Page 1

Page 2

P Contents

PRODUCT.........................................................................................................................1

1 Product List...........................................................................................................................2

2 Nomenclature........................................................................................................................2

3 Specifications.......................................................................................................................3

CONTROL.........................................................................................................................5

1 Wired Controller....................................................................................................................6

2 Remote Controller YAP1F...................................................................................................9

3 Introduction to IDU Functions..........................................................................................10

4 Monitoring Software...........................................................................................................20

INSTALLATION..............................................................................................................63

1 Engineering Installation Preparation and Notice..........................................................64

2 Installation Materials Selection........................................................................................65

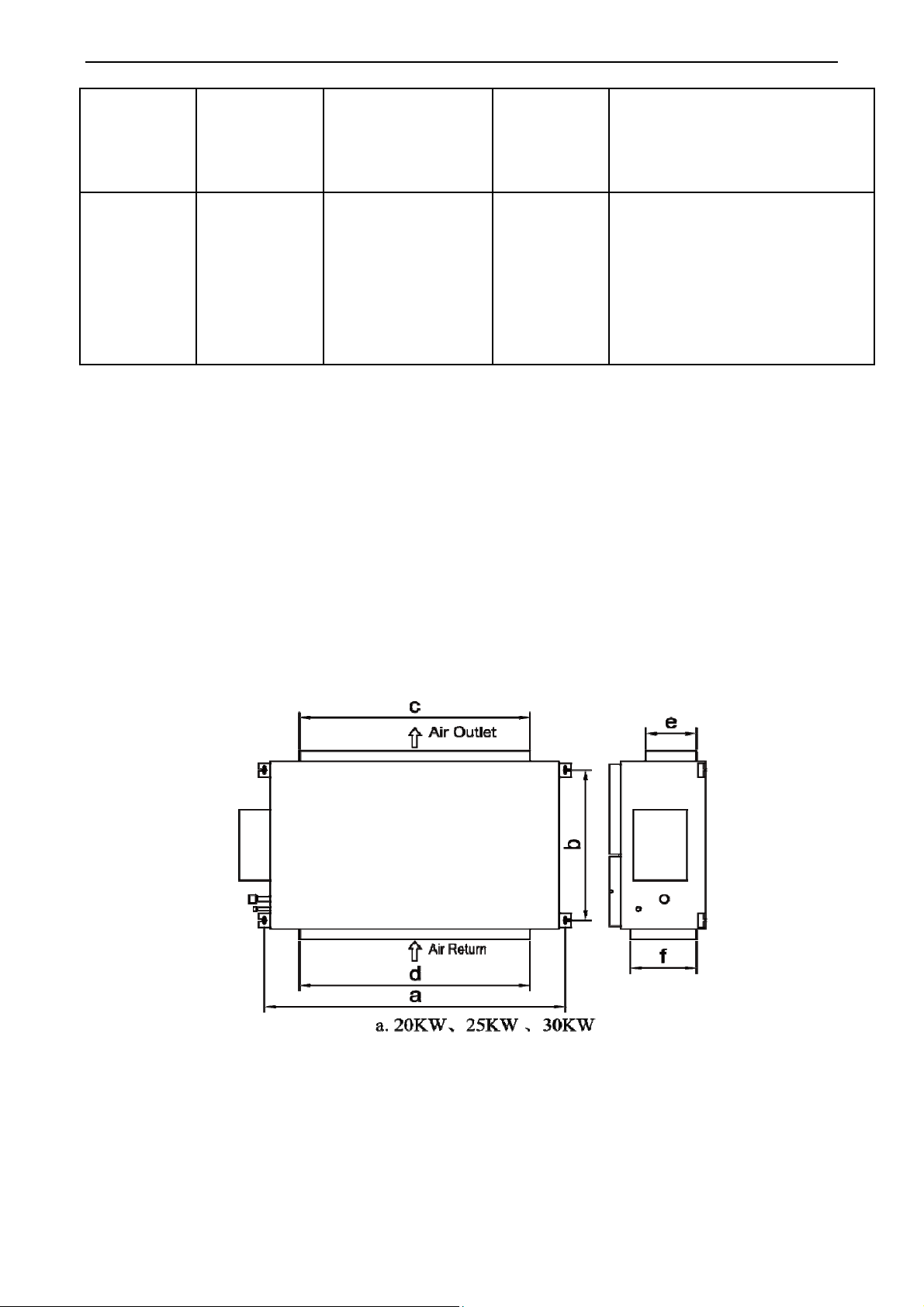

3 Installation of Indoor Unit..................................................................................................67

4 Installation of outdoor unit...............................................................................................71

5 Installation of drain pipe....................................................................................................73

6 Electrical Installation.........................................................................................................76

DEBUGGING & MAINTENANCE..................................................................................78

1 Debugging of Unit..............................................................................................................79

2 Malfunction List..................................................................................................................83

3 Troubleshooting..................................................................................................................85

4 After-sales Emergency Masures....................................................................................104

5 Wiring Diagram.................................................................................................................105

6 Disassembly And Assembly Procedure Of Main Parts..............................................107

7 Exploded Views And Part List........................................................................................109

Page 3

Duct type split Air conditioner Inverter Series

PRODUCT

1

Page 4

Duct type split Air conditioner Inverter Series

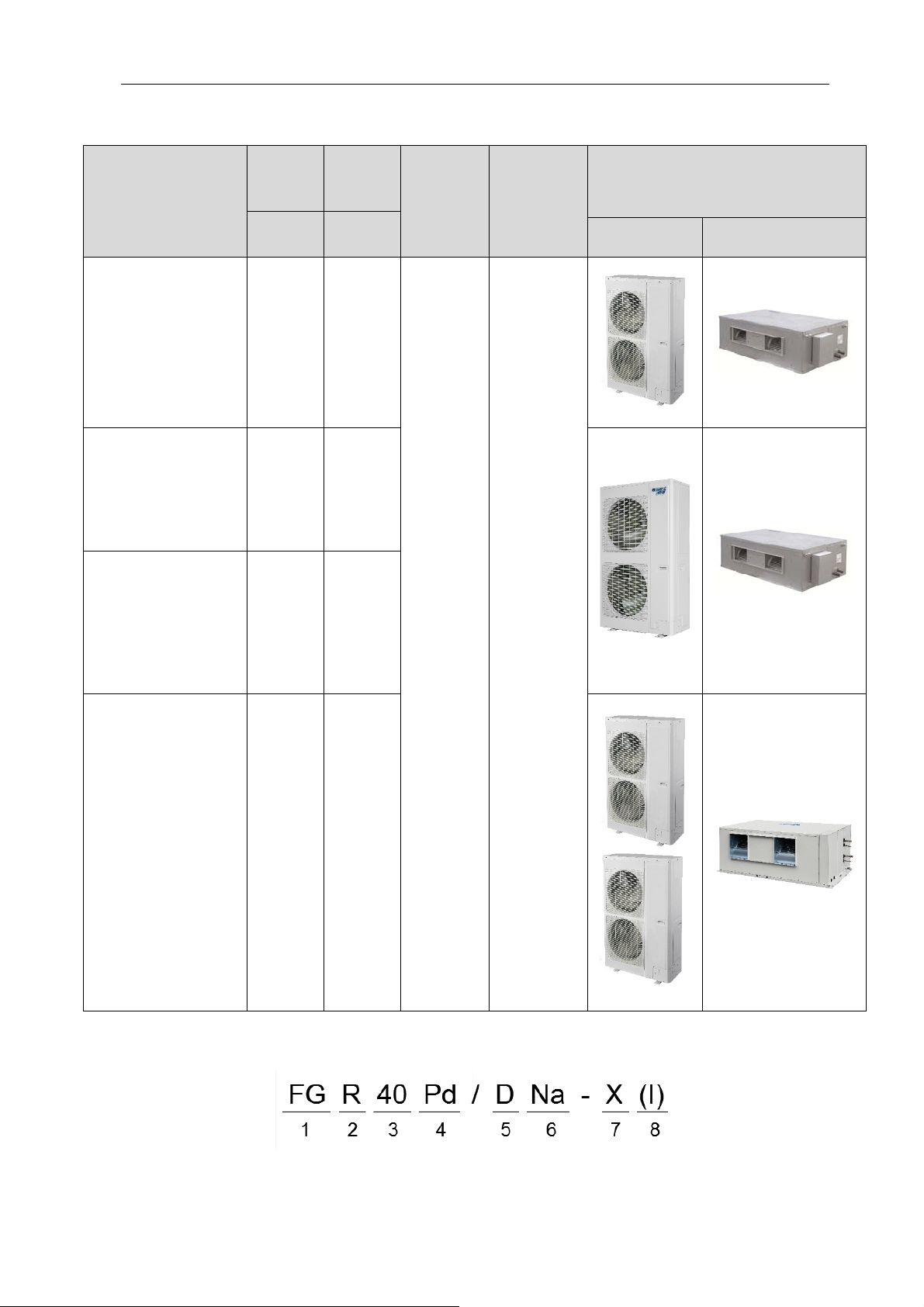

1 Product List

Cooling

Capacity

Model

kW kW

FGR20Pd/DNa-X 20 22

FGR25Pd/DNa-X 25 27.5

FGR30Pd/DNa-X 30 33

Heating

Capacity

3N/380-41

5V/50Hz/

Power

Supply

60Hz

Refrigerant

R410a

Appearance

Outdoor Indoor

FGR40Pd/D(2)Na-X 40 43

2 Nomenclature

2

Page 5

Duct type split Air conditioner Inverter Series

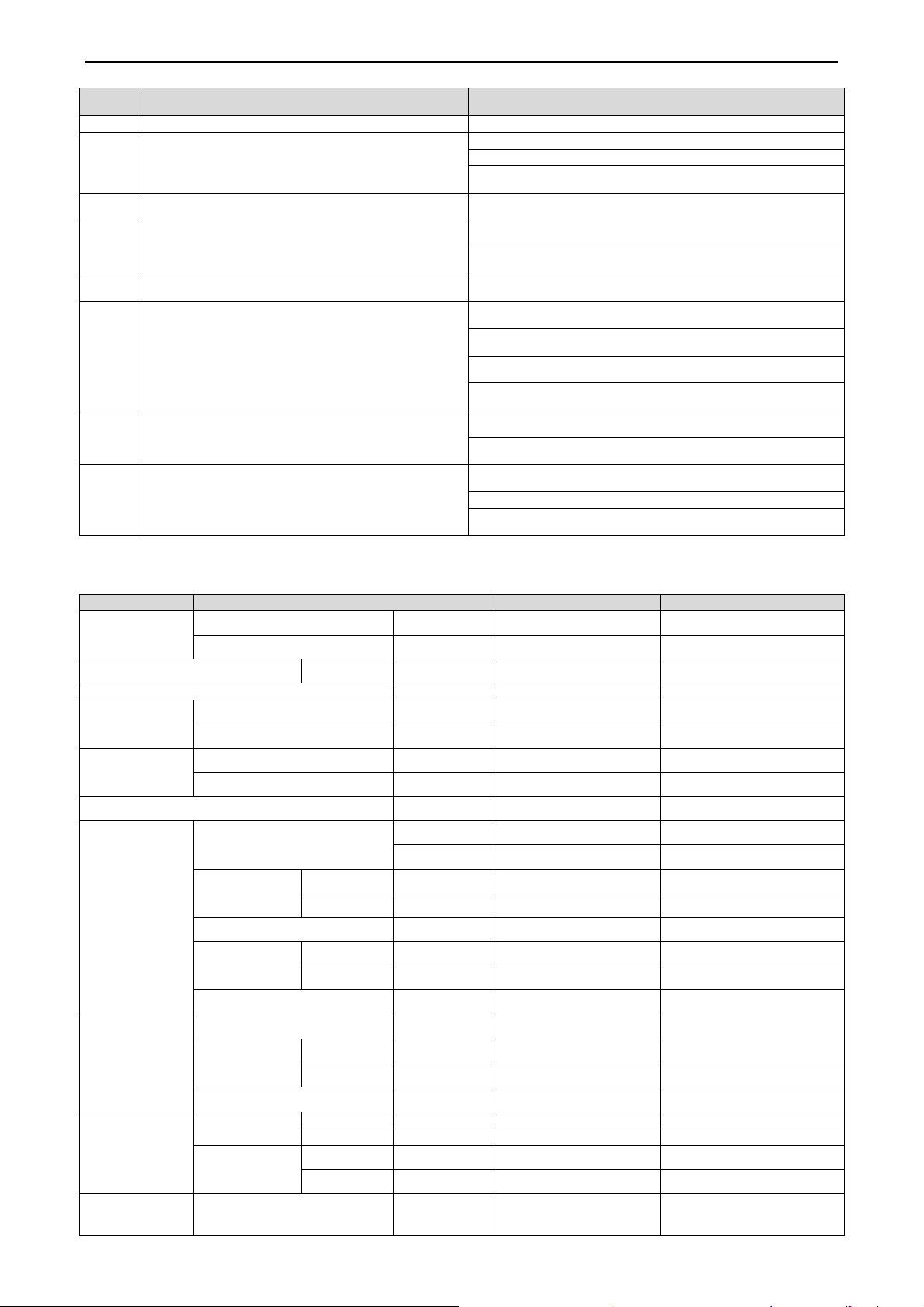

NO. Description Options

1 Ducted Type Air Conditioner -

Cooling only type-omitted

2 Unit type

Auxiliary hot water plate and pipe type-W

3 Cooling capacity Nominal cooling capacity (kW)

Heat pump

4 Frequency conversion system

5 Design No. Arranged based on A, B, C, D,and so on

6 Refrigerant

Others to be applied for when they are used

7 Power type

(The unit to be exported must be expressed)

8 Indoor and outdoor unit code

Fixed frequency-omitted

Frequency conversion-Pd

R22-omitted

R407-N

R410a-Na

380-415V 3Ph~,50/60Hz-X

Outdoor unit-(O)

Indoor unit-(I)

The entire unit is not expressed.

3 Specifications

Model Heat pump FGR20Pd/DNa-X FGR25Pd/DNa-X

Capacity

Power input

Current input

Indoor unit

Outdoor unit

Connection

pipe

Loading

quantity

EER/COP W/W 2.55/3.25 2.65/3.10

Power supply Ph/V/Hz 3N/380-415/(50/60) 3N/380-415/(50/60)

Refrigerant charge volume kg 6.4 8.0

Dimension

(W×D×H)

Net Weight/Gross weight kg 82/104 99/134

Dimension

(W×D×H)

Net Weight/Gross weight kg

diameter

Max. distance

Cooling kW 20 25

Heating kW 22 27.5

Cooling kW 7.8 9.4

Heating kW 6.8 8.9

Cooling A 16.5 18.9

Heating A 14.4 17.2

Airflow volume

ESP

Sound pressure level dB(A) 52 53

Sound pressure level dB(A) 62 63

Outer

20'GP/40'GP/40'HQ set 12/24/24 10/20/22

Rated Pa 120 120

Range Pa 0-250 0-250

Outline mm 1460×790×365 1690×870×440

Package mm 1575×880×385 1785×985×450

Outline mm 940×320×1430 940×460×1615

Package mm 1020×420×1460 1020×560×1645

Liquid Inch(mm) Φ3/8 Φ3/8

Gas Inch(mm) Φ3/4 Φ7/8

Height mm 30 30

Length mm 50 50

CFM

m3/h

2178

3700

120/130

2472

4200

146/162

3

Page 6

Duct type split Air conditioner Inverter Series

Model Heat pump FGR30Pd/DNa-X FGR40Pd/D(2)Na-X

Capacity

EER/COP W/W 2.65/3.20 2.60/3.10

Power input

Current input

Refrigerant charge volume kg 9.5 6.4×2

Indoor unit

Outdoor unit

Cooling kW 30 40

Heating kW 33 43

Power supply Ph/V/Hz 3N/380-415/(50/60) 3N/380-415/(50/60)

Cooling kW 11.3 15.4

Heating kW 10.3 13.9

Cooling A 22.7 27.8

Heating A 20.7 26.4

Airflow volume

ESP

Sound pressure level dB(A) 55 56

Dimension

(W×D×H)

Net Weight/Gross weight kg 105/145

Sound pressure level dB(A) 65 66

Dimension

(W×D×H)

Net Weight/Gross weight kg 175/190

Rated Pa 120 120

Range Pa 0-250 0-250

Outline mm 1690×870×440 1680X900X650

Package mm 1785×985×450 1800X1020X670

Outline mm 940×460×1615 940×320×1430

Package mm 1020×560×1645 1020×420×1460

CFM 3060 4120

m3/h 5200 7000

165/210

(120/130) X2

Outer

Connection

pipe

Loading

quantity

Note:

Specifications may be changed due to product improvement. Please refer to nameplates of the units.

◆

Noise data are collected from a semi-anechoic room. Decibels may be slightly higher in actual operation due to

◆

environmental change.

Above parameters are tested under the condition:high fan speed

◆

Cooling : Indoor air temperature 27°C DB/19°C WB, Outdoor air temperature 35°C DB/24°C WB;

◆

Heating : Indoor air temperature 20°C DB/15°C WB, Outdoor air temperature 7°C DB/6°C WB.

◆

diameter

Max.

distance

20'GP/40'GP/40'HQ set 10/20/22 7/18/18

Liquid Inch(mm) Φ1/2 Φ3/8

Gas Inch(mm) Φ1 Φ3/4

Height mm 30 30

Length mm 50 50

4

Page 7

Duct type split Air conditioner Inverter Series

CONTROL

5

Page 8

Duct type split Air conditioner Inverter Series

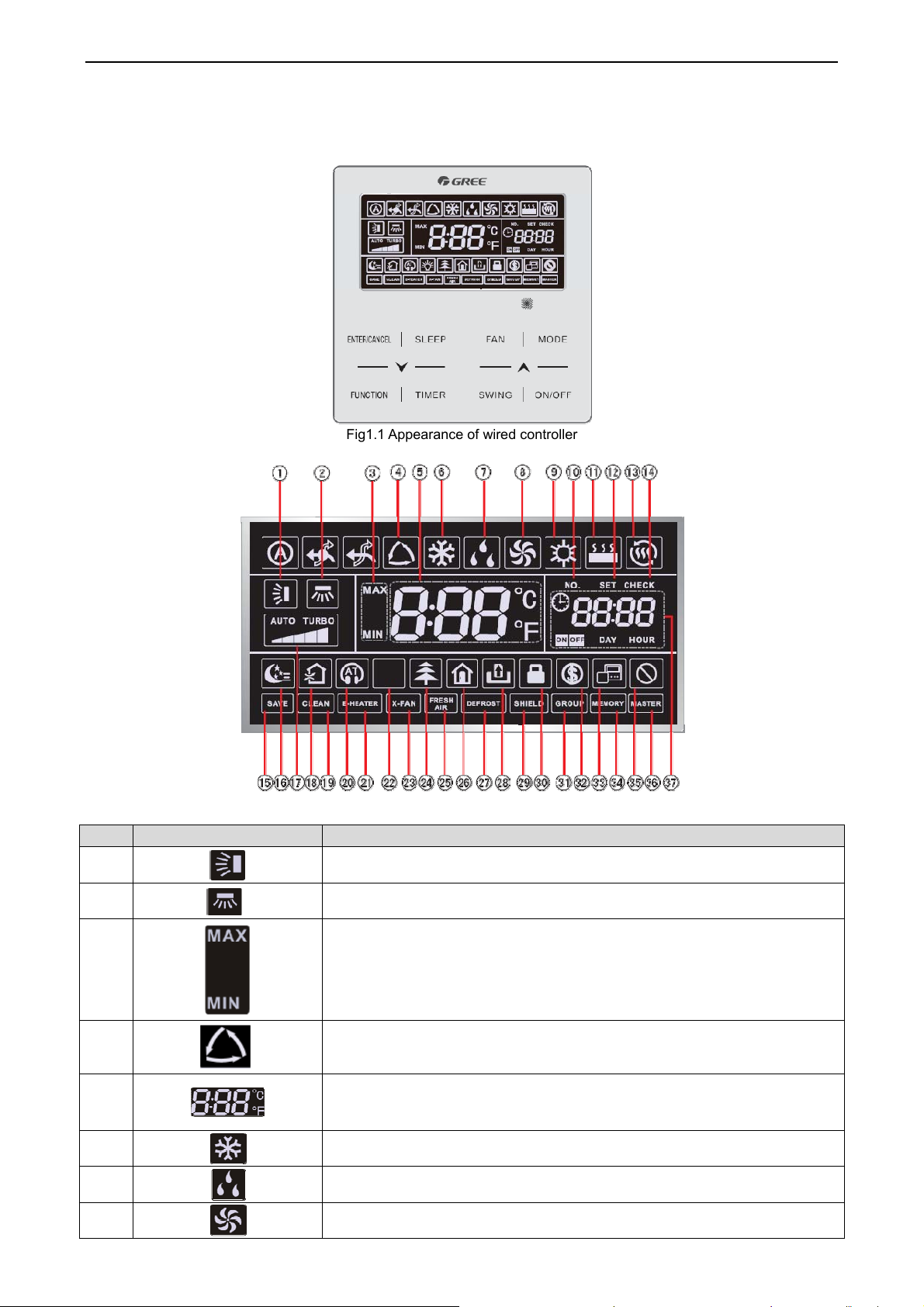

1 Wired Controller

1.1 Control panel

Fig1.1 Appearance of wired controller

Fig1.2 LED graphics of wired controller

Table 1.1 LED display instruction

No. Symbols Instructions

1

Up and down swing function

2

3

4

5

6

7

8

*

*

Left and right swing function

It's valid under Save mode and displays during setting process.

Temperature lower limit for Cooling: Limit the minimum temperature value

under Cooling or Dry mode.

Temperature upper limit for Heating: Limit the maximum temperature value

under Heating, Space Heating or 3D Heating

mode.

Auto mode (Under Auto mode, the indoor units will automatically select their

operating mode as per the temperature

change so as to make the ambient comfortable.)

It shows the setting temperature value(In case the wired controller is controlling

a Fresh Air Indoor Unit, then the

temperature zone will display FAP)

Cooling mode

Dry mode

Fan mode

6

Page 9

Duct type split Air conditioner Inverter Series

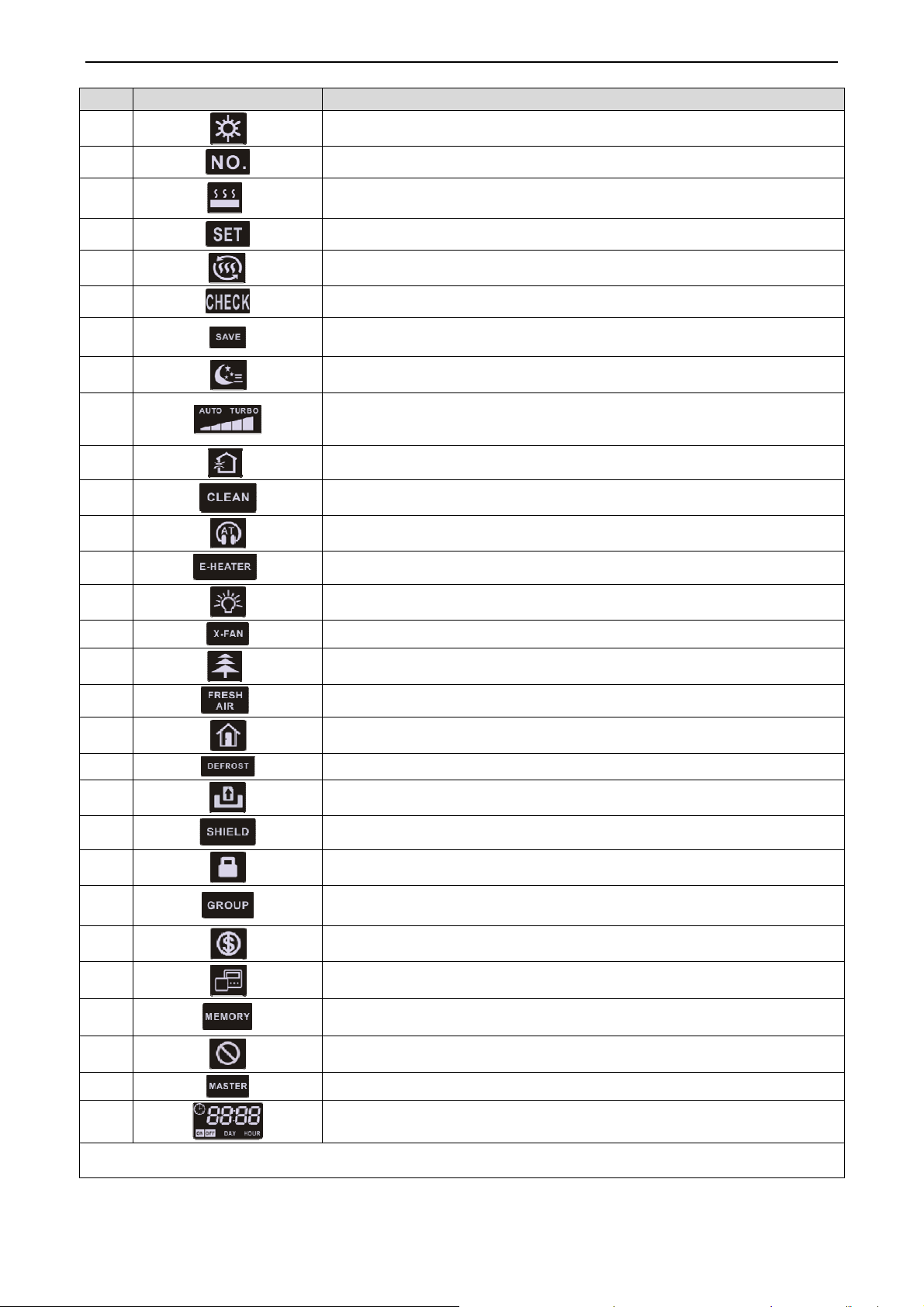

No. Symbols Instructions

9

10

11

12

13

14

15

16

17

18

19

20

21

*

-*

*

*

Heating mode

When inquiring or setting project number of indoor unit, it displays "NO." icon

Floor Heating mode (When Heating and Floor Heating simultaneously shows

up, it indicates 3D Heating is activated.)

Display "SET" icon under parameter setting interface

Space Heating mode

Display "CHECK" icon under parameter view interface

Outdoor unit operates under Save mode/upper limit of system capacitor less

100%/remote Save status

Sleep status

Current set fan speed (including auto, low speed, medium-low speed, medium

speed, medium-high speed, high speed

and turbo seven status)

Air status, Indoor unit optional function

Remind to clean the filter

Quiet status (including Quiet and Auto Quiet two status)

Allow auxiliary electric heating On icon

22

23

24

25

26

27

28

29

30

31

32

33

34

*

*

Light On/Off function

X-fan function

Health function, Indoor unit optional function

Reserved function

Out function

Outdoor unit defrosting status

Gate-control function

Shielding status

Child Lock status

One wired controller controls multiple indoor units

Save status of indoor unit

It indicates the current wired controller is the slave wired controller (address of

wired controller is 02)

Memory status (The indoor unit resumes the original setting state after power

failure and then power recovery)

35

36

37

Note: When wired controller is connected with different indoor units, some functions will be different

Invalid operation

Current wired controller connects master indoor unit

Timer zone:Display system clock and timer status

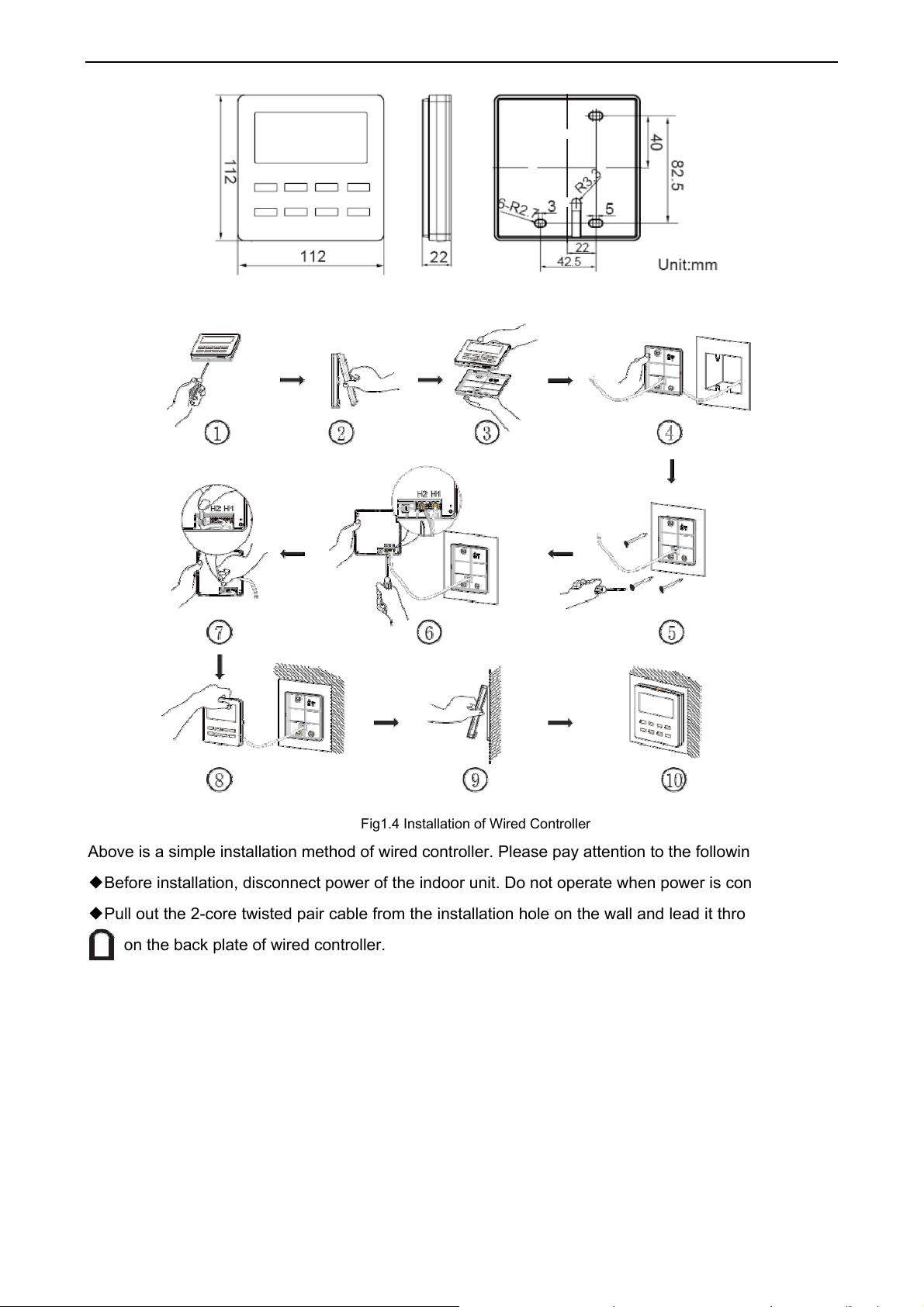

1.2 Installation and removal

1.2.1 Installation dimensions

7

Page 10

Duct type split Air conditioner Inverter Series

1.2.2 Installation method

Fig1.3 Installation dimensions

Fig1.4 Installation of Wired Controller

Above is a simple installation method of wired controller. Please pay attention to the following:

Before installation, disconnect power of the indoor unit. Do not operate when power is connected.

◆

Pull out the 2-core twisted pair cable from the installation hole on the wall and lead it through the hole

◆

on the back plate of wired controller.

Place the wired controller on wall and secure its back plate on

◆

ect the 2-core twisted pair cable to terminal H1 and termi

Conn

◆

Stick the cable in the slot that is left of the terminals and buc

◆

back plate.

Note:

If

caliber of the communication cord is too large, which causes difficulty in leading or sticking the cord

according to above point 2 and point 5, strip some of the sheath of the communication cable to meet the

installation requirement.

wall with screw M4X25.

nal H2. Tighten up the screws.

kle the wired

controller’s panel with its

1.2.3 Removal method

8

Page 11

Duct type split Air conditioner Inverter Series

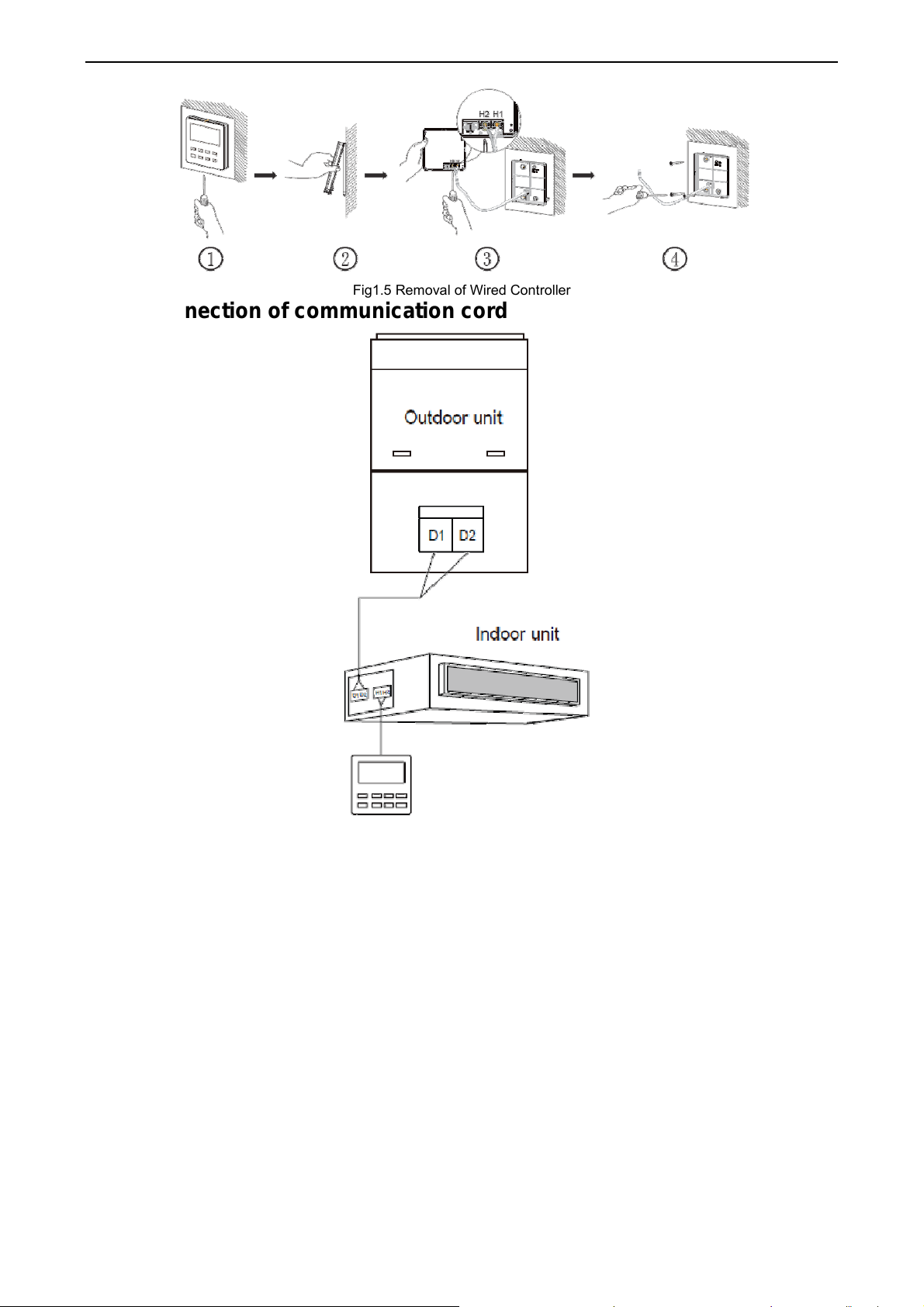

Fig1.5 Removal of Wired Controller

1.2.4 Connection of communication cord

Fig1.6 One wired controller controls one indoor unit

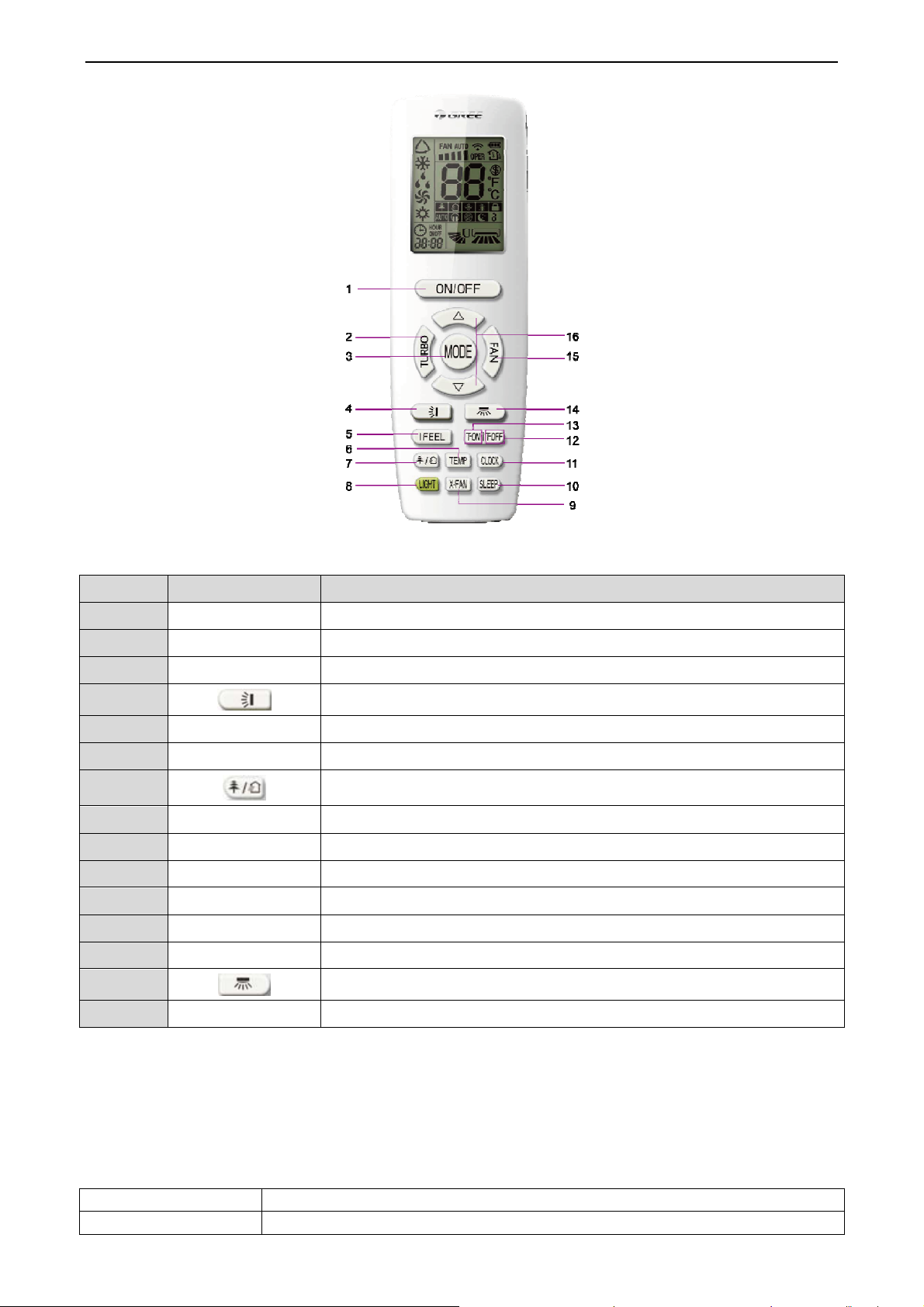

2 Remote Controller YAP1F

9

Page 12

Duct type split Air conditioner Inverter Series

Button name and function introduction

No. Button name Function

1 ON/OFF Turn on or turn off the unit

2 TURBO Set turbo function

3 MODE Set operation mode

4 Set up&down swing status

5 I FEEL Set I FEEL function

6 TEMP Switch temperature displaying type on the unit’s display

7 Set health function and air function

8 LIGHT Set light function

9 X-FAN Set X-FAN function

10 SLEEP Set sleep function

11 CLOCK Set clock of the system

12 TOFF Set timer off function

13 TON Set timer on function

14 Set left&right swing status

15 FAN Set fan speed

3 Introduction to IDU Functions

Indoor unit functions cover user operation functions and engineering application functions. For user

operation functions, refer to wired controller and remote controller.

Engineering application functions include:

SN Function Name

1 User parameter query

10

Page 13

Duct type split Air conditioner Inverter Series

2 User parameter settings

3 Engineering parameter query

4 Engineering parameter settings

Engineering application functions can be operated through the IDU wired controller(XK46).

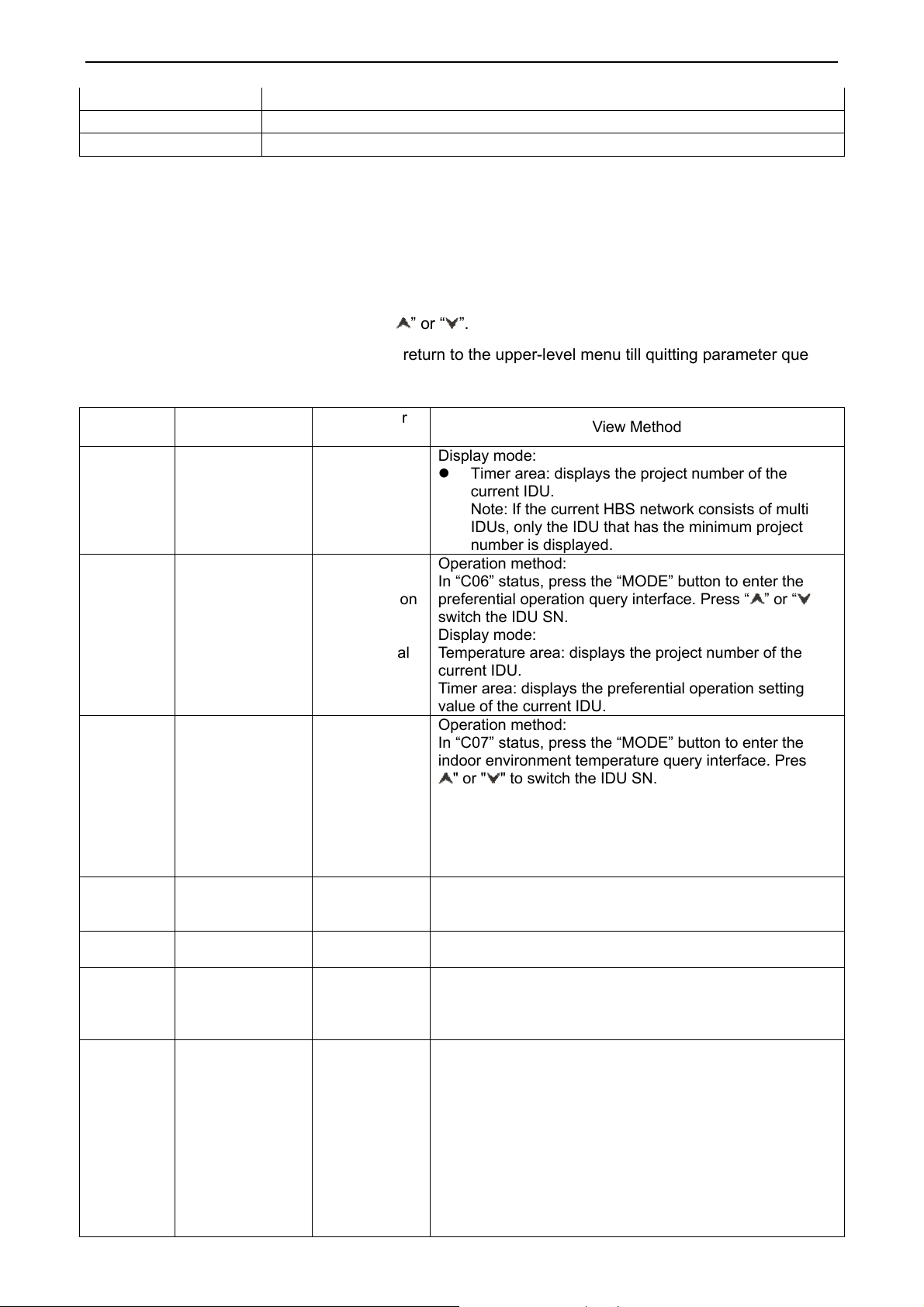

3.1 User Parameter Query

User parameters can be queried in power-on or power-off status.

(1) Press and hold the “FUNCTION” button for five seconds to enter the user parameter query interface.

The temperature area displays “C00” and “V

Select a parameter code by pressing “ ” or “ ”

(2)

Press the “ENTER/CANCEL” button to return to the upper-level menu till quitting parameter query.

(3)

iew” is on.

.

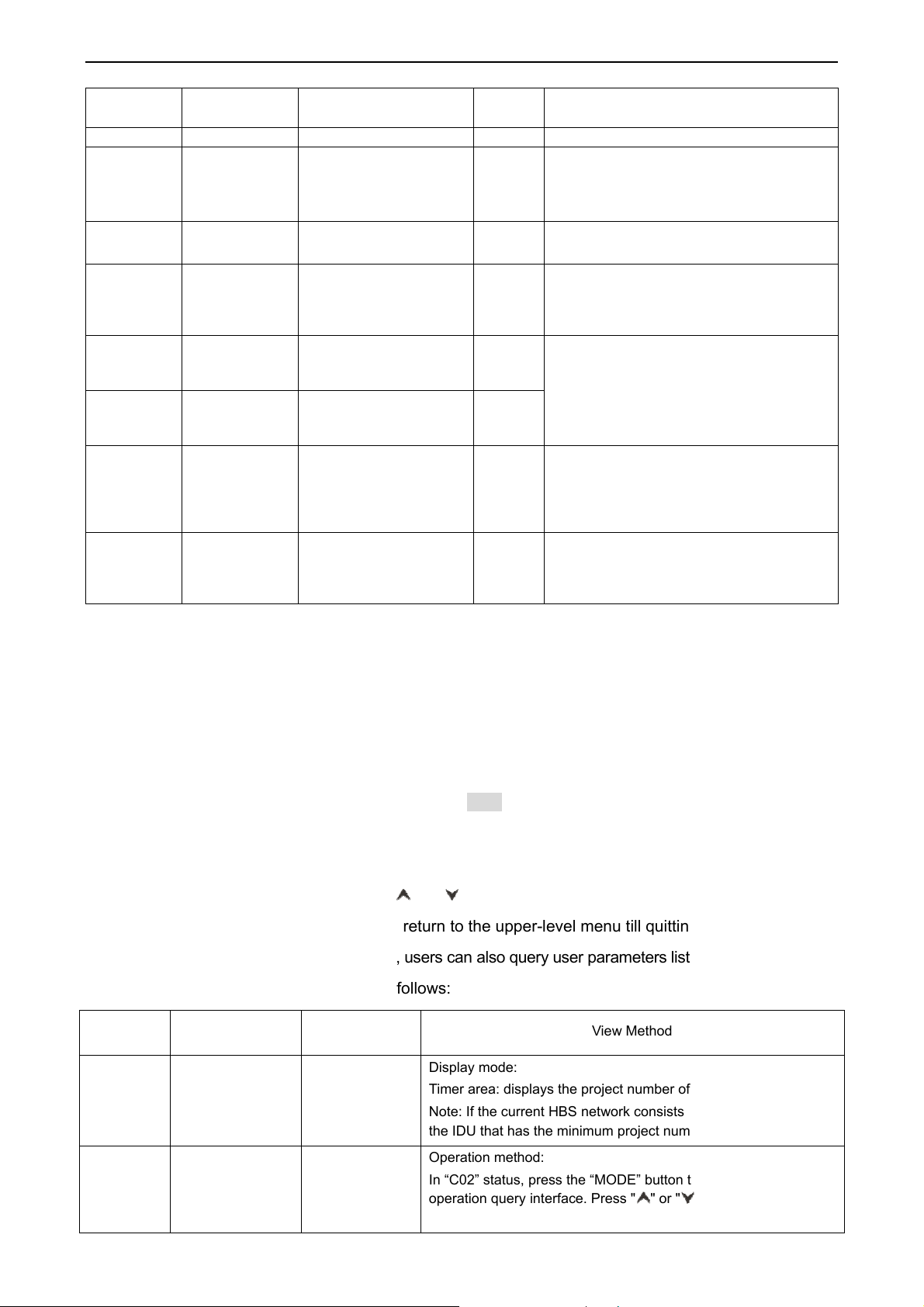

The user parameter query list is as follows:

Parameter

Code

C00

C06

C07

C08

C09

C12

C17

Parameter Name

Parameter

setting ingress

Preferential

operation query

Indoor

environment

temperature

query

Prompt time

query for air filter

cleaning

Wired controller

adress query

Outdoor

environment

temperature

query

Indoor relative

humidity query

Parameter

Range

Display mode:

Timer area: displays the project numbe

-

00: common

operation

01:

preferential

operation

-9 to 99

4-416: days Timer area: displays the prompt time for air filter cleaning.

01, 02

-9 to 99

20-90

current IDU.

Note: If the current HBS network consists of multiple

IDUs, only the IDU that has the minimum project

number is displayed.

Operation method:

In “C06” status, press the “MODE” button to enter the

preferential operation query interface. Press “ ” or “ ” to

switch the IDU SN.

Display mode:

Temperature area: displays the project number of the

current IDU.

Timer area: displays the preferential operation setting

value of the current IDU.

Operation me

In “C07” status, press the “MODE” button to enter the

indoor environment temperature query interface. Press "

" or " " to switch the IDU SN.

Display mode:

Temperature area: displays the project number of the

current IDU.

Timer area: displays the temperature value of the indoor

environment temperature sensor after replenishment.

Timer area: displays the adress of the current wired

controller.

Timer area: displays the temperature value of the

environment temperature sensor of the master ODU.

Operation method:

In “C17” status, press the “MODE” button to enter the

indoor relative humidity query interface. Press “▲” or “▼”

to switch the IDU SN.

Display mode:

Temperature area: displays the relative humidity value.

Timer area: displays the project number of IDU (project

numberes are arranged from small to large).

If the HBS network consists of only one IDU, the timer

area directly displays the IDU relative humidity value in

the “C17” interface.

thod:

View Method

r of the

11

Page 14

Duct type split Air conditioner Inverter Series

Note:

In parameter query status, "FAN", “TIMER”, "SLEEP", and "SWING" are invalid. By pressing the

“ON/OFF” button, users can return to the main interface but not power on/off the unit.

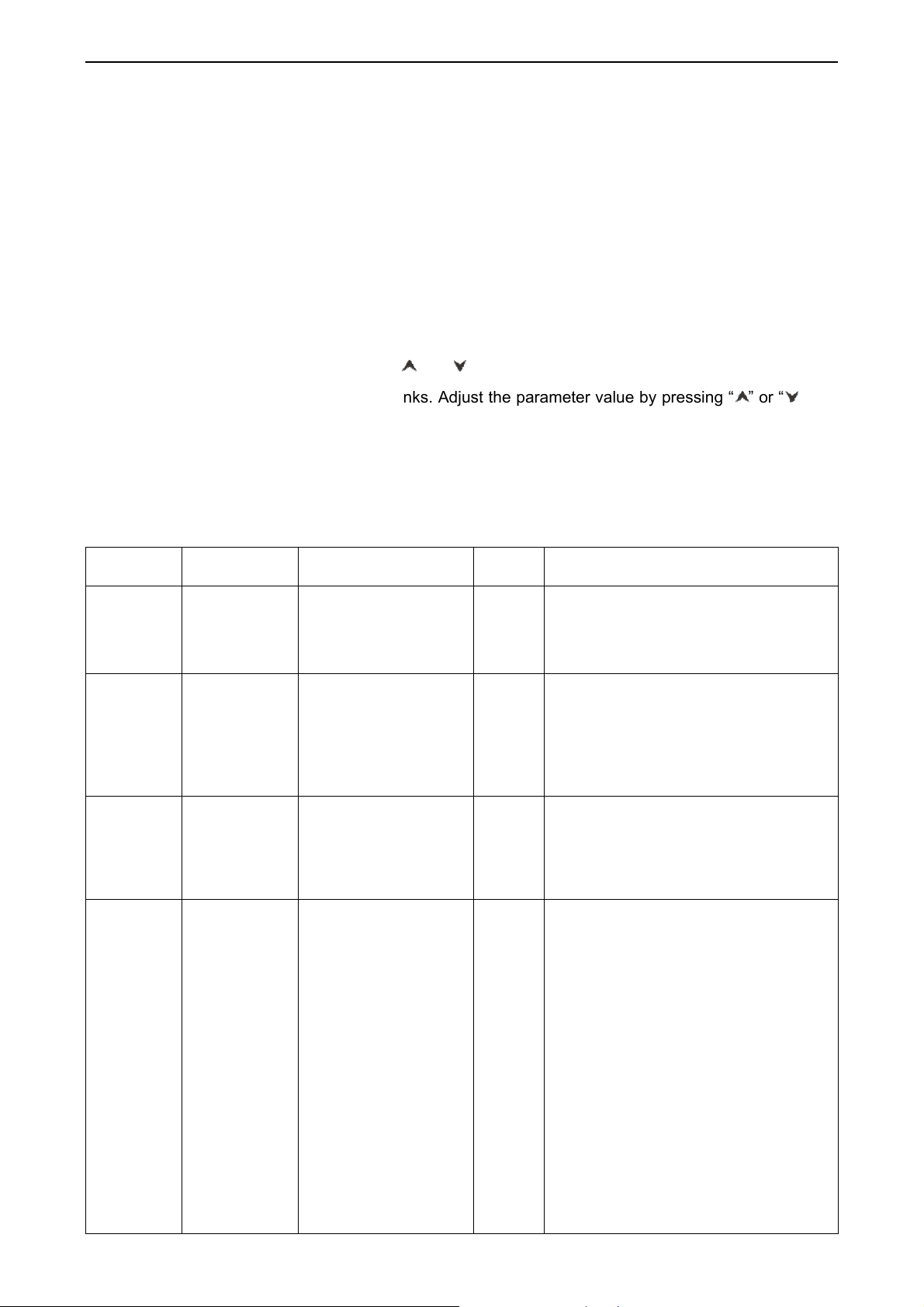

3.2 User Parameter Settings

User parameters can be set in power-on or power-off status.

(1) Press and hold the “FUNCTION” button for five seconds. The temperature area displays “C00”.

Press and hold the “FUNCTION” button for another five seconds to enter the wired controller

parameter setting interface. The temperature area

displays “P00”.

(2) Select a parameter code by pressing “ ” or “ ”. Press the “MODE” button to switch to parameter

value settings. The parameter value blinks. Adjust the parameter value by pressing “ ” or “ ” and

then press the “ENTER/CANCEL”

(3)

Press the “ENTER/CANCEL” button to return to the upper-level menu till quitting parameter

button to complete settings.

settings.

(4) The user parameter setting list is as

Parameter

Code

P10

P11

P13

P30

Parameter

Name

Master IDU

settings

Infrared

connection

settings of

wired controller

Wired controller

address

settings

Static pressure

settings for

indoor fan

Parameter Range

00: does not change the

master/slave status of the

01: sets the current IDU

01: master wired

02: slave wired controller

Type 1: 03.04.05.06.07

01.02.03.04.05.06.07.08.

follows:

current IDU

to master IDU

00: disabled

01: enabled

controller

Type 2:

09

Default

Val ue

00

01

01

05

Remark

After the IDU connected

with the current wired controller is

successfully set to master IDU, "MASTER"

on the wired controller is on.

This setting can only be enabled through the

master wired controller.

When the infrared remote receiving function

of the wired controller is disabled, neither the

master nor slave wired controller can receive

remote signals. The wired controllers can

only be operated by pressing.

When two wired controllers simultaneously

control one IDU, the two wired controllers

should use different addresses. The slave

wired controller (address: 02) does not have

the unit parameter setting function except its

own address settings.

After identifying the IDU type, the wired

controller only displays the available

static pressure levels.

The static pressure levels fall into

1)

levels

and nine levels for VRF IDUs. T

w

ired controller only displays t

pressur

identified IDU t

2) W

w

levels, the

adj

accord

princi

receiv

control

monitori

rang

3)Duri

setting val

e levels matched with t

ype.

hen the HBS network co

ith both five and nine static pr

wired controller displays ni

ustable static pressure leve

ing to the maximum co

ple. If the static pressure

ed by the IDU from the wi

ler, remote controller

ng system exceed the

e, the limit value prevai

ng power-on and synchroniza

ue of static pressure

five

he

he static

he

nsists of IDUs

essure

ne

ls

ntrol

levels

red

, or remote

setting

ls.

tion, the

levels is

12

Page 15

Duct type split Air conditioner Inverter Series

Parameter

Code

P31

P33

P34

P37

P38

P43

P46

Parameter

Name

High-ceiling

installation

Timer function

settings

Repeating

validity for

time-point

timing

Cooling setting

temperature in

automatic mode

Heating setting

temperature in

automatic mode

Preferential

operation

settings

Accumulated

time clearing for

air filter

cleaning

Parameter Range

00: standard-ceiling

installation height

01: high-ceiling

installation height

00: common timing

01: time-point timing

00: single timing

01: repeated everyday

17°C -30°C 25

16°C -29°C 20

00: common operation

01: preferential operation

00: not cleared

01: cleared

Default

Val ue

00

00

00

00

00

Remark

determined by settings of the IDU.

This setting is valid only when the timer

function is set to time-point timing.

Cooling setting temperature – heating setting

temperature ≥ 1.

Note: The two settings are still valid in

remote shielding status.

When power supply is insufficient, users are

allowed to power on/off the IDU set with

preferential operation and other IDUs are

forcibly powered off. A fault code is displayed

on the IDU that is forcibly powered off.

Note:

In parameter setting status, "FAN", “TIMER”, "SLEEP", and "SWING" are invalid. By pressing the

“ON/OFF” button, users can return to the main interface but not power on/off the unit.

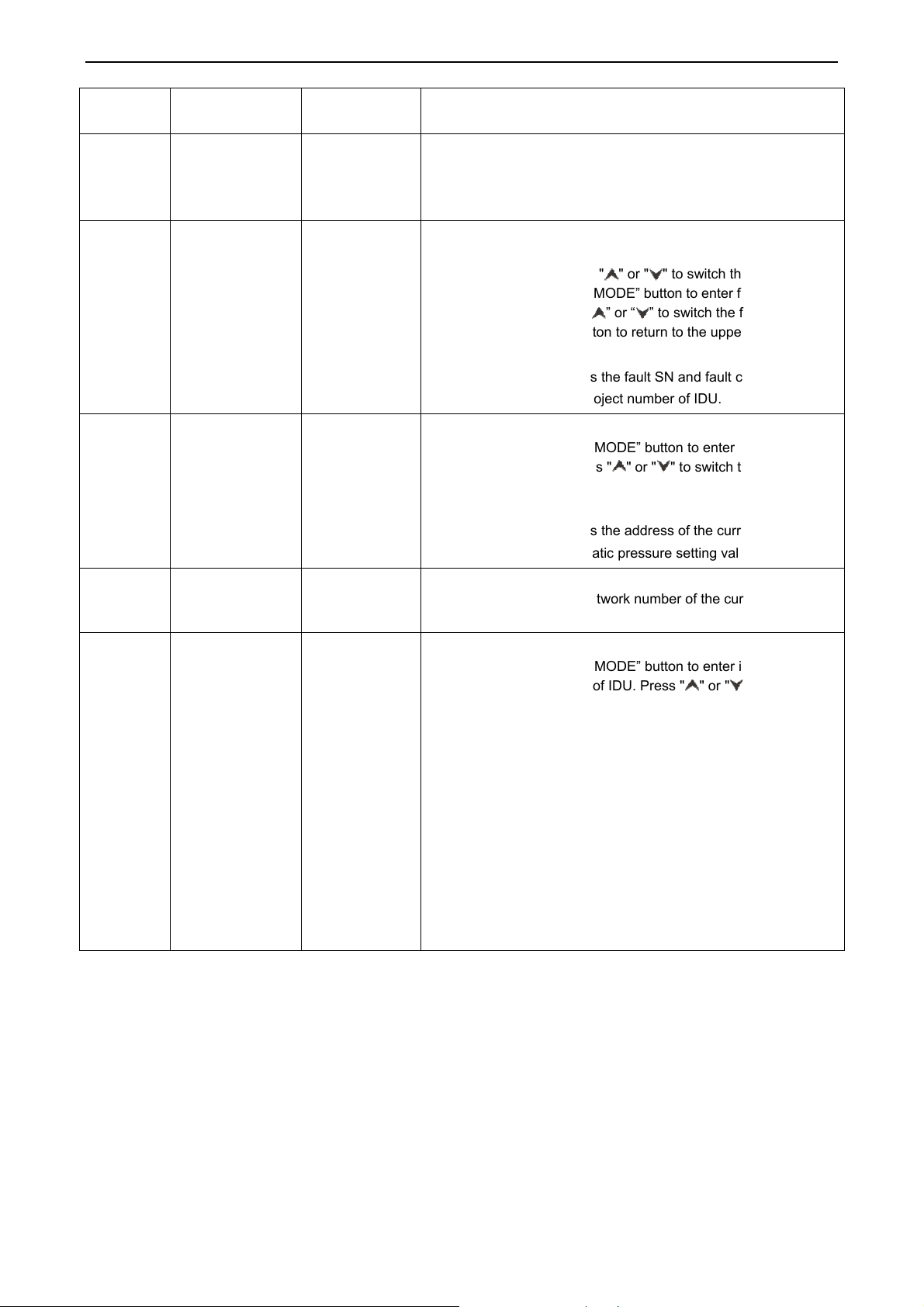

3.3 Engineering Parameter Query

Engineering parameters can be queried in power-on or power-off status.

Press and hold the “FUNCTION” button for five seconds to enter the engineering parameter query

interface. The temperature area displays “C00” and “View” is on.

(1) Within five seconds after “C00” is displayed, continuously press the “MODE” button for three times in

an interval less than one second to enter engineering parameter query.

(2) Select a parameter code by pressing “ ” or “ ”

Press the “ENTER/CANCEL” button to return to the upper-level menu till quitting parameter query.

(3)

In the engineering parameter query interface, users can also query user parameters listed in Table 3.1.

The engineering parameter query list is as

Parameter

Code

C00

C02

Parameter Name

Parameter setting

ingress (default)

Indoor unit

capacity query

Parameter

Range

follows:

-

-

.

View Method

Display mode:

Timer area: displays the project number of the current IDU.

Note: If the current HBS network consists of multiple IDUs, only

the IDU that has the minimum project number is displayed.

Operation method:

In “C02” status, press the “MODE” button to enter the preferential

operation query interface. Press " " or " " to switch the project

number of IDU.

13

Page 16

Duct type split Air conditioner Inverter Series

Parameter

Code

C05

C10

C13

C14

Parameter Name

Historical fault

query ingress of

IDU

Static pressure

setting query of

ODU

Outdoor unit

network number

query

Temperature

query for

inlet-tube

temperature

sensor of IDU

Parameter

Range

Display mode:

Temperature area: displays the project number of the current IDU.

Timer area: displays the current IDU capacity/IDU capacity after

adjustment.

Operation method:

1. In “C05” status, press the “MO

fault quer

Five historical

faults

00: 0 Pa

20: 20 Pa

50: 50 Pa

82: 82 Pa

1-255 Timer area: displays the network number of the current ODU.

-9 to 99

numb

of the current IDU. Press “

the “ENTER/CANCEL” button to return to the upper-level menu.

Display mode:

Temperature area: displays the fault SN and fault code.

Timer area: displays the project number of IDU.

Operation method:

In “C10” status, press the “MODE” button to enter static pressure

setting query of ODU. Press " " or " " to switch the ODU

address.

Display mode:

Temperature area: displays the address of the current ODU.

Timer area: displays the static pressure setting value.

O

peration method:

In “C14” status, press the “MODE” button to enter inlet-tube

temperature sensor query of IDU. Press " " or " " to switch the

IDU SN.

Display mode:

Temperature area: displays the project number of the current IDU.

Timer area: displays the temperature value.

If the HBS network consists of only one IDU, the timer area

directly displays the temperature value in the “C14” interface.

No matter Fahrenheit or Centigrade remote signals are received,

the temperature is displayed in Centigrade.

When the wired controller displays the inlet-tube temperature after

receiving signals from the remote controller, the inlet-tube

temperature of the IDU that has the minimum project number in the

HBS network is displayed by default.

y interface. Press " " or " " to switch the proj

er of IDU. Press the “MODE” button to enter fault code quer

View Method

DE” button to enter the hist

” or “ ” to switch th

e fault SN. Press

orical

ect

y

14

Page 17

Duct type split Air conditioner Inverter Series

Parameter

Code

C15

C16

n2

Parameter Name

Temperature

query for outlet

temperature

sensor of IDU

Opening degrees

query of electronic

expansion valve

of IDU

Capacity

configuration ratio

upper-limit of

outdoor/IDU

Parameter

Range

-9 to 99

0-20

35: 135%

50: 150%

View Method

O

peration method:

In “C15” status, press the “MODE” button to enter outlet

temperature sensor query of IDU. Press " " or " " to switch the

IDU SN.

Display mode:

Temperature area: displays the project number of the current IDU.

Timer area: displays the temperature value.

If the HBS network consists of only one IDU, the timer area

directly displays the temperature value in the "C14" interface.

No matter Fahrenheit or Centigrade remote signals are received,

the temperature is displayed in Centigrade.

When the wired controller displays the inlet-tube temperature after

receiving signals from the remote controller, the inlet-tube

temperature of the IDU that has the minimum project number in the

HBS network is displayed by default.

Operation method:

In “C16” status, press the “MODE” button to enter electronic

expansion valve opening degree query of IDU. Press " " or " "

to switch the IDU SN.

Display mode:

Temperature area: displays the project number of the current IDU.

Timer area: displays the opening degree value.

If the HBS network consists of only one IDU, the timer area

directly displays the opening degree value of electronic expansion

valve in the “C16” interface.

When the wired controller displays the opening degree of

electronic expansion valve after receiving signals from the remote

controller, the opening degree of electronic expansion valve of the

IDU that has the minimum project number in the HBS network is

displayed by default.

Temperature area: displays the parameter code.

Timer area: displays the setting value of capacity configuration

ratio of the current outdoor/IDU.

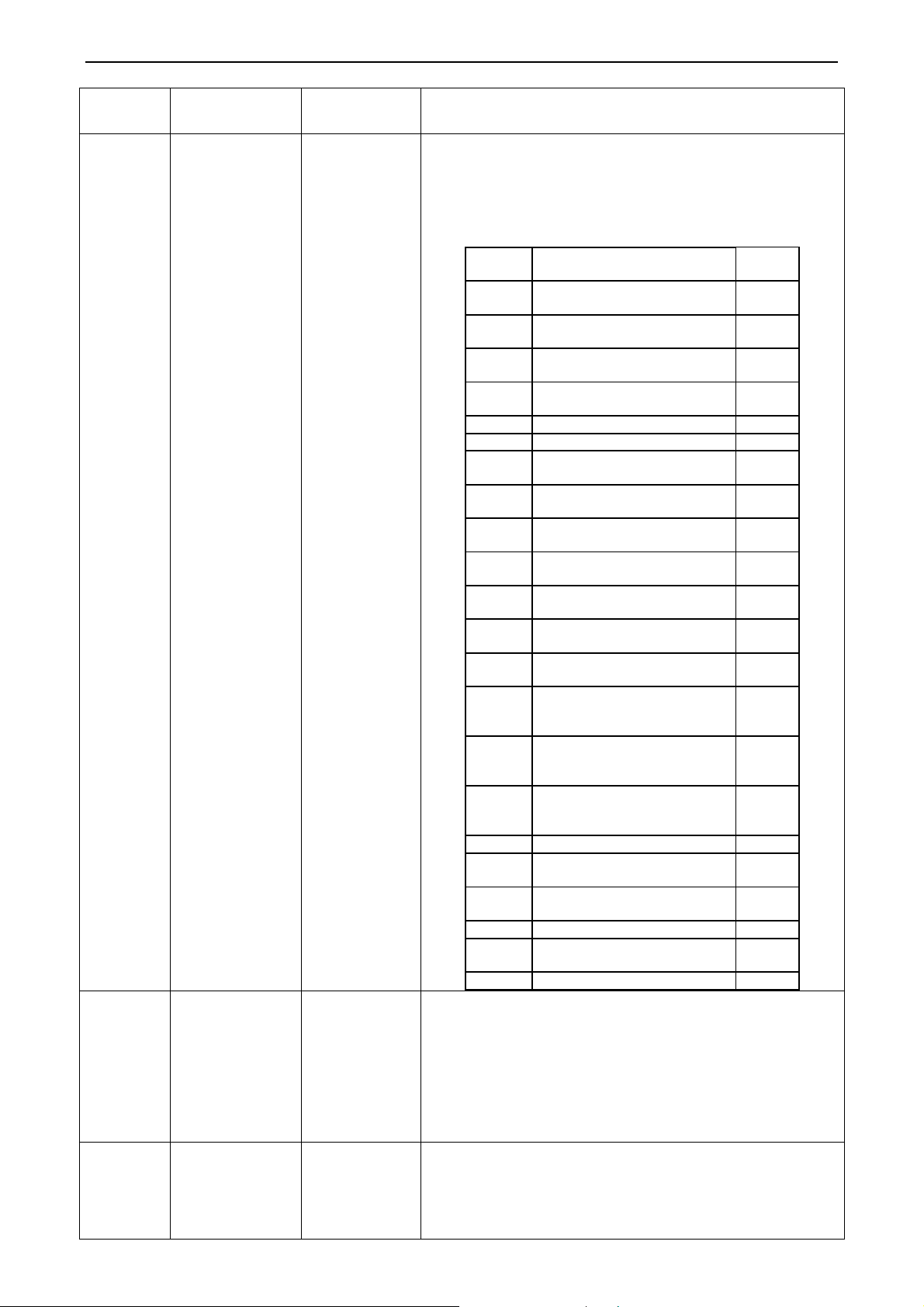

n6

n7

Historical fault

query ingress of

ODU

Parameter query

ingress of ODU

Five historical

faults

01-13

25-29

Operation method:

In “n6” status, press the “MODE” button to enter fault code query

of ODU (when a wired controller controls multiple IDUs, only the

faults memorized by the IDU that has the minimum project number

can be queried). Press “ ” or “ ” to switch the fault SN. Press

the “ENTER/CANCEL” button to return to the upper-level menu.

Display mode:

Temperature area: displays the fault SN and fault code from left to

right (1-5, faults are arranged from the earliest to the latest).

Timer area: displays the project number of the ODU.

Operation method (n7 query is not supported for the slave wired

controller):

In “n7” status, the timer area is not displayed. Press the “MODE”

button to enter parameter query of ODU. The first bit in the

temperature area (display bit of the ODU module ID) blinks. Press

“▲” or “▼” to switch the ODU module ID. Press the “MODE”

button to select an ODU module. In this case, the first bit in the

temperature area stops blinking, and the second and third bits in

the temperature area display the parameter code. The timer area

15

Page 18

Duct type split Air conditioner Inverter Series

Parameter

Code

A6

nb

Parameter Name

Unit

cooling/heating

function

Bar code query of

IDU

Parameter

Range

nA:

cooling/heating

nC:

single-cooling

nH:

single-heating

nF: air supply

0-9, A-Z, a-z, -

View Method

displays a corresponding parameter value. Press “▲” or “▼” to

switch the parameter code and press the “ENTER/CANCEL”

button to return to the upper-level menu.

Display mode:

Temperature area: displays the ODU module ID and parameter

code from left to right.

Timer area: displays a corresponding parameter value to the right.

Parameter

Code

01

02

03

04

05 Module high-pressure °C

06 Module low-pressure °C

07

08

09

10

11

12

13

25

(Actual value = Displayed value *

26

(Actual value = Displayed value *

27

(Actual value = Displayed value *

28 Defrosting temperature °C

29

30

31 Oil return temperature °C

32

33 Outlet temperature of condenser °C

Temperature area: displays the parameter code.

Timer area: displays the cooling/heating function setting value of

the current unit.

Operation method (nb query is not supported for the slave wired

controller):

In “nb” status, the timer area is not displayed. Press the “MODE”

button to enter bar code query. The temperature area displays

“nb” and the project number in the timer area blinks. Press “▲” or

Parameter Name Unit

Outdoor environment

temperature

Operation frequency of

compressor 1

Operation frequency of

compressor 2

Operation frequency of outdoor

fan

Discharge temperature of

compressor 1

Discharge temperature of

compressor 2

Discharge temperature of

compressor 3

Discharge temperature of

compressor 4

Discharge temperature of

compressor 5

Discharge temperature of

compressor 6

Operation frequency of

compressor 3

Outdoor unit heating EXV1

10)

Outdoor unit heating EXV2

10)

Subcooler EXV

10)

Liquid-extracting temperature of

subcooler

Outlet temperature of

accumulator

Inlet-tube temperature of

condenser

°C

Hz

Hz

Hz

°C

°C

°C

°C

°C

°C

Hz

PLS

PLS

PLS

°C

°C

°C

16

Page 19

Duct type split Air conditioner Inverter Series

Parameter

Code

Parameter Name

Parameter

Range

View Method

“▼” to switch the project number of IDU.

Press the “MODE” button to select an IDU. The temperature area

displays “Un” and the timer area displays “-n”. Press “▲” or “▼” to

display the entire-unit bar code and controller bar code of IDU.

Press the “ENTER/CANCEL” button to return to the upper-level

menu. The temperature area displays “nb” and the timer area

displays the project number of the queried IDU. Press the

“ENTER/CANCEL” button again to return to the upper-level menu.

Display mode:

Temperature area: displays nb/Un/Pc/bar code.

Timer area: displays -n/project number/bar code.

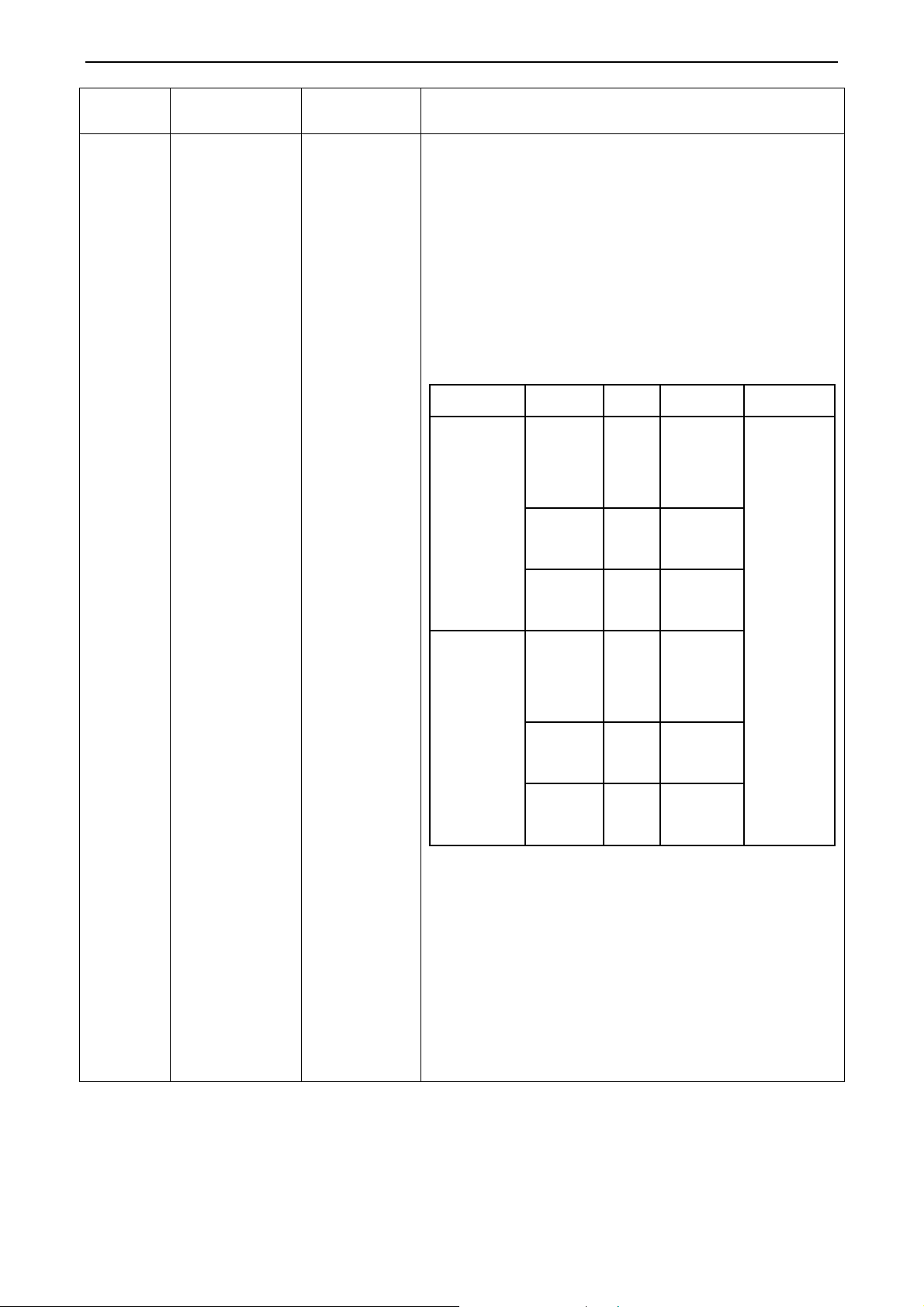

The following is an example:

Example

Entire-init bar

code of IDU

N1r0128150066

Controller bar

code of IDU

N1r0128150067

Temperature

Area

Un (to the

right)

N1r 0128

150 066

Pc -n

N1r 0128

150 067

Timer

Area

-n

(in the

middle)

Remark 1 Remark 2

indicates

It

that the

following is

the entire-unit

bar code of

IDU.

indicates

It

the former

seven bits of

the bar code.

indicates

It

the latter six

bits of the bar

code.

It

indicates

that the

following is

the controller

bar code of

IDU.

indicates

It

the former

seven bits of

the bar code.

It

indicates

the latter six

bits of the bar

code.

Press “▼” to

display

downward and

press “▲” to

display

upward.

Note:

1. Un indicates the entire-unit bar code of IDU and Pc indicates

the controller bar code of IDU.

2. When there is only one IDU, press the “MODE” button in “nb”

status to enter bar code query without selecting the project

number of IDU.

3. The system quits the query status if no operations are

performed in 60 seconds.

4. The bar code query starts from the entire-unit bar code of IDU

and ends at the controller bar code of IDU without circulation. That

is, the query does not start again even if users press “▼”.

Note:

In parameter query status, "FAN", “TIMER”, "SLEEP", and "SWING" are invalid. By pressing the

“ON/OFF” button, users can return to the main interface but not power on/off the unit.

3.4 Engineering Parameter Settings

Engineering parameters can be set in power-on or power-off status.

17

Page 20

Duct type split Air conditioner Inverter Series

(1) Press and hold the “FUNCTION” button for five seconds. The temperature area displays “C00”.

Continuously press the “MODE” button for

“FUNCTION” button for

temperature

Select a parameter code by pressing “ ” or “ ”. Press the “MODE” button to switch to parameter

(2)

area displa

five seconds to enter the engineering paramete

ys “P00”.

three times, and then press and hold the

r setting interface. The

value settings. The parameter value blinks. Adjust the parameter value by pressing “ ” or “ ” and

then press the “ENTER/CANCEL”

(3)

Press the “ENTER/CANCEL” button to return to the upper-level menu till quitting parameter

button to complete settings.

settings.

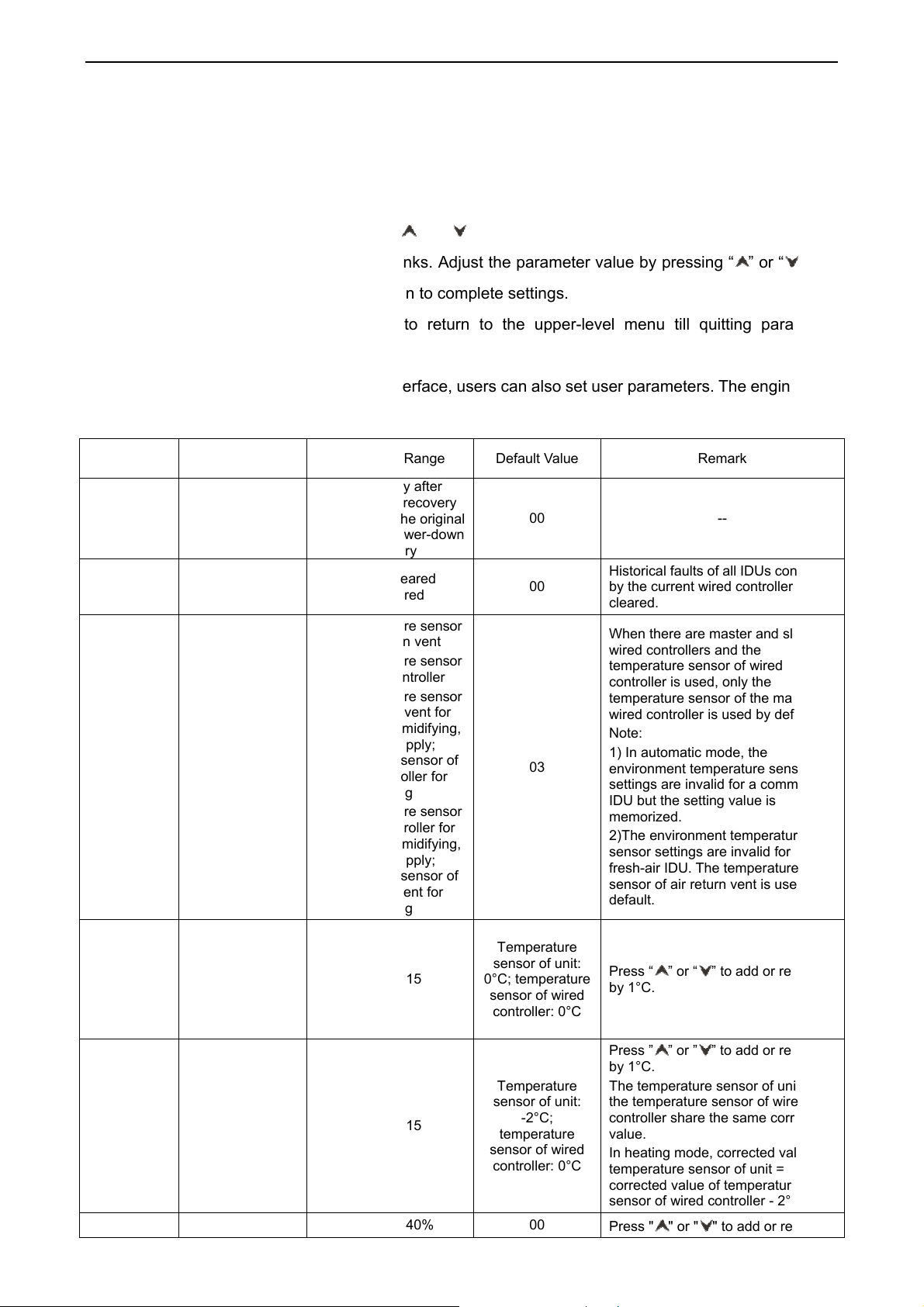

In the engineering parameter setting interface, users can also set user parameters. The engineerin

paramete

Parameter

r setting list is as follows:

Code

P15

P17

P20

P21

P22

P32

Parameter Name Parameter Range Default Value Remark

Power-down

memory mode

Historical fault

clearing for IDU

Environment

temperature

sensor settings

for IDU

Corrected value

of environment

temperature

sensor of IDU (for

cooling,

dehumidifying,

and air supply)

Corrected value

of environment

temperature

sensor of IDU (for

heating, fast

heating, and air

warming)

Capacity

00: standby after

power-down recovery

01: restoring the original

status after power-down

recovery

00: not cleared

01: cleared

01: temperature sensor

of air return vent

02: temperature sensor

of wired controller

03: temperature sensor

of air return vent for

cooling, dehumidifying,

and air supply;

temperature sensor of

wired controller for

heating

04: temperature sensor

of wired controller for

cooling, dehumidifying,

and air supply;

temperature sensor of

air return vent for

heating

-15 to +15

-15 to +15

-40% to +40% 00

00 --

Historical faults of all IDUs controlled

00

03

Temperature

sensor of unit:

0°C; temperature

sensor of wired

controller: 0°C

Temperature

sensor of unit:

-2°C;

temperature

sensor of wired

controller: 0°C

by the current wired controller are

cleared.

When there are master and slave

wired controllers and the

temperature sensor of wired

controller is used, only the

temperature sensor of the master

wired controller is used by default.

Note:

1) In automatic mode, the

envir

settings are invalid for a common

IDU but the setting value is

memorized.

2)The environment temperat

sensor settin

fresh-air IDU.

sensor of air return vent is used by

defau

Press “ ” or “ ” to add or reduce

by 1°C.

Press ” ” or ” ” to add or reduce

by 1°C.

The temperature sensor of unit and

the temperature sensor of wired

controller share the same corrected

value.

In heating mode, corrected value of

temperature sensor of unit =

corrected value of temperature

sensor of wired controller - 2°C.

Press " " or " " to add or reduce

onment temperature sensor

gs are invalid for

The temperature

lt.

g

ure

a

18

Page 21

Duct type split Air conditioner Inverter Series

Parameter

Code

P35

P36

P40

P52

Parameter Name Parameter Range Default Value Remark

adjustment

function of IDU

Factory setting

recovery for user

functions

Factory setting

recovery for

engineering

settings

Prevention for

heat collection

Setting of indoor

rotate speed in

efficiency testing

mode

00: invalid

01: valid

00: invalid

01: valid

00: disabled

10: 10 seconds

20: 20 seconds

30: 30 seconds

40: 40 seconds

50: 50 seconds

60: 60 seconds

100~1800

00

00

00

by 10%.

Select "01" and then press and hold

the “ENTER/CANCEL” button to

restore the factory settings for user

functions (factory setting recovery

fails if remote shielding is valid).

Select "01" and then press and hold

the “ENTER/CANCEL” button to

restore the factory status for

engineering settings (factory setting

recovery fails if remote shielding is

valid).

It indicates the number of seconds

for enabling the low-level fan every

15 minutes.

In P52, timer area show the actual

rotate speed of AHRI indoor fan

motor. Quick press “MODE”, enter

into setting interface, timer area

show the rotate speed of indoor fan

motor and twinkle, press “▲”

and”▼” to select the rotate speed,

Press “Mode” and hold for

0~5s, the rotate speed of indoor fan

motor will increase or decrease by

single digits; Press “MODE” and

hold for 5~10s, the rotate speed of

indoor fan motor will increase or

decrease by ten digits, within its

maximum and minimum value

(100~1800). Quick press

“Confirm/Cancel” to confirm and

return to last status,

P67

n0

n1

n3

n4

A7

Select the way of

adjusting static

pressure

System

conservation

operation settings

Defrosting period

settings

Forcible

defrosting

Highest capacity

output limitation

settings for ODU

Silent function of

ODU

00: manually

01:automatically

00: comfortability

preferred

01: conservation

preferred

40: 40 minutes

50: 50 minutes

60: 60 minutes

00: common

01: forcible defrosting

08: 80%

09: 90%

10: 100%

00: no silent function

01-09: intelligent

00

00

50

-

10

00

Present Way:

Temperature area: P52

Timer arer: Indoor fan motor rotate

speed.

-

After settings, it automatically

restores to "00".

Enter query in “n4” status. The

temperature area displays the

function code and the timer area

displays the corresponding function

setting value.

Enter query in “A7" status. The

temperature area displays the

function code and the timer area

19

Page 22

Duct type split Air conditioner Inverter Series

Parameter

Code

Note:

In parameter setting status, "FAN", “TIMER”, "SLEEP", and "SWING" are invalid. By pressing the

“ON/OFF” button, users can return to the main interface but not power on/off the unit.

Parameter Name Parameter Range Default Value Remark

nighttime silent mode

10-12: forcible silent

mode

displays the corresponding function

setting value.

3.5 Failure Display

When a fault occurs during the system operation, the temperature area of wired controller displays

the fault code. When multiple faults occur, fault codes are circularly displayed.

When a fault occurs, power off the unit and ask for professional maintenance personnel for help.

The following figure shows the power-on high-pressure protection fault interface.

Power-on High-pressure Protection Fault Interface

4 Monitoring Software

4.1 Function introduction

Integrating with telecommunication technology and computing software, Gree Commissioning Tool

Kits can realize the comprehensive monitor, control and commissioning on central air conditioners. It is

an efficient solution for the management of central air conditioners that are separated in different parts of

a building. Administrator doesn’t need to control every unit on site, but rather controls the units by just

sitting in front of a computer. This will not only improve the productivity, but also reduce cost on human

resources, property and management.

Gree Commissioning Tool Kits can monitor and control the duct type split air conditioner inverter

series. User can monitor and control units by monitoring the computer. This software is an efficient tool

for the intelligent air conditioning management as well as installation and after-sales service and

commissioning. It can debug units and control units’ operation status quickly and conveniently. It will not

only improve the productivity but also reduce the difficulty and cost of commissioning and maintenance,

providing better and faster service to customers.

20

Page 23

Duct type split Air conditioner Inverter Series

4.2 Connection of computer and units

It can be connected with single-system network or multi-system network. In the single-system

network, indoor units or outdoor units are connectable, while in the multi-system network, only the

master outdoor unit can be connected.

Seen from the diagram, Gree commissioing network is made up of 3 parts:

The 1st part is the monitoring computer, including Gree debugger and Gree USB converter driver

that are installed in the computer.

The 2nd part is Gree USB converter, which is to convert the air conditioning communication into

computing communication. This part is made up of Gree USB data converter and USB data wire.

The 3rd part is air conditioners, including outdoor units, indoor units and the connection wires. If

connection wire is not long enough, it’s OK to connect via the patching board of the commissioning tool

kits. In a single-system network, both indoor units and outdoor units can be connected, while in a

multi-system network, only the master outdoor unit can be connected.

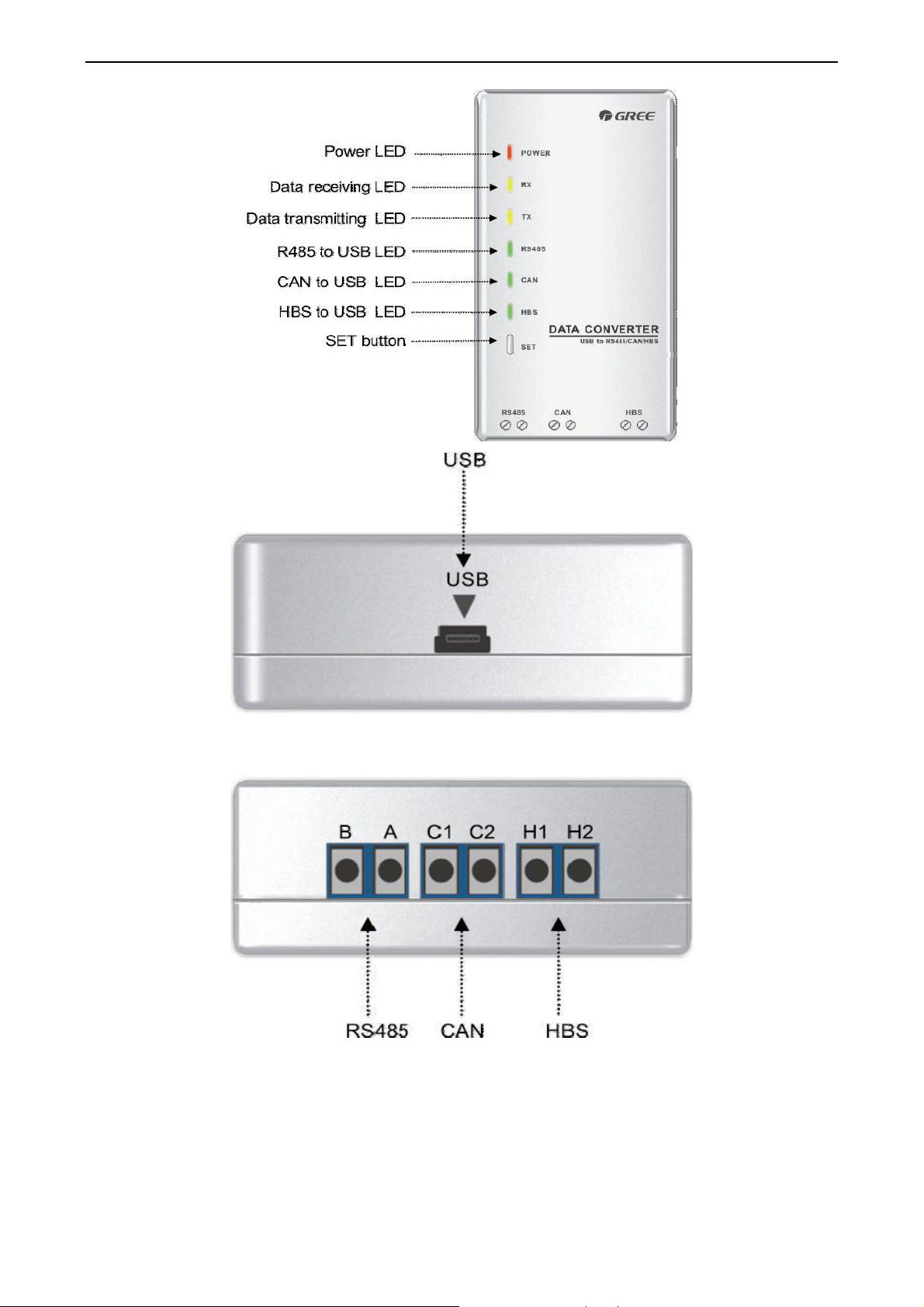

4.3 Parts introduction

4.3.1 List of parts

Name Model Material no. Remark

Gree USB data converter MC40-00/B 30118027

Gree Commissioning Tool Kits

(CD-ROM)

USB wire \ 40020082

Communicaiton board \ 30118015

Board connection wire (1m) \ 4001023229 4-core wire connecting units and converter

Board connection wire (5.5m) \ 4001023214 4-core wire connecting units and converter

Instruction manual \ 66174100018 Instruction manual

DG40-33/A(C) 36400000003

4.3.2 Gree USB data converter

4.3.2.1 Functions introduction

Convert the air conditioning communication

into computing communication

Include Gree debugger, monitoring software,

USB driver and USB converter configuring

software.

Wire connecting computer’s USB interface

and converter

This board can be used when units are far

from the computer.

Gree USB data converter will convert the RS485, HBS and CAN commucation within the air

conditioners into the communication that is recognizable by computer’s USB interface.

4.3.2.2 Appearance

21

Page 24

Duct type split Air conditioner Inverter Series

4.3.2.3 Operation instruction

Power LED: a red light. If the red light is on, it indicates normal power supply. If the red light is off,

it indicates the power supply of converter is not normal.

Communication LEDs: yellow lights. When converter is working and the computer is transmitting

data, the TX data transmitting light will be flickering. When units are uploading data to the

22

Page 25

Duct type split Air conditioner Inverter Series

computer, the RX data receiving light will be flickering.

When converter is under RS485 data transferring mode, the function LED

be on.

When converter is under CAN data transferring m

on.

When converter is under HBS data transferring mode, the function LED of HBS to USB will be

on.

USB interface: connect U

CAN interface: When converter is under CAN communication mode, conn

CAN data interface. CAN interface exh

HBS interface: When HBS converter is under HBS communication mode, connect air

conditioner’s HBS data interface. HBS interface exhibits no polarity (This interface is not yet

available for Gree debugger and the monitoring software)

RS485 interface: When RS485 converter is under RS485 communication mode, co

conditioner’s RS485 d

different.

SB data wire.

ibits no polarity (A and B are equal).

ata interface. RS485 interface exhibits polarity and terminal A and B are

ode, the function LED of CAN to USB will be

.

of RS485 to USB will

ect air conditioner’s

nnect air

4.3.2.4 Installation notice

Install indoors. To avoid collision, it is suggested to place it in the monitoring room together with

the computer.

No need of power supply. Power is supplied through computer’s USB interfac

e.

4.3.3 Communication board

Communication board is mainly used for transferring data. It functions similar with a patching board.

Provided that units are far away from the monitoring computer, communication board can be used for

connection.

4.3.4 Communication cord

4.3.4.1 USB wire

Connect USB wire with computer’s USB interface at one end and with the USB interface of USB

data convert

er at the other end, as indicated below

:

USB Wire

4.3.4.2 Board Connection Wire

There are 2 board connection wires supplied for the commissioning tool kits. One is 1 meter’s

long and the

other is 5.5 meters’ long. They are only different in l

23

ength. One end of the wire shall

Page 26

Duct type split Air conditioner Inverter Series

connect with air conditioner’s communication interface and the other end shall connect with CAN

interface of Gree USB converter. As shown below, the wire can be connected to the

communication interface of outdoor unit or the communication interface of indoor unit:

4.4 Software introduction

Board Connection Wire

One-bu

(1)

Personnel r

pressing one button according to the commissioning logic of

commissioning order to units. Then commissioning

During the commissionin

interface. If any commissioning pr

Compr

(2)

tton commissioning

esponsible for the commissioning of

g, the corresponding process will be ticked in

ocess is not normal, it will be displayed in r

ehensive monitoring

air conditioners can start commissioning by

software, which will give the

will be started up automatically step by step.

green on the software

ed.

The software can monitor every part of the air conditioning system, including functions, eq

and components operating statu

user can acquire the ope

(3)

Real-tim

e control

Air conditioner’s oper

rating status of the entire system conveniently and straightforwardly.

ating time and requirements may be different based on areas and functions.

s. The monitoring results will be displayed in text or curve so

User can set units’ parameters on computer according to actual needs, such as th

temperature,

fan speed, mode, etc. Meanwhile, the software can also set or view the

parameters of outdoor units, gateway and other equipment. In this way, the mangement of central

uipment

that

e on/off,

function

air conditioners is realized

ay history

Repl

(4)

Software can replay and

speed can be selected and the information will be shown in text or cu

saved the time to track p

Applicable to multiple series, mo

(5)

Gree Commissioning Tool Kits is applicable to

.

save the historical monitoring information in the

data base. The replay

rve. This function has greatly

roblem cause and resolved the difficulty of problem reprod

dels and users

air conditioning system that comsists of multiple

uction.

series and models. Later, it will be developed to cover all series of Gree central air conditioners,

such as multi VRF, centrifugal chiller, screw type chiller, ground source heat pump units,

24

modular

Page 27

Duct type split Air conditioner Inverter Series

units, fan coiled units, close control units, etc. It can be used by system and controller designers to

develop and monitor units, or used for maintenance and commissioning.

Other functions

(6)

For the convenience of users, the software has added functions like connection guide, printing

screen, opening database folder, rebuilding database, changing database saving path, etc.

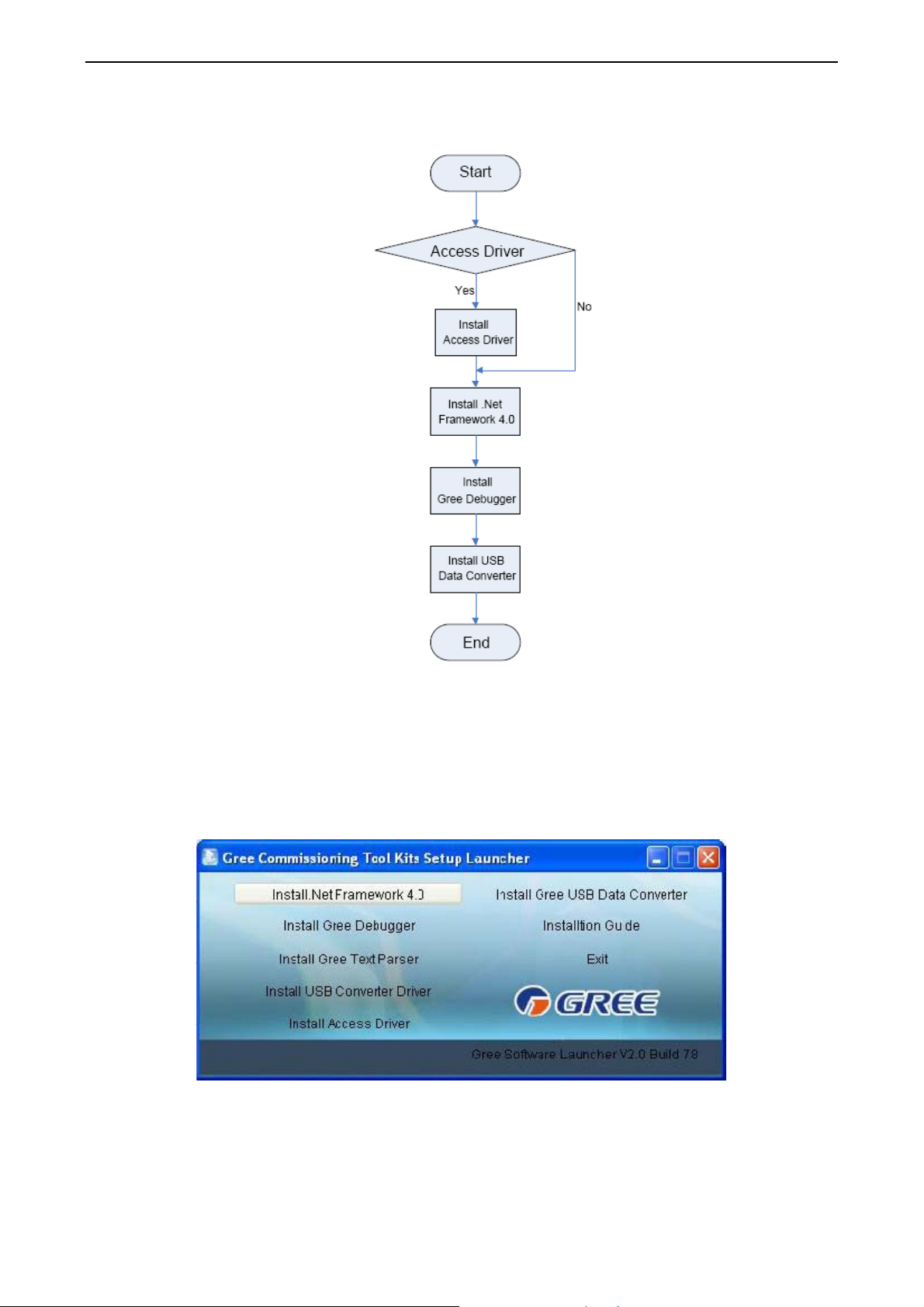

4.4.1 Software installation

4.4.1.1 Installation requirements

Computer Configuration

(1)

Memory

Hard Disc 10 GB available

CPU

Windows Server 2003 SP3 or higher

Operation System

1 GB at least

2 GB or above is preferred

Core 2 or higher

1 GHz at least

2 GHz or above is preferred

Windows XP SP3 or higher

Windows Vista

Windows 7

(2) CD Playing

Make sure you have administrator access to the computer and there is a CD-ROM in the computer.

Put the CD into the CD-ROM. If it’s automically running, then the following display will be shown. Or

double-click the file “Launcher.exe”.

For the first time to use Gree Commissioning Tool Kits, install these programmes: .Net Framework

4.0, USB Data Converter, Access Driver (necessary for versions below OFFICE 2007), Gree Debugger.

25

Page 28

Duct type split Air conditioner Inverter Series

4.4.1.1 Installation flowchart

Button Graphics

This flowchart describes basically the software installation process. See below for details.

4.4.1.2 Installation process

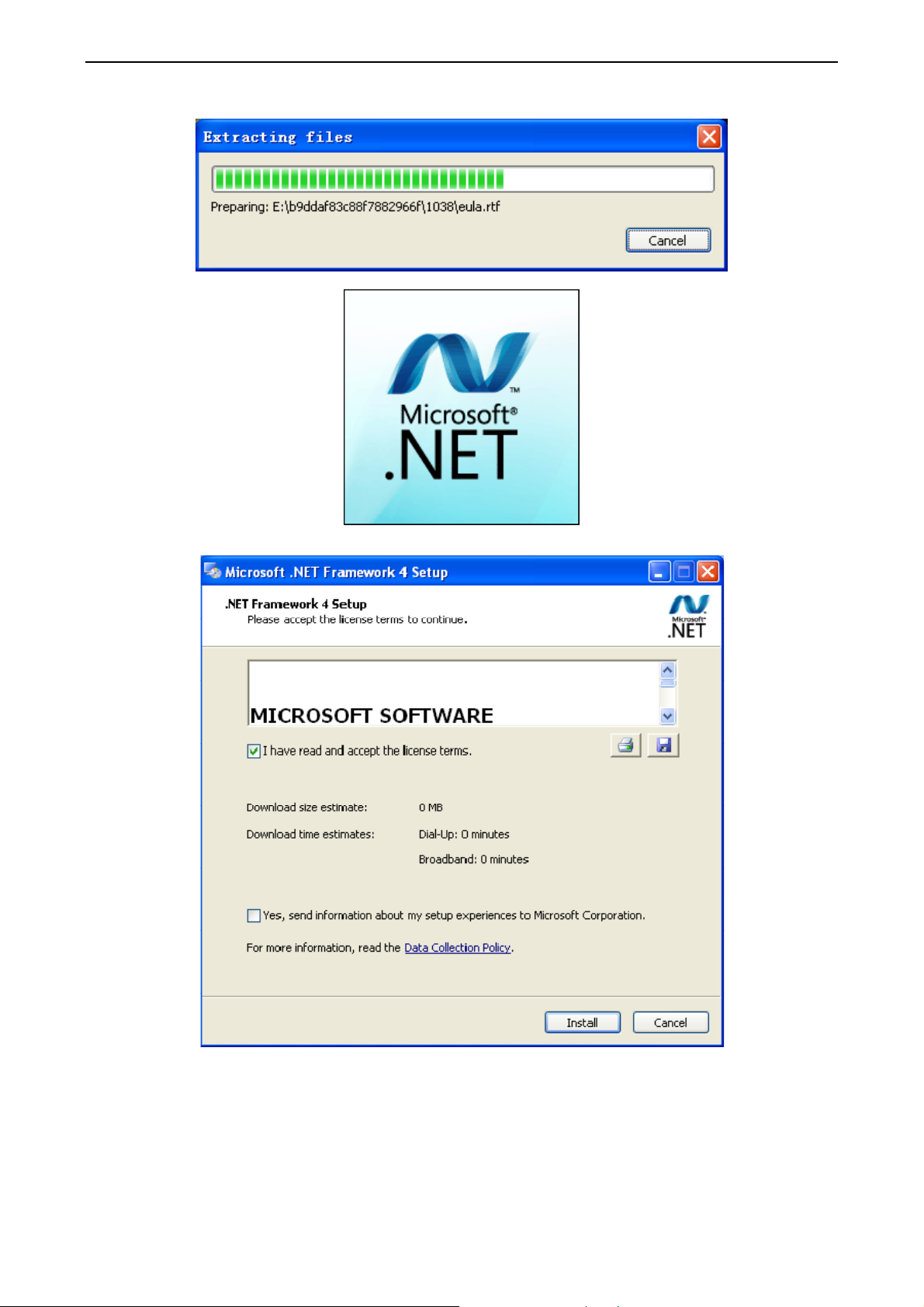

(1) Install .Net Framework 4.0

If your computer has installed .Net Framework 4.0 or versions above, there’s no need to install

again. Otherwise, click “Install .Net Framework 4.0”.

26

Page 29

Extracting files

Duct type split Air conditioner Inverter Series

Click and select “I have read and accept the license terms”. Then click “Install”.

27

Page 30

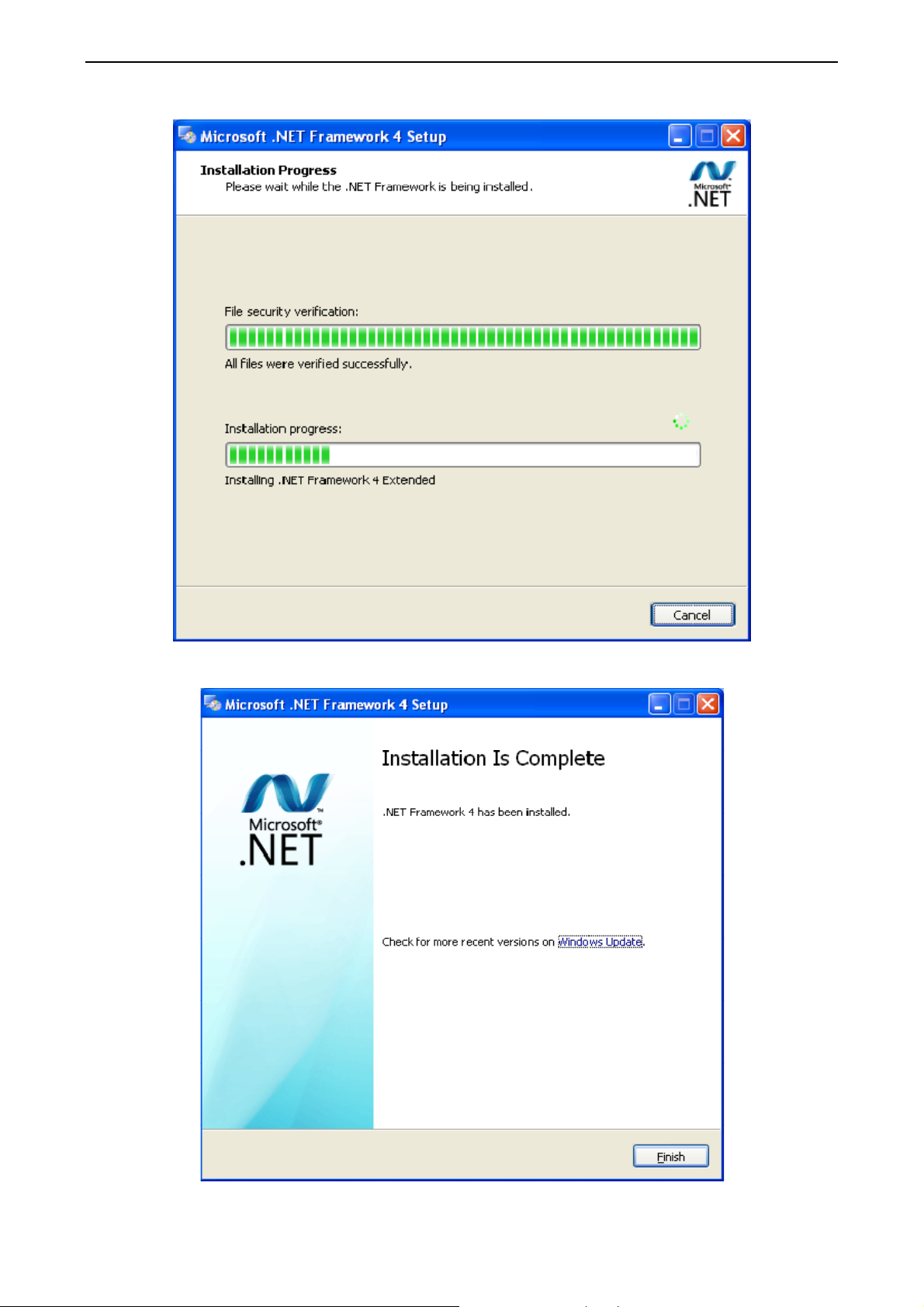

Installation is in progress.

Duct type split Air conditioner Inverter Series

Click “Finish” to complete the installation.

28

Page 31

Duct type split Air conditioner Inverter Series

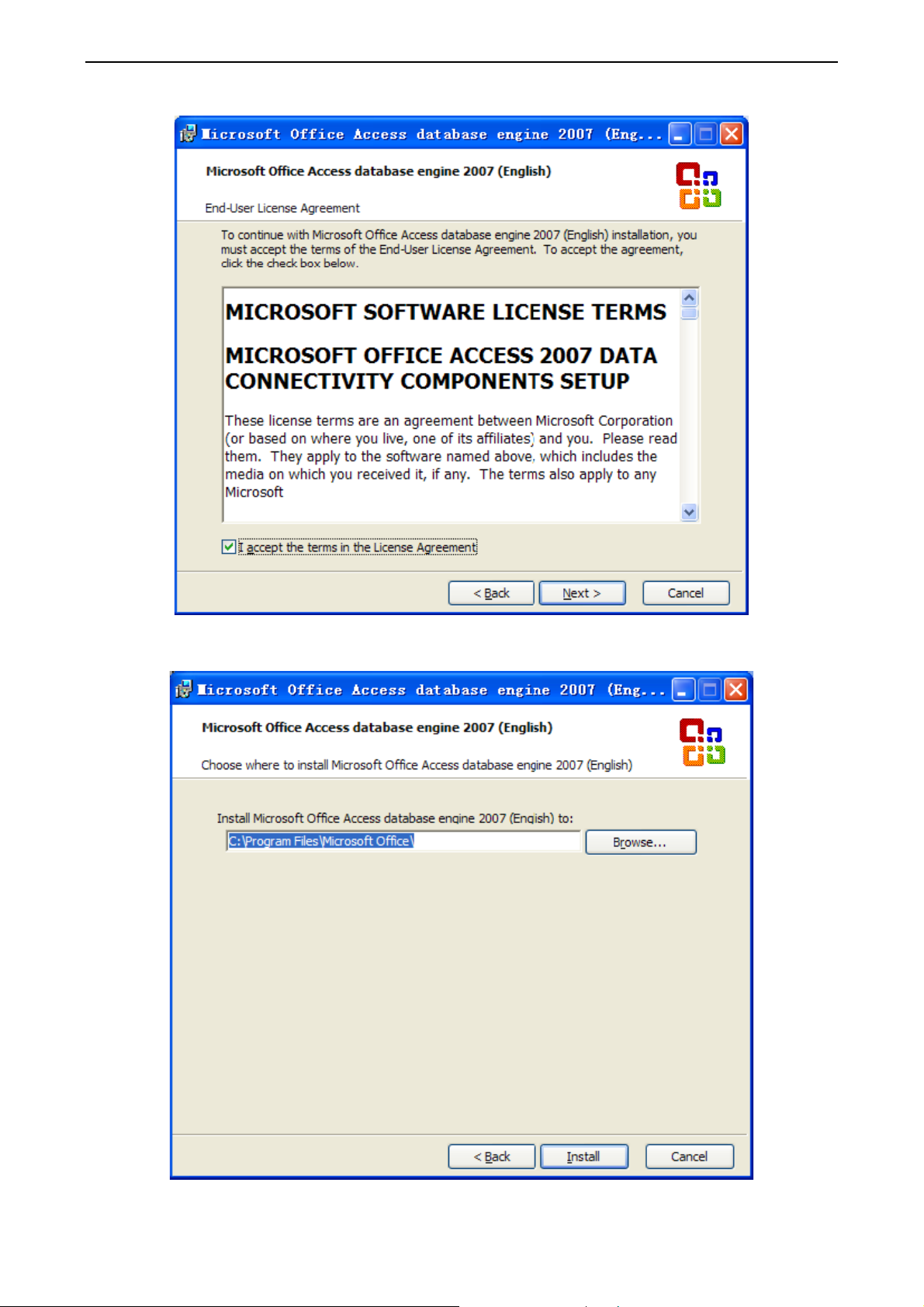

(2) Install Access Driver

Before operating Gree commissioning software, please first install Access Driver (necessary for

versions below OFFICE 2007). Click “Install Access Driver”.

Click ”Next”.

29

Page 32

Duct type split Air conditioner Inverter Series

Tick “I accept the terms in the License Agreement” and then click “Next”

Click “Browse” to change the default folder to the expected one, or click “Install” to continue the

installation.

30

Page 33

Installation is in progress.

Duct type split Air conditioner Inverter Series

Click “Ok” to complete the installation.

(3) Install Gree Debugger

Before installing Gree debugger, make sure that your computer is installed with .Net Framework

4.0 or versions above. Then click “Install Gree Debugger”.

31

Page 34

Click “Next”.

Duct type split Air conditioner Inverter Series

Click “Browse” to select installation folder. If no change is needed for the folder, click “Next” to

continue the installation.

32

Page 35

Click “Next”.

Duct type split Air conditioner Inverter Series

Installation is in progress.

33

Page 36

Duct type split Air conditioner Inverter Series

Click “Close” to complete the installation.

(4) Install USB Converter Driver

If USB converter driver is already installed in your computer, this part can be skipped. Otherwise,

click “Install USB Converter Driver”.

34

Page 37

Duct type split Air conditioner Inverter Series

Then the following installation window will be shown.

This window will exit after installation is finished.

35

Page 38

Duct type split Air conditioner Inverter Series

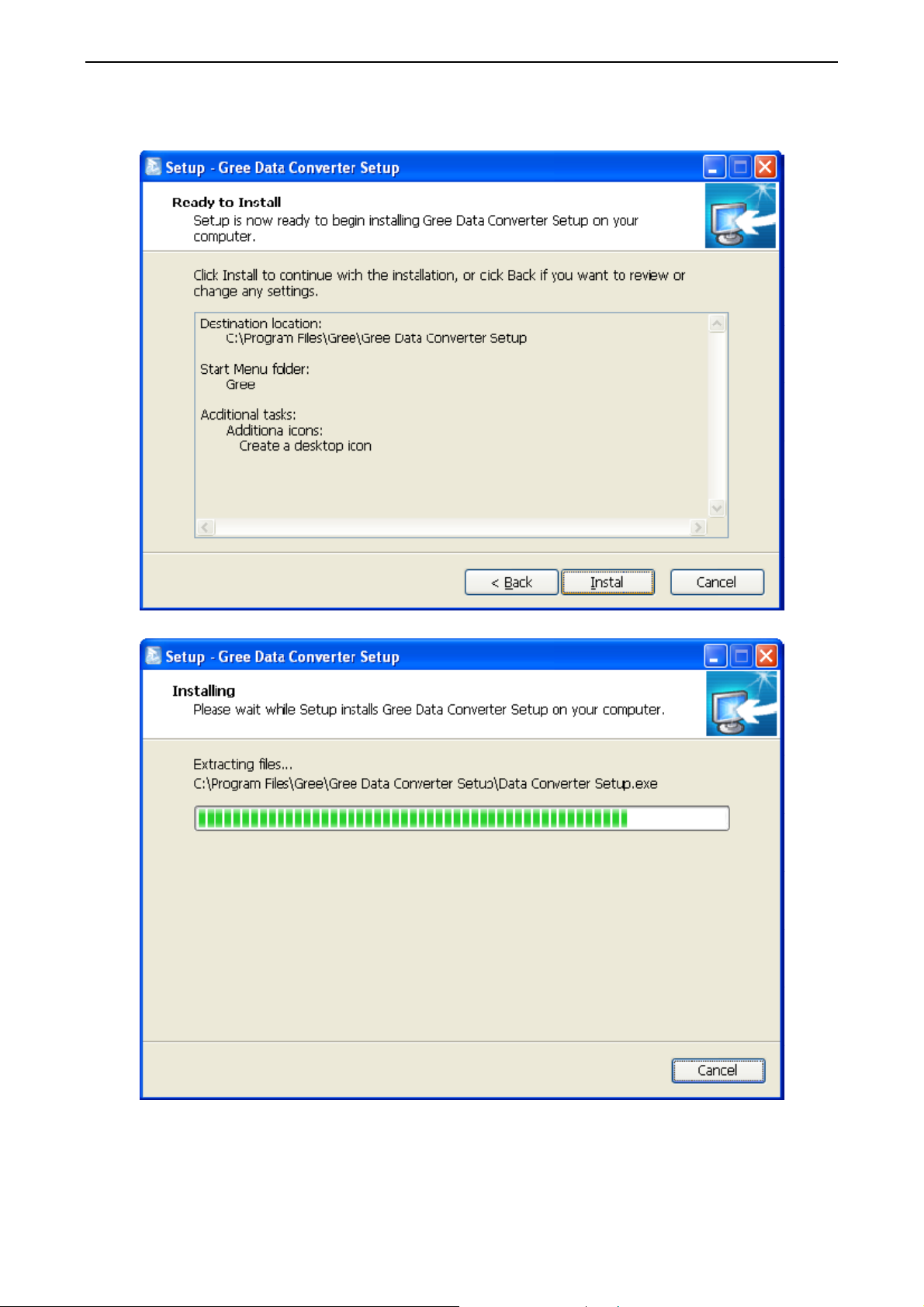

(5) Install Gree USB Data Converter

If converter baud rate is needed to be set, then converter configuring software must be installed.

Click “Install Gree USB Data Converter”.

Then select the setup language. You can choose Chinese ”simplified”, Chinese “traditional” or

English. Then click “OK”.

Click “Next”.

36

Page 39

Duct type split Air conditioner Inverter Series

Tick “I accept the agreement”. Then click “Next” to continue installation.

Click “Browse” to select your expected installation folder. Click “Next” to continue.

37

Page 40

Duct type split Air conditioner Inverter Series

Click “Browse” to change folder. Click “Next” to continue.

If you want to create s desktop shortcut, tick “Creat a desktop icon”. Then click “Next” to continue.

38

Page 41

Duct type split Air conditioner Inverter Series

Destiniation location, folder and additional task will be shown in the next step. If you need to change

any of it, please click “Back”. If not, click “Install” to start installation.

Installaiton is in progress.

39

Page 42

Duct type split Air conditioner Inverter Series

Click “Finish” to complete the installation.

4.4.2 Data monitoring

Start up Gree Debugger.

On the original interface, user can select language and units system. Click “OK” to confirm the

defaulted language and units system and start up the software.

40

Page 43

Select language.

Select system of units.

Duct type split Air conditioner Inverter Series

41

Page 44

Duct type split Air conditioner Inverter Series

If units you want to monitor are already connected, and able to communicate normally, with correct

COM and protocal, then you may click “Connect” to enter the interface of numbers. Otherwise,

connect in accordance with the connection diagram shown below.

COM selection: the serial port in your computer can be detected automatically. You just need to

select your desired serial port.

42

Page 45

Duct type split Air conditioner Inverter Series

Protocal selection: This is to select the communication method of your units. Currently, CAN is

applicable to the units.

After the selection, click “Connnect”. If units can communicate normally with computer, then the

interface of numbers will be shown soon. Otherwise, “Connecting” will be shown.

43

Page 46

Duct type split Air conditioner Inverter Series

There are several display zones on this interface. You can hide devices information and system

information by clicking devices information icon and system icon . Display zones of indoor

unit information and errors can be dragged up and down at the dividing lines. As to the display zone

of outdoor modules information, it can show information of only one module and hide information of

others (two modules are defaulted to be shown). Menu bar can be hidden by clicking icon .

Status bar shows the current time and period for data collection.

Title bar

Error display

System info

Outdoor modules info

Devices info

Menu bar

44

IDU info

Status bar

Page 47

Duct type split Air conditioner Inverter Series

On the display zone of devices information, you may click to select and view units that need

monitoring.

4.4.3 Project debugging

Click icon of “Debug” on the menu bar and the interface will be switched to project debugging,

where auto debugging will be started from up to down and from left to right. Note: Debugging

function is only applicable to a single-system network.

45

Page 48

Duct type split Air conditioner Inverter Series

Click “Start” to enable the debugging function. Then debugging will be started up automatically.

indicates that debugging is in progress while indicates debugging is completed.

If “OK” button is displayed, it means user needs to judge whether to continue debugging or not.

Click icon and relevant information will be shown for your reference. Click “Close” to close the

pop-up (For No.3 Confirm ODU Basic Module NO. and No.4 Confirm IDU NO., the current number

of units under debugging will be displayed. See the following marked with circle. For No.8 Compr.

Preheat Confirmation, the preheat time will be displayed. See the following marked with circle).

46

Page 49

Duct type split Air conditioner Inverter Series

Icon indicates that there is problem found during debugging. Debugging will not be completed

unless problem is solved (after problem is solved, step without “OK” button will switch to the next

step automatically, otherwise user needs to click “OK” to continue). Click icon and relevant

information detected in this step will be displayed for your reference in order to solve problems.

Click “Close” to close the pop-up.

During debugging, a click on “Break” can stop debugging. Click “Start” to resume debugging and

then debugging will be finished step by step. For No.10 ODU Valves Check Before Startup, there

are “Back” and “Skip” buttons. If there is error in this step, you can back to step No.9 and click “OK”

to restart debugging on step No.10. If the error in step No.10 is U6 error (valve error alarm), you can

click “Skip”. In other cases, “Skip” button is null.

Step 11, 13 and 14 are reserved steps. And step 13, 14, 15 and 16 are steps in parallel (only one of

the four will be selected according to actual needs).

47

Page 50

Duct type split Air conditioner Inverter Series

4.4.4 Control units

Click icon of “Setting” on menu bar and select parameter settings, which include “Gateway Settings”,

“IDU Settings”, “System Settings”, “Project Number Conflict (In case there is project number conflict

in indoor units, other functions will be shielded. Then this parameter needs to be set in order to

eliminate the conflict)” and “System Historical Info”. Click the corresponding set and adjust the

parameters.

Take indoor unit as an example. Click “IDU Settings” and a dialog box will pop up.

48

Page 51

Duct type split Air conditioner Inverter Series

Tick the indoor units that need setting in the IDU selection zone or you may click “Select All” to

select all of them or “Select Inverted” to select none of them. After selection, the current values of

the corresponding parameters will be displayed in the zone of settings. Click “Set” and then click

in the pop-up dialog box to select values. Click “Set” and then the corresponding order will be

sent to units. If setting is successful, it will be displayed at the current values.

49

Page 52

Duct type split Air conditioner Inverter Series

4.4.5 Other functions

Capture screen

Click icon of “Capture Screen” to print the interface. If you want to open the interface, click “Open”.

50

Page 53

Duct type split Air conditioner Inverter Series

Search for database folder

Click icon of “Open Data Folder” on the menu bar to open database folder.

51

Page 54

Duct type split Air conditioner Inverter Series

Conversion of pressure value

Click icon of “Others” on the menu bar and then click “Display Settings” to select “High Low

Pressure Value” and “Refrigerant Type”. Select “Temperature” and the pressure parameter

displayed on the interface will be temperature. Select “Pressure” and the pressure parameter

displayed on the pressure interface will be pressure. Refrigerant type will affect the pressure

parameter displayed on the interface.

52

Page 55

Duct type split Air conditioner Inverter Series

Database saving of multiple systems

Click icon of “Others” on the menu bar and click “Database Save Settings” to select which system

that needs to save database. Because there is a large quantity of data in a network that contains

multiple systems, data of only one system can be saved.

53

Page 56

Duct type split Air conditioner Inverter Series

Change database saving path and rebuild database

Change of database saving path and rebuilding of database should be set before the software

starts monitoring (see below interface). Click “Change database saving path” and click “Browse” to

change the saving path. Click “Rebuild Database” to rebuild the database folder. You can also stop

monitoring and turn back to the connection interface to change saving path or rebuild database

during monitoring.

54

Page 57

Duct type split Air conditioner Inverter Series

4.4.6 Usage of USB Converter

Usage of converter

Gree commissioning software should be connected with CAN interface when converter is used. For

air conditioners with a single system, connect D1 and D2 interfaces of the wiring board. For air

conditioners with multiple systems, connect G1 and G2 interfaces of the wiring board.

Gree monitoring software should be connected with RS485 interface when converter is used.

Connect outdoor or indoor units or the mainboard of wired controller according to actual needs.

HBS, CAN and RS485 of the converter can be switched by buttons. Press the button “SET” on the

converter to realize the conversion among HBS, CAN and RS485 interfaces. You can check the

setting through the function LEDs.

Notice: If it’s the first time your PC uses Gree USB data converter, in order to prevent Gree USB

data converter from being mistaken by your computer as other devices and make sure your mouse

can work well, it is necessary to turn off the Serail Enumerator of computer after Gree USB data

converter is connected. Below are the steps:

Step 1: Right-click ”My Computer” on the desktop and click ”Manage”.

Step 2: In the pop-up window, select “Device Manager” in the left column and then find “Port

(COM and LPT)” in the right column. Click its .

55

Page 58

Duct type split Air conditioner Inverter Series

56

Page 59

Duct type split Air conditioner Inverter Series

Step 4:

Right-click ”USB Serial Port (COM6) and then click ”Properties”. The dialog box of properties will

then pop up.

Step 5: Then click ”Port Settings” in the dialog box.

57

Page 60

Duct type split Air conditioner Inverter Series

Step 6: Click ”Advanced” and then a new dialog

box will pop up. Find the ”Serial Enumerator” in

the miscellaneous options and cancel the tick. Click ”OK” to exit.

58

Page 61

Duct type split Air conditioner Inverter Series

Usage of converte

r configuring software:

When the converter is working, hold the button ”SET” for 5 sec. Function LED will be flickering,

indicating that the converter has enter the baud rate setting mode. Then you can use the converter

configuring software to set the baud rate of converter. Baud rate supported by the converter (baud

rate of air conditioner’s communication interface matches with the baud rate of USB interface

automatically):

Ex-factory defaulted baud rate: (unit: bps)

AC is connected with Baud rate of air conditioner interface Baud rate of USB interface

CAN 20000/50000 self-adaptive 115200

HBS 57600 38400

RS485 9600 9600

Baud rate look-up table for RS485 interface (unit: bps)

RS485 interface

USB interface

HBS interface

USB interface 4800

4800 9600 19200 38400 57600 115200

4800 9600 19200 38400 57600 115200

Baud rate l

9600 19200

Baud rate look-up table of CAN interface (unit: bps)

ook-up table for HBS interface (unit: bps)

38400

9600 19200

57600

38400

CAN interface

USB interface

20000 50000 100000 125000

115200 115200 256000 256000

Double-click the desktop shortcut.

59

Page 62

Duct type split Air conditioner Inverter Series

Select the needed communication serial port and language in the “System Settings”.

Select the function that is to be set and the corresponding baud rate (refer to the look-up table) in

the “Converter Setup”.Then click “Set”.

60

Page 63

Duct type split Air conditioner Inverter Series

If you want to restore ex-factory settings, click “Default” to restore the default settings.

Click “Get” to get the current setting details of converter.

61

Page 64

Duct type split Air conditioner Inverter Series

Switchover of Software Languages

62

Page 65

Duct type split Air conditioner Inverter Series

INSTALLATION

63

Page 66

Duct type split Air conditioner Inverter Series

1 Engineering Installation Preparation and

Notice

1.1 Installation notice

Personnel and property safety are highly concerned during the entire installation process.

Installation implementation must abide by relevant national safety regulations to ensure personnel and

property safety.

All personnel involved in the installation must attend safety education courses and pass

corresponding safety examinations before installation. Only qualified personnel can attend the

installation. Relevant personnel must be held responsible for any violation of the regulation.

1.2 Installation key points and importance

The system use refrigerant, instead of other agent, to directly evaporate to carry out the system heat.

High level of pipe cleanness and dryness is required in the system. Since various pipes need to be

prepared and laid out onsite, carelessness or maloperation during installation may leave impurities,

water, or dust inside refrigerant pipes. If the design fails to meet the requirement, various problems may

occur in the system or even lead to system breakdown.

Problems that usually occur during installation are as follows:

No. Installation Problem Possible Consequence

are more likely to be blocked; air conditioning performance is reduced;

Dust or impurities enter into the

1

2

3

4

5

6

7

8

9

10

11

12

13

refrigeration system.

Nitrogen is not filled into the

efrigerant pipe or insufficient

r

Nitrogen is filled before welding.

The vacuum degree in the

r

efrigerant pipe is insufficient.

Water enters into

the refrigeration

system.

The refrigerant pipe

pecifications do not meet the

s

configuration requirements.

Refrigerant pipe is

Refr

igerant pipe exceeds the

Incorrect amount of refrigerant is

The refrigerant pipe leaks.

Water drainage from

condensate water pipe is not

smooth.

The ratio of slop for condensate

water pipe is insufficient or the

ondensate water pipe is

c

incorrectly connected.

channel is improperly

The air

The guide vane of air channel is

not reasonably manufac

blocked.

limit.

filled.

fixed.

the

tured.

Pipes

compressor wear is increased or even hinder the normal operation of the system

are more likely to be blocked; air conditioning performance is reduced;

Pipes

compressor wear is increased or even hinder the normal operation of the system

The refrigeration performance is reduced. The system fails to keep normal

ation due to frequent protection measures. When the problem getting serious,

oper

Copper

efficiency with abnormal noise generated; failures may occur in the system due to

maller configuration specifications can increase the system pipe resistance and

S

affect the cooling performance; larger configuration specifications are waste of

The c

compressor operating under overheat conditions; the lubricating effect can be

affected and the compressor may be burnt if impurities were mixed with the

The loss in pipe is c

The system cannot correc

operating under over-heating environment or running when the refrigerant flows

Insufficient refrigerant circulating in the s

of the air conditioner. Long-term operation under such circumstance may cause an

Res

Rev

The air

compressor and other major components can be damaged.

plating may appear on the compressor and reduce the compressor

materials and can also reduce the cooling performance.

ooling performance is reduced; in certain cases, it may cause long-term

are harmful for long-term running of the system.

overheating compressor or even damage the compressor.

idual water in IDUs can affect the normal operation of the system. The

possible water leakage can damage the IDU's decoration.

erse slop or inconsistent connection of condensate water pipe can hinder the

smooth drainage and cause leakage of the IDU.

channel will deform; vibration and noise occur during unit operating.

Unev

en air quantity allocation reduces the overall performance of the air

and burn the compressor.

and burn the compressor.

ice plug.

lubricating oil.

onsiderable and the unit energy efficiency decreases, which

tly control the flow allocation; the compressor may be

back to the compressor.

ystem decreases the cooling performance

conditioner.

64

Page 67

Duct type split Air conditioner Inverter Series

No. Installation Problem Possible Consequence

The refr

condensate water pipe does not

14

meet the insulation requirement.

igerant pipe or

can easily condensate and drip to damage the indoor decoration, or even

Water

trigger the protection mode of system due to overheating operation.

The installation space for IDU is

15

The IDU or the location of the air

outlet or return air inlet is not

16

The ODU is improperly ins

17

Power c

18

Control communication cables

19

20

ar

Control communication cables

are not pr

insufficient.

designed r

e incorrectly provided or

improperly connected.

easonably.

ables are incorrectly

provided.

operly protected.

talled.

Since there is a lack of s

might need to be damaged during such operation.

The air outlet or r

The ODU is difficult to be maintained; unit exhaust is not smooth, which reduces

the heat exchanging performance or even prevent the system from norm

operation; in addition, the cold and hot air for heat exchange and the noise may

Unit components may be damaged and potential safety haz

The normal communication in the system fails or the contr

The communication cables are short-circ

cannot be started up due to communication failure.

pace for maintenance and checking, indoor decoration

eturn air inlet may be short-circuited, thus affecting the air

conditioning performance.

al

annoy people in surrounding areas.

ard may occur.

ol over IDUs and ODUs

turn in a mess.

uited or disconnected, and the unit

Understand the special requirement (if any) for unit installation before implementation to ensure

installation quality. Relevant installers must have corresponding engineering construction qualifications.

Special type operators involved in the engineering implementation, such as welders, electricians,

and refrigeration mechanics must have relevant operating licenses and are accredited with vocational

qualification certification.

2 Installation Materials Selection

The materials, equipment and instruments used during air conditioning engineering construction

must have certifications and test reports. Products with fireproof requirements must be provided with

fireproof inspection certificates and must meet national and relevant compulsory standards. If

environmentally-friendly materials are to be used as required by customers, all such materials must

meet national environmental protection requirement and be provided with relevant certificates.

2.1 Refrigerant piping

a. Material requirement: Dephosphorization drawing copper pipe for air conditioners;

b. Appearance requirement: The inner and outer surface of pipe should be smooth without pinhole,

crack, peeling, blister, inclusion, copper powder, carbon deposition, rust, dirt or severe oxide film, and

without obvious scratch, pit, spot and other defects.

c. Test report: Certifications and quality test reports must be provided.

d. The tensile strength must be at least 240 kgf/mm².

e. Specifications requirement

R410A Refrigerant System

OD (mm/inch) Wall Thickness (mm) Model

0.8

Ф6.35(1/4)

Ф9.52(3/8)

65

≥

≥

0.8

0

0

Page 68

Duct type split Air conditioner Inverter Series

0.8

Ф12.70(1/2)

Ф15.9(5/8)

Ф19.05(3/4)

Ф22.20(7/8)

Ф25.40(8/8)

≥

≥

≥

≥

≥

1.0

1.0

1.2

1.2

f. After the inner part of the copper pipe is cleaned and dried, the inlet and outlet must be sealed

tightly by using pipe caps, plugs or adhesive tapes.

2.2 Condensate water pipe

a. Pipes that can be used for air conditioner drainage include: water supplying UPVC pipe, PP-R

pipe, PP-C pipe, and HDG steel pipe;

b. All relevant certificates and quality test reports are provided.

c. Requirements for specifications and wall thickness

Water supplying UPVC pipe: Φ32mm×2mm,Φ40mm×2mm,Φ50mm×2.5mm;

0

0

0

0

0