Gree GMV-560WM/B-X, GMV-280WM/B-X, GMV-615WM/B-X, GMV-680WM/B-X, GMV-400WM/B-X Owner's Manual

...

Change for life

D.C. Inverter

Multi VRF Modular

Owner's Manual

Air Conditioners

GMV-224WM/B-X

GMV-280WM/B-X

GMV-335WM/B-X

GMV-400WM/B-X

GMV-450WM/B-X

GMV-504WM/B-X

GMV-1800WM/B-X

Thank you for choosing Air Conditioners, please read this owner’s manual carefully before

operation and retain it for future reference.If you have lost the Owner’s Manual, please

contact the local agent or visit www.gree.com or sent email to global@gree.com.cn or

electronic version.

GREE reserves the right to interpret this manual which will be subject to any change due

to product improvement without further notice.

GREE Electric Appliances, Inc. of Zhuhai reserves the nal right to interpret this manual.

Preface

Gree DC Inverter Multi VRF System, with the most advanced technologies in the world, uses ecofriendly refrigerant R410A as its cooling medium. For correct installation and operation, please read

this manual carefully. Before reading the manual, please note that:

(1) For safety operation, please strictly follow the instructions in this manual.

(2) During operation, the gross rated capacity of working IDU should be within the gross rated

capacity of ODU. Otherwise, IDU’s cooling/heating performance will be reduced.

(3) This manual must be in the hands of direct operators or maintenance men.

(4) In case of malfunction and operation failure, please examine the following items and contact

our authorized service centers as soon as possible.

1) Nameplate (model, cooling capacity, product code, ex-factory date).

2) Malfunction status (detail description of conditions before and after malfunction occurs)

(6) All units have been strictly tested and proved to be qualied before ex-factory. To avoid unit

damage or even operation failure which may be caused by improper disassembly, please do

not disassemble units by yourself. If disassembly is needed, please contact our authorized

serve centers for help.

(7) All graphics and information in this manual are only for reference. Manufacturer reserves the

right for changes in terms of sales or production at any time and without prior notice.

This appliance can be used by children aged from 8 years and above and persons with reduced

physical, sensory or mental capabilities or lack of experience and knowledge if they have been given

supervision or instruction concerning use of the appliance in a safe way and understand the hazards

involved. Children shall not play with the appliance. Cleaning and user maintenance shall not be

made by children without supervision.

DISPOSAL:Donot dispose this product as unsorted municipal waste. Collection of such waste

separately for special treatment is necessary.

Contents

1 Safety Precautions ..................................................................................1

2 Product Introduction ................................................................................3

2.1 Names of Main Parts ................................................................................ 3

2.2 Combinations of Outdoor Units ................................................................. 3

2.3 Combinations of Indoor and Outdoor Units .............................................. 4

2.4 The Range of Production Working Temperature ....................................... 5

3 Preparation before Installation.................................................................6

3.1 Standard Parts .......................................................................................... 6

3.2 Installation Site ......................................................................................... 6

3.3 Piping Work Requirements ..................................................................... 10

4 Installation Instruction ........................................................................... 11

4.1 Physical Dimension of the Outdoor Unit and Mounting Hole ...................11

4.2 Connection Pipe ..................................................................................... 12

4.3 Installation of the Connection Pipe ......................................................... 22

4.4 Air Purging and Refrigerant Charge ........................................................ 24

4.5 Electric Wiring ......................................................................................... 25

4.6 System Communication .......................................................................... 29

4.7 Connection Method and Steps for System Communication ................... 33

4.8 External Electrical Wiring Diagram ......................................................... 38

5 Check Items after Installation and Trial Run ......................................... 40

5.1 Check Items after Installation ................................................................. 40

5.2 Trial Run ................................................................................................ 40

6 Common Malfunction and Troubleshooting ........................................... 52

7 Error Indication ......................................................................................54

8 Maintenance and Care ..........................................................................56

8.1 Outdoor Heat Exchanger ........................................................................ 56

8.2 Drain Pipe ............................................................................................... 56

8.3 Notice before Seasonal Use ................................................................... 56

8.4 Maintenance after Seasonal Use ............................................................ 56

8.5 Parts Replacement ................................................................................. 56

9 After-sales Service................................................................................56

D.C. Inverter Multi-variable Modular

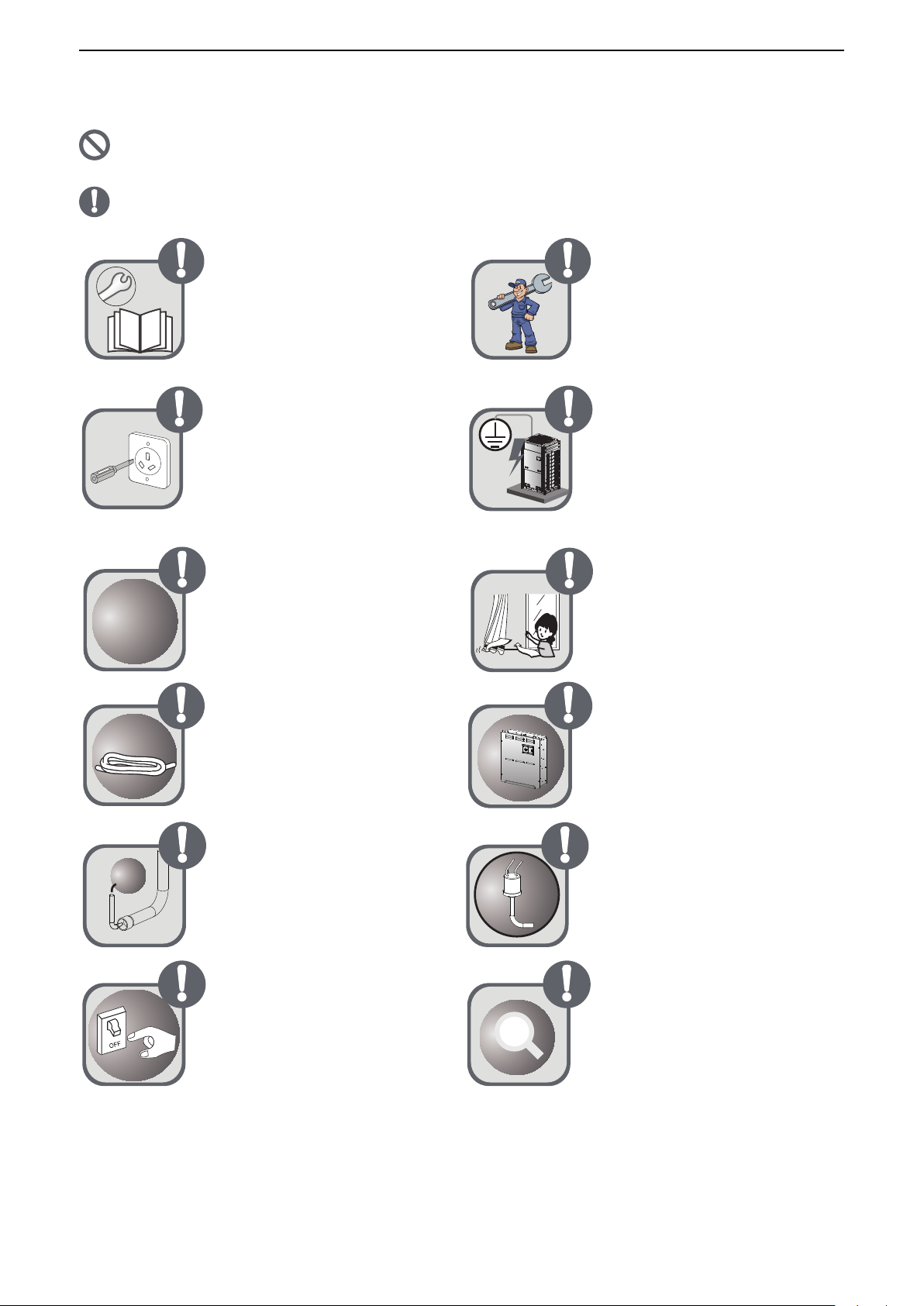

1 Safety Precautions

Refers to things that are not allowed. Incorrect operation may cause personal injury

or death.

refers to things that must be followed. Incorrect operation may cause personal injury

or death.

Installation should be conducted

Follow this instruction to complete

the installation work. Please

carefully read this manual before

unit startup and service.

by dealer or qualied personnel.

Please do not attempt to install the

unit by yourself. Improper handling

may result in water leakage,

electric shock or re disaster etc.

Exclusive

accessory

exclusive

Before installation, please check if

the power supply is in accordance

with the requirements specied on

the nameplate. And also take care

of the power safety.

Be sure to use the exclusive

accessory and part to prevent the

water leakage, electric shock and

re accidents.

Wire size of power cord should

be large enough.The damaged

power cord and connection wire

should be replaced by exclusive

cable.

Make sure the unit can be earthed

properly and soundly after

plugging into the socket so as to

avoid electric shock. Please do

not connect the ground wire to gas

pipe, water pipe, lightning rod or

telephone line.

If refrigerant leakage happens

during installation, please ventilate

immediately. Poisonous gas will

emerge if the refrigerant gas meets

re.

After connecting the power cord,

please x the electric box cover

properly in order to avoid accident.

N2

Never fail to comply with the

nitrigen charge requirements.

Charge nitrogen when welding

pipes.

Please rstly connect the wired

controller before energization,

otherwise wired controller can

not be used.

Never short-circiut or cancel the

pressure switch to prevent unit

damage.

Before using the unit, please check

if the piping and wiring are correct

to avoid water leakage, refrigerant

leakage, electric shock, or re etc.

1

Do not insert fingers or objects

26

C

30

C

into air outlet/inlet grille.

D.C. Inverter Multi-variable Modular

Open the door and window and

keep good ventilation in the room

to avoid oxygen decit when

the gas/oil supplied heating

equipment is used.

Never start up or shut off the air

conditioner by means of directly

plug or unplug the power cord.

Do not allow children

operate this unit.

Turn off the unit or cut off the

power supply before cleaning the

unit, otherwise electric shock or

injury may happen.

Do not expose the unit

to the moist or corrosive

circumstances.

<5Min

24H

Turn off the unit after it runs at

least ve minutes; otherwise it

will inuence oil return of the

compressor.

Do not operate this unit

with wet hands.

Never spray or ush water

towards unit, otherwise

malfunction or electric shock

may happen.

Electrify the unit 8 hours before

operation. Please switch on for

8 hours before operation. Do not

cut off the power when 24 hours

short-time halting (to protect the

compressor).

Volatile liquid, such as diluent

or gas will damage the unit

appearance.Only use soft cloth

with a little neutral detergent to

clean the outer casing of unit.

If anything abnormal happens

(such as burning smell), please

power off the unit and cut off

the main power supply, and

then immerdiately contact Gree

appointed service center.If

abnormality keeps going, the unit

might be damaged and lead to

electric shock or re.

Under cooling mode, please

don't set the room temperature

too low and keep the

temperature difference between

indoor and outdoor unit within

.

5

User is not allowed to repair the

unit. Fault service may cause

electric shock or re accidents.

Please contact Gree appointed

service center for help.

GREE will not assume responsibility of personal injury or equipment damage caused by

improper installation and commission, unnecessary service and incapable of following the rules and

instructions listed in this manual.

2

D.C. Inverter Multi-variable Modular

2 Product Introduction

Gree Multi VRF Modular System adopts inverter compressor technology. According to change

the displacement of compressor, stepless capacity regulation within range of 10%-100% can be

realized. Various product lineup is provided with capacity range from 22.4kW to 180kW, which can be

widely used in working area and especially applicable to the place with variable load change.Gree air

conditioner is absolutely your best choice.

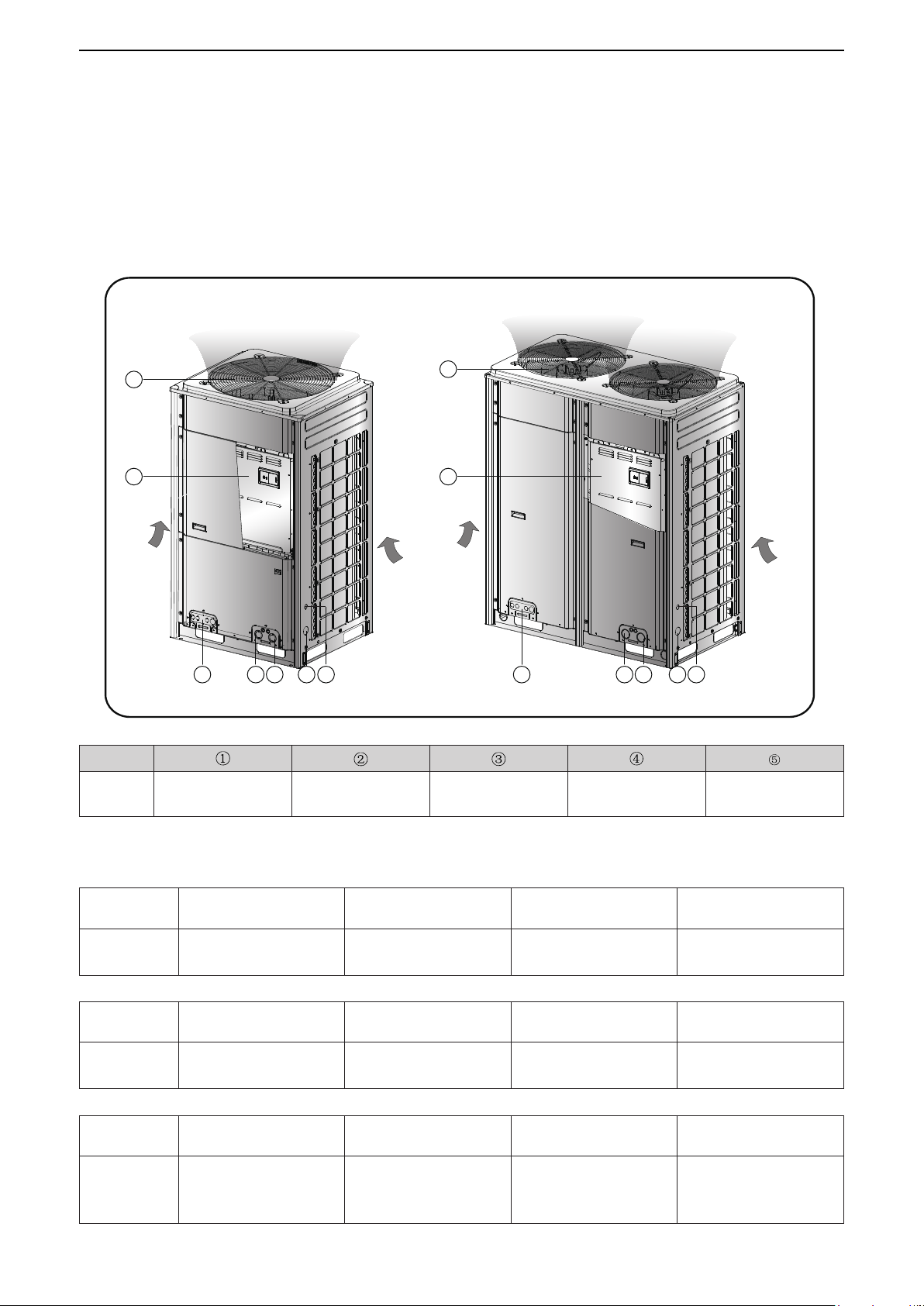

2.1 Names of Main Parts

Air outlet

Air outlet

Air outlet

1

2

Air inlet

3 3 4 54 5 4 5 4 5

NO.

Name Fan, Motor

Air inlet

Electric Box

Assembly

1

2

Air inlet

Fig.1

Valve interface

Power cord

through-hole

Air inlet

Communication

code through-hole

2.2 Combinations of Outdoor Units

Model

(Single)

Model

(Combined)

Model

(Single)

Model

(Combined)

Model

(Single)

Model

(Combined)

GMV-504WM/B-X GMV-560WM/B-X GMV-615WM/B-X GMV-680WM/B-X

GMV-224WM/B-X

+GMV-280WM/B-X

GMV-730WM/B-X GMV-785WM/B-X GMV-850WM/B-X GMV-900WM/B-X

GMV-280WM/B-X

+GMV-450WM/B-X

GMV-960WM/B-X GMV-1010WM/B-X GMV-1065WM/B-X GMV-1130WM/B-X

GMV-280WM/B-X

+GMV-280WM/B-X

+GMV-400WM/B-X

GMV-280WM/B-X

+GMV-280WM/B-X

GMV-335WM/B-X

+GMV-450WM/B-X

GMV-280WM/B-X

+GMV-280WM/B-X

+GMV-450WM/B-X

GMV-280WM/B-X

+GMV-335WM/B-X

GMV-400WM/B-X

+GMV-450WM/B-X

GMV-280WM/B-X

+GMV-335WM/B-X

+GMV-450WM/B-X

GMV-280WM/B-X

+GMV-400WM/B-X

GMV-450WM/B-X

+GMV-450WM/B-X

GMV-280WM/B-X

+GMV-400WM/B-X

+GMV-450WM/B-X

3

D.C. Inverter Multi-variable Modular

Model

(Single)

Model

(Combined)

Model

(Single)

Model

(Combined)

Model

(Single)

Model

(Combined)

GMV-1180WM/B-X GMV-1235WM/B-X GMV-1300WM/B-X GMV-1350WM/B-X

GMV-280WM/B-X

+GMV-450WM/B-X

+GMV-450WM/B-X

GMV-1410WM/B-X GMV-1460WM/B-X GMV-1515WM/B-X GMV-1580WM/B-X

GMV-280WM/B-X

+GMV-280WM/B-X

+GMV-400WM/B-X

+GMV-450WM/B-X

GMV-1630WM/B-X GMV-1685WM/B-X GMV-1750WM/B-X GMV-1800WM/B-X

GMV-280WM/B-X

+GMV-450WM/B-X

+GMV-450WM/B-X

+GMV-450WM/B-X

GMV-335WM/B-X

+GMV-450WM/B-X

+GMV-450WM/B-X

GMV-280WM/B-X

+GMV-280WM/B-X

+GMV-450WM/B-X

+GMV-450WM/B-X

GMV-335WM/B-X

+GMV-450WM/B-X

+GMV-450WM/B-X

+GMV-450WM/B-X

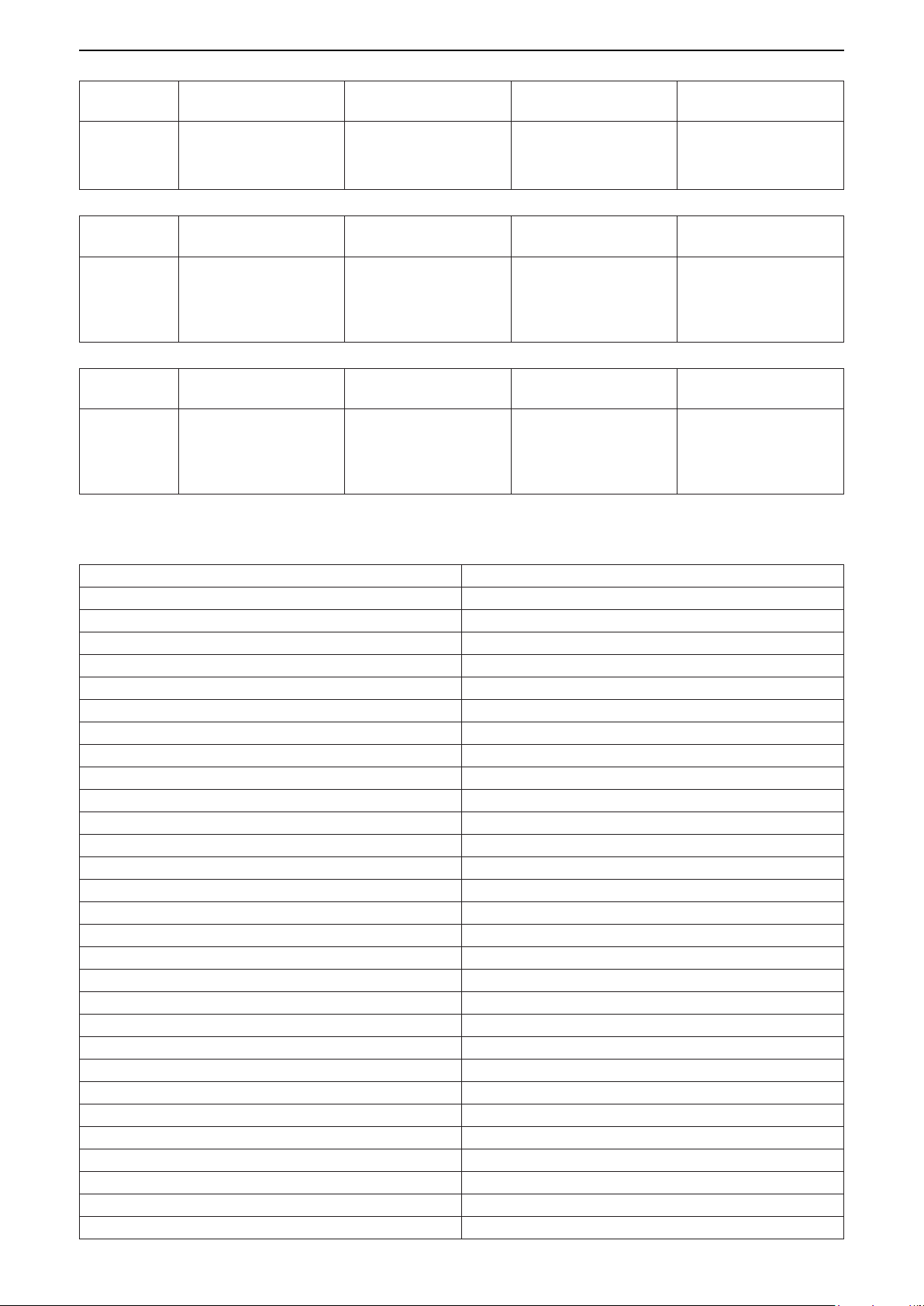

2.3 Combinations of Indoor and Outdoor Units

GMV-400WM/B-X

+GMV-450WM/B-X

+GMV-450WM/B-X

GMV-280WM/B-X

+GMV-335WM/B-X

+GMV-450WM/B-X

+GMV-450WM/B-X

GMV-400WM/B-X

+GMV-450WM/B-X

+GMV-450WM/B-X

+GMV-450WM/B-X

GMV-450WM/B-X

+GMV-450WM/B-X

+GMV-450WM/B-X

GMV-280WM/B-X

+GMV-400WM/B-X

+GMV-450WM/B-X

+GMV-450WM/B-X

GMV-450WM/B-X

+GMV-450WM/B-X

+GMV-450WM/B-X

+GMV-450WM/B-X

(1) The following table indicates the number of IDU for ODU

ODU model Max number of connectable IDU (unit)

GMV-224WM/B-X 13

GMV-280WM/B-X 16

GMV-335WM/B-X 19

GMV-400WM/B-X 23

GMV-450WM/B-X 26

GMV-504WM/B-X 29

GMV-560WM/B-X 33

GMV-615WM/B-X 36

GMV-680WM/B-X 39

GMV-730WM/B-X 43

GMV-785WM/B-X 46

GMV-850WM/B-X 50

GMV-900WM/B-X 53

GMV-960WM/B-X 56

GMV-1010WM/B-X 59

GMV-1065WM/B-X 63

GMV-1130WM/B-X 64

GMV-1180WM/B-X 64

GMV-1235WM/B-X 64

GMV-1300WM/B-X 64

GMV-1350WM/B-X 64

GMV-1410WM/B-X 66

GMV-1460WM/B-X 69

GMV-1515WM/B-X 71

GMV-1580WM/B-X 74

GMV-1630WM/B-X 77

GMV-1685WM/B-X 80

GMV-1750WM/B-X 80

GMV-1800WM/B-X 80

4

D.C. Inverter Multi-variable Modular

The total capacity of indoor units should be within 50%~135% of that of outdoor units.

Outdoor Unit

Indoor Unit

Four-way Cassette Type One-way Cassette Type Wall Mounted Type Duct Type

Fig.2

Fig.2 is the combination view of the ODU of Modular DC Inverter Multi VRF System and the IDU

of Multi VRF System. IDU can be cassette type, one-way cassette type, wall-mounted type, duct type,

etc. When any one IDU receives operation signal, ODU will start to work according to the capacity;

when all IDUs stop, ODU will also stop.

2.4 The Range of Production Working Temperature

Cooling Ambient temperature: -5 ~52

Heating Ambient temperature: -20 ~24

When the indoor units are all VRF fresh air processor, the unit operating range is as follows:

Cooling Ambient temperature: 16°C~45°C

Heating Ambient temperature: -7°C~16°C

If the temperature is beyond the range, the safety protection measure of the unit may take effect,

and the air conditioning unit will stop.

5

D.C. Inverter Multi-variable Modular

3 Preparation before Installation

Note: The picture is only used for reference and the actual product prevails. Unit: mm.

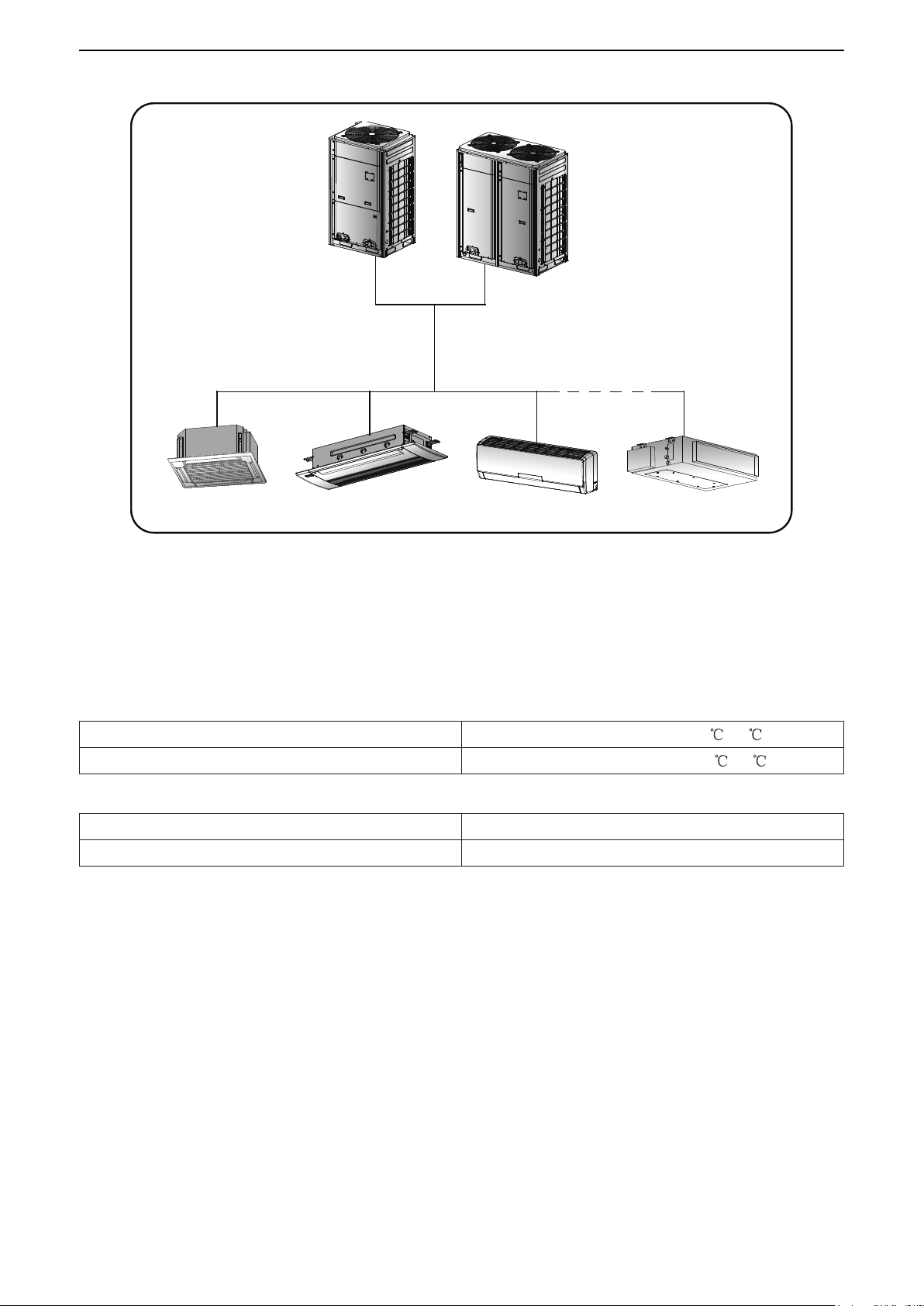

3.1 Standard Parts

Please use the following standard parts supplied by Gree.

Parts for Outdoor Unit

Number Name Picture Quantity Remarks

Change for life

D.C. Inverter

Multi VRF Modular

Owner's Manual

Air Conditioners

GMV-224WM/B-X

1 Owner's Manual

GMV-280WM/B-X

GMV-335WM/B-X

GMV-400WM/B-X

GMV-450WM/B-X

GMV-504WM/B-X

GMV-1800WM/B-X

Thank you for choosing Air Conditioners, please read this owner’s manual carefully before

operation and retain it for future reference.

GREE reserves the right to interpret this manual which will be subject to any change due

to product improvement without further notice.

GREE Electric Appliances, Inc. of Zhuhai reserves the nal right to interpret this manual.

1

2

Wiring (match with

resistance)

3 Mark (Master )

1

2

Must be connected to the

last IDU of communication

connection

Attach on the wired controller of

master IDU or on the front panel

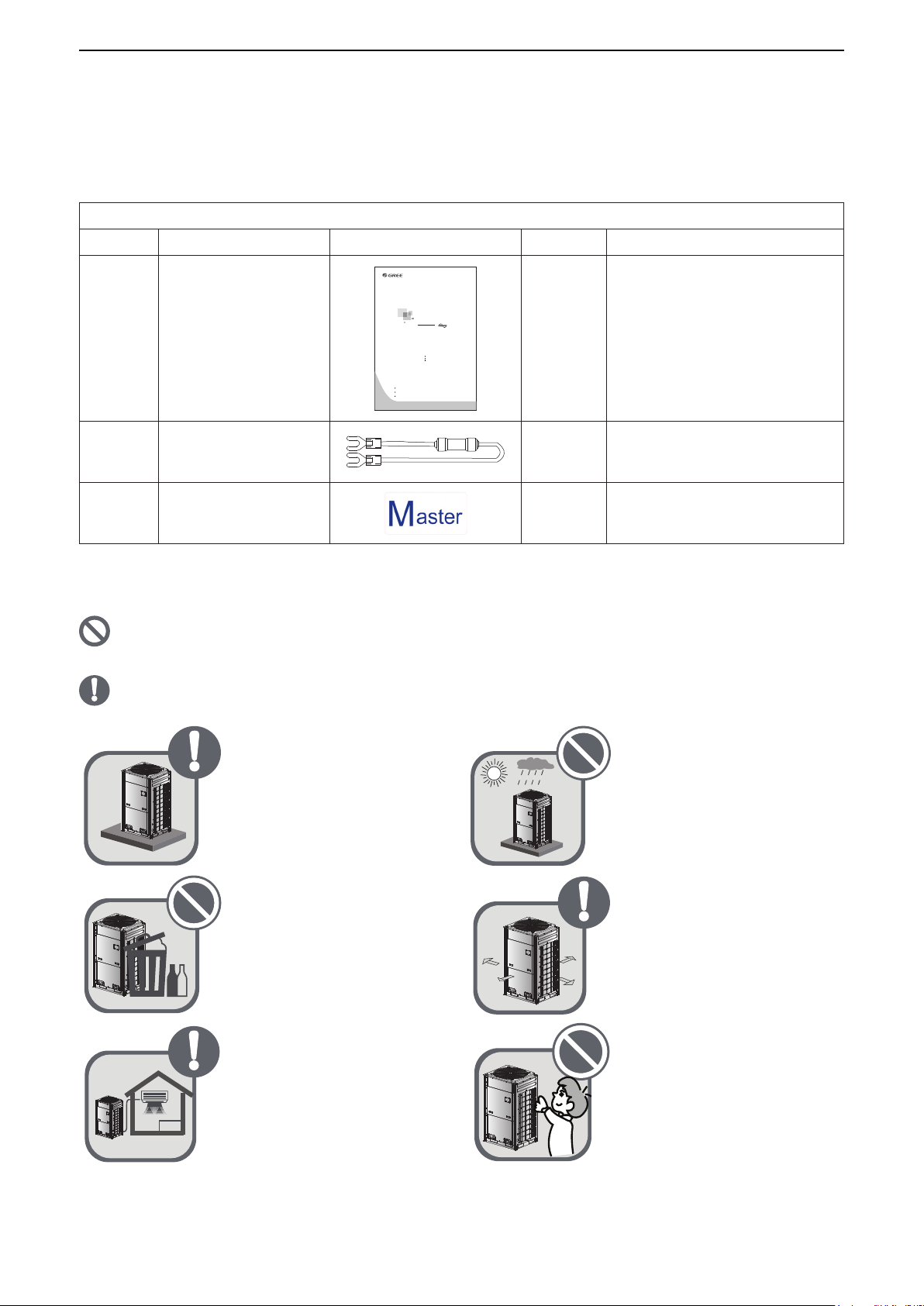

3.2 Installation Site

Forbidden Items! It indicates that improper operation might lead to human casualty or

sever injury.

Items need to be followed. It indicates that improper operation might lead to personal

injury or property damage.

Install the unit at a place where

is adequate to withstand the

weight of the unit and make

sure the unit would not shake

or fall off.

Never expose the unit under

direct sunshine and rainfall.

Install the unit at a place where

is against dust, typhoon and

earthquake.

Try to keep the unit away

from combustible,inammable

and corrosive gas or exhaust

gas.

Keep the indoor and outdoor

units close to each other as

much as possible so as to

decrease the pipe length and

bends.

Leave some space for heat

exchanging and servicing so

as to guarantee unit normal

operation.

Never allow children to

approach to the unit and take

measures to prevent children

touching the unit.

6

D.C. Inverter Multi-variable Modular

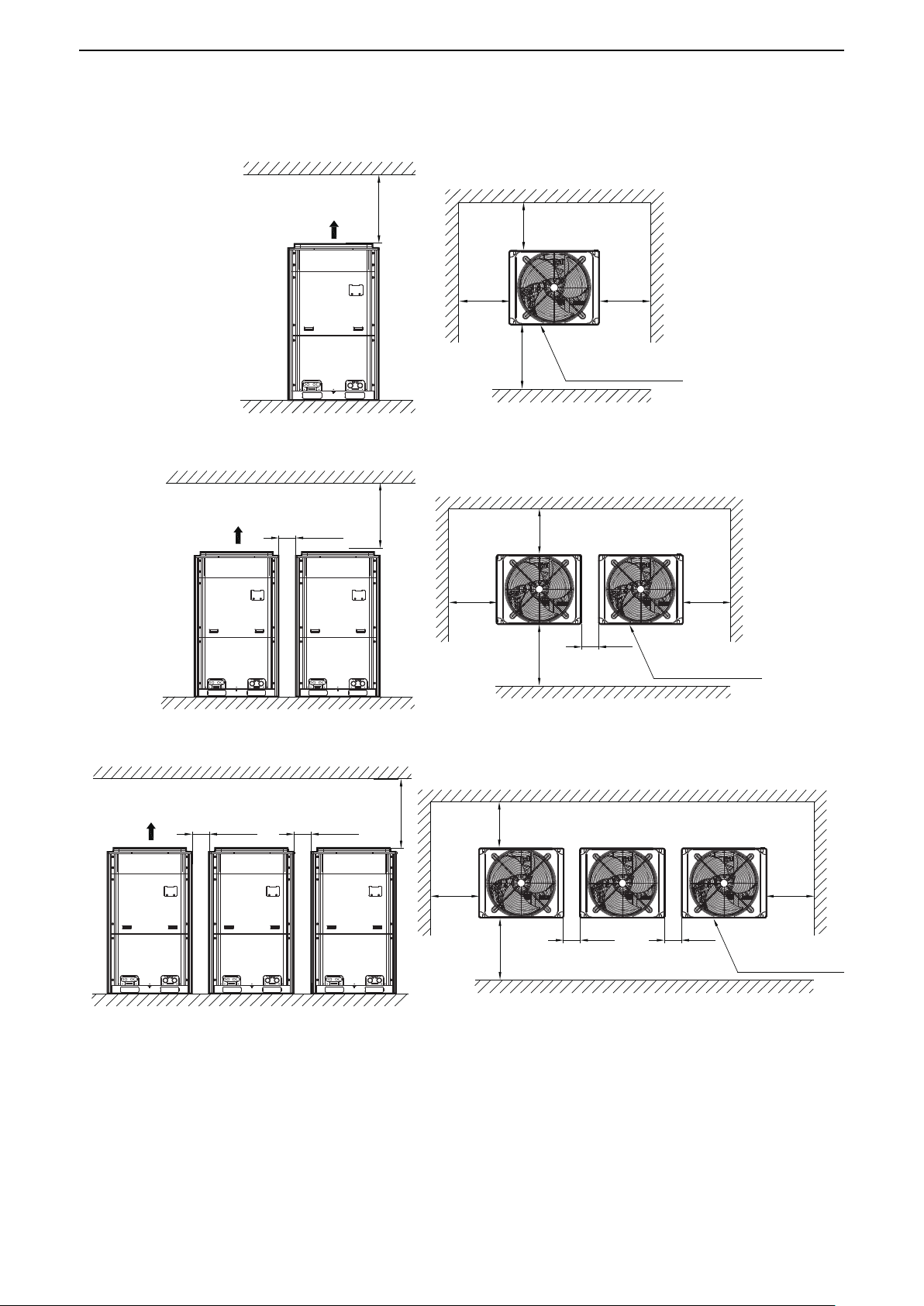

A

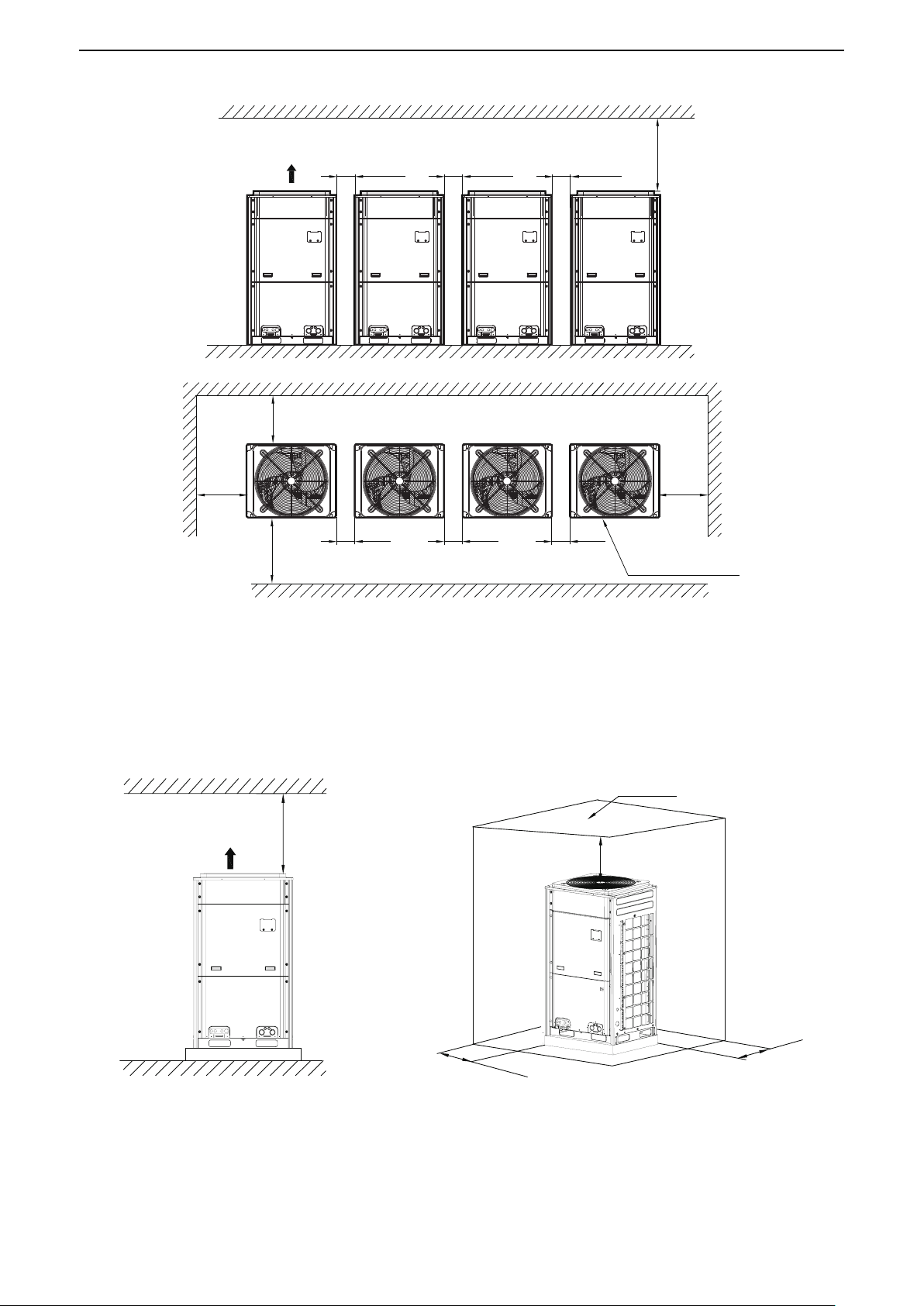

3.2.1 When the outdoor unit is totally surrounded by walls, please refer to following

gures for space dimension.

3.2.1.1 Space dimension for single-module unit

Air Outlet

>3000

3.2.1.2 Space dimension for dual-module unit

Air Outlet

>200

>3000

Fig. 3

>1000

>1200

>1000

>1200

>1000>1000

Electrical Box

Outlet on this side

>1000>1000

>200

Electrical Box

Outlet on this side

Fig. 4

3.2.1.3 Space dimension for three-module unit

ir Outlet

>200>200

>3000

Fig.5

>1000

>1200

>1000>1000

>200>200

Electrical Box

Outlet on this side

7

3.2.1.4 Space dimension for four-module unit

e

Crown wall

1000

200

D.C. Inverter Multi-variable Modular

Air Outlet

>1000

>1200

Fig.6

>200>200

>200

>200>200>200

>3000

>1000>1000

Electrical Box

Outlet on this sid

3.2.2 When there is wall (or similar obstruction) above the unit, keep the distance

between the unit top and the wall at least 300mm or above. When the unit is located

in a totally open space with no obstructions in four directions, keep the distance

between the unit top and wall at least 1500mm or above (See Fig.7). When space

is limited within 1500mm or the unit is not set in an open space, air return pipe is

required to be installed in order to keep good ventilation (See Fig.8).

Air Outlet

>1500

>

Fig.7 Fig.8

When the distance is less than

1500mm, connect an air duct

so as to keep good ventilation.

>

8

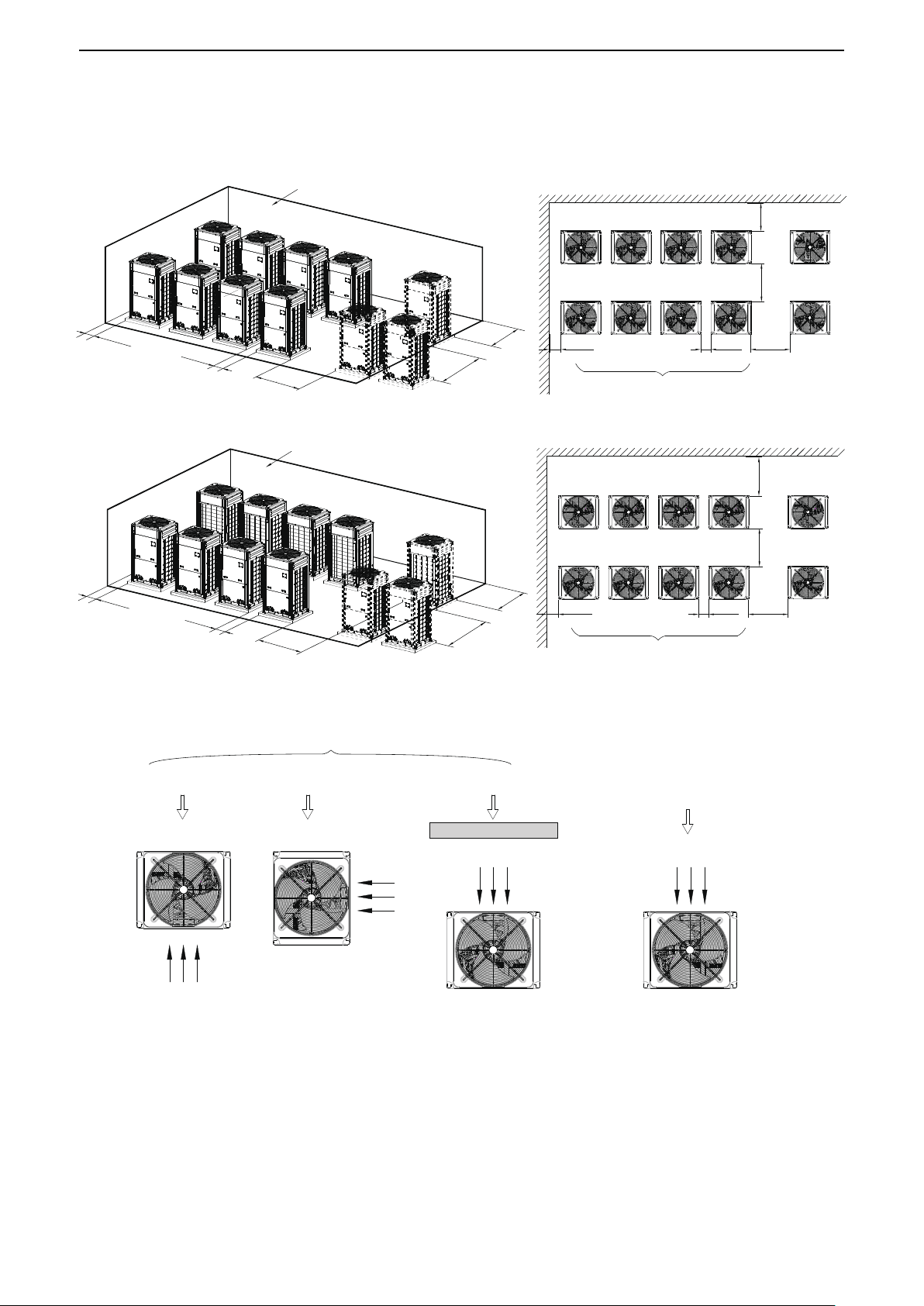

D.C. Inverter Multi-variable Modular

No limit on the height of wall

Max. 4 sets side by side

No limit on the height of wall

Max. 4 sets side by side

Correct

Incorrect:

In this case,

S

Front Front

3.2.3 Space dimension for multiple-module unit

For keeping good ventilation, make sure there is no obstructions above the unit.

When the unit is located at a half-open space (front and left/right side is open), install the unit as

per the same or opposite direction.

>200

>200

>200

>200

>1000

>1000

>1200

Fig.9

>1200

Fig.10

>1000

>1200

>200

>200

Back side

Front side

Back side

Front side

Front side

Back side

Back side

Front side

>200

>200

>1000

>1200

>1000

>1200

>1200

>1000

3.2.4 Take seasonal wind into consideration when installing the outdoor unit

the defrosting duration

easonal wind Seasonal wind Seasonal wind

Front

Front

Return air

Protective cover

Return air

Return air

Fig.11

will be extended.

Seasonal wind

Return air

9

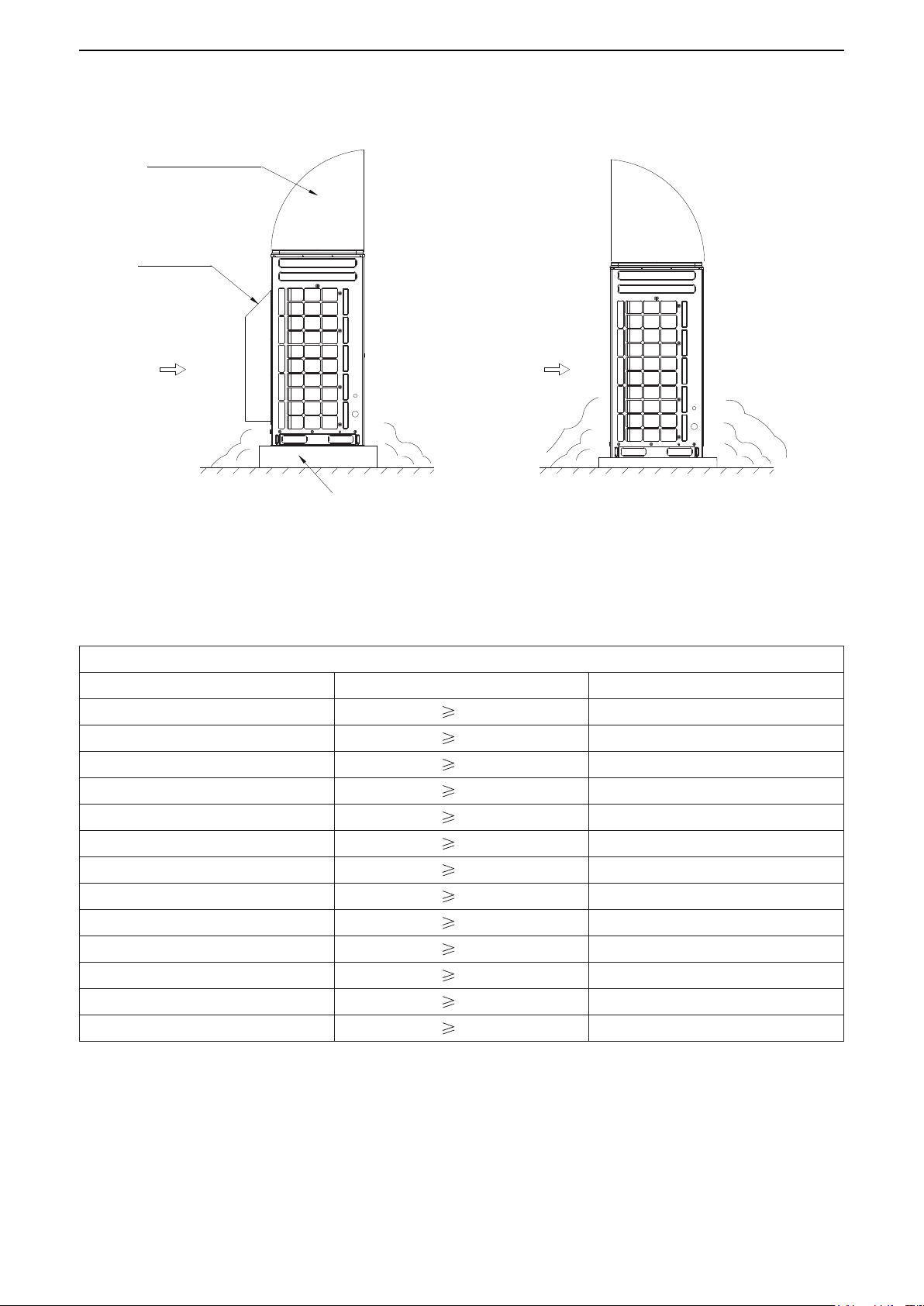

D.C. Inverter Multi-variable Modular

S

Protective cover at

Protective cover at

the return air inlet

(field supplied)

higher than that of the snowfall.

3.2.5 Take snow into consideration when installing the outdoor unit

the supply air outlet

(field supplied)

easonal wind Seasonal wind

Correct

The height of the base should

3.3 Piping Work Requirements

Incorrect

Fig.12

There should be no fall among outdoor modules. Refer to the table below for piping work

requirements.

R410A Refrigerant System

Outer Diameter (mm) Wall Thickness (mm) Type

Φ6.35 0.8 0

Φ9.52 0.8 0

Φ12.70 0.8 0

Φ15.9 1.0 0

Φ19.05 1.0 1/2H

Φ22.2 1.2 1/2H

Φ25.40 1.2 1/2H

Φ28.60 1.2 1/2H

Φ34.90 1.3 1/2H

Φ38.10 1.5 1/2H

Φ41.30 1.5 1/2H

Φ44.5 1.5 1/2H

Φ54.1 1.5 1/2H

10

D.C. Inverter Multi-variable Modular

930 765

1

2

Installation hole

4 Installation Instruction

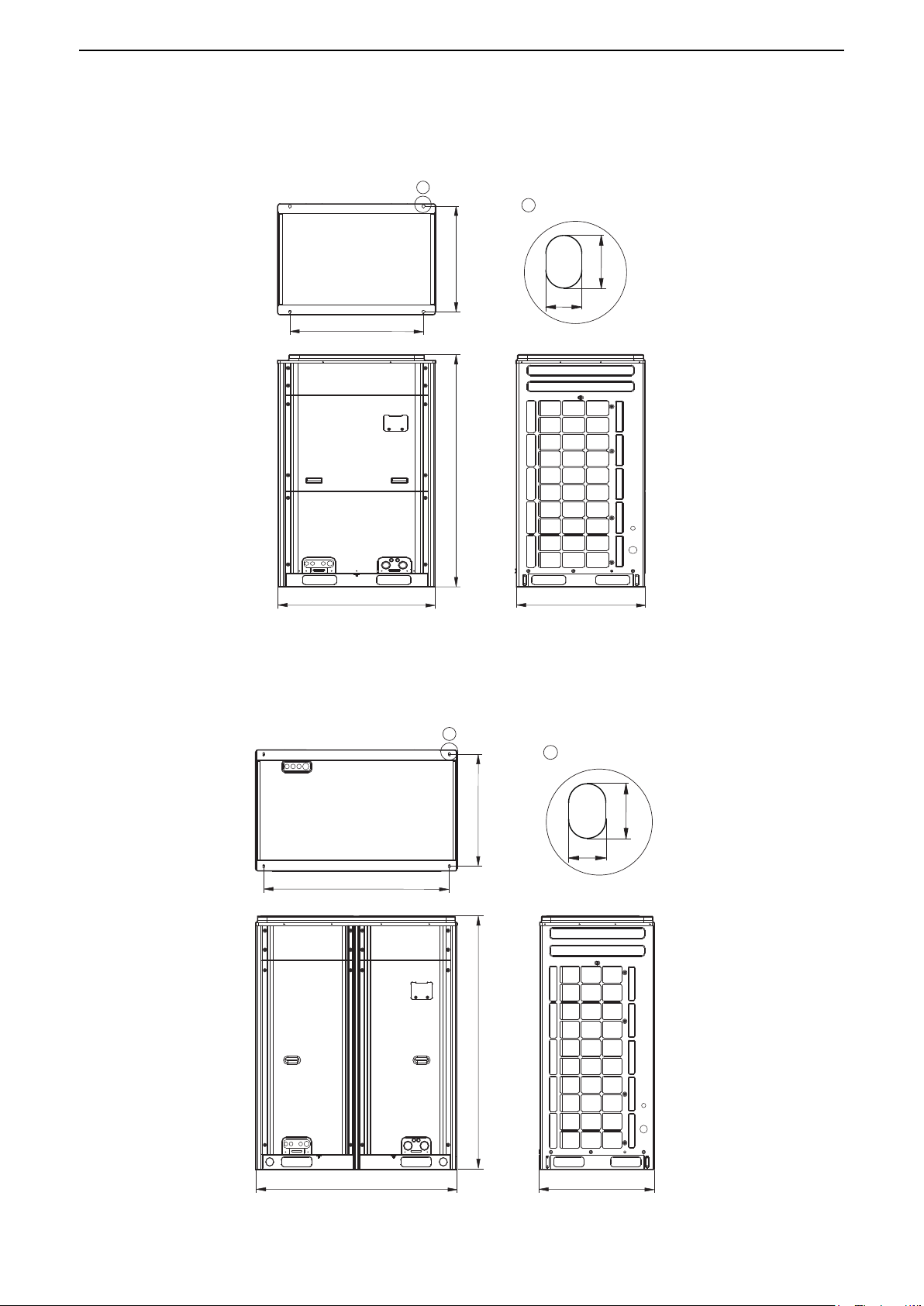

4.1 Physical Dimension of the Outdoor Unit and Mounting Hole

Outline and Physical Dimention of GMV-224WM/B-X and GMV-280WM/B-X unit.

1

Installation hole

7291605

792

Fig.13

22

15

Outline and Physical Dimention of GMV-335WM/B-X, GMV-400WM/B-X and GMV-450WM/B-X

unit.

2

729

1200

1605

1340

Fig.14

22

15

765

11

4.2 Connection Pipe

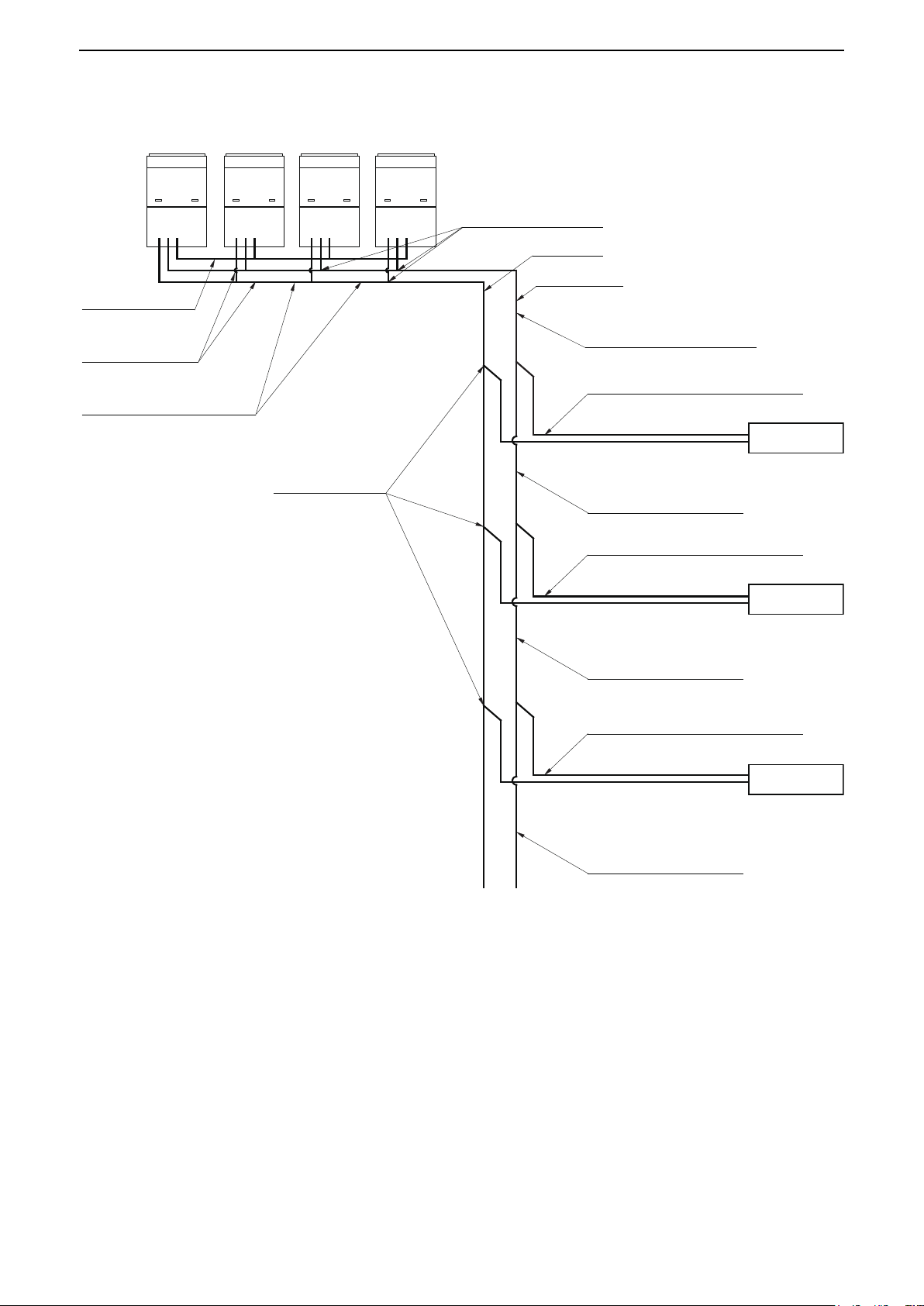

Oil balance pipe

4.2.1 Schematic Diagram of Piping Connection

D.C. Inverter Multi-variable Modular

Module

No.1

Module

No.2

Outdoor

connection pipe

Connection pipe between

outdoor manifolds

Module

No.3

Module

Manifold between

indoor units

No.4

Manifold between

outdoor units

Gas pipe

Liquid pipe

Connection pipe between outdoor

manifold and the first indoor manifold

Connection pipe between indoor

manifold and indoor units

Indoor unit 1

Connection pipe between

indoor manifolds

Connection pipe between indoor

manifold and indoor units

Indoor unit 2

Connection pipe between

indoor manifolds

Connection pipe between indoor

manifold and indoor units

Indoor unit 3

Connection pipe between

indoor manifolds

Fig.15

12

D.C. Inverter Multi-variable Modular

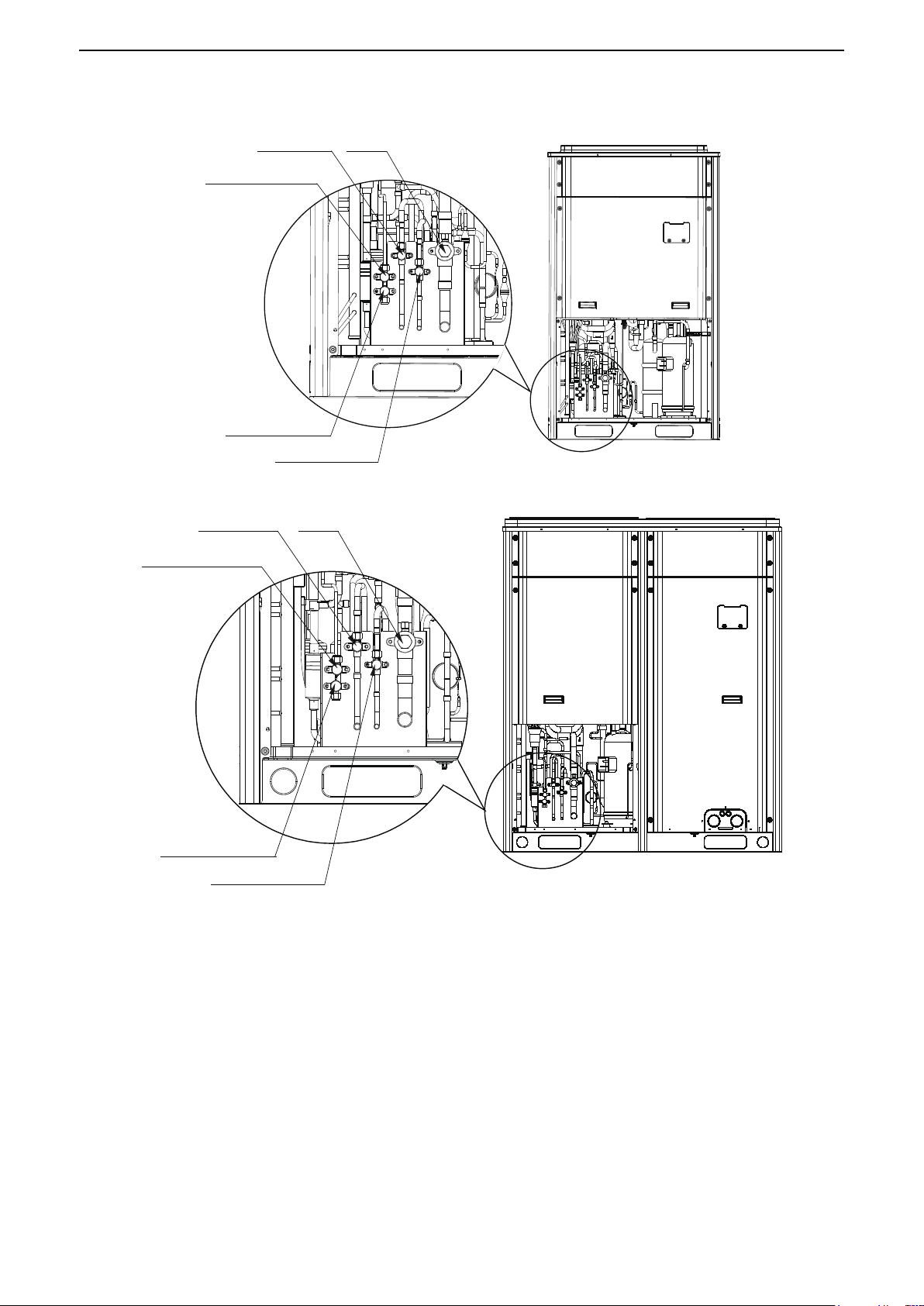

Liquid pipe Gas pipe

Oil checking valve

Liquid pipe Gas pipe

Oil checking valve

4.2.2 Schematic Diagram of Piping Sequence

GMV-224WM/B-X and GMV-280WM/B-X

Low pressure

check valve

Oil balance pipe

Fig.16

GMV-335WM/B-X, GMV-400WM/B-X and GMV-450WM/B-X

Low pressure

check valve

Oil balance pipe

Fig.17

13

D.C. Inverter Multi-variable Modular

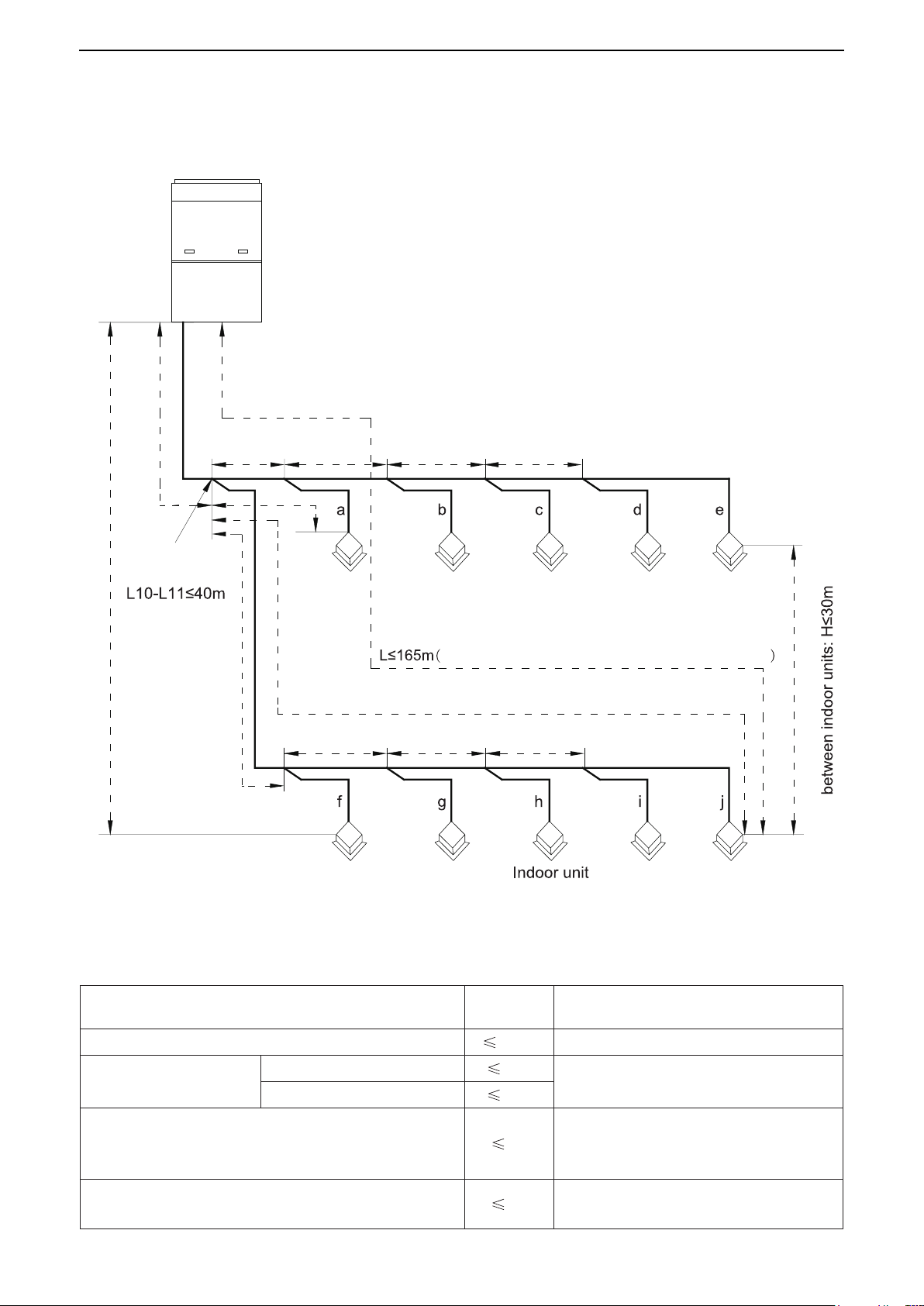

4.2.3 Allowable pipe length and drop height among indoor and outdoor units

Y type branch joint is adopted to connect indoor and outdoor units. Connecting method is shown

in the gure below.

Remark: Equivalent length of one Y-type manifold is about 0.5m.

Outdoor unit

L1

L2

L11

The 1st

branch section

L6

L3

L4 L5

between outdoor unit and the farthest indoor unit

L7 L8 L9

Height difference between indoor unit and outdoor unit: H

Fig.18

L10: Length from the rst branch to the farthest IDU;

L11: Length from the rst branch to the nearest IDU;

Equivalent length of branch of IDU is 0.5m

Indoor unit

L10

Height difference

R410A Refrigerant System

Total length (actual length) of tting pipe 1000 L1+L2+L3+L4+…+L9+a+b+…+i+j

Length of farthest tting

pipe(m)

Difference between the pipe length from the rst branch

of IDU to the farthest IDU and the pipe length from the

rst branch of IDU to the nearest IDU

Equivalent length from the rst branch to the furthest

piping (1)

Actual length 165

Equivalent length 190

14

Allowable

Value

40 L10-L11

40 L6+L7+L8+L9+j

Fitting Pipe

L1+L6+L7+L8+L9+j

D.C. Inverter Multi-variable Modular

Height difference

Outdoor unit at upper(2) 90 ——

between outdoor unit and

indoor unit

Outdoor unit at lower 90 ——

Height difference between indoor units (m) 30 ——

Maximum length of Main pipe(3) 90 L1

From IDU to its nearest branch (4) 10 a,b,c,d,e,f,g,h,i,j

Notices:

(1) Normally, the pipe length from the rst branch of IDU to the farthest IDU is 40m. When those

three conditions as below are satised, the length can reached 90cm..

1) Actual length of pipe in total: L1+L2x2+L3x2+L4x2+…+L9x2+a+b+…+i+j≤1000m;

2) Length between each IDU and its nearest branch a, b, c, d, e, f, g, h, i, j≤40m;

3) Difference between the pipe length from the rst branch of IDU to the farthest IDU and the

pipe length from the rst branch of IDU to the nearest IDU: L10-L11≤40m.

(2) When the outdoor unit is at upper side and height difference is more than 50m, please consult

company for the related technical requirement.

(3) When the maximum length of the main pipe from ODU to the rst branch of IDU is≥90m, then

adjust the pipe size of the gas pipe and liquid pipe of main pipe according to the following

table.

Outdoor Model Gas pipe size(mm) Liquid pipe size(mm)

GMV-224WM/B-X

GMV-280WM/B-X

GMV-335WM/B-X Φ28.6 Φ15.9

GMV-400WM/B-X Φ31.8 Φ15.9

GMV-450WM/B-X Φ31.8 Φ15.9

GMV-504WM/B-X Φ34.9 Φ19.05

GMV-560WM/B-X Φ34.9 Φ19.05

GMV-615WM/B-X Φ34.9 Φ19.05

GMV-680WM/B-X

GMV-730WM/B-X Φ38.1 Φ22.2

GMV-785WM/B-X Φ38.1 Φ22.2

GMV-850WM/B-X Φ38.1 Φ22.2

GMV-900WM/B-X Φ38.1 Φ22.2

GMV-960WM/B-X Φ41.3 Φ22.2

GMV-1010WM/B-X Φ44.5 Φ22.2

GMV-1065WM/B-X Φ44.5 Φ22.2

GMV-1130WM/B-X Φ44.5 Φ22.2

GMV-1180WM/B-X Φ44.5 Φ22.2

GMV-1235WM/B-X Φ44.5 Φ22.2

GMV-1300WM/B-X Φ44.5 Φ22.2

GMV-1350WM/B-X Φ44.5 Φ22.2

GMV-1410WM/B-X

GMV-1460WM/B-X

GMV-1515WM/B-X

GMV-1580WM/B-X

GMV-1630WM/B-X

GMV-1685WM/B-X

GMV-1750WM/B-X

No need to enlarge pipe size No need to enlarge pipe size

No need to enlarge pipe size

No need to enlarge pipe size

No need to enlarge pipe size

No need to enlarge pipe size

No need to enlarge pipe size

No need to enlarge pipe size

No need to enlarge pipe size

No need to enlarge pipe size

No need to enlarge pipe size

Φ12.7

Φ19.05

Φ25.4

Φ25.4

Φ25.4

Φ25.4

Φ25.4

Φ25.4

Φ25.4

15

Loading...

Loading...