Gree DUCT09HP230V1BD, DUCT12HP230V1BD, DUCT18HP230V1BD, GFH(21)DB-D3DNA1A/I, DUCT24HP230V1BD Service Manual

Service Manual

Change for life

GREE ELECTRIC APPLIANCES, INC. OF ZHUHAI

Models: DUCT09HP230V1BD

DUCT12HP230V1BD

DUCT18HP230V1BD

GFH(21)DB-D3DNA1A/I

DUCT24HP230V1BD

(Refrigerant R410A)

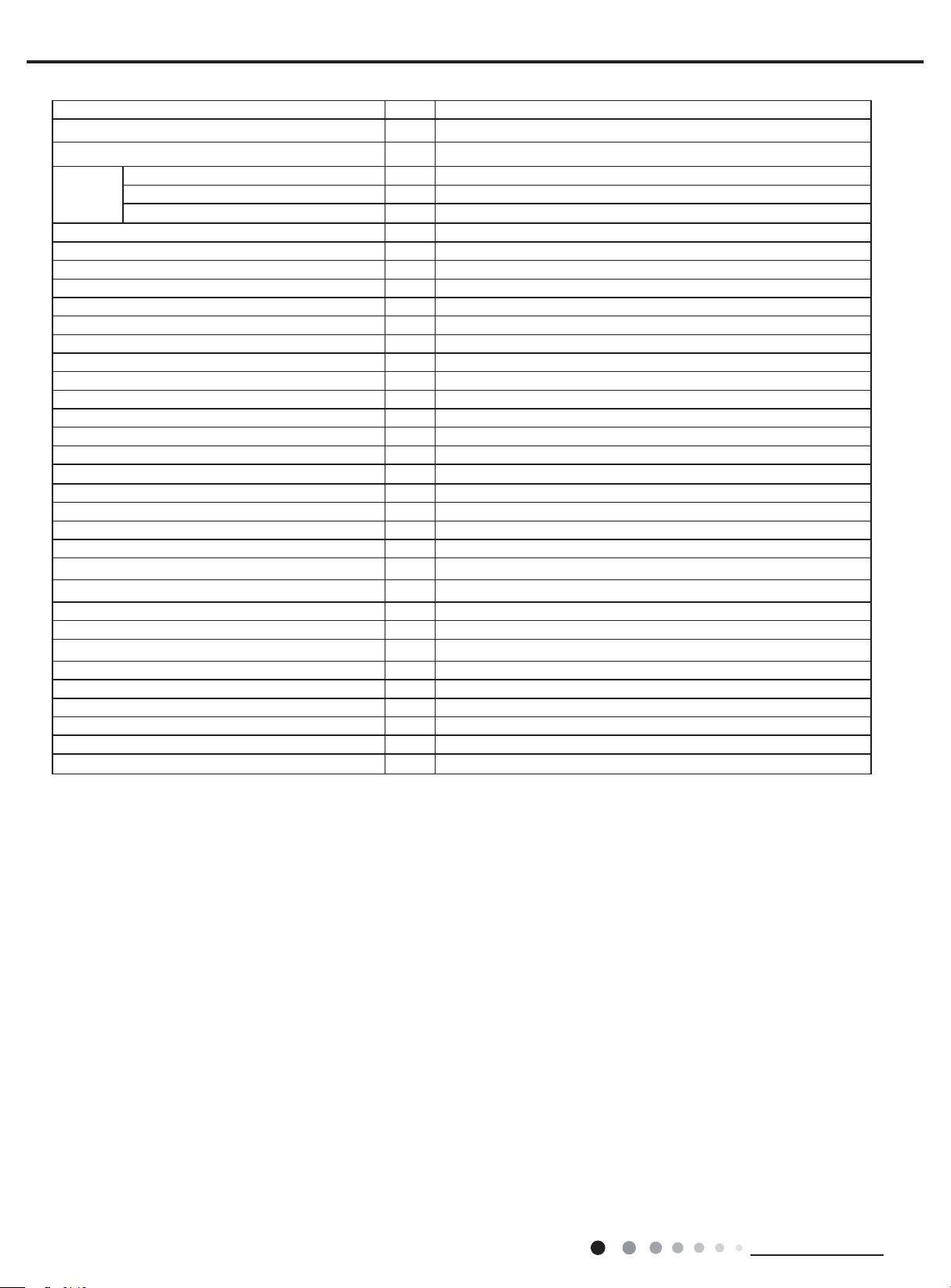

Table of Contents

Service Manual

Part

1. Summary

2. Specications

: Technical Information

Ⅰ

......................................................................................................................1

..........................................................................................................2

3. Outline Dimension Diagram

4. Refrigerant System Diagram

5. Electrical Part

5.1 Wiring Diagram .................................................................................................................7

5.2 PCB Printed Diagram .......................................................................................................8

6. Function and Control

6.1 Introduction of Control Panel

6.2 Introduction of Control Panel .......................................................................................... 11

Part

: Installation and Maintenance

Ⅱ

...........................................................................................................7

........................................................................................9

............................................................................................9

7. Notes for Installation and Maintenance

.......................................................................1

........................................................................5

......................................................................6

.................................................13

..........................................13

8. Installation Manual

8.1 Preparations for Installation ............................................................................................17

8.2 Location for Installation ..................................................................................................17

8.3 Wiring Requirements ......................................................................................................18

9. Installation Instructions

10. Wiring Work

11. Maintenance

11.1 Error Code List .............................................................................................................30

11.2 Troubleshooting for Main Malfunction ...........................................................................38

11.3 Maintenance Method for Normal Malfunction ...............................................................42

..........................................................................................................28

.........................................................................................................30

12. Exploded View and Parts List

11. Removal Procedure

............................................................................................16

................................................................................20

..............................................................44

.......................................................................................48

Table of Contents

Service Manual

Part

Ⅰ

: Technical Information

1. Summary

Outdoor Unit

DUCT09HP230V1BD

DUCT12HP230V1BD

DUCT18HP230V1BD

GFH(21)DB-D3DNA1A/I

DUCT24HP230V1BD

Technical Information

1

Service Manual

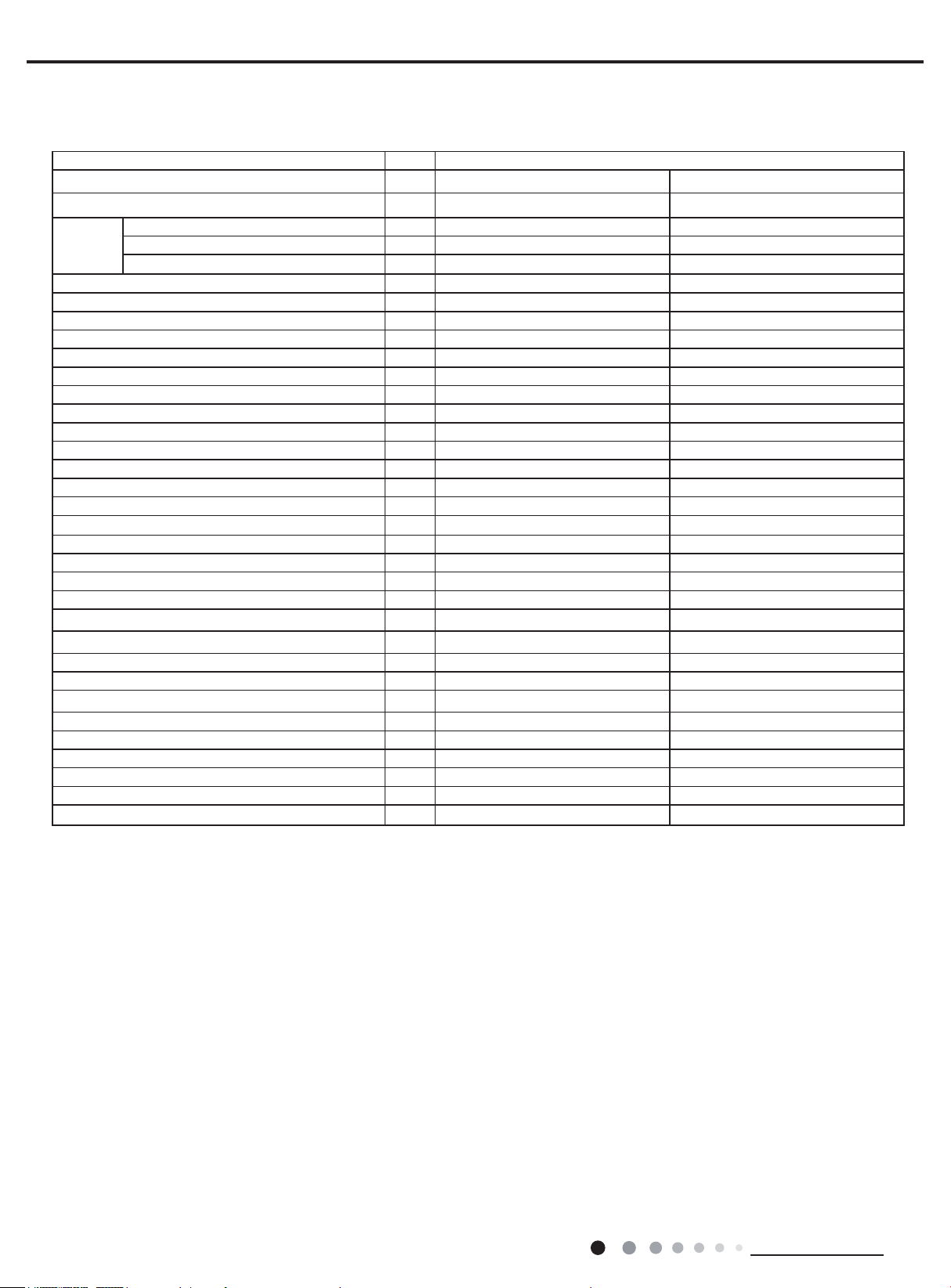

2. Specications

Parameter Unit Value

Model

Product Code CF022N1420 CF022N1400

Power

Supply

Cooling Capacity Btu/h 9000 12000

Heating Capacity Btu/h 9500 13000

Cooling Power Input KW 0.09 0.09

Heating Power Input KW 0.09 0.09

Cooling Current Input A 0.4 0.4

Heating Current Input A 0.4 0.4

Air ow volume(SH/H/M/L/SL) CFM 324/253/212/188/- 324/253/212/188/-

Dehumidifying Volume Pint/h 1.69 1.69

Fan Type Centrifugal Centrifugal

Fan Diameter-height inch Φ8~4 7/32 Φ8~4 7/32

Fan Motor Speed rpm 860/670/570/510 940/770/670/570

Fan Motor Power Output W 150 150

Fan Motor Power Input W / /

Motor Full Load Amp(FLA) A 0.4 0.4

Fan Motor Capacitor μF / /

Evaporator Material Aluminum n-copper tube Aluminum n-copper tube

Evaporator Pipe Diameter inch Φ5/16 Φ5/16

Evaporator Number of Rows-Fin Pitch - 2 2

Evaporator Length(L)XHeight(H)XWidth(W) inch 18 1/2X12 1/8X1/2 470X308X38

Fuse Current A 5 5

Sound Pressure Level(SH/H/M/L/SL) dB (A) 38/35/30/26/- 38/35/30/26/-

Sound Power Level(SH/H/M/L/SL) dB (A) 52/49/44/40/- 52/49/44/40/-

Dimension of Outline(LXWXH) inch 32 43/64X29 11/16X11 13/16 32 43/64X29 11/16X11 13/16

Dimension of Carton Box(LXWXH) inch 35 13/64X31 11/16X13 37/64 35 13/64X31 11/16X13 37/64

Dimension of Package(LXWXH) inch 35 5/16X31 13/16X14 11/16 35 5/16X31 13/16X14 11/16

Net Weight Ib 70.6 70.6

Gross Weight Ib 83.8 83.8

Liquid pipe

Gas Pipe(to indoor unit) inch Φ1/4 Φ1/4

Rated Voltage V~ 208/230 208/230

Rated Frequency Hz 60 60

Phases 1 1

inch Φ3/8 Φ1/2

DUCT09HP230V1BD DUCT12HP230V1BD

The above data is subject to change without notice. Please refer to the nameplate of the unit.

2

Technical Information

Service Manual

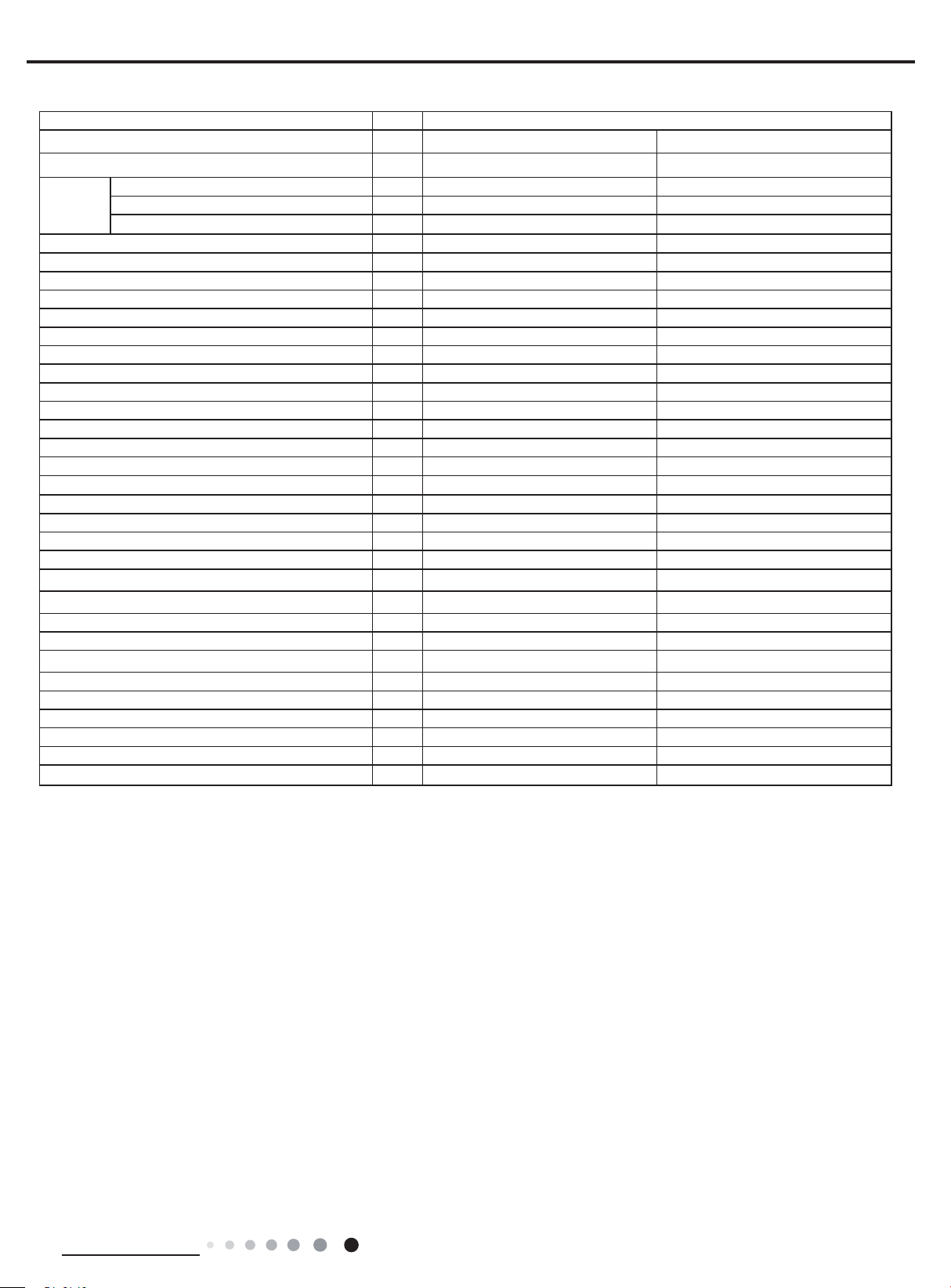

Parameter Unit Value

Model

Product Code CF022N1390 CF022N1410

Power

Supply

Cooling Capacity Btu/h 18000 21000

Heating Capacity Btu/h 19000 23000

Cooling Power Input KW 0.16 0.16

Heating Power Input KW 0.16 0.16

Cooling Current Input A 0.7 0.7

Heating Current Input A 0.7 0.7

Air ow volume(SH/H/M/L/SL) CFM 589/412/312/288/- 589/412/312/288/-

Dehumidifying Volume Pint/h 2 1.0

Fan Type Centrifugal Centrifugal

Fan Diameter-height inch Φ8~4 7/32 Φ8~4 7/32

Fan Motor Speed rpm 990/700/530/490 990/700/530/490

Fan Motor Power Output W 200 200

Fan Motor Power Input W / /

Motor Full Load Amp(FLA) A 0.7 0.7

Fan Motor Capacitor μF / /

Evaporator Material Aluminum n-copper tube Aluminum n-copper tube

Evaporator Pipe Diameter inch Φ5/16 Φ5/16

Evaporator Number of Rows-Fin Pitch - 3 3

Evaporator Length(L)XHeight(H)XWidth(W) inch 29 41/64X12 1/8X2 1/2 29 41/64X12 1/8X2 1/2

Fuse Current A 5 5

Sound Pressure Level(SH/H/M/L/SL) dB (A) 39/33/29/26/- 39/33/29/26/-

Sound Power Level(SH/H/M/L/SL) dB (A) 49/43/39/36/- 49/43/39/36/-

Dimension of Outline(LXWXH) inch 44 31/64X29 11/16X11 13/16 44 31/64X29 11/16X11 13/16

Dimension of Carton Box(LXWXH) inch 47 21/64X37 57/64X13 37/64 47 21/64X37 57/64X13 37/64

Dimension of Package(LXWXH) inch 47 7/16X32 1/64X14 11/64 47 7/16X32 1/64X14 11/64

Net Weight Ib 92.6 92.6

Gross Weight Ib 106.9 106.9

Liquid pipe

Gas Pipe(to indoor unit) inch Φ3/8 Φ3/8

Rated Voltage V~ 208/230 208/230

Rated Frequency Hz 60 60

Phases 1 1

inch Φ5/8 Φ5/8

DUCT18HP230V1BD GFH(21)DB-D3DNA1A/I

The above data is subject to change without notice. Please refer to the nameplate of the unit.

Technical Information

3

Parameter Unit Value

Model

Product Code CF022N1430

Power

Supply

Cooling Capacity Btu/h 24000

Heating Capacity Btu/h 27000

Cooling Power Input KW 0.21

Heating Power Input KW 0.21

Cooling Current Input A 0.9

Heating Current Input A 0.9

Air ow volume(SH/H/M/L/SL) CFM 736/559/453/406/-

Dehumidifying Volume Pint/h 2.5

Fan Type Centrifugal

Fan Diameter-height inch Φ8~4 7/32

Fan Motor Speed rpm 1050/800/650/580

Fan Motor Power Output W 200

Fan Motor Power Input W /

Motor Full Load Amp(FLA) A 0.7

Fan Motor Capacitor μF /

Evaporator Material Aluminum n-copper tube

Evaporator Pipe Diameter inch Φ5/16

Evaporator Number of Rows-Fin Pitch - 2

Evaporator Length(L)XHeight(H)XWidth(W) inch 29 41/64X12 1/8X2 1/2

Fuse Current A 5

Sound Pressure Level(SH/H/M/L/SL) dB (A) 39/33/29/26/-

Sound Power Level(SH/H/M/L/SL) dB (A) 49/43/39/36/-

Dimension of Outline(LXWXH) inch 44 31/64X29 11/16X11 13/16

Dimension of Carton Box(LXWXH) inch 47 21/64X37 57/64X13 37/64

Dimension of Package(LXWXH) inch 47 7/16X32 1/64X14 11/64

Net Weight Ib 92.6

Gross Weight Ib 106.9

Liquid pipe inch Φ5/8

Gas Pipe(to indoor unit) inch Φ3/8

The above data is subject to change without notice. Please refer to the nameplate of the unit.

Rated Voltage V~ 208/230

Rated Frequency Hz 60

Phases 1

DUCT24HP230V1BD

Service Manual

4

Technical Information

Service Manual

C

A

C

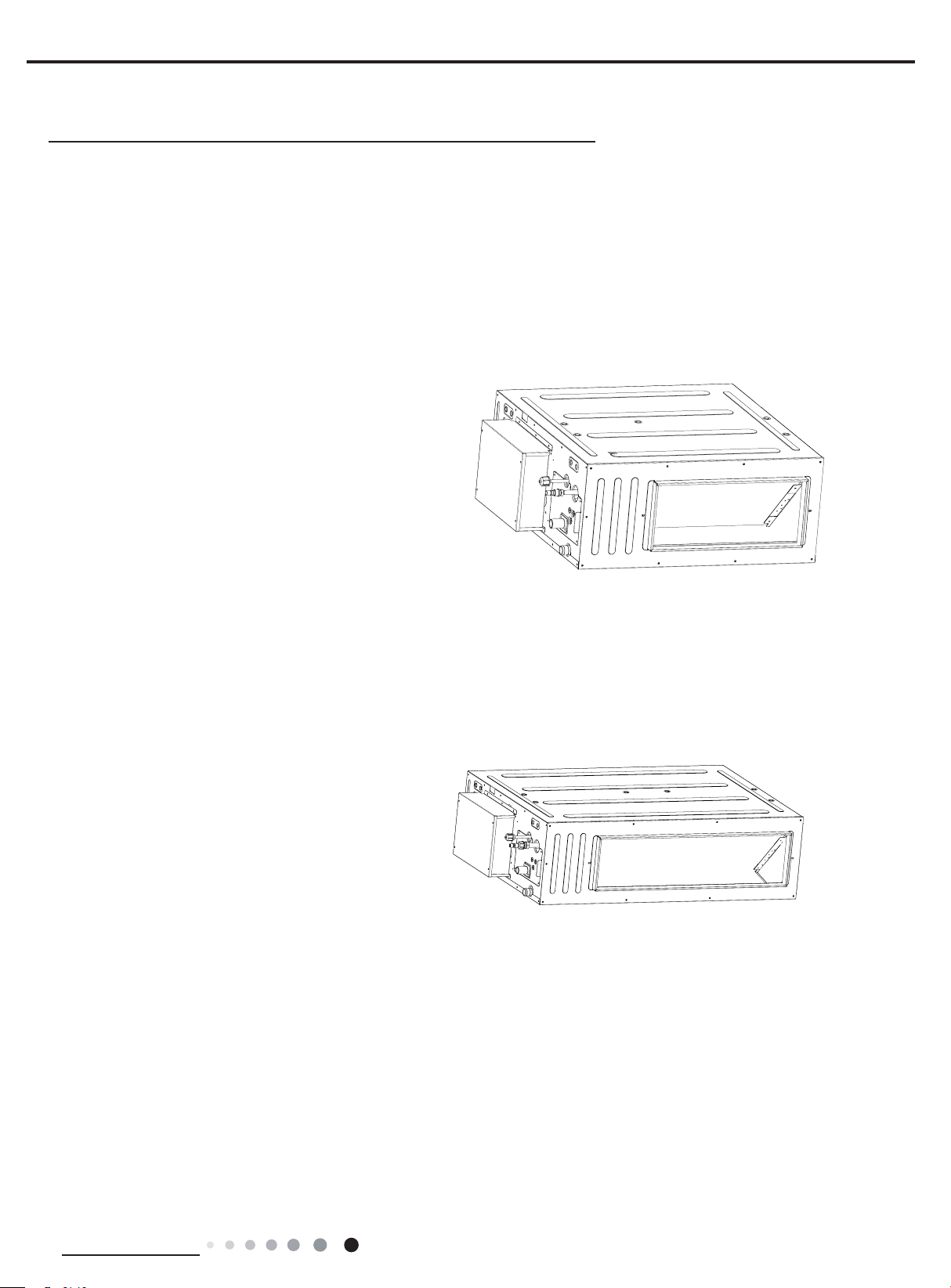

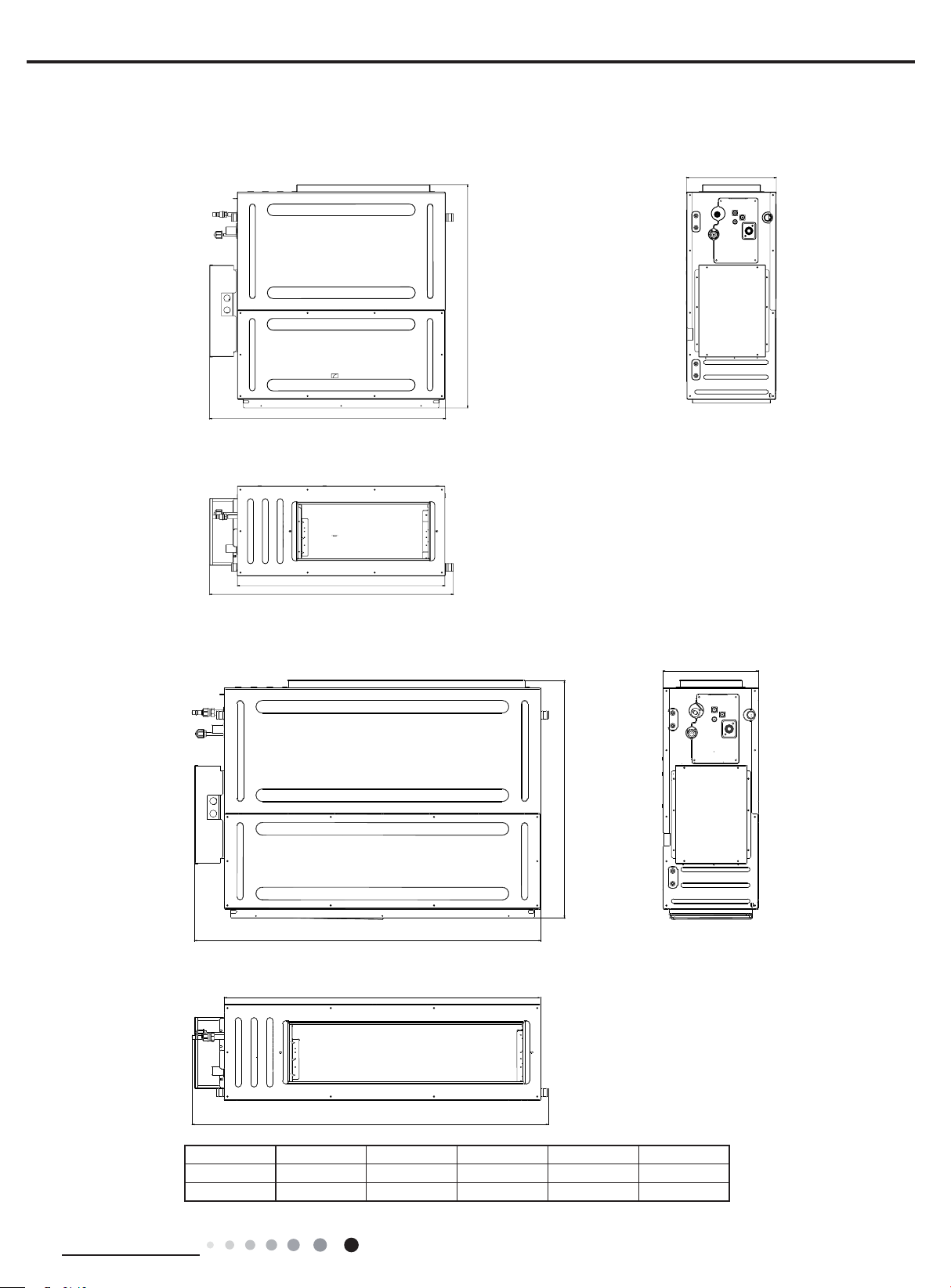

3. Outline Dimension Diagram

DUCT09HP230V1BD DUCT12HP230V1BD

D

B

E

A

DUCT18HP230V1BD GFH(21)DB-D3DNA1A/I DUCT24HP230V1BD

D

E

B

Technical Information

Model A B C D E

09/12K 32 43/64 29 11/16 11 13/16 31 11/32 27 9/16

18/21/24K 44 31/64 29 11/16 11 13/16 43 7/64 39 3/8

5

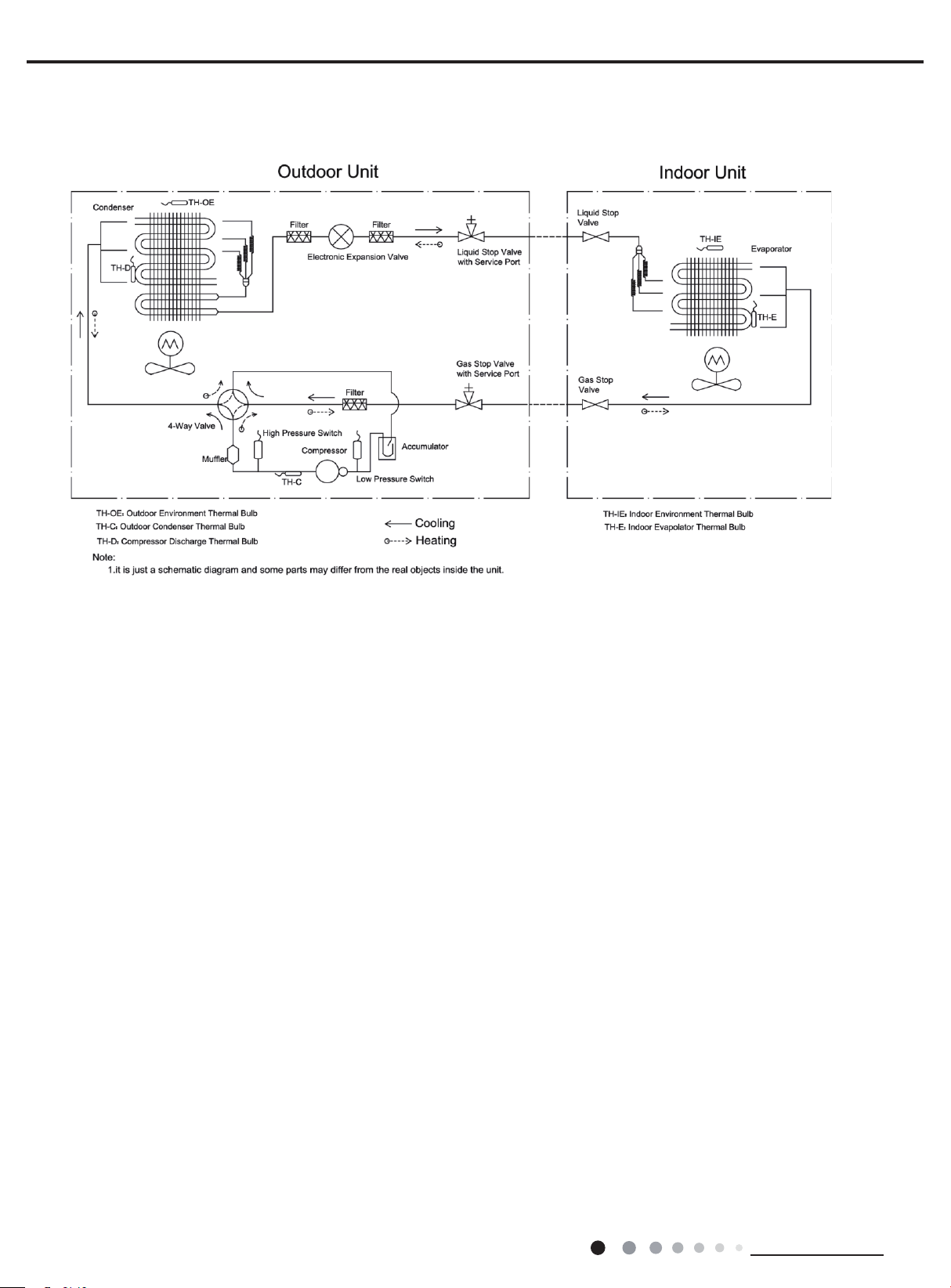

4. Refrigerant System Diagram

Service Manual

6

Technical Information

Service Manual

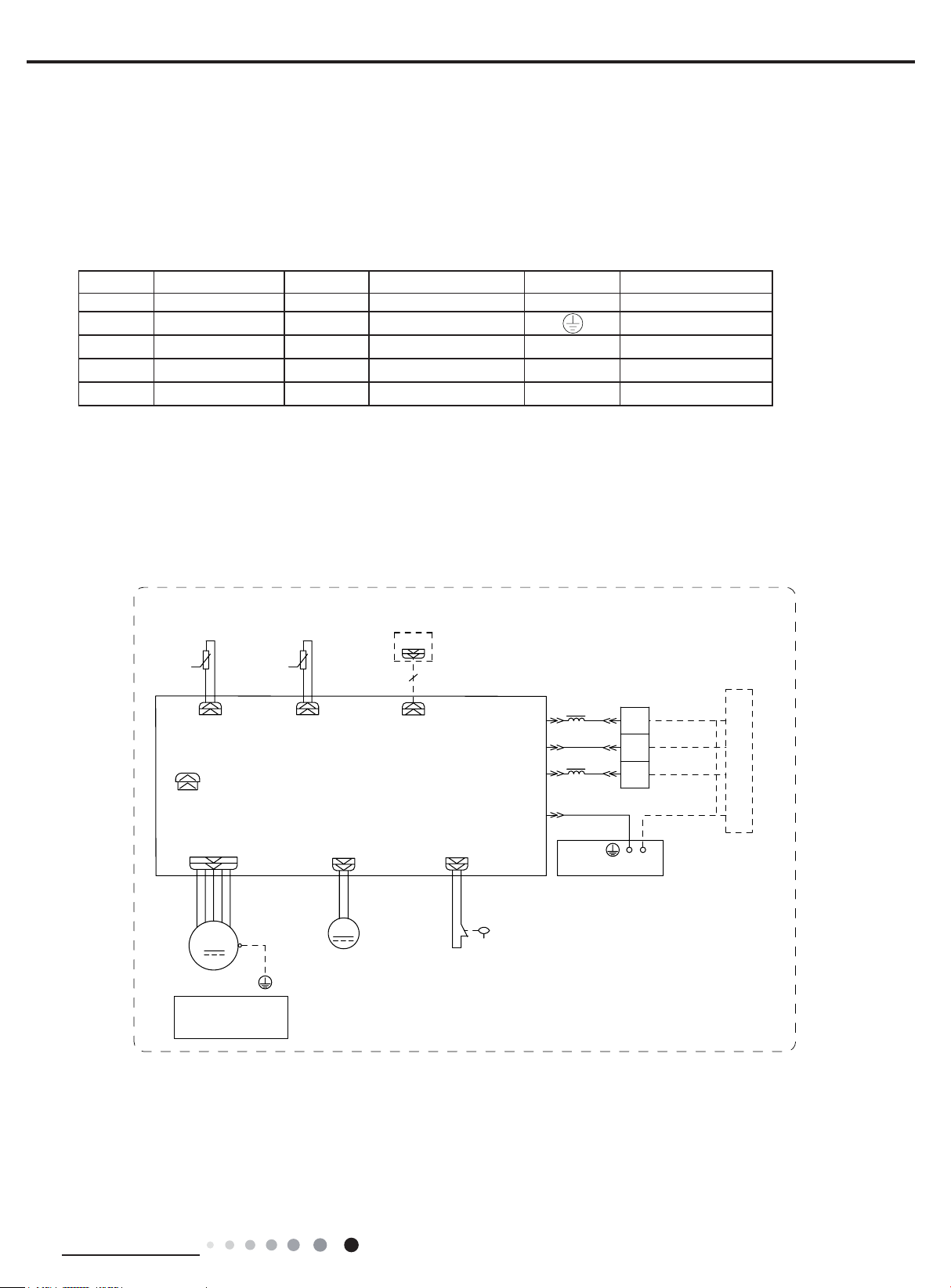

5. Electrical Part

5.1 Wiring Diagram

●Instruction

Symbol Symbol Color Symbol Symbol Color Symbol Name

WH White GN GREEN COMP Compressor

YE Yellow BN Brown Grouding wire

RD Red BU Blue

YEGN Yellow/Green BK Black

VT Violet OG Orange

● Outdoor Unit

78%(7(0352207(03

6(16256(1625

.

5220

&$3

.

$3φ35,17('&,5&8,7%2$5'

-803

'&02725

0

)$102725

1RWH0RWRUJURXQG

RQO\DSSOLHVWRWKH

LURQVKHOOPRWRU

*

78%(

&21752//(5

&200$18$/

0

:$7(53803

02725

:,5('

$3

:$7(5'7&73803

1δ1ε

&20287

$&/

/,48,'/(9(/

6:,7&+

0$*1(7,&

5,1*

3(

(/(&75,&%2;

7(50,1$/

%/2&.

/

%8

%.

/

%1

<(*1

*

:+%8

1

%.

5'%1

;7

*1<(*1

&211(&7,1*

,1'22581,7

600007060236

287'22581,7

&$%/(

These circuit diagrams are subject to change without notice, please refer to the one supplied with the unit.

Technical Information

7

12 3

11

5.2 PCB Printed Diagram

TOP VIEW

●

14

13

12

Service Manual

12Interface of dry contact

Wired controlller terminal

3

Dispaly

4

Jumper cap

4

Water overflow protection

5

Interface of tube temperature sensor

6

Interface of ambient temperature

7

sensor

8

Water pump

Terminal with indoor unit communication

9

Neutral wire terminal

10

Fuse

11

Live wire terminal

12

Neutral wire terminal

13

Wiring terminal for DC motor

14

910

BOTTOM VIEW

●

5678

8

Technical Information

Service Manual

6. Function and Control

After putting through the power, air conditioner will give out a sound and indicators on control panel will be on. After that, you operate the

air conditioner through remote controller or control panel.

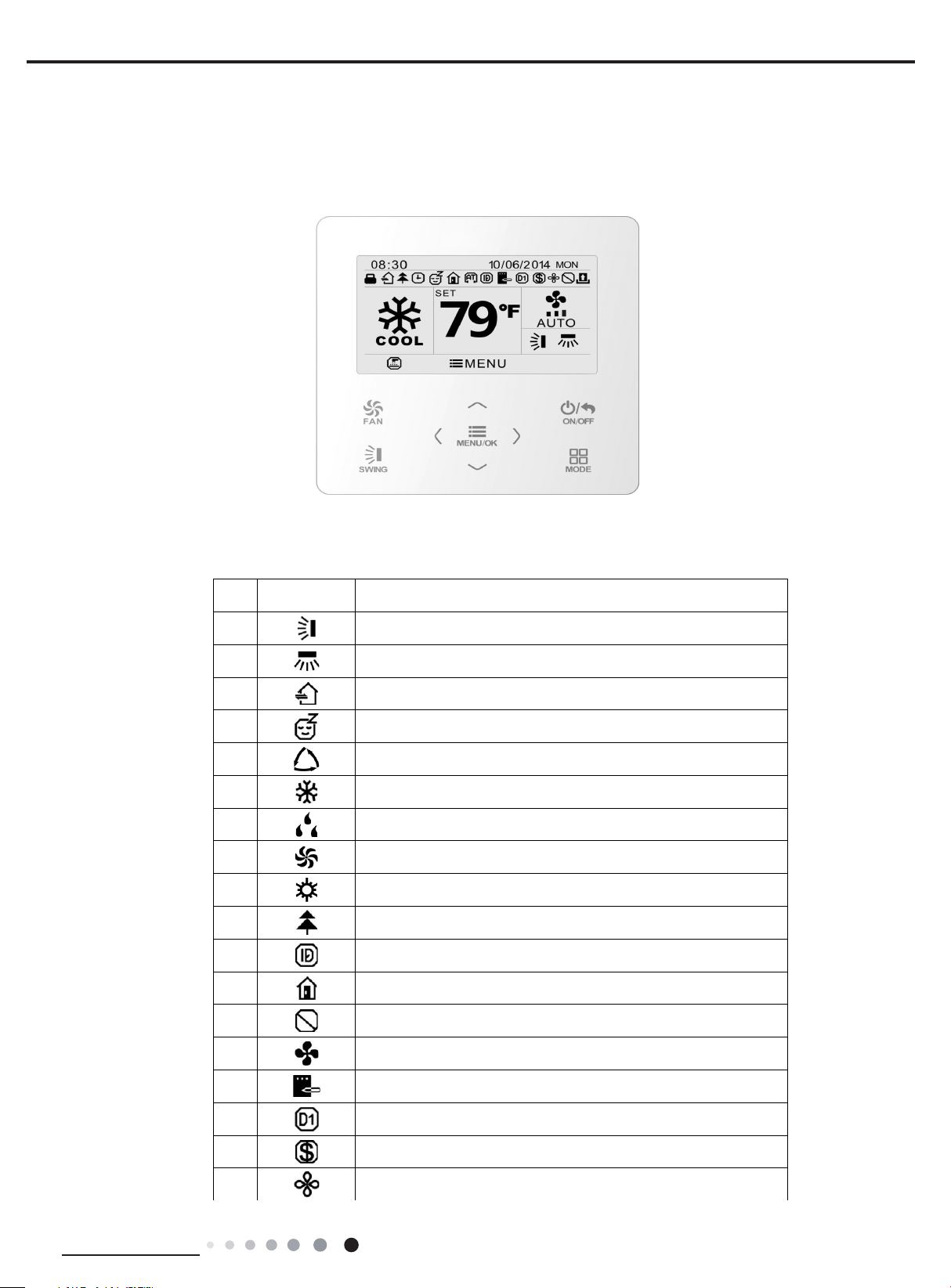

6.1 Introduction of Control Panel

1.1 Display

Fig.1 Appearance of wired controller

1.2 Instructions for Related Displayed Symbols

No. Symbols Instructions

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

Shielding status (Buttons, temperature, ON/OFF, mode or energy saving is

Up and down swing function

Left and right swing function

Fresh air function

Sleep function

Auto mode

Cooling mode

Dry mode

Fan mode

Heating mode

Health function

I-Demand function

Absence function

shielded by remote monitor)

Current set fan speed

Memory function (Memory in power failure)

DRED function

Technical Information

17

18

Save function

X-fan function

9

Service Manual

20

21

22

23

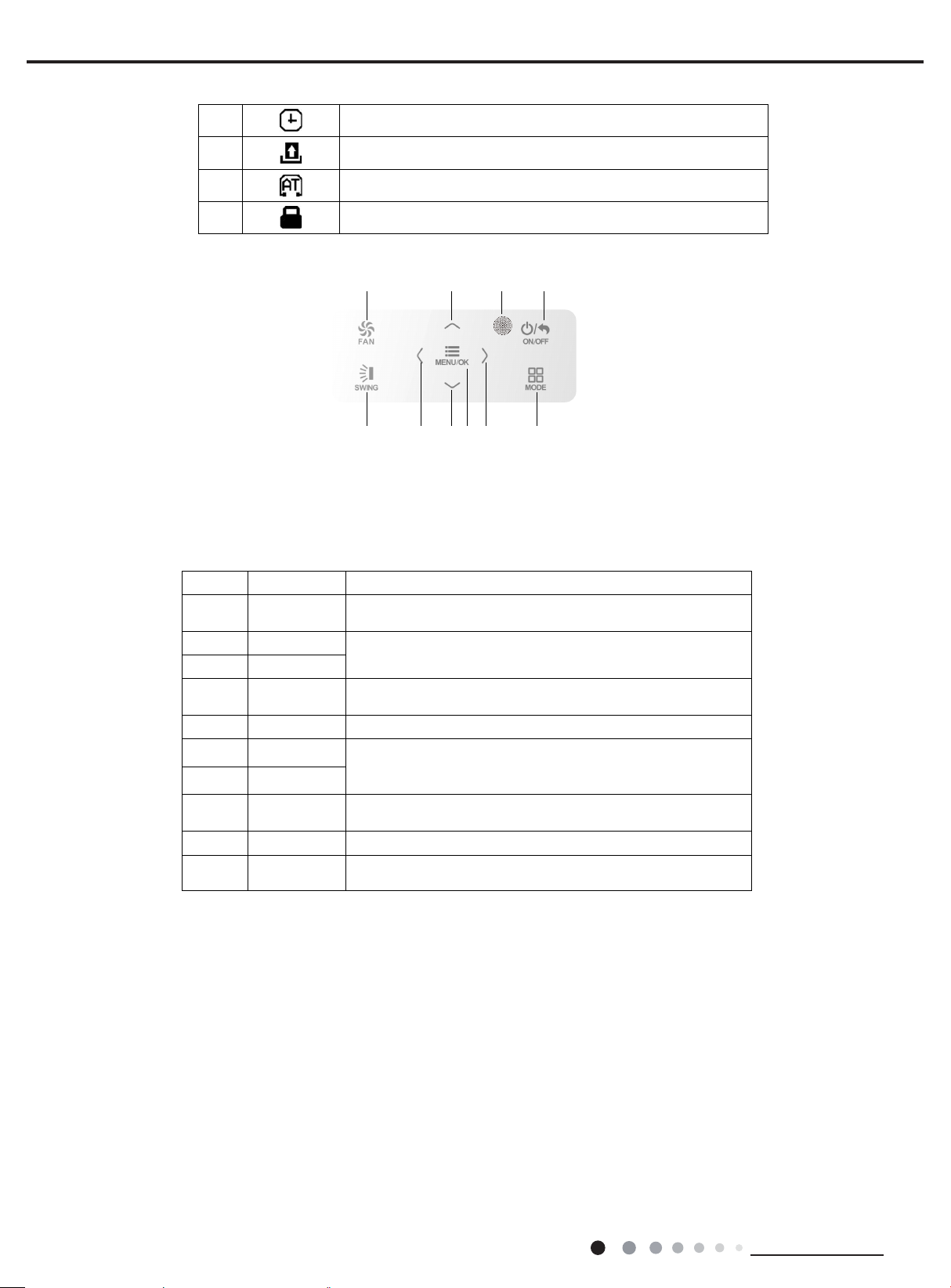

1.3 Button Grapics

1.4 Function Instructions of Buttons

Timer on status

Gate card pulled-off status or nobody presented status

Quiet function

Function lock

12 3

456

10

978

Fig. 2 Button graphics

No.Button name Button Function

1FAN

2

6

3ON/OFF/BACK

4SWING Setup&down swingand set left&right swing

5

8

7MENU/OK

9

10

∧

Z

¥

MODE Setauto, cooling, dry, fan and heating modes for indoor unit.

Remote control

receiver window

Set low speed, medium speed,high speed, turbo and auto speed.

(1) Set temperature

(2) Set parameter

(3) Move option cursor

(1) Turn on or turn off unit

(2) Return to last page

(1)Set relatedfunction on or off

(2) Move option cursor

(3)Set parameter

(1) Enter menu page

(2) Confirm setting

10

Technical Information

Service Manual

6.2 Introduction of Control Panel

1.Basic function of system

(1)Cooling mode

(1) Under this mode, fan and swing operates at setting status. Temperature setting range is 16~30OC.

(2) During malfunction of outdoor unit or the unit is stopped because of protection, indoor unit keeps original operation status.

(2)Drying mode

(1) Under this mode, fan operates at low speed and swing operates at setting status. Temperature setting range is 16~30OC.

(2) During malfunction of outdoor unit or the unit is stopped because of protection, indoor unit keeps original operation status.

(3) Protection status is same as that under cooling mode.

(4) Sleep function is not available for drying mode.

(3)Heating mode

(1) Under this mode, Temperature setting range is 16~30OC.

(2) Working condition and process for heating mode:

When turn on the unit under heating mode, indoor unit enters into cold air prevention status. When the unit is stopped or at OFF status,

and indoor unit has been started up just now, the unit enters into residual heat-blowing status.

(4)Working method for AUTO mode:

1.Working condition and process for AUTO mode:

a.Under AUTO mode, standard heating Tpreset=20OC and standard cooling Tpreset=25OC. The unit will switch mode automatically

according to ambient temperature.

2.Protection function

a. During cooling operation, protection function is same as that under cooling mode.

b. During heating operation, protection function is same as that under heating mode.

3. Display: Set temperature is the set value under each condition. Ambient temperature is (Tamb.-Tcompensation) for heat pump unit

and Tamb. for cooling only unit.

4. If theres I feel function, Tcompensation is 0. Others are same as above.

(5)Fan mode

Under this mode, indoor fan operates at set fan speed. Compressor, outdoor fan, 4-way valve and electric heating tube stop operation.

Indoor fan can select to operate at high, medium, low or auto fan speed. Temperature setting range is 16~30OC.

2. Other control

(1) Buzzer

Upon energization or availably operating the unit or remote controller, the buzzer will give out a beep.

(2) Auto button

If press this auto button when turning off the unit, the complete unit will operate at auto mode. Indoor fan operates at auto fan speed

and swing function is turned on. Press this auto button at ON status to turn off the unit.

(3) Auto fan

Heating mode: During auto heating mode or normal heating ode, auto fan speed will adjust the fan speed automatically according to

ambient temperature and set temperature.

(4) Sleep

After setting sleep function for a period of time, system will adjust set temperature automatically.

(5) Timer function:

General timer and clock timer functions are compatible by equipping remote controller with different functions.

(6) Memory function

memorize compensation temperature, off-peak energization value.

Memory content: mode, up&down swing, light, set temperature, set fan speed, general timer (clock timer cant be memorized).

After power recovery, the unit will be turned on automatically according to memory content.

(7) Health function(only for the model with this function)

During operation of indoor fan, set health function by remote controller. Turn off the unit will also turn off health function.

Turn on the unit by pressing auto button, and the health is defaulted ON.

Technical Information

11

Service Manual

(8)Off-peak energization function:

Adjust compressors minimum stop time. The original minimum stop time is 180s and then we change to:

The time interval between two start-ups of compressor cant be less than 180+T s(0≤T≤15). T is the variable of controller. Thats to say

the minimum stop time of compressor is 180s~195s. Read-in T into memory chip when refurbish the memory chip each time. After power

recovery, compressor can only be started up after 180+T s at least.

(9) SE control mode

The unit operates at SE status.

(10) X-fan mode

When X-fan function is turned on, after turn off the unit, indoor fan will still operate at low speed for 2min and then the complete unit will be

turned off. When x-fan function is turned off, after turn off the unit, the complete unit will be turned off directly.

(11) 8ºC heating function

Under heating mode, you can set 8ºC heating function by remote controller. The system will operate at 8ºC set temperature.

(12) Turbo fan control function

Set turbo function under cooling or heating mode to enter into turbo fan speed. Press fan speed button to cancel turbo wind.

No turbo function under auto, dry or fan mode.

12

Technical Information

Service Manual

Part

: Installation and Maintenance

Ⅱ

7. Notes for Installation and Maintenance

Safety Precautions:

Important!

Please read the safety precautions carefully before

installation and maintenance.

The following contents are very important for installation

and maintenance.

Please follow the instructions below.

●The installation or maintenance must accord with the

instructions.

●Comply with all national electrical codes and local

electrical codes.

●Pay attention to the warnings and cautions in this

manual.

●All installation and maintenance shall be performed by

distributor or qualied person.

●All electric work must be performed by a licensed

technician according to local regulations and the

instructions given in this manual.

●Be caution during installation and maintenance. Prohibit

incorrect operation to prevent electric shock, casualty and

other accidents.

Warnings

Electrical Safety Precautions:

1. Cut off the power supply of air conditioner before

checking and maintenance.

2. The air condition must apply specialized circuit and

prohibit share the same circuit with other appliances.

3. The air conditioner should be installed in suitable

location and ensure the power plug is touchable.

4. Make sure each wiring terminal is connected firmly

during installation and maintenance.

5. Have the unit adequately grounded. The grounding wire

cant be used for other purposes.

6. Must apply protective accessories such as protective

boards, cable-cross loop and wire clip.

7. The live wire, neutral wire and grounding wire of power

supply must be corresponding to the live wire, neutral

wire and grounding wire of the air conditioner.

8. The power cord and power connection wires cant be

pressed by hard objects.

9. If power cord or connection wire is broken, it must be

replaced by a qualied person.

10. If the power cord or connection wire is not long enough,

please get the specialized power cord or connection wire

from the manufacture or distributor. Prohibit prolong the wire

by yourself.

11. For the air conditioner without plug, an air switch must

be installed in the circuit. The air switch should be all-pole

parting and the contact parting distance should be more than

1/8 inch.

12. Make sure all wires and pipes are connected properly and

the valves are opened before energizing.

13. Check if there is electric leakage on the unit body. If yes,

please eliminate the electric leakage.

14. Replace the fuse with a new one of the same specication

if it is burnt down; dont replace it with a cooper wire or

conducting wire.

15. If the unit is to be installed in a humid place, the circuit

breaker must be installed.

Installation Safety Precautions:

1. Select the installation location according to the requirement of this manual.(See the requirements in installation

part)

2. Handle unit transportation with care; the unit should not

be carried by only one person if it is more than 44.09lb.

3. When installing the indoor unit and outdoor unit, a sufcient xing bolt must be installed; make sure the installation

support is rm.

4. Ware safety belt if the height of working is above 78 3/4

inch.

5. Use equipped components or appointed components during installation.

6. Make sure no foreign objects are left in the unit after nishing installation.

Refrigerant Safety Precautions:

1. Avoid contact between refrigerant and re as it generates

poisonous gas; Prohibit prolong the connection pipe by

welding.

2. Apply specied refrigerant only. Never have it mixed with

any other refrigerant. Never have air remain in the refrigerant

line as it may lead to rupture or other hazards.

3. Make sure no refrigerant gas is leaking out when installation

is completed.

4. If there is refrigerant leakage, please take sufcient measure

to minimize the density of refrigerant.

5. Never touch the refrigerant piping or compressor without

wearing glove to avoid scald or frostbite.

Improper installation may lead to re hazard, explosion,

electric shock or injury.

Installation and Maintenance

13

Service Manual

Safety Precautions for Installing and Relocating the Unit:

To ensure safety, please be mindful of the following precautions.

Warnings

1. When installing or relocating the unit, be sure to keep the refrigerant circuit free from air or substances other than the

specied refrigerant.

Any presence of air or other foreign substance in the refrigerant circuit will cause system pressure rise or compressor rupture, resulting in

injury.

2.When installing or moving this unit, do not charge the refrigerant which is not comply with that on the nameplate or

unqualied refrigerant.

Otherwise, it may cause abnormal operation, wrong action, mechanical malfunction or even series safety accident.

3.When refrigerant needs to be recovered during relocating or repairing the unit, be sure that the unit is running in cooling

mode.Then, fully close the valve at high pressure side (liquid valve).About 30-40 seconds later, fully close the valve at low

pressure side (gas valve), immediately stop the unit and disconnect power. Please note that the time for refrigerant recovery

should not exceed 1 minute.

If refrigerant recovery takes too much time, air may be sucked in and cause pressure rise or compressor rupture, resulting in injury.

4.During refrigerant recovery, make sure that liquid valve and gas valve are fully closed and power is disconnected before

detaching the connection pipe.

If compressor starts running when stop valve is open and connection pipe is not yet connected, air will be sucked in and cause pressure

rise or compressor rupture, resulting in injury.

5.When installing the unit, make sure that connection pipe is securely connected before the compressor starts running.

If compressor starts running when stop valve is open and connection pipe is not yet connected, air will be sucked in and cause pressure

rise or compressor rupture, resulting in injury.

6.Prohibit installing the unit at the place where there may be leaked corrosive gas or ammable gas.

If there leaked gas around the unit, it may cause explosion and other accidents.

7.Do not use extension cords for electrical connections. If the electric wire is not long enough, please contact a local service

center authorized and ask for a proper electric wire.

Poor connections may lead to electric shock or re.

8.Use the specied types of wires for electrical connections between the indoor and outdoor units. Firmly clamp the wires so

that their terminals receive no external stresses.

Electric wires with insufcient capacity, wrong wire connections and insecure wire terminals may cause electric shock or re.

14

Installation and Maintenance

Loading...

Loading...