Gree GDN12AJ-K4EBC1A, GDN16AJ-K4EBC1A, GDN12AJ-K4EBC1B Service Manual

Service Manual

Change for Life

Service Manual

Models: GDN12AJ-K4EBC1A

GDN12AJ-K4EBC1B

GDN16AJ-K4EBC1A

(Refrigerant R134a)

GREE ELECTRIC APPLIANCES,INC.OF ZHUHAI

Table of Contents

Service Manual

Part

1. Summary

2. Specications

: Technical Information

Ⅰ

.................................................................................................... 1

.......................................................................................... 2

3. Outline Dimension Diagram

4. Refrigerant System Diagram

5. Electrical Part

5.1 Wiring Diagram ........................................................................................... 5

5.2 PCB Printed Diagram .................................................................................. 6

6. Function and Control

6.1 Control Panel Instruction ............................................................................. 8

6.2 Introduction of Basic Mode Function ........................................................... 9

Part

: Maintenance

Ⅱ

7. Notes Maintenance

........................................................................................... 5

........................................................................... 8

............................................................................ 11

............................................................................. 11

............................................................ 1

............................................................. 3

........................................................... 4

8. Maintenance

8.1 Error Code ................................................................................................. 12

8.2 Malfunction Detection Flowchart ............................................................... 13

8.3 Maintenance Method for Common Malfunction ........................................ 14

9. Exploded View and Parts List

10. Removal Procedure

Appendix:

Appendix 1: Reference Sheet of Celsius and Fahrenheit ............................... 25

Appendix 2: Resistance Table of Temperature Sensor ................................... 26

Appendix 3: Resistance Value Table of Humidity Sensor ............................... 29

...................................................................................................... 25

........................................................................................... 12

....................................................... 16

......................................................................... 20

Table of Contents

Service Manual

Part

: Technical Information

Ⅰ

1.Summary

Models:

GDN12AJ-K4EBC1A

GDN16AJ-K4EBC1A

GDN12AJ-K4EBC1B

Technical Information

1

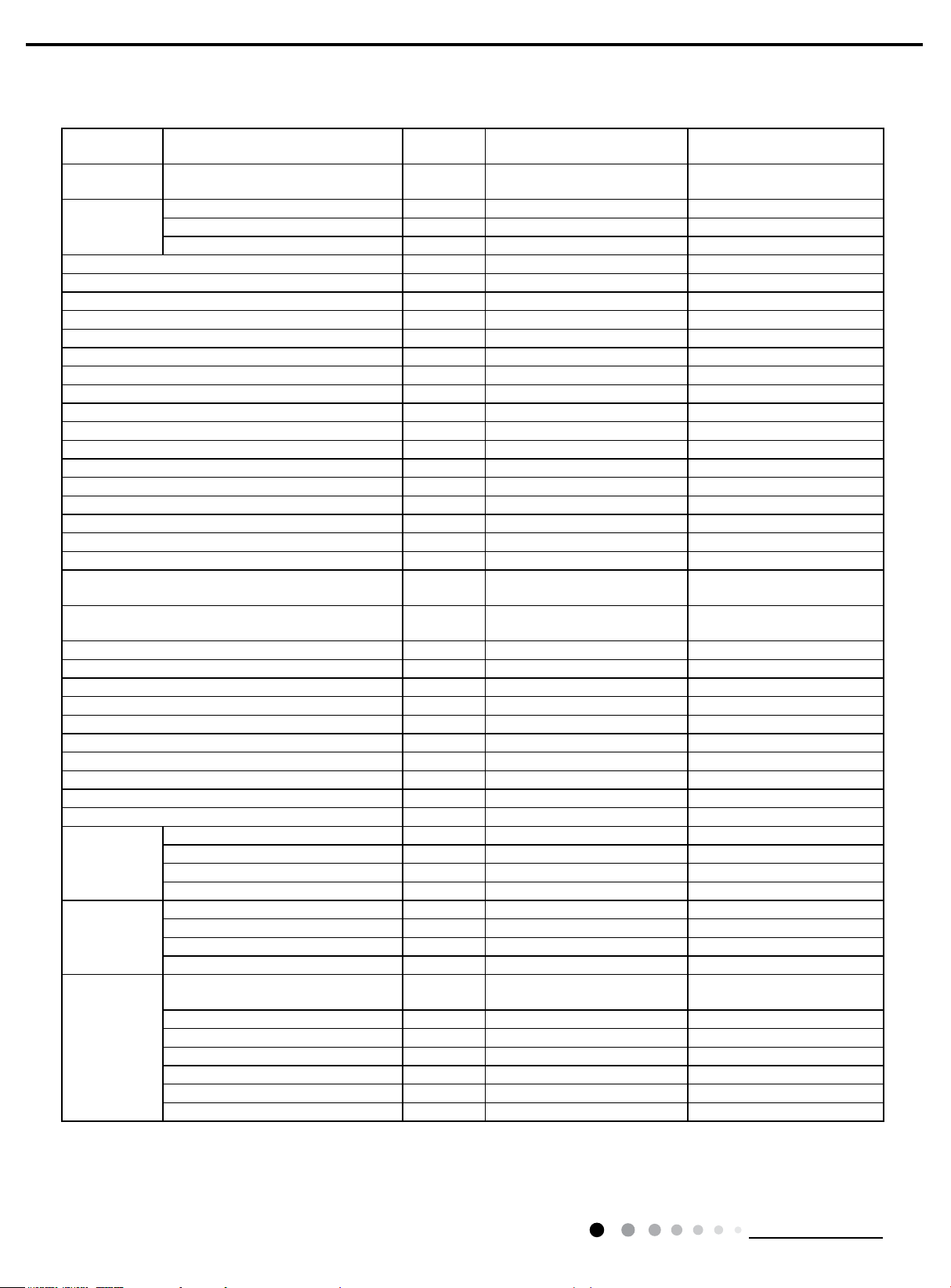

2.Specications

Service Manual

Model

Product Code

Rated Voltage V~ 220-240 220-240

Power Supply

Rated Dehumidifying Volume L/h 0.23 0.4

Power Input W 230 295

Power Current A 1.3 1.3

Set Humidity Range % 35~80 35~80

Air Flow Volume(H/M/L) m

Fan Motor Speed (H/M/L) r/min 1100/-/950 1100/-/950

Output of Fan Motor W 4 4

Fan Motor Capacitor μF 1.5 1.5

Fan Type Centrifugal Centrifugal

Diameter Length(DXL) mm Φ180X54.5 Φ180X54.5

Throttling Method Capillary Capillary

Fuse A 3.15 3.15

Sound Pressure Level (H/M/L) dB (A) 43/-/41 45/-/43

Sound Power Level ((H/M/L) dB (A) 53/-/51 53/-/51

Climate Type T1 T1

Isolation I I

Moisture Protection IPX0 IPX0

Permissible Excessive Operating Pressure for the

Discharge Side

Permissible Excessive Operating Pressure for the

Suction Side

Dimension (WXHXD) mm 353X496X225 353X496X225

Dimension of Carton Box (LXWXH) mm 393X271X510 393X271X510

Dimension of Package (LXWXH) mm 396X274X525 396X274X525

Application Area m

Net Weight kg 11 13.5

Gross Weight kg 12 14.5

Refrigerant R134a R134a

Refrigerant Charge kg 0.09 0.17

Bucket Capacity L 3/3.5 3/3.5

Control Type Electronic Electronic

Evaporator

Condenser

Compressor

Rated Frequency Hz 50 50

Phases 1 1

3

/h 115/-/100 115/-/100

MPa 3 3

MPa 1.8 1.8

2

Form Aluminum Fin-copper Tube Aluminum Fin-copper Tube

Pipe Diameter mm Φ7 Φ7

Row-n Gap mm 1-1.4 2-1.6

Coil Length (LXDXW) mm 210X12.7X152.4 210X25.4X152.4

Form Aluminum Fin-copper Tube Aluminum Fin-copper Tube

Pipe Diameter mm Φ5 Φ7

Rows-n Gap mm 2-1.4 2-1.4

Coil Length (LXDXW) mm 210X22.8X152.4 210X25.4X152.4

Compressor Manufacturer/Trademark

Model BSA418CV-R1AUN 39E0G3HR&F^YA

Type Rotary Rotary

Power Input W 213 265

Overload Protector URP-191-78 or equivalent UP3-106

L.R.A. A 3.4 5.5

Working Current A 1.1 1.2

1.GDN12AJ-K4EBC1A

2.GDN12AJ-K4EBC1B

1.CK051012901/CK051012902

2.CK051019102

15 20

Shanghai Hitachi Electrical

Appliances Co.,Ltd/HIGHLY

GDN16AJ-K4EBC1A

CK051013001

CK051013003

Shanghai Hitachi Electrical

Appliances Co.,Ltd/HIGHLY

The above data is subject to change without notice; please refer to the nameplate of the unit.

2

Technical Information

Service Manual

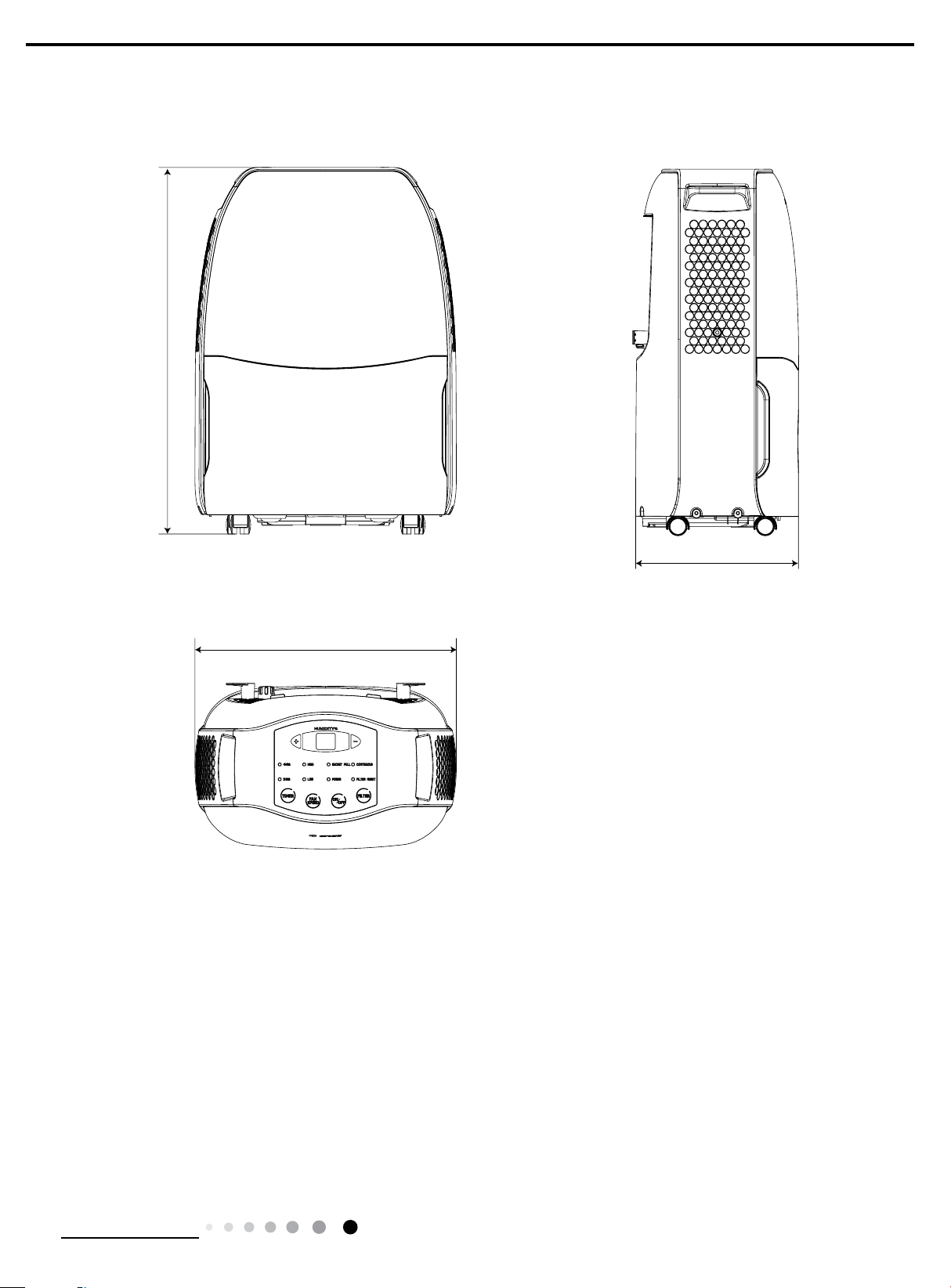

496

3.Outline Dimension Diagram

225

353

Unit:mm

Technical Information

3

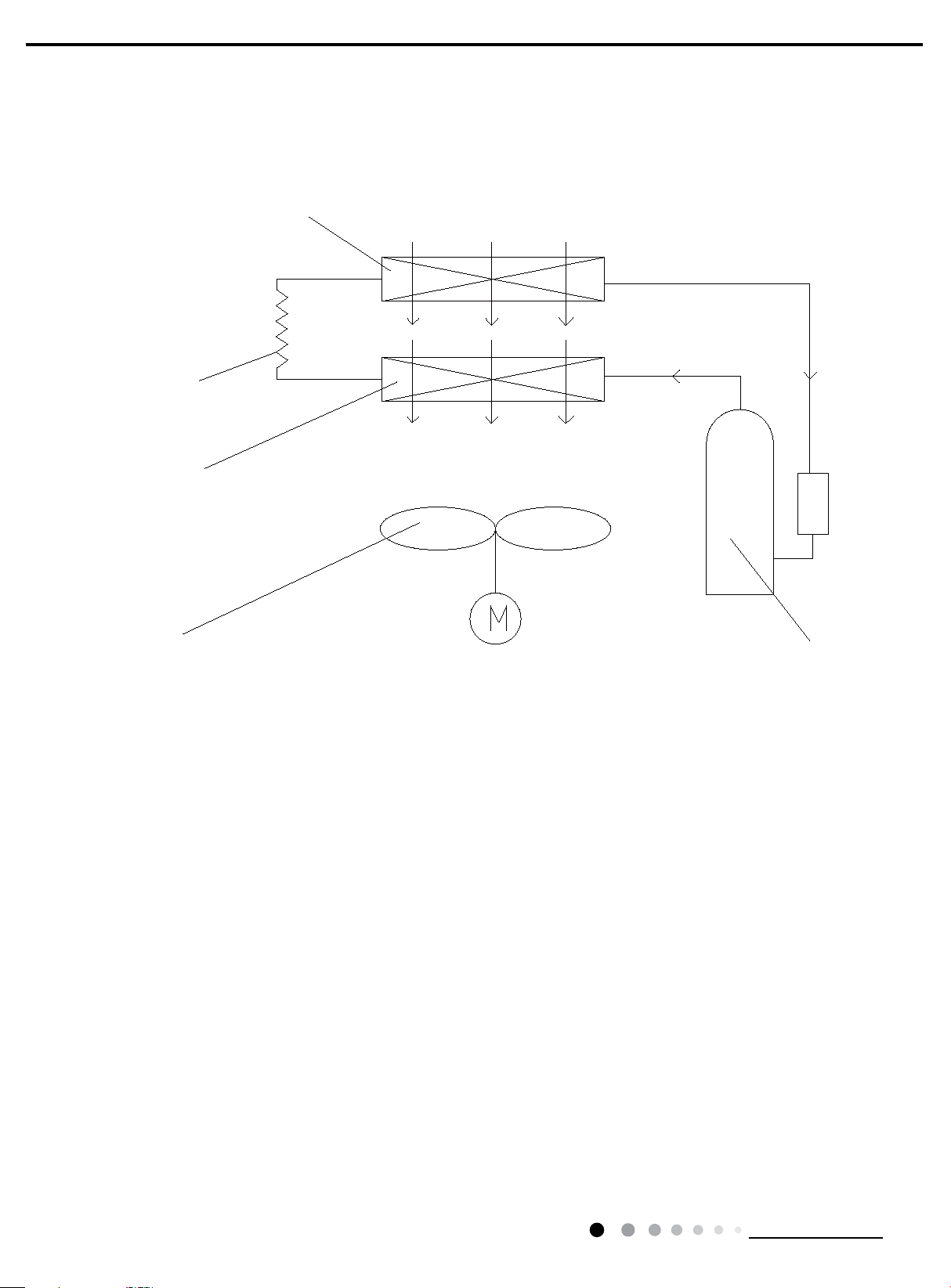

4.Refrigerant System Diagram

evaporator

capillary

condenser

Service Manual

air in

air out

fan motor

compressor

Dehumidifying principle of dehumidier:

When temperature is decreased to the temperature point of dew, water vapor in humid air will condensate. Dehumidier is

dehumidifying the air by using this principle.

During operation of the system, air will pass through evaporator and condenser in turn and then be discharged due to centrifugal

blade. When the air is passing through evaporator, refrigerant will absorb the heat in air to let its temperature decrease to the

temperature point of dew, water vapor in air will condensate. Condensate water comes into water tank through water tray, or is

discharged directly through drainage hose. The saturated low-temperature air passed through the evaporator will absorb the heat

when owing along the condenser, and then become the dry air. Under normal condition, the nearby air will become warm during

operation of dehumidier.

4

Technical Information

Service Manual

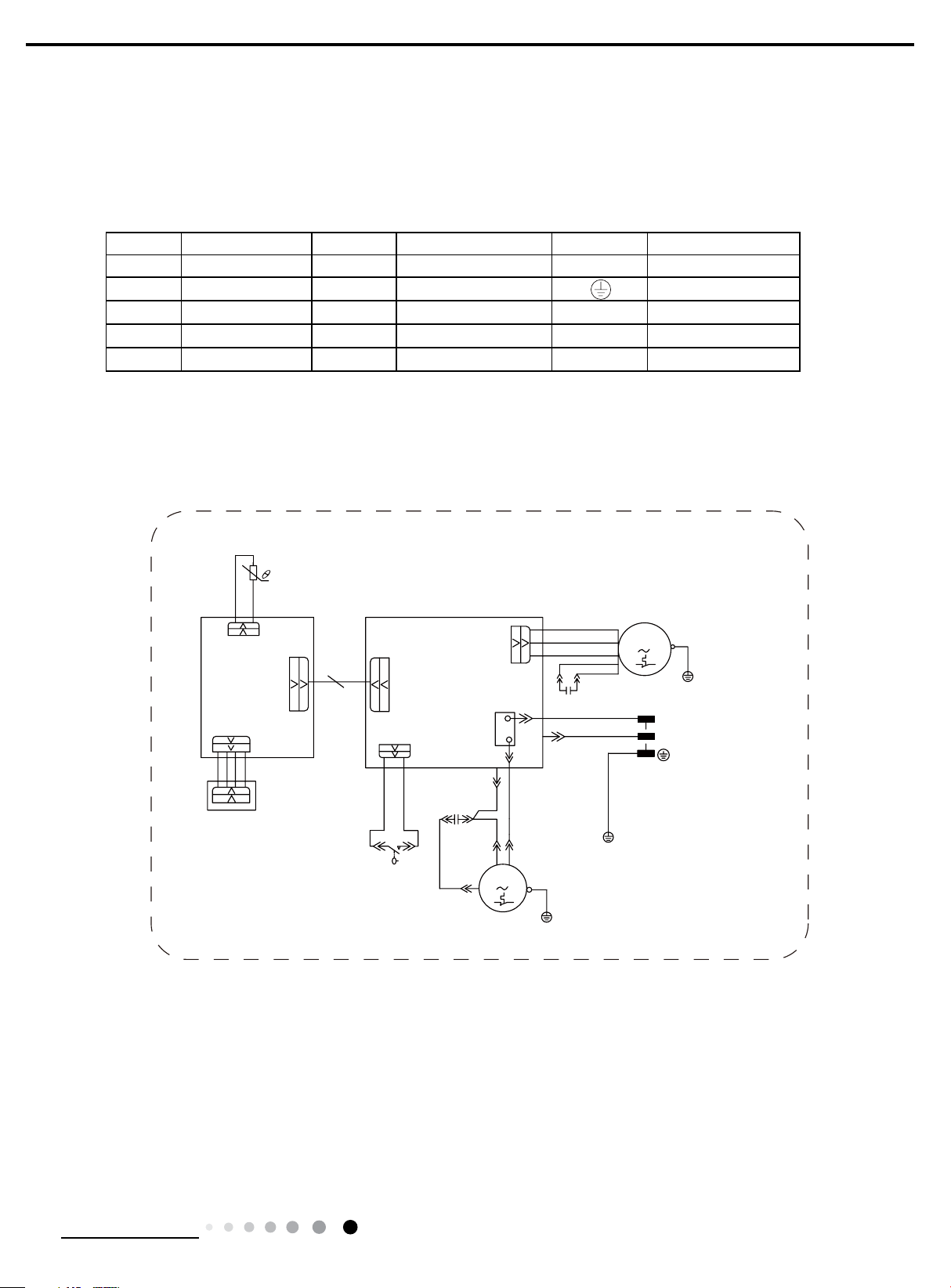

5.Electrical Part

5.1 Wiring Diagram

●Instruction

Symbol Symbol Color Symbol Symbol Color Symbol Name

WH White GN Green COMP Compressor

YE Yellow BN Brown Grounding wire

RD Red BU Blue / /

YEGN Yellow/Green BK Black / /

VT Violet OG Orange / /

TUBE TEMP.SENSOR

TUBE

AP2

CN4

RT1

CN1

CN1

CN2

AP1

AC-L

COMP

CN3

K1

N

FAN MOTOR

C1

BN(BK)

BU(WH)

M1

L

N

YEGN

PE

POWER

N1

RD

BN

ST

BU

HUMIDITY

SENSOR

COM

LIQUID LEVEL

These circuit diagrames are subject to change without notice ,please refer to the one supplied with the unit.

NO

SA

SWITCH

C2

YE

BU

BU

R(M)

COMP.

S

YEGN(GN)

C

YEGN

PE

PE

63610000213

Technical Information

5

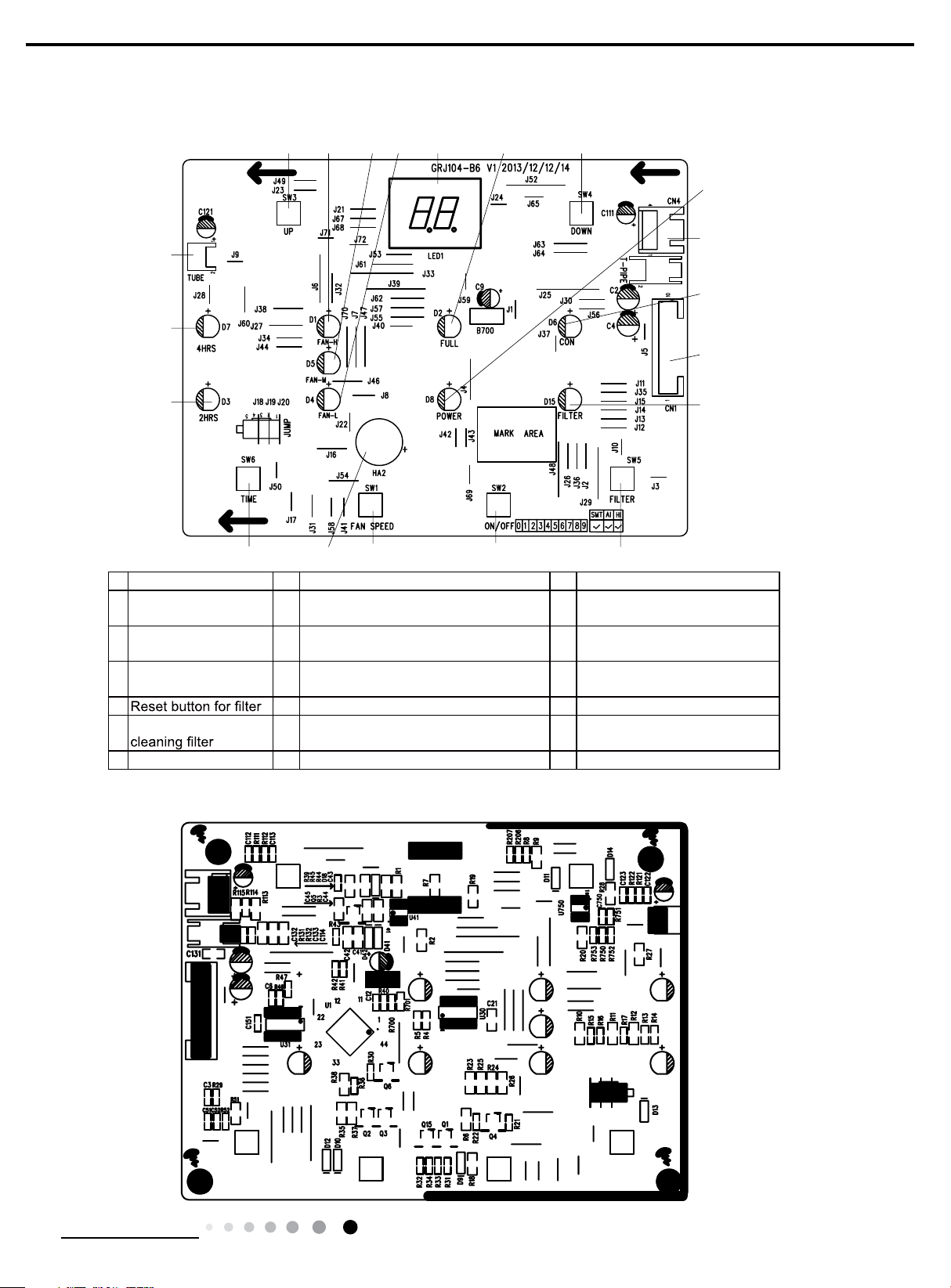

5.2 PCB Printed Diagram

Silk Screen on Main Board

● Top view

Service Manual

16

2

5

4

3

No. Name Description No. Name Description

Needle stand of board

1

connection wire

2 Needle stand of fan Connect to fan 5 Interface of compressor Connect to compressor

3 Interface of live wire

Connect to display board 4 Interface of neutral wire

Connect to live wire of

commercial wire

Needle stand of water

6

blow protection switch

● Bottom view

Connect to neutral wire

of commercial wire

Connect to water blow

protection switch

6

Technical Information

Service Manual

Silk Screen on Display Board

● Top view

11121314171516

18

19

20

12345

1Timer button 8 Indicator of dehumidifying continuously15Indicator of high fan speed

2 Buzzer 9

Connection between humidity sensor

(needle stand)

16 Button for setting humidity (+)

10

9

8

7

6

3 Fan speed button 10 Power indicator Indicator of mid fan speed17

4 ON/OFF button 11 Button for setting humidity (-) 18

5 12 Indicator for bucket full protection 19 4H timer indicator

Alarming indicator for

6

7 Wire connection 14 Indicator for low fan speed

13 Dual-8 nixie tube 20 2H timer indicator

Needle stand for tube

temperature sensor

● Bottom view

Technical Information

7

6.Function and Control

3

1

Continuous operation on

4 hour or 2 hour

indicator lights

delay on/o

6.1 Control Panel Instruction

High and Low fan

indicator lights

Service Manual

4

Bucket full light indicates

bucket needs to be emptied

or it is not in the proper place

ff

Power On

indicator light

1.ON/OFF Pad

Press to turn the dehumidier on or off.

6

5

2

indicator light

Clean the Filter

indicator light

2.FILTER Pad

After 250 hours of operation, the Clean the Filter indicator light will glow to remind you to clean the lter. Remove the lter and

clean it. Press to turn off the Clean the Filter light. See the Care and Cleaning section.

3.Humidity Set Control Pads

The humidity level can be set within a range of 80% RH (Relative Humidity) to 35% RH (Relative Humidity) in 5% reduce or at

CO for continuous operation.

NOTE: If CO (Continuous) is selected, the dehumidier will operate continuously at its maximum dehumidication settings if

attached to a hose to drain or until the bucket is full.

For drier air, press the - pad and set to a lower percent value (%).

For damper air, press the + pad and set to a higher percent value (%).

When you first use the dehumidifier, set the humidity control to 45% or 50%. Allow at least 24 hours for the dehumidifier to

achieve the humidity level. If you still have damper air than desired, set the humidity level to a lower setting or select Continuous

for maximum dehumidication.

This unit has 3-min lag due to the device for protecting circuit .In order to prolong the compressor's working life, the compressor

will not start until the unit has run for 3 minutes.

4.Display

Shows the set % humidity level while setting, then shows the actual (+/– 5% accuracy) room % humidity level.

5.FAN SPEED Pad

Controls the fan speed. Press to select High or Mid or Low fan speed.

Set the fan control to High for maximum moisture removal. When the humidity has been reduced and quiet operation is preferred,

set the fan control to Mid or Low.

6.TIMER Pad

If unit is turned on and running in timer mode for 2hr or 4hr,can turn off the unit. When unit stand by and running in timer mode

for 2hr or 4hr can turn on the unit.

Other Features

BUCKET FULL Light

Glows when the bucket is ready to be emptied, or when the bucket is removed or not replaced in the proper position.

Alarm

If the bucket is full or missing for more than three minutes, an alarm will sound for about 10 seconds to remind you to empty and

replace the bucket.

Auto Shut Off

The Water Level Control Switch shuts off the dehumidier when the bucket is full, or when the bucket is removed or not replaced

in the proper position.

8

Auto Defrost

When frost builds up on the evaporator coils, the compressor will cycle off and the fan will continue to run until the frost

disappears.

Power Outage

In the case of a power outage or interruption, the unit will automatically re-start, in the settings last used, after the power is

restored.

Technical Information

Service Manual

6.2 Introduction of Basic Mode Function

1. Basic functions of system

(1) Drying mode

Dry conditions and process: under operation status

①

a. When set humity≤ambient humidity-5%, compressor and fan will operate.

b. When set humidity≥ambient humidity+5%, compressor stop operation and fan will stop operation after 3min.

c. When ambient humidity-5%<set humidity<ambient humidity+5%, if compressor is operating, and it will operation with condition a; if

compressor stops operation, it will operate with condition b.

Humidity Range

②

a. 5% is the rst notch. It can be adjusted continuously from CO, 35%-80% (CO stands for dehumidify continuously).

b. Adjust set humidity by “+” and “-” buttons.

2. Protection Function

(1) Compressor Protection

After energization, under any situation and after compressor stops, it will restart 3min delay at least.

Under operation state except there's malfunction of temperature sensor , when turn off unit by on/off button, water-blow protection,

or after compress is starts up, the compressor will stop operation after it operates for 3min at least.

(2) Detection for temperature sensor malfunction

When there's malfunction for temperature sensor, compressor and fan stop operation. LED indicator is OFF and buttons are invalid.

Nixie tube displays F2. After the temperature is resumed normally, restart the unit.

(3) Bucket full protection (off switch)

Under operation status, if there's bucket full protection or the water tank hasn't been installed well, compressor stop operation and

the fan also stop operation after the fan operates continously for 3min. If water blow protection occurred for 3min, the buzzer will

stop after it gives out a beep for 10s.Indicator of bucket full blinks and all the buttons are invalid except on/off button. When the water

level or assembly of water tank resume to normal, signal of bucket full protection will cancelled. Indicator is off, buzzer stops to give

out a beep and the fan resumes to normal operation state. Compressor resumes to operation normally after 3mins. When the unit is

off, bucket full protection is occurred, water blow indicator blinks, compressor and fan stop operation, and all the buttons are invalid

except on/off button.

(4) Freeze protection

If freeze protection is detected during operation, compressor stops operation, fan operates at compulsory high speed and the fan

speed buttons are invalid. When freeze protection is completed, fan speed button are valid, fan operates at set status and the

compressor can be restarted up after stopping for 3 minutes.

3. Other Functions

(1) Buttons on front panel

Timer button: use for timer setting

Fan speed button: adjust fan speed

+/- button : adjust humidity

Filter button: adjust lter function

Power button: turn on or turn off unit

(2) LED indicator

2H timer indicator: the indicator is on after setting 2H timer;

4H timer indicator: the indicator is on after setting 4H timer;

High fan speed indicator: the indicator is on after the fan is set at high fan speed;

Low fan speed indicator: the indicator is on after the fan is set at low fan speed;

CONTINUOUS indicator: After continue humidifying is set, continue humidifying indicator is on;

FILTER RESET indicator: the indicator is on when the operation time of fan reaches to 250h totally. After lter is cleaned, press

Technical Information

9

Service Manual

FILTER button and then this indicator is off.

BUCKET FULL indicator: the indicator blinks if bucket full protection is occurred or the water tank hasn’t been installed well.

(3) Timer OFF control

2h or 4h timer OFF can be set. Timer off can be set under on status. Timer setting is recorded every 30min by memory function.

(4) Display of nixie tube (green)

Under on status, the nixie tube displays current humidity. Press "+" button or "-" button to display set humidity. After humidity is set for

5s, it resumes to display current ambient humidity. If “CO” is set, the nixie tube displays “CO”;

When there’s malfunction of temperature sensor, nixie tube displays “F2” and LED is OFF.

(5) Filter alarming function

a. After the fan operates for 250s totally, the lter indicator is on for reminding customer to clean lter. User presses "lter" button to

clear time and then lter indicator is OFF.

b. Under off status, the lter indicator is off; the lter clean time is recorded every 30mins.

(6) Buzzer

When the controller is energized or receives any command or signal from the buttons or the remote controller, the buzzer will give out

a beep.

(7) Power-off memory function

System can memorize the operation status before power failure. The unit can operate at that status automatically when power

recovery.

(8) Ex-factory default setting

Ex-factory default setting: fan speed: high speed

humidity: continue humidifying (CO).

10

Maintenance

Loading...

Loading...