Page 1

CASSETTE TYP FAN COIL UNIT SERVICE MANUAL

(GC201409-I)

Page 2

CONTENTS

PRODUCT .....................................................................................................2

1. MODELS LIST ........................................................................................................ 2

2. NOMENCLATURE OF THE UNIT ........................................................................... 4

3. FUNCTION ..............................................................................................................4

4. PRODUCT DATA .....................................................................................................5

CONTROL ...................................................................................................17

1. WIRELESS REMOTE CONTROLLER ................................................................. 17

2. WIRED REMOTE CONTROLLER ......................................................................... 24

INSTALLTION .............................................................................................28

1. SELECTION THE MOUNTING POSITION ...........................................................28

2. DRAINAGE PIPE ................................................................................................... 29

3. PRECAUTIONS FOR DRAINAGE RAISING PIPE ............................................... 30

4. ELECTRIC WIRING ............................................................................................... 32

5. INSTALLATION OF PANEL ..................................................................................34

MAINTENANCE ..........................................................................................37

1.TROUBLESHOOTING ...........................................................................................37

2.CARE AND MAINTENANCE ..................................................................................37

3. WIRING DIAGRAM ...............................................................................................40

4. DISASSEMBLY AND ASSEMBLY PROCEDURE OF MAIN PARTS ................... 42

5. EXPLODED VIEWS AND SPARE PART LISTS ...................................................48

Page 3

1

Cassette Type Fan Coil

Unit Service Manual

PRODUCT

PRODUCT

Page 4

2

Cassette Type Fan Coil

Unit Service Manual

PRODUCT

PRODUCT

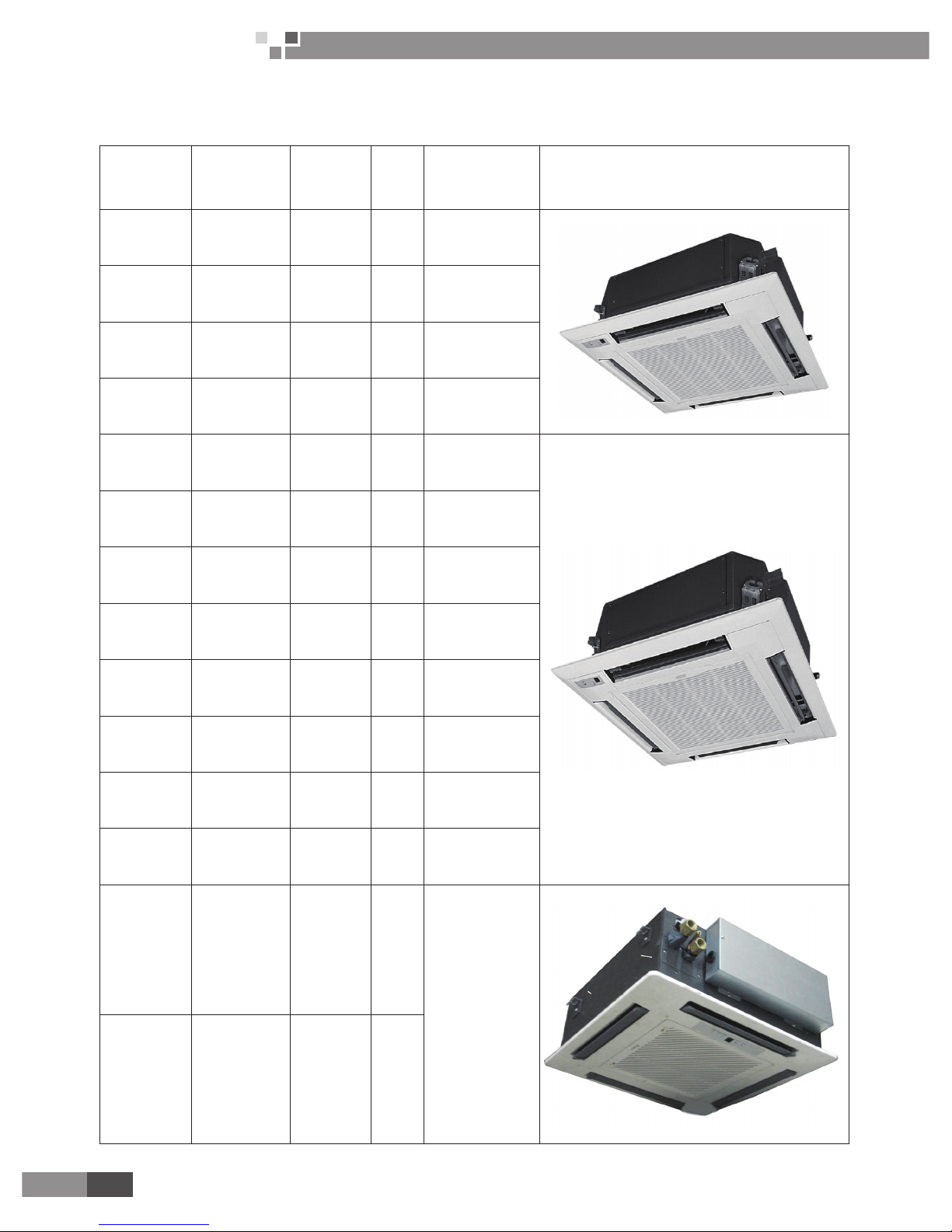

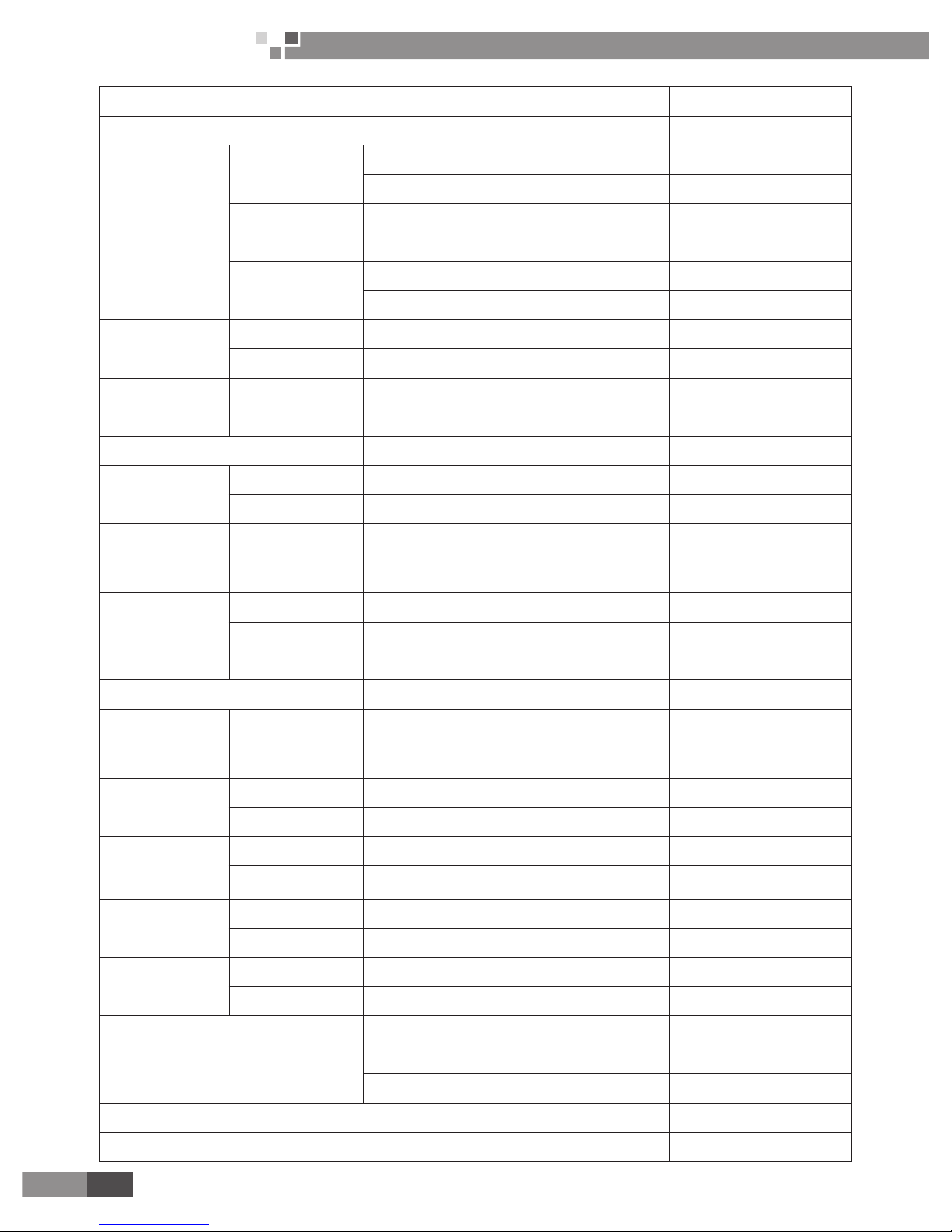

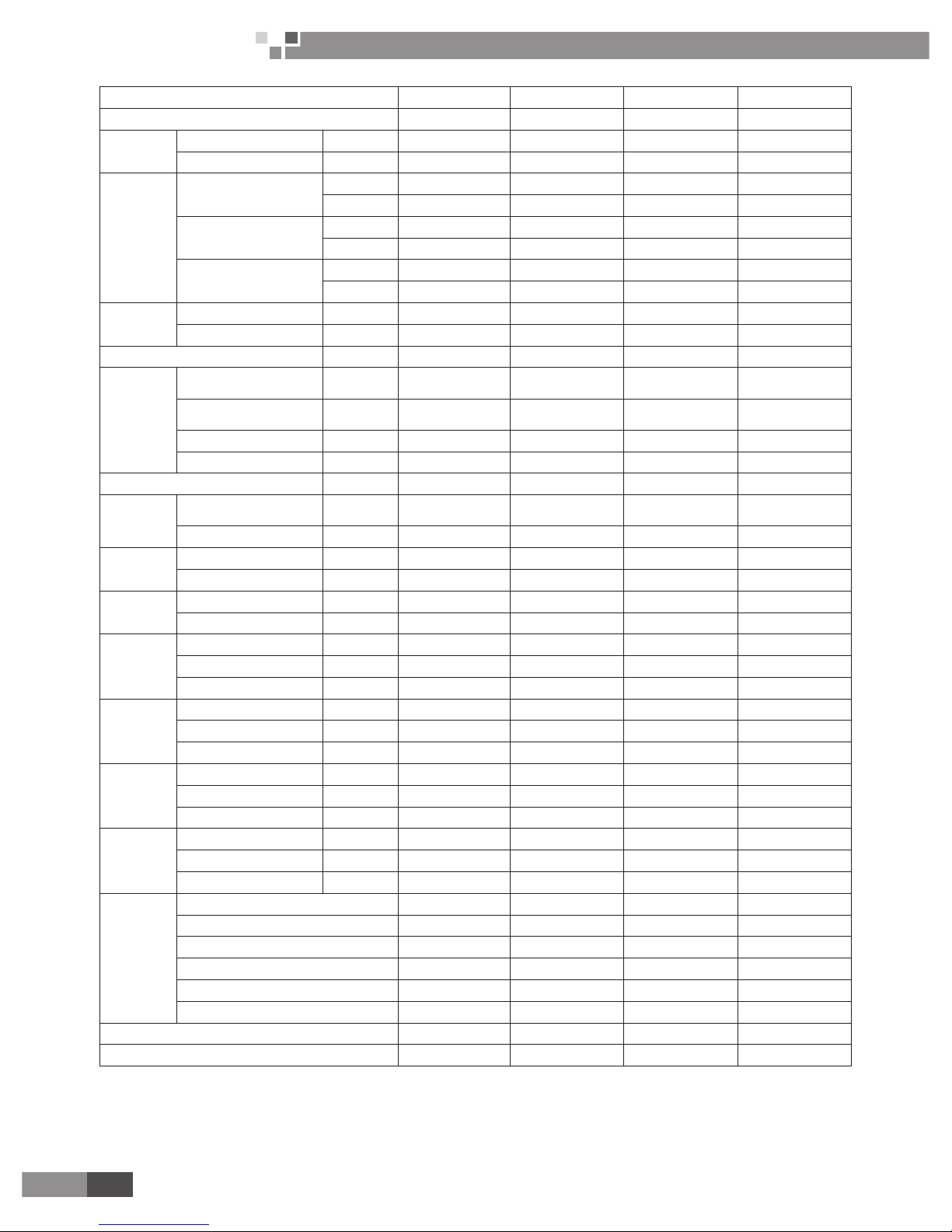

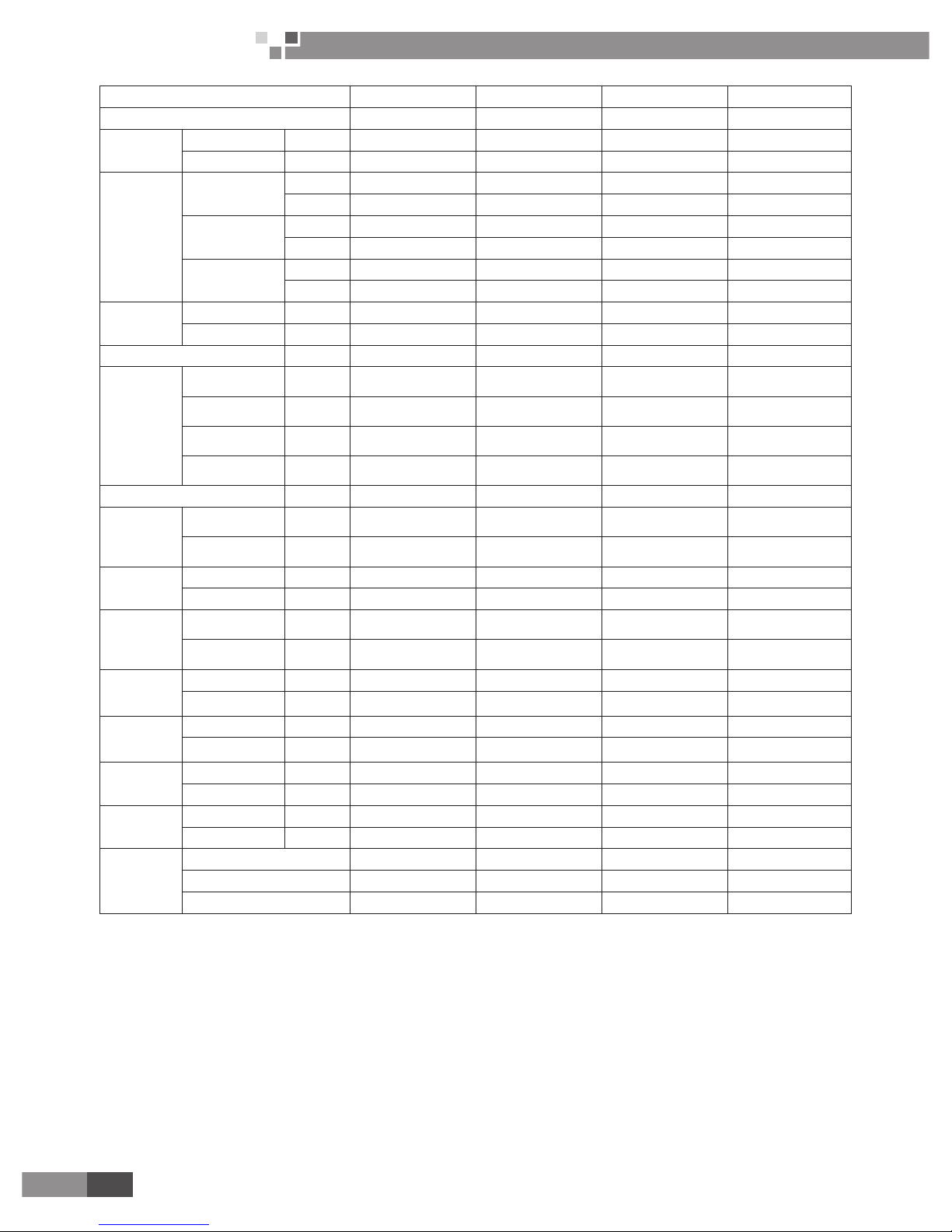

1. MODELS LIST

Model Name Product Code

Cooling

Capacity

(W)

Air ow

Volume

(m3/h)

Power Supply

(V, Ph, Hz)

Remarks

FP-8XD-E EM52000051 4600/7500 850 220-240V~ 50Hz

FP-8XD/A-E EM5200045010 4640/7500 850 220-240V~ 50Hz

FP-10XD-E EM52000061 5400/9100 1020 220-240V~ 50Hz

FP-10XD/A-E EM5200046010 5400/9100 1020 220-240V~ 50Hz

FP-12.5XD-E EM52000031 6700/10500 1270 220-240V~ 50Hz

FP-12.5XD/A-E EM5200047010 6700/10500 1250 220-240V~ 50Hz

FP-14XD-E EM52000071 7700/11200 1560 220-240V~ 50Hz

FP-14XD/A-E EM5200048010 7740/11200 1430 220-240V~ 50Hz

FP-16XD-E EM52000081 8700/12900 1640 220-240V~ 50Hz

FP-16XD/A-E EM5200049010 8700/12900 1640 220-240V~ 50Hz

FP-18XD-E EM52000041 9600/14600 1850 220-240V~ 50Hz

FP-18XD/A-E EM5200050010 9600/14600 1800 220-240V~ 50Hz

FP-51XD-E EM52000011 3000/4000 510

220-240V~ 50Hz

FP-68XD-E EM52000021 3500/5000 680

Page 5

3

Cassette Type Fan Coil

Unit Service Manual

PRODUCT

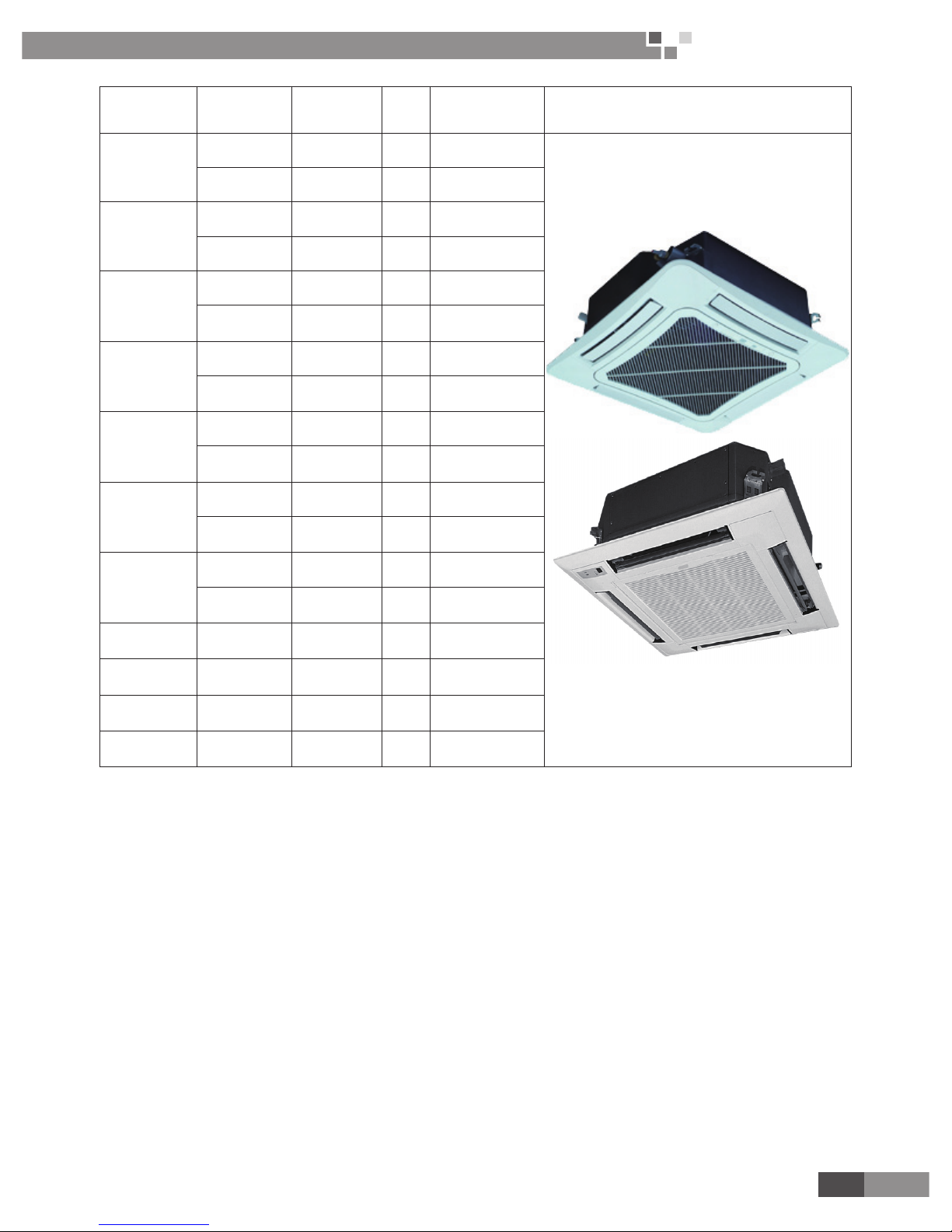

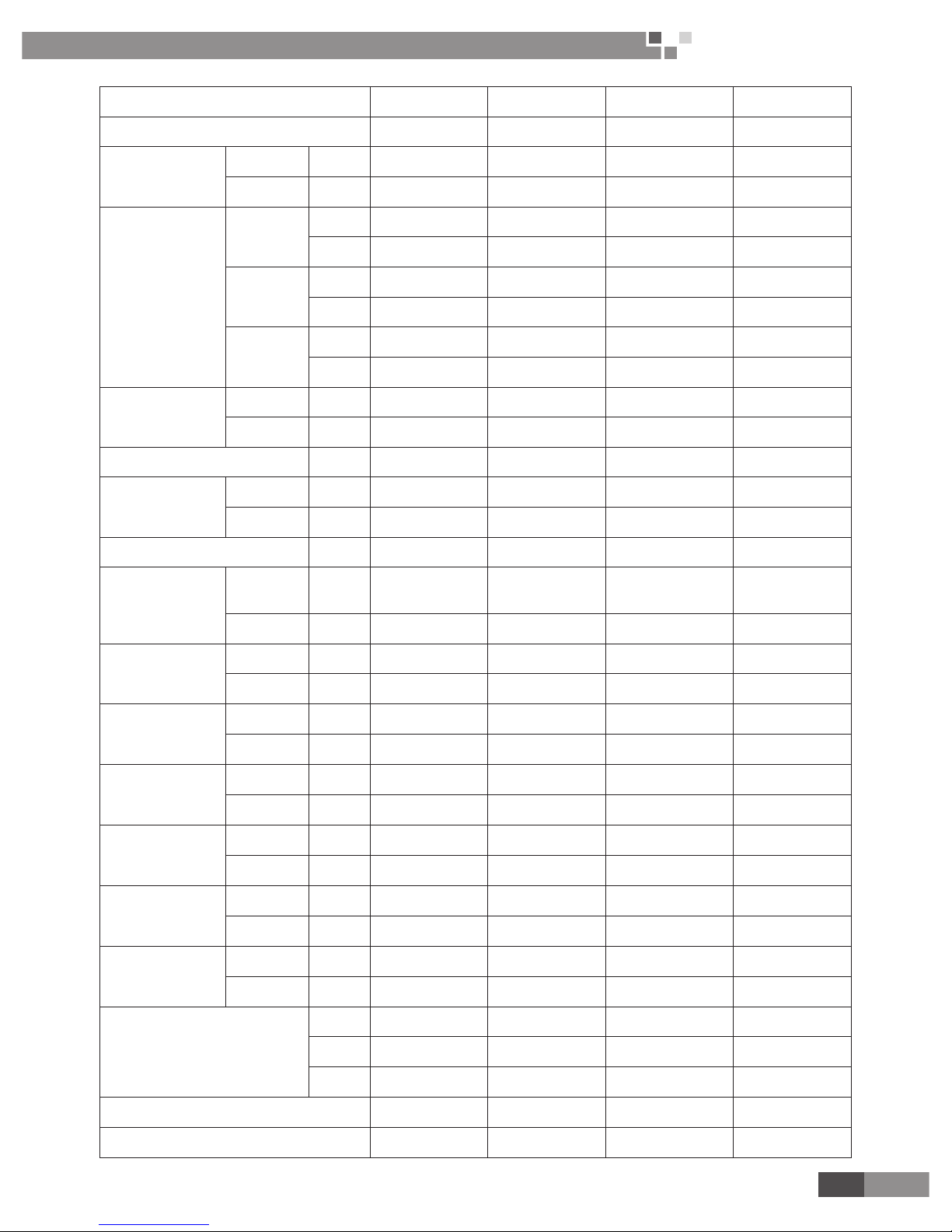

Model Name Product Code

Cooling/Heating

Capacity

(W)

Air ow

Volume

(m3/h)

Power Supply

(V, Ph, Hz)

Remarks

FP-85XD/B-T

EM520N0930 4150/5600 800 220-240V~ 50Hz

EM520N0940 4160/7800 780 208-230V~ 60Hz

FP-102XD/B-T

EM520N0910 500/6500 1020 220-240V~ 50Hz

EM520N0920 540/9000 1020 208-230V~ 60Hz

FP-125XD/B-T

EM520N0890 6000/7800 1180 220-240V~ 50Hz

EM520N0900 6300/10000 1130 208-230V~ 60Hz

FP-140XD/B-T

EM520N0870 8000/9000 1400 220-240V~ 50Hz

EM520N0880 8000/12000 1350 208-230V~ 60Hz

FP-160XD/B-T

EM520N0850 8700/10000 1550 220-240V~ 50Hz

EM520N0860 9000/14000 1550 208-230V~ 60Hz

FP-180XD/B-T

EM520N0830 9500/11000 1800 220-240V~ 50Hz

EM520N0840 10000/16000 1800 208-230V~ 60Hz

FP-200XD/B-T

EM520N0810 1300/14600 2000 220-240V~ 50Hz

EM520N0820 1300/19000 2000 208-230V~ 60Hz

FP-68XDT/B-K EM520N0990 3500/6000 680 220-240V~ 50Hz

FP-85XDT/B-K EM520N0960 4100/6800 850 220-240V~ 50Hz

FP-125XDT/B-K EM520N0970 6000/9500 1250 220-240V~ 50Hz

FP-180XDT/B-K EM520N0980 8000/13000 1800 220-240V~ 50Hz

Page 6

4

Cassette Type Fan Coil

Unit Service Manual

PRODUCT

2. NOMENCLATURE OF THE UNIT

FP - □ □ □ / □ - □

1 2 3 4 5 6

NO. Description Options

1 Fan coil Fan coil unit

2 Air ow volume Number×10 m

3

/h(FP-51XD-E;FP-68XD-E);Number×100 m3/h(8,10,12.5,14,16,18)

3 Structure type XD-Cassette Type

4 Pipes type Default- 2 pipes; T-4 pipes

5 Design Sequence Arranged by A, B,C…

6 Power code E-220-240V~ 50Hz;T-220-240V~ 50Hz, 208-230V~ 60Hz; K-220-240V~ 50Hz

3. FUNCTION

1. Novel pattern: the exposed skin plates of unit looks so elegant and luxurious that they can be taken as

the indoor decorations.

2. Compact design: A large number of non-metallic materials have been used, so that the body of the unit

is quite light-weight and thin, which makes the unit looks sensuous.

3. Low noise: Dynamic principles have been adopted for the design of the fan blades so as to make sure

the air volume is enough and running noise is considerably low.

4. Durable lter screen: The durable lter screen shares a cleaning cycle 20 times longer than that of the

conventional lter screen, needless to clean it frequently.

5. Microcomputer control: The unit is able to automatically adjust the fan speed in accordance with the

indoor ambient temperature to meet a wide range of users’ requirements.

6. Small height of the unit, saving much installation space

7. Large cooling (heating) capacity, low noise, three-speed motor which can adjust the air volume and

meet a wide range of users’ requirements.

8. Excellent material, stringent process control, which guarantee the hi-quality and long life of the unit.

9. Die-formed drain pan, entirely bonded insulating material, carefree about the condensate water.

Page 7

5

Cassette Type Fan Coil

Unit Service Manual

PRODUCT

4. PRODUCT DATA

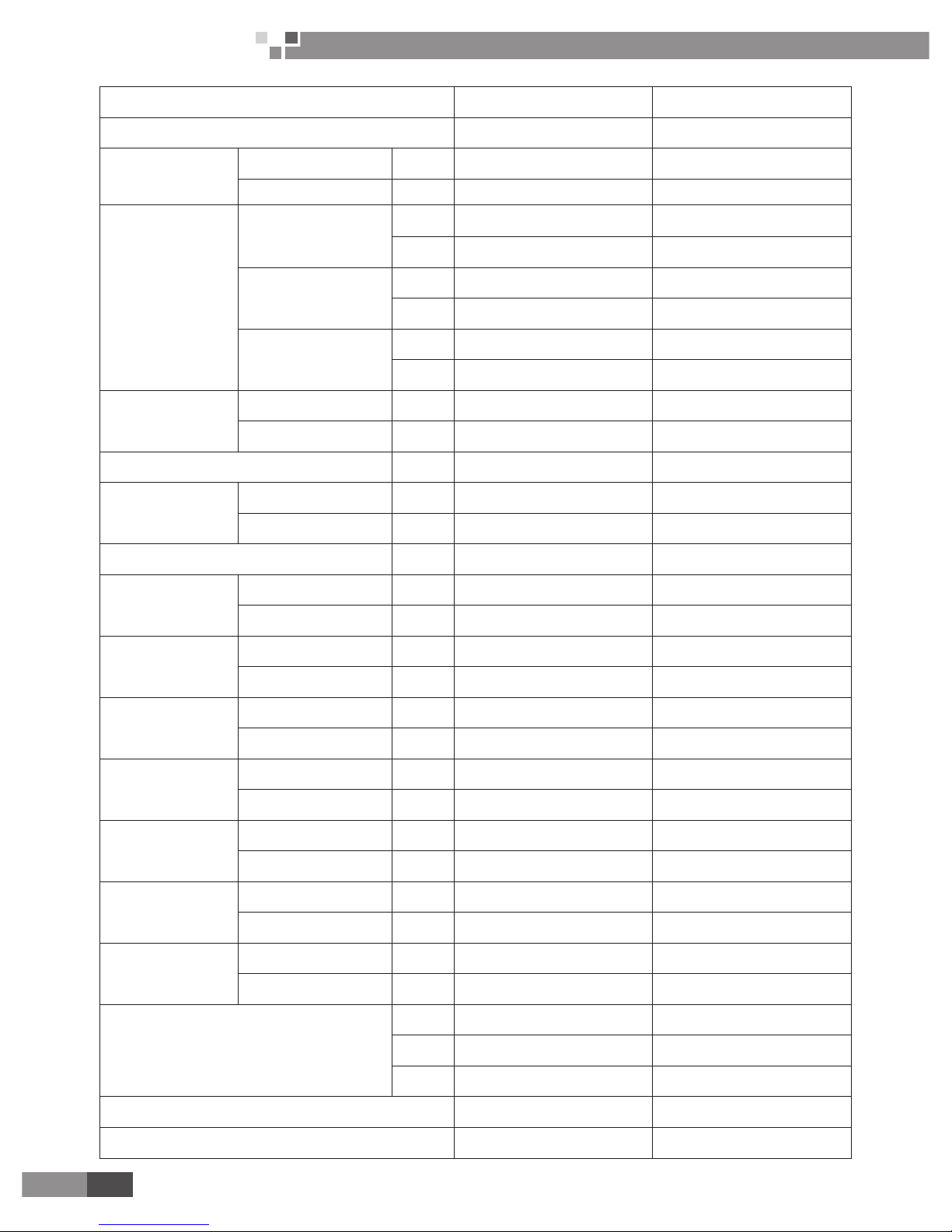

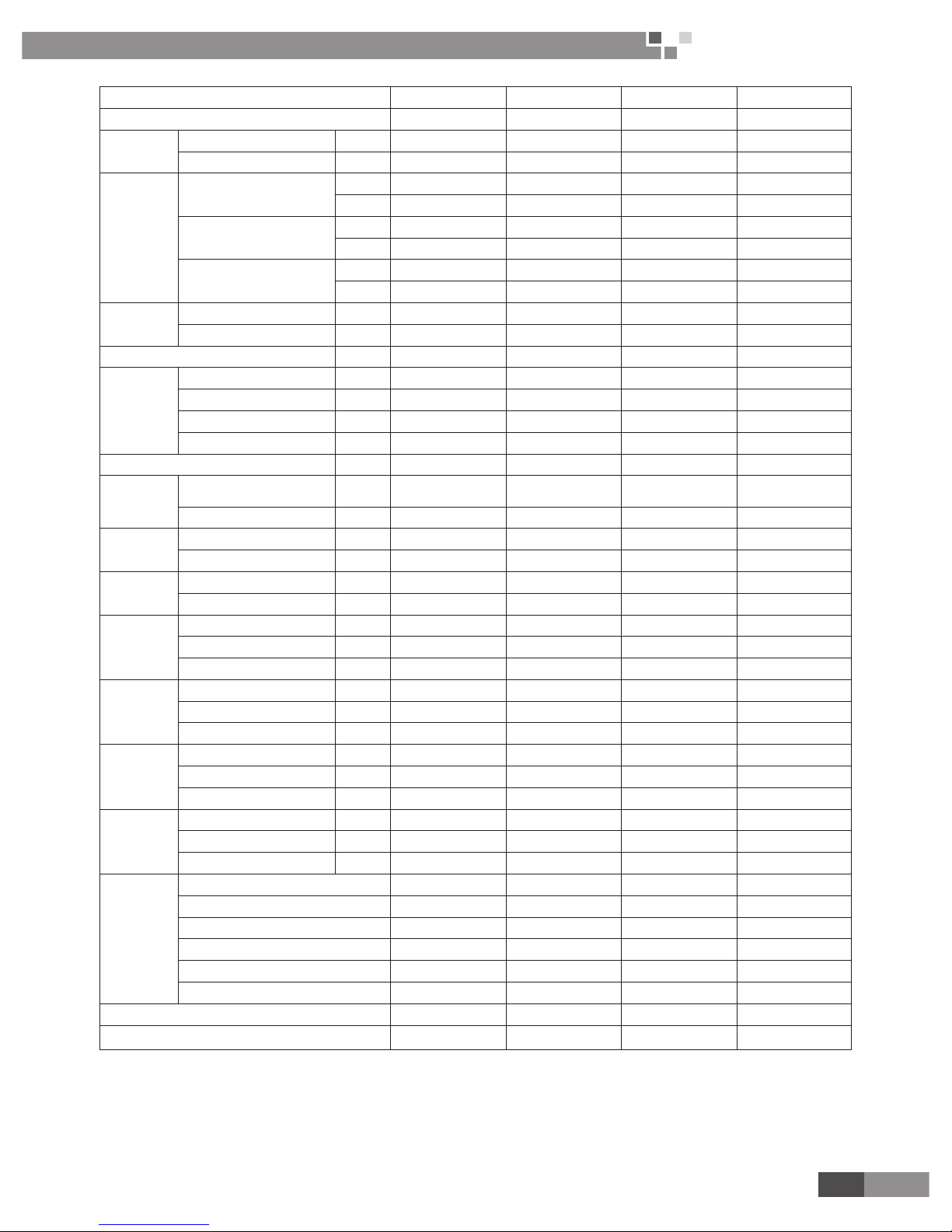

Model FP-8XD/A-E FP-10XD/A-E FP-12.5XD/A-E FP-14XD/A-E

Code EM5200045010 EM5200046010 EM5200047010 EM5200048010

Air ow volume

High

CFM 500 600 735 841

m

3

/h 850 1020 1250 1430

Medium

CFM 375 464 606 802

m

3

/h 637 789 1030 1363

Low

CFM 303 362 538 705

m

3

/h 515 615 915 1200

Capacity

Cooling W 4640 5400 6700 7740

Heating W 7500 9100 10500 11200

Power system

Type V-Ph-Hz 220-240V~ 50Hz 220-240V~ 50Hz 220-240V~ 50Hz 220-240V~ 50Hz

Input W 100 100 150 140

Exterior static pressure Pa 0 0 0 0

Water system

Water ow volume m

3

/h 0.829 0.964 1.196 1.382

Pressure drop kPa 15 25 25 30

Coil

Type -

Aluminum n-

copper tube

Aluminum n-

copper tube

Aluminum n-

copper tube

Aluminum n-

copper tube

Operating pressure MPa ≤1.6MPa ≤1.6MPa ≤1.6MPa ≤1.6MPa

Motor

Type - FN35B FN35B FN35B FN50T

Capacitor µF 2.5 3.5 3.5 2.5

Power output W 35 35 35 50

Sound pressure level dB(A) 46 46 47 52

Connection

pipe size

Water inlet &outlet inch G3/4" G3/4" G3/4" G3/4"

Condensing water drain mm 32 32 32 32

Outline dimension

(W×D×H)

Body mm 840×840×240 840×840×240 840×840×240 840×840×320

Panel mm 960×960×60 960×960×60 960×960×60 960×960×60

Package dimension

(W×D×H)

Body mm 960×960×310 960×960×310 960×960×310 960×960×394

Panel mm 1040×1025×115 1040×1025×115 1040×1025×115 1040×1025×115

Net weight

Body kg 27 27 27 33

Panel kg 6.5 6.5 6.5 6.5

Gross weight

Body kg 35 35 35 42

Panel kg 10 10 10 10

Loading quantity

20'GP 84 84 84 72

40'GP 168 168 168 120

40'HQ 192 192 192 144

Wired remote controller Z5K351/Z4E351B Z5K351/Z4E351B Z5K351/Z4E351B Z5K351/Z4E351B

Wireless remote controller YB1F2(X-FAN) YB1F2(X-FAN) YB1F2(X-FAN) YB1F2(X-FAN)

Page 8

6

Cassette Type Fan Coil

Unit Service Manual

PRODUCT

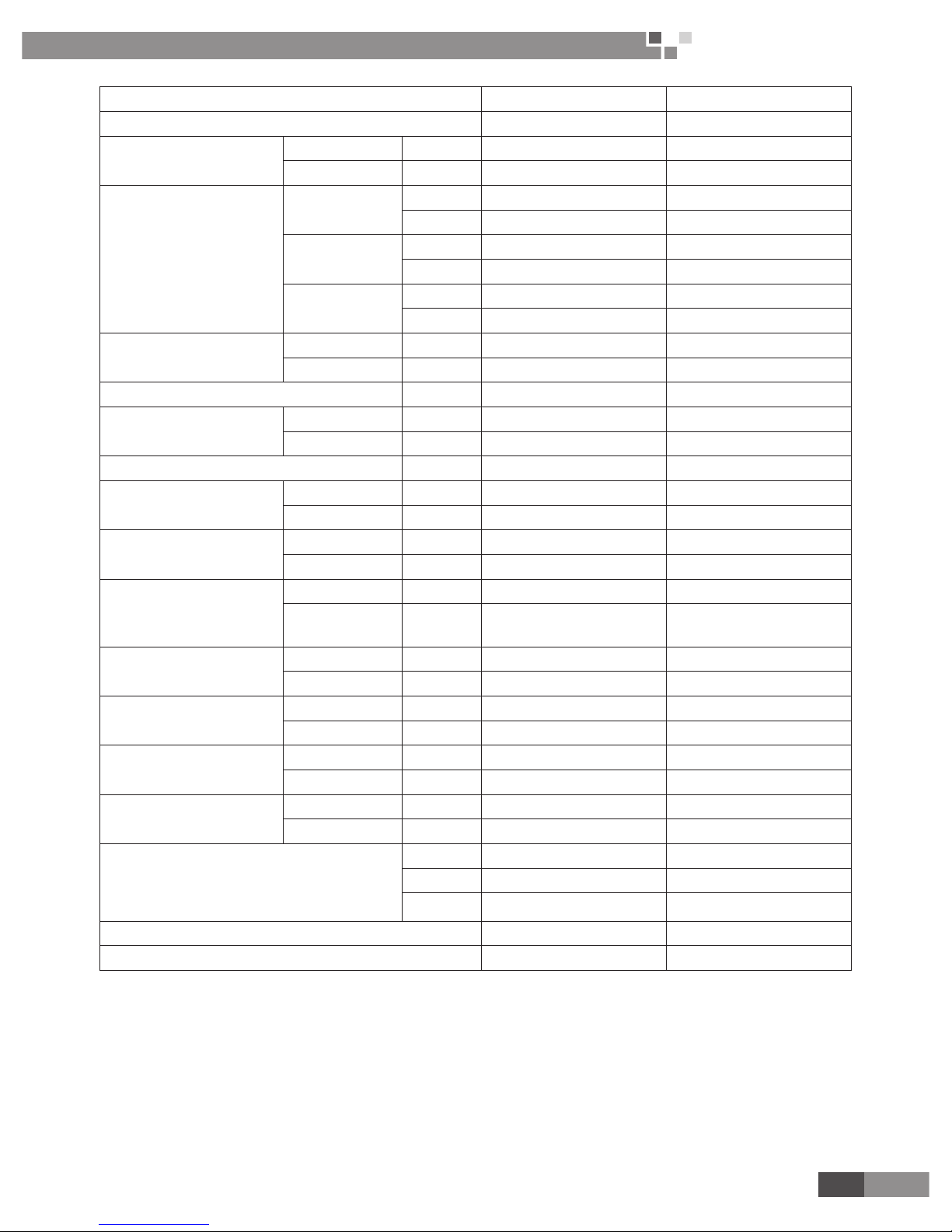

Model FP-16XD/A-E FP-18XD/A-E

Code EM5200049010 EM5200050010

Air ow volume

High

CFM 965 1060

m

3

/h 1640 1800

Medium

CFM 853 1035

m

3

/h 1460 1760

Low

CFM 781 932

m

3

/h 1327 1584

Capacity

Cooling W 8700 9600

Heating W 12900 14600

Power system

Type V-Ph-Hz 220-240V~ 50Hz 220-240V~ 50Hz

Input W 150 155

Exterior static pressure Pa 0 0

Water system

Water ow volume m

3

/h 1.554 1.714

Pressure drop kPa 30 30

Coil

Type - Aluminum n-copper tube Aluminum n-copper tube

Operating pressure MPa ≤1.6MPa ≤1.6MPa

Motor

Type - FN50T FN50T

Capacitor µF 4.5 4.5

Power output W 50 50

Sound pressure level dB(A) 53 54

Connection pipe size

Water inlet &outlet inch G3/4" G3/4"

Condensing water drain mm 32 32

Outline dimension

(W×D×H)

Body mm 840×840×320 840×840×320

Panel mm 960×960×60 960×960×60

Package dimension

(W×D×H)

Body mm 960×960×394 960×960×394

Panel mm 1040×1025×115 1040×1025×115

Net weight

Body kg 33 33

Panel kg 6.5 6.5

Gross weight

Body kg 42 42

Panel kg 10 10

Loading quantity

20'GP 72 72

40'GP 120 120

40'HQ 144 144

Wired remote controller Z5K351/Z4E351B Z5K351/Z4E351B

Wireless remote controller YB1F2(X-FAN) YB1F2(X-FAN)

Page 9

7

Cassette Type Fan Coil

Unit Service Manual

PRODUCT

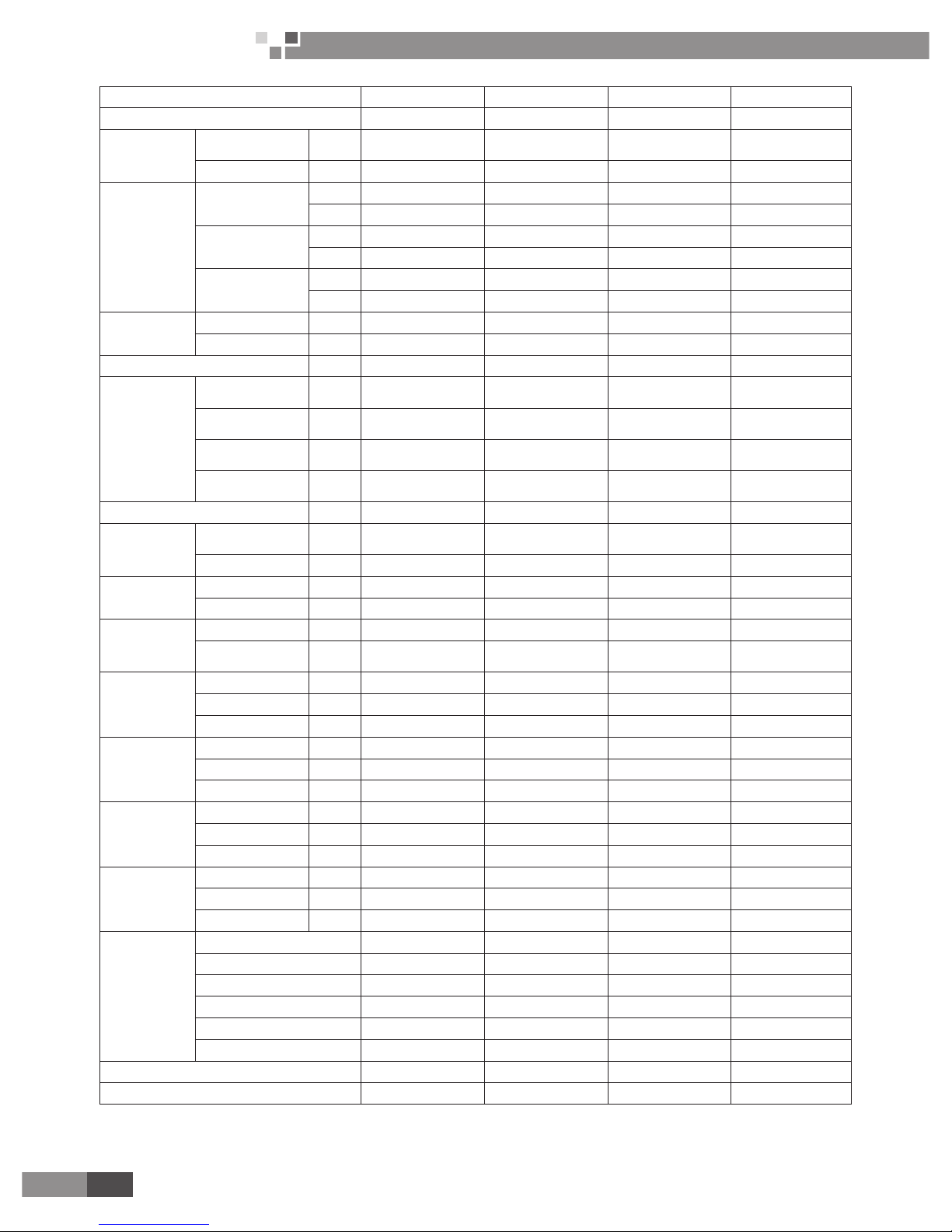

Model FP-8XD-E FP-10XD-E FP-12.5XD-E FP-14XD-E

Code EM52000051 EM52000061 EM52000031 EM52000071

Power system

Type V-Ph-Hz 220-240V~ 50Hz 220-240V~ 50Hz 220-240V~ 50Hz 220-240V~ 50Hz

Input W 100 100 150 140

Air ow volume

High

CFM 500 600 735 840

m

3

/h 850 1020 1250 1430

Medium

CFM 375 464 606 802

m

3

/h 638 789 1030 1363

Low

CFM 303 363 538 705

m

3

/h 515 617 914 1198

Capacity

Cooling W 4640 5400 6700 7740

Heating W 7500 9100 10500 11200

Electric heater rated power W 1400 1400 1400 1400

Water system

Water ow

volume

m

3

/h 0.81 0.95 1.18 1.36

Pressure

drop

kPa 15 25 25 25

Sound pressure level dB(A) 46 46 47 52

Coil

Type -

Aluminum n-

copper tube

Aluminum n-

copper tube

Aluminum n-

copper tube

Aluminum n-

copper tube

Operating

pressure

MPa ≤1.6MPa ≤1.6MPa ≤1.6MPa ≤1.6MPa

Motor

Type - FN35B FN35B FN35B FN50T

Capacitor µF 2.5 3.5 3.5 2.5

Connection pipe size

Water inlet

&outlet

inch G3/4" G3/4" G3/4" G3/4"

Condensing

water drain

mm 32 32 32 32

Outline dimension

(W×D×H)

Body mm 840×840×240 840×840×240 840×840×240 840×840×320

Panel mm 960×960×60 960×960×60 960×960×60 960×960×60

Package dimension

(W×D×H)

Body mm 960×960×310 960×960×310 960×960×310 960×960×394

Panel mm 1040×1025×115 1040×1025×115 1040×1025×115 1040×1025×115

Net weight

Body kg 30 30 30 38

Panel kg 6.5 6.5 6.5 6.5

Gross weight

Body kg 38 38 38 46

Panel kg 10 10 10 10

Loading quantity

20'GP 61 61 51 51

40'GP 11 6 11 6 116 93

40'HQ 133 133 133 112

Wired remote controller Z5K351/Z4E351B Z5K351/Z4E351B Z5K351/Z4E351B Z5K351/Z4E351B

Wireless remote controller YB1F2(X-FAN) YB1F2(X-FAN) YB1F2(X-FAN) YB1F2(X-FAN)

Page 10

8

Cassette Type Fan Coil

Unit Service Manual

PRODUCT

Model FP-16XD-E FP-18XD-E

Code EM52000081 EM52000041

Power system

Type V-Ph-Hz 220-240V~ 50Hz 220-240V~ 50Hz

Input W 160 155

Air ow volume

High

CFM 965 1059

m

3

/h 1640 1800

Medium

CFM 853 1035

m

3

/h 1450 1760

Low

CFM 781 932

m

3

/h 1328 1584

Capacity

Cooling W 8700 9600

Heating W 12900 14600

Electric heater rated power W 1400 1400

Water system

Water ow volume m

3

/h 1.53 1.68

Pressure drop kPa 27 29

Sound pressure level dB(A) 53 54

Coil

Type - Aluminum n-copper tube Aluminum n-copper tube

Operating pressure MPa ≤1.6MPa ≤1.6MPa

Motor

Type - FN50T FN50T

Capacitor µF 4.5 4.5

Connection pipe size

Water inlet &outlet inch G3/4" G3/4"

Condensing water drain mm 32 32

Outline dimension

(W×D×H)

Body mm 840×840×320 840×840×320

Panel mm 960×960×60 960×960×60

Package dimension

(W×D×H)

Body mm 960×960×394 960×960×394

Panel mm 1040×1025×115 1040×1025×115

Net weight

Body kg 38 38

Panel kg 6.5 6.5

Gross weight

Body kg 46 46

Panel kg 10 10

Loading quantity

20'GP 51 51

40'GP 93 93

40'HQ 11 2 112

Wired remote controller Z5K351/Z4E351B Z5K351/Z4E351B

Wireless remote controller YB1F2(X-FAN) YB1F2(X-FAN)

Page 11

9

Cassette Type Fan Coil

Unit Service Manual

PRODUCT

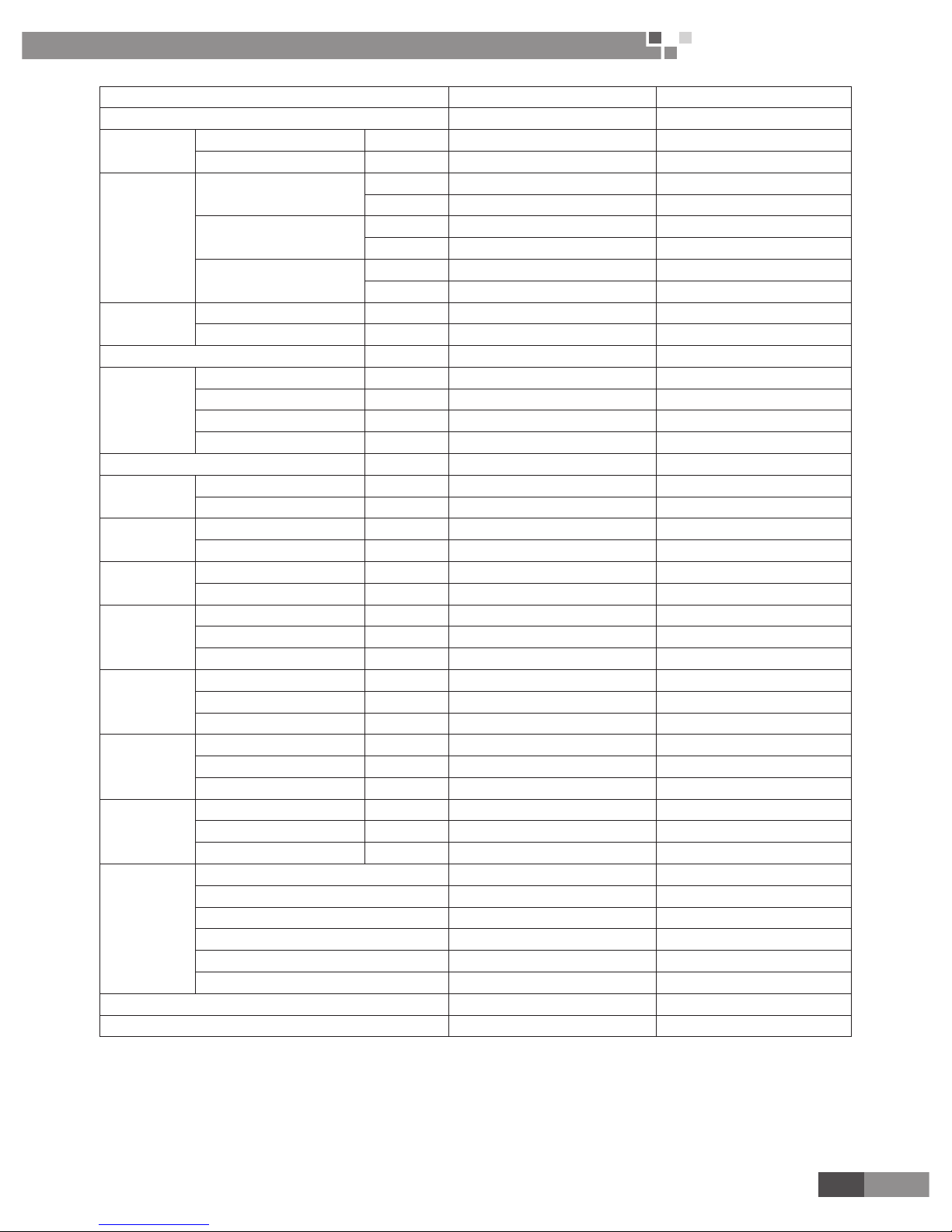

Model FP-51XD-E FP-68XD-E

Code EM52000011 EM52000021

Power system

Type V-Ph-Hz 220-240V~ 50Hz 220-240V~ 50Hz

Input W 49 56

Air ow volume

High

CFM 300 371

m

3

/h 510 680

Medium

CFM 247 318

m

3

/h 420 540

Low

CFM 206 265

m

3

/h 350 450

Capacity

Cooling W 3000 3500

Heating W 4000 5000

Electric heater rated power W - -

Water system

Water ow volume m

3

/h 0.49 0.616

Pressure drop kPa 5 9

Sound pressure level dB(A) 43 48

Coil

Type - Aluminum n-copper tube Aluminum n-copper tube

Operating pressure MPa ≤1.6MPa ≤1.6MPa

Motor

Type - FN11T FN11T

Capacitor µF 1 2.5

Connection pipe size

Water inlet &outlet inch G3/4" G3/4"

Condensing

water drain

mm 25 25

Outline dimension (W×D×H)

Body mm 600×600×230 600×600×230

Panel mm 650×650×50 650×650×50

Package dimension (W×D×H)

Body mm 848×678×310 848×678×310

Panel mm 730×670×102 730×670×102

Net weight

Body kg 19.3 19.3

Panel kg 5 5

Gross weight

Body kg 27 27

Panel kg 6 6

Loading quantity

20'GP 114 114

40'GP 216 216

40'HQ 256 256

Wired remote controller Z5K351 Z5K351

Wireless remote controller YB1F2(X-FAN) YB1F2(X-FAN)

Notes:

1. The water working temperature is from 7°C(44.6°F) to 60°C(140°F).

2. The temperature exchange efficiency and enthalpy exchange efficiency are tested under these

testing conditions as below:

(1) Cooling efciency: air 27°C(80.6°F) DB, 19.5°C(67.1°F) WB, water temperature in 7°C(44.6°F),water out 12°C(53.6°F).

(2) Heating capacity: air 21°C(69.8°F) DB, Water temperature intake 60°C(140°F), the water-ow volume is same as

Cooling capacity.

Page 12

10

Cassette Type Fan Coil

Unit Service Manual

PRODUCT

Model FP-85XD/B-T FP-85XD/B-T FP-102XD/B-T FP-102XD/B-T

Code EM520N0940 EM520N0930 EM520N0920 EM520N0910

Power

system

Type V-Ph-Hz 208-230V~ 60Hz 220-240V~ 50Hz 208-230V~ 60Hz 220-240V~ 50Hz

Input W 70 75 130 11 0

Air ow

volume

High

CFM 459 471 600 600

m

3

/h 780 800 1020 1020

Medium

CFM 371 382 599 599

m

3

/h 630 650 950 950

Low

CFM 324 324 529 529

m

3

/h 550 550 900 900

Capacity

Cooling W 4600 4500 5400 5000

Heating W 7800 5600 9000 6500

Electric heater rated power W - - - -

Water

system

Cooling water ow

volume

l/s 0.22 0.21 0.26 0.24

Heating water ow

volume

l/s 0.22 0.13 0.26 0.17

Cooling pressure drop kPa 27 24 48 36

Heating pressure drop kPa 24 8 47 13

Sound pressure level dB(A) 39 39 49 49

Coil

Type -

Aluminum n-

copper tube

Aluminum n-

copper tube

Aluminum n-

copper tube

Aluminum n-

copper tube

Operating pressure MPa ≤1.6MPa ≤1.6MPa ≤1.6MPa ≤1.6MPa

Motor

Type - FN35D-1 FN35D-1 FN35D-1 FN35D-1

Capacitor µF 2.00 2.00 5.00 5.00

Connection

pipe size

Water inlet &outlet inch G3/4" G3/4" G3/4" G3/4"

Condensing water drain mm 25 25 25 25

Outline

dimension

(W×D×H)

Body mm 840×840×190 840×840×190 840×840×190 840×840×190

Panel T01 mm 950×950×60 950×950×60 950×950×60 950×950×60

Panel TB03 mm 950×950×85 950×950×85 950×950×85 950×950×85

Package

dimension

(W×D×H)

Body mm 963×963×272 963×963×272 963×963×272 963×963×272

Panel T01 mm 1028×1043×130 1028×1043×130 1028×1043×130 1028×1043×130

Panel TB03 mm 1033×1038×133 1033×1038×133 1033×1038×133 1033×1038×133

Net weight

Body kg 25.0 25.0 25.0 25.0

Panel T01 kg 3.0 3.0 3.0 3.0

Panel TB03 kg 7 7 7 7

Gross

weight

Body kg 33.0 33.0 33.0 33.0

Panel T01 kg 5.0 5.0 5.0 5.0

Panel TB03 kg 11 11 11 11

Loading

quantity

20'GP(with panel T01) 57 57 57 57

40'GP (with panel T01) 133 133 133 133

40'HQ (with panel T01) 149 149 149 149

20'GP (with panel TB03) 56 56 56 56

40'GP (with panel TB03) 131 131 131 131

40'HQ (with panel TB03) 147 147 147 147

Wired remote controller Z4E351B Z4E351B Z4E351B Z4E351B

Wireless remote controller YB1FA(X-FAN) YB1FA(X-FAN) YB1FA(X-FAN) YB1FA(X-FAN)

Page 13

11

Cassette Type Fan Coil

Unit Service Manual

PRODUCT

Model FP-125XD/B-T FP-125XD/B-T FP-140XD/B-T FP-140XD/B-T

Code EM520N0900 EM520N0890 EM520N0880 EM520N0870

Power

system

Type V-Ph-Hz 208-230V~ 60Hz 220-240V~ 50Hz 208-230V~ 60Hz 220-240V~ 50Hz

Input W 130 82 140 120

Air ow

volume

High

CFM 665 694 794 824

m

3

/h 1130 1180 1350 1400

Medium

CFM 529 588 647 735

m

3

/h 900 1000 1100 1250

Low

CFM 441 529 588 676

m

3

/h 750 900 1000 1150

Capacity

Cooling W 6300 6000 8000 8000

Heating W 10000 7800 12000 9000

Electric heater rated power W - - - -

Water

system

Cooling water ow volume l/s 0.3 0.29 0.38 0.38

Heating water ow volume l/s 0.3 0.18 0.38 0.21

Cooling pressure drop kPa 27 24 33 30

Heating pressure drop kPa 28 9 29 10

Sound pressure level dB(A) 43 43 48 50

Coil

Type -

Aluminum n-

copper tube

Aluminum n-

copper tube

Aluminum n-

copper tube

Aluminum n-

copper tube

Operating pressure MPa ≤1.6MPa ≤1.6MPa ≤1.6MPa ≤1.6MPa

Motor

Type - FN35B-1 FN35B-1 FN35C FN35C

Capacitor µF 2.00 2.00 4.00 4.00

Connection

pipe size

Water inlet &outlet inch G3/4" G3/4" G3/4" G3/4"

Condensing water drain mm 25 25 25 25

Outline

dimension

(W×D×H)

Body mm 840×840×240 840×840×240 840×840×240 840×840×240

Panel T01 mm 950×950×60 950×950×60 950×950×60 950×950×60

Panel TB03 mm 950×950×85 950×950×85 950×950×85 950×950×85

Package

dimension

(W×D×H)

Body mm 963×963×325 963×963×325 963×963×325 963×963×325

Panel T01 mm 1028×1043×130 1028×1043×130 1028×1043×130 1028×1043×130

Panel TB03 mm 1033×1038×133 1033×1038×133 1033×1038×133 1033×1038×133

Net weight

Body kg 27.0 27.0 27.0 27.0

Panel T01 kg 3.0 3.0 3.0 3.0

Panel TB03 kg 7 7 7 7

Gross

weight

Body kg 34.0 34.0 35.0 35.0

Panel T01 kg 5.0 5.0 5.0 5.0

Panel TB03 kg 11 11 11 11

Loading

quantity

20'GP(with panel T01) 50 50 50 50

40'GP (with panel T01) 121 121 121 121

40'HQ (with panel T01) 134 134 134 134

20'GP (with panel TB03) 50 50 50 50

40'GP (with panel TB03) 117 117 11 7 117

40'HQ (with panel TB03) 133 133 133 133

Wired remote controller Z4E351B Z4E351B Z4E351B Z4E351B

Wireless remote controller YB1FA(X-FAN) YB1FA(X-FAN) YB1FA(X-FAN) YB1FA(X-FAN)

Page 14

12

Cassette Type Fan Coil

Unit Service Manual

PRODUCT

Model FP-160XD/B-T FP-160XD/B-T FP-180XD/B-T FP-180XD/B-T

Code EM520N0860 EM520N0850 EM520N0840 EM520N0830

Power system

Type

V-Ph-

Hz

208-230V~ 60Hz 220-240V~ 50Hz 208-230V~ 60Hz 220-240V~ 50Hz

Input W 140 125 160 160

Air ow volume

High

CFM 912 912 1059 1059

m

3

/h 1550 1550 1800 1800

Medium

CFM 765 824 824 853

m

3

/h 1300 1400 1400 1450

Low

CFM 676 765 765 794

m

3

/h 1150 1300 1300 1350

Capacity

Cooling W 9000 8700 10000 9500

Heating W 14000 10000 16000 11000

Electric heater rated power W - - - -

Water system

Cooling water ow

volume

l/s 0.43 0.42 0.48 0.45

Heating water ow

volume

l/s 0.43 0.23 0.48 0.27

Cooling pressure

drop

kPa 34 30 42 34

Heating pressure

drop

kPa 34 11 43 12

Sound pressure level dB(A) 51 51 50 50

Coil

Type -

Aluminum n-copper

tube

Aluminum n-copper

tube

Aluminum n-copper

tube

Aluminum n-copper

tube

Operating pressure MPa

≤

1.6MPa

≤

1.6MPa

≤

1.6MPa

≤

1.6MPa

Motor

Type - FN35C FN35C FN50K-1 FN50K-1

Capacitor µF 5.00 5.00 3.50 3.50

Connection

pipe size

Water inlet &outlet inch G3/4" G3/4" G3/4" G3/4"

Condensing water

drain

mm 25 25 25 25

Outline

dimension

(W×D×H)

Body mm 840×840×240 840×840×240 840×840×320 840×840×320

Panel T01 mm 950×950×60 950×950×60 950×950×60 950×950×60

Panel TB03 mm 950×950×85 950×950×85 950×950×85 950×950×85

Package

dimension

(W×D×H)

Body mm 963×963×325 963×963×325 963×963×409 963×963×409

Panel T01 mm 1028×1043×130 1028×1043×130 1028×1043×130 1028×1043×130

Panel TB03 mm 1033×1038×133 1033×1038×133 1033×1038×133 1033×1038×133

Net weight

Body kg 27.0 27.0 32.0 32.0

Panel T01 kg 3.0 3.0 3.0 3.0

Panel TB03 kg 7 7 7 7

Gross weight

Body kg 35.0 35.0 41.0 41.0

Panel T01 kg 5.0 5.0 5.0 5.0

Panel TB03 kg 11 11 11 11

Loading

quantity

20'GP(with panel T01) 50 50 42 42

40'GP (with panel T01) 121 121 98 98

40'HQ (with panel T01) 134 134 11 2 112

20'GP (with panel TB03) 50 50 42 42

40'GP (with panel TB03) 11 7 117 98 98

40'HQ (with panel TB03) 133 133 11 2 112

Wired remote controller Z4E351B Z4E351B Z4E351B Z4E351B

Wireless remote controller YB1FA(X-FAN) YB1FA(X-FAN) YB1FA(X-FAN) YB1FA(X-FAN)

Page 15

13

Cassette Type Fan Coil

Unit Service Manual

PRODUCT

Model FP-200XD/B-T FP-200XD/B-T

Code EM520N0820 EM520N0810

Power system

Type V-Ph-Hz 208-230V~ 60Hz 220-240V~ 50Hz

Input W 230 210

Air ow volume

High

CFM 1176 1176

m

3

/h 2000 2000

Medium

CFM 912 1000

m

3

/h 1550 1700

Low

CFM 735 853

m

3

/h 1250 1450

Capacity

Cooling W 13000 13000

Heating W 19000 14600

Electric heater rated power W - -

Water system

Cooling water ow volume l/s 0.62 0.62

Heating water ow volume l/s 0.62 0.25

Cooling pressure drop kPa 35 34

Heating pressure drop kPa 35 30

Sound pressure level dB(A) 55 55

Coil

Type - Aluminum n-copper tube Aluminum n-copper tube

Operating pressure MPa

≤

1.6MPa

≤

1.6MPa

Motor

Type - FN50K-2 FN50K-2

Capacitor µF 5.00 5.00

Connection

pipe size

Water inlet &outlet inch G3/4" G3/4"

Condensing water drain mm 25 25

Outline

dimension

(W×D×H)

Body mm 840×840×320 840×840×320

Panel T01 mm 950×950×60 950×950×60

Panel TB03 mm 950×950×85 950×950×85

Package

dimension

(W×D×H)

Body mm 963×963×409 963×963×409

Panel T01 mm 1028×1043×130 1028×1043×130

Panel TB03 mm 1033×1038×133 1033×1038×133

Net weight

Body kg 33.0 33.0

Panel T01 kg 3.0 3.0

Panel TB03 kg 7 7

Gross weight

Body kg 42.0 42.0

Panel T01 kg 5.0 5.0

Panel TB03 kg 11 11

Loading

quantity

20'GP(with panel T01) 42 42

40'GP (with panel T01) 98 98

40'HQ (with panel T01) 112 112

20'GP (with panel TB03) 42 42

40'GP (with panel TB03) 98 98

40'HQ (with panel TB03) 112 112

Wired remote controller Z4E351B Z4E351B

Wireless remote controller YB1FA(X-FAN) YB1FA(X-FAN)

Page 16

14

Cassette Type Fan Coil

Unit Service Manual

PRODUCT

Model FP-68XDT/B-K FP-85XDT/B-K FP-125XDT/B-K FP-180XDT/B-K

Code EM520N0990 EM520N0960 EM520N0970 EM520N0980

Power

system

Type V-Ph-Hz 220-240V~ 50Hz 220-240V~ 50Hz 220-240V~ 50Hz 220-240V~ 50Hz

Input W 82 82 135 191

Air ow

volume

High

CFM 400 500 736 1059

m

3

/h 680 850 1250 1800

Medium

CFM 364 450 652 897

m

3

/h 618 764 1108 1525

Low

CFM 336 410 597 836

m

3

/h 571 697 1014 1421

Capacity

Cooling W 3500 4100 6000 8000

Heating W 6000 6800 9500 13000

Electric heater rated power W - - - -

Water

system

Cooling water

ow volume

l/s 0.21 0.24 0.29 0.44

Heating water

ow volume

l/s 0.17 0.19 0.27 0.36

Cooling

pressure drop

kPa 34.14 56.71 43.07 39.65

Heating

pressure drop

kPa 76.44 86.08 91.94 102.21

Sound pressure level dB(A) 39 40 43 50

Coil

Type -

Aluminum n-

copper tube

Aluminum n-

copper tube

Aluminum n-

copper tube

Aluminum n-

copper tube

Operating

pressure

MPa ≤1.6MPa ≤1.6MPa ≤1.6MPa ≤1.6MPa

Motor

Type - FN35D-1 FN35D-1 FN35B-1 FN50K-1

Capacitor µF 2.0 3.0 4.0 4.5

Connection

pipe size

Water inlet

&outlet

inch G3/4" G3/4" G3/4" G3/4"

Condensing

water drain

mm 25 25 25 25

Outline

dimension

(W×D×H)

Body mm 840×840×190 840×840×190 840×840×240 840×840×320

Panel TB03 mm 950×950×85 950×950×85 950×950×85 950×950×85

Package

dimension

(W×D×H)

Body mm 960×960×257 960×960×257 960×960×310 960×960×394

Panel TB03 mm 1033×1038×133 1033×1038×133 1033×1038×133 1033×1038×133

Net weight

Body kg 25.0 25.0 27.0 32.0

Panel TB03 kg 7 7 7 7

Gross weight

Body kg 33.0 33.0 34.0 41.0

Panel TB03 kg 11 11 11 11

Loading

quantity

20'GP (with panel TB03) 56 56 50 42

40'GP (with panel TB03) 131 131 121 98

40'HQ (with panel TB03) 147 147 134 112

Page 17

15

Cassette Type Fan Coil

Unit Service Manual

CONTROL

Testing condition:

For 60Hz :

The FCU designed for installation indoor. The environmental temperature is from 5°C to 43°C, water

working temperature is from 7°C to 60°C.

The temperature exchange efficiency and enthalpy exchange efficiency are tested under these testing

conditions as below:

1). Cooling capacity: air 27°C DB, 19.5°C WB, water temperature: intake 7°C, outlet12°C.

2).Heating capacity: air 21°C DB, Water temperature intake 60°C, the water-flow volume is same as

Cooling capacity .

3).Freeze-up : air 27°C DB, 24°C WB, water temperature intake 6°C, outlet 9°C.

4).Sound power level according to ISO 5151. Sound pressure level are calculated at the below of air-outlet

1m and 1m distance. The noise are tested before leaving factory.

For 50 Hz :

The FCU designed for installation indoor. The environmental temperature is from 5°C to 43°C, water

working temperature is from 7°C to 60°C.

The temperature exchange efficiency and enthalpy exchange efficiency are tested under these testing

conditions as below:

1).Cooling capacity: air 27°C DB , 19°C WB, water temperature intake 7°C, outlet 12°C.

2).Heating capacity: air 20°C DB , Water temperature intake 50°C, outlet 40°C.

3).Freeze-up : air 27°C DB, 24°C WB , water temperature 6°C intake , 10°C outlet .

4).Sound power level according to ISO 5151. Sound pressure level are calculated at the below of air-outlet

1m and 1m distance. The noise are tested before leaving factory.

For 4 pipes:

The FCU designed for installation indoor. The environmental temperature is from 5°C to 43°C, water

working temperature is from 7°C to 70°C.

The temperature exchange efciency and enthalpy exchange efciency are tested under these testing

conditions as below:

1).Cooling capacity: air 27°C DB , 19°C WB, water temperature intake 7°C, outlet 12°C.

2).Heating capacity: air 20°C DB , Water temperature intake 70°C, outlet 60°C.

3).Freeze-up : air 27°C DB, 24°C WB , water temperature 6°C intake , 10°C outlet .

4).Sound power level according to ISO 5151. Sound pressure level are calculated at the below of air-outlet

1m and 1m distance. The noise are tested before leaving factory.

Page 18

16

Cassette Type Fan Coil

Unit Service Manual

CONTROL

CONTROL

Page 19

17

Cassette Type Fan Coil

Unit Service Manual

CONTROL

CONTROL

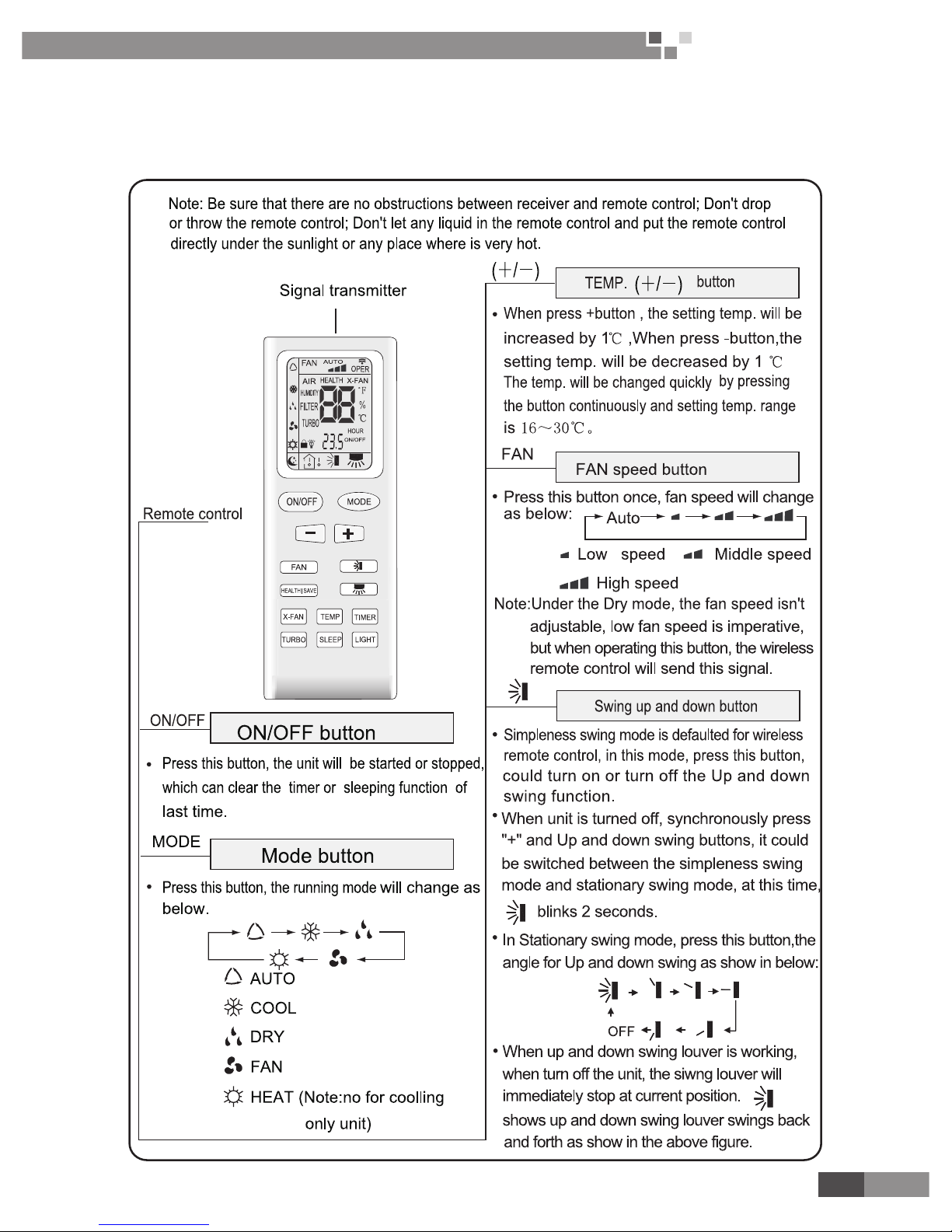

1. WIRELESS REMOTE CONTROLLER

1.1 YB1F2(X-FAN)

Page 20

18

Cassette Type Fan Coil

Unit Service Manual

CONTROL

Page 21

19

Cassette Type Fan Coil

Unit Service Manual

CONTROL

Page 22

20

Cassette Type Fan Coil

Unit Service Manual

CONTROL

1.1.1 Guide for operation-general operation

① .

Press ON/OFF button to start the unit after poweringthe main unit on.(Note:

Power the unit on every time,the big-guide louver and small-guide louver will beclosed

rstly.)

② .

Press MODE button to select desired running mode.

③ .

Press +/ - button to set the desired temperature.(It is unnecessary to set the

temperature at AUTO mode)

④ .

Press FAN button to set fan speed, the AUTO FAN,LOW, MID or HIGH could

be selected.

⑤ .

Press

and button to set swing mode.

1.1.2 Guide for operation-optional operation

① .

Press SLEEP button, set the sleep mode.

② .

Press TIMER button, then press +/- button,

to set the cheduled timer on or timer off.

③ .

Press light button to control displayer light on or off.

④ .

Press X-FAN button to set X-FAN function on or off.

⑤ .

Press turbo button to set this function on or off.

1.1.3 Introduction for special function

● About X-FAN function

This function indicates that moisture on evaporator of indoor unit will be blowed after the unit About X-FAN

functionis stopped to avoid mould.

Having set X-FAN function on: After turning off the unit by pressing ON/OFF buttonindoor fan will continue

running for about 10 min. at low speed. In this period, press X-FAN button to stop indoor fan directly.2. Having

set X-FAN function off: After turning off the unit by pressing ON/OFF button, the complete unit will be off directly.

● About AUTO RUN

When AUTO RUN mode is selected, the setting temperature will not be displayed on the LCD, the unit will

be in accordance with the room temp. automatically to select the suitable running method and to make ambient

comfortable.

● About turbo function

If start this function, the unit will run at super-high fan speed to cool or heat quickly so that the ambient

temp. approachs the preset temp. as soon as possible.

● About lock

Press +and - buttons simultaneously to lock or unlock the keyboard. If the remote controller is locked,

the icon

will be displayed on it, in which case, press any button, the mark will icker for three times. If the

keyboard is unlocked, the mark will disappear.

● About switch between Fahrenheit and Centigrade

Under status of unit off, press MODE and - buttons simultaneously to switch ºC and ºF.

● About new function of defrosting

It indicates: after starting this function by remote controller and the unit has been under defrost status, If

turn off the unit by remote controller, the unit will not stop defrosting until it is nished; if change setting mode by

remote controller, the function ,which is set last time, won't be carried out until defrosting nished.

Operation of this function on or off: If remote controller is under off status, press mode button and X-FAN

button simultaneously in order to enter or cancel this new function. If the unit is under defrost mode, dual eight

position on remote controller will display H1.If switch to heat mode, the position will display H1, which ickers

for 5s, in which case, press +/- button, H1 will disappear and setting temp. be displayed.

After remote controller is powered on, the new defrost function will be defaulted to be closed.

3.4 Changing batteries and notices

① .

Slightly to press the place with

along the arrowhead direction to push the

back cover of remote control.(As shown in Fig.① )

② .

Take out the old batteries, insert two AAA alkaline cells.(AS shown in

Fig

②③

.).

③ .

Attach the back cover of remote control.(Fig④)

Page 23

21

Cassette Type Fan Coil

Unit Service Manual

CONTROL

NOTE:

♦When changing the batteries, do not use the old ordifferent batteries,

otherwise, it can cause the malf-unction of the wireless remote control.

♦If the wireless remote control will not be used for along time, please take them

out, and don't let the leakage liquid damage the wireless remote control.

♦The operation should be in its receiving range.

♦It should be placed where is 1m away from the TVset or stereo sound sets.

♦If the remote control cannot operate normally, please take the batteries out,

and then reinsert it 30s later; it is also abnormal ,please replace the batteries.

♦If the main unit needs to be remote controlled, please aim remote control at the receiver of main unit in

orderto improve the receiving sensitivity of the main unit.When the remote control sends out signal, a mark will

icker for about 1s. The bell will ring if the main unit receives effective signal.

♦When the remote control sends out signal, a mark will icker for about 1s. The bell will ring if the

main unit receives effective signal.

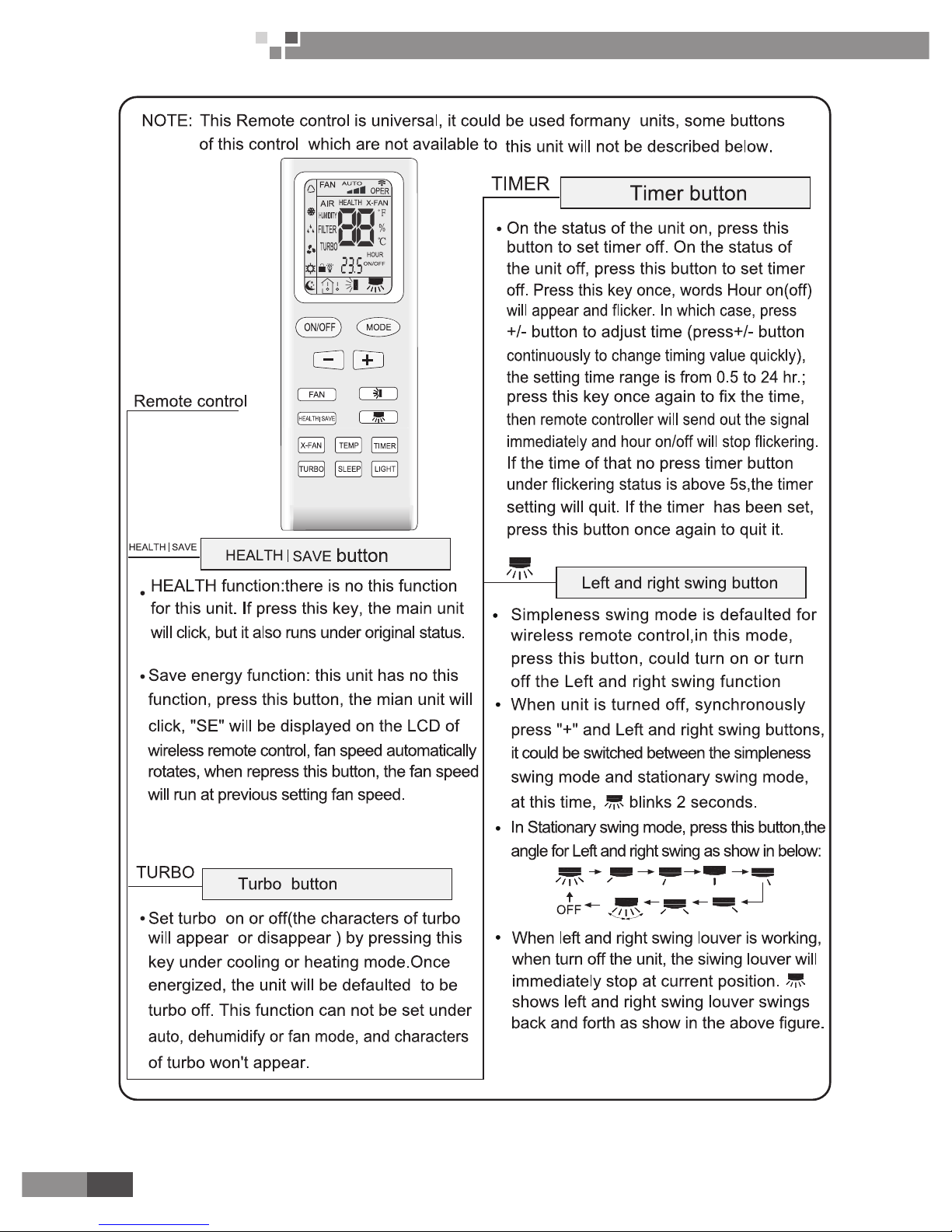

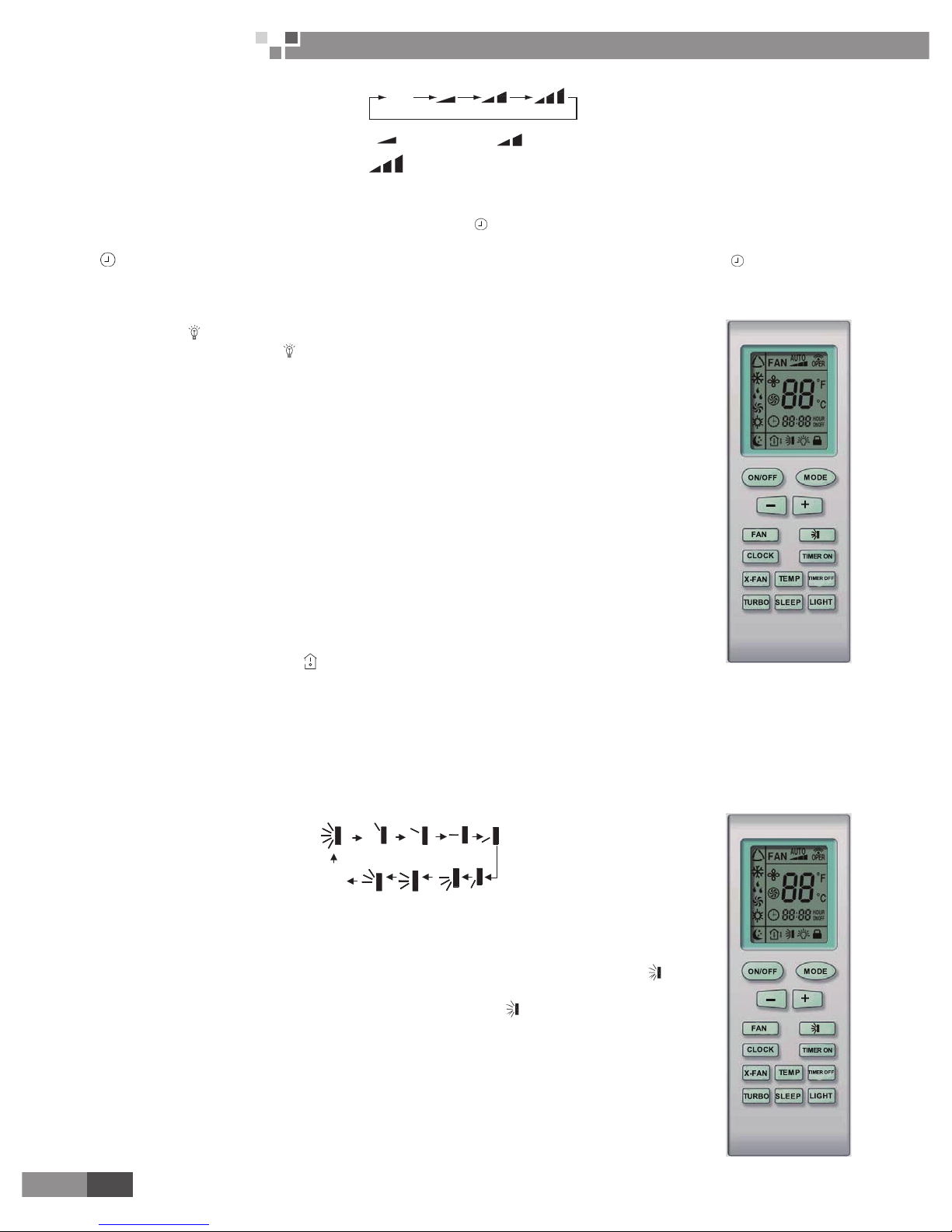

1.2 YB1FA(X-FAN)

Note:

♦ Be sure that there are no obstructions between receiver and remote control; Donot drop or throw the

remote control; Don't let any liquid drop into the remote control or leave the remote control under the sunlight or

place where is very hot.

♦This is a general remote control, it could be used for multiple types (functions) of air conditioners. For

some models without the functions specied here, we preserve the right to not to inform exclusively.

AUTO

COOL

DRY

FAN

HEAT

● ON/OFF button

Press ON/OFF button to turn on/off the unit. When the unit is turned off, the Timer, Sleep function will not

be retained in memory, but the time will be retained and is still displaying.

● MODE button

Press this button, Auto, Cool, Dry, Fan Heat mode can be selected circularly.

Auto mode is not available in this mode.

● SLEEP button

Press this button to select Sleep On/Sleep Off. If power is on, Sleep Off is default. If the unit is turned off,

the Sleep function setting will be not retained in memory. If Sleep function is on, the mark of Sleep will display.

In this mode, the time of timer can be adjusted. Under Fan and Auto modes, this function is not available.

● FAN button

Press this button, Auto, Low, Medium, High-speed can be circularly selected. After powered on, Auto fan

speed is default. Under Dehumidify mode, Low fan speed is default.

Page 24

22

Cassette Type Fan Coil

Unit Service Manual

PRODUCT

AUTO

Low

Medium

High

Note: Under the Dry mode, the fan speed isn't adjustable, low fan speed is default.

● CLOCK button

Press Clock button to set the time of clock. When blinks and displays, you can set the time by pressing

+ or - button. If no button is pressed within 10 seconds the remote will revert back to the normal display. Press

again to accept the setting. If it is set the rst time, 12:00 is the initial value. Note: If mark displays on the

LCD, it means it is the time of clock, if not, it is the time of timer.

● LIGHT button

Press this button to select LIGHT On/Off in the displayer. When the LIGHT On is

set,the mark will be displayed and the indicator light in the displayer will be on. When the

LIGHT Off is set, the mark will disappear and the indicator light will be off.The function is

not available for this mode.

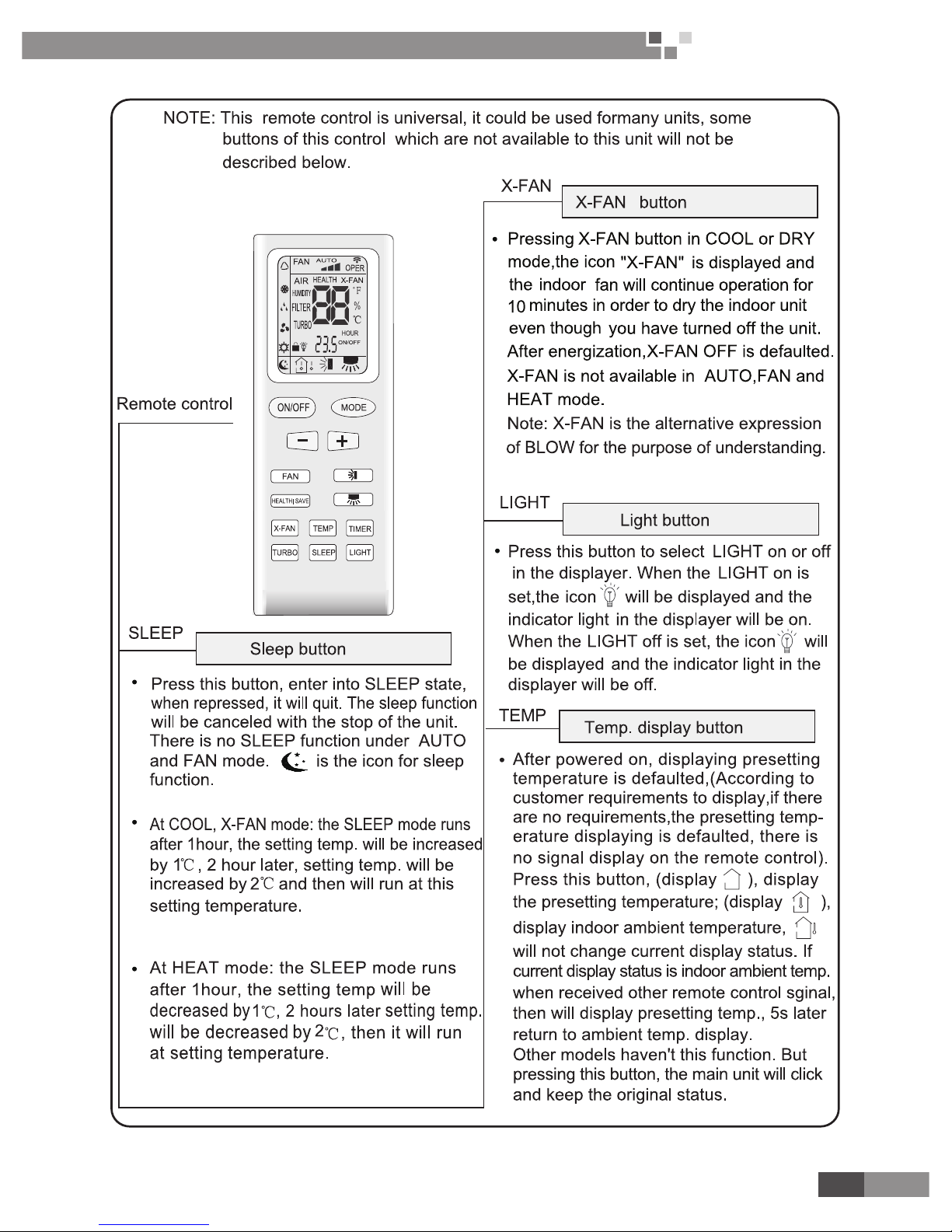

● X-FAN button

Press this button to turn on/off the X-FAN function.

The function is not available for this mode.

● - button

Presetting temperature can be decrease the temperature by 1 degree Celsius

once. press and hold for more than two seconds so that we can change the temperature

continuously. The minimum and maximum setting range of the temperature is 16 to 30

degree Celsius.

● + button

Press this button increase the temperature by 1 degree Celsius once. Press and

hold for more than two seconds so that we can change the temperature continuously. The

minimum and maximum setting range of the temperature is 16 to 30 degree.

● TEMP button

Press this button to select the display of either indoor setting temperature or indoor

ambient temperature. When the indoor unit powered on rstly, setting temperature display

is default. Change status to

to display the ambient temperature. If received control

signal in 5 seconds, the display temp.will revert back to setting temperature. When unit is off, indoor setting

temperature display is default. Note: This function is only available for certain models.

● TURBO button

In Cool or Heat mode, press this button to turn on/off the Turbo function.

Note: This is a general remote control, it could be used for multiple types (functions) of air conditioners.

For some models without the functions specied here, we preserve the right to not to inform exclusively.

● SWING UP AND DOWN button

Press this button to adjust swing angle, which circularly changes as below:

OFF

This is a universal wireless remote controller; however, the unit covered in this manual

is only of the simplied SWING function. As a result, when the wireless remote controller is

energized initially with the unit under the OFF status, this simplied function should be set

by pressing the + button and the SWING button simultaneously, with the symbol

blinking

twice. Then, after the unit is turned on, this function can be activated or deactivated simply

by pressing the SWING button, with the displayed symbol indicating this function is on

and without this displayed symbol indicating this function is off.

● TIMER ON button

Press the TIMER ON button to set the timed On. Press +/- once to increase or

decrease the minute by 1 minute. If pressed and held for 2 seconds, the minute will

increase or decrease constantly by 1 minute. If held constantly for more than 5 seconds,

the minute will begin to change in every 10 minutes. Press TIMER ON again to accept the

setting and ON will show besides the time of clock meaning the setting succeeds. Press the

Page 25

23

Cassette Type Fan Coil

Unit Service Manual

PRODUCT

TIMER ON again to cancel the setting.

TIMER OFF button

Press the TIMER OFF button to set the timed off. The procedures are similar as above.

1.2.1 Operation of wireless remote control

1). Guide for operation – General operation

a. Press SLEEP button to set the sleep state.

b. Press TIME ON and TIME OFF button to scheduled the unit ON/OFF.

c. Press LIGHT button to control on and off the indicator board.(This function maybe

not available for some units.)

2). Guide for operation-Optional operation

a. After powered on, press ON/OFF button, the unit will start to run.

(Note: When it is powered off , the guide louver of main unit will close automatically.)

b. Press MODE button, select desired running mode ,or press COOL or HEAT mode to enter the

corresponding operation directly.

c. Press + or-button to set the desired temperature.

d. Press FAN button to set fan speed from AUTOFAN , LOW , MID and HIGH.

e. Press

button to select SWING mode.

f. Press +and - buttons simultaneously to lock or unlock the wireless remote control. If it is locked, the

mark will display; when pressing any button, the mark

will blink for three times but the air conditioner has no

respondence. If unlocked, the mark will disappear.

g. Switch between Fahrenheit and Centigrade.

When unit is under Off state, press MODE and – button simultaneously to switch between ºC and ºF.

1.2.2 Changing batteries and notices.

Slightly to press the place with , along the arrowhead direction to push the back

cover of wireless remote control. (As show in gure)

Take out the old batteries. (As show in gure.)

Insert two new AAA1.5V dry batteries, and pay attention to the polarity. (As show in

gure)

Attach the back cover of wireless remote control. (As show in gure)

NOTE:

♦The design of this unit conforms to the requirements of ISO5151 standard.

♦The air volume is measured at the 0Pa external static pressure.

♦Cooling (heating) capacity stated above is measured under nominal working

conditions corresponding to 0Pa external static pressure. The parameters are subject to

change with the improvement of products, in which case the values on the nameplate will

prevail.

Fig.24

Fig.25

Sketch map for

changing batteries

Page 26

24

Cassette Type Fan Coil

Unit Service Manual

PRODUCT

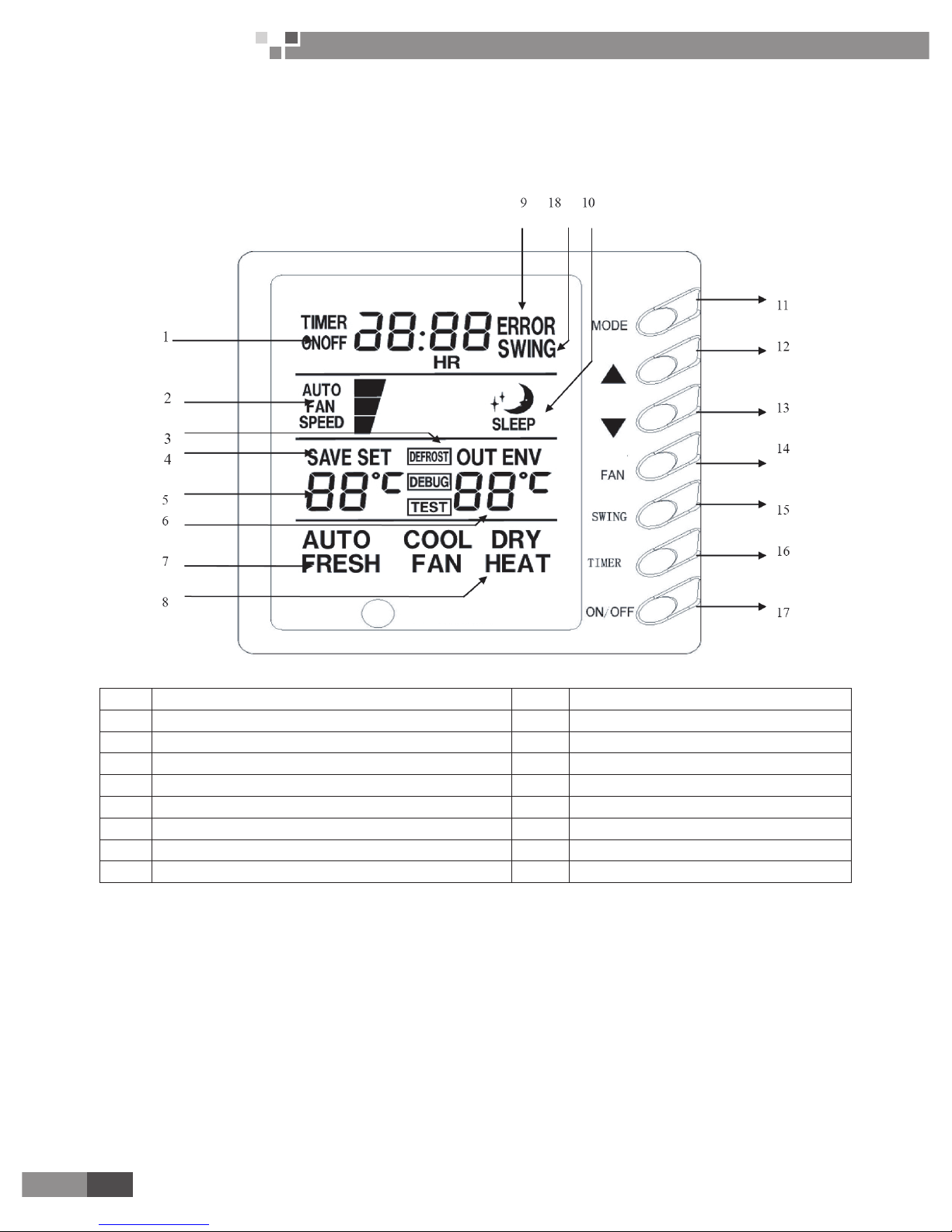

2. WIRED REMOTE CONTROLLER

2.1 Introduction to Z5K351(optional)

NOTE: Never install the wired remote controller in a place where there is water leakage.

Avoid bumping, throwing, tossing or frequently opening the wired remote controller.

1 Time display 10 Sleep display

2 Fan speed display(Auto, High, Middle, Low) 11 MODE button

3 Defrosting display 12 Button for temp. increase

4 Saving state display 13 Button for temp. decrease

5 Set temp. display 14 FAN button

6 Ambient temp. display 15 SWING button

7 Fresh air display 16 TIMER button

8 Mode(COOL, DRY, FAN, AUTO) 17 ON/OFF button

9 Malfunction display 18 Display of Swing state

Page 27

25

Cassette Type Fan Coil

Unit Service Manual

PRODUCT

2.2 Introduction to Z4E351B (optional)

2.2.1 Symbols on the LCD

Introduction to the Symbols on the LCD.

No. Symbol Function Description

1

It indicates the swing function.

2

It indicates the function of air exchange. (It is unavailable for this wired controller.)

3

It indicates the sleeping status.

4

It indicates each running mode of the indoor unit (AUTO mode).

(It is unavailable for this wired controller. )

5

It indicates the “ Cool ” mode.

6

It indicates the “ Dry ” mode.

7

It indicates the “ Fan ” mode.

8

It indicates the “ Heat ” mode.

9

It indicates the defrosting mode. (It is unavailable for this wired controller.)

10

It indicates the gate control status.

11

It indicates the locking status.

12

It indicates the shield status. (It appears when all functions, or the function “On/Off ”, “

Temp ”, “ Mode ”, or “ Save ” is shielded through the Long-distance monitoring System.)

13

It indicates the current fan speed.

Page 28

26

Cassette Type Fan Coil

Unit Service Manual

PRODUCT

14

It indicates the memory function is activated, that is, the unit will

back to the previous set status after powered on again.

15

It indicates the turbo status.

16

It ashes animatedly when the unit is started and the ambient temperature is displayed.

17

It indicates the ambient temperature/set temperature.

18

It indicates the energy saving status.

19

It indicates that the auxiliary electric heater can be activated.

20 It indicates the blow function is activated.

21

It indicates the timer status.

22

It indicates the quiet operation status. (including two statuses, “ Quiet ” and “ Auto Quiet ”. )

Note: Symbols “ MASTER ” and “ CO

2

” will not displayed on the LCD of the wired controlled XK26.

2.2.2 Introduction to the Functions of the Press Keys

1

5 6 7 8

2 3

Introduction to the Functions of the Press Keys.

No. Press Bottoms Function Description

1 Enter/Cancel It is used to select the desired function or cancel the selected function.

2 ▲

(1) It is used to adjust the running temperature of the indoor unit among16~30℃.

(2) It is used to adjust the temperature under the energy saving condition among16~30

℃.

(3) It is used to adjust the timer among 0.5~24 hours.

(4) It is used to switch between the modes of “ Quiet ” and “Auto Quiet ”.

6 ▼

3 Fan There are four fan speed options, High, Medium, Low and Auto.

4 Mode

(1) It is used to set the mode of “ Cool ”,“ Dry ”, “ Fan ”, and “ Heat ”.

(2) When the “Save” function is being set, it is used to switch

between the mode options of “ Heat ” and “ Cool ”.

(3) When the “ Timer ” is being set, it is used to switch

between the options of “Unit On” and “Unit Off”.

5 Function

It is used to switch the functions of “Swing”, “Sleep”, “Turbo”,

“Save”, “E-Heater”, “Blow”, “Quiet”, etc.

7 Timer It is used to set the timer.

8 On/Off It is used to start/stop the indoor unit.

4 +2

Mode +▲

(MEMORY)

Under the “ Off ” status of the unit, press “Mode” and “▲” simultaneously for ve

seconds to activate or deactivate the “MEMORY” function. (once this function

is activated, the unit with power failure will resume the previous set status

after powered on again; otherwise it will go to the “Off ” status.)

2 +6

▲+▼

(LOCK)

Press “▲” and “▼” simultaneously for ve seconds to go to the lock

status, in which case the press on any other key will get no response. And

another press on “▲” and “▼” for ve seconds will quit this status.

5+ 7

Function +Timer

(Ambient Temperature

Sensor; Anti Cold/

Hot Air)

Under the “Off ” status of the unit, press “ Function ” and “ Timer ” simultaneously

for ve seconds to call out the debugging menu, after that press “ Mode ” to

select the desired submenu and press “▲”/“▼” to set the parameter, nally

press “ Enter/Cancel ” to save the setting and quit the setting status.

4 +6 Mode +▼

Under the “Off ” status of the unit, press “ Mode ” and “▼”simultaneously

for ve seconds to switch the Celsius scale and Fahrenheit scale.

Page 29

27

Cassette Type Fan Coil

Unit Service Manual

INSTALLATION

Page 30

28

Cassette Type Fan Coil

Unit Service Manual

INSTALLTION

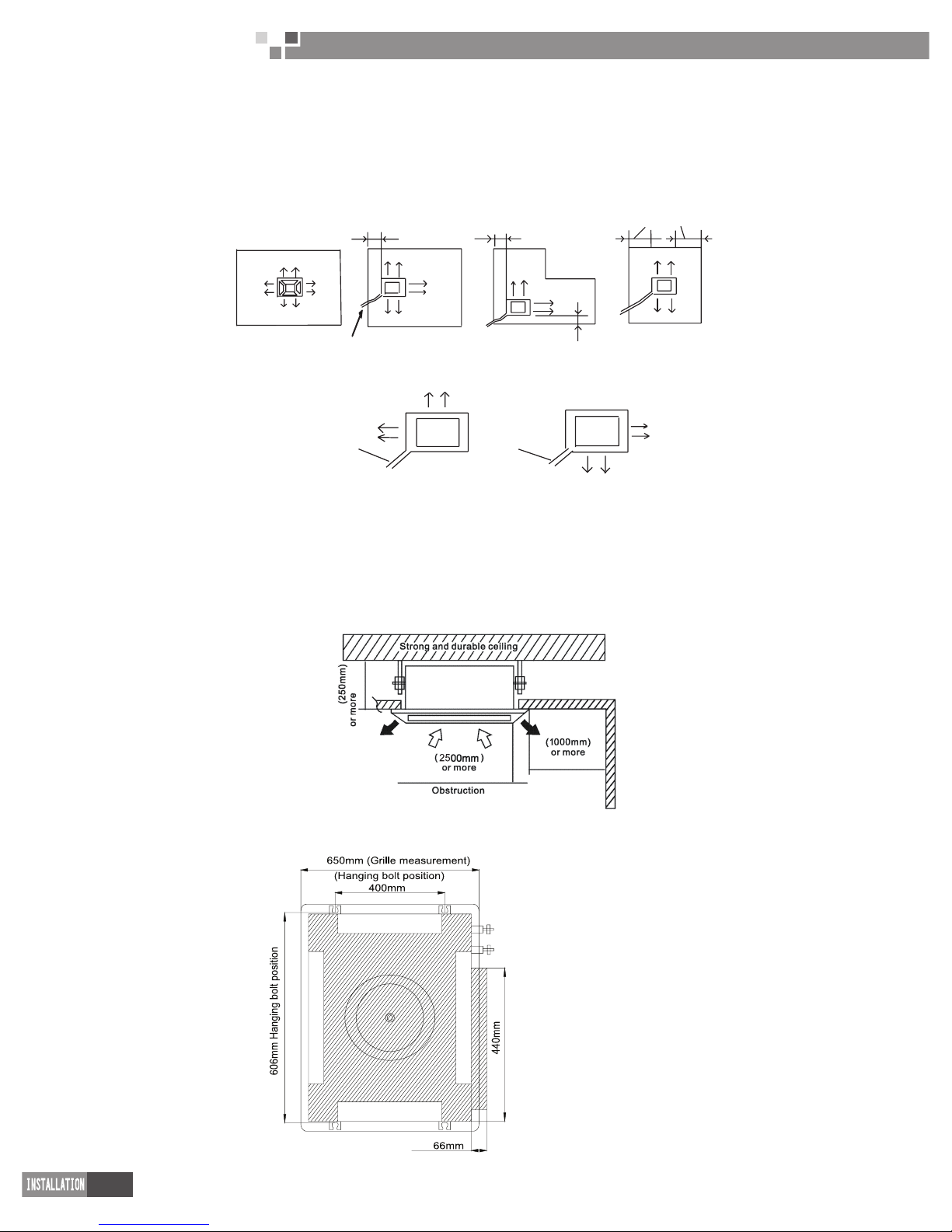

1. SELECTION THE MOUNTING POSITION

Especially, the installation place is very important for the fan coil unit because it is very difcult to move

from placc aftr the rst installation.

Decide the mounting position together with the customer as follows:

The discharge direction can be selected as shown below.

(4 directions)

(3 directions)

4''(100mm) or more

4''(100mm) or more

4''(100mm) or more

39''(1,000mm) or more

(2 directions)

(2 directions)

Piping position

Since 2 -way outlet causes performance problems, do not set it .

pipe

pipe

Install the indoor unit on a place having a sufcient strength so that it with stands against the weight of the

unit.

The inlet and outlet ports should not be obstructed; the air should be able to blow all over the room.

Leave the space required to service the air conditioner.

The ceiling rear height is 9-3/8 " inches(250mm) or more.

A place from where the air can be distributed evenly throughout the room by the unit.

A place from where drainage can be extracted outdoor easily.

1.1Ceiling opening and suspension bolt (M l0) pitch emension

Be suitable for:

FP-51XD-E

FP-68XD-E

Page 31

29

Cassette Type Fan Coil

Unit Service Manual

680(Gaps between hoisting screw rods

)

840(Indoor unit )

890(Ceiling opening)

950 ( Decorated surface boards)

Hoisting screw (×4)

Water pipe

780(Gaps between hoisting screw rods)

840(Indoor unit)

890(Ceiling opening)

950 ( Decorated surface boards)

Be suitable for:

P-85XD/B-T; FP-102XD/B-T; FP-125XD/B-T; FP-140XD/B-T; FP-160XD/B-T; FP-180XD/B-T; FP-200XD/

B-T; FP-10XD–E; FP-12.5XD-E; FP-14XD-E; FP-16XD-E; FP-18XD-E;P-8XD/A-E; FP-10XD/A–E; FP-12.5XD/

A-E; FP-14XD/A-E; FP-16XD/A-E; FP-18XD/A-E; FP-85XD/B-T; FP-102XD/B-T; FP-125XD/B-T; FP-140XD/B-T;

FP-160XD/B-T; FP-180XD/B-T; FP-200XD/B-T; FP-68XDT/B-K; FP-85XDT/B-K; FP-125XDT/B-K; FP-180XDT/

B-K;

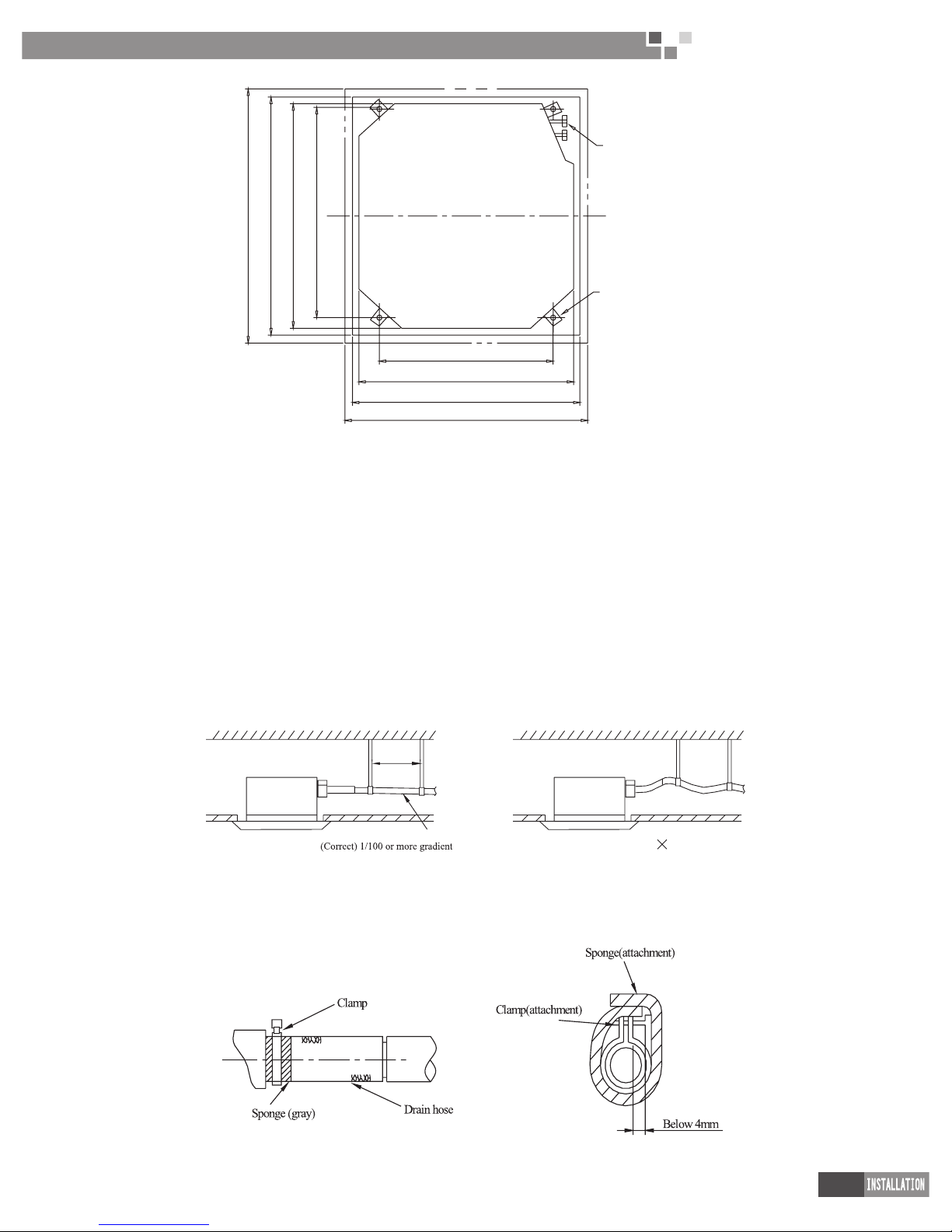

2. DRAINAGE PIPE

The diameter of the drain pipe should be greater than of equal to the diameter of the connecting pipe [vinyl

tube, pipe size: Outer diameter 25mm (outer dimension)].

Keep the drainage pipe short and sloping downwards at a gradient of at least 1/100 to prevent air pockets

from forming.

If the drainage hose cannot be sufciently set on, add a drainage raising pipe.

To keep the drainage hose from sagging, keep space between hanging hooks at 1~1.5m.

1-1.5m

(Wrong)

Use the drain hose and clamp attached. Insert the drain hose to the drain vent, and then tighten the clamp.

Entwine the big sponge on the clamp of drain hose to insulate heat.

Heat insulation should be done to indoor drain hose.

Page 32

30

Cassette Type Fan Coil

Unit Service Manual

3. PRECAUTIONS FOR DRAINAGE RAISING PIPE

The install height of the drain raising pipe should less than 280mm.

The drain raising pipe should form a upright angle with the unit, and distance to unit should not beyond

300mm.

3.1 Instruction

♦The slant gradient of the attached drain hose should be within 75mm so that the drain hole doesn’t has

to endure the unnecessary outside force.

♦Please install the drain hose according to the following process if several drain hoses join together.

♦The installation of the motorized valve should be done according as .Firstly connect one end of the

tube joint with the water inlet tube of the unit, then connect the other end with the motorized valve, and lastly

connect the motorized valve with the are nut . During the installation, both the torque wrench and the spanner

should be used and the moment of torque should be within 90 N.m. Besides, a secure connection should be

guaranteed.

Flare nut

Wiring interface

water inlet tube

Torque wrench

Thread fasten

Spanner

Valve

Tape

Water tube joint

♦Both the tube joint and the motorized valve are G3/4" threaded. Prior to the connection, it is

recommended to wrap the tacky tape on the thread for two or three cycles for better sealing effects .

♦After the tube joint, motorized valve, water inlet tube, water outlet tube are connected reliably, start the

Page 33

31

Cassette Type Fan Coil

Unit Service Manual

water pump of the outdoor unit to check if they leak or not.

♦What should be done lastly is wrapping sponge around the motorized valve and the tube for heat

insulation.

(1) For 2 pipes:

Body

Vavle

Intlet tube

Outlet tube

Pipe sleeve

HL-G3-3/4S

Powerr cord

(connecteddr with rther unit)

PE

WATER

VALVE

N

L

(2) For 4 pipes:

FCU

the FCU

Valve

PE

N

L

POWER

HOT WATER

COLD WATER

VALVE

VALVE

YV2

YV2

YV1

YV1

L

N

TERMINAL BOARD

♦Check the smoothness of drain after installation.

♦Check the drain state by imitating 600cc water slowly from the outlet vent or test hole.

♦Check the drain in the state of refrigerating after installation of the electric circuit.

Warning: Before obtaining access to terminals, all supply circuits must be disconnected.

Page 34

32

Cassette Type Fan Coil

Unit Service Manual

4. ELECTRIC WIRING

1. All eld supplied parts and materials must conform to local laws and regulations.

2. For electric wiring, refer to WIRING DIAGRAM attached to the unit body.

3. All wiring must be performed by a skilled technician.

4. A circuit breaker capable of shutting down power supply to the entire system and which have at least

mm contact separation in each jole must be installed in the xed wiring.

5. Earth properly.

6. Wiring must conform to national laws and regulations.

7. The xed wiring must be installed with a protector with no more that 30 mA leakage current.

8. If the supply cord is damaged, it must be replaced by the manufactory or its service agents or a

similarity qualied person in order to avoid a hazard.

4.1 Wiring of unit and the controller

4.1.1 Wiring of the unit

(1) For 2 pipes

Remove the control box lid, pull the wires inside through rubber bush and wiring according to the WIRING

DIAGRAM, then tighten it with clamp.

Wiring of the controller

♦Remove the control box lid, pull wires inside through rubber bush and connect to the controller.

♦Wrap the wire with sealing pad.

♦After wiring, tighten it with clamp and x the control box lid.

♦Heating and cooling: connect the rubber wire (5-cords) to the power supply terminal board in properly.

♦Cooling: connect the rubber wire (3-cords) to the power supply terminal board properly.

Precautions: Be sure to connect the unit at right poles.

(2) For 4 pipes

The "WIRING DIAGRAM" in the manual is reference. The correct wiring should agree with the "WIRING

DIAGRAM "on controller box of the unit.

1) Remove the control box lid (1). Pull the wires inside through rubber bush I and wiring according to the “

WIRING DIAGRAM ”, then tighten it with clamp.After wiring, tighten it with clamp and x the control box lid(1).

(2) .

2) When the wiring is completed, take a careful check and then start the water pump and unit to see if the

motorized valve works normally.

Page 35

33

Cassette Type Fan Coil

Unit Service Manual

Control box lid(1)

Control box lid(2)

Rubber bush I

Rubber bush II

Clamp

Seal here to avoid leakage

YV2 YV2

YV1 YV1

L

N

Power supply

Connected with water valve

Connected with user power

terminal board

Page 36

34

Cassette Type Fan Coil

Unit Service Manual

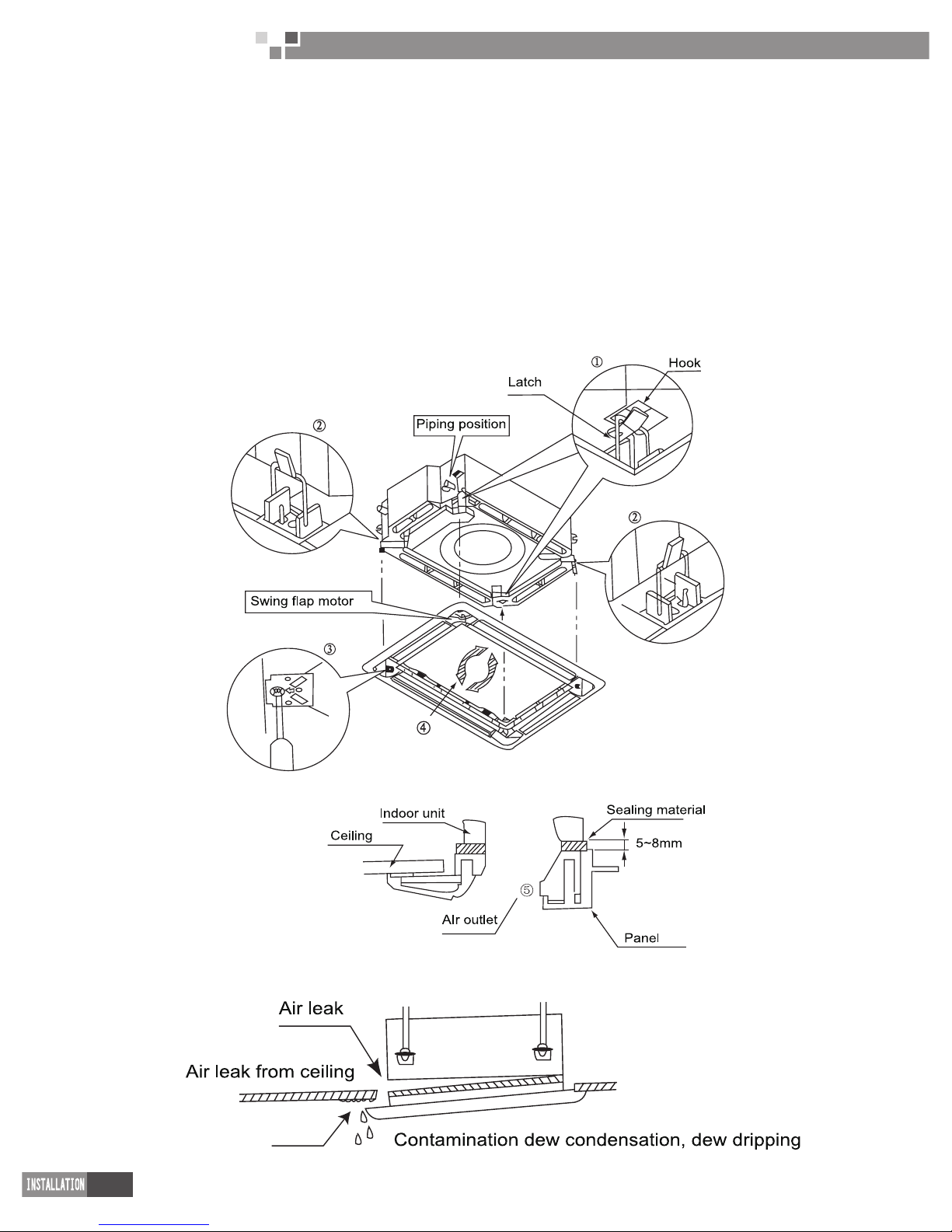

5. INSTALLATION OF PANEL

Set the panel to the unit body by matching the position of the swing ap motor of the decoration panel to

the piping position of the indoor unit as shown as below.

Install the decoration panel.

1. Hang the latch, which is located on the opposite side of the swing ap motor on the panel, temporarily

to the hook of the unit. (2 Positions)

2. Temporarily hang the remaining 2 latches to the hooks on the sides of the unit.(be careful not to let the

swing motor lead wire get caught in the sealing material.)

3. Screw all 4 hexagon head screws located right beneath the latches in approximately 15mm.(panel will

rise)

4. Adjust the panel by turning it to the arrowed direction in Fig.4 so that the ceiling opening is completely

covered.

5. Tighten the screws until the thickness of the sealing material between the panel and the unit.

6. Body is reduced to 5~8 mm.

5.1 Precautions

Improper screwing of the screws may cause the troubles.

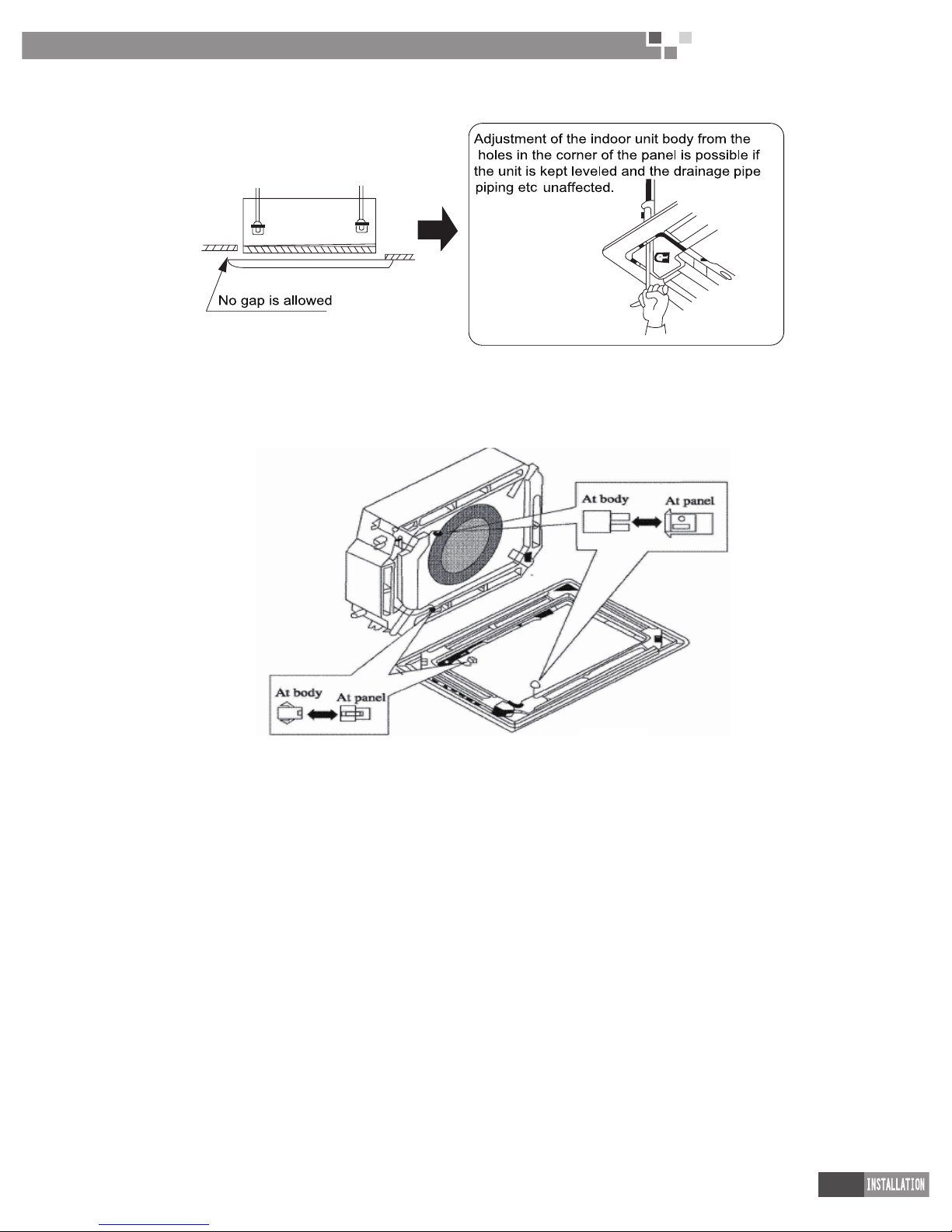

Page 37

35

Cassette Type Fan Coil

Unit Service Manual

If gap is still left between the ceiling and the panel after screwing the screws, readjust the height of the unit

body.

5.2 After xing be sure no gap left between the ceiling and the panel

Wiring of the decoration panel.

Connect the joints for swing ap motor lead wire (at 2 places) installed on the panel.

Page 38

36

Cassette Type Fan Coil

Unit Service Manual

MAINTENANCE

Page 39

37

Cassette Type Fan Coil

Unit Service Manual

MAINTENANCE

1.TROUBLESHOOTING

Panel TB03 displaying the error code :

Error code Error

E0 Water pump error

E6 Communications error

F0 temperature sensor error at the return air inlet

F1 Evaporator temp. sensor error

F5 temperature sensor error at the wire controller

E9 Full water protection

FE Entering cooling temp. sensor error of the evaporator

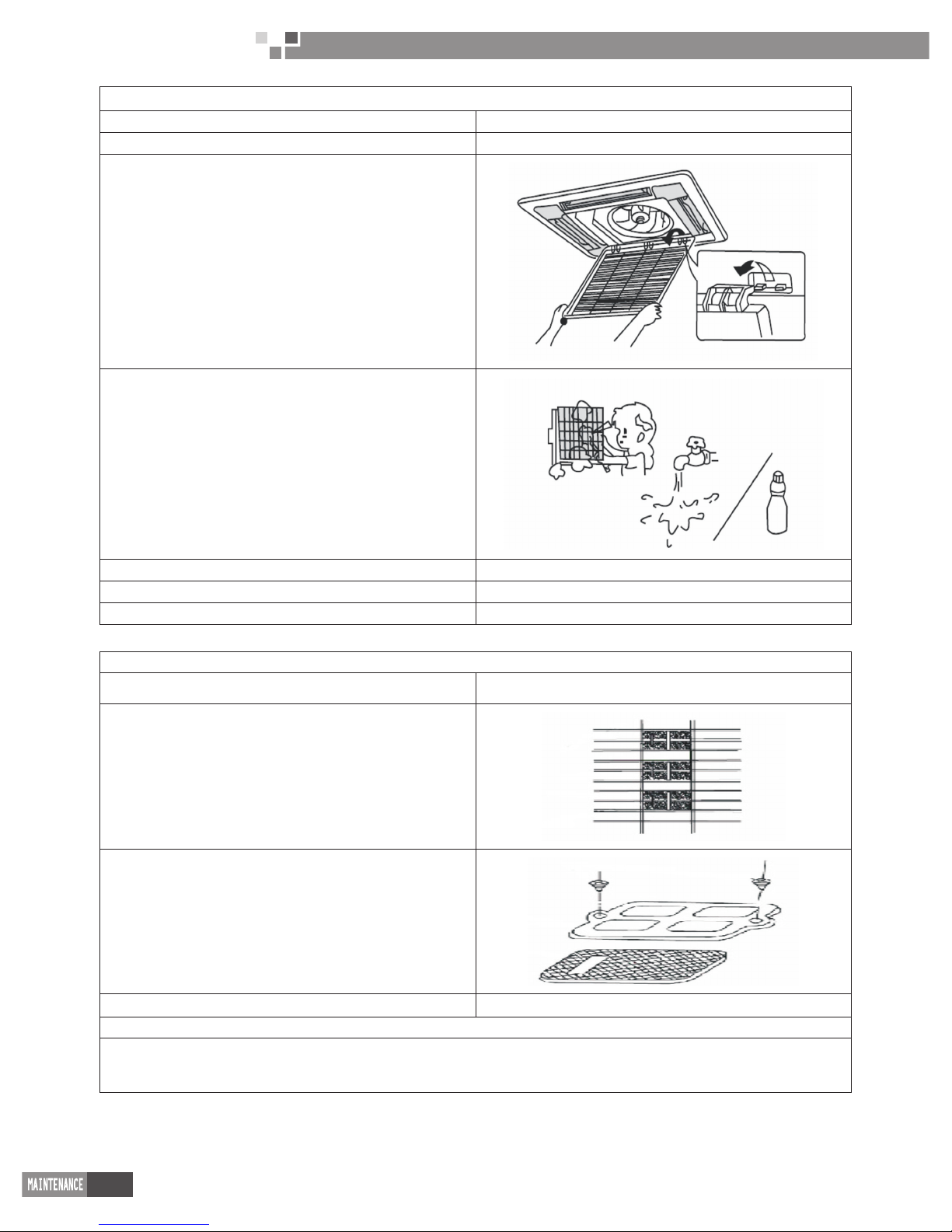

2.CARE AND MAINTENANCE

Please pull out the power plug after you used the air condition.

Warning:

1. Pull out the power plug before cleaning.

2. Do not splash water directly.

How to clean the air lter

1. Open the suction grille.

2. Slide both knobs simultaneously as shown and then pull them downward slowly.

buckle

1. Remove the air lters.

2. Slide knobs on the back of the suction grille out ward and remove the air lter.

3. Then remove three air cleaners on it.

●Clean the lter

Use vacuum or wash the air lter with water when the air lter is very dirty, use neutral

detergent and water. Let the lter dry naturally at shady place.

Note:

1. Do not clean with hot water.

2. Do not dry over re.

3. Do not run the air condition without the air lter.

4. The suction grille must be opened by skilled personnel.

●Fix the air lters

1. Fix three air-cleaner on the air lter and then x the air lter to the suction grille by

hanging it to the projected portion above suction grille.

2. Set air lter by sliding the knob on the back of the suction grille inward.

Shut the suction grille. Refer to step.1

Page 40

38

Cassette Type Fan Coil

Unit Service Manual

How to clean to the suction grille

1. Open the suction grille See step 1 of “How to clean the air lter”.

2. Remove the air lters See step 2 of “How to clean the air lter”.

3. Remove the suction grille

Open the suction grille at 45°and then lift.

4. Wash with water.

When the suction grille is very dirty, use soft brush and neutral

detergent. Shake water and dry in a shady place.

5. Fix the suction grille. Refer to step 3.

6. Fix air lter. See step 4 of “How to clean the air lter”.

7. Close the suction grille. Refer to step 1.

Changing air cleaner

1. Open the suction grille See step 1 of “How to clean the air lter”

2.Remove the air cleaner

Remove the air lter and remove the air cleaner after unscrewing.

3. Take off packing bag and put in new static electricity ber lter,

then x them on the air lter.

4. Fix the air lter See step 4 of “How to clean the air lter”

Air cleaner functions and service cycle time.

Absorbs bad smell in air such as carbon monoxide carbon dioxide, benzyl, gasoline and so on.

Absorbs harmful objects bigger than 1.0 um in air such as dust, germ, virus and so on.

It can be used for about half a year to one year.

Page 41

39

Cassette Type Fan Coil

Unit Service Manual

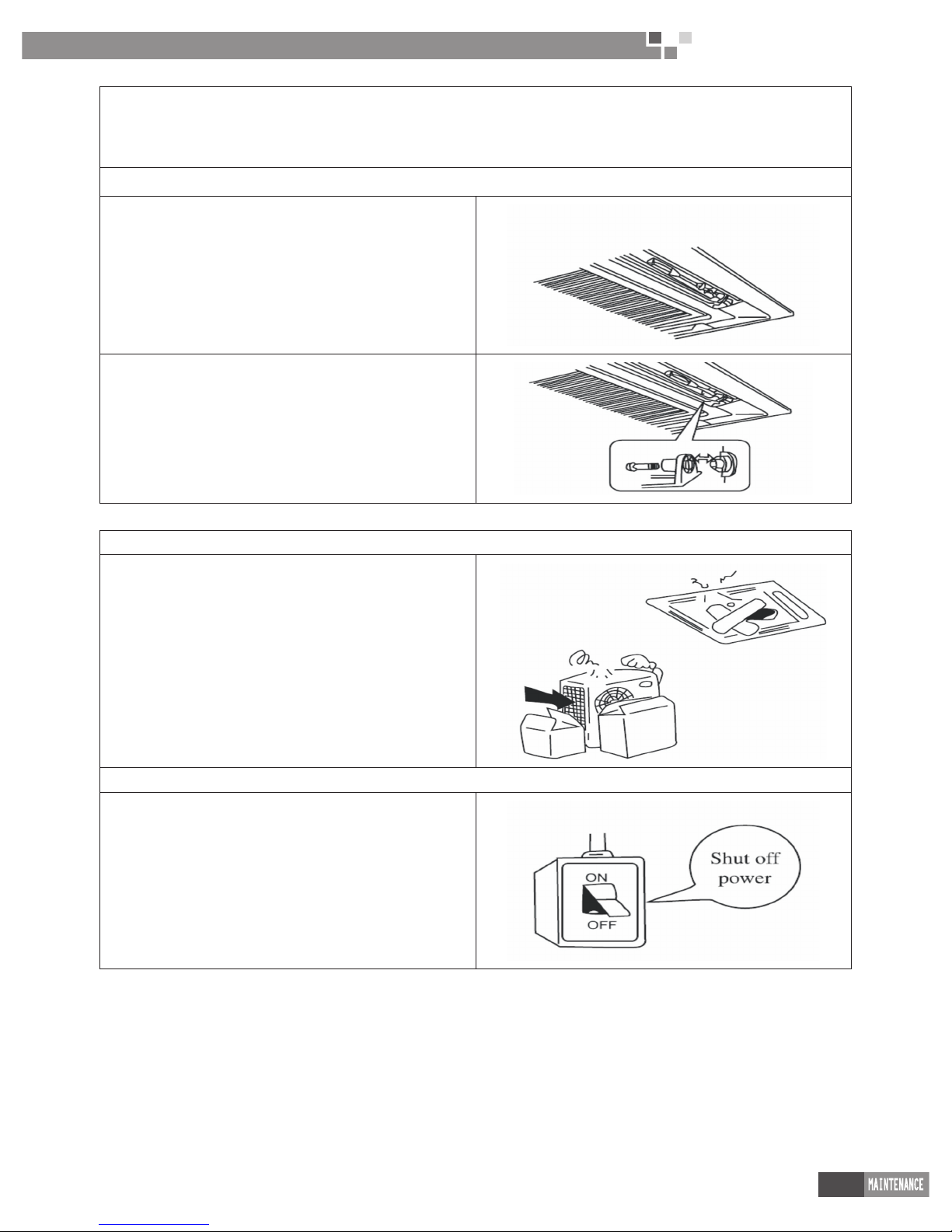

How to clean the air outer and case.

●Clean with soft cloth or use water and neutral detergent.

●Do not use gasoline, benzene, thinner, polishing powder, liquid insecticide, which may cause discoloring or warping.

●If the air ow ap is very dirty, you may remove it to clean as shown below.

Detach and x the ap.

1. Detach the ap

Loosen the screws on the sides of the ap clean with soft cloth.

2. Fix the ap

Set the ribs on the sides of the air outlet to the slit of the ap and

then screw together to x the ap.

Before starting the air conditioner for the rst time in the season.

1. Check to make sure no objects obstructing the intake and

outlets parts on both the indoor and outdoor units.

2. Check to make sure ground wire is connected and that is not

damaged.

3.Check to make sure air lter has been cleaned.

4. Turn on the power 6 hours before starting the air conditioner.

End of season cleaning

1. Clean the lter and the body of the unit.

2. Turn off power.

3. Clear outdoor of dust.

4. If there is any rust in the outdoor unit, this should be painted

over to prevent the rust from spreading.

Page 42

40

Cassette Type Fan Coil

Unit Service Manual

3. WIRING DIAGRAM

FP-8XD-E; FP-10XD–E; FP-12.5XD-E; FP-14XD-E;FP-14XD-E;FP-18XD-E.

POWER:

WATER

VALVE

COMMUNICATION CORD

Manual Panel

LIMIT

W6

W14

W13

SWITCH

HEAT

Temperature limiter

PUMP MOTOR

POWER TRANSFORMER

Attention:The Manal Panel

is the optional accessory

FANM OTOR

GN

ROOM TEMP

SENSOR

PIPE TEMP

SENSOR

LIQUID

SWITCH

Evaporator

FP-8XD/A-E; FP-10XD/A–E; FP-12.5XD/A-E; FP-14XD/A-E;FP-16XD/A-E; FP-18XD/A-E.

POWER:

VALVE

WATER

COMMUNICATION CORD

Manual Panel

PUMP

FAN MOTOR

MOTOR

POWERT RANSFORMER

SWING MOTOR

Attention:The Manual Panel

is the optional accessory

ROOM TEMP.

SENSOR

PIPE TEMP.

Evaporator

LIMIT

SWITCH

SENSOR

LIQUID

SWITCH

Page 43

41

Cassette Type Fan Coil

Unit Service Manual

Model: FP-51XD –E; FP-68XD –E.

POWER:

VALVE

WATER

Manual Panel

FANM OTOR

PUMP MOTOR POWERT RANSFORMER

SWING MOTOR

FUT

Attention:The Manual Panel

is the optional accessory

ROOM TEMP.

SENSOR

PIPE TEMP.

SENSOR

LIQUID

SWITCH

Model:FP-85XD/B-T;FP-102XD/B-T;FP-125XD/B-T;FP-140XD/B-T;FP-160XD/B-T;FP-180XD/B-T;FP200XD/B-T.

Page 44

42

Cassette Type Fan Coil

Unit Service Manual

Model:FP-68XDT/B-K; FP-85XDT/B-K; FP-125XDT/B-K; FP-180XDT/B-K.

4. DISASSEMBLY AND ASSEMBLY PROCEDURE OF MAIN PARTS

Model;FP-8XD-E; FP-10XD–E; FP-12.5XD-E; FP-14XD-E; FP-16XD-E; FP-18XD-E;P-8XD/A-E; FP-10XD/

A–E; FP-12.5XD/A-E; FP-14XD/A-E;FP-16XD/A-E; FP-18XD/A-E; FP-85XD/B-T; FP-102XD/B-T: FP-125XD/

B-T; FP-140XD/B-T; FP-160XD/B-T; FP-180XD/B-T; FP-200XD/B-T; FP-85XD/B-T; FP-102XD/B-T: FP-125XD/

B-T; FP-140XD/B-T; FP-160XD/B-T; FP-180XD/B-T; FP-200XD/B-T; FP-68XDT/B-K; FP-85XDT/B-K; FP125XDT/B-K; FP-180XDT/B-K.

Disassembly Procedures of Indoor Unit ( Panel T01)

Remark: Make sure that the unit is stopped running and power supply is cut off before removal of the motor.

Process Pictorial View Handling Description

1.Disassemble

the grille of the

front panel

Push the left and right buckles on the grille of the

front panel toward the center and meanwhile pull

it upward until it forms a 45℃angle, after that pull

the grille backward.

2. Disassemble

the front panel.

Cover

Screw

Six-Creo

Plug

Electric Box Cover I

Electric Box Cover II

Disconnect the power cord of the fan motor and

the plug of the limit switch.

Open the cover װ of the electric box and

disconnect the six-cord plug, then remove covers

on four corners away, after that, loosen the screws

to the right position and turn the front panel

counter clockwise and lastly pull it out upward.

Page 45

43

Cassette Type Fan Coil

Unit Service Manual

3. Disassemble

the drain pan.

Electrical Box Cover

Loosen the screws on the coverⅠ of the

electrical box and then open the cover.

4.Disassemble

the electrical box

Screw

Loosen two screws xing the electric box and then

disconnect each wiring terminals, after that take the

electric box out upward.

5.Disassemble the

ow-guide loop

Scre

w

Flow-Guide Loop

Loosen the screws fixing the flow-guide loop and

then turn it counter clockwise.

6.Disassemble

the drain pan

Screw

Loose the screws on the drain pan and take it out

upward.

7.Disassemble

the fan blade

Nut with W

asher

Fan Blade

Loosen the screws on the fan blade and then take it

out upward.

Page 46

44

Cassette Type Fan Coil

Unit Service Manual

8. Disassemble

the evaporator

Screw

Screw

Connection Board

Clamp

Fixed Mount

Mounting Plate

Baffle

S

crew

Evaporator

Loosen the screws on the mounting plate and

take it out.

Loosen the screws on the baffle of the pipe

outlet, and then press it downward to pull out the

buckles on both side, after that, take the baffle

away.

Loosen the screws and clamps on the connection

board of the evaporator, disconnect the earth

lead, and then take the power cord of the motor,

electric heater and earth lead out through the

wire-cross hole, after that loosen the screws on

the xed mount and remove it away, nally take

the evaporator out upward.

9. Disassemble

the motor

Screw

Motor

Retaining Plate

Loosen the screws on the retaining plate and

the screw bolts on the motor, after that, take the

motor out.

10. Disassemble

the water pump

and the drain pipe

Drain Pipe

Screw

Screw

Loosen four screws fixing the water pump,

disconnect the water pipe of the pump, take the

mounting bracket away, then loosen these two

screws xing the water pipe, after that, take the

water pipe away.

Page 47

45

Cassette Type Fan Coil

Unit Service Manual

Model: FP-51XD –E; FP-68XD –E.

Disassembly Procedures of Indoor Unit

Remark: Make sure that the unit is stopped running and power supply is cut off before removal of the motor.

Process Pictorial View Handling Description

1. Disassemble

the grille of the

front panel

Buckle

Buckle

Push the left and right buckles on the grille of the

front panel toward the center and meanwhile pull

it upward until it forms a 45℃angle, after that pull

the grille backward.

2.Disassemble

the front panel

Screw

Screw

Front panel

Disconnect the power cord of the fan motor and

the plug of the limit switch.

Open the cover

Ⅱ

of the electric box and

disconnect the six-cord plug, then remove covers

on four corners away, after that, loosen the screws

to the right position and turn the front panel

counter clockwise and lastly pull it out upward.

3. Disassemble

the drain pan

Drain Pan

Screw

Screw

Drain Pan

Loose the screws on the cover Ⅰof the electric

box and then take the cover away.

Page 48

46

Cassette Type Fan Coil

Unit Service Manual

4. Disassemble

the electrical box

Screw

Screw

Screw

Electrical Box Cover

Electrical Box Cov

Screw

Screw

Screw

Electrial Box Cover

Electrial Box

Loosen two screws on the cover of the electric box

and then remove it away.

Disconnect the wiring terminals of the motor and

the temperature sensing bulb, then loosen two

screws fixing the electric box, after that, remove

the electric box away.

5. Disassemble

the baffle at the

pipe outlet.

Baffle

Screw

Screw

Bafe

Loosen two screws on the bafe and take it out by

turning it upward.

6. Disassemble

the water pump

Water Pump

S

crew

Drain Pipe

Screw

Screw

Screw

Drain Pipe

Water Pump

Loosen the screws xing the drain pan and then

take the it out upward.

Page 49

47

Cassette Type Fan Coil

Unit Service Manual

7. Disassemble

the left fender

Left Fender

Screw

Screw

Left Fender

Loosen two screws on the left fender and then

take it out upward.

8.Disassemble

the fan blade

Screw

Fan Blade

Fan Blade

Screw

Loosen the screws on the fan

blade and then take it out.

9.Disassemble

the evaporator

Connection Board

Evaporator

Fixed Mount

Connection Board

Fixed Mount

Evaporator

Loosen the screws on the connection board and

the xed mount of the evaporator, and then remove

them away, after that, take the evaporator out.

10.Disassemble

the motor

Screw

Motor

Screw

Loosen four screws xing the motor

and take the motor out.

Page 50

48

Cassette Type Fan Coil

Unit Service Manual

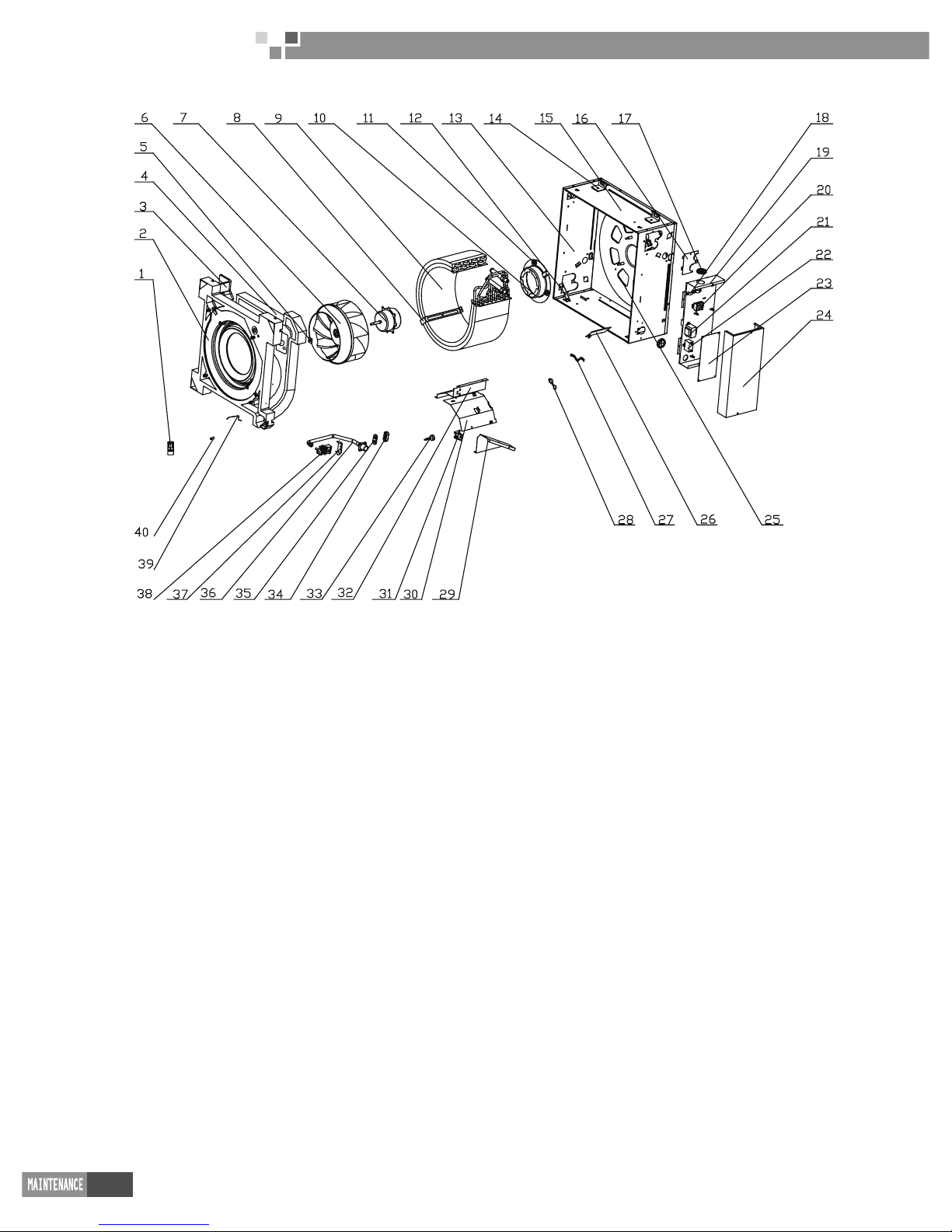

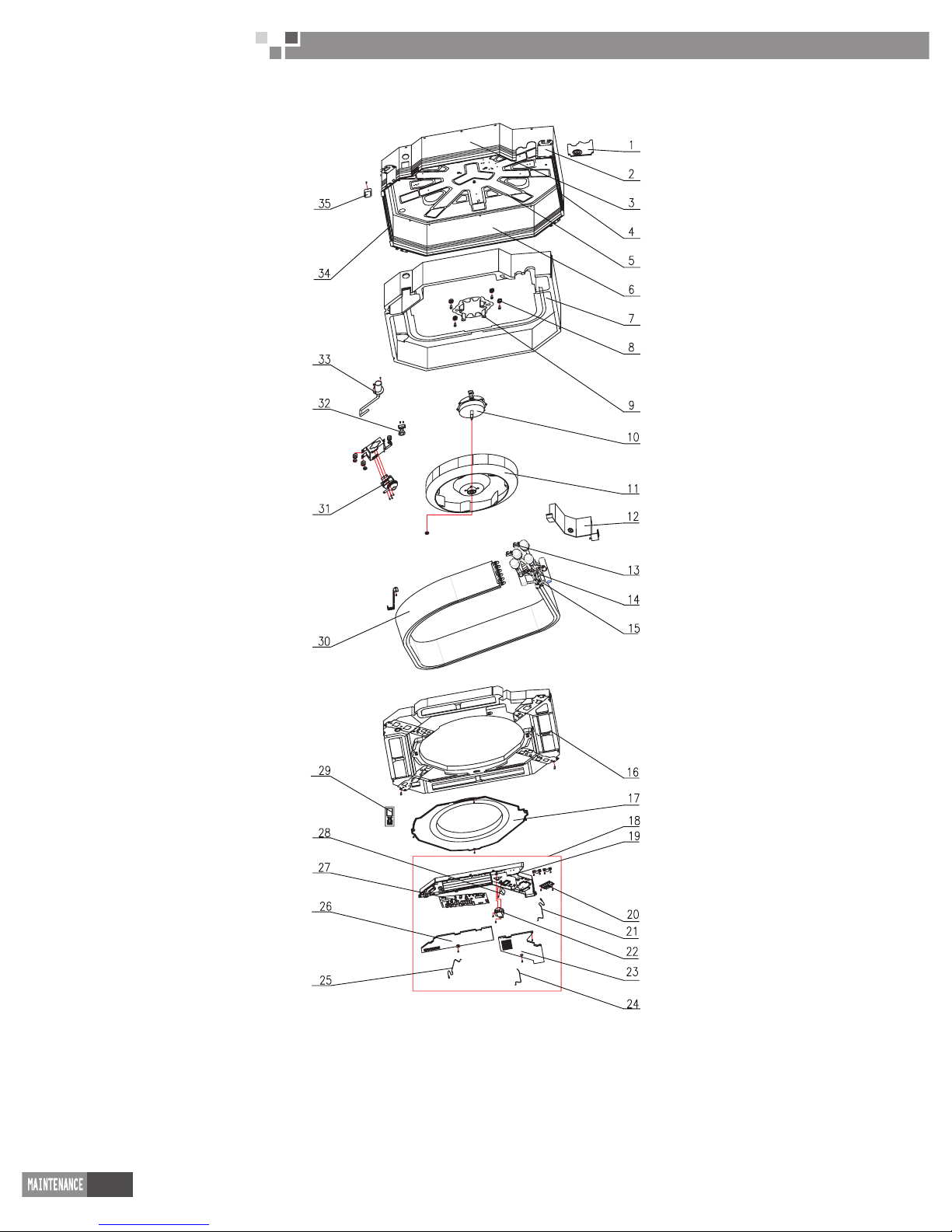

5. EXPLODED VIEWS AND SPARE PART LISTS

Model: FP-8XD-E; FP-10XD–E; FP-12.5XD-E; FP-14XD-E;FP-16XD-E; FP-18XD-E exploded views and

spare parts list.

Page 51

49

Cassette Type Fan Coil

Unit Service Manual

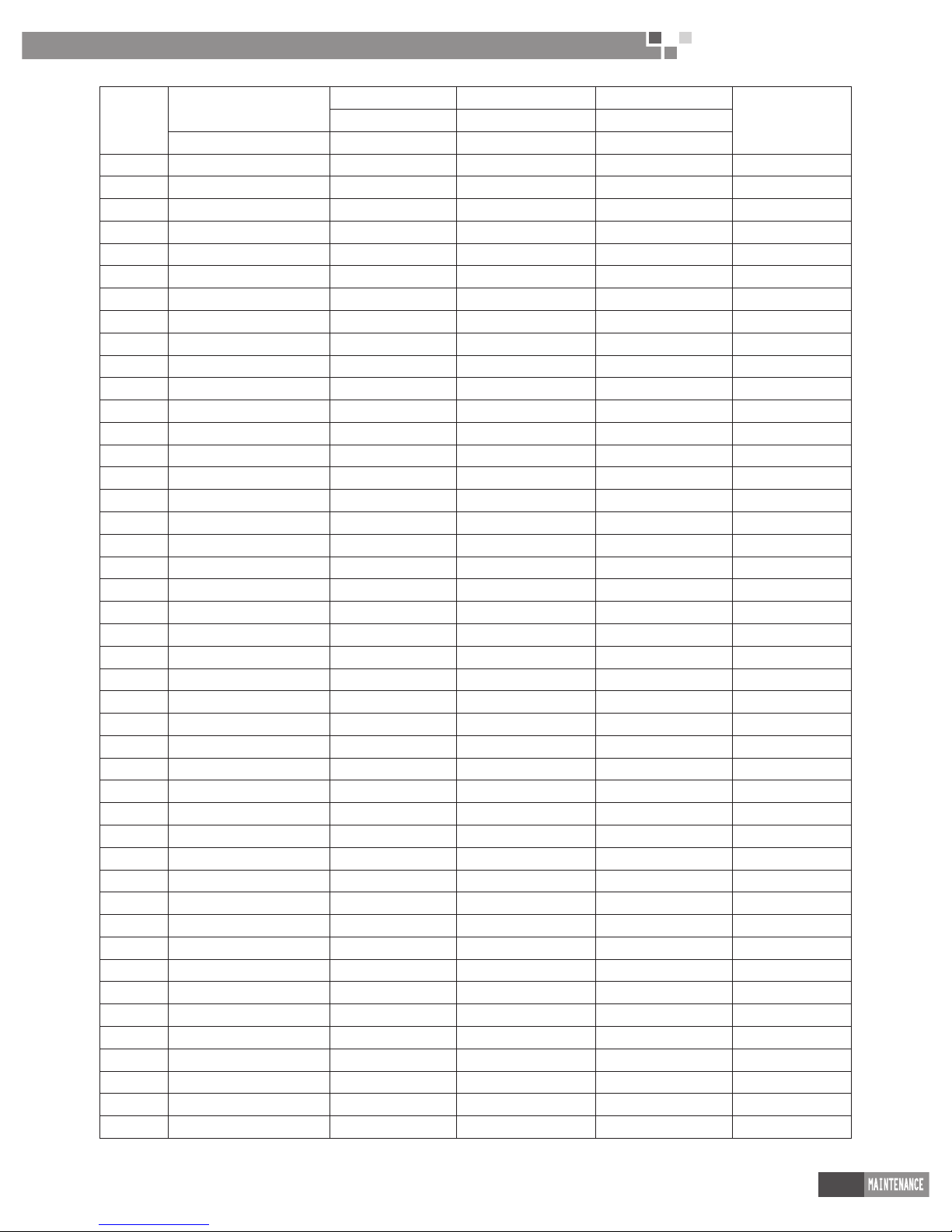

NO.

Discription

FP-8XD-E FP-10XD-E FP-12.5XD-E

Quantity EM52000050 EM52000060 EM52000030

Name of Parts Part Code Part Code Part Code

1 Tube Exit plate 02217102 02217102 02217102 1

2 Body Fixing Plate 01332701 01332701 01332701 4

3 Front Side Plate 01302718 01302718 01302718 1

4 Left Side Plate 01302715 01302715 01302715 1

5 Base Plate 01222701 01222701 01222701 1

6 Rear Side Plate 01302714 01302714 01302714 1

7 Bottom Foam 52012722 52012722 52012722 1

8 Motor Gasket 76712711 76712711 76712711 4

9 Bolt M6 70212711 70212711 70212711 4

10 Motor Support 01702701 01702701 01702701 1

11 Motor 15012703 15012703 15012703 1

12 Electric Heater 32002701 32002701 32002701 1

13 Centrifugal Fan 10312705 10312705 10312705 1

14 Evaporator Linkage 01074042 01074042 01074042 1

15 Cable-cross Loop 76512701 76512701 76512701 1

16 Tube sensor 3900012125 3900012125 3900012125 1

17 sensor insert B 42020063 42020063 42020063 1

18 Heat exchanger 01127104 01127104 01127104 1

19 Water Tray Assy 20182701 20182701 20182701 1

20 Rubber Stem 76712701 76712701 76712701 1

21 Electric Base Plate 01412722 01412721 01412721 1

22 Flow-guide Loop 10372701 10372701 10372701 1

23 Electric Box 20102701 20102701 20102701 1

24 Wire Clamp 71010102 71010102 71010102 4

25 Terminal Board 42011142 42011142 42011142 1

26 relay 44010206 44010206 44010206 1

27 Transformer 43110170 43110170 43110170 1

28 Electric Box Cover I 20102702 20102702 20102702 1

29 Room sensor 39000110 39000110 39000110 1

30 Remote Controller 30512506 30512506 30512506 1

31 Electric Box Cover II 20102703 20102703 20102703 1

32 Main 30225904 30225904 30225904 1

33 Capacitor 33010026 33010010 33010010 1

34 Drainage Plastic 06122702 06122702 06122702 1

35 Evap Support 01072703 01072703 01072703 1

36 Nut with Washer M6 70310012 70310012 70310012 1

37 Fan Fixer 10312701 10312701 10312701 1

38 Water Pump 43130324 43130324 43130324 1

39 Pump Gasket 76712702 76712702 76712702 3

40 Pump Support 01332702 01332702 01332702 1

41 Water Level Switch 45010201 45010201 45010201 1

42 Pump Drainpipe 05230026 05230026 05230026 1

43 Right Side Plate 01302716 01302716 01302716 1

44 Cable-cross Block 76512702 76512702 76512702 1

45 Pump Cover Plate 01252713 01252713 01252713 1

46 Bolt 70212701 70212701 70212701 3

Above data is subject to change without notice,pls refer the SP in global service website.

Page 52

50

Cassette Type Fan Coil

Unit Service Manual

NO.

Discription

FP-14XD-E FP-16XD-E FP-18XD-E

Quantity EM52000070 EM52000080 EM52000040

Name of Parts Part Code Part Code Part Code

1 Tube-exit Plate 02217102 02217102 02217102 1

2 Body Fixing Plate 01332701 01332701 01332701 4

3 Front Side Plate 01302713 01302713 01302713 1

4 Left Side Plate 01302711 01302711 01302711 1

5 Base Plate 01222732 01222732 01222732 1

6 Rear Side Plate 01302709 01302709 01302709 1

7 Bottom Foam 52012721 52012721 52012721 1

8 Motor Gasket 76712711 76712711 76712711 4

9 Bolt 70210012 70210012 70210012 4

10 Motor Support 01702701 01702701 01702701 1

11 Motor FN50T 15012710 15012710 15012710 1

12 Electric Heater 32002701 32002701 32002701 1

13 Centrifugal Fan 10310101 10310101 10310101 1

14 Evap Connection 01072735 01072735 01072735 1

15 Cable-cross Loop 76515202 76515202 76515202 1

16 Tube sensor 3900012125 3900012125 3900012125 1

17 sensor insert B 42020063 42020063 42020063 1

18 Heat exchanger 01187104 01187104 01187104 1

19 Water Tray 20182701 20182701 20182701 1

20 Screw 70140032 70140032 70140032 4

21 Electric Plate 01412721 01412721 01412721 1

22 Flow-guide Loop 10372722 10372722 10372722 1

23 Electric Box 20102701 20102701 20102701 1

24 Wire Clamp 71010103 71010103 71010103 3

25 Terminal Board 42011142 42011142 42011142 1

26 relay 44010206 44010206 44010206 1

27 Transformer 43110170 43110170 43110170 1

28 Electric Box Cover I 20102702 20102702 20102702 1

29 Room sensor 39000110 39000110 39000110 1

30 Remote Controller 30505004 30505004 30505004 1

31 Electric Box Cover II 20102703 20102703 20102703 1

32 Main 30225904 30225904 30225904 1

33 Capacitor 33010010 33010013 33010012 1

34 Drainage Plastic 06122702 06122702 06122702 1

35 Evap Support 01072705 01072705 01072705 2

36 Nut with Washer 70310012 70310012 70310012 1

37 Fixer 10312701 10312701 10312701 1

38 Water Pump 43130324 43130324 43130324 1

39 Pump Gasket 76712702 76712702 76712702 3

40 Pump Support 01332721 01332721 01332721 1

41 Water Level Switch 45010201 45010201 45010201 1

42 Pump Drainpipe 05230026 05230026 05230026 1

43 Right Side Plate 01302712 01302712 01302712 1

44 Cable-cross Block 76512702 76512702 76512702 1

45 Pump Cover Board 01252713 01252713 01252713 1

46 Bolt 70212701 70212701 70212701 3

Above data is subject to change without notice,pls refer the SP in global service website.

Page 53

51

Cassette Type Fan Coil

Unit Service Manual

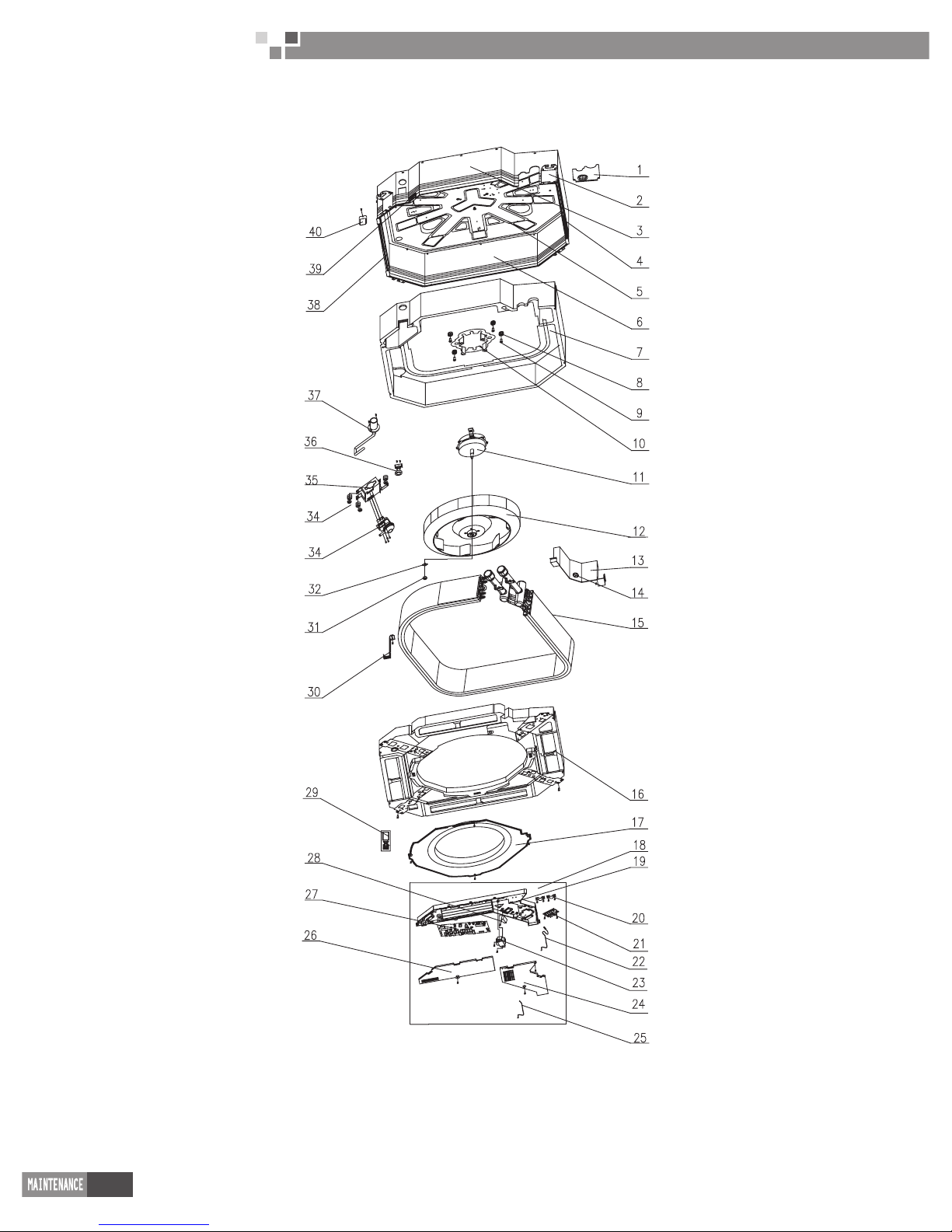

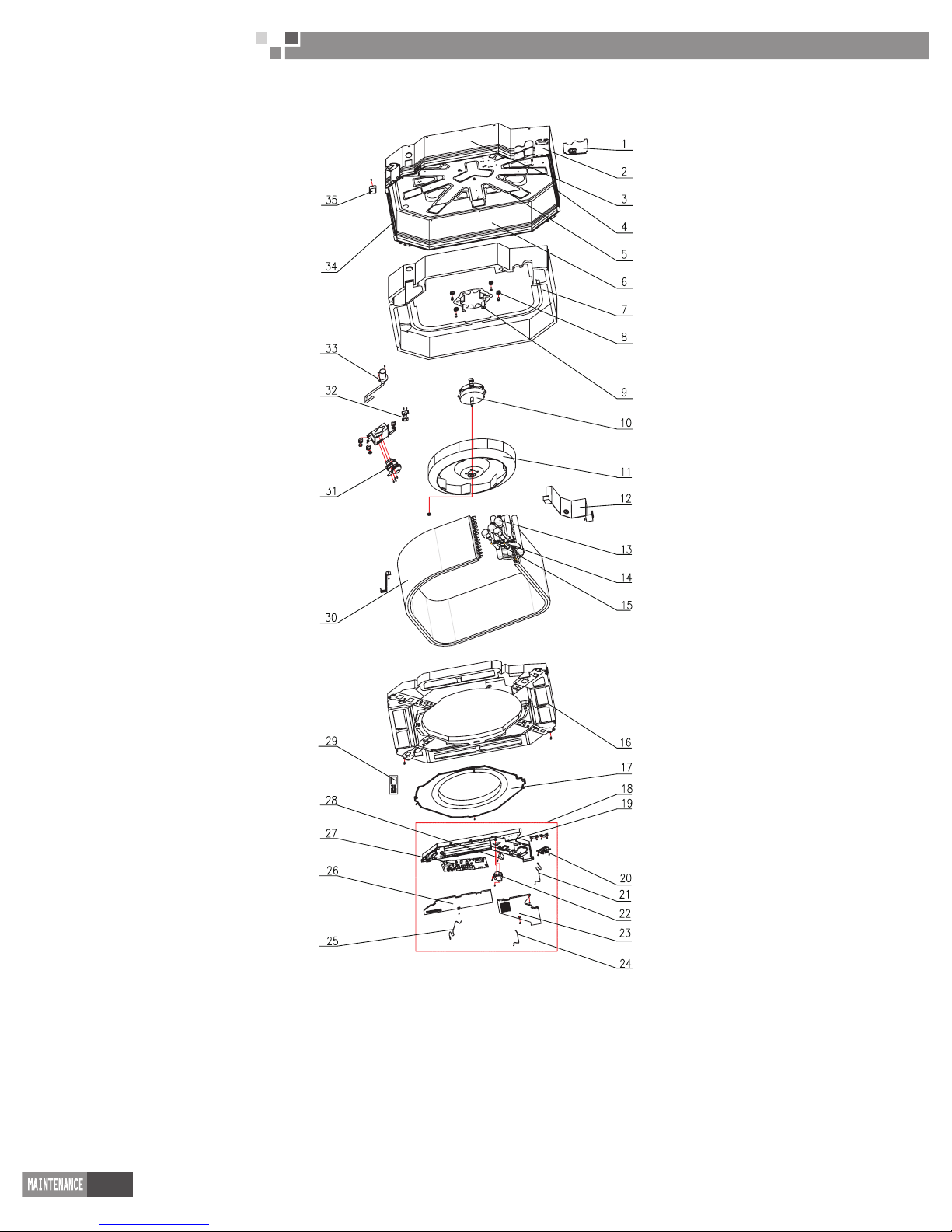

P-8XD/A-E; FP-10XD/A–E; FP-12.5XD/A-E; FP-14XD/A-E;FP-16XD/A-E; FP-18XD/A-E exploded views

and spare parts list.

Page 54

52

Cassette Type Fan Coil

Unit Service Manual

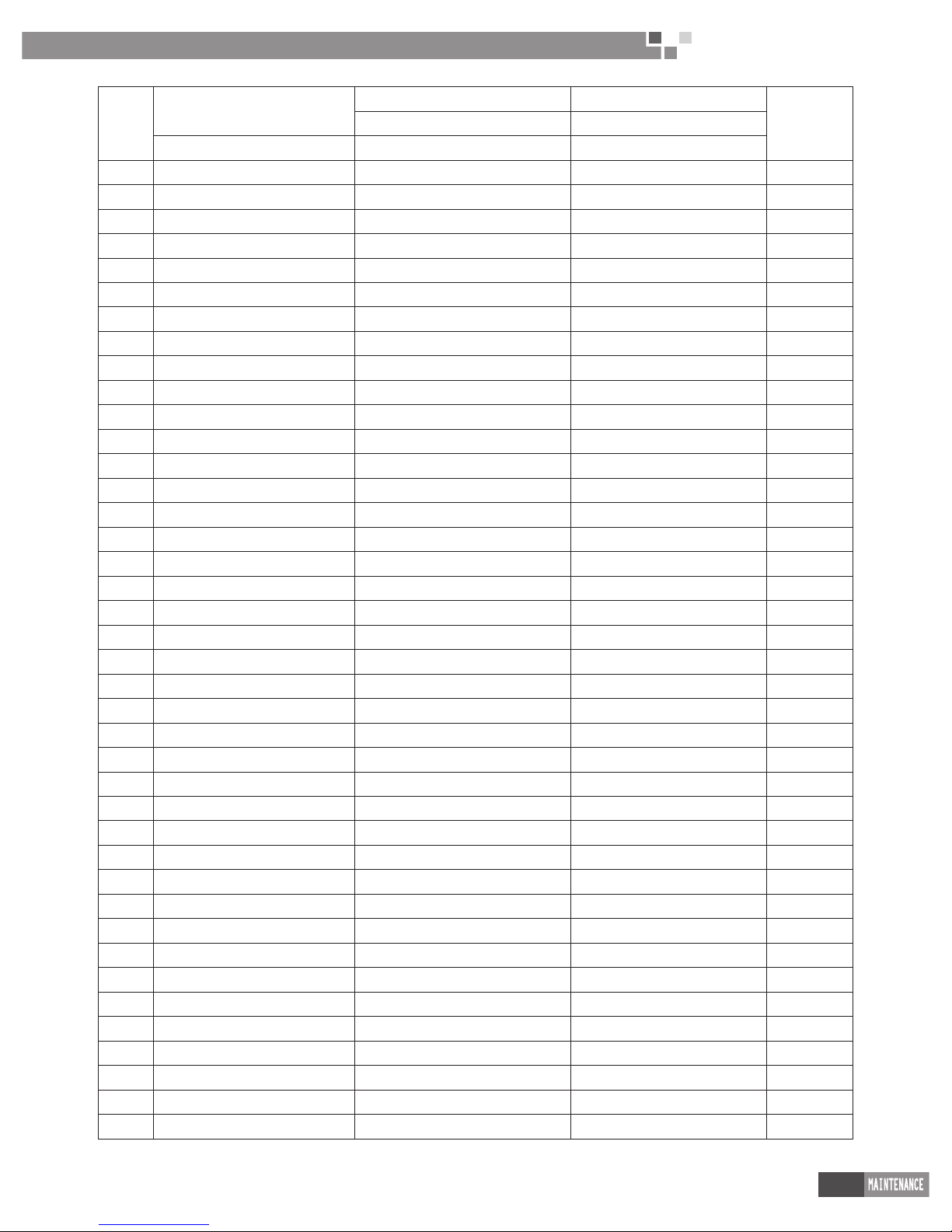

NO.

Discription

FP-8XD/A-E FP-10XD/A-E FP-12.5XD/A-E

Quantity EM52000450 EM52000460 EM52000470

Name of Parts Part Code Part Code Part Code