GREAT WATER M1D2 Installer And User Manual

Great Water M1D2

Water Softener

Installer and User Guide

Effective January 2019

Great Water Limited

Unit 9b Camphill Industrial Estate

West Byfleet

Surrey

KT14 6EW

01932 245783

www.greatwater.co.uk

info@greatwater.co.uk

Important: please don’t forget to register your Warranty for

7 years Parts and 2 Years Labour Guarantee

Programming and Installation Instructions

Thank you for choosing a Great Water product. Please read the following instructions carefully to

ensure a trouble free installation.

1. Planning The installation

• Always observe the relevant water regulations.

• Make sure your selected location allows sufficient space and access for salt filling and

maintenance.

• Make Sure your mains water pressure is within the specified parameters of 1.5 – 5 Bar. If the

daytime pressure exceeds 3.5 Bar then we recommend a Pressure limiting valve be installed

to 5 Bar

• Identify how and where you will be able to run your waste and overflow connections

• Identify your available power source.

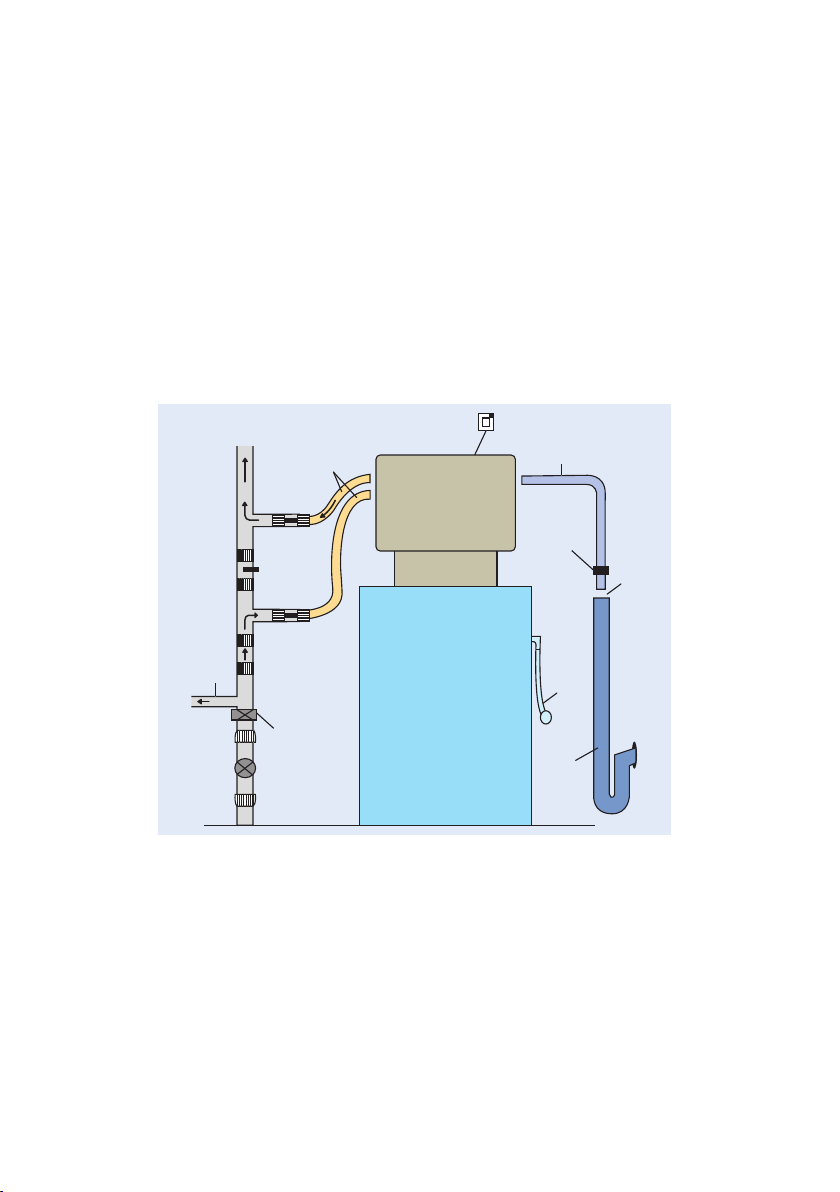

The water softener should be installed as per the diagram below.

Power

CONTROL

VALVE

SALT

STORAGE

TANK

Drain Hose

Drain Clip

Overflow

hose

through

outside

wall

Trapped

Upstand OR

run drain

hose to

external gully

20mm

air gap

Bypass Valve

(shut)

Check Valve

Hard Water

Supply

SOFT WATER

TO SERVICE

Inlet and Outlet

Flexible Hoses

Outlet Valve

(open)

Inlet Valve

(open)

Pressure Limiting

Valve (if required)

STOP TAP ON

INCOMING MAIN

Notes

a. Keep the distance to the drain as short as possible and ensure that the drain and overflow

connections are not subject to freezing.

b. If siting the softener in a cupboard or in a loft ensure that the base is flat strong enough and

adequately supported for the weight of the water softener including salt (approx. 40kg)

c. If the softener is to be sited in a loft it is strongly recommended that the softener be housed

within a 25 gallon storage (safety) tank with a minimum ¾” overflow connection. It is essential

that the overflow connection be as low as possible on the safety tank and in any event below

the height of the overflow connection from the water softener.

d. Check valve. Domestic ion exchange water softeners are considered a Fluid category 2 risk.

Therefore a type EA or EB single check valve should be fitted to the pipework immediately

before the tee feeding the water softener as a suitable backflow prevention.

e. Drinking Water – it is recommended that a hard water supply be used for the kitchen cold

drinking water and any outside taps.

2

CHECK

Check that you have the correct installation kit for your application before commencing the works.

• 15mm Standard Kit (SK-15) – Suitable for Conventional plumbing systems with roof tanks.

• 15mm High Flow Kit (HFK–15) – Suitable for 15mm systems with mains fed appliances

e.g. Combi Boilers, Electric Showers etc.

• 22mm Pressurised System Kit (PSK–22) – Suitable for unvented and pressurised systems

with 22mm plumbing connections.

Available from your merchant supplier.

WATER PRESSURE – Be Careful – Daytime pressure of 3.5 Bar (50 psi) can easily exceed

100psi overnight. If in doubt fit a pressure limiting valve set to 5 bar.

2. Inlet and Outlet Connections

Connect the elbow end of the hoses provided to the inlet and outlet connections on the rear of

the softener.

Important: under no circumstances should you use washing machine hoses or plumb the water

softener in solid copper pipe.

A B

C

A = Inlet Connection

B = Outlet Connection

C= Overflow Connection

D = Waste connection

D

Loading...

Loading...