Page 1

WARRANTY

Great Planes®Model Manufacturing Co.guarantees this kit to be free from defects in both material and workmanship

at the date of purchase.This warranty does not cover any component parts damaged by use or modification.In no case

shall Great Planes’ liability exceed the original cost of the purchased kit. Fur ther, Great Planes reserves the right

to change or modify this warranty without notice.

In that Great Planes has no control over the final assembly or material used for final assembly, no liability shall be

assumed nor accepted for any damage resulting from the use by the user of the final user-assembled product.By the act

of using the user-assembled product, the user accepts all resulting liability.

If the buyers are not prepared to accept the liability associated with the use of this product,they are advised

to return this kit immediately in new and unused condition to the place of purchase.

READ THROUGH THIS INSTRUCTION MANUAL

FIRST. IT CONTAINS IMPORTANT INSTRUCTIONS

AND WARNINGS CONCERNING THE ASSEMBLY

AND USE OF THIS MODEL.

GPMZ0281 for GPMQ1882 V1.1Entire Contents © Copyright 2004

Champaign, IL 61822

(217) 398-8970, Ext. 5

airsupport@greatplanes.com

INSTRUCTION MANUAL

Page 2

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

PRECAUTIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

POINTS TO CONSIDER . . . . . . . . . . . . . . . . . . . . . . . . 3

PREPARATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Adhesives and Building Supplies . . . . . . . . . . . . . . . . 3

Optional Supplies and Tools . . . . . . . . . . . . . . . . . . . . 3

Hardware and Accessories. . . . . . . . . . . . . . . . . . . . . 3

Parts Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Important Building Notes . . . . . . . . . . . . . . . . . . . . . . 4

ASSEMBLY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Install the Steering Servo . . . . . . . . . . . . . . . . . . . . . . 5

Assemble the Water Rudder. . . . . . . . . . . . . . . . . . . . 6

Install the Water Rudder. . . . . . . . . . . . . . . . . . . . . . . 7

POSITIONING OF FLOATS. . . . . . . . . . . . . . . . . . . . . . 9

PREP ARE THE MODEL . . . . . . . . . . . . . . . . . . . . . . . 10

INST ALL THE FLOA TS . . . . . . . . . . . . . . . . . . . . . . . . 11

Install the Float Gear Wires. . . . . . . . . . . . . . . . . . . . 11

Install the Floats on the Model . . . . . . . . . . . . . . . . . 12

Connect the Float Servo. . . . . . . . . . . . . . . . . . . . . . 12

Install the Air Rudder Pushrod . . . . . . . . . . . . . . . . . 13

Set the Water Rudder Throw . . . . . . . . . . . . . . . . . . . 14

Install the Ventral Fin . . . . . . . . . . . . . . . . . . . . . . . . 14

Balance the Model . . . . . . . . . . . . . . . . . . . . . . . . . . 15

FLYING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Thank you for purchasing the Great Planes ARF Sport

Floats. During our flight testing with these floats, we were

amazed by the superb handling characteristics on the water

and the ultra-smooth, realistic takeoffs and landings.

While the Great Planes ARF Sport Floats were designed for the

.40 size Great Planes Piper J-3 Cub ARF, they will work well

with other models, too.Although the Great Planes Cub ARF is

used as an example, the same procedures and guidelines apply

if you are installing your floats on a different model.

You will discover that the Great Planes ARF Sport Floats are

easily installed, often in just one hour. All of the parts you

need are included in this kit.

1. Your Great Planes ARF Sport Floats and model should

not be considered a toy, but rather a sophisticated, working

model that functions very much like a full-size airplane.

Because of its performance capabilities, the ARF Sport

Floats and model, if not assembled and operated correctly,

could possibly cause injury to yourself or spectators and

damage to property.

2. You must assemble the Sport Floats according to the

instructions. Do not alter or modify the floats, as doing so may

result in an unsafe or unflyable model. In a few cases the

instructions may differ slightly from the photos.In those instances

the written instructions should be considered as correct.

3. You must use an R/C radio system that is in first-class

condition, and a correctly sized engine and components

(fuel tank, etc.) throughout the building process.

4. You must correctly install all R/C and other components

so that the model operates correctly on the ground, on the

water and in the air.

5.You must check the operation of the model before every

flight to insure that all equipment is operating and that the

model has remained structurally sound. Be sure to check

clevises or other connectors often and replace them if they

show any signs of wear or fatigue.

6. If you are not already an experienced R/C pilot, you

should fly the model only with the help of a competent,

experienced R/C pilot.

7.You should have a boat available to retrieve your model.

Do not attempt to swim after your model.

PRO TECT YOUR MODEL,YOURSELF

& OTHERS...FOLLOW THESE

IMPORTANT SAFETY PRECAUTIONS

INTRODUCTION

TABLE OF CONTENTS

2

Page 3

Remember: Take your time and follow the instructions to

end up with a well-built model that is straight and true.

If you have not flown this type of model before, we

recommend that you get the assistance of an

experienced pilot in your R/C club for your first flights.

You’ll learn faster and avoid risking your model before you

are truly ready to fly it. Your local hobby shop has

information about clubs in your area whose membership

includes experienced pilots.

In addition to joining an R/C club, we strongly recommend you

join the AMA (Academy of Model Aeronautics). AMA

membership is required to fly at AMA sanctioned clubs. There

are over 2,500 AMA chartered clubs across the country .Among

other benefits, the AMA provides insurance to its members who

fly at sanctioned sites and events. Additionally, training

programs and instructors are availab le at AMA club sites to help

you get started the right way .Contact the AMA at the address or

toll-free phone number below:

Academy of Model Aeronautics

5151 East Memorial Drive

Muncie, IN 47302-9252

Tele. (800) 435-9262

Fax (765) 741-0057

Or via the Internet at: http://www.modelaircraft.org

For steering your model on the water, a water rudder will be

installed on the right float.The water rudder can be connected

to the aircraft rudder by a pushrod, or a servo can be installed

inside the float. All parts required for either type installation are

included with this kit (servo not included).

We highly recommend that you install a servo inside the

float. It is easy to do and it makes installation/removal of the

floats on the aircraft easier.

Floats increase the weight of the model they are installed

on. In addition, water drag and surface tension increase the

amount of power required for takeoff. In-flight drag is also

greatly increased.

If your model had “adequate” power before floats are installed,

it will likely be very marginally powered with the floats. It is

recommended that you use an engine in the upper end of the

recommended power range with these floats.

For the .40 size Great Planes Piper J-3 Cub ARF, we recommend

an O.S.®.46 FX 2-stroke or an O.S.FS 70 4-stroke engine.

❏ 1/2 oz. [15g] Thin Pro™CA (GPMR6001)

❏ 1/2 oz. [15g] Medium Pro CA+ (GPMR6007)

❏ Pro 6-minute epoxy (GPMR6045)

❏ 2-56 Tap and Drill (GPMR8100)

❏ Stick-on segmented lead weight (GPMQ4485)

❏ #1 Hobby knife (HCAR0105)

❏ #11 blades (5-pack, HCAR0211)

❏ Clear water proof tape

❏ Dr ill bits: 1/16” [1.6mm], 5/64" [2mm], 1/8" [3.2mm].

(25/64" or 3/8" [9.9 or 9.5mm] for optional

servo installation.)

❏ Razor saw

❏ 2 oz. [57g] spray CA activator (GPMR6035)

❏ CA applicator tips (HCAR3780)

❏ CA debonder (GPMR6039)

❏ Mixing sticks (50, GPMR8055)

❏ Mixing cups (GPMR8056)

❏ Pliers with wire cutter (HCAR0630)

❏ Denatured alcohol (for epoxy clean up)

❏ Z-bend pliers (HCAR2000)

❏ Rotar y tool such as Dremel

®

❏ Rotar y tool reinforced cut-off wheel

❏ Ser vo horn dr ill (HCAR0698)

❏ CG Machine™(GPMR2400)

For internal servo:

❏ (1) standard ser vo

❏ (1) 12" [300mm] ser vo extension

❏ (1) Y -harness

Hardware & Accessories

Optional Supplies & Tools

Adhesives & Building Supplies

PREPARATIONS

POINTS TO CONSIDER

3

Page 4

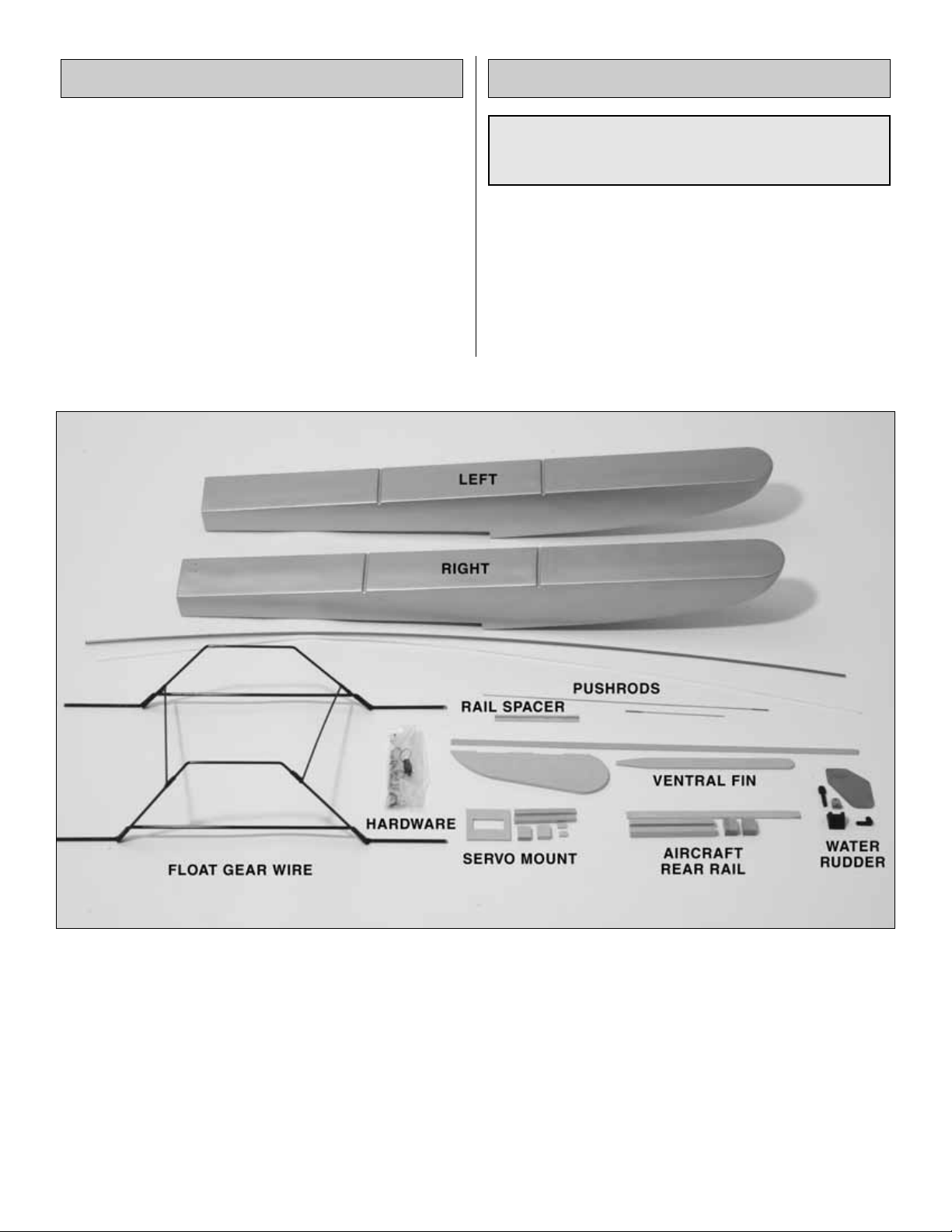

Before starting to build, use the Parts Identification list to

take an inventory of this kit to make sure it is complete, and

inspect the parts to make sure they are of acceptable

quality. If any parts are missing or are not of acceptable

quality, or if you need assistance with assembly, contact

Product Support. When reporting defective or missing

parts, use the part names exactly as they are written in the

Kit Contents list on this page.

Great Planes Product Support:

Telephone: (217) 398-8970

Fax: (217) 398-7721

E-mail: airsupport@greatplanes.com

If you are not going to install a servo inside the float, skip the

following section and go to “Assemb le the Water Rudder”on

page 6.

Before starting assembly, assemble the model and mark

the balance point of the model.You will need to know this

later when the model is balanced with the floats installed.

Important Building NotesParts Identification

4

Hardware bag contents:

(3) SMALL NYLON TIE STRAP

(3) FLAT LANDING GEAR STRAPS, TREE OF 4

(34) #4 X 1/2" PHILLIPS HEAD SHEET METAL SCREW

(4) WHEEL COLLAR SET SCREW

(4) 5 mm WHEEL COLLAR

(35) #4 FLAT WASHER

(1) 2-56 HEX NUT

(1) 4-40 LOCK NUT

(4) #62 RUBBER BAND

(1) 2-56 X 3/8" PHILLIPS HEAD SHEET METAL SCREW

(1) 4-40 X 1/4" SOCKET HEAD CAP SCREW

(3) 2-56 X 1/2" PHILLIPS HEAD MACHINE SCREW

(1) BRASS BODY FOR SCREW-LOCK CONNECTOR

(1) NYLON RETAINER

(1) FASLINK

(1) RUBBER BOOT

(1) 4-40 x 1/8" SOCKET HEAD CAP SCREW

(1) LARGE NYLON CONTROL HORN

(1) 5/32" GEAR HUMP STRAP, TREE OF 4

(2) NYLON CLEVIS

(2) SILICONE CLEVIS RETAINER

(1) 2-56 X 1" ROD THREADED FULL LENGTH

(1) 2-56 x 6" THREADED ONE END WIRE

Page 5

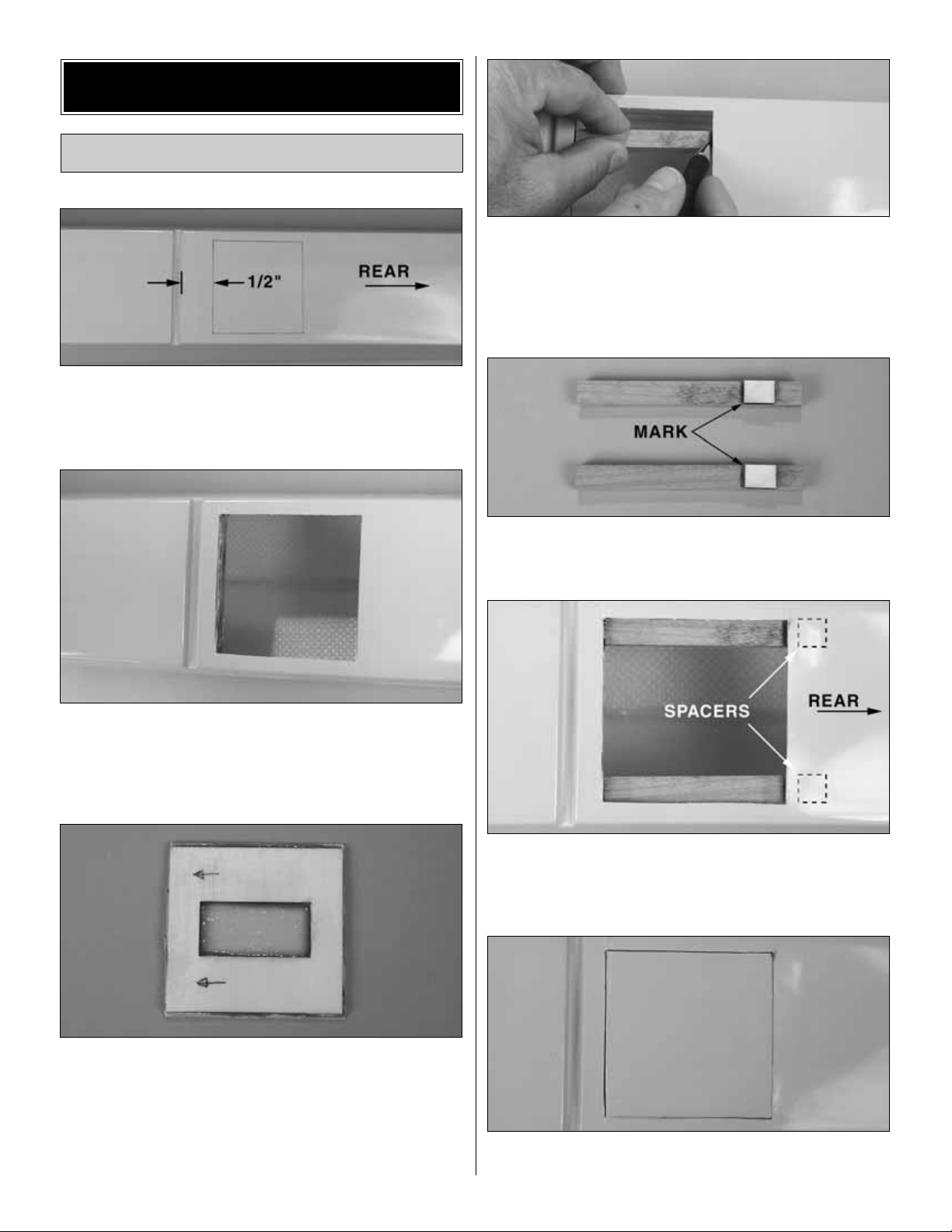

❏ 1. Use the servo tray to mark the outline of the tray on

one of the floats with a fine-tipped marking pen as shown in

the photo above.The tray should be located 1/2" [13mm] aft

of the rear groove in the float.This float is now the right float.

❏ 2. Very carefully cut the marked area from the float with

a razor saw. The piece you cut out will be used as the tray

cover, so use care not to damage it. Mark the end of the

cover that was facing forward.

❏ 3. Glue the servo tray to the inside of the cover with

epoxy. Use some medium grit sandpaper to rough up the

inside of the cover first. Mark the tray indicating which end

of the cover faces forward.

Note: The tray may not have the cutout shown in the

above photo.

❏ 4. Clean any resin residue from the tray opening in the

float.Trim any resin from the hardwood mounting rail inside

the float. Put one of the 1/4" x 3/8" x 3-1/2" [6.4 x 9.5 x

89mm] basswood servo tray rails in the float, butting one

end against the mounting rail. Mark the rear of the opening

on the rail.Transfer the mark to the other rail as well.

❏ 5. Glue a 1/8" x 3/8" x 1/2" [3.2 x 9.5 x 12.7mm] ply rail

spacer to each of the servo tray r ails as shown in the photo.

In the photo, the mark is to the left of the spacers.

❏ 6. Using medium CA, tack glue the servo tray rails into

the float opening with the spacers toward the rear of the

float. Scuff the area with some medium grit sandpaper to

improve the adhesion.

❏ 7. Trial fit the servo tray to the top of the rails. If the tray

sticks up above the top of the float, remove the servo tray

Install the Steering Servo

ASSEMBLY

5

Page 6

rails and make some shims from leftover ply.Tack glue the

servo tray rails in place again and check the fit of the servo

tray. When satisfied with the fit, use 6-minute epoxy to glue

the rails permanently in place.

❏ 8. Mount the ser vo to the 5/16" x 3/4" x 7/8" [8 x 19 x

22.2mm] basswood blocks, using the hardware supplied

with the servo.Make sure the servo is oriented as shown in

the photo with the servo arm pointing as shown. The edge

of the block should extend past the rear side of the servo

slightly. See the photo at step 10.

❏9.Position the servo tray as shown and mark the location

of the mounting rails.

❏ 10. Use 6-minute epoxy to glue the basswood blocks to

the servo tray, with the servo attached.The servo should be

centered between the lines marking the location of the rails.

After the epoxy has cured, install the tray into the opening

in the float and make sure it fits properly.

❏ 1. If your water rudder is already assembled, proceed to

step 7. Otherwise, refer to the above photos as you

assemble the water rudder.

❏ 2. Drill two 1/8" [3.2mm] holes in the aluminum water

rudder at the locations shown in the above photo.

❏ 3. Drill and tap a 2-56 hole in the nylon rudder post at

the location shown in the above photo .Install the 2-56 x 1/2"

[12.7mm] screw in the hole.

Assemble the Water Rudder

6

Page 7

❏ 4. Assemble the Nylon rudder bearing, rudder post,

aluminum bracket and nylon control horn as shown in

the photo. Hold the control horn in place with a #2 x 3/16"

[4.8mm] screw.

❏5. Assemble the water rudder to the aluminum brac k et with a

4-40 x 1/4" [6.4mm] socket head cap screw and 4-40 lock

nut. Tighten the nut, but leave it loose enough that the water

rudder can pivot freely in the bracket. If the bracket does not

have a hole drilled in it, use a 1/8" drill to drill the hole.

❏ 6. Drill a 5/64" [2mm] hole in the aluminum bracket and

rudder post at the location shown in the above photo,

making sure the water rudder and control horn are aligned

as shown. Install a 2-56 x 3/8" [9.5mm] screw and 2-56 nut

to hold the bracket to the rudder post.Use Great Planes Pro

Threadlocker™to hold the nut in place.

Hint: Center punch the bracket before drilling the hole.

❏ 7. Install a screw-lock connector, nylon retainer and

4-40 x 1/8 [3.2mm] socket head cap screw in the outer

hole of the long tiller arm on the water rudder. Also install

the rubber band.

If you are installing a servo inside the right float, proceed to

step 2.

❏ 1. Do this step only if you are installing a pushrod from the

aircraft rudder to the water rudder. Mount the water rudder

assembly in the location shown in the above photo.The top of

the mounting bracket should be even with the top of the float,

on the centerline of the transom (rear of the float). Mark the

location of the holes in the mounting bracket on the transom.

Drill a 5/64" [2mm] hole at the marked locations and mount the

water rudder assembly to the transom with two #4 x 1/2"

[12.7mm] sheet metal screws and two #4 flat washers.

Proceed to “Prepare the Model” on Page 10.

Install the Water Rudder

7

Page 8

❏2. Mount the water rudder assembly in the location shown in

the above photo. The top of the mounting bracket should be

3/4" [19mm] from the top of the float, on the centerline of the

transom (rear of the float).Mark the location of the holes in the

mounting bracket on the transom. Drill a 5/64" [2mm] hole at

the marked locations and mount the water rudder assembly to

the transom with two #4 x 1/2" [12.7mm] sheet metal screws

and two #4 flat washers.

❏ 3. Drill a 25/64" [9.9mm] hole in the transom of the float

as shown. This hole must be drilled very carefully as there

is a wood block installed in the transom for mounting the

water rudder assembly. If the hole is drilled too close to the

water rudder assembly, the drill bit will catch on the edge of

the wood block, causing the drill bit to twist sideways. Hold

the float up to a strong light so that you can determine

where the edge of this block is located. Drill the hole as

close to the water rudder assembly as possible, while still

missing the wood block. If you can't locate the edge of the

wood block, drill a locating hole as noted in the photo. If the

locating hole hits wood, drill another hole farther over.

Note:If you don’t have a 25/64" [9.9mm] drill use a 3/8" [9.5mm]

drill, and then slightly enlarge the hole with a hobby knife.

❏ 4. Cut the .074 x 17-1/2 [445mm] wire pushrod to a

length of 12" [25.4mm]. Cut the threaded portion of the wire

off, leaving a 12" [25.4mm] wire with no threads. Make a

small bend 3/4" [19mm] from the end of the wire. Insert the

wire into the rubber bushing.

❏ 5. Insert the wire and r ubber bushing into the hole you

drilled in the transom.The rubber bushing is easier to insert

if you stretch it on the wire as it is inserted. Use a

screwdriver to carefully poke it through as needed. The

rubber bushing is now inside the float. Secure the rubber

bushing to the transom with some silicone rubber glue or

medium CA. Insert the wire into the screw-lock connector.

❏ 6. Mark the location of the hole in the ser vo arm on the

servo mounting rail and on the wire pushrod.Make sure that

the water rudder is centered and the pushrod is centered in

the screw-lock connector.

❏ 7. Make a 90-degree bend in the wire at the mark. The

bend should face the right side of the float as shown in the

photo.Enlarge the middle hole of the servo arm with a 5/64"

[2mm] drill. Insert the pushrod into the servo arm and

secure it with a Faslink connector. Remove the screw and

servo arm from the servo. Plug the ser vo into the receiver

and center the trims on the transmitter. Turn the radio on,

and then push the servo arm onto the servo with the arm at

90 degrees to the servo.Install the mounting screw into the

servo arm. Turn the radio off and unplug the servo.

8

Page 9

❏ 8. Cut a small notch in the servo hatch for the servo

extension wire. Install a 12" servo extension wire on the

servo lead. Secure the connection with tape, keeping the

connection as water tight as possible. Position the servo

hatch onto the rails with the taped connection inside the

float. Secure the hatch into place with some clear

waterproof tape. Put a dab of silicone glue where the servo

wire exits the hatch to waterproof it.

Before you continue, take a break from building and

study the following information to be sure you

understand the positioning of the floats in relation to

the wing and fuselage.

While the following instructions show the Sport Floats on

Great Planes Piper Cubs, there are general tips and

guidelines that apply to all models which will insure proper

handling characteristics in the water and good landing and

takeoff tendencies.

The relationship between the “step” on the floats and the

center of gravity on the model is important. First, the floats

should be mounted on the model so the step is positioned as

detailed in the “Step Sketch” for your particular model. Then,

when the floats are mounted on the model, move the C.G.

slightly forward as listed below. Although you may ha v e added

the recommended ballast inside the front of the float, in some

cases a little more ballast may be required on the model.

• For 60-size floats: Move the CG (Balance point) 1/2"

ahead of the manufacturers recommended CG.

• For 40-size floats: Move the CG (Balance point) 3/8"

ahead of the manufacturers recommended CG.

• For 20-size floats: Move the CG (Balance point) 9/32"

ahead of the manufacturers recommended CG.

Another important relationship between the wing and the

floats is the relative “angle of attack.’’ With a virtually flat

bottom wing such as a Piper Cub, the deck of the floats

should be parallel to the bottom of the wing. Since the Cub

does not have a truly flat wing, this yields a slight positive

wing incidence in relation to the floats, and the airplane will

tend to rise off the water at the correct time. If you have a

model with a symmetrical wing, the wing incidence in

relation to the float deck should be positive 1-1/2 degrees.

Finally, each float should be set so that it is parallel to the

centerline of the fuselage.

POSITIONING OF FLOATS

9

Page 10

❏ 1. Install a 5mm wheel collar and set screw on each of

the four ends of the float gear wires.The photo shows the

two right ends of the gear wires.

You must now determine how the floats will be mounted to

your model. In most cases, you will be able to use the

existing landing gear mounting block, already installed in

your model, for the front mount of the float wires. You will

probably need to install a rear mount, however.

If you are installing the floats on a recently produced Great

Planes J-3 ARF (fabric covered), the model may already

have the rear mount installed.Other models will require that

you install a rear mounting block.

❏ 2. Place the fuselage of your model on your work bench,

upside down. Place the float gear wires on the fuselage.

Determine if there is a rear mounting block in your model.If

there is, cut the covering from the groove in the block, then

proceed to “Install the Float Gear Wires” on page 11.

❏ 3. If there is no rear mounting block, you must install one.

Remove the landing gear from your model.Place the float gear

wires on the model and mark the location of the rear float wire.

Note that we have reinstalled as man y of the screws, etc.as we

could, so as not to lose them and to seal the holes in the

bottom of the fuselage. In the steps that follow, we will show

how we installed the mounting block in the Great Planes J-3

ARF.Your model may require some changes.

❏ 4. Check for a former inside the fuselage in the location

you have marked. Use a pin to poke through the bottom of

the fuselage and locate the edge of the former.Notice in the

photo how the mounting block will fit against the former.Do

not be concerned if your model does not have a former that

is so conveniently located.

❏ 5. Mark the outline of the mounting block on the fuselage

bottom so that the groove in the mounting block will be

directly under the location of the wire already marked on the

fuselage. Cut the covering and balsa sheeting from the

fuselage at the marks. Save the covering.

PREP ARE THE MODEL

10

Page 11

❏6.This fuselage has a 1/8" [3.2mm] balsa side and a 1/8"

[3.2mm] ply doubler. There is also a 1/4" x 1/4" [6.4 x

6.4mm] balsa filler stick glued to the bottom sheeting and

resting on the edge of the ply doubler. Cut the stick and

fuselage side down to the ply doubler. Do not cut deeper

than 1/2" [12.7mm], the thickness of the mounting block.

❏ 7. After cutting down to the ply doubler, the mounting

block will likely protrude from the bottom of the fuselage

slightly; in our case it was 1/8". Trim the fuse side and ply

doubler until the mounting block is flush with the bottom of

the fuselage.

❏ 8. Using epoxy, glue the 1/2" x 3/4" x 1" [12.7 x 19 x

25.4mm] support blocks to the fuselage sides as shown in

the photo. If your model does not have a former that the

mounting block can be glued to, you should make longer

support blocks to provide additional support.

❏ 9. Using epoxy, glue the mounting block to the support

blocks, fuselage sides and former. Glue a filler strip to the

mounting block, if needed, so that the bottom sheeting can

be glued to the mounting block.

❏ 10. Use the covering that you saved to cover the mounting

block and the fuselage sides. There may not be enough

covering, so do the visible part of the fuselage sides first.

Leftover Cub Yellow MonoKote®can be used on the bottom.

If the landing gear is still installed on the model, remove it.

Set the parts aside where you won’t misplace them.

❏ 1. Install four nylon landing gear straps on each float

using eight #4 x 1/2" [12.7mm] sheet metal screws and

eight #4 flat washers. The side of the straps should be

Install the Float Gear Wires

INST ALL THE FLOA TS

11

Page 12

about 3/8" [9.5mm] from the sides of the floats. Drill 1/16"

[1.6mm] pilot holes for the screws.

❏ 2. Mount the floats to the float gear wires, making sure

the right float is on the right side. Note the orientation of the

wires on the floats.

❏ 1. Install two nylon landing gear straps on the rear

fuselage mounting block using four #4 x 1/2" [12.7mm]

sheet metal screws and four #4 flat washers. Drill 1/16"

[1.6mm] pilot holes for the screws.

❏2.Place the floats and wires into position on the fuselage.

Secure the rear wire in place with the landing gear straps.

❏3.Waterproof the ply spacer assembly with some thin CA or

paint.Install the ply spacer assembly in the front gear wire.This

will prevent the forward float wire from moving in the groove.

Secure the wire into place with the landing gear straps.

❏4. Remove all of the mounting scre ws from the fuselage and

floats.Harden all of the holes with a couple of drops of thin CA.

After the CA cures, reinstall all of the screws.

If you have not installed an internal servo , proceed to “Install

the Air Rudder Pushrod” on page 13.

❏ 1. Plug a “Y” connector into the rudder channel on the

receiver. Plug the rudder ser vo into one end of the “Y.” Route

the other end of the “Y” to the right rear float wire area.

Note: If you have a computer radio system, you could use a

spare receiver channel for the water rudder servo and mix

the air rudder to the water rudder servo. This would allow

independent setup of the throws and trim.

❏ 2. Cut a small slot in the fuselage side for the connector.

Connect the Float Servo

Install the Floats on the Model

12

Page 13

❏ 3. Use the small nylon tie straps to secure the servo

extension wire to the float landing gear wires.Plug the servo

extension wire into the “Y”connector from the receiver.

IMPORTANT: Secure the connection with tape, keeping the

connection as water tight as possible.Inser t the connection

into the fuselage so that it is entirely inside the fuselage.

Seal the cutout and wire with some clear silicone sealant.

Continue with “Set the Water Rudder Throw.”

❏1. Install a large nylon control horn on the right side of the

rudder as shown in the photo above. Use two 2-56 x 1/2"

[12.7mm] screws and the nylon back plate to mount the horn.

❏ 2. Install a nylon clevis, clevis retainer and 2-56 x 1"

[25.4mm] threaded stud on the inner pushrod. Thread

the stud about 13 turns into both the clevis and pushrod.

Insert the inner pushrod into the outer pushrod tubing.

❏ 3. Attach the pushrod assembly to the rear of the

fuselage with a nylon strap and two #4 x 1/2" [12.7] screws

and two #4 flat washers. Drill 1/16" [1.6mm] pilot holes for

the screws. Connect the clevis to the control horn in the

second hole closest to the rudder.

❏4. Route the assembled pushrod to the water rudder.Attach

the pushrod to the float landing gear wires with the small nylon

tie straps.The above photo shows the finished installation.

USE THIS PHOTO FOR THE NEXT FOUR STEPS

❏ 5. Use the photo above as a guide in cutting the pushrod

to length. With the pushrod properly positioned, mark the

Install the Air Rudder Pushrod

13

Page 14

pushrod 1/8" [3.2mm] from the rear of the float. Cut the

inner and outer pushrods at the marked location.

❏ 6. Disconnect the pushrod clevis from the rudder control

horn and pull the inner pushrod out a few inches. Cut the

outer pushrod 3/8" [9.5mm] from the end (at the float end).

Reconnect the clevis back to the control horn.

❏ 7. Thread the 2-56 x 6" [152mm] wire 13 turns into the

inner pushrod. Insert the wire into the screw-lock connector

on the water rudder control arm and cut the wire to length.

❏ 8. Attach the pushrod assembly to the rear of the float

with a nylon strap and two #4 x 1/2" [12.7] screws and two

#4 flat washers.

❏ 9. Center the rudder and tighten the screw on the

screw-lock connector.

Note:Two additional nylon straps and screws are included if

additional support is needed.

❏ 1. Turn on the transmitter and receiver. With the r udder

centered, adjust the water rudder linkage as needed to

center the water rudder.

❏2.Move the rudder left and right with the transmitter stick.

Make sure the water rudder responds smoothly and in the

correct direction.

❏ 3. Adjust the linkage for a water rudder throw of 1"

[25.4mm].This can be done by moving the clevis to another

hole on the rudder control horn (external pushrod) or by

adjusting the ATV (internal servo). The amount of throw

should be adjusted as needed for good water handling.

Floats on a model generally add more side area forward of

the CG than aft.This can create a stability problem. This kit

includes a ventral fin that can be installed on the rear of the

fuselage to increase the rearward side area. The Great

Planes J-3 ARF flies well without the ventral fin. However,

there is noticeably less yaw stability.

❏ 1. Remove the covering from the slots in the ventral fin

mounting base.

❏ 2. Inser t the ventral fin in the mounting base. Mark the

fin where it meets the mounting base.Remove the covering

from the fin and mounting base at the marks.

❏ 3. Mount the ventral fin base to the bottom rear of the

fuselage with four #4 x 1/2" [12.7mm] screws and four #4

flat washers. Drill 1/16" [1.6mm] pilot holes for the screws.

Enlarge the holes in the mounting base only with a 1/8"

[3.2mm] drill bit.Harden the holes in the fuselage with some

thin CA.

❏ 4. Tack glue the ventral fin to the mounting base with

medium CA. Be very careful not to glue the mounting base

to the fuselage.

Install the Ventral Fin

Set the Water Rudder Throw

14

Page 15

Note: Make sure the ventral fin is perpendicular to the

bottom of the fuselage.

❏ 5. Remove the ventral fin assembly from the fuselage.

Solidly glue the ventral fin to the mounting base.

Most models are less stable with floats installed.The airflow

across the model is considerably different and the weight of

the floats is well below the CG, causing a pendulum effect

when the model is turned or rolled. In addition, the total

weight of the model is considerably higher. For these

reasons the model will not fly as you have become

accustomed to in the past.

For the first few flights with the floats installed, we

recommend that you balance the model for a somewhat

more nose heavy condition.This will increase the stability of

the model until you become accustomed to the changed

handling characteristics of the model. Remember that the

model is heavier and you must increase the takeoff and

landing speeds accordingly.

❏1.Place a mark 1/4" forward of the mark you made bef ore

you installed the floats. This will give a balance point 1/4"

more nose heavy.

❏ 2. With the model assembled and the fuel tank empty,

balance the model at the new balance point. It is likely that

you will need about two ounces of lead to accomplish this.

Note:The added lead required to balance the model can be

added to the firewall or to the front of the floats. We

recommend that you add it to the top front of the floats,

though this is a bit unsightly.In the future when you remove

the floats and install the normal landing gear (and vice

versa), you won’t need to be concerned with removing or

adding weight – or forget to do so.

Before setting the model in the water, be sure the water

rudder on the float is extended. A reliable, slow idle is a

must. First flight attempts with floats should be reserved for

relatively calm days when the water is not very choppy.

Practice taxiing around in the water to learn the handling

characteristics, and see if you hav e built in enough throw on

the water rudder. Make adjustments if required. During

taxiing, hold “up” elevator to keep the nose of the aircraft

high and the propeller out of the water spray.

Always takeoff into the wind. Gently add throttle and

gradually release some of the up elevator as the speed

increases and the aircraft lifts “on the step”of the floats.Just

like the model takes off on the ground, when it has enough

speed it will lift into the air – don’t force it off. If the surface

of the water is very smooth, it may take a bit more elevator

to break the aircraft free of the surface tension of the water.

Continue a gradual, conservative climb out until you are at

an altitude where you are comfortable making the downwind

turn. Remember, the aircraft is heavier and has more drag

than you are used to.Many modelers snap roll into the water

on takeoff because they do not gain enough speed to allow

for the added weight and drag.

Learn the flight characteristics of the model with the added

weight and drag of the floats.The aerobatic response of the

model will be considerably different with the floats installed.

While the model should be perfectly capable of loops, rolls,

stall turns and inverted flight – these maneuvers will require

a much different pilot technique to do well.

Landing approach is the same on water as it is on land.Touch

down slowly to avoid bouncing the aircraft off the water and

back into the air. There is nothing that compares to a slow,

smooth touchdown on the water. “Crabbing” or “Slipping” is a

great technique used to bleed off excess airspeed during an

approach. This is done by applying a balance of rudder and

opposite aileron to make the aircraft fly “sideways”.The path of

the aircraft is “down the runway” while the nose is pointing off

to one side.Just before the floats contact the water , release the

rudder and opposite aileron.

Although it is difficult to do, the model can contact the water at

such an angle as to allow the tips of the floats to “catch”the tops

of any wav es , thus flipping the model immediately. A v oid letting

the floats contact the water at anything but a level attitude;and

slightly nose high if there is much wave action.

Be considerate of others at the lake and enjoy your Great

Planes ARF Sport Floats.

FLYING

More than any other factor, the C.G. (balance point) can

have the greatest effect on how a model flies, and may

determine whether or not your first flight will be

successful. If you value this model and wish to enjoy it for

many flights, DO NOT OVERLOOK THIS IMPORTANT

PROCEDURE. A model that is not properly balanced will

be unstable and possibly unflyable.

Balance the Model

15

Page 16

GPMR6002 Thin Pro CA 1 oz.

GPMR6008 Medium Pro CA+ 1 oz.

GPMR6045 Pro 6-Minute Epoxy 9 oz.

High-quality Pro Adhesives provide

model building’s best bonds...and a

“Best If Used By” date on the label for

visible proof of freshness! Thinformula Pro CA offers instant bonds,

curing in just 1-3 seconds – it’s ideal for most assembly

needs. Medium CA+ is an excellent gap filler that cures in

10-15 seconds for a little more positioning time. The

uniquely precise cure time of Pro 6-Minute Epoxy allows

you to continue building with the confidence that epoxied

parts won’t be accidentally bumped out of alignment.

These pliers automatically locate the precise Z-bend point

for maximum servo arm performance – and they’re so easy

to use, even inexperienced modelers can make perfect

Z-bends in minutes.Just insert the pliers’ alignment pin into

the servo horn hole that your pushrod will be connected to,

and lightly hold the music wire where the bend will be

placed.Remove the pliers from the servo horn, squeeze the

handles, and make the bend...exactly where you need it!

Works with wire up to 1/16" in diameter.

This standard servo with preinstalled, round servo horn is

ideal for car, boat and other applications. It comes with “J”

connector on a 5 in.lead and hardware, including four brass

eyelets, four rubber grommets, four mounting screws, and

large and small “X” horns. Speed: 0.23 sec/60 degrees

(4.8V). Torque: 44.4 oz-in (4.8V). Weight: 1.31 oz [37.2g].

Dimensions: 1.59 x 0.78 x 1.42 in [40.4 x 19.8 x 36mm].

Every

flier needs this ingenious tool! For optimum

performance – or to achieve specific flight characteristics –

every plane must be balanced correctly. Yet checking the

balance in the “traditional” way (by hand) has always been

difficult and imprecise.The C.G. Machine makes balancing

easy and exact:Its slanted wire balancing posts accept any

plane up to 40 lb...built-in rulers position it exactly at the

recommended center of gravity. There’s no guesswork!

Great Planes®Precision Z-Bend Pliers

(GPMR8025)

Great Planes®Pro™Adhesives

Futaba®S3003 Standard Servo

(FUTM0031)

Great Planes®C.G. Machine™Airplane Balancer

(GPMR2400)

Loading...

Loading...