Great Wall 4G64S4M Service Manual

Preface

This manual is specially made for those who

engage in automobile maintenance and repairing.

Following general rules of system division of vehicles

(engine, clutch, etc.), this manual adopts the division

methods by major assembly. In order to describe all

parts belonging to an assembly, assemblies are further

divided into several parts.

Brief introductions, specifications, main points

of adjustments, mounting and dismounting,

assembling and disassembling of the assembly

components are covered in this manual. On the top of

the first page of all assemblies are the content, through

which the needed information can be easily found.

All explanations and specifications in this

manual is the latest till the date of printing.

GENERAL 00

ENGINE 11

General

Contents

page

Guide on Using the Manual.......................................... 00-3

Engine .......................................................................... 00-5

Tightening Torque......................................................... 00-6

Sealant (FIPG) ............................................................. 00-7

00-1

00

GENERAL GUIDE ON USING THE MANNUAL

00-2

Guide on Using the Manual

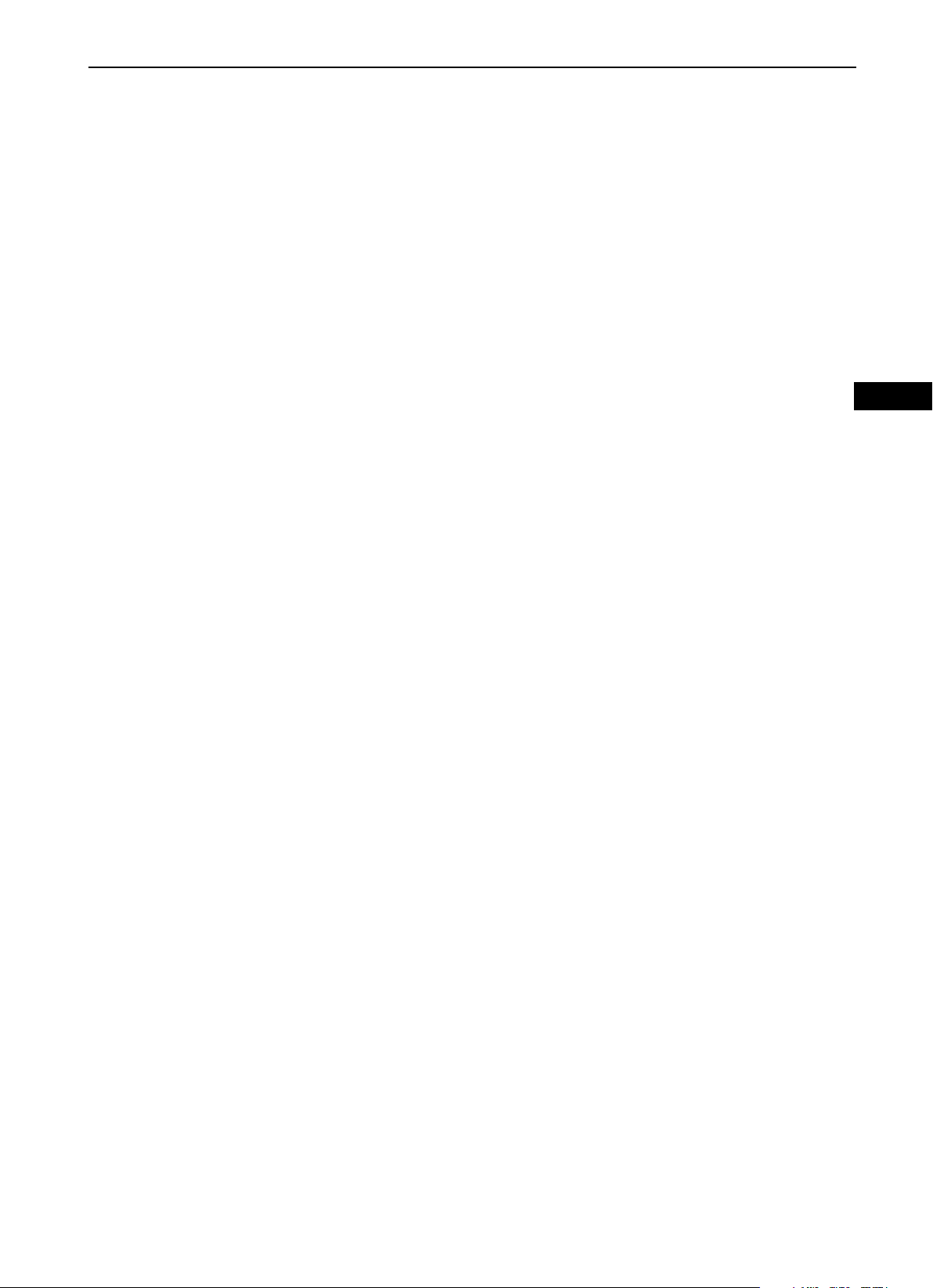

Maintaining Steps

(1) Profile plots are provided for you to

understand the installation of each

component.

(2) Use reference number of the parts to

show operation steps, mark the parts

that can not be used repeatedly (marked

as ) and the tightening torque.

N

Dismantling Steps: Corresponding number of parts to the

number in the figure of composing parts to show

the dismantling steps.

Disassembly Steps: Corresponding number of parts to the

number in the figure of composing parts to show

the disassembly steps.

Mounting Steps: Mounting steps should be indicated when the

mounting may not in the reverse order with

dismantling steps. Otherwise, the mounting steps

can be omitted.

Assembly Steps: Mounting steps should be indicated when the

mounting may not in the reverse order with

dismantling steps. Otherwise, the mounting steps

can be omitted.

Front Cover, Oil Pump

Dismantling and Mounting

Stands for part that may not

be used repeatedly

11

1.4Kg.m

N

10

Grouping name Section Name Page

Engine Front cover, Oil pump 11-33

1

13

14

N

12

15

1

6

5

9

8

7 4.5Kg.m

1.9

Kg.m

Division of Notes for Maintaining

When there are notes for maintaining, standard value and usage of special tools, detailed explanation is given.

Marks for Lubricant, Sealant and

Adhesive

Indicate in the figure of composing parts the

location where lubricant, smearing or supplying of sealant and adhesive are to be

applied.

Indicates Notes for dismantling or disassembly

A

available.

Indicates Notes for mounting or assembly

A

available.

Lubricating grease

[Means all-purpose lubricating grease if not

specially indicated otherwise.]

Sealant or adhesive

Engine oil or gear oil

Dismantle steps:

BA

BA

MD998727

Smear the engine oil on all the

movement parts while assembling

1. oil filter

E

2. oil drain plug

3. oil plug washer

4. oil pan

DA

5. oil filter screen

6. oil filter screen washer

7. overflow valve plug

8. overflow valve string

9. overflow valve core

10. oil seal

C

11. oil pump shell

B

12. O-ring

13. oil pump shell cover

14. outer rotor

15. inner rotor

MD998727

stands for tightening torque

These numbers are corresponding to the

numbers in the steps of dismantling,

disassembly, mounting and assembly.

Disassembly notes:

Oil pan disassembly

A

After you take down the bolt , disassembly the oil pan with

special tool.

9EN0040

DILD583 DILD584

These English letters corresponds to the

letters in the steps of dismantling,

mounting, disassembly and assembly.

Explanations are given for the

maintaining essentials and

notes for dismantling and

mounting, disassembly and

assembly.

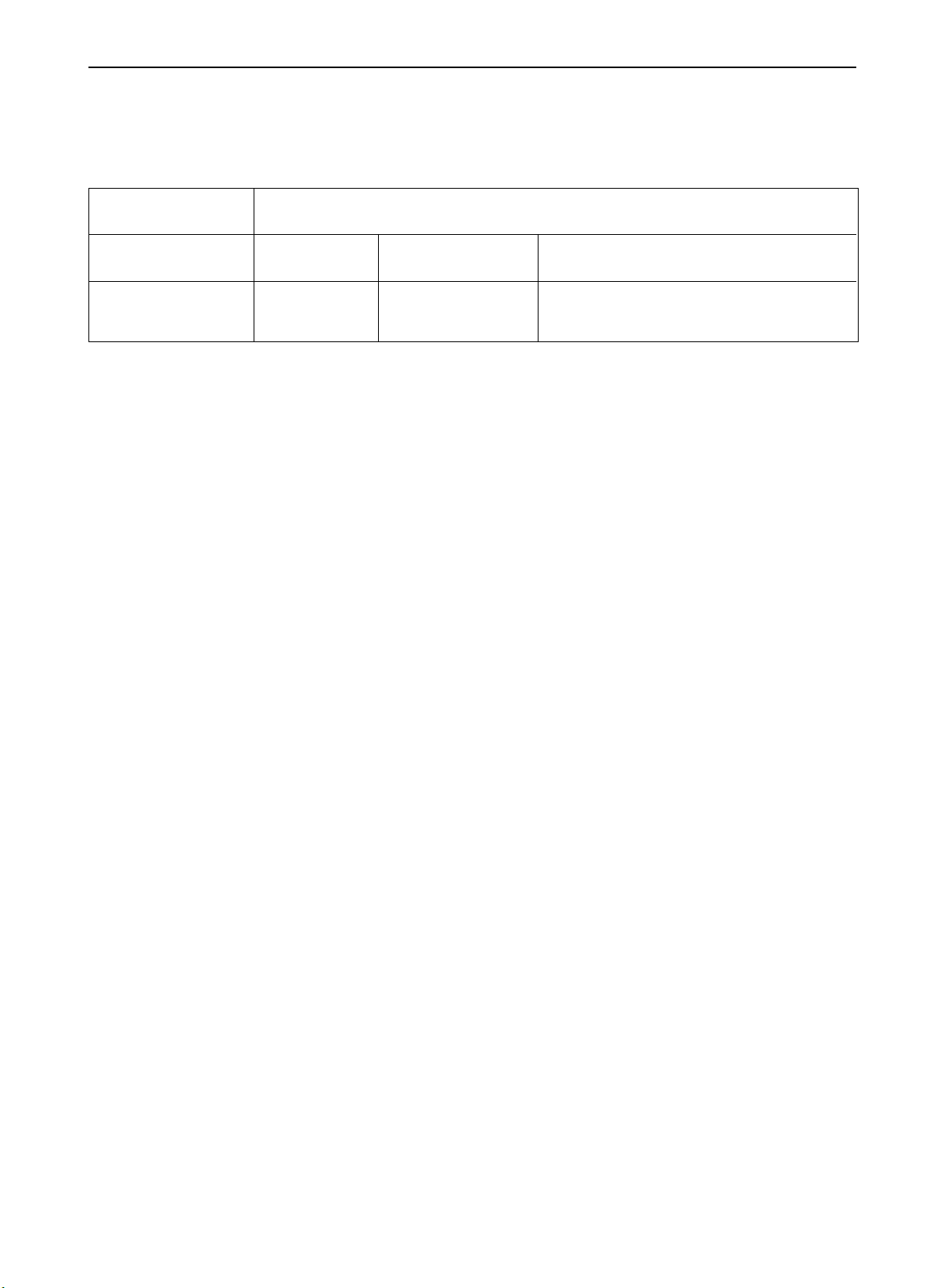

OVERVIEW ENGINE

ENGINE MODEL

VEHICLE MODEL ENGINE

MODEL DISPLACEMENT TYPE

HOVER CUV 4G64-D-Y7 2,351 ML FOUR CYLINDERS, IN-LINE, SOHC

00-5

00-6

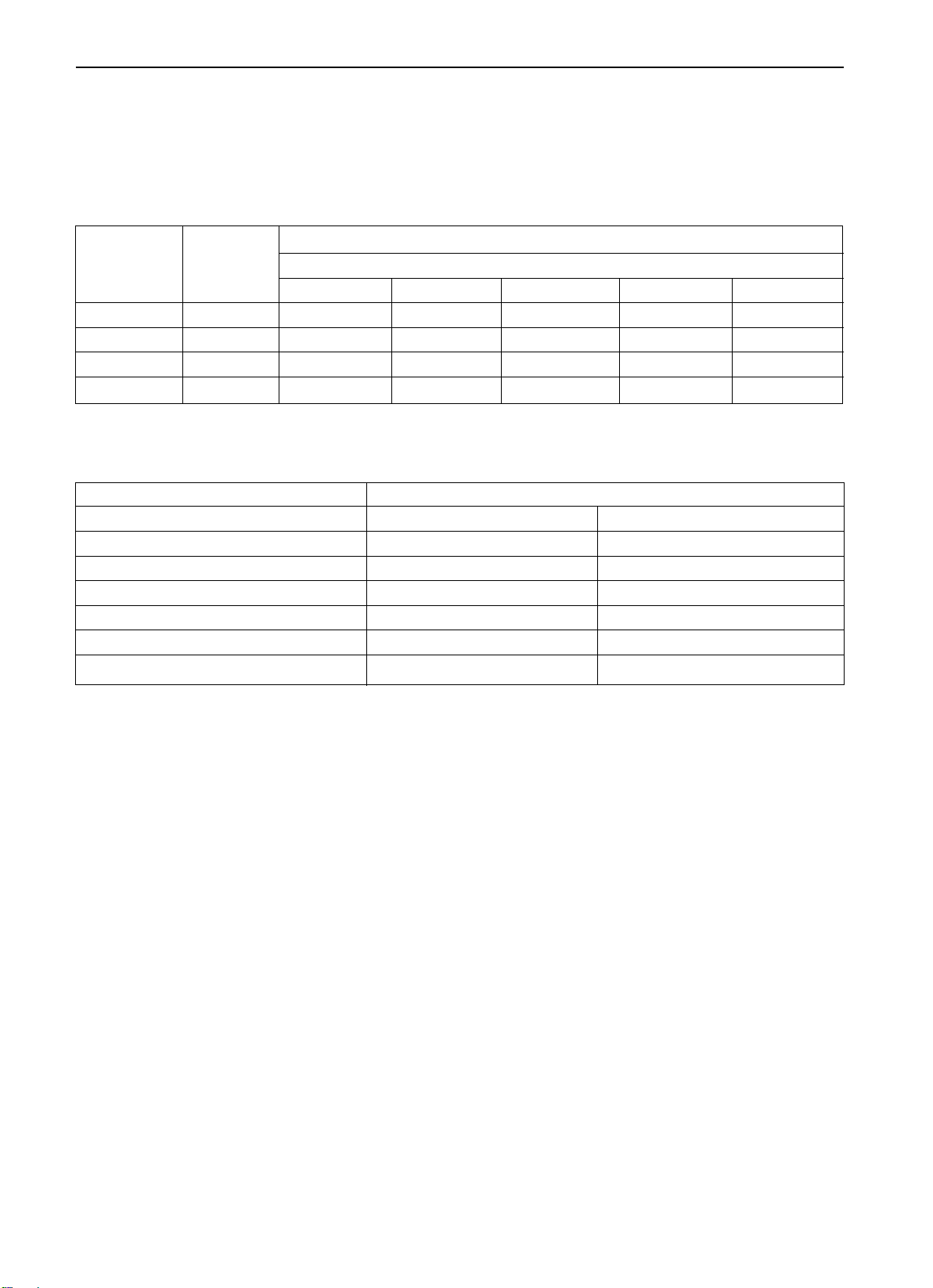

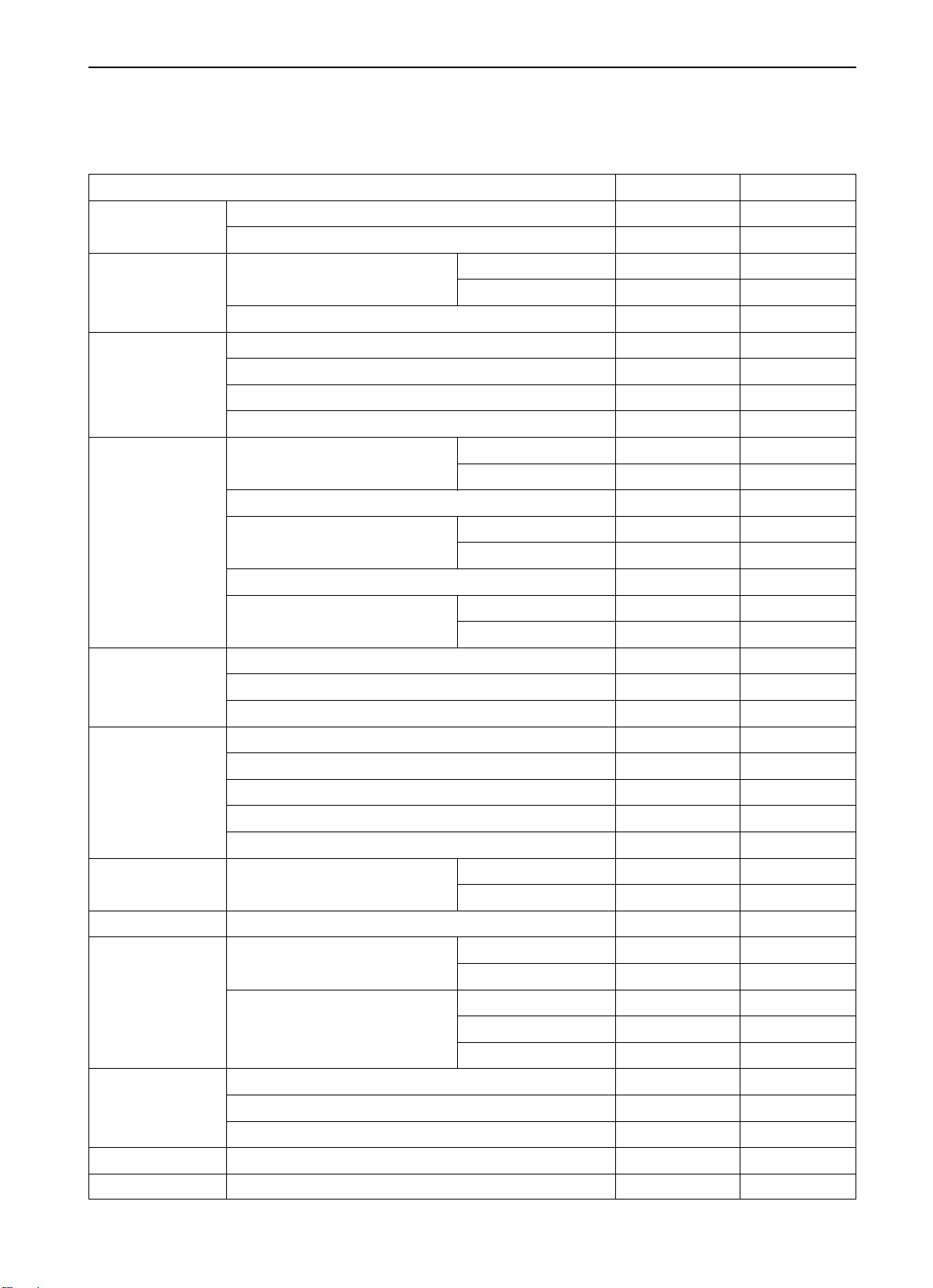

OVERVIEW TIGHTENING TORQUE

Tightening Torque

The common tightening torque is shown in the list.

Tightening torque of special parts is shown at the beginning of each group.

Tightening torque of bolts and nuts

Diameter

of bolt

M6 1.0 0.9 1.3 1.1

M8 1.25 1.1 1.8 3.0 1.4 2.4

M10 1.25 2.0 3.4 6.0 3.0 5.0

M12 1.25 3.6 6.2 10.8 5.5 9.0

Tightening torque of taper thread

Thread Dimension Torque (Kg. M)

NPTF 1/16 0.5 0.8 0.8 1.2

PT 1/8 0.8 1.2 1.5 2.2

PT 1/4 2.0 3.0 3.5 4.5

NPTF 1/4 2.0 3.0 3.5 4.5

PT 3/8 4.0 5.5 5.5 7.5

PT 1/2 7.0 10.0 12.0 16.0

Thread

pitch

Bolt (with spring washer) Valve bolt

Head mark 4 Head mark 7 Head mark 10 Head mark 4 Head mark 7

Light alloy Cast iron, steel

Torque (Kg. M)

OVERVIEW SEALANT(FIGP)

00-7

Sealant (FIPG)

Sealant is used on many parts of the engine and gearbox. The using of sealant is for the purpose of adequately sealing,

therefore, much attention should be paid to the dosage, position and the surface of sealant. Insufficient dosage of sealant

may result in leakage, while superfluous dosage of sealant may result in the overflow of sealant and jam the passage of

water or oil, or narrow the passage. So, in order to avoid leaking on the mounting surface, it is absolutely necessary to

keep the correct dosage that may keep from disconnection.

FIPG used in the engine is of Room Temperature Vulcanizing (RTV) and is provided in the way of 100-gram tube (Piece

No. MD970389, for engine use). RTV may vulcanize after reaction with the water content in the air; therefore, it is usually

used on the metal end face.

Disassembly

Components assembled with sealant may be disassembled without using a special method. However, in some cases, it

is necessary to lightly hit the components with a mallet or similar tools so as to break sealant on the coupling face, or

use a smooth thin sealant knife to hit into the joint face gently without damaging the coupling face. When dismounting

the engine oil pan, use special tool for dismounting oil pan (MD998727).

Cleaning of Sealing Surfaces

Remove rubbish on the sealing surface with a sealant knife or a steel wire brush. Be sure the sealing surface is flat and

smooth, and there isnt any oil stain of foreign object on it. Remember to remove the sealant inside the mounting hole

and the threaded holes.

Essentials for Smearing

Matters to be taken into consideration while assembling components with FIPG.

Smear sealant equally within the prescribed diameter to cover around the mounting hole. Sealant that is not yet vulcanized

can be removed. After the installation, the sealant should be sufficiently vulcanized (approximately 1 hour or so). Do

not apply oil on the smeared part or wet or startup the engine during this period.

11-1

Engine

Contents

page

General ........................................................................ 11-2

Specifications ............................................................... 11-3

Maintaining Standard ................................................... 11-3

Tightening Torque ........................................................ 11-5

Sealant ......................................................................... 11-7

Special Tools................................................................ 11-8

AC Generator and Ignition System .............................. 11-11

Timing Toothed-belt ..................................................... 11-14

Fuel System ................................................................. 11-23

Intake Manifold ............................................................. 11-25

Exhaust Manifold and Water Pump.............................. 11-26

Rocker Arm and Camshaft ........................................... 11-28

Cylinder Head and Valve ............................................. 11-34

Front Cover and Oil Pump ........................................... 11-40

Piston and Connecting Rod ......................................... 11-49

Crankshaft, Cylinder Block and Flywheel..................... 11-55

AC Generator ............................................................... 11-62

Starter .......................................................................... 11-66

Throttle Body ................................................................ 11-70

11

11-2

General

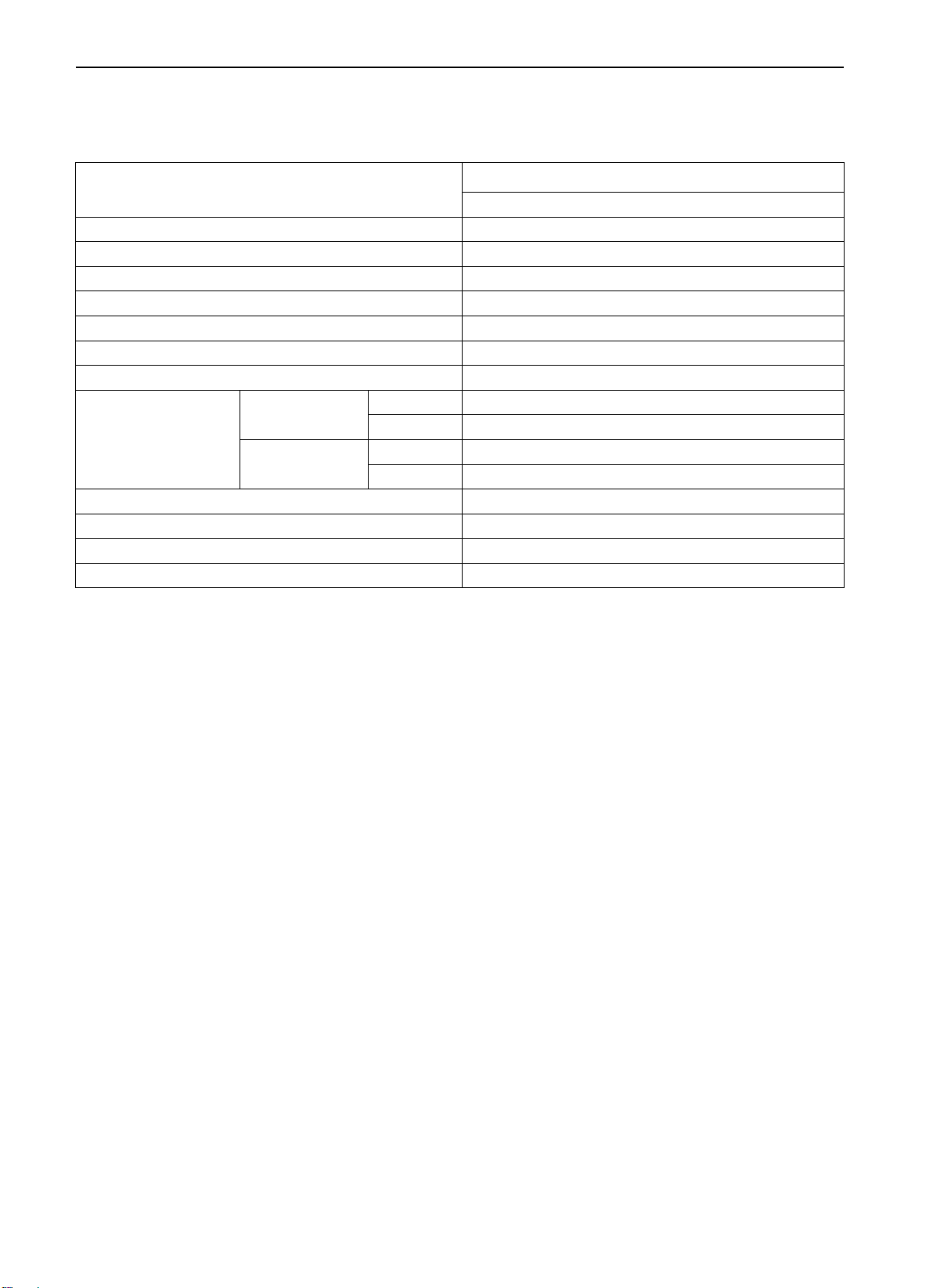

ENGINE SPECIFICATION

Items

Type In-line OHV, SOHC

Number of Cylinders 4

Combustion Chamber Single Pitch Roof

Total Displacement ml 2,351

Cylinder Bore mm 86.5

Stroke mm 100.0

Compression Ratio 9.5

Intake valve

Valve Timing

Exhaust valve

Lubrication system Compression supply, full flow filtering

Type of oil pump Gear type

Cooling system Water cooling forced circulation

Type of water pump Centrifugal impeller

On 18before top dead center

Off 53 after bottom dead center

On 50 before bottom dead center

Off 18 after top dead center

4G64 S4 MPI

Specifications

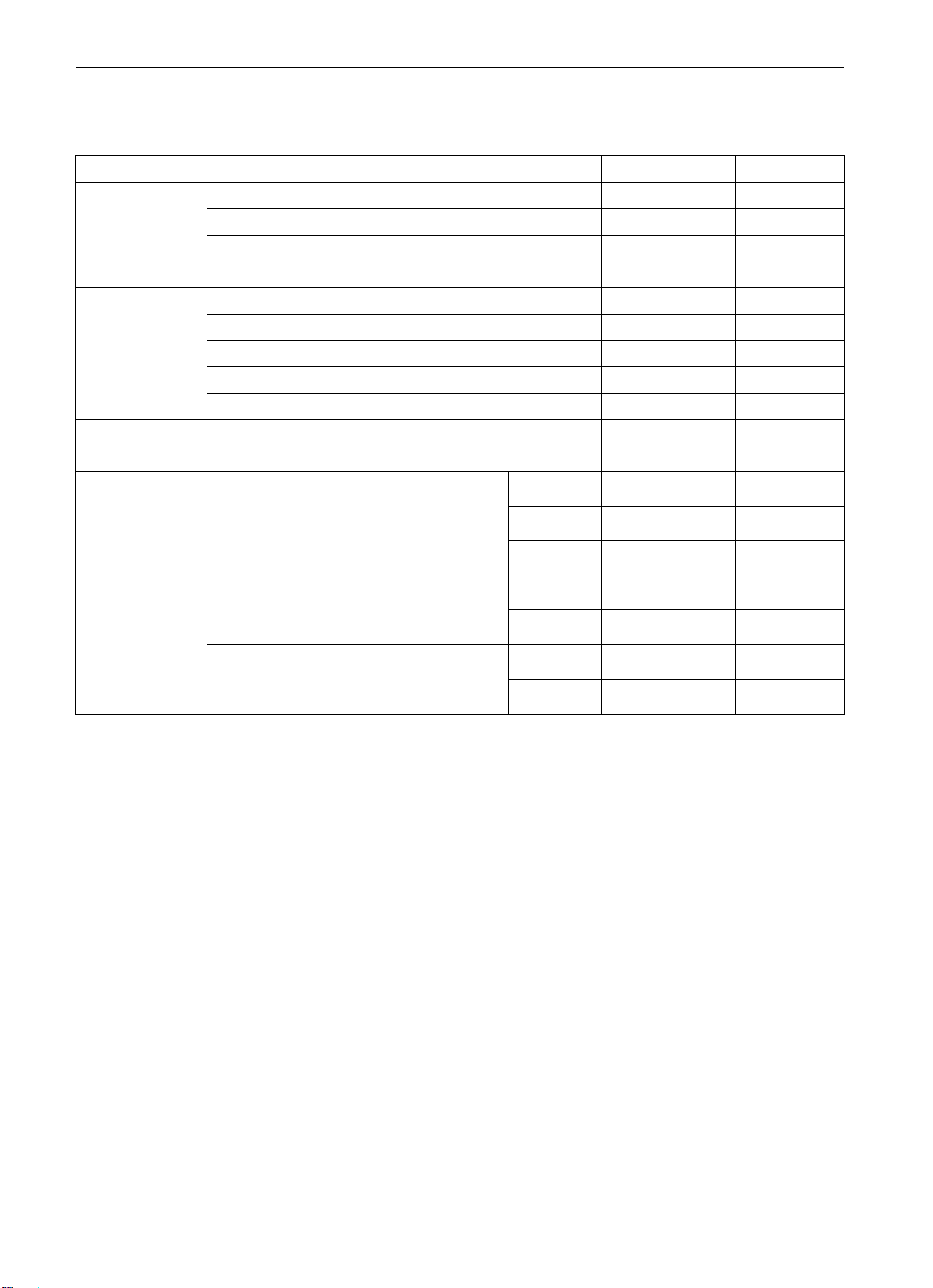

ENGINE SPECIFICATION

Specifications

Maintenance Standard

Items Standard Value Limit Value

Generator

Toothed-belt

Camshaft Air exhaust 36.83 36.33

Cylinder Head

Valve

Convex value of tensioner arm 12

Press-in value of tensioner arm (98~196N) 1

Height of cam Air intake 37.39 36.89

Shaft diameter 45.0

Planeness of Bottom Surface 0.03 0.2

Surface lapping limit*Total lapping of cylinder block and head

Total height 119.9 120.1

Length of cylinder head bol 97.4 99.4

Edge thickness

Diameter of valve stem 6.0

Radial clearance between valve

stem and valve guide

Inclination 45 45.5

Intake 1.0 0.5

Exhaust 1.2 0.7

Intake 0.02 0.05 0.10

Exhaust 0.03 0.07 0.15

* 0.2

11-3

Unitmm

Height

Free Height 51.0 50.0

Valve Spring Working pre-tightening force/Working depth Kg/mm 27.2/44.2

Verticality 2 4

Contact width 0.9 1.3

Minor diameter 6.0

Valve Guide Major diameter 11.0

Indentation depth 14.0

Convex value of valve stem 49.3 49.8

Oil Pump Lateral clearance

Piston Piston clearance 0.02 0.04

Lateral clearance

Piston Ring Ring No.1 0.25 0.35 0.8

End clearance Ring No.2 0.40 0.55 0.8

Major diameter 22.0

Piston Pin Indentation force Kg. 755 1750

Indentation temperature

Crankshaft Internal clearance of crankshaft pin 0.02 0.05 0.1

Connecting Rod Lateral clearance on big end 0.10 0.25 0.4

Intake 112.30 111.80

Exhaust 114.11 113.61

Driving gear 0.08 0.14

Driven gear 0.06 0.12

Ring No.1 0.02 0.06 0.1

Ring No.2 0.02 0.06 0.1

Oil control ring 0.10 0.40 1.0

Room temperature

11-4

ENGINE SPECIFICATION

Items Standard Value Limit Value

Axial clearance 0.05 0.18 0.25

Crankshaft

Cylinder Block

Cylinder Block Cylindricity of cylinder hole 0.01

Generator Resistance of rotor coil 3 5

Cylinder Head 0.30 O.S. 34.435 34.455

Main shaft diameter 57

Connecting rod shaft diameter 45

Radial clearance of main shaft 0.02 0.04 0.1

Planeness of top surface 0.05 0.1

Top surface lapping limit*Total lapping

of cylinder block and head

Total Height 290 0.1

Minor diameter of cylinder hole 86.5086.53

Secondary processing dimension of the

enlarging of mounting hole of valve guides

(intake valve and exhaust valve)

Secondary processing dimension of the

enlarging of round hole of intake valve seat

Secondary processing dimension of the enlarging of round hole of exhaust valve seat

0.05 O.S. 11.05 11.07

0.25 O.S. 11.25 11.27

0.50 O.S. 11.50 11.52

0.60 O.S. 34.735 34.755

0.30 O.S. 31.935 31.955

0.60 O.S. 32.235 32.255

* 0.2

Remarks:

O.S.: Diameter increased

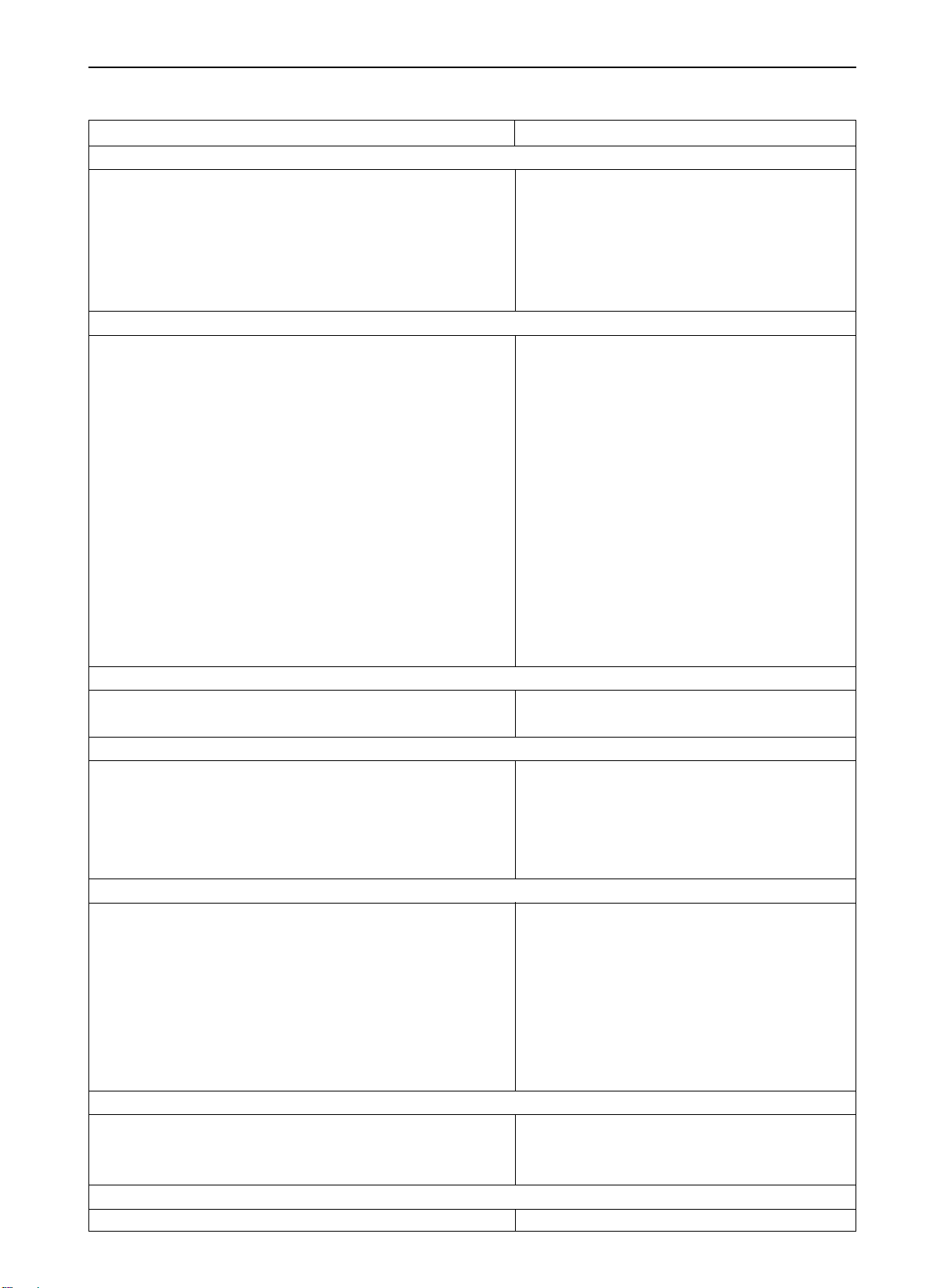

ENGINE SPECIFICATION

Tightening Torque

Fastening Location Torque (Kg.M)

Generator and Ignition System

Fastening bolt of AC generator 2.4

Stay bolt 2.4

Pivot nut 2.3

Crankshaft pulley bolt 2.5

Spark plug 2.5

Ignition coil bolt 1.1

Timing toothed-belt

Lower front cover of timing toothed-belt 1.1

Tensioning pulley bolt 4.9

Tensioning wheel arm bolt 2.2

Automatic tensioning wheel bolt 2.4

Central pulley bolt 3.6

Tensioning wheel bracket 4.9

Rear cover of timing toothed-belt 1.1

Timing belt indicator 0.9

Toothed-belt wheel of oil pump 5.5

Crankshaft toothed-belt wheel bolt 12.0

Tensioner B 1.9

Toothed-belt wheel of balancing shaft 4.6

Camshaft toothed-belt wheel bolt 9.0

Toothed-belt wheel of balancing shaft 4.6

Fuel System

Throttle 1.9

Fuel distributing pipe assembly 1.2

Intake manifold

Eye bolt of engine 1.9

Cooling water temperature sensor plug of engine 3.0

Water outlet port coupling bolt 2.0

Intake manifold bolt 2.0

Water temperature sensor 3.0

Exhaust manifold

Exhaust manifold cover bolt 1.4

Water inlet port coupling bolt 2.4

Exhaust manifold nut (M8) 3.0

Exhaust manifold nut (M10) 5.0

Cooling water bypass pipe connector bolt 2.4

Cooling water pipe assembly bolt 1.3

Thermostat shell bolt 2.4

Water pump bolt 1.4

Rocker Arm and Camshaft

Rocker cover bolt 0.4

Rocker arm and camshaft assembly bolt 3.2

Thrust cover screw 1.9

Cylinder head and valve

Cylinder head bolt 2.0 90 90

11-5

11-6

Fastening Location Torque (Kg.M)

Front cover and oil pump

Oil drain plug 4.5

Oil pan 0.7

Oil suction filter bolt and nut 1.9

Oil pressure switch 1.0

Pressure relief plug 4.5

Oil suction filter bracket bolt 1.9

Front cover bolt 2.4

Plug 2.4

Flange bolt 3.7

Oil pump cover bolt 1.6

Oil pump cover screw 1.0

Piston and connecting rod assembly

Connecting rod nut 2.0 90100

Crankshaft, cylinder block, flywheel and drive board

Flywheel bolt 13.5

Rear cover board mounting bolt 1.1

Oil-seal retainer mounting bolt 1.1

Main bearing cap bolt 2.5 90100

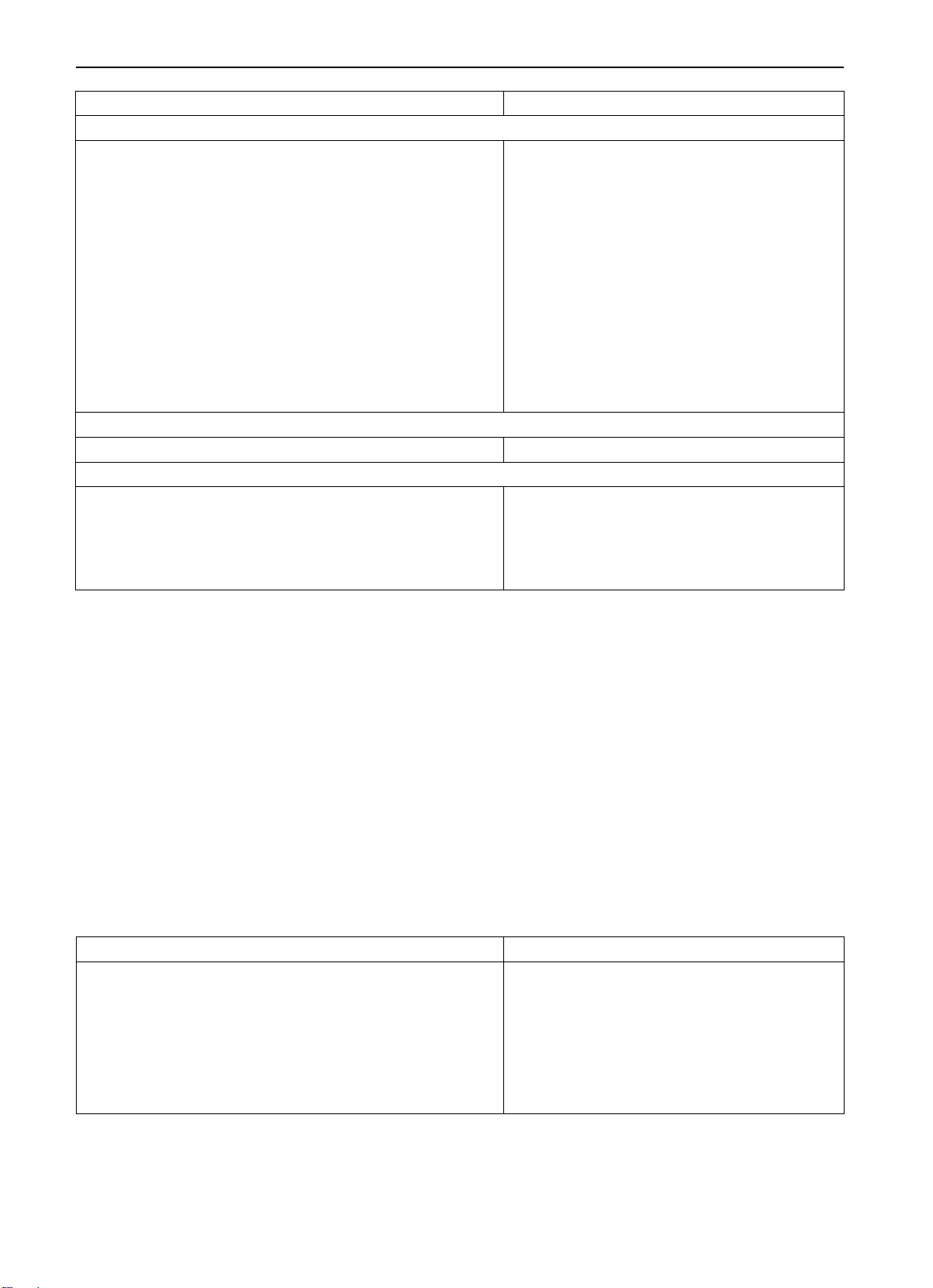

ENGINE SPECIFICATION

A New Tightening Method Bolt Tightening at Plasticity Area

A new tightening method bolt tightening at plasticity area will be used in some parts of engine. Different from

traditional tightening method, the use limit stated herein shall be followed while tightening the bolts.

This method shall be applied to the following bolts:

(1) Cylinder head bolt

(2) Main bearing cap bolt

(3) Connecting rod bolt

Tightening method:

Screw the bolt till the prescribed torque is reached, then tighten another 90100(for cylinder head bolt, 2 90

is needed). When the area is different, the method is also different. The methods stated herein shall be followed.

Sealant

Applying Location Model to Use

Water outlet port coupling MD970389 or the equivalent

Cooling water bypass pipe connector MD970389 or the equivalent

Oil pressure switch 3M ATD No.8660 or the equivalent

Oil pan MD970389 or the equivalent

Oil-seal retainer MD970389 or the equivalent

Water temperature sensor 3M NUT LOCKING No.4171 or the equivalent

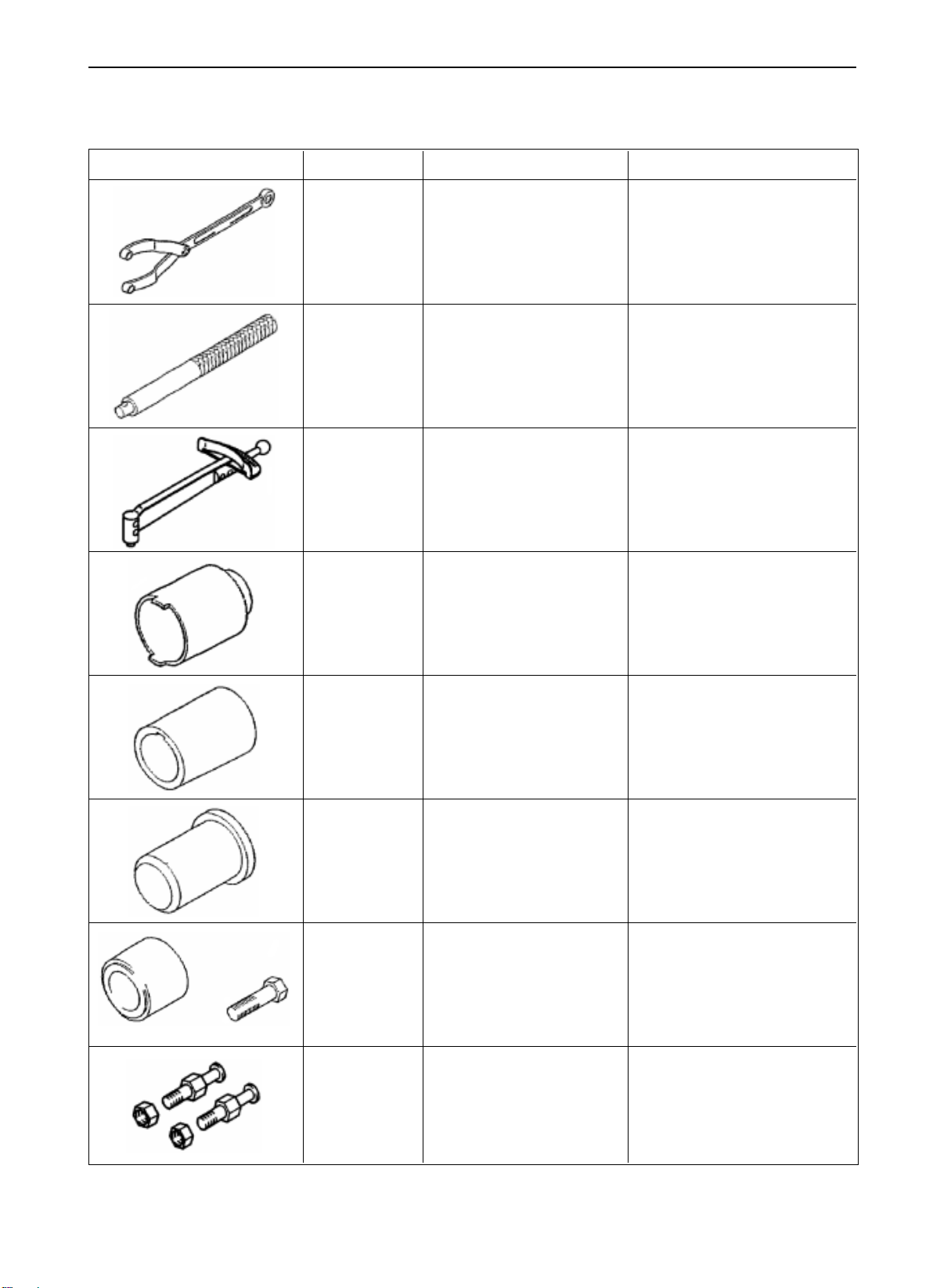

SPECIAL TOOLS

Tools REF. NO. NAME PURPOSE

ENGINE SPECIAL TOOLS

11-7

MB990767

MB990938 HANDLE Use together with MD998776

MD990685 TORQUE WRENCH

MD998162

CRANKSHAFT PULLEY

WRENCH

SCREW-PLUG

WRENCH

Use MD998719 for Fastening

camshaft toothed-belt wheel

Use MD998767 for timing

toothed-belt tensioning

Disassembly and mounting of

front cover plug

CRANKSHAFT FRONT

MD998285

MD998375

MD998713 Mounting of camshaft oil seal

MD998719 PULLEY FIXING PIN

OIL SEAL GUIDE

CRANKSHAFT FRONT

OIL SEAL ASSEMBLER

CAMSHAFT OIL SEAL

ASSEMBLER

Use MD998375 for mounting of

crankshaft front oil seal

Mounting of crankshaft front

oil seal

Use MB990767 for the fastening

of camshaft toothed-belt wheel

11-8

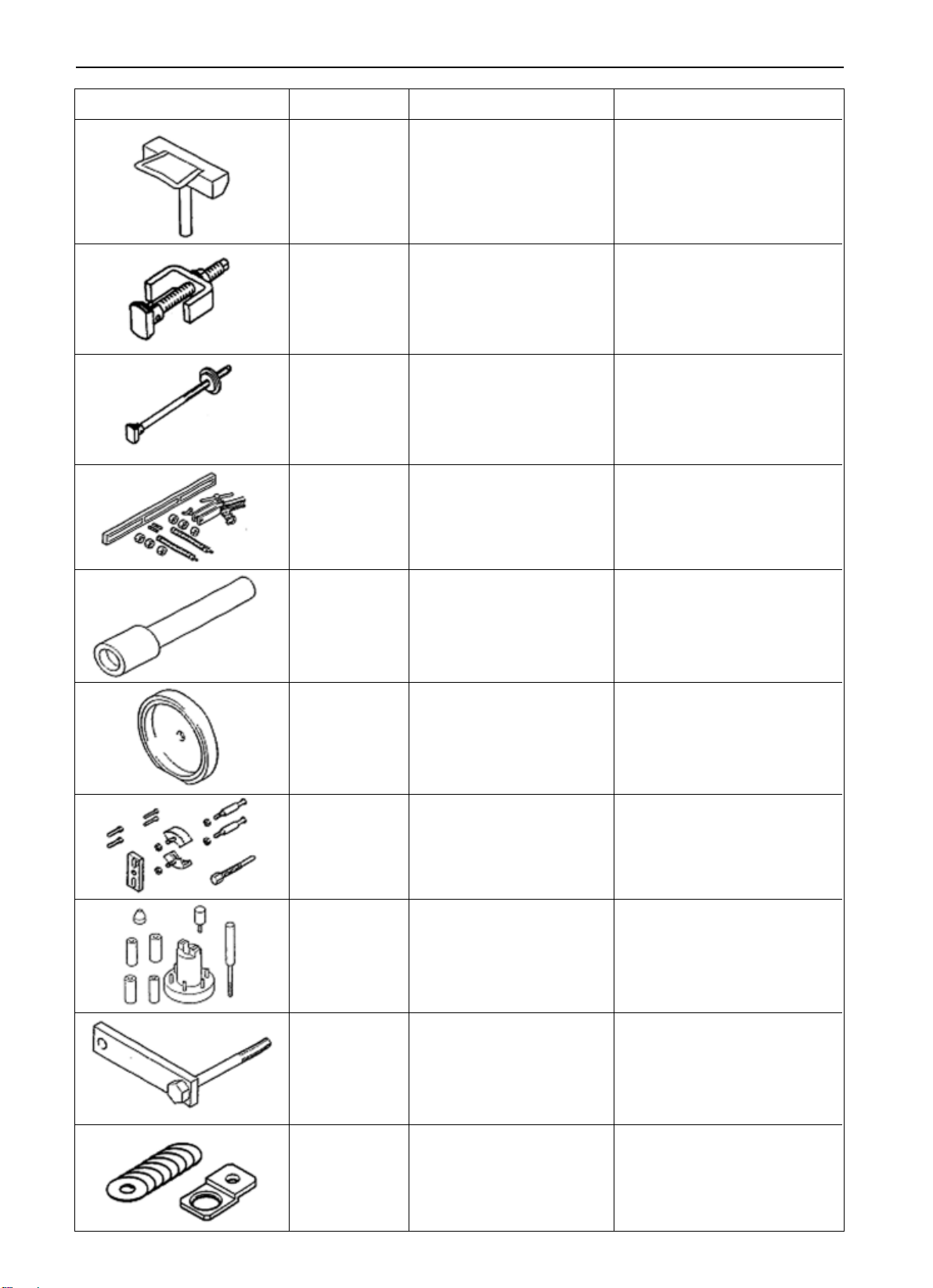

ENGINE SPECIAL TOOLS

Tools REF. NO. NAME PURPOSE

MD998727 OIL PAN DETACHER Disassembly of oil pan

MD998371

MD998372

MD998772 VALVE SPRING

MD998774 Mounting of valve oil seal

MD998776

BALANCING SHAFT

BEARING PULLER

BALANCING SHAFT

BEARING PULLER

VALVE OIL SEAL

ASSEMBLER

CRANKSHAFT REAR

OIL SEAL ASSEMBLER

Disassembly of reverse balancing shaft front bearing

Disassembly of reverse balancing shaft rear bearing

Disassembly and mounting of

valve and related spare parts

Use MB990938 for mounting

of crankshaft rear oil seal

CRANKSHAFT

MD998778

MD998780 Disassembly of piston pin

MD998781 FLYWHEEL STOPPER

MD998783

TOOTHED-BELT

WHEEL PULLER

PISTON INSTALLATION

TOOL

SCREW-PLUG

WRENCH FIXER

Disassembly of crankshaft

toothed-belt wheel

Fastening flywheel and driving plate

Disassembly and mounting of

front cover screw-plug

ENGINE SPECIAL TOOLS

Tools REF. NO. NAME PURPOSE

Guide limit for disassembly and

MB991603

BALANCING SHAFT

BEARING PULLER

assembly of reverse balancing

shaft rear bearing (used with

MD998372 together)

11-9

CYLINDER HEAD BOLT

MB991654

MD998440

MD998441

MD998442 Air exhausting of hydraulic lifter

MD998443

WRENCH

LEAKAGE-DETECTING

TESTER

HYDRAULIC LIFTER

RETAINER

HYDRAULIC LIFTER

WIRE

HYDRAULIC LIFTER RETAINER

Disassembly and mounting of

cylinder head bolt

Hydraulic lifter leakage-detect

test

Air exhausting of hydraulic

lifter

Hydraulic lifter retainer while

removing and mounting rocker

shaft assembly

MD998705

MD998785

MD998767 Adjusting tension of timing belt

BALANCING SHAFT

BEARING INSTALLER

TIMING TOOTHED-BELT

STOPPER

TENSIONER PULLING

STEEVE

Mounting of reverse balancing

shaft front & rear bearing

Retaining of balancing shaft

toothed-belt wheel

11-10

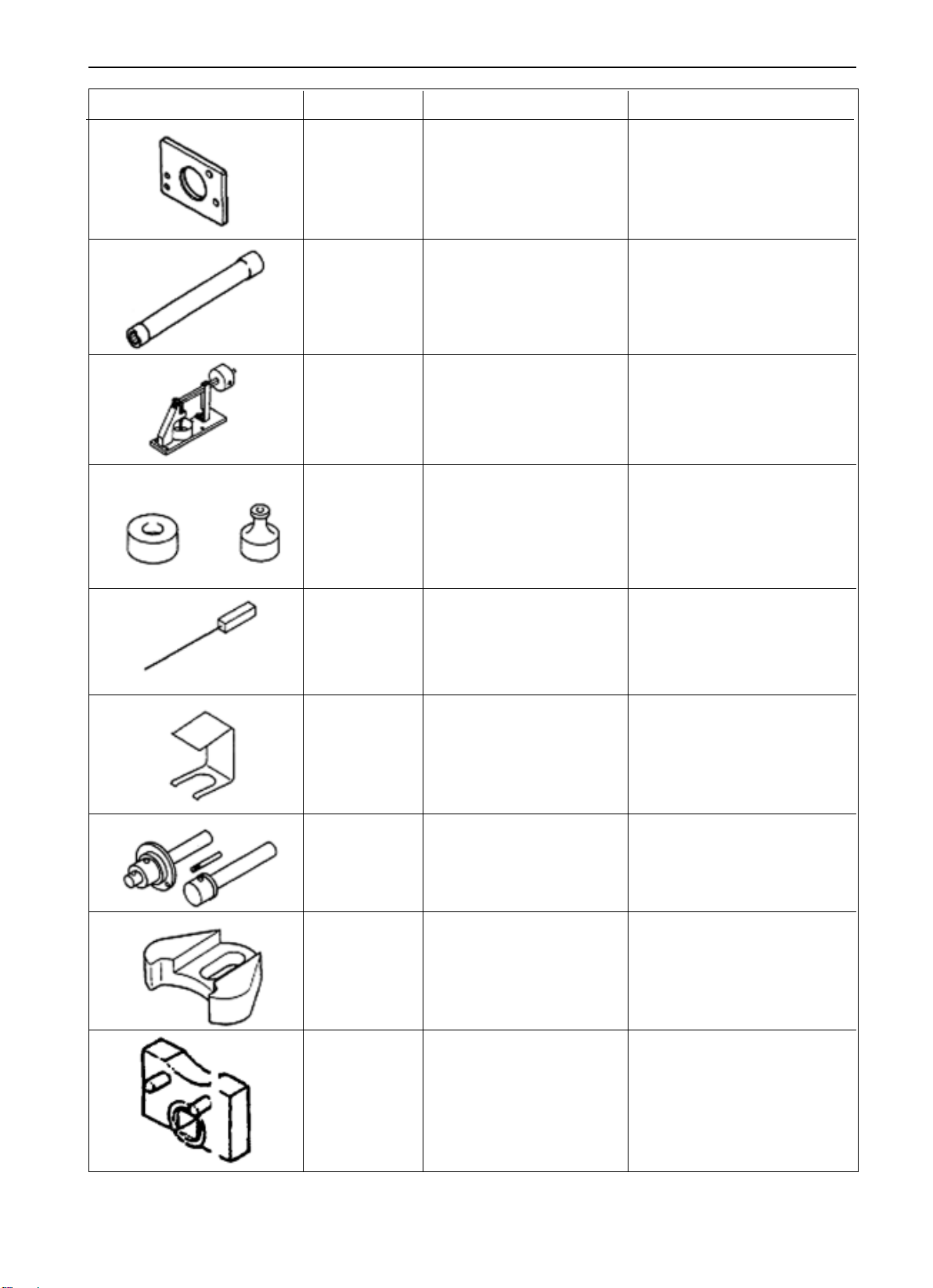

ENGINE AC GENERATOR AND IGNITIONSYSTEM

AC GENERATOR AND

IGNITION SYSTEM

DISASSEMBLY AND MOUNTING

7

23N.m

5

4

23N.m

10

11N.m

9

8

25N.m

11N.m

3

11

9

Disassembly Procedure

1. driving belt

E

2. water pump pulley

3. power steering pump pulley

4. AC generator support

5. AC generator

A D

6. crankshaft pulley

6

25N.m

7. spark plug cable

8. spark plug

9. ignition coll

10. front top cover of timing toothed-belt

11. ignition coil bracket

MD998781

MD998781

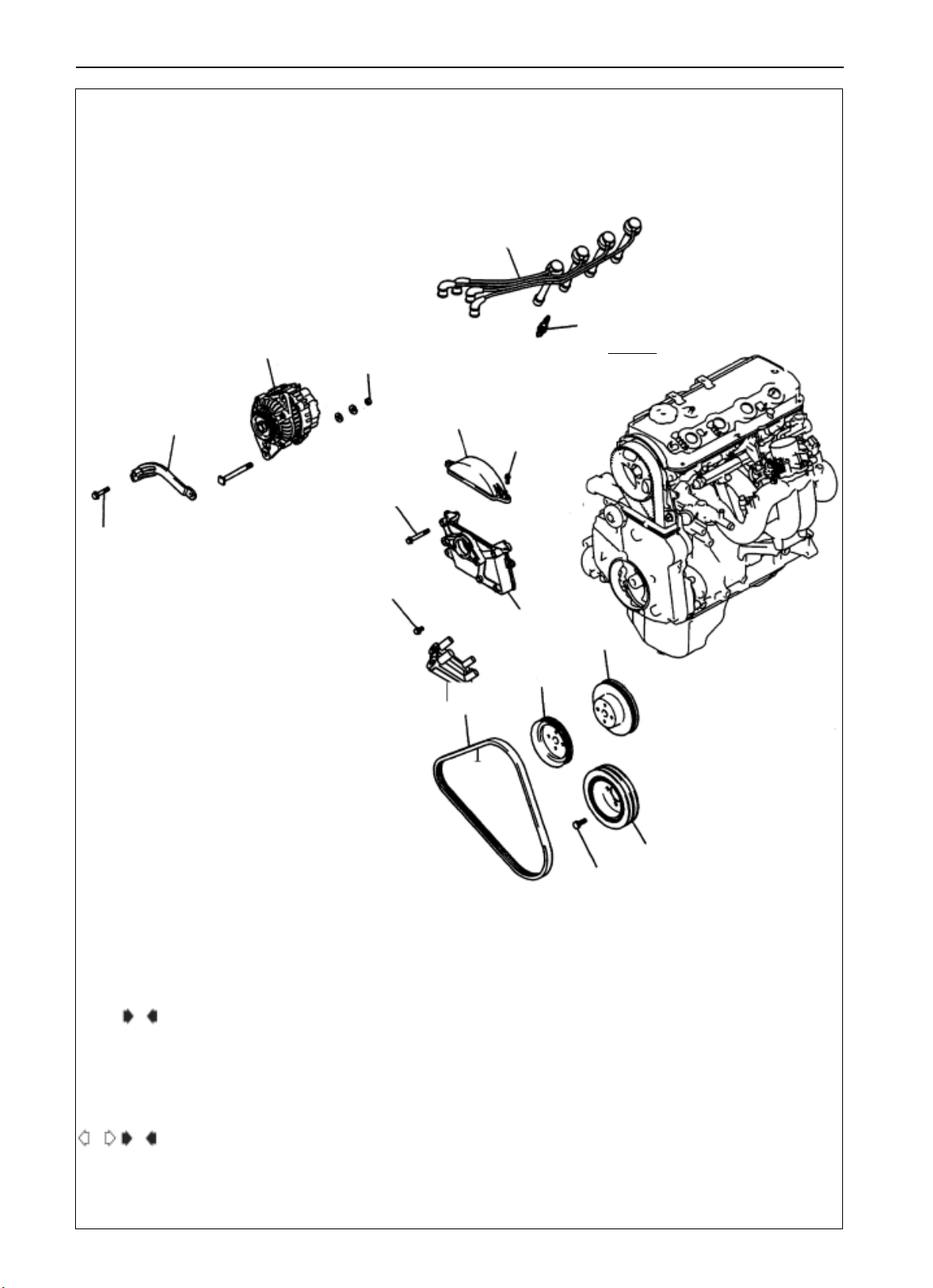

ENGINE TIMING TOOTHED-BELT

NOTES FOR DISASSEMBLY

A

DISASSEMBLY OF CRANKSHAFT BOLT

(1) Fasten flywheel with special tools

(2) Disassemble crankshaft bolt.

9EN0268

NOTES FOR MOUNTING

D

MOUNTING OF CRANKSHAFT BOLT

(1) Fasten flywheel with special tools.

(2) Mount crankshaft bolt.

11-11

100N

AC generator pulley

9EN0268

water pumo pulley

crankshaf

6EN0595

E

ADJUST DRIVING BELT TENSION TO STANDARD

VALUE WITH DEFLECTION INDICATOR OR

TENSION GAUGE

STANDARD VALUE

NEW BELT ....................................................... 5.57.5mm

OLD BELT ........................................................ 7.58.5mm

STANDARD VALUE

NEW BELT ....................................................... 50 70KG

OLD BELT ........................................................ 35 45KG

6EN0596

11-12

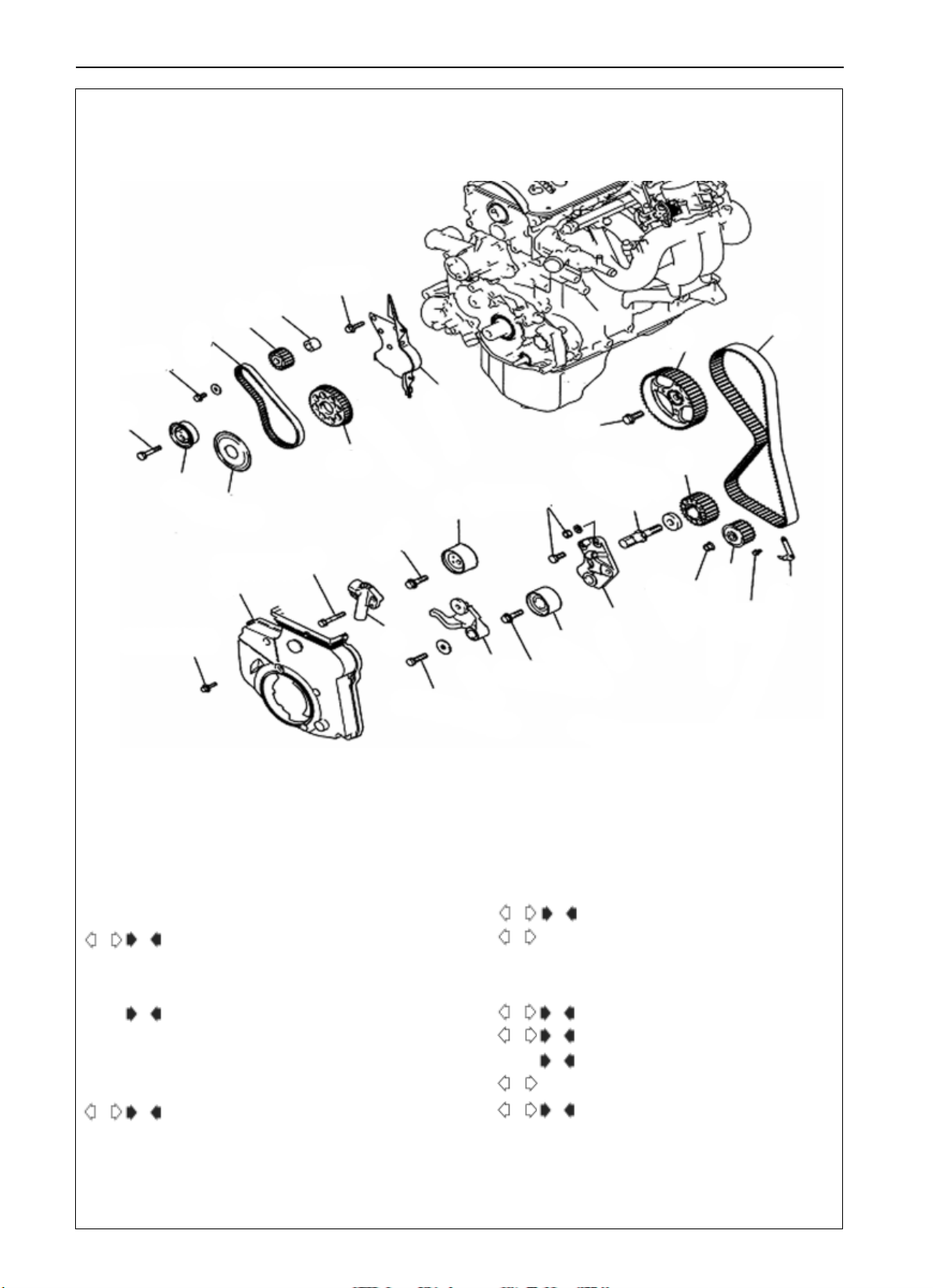

TIMING TOOTHED-BELT

DISASSEMBLY AND MOUNTING

17

16

15

45N

19N

14

13

ENGINE TIMING TOOTHED-BELT

11N.m

8

88N

19

18

48N.

3

20

2

12

162N.m

11

1

11N.m

Disassembly Procudure

1. front lower cover of timing thoothed-belt

2. timing toothed-belt

H

A

3. temsioning pulley

4. tensioning arm

G

5. automatic tensioner

6. centrual pulley

7. tensioning pulley bracket

8. rear cover of timing toothed-belt

9. timing toothed-belt indicator

FB

10. oil pump toothed-bet wheel

24N.

48N.

22N.

4

35N.

C

D

E D

F C

G

H A

10

54N.

7

6

E

11. crakshaft bolt**

8.8N.m

6EN1769

12. crankshaft toothed-belt wheel

13. flange

14. tensioner B

15. timing toothed-belt B

16. balancing shaft toothed-belt wheel

B

17. spacer

18. crankshaft toothed-belt wheel B

19. camshaft toothed-belt bolt

20. camshaft toothed-belt wheel

9

ENGINE TIMING TOOTHED-BELT WHEEL

NOTES FOR DISASSEMBLY

A

DISASSEMBLY OF TIMING TOOTHED-BELT

(1) Record the rotation direction of toothed-belt for correct re-

mounting.

Notes:

Adhering of water or grease to the toothed-belt will sharply

shorten its service life. So, after disassembly, try your best to

6EN0662

avoid the toothed-belt, toothed-belt wheel and tensioner from

being contaminated and adhered by water or grease. No need to

clean these parts. Replace it if it is seriously contaminated.

In case water or grease is found on these parts, check the front cover

oil-seal, camshaft oil-seal and water pump if there exist leakage.

B

DISASSEMBLY OF OIL PUMP TOOTHED-BELT

WHEEL

(1) Assemble the cock on the cylinder block.

(2) Insert a cross point screwdriver of 8mm diameter to fasten

the balancing shaft on the left side.

6EN0663

(3) Disassemble oil pump toothed-belt wheel nut.

(4) Disassemble oil pump toothed-belt wheel.

11-13

MD998781

6EN0634

MD998778

6EN0642

DEN0601

DISASSEMBLY OF CRANKSHAFT BOLT

C

(1) Fasten the flywheel with special tools.

(2) NOTES FOR DISASSEMBLY

DISASSEMBLY OF TIMING TOOTHED-BELT

D

DISASSEMBLY OF CRANKSHAFT TOOTHED-BELT

WHEEL

(1) In case difficult to disassemble due to adhesion, use special

tools.

E

DISASSEMBLY OF TIMING TOOTHED-BELT

WHEEL B

(1) Record the rotation direction of toothed-belt for correct re-

mounting.

Notes:

Adhering of water or grease to the toothed-belt will sharply

shorten its service life. So, after disassembly, try your best to

avoid the toothed-belt, toothed-belt wheel and tensioner from

being contaminated and adhered by water or grease. No need to

clean these parts. Replace it if it is seriously contaminated.

11-14

ENGINE TIMING TOOTHED-BELT WHEEL

In case water or grease is found on these parts, check the front

cover oil-seal, camshaft oil-seal and water pump to see if there

exist leakage.

MD998785

MD990767

6EN0636

MD998778

6EN0637

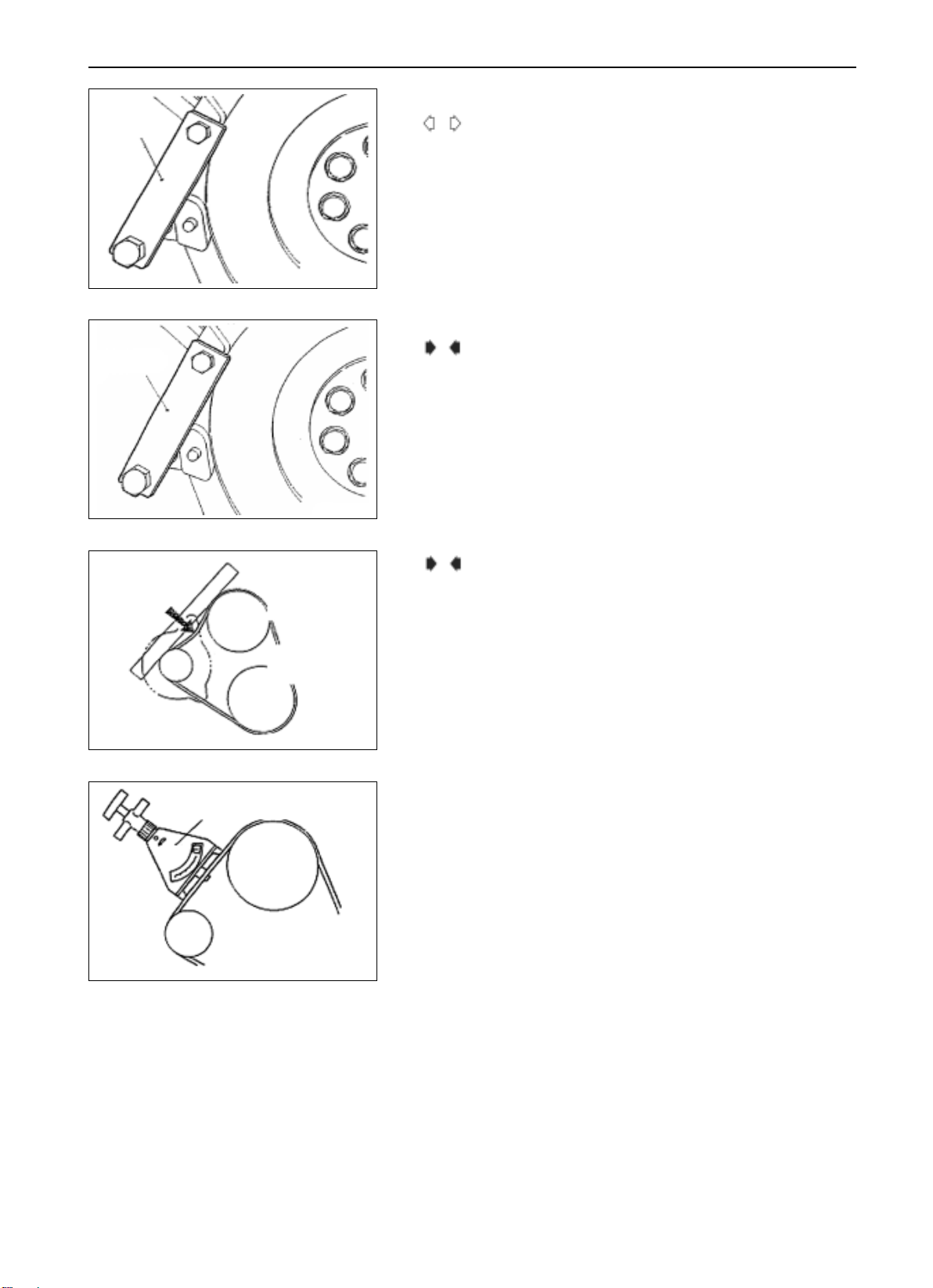

F

DISASSEMBLY OF BALANCING SHAFT TOOTHED-

BELT WHEEL

(1) Fasten balancing shaft toothed-belt wheel with the tools as

shown in the figure.

(2) Disassemble the balancing shaft toothed-belt wheel.

G

DISASSEMBLY OF CRANKSHAFT TOOTHED-BELT

WHEEL B

(1) In case difficult to disassemble due to adhesion, use special

tools.

H

DISASSEMBLY OF CAMSHAFT TOOTHED-BELT

WHEEL BOLT

(1) Fasten camshaft timing toothed-belt wheel with special tools.

(2) Disassemble camshaft toothed-belt wheel bolt.

MD998719

6EN0668

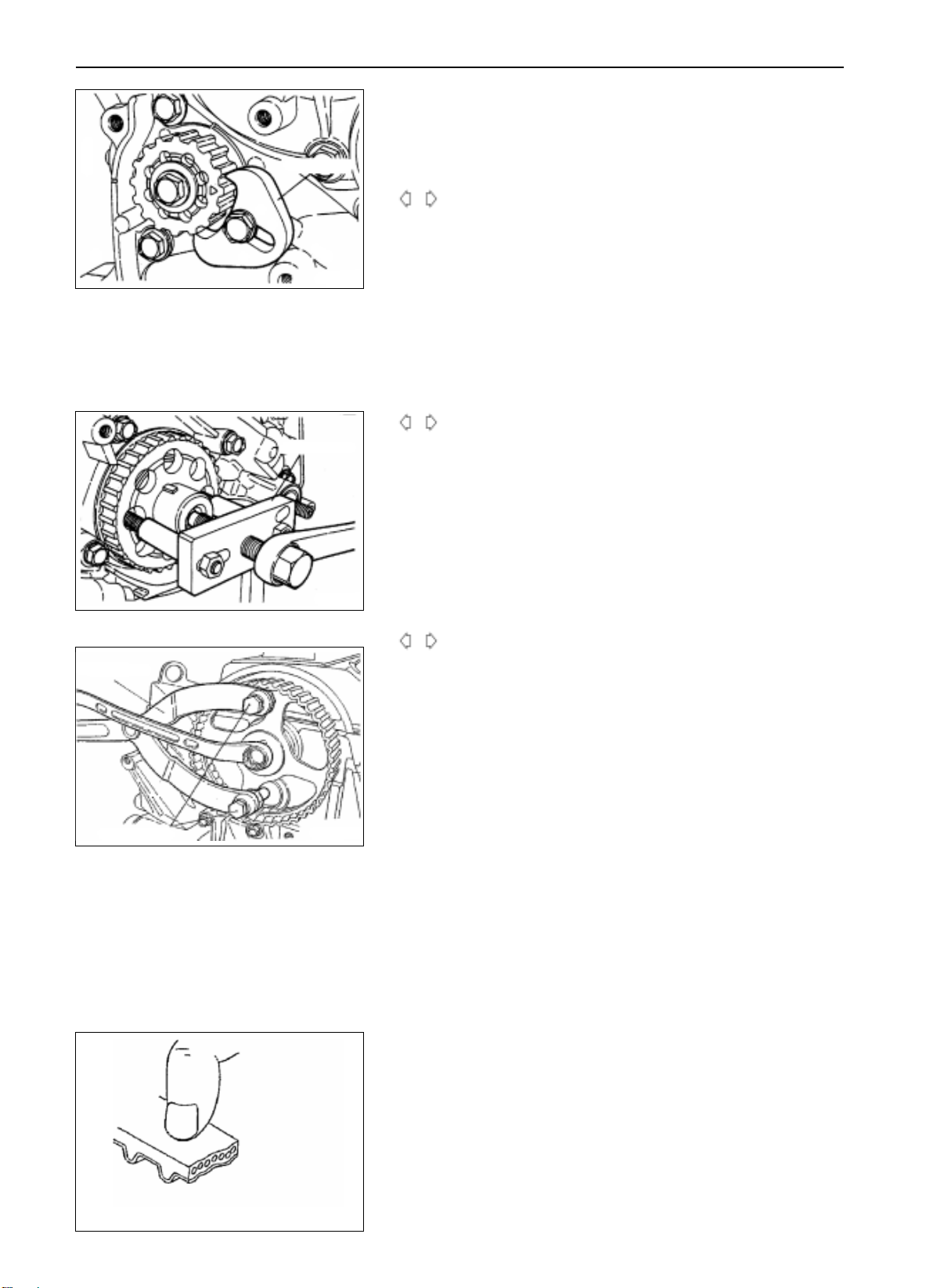

CHECK

TIMING TOOTHED-BELT WHEEL

Carefully check each part of the toothed-belt and replace a new

toothed-belt in case of the following damages:

(1) The back rubber is aged and glistened, no trail left after scraping

with a finger nail, and no elasticity;

8EN0066

ENGINE TIMING TOOTHED-BELT WHEEL

11-15

cracks

canvas peel-off

crack at bottom of tooth

belt margin roueded

abnormal abrasion (heat yarn of belt emposed)

side cracks

1EN0249

8EN0067

(2) There are cracks on the surface of back rubber;

(3) There are cracks and peel-off on the surface of canvas

(4) There are cracks at the bottom of the tooth

(5) There are cracks on the side face of toothed-belt

(6) The side face of toothed-belt is abnormally abraded. The normal

situation is the side face is as level as being cut with a sharp knife

canvas abrased ,rubber exposed

belt teeth broken off

(7) Abnormal abrasion on the tooth surface.

(8) Teeth broken off.

8EN0068

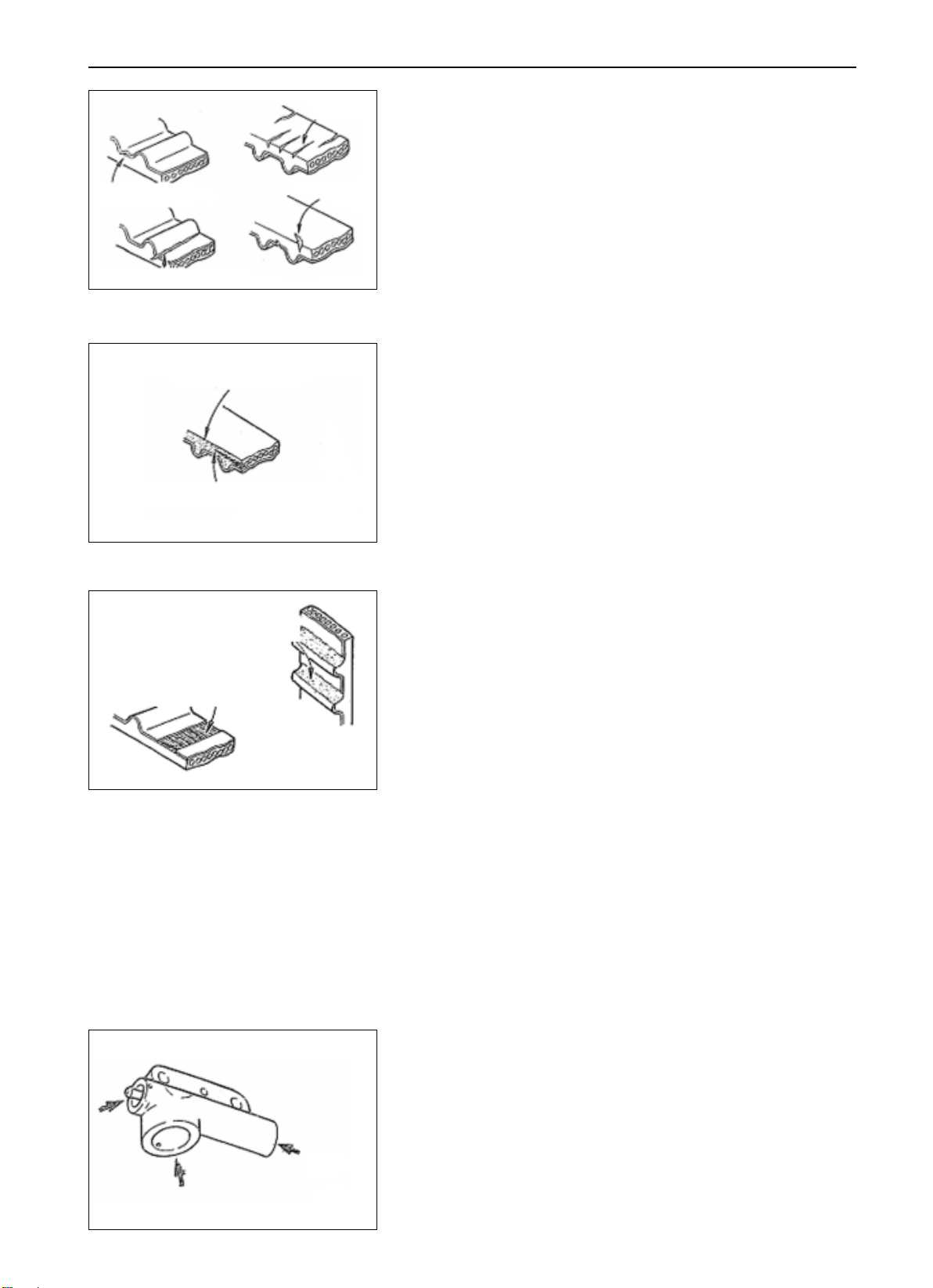

AUTOMATIC TENSIONER

(1) Check automatic tensioner to see if there is leakage and replace

with a new one if necessary.

(2) Check if there is abrasion or damages on the rod end and replace

with a new one if necessary.

6EN0280

Loading...

Loading...