Gree A Series, LSQWRF35VM/NaA-M, LSQWRF60VM/NaA-M, LSQWRF65VM/NaA-M, LSQWRF70VM/NaA-M Installation, Start-up And Maintenance Manual

A Series Inverter Modular Air-cooled Chiller (Heat Pump)

LSQWRF35VM/NaA-M、LSQWRF60VM/NaA-M

LSQWRF65VM/NaA-M、LSQWRF70VM/NaA-M

To Users

Thank you for selecting Gree’s product. Please read this instruction manual carefully before

installing and using the product, so as to master and correctly use the product. In order to

guide you to correctly install and use our product and achieve expected operating effect, we

hereby instruct as below:

(1)This equipment should be installed, operated or maintained by the qualified

servicemen who have had specific training. During operation, all safety issues

covered in the labels, User’s Manual and other literature should be followed strictly.

This equipment is not intended for use by persons (including children) with reduced

physical, sensory or mental capabilities, or lack of experience and knowledge, unless

they have been given supervision or instruction concerning use of the appliance by a

person responsibility for their safety. Children should be supervised to ensure that

they do not play with the appliance.

(2)This product has gone through strict inspection and operational test before leaving the

factory. In order to avoid damage due to improper disassembly and inspection, which

may impact the normal operation of unit, please do not disassemble the unit by

yourself. You can contact with the special maintenance center of our company if

necessary.

(3)For personal injury or property loss and damage caused by improper operation such as

improper installation and debugging, unnecessary maintenance, violation of related

national laws and rules and industrial standard, and violation of this instruction

manual, etc., we will bear no liability.

(4)When the product is faulted and cannot be operated, please contact with our

maintenance center as soon as possible by providing the following information.

1) Contents of nameplate of product (model, cooling/heating capacity, product No.,

ex-factory date).

2) Malfunction status (specify the situations before and after the error occurs).

(5)All the illustrations and information in the instruction manual are only for reference. In

order to make the product better, we will continuously conduct improvement and

innovation. We have the right to make necessary revision to the product from time to

time due to the reason of sales or production, and reserve the right to revise the

contents without further notice.

(6)The final right to interpret for this instruction manual belongs to Gree Electric

Appliances Inc. of Zhuhai.

Contents

1 Safety Notices............................................................................................................ 1

2 General Introduction .................................................................................................. 6

2.1 Product Features ................................................................................................. 7

2.2 Principle Diagrams .............................................................................................. 8

3 Operation Range ....................................................................................................... 8

4 Outline Dimensions ................................................................................................... 9

5 Installation Instructions ............................................................................................ 10

5.1 Pre-check........................................................................................................... 10

5.2 Acceptance Check............................................................................................. 10

5.3 Handling and Lifting............................................................................................11

5.4 Installation Foundation and Service Space ....................................................... 12

5.5 Vibration Reduction ........................................................................................... 13

5.6 Installation of the Water System ........................................................................ 14

6 Introduction to the Display Panel............................................................................. 16

7 Electric Wiring.......................................................................................................... 16

7.1 External Wiring of the Electric Control Cabinet ................................................. 16

7.2 Specification of Power Cord and Air Switch ...................................................... 17

7.3 Wiring of the Electric Control Cabinet................................................................ 18

7.4 Filed Wiring ........................................................................................................ 18

7.5 Networking and Wiring between Units .............................................................. 20

7.6 Setup of Toggle Switches on the Motherboard.................................................. 21

7.7 Jumpers ............................................................................................................. 22

8 Commissioning and Maintenance ........................................................................... 23

8.1 Check before Startup......................................................................................... 23

8.2 Requirements on Water Quality and Cleaning .................................................. 23

8.3 Trial Run ............................................................................................................ 25

8.4 Routine Startup/Shutdown ................................................................................ 25

8.5 Maintenance to the Main Parts.......................................................................... 26

8.6 Maintenance during Long-term Downtime ........................................................ 26

8.7 Startup after Long-term Shutdown .................................................................... 26

8.8 Parts Replacement ............................................................................................ 26

8.9 Refrigerant Charging ......................................................................................... 27

8.10 Removal of the Compressor............................................................................ 27

8.11 Freeze Protection............................................................................................. 28

8.12 Rountine Maintenance..................................................................................... 28

8.13 Precautions...................................................................................................... 29

9 Troubleshooting and After-sales Service ................................................................ 30

9.1 Troubleshooting Measures ................................................................................ 30

9.2 After-sales Service ............................................................................................ 32

A Series Inverter Modular Air-cooled Chiller (Heat Pump)

1 Safety Notices

Warning:If not abide strictly, it may cause severe damage to the unit or the people.

Note:If not abide strictly, it may cause slight or medium damage to the unit or the people.

This sign indicates that the operation must be prohibited. Improper operation may cause

severe damage or death to people.

This sign indicates that the items must be observed. Improper operation may cause

damage to people or property.

◆Safety Notices for On-site Installation

WARNING

(1)Installation should be performed by qualified servicemen who have taken

specialized training and acquired corresponding certificates in accordance with

relative laws, regulations and this manual, otherwise it would lead to damage to the

unit, water leakage, electrocution, or fire hazards etc.

(2)The unit should be installed on the smooth foundation capable of supporting the unit

and fixed with screw bolts. The foundation with inadequate strength would lead to

leakage, turn-over or personal injury or death.

(3)Special lines should be used for electric installation by qualified electricians. Lines

with inadequate capacity would lead to electrocution or fire hazards.

(4)Make sure each connector is properly tightened; otherwise it would lead to

overtemperature or fire hazards etc.

(5)When installation is finished, please check for the drainage lines, pipelines, and

electric lines to prevent water leakage, electrocution or fire hazards.

(6)This equipment should be installed where the drainage system can work well. Never

block the drain hole. Improper drainage system would lead to drainage difficulty and

make the unit suffer from malfunctions.

(7)When there is something unusual (like stinky smell) during installation or

commissioning, please cut off the main power at once and then contact the

aftersales service center. This ongoing unusual condition will damage the air

conditioning unit and lead to electrocution or fire hazards

(8)When refrigerant leaks, take corrective measures as soon as possible to prevent

oxygen depletion by increased refrigerant concentration.

1

A Series Inverter Modular Air-cooled Chiller (Heat Pump)

NOTE

(1)Do not install the unit where there is high-intensity magnetic field or it is highly basic

or acid or the voltage is quietly unstable.

(2)Do not install the unit where there would be leaked inflammable gas, as it would lead

to fire hazards.

(3)The outer casing of the unit should be grounded. Do not connect the grounding line

to the gas line, water line, lightning rod or communication line, otherwise it would

lead to electric shocks.

(4)Do not stand on the unit or place other object on it.

(5)Do not insert fingers or other objects into the outlet grill to prevent damage to the unit

or personal injury or death.

(6)Do not start or stop the unit by inserting or drawing out the power plug.

(7)Do not let children play with this unit.

(8)The unit should be equipped with the leakage protector which should be installed in

accordance with electric technical standards. Uninstallation or incorrect installation

would lead to electrocution. Do electric leakage detection after electric installation is

finished.

(9)Volatile liquid like thinner or gasoline would damage appearance of the unit. (Only

clean the outer casing with of the unit with soft dry cloth or wet cloth with neutral

detergent.

DANGER

(1)Do not install the unit where conditions are severe, where it is close to the hot spring,

coast or oil field, as it would lead to corrosion, electrocution or fire hazards.

Besides, do not install the unit where there are corrosive, inflammable substances

or smog, otherwise it would lead to normal operation failure, shortened service life,

fire hazard, or severe injury.

(2)Do not start the compressor by manually closing the AC contactor, otherwise it would

lead to electrocution or fire hazard.

(3)Do not misuse refrigerant, as it would lead to normal operation failure, unsatisfactory

performance, fire hazards or even explosion etc.

2

A Series Inverter Modular Air-cooled Chiller (Heat Pump)

CAUTION

(1)Installation should be done in accordance with this manual. Please read it manually

prior to startup or troubleshooting.

(2)Installation should be done by qualified servicemen, as incorrect installation would

lead to water leakage, electrocution or fire hazards etc.

(3)Before installation, check for all power supplies with the nameplate and check for its

safety.

(4)The unit should be grounded and there should be specialized grounding line for the

power socket to avoid of electrocution. Do not connect the groundling line to the gas

tank, water line, lightning rod, or telephone line.

(5)Only specialized accessories and parts are allowed for installation, otherwise it

would lead to water leakage, electrocution or fire hazards etc.

(6)Size of the power lines should be large enough. Only specialized power lines are

allowed for replacing the damaged ones.

(7)When power lines have been connected, install the electric box as well to avoid of

any safety problems.

(8)After all installation has been finished, take an overall check to the unit before

powering it on.

◆Safety Precautions for Usage and Maintenance

WARNING

(1)When there is something unusual (like burnt smell), cut off the power supply at once

and contact the sales agent. The ongoing unusual condition would lead to

malfunctions, electrocution or fire hazards.

(2)When refrigerant leaks, take corrective measures to prevent oxygen depletion by

increasing refrigerant concentration.

(3)Do not use or place inflammable or explosive substances near the unit.

(4)Do not do troubleshooting personally, as incorrect troubleshooting would lead to

electrocution or fire hazards. Instead, please contact GREE after-sales service

center.

(5)When the unit is charged with refrigerant, do not solder or cut any pipeline, fined

heat exchanger, shell-and-tube heat exchanger or other containers.

3

A Series Inverter Modular Air-cooled Chiller (Heat Pump)

NOTE

(1)Do not let the unit out of the designed application range; otherwise it would cause

the heat exchanging tube cracking, refrigerant leakage or even explosion.

(2)Do not let the cold/heat source directly act on the stored foods, plants, animals,

precision instruments, and curiosities, otherwise their quality would be degraded.

(3)Only circulating water with satisfactory water qualify are allowed for the unit, as

unsatisfactory water quality would shorten the service life of the unit or even

malfunctions.

(4)When the unit has been put into use for some time, check for security of the

installation foundation. Unstable foundation would lead to deformation or even

safety accident.

(5)Once the unit is started up, stop it at least 6 minutes later, otherwise it would shorten

the service life of the unit. Never deliberately start or stop the unit frequently.

(6)Under subzero climatic conditions, pay attention to freeze protection. When the unit

is out of use in short time, do not cut off the power supply, as freeze protection will

not act normally. When the unit is out of used in quite long time, add anti-freezing

agent to water or drain the water system, otherwise it would make the shell and

tube crack and then leak.

DANGER

(1)Do not use the fuse out of the normal range or replace it with the electric wire,

otherwise it would damage the unit or lead to fire hazards.

(2)Do not start or stop the unit directly by the power switch, as it would be likely to

cause electrocution or fire hazards.

(3)Do not change settings of safety devices; otherwise it would lead to fire hazards and

explosion.

(4)Do not operate the unit with wet hands.

(5)Do not clean the unit without cutting off the power supply, as it would lead to

electrocution or personal injury.

(6)Do not let children pull power lines or climb the unit to prevent of electrocution or

other dangers.

(7)Do not touch high-temperature parts of the compressor and refrigerant lines, as it

would lead to burns.

(8)Do not touch sharp edges and fins of the heat exchanger; otherwise it would lead to

personal injury.。

(9)Do not touch any moving part; otherwise it would lead to accidental injury.

(10)Do not stand on the unit or replace objects on it.

(11)Do not bend pipeline and retrofit the unit, otherwise it would lead to refrigerant

leakage, explosion, fire hazards or personal injury.

4

A Series Inverter Modular Air-cooled Chiller (Heat Pump)

CAUTION

(1)Do operate the unit in accordance with this manual and read it carefully before

startup or troubleshooting.

(2)Do turn on or off the unit with the controller.

5

A Series Inverter Modular Air-cooled Chiller (Heat Pump)

◆Safety Precaution for Handling of the Unit

Safety Precaution for Handling of the Unit

WARNING

(1)Please contact the contractor for handling and installation. Improper installation

would lead to electrocution or fire hazard.

(2)During installation or handling, do not let foreign matters mixed with refrigerant and

do not air trapped inside the pipe, as it would lead to increased system pressure or

explosion of the compressor.

(3)Only specialized power lines are allowed. Wiring terminals should suffer no any

external force and are fixed properly; otherwise it would lead to fire hazards.

Besides, make sure insulation of power lines always in good condition.

(4)Connection between two ends of the power lines is not allowed. When its length is

not enough, please contact the after-sales service center for customizing another

one long enough.

CAUTION

(1)Treatment of water, cleaning solution, refrigerant or other waste liquid or gas should

comply with local laws and regulations; otherwise it would lead to adverse effect to

health and environment.

(2)Do not misuse refrigerant, as it is one of the causes of fire hazard and explosion.

Precautions for Refrigerant Charging

NOTE

When charging is interrupted or finished, reinspect the unit but do not let the compressor

run into operation.

WARNING

Do not use mixture of refrigerant vapor and air or oxygen for pressurizing for fear of

explosion.

2 General Introduction

See the nameplate for the main technical data.

The all-inverter modular air-cooled chillers are capable of performing cooling all year around

with high energy efficient. It requires no cooling towers and is quite applicable to water-

deficient areas, and can be widely used at newly built or retrofitted industrial and civil buildings

in various sizes, such as, hotels, apartments, restaurants, office buildings, shopping malls,

theaters, gyms, workshops, hospitals, places where there is requirement on cooling under

ultra-low temperature, like cold storages, places where require cooling for dairy products,

foods and industrial products, and especially places where there are high requirements on

6

A Series Inverter Modular Air-cooled Chiller (Heat Pump)

noise level and surrounding environment and boils and cooling towers are not allowed or hard

to be installed.

2.1 Product Features

The all-inverter modular air-cooled chillers work outstandingly by virtue of their major

features stated below..

■ Excellent compatibility:

The all-inverter modular air-cooled chillers can be constructed of multiple single units with

the same or different structure or capability (30kW, 60kW, 65kW and 70kW). For the 35kW

unit, it has only one cooling system; for the 60kW, 65kW and 70kW units, they are of two

independent systems. Up to 16 single units can be modularized, with cooling capacity ranging

from 35kW to 1104kW.

■ Comfort and energy saving:

The variable-frequency technology can quickly respond to load change and lead to

decreased water temperature fluctuation and better comfort.

■ Ultra-quiet:

The high-efficiency and low-noise fan blades and motor as well as the optimized air passage

can greatly lower operation noise of the unit. Besides, the quite mode can provide the user a

ultra-quite environment.

■ Powerful self-protection:

It is equipped with the top-end microcomputer control system which is capable of providing

well-rounded protection and self-diagnosis.

■ High reliability:

It is constructed of well-designed refrigeration parts and well-designed system, structure

and electric control, adequately guaranteeing reliable operation

■ Remote ON/OFF:

The unit can be started or stopped by the ON/OFF key operation.

■ Equilibrium running:

It indicates each compressor will run alternately so as to extend their service life.

■ Shiftwork of water pumps:

Two water pumps can work alternately with equilibrium runtime so as to extend their service

life and lower the maintenance difficulty.

7

A Series Inverter Modular Air-cooled Chiller (Heat Pump)

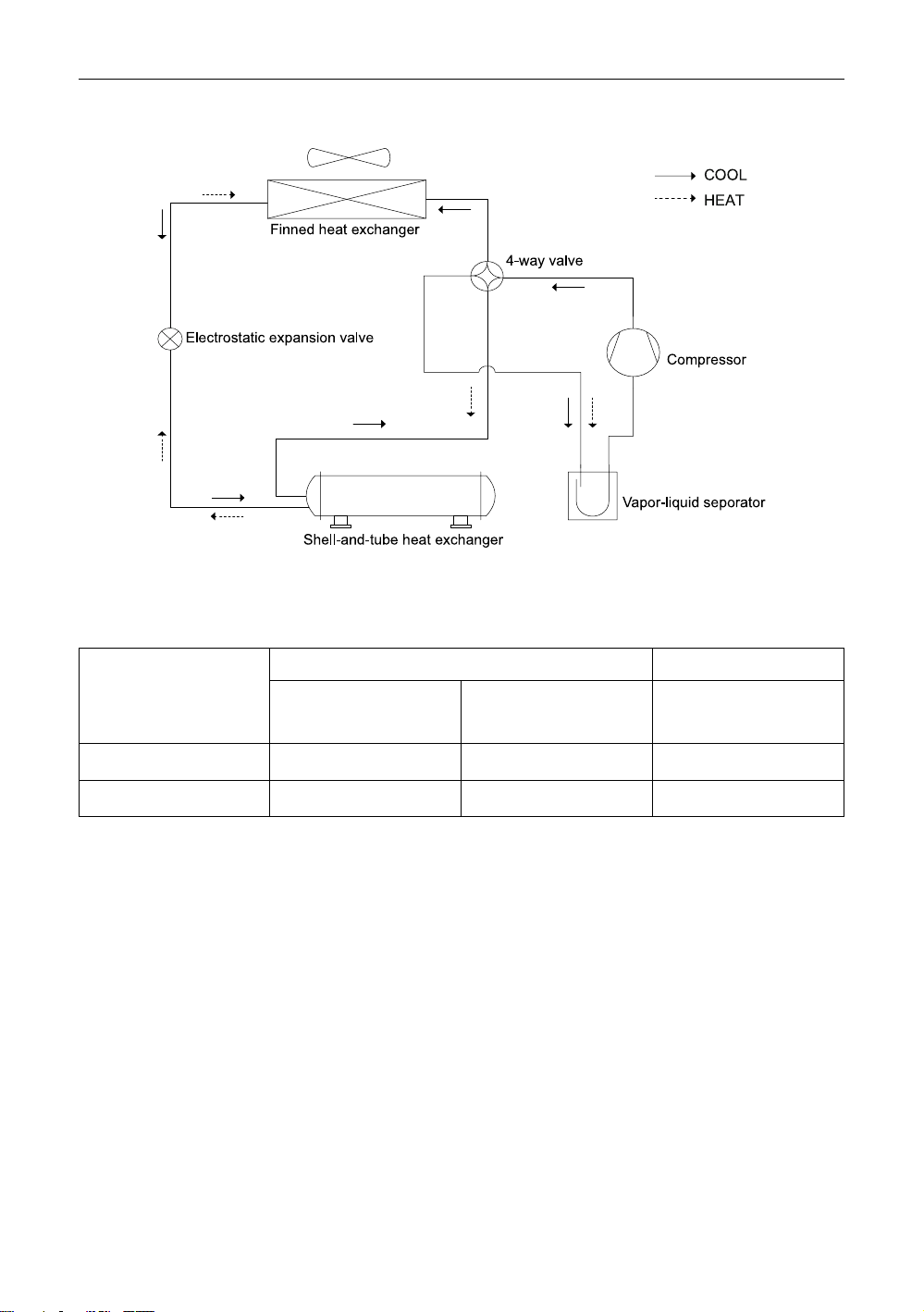

2.2 Principle Diagrams

3 Operation Range

Please run the unit under the specified operation range as shown in the table below:

■ R410A Series

Item

Cooling

Heating

Water Side Air Side

Leaving Water

Temperature(℃)

5~20 2.5~6 –15~52

35~50 2.5~6 -20~40

Water Temperature

Difference(℃)

Ambient DB

Temperature(℃)

8

Loading...

Loading...