GREAT VIGOR Muscle Car Operating Instructions And Assembly Manual

OPERATING INSTRUCTIONS AND ASSEMBLY MANUAL

®

®

INTRODUCTION

Thank you for selecting this Great Vigor Product.

Please read all instructions and familiarize yourself with the products and controls before

operation. To prevent serious personal injury and/or property damage, operate all controlled

models in a responsible manner as outlined herein. If you come across any problems and

need some help, you can contact us on the internet at www.gv-hobby.com.tw.

We hope you to enjoy our product.

˙ This product is not a toy. It is a high performance model product. It is important to familiarize yourself with the model,

its manual, and its construction before assembly or operation. A child operating under the supervision of the adults is

necessary.

˙ Always keep this instruction manual ready at your hand for your assembling and operating reference, even after

completing the assembly.

˙

˙

CAUTIONS

CHOOSE THE RIGHT PLACE TO OPERATE YOUR R/C MODEL.

˙ Do not operate model products in rain, on public roads, near crowds, near airport, or near areas with restricted radio

operation. This could cause serious accidents, personal injuries, and/or property damage.

˙ Do not run where loud noises can disturb others, such as hospitals and residential areas.

˙ Never run R/C models near people or animals.

˙ Never run indoors. There is a high risk of fire and/or damage.

˙ To avoid injury, do not run in confined spaces.

INSPECT YOUR MODEL BEFORE OPERATION.

˙ For the best performance, it is important to make sure all the moveable parts work free without binding.

˙ Always use fresh batteries for your transmitter and for your receiver to avoid losing control of the model.

˙ Check the radio system and range before every driving session. To properly check the range, have a friend hold the

car with the engine off and walk to the farthest distance that you plan to operate your model. Operate the controls

to make sure the model responds correctly. Do not operate the model if there is any problem with the radio system.

˙ Never share frequency with somebody else at the same time. Radio signals will be mixed and you will lose control of

your model. This may lead to accidents.

˙ Make sure that all screws and nuts are properly tightened. It is also a good idea to use removable thread lock

wherever metal screws go into metal.

˙ Always test the brakes and throttle before starting your engine to avoid losing control of the model.

˙ As the front end of the antenna may be dangerous, do not aim it toward faces.

˙ Never reverse connection/disassemble the battery. This may lead to damage and leakage.

˙ As the product includes small and sharp parts, assemble and store this product only in places out of the reach of

children.

AFTER OPERATION OF YOUR R/C MODEL

˙ Turn off receiver first, then turn off transmitter, this will prevent runaways.

˙ Be sure to keep your R/C model clean and free of excess dirt and grease, this will increase the life.

˙ Be careful when handling batteries, they will be hot after running.

˙ When the model is not in use, always turn off the receiver and transmitter. Furthermore, disconnect the batteries and

remove them from the model and the transmitter. This may be dangerous such as overheat and leakage.

˙ Replace any batteries, they have been dented or have frayed wires, short circuits can cause fire.

˙ Do not store this model in a high-temperature/humidity area or in direct sunlight.

INTRODUCTION

CAUTION

˙

˙

˙ ˙ ˙ ˙ ˙ ˙ ˙ ˙ ˙ ˙ ˙ ˙ ˙ ˙ ˙ ˙ ˙

˙

INTRODUCTION

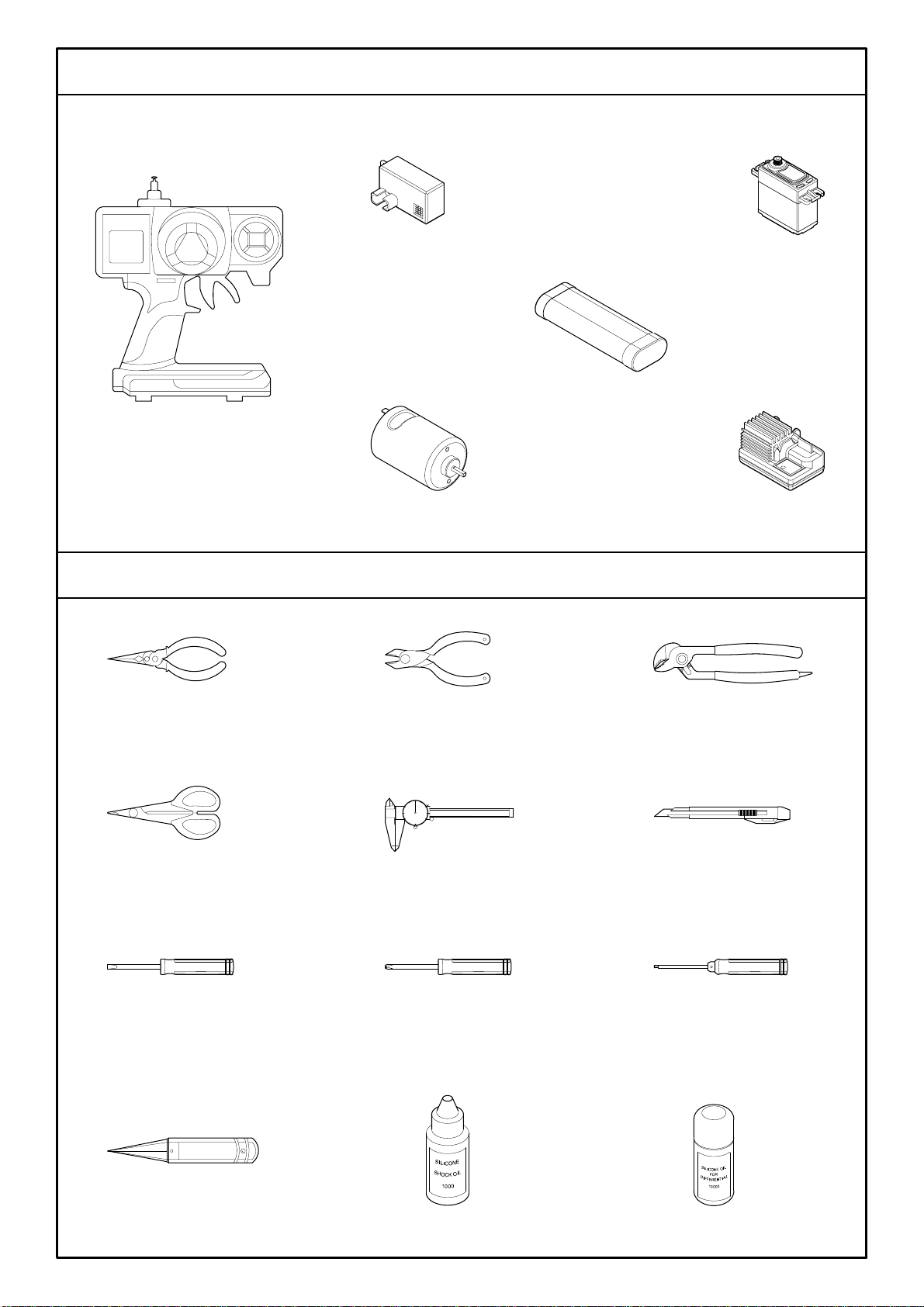

˙2 Channel Radio Set

˙Receiver

˙Steering Servo

˙Battery

˙Motor

˙Electronic Speed Control

CAUTIONS

˙Needlenose Pliers

˙Cutting Pliers

˙Tongue and Groove Pliers

˙Hobby Knife

˙Caliper

˙Body Scissors

˙Screwdriver

˙Screwdriver

˙Hex Wrench

(1.5,2.0,2.5,3.0mm)

˙Diff Silicone oil

˙Shock Oil

˙Body Reamer

EXTRA STUFF NEEDED

ADDITIONAL ITEMS NEEDED FOR OPERATION

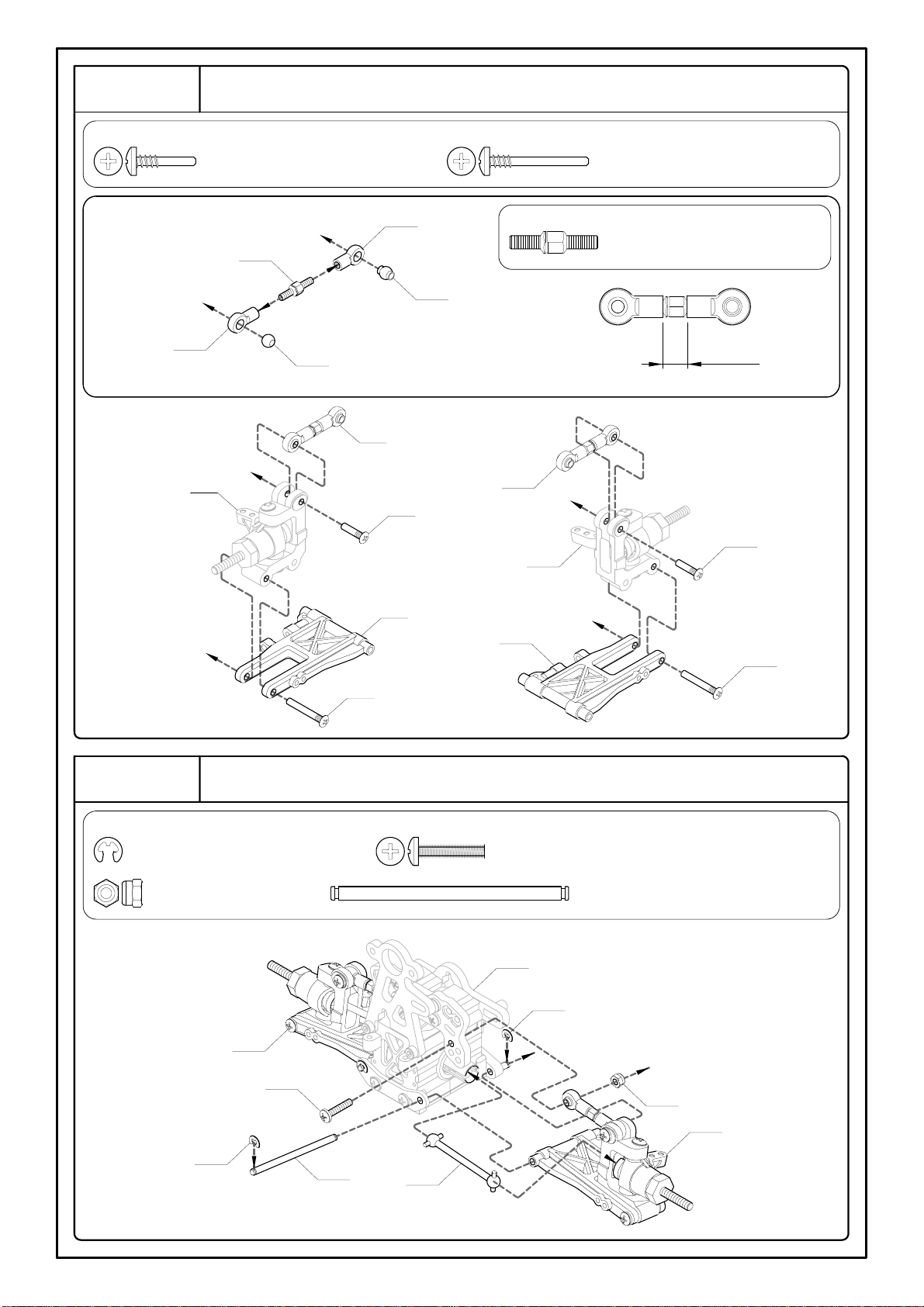

Step 1

Front and Rear Differentials

1A - Washer 2.6x6x1mm -- 4

1B - Washer 12.1x20.5x1mm -- 4

1C - Ball Bearing 5x8x2.5mm -- 2

1E

(EL2292)

1A

EL2285

Differential Oil

EL2287

1B

Differential Oil -- 1

Contain a 2.6mm Lock Nut Inside

For Front and Rear (x2)

EL2292

EL2286

1B1CDifferential Oil

EL2281

(44T)

EL2285

EL2288

1D - Lock Nut 2.6mm -- 2

1E - Cap Screw 2.5x30mm -- 2

Step 2

Front Differential Housing

2A

2B2DEL2290

EL2282

(16T)

<2-1>

Step 2-1

EL2276

2D2EStep 1

2E2C2C

EL2276

2C - F/H Tapping Screw 2x8mm -- 4

2D - Ball Bearing 5x10x4mm -- 2

2E - Ball Bearing 10x15x4mm -- 2

2B - Pin 1.5x7.8mm -- 1

2A - E-Ring 3mm -- 1

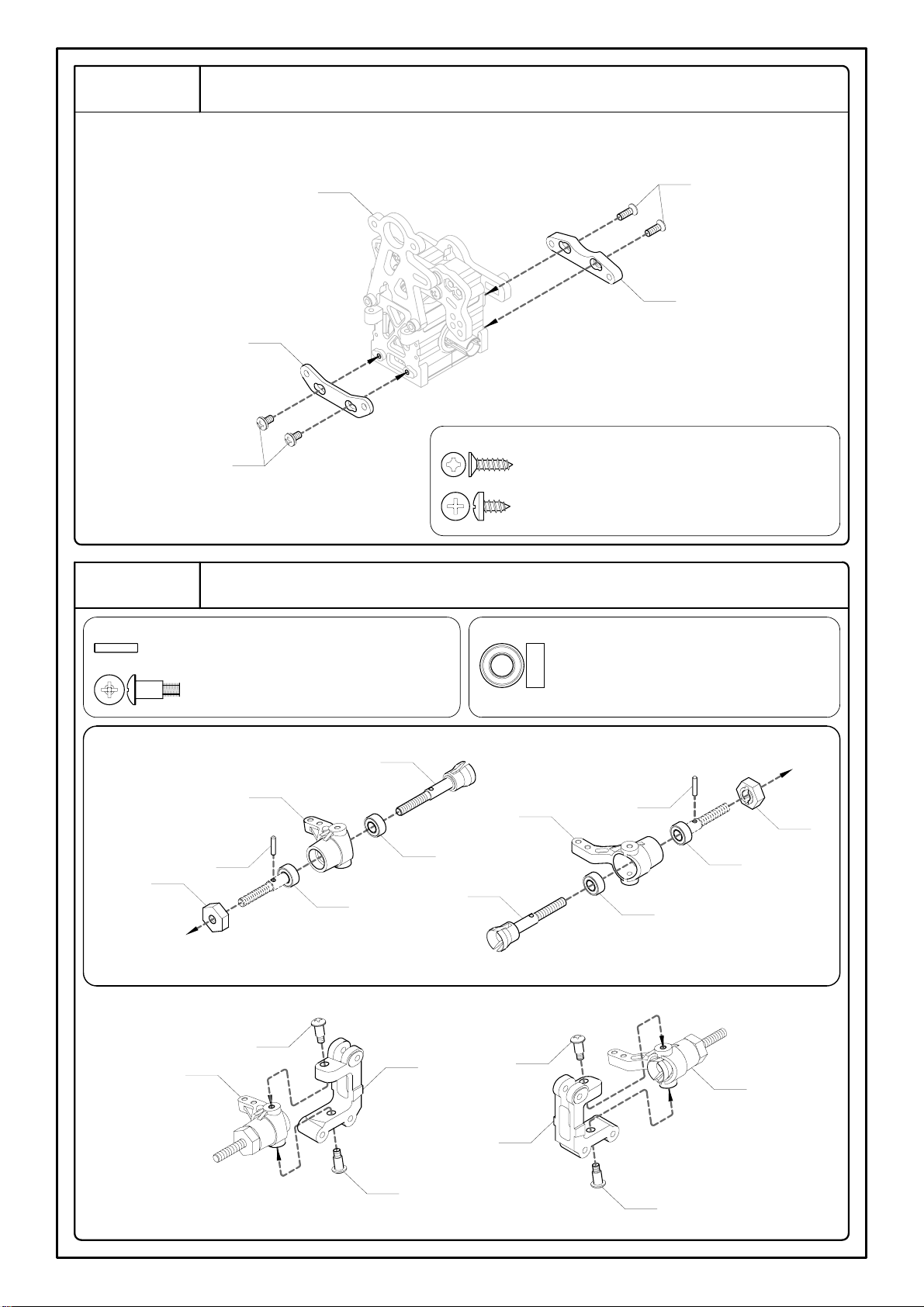

Step 3

Rear Differentials Housing

3A

3B3DEL2289

EL2282

(16T)

<3-1>

Step 3-1

EL2276

3D

3E

Step 1

3E3C3C

EL2276

3C - F/H Tapping Screw 2x8mm -- 4

3D - Ball Bearing 5x10x4mm -- 2

3E - Ball Bearing 10x15x4mm -- 2

3B - Pin 1.5x7.8mm -- 1

3A - E-Ring 3mm -- 1

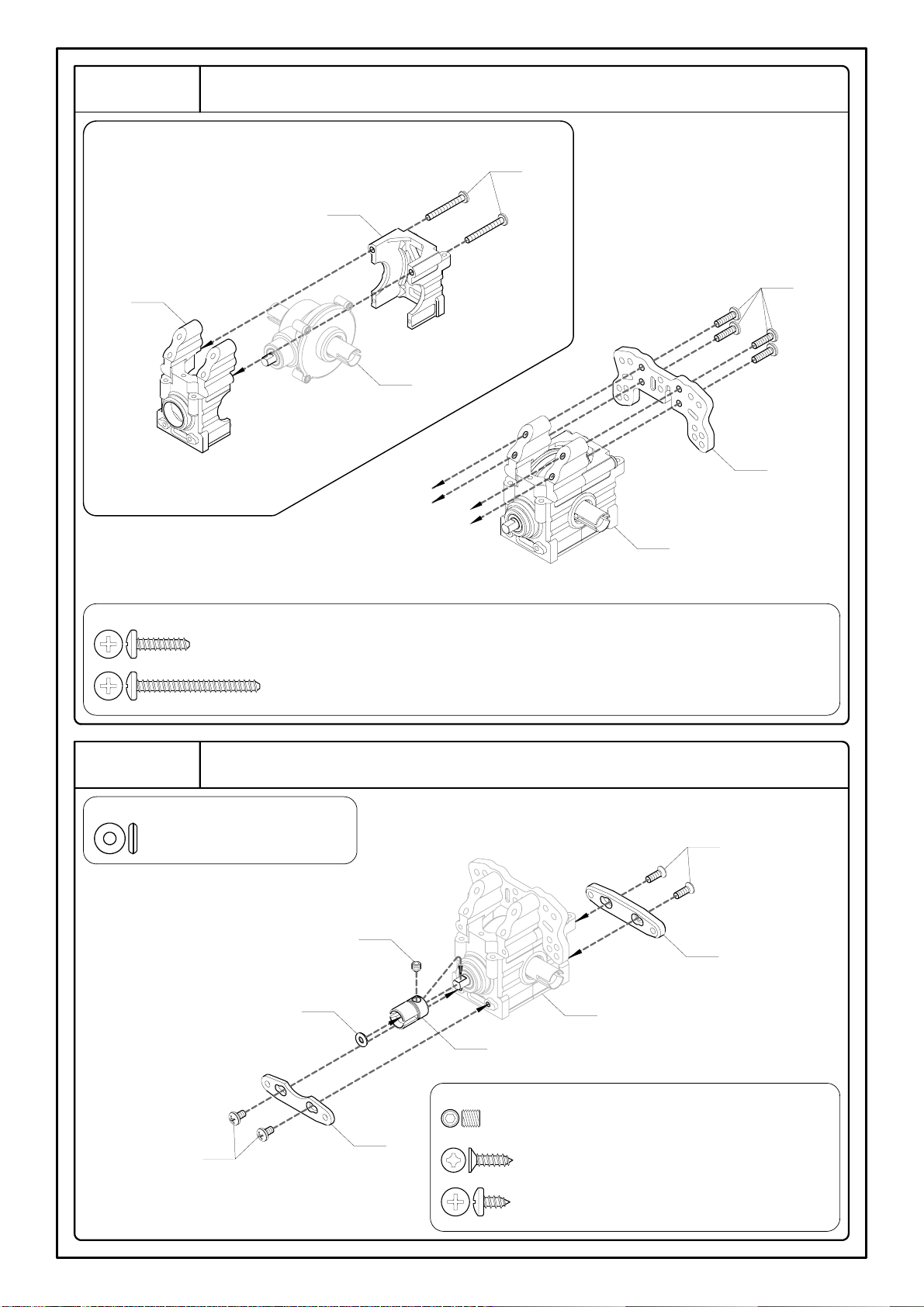

Step 4

Front Shock Tower and Gearbox

EL1322

<4-1>

4A

EL16212

Step 4-1

EL3043RE

Step 2

EL16212

EL3042RE

4B

4B - Cap Screw 3x12mm -- 2

4A - Button Head Tapping Screw 3x12mm -- 4

Step 5

Front Suspension Plate and Suspension Plate Holder

5A

EL162D4

Step 4

EL162D2

5B

5A - F/H Tapping Screw 3x10mm -- 2

5B - Button Head Tapping Screw 3x6mm -- 2

Step 6

Front Wheel Shafts and Steering Knuckles

6A - Pin 2x9.8mm -- 2

6B - Rocker Arm Pin 3x10mm -- 4

6C - Ball Bearing 5x10x4mm -- 4

V21071

6A

EL134

V210512L

6C

6C

For Left Side

V210512L

6C6CEL134

For Right Side

6A

V21071

<6-1>

For Right Side

Step 6-1

(R)

6B

(CB353)

V2348

(R)

6B

(CB353)

V2348

(L)

6B

(CB353)

Step 6-1

(L)

For Left Side

6B

(CB353)

Step 7

Front Upper, Lower Suspension Arms and Wheel Shafts

7A - Hub Stud 3x13.5mm -- 2

7B - Hub Stud 3x22.5mm -- 2

7C - Turnbuckle 5x20mm -- 2

5.6mm

For Right and Left Sides (x2)

V23492

(CB1591)

V23492

(V22151)

<7-1>

7C

(V23492)

V23492

(V22151)

CB113

Step 6

(R)

Step 7-1

(R)

7A

(CB150S)

Step 7-1

(L)

For Left Side

7A

(CB150S)

7B

(CB150A)

EL347F1

Step 6

(L)

EL347F1

7B

(CB150A)

For Right Side

Step 8

Front Suspension

8A - E-Ring 2.5mm -- 4

8B - Lock Nut 3mm -- 2

8C - Button Head Machine Screw 3x15mm -- 2

8D - Hinge Pin 3x54mm -- 2

Step 5

8A

8B

Step 7

(L)

V2355

8D

(EL1111)

8A

8C

Step 7

(R)

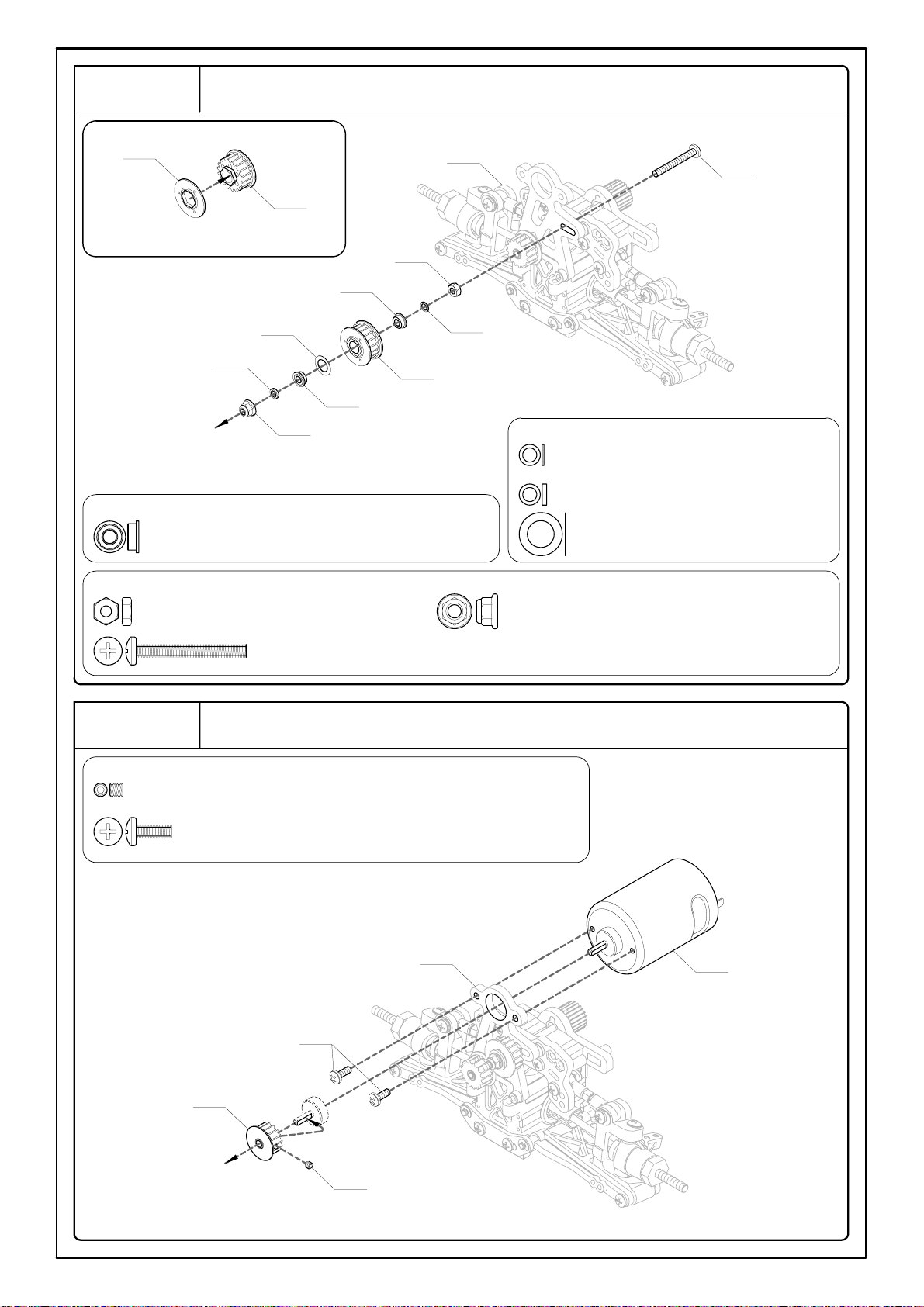

Step 9

Flanged Ball Bearing Mount

Step 8

EL3044

9A

EL3044

9A

9A - Flanged Ball Bearing 3x6x2.5mm -- 2

Step 10

Belt Pulley, Belt Pulley Shaft and Motor Pinion Gear

10A

EL02411HC

(24T)

Step 9

10B

10A

EL228162RE

(16T)

10C

(EL228161)

10C - Belt Pulley Shaft 3x67mm -- 1

10B - Shim 3.2x4.8x1mm -- 1

10A - Grub Screw w/Threadlock 3x3mm -- 2

Step 11

Belt Pulley

Step 12

Belt Pulley and Motor

12A - Grub Screw w/Threadlock 3x3mm -- 1

12B - Button Head Machine Screw w/Threadlock 3x8mm -- 2

EL007

Step 11

12B

EL22816RE

(16T)

12A

11G

Step 10

11A

11C

11D

11B

11G - Button Head Machine Screw 3x25mm -- 1

11E - Lock Nut 3mm -- 1

11F - Flange Lock Nut 3mm -- 1

11A - Flanged Ball Bearing 3x6x2.5mm -- 2

11B - Shim 3.2x4.8x0.4mm -- 1

11C - Shim 3.2x4.8x1mm -- 1

11D - Shim 6.1x9.8x0.3mm -- 1

11E

11A

11F

VX22818

(18T)

VX22818

<11-1>

Step 11-1

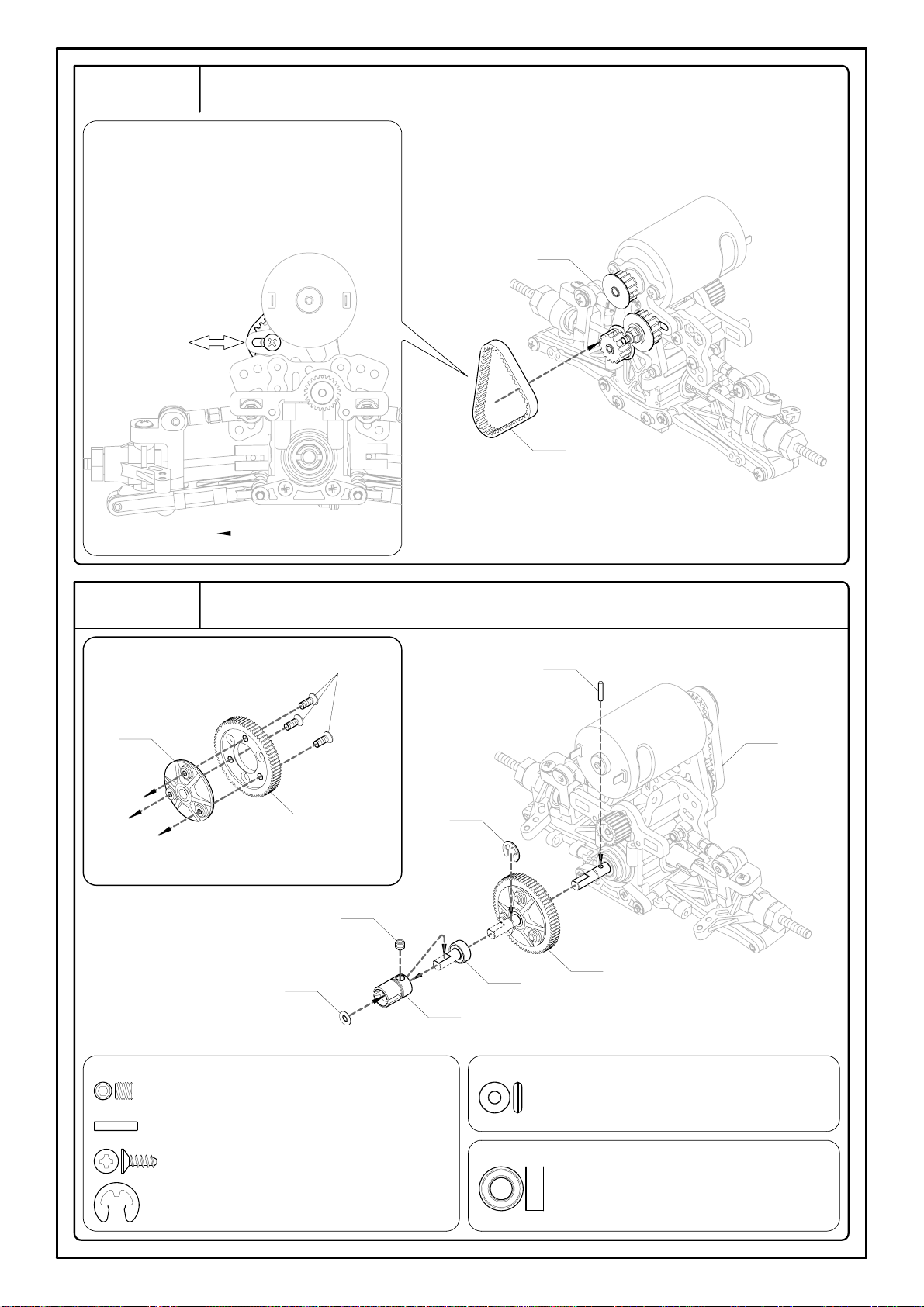

Step 13

Belt Mounting

! This button head machine screw can adjust

belt tension. Move the button head machine

screw to left side to get tighter belt tension

or move the button head machine screw to

right side to get looser belt tension.

Step 11

VX135UK01

Left

Step 14

Main Gear and Main Gear Mount

14C

EL0061

(70T)

<14-1>

EL0061

14B

Step 13

14D

14A

14E

VX103

14F

Step 14-1

14E - O-Ring 3mm -- 1

14F - Ball Bearing 5x10x4mm -- 1

14D - E-Ring 4mm -- 1

14C - F/H Tapping Screw 3x8mm -- 3

14B - Pin 2x9.8mm -- 1

14A - Grub Screw w/Threadlock 4x4mm -- 1

Step 15

Rear Shock Tower and Gearbox

15B

EL16212

Step 3

<15-1>

EL16212

15A

EL1322

Step 15-1

15A - Button Head Tapping Screw 3x12mm -- 4

15B - Button Head Tapping Screw 3x28mm -- 2

Rear Suspension Plate and Suspension Plate Holder

Step 16

16A - O-Ring 3mm -- 1

16C

EL162D4

Step 15

VX103

16B

16A

EL162D3

16D

16B - Grub Screw w/Threadlock 4x4mm -- 1

16C - F/H Tapping Screw 3x10mm -- 2

16D - Button Head Tapping Screw 3x6mm -- 2

Loading...

Loading...