Page 1

Assembly and Operation Instructions

Assembly

(Refer to the sketch on the bac k of this sheet.)

1) Select one set of the Support Wires and install one into

each side of the Base Block. Each wire should snap lightly

into the Base Block.The Short Support Wires work for most

control surfaces and the Long Support Wires should be

used on large surfaces or long rudders/elevators etc. Note:

It may be necessary to adjust the bend angle of the wire

slightly to allow complete insertion.

2) Attach the Ruler to the side of the Base using (2) 2-56 x

3/8" machine screws. Do not tighten the screws.They must

allow the ruler to slide back-and-forth.

3) Attach a Foam rubber pad to the

bottom of each Pylon. The pads have a

peel and stick backing.

4) Install the Pylon onto the end of the

Support Wire and secure using a 3/32"

wheel collar and 4-40 x 1/8" set

screw. Repeat this procedure for the

other Pylon.

To use

1) Make sure the surface of the wing/stabilizer is free of

fuel and exhaust residue.

2) Switch the transmitter and receiver on, center the trims

on your transmitter and select “High Rate” if your radio

has Dual Rates.

3) Spread the Support

Wires apart and clamp

the AccuThrow to the

fixed structure of the

wing or tail surface.

The pylons of the

AccuThrow should be

positioned on a solid

sheeted surface or on

a cap-stripped rib and

with the Ruler close to

the trailing edge of the

control surface.

4) Slide the Ruler until it is near, but not touching, the

control surface.

5) Move the Pylons fore or aft to

adjust the AccuThrow so the “0"

indication is aligned with the

center of the control surface.

6) Using your airplane

manufacturer’s control

throw recommendations

as a reference, deflect

the control surface fully

in each direction, using

the transmitter, while

observing the movement

along the ruler. Adjust

the control linkages or

the radio computer

system to obtain the proper output. Remember, moving

the connector out on the

servo arm

creates more throw,

but moving the connector out on the

control horn

of the

control surface creates less throw.

7) Now is a good time to set your Dual rates if your radio

is so equipped. Switch the rate switch to the Low Rate

and adjust the radio output to achieve the recommended

Low Rate control surface movement.

8) Repeat steps 3-7 on the remaining control surfaces.

Special note

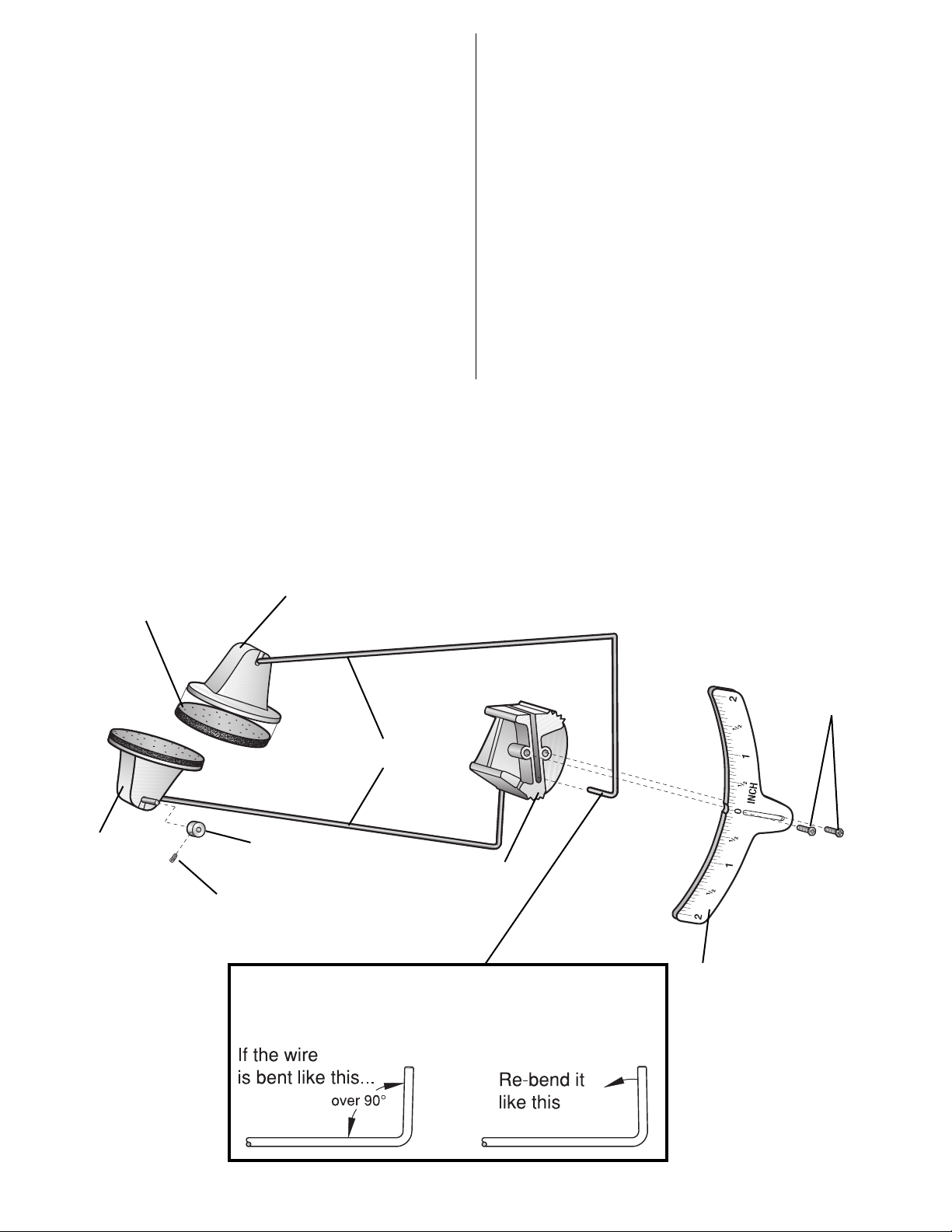

When checking the throw

of the rudder of some

models it may be difficult

to keep the AccuThrow

from sagging. If this

is a problem, slightly

“over-bend” the Support

Wires to increase the

pressure against the

surface. If this still

does not create enough

pressure, with the wing

removed, rotate the

fuselage 90 degrees and attach the unit to the vertical fin

in the same manner you would on a stabilizer or wing.

High Performance Tips

If your model is equipped with Split elevators, check the

throw of each elevator, making sure each elevator’s

movement is identical. If not, check the linkage to ensure

it is pushing and pulling straight.

Centering

The AccuThrow works well as a centering mark. After you

have set the “0" of the ruler at the trailing edge of the

control surface, deflect the surface in each direction

making sure it returns to the same centered location each

time. If not, make sure the linkages do not bind and that

the hinge moves smoothly. Finally, check the centering

accuracy of your servo.

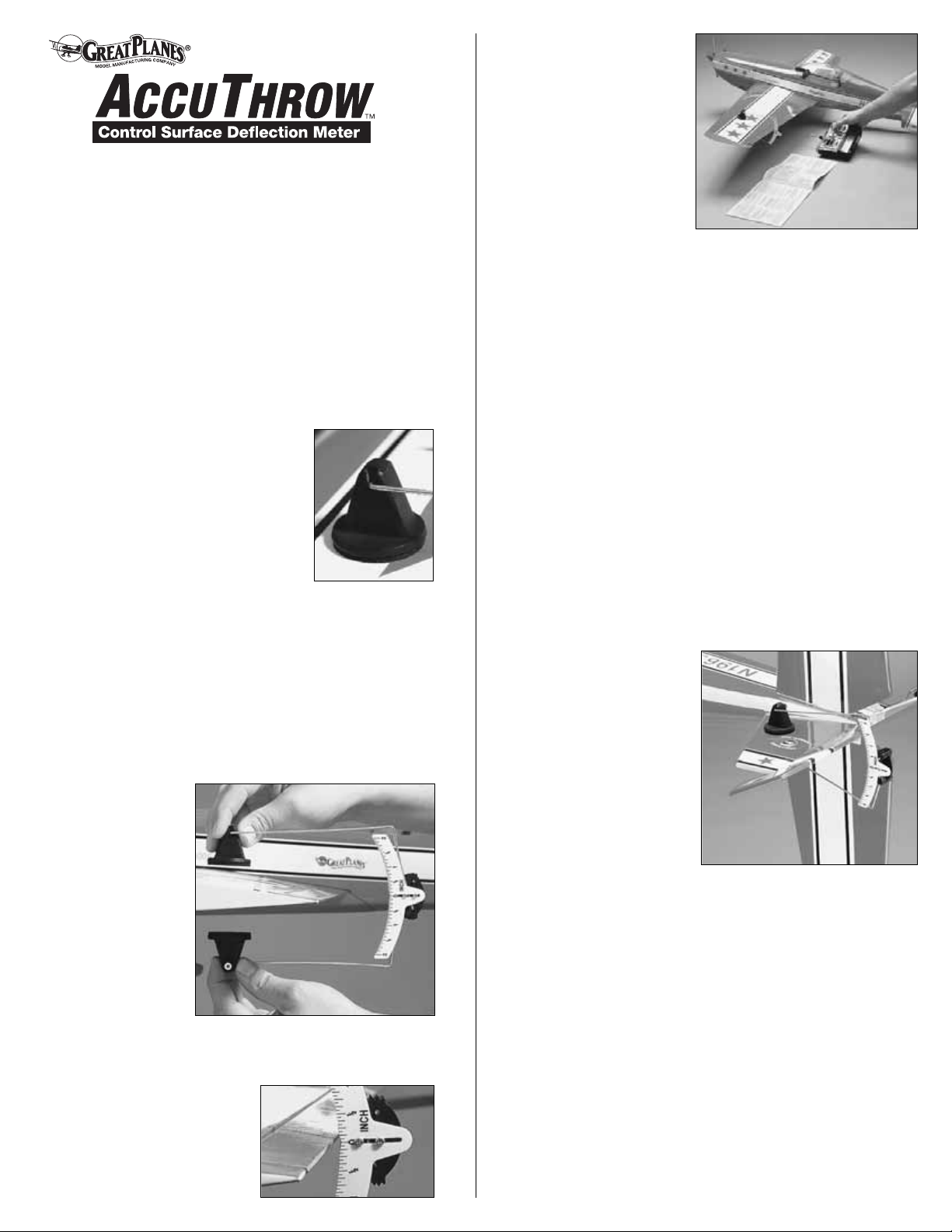

Page 2

Differential Aileron Travel

Differential aileron travel assists the model in tur ning more

aerodynamically efficiently. Aileron differential causes the

aileron to travel more up than down. This creates less drag on

the down traveling aileron, resulting in less adverse yaw. This

can be done several ways. The most popular methods are

mechanically or electronically. The AccuThrow can be used to

quickly and accurately check the amount of travel of each

aileron. This should be done with an adjust-and-fly method.

Make the adjustment, record the settings, fly the model and

readjust if necessary.

Great Planes Manufacturing

P.O. Box 788

Urbana, Il 61801

Parts List

NYLON148 1 Base Block

NYLON149 2 Pylon

RULE001 1 Ruler

WBNT265 2 Short Support Wire

WBNT266 2 Long Support Wire

FOAM015 2 Foam Rubber Pad

WCHL004 2 3/32" Wheel Collar

SCRW015 2 4-40 x 1/8" Set Screw

WRENCH03 1 .050" Hex Wrench

SCRW001 2 2-56 x 3/8" Machine Screw

If any parts are missing, broken or defective, or if you have

any questions about assembling this meter, please call us

at (217) 398-8970 and we’ll be glad to help. If you are calling

for replacement parts, please look up the part numbers and

the kit identification number (stamped on the end of the

carton) and have them ready when calling.

GPMR2405P01

BASE BLOCK

2-56 X 3/8" SCREWS

RULER

FOAM RUBBER PAD

PYLON

PYLON

3/32" WHEEL

COLLAR

4-40 X 1/8"

SET SCREW

SUPPORT WIRES

When you prepare to insert the wire into the base block, first examine the

90-degree bend in the wire.You can check this against anything square, such as

the corner of a sheet of paper. This angle must be 90-degrees or slightly less. If

the angle is greater than 90-degrees, the wire will tend to pop out of the slot. Use

a pliers to change the angle, if necessary.

Entire Contents © Copyright 2002

Loading...

Loading...