Gree FP-136WA/G-K, FP-170WA/G-K, FP-204WA/G-K, FP-34WAH/G-K, FP-51WAH/G-K Service Manual

...

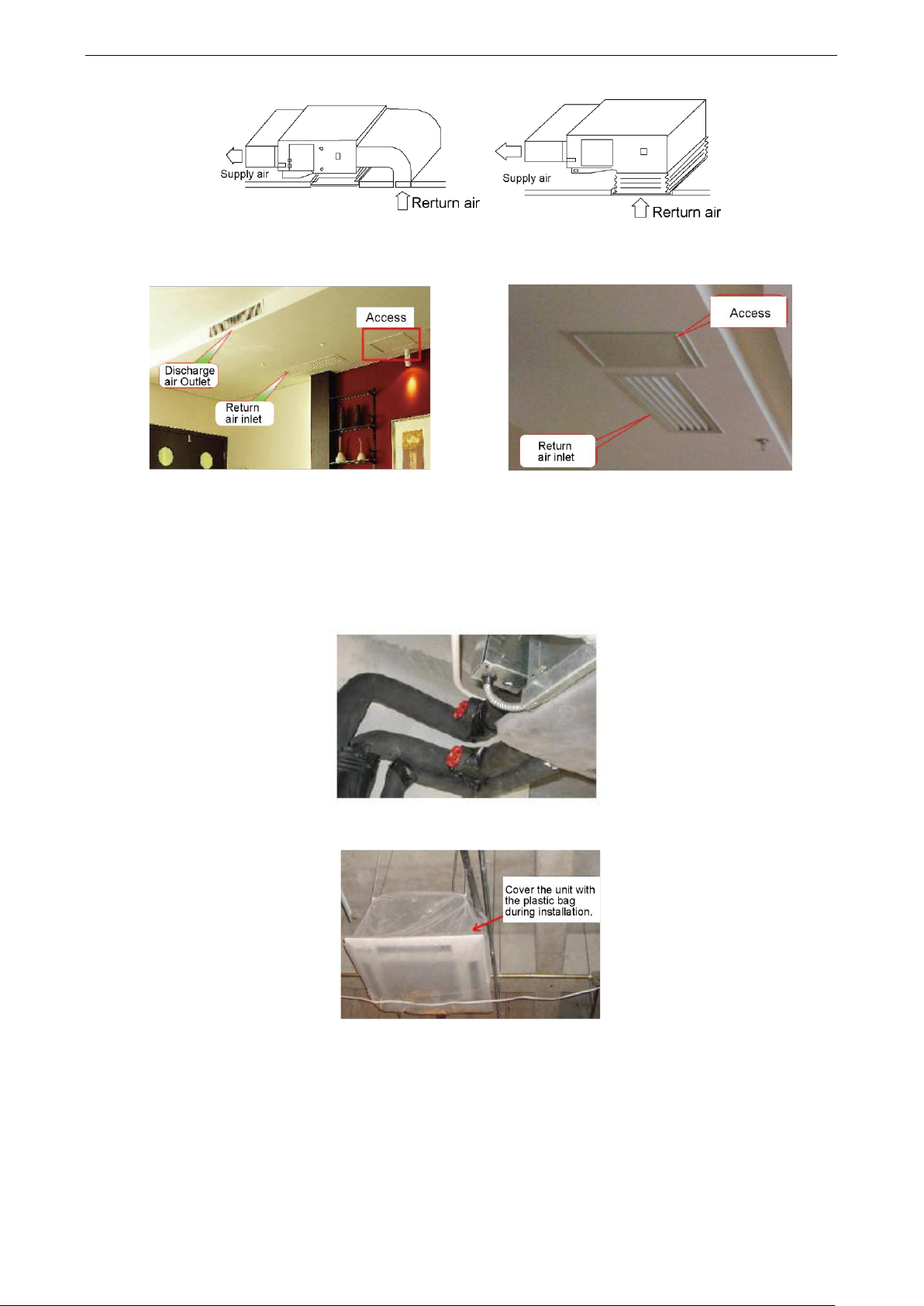

Concealed Ceiling Type FCU

Contents

Engineering Data ........................................................................................................................................ 1

1. Product Introduction ............................................................................................................................... 2

1.1 Product Lineup .............................................................................................................................. 2

1.2 Nomenclature .............................................................................................................................. 10

1.3 Product Features......................................................................................................................... 11

1.3.1 Features ............................................................................................................................ 11

1.4 Working Principle ........................................................................................................................ 12

1.5 Technical Data ............................................................................................................................ 13

1.5.1 Data at Nominal Conditions .............................................................................................. 13

1.5.2 Temperature at Nominal Conditions ................................................................................. 26

1.5.3 Operation Range .............................................................................................................. 26

1.5.4 Electric Data ..................................................................................................................... 27

1.5.5 Capacity Correction .......................................................................................................... 27

2. Dimensions of the Unit ......................................................................................................................... 28

3. Explosive Views and Part Lists ............................................................................................................ 29

4. Scope of Supply ................................................................................................................................... 54

Design & Selection ................................................................................................................................... 55

1. Selection Principle ................................................................................................................................ 56

1.1 Selection Steps ........................................................................................................................... 56

1.2 Allowable Noise Level for Buildings ............................................................................................ 56

1.3 Example for Selection ................................................................................................................. 56

Unit Control ............................................................................................................................................... 59

1. Control logic.......................................................................................................................................... 60

2. AC connected with PC (long distance monitoring) .............................................................................. 60

3. AC control principle sketch ................................................................................................................... 60

Unit Installation ......................................................................................................................................... 61

1. Preparation before Installation ............................................................................................................. 62

1.1 Tools ............................................................................................................................................ 62

1.2 Materials ...................................................................................................................................... 64

1.3 Drain Hose .................................................................................................................................. 65

1.4 Insulation ..................................................................................................................................... 66

2. Installation ............................................................................................................................................ 67

2.1 Precautions for Installation.......................................................................................................... 67

2.2 Installation Steps ......................................................................................................................... 70

Test Operation & Troubleshooting & Maintenance .................................................................................. 71

1. Error List ............................................................................................................................................... 72

2. Electric Diagrams ................................................................................................................................. 73

3. Replacement of Key Parts ................................................................................................................... 73

3.1 Replacement of the Motor........................................................................................................... 73

3.2 Replacement of the Cooler ......................................................................................................... 75

Enginnering Data

Engineering Data

1

Enginnering Data

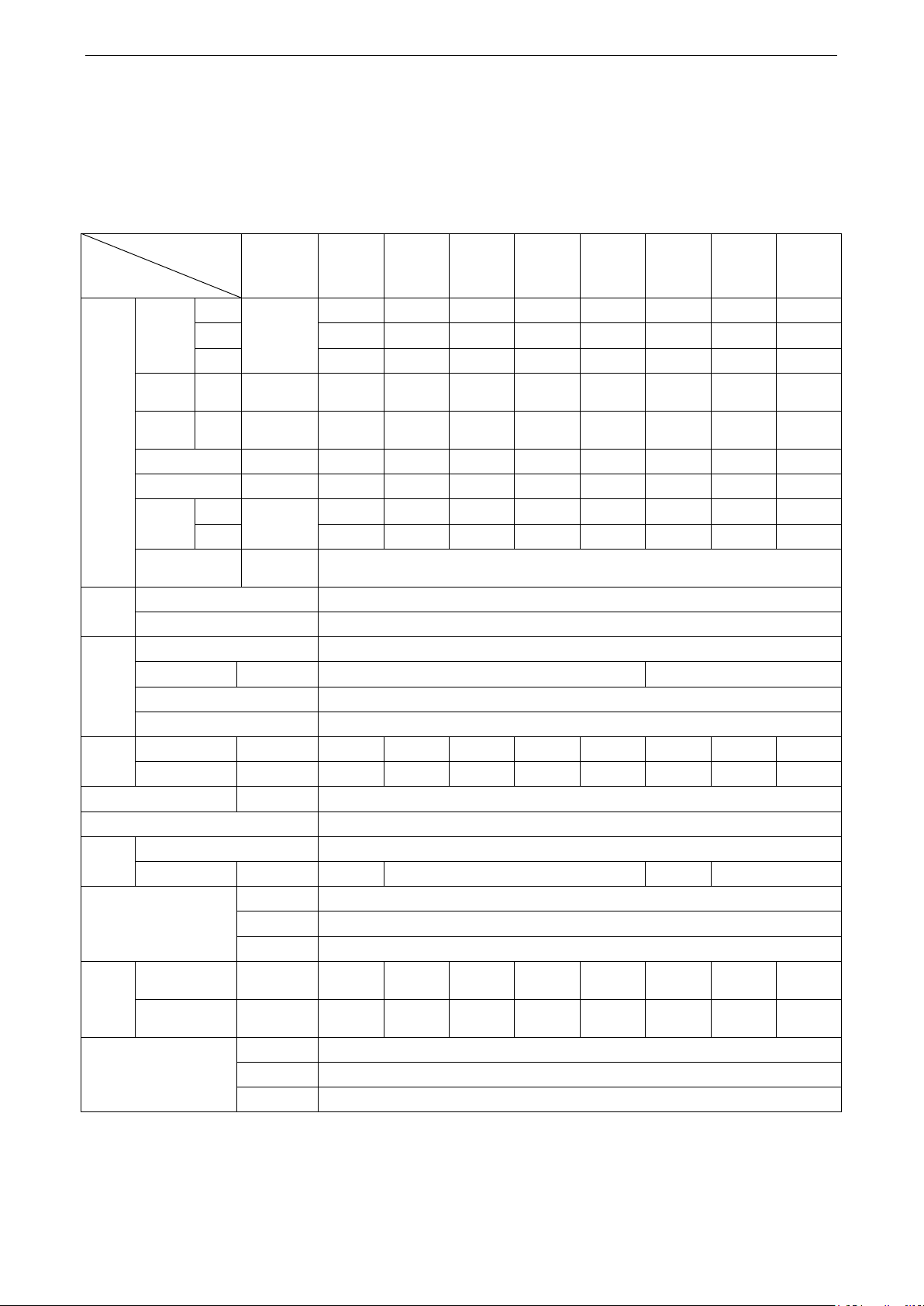

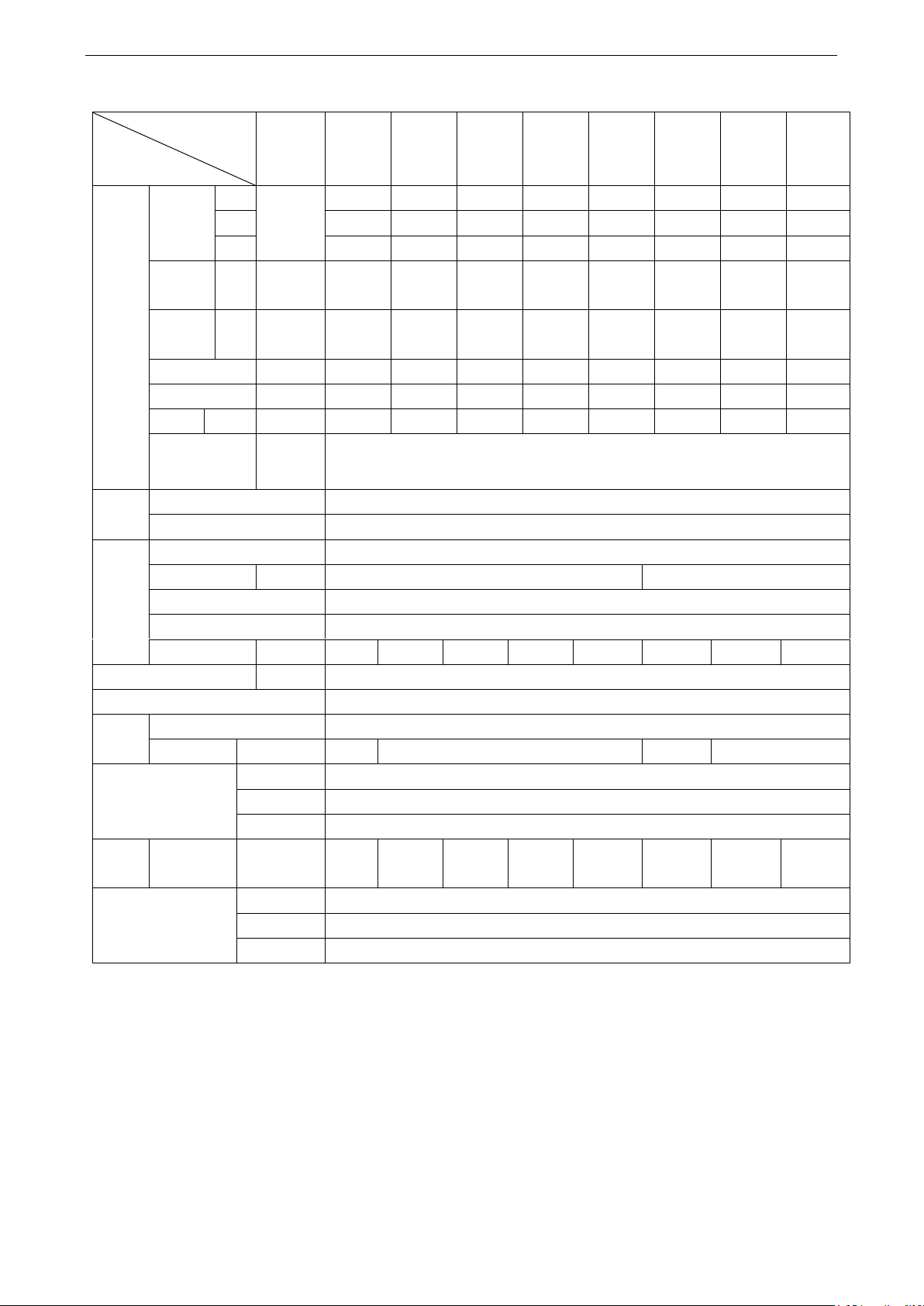

Series

Model

Product Code

Cooling

Capacity

(kW/Ton)

Heating

Capacity

(kW/Ton)

Power Supply

Picture

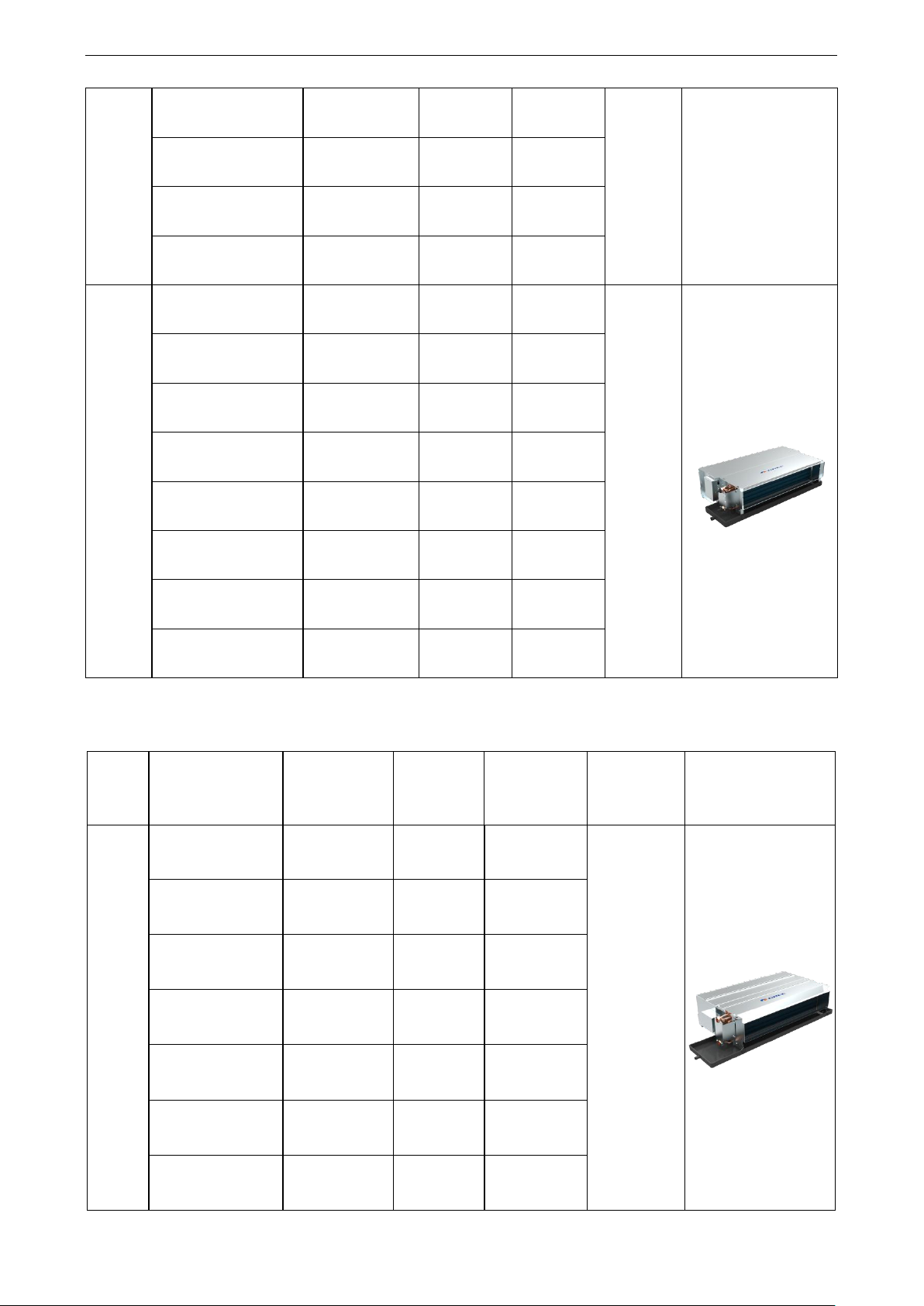

G Series FCU

FP-34WA/G-K

EM51002750

EM51002070

1.85/0.53

3.05/0.87

220-240V 50HZ

FP-51WA/G-K

EM51002140

EM51002790

2.8/0.8

4.22/1.2

FP-68WA/G-K

EM51002830

EM51002580

3.6/1.02

5.5/1.56

FP-85WA/G-K

EM51002210

EM51002870

4.5/1.28

7/1.99

FP-102WA/G-K

EM51002590

EM51002470

5.5/1.56

8.9/2.53

FP-136WA/G-K

EM51002630

EM51002490

7.35/2.09

12.1/3.44

FP-170WA/G-K

EM51002510

EM51002670

9.2/2.62

15.1/4.29

FP-204WA/G-K

EM51002710

EM51002100

11/3.13

18/5.12

G Series FCU

FP-34WAH/G-K

EM51002180

EM51002760

1.85/0.53

3.05/0.87

220-240V 50HZ

FP-51WAH/G-K

EM51002800

EM51002200

2.8/0.8

4.22/1.2

FP-68WAH/G-K

EM51002840

EM51002240

3.6/1.02

5.5/1.56

FP-85WAH/G-K

EM51002880

EM51002560

4.5/1.28

7/1.99

FP-102WAH/G-K

EM51002170

EM51002600

5.5/1.56

8.9/2.53

FP-136WAH/G-K

EM51002260

EM51002640

7.35/2.09

12.1/3.44

FP-170WAH/G-K

EM51002680

EM51002220

9.2/2.62

15.1/4.29

1. Product Introduction

1.1 Product Lineup

Section one --- countries and areas expect the European Union

50Hz (without the return air box) Standard, 3-row-pipes

2

Enginnering Data

FP-204WAH/G-K

EM51002530

EM51002530

11/3.13

18/5.12

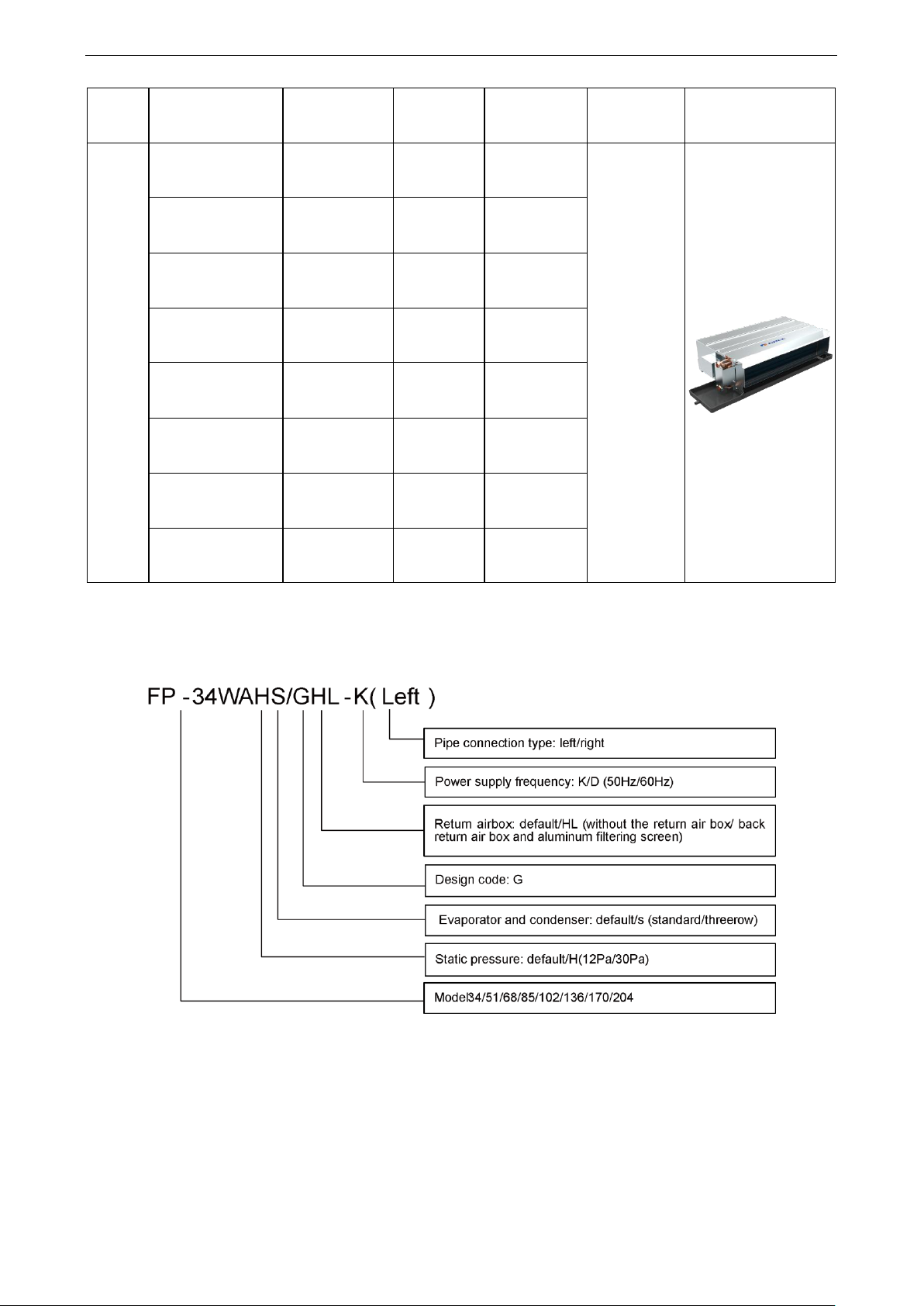

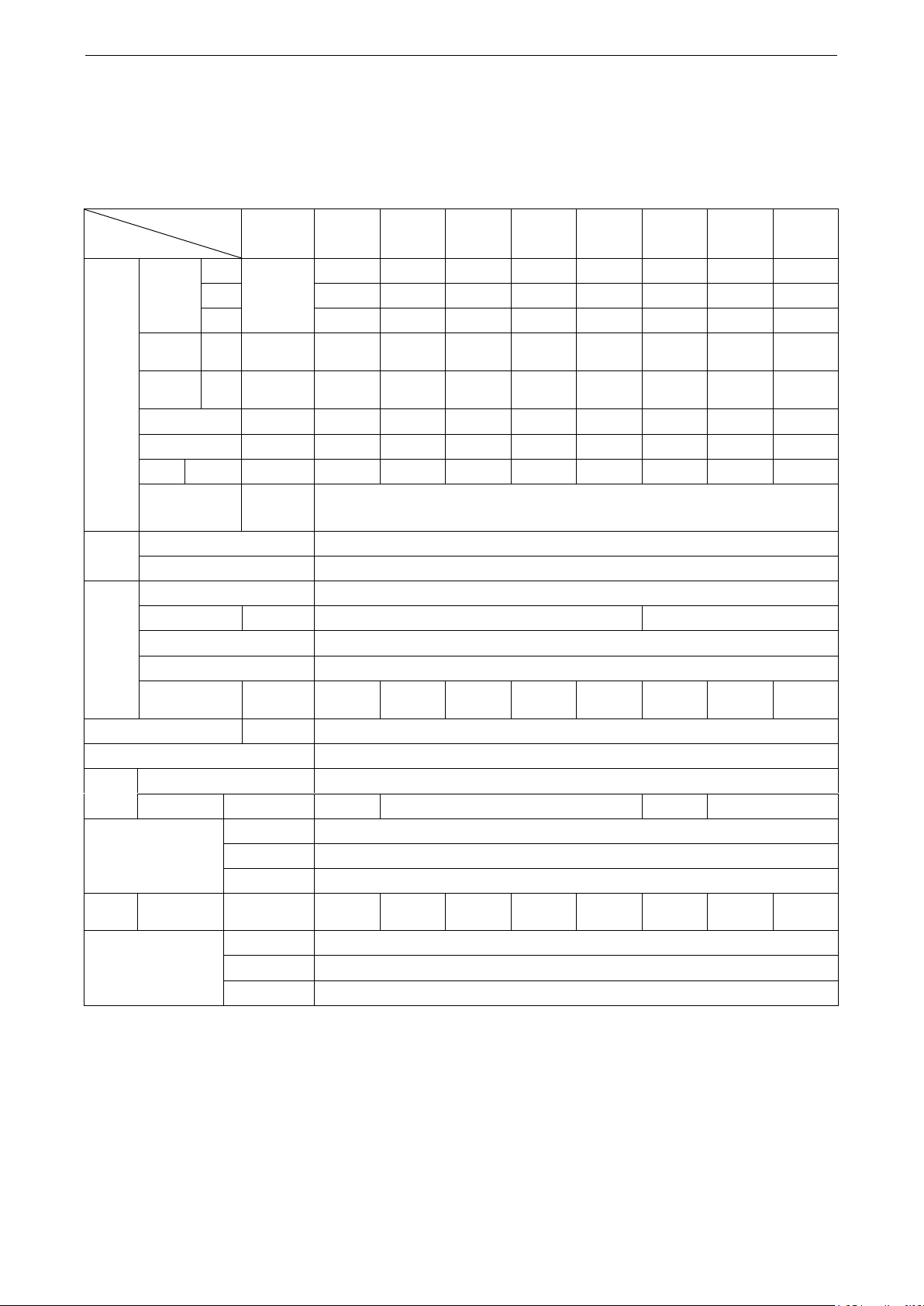

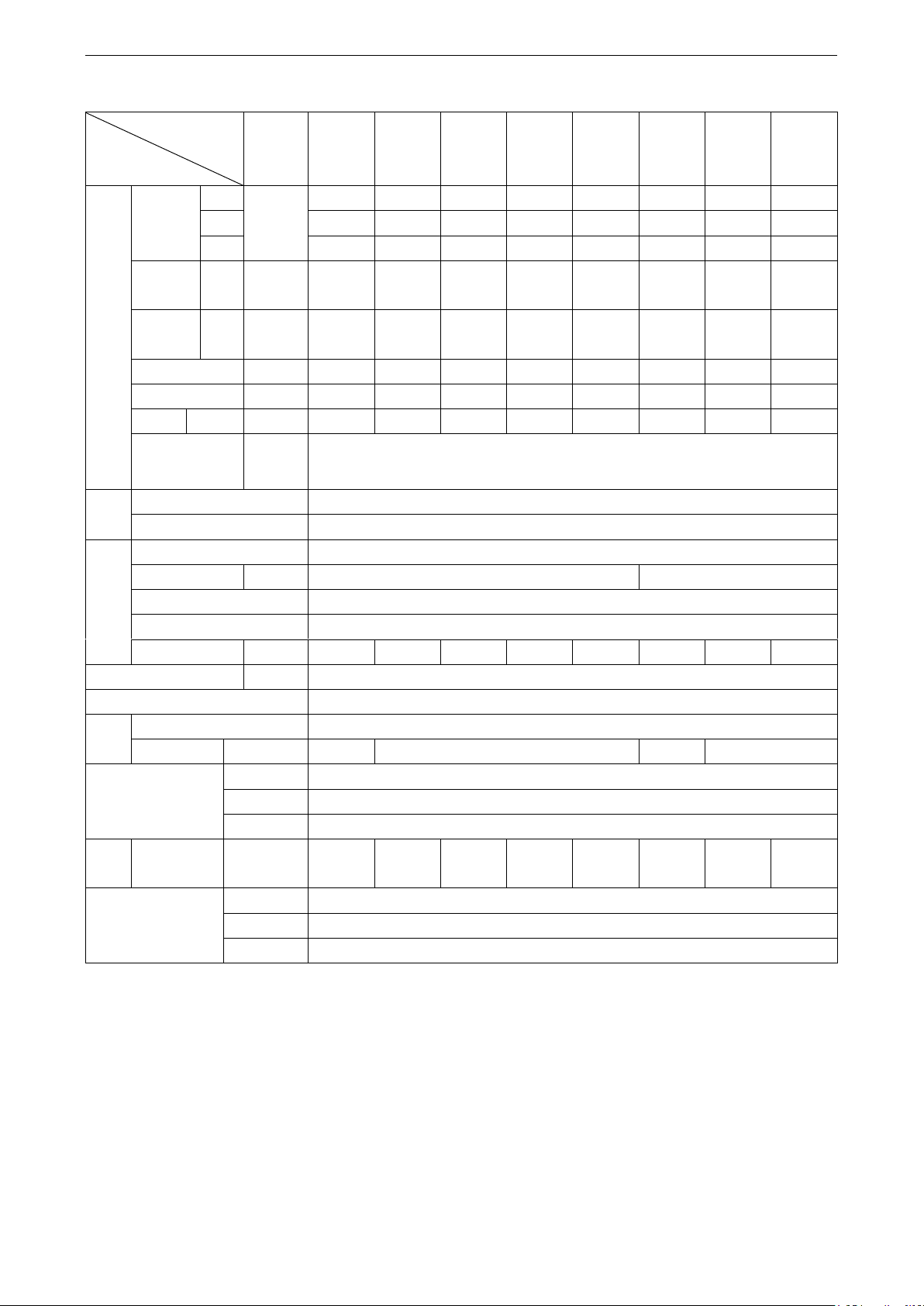

G Series FCU

FP-34WAS/G-K

EM51002080

EM51002780

2.25/0.64

3.6/1.02

220-240V 50HZ

FP-51WAS/G-K

EM51002820

EM51002110

3.3/0.94

5.9/1.68

FP-68WAS/G-K

EM51002230

EM51002860

4.3/1.22

7.3/2.08

FP-85WAS/G-K

EM51002900

EM51002190

5/1.42

8.05/2.29

FP-102WAS/G-K

EM51002480

EM51002600

6.3/1.79

10.1/2.87

FP-136WAS/G-K

EM51002250

EM51002660

8.2/2.33

13.2/3.75

FP-170WAS/G-K

EM51002700

EM51002520

9.8/2.79

15.8/4.49

FP-204WAS/G-K

EM51002550

EM51002740

11.25/3.2

18.6/5.29

G Series FCU

FP-34WAHS/G-K

EM51002770

EM51002130

2.25/0.64

3.6/1.02

220-240V 50HZ

FP-51WAHS/G-K

EM51002150

EM51002810

3.3/0.94

5.9/1.68

FP-68WAHS/G-K

EM51002120

EM51002850

4.3/1.22

7.3/2.08

FP-85WAHS/G-K

EM51002570

EM51002890

5/1.42

8.05/2.29

FP-102WAHS/G-K

EM51002610

EM51002160

6.3/1.79

10.1/2.87

FP-136WAHS/G-K

EM51002650

EM51002500

8.2/2.33

13.2/3.75

FP-170WAHS/G-K

EM51002090

EM51002690

9.8/2.79

15.8/4.49

FP-204WAHS/G-K

EM51002730

EM51002540

11.25/3.2

18.6/5.29

Note:1Ton =12000Btu/h = 3.517kW

3

Enginnering Data

Series

Model

Product Code

Cooling

Capacity

(kW/Ton)

Heating

Capacity

(kW/Ton)

Power Supply

Picture

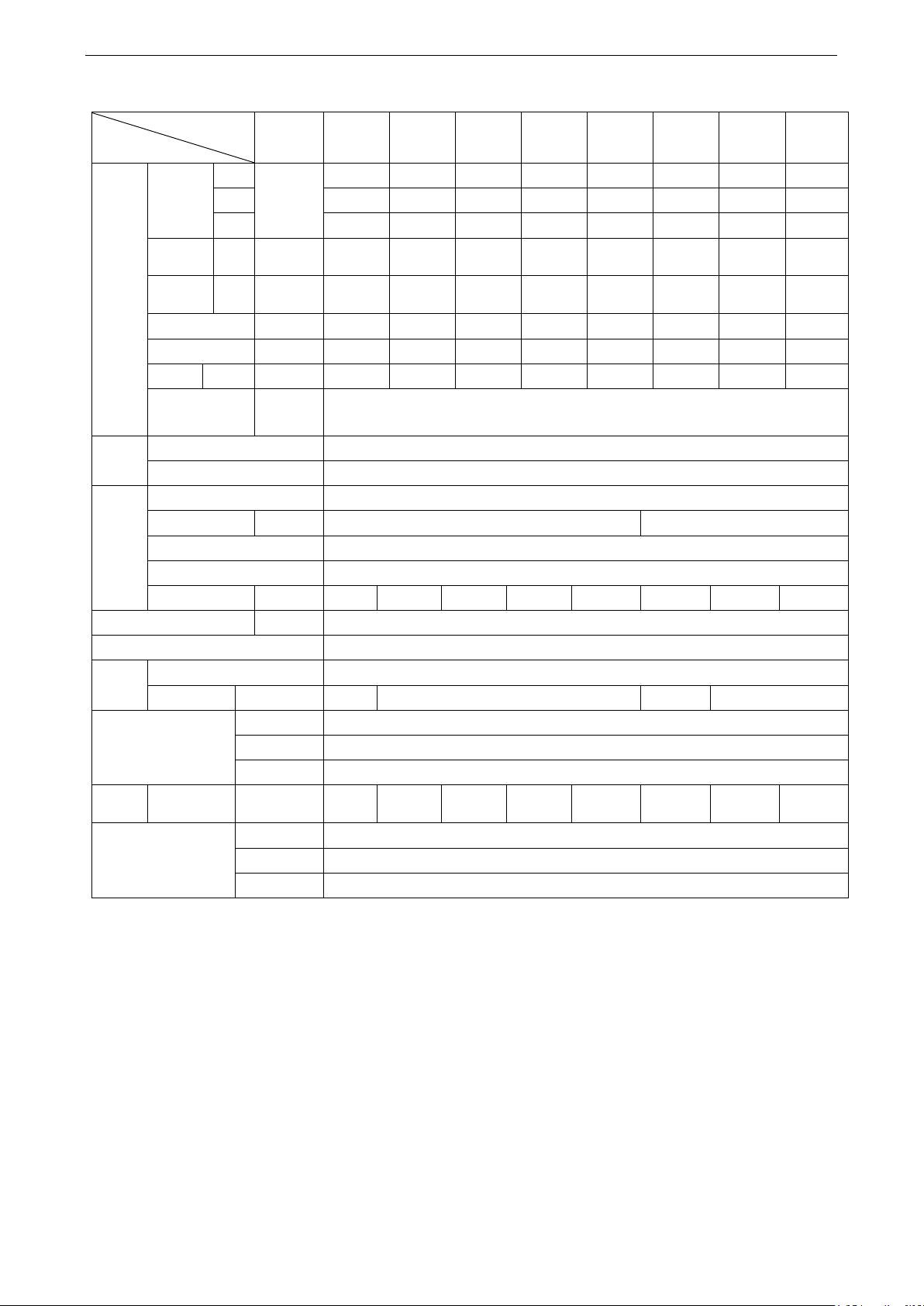

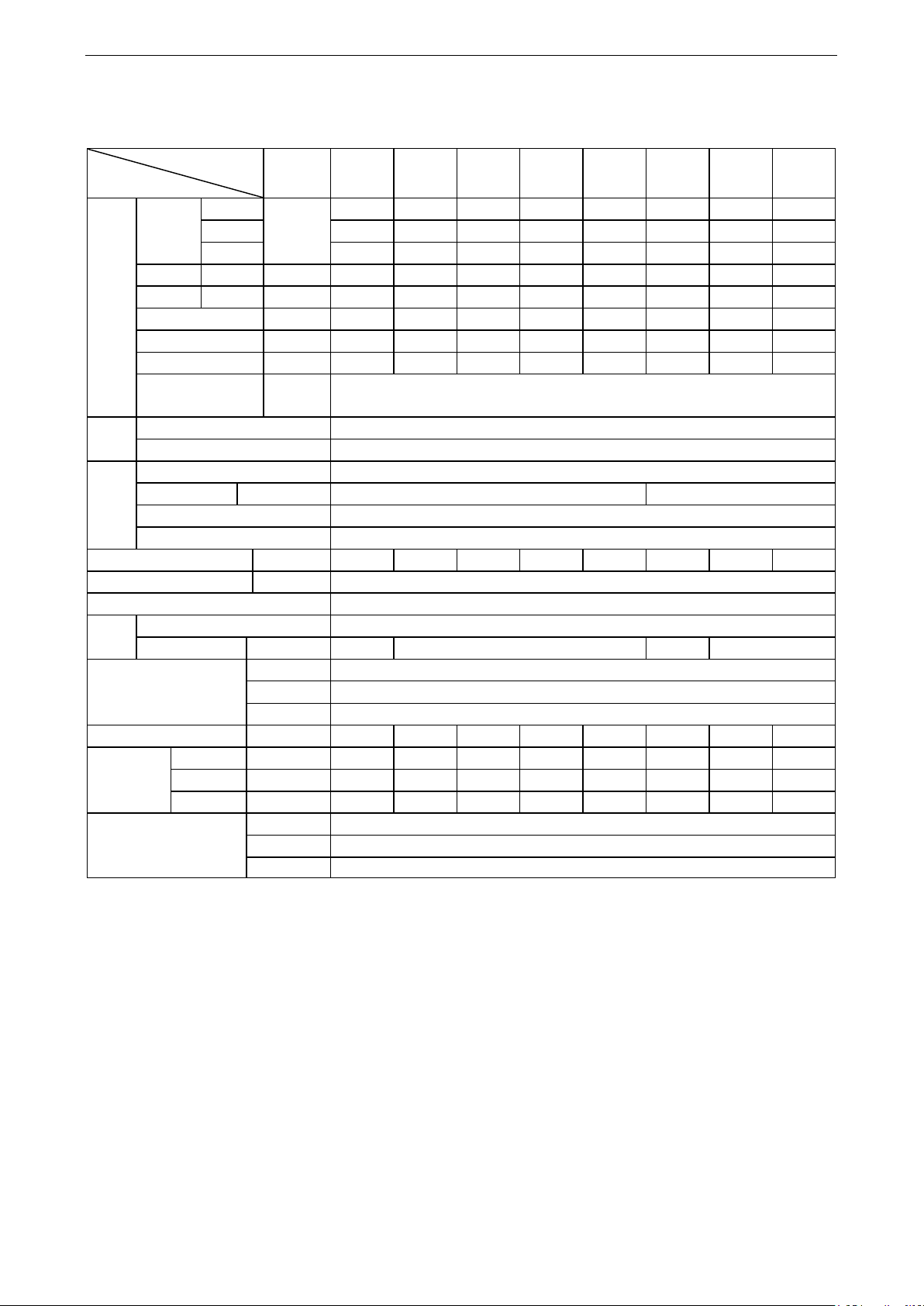

3+1 Series FCU

FP-34WAT-R

EM51000790

EM51001030

2.30/0.65

2.10/0.60

220-240V 50HZ

FP-51WAT-R

EM51000800

EM51001040

3.60/1.02

3.35/0.95

FP-68WAT-R

EM51000810

EM51001050

4.35/1.24

4.00/1.14

FP-85WAT-R

EM51000820

EM51001060

5.40/1.54

4.60/1.31

FP-102WAT-R

EM51000830

EM51001070

6.70/1.91

5.35/1.52

FP-136WAT-R

EM51000840

EM51001080

8.10/2.30

7.00/1.99

FP-170WAT-R

EM51000850

EM51001090

10.35/2.94

8.30/2.36

FP-204WAT-R

EM51000860

EM51001100

11.00/3.13

8.95/2.54

4 Series FCU

FP-34WAF-R

EM51000710

EM51001110

2.60/0.74

4.30/1.22

220-240V 50HZ

FP-51WAF-R

EM51000720

EM51001120

4.00/1.14

6.50/1.85

FP-68WAF-R

EM51000730

EM51001130

4.70/1.34

7.30/2.08

FP-85WAF-R

EM51000740

EM51001140

5.60/2.13

8.60/2.45

FP-102WAF-R

EM51000750

EM51001150

7.50/2.13

10.50/2.99

FP-136WAF-R

EM51000760

EM51001160

9.20/2.62

14.50/4.12

FP-170WAF-R

EM51000770

EM51001170

11.00/3.13

18.00/5.12

FP-204WAF-R

EM51000780

EM51001180

12.20/3.47

20.00/5.69

50Hz (without the return air box), standard, 3+1 or 4-row-pipes

4

Note:1Ton =12000Btu/h = 3.517kW

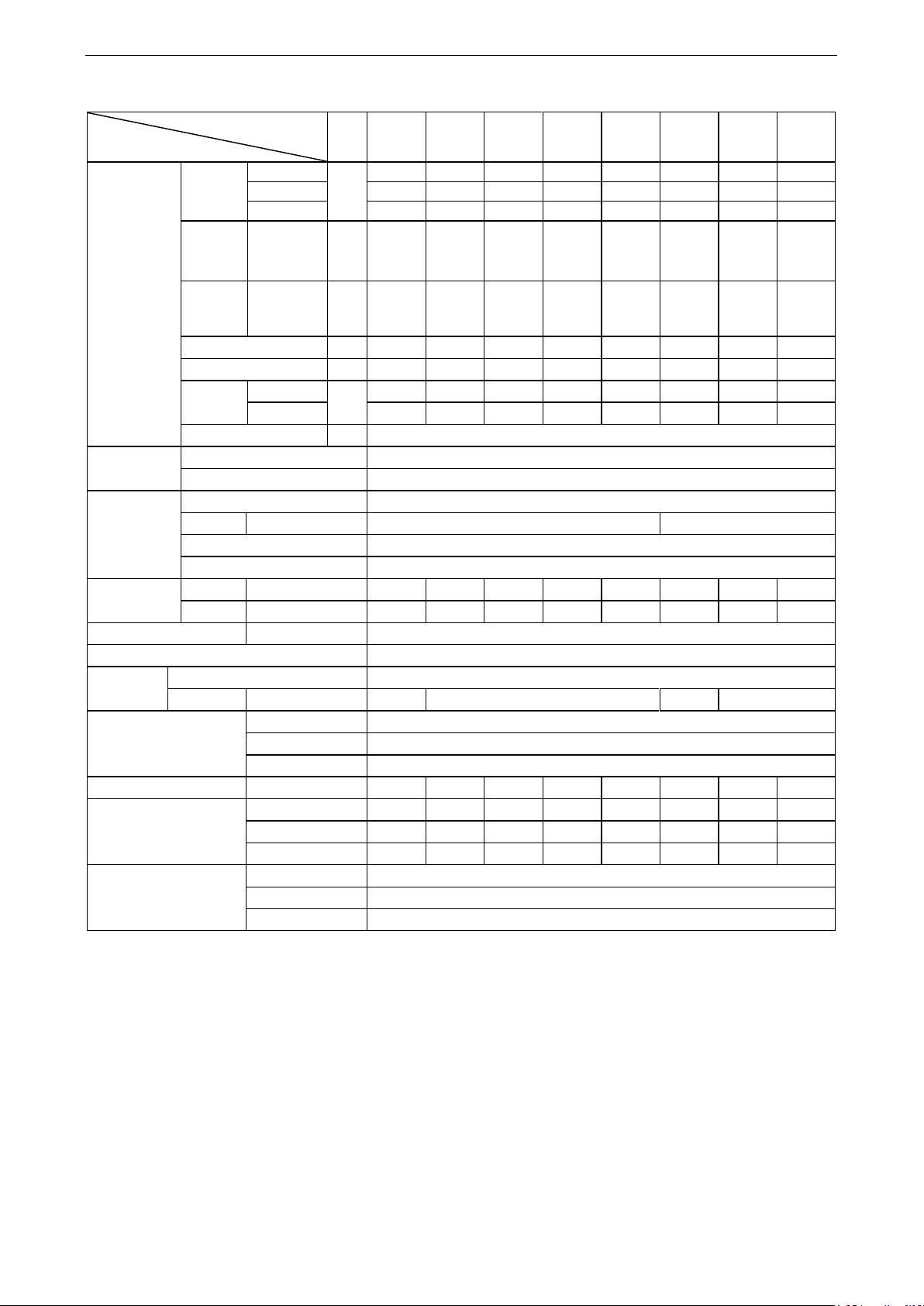

Enginnering Data

Series

Model

Product Code

Cooling capacity

(kW/Ton)

Heating capacity

(kW/Ton)

Power supply

Pictures

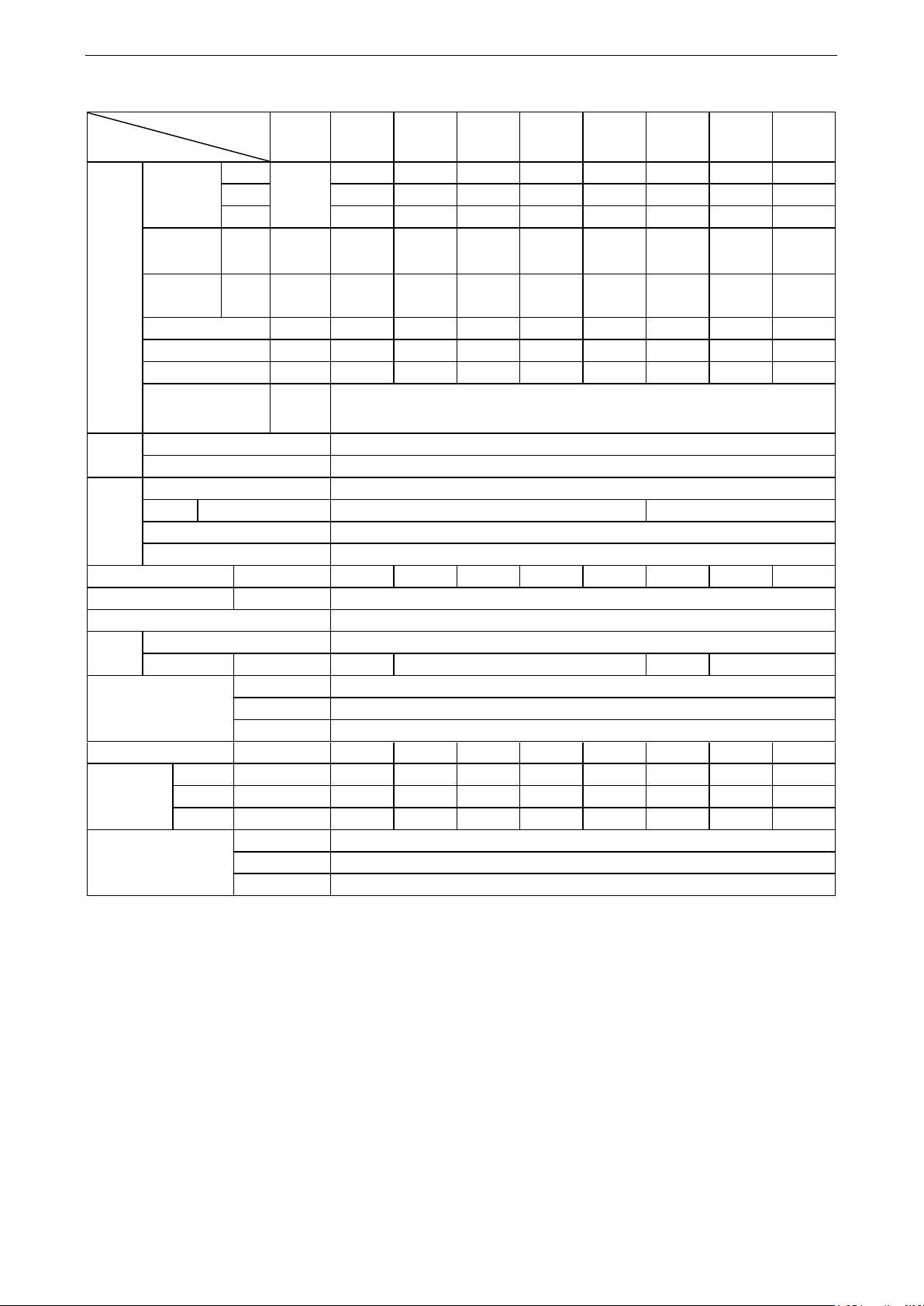

G

FP-34WA/G-D

EM51002350

EM51003310

1.9/0.54

3.05/0.87

208-230V

60HZ

FP-51WA/G-D

EM51002390

EM51003390

3/0.85

5/1.42

FP-68WA/G-D

EM51003430

EM51003440

3.6/1.02

5.9/1.68

FP-85WA/G-D

EM51003530

EM51002450

4.7/1.34

7.7/2.19

FP-102WA/G-D

EM51002920

EM51002910

5.7/1.62

9.35/2.66

FP-136WA/G-D

EM51003020

EM51003010

7.35/2.09

12.1/3.44

FP-170WA/G-D

EM51003120

EM51002300

9.5/2.7

15.8/4.49

FP-204WA/G-D

EM51002340

EM51003200

11.5/3.27

18.8/5.35

G

FP-34WAH/G-D

EM51003340

EM51002360

1.9/0.54

3.05/0.87

208-230V

60HZ

FP-51WAH/G-D

EM51002400

EM51003400

3/0.85

5/1.42

FP-68WAH/G-D

EM51003480

EM51003470

3.6/1.02

5.9/1.68

FP-85WAH/G-D

EM51002460

EM51003560

4.7/1.34

7.7/2.19

FP-102WAH/G-D

EM51002960

EM51002950

5.7/1.62

9.35/2.66

FP-136WAH/G-D

EM51003050

EM51002290

7.35/2.09

12.1/3.44

FP-170WAH/G-D

EM51002310

EM51003150

9.5/2.7

15.8/4.49

FP-204WAH/G-D

EM51003240

EM51003230

11.5/3.27

18.8/5.35

60HZ (without the return air box), standard

5

Enginnering Data

Series

Model

Product Code

Cooling

capacity

(kW/Ton)

Heating

capacity

(kW/Ton)

Power

supply

Pictures

G

FP-34WAS/G-D

EM51003380

EM51002380

2.25/0.64

3.7/1.05

208-230V

60HZ

FP-51WAS/G-D

EM51002420

EM51003420

3.3/0.94

5.4/1.54

FP-68WAS/G-D

EM51003520

EM51002440

4.4/1.25

7.35/2.09

FP-85WAS/G-D

EM51003620

EM51003610

5.2/1.48

8.5/2.42

FP-102WAS/G-D

EM51003000

EM51002280

6.6/1.88

10.65/3.03

FP-136WAS/G-D

EM51003110

EM51003100

8.3/2.36

13.5/3.84

FP-170WAS/G-D

EM51002330

EM51003190

10.2/2.9

17/4.83

FP-204WAS/G-D

EM51003300

EM51003290

12.2/3.47

20/5.69

G

FP-34WAHS/G-D

EM51002370

EM51003370

2.25/0.64

3.7/1.05

208-230V

60HZ

FP-51WAHS/G-D

EM51003410

EM51002410

3.3/0.94

5.4/1.54

FP-68WAHS/G-D

EM51002430

EM51003510

4.4/1.25

7.35/2.09

FP-85WAHS/G-D

EM51003600

EM51003590

5.2/1.48

8.5/2.42

FP-102WAHS/G-D

EM51002270

EM51002990

6.6/1.88

10.65/3.03

FP-136WAHS/G-D

EM51003090

EM51003080

8.3/2.35

13.5/3.84

FP-170WAHS/G-D

EM51003180

EM51002320

10.2/2. 9

17/4.83

FP-204WAHS/G-D

EM51003280

EM51003270

12.2/3.47

20/5.69

60HZ (without the return air box), 3-row-pipes

6

Enginnering Data

Series

Model

Product Code

Cooling

Capacity

(kW/Ton)

Heating

Capacity

(kW/Ton)

Power Supply

Picture

3+1 Series FCU

FP-34WAT-R

EM51000790

EM51001030

2.35/0.67

2.15/0.61

208~230V

60HZ

FP-51WAT-R

EM51000800

EM51001040

3.80/1.08

3.40/0.97

FP-68WAT-R

EM51000810

EM51001050

4.40/1.25

4.10/1.17

FP-85WAT-R

EM51000820

EM51001060

5.60/1.59

4.70/1.34

FP-102WAT-R

EM51000830

EM51001070

6.80/1.93

5.60/1.59

FP-136WAT-R

EM51000840

EM51001080

8.20/2.33

7.20/2.05

FP-170WAT-R

EM51000850

EM51001090

10.50/2.99

8.40/2.39

FP-204WAT-R

EM51000860

EM51001100

11.20/3.18

9.10/2.59

4 Series FCU

FP-34WAF-R

EM51000710

EM51001110

2.65/0.75

4.35/1.24

208~230V

60HZ

FP-51WAF-R

EM51000720

EM51001120

4.08/1.16

6.55/1.86

FP-68WAF-R

EM51000730

EM51001130

4.80/1.36

7.40/2.10

FP-85WAF-R

EM51000740

EM51001140

5.80/ 1.65

8.80/2.50

FP-102WAF-R

EM51000750

EM51001150

7.60/2.16

11.50/3.27

FP-136WAF-R

EM51000760

EM51001160

9.30/2.64

14.70/4.18

FP-170WAF-R

EM51000770

EM51001170

11.20/3.18

18.20/5.17

FP-204WAF-R

EM51000780

EM51001180

12.50/3.55

20.80/5.91

60Hz (without the return air box), 3+1 or 4-row-pipes

Note:1Ton =12000Btu/h = 3.517kW

7

Enginnering Data

Series

Model

Product Code

Cooling

capacity

(

kW/Ton)

Heating

capacity

(

kW/Ton)

Power

supply

Pictures

G

FP-34WA/GHL-K

EM51003330

EM51003320

1.75/0.5

2.2/0.63

220-240V

50HZ

FP-51WA/GHL-K

EM51003980

EM51003970

2.9/0.82

3.4/0.97

FP-68WA/GHL-K

EM51003460

EM51003450

3.4/0.97

4.2/1.19

FP-85WA/GHL-K

EM51003550

EM51003540

4.3/1.22

4.7/1.34

FP-102WA/GHL-K

EM51002940

EM51002930

4.9/1.39

6/1.71

FP-136WA/GHL-K

EM51003040

EM51003030

6.7/1.91

8/2.27

FP-170WA/GHL-K

EM51003140

EM51003130

7/1.99

9/2.56

FP-204WA/GHL-K

EM51003220

EM51003210

10/2.84

11.9/3.38

G

FP-34WAH/GHL-K

EM51003360

EM51003350

2/0.57

2.3/0.65

220-240V

50HZ

FP-51WAH/GHL-K

EM51003950

EM51003960

3.1/0.88

3.5/1

FP-68WAH/GHL-K

EM51003500

EM51003490

3.55/1.01

4.5/1.28

FP-85WAH/GHL-K

EM51003580

EM51003570

4.5/1.28

4.9/1.39

FP-102WAH/GHL-K

EM51002980

EM51002970

5.2/1.48

6.3/1.79

FP-136WAH/GHL-K

EM51003070

EM51003060

6.9/1.96

8.2/2.33

FP-170WAH/GHL-K

EM51003170

EM51003160

7.2/2.04

9.2/2.61

FP-204WAH/GHL-K

EM51003260

EM51003250

10.2/2.9

12/3.4

G

FP-34WAS/GHL-K

EM51003820

EM51003810

2.1/0.6

2.4/0.68

220-240V

50HZ

FP-51WAS/GHL-K

EM51003930

EM51003940

3.2/0.91

3.7/1.05

FP-68WAS/GHL-K

EM51003860

EM51003850

4.1/1.17

4.8/1.36

FP-85WAS/GHL-K

EM51003900

EM51003890

4.8/1.36

5.5/1.56

Section two --- countries and areas within the European Union

50HZ (with the return air box), standard, 3-row pipes

8

Enginnering Data

FP-102WAS/GHL-K

EM51003660

EM51003650

5.9/1.67

6.6/1.88

FP-136WAS/GHL-K

EM51003700

EM51003690

7.6/2.16

8.9/2.53

FP-170WAS/GHL-K

EM51003740

EM51003730

8.8/2.5

10.2/2.89

FP-204WAS/GHL-K

EM51003780

EM51003770

10.4/2.96

12.1/3.43

G

FP-34WAHS/GHL-K

EM51003800

EM51003790

2.5/0.71

2.8/0.8

220-240V

50HZ

FP-51WAHS/GHL-K

EM51003910

EM51003920

3.3/0.94

3.8/1.08

FP-68WAHS/GHL-K

EM51003840

EM51003830

4.2/1.19

5.1/1.45

FP-85WAHS/GHL-K

EM51003880

EM51003870

4.9/1.39

5.7/1.62

FP-102WAHS/GHL-K

EM51003640

EM51003630

6.1/1.73

6.9/1.96

FP-136WAHS/GHL-K

EM51003680

EM51003670

7.8/2.22

9 /2.55

FP-170WAHS/GHL-K

EM51003720

EM51003710

9/2.56

10.9/3.1

FP-204WAHS/GHL-K

EM51003760

EM51003750

10.5/2.99

12.4/3.53

Series

Model

Product Code

Cooling

Capacity

(kW/Ton)

(kW/Ton)

Power Supply

Picture

3+1 Series FCU

FP-34WAHT/BHL-K

EM51004030

EM51004080

2.45/0.70

3.40/0.97

220-240V

50HZ

FP-51WAHT/BHL-K

EM51004300

EM51004290

3.70/1.05

4.70/1.34

FP-68WAHT/BHL-K

EM51004340

EM51004330

4.55/1.29

5.70/1.62

FP-85WAHT/BHL-K

EM51004380

EM51004370

5.40/1.54

6.35/1.81

FP-102WAHT/BHL-K

EM51004120

EM51004110

6.35/1.81

7.55/2.15

FP-136WAHT/BHL-K

EM51004160

EM51004150

8.30/2.36

9.90/2.81

FP-170WAHT/BHL-K

EM51004200

EM51004190

10.00/2.84

11.50/3.27

50Hz (with the return air box), 3+1 or 4-row-pipes

9

Enginnering Data

FP-204WAHT/BHL-K

EM51004240

EM51004230

10.2/2.90

11.90/3.38

4 Series FCU

FP-34WAHF/BHL-K

EM51004260

EM51004250

2.65/0.75

3.15/0.90

220-240V

50HZ

FP-51WAHF/BHL-K

EM51004280

EM51004270

3.80/1.08

4.40/1.25

FP-68WAHF/BHL-K

EM51004320

EM51004310

5.00/1.42

5.45/1.55

FP-85WAHF/BHL-K

EM51004360

EM51004350

5.70/1.62

6.15/1.75

FP-102WAHF/BHL-K

EM51004100

EM51004090

7.10/2.02

7.30/2.08

FP-136WAHF/BHL-K

EM51004140

EM51004130

8.90/2.53

9.50/2.70

FP-170WAHF/BHL-K

EM51004180

EM51004170

11.00/3.13

12.30/3.50

FP-204WAHF/BHL-K

EM51004220

EM51004210

11.20/3.18

13.00/3.70

Note:1Ton =12000Btu/h = 3.517kW

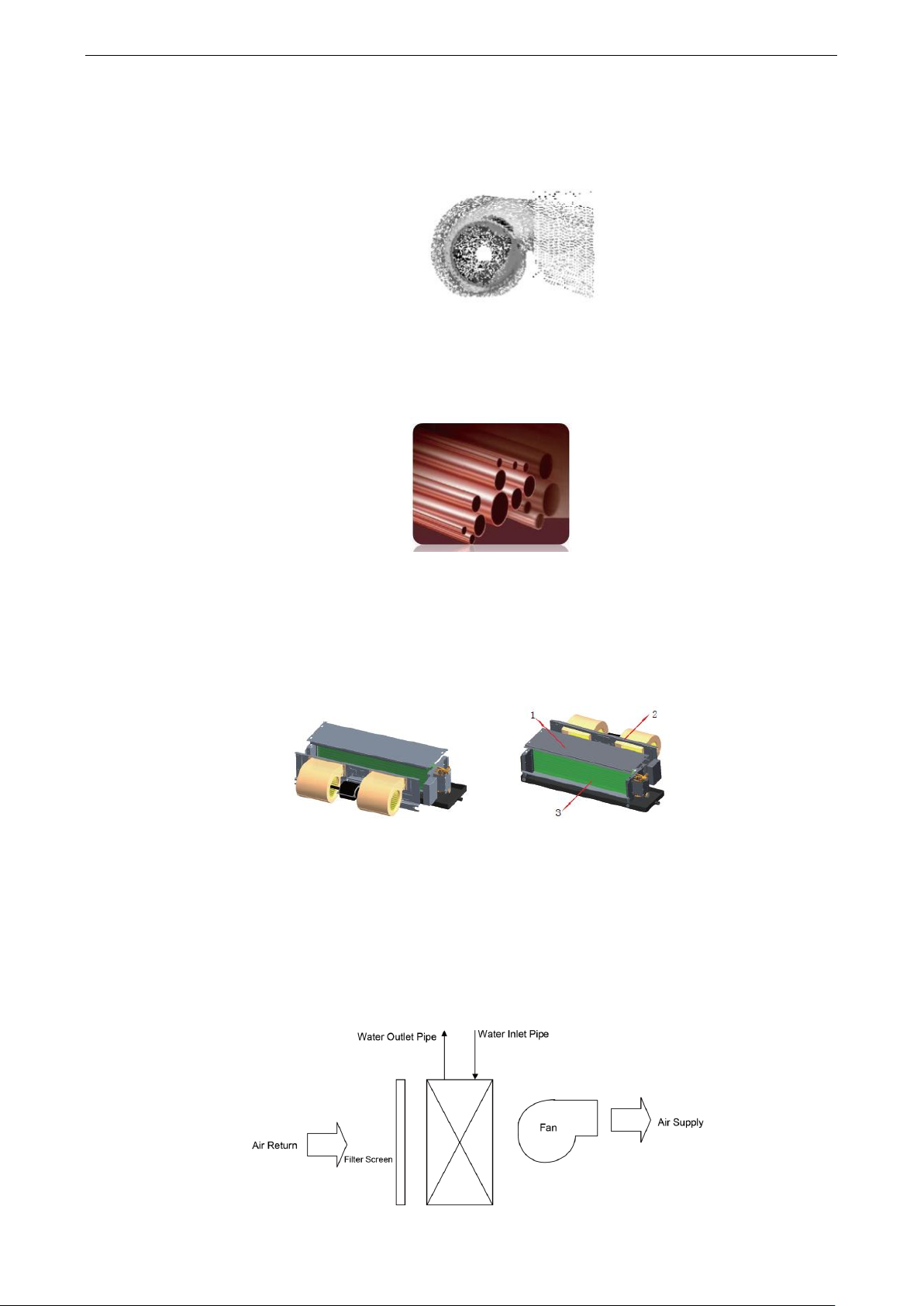

1.2 Nomenclature

10

Enginnering Data

1.3 Product Features

1.3.1 Features

FCU is the most widely used terminal unit of the air conditioning system, used fo supplying cooling

(hot) water, with the air flow below 2500m3/h and the external static pressure less than 100Pa. For

cooling, enthalpy loss of the air generally is 15.9kJ/kg. For hot water under 60℃, the cheating capacity is

1.5 times of the cooling capacity.

As the terminal unit of the central air conditioning system, it is widely used in public areas with the

following main features:

a. Three speeds are selectable for the air flow. According to the set point of the room temperature,

the water system can be controlled by the hot/cool water automatic regulating valve so that

temperature for each room can be controlled separately for meeting different requirements.

Where no one is inside the room, it can be turned off manually or by the timing function, which

will lower the operation cost of the whole system.

b. The zone control is available based on direction, height, utilization and service time, which can

avoid unreasonable conceptualized control of the large-sized duct system.

c. Compact structure, flexible arrangement, and easy installation will save installation space and

facilitate indoor decoration.

There are various structures with the same air flow and cooling capacity for different room structure,

different decoration and duct arrangement.

(1) Plastic Fan

a. Light-weighted, which will lead to increased air flow driven by the same motor.

b. Good compatibility of the angle of the blades and the cavity of the volute, which will lead to silent

operation.

c. CFD designed flow and angle of fan blades, for high operation efficiency

d. The volute is divided into the upper and lower parts, which will facilitate disassembly.

(2) CFD Designed Fan

a. Optimized flow structure

b. Evenly distributed air flow and low flow noise

c. less eddy flow

d. Novel style and advanced structure

e. Decreased height , saving installation space

f. Low noise and three fan speeds

g. High-quality material and strict processing control for guaranteeing quality and service life of

the whole unit.

h. Die formed drain pan with the entirely pressured and pasted insulation, generating no

11

Enginnering Data

condensate

i. Optimized location of the exhaust and drain valves, for better heat exchanging effect and

preventing from frost cracks in winter.

(3) High-efficiency copper tubes

The copper tubes are made of pure red copper with female threads on the inner wall. There are also

raised teeth at the inner wall, used for increasing turbulent flows and damaging the boundary layer of

water for better heat exchanging capacity.

(4) The Cooler with the Interchangeable Left/Right Structure

During installation, the left-type and right-type structure can be selected flexibly as steps stated below:

Step 1: Remove the centrifugal fan, cover plate and screws of the electric box.

Step 2: Move the side plate at the air outlet to the other side.

Step 3: Rotate the fan assembly and the cover plate for 180°and then fix them.

Step 4: Remove the electric box to the other side and then fix it..

1.: Cover plate; 2. Centrifugal fan; 3. Side plate at the air outlet

Left-type Unit Right-type Unit

1.4 Working Principle

The cool (hot) water goes in the fan coil and makes heat exchanging with the indoor circulated air

(outdoor air), to realize cooling(heating), dehumidifying, filtrating or purifying. The processed air will be

supplied to indoor directly or by air duct.

12

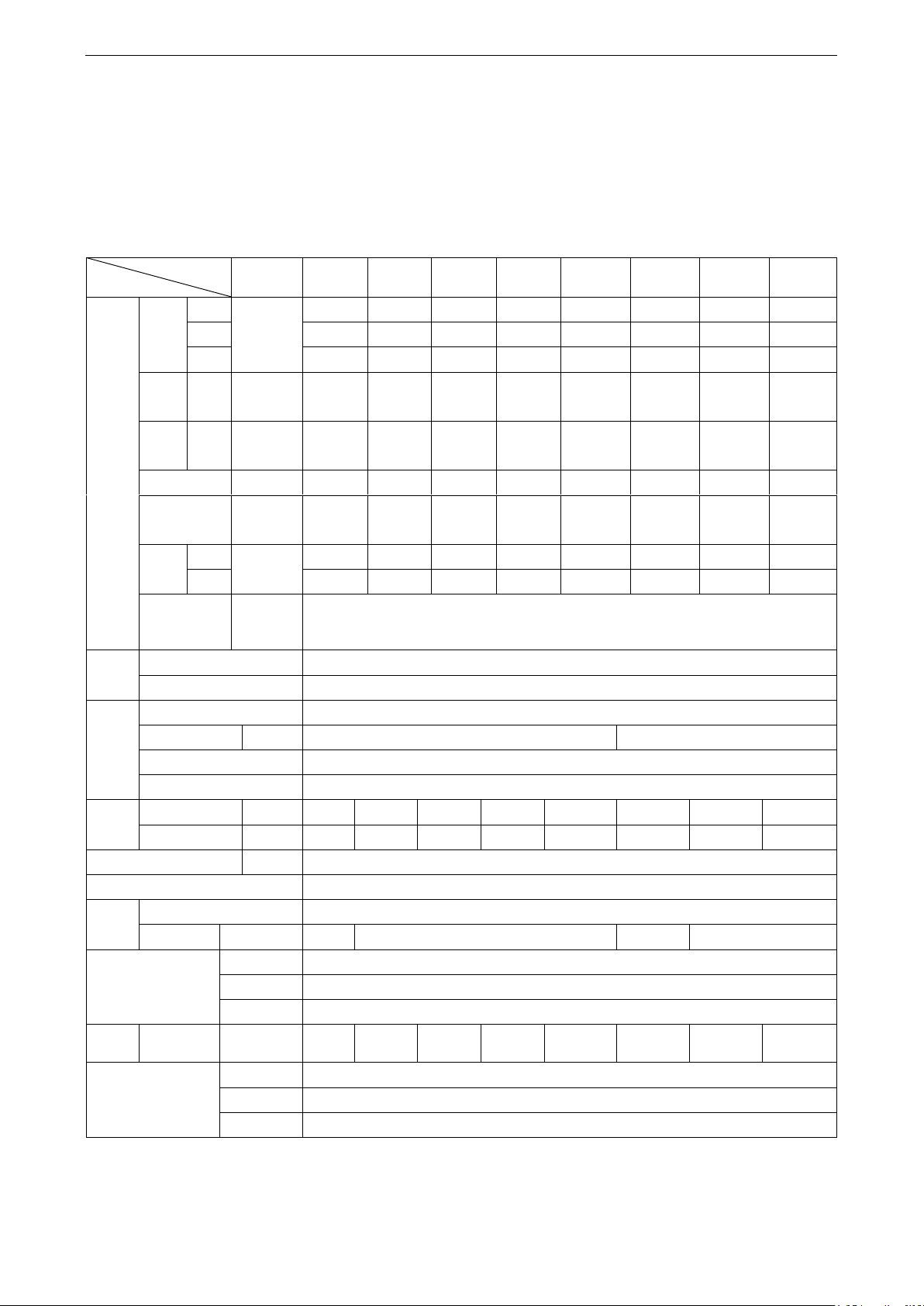

Enginnering Data

Type

Item

Concealed

ceiling type

FP-34WA/

G-K

FP-51WA/

G-K

FP-68WA/

G-K

FP-85WA/

G-K

FP-102WA/

G-K

FP-136WA/

G-K

FP-170WA/

G-K

FP-204WA/

G-K

Performance

Airflow

Hi

m3/h

340

510

680

850

1020

1360

1700

2040

Mid

248

393

510

638

788

1095

1275

1575

Low

213

263

340

425

525

730

850

1050

Cooling

capacity

Hi W 1850

2800

3600

4500

5500

7350

9200

11000

Heating

capacity

Hi W 3050

4620

5940

7400

9000

12100

15100

18100

Flow rate

m3/h

0.33

0.52

0.63

0.77

0.92

1.31

1.52

1.92

Water

resistance

kPa

15

30

23

25

35

40

46

40

Noise

12pa

dB(A)

34.5

35

40

40.5

44

45

46

49

30Pa

36

37

41

42

45.5

46

47.5

51

External static

pressure

Pa

12Pa for the standard type (with no diffuser and filter ); 30Pa for the high ESP type

Coil

Type

Copper, high-efficiency louvered fins

Pressure

≤1.6MPa

Motor

Type

Class B, capacitor start

Quantity

/

1

2

Power supply

220-240V~ 50Hz

Protection class

IP20

Input

power

12pa

W

37

52

62

76

96

134

152

189

30Pa

W

44

59

72

87

108

156

174

212

Power lines

mm2

0.5×3

Protection class

I

Fan

Type

Front-forward multi-vane low-noise centrifugal fan

Quantity

/

1 2 3

4

Connection pipe

Inlet water

Rc3/4(female thread)

Outlet water

Rc3/4(female thread)

Condensate

R23/4(female thread)

Weight

Without return

air box

kg

11.2

13

14.3

15.5

16.6

23

26.2

28

Thermostat (optional)

Mechanical

Z54352A1

Digit

WK-110PA0

Deluxe digit

WK-010PA-K-K

1.5 Technical Data

1.5.1 Data at Nominal Conditions

Section one --- countries and areas except the European Union

(1) 50Hz (without the return air box), standard, 3-row pipes

Standard Type (G Series)

Notes:

a) The left and right modes can be switched over on site. The correction coefficient for both

cooling and heating is 0.9.

13

b) Nominal cooling conditions: (27/19.5℃) indoor dry/wet bulb temperature, (7/12℃) entering

Model

Item

Concealed

ceiling type

FP-34W

AS/G-K

FP-51W

AS/G-K

FP-68W

AS/G-K

FP-85W

AS/G-K

FP-102

WAS/G-

K

FP-136

WAS/G-

K

FP-170

WAS/G-

K

FP-204

WAS/G-

K

Performance

Air flow

Hi

m3/h

340

510

680

850

1020

1360

1700

2040

Mid

248

394

495

638

788

1095

1275

1575

Low

173

263

330

425

525

730

850

1050

Cooling

capacity

Hi W 2250

3300

4300

5000

6300

8200

9800

11250

Heating

capacity

Hi W 3600

5300

6930

8050

10100

13200

15800

18600

Water flow

m3/h

0.4

0.57

0.76

0.88

0.99

1.41

1.68

1.95

Water resistance

kPa

20

21

22

30

35

40

33

40

Noise

12pa

dB(A)

34.5

37

38.5

41

44

45

46.5

50

30Pa

36

38

41

43

46

47

47.5

51.5

External static

pressure

Pa

12Pa for the standard type (with no diffuser and filter ); 30Pa for the high ESP type

Coil

Type

Copper, high-efficiency louvered fins

Pressure

≤1.6MPa

Motor

Type

Class B, capacitor start

Quantity

/

1

2

Power supply

220V~ 50Hz

Protection class

IP20

Input

power

12pa

W

37

52

62

76

96

134

152

189

30Pa

W

44

59

72

87

108

156

174

212

Power lines

mm2

0.5×3

Protection class

I

Fan

Type

Front-forward multi-vane low-noise centrifugal fan

Quantity

/

1 2 3

4

Connection pipe

Inlet water

Rc3/4(female thread)

Outlet water

Rc3/4(female thread)

Condensate

R2c3/4(female thread)

Weight

Without the

return air box

kg

11.6

13.4

14.7

16

17.4

24

26.6

28.5

With the return

air box

kg

Thermostat (optional)

Mechanical

Z54352A1

Digit

WK-110PA0

Deluxe digit

WK-010PA-K-K

and leaving water temperature. Nominal heating conditions: 21℃ indoor dry bulb

temperature, 60℃ entering water temperature.

c) The noise is tested under the semi-anechoic chamber and the actual value will change

under different environments.

Three-row type

Enginnering Data

Notes:

a) The left and right modes can be switched over on site. The correction coefficient for both

cooling and heating is 0.9.

b) Nominal cooling conditions: (27/19.5℃) indoor dry/wet bulb temperature, (7/12℃) entering

14

Enginnering Data

Type

Item

Concealed

ceiling type

FP-34WA

F-R

FP-51WA

F-R

FP-68WA

F-R

FP-85WA

F-R

FP-102W

AF-R

FP-136W

AF-R

FP-170W

AF-R

FP-204W

AF-R

Performance

Airflow

Hi

m3/h

340

510

680

850

1020

1360

1700

2040

Mid

248

393

510

638

788

1095

1275

1575

Low

213

263

340

425

525

730

850

1050

Cooling

capacity

Hi W 2600

4000

4700

5600

7500

9200

11000

12200

Heating

capacity

Hi W 4300

6500

7300

8600

10500

14500

18000

20000

Flow rate

m3/h

0.464

0.729

0.893

0.981

1.318

1.615

2.042

2.229

Water resistance

kPa

3.713

8.943

14.54

18.79

35.75

19.06

29.01

35.41

Noise

30Pa

40

42

44

46

47

48

50

52

External static

pressure

Pa

30pa

Coil

Type

Copper, high-efficiency louvered fins

Pressure

≤1.6MPa

Motor

Type

Class B, capacitor start

Quantity

/

1

2

Power supply

220-240V~ 50Hz

Protection class

IP20

Input power

30Pa

W

43

59

70

84

105

151

174

206

Power lines

mm2

0.5×3

Protection class

I

Fan

Type

Front-forward multi-vane low-noise centrifugal fan

Quantity

/

1 2 3

4

Connection pipe

Inlet water

Rc3/4(female thread)

Outlet water

Rc3/4(female thread)

Condensate

R23/4(female thread)

Weight

Without return

air box

kg

14.4

17.2

19.2

20.5

23.2

34.2

37.5

37.5

Thermostat (optional)

Mechanical

Z54352A1

Digit

WK-110PA0

Digital (deluxe)

WK-010PA-K-K

and leaving water temperature. Nominal heating conditions: 21℃ indoor dry bulb

temperature, 60℃ entering water temperature.

c) The noise is tested under the semi-anechoic chamber and the actual value will change

under different environments.

50Hz (without the return air box), 4-row pipes

Notes:

a) The left and right modes can be switched over on site. The correction coefficient for both

cooling and heating is 0.9.

b) Nominal cooling conditions: (27/19.5℃) indoor dry/wet bulb temperature, (7/12℃) entering

and leaving water temperature. Nominal heating conditions: 21℃ indoor dry bulb

temperature, 60℃ entering water temperature.

c) The noise is tested under the semi-anechoic chamber and the actual value will change

under different environments.

15

Enginnering Data

Type

Item

Concealed

ceiling type

FP-34WA

T-R

FP-51WA

T-R

FP-68WA

T-R

FP-85WA

T-R

FP-102W

AT -R

FP-136W

AT -R

FP-170W

AT -R

FP-204

WAT-R

Performance

Airflow

Hi

m3/h

340

510

680

850

1020

1360

1700

2040

Mid

248

393

510

638

788

1095

1275

1575

Low

213

263

340

425

525

730

850

1050

Cooling

capacity

Hi W 2300

3600

4350

5400

6700

8100

10350

11000

Heating

capacity

Hi W 2100

3350

4000

4600

5350

7000

8300

8950

Flow rate

m3/h

0.446

0.697

0.808

0.98

1.171

1.45

1.747

1.964

Water resistance

kPa

5.83

13.50

19.86

30.81

51.67

17.20

25.24

29.34

Noise

30Pa

40

42

44

46

47

48

50

52

External static

pressure

Pa

30pa

Coil

Type

Copper, high-efficiency louvered fins

Pressure

≤1.6MPa

Motor

Type

Class B, capacitor start

Quantity

/

1

2

Power supply

220-240V~ 50Hz

Protection class

IP20

Input power 30Pa

W

43

59

70

84

105

151

174

206

Power lines

mm2

0.5×3

Protection class

I

Fan

Type

Front-forward multi-vane low-noise centrifugal fan

Quantity

/

1 2 3

4

Connection pipe

Inlet water

Rc3/4(female thread)

Outlet water

Rc3/4(female thread)

Condensate

R23/4(female thread)

Weight

Without return

air box

kg

14.4

17.2

19.2

20.5

23.2

34.2

37.5

37.5

Thermostat (optional)

Mechanical

Z54352A1

Digit

WK-110PA0

Deluxe digit

WK-010PA-K-K

50Hz (without the return air box), 3+1-row pipes

Notes:

a) The left and right modes can be switched over on site. The correction coefficient for both

cooling and heating is 0.9.

b) Nominal cooling conditions: (27/19.5℃) indoor dry/wet bulb temperature, (7/12℃) entering

and leaving water temperature. Nominal heating conditions: 21℃ indoor dry bulb

temperature, 60℃ entering water temperature.

c) The noise is tested under the semi-anechoic chamber and the actual value will change

under different environments.

16

Enginnering Data

Model

Item

Unit

FP-34WA/

G-D

FP-51WA/

G-D

FP-68WA/

G-D

FP-85WA/

G-D

FP-102WA/

G-D

FP-136WA/

G-D

FP-170WA/

G-D

FP-204WA/

G-D

Performance

Air flow

High

m³/h

340

510

680

850

1020

1360

1700

2040

Medium

248

394

495

638

788

1095

1275

1575

Low

173

263

330

425

525

730

850

1050

Cooling

capacity

High W 1900

3000

3600

4700

5700

7350

9500

11500

Heating

capacity

High W 3050

5000

5900

7700

9350

12100

15800

18800

Water flow

m³/h

0.33

0.52

0.62

0.81

0.98

1.27

1.64

1.98

Water resistance

kPa

15

30

23

25

35

40

36

40

Noise

12pa

dB(A)

34.5

38

40

43

45

46

48

50

30Pa

36

39

42

46

47.5

48

50

52

ESP

Pa

12Pa for the standard type (without the air diffuser and filter)

30Pa for the high static pressure type

Coils

Type

Copper tube with lourved fins

Working pressure

≤1.6MPa

Motor

Type

Class B insulation, capacitor start

Quantity

Piece

1

2

Power supply

208-230VAC 60Hz

Protection class

IP20

Input

power

12pa W 36

57

70

104

105

164

180

228

30Pa

W

49

58

74

105

123

165

221

273

Power lines

mm2×piece

0.5×3

Anti electric shock class

I

Fan

Type

Forward multi-vane low-noise centrifugal fan

Quantity

piece

1 2 3

4

Connection pipe

Inlet

Rc3/4(inner thread)

Outlet

Rc3/4(inner thread)

Condensate

Rc3/4(outer thread)

Net weight

kg

11.2

13

14.3

15.5

16.6

23

26.2

28

Outline

dimensions

Width

mm

680

800

900

1000

1080

1380

1520

1620

Depth

mm

490

460

490

490

490

490

490

490

Height

mm

235

235

235

235

235

235

235

235

Thermostat (optional)

Mechanical

Z54352A1

Digital

WK-110PA0

Digital (deluxe)

WK-010PA-K-K

(2) 60Hz (without the return air box), standard, 3-row pipes

Horizontal concealed FCU— (G series, 208-230VAC 60Hz)

Notes:

a) The left and right modes can be switched over on site. The correction coefficient for both

cooling and heating is 0.9.

b) Nominal cooling conditions: (27/19.5℃) indoor dry/wet bulb temperature, (7/12℃) entering

and leaving water temperature. Nominal heating conditions: 21℃ indoor dry bulb

temperature, 60℃ entering water temperature.

c) The noise is tested under the semi-anechoic chamber and the actual value will change

under different environments.

17

Enginnering Data

Model

Item

Unit

FP-34WA

S/G-D

FP-51WA

S/G-D

FP-68WA

S/G-D

FP-85WA

S/G-D

FP-102W

AS/G-D

FP-136W

AS/G-D

FP-170W

AS/G-D

FP-204W

AS/G-D

Performance

Air flow

High

m³/h

340

510

680

850

1020

1360

1700

2040

Medium

248

394

495

638

788

1095

1275

1575

Low

173

263

330

425

525

730

850

1050

Cooling

capacity

High-speed

W

2250

3300

4400

5200

6600

8300

10200

12200

Heating

capacity

High-speed

W

3700

5400

7350

8500

10650

13500

17000

20000

Water flow

m³/h

0.39

0.57

0.76

0.90

1.14

1.43

1.76

2.10

Water resistance

kPa

20

21

22

30

35

40

33

40

Noise

12pa

dB(A)

35

39

41

43

46

46

48

50

30Pa

38

40

44

46

48

49

50

52

ESP

Pa

12Pa for the standard type (without the air diffuser and filter)

Coils

Type

Copper tube with lourved fins

Working pressure

≤1.6MPa

Motor

Type

Class B insulation, capacitor start

Quantity

Piece 1 2

Power lines

208-230VAC 60Hz

Protection class

IP20

Input power

12pa W 36

63

70

104

114

182

180

228

30Pa W 49

64

74

105

123

183

221

273

Power lines

mm2×piece

0.5×3

Anti electric shock class

I

Fan

Model

Forward multi-vane low-noise centrifugal fan

Quantity

piece

1 2 3

4

Connection pipe

Inlet

Rc3/4(inner thread)

Outlet

Rc3/4(inner thread)

Condensate

Rc3/4(outer thread)

Net weight

kg

11.6

13.4

14.7

16

17.4

24

26.6

28.5

Outline dimensions

Width

mm

680

800

900

1000

1080

1380

1520

Depth

mm

490

460

490

490

490

490

490

Height

mm

235

235

235

235

235

235

235

Thermostat (optional)

Mechanical

Z54352A1

Digital

WK-110PA0

Digital (deluxe)

WK-010PA-K-K

Horizontal concealed three-row-pipe FCU— (G series, 208-230VAC 60Hz)

Notes:

a) The left and right modes can be switched over on site. The correction coefficient for both

cooling and heating is 0.9.

b) Nominal cooling conditions: (27/19.5℃) indoor dry/wet bulb temperature, (7/12℃) entering

and leaving water temperature. Nominal heating conditions: 21℃ indoor dry bulb

temperature, 60℃ entering water temperature.

c) The noise is tested under the semi-anechoic chamber and the actual value will change

under different environments.

18

Enginnering Data

Type

Item

Concealed

ceiling type

FP-34WAF

-R

FP-51WAF

-R

FP-68WAF

-R

FP-85WAF

-R

FP-102WA

F-R

FP-136WA

F-R

FP-170WA

F-R

FP-204W

AF-R

Performance

Airflow

Hi

m3/h

340

590

690

820

1040

1490

1850

2160

Mid

248

393

510

638

788

1095

1275

1575

Low

213

263

340

425

525

730

850

1050

Cooling

capacity

Hi W 2650

4080

4800

5800

7600

9300

11200

12500

Heating

capacity

Hi W 4350

6550

7400

8800

11500

14700

18200

20800

Flow rate

m3/h

0.464

0.729

0.893

0.981

1.318

1.615

2.042

2.229

Water resistance

kPa

8

9

18

21

41

21

32

34

Noise

30Pa

40

42

44

46

47

48

50

52

External static

pressure

Pa

30pa

Coil

Type

Copper, high-efficiency louvered fins

Pressure

≤1.6MPa

Motor

Type

Class B, capacitor start

Quantity

/

1

2

Power supply

220-240V~ 50Hz

Protection class

IP20

Input power 30Pa

W

49

80

82

103

140

192

217

277

Power lines

mm2

0.5×3

Protection class

I

Fan

Type

Front-forward multi-vane low-noise centrifugal fan

Quantity

/

1 2 3

4

Connection pipe

Inlet water

Rc3/4(female thread)

Outlet water

Rc3/4(female thread)

Condensate

R23/4(female thread)

Weight

Without return

air box

kg

14.4

17.2

19.2

20.5

23.2

34.2

37.5

37.5

Thermostat (optional)

Mechanical

Z54352A1

Digit

WK-110PA0

Deluxe digit

WK-010PA-K-K

(3) 60 Hz (Without the return air box), 4-row pipes

19

Enginnering Data

Type

Item

Concealed

ceiling

type

FP-34WAT

-R

FP-51WAT

-R

FP-68WAT

-R

FP-85WAT

-R

FP-102WA

T-R

FP-136WA

T-R

FP-170WA

T-R

FP-204WA

T-R

Performance

Airflow

Hi

m3/h

360

630

690

890

1040

1490

1850

2160

Mid

248

393

510

638

788

1095

1275

1575

Low

213

263

340

425

525

730

850

1050

Cooling

capacity

Hi W 2350

3800

4400

5600

6800

8200

10500

11200

Heating

capacity

Hi W 2150

3400

4100

4700

5600

7200

8400

9100

Flow rate

m3/h

0.446

0.697

0.808

0.98

1.171

1.45

1.747

1.964

Water resistance

kPa

8

15

24

35

56

17

32

31

Noise

30Pa

40

42

44

46

47

48

50

52

External static

pressure

Pa

30pa

Coil

Type

Copper, high-efficiency louvered fins

Pressure

≤1.6MPa

Motor

Type

Class B, capacitor start

Quantity

/

1

2

Power supply

220-240V~ 50Hz

Protection class

IP20

Input power 30Pa

W

49

80

82

112

140

192

217

277

Power lines

mm2

0.5×3

Protection class

I

Fan

Type

Front-forward multi-vane low-noise centrifugal fan

Quantity

/

1 2 3

4

Connection pipe

Inlet water

Rc3/4(female thread)

Outlet water

Rc3/4(female thread)

Condensate

R23/4(female thread)

Weight

Without return

air box

kg

14.4

17.2

19.2

20.5

23.2

34.2

37.5

37.5

Thermostat (optional)

Mechanical

Z54352A1

Digit

WK-110PA0

Deluxe digit

WK-010PA-K-K

(4) 60 Hz (Without the return air box), 3+1-row pipes

20

Enginnering Data

Model

Item

Unit

FP-34WA/

GHL-K

FP-51WA/

GHL-K

FP-68WA/

GHL-K

FP-85WA/

GHL-K

FP-102WA

/GHL-K

FP-136WA

/GHL-K

FP-170WA

/GHL-K

FP-204WA

/GHL-K

Performance

Air flow

High

m³/h

370

570

720

870

1020

1360

1600

1900

Medium

260

400

504

610

788

1095

1120

1330

Low

180

280

353

426

525

730

784

931

Cooling

High W 1750

2900

3400

4300

4900

6700

7000

10000

Heating

High W 2200

3400

4200

4700

6000

8000

9000

18900

Water flow

m³/h

0.30

0.50

0.59

0.74

0.84

1.15

1.21

1.72

Water resistance

kPa

15

30

23

25

35

40

36

40

Noise

dB(A)

37

38

40.5

44

46

46

47

50.5

External static

pressure

Pa

0Pa

Coils

Type

Copper tube and lourved fins

Working pressure

≤1.6MPa

Motor

Type

Class B insulation, capacitor start

Quantity

piece 1 2

Power lines

220-240V~ 50Hz

Protection class

IP20

Input power

W

35

54

66

84

101

150

154

198

Power lines

mm2×piece

0.5×3

Anti electric shock class

I

Fan

Type

Forward multiple-vane low-noise centrifugal fan

Quantity

piece

1 2 3

4

Connection pipe

inlet

Rc3/4(inner thread)

outlet

Rc3/4(inner thread)

condensate

Rc3/4(external thread)

Net weight

kg

14.5

17

18.9

20.8

21.9

31.5

34.1

38

Outline

dimensions

Width

mm

680

800

900

1000

1080

1380

1520

1620

Depth

mm

500

500

500

500

500

500

500

500

Height

mm

235

235

235

235

235

235

235

235

Thermostat (optional)

Mechanical

Z54352A1

Digital

WK-110PA0

Digital (deluxe)

WK-010PA-K-K

Section two --- countries and areas within the European Union

Horizontal concealed FCU, standard (G series, 220~240VAC, 50Hz, EU)

Notes:

a) The left and right modes can be switched over on site. The correction coefficient for both

cooling and heating is 0.9.

b) Nominal cooling conditions: (27/19.5℃) indoor dry/wet bulb temperature, (7/12℃) entering

and leaving water temperature. Nominal heating conditions: 20℃ indoor dry bulb

temperature, 45℃ entering water temperature and 40℃ leaving water temperature.

c) The noise is tested under the semi-anechoic chamber and the actual value will change

under different environments.

21

Enginnering Data

Model

Item

Unit

FP-34WA

H/GHL-K

FP-51WA

H/GHL-K

FP-68WA

H/GHL-K

FP-85WA

H/GHL-K

FP-102WA

H/GHL-K

FP-136WA

H/GHL-K

FP-170WA

H/GHL-K

FP-204WA

H/GHL-K

Performa

nce

Air flow

High

m3/h

450

590

750

930

1100

1400

1700

2000

Medium

315

413

525

651

770

980

1190

1400

Low

220

290

367

455

539

686

833

980

Cooling

capacity

High W 2000

3100

3550

4500

5200

6900

7200

10200

Heating

capacity

High W 2300

3500

4500

4900

6300

8200

9200

12000

Water flow

m3/h

0.34

0.53

0.61

0.78

0.90

1.19

1.24

1.76

Water resistance

kPa

15

30

23

25

35

40

36

40

Noise

dB(A)

39

39

41

46

49

48

49

52

External static

pressure

Pa

0Pa

Coils

Type

Copper tube and lourved fins

Working pressure

≤

1.6MPa

Motor

Type

Class B insulation, capacitor start

Quantity

piece

1

2

Power supply

220-240VAC 50Hz

Protection class

IP20

Input power

W

48

57

72

90

111

152

185

222

Power lines

mm

2

×

piece

0.5×3

Anti electric shock class

I

Fan

Type

Forward multiple-vane low-noise centrifugal fan

Quantity

piece

1

2

3

4

Connection pipe

Inlet

Rc3/4(inner thread)

Outlet

Rc3/4(inner thread)

Condensate

Rc3/4(external thread)

Net weight

kg

14.5

17

18.9

20.8

21.9

31.5

34.1

38

Outline

dimensions

Width

mm

680

800

900

1000

1080

1380

1520

1620

Depth

mm

500

500

500

500

500

500

500

500

Height

mm

235

235

235

235

235

235

235

235

Thermostat (optional)

Mechanical

Z54352A1

Digital

WK-110PA0

Digital (deluxe)

WK-010PA-K-K

Horizontal concealed FCU, standard (G series, 220~240VAC, 50Hz, EU)

Notes:

a) The left and right modes can be switched over on site. The correction coefficient for both

cooling and heating is 0.9.

b) Nominal cooling conditions: (27/19℃) indoor dry/wet bulb temperature, (7/12℃) entering

and leaving water temperature. Nominal heating conditions: 20℃ indoor dry bulb

temperature, 45℃ entering water temperature and 40℃ leaving water temperature.

c) The noise is tested under the semi-anechoic chamber and the actual value will change

under different environments.

22

Enginnering Data

Model

Item

Unit

FP-34WAS/

GHL-K

FP-51WAS/

GHL-K

FP-68WAS/

GHL-K

FP-85WAS/

GHL-K

FP-102WA

S/GHL-K

FP-136WA

S/GHL-K

FP-170WA

S/GHL-K

FP-204WA

S/GHL-K

Performance

Air flow

High

m3/h

370

570

720

870

1020

1360

1600

1900

Mediu

260

400

504

610

788

1095

1120

1330

Low

180

280

353

426

525

730

784

931

Cooling

capacity

High W 2100

3200

4100

4800

5900

7600

8800

10400

Heating

capacity

High W 2400

3700

4800

5500

6600

8900

10200

12100

Water flow

m3/h

0.36

0.55

0.71

0.83

1.02

1.31

1.52

1.79

Water resistance

kPa

20

21

22

30

35

40

33

40

Noise

dB(A)

37

39

40.5

44

48

47

48

50.5

External static

pressure

Pa

0Pa

Coils

Type

Copper tube and lourved fins

Working pressure

≤

1.6MPa

Motor

Type

Class B insulation, capacitor start

Quantity

piece 1 2

Power supply

220-240V~ 50Hz

Protection class

IP20

Input power

W

35

58

66

78

102

161

150

192

Power lines

mm

2

×

piece

0.5×3

Anti-electric shock class

I

Fan

Type

Forward multiple-vane low noise centrifugal fan

Quantity

Piece

1 2 3

4

Connection pipe

Inlet

Rc3/4(inner thread)

Outlet

Rc3/4(inner thread)

Condensate

Rc3/4(external thread)

Net weight

kg

14.9

17.4

19.3

21.3

22.7

30.9

34.5

38

Outline dimensions

Width

mm

680

800

900

1000

1080

1380

1520

Depth

mm

500

500

500

500

500

500

500

Height

mm

235

235

235

235

235

235

235

Thermostat

(optional)

Mechanical

Z54352A1

Digital

WK-110PA0

Digital (Deluxe)

WK-010PA-K-K

Horizontal concealed FCU, 3-row-pipes (G series, 220~240VAC, 50Hz, EU)

Notes:

a) The left and right modes can be switched over on site. The correction coefficient for both

cooling and heating is 0.9.

b) Nominal cooling conditions: (27/19℃) indoor dry/wet bulb temperature, (7/12℃) entering

and leaving water temperature. Nominal heating conditions: 20℃ indoor dry bulb

temperature, 45℃ entering water temperature and 40℃ leaving water temperature.

c) The noise is tested under the semi-anechoic chamber and the actual value will change

under different environments.

23

Enginnering Data

Model

Item

Unit

FP-34WAH

S/GHL-K

FP-51WAH

S/GHL-K

FP-68WAH

S/GHL-K

FP-85WAH

S/GHL-K

FP-102WAH

S/GHL-K

FP-136WA

HS/GHL-K

FP-170WA

HS/GHL-K

FP-204WA

HS/GHL-K

Performance

Air flow

High

m3/h

450

590

750

930

1100

1400

1700

2000

Medium

315

413

525

651

770

980

1190

1400

Low

220

290

367

455

539

686

833

980

Cooling

capacity

High W 2500

3300

4200

4900

6100

7800

9000

10500

Heating

capacity

High W 2800

3800

5100

5700

6900

9000

10900

12400

Water flow

m3/h

0.43

0.57

0.72

0.84

1.05

1.34

1.55

1.81

Water resistance

kPa

20

21

22

30

35

40

33

40

Noise

dB(A)

39

40

42

46

49

49

49

52

External static

pressure

Pa

0Pa

Coils

Type

Copper tube with lourved fins

Working pressure

≤1.6MPa

Motor

Type

Class B insulation, capacitor start

Quantity

piece

1

2

Power supply

220-240VAC 50Hz

Protection class

IP20

Input power

W

46

57

72

83

108

164

185

221

Power lines

mm2×pieces

0.5×3

Anti electric shock class

I

Fan

Type

Forward multi-vane low-noise centrifugal fan

Quantity 个

1 2 3

4

Connection pipe

Inlet

Rc3/4(inner thread)

Outlet

Rc3/4(inner thread)

Condensate

Rc3/4(external thread)

Net weiht

kg

14.9

17.4

19.3

21.3

22.7

30.9

34.5

38

Outline dimensions

Width

mm

680

800

900

1000

1080

1380

1520

Depth

mm

500

500

500

500

500

500

500

Height

mm

235

235

235

235

235

235

235

Thermostat (optional)

Mechanical

Z54352A1

Digital

WK-110PA0

Digital

(Deluxe)

WK-010PA-K-K

Horizontal concealed FCU, 3-row-pipe (G series, 220~240VAC, 50Hz, EU)

Notes:

a) The left and right modes can be switched over on site. The correction coefficient for both

cooling and heating is 0.9.

b) Nominal cooling conditions: (27/19℃) indoor dry/wet bulb temperature, (7/12℃) entering

and leaving water temperature. Nominal heating conditions: 20℃ indoor dry bulb

temperature, 45℃ entering water temperature and 40℃ leaving water temperature.

c) The noise is tested under the semi-anechoic chamber and the actual value will change

under different environments.

24

Enginnering Data

Type

Item

Concealed

ceiling type

FP-34WA

HF/BHL-K

FP-51WA

HF/BHL-K

FP-68WA

HF/BHL-K

FP-85WA

HF/BHL-K

FP-102W

AHF/BHL-

K

FP-136W

AHF/BHL-

K

FP-170W

AHF/BHL-

K

FP-34WA

HF/BHL-K

Performance

Airflow

Hi

m3/h

340

510

680

850

1020

1360

1700

2040

Mid

248

393

510

638

788

1095

1275

1575

Low

213

263

340

425

525

730

850

1050

Cooling

capacity

Hi W 2600

4000

4700

5600

7500

9200

11000

12200

Heating

capacity

Hi W 4300

6500

7300

8600

10500

14500

18000

20000

Flow rate

m3/h

0.464

0.729

0.893

0.981

1.318

1.615

2.042

2.229

Water resistance

kPa

3.713

8.943

14.54

18.79

35.75

19.06

29.01

35.41

Noise

30Pa

40

42

44

46

47

48

50

52

External static

pressure

Pa

30pa

Coil

Type

Copper, high-efficiency louvered fins

Pressure

≤1.6MPa

Motor

Type

Class B, capacitor start

Quantity

/

1

2

Power supply

220-240V~ 50Hz

Protection class

IP20

Input power 30Pa

W

43

59

70

84

105

151

174

206

Power lines

mm2

0.5×3

Protection class

I

Fan

Type

Front-forward multi-vane low-noise centrifugal fan

Quantity

/

1 2 3

4

Connection pipe

Inlet water

Rc3/4(female thread)

Outlet water

Rc3/4(female thread)

Condensate

R23/4(female thread)

Weight

Without return

air box

kg

14.4

17.2

19.2

20.5

23.2

34.2

37.5

37.5

Thermostat (optional)

Mechanical

Z54352A1

Digit

WK-110PA0

Deluxe digit

WK-010PA-K-K

50Hz (with the return air box), 4-row pipes

25

Enginnering Data

Type

Item

Concealed

ceiling type

FP-34WA

HT/BHL-

K

FP-51WA

HT/BHL-

K

FP-68WA

HT/BHL-

K

FP-85WA

HT/BHL-

K

FP-102W

AHT/BHL

-K

FP-136W

AHT/BHL

-K

FP-170W

AHT/BHL

-K

FP-204W

AHT/BHL

-K

Performance

Airflow

Hi

m3/h

340

510

680

850

1020

1360

1700

2040

Mid

248

393

510

638

788

1095

1275

1575

Low

213

263

340

425

525

730

850

1050

Cooling

capacity

Hi W 2300

3600

4350

5400

6700

8100

10350

11000

Heating

capacity

Hi W 2100

3350

4000

4600

5350

7000

8300

8950

Flow rate

m3/h

0.446

0.697

0.808

0.98

1.171

1.45

1.747

1.964

Water resistance

kPa

5.83

13.50

19.86

30.81

51.67

17.20

25.24

29.34

Noise

30Pa

40

42

44

46

47

48

50

52

External static

pressure

Pa

30pa

Coil

Type

Copper, high-efficiency louvered fins

Pressure

≤1.6MPa

Motor

Type

Class B, capacitor start

Quantity

/ 1 2

Power supply

220-240V~ 50Hz

Protection class

IP20

Input power

30Pa

W

43

59

70

84

105

151

174

206

Power lines

mm2

0.5×3

Protection class

I

Fan

Type

Front-forward multi-vane low-noise centrifugal fan

Quantity

/

1 2 3

4

Connection pipe

Inlet water

Rc3/4(female thread)

Outlet water

Rc3/4(female thread)

Condensate

R23/4(female thread)

Weight

Without return air

box

kg

14.4

17.2

19.2

20.5

23.2

34.2

37.5

37.5

Thermostat (optional)

Mechanical

Z54352A1

Digit

WK-110PA0

Deluxe digit

WK-010PA-K-K

Item

Water Side

Air Side

Entering water

temperature (℃)

Leaving water

temperature (℃)

DB Temperature

(℃)

WB Temperature (℃)

Cooling

7

12

27

19.5

Heating

60

-

21

-

Item

Water Side

Air Side

Leaving water temperature (℃)

Environment DB Temperature (℃)

Cooling

>5

16~40

Heating

<80

10~35

50Hz (with the return air box), 3+1-row pipes

1.5.2 Temperature at Nominal Conditions

1.5.3 Operation Range

Note: when conditions are out of the range, please contact GREE.

26

Enginnering Data

Model

Power Supply

Fan Quantity

FP-34

220-240 1 Ph 50Hz

1

FP-51

220-240 1 Ph 50Hz

2

FP-68

220-240V 1 Ph 50Hz

2

FP-85

220-240V 1 Ph 50Hz

2

FP-102

220-240 1 Ph 50Hz

2

FP-136

220-240 1 Ph 50Hz

3

FP-170

220-240 1 Ph 50Hz

4

FP-204

220-240 1 Ph 50Hz

4

1.5.4 Electric Data

1.5.5 Capacity Correction

Air Flow Rate and External Static Pressure Curve

Water Flow Rate and Water Resistance Pressure Curve

27

2. Dimensions of the Unit

Model

Legend

FP-34

FP-51

FP-68

FP-85

FP-102

FP-136

FP-170

FP-204

FP-238

A

680

800

900

1000

1080

1380

1520

1620

1820 B 490

460

490

490

490

490

490

490

485 C 235

235

235

235

235

235

235

235

276 D 512

632

732

832

912

1212

1352

1452

1652 E 132

132

132

132

132

132

132

132

194 F 512

682

782

882

962

1262

1402

1502

1652 G 235

235

235

235

235

235

235

235

276 H 486

606

706

806

886

1186

1326

1426

1626 I 512

632

732

832

912

1212

1352

1452

1652 J 214

214

214

214

214

214

214

214

255 K 57

57

57

57

57

57

57

57

57

Enginnering Data

Standard, 3-row pipes

K for the extended drain tray is 300mm.

28

Standard, 3+1 or 4-row-pipes

F-T Series

L a b

F-T Series

L a b

FP-34WAF(T)-R

490

45

310

FP-102WAF(T)-R

980

45

310

FP-51WAF(T)-R

620

45

310

FP-136WAF(T)-R

1400

75

250

FP-68WAF(T)-R

740

45

310

FP-170WAF(T)-R

1500

75

310

FP-85WAF(T)-R

820

45

310

FP-204WAF(T)-R

1500

75

310

Enginnering Data

3. Explosive Views and Part Lists

FP-34WA(H)/G、FP-34WA(H)S/G Explosive Views:

29

FP-34WA(H)/G Part Lists:

No

Name

Code

Quantity 1 Water Tray Assy

81211150017

1

2

Base Plate

02225200066

1 3 Surface-Cooler Assy

01126000766/01126000767

1 4 Cover Plate Sub-Assy

01265200190

1

5

End-Plate

02226001407

2 6 Surface Cooler Cover Sheet

01496000327

1 7 Motor Retaining Plate

01845200033

1 8 Propeller Housing(Lower)

26906000024

1

9

Centrifugal Fan

10456000102

1

10

Centrifugal fan assy

01396001421

1

11

Propeller Housing(Upper)

26906000023

1

12

Fan Motor

150195264/15707301

1

13

Hoop

70819521

4

14

Bar Clasp

70819522

1

15

Motor Support

01806000437

1

16

Side Plate of the Air Outlet

02226001530

1

17

Divided ( collective) water joint support

01846000179

1

18

Electric Box Assy

01396001537

1

19

Electric Box Cover Plate

01426000259

1

20

Wire Clamp

71010003

1

21

Cable Cross Loop

26900000008

2

22

Insulation Gasket

70410503

1

23

Terminal Board

4201026502

1

24

Electric Base Plate

01426000258

1

25

Capacitor CBB61

33010089

1

No

Name

Code

Quantity 1 Water Tray Assy

81211150017

1

2

Base Plate

02225200066

1 3 Surface-Cooler Assy

01126000741/01126000768

1 4 Cover Plate Sub-Assy

01265200190

1

5

End-Plate

02226001407

2

6

Surface Cooler Cover Sheet

01496000327

1 7 Motor Retaining Plate

01845200033

1 8 Propeller Housing(Lower)

26906000024

1

9

Centrifugal Fan

10456000102

1

10

Centrifugal fan assy

01396001421

1

11

Propeller Housing(Upper)

26906000023

1

12

Fan Motor

150195264/15707301

1

13

Hoop

70819521

4

14

Bar Clasp

70819522

1

15

Motor Support

01806000437

1

Enginnering Data

FP-34WA(H)S/G Part Lists:

30

Enginnering Data

16

Side Plate of the Air Outlet

02226001530

1

17

Divided ( collective) water joint support

01846000179

1

18

Electric Box Assy

01396001449/01396001537

1

19

Electric Box Cover Plate

01426000259

1

20

Wire Clamp

71010003

1

21

Cable Cross Loop

26900000008

2

22

Insulation Gasket

70410503

1

23

Terminal Board

4201026502

1

24

Electric Base Plate

01426000258

1

25

Capacitor CBB61

33000064/33010089

1

No

Name

Code

Quantity 1 Water Tray Assy

81211150018

1

2

Base Plate

02225200067

1

3

Surface-Cooler Assy

01126000769/01126000770

1 4 Cover Plate Sub-Assy

01265200191

1

5

End-Plate

02226001407

2 6 Surface Cooler Cover Sheet

01496000327

1 7 Motor Retaining Plate

01845200034

1 8 Propeller Housing(Lower)

26905200019

2

9

Centrifugal Fan

10425200003

2

10

Centrifugal fan assy

01396001422

1

11

Propeller Housing(Upper)

26905200018

2

FP-51WA(H)/G

FP-68WA(H)/G

、

FP-85WA(H)/G

、

FP-102WA(H)/G

、

FP-68WA(H)S/G、FP-85WA(H)S/G、FP-102WA(H)S/G Explosive Views:

FP-51WA(H)S/G

、

、

FP-51WA(H)/G Part Lists:

31

12

Fan Motor

15707302/157073021

1

13

Hoop

70819521

1

14

Bar Clasp

70818025

4

15

Motor Support

01805200144

1

16

Side Plate of the Air Outlet

02225200064

1

17

Divided ( collective) water joint support

01846000179

1

18

Electric Box Assy

01396001540 /01396001541

1

19

Electric Box Cover Plate

01426000259

1

20

Wire Clamp

71010003

1

21

Cable Cross Loop

26900000008

2

22

Insulation Gasket

70410503

1

23

Terminal Board

4201026502

1

24

Electric Base Plate

01426000258

1

25

Capacitor CBB61

33010089 /33010089

1

No

Name

Code

Quantity 1 Water Tray Assy

81211150010

1

2

Base Plate

02226001409

1 3 Surface-Cooler Assy

01126000754/01126000775

1 4 Cover Plate Sub-Assy

02226001410

1

5

End-Plate

02226001407

2 6 Surface Cooler Cover Sheet

01496000327

1 7 Motor Retaining Plate

01846000180

1 8 Propeller Housing(Lower)

26906000024

1

9

Centrifugal Fan

10456000102

1

10

Centrifugal fan assy

15406002335

1

11

Propeller Housing(Upper)

26906000023

1

12

Fan Motor

15019523/15019523

1

13

Hoop

70819521

4

14

Bar Clasp

70819522

1

15

Motor Support

01806000437

1

16

Side Plate of the Air Outlet

01376000082

1

17

Divided ( collective) water joint support

01846000179

1

18

Electric Box Assy

01396001546/01396001547

1

19

Electric Box Cover Plate

01426000259

1

20

Wire Clamp

71010003

1

21

Cable Cross Loop

26900000008

1

22

Insulation Gasket

70410503

1

23

Terminal Board

4201026502

1

24

Electric Base Plate

01426000258

1

25

Capacitor CBB61

33010025/33010026

1

FP-68WA(H)/G Part Lists:

Enginnering Data

32

FP-85WA(H)/G Part Lists:

No

Name

Code

Quantity

1

Water Tray Assy

81211150010

1

2

Base Plate

02226001409

1 3 Surface-Cooler Assy

01126000754/01126000775

1 4 Cover Plate Sub-Assy

02226001410

1

5

End-Plate

02226001407

1 6 Surface Cooler Cover Sheet

01496000327

1 7 Motor Retaining Plate

01846000180

1 8 Propeller Housing(Lower)

26906000024

1

9

Centrifugal Fan

10456000102

1

10

Centrifugal fan assy

15406002335

1

11

Propeller Housing(Upper)

26906000023

1

12

Fan Motor

15019523/15019523

1

13

Hoop

70819521

4

14

Bar Clasp

70819522

1

15

Motor Support

1806000437

1

16

Side Plate of the Air Outlet

01376000082

1

17

Divided ( collective) water joint support

1846000179

1

18

Electric Box Assy

01396001546/01396001547

1

19

Electric Box Cover Plate

1426000259

1