Gree GEH12AA-K6DNA1A/O, GEH12AA-K6DNA1A, GEH18AA-K6DNA1F/O, GEH18AA-K6DNA1F, GEH09AA-K6DNA1F/I Service Manual

...

Change for life

Service Manual

GREE ELECTRIC APPLIANCES, INC. OF ZHUHAI

Table of Contents

Service Manual

Part

1. Summary

2. Specications

2.1 Specication Sheet ...........................................................................................................3

2.2 Operation Characteristic Curve ........................................................................................7

2.3 Capacity Variation Ratio According to Temperature .........................................................7

2.4 Noise Curve ......................................................................................................................8

3. Outline Dimension Diagram

3.1 Indoor Unit ........................................................................................................................9

3.2 Outdoor Unit ...................................................................................................................10

: Technical Information

Ⅰ

......................................................................................................................1

..........................................................................................................3

.........................................................................................9

4. Refrigerant System Diagram

5. Electrical Part

5.1 Wiring Diagram ...............................................................................................................13

5.2 PCB Printed Diagram .....................................................................................................17

6. Function and Control

.........................................................................................................13

......................................................................................20

.......................................................................1

....................................................................12

6.1 Remote Controller Introduction .....................................................................................20

6.2 GREE+ App Operation Manual ......................................................................................24

6.3 Ewpe Smart App Operation Manual ...............................................................................25

6.4 Brief Description of Modes and Functions ......................................................................26

Part

: Installation and Maintenance

Ⅱ

7. Notes for Installation and Maintenance

8. Installation

8.1 Requirements for Electric Connection ............................................................................32

8.2 Installation of indoor unit ................................................................................................32

8.3 Outdoor Unit Installation .................................................................................................38

8.4 Vacuum Pumping and Leak Detection ...........................................................................39

8.5 Check after Installation and Test Operation ...................................................................39

9. Maintenance

9.1 Error Code List ...............................................................................................................40

................................................................................................................32

............................................................................................................40

.................................................28

..........................................28

9.2 Procedure of Troubleshooting ........................................................................................47

9.3 Maintenance Method for Normal Malfunction .................................................................60

Table of Contents

Service Manual

10. Exploded View and Parts List

10.1 Indoor Unit ....................................................................................................................62

10.2 Outdoor Unit .................................................................................................................65

11. Removal Procedure

11.1 Removal Procedure of Indoor Unit ...............................................................................71

11.2 Removal Procedure of Outdoor Unit ............................................................................75

Appendix:

Appendix 1: Reference Sheet of Celsius and Fahrenheit ....................................................90

Appendix 2: Conguration of Connection Pipe .....................................................................90

Appendix 3: Pipe Expanding Method ...................................................................................91

Appendix 4: List of Resistance for Temperature Sensor ......................................................92

........................................................................................................................90

.......................................................................................71

..............................................................62

Service Manual

Part

Ⅰ

: Technical Information

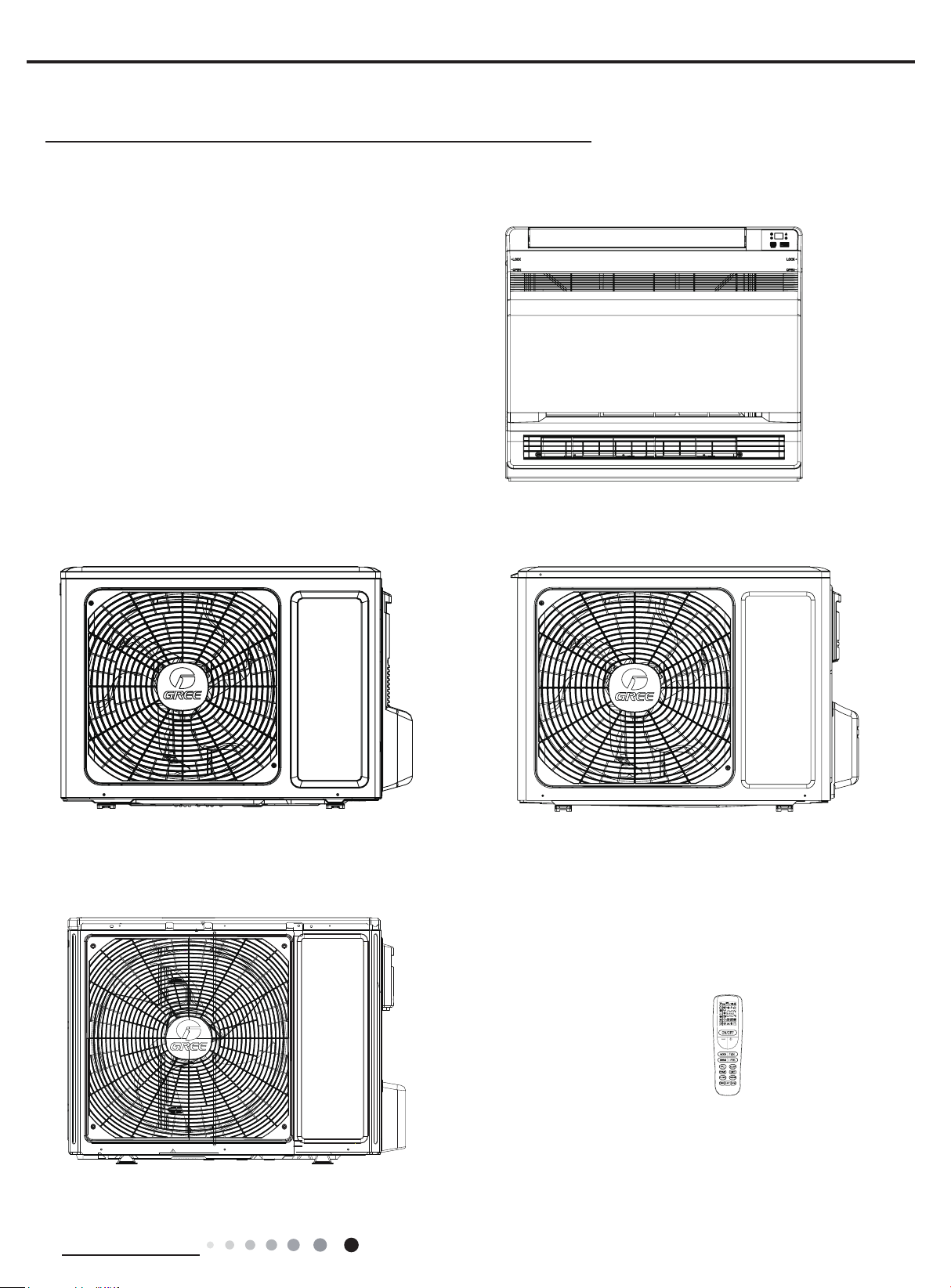

1. Summary

Indoor Unit

GEH12AA-K6DNA1A/I

GEH09AA-K6DNA1F/I

GEH18AA-K6DNA1F/I

Outdoor Unit

GEH09AA-K6DNA1F/O

GEH12AA-K6DNA1A/O

GEH18AA-K6DNA1F/O

Technical Information

Remote Controller

YAA1FB8(WiFi)

1

Model List:

Service Manual

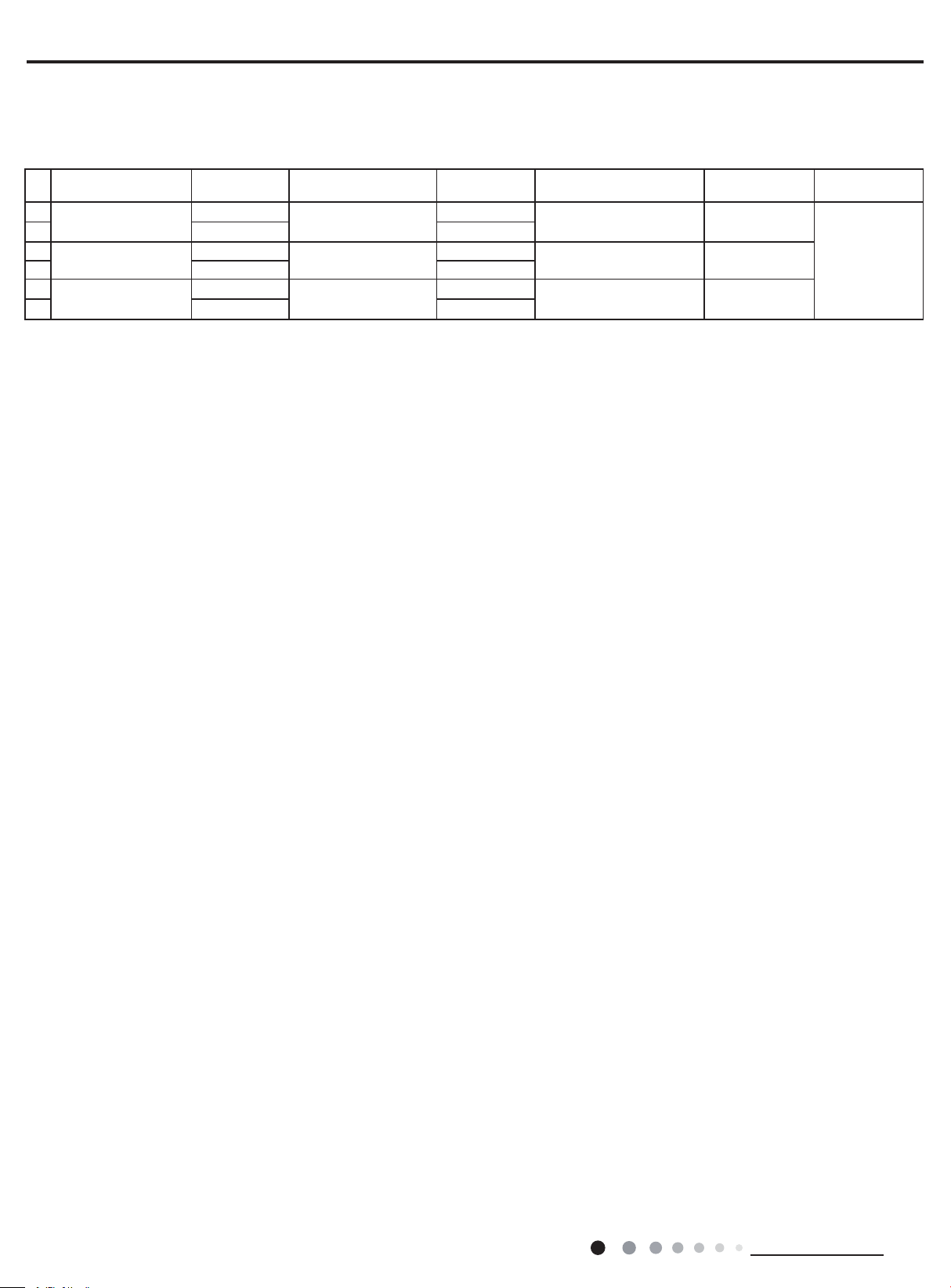

No Model Product code Indoor model

1

GEH09AA-K6DNA1F

2 CV010002701 CV010N02701

3

GEH12AA-K6DNA1A

4 CV010002901 CV010N02901

5

GEH18AA-K6DNA1F

6 CV010002801 CV010N02801

CV010002700

CV010002900

CV010002800

GEH09AA-K6DNA1F/I

GEH12AA-K6DNA1A/I

GEH18AA-K6DNA1F/I

Indoor product

code

CV010N02700

CV010N02900

CV010N02800

Outdoor model

GEH09AA-K6DNA1F/O CV010W02700

GEH12AA-K6DNA1A/O CV010W02900

GEH18AA-K6DNA1F/O CV010W02800

Outdoor product

code

Remote

Controller

YAA1FB8(WiFi)

2

Technical Information

Service Manual

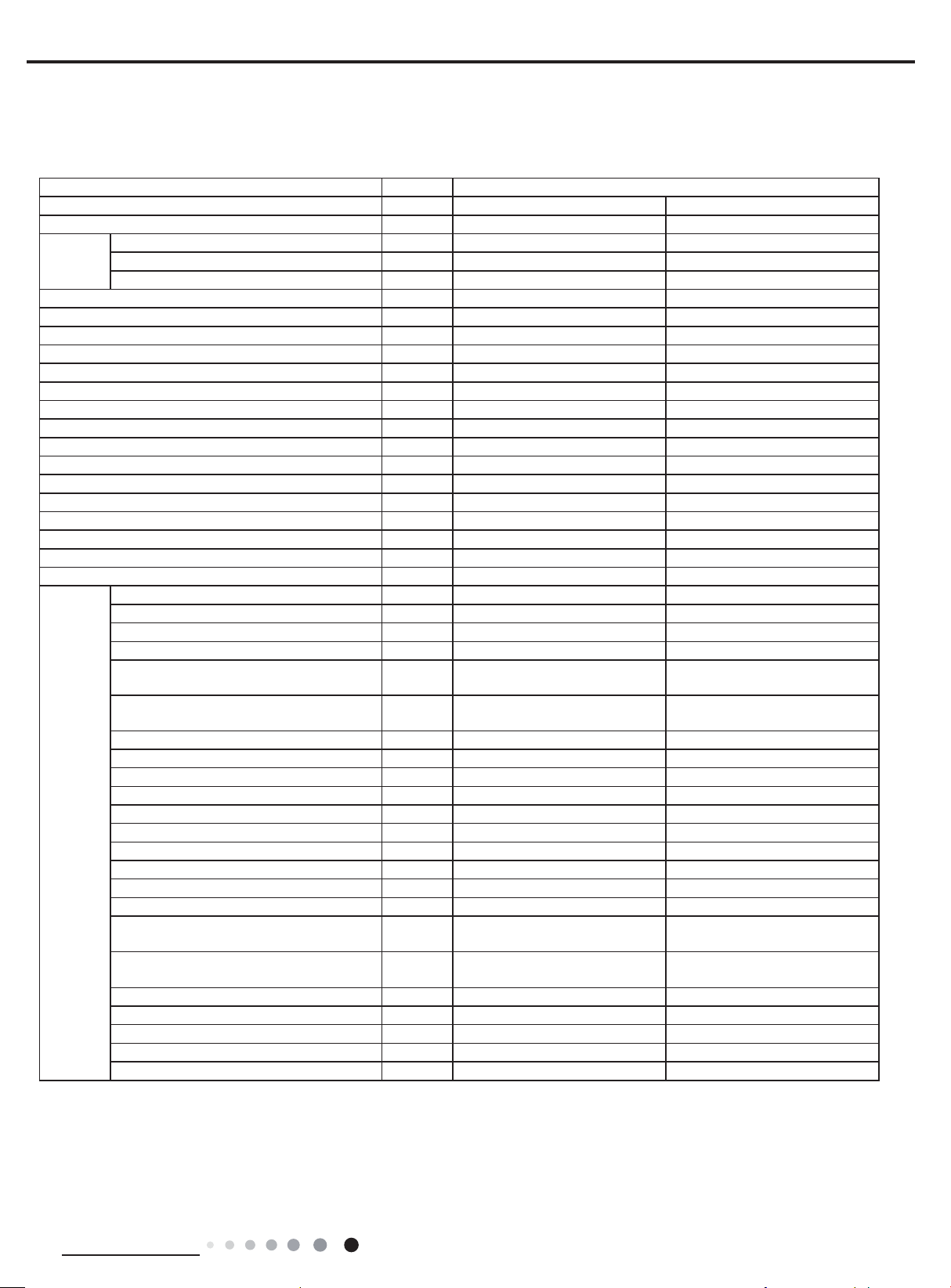

2. Specications

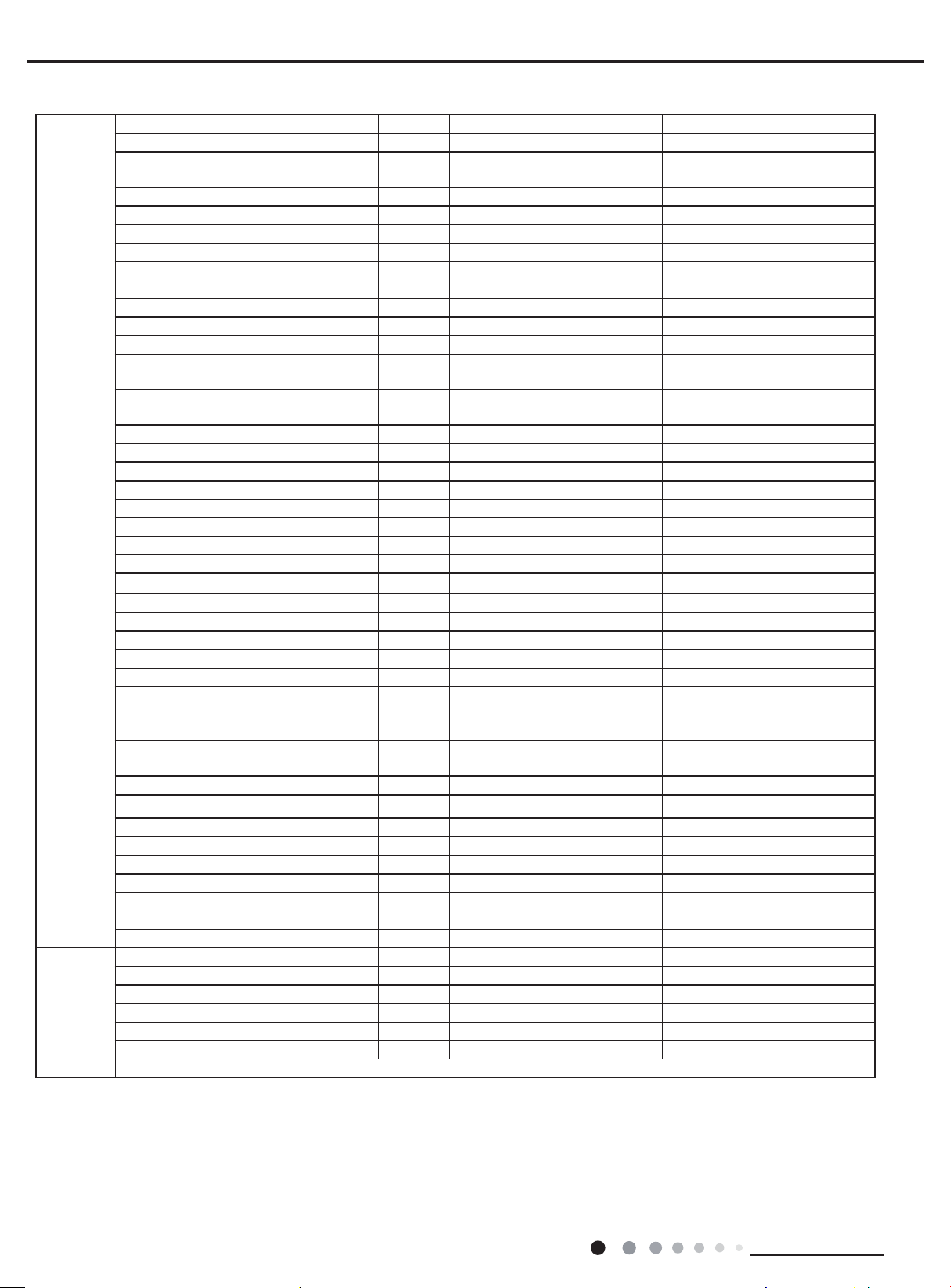

2.1 Specication Sheet

Parameter Unit Value

Model GEH12AA-K6DNA1A GEH09AA-K6DNA1F

Product Code CV010002900/CV010002901 CV010002700/CV010002701

Power

Supply

Power Supply Mode Outdoor Outdoor

Cooling Capacity(Min~Max) W 3520(800~4400) 2700(700~3400)

Heating Capacity(Min~Max) W 3800(1100~4400) 2900(600~3500)

Cooling Power Input(Min~Max) W 1000(160~1500) 720(170~1300)

Heating Power Input(Min~Max) W 960(165~1500) 730(130~1350)

Cooling Current Input A 4.48 3.5

Heating Current Input A 4.30 3.6

Rated Input W 1500 1350

Rated Current A 6.72 6.0

Air Flow Volume(SH/H/HM/M/LM/L/SL) m3/h 600/520/480/440/400/360/280 500/430/410/370/330/280/250

Dehumidifying Volume L/h 1.2 0.8

EER W/W 3.52 3.75

COP W/W 3.96 3.97

SEER W/W 7.0 7.2

SCOP(Average/Warmer/Colder) W/W 4.1/5.3/- 4.0/5.3/Application Area m

Indoor

Unit

Rated Voltage V

Rated Frequency Hz 50 50

Phases 1 1

Indoor Unit Model GEH12AA-K6DNA1A/I GEH09AA-K6DNA1F/I

Indoor Unit Product Code CV010N02900/CV010N02901 CV010N02700/CV010N02701

Fan Type Centrifugal Centrifugal

Fan Diameter Length(DXL) mm Φ370X80 Φ370X80

Cooling Speed

(SH/H/HM/M/LM/L/SL)

Heating Speed

(SH/H/HM/M/LM/L/SL)

Fan Motor Power Output W 30 30

Fan Motor RLA A 0.15 0.15

Fan Motor Capacitor μF / /

Evaporator Form Aluminum Fin-copper Tube Aluminum Fin-copper Tube

Evaporator Pipe Diameter mm Φ7 Φ7

Evaporator Row-n Gap mm 2-1.3 2-1.3

Evaporator Coil Length (LXDXW) mm 511X400X25.4 511X400X25.4

Swing Motor Model MP24EB/MP24AE MP24EB/MP24AE

Swing Motor Power Output W 1.5/1.5 1.5/1.5

Fuse Current A 3.15 3.15

Sound Pressure Level

(SS/H/MH/M/ML/L/SL)

Sound Power Level

(SS/H/MH/M/ML/L/SL)

Dimension (WXHXD) mm 700X215X600 700X215X600

Dimension of Carton Box (LXWXH) mm 785X280X682 785X280X682

Dimension of Package(LXWXH) mm 788X295X685 788X295X685

Net Weight kg 15.5 15.5

Gross Weight kg 18.5 18.5

~

2

r/min 750/650/600/550/500/450/350 650/560/530/480/430 /370/320

r/min 750/650/600/550/500/450/350 650/560/530/480/430/370/320

dB (A)

dB (A)

Cooling:44/40/38/36/33/29/25

Heating:44/40/38/36/33/29/25

Cooling:54/50/48/46/43/39/35

Heating:54/50/48/46/43/39/35

220-240 220-240

16-24 12-18

Cooling:39/36/33/31/29/26/23

Heating:38/36/32/30/28/25/22

Cooling:50/48/45/44/42/38/34

Heating:50/48/45/44/42/38/34

Technical Information

3

Outdoor

Unit

Connection

Pipe

Service Manual

Outdoor Unit Model GEH12AA-K6DNA1A/O GEH09AA-K6DNA1F/O

Outdoor Unit Product Code CV010W02900 CV010W02700

Compressor Manufacturer

Compressor Model QXF-A102zE190B QXF-A079zE190A

Compressor Oil FW68DA FW68DA

Compressor Type Rotary Rotary

Compressor LRA. A / /

Compressor RLA A 4.60 4.6

Compressor Power Input W 1023 790

Compressor Overload Protector HPC115/95U1/KSD115ºC HPC115/95U1/KSD115ºC

Throttling Method Electron expansion valve Electron expansion valve

Set Temperature Range ºC 16~30 16~30

Cooling Operation Ambient Temperature

Range

Heating Operation Ambient Temperature

Range

Condenser Form Aluminum Fin-copper Tube Aluminum Fin-copper Tube

Condenser Pipe Diameter mm Φ7.94 Φ7

Condenser Rows-n Gap mm 1-1.4 1-1.4

Condenser Coil Length (LXDXW) mm 731X19.05X550 710X19.05X508

Fan Motor Speed rpm 900 900

Fan Motor Power Output W 30 30

Fan Motor RLA A 0.36 0.36

Fan Motor Capacitor μF / /

Outdoor Unit Air Flow Volume m3/h 2200 1600

Fan Type Axial-ow Axial-ow

Fan Diameter mm Φ438 Φ400

Defrosting Method Automatic Defrosting Automatic Defrosting

Climate Type T1 T1

Isolation I I

Moisture Protection IPX4 IPX4

Permissible Excessive Operating

Pressure for the Discharge Side

Permissible Excessive Operating

Pressure for the Suction Side

Sound Pressure Level (H/M/L) dB (A) 52/-/- 49/-/-

Sound Power Level (H/M/L) dB (A) 62/-/- 60/-/-

Dimension(WXHXD) mm 848X596X320 782X540X320

Dimension of Carton Box (LXWXH) mm 878X360X630 820X355X580

Dimension of Package(LXWXH) mm 881X363X645 823X358X595

Net Weight kg 30.5 27.5

Gross Weight kg 33.5 30

Refrigerant R32 R32

Refrigerant Charge kg 0.75 0.55

Connection Pipe Length m 5 5

Connection Pipe Gas Additional Charge g/m 16 16

Outer Diameter Liquid Pipe mm Φ6 Φ6

Outer Diameter Gas Pipe mm Φ9.52 Φ9.52

Max Distance Height m 10 10

Max Distance Length m 20 20

Note: The connection pipe applies metric diameter.

MPa 4.3 4.3

MPa 2.5 2.5

ZHUHAI LANDA COMPRESSOR

CO.,LTD

ºC -15~43 -15~43

ºC -22~24 -22~24

ZHUHAI LANDA COMPRESSOR

CO., LTD

The above data is subject to change without notice. Please refer to the nameplate of the unit.

4

Technical Information

Service Manual

Parameter Unit Value

Model GEH18AA-K6DNA1F

Product Code CV010002800/CV010002801

Power

Supply

Rated Voltage V

~

Rated Frequency Hz 50

Phases 1

220-240

Power Supply Mode Outdoor

Cooling Capacity(Min~Max) W 5200(1260~6600)

Heating Capacity(Min~Max) W 5330(1120~6800)

Cooling Power Input(Min~Max) W 1550(380~2450)

Heating Power Input(Min~Max) W 1500(350~2500)

Cooling Current Input A 7.1

Heating Current Input A 6.7

Rated Input W 2500

Rated Current A 11.1

Air Flow Volume(SH/H/HM/M/LM/L/SL) m3/h 700/650/580/520/460/410/320

Dehumidifying Volume L/h 1.8

EER W/W 3.4

COP W/W 3.55

SEER W/W 6.6

SCOP(Average/Warmer/Colder) W/W /

Application Area m

2

23-34

Indoor Unit Model GEH18AA-K6DNA1F/I

Indoor Unit Product Code CV010N02800/CV010N02801

Fan Type Centrifugal

Fan Diameter Length(DXL) mm Φ370X80

Cooling Speed

(SH/H/HM/M/LM/L/SL)

Heating Speed

(SH/H/HM/M/LM/L/SL)

r/min

r/min

840/800/720/650/580/530/410

810/770/690/620/550/500/380

930/840/760/690/620/570/480

850/800/720/650/580/530/470

Fan Motor Power Output W 30

Fan Motor RLA A 0.15

Fan Motor Capacitor μF /

Evaporator Form Aluminum Fin-copper Tube

Indoor

Unit

Evaporator Pipe Diameter mm Φ7

Evaporator Row-n Gap mm 2-1.3

Evaporator Coil Length (LXDXW) mm 511X400X25.4

Swing Motor Model MP24EB/MP24AE

Swing Motor Power Output W 1.5/1.5

Fuse Current A 3.15

Sound Pressure Level

(SS/H/MH/M/ML/L/SL)

Sound Power Level

(SS/H/MH/M/ML/L/SL)

dB (A) 47/45/42/40/37/35/31

dB (A) 57/55/52/50/47/45/41

Dimension (WXHXD) mm 700X215X600

Dimension of Carton Box (LXWXH) mm 785X280X682

Dimension of Package(LXWXH) mm 788X283X697

Net Weight kg 15.5

Gross Weight kg 18.5

Technical Information

5

Outdoor

Unit

Connection

Pipe

Outdoor Unit Model GEH18AA-K6DNA1F/O

Outdoor Unit Product Code CV010W02800

Compressor Manufacturer ZHUHAI LANDA COMPRESSOR CO.,LTD

Compressor Model QXF-B141zF030A

Compressor Oil 68DA

Compressor Type Rotary

Compressor LRA. A 25

Compressor RLA A 6.5

Compressor Power Input W 1410

Compressor Overload Protector 1NT11L-6233 or KSD115ºC or HPC115/95U1

Throttling Method Electron expansion valve

Set Temperature Range ºC 16~30

Cooling Operation Ambient Temperature

Range

Heating Operation Ambient Temperature

Range

Condenser Form Aluminum Fin-copper Tube

Condenser Pipe Diameter mm Φ7

Condenser Rows-n Gap mm 2-1.4

Condenser Coil Length (LXDXW) mm 851X38.1X660

Fan Motor Speed rpm 800

Fan Motor Power Output W 60

Fan Motor RLA A 0.4

Fan Motor Capacitor μF /

Outdoor Unit Air Flow Volume m3/h 3200

Fan Type Axial-ow

Fan Diameter mm Φ520

Defrosting Method Automatic Defrosting

Climate Type T1

Isolation I

Moisture Protection IPX4

Permissible Excessive Operating

Pressure for the Discharge Side

Permissible Excessive Operating

Pressure for the Suction Side

Sound Pressure Level (H/M/L) dB (A) 57/-/-

Sound Power Level (H/M/L) dB (A) 65/-/-

Dimension(WXHXD) mm 965X700X396

Dimension of Carton Box (LXWXH) mm 1026X455X735

Dimension of Package(LXWXH) mm 1029X458X750

Net Weight kg 46

Gross Weight kg 50.5

Refrigerant R410A

Refrigerant Charge kg 0.95

Connection Pipe Length m 5

Connection Pipe Gas Additional Charge g/m 20

Outer Diameter Liquid Pipe mm Φ6

Outer Diameter Gas Pipe mm Φ12

Max Distance Height m 10

Max Distance Length m 25

Note: The connection pipe applies metric diameter.

ºC -15~43

ºC -22~24

MPa 4.3

MPa 2.5

Service Manual

The above data is subject to change without notice. Please refer to the nameplate of the unit.

6

Technical Information

Service Manual

10

gnilooC

Capacity ratio(%)

gnitaeH

Outdoor temp.(°C)

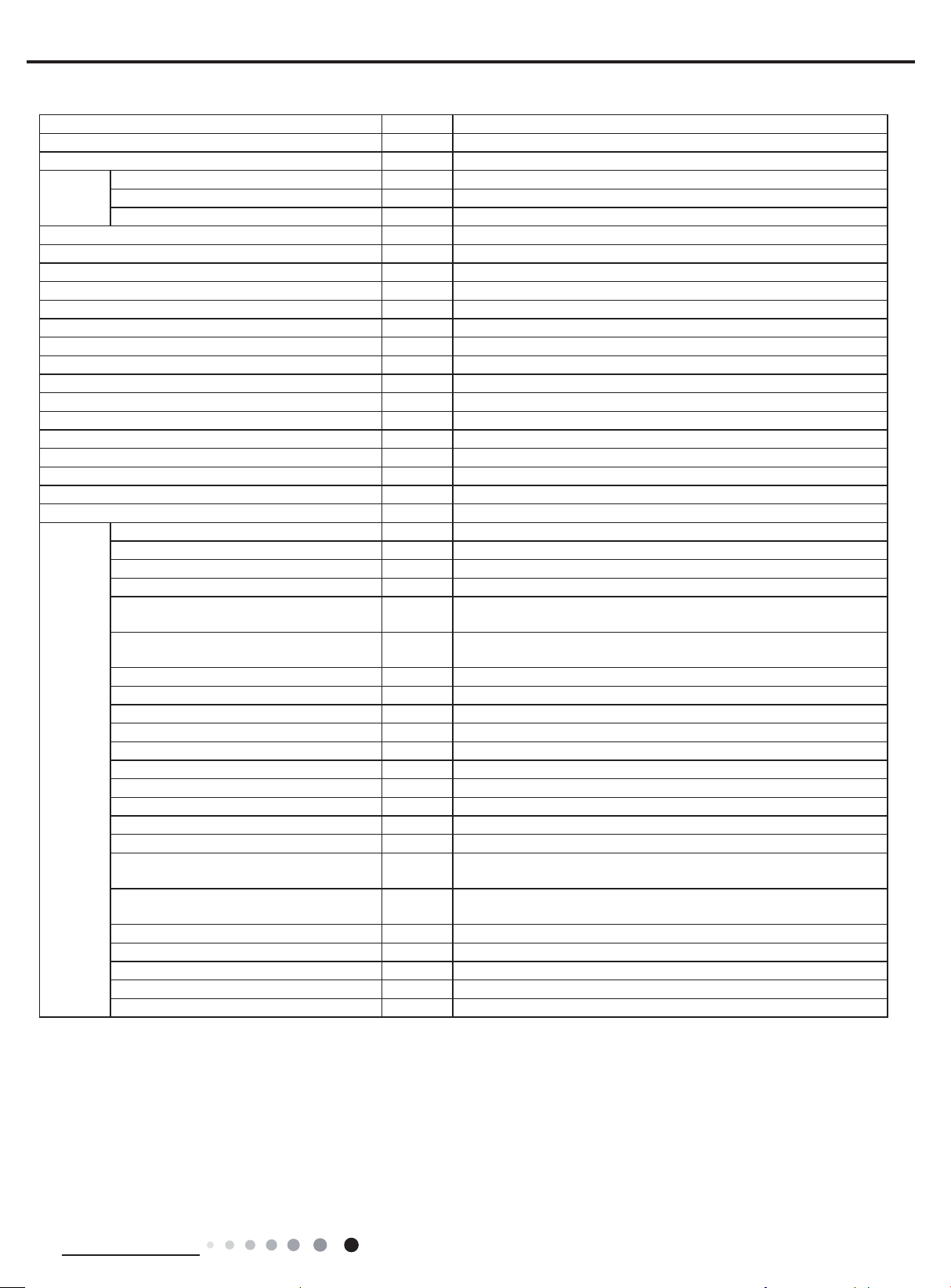

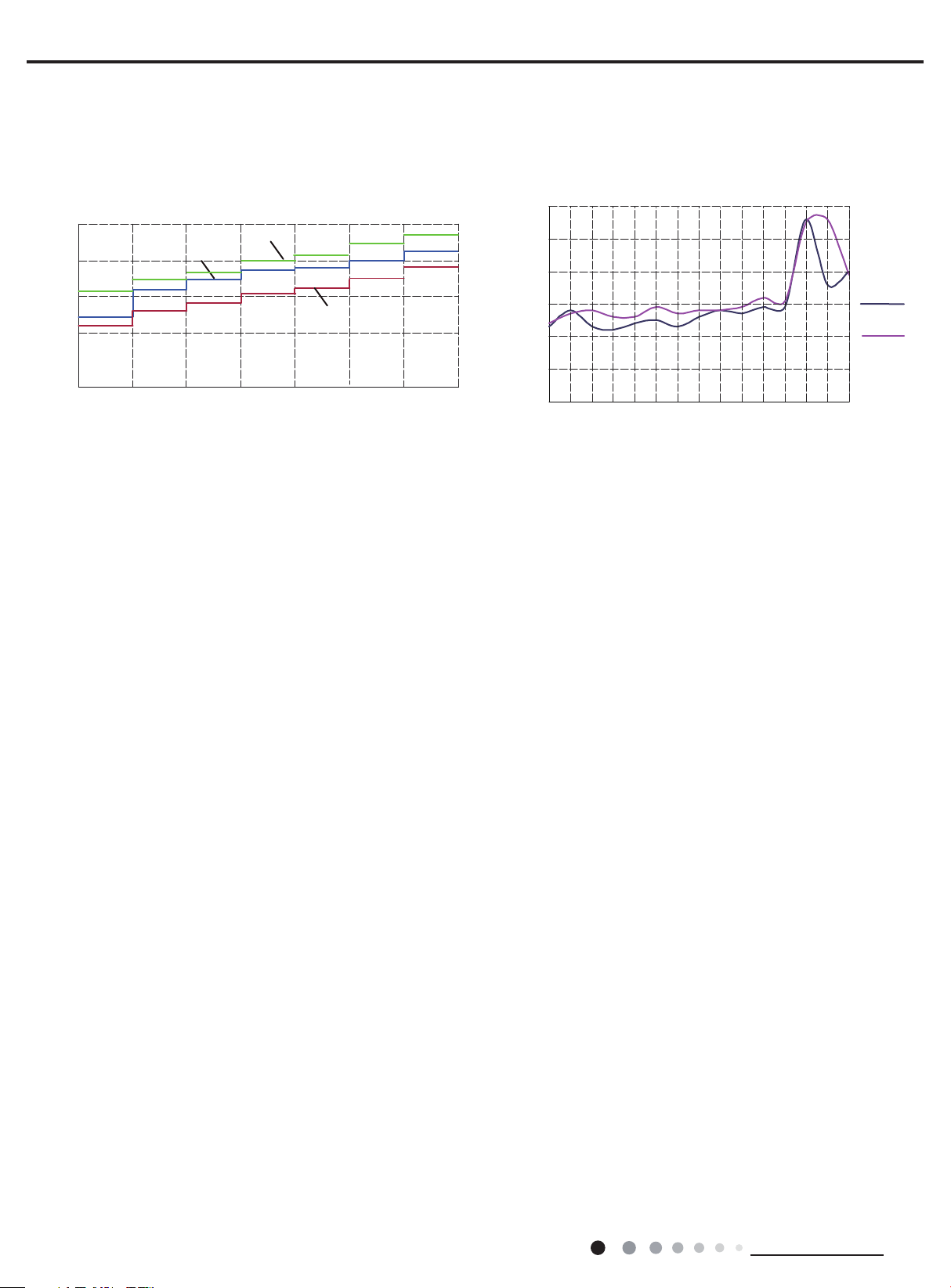

2.2 Operation Characteristic Curve

Cooling

11

10

9

8

7

6

5

Current (A)

4

3

2

1

0

• Conditions

Indoor : DB27˚C/WB19˚C

Outdoor : DB35˚C/WB24˚C

Indoor air flow : High

Pipe length : 5m

Compressor frequency(Hz)

240V

220V

230V

80

09070605040302010

Heating

11

10

9

8

7

6

5

Current (A)

4

3

2

1

0

220V

230V

240V

• Conditions

Indoor : DB20˚C/WB15˚C

Outdoor: DB7˚C/WB6˚C

Indoor air flow : High

Pipe length : 5m

Compressor frequency(Hz)

0

1

210010908070605040302010

2.3 Capacity Variation Ratio According to Temperature

140

120

100

80

60

Condition

40

20

0

-15-10 -5 0510 15 20 25 30 35 43

Indoor:DB27°C WB19°C

Indoor air flow:

High

Pipe length:5m

Outdoor temp.(°C)

140

120

%)

100

80

60

40

Capacity ratio(

20

0

-22 -15 -10 -7 0 2 7 15 18 21 24

Conditions

Indoor:DB20°C

Indoor air flow:Super High

Pipe length:5m

Technical Information

7

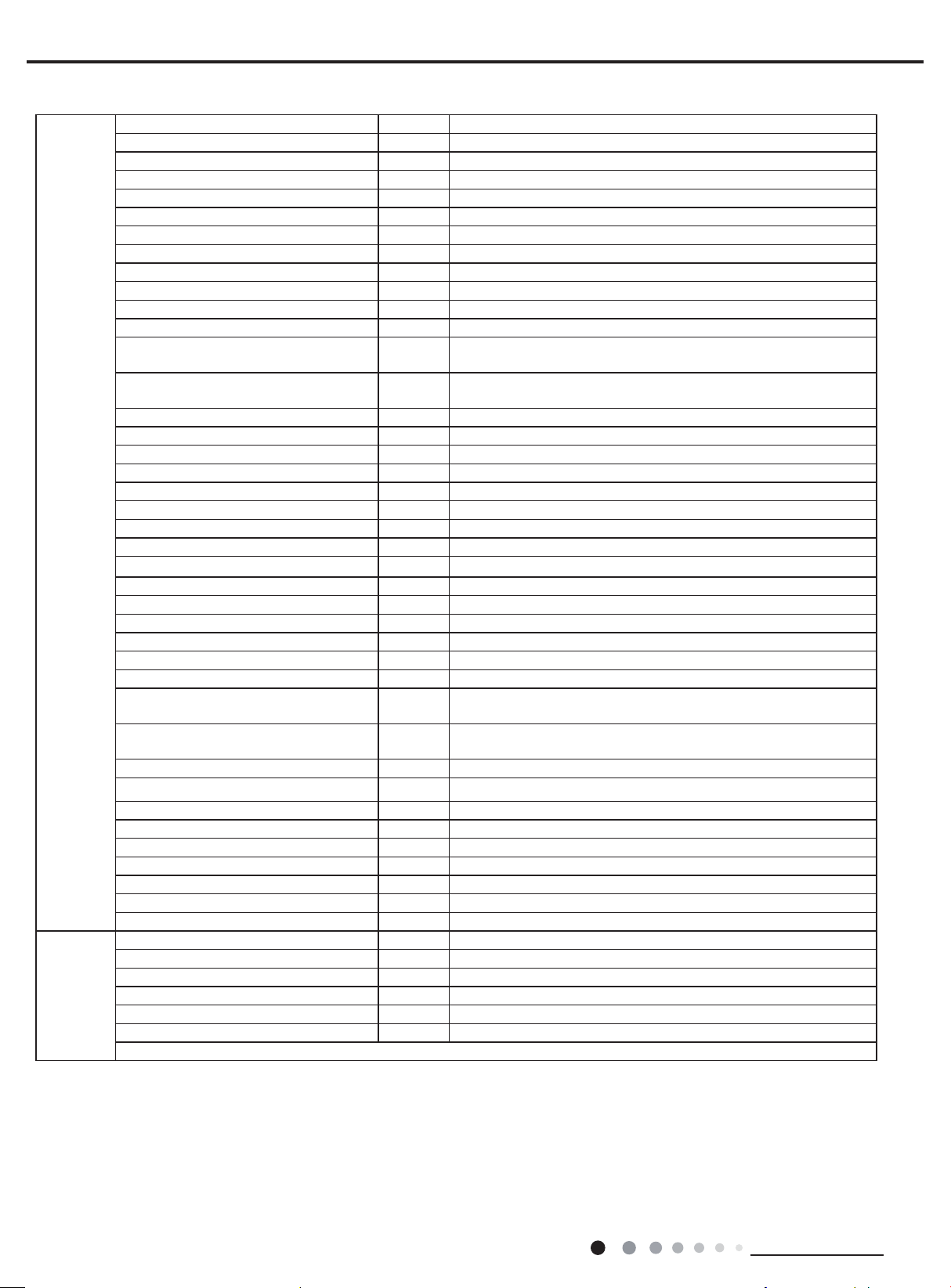

2.4 Noise Curve

45

46

47

48

49

50

51

52

53

12345678910 11 12 13 14 15 16 17

Compressor frequency(Hz)

Noise dB(A)

Cooling

Heating

Indoor side noise when blowing Outdoor side noise when blowing

20

30

40

50

Outdoor side noise when blowing

Heating

Compressor frequency(Hz)

Service Manual

52

12K

SL LLM

Indoor fan motor rotating speed

18K

09K

MHMHSH

51

50

49

48

Noise dB(A)

47

46

15 20 25 30 35 40 45 50 55 60 65 70 75 80 85

Cooling

8

Technical Information

Service Manual

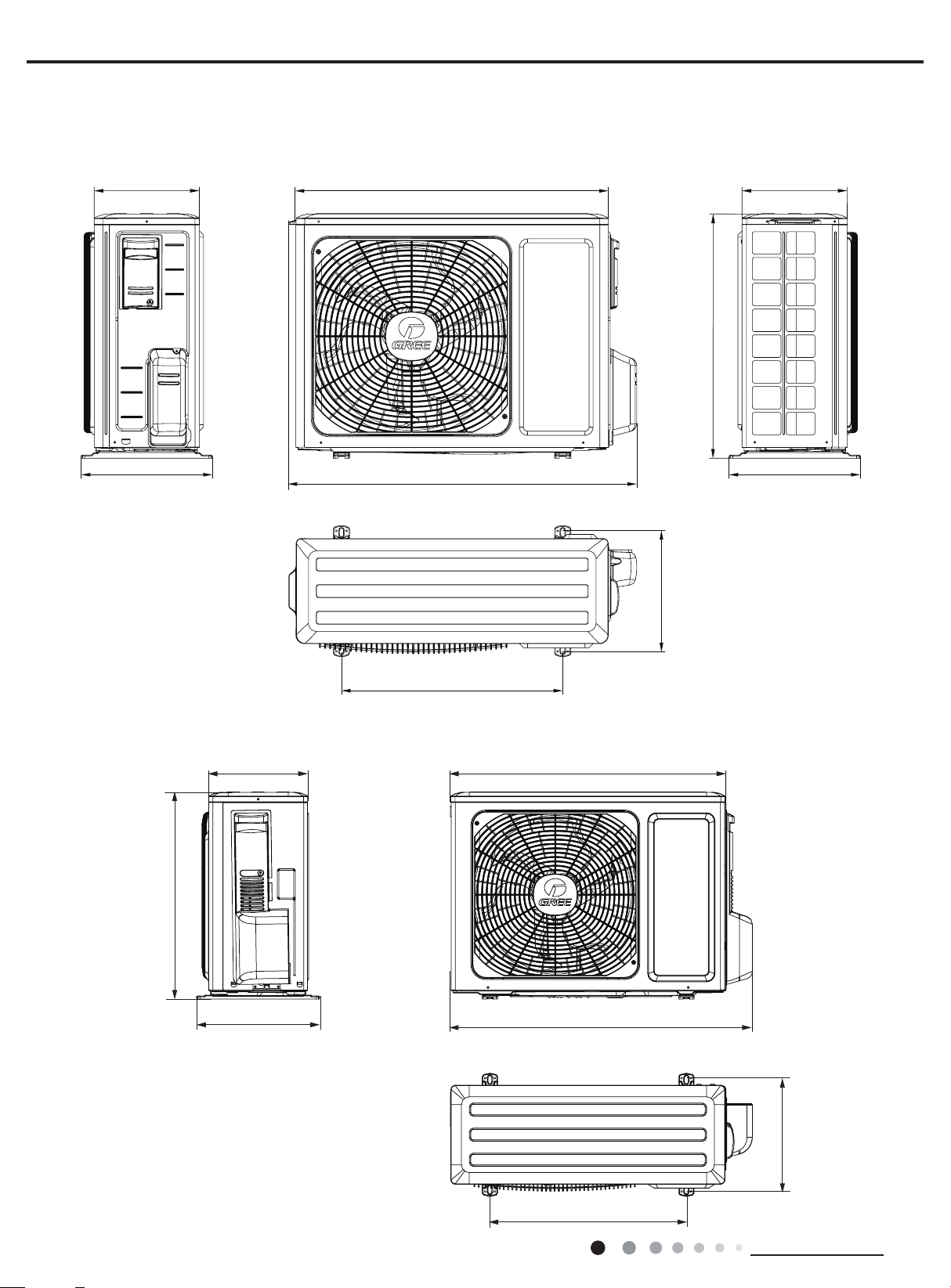

3. Outline Dimension Diagram

3.1 Indoor Unit

22

205

700

215

600

398

Technical Information

Unit:mm

9

3.2 Outdoor Unit

257

257

780

712

540

GEH12AA-K6DNA1A/O

Service Manual

596

320 320

GEH09AA-K6DNA1F/O

257

848

286

Unit:mm

540

10

320

782

286

Unit:mm Unit:mm

510

Technical Information

Service Manual

892

700

GEH18AA-K6DNA1F/O

341

Unit:mm

396

963

368

560

Technical Information

11

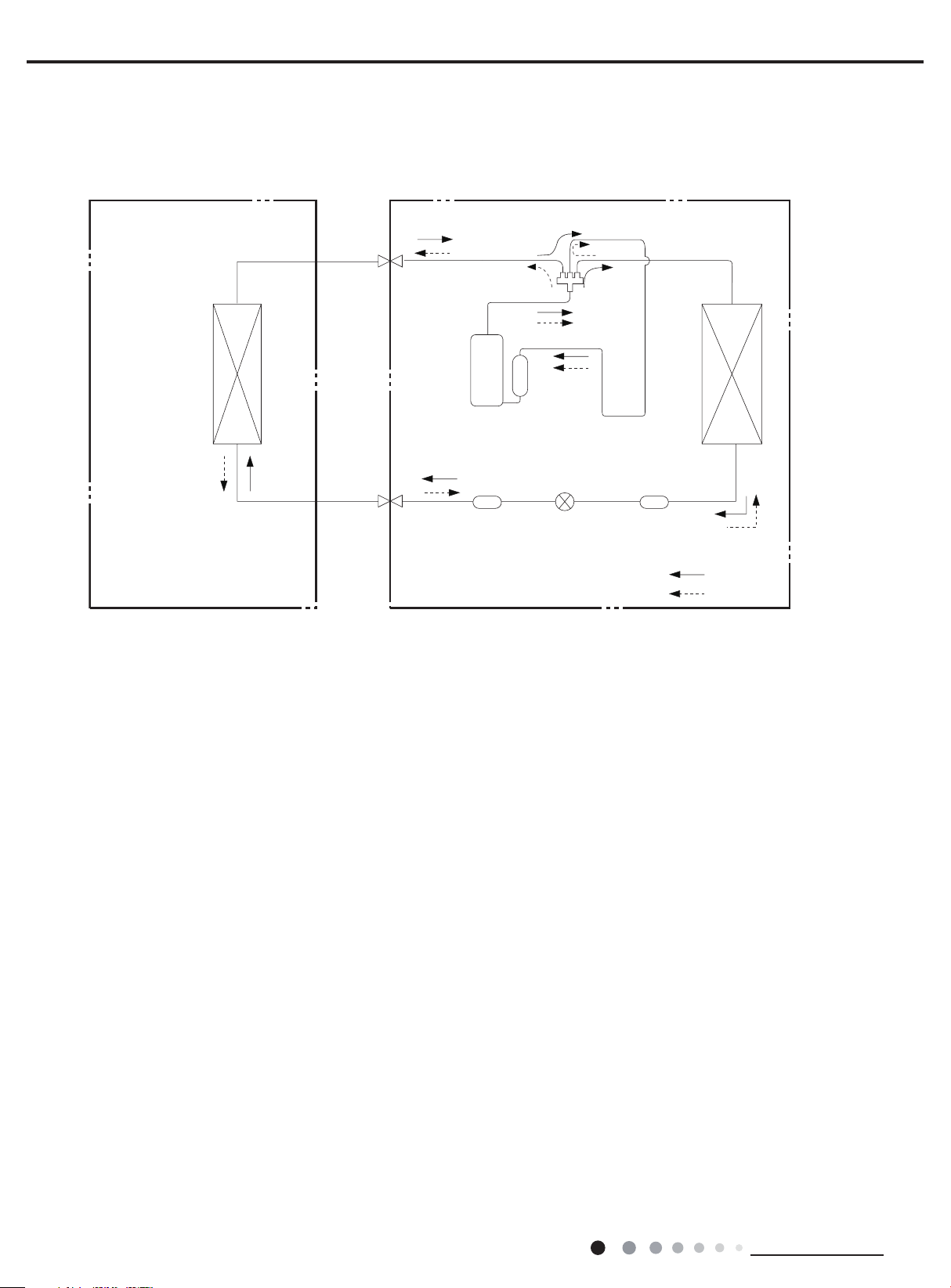

Indoor unit

Outdoor unit

4. Refrigerant System Diagram

Gas pipe

side

Valve

Service Manual

4-Way valve

Discharge

Heat

exchanger

(evaporator)

Connection pipe specication:

Liquid pipe:1/4" (6mm)

Gas pipe:3/8" (9.52mm)(09/12K)

Gas pipe:1/2" (16mm)(18K)

Liquid pipe

side

Valve

Suction

Strainer

Electron

expansion

valve

Heat

exchanger

(condenser)

Strainer

COOLING

HEATING

12

Technical Information

Service Manual

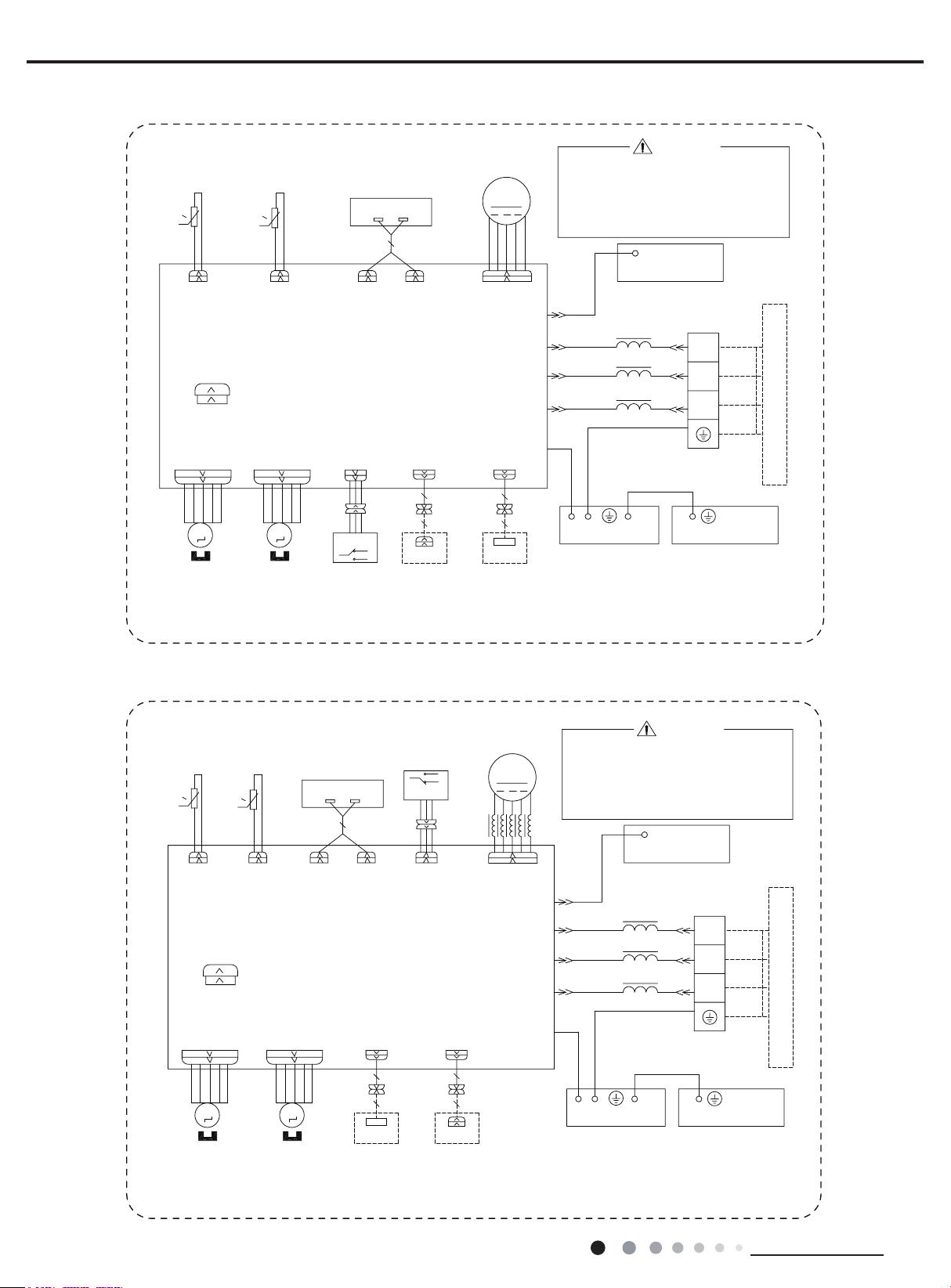

5. Electrical Part

5.1 Wiring Diagram

● Instruction

Symbol Symbol Color Symbol Symbol Color Symbol Name

WH White GN Green CAP Jumper cap

YE Yellow BN Brown COMP Compressor

RD Red BU Blue Grounding wire

YEGN Yellow/Green BK Black / /

VT Violet OG Orange / /

Note: Jumper cap is used to determine fan speed and the swing angle of horizontal lover for this model.

● Indoor Unit

GEH12AA-K6DNA1A/I(CV010N02900) GEH18AA-K6DNA1F/I(CV010N02800)

52207(03

78%(7(03

6(1625

57

57

5220

6(1625

78%(

5(&(,9(5$1'

',63/$<%2$5'

$3

',63/$<

',63

',63

6:,7&+

6(/(&7

6

$3

0$*1(7,&

&1

)$1

0

5,1*

'&02725

02725

$335,17('&,5&8,7%2$5'

&$3

-803

6:,1*'2:1

0

67(33,1*

02725

6:,1*83

0

67(33,1*

02725

:,),

$3

:,),02'8/(

237,21$/

&200$18$/

:,5('

&21752//(5

$3

&20287

$&/

+($/7+/

+($/7+1

&2/'3/$60$

*(1(5$725

237,21$/

3OHDVHGRQWWRXFKDQ\HOHFWURQLF

FRPSRQHQWRUWHUPLQDOZKHQWKH

PDFKLQHLVUXQQLQJVWRSSLQJRU

KDVEHHQSRZHUHGRIIIRUOHVV

WKDQPLQXWHVWRSUHYHQW

HOHFWULFVKRFN

/

02725)5$0(

0$*1(7,&

:$51,1*

&1

1

(

2*

%8

%.

%1

<(*1

5,1*

/

/

/

<(*1

<(*1

%85'

3(

%85'

(9$325$725

(/(&75,&%2;

60000700126803

;7

%8

1

%.

%1

<(*1

7(50,1$/

%/2&.

3(

287'22581,7

Technical Information

13

GEH09AA-K6DNA1F/I(CV010N02701)

Service Manual

52207(03

6(1625

57

5220

&$3

-803

6:,1*'2:1

0

67(33,1*

02725

78%(7(03

6(1625

5(&(,9(5$1'

',63/$<%2$5'

$3

',63/$<

57

78%(

',63

',63

$335,17('&,5&8,7%2$5'

6:,1*83

0

67(33,1*

02725

&1

$3

6

6(/(&7

6:,7&+

&200$18$/

$3

:,5('

&21752//(5

237,21$/

02725

)$1

0

'&02725

&1

1

&20287

$&/

<(*1

(

:,),

$3

:,),02'8/(

237,21$/

3OHDVHGRQWWRXFKDQ\HOHFWURQLF

FRPSRQHQWRUWHUPLQDOZKHQWKH

PDFKLQHLVUXQQLQJVWRSSLQJRU

KDVEHHQSRZHUHGRIIIRUOHVV

WKDQPLQXWHVWRSUHYHQW

HOHFWULFVKRFN

02725)5$0(

:$51,1*

0$*1(7,&

2*

%8

%.

%1

5,1*

/

/

/

;7

1

%8

%.

%1

<(*1

<(*1

7(50,1$/

%/2&.

<(*1

3(

(9$325$725

60000700126801

3(

(/(&75,&%2;

287'22581,7

GEH12AA-K6DNA1A/I(CV010N02901) GEH18AA-K6DNA1F/I(CV010N02801)

52207(03

78%(7(03

6(1625

57

57

5220

6(1625

78%(

5(&(,9(5$1'

',63/$<%2$5'

$3

',63/$<

',63

',63

6:,7&+

6(/(&7

6

$3

0$*1(7,&

&1

)$1

0

5,1*

'&02725

02725

/

&1

&$3

-803

6:,1*'2:1

0

67(33,1*

02725

$335,17('&,5&8,7%2$5'

6:,1*83

0

67(33,1*

02725

:,),

$3

&200$18$/

:,),02'8/(

237,21$/

&21752//(5

$3

:,5('

&20287

$&/

1

(

<(*1

237,21$/

3OHDVHGRQWWRXFKDQ\HOHFWURQLF

FRPSRQHQWRUWHUPLQDOZKHQWKH

PDFKLQHLVUXQQLQJVWRSSLQJRU

KDVEHHQSRZHUHGRIIIRUOHVV

WKDQPLQXWHVWRSUHYHQW

HOHFWULFVKRFN

02725)5$0(

0$*1(7,&

:$51,1*

2*

%8

%.

%1

5,1*

/

/

/

;7

1

%8

%.

%1

<(*1

<(*1

7(50,1$/

%/2&.

<(*1

3(

(9$325$725

60000700126804

3(

(/(&75,&%2;

287'22581,7

14

Technical Information

Service Manual

GEH09AA-K6DNA1F/I(CV010N02700)

52207(03

78%(7(03

6(1625

57

57

5220

&$3

-803

6:,1*'2:1

0

67(33,1*

02725

6:,7&+

6(/(&7

6

6(1625

78%(

5(&(,9(5$1'

',63/$<%2$5'

$3

',63/$<

',63

',63

$335,17('&,5&8,7%2$5'

6:,1*83

0

67(33,1*

02725

:,),

$3

:,),02'8/(

237,21$/

&200$18$/

:,5('

&21752//(5

$3

237,21$/

$3

&1

02725

)$1

0

'&02725

&1

&20287

$&/

+($/7+/

&2/'3/$60$

+($/7+1

%85'

%85'

*(1(5$725

3OHDVHGRQWWRXFKDQ\HOHFWURQLF

FRPSRQHQWRUWHUPLQDOZKHQWKH

PDFKLQHLVUXQQLQJVWRSSLQJRU

KDVEHHQSRZHUHGRIIIRUOHVV

WKDQPLQXWHVWRSUHYHQW

HOHFWULFVKRFN

02725)5$0(

0$*1(7,&

:$51,1*

1

(

2*

%8

%.

%1

<(*1

5,1*

<(*1

/

/

/

<(*1

;7

1

7(50,1$/

%/2&.

3(

(9$325$725

(/(&75,&%2;

600007001268

%8

%.

%1

<(*1

287'22581,7

3(

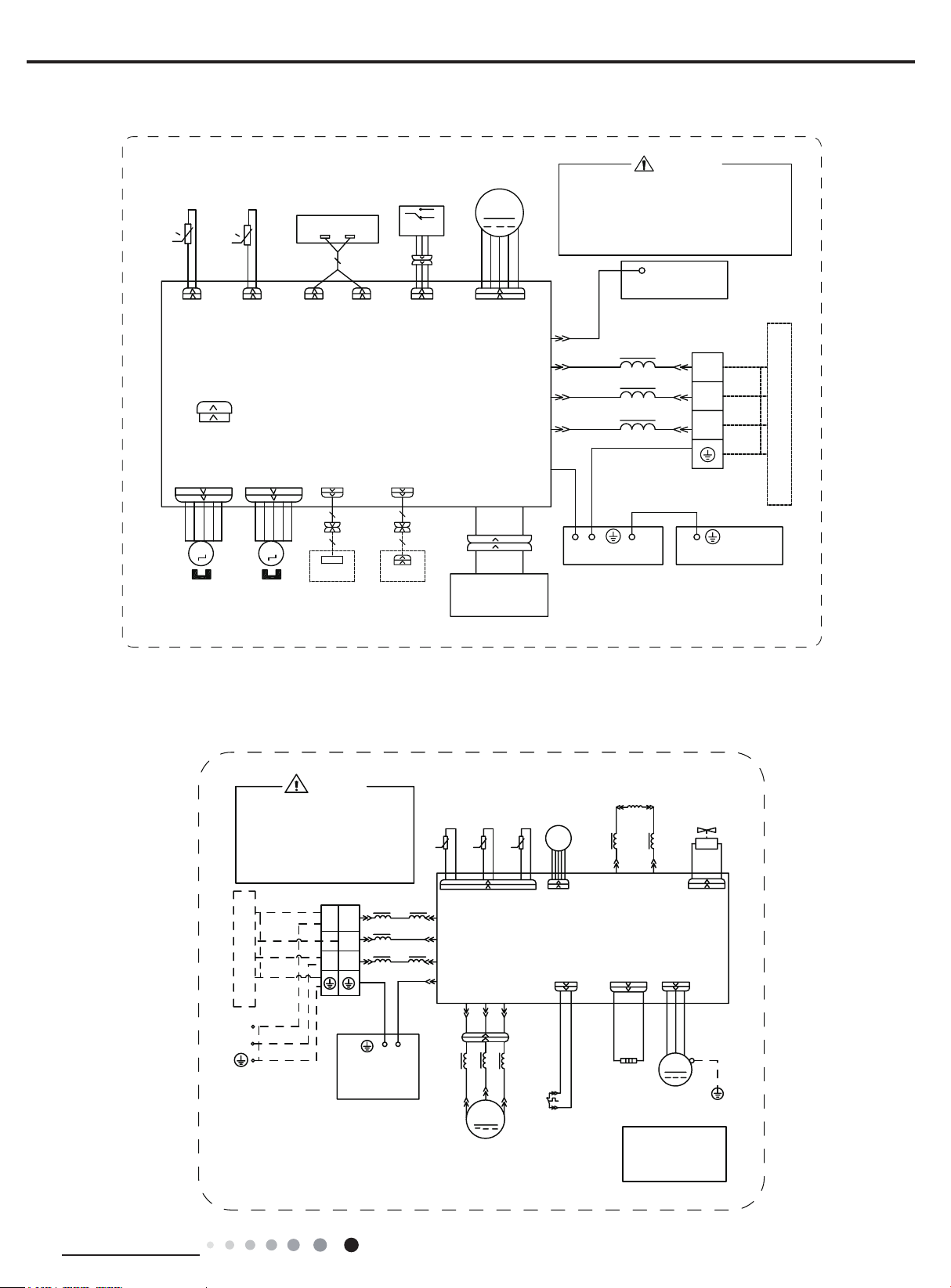

● Outdoor Unit

GEH09AA-K6DNA1F/O

%8

%.

%1

<(*1

%8

%1%.

<(*1

:$51,1*

;7

1

1

/

7(50,1$/

%/2&.

3(

(/(&75,&$/

%2;

N

0$*1(7,&5,1*

<(*1

/

/

/

%8

%.

%1

<(*1

/

/

3OHDVHGRQWWRXFKDQ\

WHUPLQDOZKHQWKHPDFKLQHLV

UXQQLQJVWRSSLQJRUKDVEHHQ

SRZHUHGRIIIRUOHVVWKDQ

PLQXWHVWRSUHYHQWWKHULVN

RIHOHFWULFVKRFN

,1'22581,7

1

/

32:(5

600007061371

2875220

28778%(

7(03

7(03

6(1625

6(1625

57

57

N

1

&208

$&/$&/

3(

8

%8

<(

5,1*

0$*1(7,&

%8

<(

9

8

&203

&203

(;+$867

7(03

6(1625

57

N

&1

$30DLQ%RDUG

:

9

5'

;

/

5'

:

29(5/2$'

3527(&725

(/(&7521,&

(;3$16,21

9$/9(

(.9

0$*1(7,&

&1

29&&203

5'

5'

6$7

5($&725

/

%8

5,1*

/;

%1

/

/

/;

+($7

(+

%RWWRP

%DQG

+HDWHU

127(0RWRU

JURXQGRQO\

DSSOLHVWRWKH

LURQVKHOOPRWRU

97

2)$1

0

)$1

02725

:$<

9$/9(

<9

97

:$<

<(*1

3(

3(

Technical Information

15

GEH18AA-K6DNA1F/O

Service Manual

3(

%1%.

/1

:$51,1*

7(50,1$/

%/2&.

%8

1

%.

%1

/

%8

1

;7

<(*1

32:(5

%8

%1

0$*1(7,&

3(

5,1*

3OHDVHGRQWWRXFKDQ\

WHUPLQDOZKHQWKHYROWDJH

RIWHUPLQDO3'&DQG

1'&DW$3LVKLJKHU

WKDQ9WRSUHYHQWWKH

ULVNRIHOHFWULFVKRFN

<(*1

,1'22581,7

600007061783

29(5/2$'3527(&725

6$7

&203

7(036(1625

28778%(

2875220

(;+$867

7(036(1625

57 57 57

. ..

:+ %.

/

%.

/

%1

/

%8

<(*1

/

7B6(1625

&20B,11(5

$&B/

1

+($7B%

3(

5'

(+

%27720

%$1'

3(

+($7(5

:$<)$

5'

<9

:$<

9$/9(

:+:+

7(036(1625

0$*1(7,&

5,1*

29&B&203

$3

35,17('&,5&8,7%2$5'

9797

(.9

(OHFWURQLF

([SDQVLRQ

9DOYH

8

&203

9

:

/

/ /

5'

<(%8

<(%8

8%8 9<( :5'

)$102725

1RWH0RWRUJURXQG

RQO\DSSOLHVWRWKH

LURQVKHOOPRWRU

2)$1

0

;

5'

3(

<(*1

3(

GEH12AA-K6DNA1A/O

3OHDVHGRQWWRXFKDQ\

WHUPLQDOZKHQWKHPDFKLQHLV

UXQQLQJVWRSSLQJRUKDVEHHQ

SRZHUHGRIIIRUOHVVWKDQ

PLQXWHVWRSUHYHQWWKHULVN

RIHOHFWULFVKRFN

%8

%.

<(*1

,1'22581,7

%8

1

%1%.

/

<(*1

32:(5

600007061430

%1

:$51,1*

;7

1

1

/

7(50,1$/

%/2&.

3(

(/(&75,&$/

%2;

28778%(

7(03

6(1625

57

N

0$*1(7,&5,1*

/

%8

/

%.

/

%1

<(*1

<(*1

0$*1(7,&

2875220

7(03

7(03

6(1625

57

57

N

N

&1

1

&208

$&/$&/

3(

8

:

9

5'

%8

<(

<(

9

&203

/

5'

:

5,1*

%8

8

&203

(/(&7521,&

(;+$867

(;3$16,21

9$/9(

6(1625

(.9

0$*1(7,&

/;

&1

$30DLQ%RDUG

29&&203

5'

;

6$7

29(5/2$'

3527(&725

+($7

5'

%RWWRP

%DQG

+HDWHU

5($&725

/

/

%1

/

97

%8

5,1*

/;

2)$1

(+

)$1

02725

127(0RWRU

JURXQGRQO\

DSSOLHVWRWKH

LURQVKHOOPRWRU

:$<

9$/9(

:$<

0

<9

97

<(*1

3(

3(

16

These circuit diagrams are subject to change without notice, please refer to the one supplied with the unit.

Technical Information

Service Manual

11 12 13

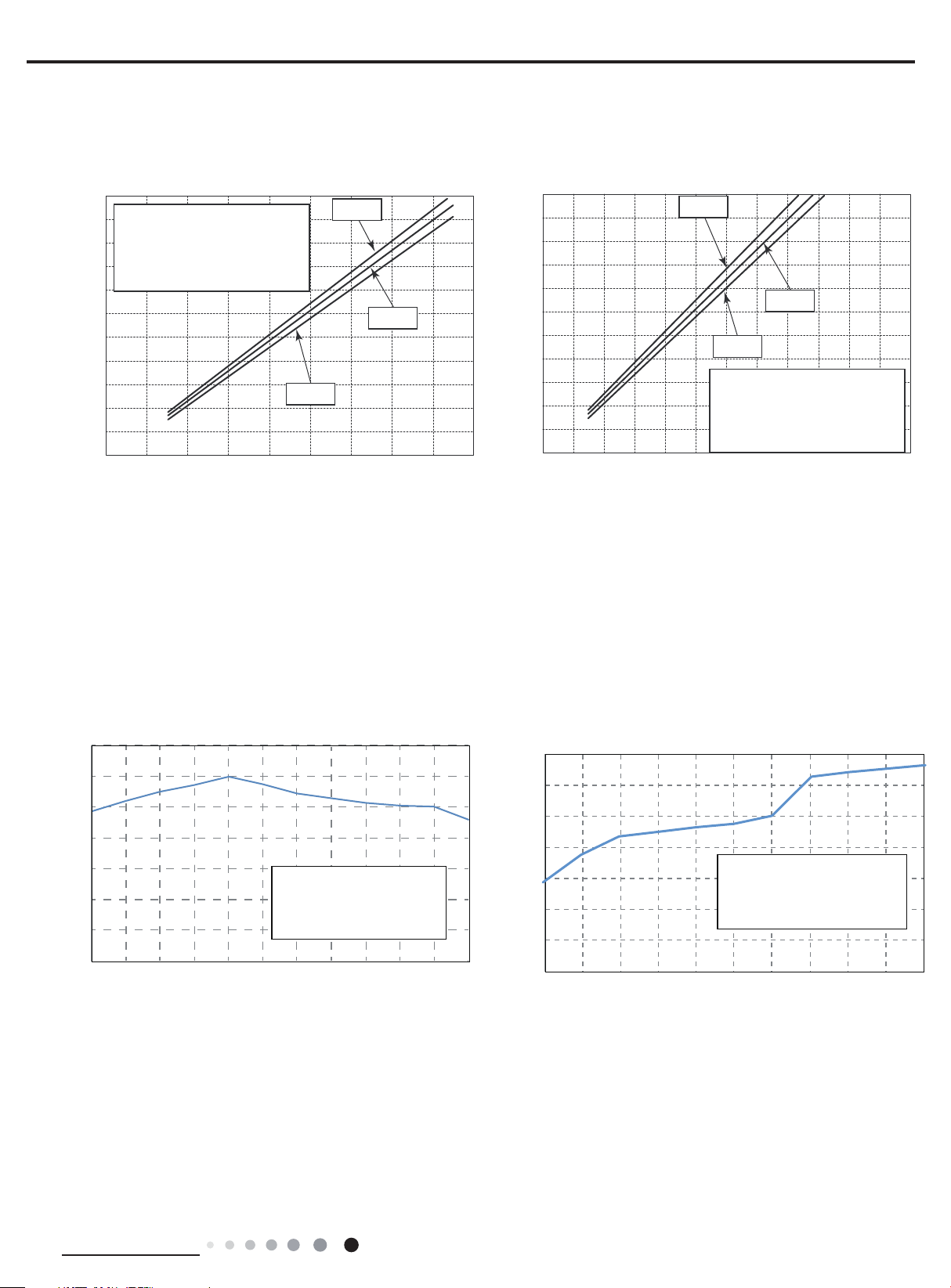

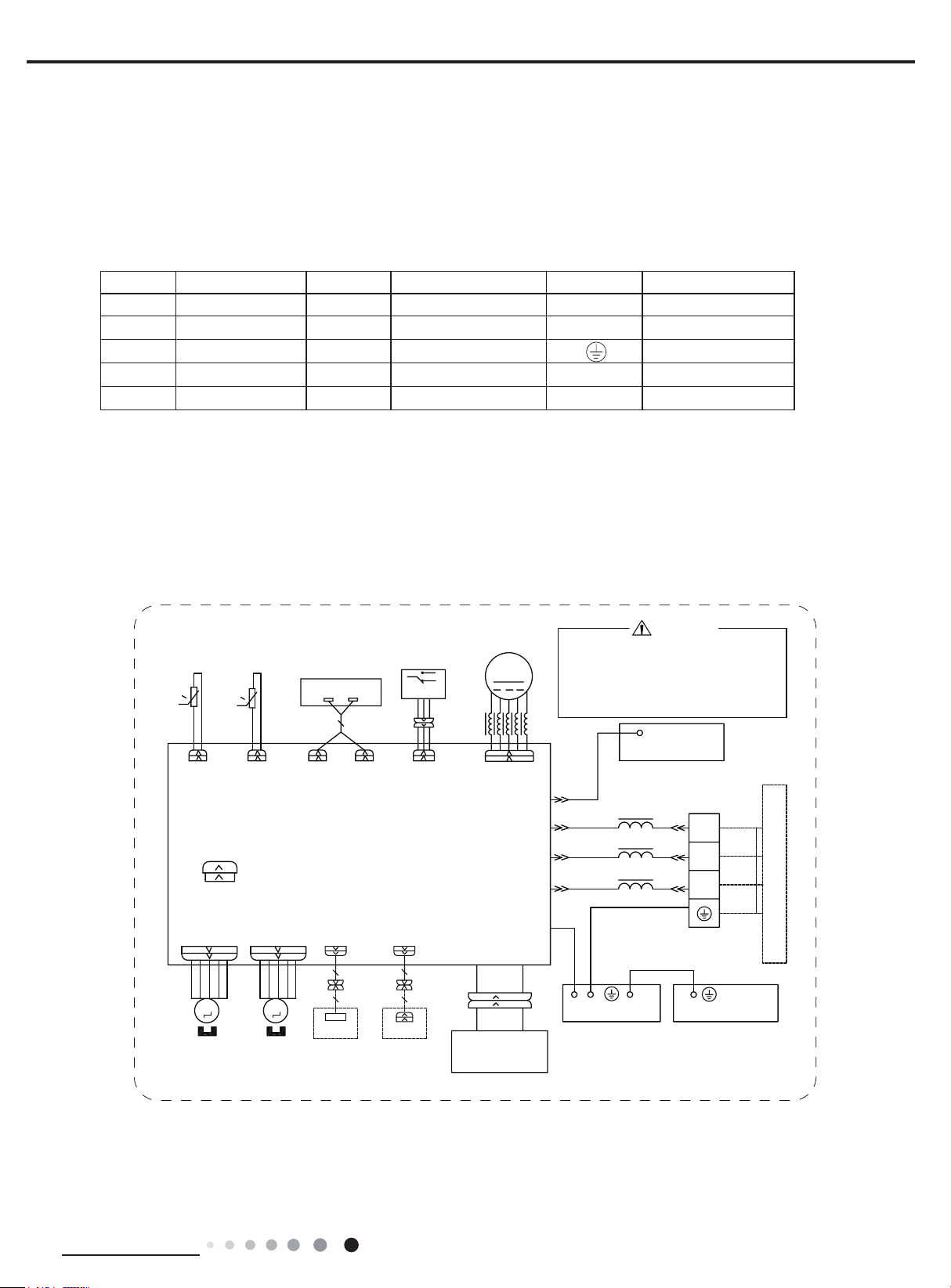

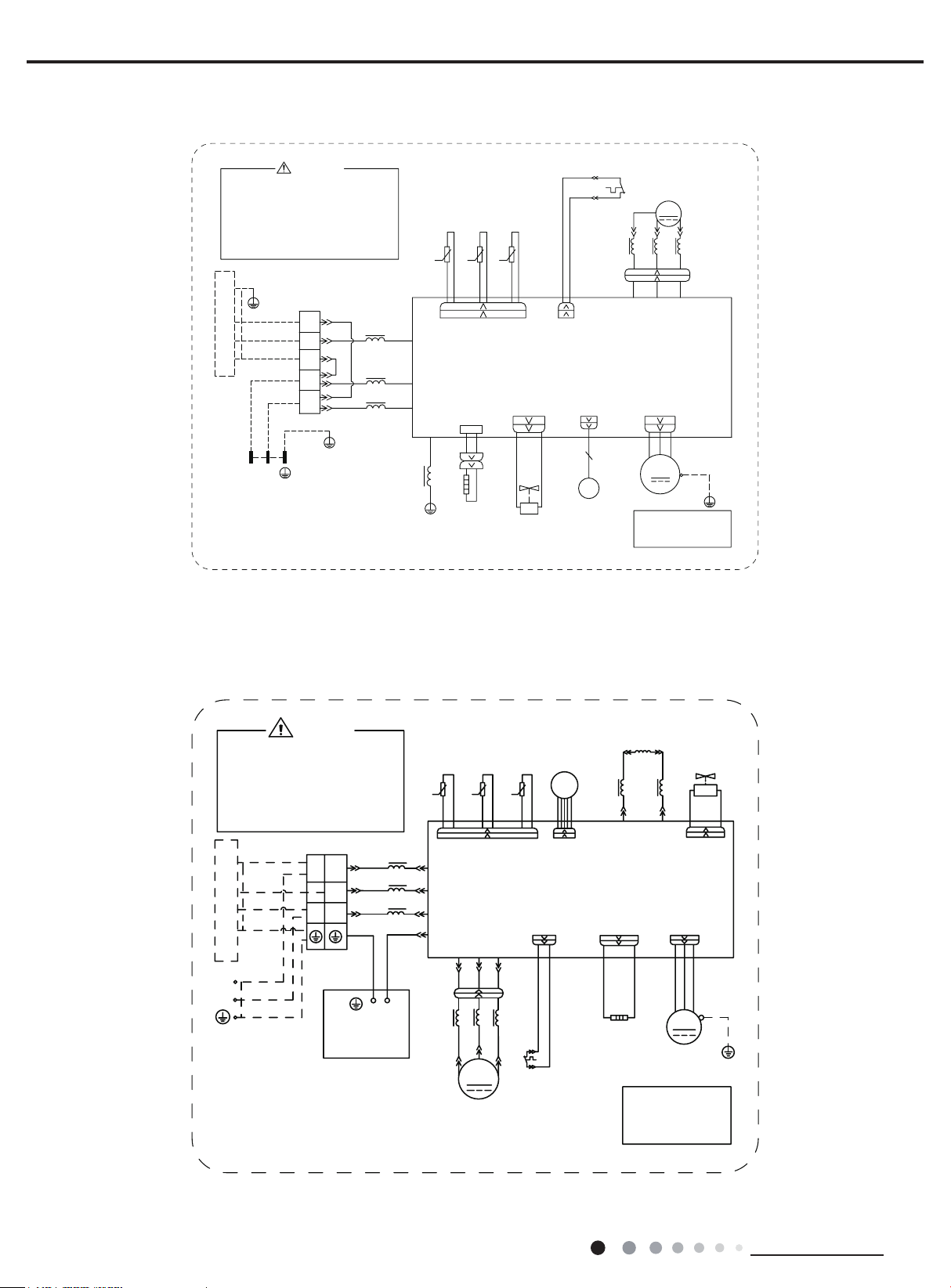

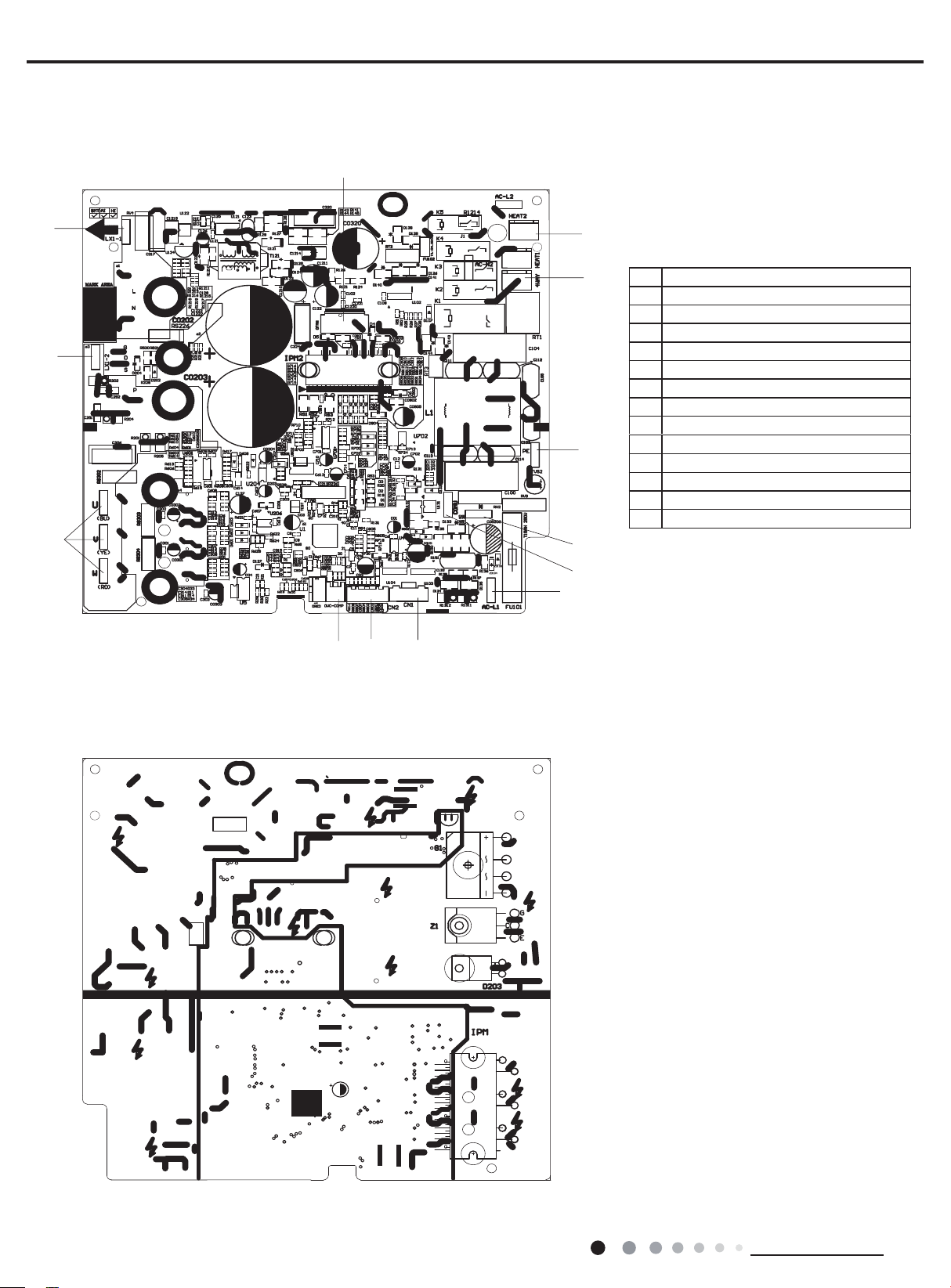

5.2 PCB Printed Diagram

Indoor Unit

● Top view

8

910

● Bottom view

7

14

NO. Name

1 Interface of tube temperature sensor

Interface of ambient temperature

2

sensor

3 Up swing interface

4 Down swing interface

17

5 WIFI interface

16

6 Interface of EMC shielding wire

7 DC motor interface

8 Earthing wire of main board

9 Terminal of live wire

10 Fuse

Terminal for health function

11

5

15

6

34

12

(only for the mode with this function)

12 Terminal of neutral wire

Communication interface between

13

indoor unit and outdoor unit

14 Control interface of Down swing

15 Wired controlled interface

16 Needle stand of jumper cap

17 Interface of display board

Technical Information

17

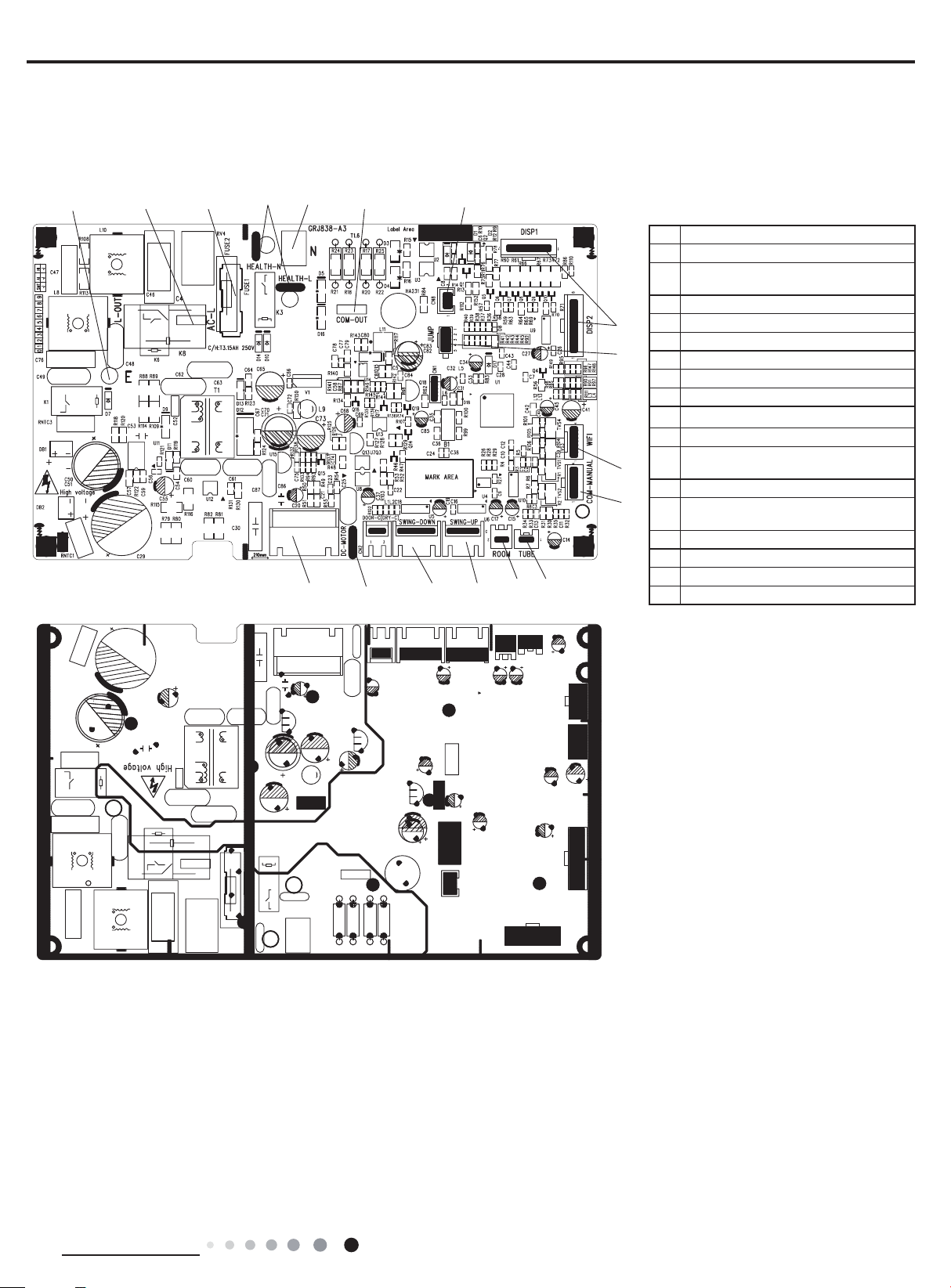

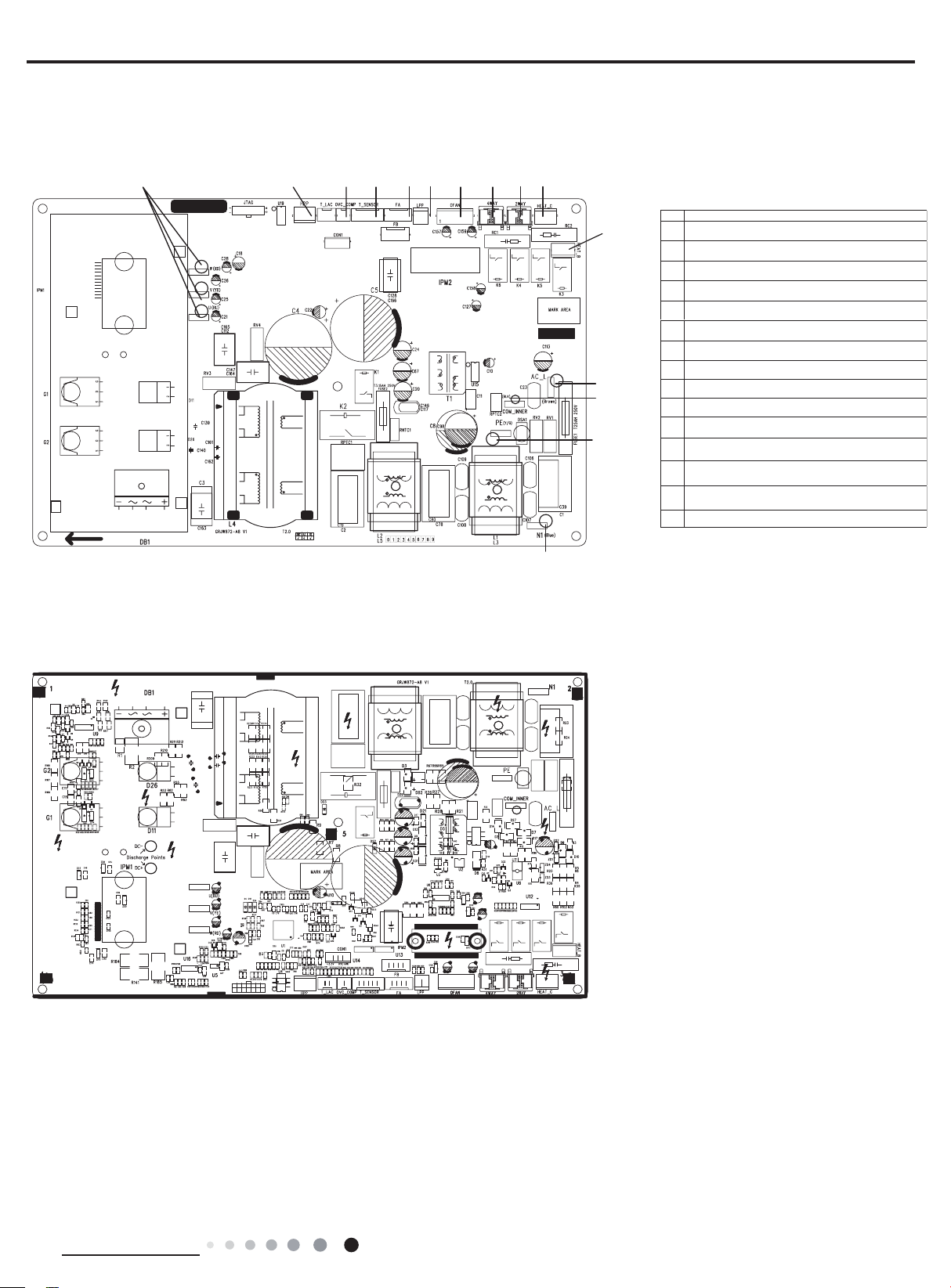

Outdoor Unit

3

● Top view

09/12K

Service Manual

13

2

13

1

4

5

6

No. Name

1 Interface of compressor wire

2 Reactor wiring terminal 2

3 Reactor wiring terminal 1

4 Terminal of chassis electric heater

5

4-way valve terminal

6

Grounding wire

7 Neutral wire

8 Communication wire

Live wire

9

10 Terminal of electronic expansion valve

11 Interface of temperature sensor

12 Overload interface of compressor

Terminal of outdoor fan

13

7

8

9

12

1011

● Bottom view

18

Technical Information

Service Manual

● Top view

GEH18AA-K6DNA1F/O

10

1

2

3

45 78

6

9

No Name

11

1

Compressor wiring terminal for U V W

2Terminal of system high pressure protection

3

Compressor overload protection terminal

4Interface of temperature sensor

5Terminal of electronic expansion valve

67Terminal of system low pressure protection

Terminal of outdoor fan

12

13

14

84-way valve terminal

9Terminal of compressor electric heater

Terminal of compressor electric heater

10

Interface of electric heating belt of chassis

11

Terminal of power supply live wire terminal

12

Interface of communication wire for indoor

13

unit and outdoor unit

14

Terminal of power supply earthing wire

15 Terminal of power supply neutral wire

● Bottom view

15

Technical Information

19

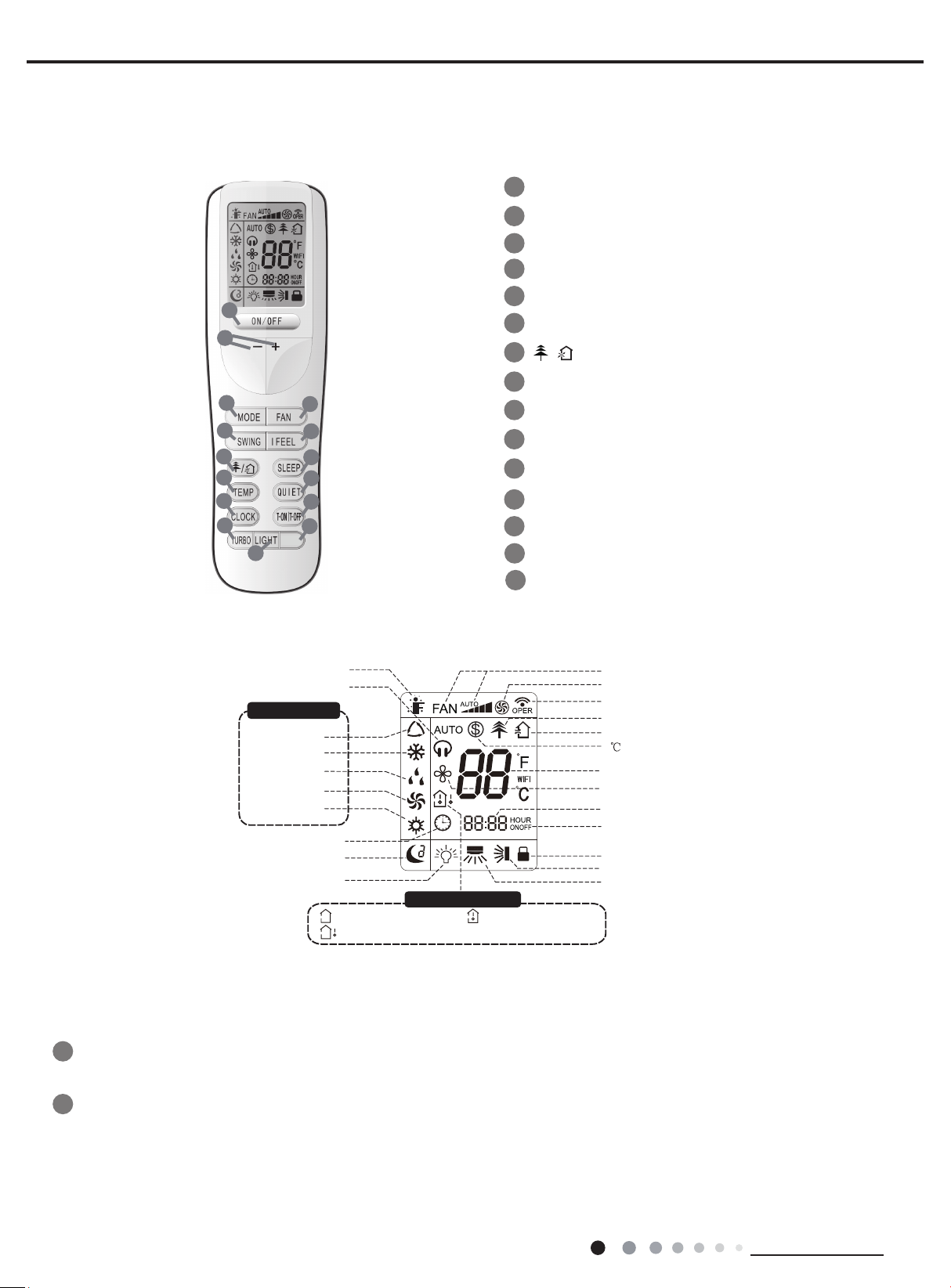

6. Function and Control

Buttons on Remote Controller

6.1 Remote Controller Introduction

1

2

3

5

7

9

11

13

15

WiFi

4

6

8

10

12

14

ON/OFF button

1

2

+/- button

MODE button

3

4

FAN button

SWING button

5

6

I FEEL button

7

8

SLEEP button

9

TEMP button

10

QUIET button

11

ClOCK button

12

T-ON T-OFF button

13

TURBO button

14

WiFi button

15

button

/

/

LIGHT button

Service Manual

Introduction for Icons on Display Screen

I feel

Quiet

Operation mode

Auto mode

Cool mode

Dry mode

Fan mode

Heat mode

Clock

Sleep mode

Light

Temp. display type

:Set temp.

:Outdoor ambient temp.

:Indoor ambient temp.

Set fan speed

Turbo mode

Send signal

Healthy mode

Scavenging functions

heating function

8

Set temperature

X-FAN function

Set time

TIMER ON /TIMER OFF

Child lock

Up & down swing

Left & right swing

Introduction for Buttons on Remote Controller

Note:

This is a general use remote controller, it could be used for the air conditioners with multifunction; For some function, which the model

doesn't have, if press the corresponding button on the remote controller that the unit will keep the original running status.

ON/OFF button

1

Press this button to turn on the unit. Press this button again to turn off the unit.

20

2

- button

Press this button to decrease set temperature. Holding it down above 2 seconds rapidly decreases set temperature. In AUTO

mode, set temperature is not adjustable.

+ button

Press this button to increase set temperature. Holding it down above 2 seconds rapidly increases set temperature. In AUTO

mode, set temperature is not adjustable.

Technical Information

Service Manual

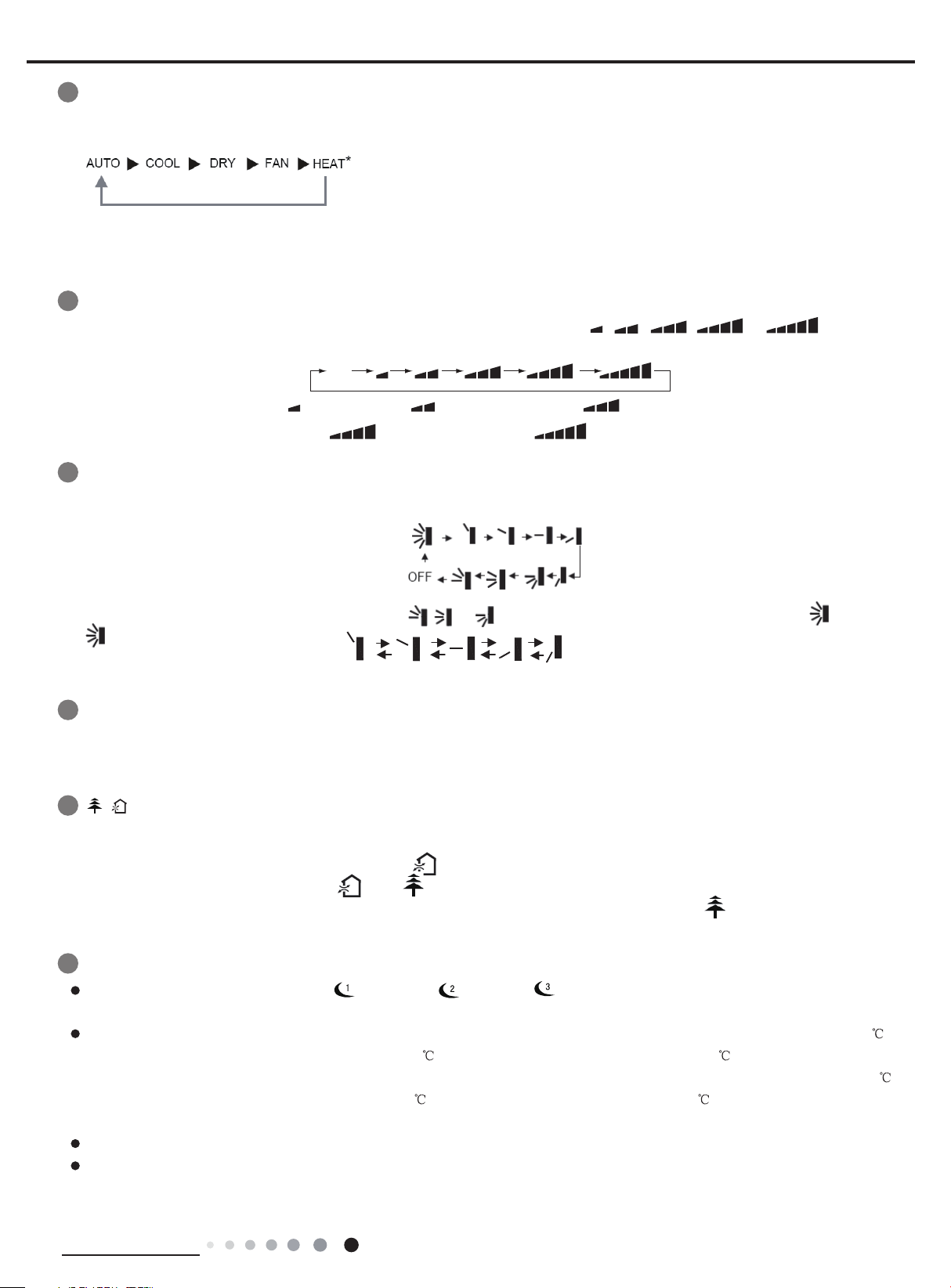

the

fter

,

Sleep 3- the sleep curve setting under Sleep mode by DIY:

MODE button

3

Each time you press this button , a mode is selected in a sequence that goes from AUTO,COOL, DRY, FAN, and HEAT * , as

following:

*Note:Only for models with heating function.

After energization, AUTO mode is defaulted. In AUTO mode, the set temperature will not be displayed on the LCD, and the unit

will automatically select the suitable operation mode in accordance with the room temperature to make indoor room comfortable.(As

for cooling only unit,it won’t have any action when it receives the signal of heating operation.)

4

FAN button

,

This button is used for setting Fan Speed in the sequence that goes from AUTO, to then back

to Auto.

Auto

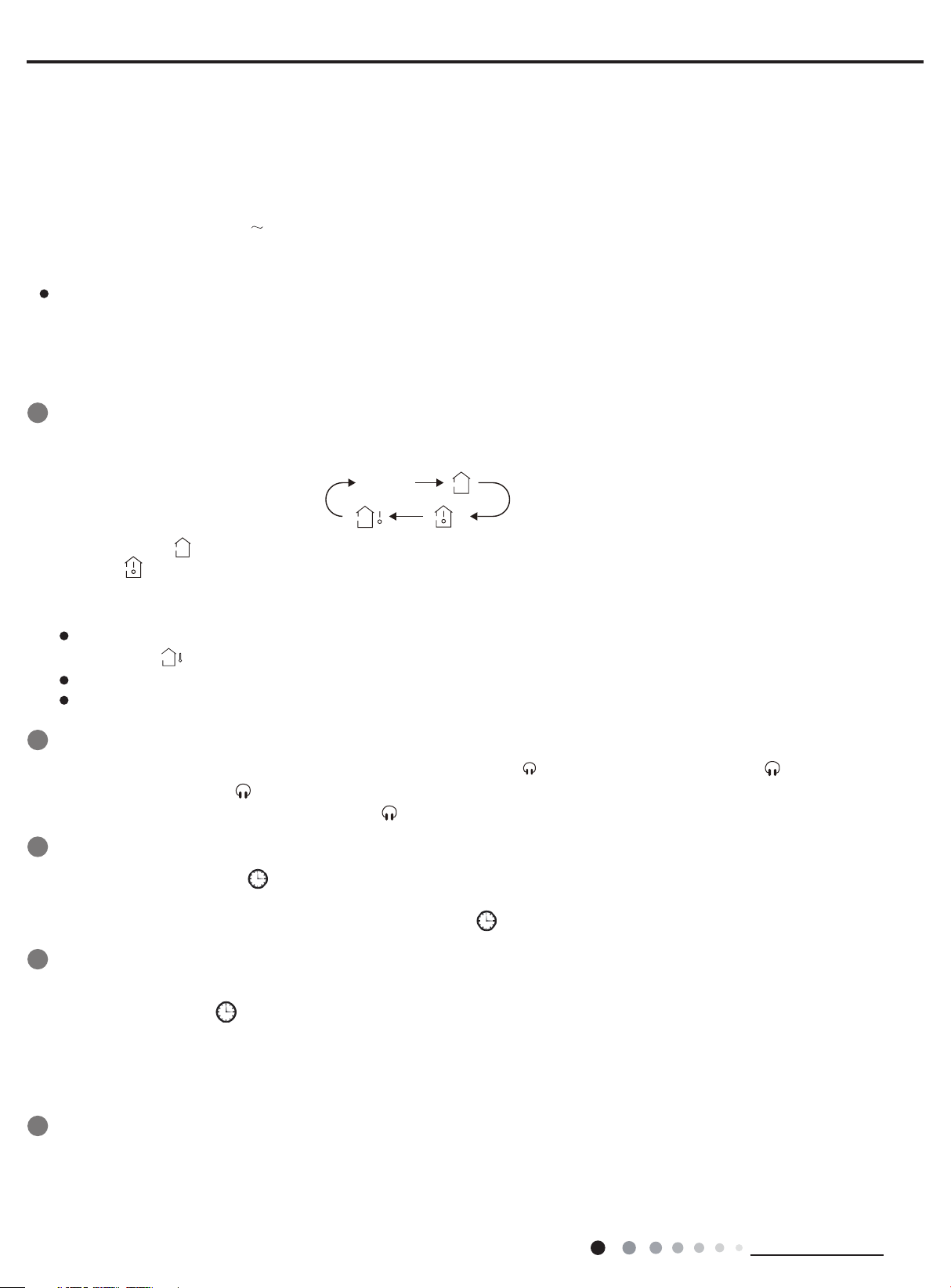

SWING button

5

Press this button to set up &down swing angle, which circularly changes as below:

This remote controller is universal. If any command

indicates the guide louver swings as:

, or is sent out, the unit will carry out the command as

,

Medium speedLow-Medium speedLow speed

High speedMedium-High speed

,

,

6

I FEEL button

Press this button to turn on I FEEL function. The unit automatically adjust temperature according to the sensed temperature.

Press this button again to cancel I FEEL function.

7

Press this button to achieve the on and off of healthy and scavenging functions in operation status. Press this button for the

fi rst time to start scavenging function; LCD displays "

functions simultaneously; LCD displays "

functions simultaneously. Press the button for the fourth time to start healthy function; LCD display "

to repeat the operation above.

8

SLEEP button

Press this button, can select Sleep 1 ( ), Sleep 2 ( ),Sleep 3 ( ) and cancel the Sleep,circulate between these, a

electrifi ed, Sleep Cancel is defaulted.

Sleep 1 is Sleep mode 1, in Cool mode: after run for one hour in sleep mode, the main unit setting temperature will increase 1

after 2 hours, the setting temperature will increase 2 , but the maximal setting temperature is 30 , then the unit will run at

this setting temperature all along; In Heat mode: after run for one hour in sleep mode, the setting temperature will decrease 1

after 2 hours the setting temperature will decrease 2 , but the minimal setting temperature is 16 , then the unit will run at this

setting temperature all along.

Sleep 2 is sleep mode 2, that is air conditioner will run according to the presetting a group of sleep temperature curve.

/

button

". Press the button for the second time to start healthy and scavenging

" and " ". Press this button for the third time to quit healthy and scavenging

". Press this button again

Technical Information

21

Service Manual

(1) Under Sleep 3 mode, press "Turbo" button for a long time, remote control enters into user individuation sleep setting status, at this

last

the

y

, the sleep

cedure, press

in

time.

high fan speed.

+ or - button

time, the time of remote control will display "1hour ",the setting temperature "88" will display the corresponding temperature of

setting sleep curve and blink (The fi rst entering will display according to the initial curve setting value of original factory);

(2) Adjust "+" and "-" button, could change the corresponding setting temperature, after adjusted, press "Trubo "button for confi rmation;

(3) At this time, 1hour will be automatically increased at the timer postion on the remote control, (that are "2hours " or "3hours " or

"8hours "), the place of setting temperature "88" will display the corresponding temperature of last setting sleep curve and blink;

(4) Repeat the above step (2)

remote control will resume the original timer display;temperature display will resume to original setting temperature.

Sleep3- the sleep curve setting under Sleep mode by DIY could be inquired:

The user could accord to sleep curve setting method to inquire the presetting sleep curve,enter into user individuation sleep setting

status, but do not change the temperature, press "Turbo" button directly for confirmation.Note: In the above presetting or enquir

procedure,if continuously within10s, there is no button pressed, the sleep curve setting within 10s, there is no button pressed

curve setting status will be automatically quit and resume to display the original displaying. In the presetting or enquiry pro

"ON/OFF" button, "Mode" button, "Timer"button or "Sleep" button, the sleep curve setting or enquiry status will quit similarly.

9

TEMP button

Press this button, you can see indoor set temperature, indoor ambient temperature on indoor unit’s display. The setting on remote

controller is selected circularly as below:

(3) operation, until 8hours temperature setting fi nished,sleep,curve setting fi nished, at this time,

no display

When selecting " " with remote controller or no display, temperature indicator on indoor unit displays set temperature; When

selecting " " with remote controller, temperature indicator on indoor unit displays indoor ambie nt temperature; 5s later or within 5s

it receives other remote control signal that will return to display the setting temperature.

Caution:

This model hasn't outdoor ambient temperature display function. While remote controller

can operate " " and indoor unit displays set temperature.

It’s defaulted to display set temperature when turning on the unit.

Only for the models with temperature indicator on indoor unit.

10

QUIET button

Press this button, the Quiet status is under the Auto Quiet mode (display " "signal )and Quiet mode (display " " singal) and Quiet

OFF (there is no signal of " "displayed),after powered on, the Quiet OFF is defaulted. Note: the Quiet function cannot be set up

Fan and Dry mode;Under the Quiet mode (Display" " Under the Quiet mode) the fan speed is not available.

11

ClOCK button

Press CLOCK button,blinking.

2 seconds increases or decreases the time by 1 minute every 0.5 second and then by 10 minutes every 0.5 second. During blinking

after setting, press CLOCK button again to confi rm the setting, and

12

13

/

T-ON T-OFF button

Press T-ON button to initiate the auto-ON timer. To cancel the auto-timer program, simply press this button again.

After press of this button, disappears and "ON "blink s . 00:00 is displayed for ON time setting. Within 5 seconds, press

to adjust the time value. Every press of either button changes the time setting by 1 minute. Holding down either button rapidly changes

the time setting by 1 minute and then 10 minutes. Within 5 Seconds after setting, press TIMER ON button to confi rm.

Press T-OFF button to initiate the auto-off timer. To cancel the auto-timer program, simply press the button again.TIMER OFF setting is

the same as TIMER ON.

TURBO button

Press this button to activate / deactivate the Turbo function which enables the unit to reach the preset temperature in the shortest

In COOL mode, the unit will blow strong cooling air at super high fan speed. In HEAT mode, the unit will blow strong heating air at super

Auto

Within 5 seconds, pressing + or - button adjusts the present time. Holding down either button above

then will be constantly displayed.

22

Technical Information

Service Manual

s

14

WiFi button

Press " WiF "i button to turn on or turn off WiFi function. When WiFi function is turned on, the " W i F i " icon will be displayed on remote

controller; Under status of unit off, press "MODE" and "W i F i " " buttons simultaneously for 1s, WiFi module will restore to factory

default setting.

● This function is only available for some models.

15

LIGHT button

Press LIGHT button to turn on the display's light and press this button again to turn off the display 's light. If the light is turned on , i

displayed. If the light is turned of

If “H1” is displayed on the remote controller while it’s not operated by the professional person/after-sales person, it belongs to the

misoperation.

Please operate it as below to cancel it.Under the OFF status of remote controller, hold the Mode button for 5s to cancel “H1” display.

Note:

● If remote controller displays “H1”, it belongs to the normal function reminder. If the unit is defrosting under heating mode, it operates

according to H1 defrosting mode. “H1” won’t be displayed on the panel of indoor unit;

● Once you set H1 mode, if you turn off unit by remote controller, H1 will display 3 times on the remote controller and then disappear;

● Also, when you set H1 mode, when you change to heating mode, H1 will display 3 times on the remote controller and then disappear.

Combination of "+" and "-" buttons: About lock

Press "+" and "-" buttons simultaneously to lock or unlock the keypad. If the remote controller is locked,

pressing any button,

Combination of "MODE" and "-" buttons:About switch between Fahrenheit and centigrade

At unit OFF, press "MODE" and "-" buttons simultaneously to switch between °C and °F.

Combination of "TEMP" and "CLOCK" buttons:About Energy-saving Function

Press "TEMP" and "CLOCK" simultaneously in COOL mode to start energy-saving function.Nixie tube on the remote controller displays

"SE". Repeat the operation to quit the function.

Combination of "TEMP" and "CLOCK" buttons:About 8°C Heating Function

Press "TEMP" and "CLOCK" simultaneously in HEAT mode to start 8°C Heating Function Nixie tube on the remote controller displays

" and a selected temperature of "8°C".(46°F if Fahrenheit is adopted). Repeat the operation to quit the function.

"

About Back-lighting Function

The unit lights for 4s when energizing for the

blinks three times.

f, disappears.

is displayed. In this case,

fi rst time, and 3s for later press.

Replacement of Batteries in Remote Controller

1.Press the back side of remote controller marked with“

of battery box along the arrow direction.

2. Replace two 7# (AAA 1.5V) dry batteries, and make sure the position of “+” polar and “-“ polar are correct.

3. Reinstall the cover of battery box.

Note:

● During operation, point the remote control signal sender at the receiving window

on indoor unit.

● The distance between signal sender and receiving window should be no more than

8m, and there should be no obstacles between them.

● Signal may be interfered easily in the room where there is fluorescent lamp or

wireless telephone; remote controller should be close to indoor unit during operation.

● Replace new batteries of the same model when replacement is required.

● When you don’t use remote controller for a long time, please take out the batteries.

● If the display on remote controller is fuzzy or there’s no display, please replace

batteries.

”as shown in the fi g, and then push out the cover

battery

reinstall

remove

Cover of battery box

Technical Information

23

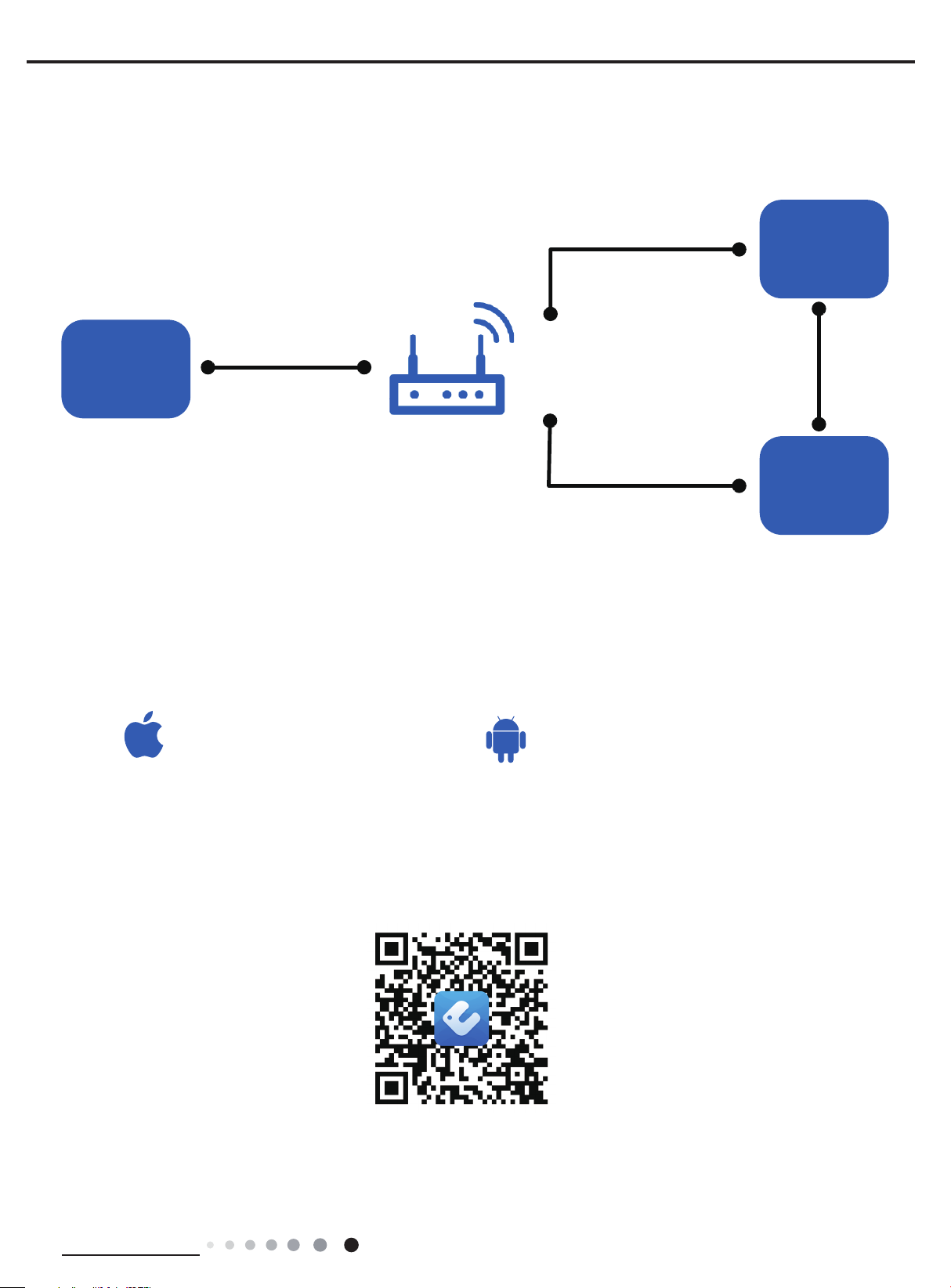

6.2 GREE+ App Operation Manual

iOS system

Android system

and

GREE+ App Download Linkage

Control Flow Chart

Service Manual

Internet

Gree Cloud

Gree

intelligent

Home Wi-Fi

home

appliances

Operating Systems

Requirement for User's smart phone:

Support iOS7.0 and

above version

Cellular/

Other Wi-FI

Home wireless router

Home Wi-Fi

GREE+ APP

Support Android 4.4

above version

Download and installation

Scan the QR code or search "GREE+" in the application market to download and install it. When "GREE+" App is installed, register the

account and add the device to achieve long-distance control and LAN control of Gree smart home appliances.

For more information, please refer to "Help" in App.

24

Technical Information

Service Manual

iOS system

Android system

and

6.3 Ewpe Smart App Operation Manual

Control Flow Chart

Internet

Cloud

intelligent

Home Wi-Fi

home

appliances

Operating Systems

Requirement for User's smart phone:

Support iOS7.0 and

above version

Cellular/

Other Wi-FI

Home wireless router

Home Wi-Fi

APP

Support Android 4.4

above version

Download and installation

App Download Linkage

Scan the QR code or search "Ewpe Smart" in the application market to download and install it. When "Ewpe Smart" App is installed,

register the account and add the device to achieve long-distance control and LAN control of smart home appliances.

For more information, please refer to "Help" in App.

Technical Information

25

Service Manual

6.4 Brief Description of Modes and Functions

1. Cooling mode

(1) Under this mode, the fan and the up swing will operate at setting status. The temperature setting range is 16~30ºC.

(2) The unit is stopped because of malfunction of outdoor unit or protection. The indoor unit keeps original operation status and the

error code is displayed.

(3) Indoor unit is stopped due to mode shock.

2. Drying mode

(1) Under this mode, the fan operates at low speed and the swing operates at setting status. The temperature setting range is

16~30ºC.

(2) The unit is stopped because of malfunction of outdoor unit or protection. The indoor unit keeps original operation status and the

error code is displayed.

3. Heating mode

(1) Under this mode, the temperature setting range is 16~30ºC.

(2) Working condition and process for heating

When the unit is turned on under heating mode, the indoor unit turns to cold air prevention status. When the unit is turned off and the

indoor unit has been started up before, the indoor unit blows the residual heat.

(3) Protection function: When the compressor is stopped due to malfunction under heating mode, the indoor unit blows the

residual heat.

(4) Blow residual heat

When the unit stops operation as it reaches the temperature point, indoor unit will continue to run for 60s. The fan speed cant be

switched during blowing residual heat period. The upper horizontal louver will turn to the defaulted position in cooling. When the unit

operates under heating mode or auto heating mode, compressor will be turned on and the corresponding electric expansion valve is

more than 65 and the unit stops operation during the operation status of indoor unit. The upper horizontal louver will turn to the

defaulted position in heating mode. The indoor unit operates at low speed for 10s and then the unit stops operation.

(5) Defrosting, oil-returning

As it received the signal of defrosting and oil-returning from outdoor unit, the upper horizontal louver will turn to the minimum angle in

cooling. 10s later, the in door fan stop operation. During defrosting and oil-returning process and they are quitted within 5mins, all

malfunctions for indoor tube temperature sensor wont be detected.

4. Working process for AUTO mode (Mode judgment will be performed every 30s)

Under AUTO mode, standard cooling Tpreset=25ºC (77ºF), standard heating Tpreset=20ºC (68ºF), and standard fan Tpreset= 25ºC

(77ºF).

(1) When Tamb≥26ºC (79ºF), the unit operation in cooling mode;

(2) Heating pump unit: When Tamb≤19ºC (66ºF), the unit operates in heating mode;

(3) Cooling only unit: Tamb≤19ºC (66ºF), the unit operates in fanmode;

(4) When 19ºC<Tindoor amb.<26ºC, if it turns to auto mode as the unit is turned on for the rst time the unit will operates at auto fan

mode. If it switch to auto mode from other modes, the unit will keep previous operation mode (when it turns to dry mode, the unit

operates at auto fan mode).

(5) Protection function

Protection function is the same as that in cooling or heating mode.

5. Fan mode

Under fan mode, only indoor fan and swing operates. When it operates at auto fan speed, it will operate according to auto fan speed

condition in cooling.

6. Mode shock

If the mode shock is 1 which is received by indoor unit from outdoor unit, the loads of indoor unit (indoor unit, auxiliary heating,swing)

stop operation and the error code is displayed. The mode sent to outdoor unit is still remote control receiving mode. The unit will be

turned off during mode shock.

If timer ON is reached, and the mode shock is 1 which is received by indoor unit from outdoor unit, the loads of indoor unit (indoor

unit,auxiliary heating, swing) stop operation and the error code is displayed. The mode sent to outdoor unit is still remote control receiving

mode.

7. Other control

7.1 Buzzer

Upon energization or availably operating the unit or remote controller, the buzzer will give out a beep.

7.2 Auto button

If this button is pressed, the unit will operate in AUTO mode and indoor fan will operate at auto speed; meanwhile, the swing motor

operates. Press this button again to turn off the unit.

7.3 8 ºC heating function

Under heating mode, press TEMP+CLOCK buttons simultaneously. Under this mode, “cold air prevention protection” will be shielded.

26

Technical Information

Service Manual

7.4 I FEEL function

When I FEEL command is received, the controller will operate according to the ambient temperature sent by the remote controller (For

defrosting and cold blow prevention, the unit operates according to the ambient temperature sensed by the air conditioner). The

remote controller will send ambient temperature data to the controller every 10min. When the data has not been received after

11mins,the unit will operate according to the temperature sensed by the air conditioner. If I FEEL function is not selected, the ambient

temperature will be that sensed by the air conditioner. I FEEL function will not to be memorized.

7.5 Timer function

General timer and clock timer functions are compatible by equipping remote controller with different functions.

(1)General Timer

Timer ON can be set at unit OFF. If selected ON time is reached, the unit will start to operate according to previous setting status.

Time setting range is 0.5-24hr in 30-minute increments.

Timer OFF can be set at unit ON. If selected OFF time is reached, the unit will stop operation. Time setting range is 0.5-24hr in

30-minute increments.

(2)Clock Timer

Timer ON

If timer ON is set during operation of the unit, the unit will continue to operate. If timer ON is set at unit OFF, upon ON time reaches

the unit will start to operate according to previous setting status.

Timer OFF

If timer OFF is set at unit OFF, the system will keep standby status. If timer OFF is set at unit ON, upon OFF time reaches the unit

will stop operation.

Timer Change

Although timer has been set, the unit still can be turned on/off by pressing ON/OFF button of remote controller. You can also set

the timer once again, and then the unit will operate according to the last setting. If timer ON and timer OFF are set at the same time

during operation of the unit, the unit will keep operating at current status till OFF time reaches. If timer ON and timer OFF are set at

the same time at unit OFF, the unit will keep stop till ON time reaches. In the future’s every day, the system will operate according to

presetting mode till OFF.

7.6 Sleep function

This mode is only valid in cooling and heating modes. The unit will select proper sleep curve to operate according to different set

temperature.

7.7 Compulsory defrosting function

When the unit is turned on in heating by remote controller and the set temperature is 16oC, press “+,-,+,-,+,-”continuously within 5s,

the indoor unit turns to compulsory defrosting setting and it will send compulsory defrosting mode to outdoor unit.

When indoor unit received the compulsory defrosting signal from outdoor unit, the indoor unit will quit from the compulsory defrosting

setting and it will cancel to send compulsory defrosting mode to outdoor unit.

7.8 Refrigerant recovery function

Turn to Freon recovery mode: After the unit is energized for 5min, and the unit is turned on at 16ºC under cooling mode, press light

button on remote controller for 3 times successively within 3s to turn to Freon recovery mode. Fo is displayed and it will send Freon

recovery mode to outdoor unit.

Quit from Freon recovery mode:After it turns to Freon mode, if it receives any signal from remote controller or it turns to Freon

recovery mode for 25 mins, it will quit from Freon recovery mode.

Turn to the action for Freon recovery mode: indoor unit will be turned on in cooling mode. The fan speed is super-high fan speed and

the set temperature is 16oC. The horizontal louver will turn to the minimum operation angle.

Quit the action for Freon recovery mode: The indoor fan operates at the previous set status by remote controller.

7.9 Pilot run function

When the set temperature is 30oC under cooling mode, press “+,-,+,-,+,-”continuously within 5s, the indoor unit turns to pilot run

setting mode and it will send pilot run mode to outdoor unit.

Pilot run mode: it operates under cooling mode and “dd” is displayed.

Quit the pilot run mode and indoor unit cancels “dd” display. If it receives “wrong wire connection of malfunction of expansion valve”

from outdoor unit, “dn” will be displayed.

Technical Information

27

Loading...

Loading...