Gree GEH09AA-K3DNA1B, GEH09AA-K3DNA1C, GEH12AA-K3DNA1B, GEH12AA-K3DNA1C, GEH18AA-K3DNA1B Service Manual

...

GREE ELECTRIC APPLIANCES,INC.OF ZHUHAI

Change for Life

Service Manual

Models: GEH09AA-K3DNA1B

GEH09AA-K3DNA1C

GEH12AA-K3DNA1B

GEH12AA-K3DNA1C

GEH18AA-K3DNA1B

GEH18AA-K3DNA1C

(Refrigerant R410A)

Service Manual

Table of Contents

Table of Contents

Part

Ⅰ

: Technical Information

.........................................................................1

1. Summary

........................................................................................................................1

2. Specications

............................................................................................................2

2.1 Specication Sheet .............................................................................................................2

2.2 Operation Characteristic Curve ..........................................................................................8

2.3 Capacity Variation Ratio According to Temperature ...........................................................9

2.4 Cooling and Heating Data Sheet in Rated Frequency .....................................................10

2.5 Noise Curve ......................................................................................................................10

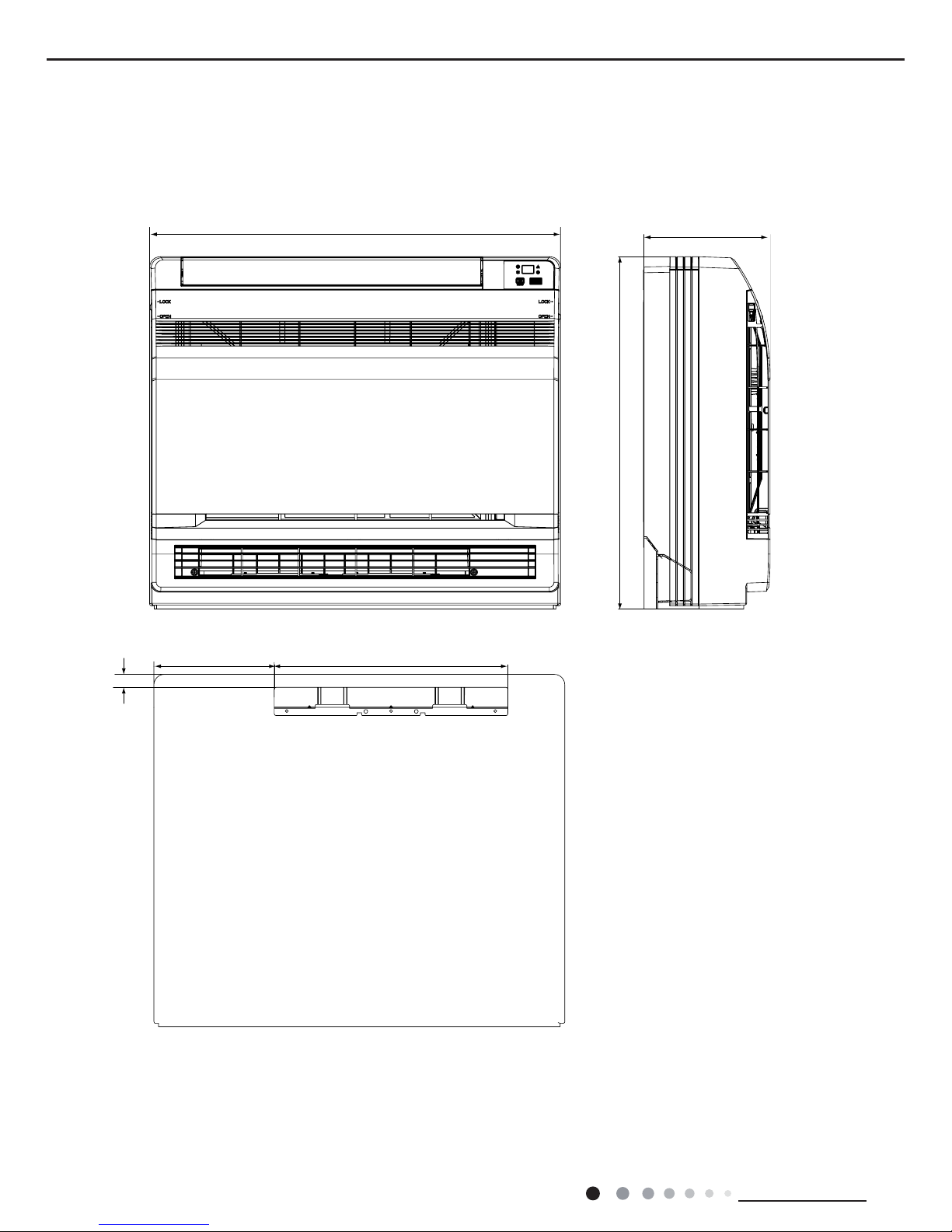

3. Outline Dimension Diagram

.........................................................................................12

3.1 Indoor Unit ........................................................................................................................12

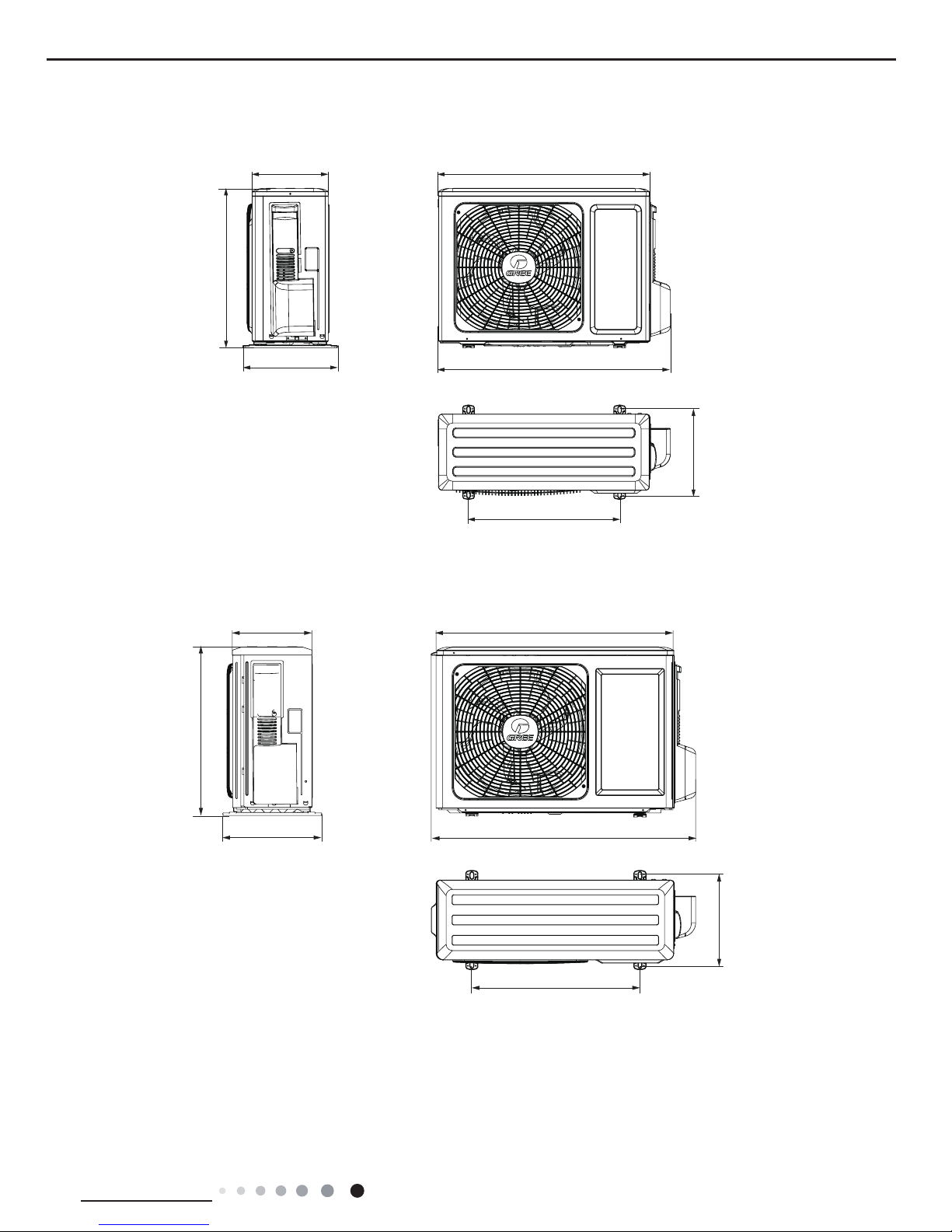

3.2 Outdoor Unit .....................................................................................................................13

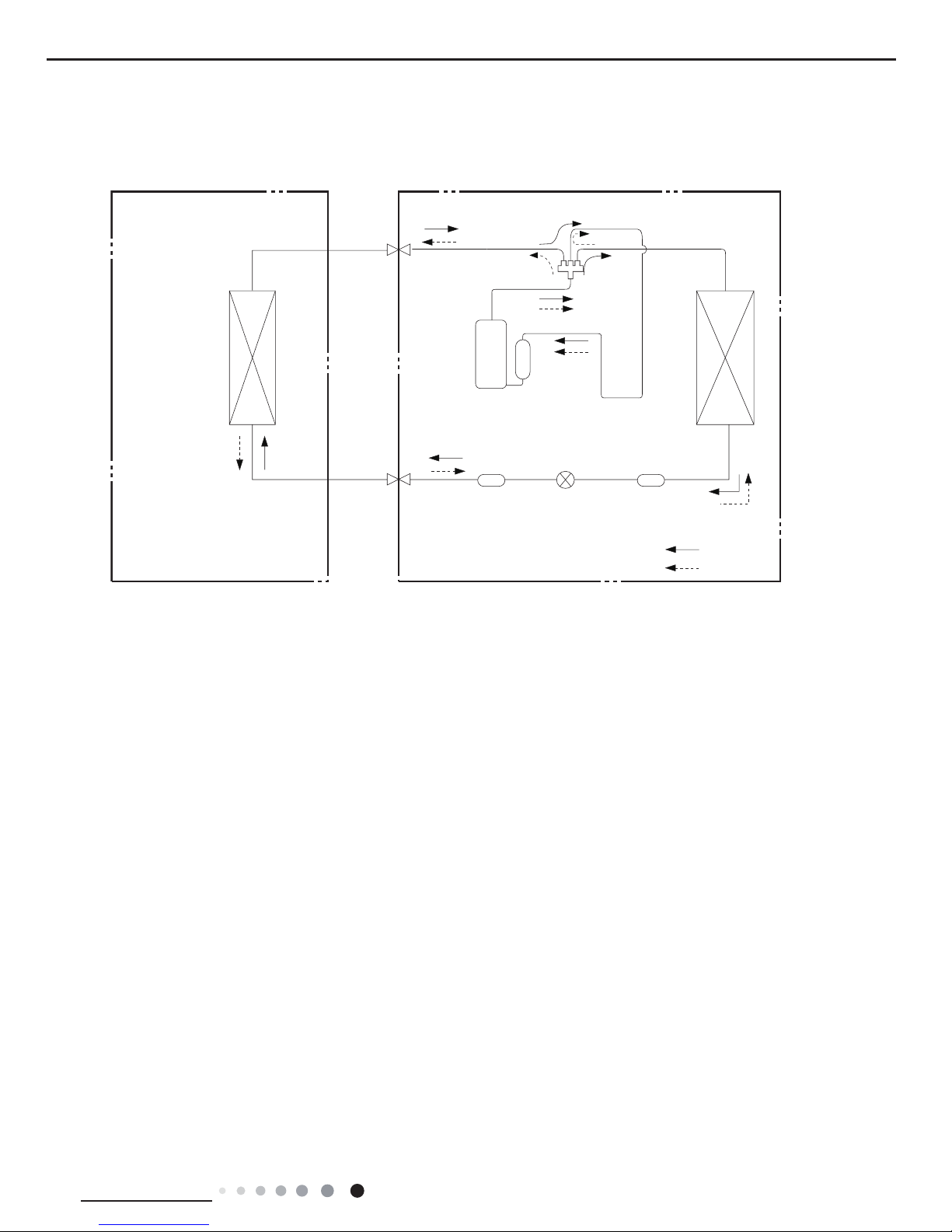

4. Refrigerant System Diagram

......................................................................15

5. Electrical Part

...........................................................................................................16

5.1 Wiring Diagram .................................................................................................................16

5.2 PCB Printed Diagram .......................................................................................................19

6. Function and Control

........................................................................................24

6.1 Remote Controller Introduction .......................................................................................24

6.2 Brief Description of Modes and Functions ........................................................................28

Part

Ⅱ

: Installation and Maintenance

...................................................30

7. Notes for Installation and Maintenance

............................................30

8. Installation

..................................................................................................................32

8.1 Choosing an Installation Site ............................................................................................32

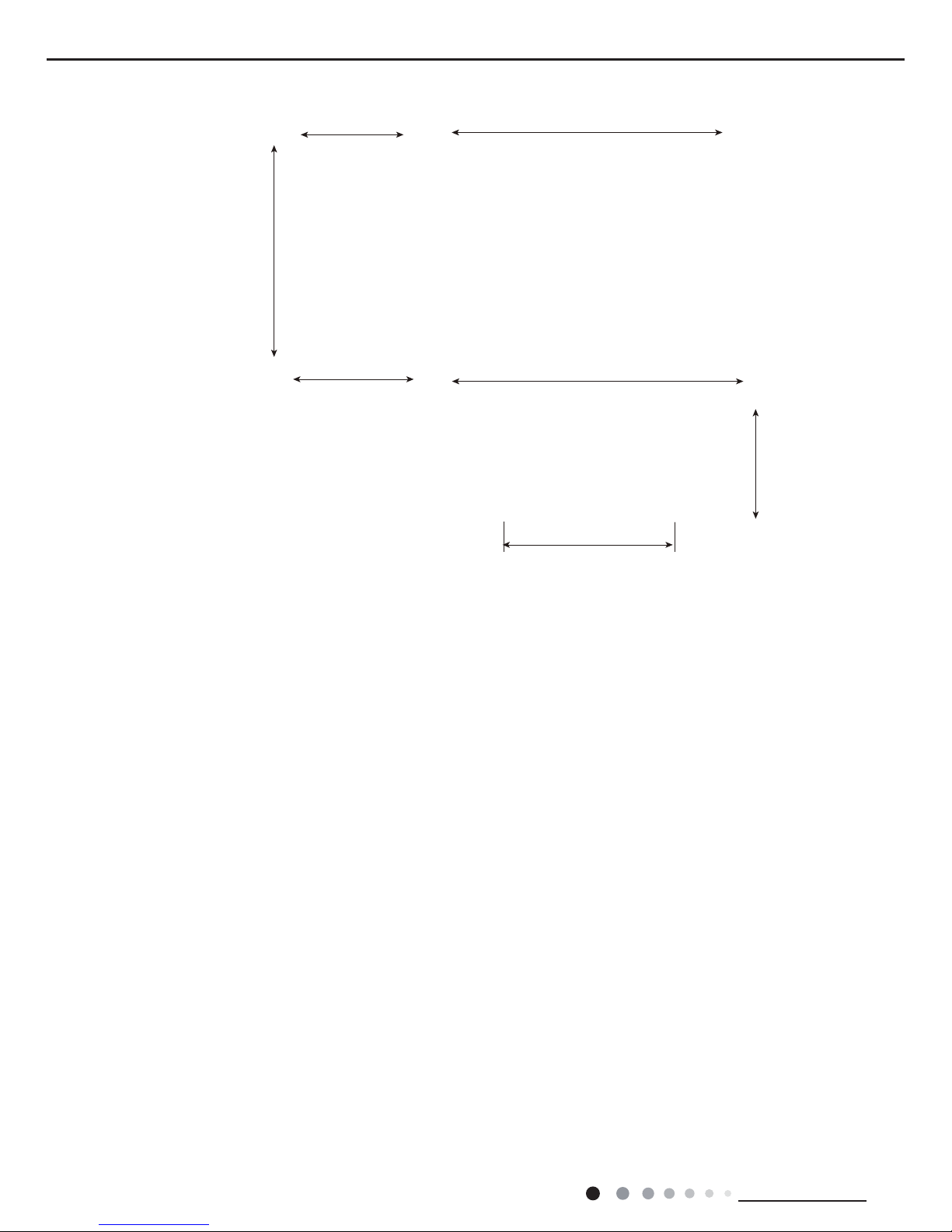

8.2 Indoor Unit Installation Drawings ......................................................................................32

8.3 Installation Tips .................................................................................................................34

8.4 Indoor Unit Installation ......................................................................................................34

8.5 Outdoor Unit Installation ...................................................................................................39

8.6 Vacuum Pumping and Leak Detection .............................................................................40

8.7 Check after Installation and Test Operation .....................................................................41

Service Manual

9. Maintenance

............................................................................................................42

9.1 Error Code List ...............................................................................................................42

9.2 Troubleshooting for Main Malfunction ............................................................................44

9.3 Maintenance Method for Normal Malfunction .................................................................49

10. Exploded View and Parts List

..............................................................51

10.1 Indoor Unit ....................................................................................................................51

10.2 Outdoor Unit .................................................................................................................54

11. Removal Procedure

.......................................................................................60

11.1 Removal Procedure of Indoor Unit ...............................................................................60

11.2 Removal Procedure of Outdoor Unit ............................................................................64

Appendix:

........................................................................................................................76

Appendix 1: Reference Sheet of Celsius and Fahrenheit ....................................................76

Appendix 2: Conguration of Connection Pipe .....................................................................76

Appendix 3: Pipe Expanding Method ...................................................................................77

Appendix 4: List of Resistance for Temperature Sensor ......................................................78

1

Technical Information

Service Manual

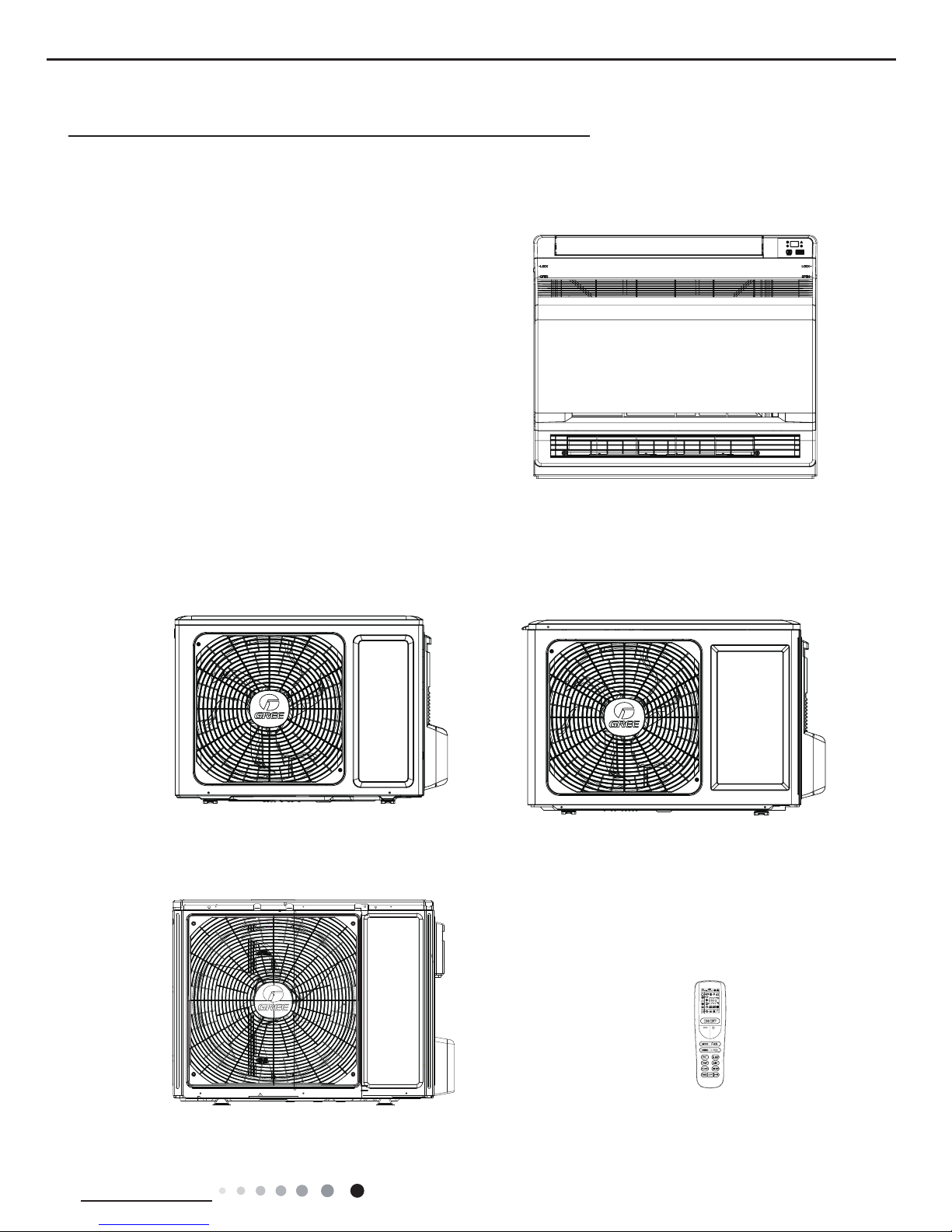

1. Summary

Part

Ⅰ

: Technical Information

Indoor Unit

Outdoor Unit

GEH09AA-K3DNA1B/O

GEH09AA-K3DNA1C/O

GEH12AA-K3DNA1B/O

GEH12AA-K3DNA1C/O

GEH18AA-K3DNA1B/O

GEH18AA-K3DNA1C/O

GEH09AA-K3DNA1B/I

GEH09AA-K3DNA1C/I

GEH12AA-K3DNA1B/I

GEH12AA-K3DNA1C/I

GEH18AA-K3DNA1B/I

GEH18AA-K3DNA1C/I

Remote Controller

YAA1FB1

2

Technical Information

Service Manual

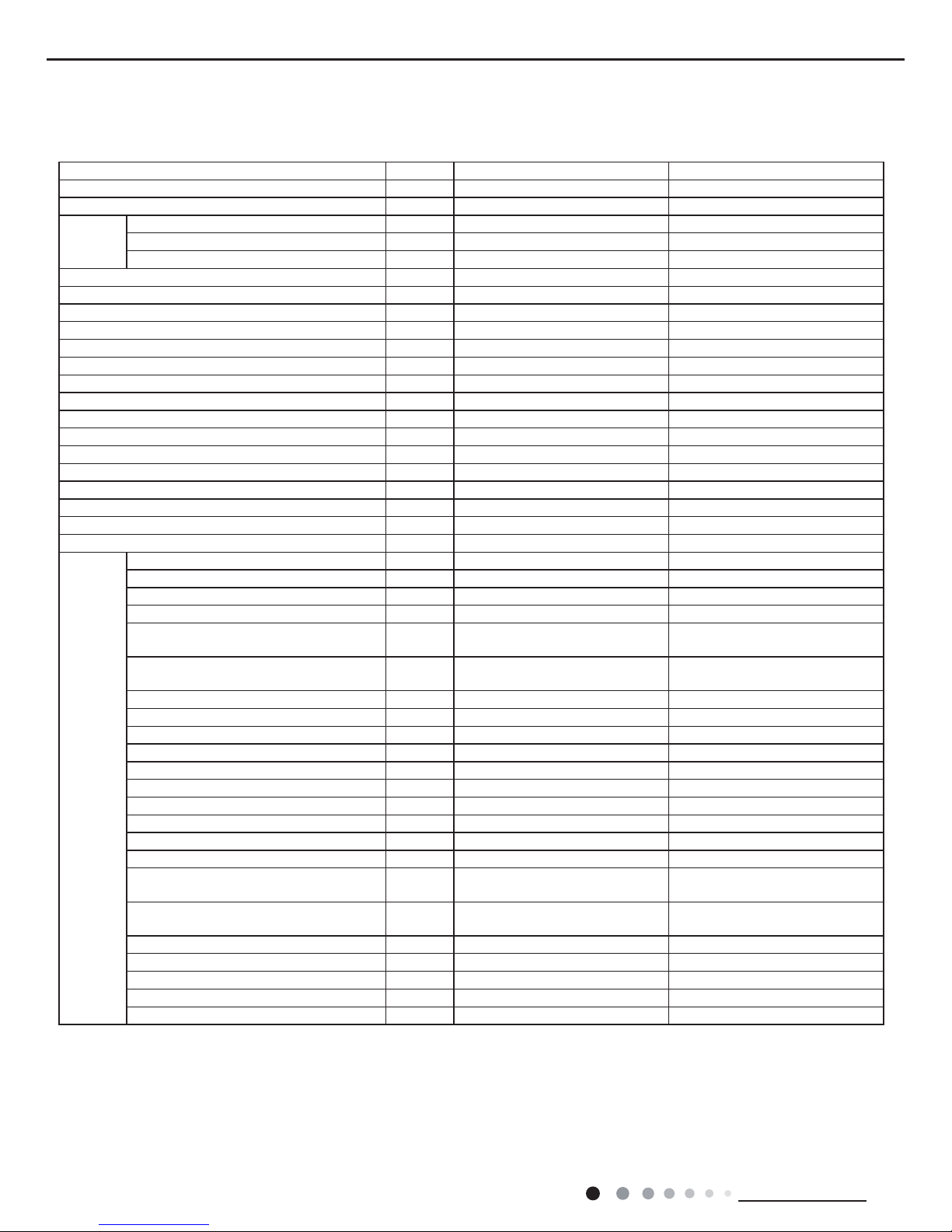

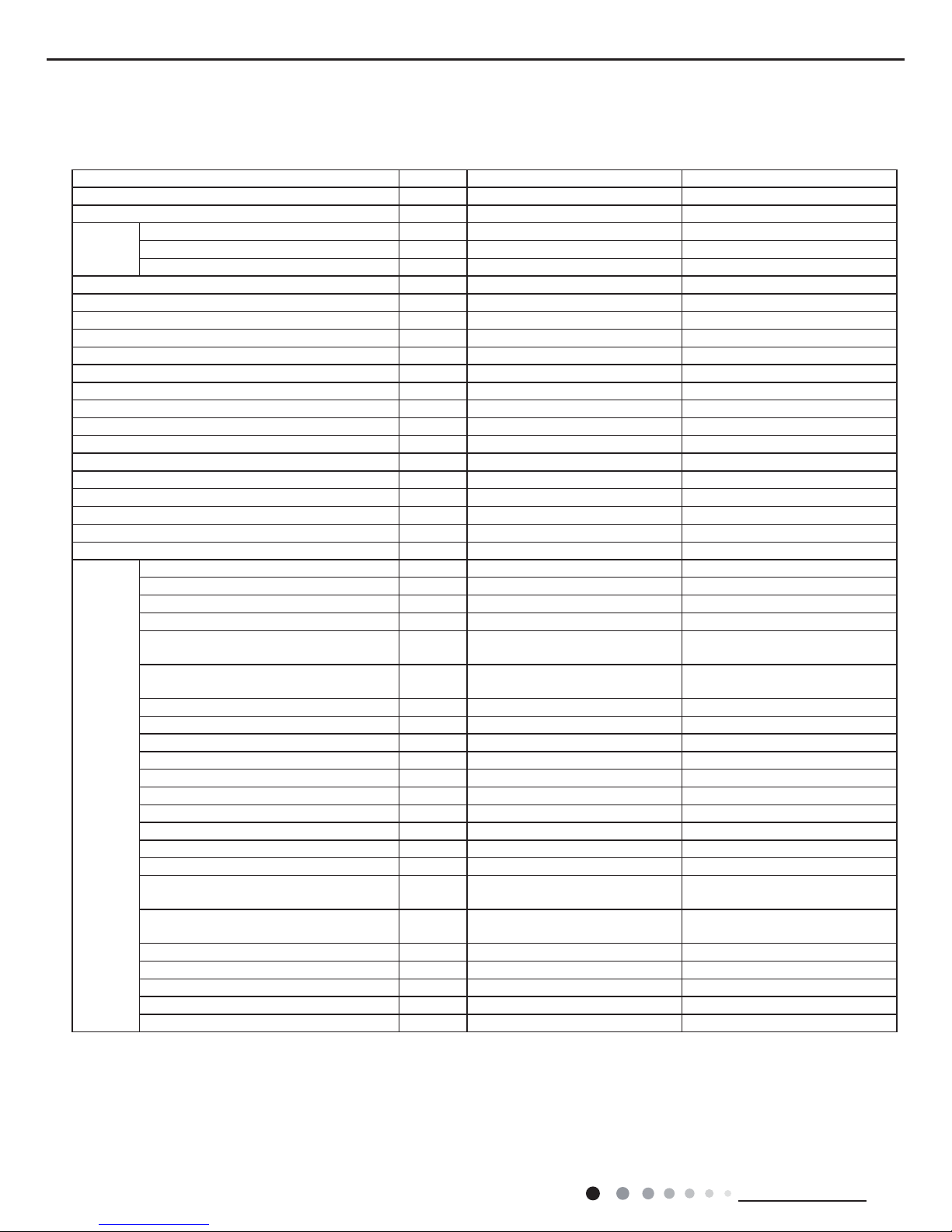

2. Specications

2.1 Specication Sheet

Parameter Unit Value

Model GEH09AA-K3DNA1B GEH09AA-K3DNA1C

Product Code CV010001200 CV010002000

Power

Supply

Rated Voltage V

~

220-240 220-240

Rated Frequency Hz 50 50

Phases 1 1

Power Supply Mode Indoor Indoor

Cooling Capacity(Min~Max) W 2600(450~3200) 2600(450~3200)

Heating Capacity(Min~Max) W 2750(450~3750) 2750(450~3750)

Cooling Power Input(Min~Max) W 720(200~1200) 720(200~1200)

Heating Power Input(Min~Max) W 720(200~1550) 740(200~1550)

Cooling Current Input A 3.2 3.1

Heating Current Input A 3.2 3.3

Rated Input W 1550 1550

Rated Current A 5.3 5.3

Air Flow Volume(SH/H/HM/M/LM/L/SL) m3/h 500/430/410/370/330/280/250 500/430/410/370/330/280/250

Dehumidifying Volume L/h 0.8 0.8

EER W/W 3.61 3.71

COP W/W 3.82 3.72

SEER W/W 6.1 6.5

HSPF W/W / /

Application Area m

2

12-18 12-18

Indoor

Unit

Indoor Unit Model GEH09AA-K3DNA1B/I GEH09AA-K3DNA1C/I

Indoor Unit Product Code CV010N01200 CV010N02000

Fan Type Centrifugal Centrifugal

Fan Diameter Length(DXL) mm Φ80X370 Φ80X370

Cooling Speed

(SH/H/HM/M/LM/L/SL)

r/min 650/560/530/480/430/370/320 650/560/530/480/430/370/320

Heating Speed

(SH/H/HM/M/LM/L/SL)

r/min 650/560/530/480/430/370/320 650/560/530/480/430/370/320

Fan Motor Power Output W 30 30

Fan Motor RLA A 0.15 0.15

Fan Motor Capacitor μF / /

Evaporator Form Aluminum Fin-copper Tube Aluminum Fin-copper Tube

Evaporator Pipe Diameter mm Φ6.35 Φ7

Evaporator Row-n Gap mm 2-1.2 2-1.3

Evaporator Coil Length (LXDXW) mm 511X24X396 511X25.4X400

Swing Motor Model MP24EB/MP24AE MP24EB/MP24AE

Swing Motor Power Output W 1/1 1.5/1.5

Fuse Current A 3.15 3.15

Sound Pressure Level

(SH/H/HM/M/LM/L/SL)

dB (A) 40/38/36/33/30/26/24 40/38/36/33/30/26/24

Sound Power Level

(SH/H/HM/M/LM/L/SL)

dB (A) 50/48/46/43/40/36/34 50/48/46/43/40/36/34

Dimension (WXHXD) mm 700X600X215 700X600X215

Dimension of Carton Box (LXWXH) mm 785X682X280 785X682X280

Dimension of Package(LXWXH) mm 788X697X283 788X697X283

Net Weight kg 15 15

Gross Weight kg 18 18

3

Technical Information

Service Manual

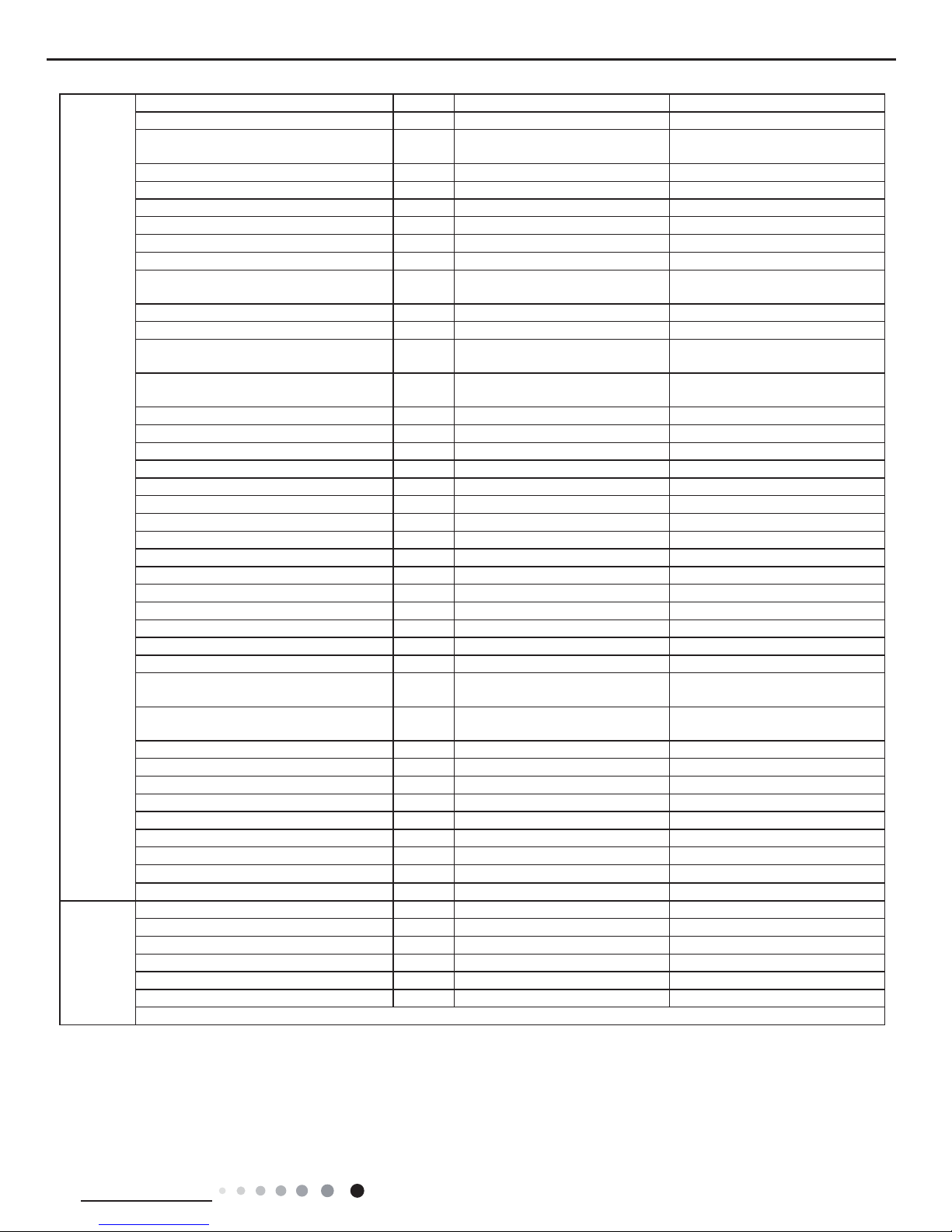

The above data is subject to change without notice. Please refer to the nameplate of the unit.

Outdoor

Unit

Outdoor Unit Model GEH09AA-K3DNA1B/O GEH09AA-K3DNA1C/O

Outdoor Unit Product Code CV010W01200 CV010W02000

Compressor Manufacturer

ZHUHAI LANDA COMPRESSOR

CO.,LTD

ZHUHAI GREE DAIKIN DEVICE

CO.,LTD

Compressor Model QXA-A086zE190A 1GDY23AXD

Compressor Oil FVC 68D or RB 68EP DAPHNE FVC50K

Compressor Type Rotary Rotary

Compressor LRA. A 20 16.5

Compressor RLA A 4.5 4

Compressor Power Input W 780 845

Compressor Overload Protector

1NT11L-6233 or KSD115ºC or

HPC115/95U1

KSD115ºC or HPC115/95

Throttling Method Electron expansion valve Electron expansion valve

Set Temperature Range ºC 16~30 16~30

Cooling Operation Ambient Temperature

Range

ºC 18~43 -15~43

Heating Operation Ambient Temperature

Range

ºC -15~24 -20~24

Condenser Form Aluminum Fin-copper Tube Aluminum Fin-copper Tube

Condenser Pipe Diameter mm Φ7 Φ7

Condenser Rows-n Gap mm 2-1.4 2-1.4

Condenser Coil Length (LXDXW) mm 506X38.1X679 506X38.1X679

Fan Motor Speed rpm 900 900

Fan Motor Power Output W 30 30

Fan Motor RLA A 0.24 0.36

Fan Motor Capacitor μF / /

Outdoor Unit Air Flow Volume m3/h 1600 1600

Fan Type Axial-ow Axial-ow

Fan Diameter mm Φ400 Φ400

Defrosting Method Automatic Defrosting Automatic Defrosting

Climate Type T1 T1

Isolation I I

Moisture Protection IP24 IP24

Permissible Excessive Operating Pressure

for the Discharge Side

MPa 4.3 4.3

Permissible Excessive Operating Pressure

for the Suction Side

MPa 2.5 2.5

Sound Pressure Level (H/M/L) dB (A) 50/-/- 52/-/-

Sound Power Level (H/M/L) dB (A) 61/-/- 62/-/-

Dimension(WXHXD) mm 776X540X320 776X540X320

Dimension of Carton Box (LXWXH) mm 848X360X580 848X360X580

Dimension of Package(LXWXH) mm 851X363X595 851X363X595

Net Weight kg 31 32

Gross Weight kg 33.5 34.5

Refrigerant R410A R410A

Refrigerant Charge kg 0.9 0.9

Connection

Pipe

Connection Pipe Length m 5 5

Connection Pipe Gas Additional Charge g/m 20 20

Outer Diameter Liquid Pipe mm Φ6 Φ6

Outer Diameter Gas Pipe mm Φ9.52 Φ9.52

Max Distance Height m 10 10

Max Distance Length m 15 15

Note: The connection pipe applies metric diameter.

4

Technical Information

Service Manual

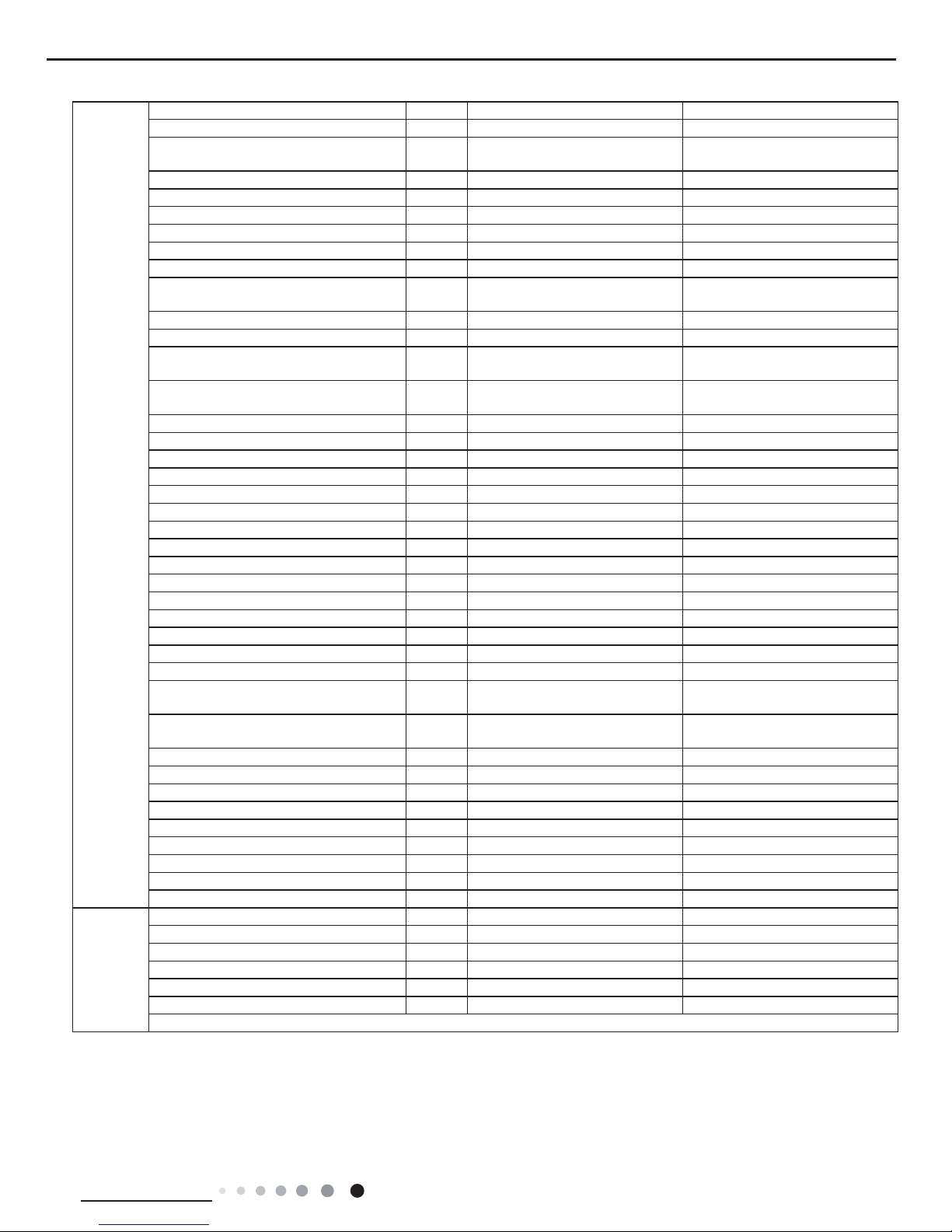

Parameter Unit Value Value

Model GEH12AA-K3DNA1B GEH12AA-K3DNA1C

Product Code CV010001300 CV010001900

Power

Supply

Rated Voltage V

~

220-240 220-240

Rated Frequency Hz 50 50

Phases 1 1

Power Supply Mode Indoor Indoor

Cooling Capacity(Min~Max) W 3500(600~3950) 3500(600~3950)

Heating Capacity(Min~Max) W 3650(600~4700) 3650(600~4700)

Cooling Power Input(Min~Max) W 1100(220~1400) 1100(220~1400)

Heating Power Input(Min~Max) W 1100(220~1580) 1000(220~1580)

Cooling Current Input A 4.9 4.9

Heating Current Input A 4.9 4.4

Rated Input W 1580 1580

Rated Current A 6.2 6.2

Air Flow Volume(SH/H/HM/M/LM/L/SL) m3/h 600/520/480/440/400/360/280 600/520/480/440/400/360/280

Dehumidifying Volume L/h 1.2 1.2

EER W/W 3.18 3.18

COP W/W 3.32 3.65

SEER W/W 6.1 6.3

HSPF W/W / /

Application Area m

2

16-24 16-24

Indoor

Unit

Indoor Unit Model GEH12AA-K3DNA1B/I GEH12AA-K3DNA1C/I

Indoor Unit Product Code CV010N01300 CV010N01900

Fan Type Centrifugal Centrifugal

Fan Diameter Length(DXL) mm Φ80X370 Φ80X370

Cooling Speed

(SH/H/HM/M/LM/L/SL)

r/min 750/650/600/550/500/450/350 750/650/600/550/500/450/350

Heating Speed

(SH/H/HM/M/LM/L/SL)

r/min 750/650/600/550/500/450/350 750/650/600/550/500/450/350

Fan Motor Power Output W 30 30

Fan Motor RLA A 0.15 0.15

Fan Motor Capacitor μF / /

Evaporator Form Aluminum Fin-copper Tube Aluminum Fin-copper Tube

Evaporator Pipe Diameter mm Φ6.35 Φ7

Evaporator Row-n Gap mm 2-1.2 2-1.3

Evaporator Coil Length (LXDXW) mm 511X24X396 511X25.4X400

Swing Motor Model MP24EB/MP24AE MP24EB/MP24AE

Swing Motor Power Output W 1/1 1.5/1.5

Fuse Current A 3.15 3.15

Sound Pressure Level

(SH/H/HM/M/LM/L/SL)

dB (A) 42/40/38/37/35/32/26 42/40/38/37/35/32/26

Sound Power Level

(SH/H/HM/M/LM/L/SL)

dB (A) 52/50/48/47/45/42/36 52/50/48/47/45/42/36

Dimension (WXHXD) mm 700X600X215 700X600X215

Dimension of Carton Box (LXWXH) mm 785X682X280 785X682X280

Dimension of Package(LXWXH) mm 788X697X283 788X697X283

Net Weight kg 15 15

Gross Weight kg 18 18

5

Technical Information

Service Manual

The above data is subject to change without notice. Please refer to the nameplate of the unit.

Outdoor

Unit

Outdoor Unit Model GEH12AA-K3DNA1B/O GEH12AA-K3DNA1C/O

Outdoor Unit Product Code CV010W01300 CV010W01900

Compressor Manufacturer

ZHUHAI LANDA COMPRESSOR

CO.,LTD

ZHUHAI GREE DAIKIN DEVICE

CO.,LTD

Compressor Model QXA-A091zE190A 1GDY23AXD

Compressor Oil FVC 68D or RB 68EP DAPHNE FVC50K

Compressor Type Rotary Rotary

Compressor LRA. A 20 16.5

Compressor RLA A 4.5 4

Compressor Power Input W 780 845

Compressor Overload Protector

1NT11L-6233 or KSD115ºC or

HPC115/95U1

KSD115ºC or HPC115/95

Throttling Method Electron expansion valve Electron expansion valve

Set Temperature Range ºC 16~30 16~30

Cooling Operation Ambient Temperature

Range

ºC 18~43 -15~43

Heating Operation Ambient Temperature

Range

ºC -15~24 -20~24

Condenser Form Aluminum Fin-copper Tube Aluminum Fin-copper Tube

Condenser Pipe Diameter mm Φ9.52 Φ9.52

Condenser Rows-n Gap mm 2-1.4 2-1.4

Condenser Coil Length (LXDXW) mm 512X44X741 512X44X741

Fan Motor Speed rpm 900 900

Fan Motor Power Output W 30 30

Fan Motor RLA A 0.24 0.36

Fan Motor Capacitor μF / /

Outdoor Unit Air Flow Volume m3/h 1800 1800

Fan Type Axial-ow Axial-ow

Fan Diameter mm Φ400 Φ400

Defrosting Method Automatic Defrosting Automatic Defrosting

Climate Type T1 T1

Isolation I I

Moisture Protection IP24 IP24

Permissible Excessive Operating Pressure

for the Discharge Side

MPa 4.3 4.3

Permissible Excessive Operating Pressure

for the Suction Side

MPa 2.5 2.5

Sound Pressure Level (H/M/L) dB (A) 54/-/- 54/-/-

Sound Power Level (H/M/L) dB (A) 63/-/- 63/-/-

Dimension(WXHXD) mm 848X540X320 848X540X320

Dimension of Carton Box (LXWXH) mm 878X360X580 878X360X580

Dimension of Package(LXWXH) mm 881X363X595 881X363X595

Net Weight kg 33 34

Gross Weight kg 35.5 36.5

Refrigerant R410A R410A

Refrigerant Charge kg 1.15 1.15

Connection

Pipe

Connection Pipe Length m 5 5

Connection Pipe Gas Additional Charge g/m 20 20

Outer Diameter Liquid Pipe mm Φ6 Φ6

Outer Diameter Gas Pipe mm Φ9.52 Φ9.52

Max Distance Height m 10 10

Max Distance Length m 20 20

Note: The connection pipe applies metric diameter.

6

Technical Information

Service Manual

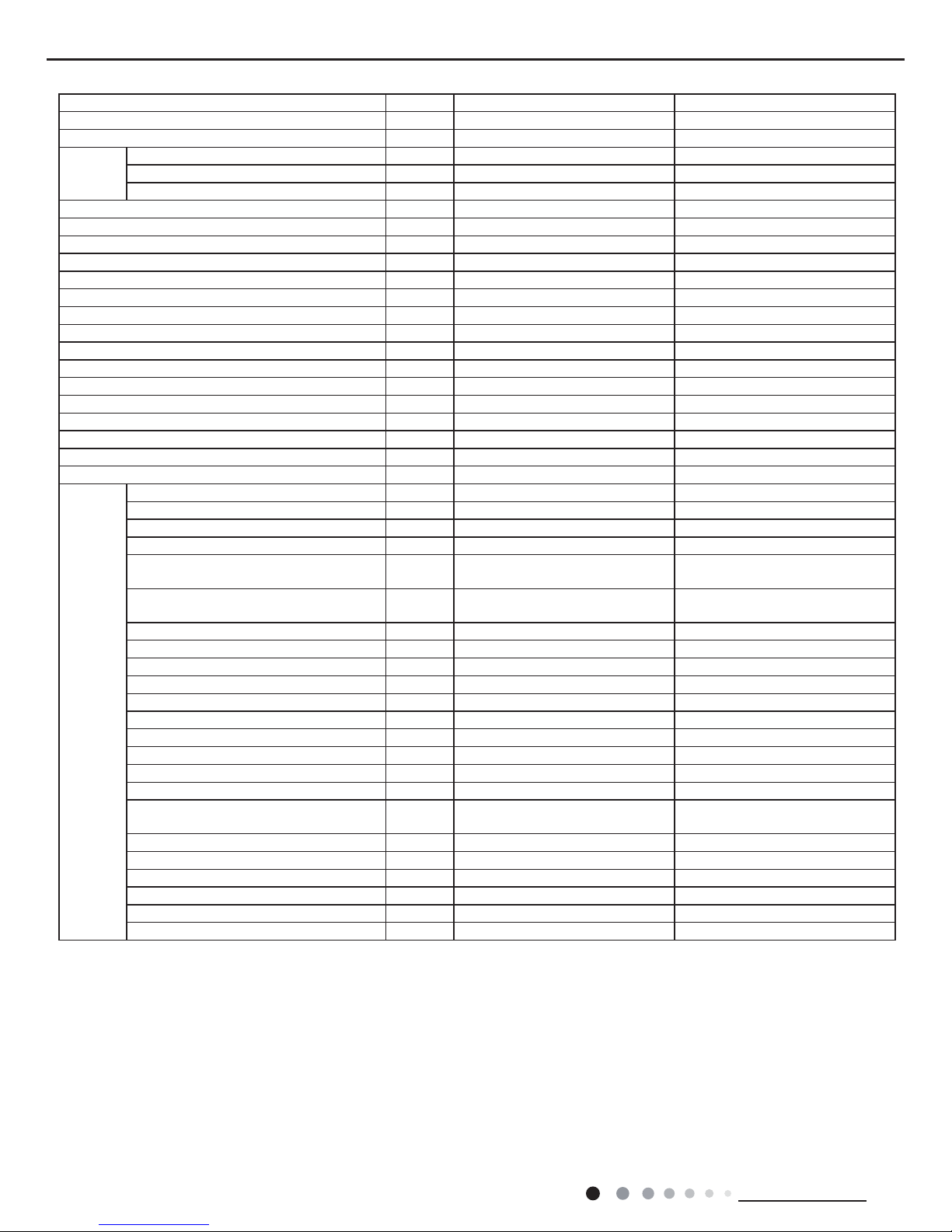

Parameter Unit Value Value

Model GEH18AA-K3DNA1B GEH18AA-K3DNA1C

Product Code CV010001400 CV010001800

Power

Supply

Rated Voltage V

~

220-240 220-240

Rated Frequency Hz 50 50

Phases 1 1

Power Supply Mode Indoor Indoor

Cooling Capacity(Min~Max) W 5200(1260~6600) 5200(1260~6600)

Heating Capacity(Min~Max) W 5500(1120~6800) 5500(1120~6800)

Cooling Power Input(Min~Max) W 1760(380~2450) 1650(380~2450)

Heating Power Input(Min~Max) W 1600(350~2500) 1550(350~2500)

Cooling Current Input A 7.8 7.3

Heating Current Input A 7.1 6.9

Rated Input W 2500 2500

Rated Current A 10.9 10.9

Air Flow Volume(SH/H/HM/M/LM/L/SL) m3/h 650/620/550/500/450/410/320 700/650/580/520/460/410/320

Dehumidifying Volume L/h 1.8 1.8

EER W/W 2.95 3.15

COP W/W 3.44 3.55

SEER W/W 5.6 5.8

HSPF W/W / /

Application Area m

2

23-34 23-34

Indoor

Unit

Indoor Unit Model GEH18AA-K3DNA1B/I GEH18AA-K3DNA1C/I

Indoor Unit Product Code CV010N01400 CV010N01800

Fan Type Centrifugal Centrifugal

Fan Diameter Length(DXL) mm Φ80X370 Φ80X370

Cooling Speed

(SH/H/HM/M/LM/L/SL)

r/min 840/800/720/650/580/530/410 840/800/720/650/580/530/410

Heating Speed

(SH/H/HM/M/LM/L/SL)

r/min 930/840/760/690/620/570/450 930/840/760/690/620/570/450

Fan Motor Power Output W 30 30

Fan Motor RLA A 0.15 0.15

Fan Motor Capacitor μF / /

Evaporator Form Aluminum Fin-copper Tube Aluminum Fin-copper Tube

Evaporator Pipe Diameter mm Φ6.35 Φ7

Evaporator Row-n Gap mm 2-1.2 2-1.3

Evaporator Coil Length (LXDXW) mm 511X24X396 511X25.4X400

Swing Motor Model MP24EB/MP24AE MP24EB/MP24AE

Swing Motor Power Output W 1.5/1.5 1.5/1.5

Fuse Current A 3.15 3.15

Sound Pressure Level

(SH/H/HM/M/LM/L/SL)

dB (A) 48/46/44/41/38/36/32 48/46/44/41/38/36/32

Sound Power Level(SH/H/HM/M/LM/L/SL) dB (A) 58/56/54/51/48/46/42 58/56/54/51/48/46/42

Dimension (WXHXD) mm 700X215X600 700X215X600

Dimension of Carton Box (LXWXH) mm 785X280X682 785X280X682

Dimension of Package(LXWXH) mm 788X283X697 788X283X697

Net Weight kg 15 15

Gross Weight kg 18 18

7

Technical Information

Service Manual

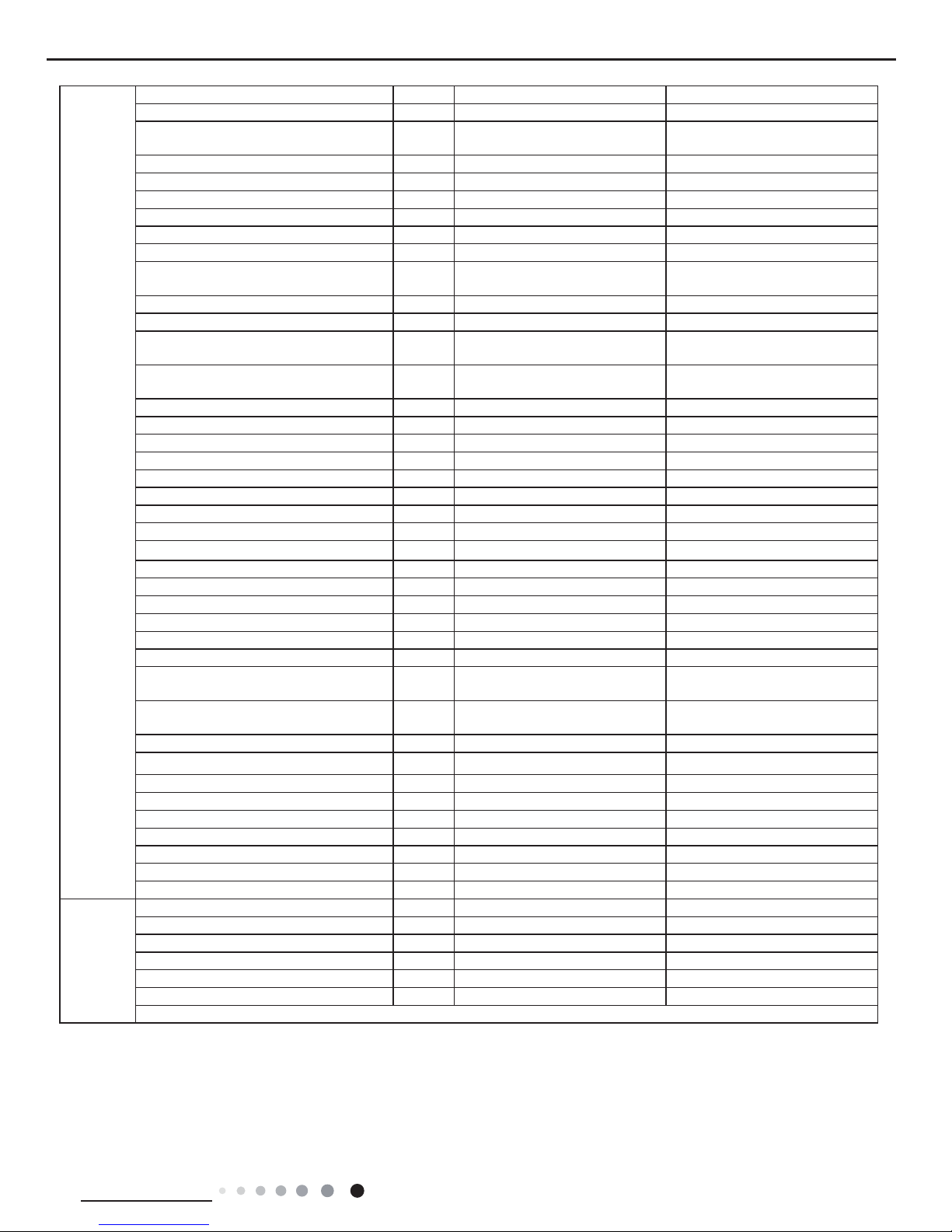

Outdoor

Unit

Outdoor Unit Model GEH18AA-K3DNA1B/O GEH18AA-K3DNA1C/O

Outdoor Unit Product Code CV010W01400 CV010W01800

Compressor Manufacturer

ZHUHAI LANDA COMPRESSOR

CO.,LTD

ZHUHAI LANDA COMPRESSOR

CO.,LTD

Compressor Model QXA-B141zF030A QXA-B141zF030

Compressor Oil 68EP 68EP

Compressor Type Rotary Rotary

Compressor LRA. A 25 18

Compressor RLA A 7.2 7.2

Compressor Power Input W 1440 1440

Compressor Overload Protector

1NT11L-6233 or KSD115ºC or

HPC115/95U1

1N T11L-6 233 o r KSD 115 ºC or

HPC115/95U1

Throttling Method Electron expansion valve Electron expansion valve

Set Temperature Range ºC 16~30 16~30

Cooling Operation Ambient Temperature

Range

ºC 18~43 -15~43

Heating Operation Ambient Temperature

Range

ºC -15~24 -20~24

Condenser Form Aluminum Fin-copper Tube Aluminum Fin-copper Tube

Condenser Pipe Diameter mm Φ7 Φ7

Condenser Rows-n Gap mm 2-1.4 2-1.4

Condenser Coil Length (LXDXW) mm 851X38.1X660 851X38.1X660

Fan Motor Speed rpm 800 800

Fan Motor Power Output W 60 60

Fan Motor RLA A 0.28 0.39

Fan Motor Capacitor μF / /

Outdoor Unit Air Flow Volume m3/h 3200 3200

Fan Type Axial-ow Axial-ow

Fan Diameter mm Φ520 Φ520

Defrosting Method Automatic Defrosting Automatic Defrosting

Climate Type T1 T1

Isolation I I

Moisture Protection IP24 IP24

Permissible Excessive Operating Pressure

for the Discharge Side

MPa 4.3 4.3

Permissible Excessive Operating Pressure

for the Suction Side

MPa 2.5 2.5

Sound Pressure Level (H/M/L) dB (A) 56/-/- 55/-/-

Sound Power Level (H/M/L) dB (A) 63/-/- 65/-/-

Dimension(WXHXD) mm 963X700X396 963X700X396

Dimension of Carton Box (LXWXH) mm 1026X455X735 1026X455X735

Dimension of Package(LXWXH) mm 1029X458X750 1029X458X750

Net Weight kg 46 45

Gross Weight kg 51 49.5

Refrigerant R410A R410A

Refrigerant Charge kg 1.3 1.3

Connection

Pipe

Connection Pipe Length m 5 5

Connection Pipe Gas Additional Charge g/m 20 20

Outer Diameter Liquid Pipe mm Φ6 Φ6

Outer Diameter Gas Pipe mm Φ12 Φ12

Max Distance Height m 10 10

Max Distance Length m 25 25

Note: The connection pipe applies metric diameter.

The above data is subject to change without notice. Please refer to the nameplate of the unit.

8

Technical Information

Service Manual

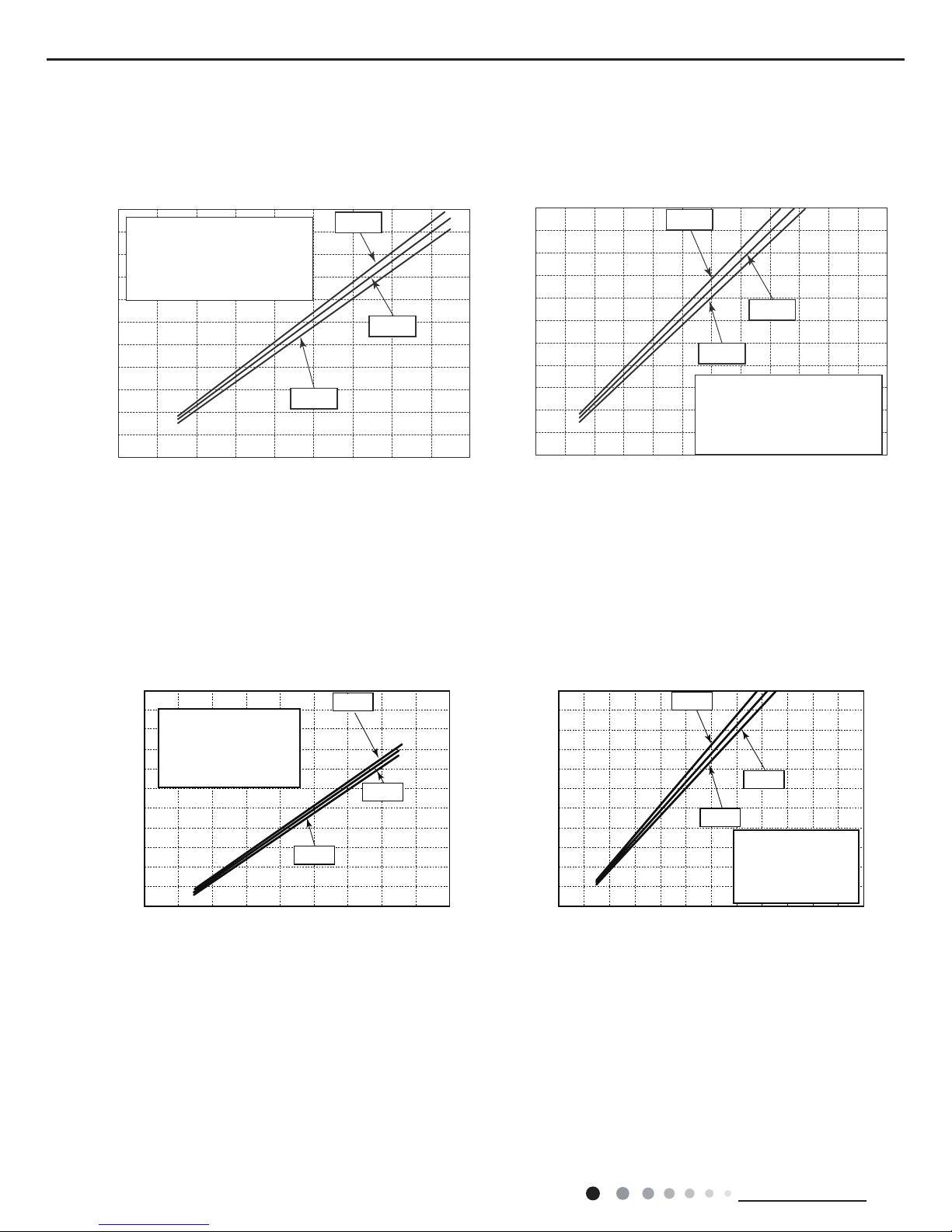

2.2 Operation Characteristic Curve

Cooling

Cooling

09K 12K

18K

Heating

Heating

0

09070605040302010

11 0210010908070605040302010

80

11

10

9

8

7

6

5

4

3

2

1

0

11

10

9

8

7

6

5

4

3

2

1

0

• Conditions

Indoor : DB27˚C/WB19˚C

Outdoor : DB35˚C/WB24˚C

Indoor air flow : High

Pipe length : 5m

• Conditions

Indoor : DB20˚C/WB15˚C

Outdoor : DB7˚C/WB6˚C

Indoor air flow : High

Pipe length : 5m

220V

230V

240V

220V

230V

240V

Current (A)

Current (A)

Compressor frequency(Hz)

Compressor frequency(Hz)

Cooling Heating

0 10 20 30 40 50 60 70 90 0 10 20 30 40 50 60 70 80 90 100 120 110

80

11

10

9

8

7

6

5

4

3

2

1

0

Compressor speed (rps)

) A ( t n e r r u C

11

10

9

8

7

6

5

4

3

2

1

0

Compressor speed (rps)

) A ( t n e r r u C

220V

230V

240V

220V

230V

240V

• Conditions

Indoor: DB27°C/WB19°C

Outdoor: DB35°C/WB24°C

Indoor air flow: High

Pipe length: 5m

• Conditions

Indoor: DB20°C/WB15°C

Outdoor: DB7°C/WB6°C

Indoor air flow: High

Pipe length: 5m

9

Technical Information

Service Manual

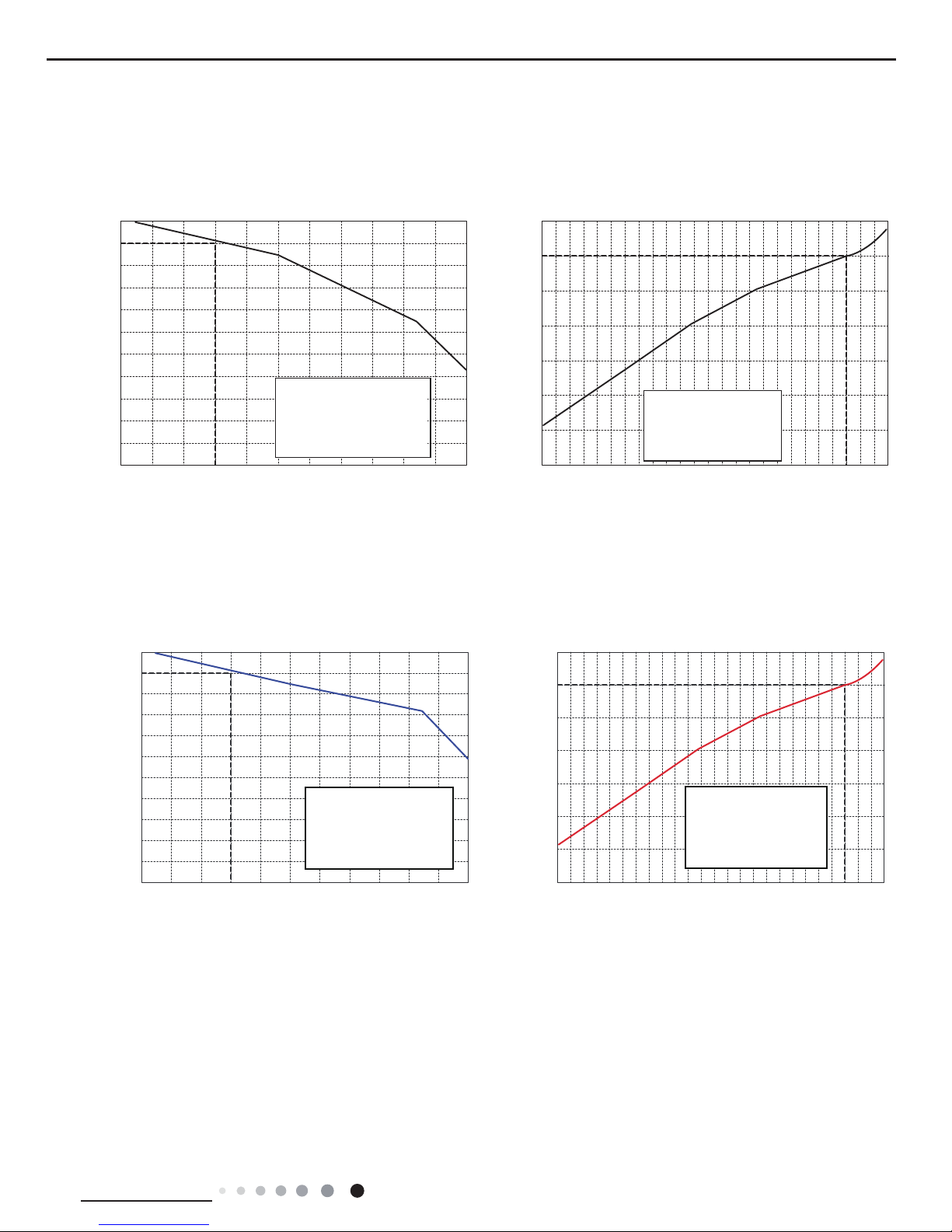

2.3 Capacity Variation Ratio According to Temperature

09K 12K

18K

Cooling

Cooling

Heating

Heating

32 33 34 35 36 37 38 39 43 –15 –10 –5 0 5 7 10

40 41 42

100

105

95

90

85

80

75

70

65

60

55

50

Outdoor temp. (˚C)

110

100

90

80

70

60

50

40

Outdoor temp. (˚C)

Capacity ratio (%)

Capacity ratio (%)

• Conditions

Indoor: DB27°C/WB19°C

Outdoor: DB35°C/WB24°C

Indoor air flow: High

Pipe length: 5m

• Conditions

Indoor: DB20°C/WB15°C

Outdoor: DB7°C/WB6°C

Indoor air flow: High

Pipe length: 5m

100

105

95

90

85

80

75

70

65

60

55

50

Outdoor temp. (˚C)

)%( oitar yticapaC

110

100

90

80

70

60

50

40

Outdoor temp. (˚C)

)%( oitar yticapaC

32

33 34 35 36 37 38 39 40 41 42 43

Cooling Heating

-15 -10 -5 0 5 7 10

• Conditions

Indoor: DB27°C/WB19°C

Outdoor: DB35°C/WB24°C

Indoor air flow: High

Pipe length: 5m

• Conditions

Indoor: DB20°C/WB15°C

Outdoor: DB7°C/WB6°C

Indoor air flow: High

Pipe length: 5m

10

Technical Information

Service Manual

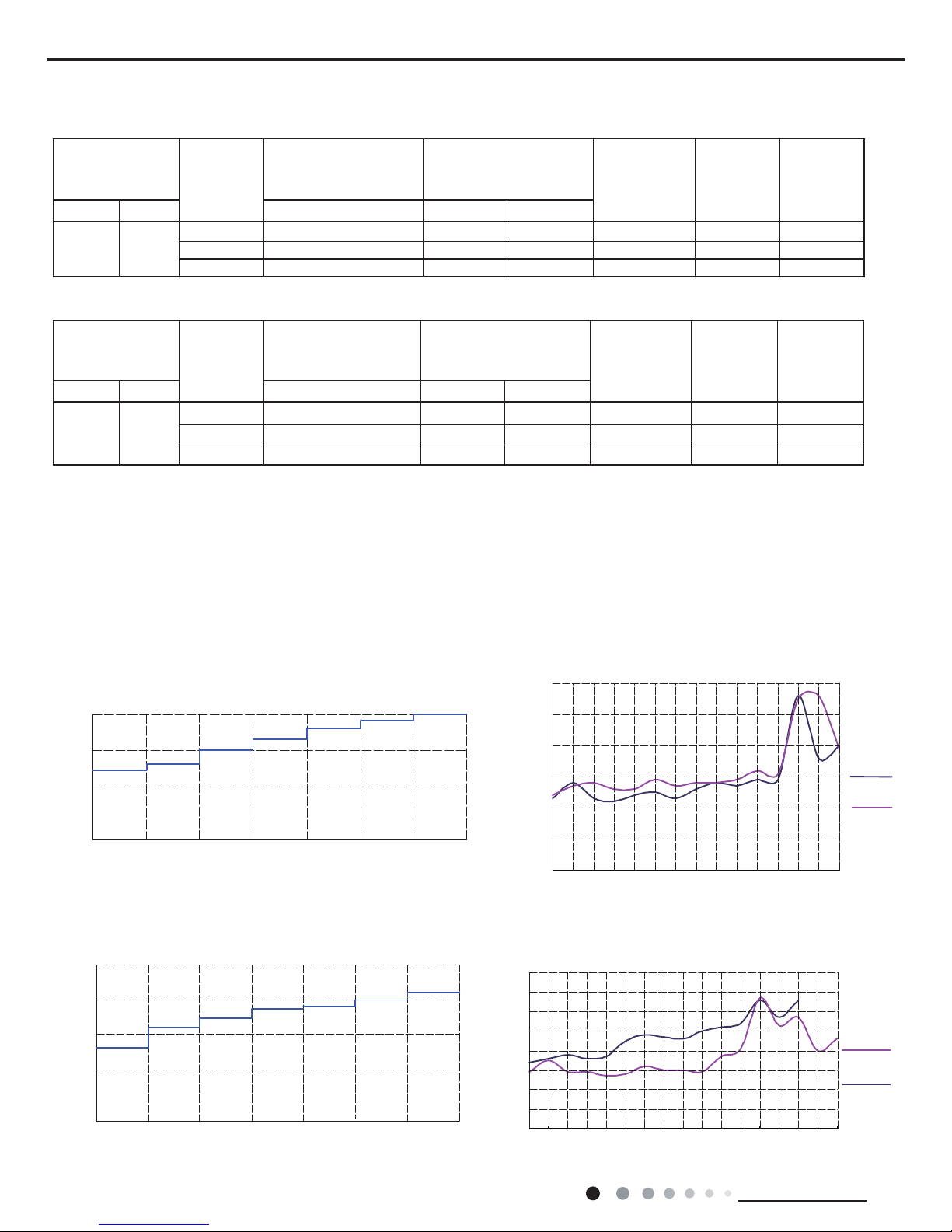

2.4 Cooling and Heating Data Sheet in Rated Frequency

Rated cooling

condition(°C)

(DB/WB)

Model

Pressure of gas pipe

connecting indoor and

outdoor unit

Inlet and outlet pipe

temperature of heat

exchanger

Fan speed of

indoor unit

Fan speed of

outdoor unit

Compressor

frequency

(Hz)

Indoor Outdoor P (MPa) T1 (°C) T2 (°C)

27/19 35/24

09K 0.9 to 1.1 12 to 14 70 to 40 Super High High 52

12K 0.9 to 1.1 12 to 14 70 to 40 Super High High 72

18K 0.9 to 1.1 12 to 14 80 to 40 Super High High 70

Rated heating

condition(°C)

(DB/WB)

Model

Pressure of gas pipe

connecting indoor and

outdoor unit

Inlet and outlet pipe

temperature of heat

exchanger

Fan speed of

indoor unit

Fan speed of

outdoor unit

Compressor

frequency

(Hz)

Indoor Outdoor P (MPa) T1 (°C) T2 (°C)

20/- 7/6

09K 2.2 to 2.4 70 to 35 2 to 4 Super High High 65

12K 2.2 to 2.4 70 to 35 2 to 4 Super High High 77

18K 2.2 to 2.4 70 to 40 1 to 5 Super High High 70

Instruction:

T1: Inlet and outlet pipe temperature of evaporator

T2: Inlet and outlet pipe temperature of condenser

P: Pressure at the side of big valve

Connection pipe length: 5 m.

Cooling:

Heating:

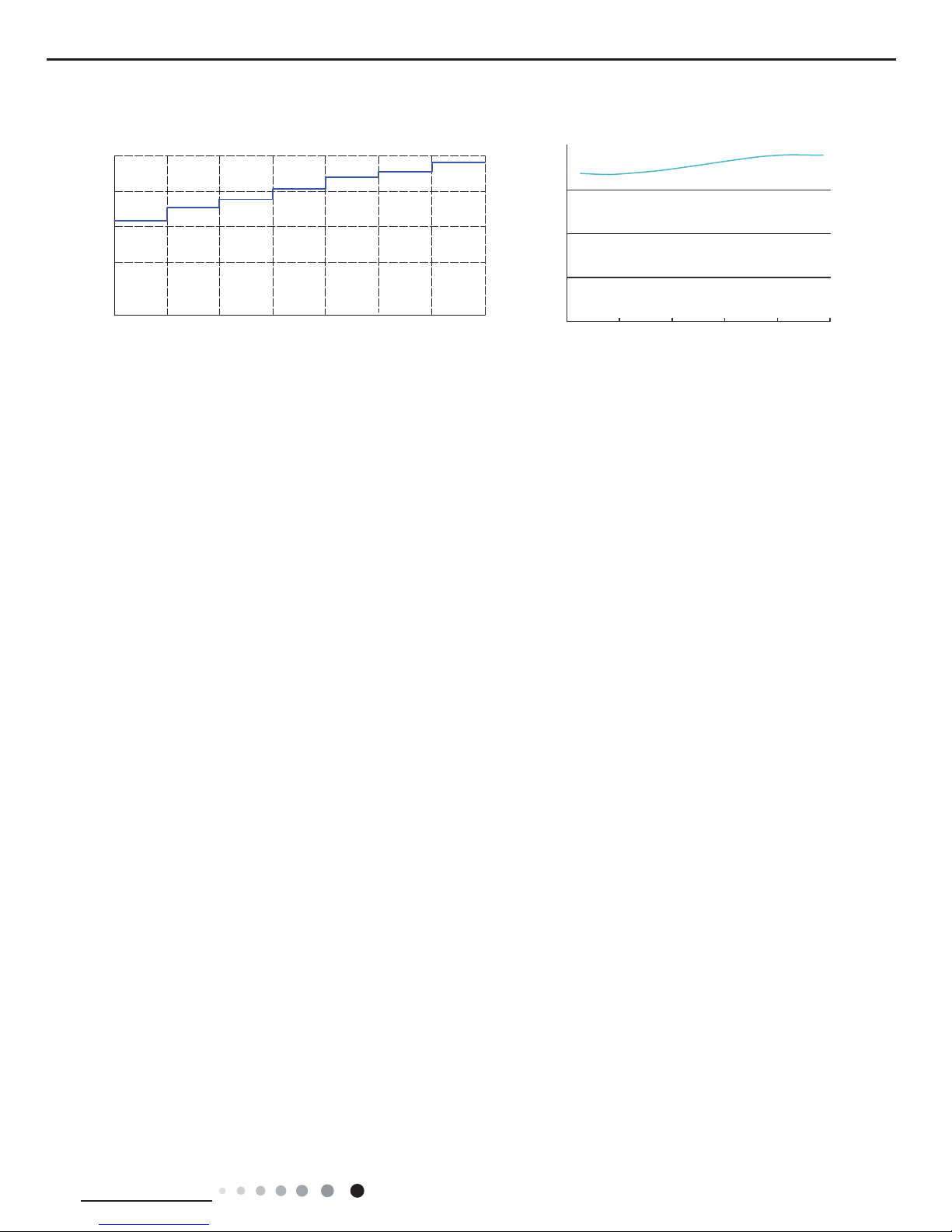

2.5 Noise Curve

20

30

40

Indoor side noise when blowing

Outdoor side noise when blowing

Indoor fan motor rotating speed

SH H HM M LM L SL

46

47

48

49

50

51

52

15 20 25 30 35 40 45 50 55 60 65 70 75 80 85

Noise dB(A)

Cooling

Heating

09K

12K

45

46

47

48

49

50

51

52

53

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17

Compressor frequency(Hz)

Noise dB(A)

Cooling

Heating

Indoor side noise when blowing Outdoor side noise when blowing

Indoor fan motor rotating speed

SLLLMMHMHSH

20

30

40

50

11

Technical Information

Service Manual

18K

Compressor frequency(Hz)

Indoor side noise when blowing Outdoor side noise when blowing

Indoor fan motor rotating speed

SLLLMMHMHSH

20

30

40

50

20

30

40

50

60

200 40 60 80 100

)A(Bd/esioN

12

Technical Information

Service Manual

3. Outline Dimension Diagram

3.1 Indoor Unit

700

215

600

398

205

22

Unit:mm

13

Technical Information

Service Manual

3.2 Outdoor Unit

762

848

257

320

540

286

540

712

766

257

320

540

286

510

09K

12K

Unit:mm

14

Technical Information

Service Manual

18K

963

892

700

396

341

368

560

15

Technical Information

Service Manual

Indoor unit

Outdoor unit

COOLING

HEATING

4-Way valve

Discharge

Suction

Heat

exchanger

(evaporator)

Heat

exchanger

(condenser)

Valve

Valve

Liquid pipe

side

Gas pipe

side

Strainer

Electron

expansion

valve

Strainer

4. Refrigerant System Diagram

Connection pipe specication:

Liquid pipe:1/4" (6mm)

Gas pipe:3/8" (9.52mm)(09K/12K)

Gas pipe:1/2" (16mm)(18K)

16

Technical Information

Service Manual

5. Electrical Part

5.1 Wiring Diagram

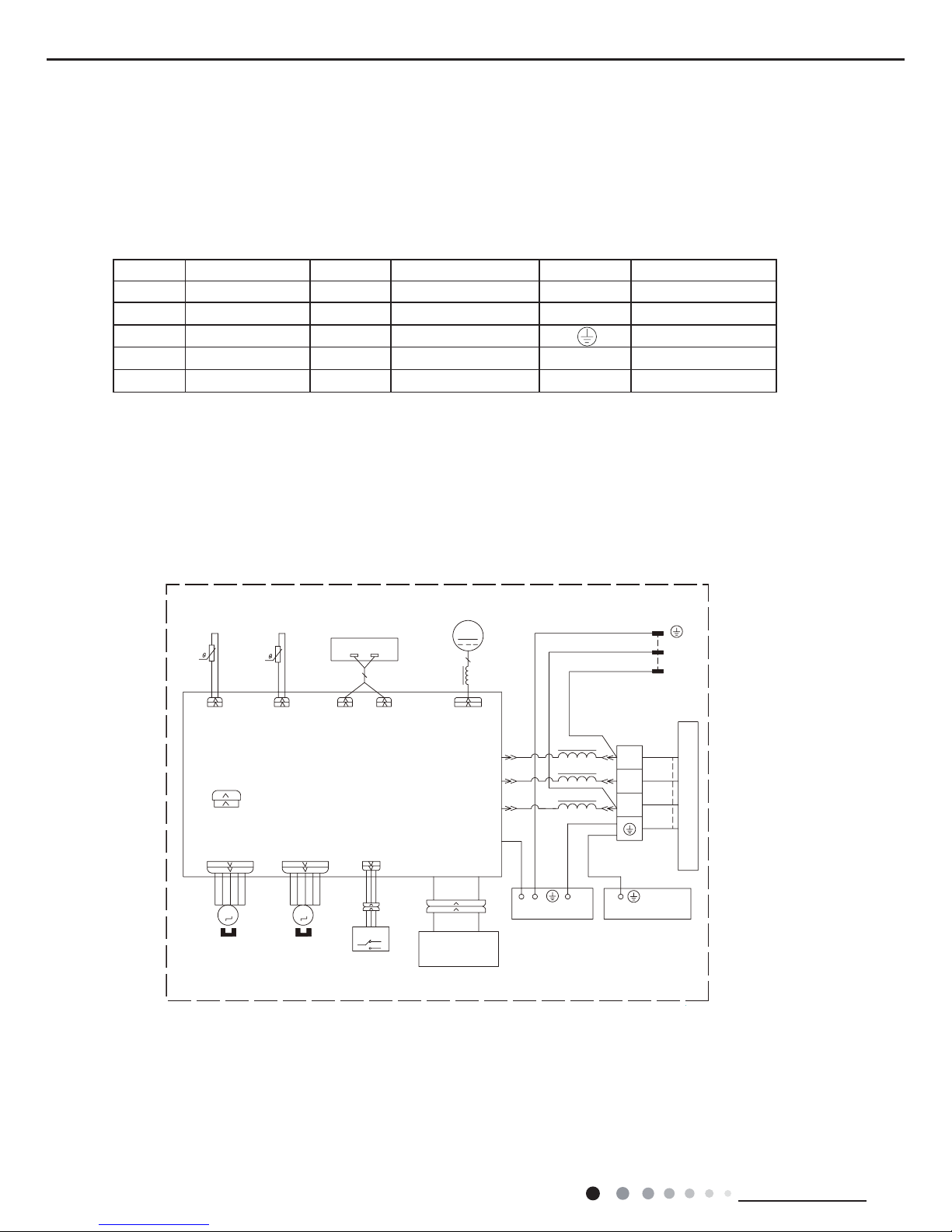

● Indoor Unit

● Instruction

Symbol Symbol Color Symbol Symbol Color Symbol Name

WH White GN Green CAP Jumper cap

YE Yellow BN Brown COMP Compressor

RD Red BU Blue Grounding wire

YEGN Yellow/Green BK Black / /

VT Violet OG Orange / /

Note: Jumper cap is used to determine fan speed and the swing angle of horizontal lover for this model.

/

/

6:,7&+

<(*1

%.

%8

0

6:,1*'2:1

287'22581,7

&$3

-803

$335,17('&,5&8,7%2$5'

5220

57

57

78%(

6(1625 6(1625

52207(03

78%(7(03

32:(5

%8:+

/

1

1

',63/$<

5(&(,9(5$1'

',63/$<%2$5'

',63

$3

',63

0

)$1

'&02725

02725

67(33,1*

6:,1*83

0

$3

6

&1

6(/(&7

02725

67(33,1*

02725

%1%.

<(*1*1

1

;7

%1

&20287

$&/

%8

%.

%1

3(

(9$325$725

<(*1

7(50,1$/

%/2&.

/

(

(/(&75,&%2;

3(

<(*1

<(*1

/

0$*1(7,&

5,1*

&2/'3/$60$

*(1(5$725

+($/7+1

+($/7+/

; ;

5' %8

5' %8

17

Technical Information

Service Manual

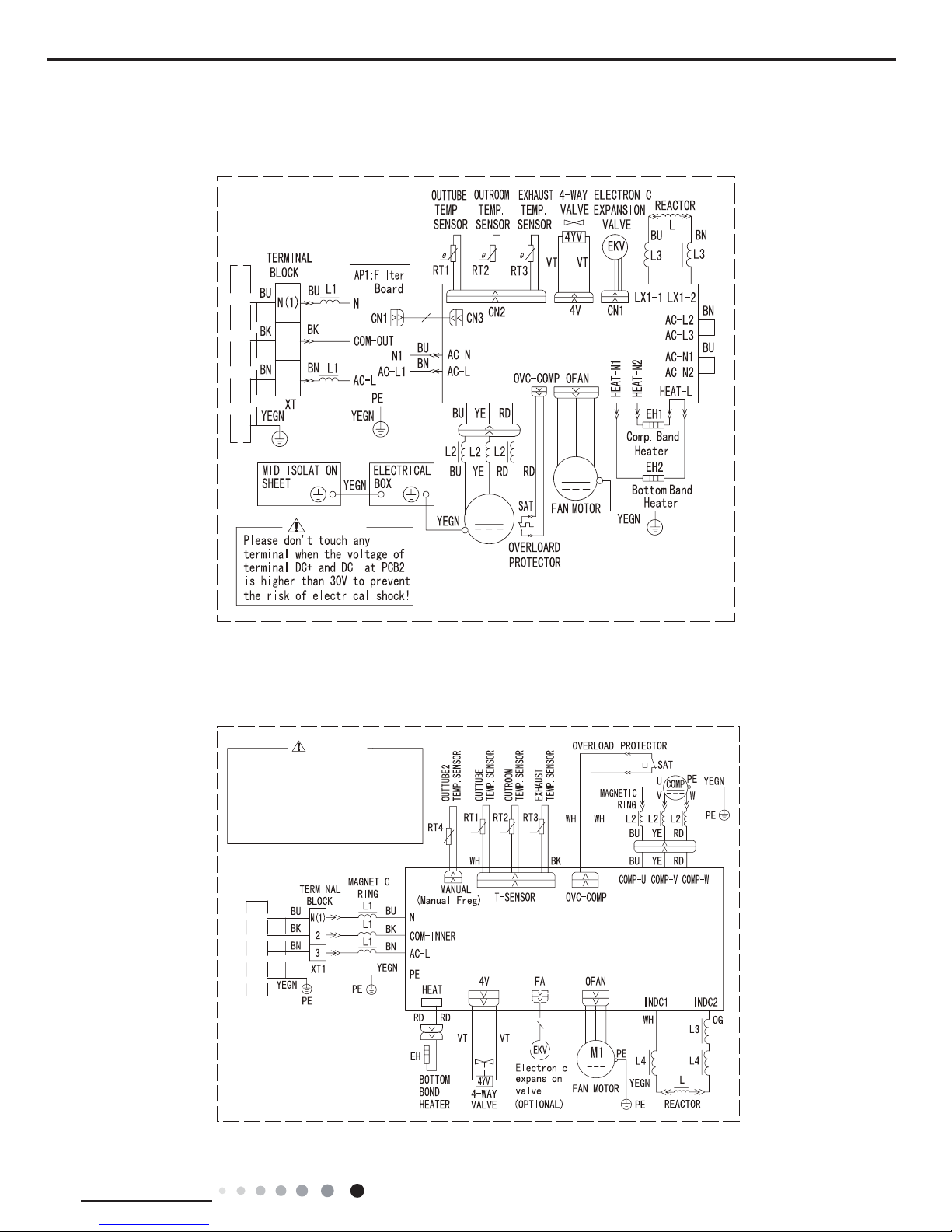

● Outdoor Unit

3(

,1'22581,7

:$51,1*

8

9

:

&203

&203

8

9

:

3(

3(

3(

3(

$30DLQ%RDUG

3(

3(

0

GEH18AA-K3DNA1B/O

$3

&203

;

,1'22581,7

3OHDVHGRQWWRXFKDQ\

HOHFWURQLFFRPSRQHQWRU

WHUPLQDOZKHQWKHPDFKLQHLV

UXQQLQJVWRSSLQJRUKDV

EHHQSRZHUHGRIIIRUOHVV

WKDQPLQXWHVWRSUHYHQW

WKHULVNRIHOHFWULFVKRFN

:$51,1*

©

©

©

©

GEH09AA-K3DNA1B/O GEH12AA-K3DNA1B/O

18

Technical Information

Service Manual

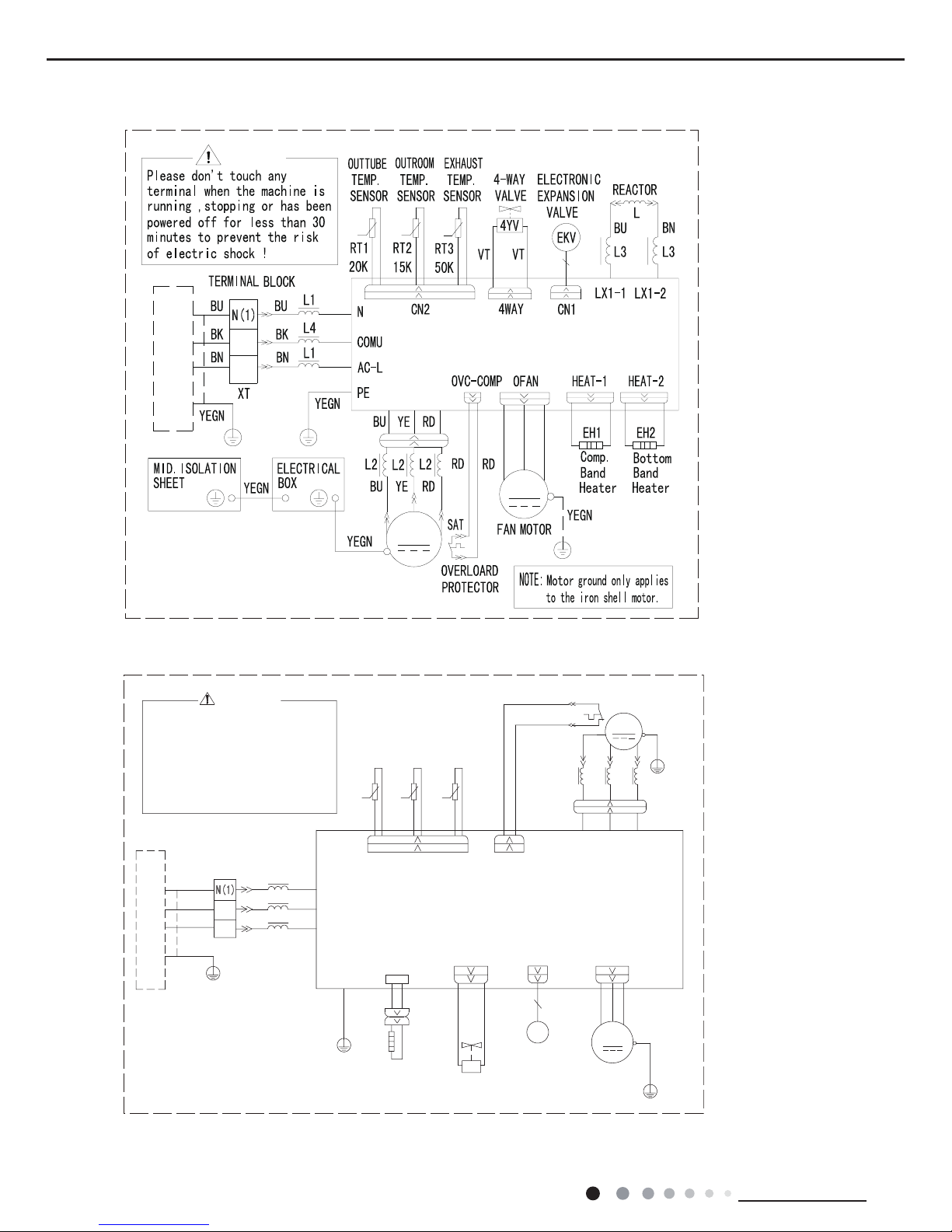

These circuit diagrams are subject to change without notice, please refer to the one supplied with the unit.

%1

%.

%8

YDOYH

H[SDQVLRQ

<(*1

(OHFWURQLF

)$

(.9

<(*1

$3

%/2&.

7(50,1$/

)$1027253(<(*1

7(036(1625

(;+$867

7(036(1625

2875220

28778%(

7(036(1625

%.:+

%8 <(

&203

;

&203

6$7

:+ :+

29&B&203

2)$1

3(

5'

0

575757

&20B,11(5

3(

3(

:98

5'%8 <(

1

$&B/

<(*1

7B6(1625

%8

%1

%.

;7

3(

,1'22581,7

29(5/2$' 3527(&725

/

/

0$*1(7,&

5,1*

0$*1(7,&

5,1*

/

/

//

:$<

<9

:$<

9$/9(

97 97

3(

3(

+($7B%

5'5'

%$1'

+($7(5

%27720

(+

3OHDVHGRQWWRXFKDQ\

WHUPLQDOZKHQWKHYROWDJH

RIWHUPLQDO3'&DQG

1'&DW$3LVKLJKHU

WKDQ9WRSUHYHQWWKH

ULVNRIHOHFWULFVKRFN

:$51,1*

0$,1%2$5'

. . .

:5'9<(8%8

GEH18AA-K3DNA1C/O

GEH09AA-K3DNA1C/O GEH12AA-K3DNA1C/O

,1'22581,7

8

9

:

&203

&203

8

9

:

3(

3(

3(

3(

$30DLQ%RDUG

3(

3(

0

3(

:$51,1*

19

Technical Information

Service Manual

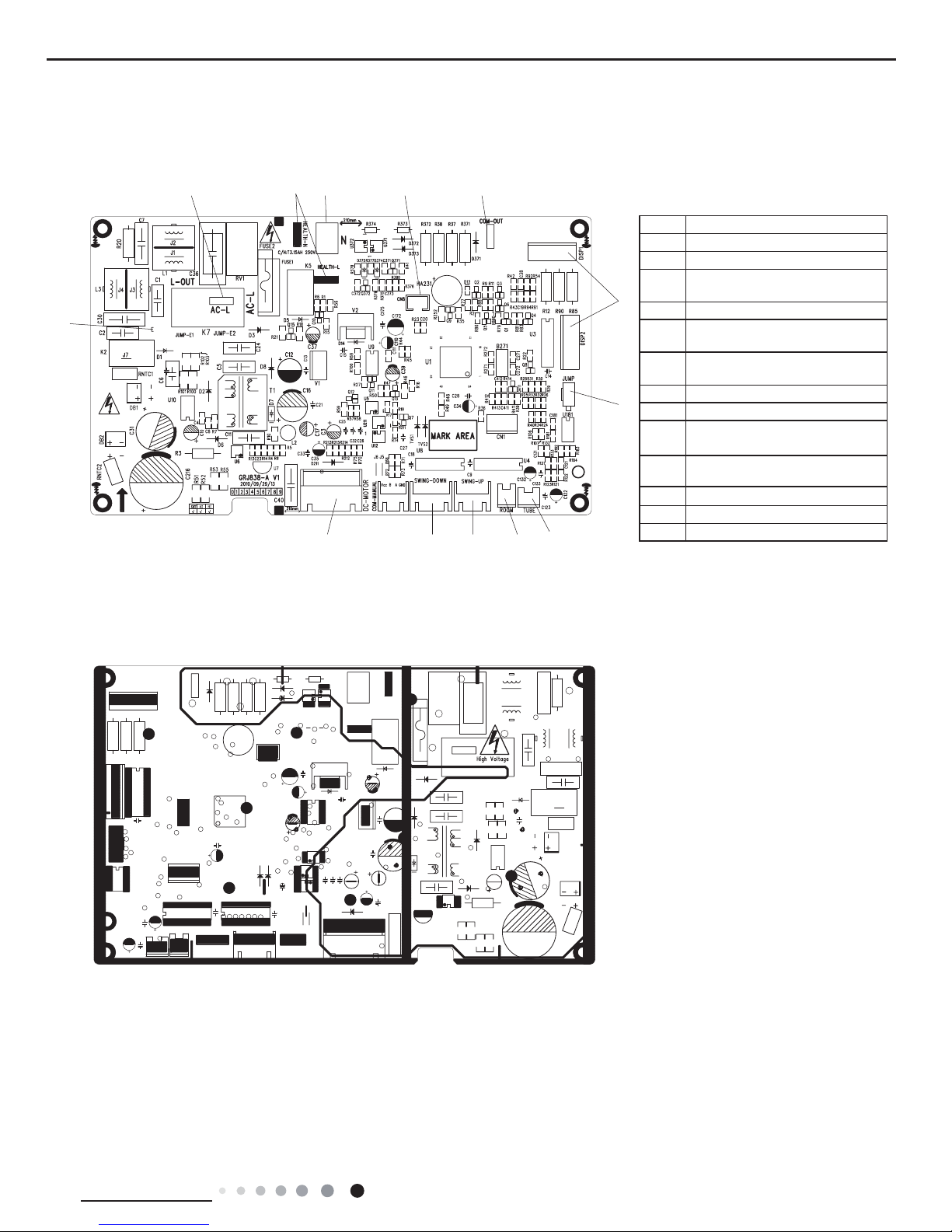

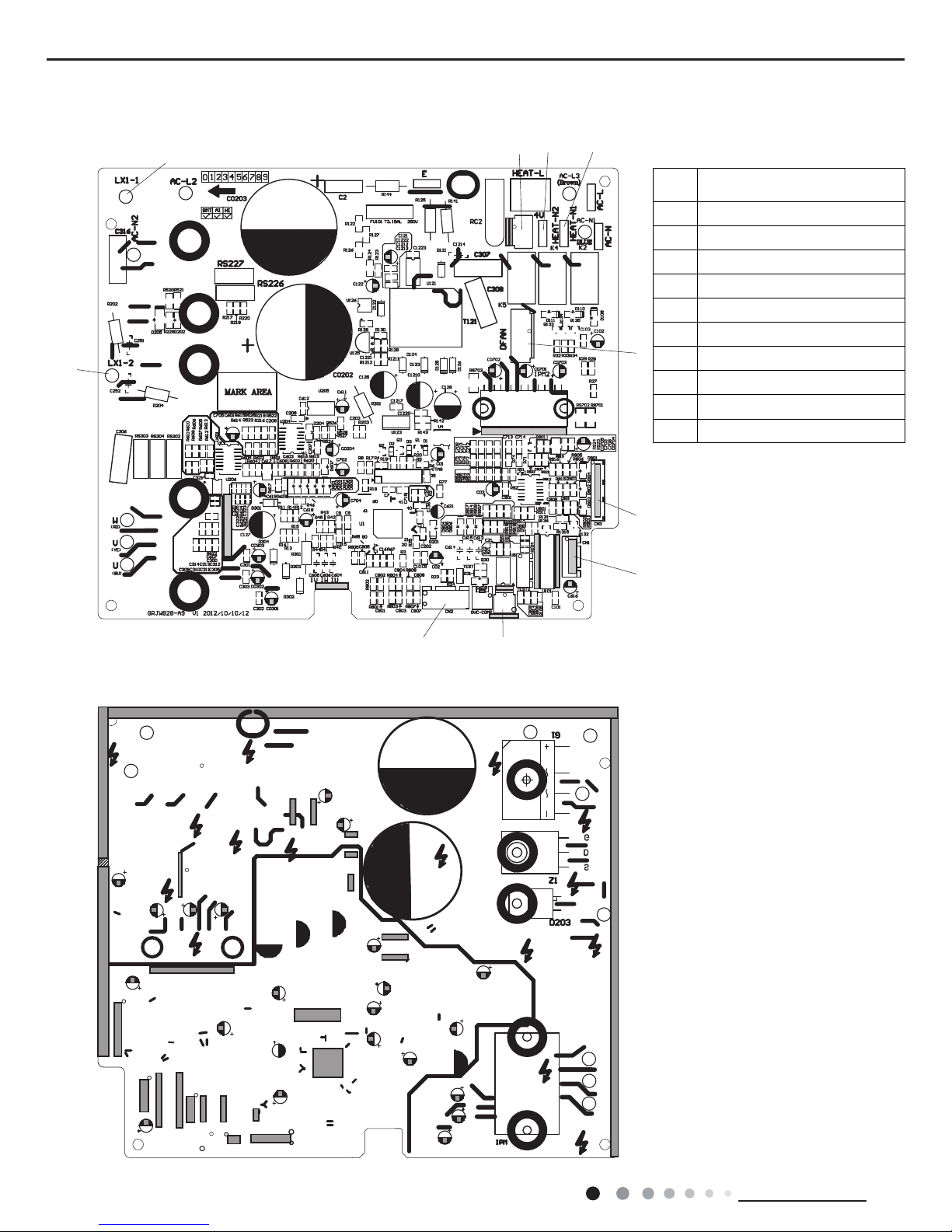

5.2 PCB Printed Diagram

Indoor Unit

● Top view

● Bottom view

No. Name

1 Connect earthing wire

2 Input of live wire

3

Wiring terminal for health

function (optional)

4 Input of neutral wire

5

Control the wiring terminal of

down swing

6

Communication interface for

indoor unit and outdoor unit

7 Terminal of display interface

8 Needle stand of jumper cap

9

Wiring terminal of indoor tube

temperature sensor

10

Wiring terminal of indoor

ambient temperature sensor

11

Wiring terminal of up swing

12 Wiring terminal of down swing

13 Wiring terminal of DC motor

1

2

3

4

5

6

7

8

9

10

1112

13

20

Technical Information

Service Manual

1

2 3 4

5

6

7

8

9

10

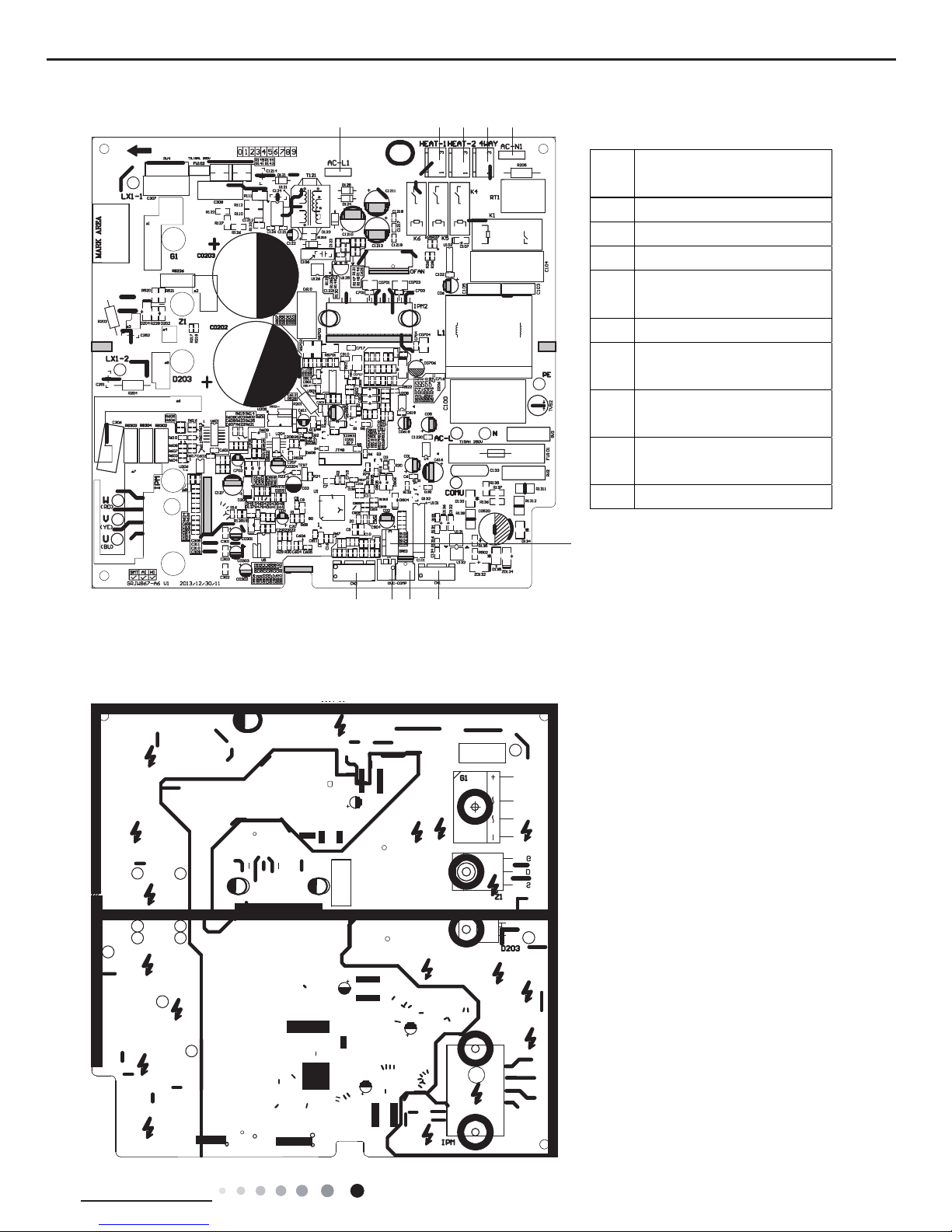

● Top view

Outdoor Unit

● Bottom view

GEH09AA-K3DNA1B/O GEH12AA-K3DNA1B/O

No.

Name

1 Leading foot 1 of induction

2 4-way valve

3 Electric heating of compressor

4 Electric heating of chassis

5 Fan

6 10-core communication wire

7 Electronic expansion valve

8 Overload protection

9 Temperature sensor

10 Leading foot 2 of induction

21

Technical Information

Service Manual

1 2 3 4 5

6

78910

● Top view

● Bottom view

GEH09AA-K3DNA1C/O GEH12AA-K3DNA1C/O

1

Live wire input of Dred

communication plate

2 Heating belt 1

3 Heating belt 2

4 4-way valve

5

Neutral wire input of Dred

communication plate

6 Dred function terminal

7

Electronic expansion valve

terminal

8

Overload terminal of

compressor

9

Overload terminal of

compressor

10 Temperature sensor terminal

22

Technical Information

Service Manual

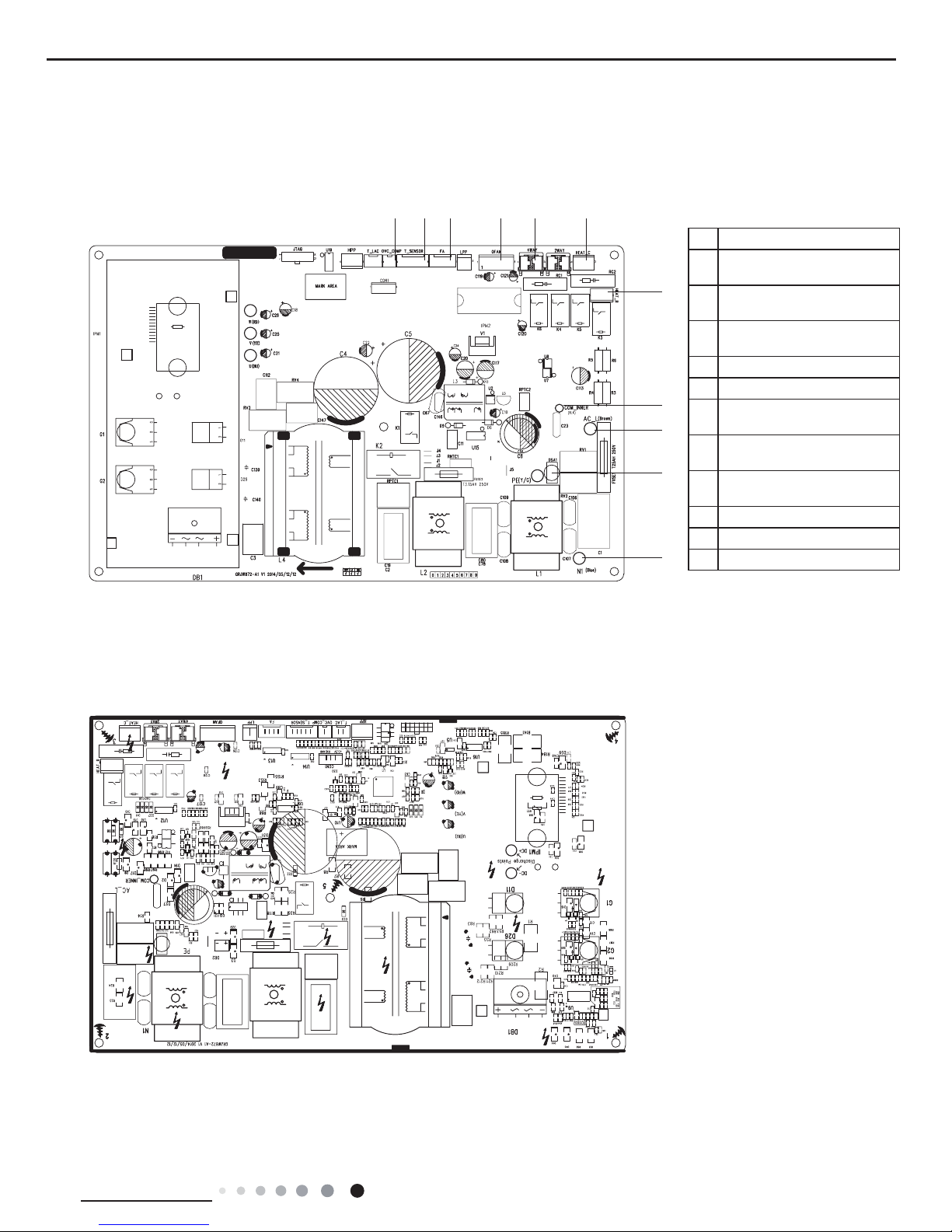

1

12

2 3

4 5

6

7

8

9

10

11

● Bottom view

No. Name

1

Wiring terminal of

compressor

2

Overload protection

terminal of compressor

3

Terminal of outdoor

temperature sensor

4

Terminal of electronic

expansion valve

5 Terminal of outdoor fan

6 Terminal of 4-way valve

7

Wiring terminal of

chassis electric heater

8

Communication wire

with IDU

5 Terminal of outdoor fan

6 Terminal of 4-way valve

7

Wiring terminal of

chassis electric heater

8

Communication wire

with IDU

9

Live wire of power

supply

10 Grounding wire

11

Neutral wire of power

supply

12 PFC induction wire

● Top view

GEH18AA-K3DNA1B/O

23

Technical Information

Service Manual

No. Name

1

Terminal of compressor

overload protection

2

Terminal of temperature

sensor

3

Terminal of electronic

expansion valve

4

Terminal of outdoor fan

5

Terminal of 4-way valve

6

Terminal of

compressorelectric heating

7

Terminal of chassis electric

heating

8

Terminal of indoor unit and

outdoor unit communication

9

Power supply live wire

10

Earthing wire

11

Power supply neutral wire

1 2 3 4 5 6

7

8

9

10

11

● Bottom view

● Top view

GEH18AA-K3DNA1C/O

Loading...

Loading...