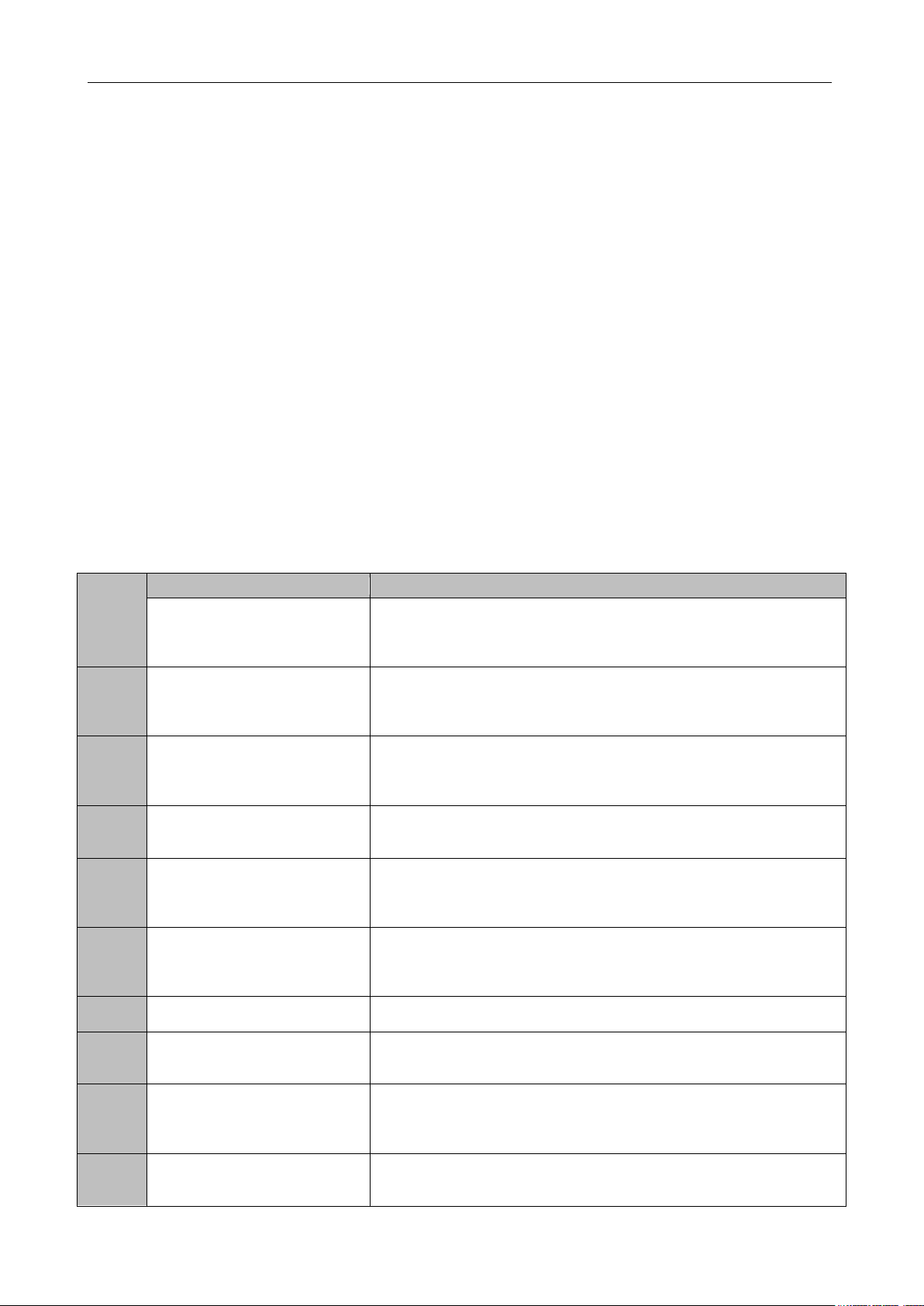

No.

Installation Problem

Possible Consequence

1

Dust or impurities enter into the

refrigeration system.

Pipes are more likely to be blocked; air conditioning performance is

reduced; compressor wear is increased

or even hinder the normal operation of the system and burn the

compressor.

2

Nitrogen is not filled into the

refrigerant pipe or insufficient

Nitrogen is filled before welding.

Pipes are more likely to be blocked; air conditioning performance is

reduced; compressor wear is increased

or even hinder the normal operation of the system and burn the

compressor.

3

The vacuum degree in the

refrigerant pipe is insufficient.

The refrigeration performance is reduced. The system fails to keep

normal operation due to frequent protection measures. When the problem

getting serious, compressor and other major components can be

damaged.

4

Water enters into the refrigeration

system.

Copper plating may appear on the compressor and reduce the

compressor efficiency with abnormal noise generated; failures may occur

in the system due to ice plug.

5

The refrigerant pipe specifications

do not meet the configuration

requirements.

Smaller configuration specifications can increase the system pipe

resistance and affect the cooling performance; larger configuration

specifications are waste of materials and can also reduce the cooling

performance.

6

Refrigerant pipe is blocked.

The cooling performance is reduced; in certain cases,

it may cause long-term compressor operating under overheat conditions;

the lubricating effect can be affected and the compressor may be burnt if

impurities were mixed with the lubricating oil.

7

Refrigerant pipe exceeds the limit.

The loss in pipe is considerable and the unit energy efficiency decreases,

which are harmful for long-term running of the system.

8

Incorrect amount of refrigerant is

filled.

The system cannot correctly control the flow allocation; the compressor

may be operating under over-heating environment or running when the

refrigerant flows back to the compressor..

9

The refrigerant pipe leaks.

Insufficient refrigerant circulating in the system decreases the cooling

performance of the air conditioner. Long-term operation under such

circumstance may cause an overheating compressor or even damage the

compressor.

10

Water drainage from the

condensate water pipe is not

smooth.

Residual water in IDUs can affect the normal operation of the system.

The possible water leakage can damage the IDU's decoration.

CHAPTER 2 INSTALLATION

1 ENGINEERING INSTALLATION PREPARATION

1.1 INSTALLATION SAFETY

Personnel and property safety are highly concerned during the entire installation process.

Installation implementation must abide by relevant national safety regulations to ensure personnel and

property safety.

All personnel involved in the installation must attend safety education courses and pass

corresponding safety examinations before installation. Only qualified personnel can attend the

installation. Relevant personnel must be held responsible for any violation of the regulation.

1.2 IMPORTANCE OF INSTALLATION ENGINEERING

VRF air conditioning systems use refrigerant, instead of other agent, to directly evaporate to carry

out the system heat. High level of pipe cleanness and dryness is required in the system. Since various

pipes need to be prepared and laid out onsite, carelessness or maloperation during installation may

leave impurities, water, or dust inside refrigerant pipes. If the design fails to meet the requirement,

various problems may occur in the system or even lead to system breakdown.

Problems that usually occur during installation are as follows:

25

GMV5 D.C INVERTER MULTI VRF SERVICE MANUAL

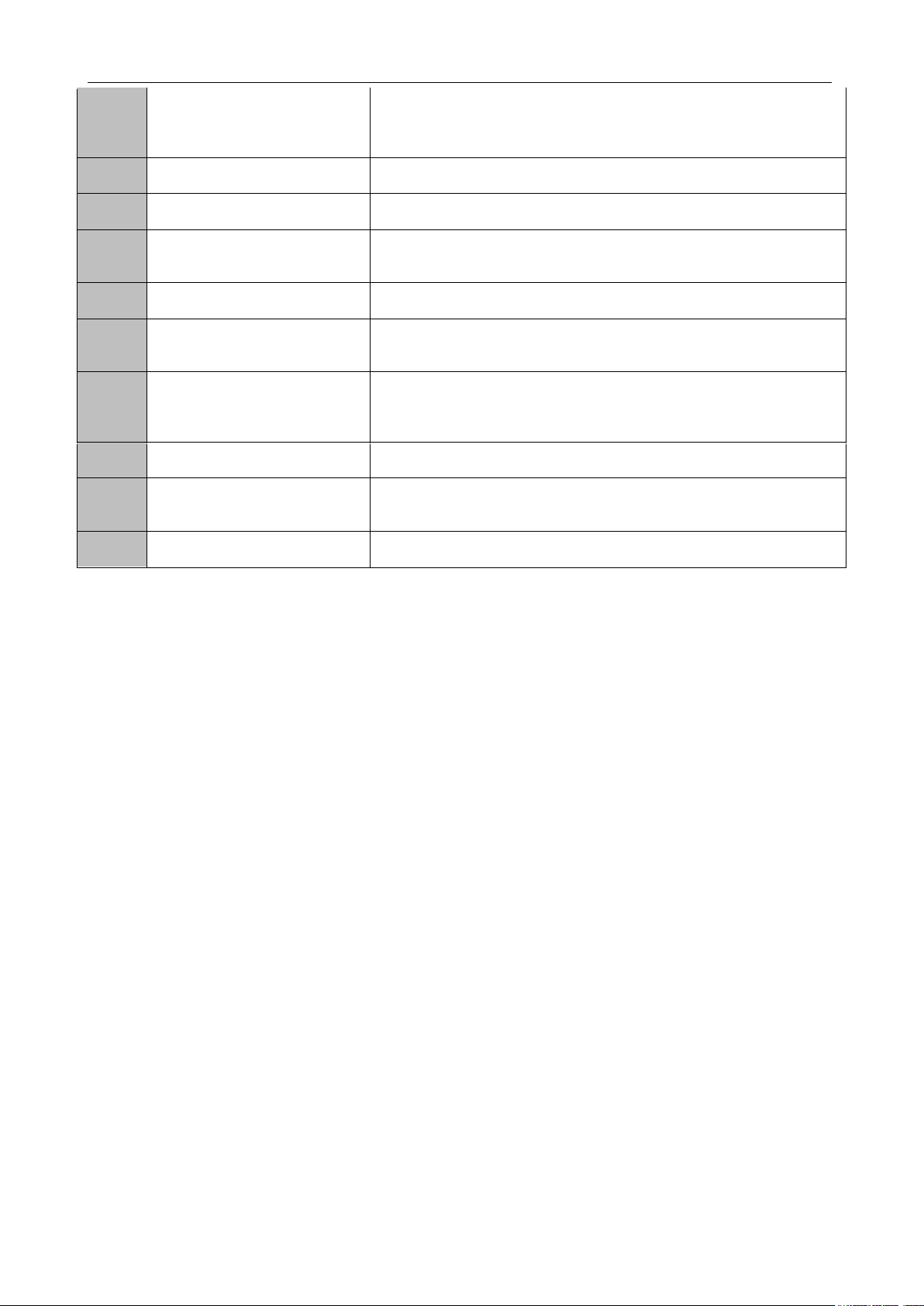

11

The ratio of slop for condensate

water pipe is insufficient or the

condensate water pipe is

incorrectly connected.

Reverse slop or inconsistent connection of condensate water pipe can

hinder the smooth drainage and cause leakage of the IDU.

12

The air channel is improperly

fixed.

The air channel will deform; vibration and noise occur during unit

operating.

13

The guide vane of air channel is

not reasonably manufactured.

Uneven air quantity allocation reduces the overall performance of the air

conditioner.

14

The refrigerant pipe or condensate

water pipe does not meet the

insulation requirement.

Water can easily condensate and drip to damage the indoor decoration,

or even trigger the protection mode of system due to overheating

operation.

15

The installation space for IDU is

insufficient.

Since there is a lack of space for maintenance and checking, indoor

decoration might need to be damaged during such operation.

16

The IDU or the location of the air

outlet or return air inlet is not

designed reasonably.

The air outlet or return air inlet may be short-circuited, thus affecting the

air conditioning performance.

17

The ODU is improperly installed.

The ODU is difficult to be maintained; unit exhaust is not smooth, which

reduces the heat exchanging performance or even prevent the system

from normal operation; in addition, the cold and hot air for heat exchange

and the noise may annoy people in surrounding areas.

18

Power cables are incorrectly

provided.

Unit components may be damaged and potential safety hazard may

occur.

19

Control communication cables are

incorrectly provided or improperly

connected.

The normal communication in the system fails or the control over IDUs

and ODUs turn in a mess.

20

Control communication cables are

not properly protected.

The communication cables are short-circuited or disconnected, and the

unit cannot be started up due to communication failure.

Understand the special requirement (if any) for unit installation before implementation to ensure

installation quality. Relevant installers must have corresponding engineering construction qualifications.

Special type operators involved in the engineering implementation, such as welders, electricians,

and refrigeration mechanics must have relevant operating licenses and are accredited with vocational

qualification certification.

1.3 COOPERATION BETWEEN DIFFERENT PROFESSIONS

A quality installation of air conditioning engineering depends on careful organization and close

cooperation between different professions such as architecture, structure, electric, water supply and

drainage, fire-fighting, and decoration. Pipes must be laid in places away from any automatic spray head

for fire-fighting, and must be reasonably arranged to ensure that the pipes fit the electric, luminaries, and

decoration.

1.3.1 Requirements for cooperation with civil engineering:

(1) The riser should be installed in the air conditioning tube well, and the horizontal pipe should be

placed in the ceiling, if possible.

(2) A place should be reserved for the ODU base to prevent the waterproof layer or insulating layer

on the roof from being damaged in later phase of installation.

(3) At places on walls or floors where pipes need to go through, holes or casing should be preserved.

If the pipe needs to go through a bearing beam, a steel casing must be prepared.

1.3.2 Requirements for cooperation with decoration engineering:

The air conditioning installation should not damage the bearing structure or the decorative style. Air

conditioning pipes should be laid out along the bottom of the beam as possible. If pipes meet one

another at the same elevation, process based on the following principles:

26

GMV5 D.C INVERTER MULTI VRF SERVICE MANUAL

(1) Drain pipes enjoy the highest priority. Air ducts and pressure pipes should leave places for

gravity pipes.

(2) Air ducts and small pipes should leave places for major pipes.

1.3.3 Requirements for cooperation with electric

After the capacity of air conditioning unit is determined, check the following aspects with relevant

electric design personnel:

(1) Whether the electrical load is designed based on the requirement of the air conditioning unit;

(2) Whether the power cable and circuit breaker meet the unit requirement and abide by relevant

national safety regulations;

(3) Whether the regional power supply quality (including voltage fluctuation and interference noise)

meet the international requirement;

(4) Any nonconformity must be resolved through coordination.

27

Loading...

Loading...