Great Wall GW491QE Service Manual

Based on the model GW491Q (4Y) carburetor petrol engine, the GW491QE petrol

engine produced by our company is of one petrol engine able to electrically inject fuel

at multiple points, and is developed from electrical control components made by Delphi

company, USA, and Shanghai United Electronic Company. This model shows a

predominant improvement in aspects of power and economical efficiency, and is in

compliance with GB18352.2-2001 “Limits and measurement methods for exhausts

of pollutants from light vehicles (II) ”(equivalent to European Class-II standard), and

conforms to stipulations at phase III for GB18352.3-2005 “Limits and measurement

methods for exhausts of pollutants from light vehicles (at phase III &IV in China)”

(equivalent to European Class-III standard).

To meet the needs from numerous maintenance /technical / management

personnel, we prepare this “GW491QE Petrol Engine Service Manual” based on the

latest technical materials.

All contents, specifications, and data stated in this manual are the latest information

before printing and this service manual will be subject to a supplemental, revision, and

completion from time to time.

This manual may be used for the reference by mechanics, drivers, and technical /

management personnel as the manual is complete in contents, definite in requirements,

and simple in maintenance.

Constrained by the level of the writer, it’s unavoidable to have some defects in

this manual, and your comments and suggestions are highly appreciated.

Preface

Model GW491QE petrol engine

Service Manual

Engine service &maintenance data......................................................................................

United Electronic engine management system..................................................................

Delphi engine management system......................................................................................

Engine body..............................................................................................................................

Cylinder head............................................................................................................................

Valve mechanism......................................................................................................................

Cooling system.........................................................................................................................

Lubrication system..................................................................................................................

Ignition system.........................................................................................................................

Starting system........................................................................................................................

Charge device..........................................................................................................................

Clutch.........................................................................................................................................

G1

EF.1

EF.2

EM.1

EM.2

EM.3

CO

LU

IG

ST

CH

CL

GI-1

Engine service /Maintenance data

Key technical parameters for model GW491QE petrol engine.......................

Specification &adjustment parameters for key components ...........................

T echnical data for maintenance......................................................................

Tightening torque for fastening elements.........................................................

Troubleshooting............................................................................................

Engine service /maintenance data..................................................................

Page

GI-2

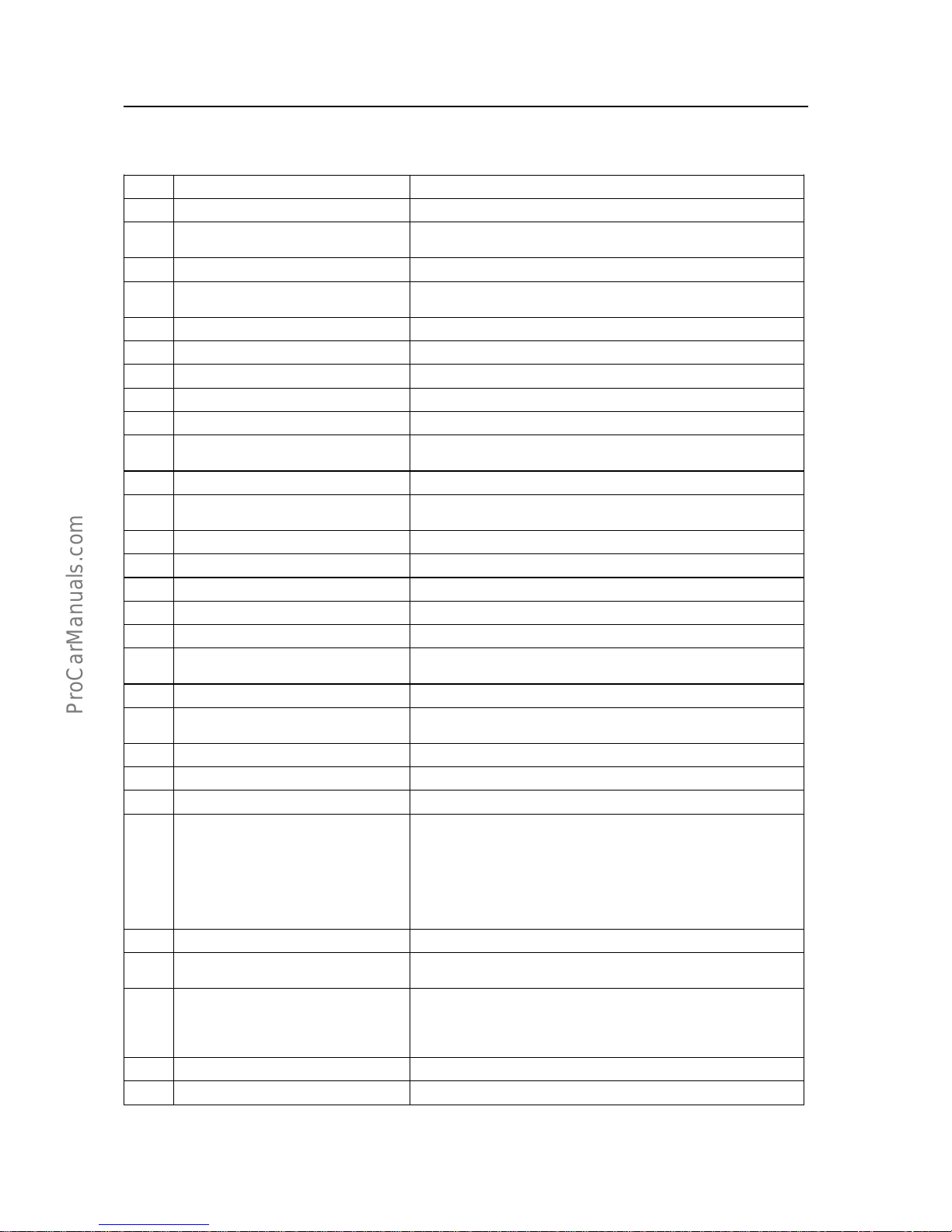

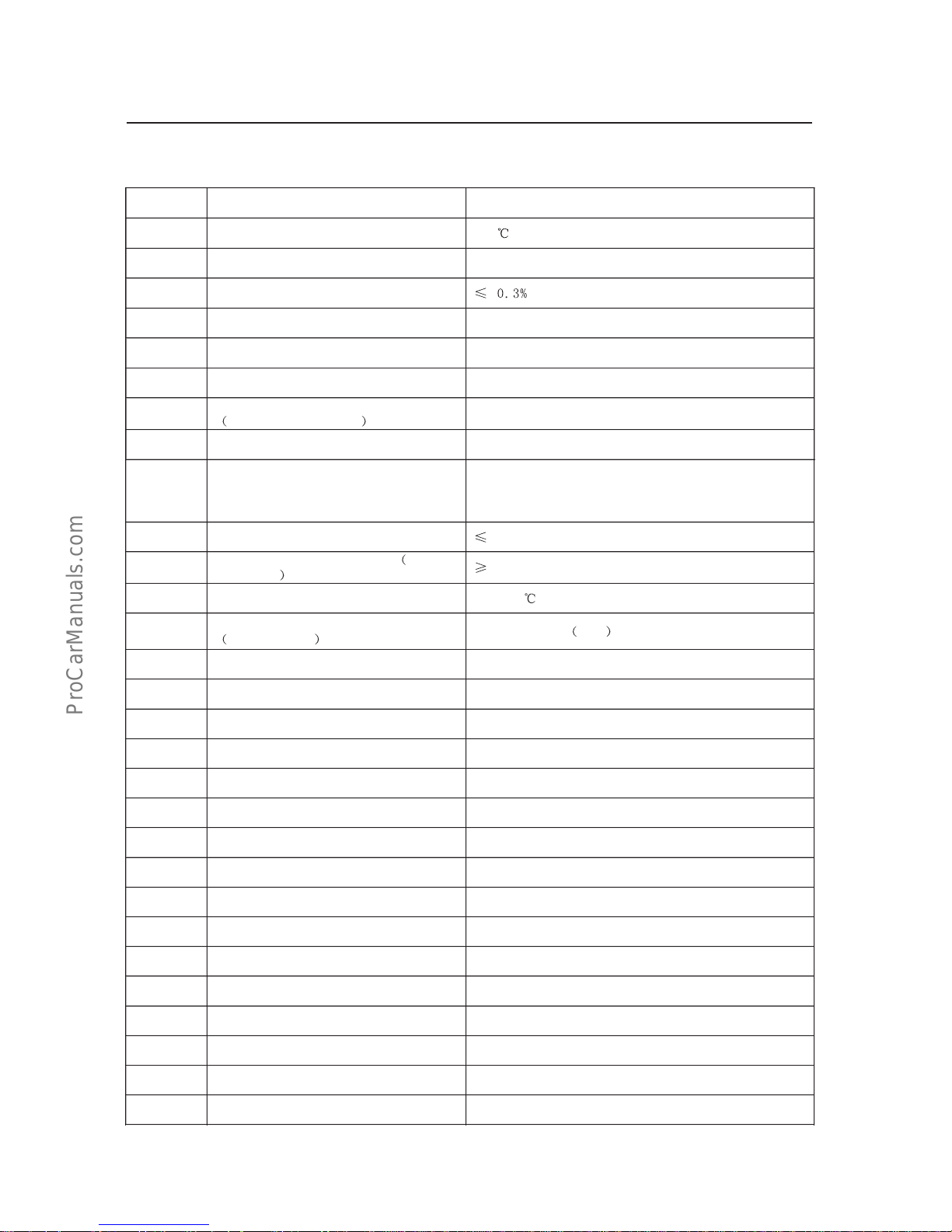

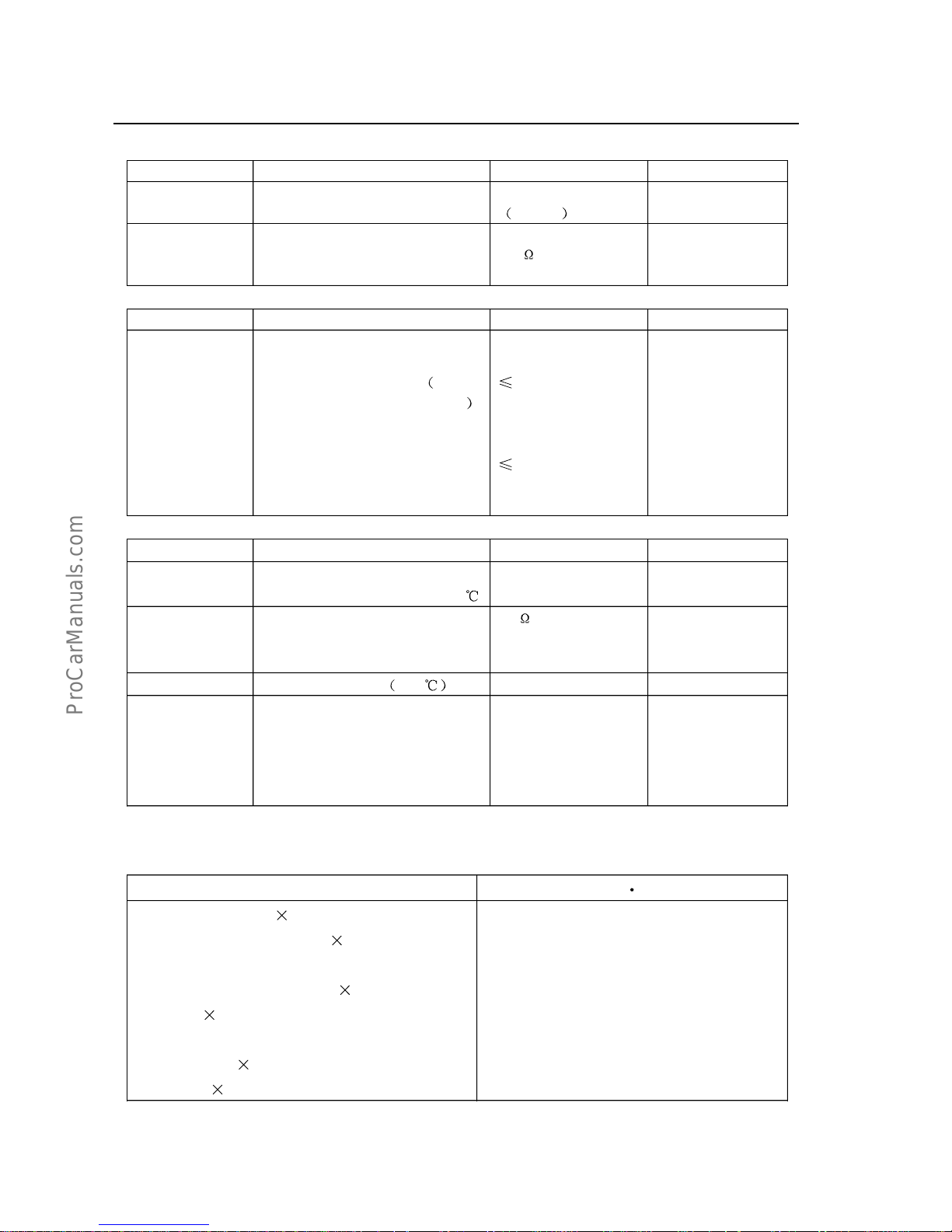

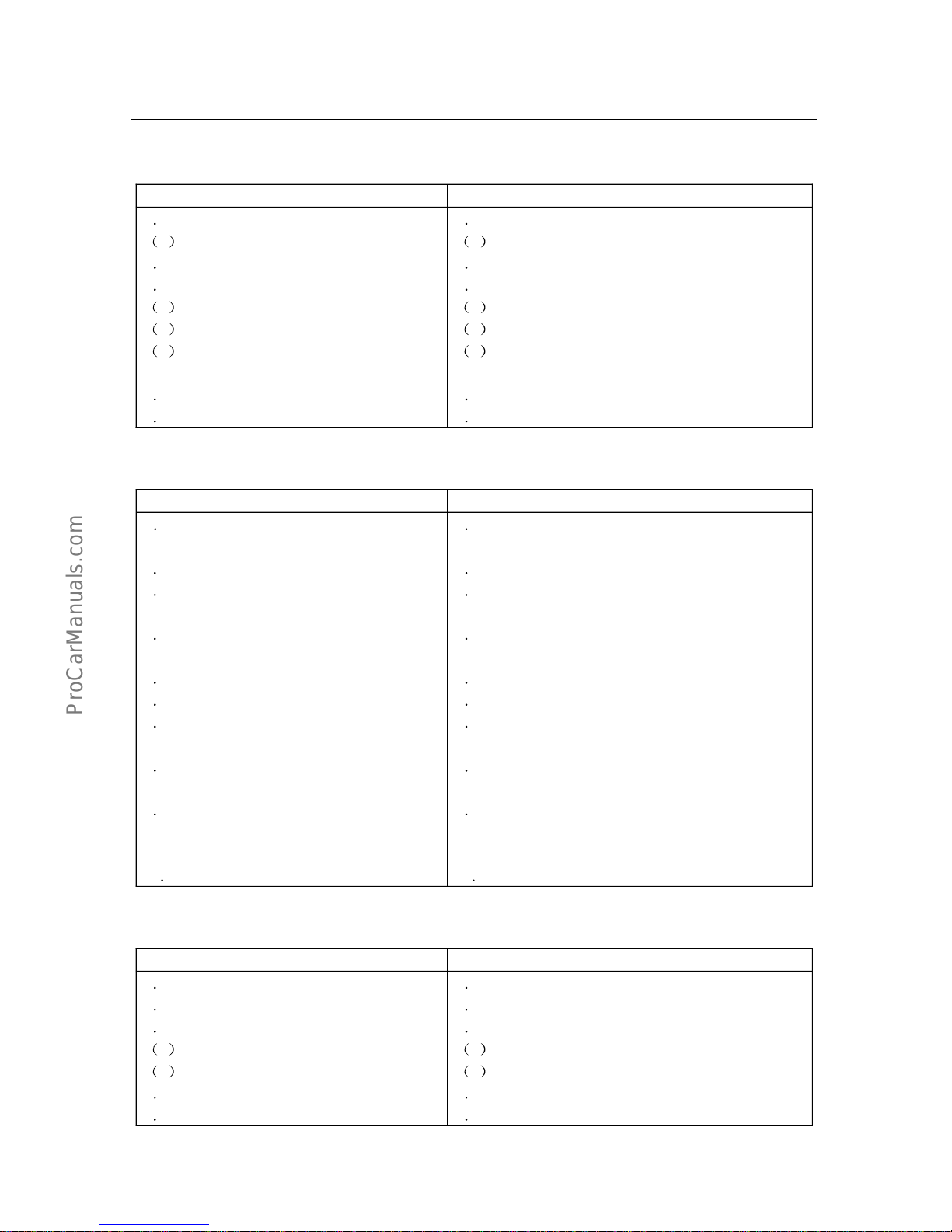

Key technical parameters for Model GW491QE petrol engine

S.N. Item Specification and parameters

1 Model Model GW491QE

2 Pattern

Four-cylinder, inline, water-cooled, overhead valve,4-stroke

petrol engine

3 Fuel supply pattern Electronic controlled jet injection by group at multiple points

4

Measurement method for air intake

amount

Velocity &density type

5 Pattern of combustion chamber Wedge typed

6 Diameter of cylinder bore 91mm

7 Piston stroke 86mm

8 Displacement 2.237L

9 Compression ratio

8.8:1(European class-II)9.1:1European class-III

10 Rated power

78kw/4600 r/min(European class-II)

78kw/4600 r/min(European class-III)

11 Max. torque

190·m/2400~2800 r/min

12 Min. fuel consumption rate

≤265g/kw·h(European class-II)≤250g/kw·h(European

class-III)

13

Fuel specRON Not lower than 93#GB17930-1999

14 Stable idle-speed

750±50r/min

15 Idle-speed control pattern Electronically closed-loop control

16 Piston average velocity 13.18m/s

17 Average valid pressure 874kpa

18

Compression pressure of cylinder

when at 250r/min

1128kpa(European class-II); 1350kpaEuropean class-III

19 Ignition sequence 1-3-4-2

20 Ignition control pattern

Without ignition distributor, and direct ignition under an

electronic control

21 Spark plug clearance 1.0~1.2mm

22 Model of spark plug F6RTC

23 Valve clearance

0mmhydraulic tappet

24

Valve timing:

Inlet-valve open lead angle;

Inlet-valve close lag angle;

Exhaust-valve open lead angle;

Exhaust-valve close lag angle;

12°before the top dead center,

48°before the bottom dead center;

54°before the bottom dead center;

10°before the top dead center;

25 Pattern of lubrication A combined pattern of pressure and splash.

26 Oil spec

SG grade machine oil API10W-40GB11121-1995for petrol

engine

27

Main passage oil pressure

When at idle-speed 750±50r/min

or 3000r/min

49 kpa

(245-490) kpa

28 Oil capacity 4.2L

29 Oil temperature

(85~90)℃

Engine service /maintenance data-Key technical parameters for Model GW491QE petrol engine

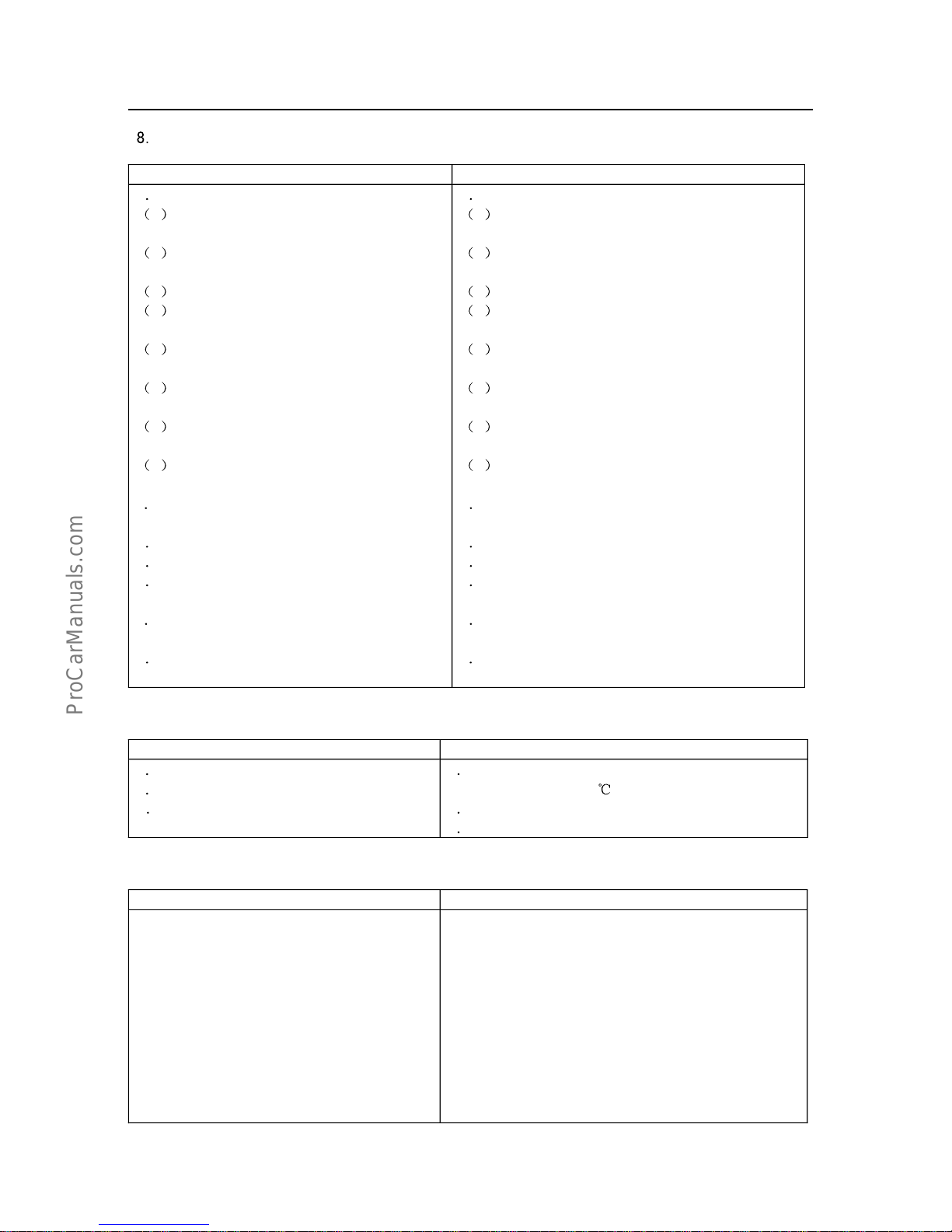

GI-3

S.N.ItemSpecificationandparameters

30Max.oiltemperature

110

31Consumptionrateofoil2g/kw·h

32Fuelconsumptionratioofmachineoil

33CoolingmethodUseforcedwatercirculationforcoolingpurpose.

34Completemass150kg

35PatternofstartupElectrical

36

Exteriordimension

length×width×height

(754.5×518×651)mm(electronicfan)

37

Dualidle-speedemission

GB18285-2005

38

Emissioncontrollevelwhenunder

operatingcondition

Withathree-waycatalytic converter,andaclosed

loopcontrolforair/fuelratio,andthewithlight-duty

vehiclesatisfiesrequirementsfromGB18352.2-2001

andGB18352.3-2005standards.

39Differencebetweencylinders

98kpa

40

Vacuuminsideairintakepipe

whenat

idle-speed

53.3kpa

41Temperatureofoutletcoolingwater(80~90)

42

Tensiondegreeoffanbelt

Pressure98N

Beltdeviation:7~8mm

Engineservice/maintenancedata-keytechnicalparametersforModelGW491QEpetrolengine

GI-4

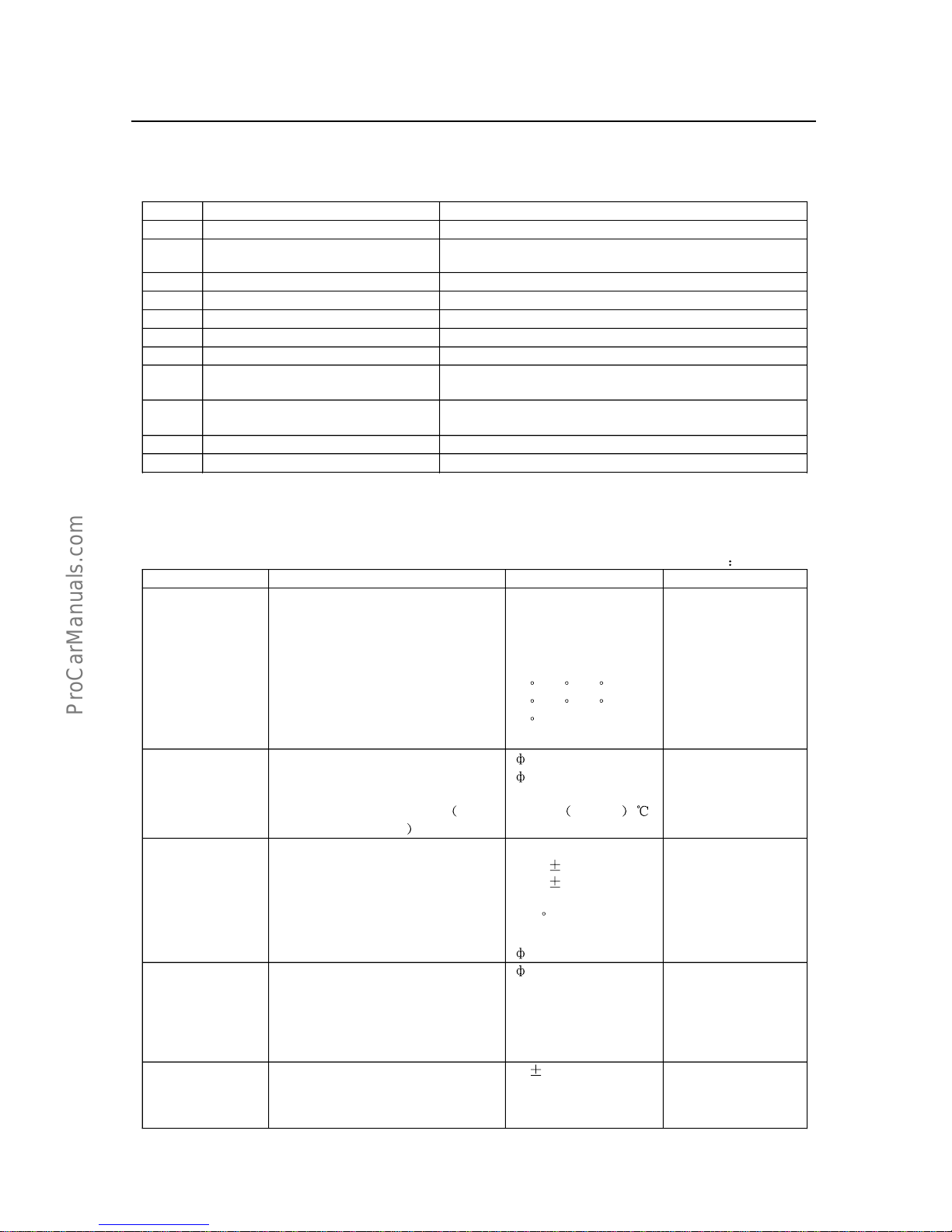

Engineservice/maintenancedata-specification/adjustmentparameters/maintenancetechnicaldata

dataforkeycomponeats

Specification/adjustmentparameters

forkeycomponents

S.N.ItemSpecificationandparameters

1SparkplugF6RTC

2Startermotor

Deceleratingtypewhenunderanelectromagnetic

controlU=12VP=1KW

3GeneratorandvoltageregulatorU=14VI=65A/90A

4PetrolpumpBlade-typeelectricalpump

5OilpumpRotortyped

6CoolingwaterpumpCentrifugaltype

7ThermostatWaxtype

8Petrolfilter

Steelcover,withsuperhighmolecularweight,and

filtrationcore

9Oilfilter

Full-flow&integraltype,screwinstalledfiltration

papercores

10IgnitioncoilU=12V

11ClutchDiaphragmspringtype

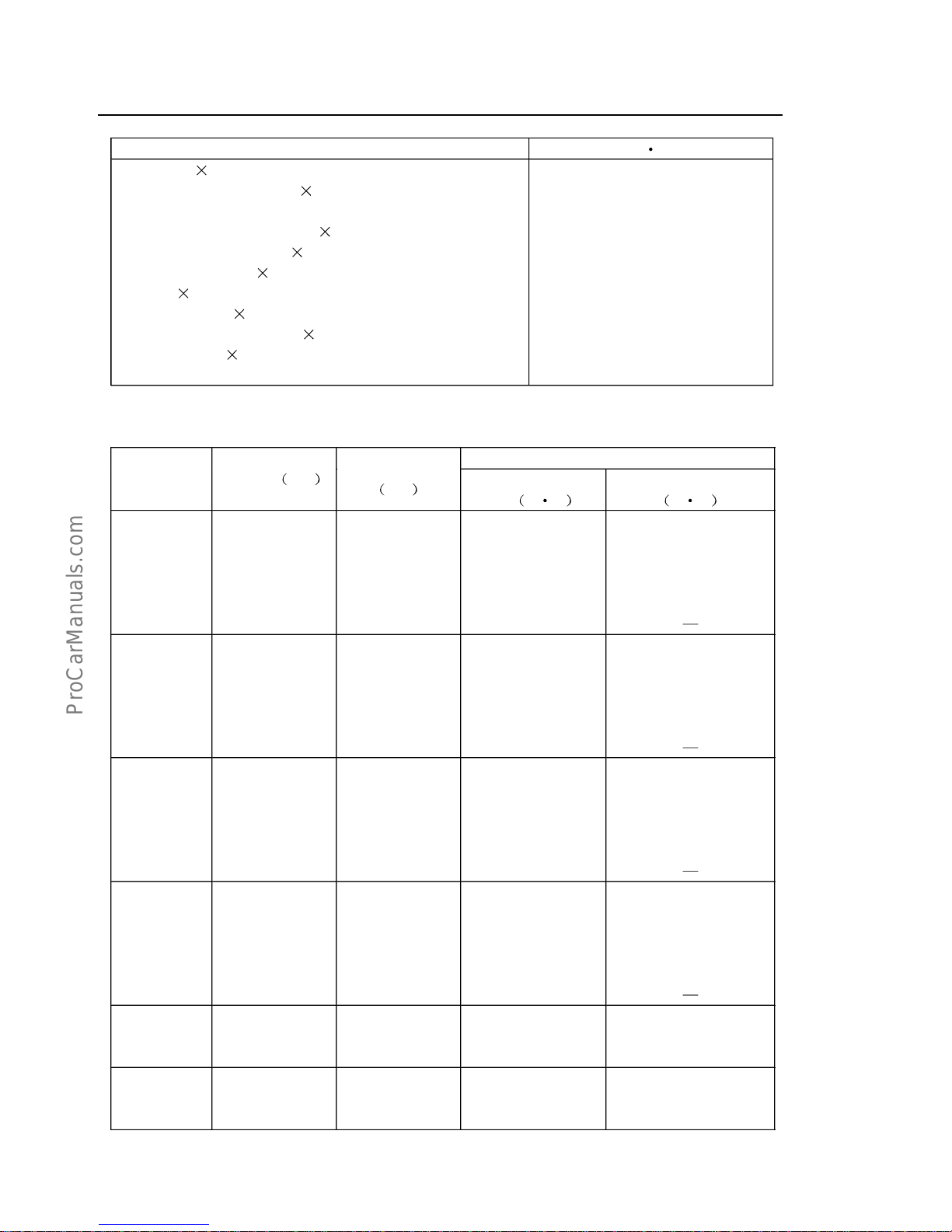

Maintenancetechnicaldata

1.Enginemechanism

Unit

mm

NameTestitemsStandardvalueUselimit

Cylinderhead

Planenessonthecontactsurfaceof

body;

Planenessonthecontactsurfaceof

manifoldpipe;

Slopeangleofvalveseat

Airintake

Airexhaust

Contactangle

Contactwidth

0.05

0.05

30

,45,60

30,45,60

45

1.2~1.6

0.15

0.10

Valveguide

Innerdiameter

Exteriordiameter

Increasedsize0.05

Temperaturewhenchanging

onthe

sideofcylinderhead

8

13

13.088~13.100

Heatto

80~100

Valve

Wholelengthofvalve

Airintake

Airexhaust

Angleofvalveworkingsurface

Airintakeandexhaust

Diameterofvalverod

Airintake

108.20.10

108.5

0.10

44.5

8

107.7

108.0

Valve

Airexhaust

GapofvalverodAirintake

Airexhaust

Edgethicknessofvalveplate

Airintake

Airexhaust

8

0.025~0.060

0.030~0.065

0.10

0.12

0.5

0.8

Valvespring

Freelength

Installationheight

Installationtension

Nonperpendicularity

47

0.5

40.6

(282~345)N282

2.0

+0.030

+0.010

+0.050

+0.038

-0.015

-0.030

-0.020

-0.035

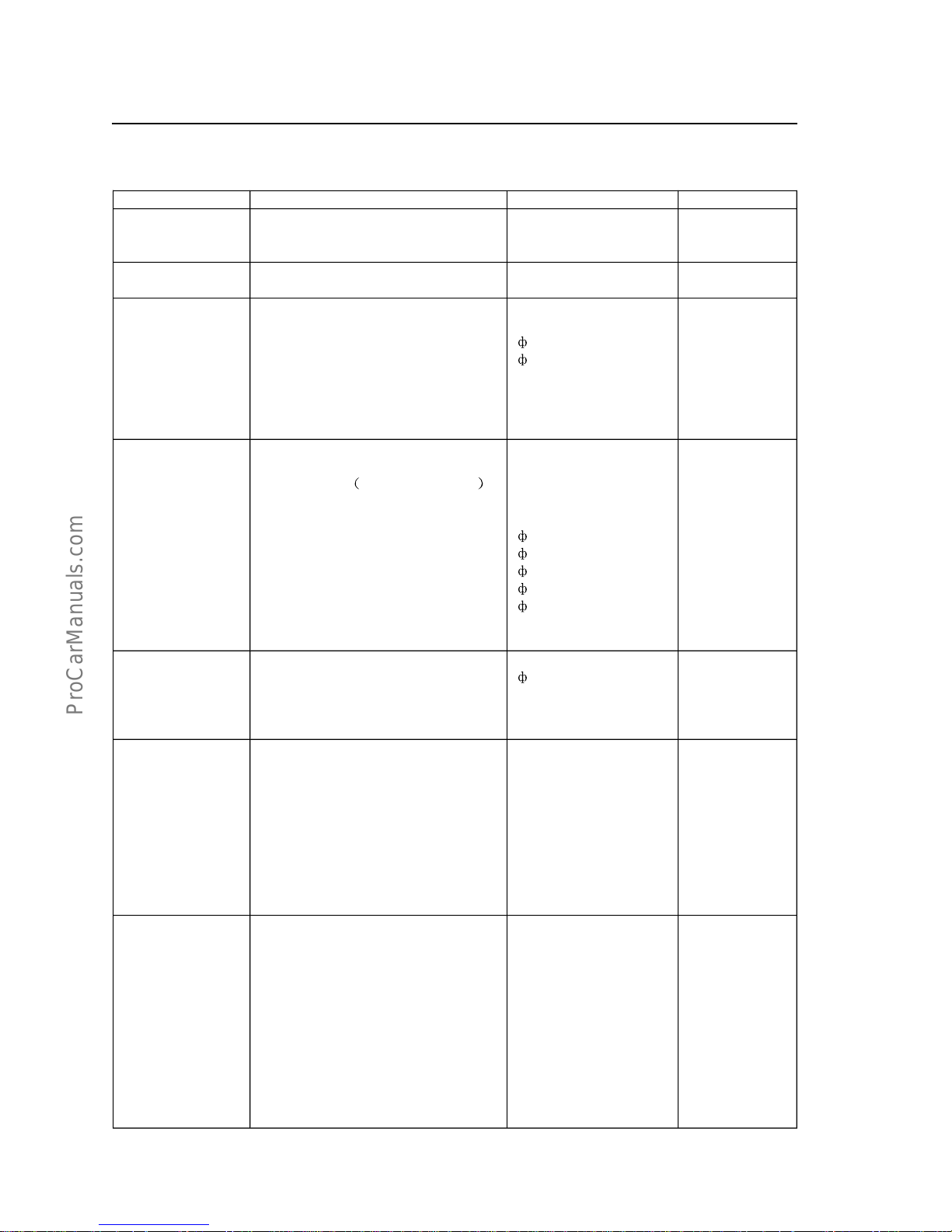

GI-5

Engineservice/maintenancedata-specification/adjustmentparameters/maintenancetechnical

dataforkeycomponents

NameTestitemsStandardvalueUselimit

Rockerandaxis

forvalve

Innerdiameterofrockerhole

Diameterofrockershaft

Gapbetweenrockerandrockershaft

18.5

18.5

0.018~0.0460.08

Intakemanifold

pipe

Planeness0.050.4

Timinggear/chain

gear

Whenthesaggingofchainis98N,

Diameterofrearchainwheel(withchain)

Crankshaft

Camshaft

Lengthofchainwarpafteruse

Thicknessofchaintensioner

Thicknessofshockabsorber

13.5

58.2

113.23

291.4

12.5

5

Camshaftand

bearing

Max.circumferentialradialbeat

eccentricity

HeightofcamMin.convexvalue

Airintake

Airexhaust

AxialdiameterofcamshaftNo.1

No.2

No.3

No.4

No.5

Clearanceofaxialdiameter

Axialclearance

0.05

38.6791

38.6869

46.5

46.25

46

45.75

45.5

0.025~0.081

0.07~0.22

0.10

0.30

Cylinderblock

Planeness

Diameterofborehole

increasedsize0.50

increasedsize0.75

increasedsize1.00

91

0.05

91.24

91.74

91.99

92.24

Pistonand piston

ring

Pistondiameter

increasedsize0.50

increasedsize0.75

increasedsize1.00

Clearanceofpiston

Sideplayofannulargroove

Openinggapofpistonring

Firstgasring

Secondgasring

Oilring

90.938~90.968

91.425~91.455

91.675~91.705

91.925~91.955

0.042~0.062

0.03~0.075

0.20~0.40

0.35~0.55

0.20~0.80

0.065~0.085

1.11

1.07

1.10

Pistonpinand

connectionrod

Axialclearanceofmainbodyfor

connectionrodonbigheadend

Axialclearanceofconnection-rod

cover

Bendofconnectionrodevery100mm

Distortofconnectionrodevery

100mm

Innerdiameterofconnectionrodon

smallhead

Exteriordiameterofpistonpin

Gapofinnerholeonsmallheadside

ofpistonpinandconnectionrod

0.16~0.31

0.021~0.051

0.03

0.03

22.010~22.016

22.003~22.006

0.004~0.013

0.18~0.32

0.05

0.15

+0.013

0

-0.018

-0.033

0

-0.2

0

-0.23

-0.025

-0.041

-0.025

-0.041

-0.025

-0.041

-0.025

-0.041

-0.025

-0.041

+0.030

0

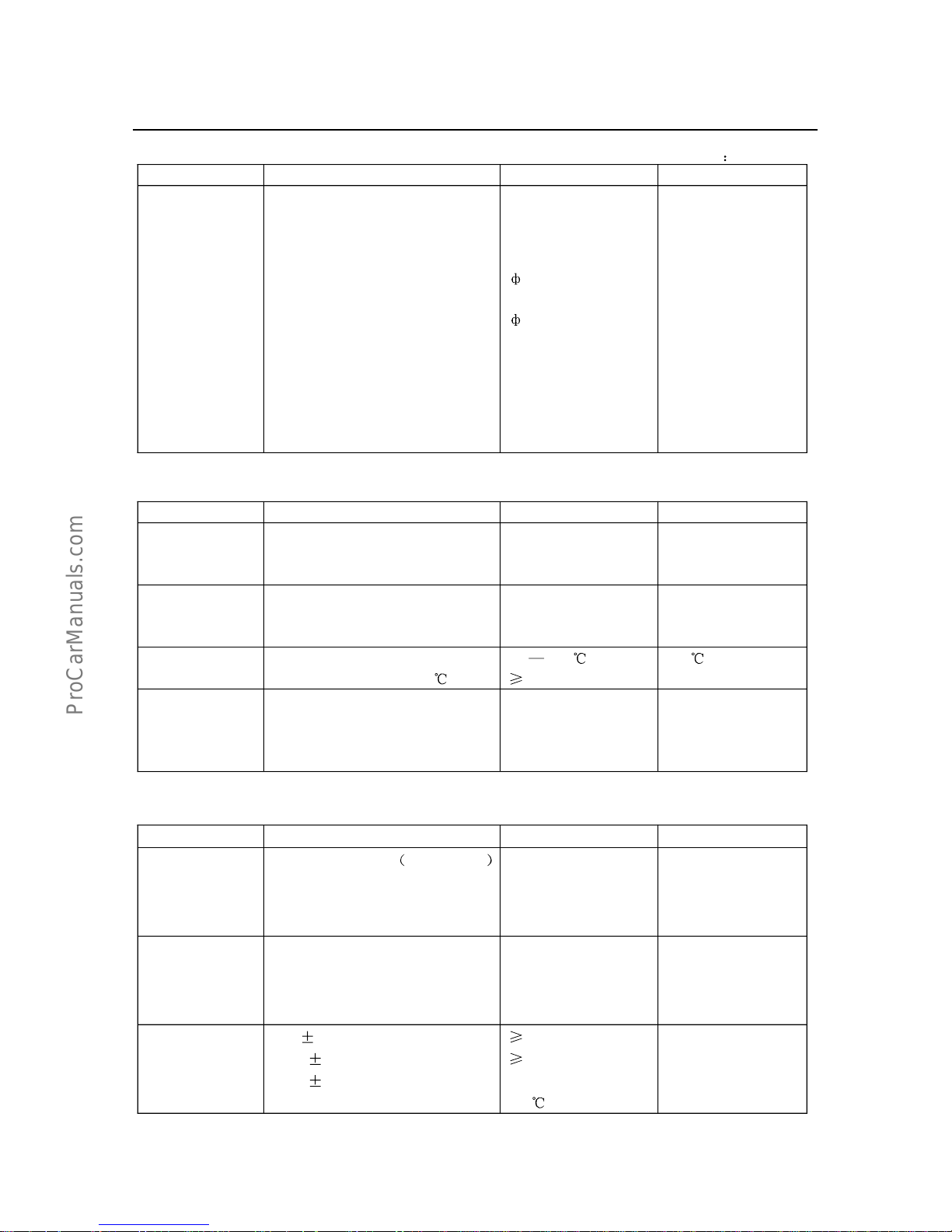

GI-6

Engineservice/maintenancedata-maintenancetechnicaldata

Unitm

m

NameTestitemsStandardvalueUselimit

Crankshaftand

bearing

Axialclearance

Thicknessofthrustwasher

Increasedby0.125

Increasedby0.250

Mainjournaldiameter

Clearanceofmainjournaldiameter

journaldiameterofconnectionrod

journalclearanceofconnectionrod

Circumferentialplayofmainaxial

diameter

Roundness/diameterofcolumn,

formainaxialdiameterand

connectionroddiameter

0.02~0.22

2.450~2.490

2.575~2.615

2.700~2.740

58

0.021~0.053

48

0.021~0.053

0.03

0.01

0.30

0.10

0.10

0.06

0.02

2.Coolingsystem

NameTestitemsStandardvalueUselimit

Capacityof

coolingfluid in

engine

7.9L

Radiator

Pressurewhenthepressurerelief

valveofcoverisopened.

(73.6~103)kpa

Min.value

notlessthan

58.9kpa

Thermostat

Temperaturewhenvalveisopened.

Liftdistanceofvalve95

(8084)

8mm

<76

<8mm

Transmissionbelt

Bendingdeflectionoftransmission

beltwhena98Nforceisapplied.

Newbelt

Usedbelt

(5~7)mm

(7~8)mm

3.Lubricationsystem

NameTestitemsStandardvalueUselimit

Capacityofoil

Totalcapacityofoil

dryinjection

Re-injectionaftertheremoval

Withoutoilfilter

Withoilfilter

4.2L

3.0L

3.5L

Oilpump

Clearancebetweenrotorandpump

Clearancebetweenmastery rotor

andslaveryrotor

Endclearanceofrotor

(0.10~0.15)mm

(0.07~0.12)mm

(0.03~0.07)mm

>0.20mm

0.20mm

0.15mm

Pressureofoil

(750

50)r/minatidle-speed

(2000

50)r/min

(3000

50)r/min

Max.temperatureofoil

49kpa

170kpa

(245.2~490.3)kpa

110

<245.2kpa

0

-0.015

0

-0.015

GI-7

Engineservice/maintenancedata-tighteningtorqueforfasteningelements

4.Ignitionsystem

NameTestitemsStandardvalueUselimit

Sparkplug

Model

Clearance

F6RTC

1.0~1.2mm

High-tension

wiringResistance16k

/m

5.Startingsystem

NameTestitemsStandardvalueUselimit

Starter

Ratedvoltage

Outputpower

Zero-loadcharacteristics

sizeof

currentspecifiedwhenit’s11.5V

RectifierExteriordiameter

DepthofTchannel

Circumferentialradialplay

Lengthofelectricbrush

Workloadofspring

12V

1kw

90A

30mm

(0.50~0.80)mm

0.05mm

13mm

(17.5~23.7)N

>90A

<29mm

<0.20mm

>0.05mm

<8.5mm

<17.56N

6.Chargedevice

NameTestitemsStandardvalueUselimit

Battery

Densityofelectrolyteforbattery

Whenfullchargeofbatteryat20

1.25~1.27

ACgenerator

Resistanceofrotorcoils

Diameterofslipring

Exposedlengthofelectricbrush

4.0

(32.3~32.5)mm

12.5mm

<32.1mm

5.5mm

RegulatorAdjustmentvoltageat20(13.95~14.4)V

Drivingbelt

A98Nbending-deflectionforceis

appliedtodrivingbeltbetweenAC

generatorandwaterpump.

Newbelt

Usedbelt

(5~7)mm

(7~8)mm

Tighteningtorqueforfasteningelements

1.Tighteningtorqueforspecialcomponents

FrequentlytightenedsparepartsN

m

ValverockerarmshaftcylinderheadM8

Cylinderheadbolt10-M12

1.25

3-M8

Airintake/exhaustmanifoldpipecylinderhead

Sparkplug

cylinderhead

Camshafttimingchaingearcamshaft

Camshaftflange

cylinderbody

Waterpump

boxoftimingchainchamber

24

90

20

50

18

90

18

18

GI-8

Engineservice/maintenancedata-Tighteningtorqueforfasteningelements

FrequentlytightenedsparepartsNm

Waterpumpcylinderbody

Boxoftimingchainchamber

cylinderblockBolt

Nut

Bearingcoverofconnectionrod

connectionrod

Bearingcoverofcrankshaft

cylinderblock

Crankshaftbeltpulley

crankshaft

Flywheel

crankshaft

Oilbottomoilpan

cylinderblock

Generatoradjustmentsupport

cylinderblock

Rearoil-sealseat

cylinderblock

Drainplugofoilpan

40

18

18

50

80

160

85

13

40

12

20~25

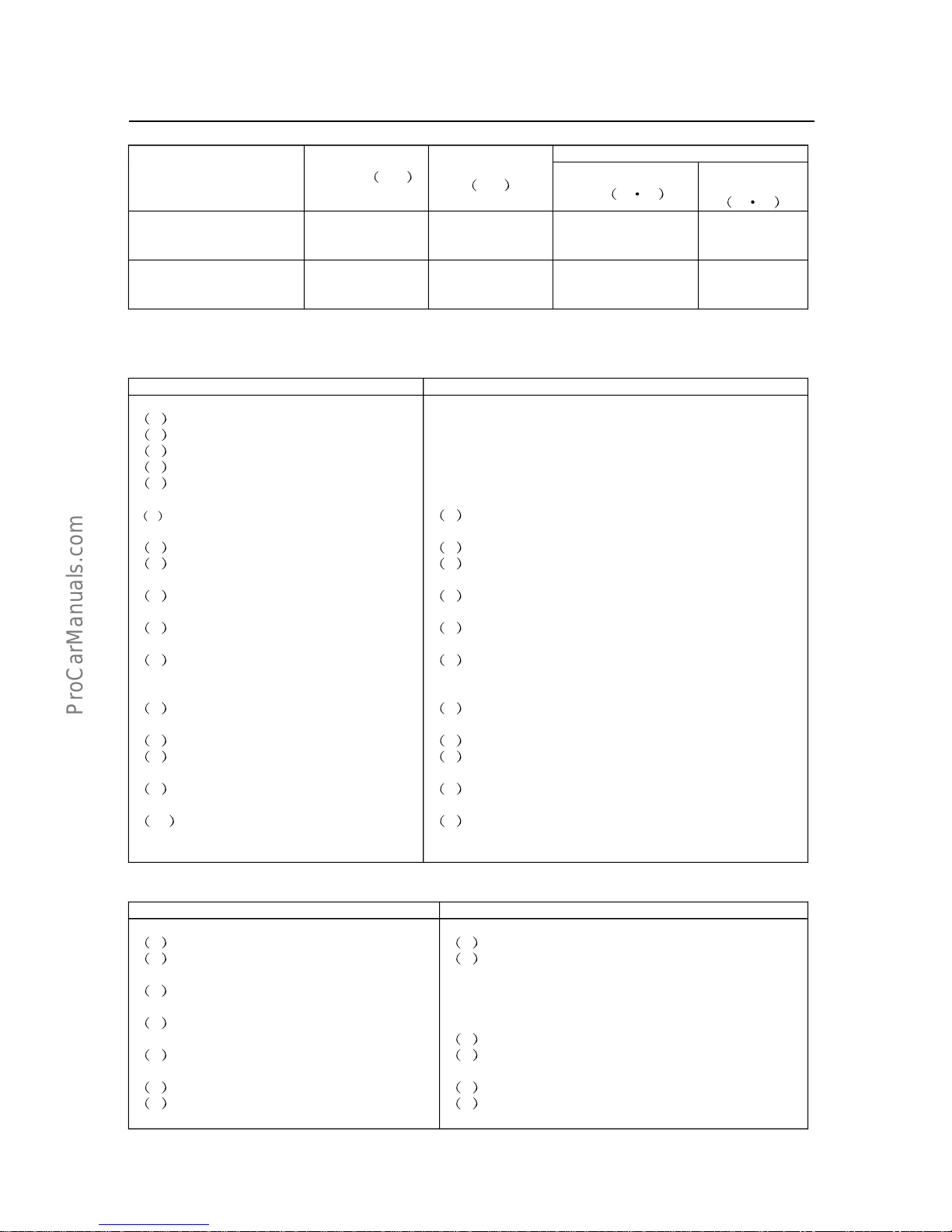

2.Standardbolttighteningtorque

Tighteningtorque

Gradediametermm

screwpitch

mm

hexagonal-headed

bolt

Nm

hexagonalflangebolt

Nm

4T

6

8

10

12

14

16

1

1.25

1.25

1.25

1.5

1.5

5

12.5

26

47

74

115

6

14

29

53

84

5T

6

8

10

12

14

16

1

1.25

1.25

1.25

1.5

1.5

6.5

15.5

32

59

91

140

7.5

17.5

36

65

100

6T

6

8

10

12

14

16

1

1.25

1.25

1.25

1.5

1.5

8

19

39

71

110

170

9

21

44

80

125

7T

6

8

10

12

14

16

1

1.25

1.25

1.25

1.5

1.5

10.5

25

52

95

145

230

12

28

58

105

165

8T

8

10

12

1.25

1.25

1.25

29

61

110

33

68

120

9T

8

10

12

1.25

1.25

1.25

34

70

125

37

78

140

GI-9Engineservice/maintenancedata-Troubleshooting

T

ighteningtorqu

e

Gradediametermm

screwpitch

mm

Hexagonal-headed

bolt

Nm

Hexagonal

flangebolt

Nm

10T

8

10

12

1.25

1.25

1.25

38

78

140

42

88

155

11T

8

10

12

1.25

1.25

1.25

42

87

155

47

97

175

Commonfailuresandtroubleshooting

1.Enginenotstartorstartwithdifficulty

CauseoffailureMethodsofelimination

1.Failureinstartingsystem

1Batteryhasinsufficientvoltage

2Batterynotconnectedwell

3Fusebroken

4Failureinstarter

5Failureinignitionswitch

2.Failureinignitionsystem

1High-tensiondampingwiringdamagedor

notconnectedwell.

2Ignitioncoildamaged

3Inappropriateclearancebetween

bothelectrodesofsparkplug.

4Sparkplugisdampedorthe

electrodehascarbondeposit.

5Insulatoronsparkplugisruptured.

3.Failureinthefuelsupplysystem

1Petrolpipelineisblockedorwithair

resistance.

4.Engineunderabadcondition

1Valveisleakingairordamagedby

burning.

2Padofcylinderisdamaged.

3Piston,pistonring,andcylinderare

muchabraded.

4Intakemanifoldisleakingair,or

vacuumplugislost.

5Pipelinefrom the ventvalve of

crankshaftboxtothethermalbaffle

ofsolenoidvalveisleakingair.

1.

(1)Chargewithpower.

(2)Cleanwiringterminalsandtightenbatteryline.

(3)Changethefuse

(4)Repairorchangestarter

(5)Repairorchangeignitionswitch

2.

1Changethehigh-tensionresistanceline

2Changetheignitioncoil

3Adjusttheclearancebetweenbothelectrodes.

4Haveitbakedorclearawaythecarbondeposit.

5Changethesparkplug

3.

1Washthepetrol-oilpipelineorclearawaytheair

resistance.

4.

1Repairorchangevalve

2Changeit.

3Repairorchangeit.

4Checktheintakemanifoldpipeandgasket,tighten

thenut,andblockwellthevacuumtube.

5Fixtheconnectionpipetightly.

2.Enginecannotbeacceleratedorisslackaccelerated.

CauseoffailureMethodsofelimination

1.Failureintheignitionsystem

1Sparkplugnotworkingwell

2Thehigh-tensiondampingwiringis

damaged.

3Theignitioncoilsaredamaged.

2.Failureinengine

1Valveisleakingairordamagedby

burning.

2Cylinderisunderabadcompression

condition.

3Padofcylinderisleakingair.

4Intakemanifoldpipeisleakingair.

1.

1Checkorchangethesparkplug

2Changethehigh-tensiondampingwiring

(3)Changetheignitioncoil

2.

1Repairorchangevalve

2Repairorchangerelevantspareparts

3Changethecylinderpad

4Checktheintakemanifoldpipeandgasket,and

tightenthenut.

GI-10

3.engineisslack.

CauseoffailureMethodsofelimination

1Engineisunderabadcompressioncondition.

1Valveisleakingair.

2Hydraulicretainingcolumnnot

workingwell.

3Valvespringiswithaninsufficient

forceorevenbroken.

4Padofcylinderisleakingair.

5Pistonringisstuckorbroken.

6Pistonorcylinderismuchabraded.

2

Failureinignitionsystem

Sparkplugnotworkingwell.

3

Petrolsupplyisblocked.

1Petroltankhascontaminantdeposits.

2Petrolpipeisblocked.

3Petrolfilterisblocked.

4Petrolpumpnotworkingwell.

5Airexistsinthefuelsystem.

4

Petrolnotconformingtothespecification.

5

Intakemanifoldpipeisleakingair.

6

Airenteringtheairpipeisinsufficient.

1Airfilterisblocked.

2Chokevalvehasnotbeenopened

completely.

7.Enginetoohot.

1

1Abradethevalve.

2Checkorchangeorwashthehydraulictappet

.

3Changethevalvespring.

4Changethecylinderpad.

5Changethepistonring.

6Repairorchangerelevantspareparts.

2

Clean,adjustorchangethesparkplug.

3

1Cleanorchangetheoiltank.

2Cleantheoilpipeormakeitthrough.

3Changethepetrolfilter.

4Repairorchangepetrolpump

5Checkandtighteneachjoint.

4

Makeitsubjecttotechnicalspecifications.

5

Checktheintakemanifoldpipeandgasket.

6

1Washthecover,andcleanthefiltrationcoreby

purging.

2Repairandadjustitscontrolmechanism.

7

Refertothe“methodsofelimination”incase

offailure“enginetoohot”.

4.Engineisbackfiredordeflagrated.

CauseoffailureMethodsofelimination

1Failureinignitionsystem

1Jointontheignitionlineisloose.

2Sparkplugnotworkingwell.

3Theheatcharacteristicsofsparkplug

areinappropriate.

2Inappropriatecontentofmixedgas

1Petrolsupplyisblocked.

3

Failureinthevalvemechanism

1Valveisstuckorleakingair.

2Thevalvehydraulicretainingcolumn

notworkingwell.

3Valvespringiswithinsufficient

strength.

4

Thecoverofcylinderunderabadcondition

1Combustionchamberhascarbon

deposit.

2Thecoverofcylinderisoverhotorthe

coolingisinsufficient.

3Thecoverofcylinderisdamaged.

5.Thehigh-tensionresistancelineis

misconnectedordamaged.

1

1Checkandtighteneachjoint.

2Wash,adjustorchangethesparkplug.

3Replacewithsparkplughavingappropriateheat

characteristics.

2

1Refertoarticle3inthe“engineslack”.

3

1Abradeorchangethevalve.

2Changeorwashthehydraulic retaining

column.

3Changethevalvespring.

4

1Clearawaythecarbondeposit.

2Clearairawayfromthecoolingwatersleeve.

3Changethecylinderhead

5

Correctorchangeit.

Engineservice/maintenancedata-Troubleshooting

GI-11

Engineservice/maintenancedata-Troubleshooting

5.Unstableidle-speedforengine

CauseoffailureMethodsofelimination

1Withairleakage

1Theintakemanifoldpipeisleakingair.

2

Failureinignitionsystem

3

Failureinvalvemechanism

1Badsealingofvalve;

2Hydraulictappetisnotworkingwell;

3Clearancebetweenthevalverodand

thevalveguidingrodismuchbig.

4Thepadofcylinderisleakingair.

5

Thesupplyofpetrolisnotsmooth.

1

1Checktheintakemanifoldpipeandgasket.

2

Article2of“enginenotstartorstartwithdifficulty”.

3

1Abradethevalve.

2Changethehydraulicretainingcolumn.

3Changethevalveortheguidingrodofvalve

4Changethecylinderpad

5

Refertoarticle3of“engineslack”.

6.Abnormalsoundoccurredinengine

CauseoffailureMethodsofelimination

1Clearanceproducedduetothefailurein

hydraulicretainingcolumn

2Pistonpintoomuchloose.

3

Piston,pistonring,andcylinderabraded

toomuch.

4

Thebushingofconnectionrodabradedtoo

much.

5

Mainbushingabradedtoomuch.

6

Thrustpieceofcrankshaftabradedtoomuch.

7

Muchclearancebetweencamshaftandthe

thrustplateofcamshaft.

8Timingchainandtimingchainwheelabraded

toomuch.

9Chaintensionernullandvoid.

10Toomuchcarbondepositinthecombustion

chamberofcylinder.

11

Petrolisnotconsistenttothespecification.

1Checkandchangethehydraulicretainingcolumn.

2Changethepistonpinorpiston.

3

Check,repair,andchangetherank.

4Changeit.

5

Changeit.

6

Changeit.

7

Changethethrustplateofcamshaft.

8Changeit.

9Changeit.

10.Clearawaythecarbondeposit.

11

Followthetechnicalspecifications.

7.Largeconsumptionofpetrol

CauseoffailureMethodsofelimination

1Pipelinehasleakageofpetroloil.

2

Airfilterisblocked.

3

Failureinignitionsystem

1Errortimingofignition.

2Failureinsparkplug.

4Badcompressionofengine.

5Slipperyofclutch.

1Tightenconnectorsandclampsateachpoint.

2

Checkandcleantheairfilter.

3

1Adjustthetiming.

2Checkorchangethesparkplug

4Refertoarticle1of“engineslack“

5Checkandadjusttheclutch.

GI-12

Engineservice/maintenancedata-Troubleshooting

Engineservice/maintenancedata-TroubleshootingLargeconsumptionofmachineo

il

CauseoffailureMethodsofelimination

1Leakageofmachineoil

1Theoil-dischargeboltonbottomoilpan

isloose.

2Thefixingboltonbottomoil panis

loose.

3Gasketofbottomoilpanisdamaged.

4Fixingboltforthecoverofchainwheel

chamberisloose.

5Sealingringofshieldcoverforvalve

chamberisdamaged.

6Front/backoil seal forcrankshaftis

damaged.

7Fixingboltforoilpumpisloose,or

gasketisdamaged.

8Fixingboltfor oil filterisloose, or

gasketisdamaged.

2

Combinedpistonoilringsareabradedtoo

muchorevendamaged.

3

Pistonandcylinderareabradedtoomuch.

4Oilsealonvalverodisdamaged.

5

Valverodandguidingrodareabradedtoo

much.

6

Theventilationsystemofcrankshaftboxis

blocked.

7

Engineisrunningwithsmallloadathigh

speedforalong-termperiod.

1

1Tightentheoil-dischargebolt.

2Tightenthefixingbolt.

3Changethegasket.

4Tightenthefixingboltorchangethegasket.

5Changethesealingring

6Changetheoilseal

7Tightenthefixingboltorchangethegasket.

8Tightenthefixingboltorchangethegasket.

2

Changethecombinedpistonoilrings.

3

Sentitonservice.

4Changethevalveoilseal

5

Changethevalveandguidingrod.

6

Check,cleanandmakeitthrough.

7

Avoidtheenginerunningwithsmallloadandat

highspeedwhenpossible.

9.Enginenotflameouraftertheignitionswitchisclosed.

CauseoffailureMethodsofelimination

1Enginetoohot.

2

Sparkplugtoohot.

3

Toomuchcarbondepositincombustion

chamber.

1

Haveenginerunningatidlespeed,decreasethewater

temperaturebelow80

,andclosetheignitionswitch.

2

Selectthespecifiedmodelofsparkplug.

3

Clearawaythecarbondeposit.

10.Enginetoohot

CauseoffailureMethodsofelimination

1.Insufficientamountofcoolingfluid

2.Fanbeltlooseordamaged

3.Failureinwaterpump

4.Failureinthermostat

5.Radiator,cylinderblock, cover/pipeline/

passageofcylinderblockedorleaked

6.Failureinsilicon-oilclutch

7.Machineoilinsufficientorthedensityislow;

8.Toomuchcarbondepositincylinderheador

combustionchamber;

9.Exhaustsystemnotthrough

1.Addcoolingfluid

2.Adjustthetensiondegreeofbeltorchangethebelt.

3.Repairorchangethewaterpump.

4.Changethethermostat.

5.Clean,repairorchangerelevantspareparts.

6.Checkorchange.

7.Addorchangethemachineoil.

8.Clearcarbondepositaway.

9.Cleanorchangesparepartsfortheexhaustsystem.

GI-13

Engineservice/maintenancedata-engineservice/maintenancedata

11.Pressureofmachineoilistoolow

CauseoffailureMethodsofelimination

1Theleakageofmachineoil

2Muchinsufficientmachineoilorthedensity

istoolow;

3Thetemperatureofmachineoilisbeyondthe

limit.

4Failurecausedbythepressurereliefvalveon

oilpump.

5Failurecausedbyoilpump

6Oilfilterisblocked,orconnection

pipeisleakingoil.

7Oilfilterisblocked.

8Failurecausedbytheoilpressuresensor

9Mainbushing,thebushingorcamshaftfor

connectionrodabradedtoomuch.

10Failureofoilmanometer.

11Toomuchoilleakageatrockershaftor

wherechainistensioned.

1Refertoarticle1 in“Toomuchmachineoil

consumption”;

2Addmachineoil,orchangethemachineoil;

3Checkthecoolingsystemwhentheenginecools

down.

4Sendthepressurereliefvalveonservice.

5Repairorchangetheoilpump.

6Wash,clean,andtightentheconnector.

7Changetheoilfilter

8Changetheoilpressuresensor

9Changethebushingorbearing.

10Changethemachineoilmanometer

11Check,repair,andfixit.

Engineservice/maintenancedata

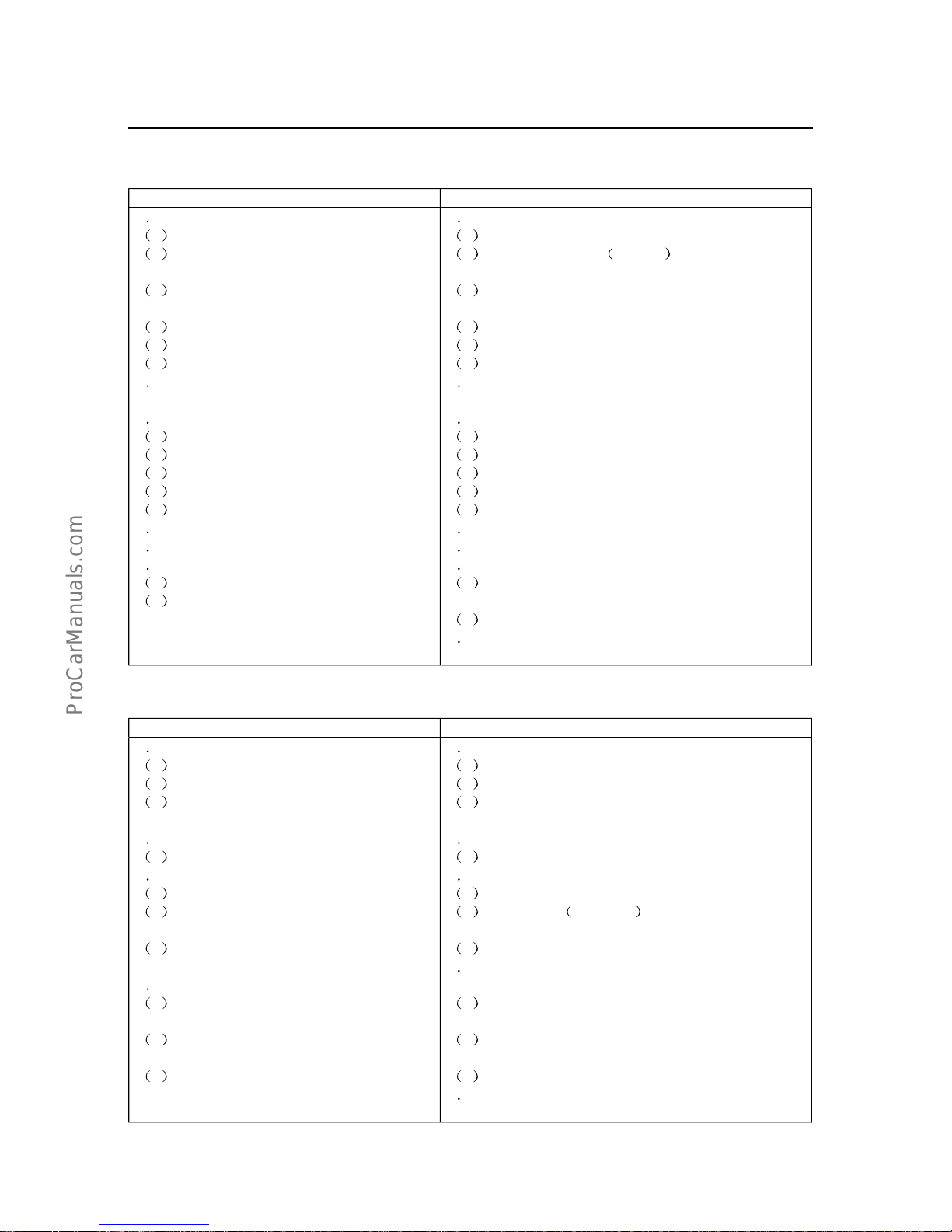

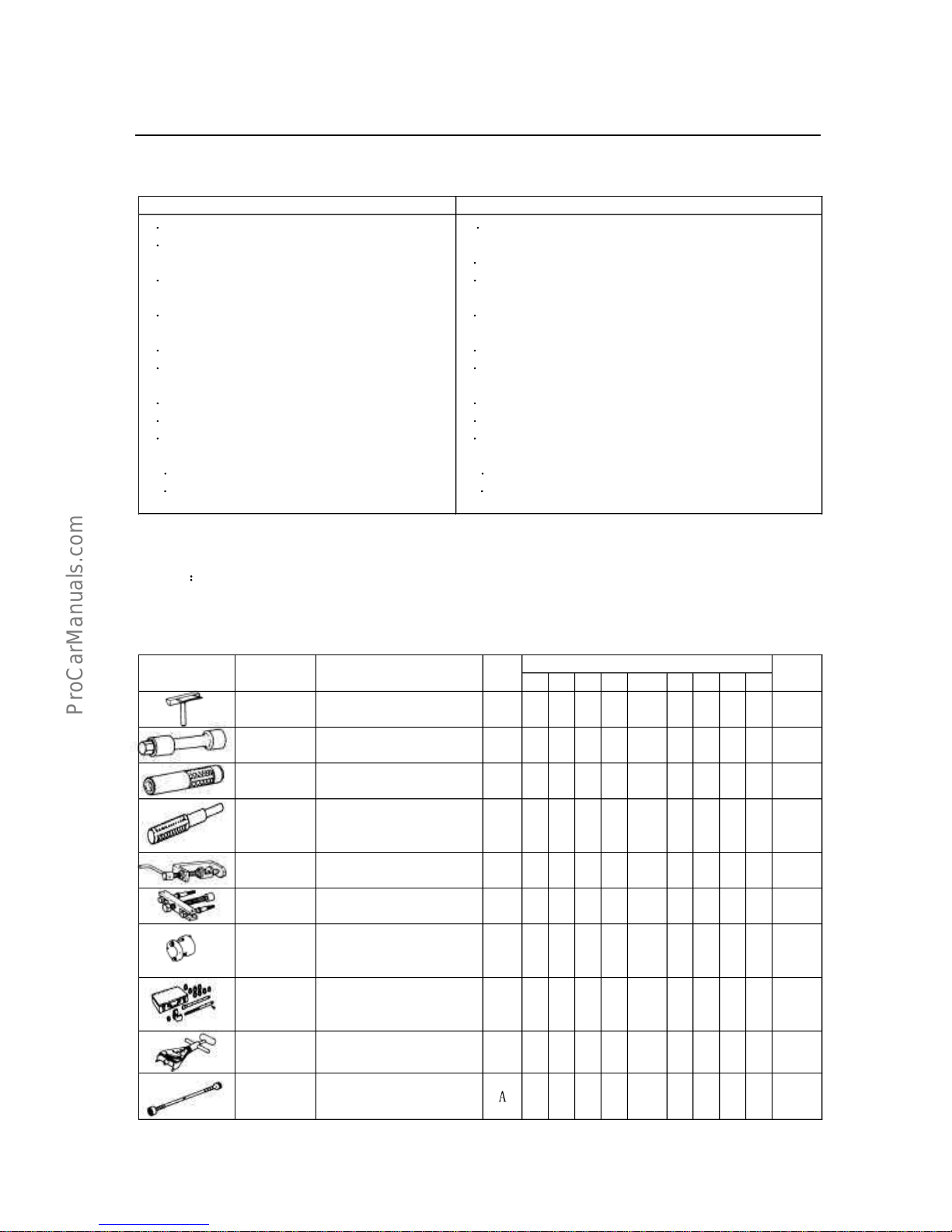

1.SSTspecialmaintenancetools

Note

sort

A=usedintheroutinerepairduringtheinspectionofvehicles,orusedasgeneraltools;

B=usedintheoverhaulingastodismantlecomponents;

C=usedintherareandspecialworkswhicharenotsimilartoAandB.

Chapter

Outlined

diagram

PartNo.Partname

Sor

t

IVVVIVII VIIIIXXXIXII

Rem

ark

09032-00

100

Toolsusedtocutoil

sealonbottomoilpan

A

09043-88

010

8mmhexagonalnut

spanner

A

09201-41

020

Tools used tochange

theoilsealonvalverod

B

09201-60

011

Toolsusedtodismantle

andrepairguidingrod

onvalve

A

09202-43

013

Springpresserforvalve

A

09213-31

021

Removerforbeltpulley

oncrankshaft

A

09213-70

010

Toolsusedtofix the

beltpulleyonto

crankshaft

A

09215-00

100

Toolsusedtodismantle

andrepairthecamshaft

bearing

C

09216-00

020

Belttension-gauge

A

09216-00

030

Belttensioncable

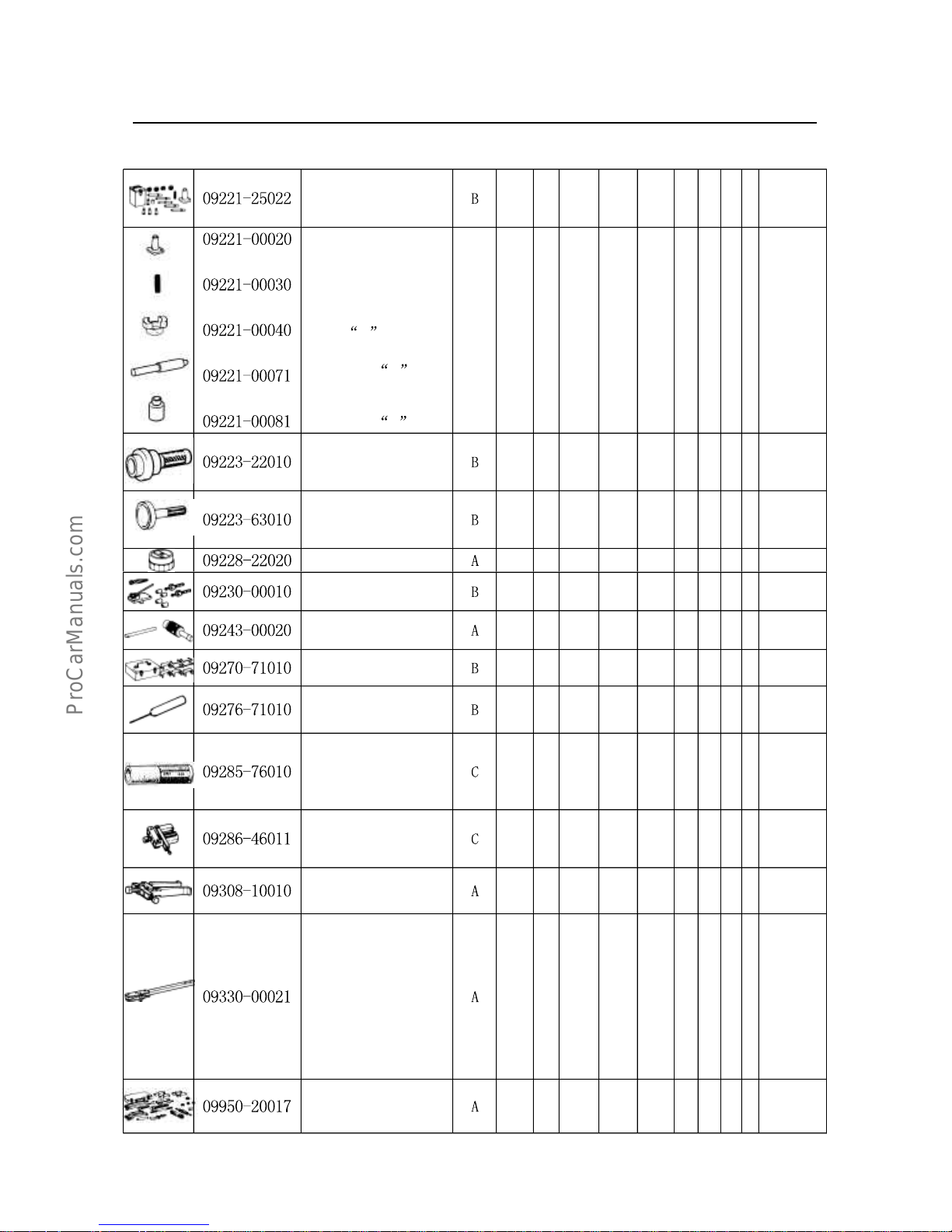

GI-14

Engineservice/maintenancedata-engineservice/maintenancedata

Toolsusedtodismantle

andchangethepiston

pins

Mainbody

Spring

sleeve A

guidingrod A

guidingrod B

Toolsusedtochange

theoilsealbeforethe

crankshaft

Toolsusedtochange

theoilseal afterthe

co-axis.

Spannerforoilfilter

Tools usedtorepair

radiator

Spannerusedtoadjust

idle-speedscrews

Rockersupporttools

Valvepushrodtools

Cone-shapedtoolsused

forthecrankshaft

bearingoninjection

pump

Toolsusedtodismantle

thesplinedshaftfrom

injectionpump

Oil-sealremover

Toolsusedtofix

flangesinpairs

Universalremover

Beltpulley

for

crankshaft

GI-15Engineservice/maintenancedata-engineservice/maintenancedata

Clutch

guidingtools

Toolsusedto

dismantle

guidebearing

from

crankshaft

Toolsusedto

dismantle

guidebearing

from

crankshaft

Toolsusedto

alignwith

clutchfilm

spring

2.SSMspecialrepairdata

NameofmaterialProductNo.Usage,etc.

1282Bsealant

1282BThreebondorsimilarproducts

08823-00100

Cooling-waterbypassflange

Rear-endcoverplateforcylinder

1324bond

1324Threebondorsimilarproducts

08833-00070

Thermostatformanifoldpipe

Boltsforflywheelordrivingplate

Fixingscrewsforinductioncoil

1324bond

1324Threebond

242Letaiorsimilarproducts

08833-00080

Cooling-fluiddischargevalveforengine

Oilpressureswitch

EF.1-1

Page

Description of system.................................................................................................

Precautions to the maintenance of electric-injection system..........................................

Analysis of the function /principal /failure for system parts &components .....................

General troubleshooting and steps to engine ...............................................................

Criterion to flashing code /mounting torque of components within M1.5.4 system........

Description of the diagnosis function on M7.9.7 system failure....................................

M7.9.7 system service &diagnosis flow process based on fault code..........................

United Electronic engine management system

EF.1-2

Model GW491QE petrol engine adopts BOSCH Motronic1.5.4 and Motronic7.9.7 engine management system

for electric-injection: As for the exhaust, the former is in compliance with European Class-II standard, and the

latter is in compliance with European Class-III standard.

BOSCH Motronic1.5.4 engine management system for electric-injection

As one set of advanced engine management system, M1.5.4 system has one engine electronic control unit

abbreviated to ECU used as the control center, and is able to measure various working parameters of

engine using appropriate sensors installed at different position of engine, to precisely control the oil injection

amount and the ignition lead-angle as per control programs set in engine electronic control unit, and to have

engine working with best performance under various conditions, ie. optimum dynamic output, most costeffective oil consumption, and best tail gas exhaust.

M1.5.4 system is subject to a multi-point oil injection control as per some sequence, and its control strategy

covers: starting control, closed-loop control of idle-speed, closed-loop control of air /fuel ratio, carbon-canister

control, transition working condition control, ignition angle control, knock control, air-conditioner control, slide

oil cut control, over-speed oil cut control, heating &protection control by three-way catalytic converter, and

system self-diagnosis, etc. The system has provided ABS, automatic gear box, air bag, etc, with applicable

communication interfaces, and is with theft-prevention function. The system is composed of three parts: sensor

air inlet pressure /temperature sensor, throttle position sensor, cooling-fluid temperature sensor, knock sensor,

oxygen sensor LSH25, rotating speed sensor, phase sensor

, actuator idle-speed adjustor EWD3, oil injector

EV6, electrical fuel pump, fuel pressure adjustor DR, carbon-canister control valve TEV, and ignition coil

ZSK

, and ECU electronic controller.

BOSCH Motronic7.9.7 engine management system for electric-injection

The key feature of M7.9.7 engine electronic control management system is the application of a control

strategy based on torque aimed at linking a number of various controlled objects together. And this is the only

fixed method to have various functions integrated on ECU flexibly in accordance with the model of engine and

vehicle.

Basic components within the M7.9.7 engine electronic control system include: electronic controller

,

air inlet pressure /temperature sensor, air mass flowmeter, cooling-fluid temperature sensor, throttle position

sensor, phase sensor, rotating speed sensor, knock sensor, oxygen sensor, idle-speed adjustor, oil injector,

electronic fuel pump, fuel pressure adjustor, oil pump support, fuel distributing pipe, carbon-canister control

valve, and ignition coil.

M7.9.7 engine management system, namely a petrol engine electronic control system, is available with many

control characteristics fit for operator, vehicle, and device, and is the combination of open-looped control and

closed loop control

feedback to provide various control signals while engine is running. Key function of

system includes:

1. An application physical model of basic engine management function

(a) System structure based on torque

(b) The cylinder loading capacity to be determined by the air inlet pressure sensor /air-flow sensor

(c) Improve the function as to control the gas mixture under a static or dynamic status;

(d)

typed closed-loop control

(e) Fuel injection by cylinder as per some sequence

(f) Ignition timing, inclusive of knock control by cylinder

Description of system

UASE Electronic Control Engine Management System -System Introduction

EF.1-3

(g) Exhaust control function

(h) Heating function of catalytic converter

(i) Carbon-canister control

(j) Idle-speed control

(k) Limped back home

(l) Speed sensing through an incremental system

2. Additional function

(a) Theft-detector function

(b) Connection between torque and exterior system

eg. transmission mechanism, or vehicle dynamic control

(c) Control over several types of engine parts and components

(d) Provide a matching interface across EOL-programming tool and maintenance tools.

3. Online diagnosis OBD

(a) Fulfill a series of OBD function

(b) A management system used for diagnosis function

UASE Electronic Control Engine Management System -System Introduction

EF.1-4

cases)

Precautions to the maintenance of electric-injection system

UAES Electronic Control Engine Management System-Notes for Electronic Injection

System Service

EF.1-5

6. Precautions to the replacement with new ECU:

(a)Prior to the change of ECU, remove the negative electrode line from accumulator jar.

(b)Check whether the power supply and the overlapped steel on ECU wiring harness are under a normal condition.

(c)As for the first engine starting process after new ECU has been installed, do not start the engine immediately,

instead, open the ignition switch before wait for ten seconds to restart the engine, Following a successful

starting process, perform a ECU self-learning as per following sequence:

Have the engine running at idle-speed for at least ten minutes;

Flameout for at least ten minutes;

Open the ignition switch rather than an immediate starting process, and wait for at least ten seconds;

UAES Electronic Control Engine Management System-Notes for Electronic Injection

System Service

EF.1-6

Analysis of function /principal /failure for system parts &components

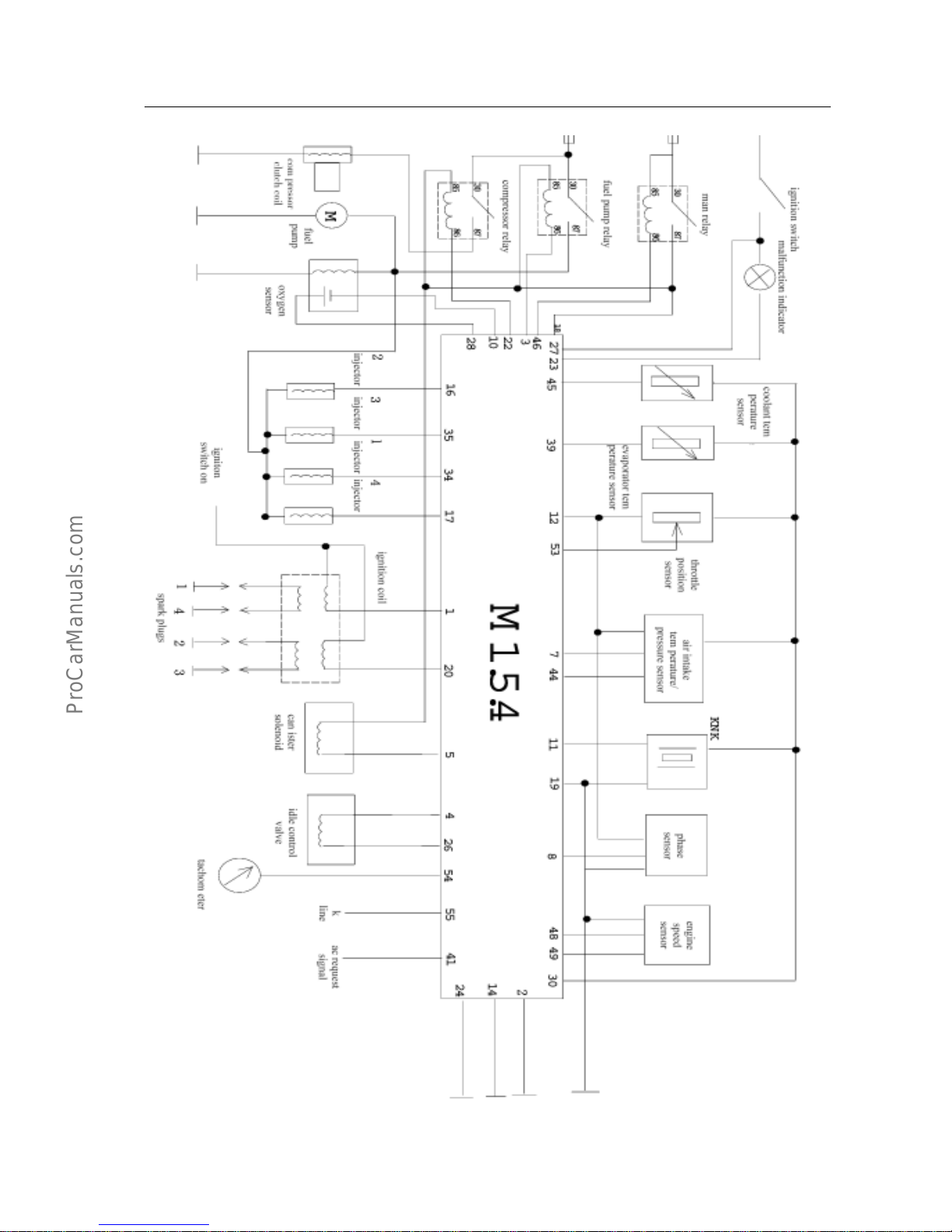

1. System circuit diagram and the definition of ECU Pins

(a)United Electronic M1.5.4 system circuit diagram

United Electronic engine management system-Analysis of function /principal /

failure for system parts &components

EF.1-7

United Electronic engine management system-Analysis of function /principal /

failure for system parts &components

EF.1-8

United Electronic engine management system-Analysis of function /principal /

failure for system parts &components

(b)Definition of ECU pins within Motronic 1.5.4 system

S.N. Description of function Type S.N. Description of function Type

1 Ignition coil(pin 2) Output 28 Signal of oxygen sensor(pin 4) Inpu t

2 Power ground Ground 29

Pin A on step motor, or

at EWD3.1 case: idle pin

Output

3

Holding coil of oil pump relay (pin

86)

Output 30 Sensor ground Ground

4

Pin B on step motor or

pin 1 on EWD3

Output 31

Holding coil of

cooling-fan relay, or

when without fan relay:idle pin

Output

5

Control valve of

carbon-canister(pin 2)

Output 32 Idle pin

6 Function reserved 33 Idle pin

7

Signal of inlet-air pressure

sensor(pin 4)

Input 34 Injector (pin 2) for cylinder 4 Output

8 Signal of phase sensor Input 35 Injector (pin 2) for cylinder 3 Output

9 Signal of vehicle speed 36 Function reserved

10 Ground of oxygen sensor(pin 3) Ground 37 Power supply of main relay(pin 87)

Power

supply

11 Signal of knock sensor(pin 1) Input 38 Idle pin

12 Internal power supply(5V)

Power

supply

39

Signal of air-conditioner temperature

sensor

Input

13 Function reserved 40

Connect to the electromagnetic clutch

relay output for air-conditioner

compressor(pin 87), or short-circuit

connected to Pin 1 of cylinder 4

depending on the type of vehicle

Input

14

Ground of driving stages for oil

injector and carbon-canister control

valve

Ground 41 Signal o A/C switch Input

15 Function reserved 42 Idle pin

16 Oil injector (pin 2) for cylinder 2 Output 43 Idle pin

17

Oil injector (pin 2) for cylinder 1

Output 44

Signal of air-inlet temperature sensor(pin

2)

Input

18 8A fuse-accumulator voltage

Power

supply

45 Engine water-temperature signal(pi n 1) Input

19 Electronic ground Ground 46 Signal of main relay Output

20

Second ground of idle pin, and

dual-spark ignition coil(pin 1)

Output 47 Idle pin

21

Pin D on step motor, or at EWD3.1

case; idle pin

Output 48

Ground of Hall sensor(pin 1),or

Ground of rotating speed sensor (pin B)

Ground

22

Electromagnetic clutch relay for

holding coil of air-conditioner

compressor

(pin 86)

Output 49

Ground of Hall sensor(pin 1),or

ground of rotating speed sensor (Pin A)

Input

23

Fault indicator lamp, or at a case

without fault indicator lamp; idle

pin

Output 50 Pre-set

24

Power ground for other driving

stages(air-conditioner compressor,

motorized fuel pump)

Ground 51

Correction of basic ignition timing, or at

a case without ignition distributor: idle

pin

Input

25 Function reserved 52

Ground enhanced, or at a case without

ignition distributor: idle pin

Input

26

Pin C on step motor,

or Pin 2 on EWD3

Output 53 Signal of throttle position sensor(pin 3) Input

27 Key switch Input 54 Engine tachometer output Output

55

Fault diagnosis interface

(line K)

Input/Output

EF.1-9

UnitedElectronicenginemanagementsystem-Analysisoffunction/principal/

failureforsystemparts&components

cDefinitionofECUpinswithinMotronic7.9.7system

PinConnectionpointTypePinConnectionpointType

1

Heatingpoint

ofoxygensensor

Output42

Air-conditioner

temperaturesensor

Input

2Ignitioncoil2Output43

3IgnitiongroundGround44IntermittentpowersupplyInput

445IntermittentpowersupplyInput

5Ignitioncoil1Output46

Solenoidvalveof

carbon-canister

Output

6

Oilinjectionnozzle4(cylinder

No.2)

Output47

Oilinjectionnozzle3(cylinder

No.4)

Output

7

Oilinjectionnozzle2(cylinder

No.3)

Output48

8INoutputOutput49

950Fancontrol1Output

1051Electronicground2Ground

1152

12UninterruptedpowersupplyInput53Electronicground1Ground

13IgnitionswitchInput54

14MainrelayOutput55

15

Engine

rotating-speedsensorA

Input56

16

Throttlepositionsensor

Input57

Air-conditioner

compressorswitch

Input

17Sensorground1Ground58

18OxygensensorInput59VehiclespeedsignalInput

19KnocksensorAInput60

20KnocksensorBInput61Powerground1Ground

2162

2263IntermittentpowersupplyInput

2364PhaseDonstepmotorOutput

2465PhaseAonstepmotorOutput

2566PhaseBonstepmotorOutput

2667PhaseConstepmotorOutput

27

Oilinjectionnozzle1(cylinder

No.1)

Output68

2869OilpumprelayOutput

29DetectorlampOutput70

Air-conditioner

compressorrelay

Output

3071DiagnosislineK

Output,

input

3172

32A5Vpowersupply2Output73

33A5Vpowersupply1Output74

34

Engine

rotating-speedsensorB

Input75Air-conditionerswitchInput

35Sensorground3Ground76

36Sensorground2Ground77

Polechanger

forboosterpump

Input

37Inlet-airpressuresensorInput78

3879PhasesensorInput

39

Enginecooling-fluidtemperature

sensor

Input80Powerground2Ground

40Air-inlettemperaturesensorInput81

41

EF.1-10

United Electronic engine management system-Analysis of function /principal /

failure for system parts &components

resistance

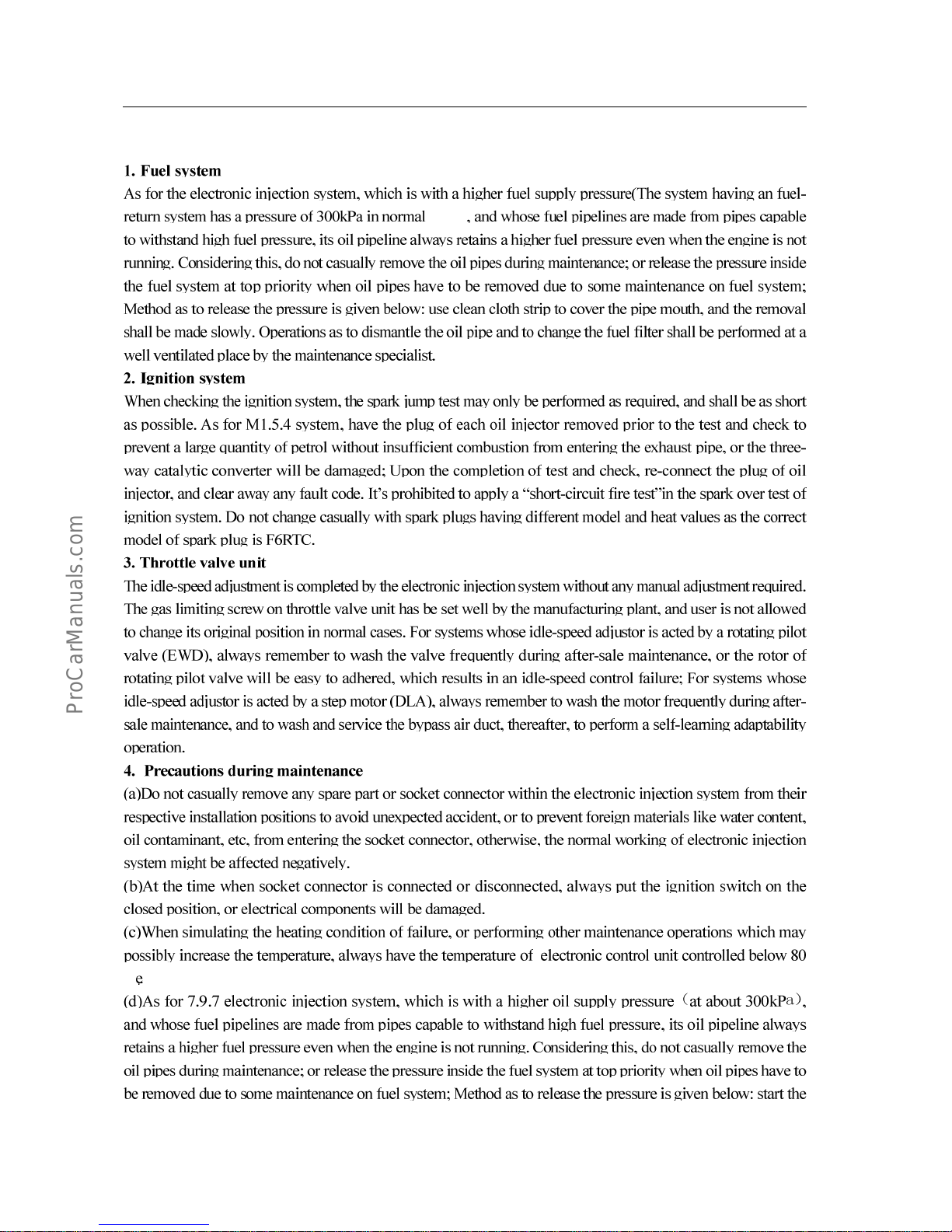

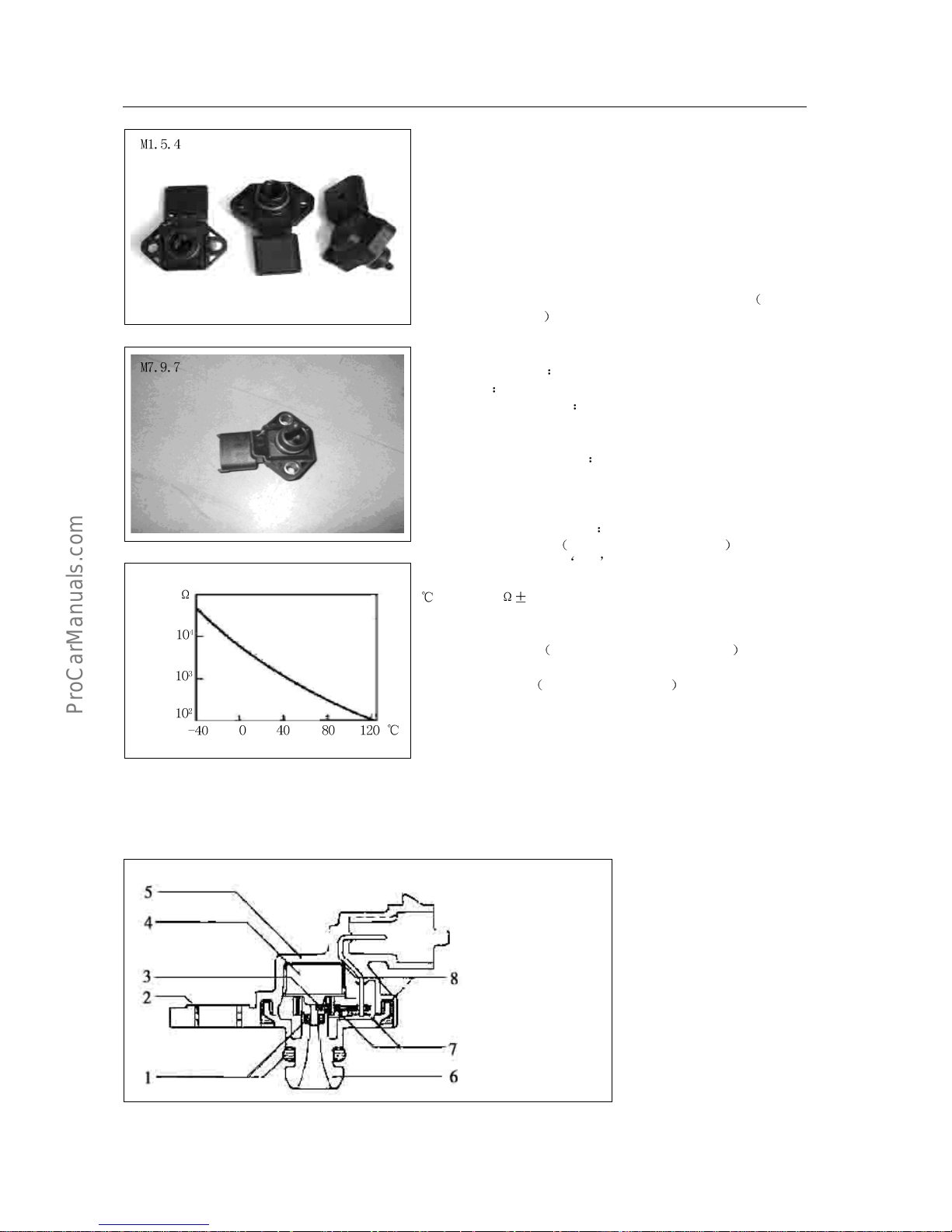

2. Air inlet pressure /temperature sensor DS-S-TF

(a) Function: this sensor is used to measure the absolute-pressure /

temperature of inlet manifold, and to provide information concerning engine

load and air-inlet temperature.

(b) Principal: The part measuring the inlet-air pressure is of a piezoelectric

sensor, which is able to provide the controller with “load signal” depending

on the difference of atmospheric pressure and the pressure of inlet manifold;

And the controller will produce a 5V voltage, and a 0-5V voltage will be

feedback to the controller depending on the different inlet-air pressure.

The part measuring the inlet-air temperature is one NTC typed

negative

temperature coefficient sensor, whose resistance will be changed by the

change of air-inlet temperature. And the sensor will transmit a voltage

reflecting the change of air-inlet temperature to the controller.

(c) Installation position on the inlet manifold.

(d) Symptom flameout, inferior idle-speed, etc.

(e) Cause of general failures

There’s abnormal high voltage or reversedly large current during operation;

V acuum elements are damaged during maintenance.

(f) Precautions to maintenance

during maintenance, it’s prohibited to

use highly pressurized air to impact vacuum elements; Whereby the sensor

needs to be changed in case of failure, check whether the output voltage and

current from generator is under a normal condition.

(g) Simple measurement method

Temperature sensor part: after disconnection of joint Have digital

multimeter adjusted to the ohm position, and connect two pens with

Pin 1 and Pin 2 of sensor respectively; And the rated resistance when at 20

shall be 2.5k 5%, Other corresponding resistances may be measured

from the characteristic curve shown above. A simulation method may be

applied during measurement, details as shown below: send air to the sensor

using an electric blower

Keep some distance when blowing , and observe

the change of sensor resistance, and the resistance shall be decreased.

Pressure sensor part: after connection of joint Have digital multimeter

adjusted to the DC voltage position, and connect the black pen to ground,

the red pen to Pin 3 &4 successively. When under an idle-speed status, a 5V

reference voltage will be produced on Pin 3, and an approx. 1.3V voltage

will be produced on Pin 4; When under a zero load status, slowly open the

throttle valve, and the voltage on Pin 4 will be with slight changes; Quickly

open the throttle valve, the voltage on Pin 4 will reach approx. 4V

instantaneously before being decreased to 1.5V gradually.

characteristic curve of temperature sensor

temperature

1.sealing ring

2. stainless liner

3. PCB plate

4. sensing element

5. shell body

6. stress support

7. welded connection

8. bonded connection

EF.1-11

United Electronic engine management system-Analysis of function /principal /

failure for system parts &components

Performance data

Measurement Value

Min. Typical Max.

Unit

Scope of testing pressure 20 115 kPa

Operation temperature -10 125 ℃

Operation supply voltage 4.5 5.0 5.5 V

Current when US=5.0V 6.0 9.0 12.5 mA

Load current in output loop -0.1 0.1 mA

Load resistance to ground or to accumulator 50 kΩ

Response time 0.2 ms

Weight 27 g

(h)Technical &characteristic parameter

Limit data

Measurement Value

Min. Typical Max.

Unit

Tolerable supply voltage

16 V

Tolerable pressure

500 kPa

Tolerable storage

temperature

-40 +130 ℃

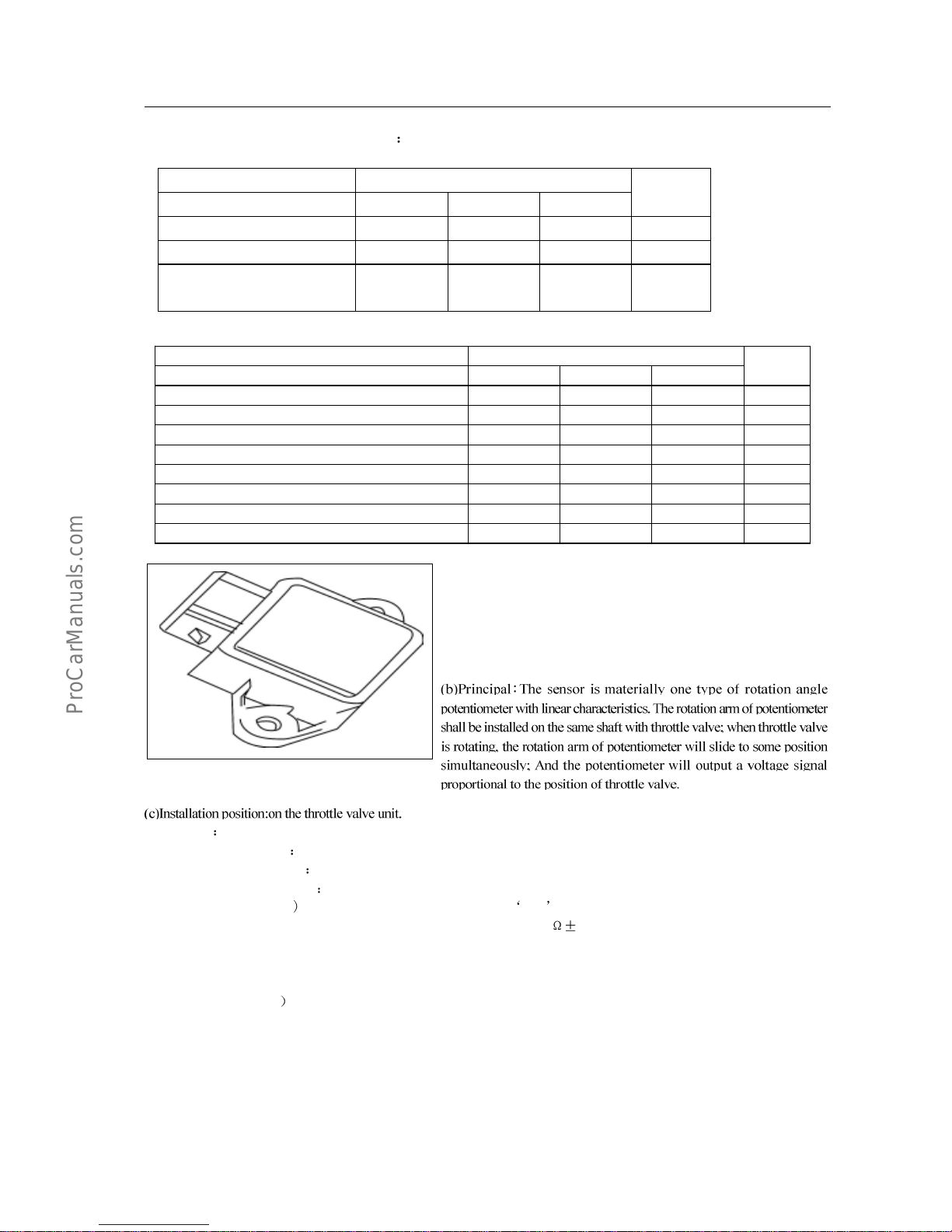

3. Throttle position sensor DKG

(a)Function: this sensor is used to provide ECU with information concerning

the rotation angle of throttle valve. Based on such information, ECU may

obtain relevant information concerning engine load, working condition, (eg.

starting, idle-speed, reverse, partial load, full load), acceleration and

deceleration.

(d)Symptom bad acceleration, etc.

(e)Cause of general failures

artifical failure.

(f)Precautions to maintenance

take note of the installation position.

(g)Simple measurement method

(after disconnection of joint Have digital multimeter adjusted to the ohm position, connect two pens with Pin 1 and Pin 2 of

sensor respectively; And the resistance value at room temperatrure shall be 2k

20%; Connect two pens with Pin 1 and Pin 3 of

sensor respectively, rotate the throttle valve, and the resistance value will be subject to a linear change with the opening of throttle

valve; When connected with Pin 2 and Pin 3, an opposite situation will be produced.

Remark: When observing the change of resistance value, the main focus is to observe whether the resistance value has a larger leap.

(after connection of joint

Open the ignition switch rather than to start the engine, have digital multimeter adjusted to the DC

voltage position, and connect the black pen to ground, the red pen to Pin 2, and a 5V reference voltage shall be produced; Connect the

red pen to Pin 3, and the voltage shall be at about 0.3V when throttle valve is at a full closed position, or about 3V when throttle valve

is at a full open position.

EF.1-12

UnitedElectronicenginemanagementsystem-Analysisoffunction/principal/

failureforsystemparts&components

(h)Technical&characteristicparameter

Limitdata

MeasurementValueUnit

MechanicrotationanglebetweentwoextremepositionsDegree

AvailableelectricalrotatinganglebetweentwoextremepositionsDegree

Allowablecurrentonslidingcontactarm

Storagetemperature

Allowablevibrationacceleration

Performancedata

MeasurementValue

Min.TypicalMax.

Unit

TotalresistancePin1-2

Protectionresistanceonslidingcontactarm(when

slidingcontactarm

isatzeroposition

Pin2-3)

Operationtemperature

Supplyvoltage

Voltageratioonrightextremeposition

Voltageratioonleftextremeposition

IncrementrateofUp/Us

fortherotationangleofthrottlevalve

degree

Weight

EuropeanClass-II

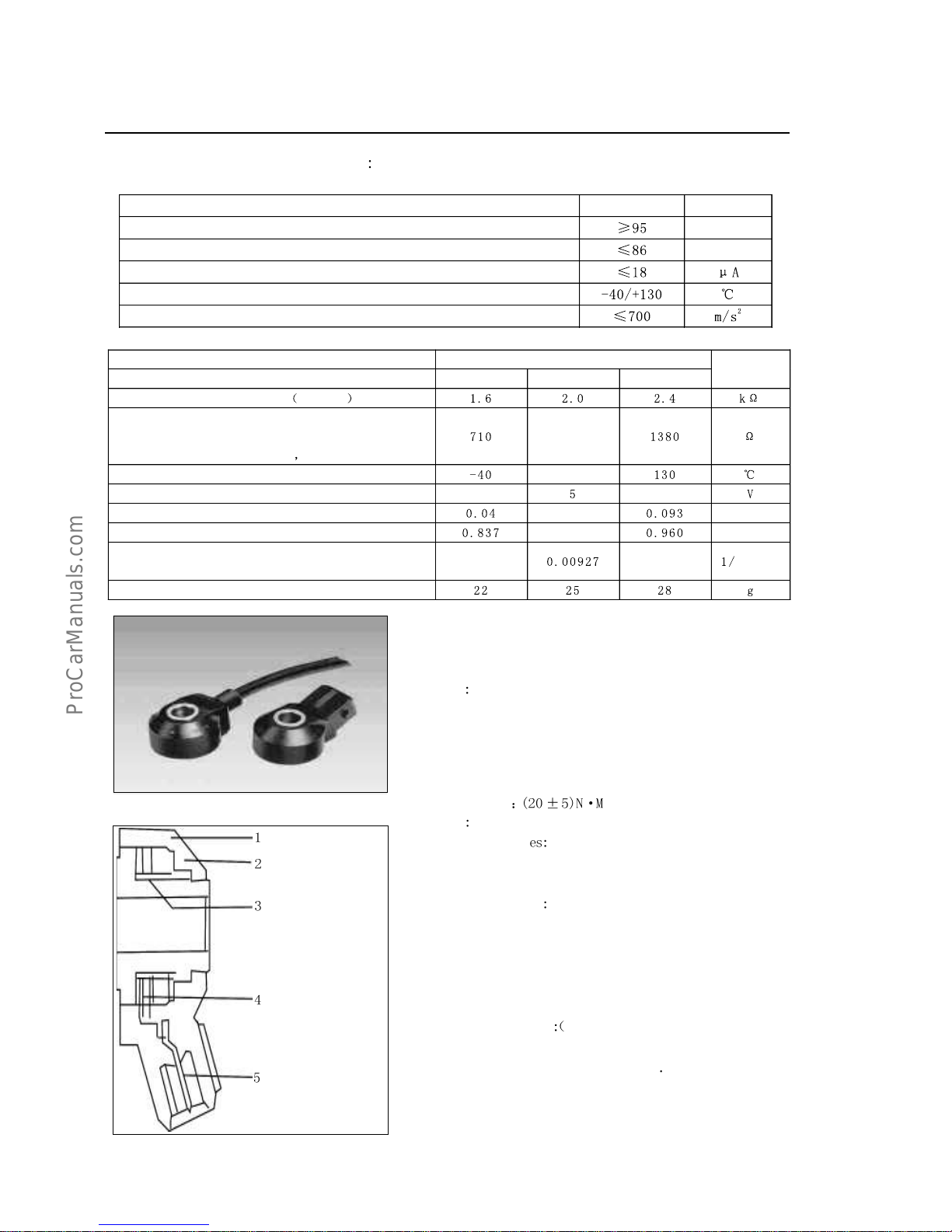

4.KnocksensorKS

(a)Function:thissensorisusedtoprovidetheelectroniccontrollerECU

withengineknockinformationforaknockcontrolpurpose.

(b)Principal

Beingonetypeofvibrationaccelerationsensor,theknock

sensorisinstalledontheenginebody;Itssensingelementisofone

piezoelectriccrystal,towhichthevibrationonenginebodymaybetransmited

viamassblockinsidethesensor.Underthevibrationstressofmassblock,a

voltagewillbeproducedontwopolefacesofpiezoelectriccrystaltoconverse

thevibrationsignalintovoltagesignal

(d)Mountingtorque

(e)SymptomBadacceleration,etc.

(f)Causeofgeneralfailur

Thesensormightbecorrodedwhencontacting

withvariousliquidsforlongtermperiod,suchasmachine-oil,cooling-fluid,

braking-fluid,water,etc.

Precautionstomaintenance

Thesensormusthaveitsmetalsurfaceclosely

contactedwiththeenginebody,andanytypeofwasherisunallowablefor

useduringinstallation.Duringthesignalcablepavementforsensor,it’s

notedthatdonotallowanysyntonyproducedonsignalcabletoavoid

rupture.Alwaysavoidtheconnectionofhigh-voltagecurrentbetweenPin1

andPin2ofsensor,otherwise,piezoelectricelementswillbedamaged.

Simplemeasurementmethod

afterdisconnectionofjoint£©Havedigital

multimeteradjustedwithPin1andPin3respectively.Andtheresistance

valueatroomtemperatureshallbegreaterthan1M¦¸Havedigitalmultimeter

adjustedtothemillivoltposition,anduseasmallhammertogentlyknock

ontheareanearbytheknocksensor,andavoltagesignaloutputwillbe

produced.

EuropeanClass-III

1.shockblock

2.exteriorcover

3.piezoelectric

ceramicbody

4.contacthead

5.electricalplug

Loading...

Loading...