Gree CAS12HP230V1AC, CAS18HP230V1AC, CAS24HP230V1AC, FLRO9HP230V1AF, FLR12HP230V1AF Installation Manual

...

CEILING CASSETTE

INSTALLATION MANUAL

Models:

CAS12HP230V1AC

CAS18HP230V1AC

CAS24HP230V1AC

Thank you for choosing a

Multi21Ceiling Cassette Ductless

Heat Pump System for your customer.

Please read this installation manual carefully before installing and starting up

the Ceiling Cassette Ductless System. Take a moment to fill out the product and

installation form on the back cover. Retain both the manual and installation

record for future reference.

Table of Contents

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Nomenclature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

System Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Suggested Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

System Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Installation Site Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Indoor Unit Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-8

Indoor Unit Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Piping Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-13

Power & Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-16

Controller Installation and Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Fresh Air Intake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Decorative Grille Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Testing and Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Diagnostic Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22-25

Installation Record . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Back

SAFETY PRECAUTIONS

Please read the following before installation.

This is the safety alert symbol. It is used to alert you to potential

personal injury hazards. Obey all safety messages that follow this

symbol to avoid possible injury or death.

WARNING

CAUTION

NOTICE

This mark indicates procedures which, if improperly performed,

might lead to the death or serious injury of the user.

This mark indicates procedures which, if improperly performed, might

possibly result in personal harm to the user, or damage to property.

Notice is used to address practices not related to personal injury.

General Safety Precautions

1. Instructions for installation and use of this product are provided by the manufacturer.

For proper operation, the system must be installed in accordance with this

installation manual.

2. Installation must be performed in accordance with local laws, regulations and

National Electrical Codes (NEC).

3. If there is a refrigerant leak while work is being carried out, ventilate the area.

Do not allow refrigerant to come in contact with a flame as it produces toxic gas.

4. Disconnect all electrical power to the indoor and outdoor units until the system is

ready for start-up and checkout.

5. When installing or repairing the system, use only R410A refrigerant. Do not

mix refrigerant with other gases. If air or other gas enter the refrigeration system,

the pressure inside the system may rise to an abnormally high value and cause

damage or injury.

WARNING

This appliance is not intended for use by persons (including children) with reduced physical,

sensory or mental capabilities, or lack of experience and knowledge, unless they have been given

supervision or instruction concerning use of the appliance by a person responsible for their safety.

2

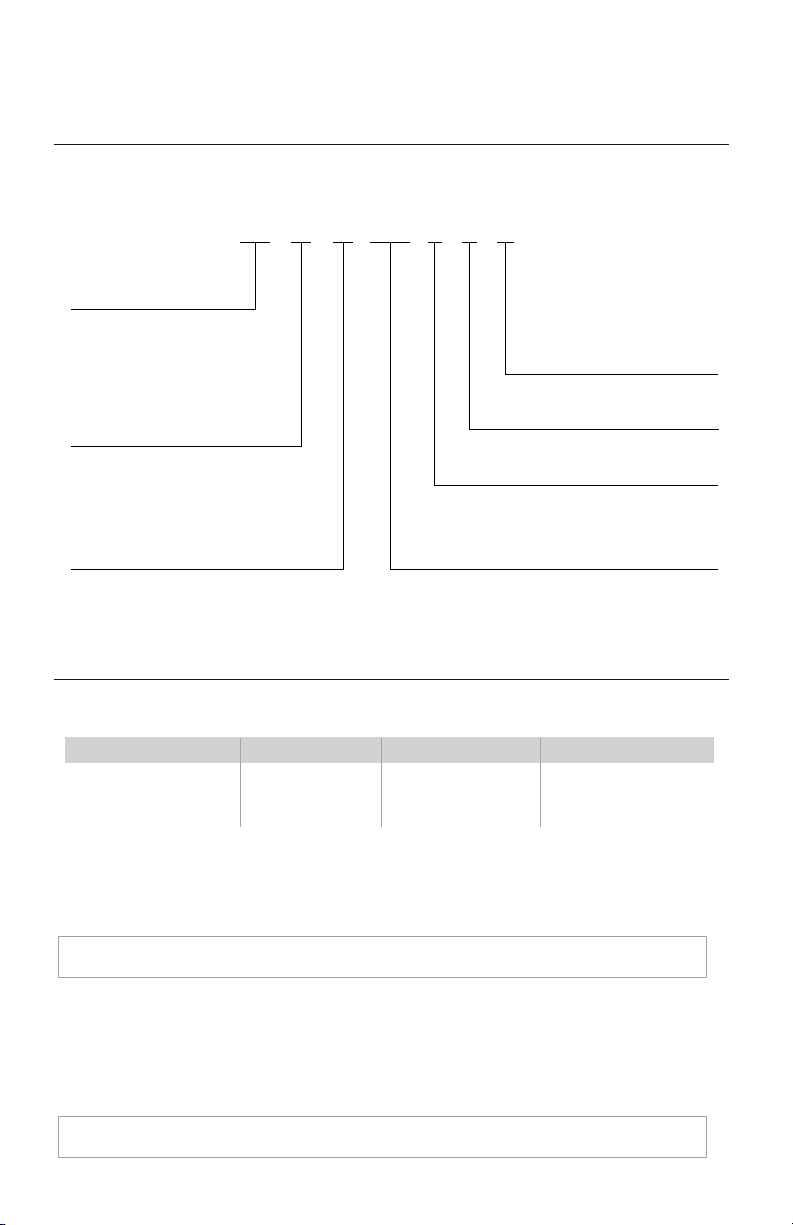

NOMENCLATURE

Cooling Capacity

12 - 12,000 BTUH

18 - 18,000 BTUH

24 - 24,000 BTUH

Series Designation

Revision Level

Style/Color Designation

Product Type

S

- System

O - Outdoor units

H

- Indoor High Wall

D

- Indoor Duct

C - Indoor Cassette

F - Indoor Floor/Ceiling

Electrical Rating

230V - 208/230V 60Hz 1PH

Model Type

AC - Cooling Only

HP - Heat Pump

HC - Heat/Cool

115V - 115V 60Hz 1PH

Example: CAS18HP230V1AC

CCAS 18 HP 230V 1 A

CAS - Ceiling Cassette

SYSTEM REQUIREMENTS

PIPE SIZE in (mm)

Unit Size

Interconnecting Cable

The ceiling cassette unit is powered from the outdoor unit. Use recommended 14/4 AWG

stranded bare copper conductors THHN 600V unshielded wire.

NOTE:

Condensate Drainage

It is recommended that condensate drainage systems use pipe either the same diameter

(BtuH)

12,000 1/4 (6) 3/8 (9.5) 44/51 lbs.

18,000 1/4 (6) 1/2 (12) 48/55 lbs.

24,000 3/8 (9.5) 5/8 (16) 66/84 lbs.

Liquid Line Suction/Gas Line

Net/Gross Weight

Use shield cable if installation is in close proximity of RF and EMI transmitting devices.

or larger (excluding the raising section) than that of the connecting pipe. The unit condensate

port is 1.2 in. (31mm) outside diameter.

NOTE:

Insulate all condensate drain pipes to prevent sweating and possible water damage.

3

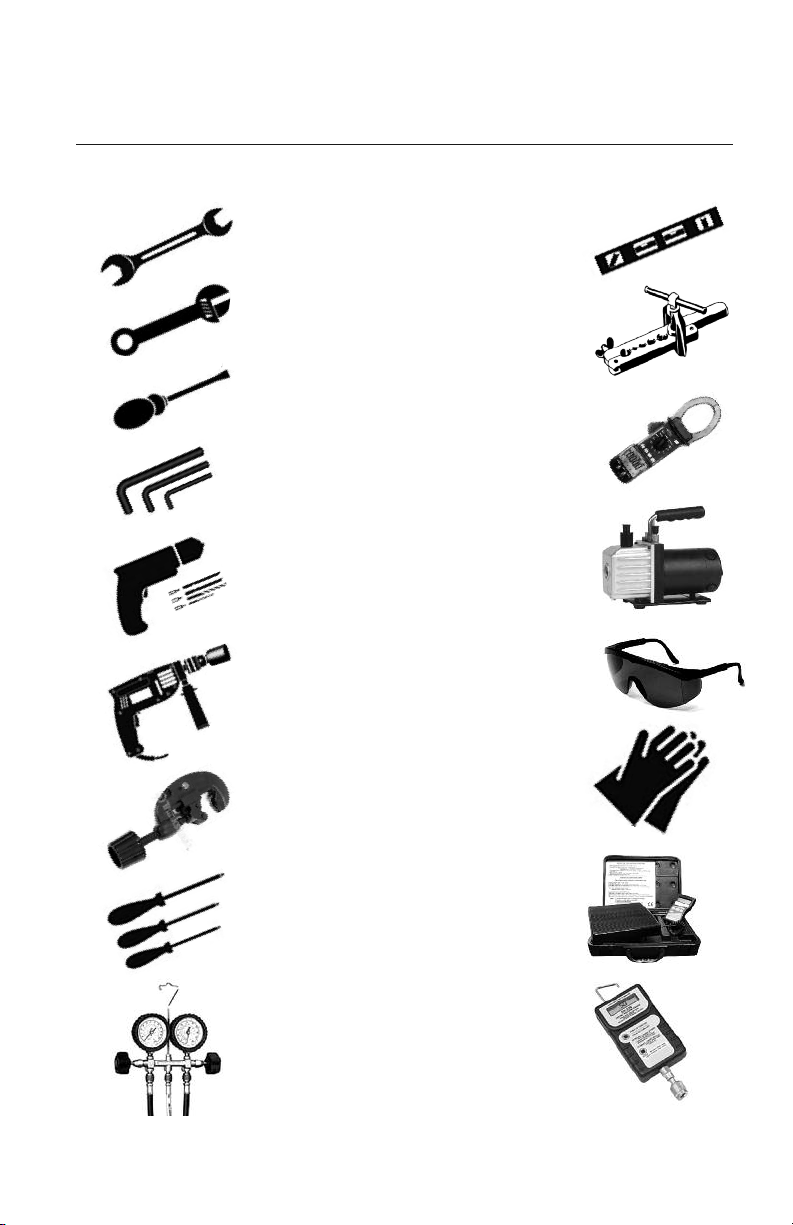

SUGGESTED TOOLS

• Standard Wrench

• Adjustable/Crescent Wrench

• Torque Wrench

• Hex Keys or Allen Wrenches

• Drill & Drill Bits

• Hole Saw

• Pipe Cutter

• Screw drivers (Phillips & Flat blade)

• Manifold and Gauges

• Level

• R410A Flaring Tool

• Clamp on Amp Meter

• Vacuum Pump

• Safety Glasses

• Work Gloves

• Refrigerant Scale

• Micron Gauge

4

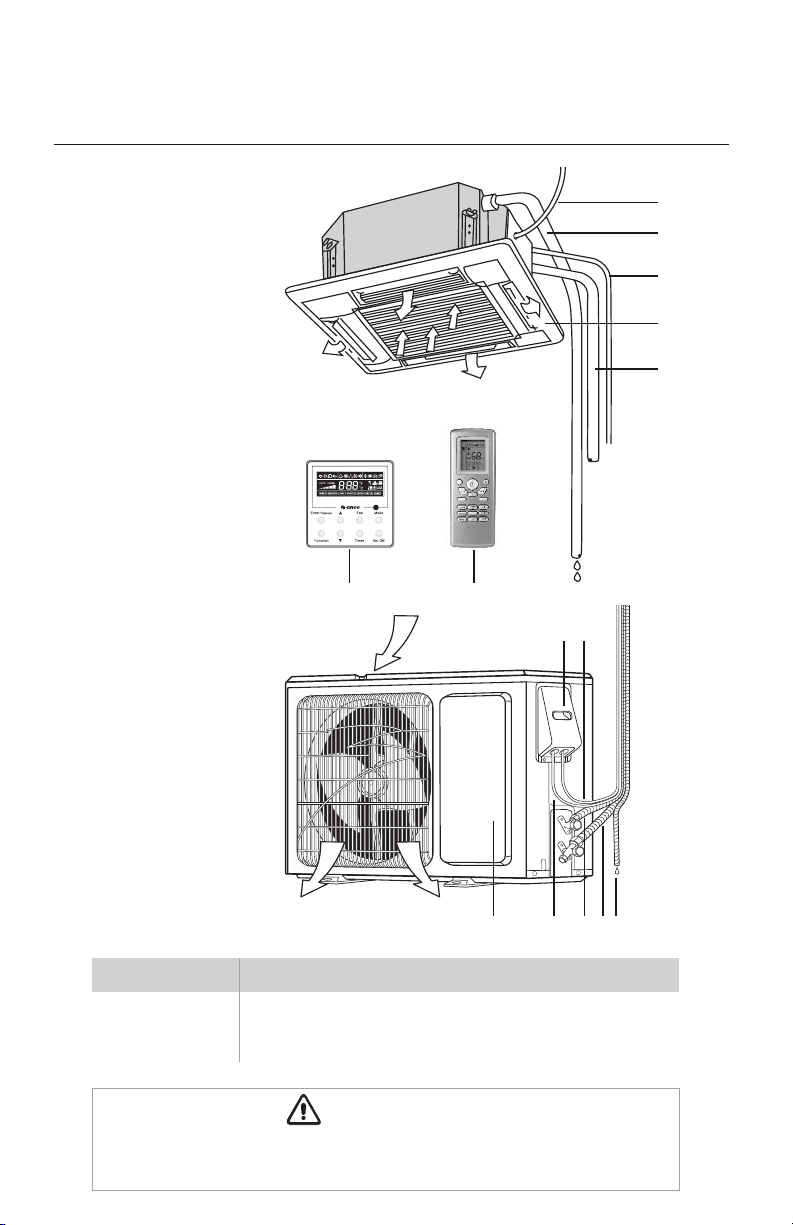

SYSTEM PARTS

1

2

Indoor unit

Part Name

1. Power Supply and

Communication Wires

2. Drain Pipe

3. Liquid Pipe

4. Decorative Discharge Air

Grille (sold separately)

5. Gas Pipe

6. Wired Tether Controller

7. Remote Controller

8. Service Cover

9. Power Supply and

Communication Wires

10. Front Panel

11. Outdoor Power Supply

12. Liquid Pipe

13. Gas Pipe

14. Drain Hose

Air outlet

3

4

5

Air inlet

67

98

Air inlet

Outdoor Unit

Air outlet

Part Numbers Description

CASGRILLE1SM Decorative Grille for 12,000 & 18,000 BTU Cassettes

CASGRILLE1LG Decorative Grille for 24,000 BTU Cassette

MC20700140 XK-19 Wired Tether Controller with touch buttons.

CAUTION

The refrigerant pipe, drain pipe and electrical wiring for this unit should be

installed by a qualified HVAC professional only.

10

14

12

11

13

5

INSTALLATION SITE INSTRUCTIONS

Indoor Unit

WARNING

The unit must be installed in a location which can withstand four times the weight of the unit.

Inadequate support may result in serious property damage and injuries.

Select a site that allows for the following:

• Ensure the installation complies with the installation minimum dimensions and meets the

minimum and maximum connecting piping length and maximum change in elevation.

• Air inlet and outlet should be clear of obstructions, ensuring proper airflow throughout the room.

• Condensate can be easily and safely drained.

• All connections can be easily made to outdoor unit.

• Indoor unit is out of reach of children.

• A structure strong enough to withstand four (4) times the full weight and vibration of the unit.

• Filter can be easily accessed for cleaning.

• Leave enough free space to allow access for routine maintenance.

• Do not install in a laundry room or by a swimming pool due to chemicals corroding cassette coil.

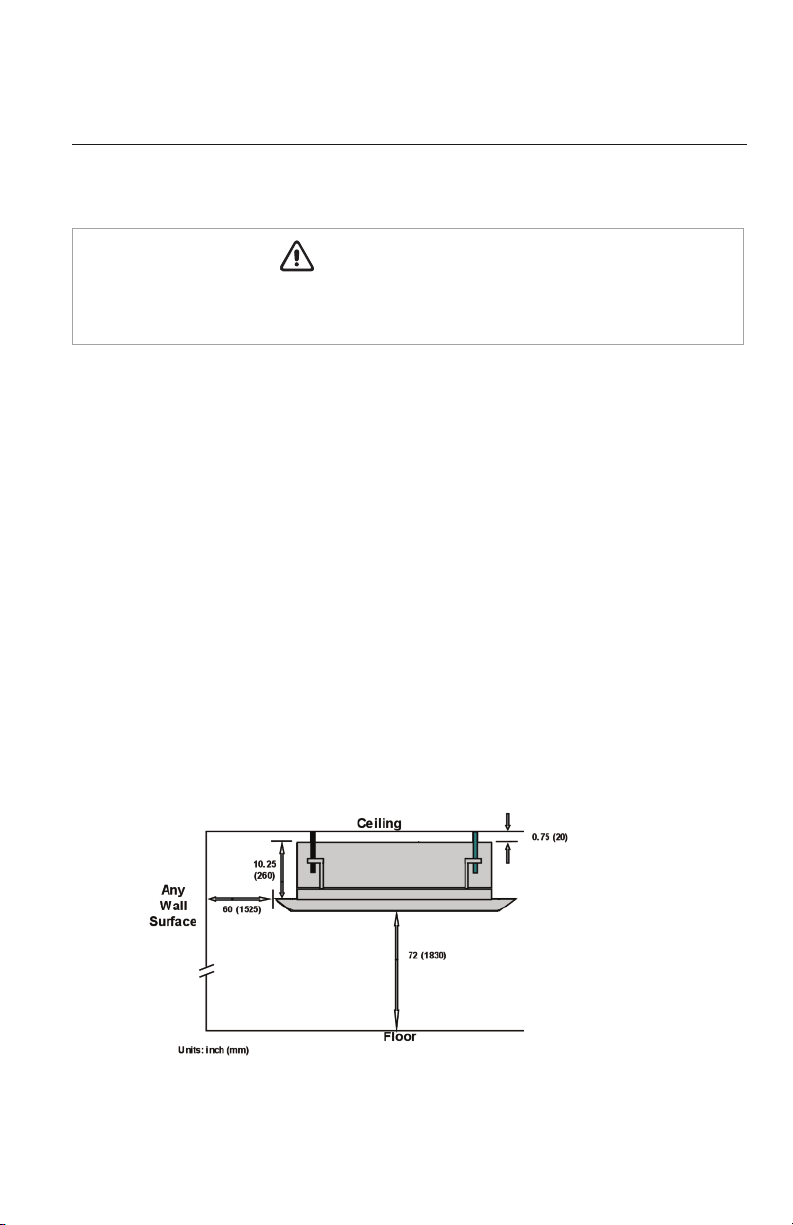

Minimum Indoor Clearances

6

INDOOR UNIT DIMENSIONS

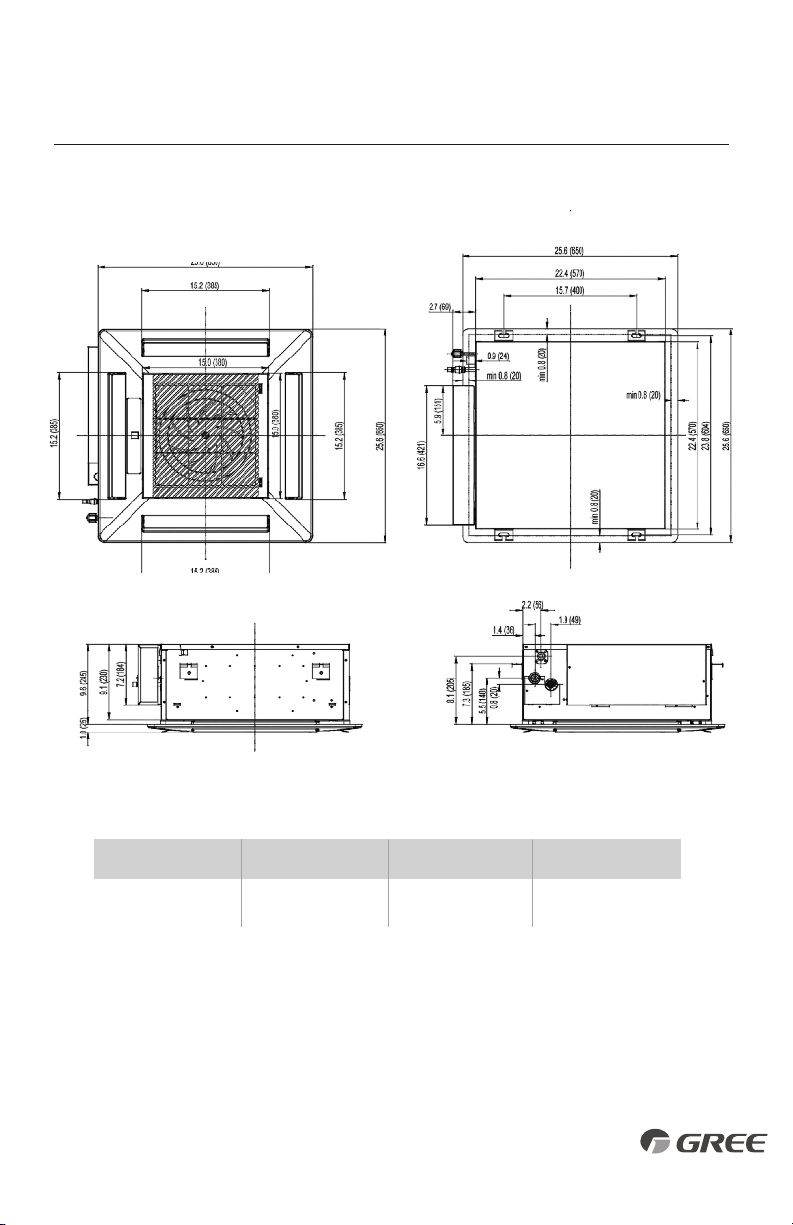

12-18K Indoor Unit Dimensions

Model

12,000 3/8-in OD Flared 1/4-in OD Flared 1.2-in OD

18,000 1/2-in OD Flared 1/4-in OD Flared 1.2-in OD

Suction/Gas Line Liquid Line

Port Size Port Size Connection

Drain Line

7

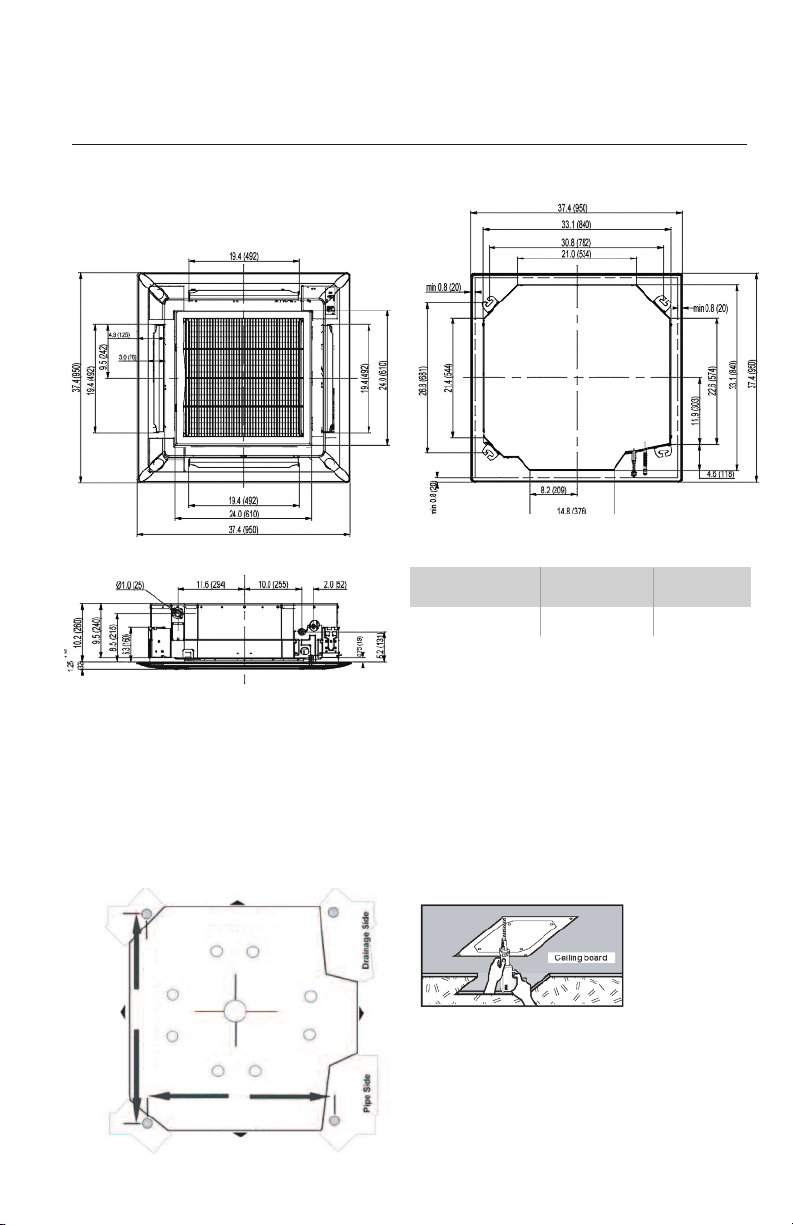

INDOOR UNIT DIMENSIONS

Hanger Bolts Distance 22.5in (570mm)

Hanger Bolts Distance 23.75in (604mm)

Ceiling Center Point

Ceiling Center Point

24K Indoor Unit Dimensions

Suction/Gas Line Liquid Line

Port Size Port Size Connection

5/8-in OD Flared 3/8-in OD Flared 1.2-in OD

Laying Out Indoor Location

• Locate the factory supplied installation template included in carton.

• Use the template to make an opening in the ceiling for the ceiling cassette main body.

• Mark the position of the 4 hanger bolts, refrigerant lines and condensate drain pipes.

Drain Line

8

Threaded

Hanger Bolt

Was he r

Nut

Was he r

Nut

Nut

INDOOR UNIT INSTALLATION

Indoor Unit Hanger Mounting

Depending on the type of ceiling, attach the threaded hanger bolts securely to the support stud. Before

lifting the indoor unit to the installation location, insert the upper nuts, flat washers (with insulation),

flat washers (without insulation), lower nuts and double locking nuts on the threaded hanger bolts.

NOTE: The hanger bolts, nuts, and washers are field supplied. Install the washer with

cushion so that the insulation faces downward.

Installation of Ceiling Cassette

Lift the Ceiling Cassette main body to the threaded hanger bolts. Insert the unit mounting brackets

between washers and then fasten it securely.

Hanging bolt

Nut

Flat washer

Flat washer

Nut

Confirm the position of the Indoor Unit

1. Adjust the height of the Indoor Unit main body to align with false ceiling. Be sure to confirm

this, otherwise condensation may form during cooling mode. Adjust mounting nuts as needed.

2. Confirm that the indoor unit main body is level. Adjust mounting nuts as needed.

3. After checking the positioning of the indoor unit main body, tighten the nuts of the hanger

bolts securely to fasten the Indoor Unit main body in place.

9

PIPING INSTALLATION

Oil return bend

Indoor

Outdoor

20 ft.

30 ft.

Oil return bend

Refrigerant Piping

Drill Hole in Wall

1.

Locate and mark proper location for the wall hole.

2.

Cut the 2 3/4” wall hole with a 5° to 10°

Indoor

Wall

Hole Sleeve

Outdoor

downward slant to the outdoors.

3. Insert a wall sleeve (field supplied) into hole to

to prevent damage to refrigerant pipes, insulation,

condensate drain hose and wiring.

4. Proper weather proofing of the wall surface and

Wall Hole Diagram

wall sleeve is essential to assure a trouble-free

installation. Apply sealant, caulking or equivalent

weather proofing material around the perimeter of

the wall sleeve (interior & exterior) to eliminate

outdoor air and water leaks into the indoor space.

Unit Size

(BtuH) Dia -inch (mm)

12,000 2 1/4 (55)

18,000 2 3/4 (70)

24,000 2 3/4 (70)

Wall

Hole Size

NOTE: Expandable foam insulation may be added to fill large wall gaps.

Apply per manufacturer's instructions.

Piping Preparation

1. Do not open service valves or remove protective caps on pipes until instructed by this manual.

2. Keep tubing free of dirt, sand, moisture and contaminants.

3. Insulate each refrigerant pipe and condensate hose with minimum 3/8” (10 mm) wall

thermal pipe insulation.

4. Bind refrigerant pipes and communication cable together with cable ties at 12-inch intervals.

5. Include the condensate hose in bundle for exterior portion only.

Seal Hole

Hole Size

Indoor Unit below Outdoor Unit Application

When height difference between indoor unit and outdoor

unit is more than 30 feet, an oil return bend should be added

for every 20 feet of connection pipe as shown.

10

PIPING INSTALLATION

Gas pipe

3-way valve

Reference A:

Reference A:

Cover this portion with insulation

Pipe insulation

Liquid pipe

Gas pipe

Front outlet

Insulate pipe connection

Insulate pipe

Insulate pipe

2-way valve

Liquid pipe

or

Pipe

coupling

Gas pipe

3-way valve

Reference A:

Cover this portion with insulation

Pipe insulation

2-way valve

Liquid pipe

or

Pipe

coupling

WARNING

CAU TION

WARNING

Connecting Refrigerant Pipes to Ceiling Cassette

1. Feed refrigerant pipes, drain hose and communication cable assembly through wall hole

from outdoor to the Ceiling Cassette.

2. Pull the piping assembly to the indoor unit. Carefully bend refrigerant pipes to meet indoor

unit connection ports. Use proper tools to avoid kinks.

3. Add a small amount of refrigerant oil to both ends of the flare fittings.

4. Properly align piping and tighten flare nut using a standard wrench and a torque wrench as

shown in figure to the below. Carefully tighten flare nuts to correct torque level referring to

the illustration and Torque Table below:

I

n

d

o

o

r

U

n

i

t

P

i

p

i

n

g

W

r

e

n

c

h

T

P

i

p

i

n

a

p

e

r

g

N

u

t

T

o

r

q

u

e

W

r

e

n

c

h

5. Individually insulate each bare refrigerant pipe and joint as shown below to prevent sweating.

Pipe Diameter Nut Size

inch (mm) inch (mm) ft-lbs N-m

1/4 (6.35) 1/4 (17) 10 to 13 14 to 18

3/8 (9.5) 3/8 (22) 25 to 30 34 to 42

1/2 (12.7) 1/2 (25) 36 to 45 49 to 61

5/8 (15.9) 5/8 (29) 50 to 60 68 to 82

CAUTION

Over tightening may damage flare connections and cause leaks.

Ceiling Cassette Unit

Tightening Torque

11

PIPING INSTALLATION

WARNING

CAU TION

WARNING

Outdoor Unit Pipe Connections

eet

m

o

t

es

ip

p

t

an

er

ig

efr

r

f

o

h

t

g

len

t

s

ju

ad

d

an

d

en

b

lly

efu

ar

C

s

n

io

ct

u

r

t

s

in

n

io

allat

t

s

in

See

s.

n

io

ect

n

n

co

t

r

o

p

it

n

u

r

o

o

d

t

u

o

.

s.

n

io

ct

u

r

t

s

in

er

h

t

r

fu

r

fo

it

n

u

r

o

o

d

t

u

o

e

h

t

h

wit

ed

p

ip

h

s

Indoor Condensate Drain Piping

WARNING

Observe all local sanitary codes when installing condensate drains.

It is recommended to install the condensate drain system with hard polyvinyl chloride (PVC) pipe

and matching connectors. Use piping of the same diameter or larger as the unit connection.

The Ceiling Cassette drainage port diameter is 1.2 in. (31mm) OD.

Pitch the condensate drain pipe at a gradual 2.5% pitch (Example: ¼-in drop over a 10-in length)

without obstructions. Use pipe hanger/brackets to support the condensate drain pipe from dropping.

NOTE: Insulate condensate hose and/or pipes to prevent sweating which may cause

water stains or wall damage.

Gravity Drainage Systems

The following are recommended gravity drainage systems for the ceiling cassette.

Typical Gravity System

Common Drain Pipe System

with P-Trap and Vent

12

PIPING INSTALLATION

Sealed

Drain

pipe

Clamps

Vertical Lift Drainage System

If a gradual pitch from the drainage port is not obtainable, the Ceiling Cassette contains an internal

condensate drain pump with limited head or lift. The condensate drain pipe may have a vertical height of

11-in. (280mm) maximum above the unit drainage port within the first 12-in as long as the remaining

condensate drain pipe gradually descends from that point and is aligned with drainage port.

Use an auxiliary condensate pump with float valve for vertical height greater than of 11-in.

(280 mm) above the unit drainage port. A float valve is recommended to shut off the system if

the auxiliary pump fails.

Completing Condensate Drainage Piping

• Include the exterior section of condensate hose in the

pipe/wire bundle.

• Fasten the refrigerant and condensate pipe assembly to

the exterior wall for support.

• The drain pipe should terminate 6 inches above grade.

13

POWER AND WIRING INSTALLATION

WARNING

CAU TION

WARNING

WARNING

CAU TION

WARNING

WARNING

1. Before obtaining access to wire terminals, all electrical supply circuits must be

disconnected, locked out and tagged.

2. Always use an independent (dedicated) circuit and provide an independent (dedicated)

circuit breaker to supply power to the system.

3. Use a circuit breaker with adequate capacity to meet the requirements of the total system.

4. All circuit breakers or fuses for the indoor and outdoor units should be installed per the

National Electric Code (NEC) and local regulations.

5. Electrical wiring must be completed in accordance with NEC, local laws, and regulations

of the electric company so that the system will operate properly.

6. Provide a GFI circuit breaker at the electrical panel in accordance with the NEC and the

local electrical company standards.

7. Connect the power supply firmly to the terminal block. Improper installation may

cause a fire.

CAUTION

1. The main power supplies are high-voltage, while the communication wire and the Tether

Controller are low-voltage. They should be installed separately to avoid electromagnetic

interference.

2. High-voltage and low-voltage lines should pass through separate rubber rings at electric

box covers.

3. If the indoor unit communication wire (to the outdoor unit) and power wire are connected

incorrectly, the air conditioner may be damaged.

4.

Ground both indoor unit and outdoor unit to earth ground in accordance with the applicable

local and national codes.

14

POWER AND WIRING INSTALLATION

G

Power:

W

ired Tether

Controller

XK-19

NN((11

))

22

3

3

CN1CN1

22

3

3

NN((11

))

CN9CN9

Screw with

special washer

Round

terminal

Terminal

board

Insulation tube

Insulation tube

Wire clamp

W

ire

Cassette Unit

WARNING

CAU TION

WARNING

Electric Wiring Between Indoor Unit and Outdoor Unit

hite

W

ed

R

Black

Green

Typical Wiring Diagram

Outdoor Electrical Wiring

For Outdoor Unit wire connections, see installation instructions shipped with the outdoor unit.

Electrical Connections to Ceiling Cassette

WARNING

Disconnect all electrical power to indoor and outdoor units including disconnects,

fuses and circuit breakers. Lockout and tag all disconnect switches.

1. Adjust the length of the interconnecting wires so that it can easily reach the Ceiling Cassette

electrical control box.

2. Open electrical control box cover and route the interconnecting wires to field wiring terminal block.

NOTE:

The indoor unit is powered from the outdoor unit, depending on local code, a

disconnect switch may need to be installed to a power supply circuit.

3. Secure interconnecting wires to the terminal block

as shown in the connection diagram at right:

NOTE:

Record wire colors and terminal references

for uses with Outdoor Unit wire connections.

4. Secure all wires inside wire clamp/strain relief. Verify wires

are secure, not loose and no external force on wires affects

the connections at the terminals.

NOTE:

Crossing interconnecting wires will cause system malfunction and possible damage.

White

Red

5. Replace field wiring cover on unit.

Green

Black

15

POWER AND WIRING INSTALLATION

Indoor Disconnect Switch (Optional)

Local codes may require a disconnect switch within sight of the indoor unit. Use a DFS Disconnect

Switch Accessory Kit (Part No: DFS-SWITCH-A) to break interconnecting wires going to the N(1),

2, 3, terminals on the indoor unit, as shown in the wiring diagram below:

Indoor Unit

White

Indoor Unit

Red

Black

Green

Disconnect Switch

Wires

Outdoor Unit

Outdoor Unit

Installing Wired Tether Controller to Ceiling Cassette

1. Open decorative grille and locate 4 pin connector for wired controller on Ceiling Cassette

main body

2. Route wired controller wires to 4-pin connector and connect Tether Controller to ceiling

cassette.

NOTE:

Use the supplied cable, with OEM plugs on either end. Do not cut or splice.

Conceal any excess cable.

1. Replace decorative grille being careful not to pinch wires.

2. Remove back plate from Wired Controller.

16

CONTROLLER INSTALLATION AND SETUP (Optional)

The following is a brief overview of the Wired Tether Controller installation. See Tether Controller

Owner's Manual for more detailed instructions for setup and operation.

Preparation for Installation

Select a proper location on the wall for mounting the Tether

Controller. Install switch box, if required by code. The maximum

wire length between indoor and Tether Controller is 26 ft (8m).

Run communication cable (as desired) between indoor unit

and selected wall mounting location. See Indoor Unit wiring

section for instruction to connect the Wired Tether Controller

to the indoor unit.

Wired Tether Controller Installation

Pull communication cable through switch box (if one

is used) and Wired Tether Controller backplate. Securely

fasten backplate to the switch box or wall.

Locate wire terminals connector on rear of Tether

Controller panel. Carefully connect wire to controller

connector. Verify connector is secure, not loose and

no external force on wires affects the connections at

the terminals. Push extra cable into wall and secure

controller panel to backplate mounted on the wall.

NOTE: Do not cut or splice communication cable.

17

FRESH AIR INTAKE (24K Size Only)

Connecting Fresh Air Duct

The indoor ceiling cassettes have a fresh air intake port for ventilation. A booster fan and

duct (field supplied) must be used to feed outdoor air to the indoor unit.

Determine the duct diameter, length and booster fan size based on the required airflow.

See table below for duct and hole sizes:

Unit Size Hole Diameter

(BtuH) inch (mm) inch (mm)

24,000 4.4 (113) 2.9 (73)

Duct Diameter

NOTE: Fresh air intake amount should be 10% or less of whole air amount to

prevent condensation.

Fresh air hole

Fresh air hole

To install fresh air intake:

1. Locate and remove the pre-punched knockouts hole for ventilation duct on ceiling cassette unit.

Do not remove the knockout and open the hole at this point.

2. Remove the factory installed insulation on the outside of ceiling cassette where the pre-punched

knockout was located.

3. Install field supplied ductwork. Recommended ductwork is either an insulated flex duct, or

insulated sheet metal duct suitable for working temperatures up to 140° F (60° C).

4. Use a field-supplied power ventilation fan to increase airflow to meet job requirements.

Follow the manufacturer's installation instructions provided with the power ventilation kit.

5. Install a field supplied air filter to prevent dust and dirt from entering the ceiling cassette unit

and fouling indoor coil.

6. Install a field supplied mechanical duct damper to close during shutdown periods.

7. All metal ductwork should be covered with insulation to prevent condensation forming.

18

DECORATIVE GRILLE INSTALLATION

Mounting Decorative Grille

1. Carefully unpack decorative grille and align the

decorative grille to the Ceiling Cassette main body.

Ceiling Cassette

main body

Refrigerant

pipes

Hook & latch

2. Temporarily attach the decorative grille to the

Hook & latch

ceiling cassette main body at two (2) corner points.

3. Locate the two (2) Swing Louver electrical

H

connectors on the decorative grille.

Height adjustment screw

Decorative grille

4. Connect both Swing Louver connectors on

decorative grille to matching connectors on the

Ceiling Cassette body.

Swing louver connector

5. Complete the decorative grille attachment by

hooking the remaining two (2) corners to the

Ceiling Cassette main body.

Note: Be careful not to pinch the swing

louver motor wires between the decorative

Swing louver connector

grille and ceiling cassette main body.

6. Find the four (4) height adjustment screws located on the corners of the decorative grille.

Use the four (4) height adjustment screws to adjust gap between decorative grille and

Ceiling Cassette body so that gap is reduced to 1/4-in (6mm) to 3/8-in (9mm). Make certain

the decorative grille is not distorted by excessive tightening.

7. Verify that the seal between decorative grille

and Ceiling Cassette main body is tight all the

way around the unit to prevent air leak. Use the

height adjustment screws to adjust the gap.

Ceiling

Between 1/4-in.

and 3/8-in.

Ceiling

Decorative grille

ook & latch

1918

TESTING AND INSPECTION

Start-up Checklist

Turn on main power to indoor and outdoor units.

□

• Verify the system is not displaying an error code on the indoor unit display.

Point the Remote Controller at the Ceiling Cassette

□

and Press the On button.

• Verify the remote controller display turns ON and the Power

Indicator lights up on the Ceiling Cassette.

Press the Mode button to Cooling.

□

Adjust the room setpoint to bring the system on in cooling mode. The system should start cooling mode within 3-5 min.

• Verify the setpoint lights up on the Ceiling Cassette display.

• Verify the outdoor fan and compressor are operating.

• Verify the indoor fan is operating.

• Verify the indoor discharge air is cooling the room.

Press the Mode button to Heating.

□

Adjust the room setpoint to bring the system on in heating mode. The system should start heating mode within 3-5 min.

• Verify the new setpoint lights up on the Ceiling Cassette display.

• Verify the outdoor fan and compressor are operating.

• Verify the indoor fan is operating.

• Verify the indoor discharge air is heating the room.

Press the OFF button on the Remote Controller.

□

• Verify Remote Controller display turns OFF and the system shuts OFF.

Test the Drain Piping.

□

The Ceiling Cassette contains a condensate pump and float switch. Test the condensate disposal system by the following:

1. Remove grille and frame from the unit and find the drainage port.

2. Locate and remove the access cover.

Place the unit in cooling mode and wait until the compressor turns on.

3.

4. Slowly add 20 to 24 oz. of a water bottle to the drain pan.

5. Water must drain freely from the unit with condensate pump

energized. If not, check the pipe slope or see if there are any

pipe restrictions. Verify all piping joints are leak free.

Note: This unit is equipped with a safety float switch to

de-energize the compressor if the water level gets too high.

Drain hose Test hole cover

Test hole

Use plastic water bottle

with a minimum 4-inch pipe

20

TROUBLESHOOTING

PROBLEM

System does not restart.

ndoor unit emits unpleasant odor

I

when started

You hear a“water flowing”sound.

A thin fog or vapor coming out

of the discharge register when

system is running.

You hear a slight cracking sound

when the system stops or starts.

The system will not run.

The unit is not heating or cooling

adequately.

Water leaking from the indoor

unit into the room.

The unit will not deliver air.

CAUSE/SOLUTION

Cause: The system has a built-in three-minute delay to prevent short and/or rapid cycling of

the compressor.

Solution: Wait three minutes for the protection delay to expire.

Cause: Typically unpleasant odors are the result of mold or mildew forming on the coil surfaces

or the air filter.

Solution: Wash indoor air filter in warm water with mild cleaner. If odors persist, contact a

qualified service professional to clean the coil surfaces.

Cause: It is normal for the system to make“water flowing”or “gurgling”sounds from

refrigerant pressures equalizing when the compressor starts and stops

Solution: The noises should discontinue as the refrigerant system equalizes after two or three minutes.

Cause: It is normal for the system to emit a slight fog or water vapor when cooling extremely humid

warm air.

Solution: The fog or water vapor will disappear as the system cools and dehumidifies the room space.

Cause: It is normal for the system to make “slight cracking” sounds from parts expanding and

contracting during system starts and stops.

Solution: The noises will discontinue as temperature equalizes after two or three minutes.

Cause: There are a number of situations that will prevent the system from running.

Solution: Check for the following:

• Circuit breaker is “tripped” or “turned off.”

• Power button of controller is not turned on.

• Controller is in sleep mode or timer mode.

• Otherwise, contact a qualified service professional for assistance.

Cause: There are a number of reasons for inadequate cooling or heating.

Solution: Check the following:

• Remove obstructions blocking airflow into the room.

• Clean dirty or blocked air filter that is restricting airflow into the system.

• Seal around door or windows to prevent air infiltration into the room.

• Relocate or remove heat sources from the room.

Cause: While it is normal for the system to generate condensate water in cooling mode,

it is designed to drain this water via a condensate drain system

to a safe location.

Solution: If water is leaking into the room, it may indicate one of the following.

• The indoor unit is not level right to left. Level indoor unit.

• The condensate drain pipe is restricted or plugged. All restrictions must be removed

to allow continuous drainage by gravity.

• If problem persists, contact a qualified service professional for assistance.

Cause: There are a number of system functions that will prevent air flow.

Solution: Check for the following:

• In heating mode, the indoor fan may not start for three minutes if the room

temperature is very low. This is to prevent blowing cold air.

• In heat mode, if the outdoor temperature is low and humidity is high, the system

may need to defrost for up to 10 minutes before beginning a heating cycle.

• In dry mode, the indoor fan may stop for up to three minutes during the compressor off delay.

• Otherwise, you should contact a qualified service professional for assistance.

2120

DIAGNOSTIC CODES

Troubleshooting

The unit has onboard diagnostics. The outdoor unit will provide status indicators. The indoor

wall unit and remote controller will display error codes. The following is a summary of the

codes with explanation:

Malfunction Name Possible Causes

X-fan Mode

Indoor Evap Coil Temperature

Sensor Malfunction

Gas valve temperature sensor

is open/short circuited

System Configuration

Malfunction

Communication wire error or

electronic expansion valve

malfunction

Wrong connection of communication

wire or malfunction of electronic

expansion valve

System High Pressure

Indoor Anti-Freeze Protection

Low Pressure Protection

Indoor Unit

& Remote

Display

AL

b5

b7

C5

dd

dn

E1

E2

E3

Outdoor Unit Indicators

Yellow

3 flashes

and 1 sec Off

Red

9 flashes

and 1 sec Off

Operation status

1) Loose or bad connection between sensor and control board

2) Indoor Evap Coil temperature sensor damaged

3) Control board malfunction

Hardware malfunction

1) No jumper cap inserted on the control board

2) Incorrect or damaged jumper cap on control board

3) Indoor and outdoor units are not compatible

Operation status

Hardware malfunction

1) Over charged with refrigerant

2) Blocked or dirty outdoor coil

3) Extreme outdoor ambient conditions

1) Low return airflow

2) Indoor fan speed is too low

3) Indoor coil is blocked or dirty

1) Low on refrigerant

2) Pressure sensor is damaged

Compressor High Discharge

Temperature Protection

Overcurrent Protection

Communication Malfunction

Mode conflict (Indoor units

calling for simultaneously

Heating and Cooling)

E4

7 flashes

and 1 sec Off

E5

5 flashes

and 1 sec Off

E6

Continuous

On

E7

Please refer to the malfunction analysis (discharge

temperature, overload) in service manual

1) Supply voltage is unstable

2) Supply voltage is too low and system load is too high

3) Indoor coil is blocked or dirty

1) Communication cable is mis-wired between indoor

and outdoor units

2) Indoor or Outdoor control board malfunction

Operation status

22

DIAGNOSTIC CODES

E8

and 1 sec Off

E9

EE

and 1 sec Off

En

EU

F0

F1

F2

F3

Outdoor Unit Indicators

ellow

Y

6 flashes

11 flashes

ed

R

11 flashes

and 1 sec Off

9 flashes

and 1 sec Off

6 flashes

and 1 sec Off

1) Incorrect refrigerant charge level

2) Refrigerant metering device malfunction

3) Compressor malfunction

1) Indoor coil has not reach minimum heating temperature

2) Indoor ambient is abnormally cold

3) Indoor control board malfunction

Control board malfunction

Outdoor control board malfunction

1) IPM module over heating or malfunctioning

2) Improper voltage at IPM Module

1) refrigerant leak(s)

2) Indoor coil temperature sensor no calibrated

3) Refrigerant flow is restricted ( ex. valve, exv, debris)

1) Loose or bad connection between sensor and control board

2) Indoor ambient temperature sensor damaged

3) Control board malfunction

1) Loose or bad connection between sensor and control board

2) Indoor coil temperature sensor damaged

3) Control board malfunction

1) Loose or bad connection between sensor and control board

2) Outdoor ambient temperature sensor damaged

3) Control board malfunction

alfunction Name Possible Causes

M

High Temperature

Resistant Protection

Cold Air Protection

EEPROM Memory Malfunction

Module Phase Current Protection Frequency Decrease/Limit Mode

Module Temperature Protection Frequency Decrease/Limit Mode

Refrigerant Leakage Protection

Indoor Ambient Temperature

Sensor Malfunction

Indoor Coil Temperature

Sensor Malfunction

Outdoor Ambient Temperature

Sensor Malfunction

Indoor Unit

Display

Outdoor Coil Temperature

Sensor Malfunction

Outdoor Discharge Temperature

Sensor Malfunction

Compressor Overload Protection Frequency Decrease/Limit Mode

Oil Return Protection - Frequency

Decrease/Limit Mode

System Current Overload Protection Frequency Decrease/Limit Mode

High Compressor Discharge

Temperature - Frequency

Decrease/Limit Mode

F4

F5

F6

F7

F8

F9

5 flashes

and 1 sec Off

7 flashes

and 1 sec Off

3 flashes

and 1 sec Off

1 flashes

and 1 sec Off

2 flashes and

1 sec Off

1) Loose or bad connection between sensor and control board

2) Outdoor coil temperature sensor damaged

3) Control board malfunction

1) Loose or bad connection between sensor and control board

2) Discharge temperature sensor damaged

3) Control board malfunction

1) Incorrect refrigerant charge

2) Metering device malfunction

3) Compressor malfunction

Normal function status code only

1) Input voltage too low

2) System pressure too low

1) Cooling load is too great

2) Outdoor ambient temperature too high

3) Refrigerant charge too low

4) Metering device malfunction

23

DIAGNOSTIC CODES

H

F

Fo

and 1 sec Off

H0

H1

H3

and 1 sec Off

6 flashes and

H4

H5

and 1 sec Off

H6

H7

Outdoor Unit Indicators

ellow

Y

17 flashes

8 flashes

1 sec Off

4 flashes

ed

R

flashes

4

nd 1 sec Off

a

) Indoor coil has not reach minimum heating temperature

1

) Indoor ambient is abnormally cold

2

) Indoor control board malfunction

3

Optional Service Mode

1) Incorrect refrigerant charge

2) Metering device malfunction

3) Compressor malfunction

Operation status

1) Wiring terminal OVC-COMP is loose

2) Refer to the malfunction analysis in Service Manual

1) Incorrect refrigerant charge

2) Metering device malfunction

3) Compressor malfunction

1) IPM module over heating

2) Improper or Low voltage at the IPM module

3) IPM module malfunction

1) Loose connections between fan motor and control board

2) Fan motor or blower wheel bearings malfunction

3) Control board malfunction

1) Compressor voltage is not balance

2) Control board malfunction

3) Compressor malfunction

alfunction Name Possible Causes

M

ndoor Coil Freeze Protection -

I

requency Decrease/Limit Mode

F

Pump Down or Gathering

Refrigerant Status

High Indoor Coil Temperature

in Heating- Frequency

Decrease/Limit Mode

Defrost Mode in Heating

Compressor Overload Protection

Compressor Overload Protection

IPM Module Protection

Indoor DC Fan Motor

Malfunction

Compressor De-Synchronized

Malfunction

Indoor Unit

Display

Power Factor Correction (PFC)

Protection

Compressor Demagnetization

Protection

Outdoor Fan Motor

Malfunction

High Input Power Protection

Start-Up Malfunction

Compressor phase-lacking/

phase-inverse protection

14 flashes

HC

and 1 sec Off

HE

L3

L9

9 flashes

and 1 sec Off

LC

Ld

14 flashes

and 1 sec Off

1) Mis-wiring of the reactor filter and PFC capacitor

2) Reactor filter or PFC capacitor malfunction

3) Control board malfunction

Compressor malfunction

1) Loose connections between fan motor and control board

2) Fan motor malfunction

3) Control board malfunction

1) Compressor malfunction

2) Power circuit malfunction

1) Over charged with refrigerant

2) Control board malfunction

3) Compressor malefaction

Hardware malfunction

24

DIAGNOSTIC CODES

isplay

L

ote 1

n

P5

P7

P8

PH

PL

PU

U1

U2

P

Outdoor Unit Indicators

ellow

Y

6 flashes

1

nd 1 sec Off

a

6 flashes

1

and 1 sec Off

13 flashes

and 1 sec Off

12 flashes

and 1 sec Off

R

ed

ndoor and outdoor units are not compatible

I

1) IPM module malfunction

2) Outdoor control board malfunction

3) Compressor malfunction

Outdoor control board malfunction

1) Lack of thermal grease on IPM module

2) Heat sink (radiator) not tightly mounted

3) Control board malfunction

1) Supply voltage on L1 and N is above 265Vac

2) Capacitor on control board malfunction

3) Outdoor control board malfunction

1) Supply voltage on L1 and N is below 150Vac

2) Capacitor on control board malfunction

3) Outdoor control board malfunction

Capacitor malfunction

Outdoor control board malfunction

Unstable supply voltage

Malfunction Name Possible Causes

ncompatible Indoor and

I

utdoor Units

O

efrosting Status

D

Compressor Phase Current

Protection

Module Temperature Sensor

Malfunction

Module Temperature Protection

High DC Bus Voltage Protection

Low DC Bus Voltage Protection

Capacitor Charging Malfunction

Compressor Phase-Current

Detection Malfunction

DC Bus Voltage Level Dropping

Malfunction

Indoor Unit

D

Current Detection Malfunction

Reversing Valve Malfunction

Input Current Detection Malfunction

The four-way valve is abnormal

Zero cross detection circuit

malfunction(for indoor unit)

Zero cross detection malfunction

Notes: 1) During defrosting process, the heating indicator is on for 10s and off for 0.5s.

2) Refer to Service Manual for additional information.

U3

U4

U5

U7

U8

U9

Outdoor control board malfunction

1) Voltage to reversing valve is less than 175V

2) Loose connections between reversing valve and control board

3) Reversing valve solenoid malfunction

Outdoor control board malfunction

Hardware malfunction

Hardware malfunction

Outdoor control board malfunction

25

GREE ELECTRIC APPLIANCES, INC.

www.greecomfort.com

PRODUCT & INSTALLATION RECORD

For your convenience, please record the model and serial numbers of your new equipment in the

spaces provided. This information, along with the installation data and dealer contact information,

will be helpful should your system require maintenance or service.

UNIT INFORMATION

Outdoor Unit:

Model No.

Serial No.

Indoor Unit:

Model No.

Serial No.

INSTALLATION INFORMATION

Date Installed:

DEALERSHIP/INSTALLER INFORMATION

Company Name:

Address:

Phone Number:

Technician Name:

Gree Electric Appliances, Inc ©2016 Cat No: DFS-CASS-HP-2IN v2.0

Loading...

Loading...