Page 1

WARRANTY

Great Planes Model Manufacturing Co. guarantees this kit to be free from defects in both material and

workmanship at the date of purchase. This warranty does not cover any component parts damaged by use or

modification. In no case shall Great Planes' liability exceed the original cost of the purchased kit. Further, Great

Planes reserves the right to change or modify this warranty without notice.

In that Great Planes has no control over the final assembly or material used for final assembly, no liability shall be

assumed nor accepted for any damage resulting from the use by the user of the final user-assembled product. By the

act of using the user-assembled product, the user accepts all resulting liability.

If the buyers are not prepared to accept the liability associated with the use of this product,they are advised

to return this kit immediately in new and unused condition to the place of purchase.

READ THROUGH THIS INSTRUCTION MANUAL

FIRST. IT CONTAINS IMPORTANT INSTRUCTIONS

AND WARNINGS CONCERNING THE ASSEMBLY

AND USE OF THIS MODEL.

FLT246P1 V2.0 Printed in USA Entire Contents © Copyright 2004

P.O.Box 788 Urbana, IL 61803 (217) 398-8970

INSTRUCTION MANUAL

SPORT FLOAT KITSPORT FLOAT KIT

SPORT FLOAT KIT

For R/C Aircraft

Page 2

INTRODUCTION...............................................................2

PRECAUTIONS.................................................................2

PREPARATIONS...............................................................2

Covering method ............................................................2

Suggested tools and supplies.........................................3

Other suggested items....................................................3

Get ready to build ...........................................................3

Parts identification ..........................................................3

Die-cut patterns........................................................4 & 5

60 FLOATS PREASSEMBLY............................................6

Spine...............................................................................6

Forward keel...................................................................6

Sides and deck...............................................................6

CONSTRUCTION OF 20, 40, 60 SPORT FLOATS...........6

Framing...........................................................................6

Aft stringers ....................................................................8

Forward stringers............................................................8

Prepare for sheeting.......................................................9

Aft bottom sheeting.........................................................9

Forward bottom sheeting................................................9

Nose block and finishing...............................................10

COVERING......................................................................11

Covering method ..........................................................11

MonoKote film...............................................................11

Glass cloth & resin........................................................11

POSITIONING OF FLOATS ............................................12

Prepare your airplane to accept the floats....................13

60 FLOATS ONLY ...........................................................14

Notes about soldering...................................................14

Solder the cross braces................................................14

Mount the struts to the floats

and solder the diagonal braces.....................................15

Mounting the 60 floats ..................................................16

20 AND 40 FLOATS ONLY..............................................16

Mount the struts to the floats ........................................16

Mount the floats to the airplane ....................................16

ALL MODELS .................................................................17

Build the rudder ............................................................17

Pushrod hookup............................................................17

Connect the rudder ......................................................18

(20 and 40 floats)......................................................18

(60 floats)..................................................................19

VENTRAL FIN.................................................................19

BEFORE GOING TO THE LAKE.....................................20

WATERPROOFING.........................................................20

FLYING............................................................................20

Thank you for purchasing the Great Planes Sport Floats.

During our first flight tests with our Piper Cub 60 and Cub

20 on floats, we were amazed by the superb handling

characteristics on the water and ultra–smooth, realistic

takeoffs.Of course, the Great Planes Sport Floats will work

well with other models too.

The 20, 40 or 60 Sport Floats may be properly assembled

from this single manual. Although the Great Planes Piper

Cubs are used as examples, the same procedures and

guidelines apply if you are installing your floats on a

different model.

Please inspect all parts carefully before starting to

build! If any parts are missing, broken or defective, or if

you have any questions about building or flying these

floats, please call us at (217) 398-8970. If you are

calling for replacement parts, please look up the part

numbers and the kit identification number (stamped on

the end of the carton) and have them ready

when calling.

Remember:Take your time and follow directions to end

up with a sturdy, well-built set of floats that are straight

and true.

After the floats are built, you will have to decide how you

will finish them. Iron-on film such as Top Flite®MonoKote

®

covering is our recommended method. The alternative is

3/4 oz. fiberglass cloth and epoxy resin, then paint.

You do not have to make this decision immediately, but

refer to the Finishing section in this instruction manual

for more information. This is something you can ponder

during construction.

Covering Method

PREPARATIONS

PRECAUTIONS

INTRODUCTIONTABLE OF CONTENTS

2

Page 3

3

Metric Conversions

❏ 1/2 oz. Medium CA Adhesive - (GPMR6007)*

❏ 1/2 oz.Thin CA Adhesive - (GPMR6001)

❏ 1/2 oz.Thick CA Adhesive - (GPMR6013)

❏ CA accelerator (optional) - (GPMR6035)

❏ CA applicator tips (optional) - (HCAR3780)

❏ T-Pins - (HCAR5150)

❏ Waxed Paper

❏ 6-Minute Epoxy - (GPMR6045)

❏ 30-Minute Epoxy - (GPMR6047)

❏ Small building square or draftsman's triangle

❏ Reinforced cut-off wheel - (GPMR8200)

❏ Hand or Electric Drill

❏ Drill Bits: 1/16", 1/8",13/64" or #12

❏ Razor Saw

❏ #1 Hobby knife handle

❏ #11 Blades - (HCAR0311, box of 100)

❏ Common pliers

❏ Screwdrivers (phillips and flat)

❏ Sandpaper (coarse, medium, fine grit)

❏ T-Bar or sanding block

❏ Soldering iron

❏ Silver Solder - (GPMR8070 w/flux)

❏ Lightweight Balsa Filler - (HCAR3401)

❏ Propane torch or heavy-duty soldering iron

(for 60 floats only)

❏ Double-sided foam tape - (GPMQ4442)

❏ RTV silicone rubber

❏ Lead weights - (GPMQ4485)

Finishing Supplies

For iron-on covering:

❏ Top Flite MonoKote

®

film (recommended)

❏ Sealing Iron - (TOPR2100)

For “glassing”:

❏ Finishing resin (GPMR6049)

❏ 3/4 oz. fiberglass cloth - (HCAR5000)

❏ Mixing cups

❏ 1" wide paint brush

❏ Mixing sticks - (GPMR8055)

❏ Epoxy brushes - (GPMR8060)

❏ Fuelproof primer and paint

(Top Flite LustreKote®recommended)

*Items in parentheses (GPMR6007) are suggested part

numbers recognized by distributors and hobby shops and

are listed for your convenience. Our own brand has been

provided where possible: GPM is the Great Planes brand,

HCA is the Hobbico®brand, TOP is Top Flite.

IMPORTANT: For your model to handle properly on the

water and in the air, the Sport Floats must be built on a flat

surface. Also, a relatively soft, flat building board that you

can stick “T” pins into is required. This is for pinning down

individual parts that make up the completed assembly. A

suitable building board is a sheet of ceiling tile or “Celotex”

used in home construction. This material may be found at

hardware or home improvement stores. If the building

board is not flat, it must be clamped to your flat building

table.Now we're ready to begin!

During construction of the floats, most of the procedures

will have to be performed two times as there are two floats.

You may build each float individually to completion or

simultaneously build one float alongside the other.

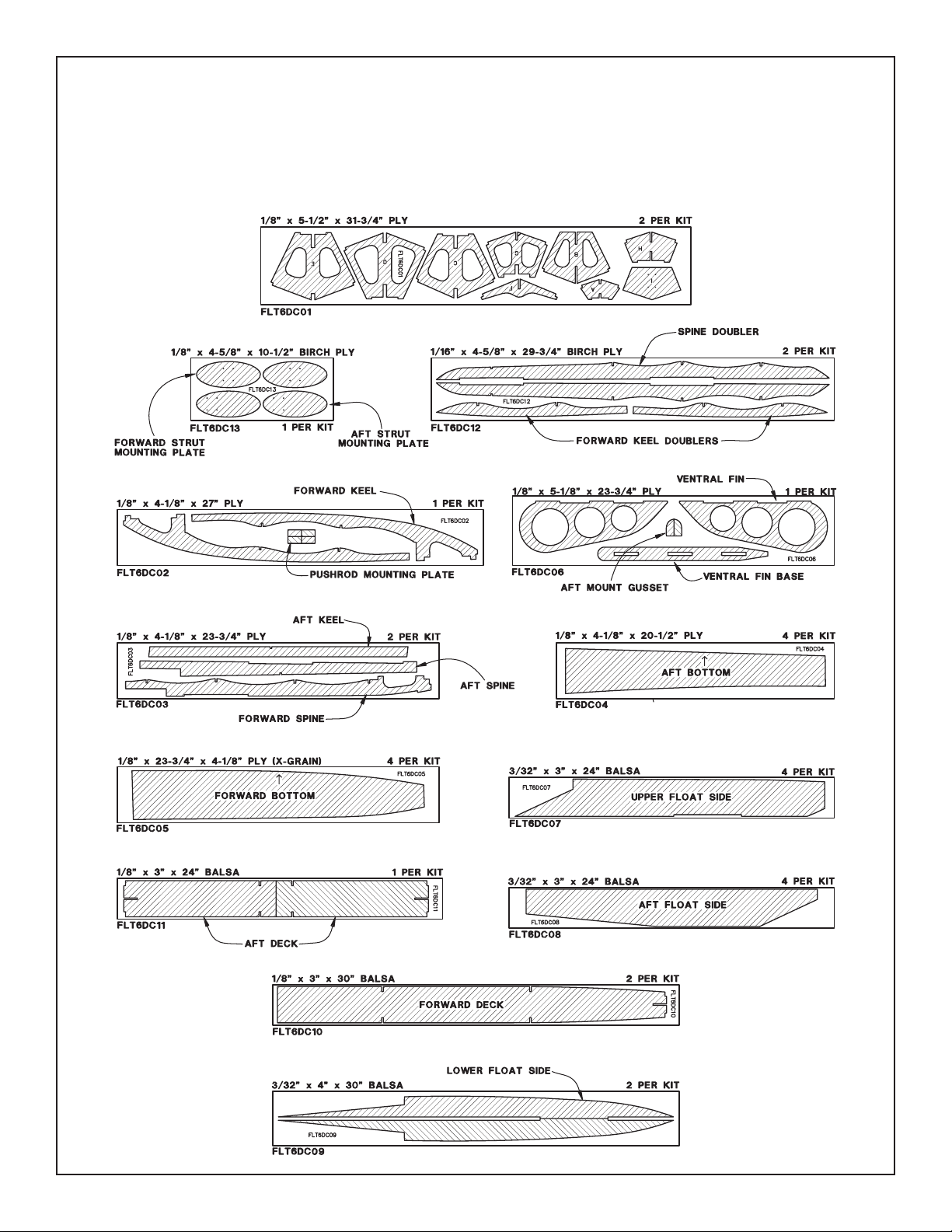

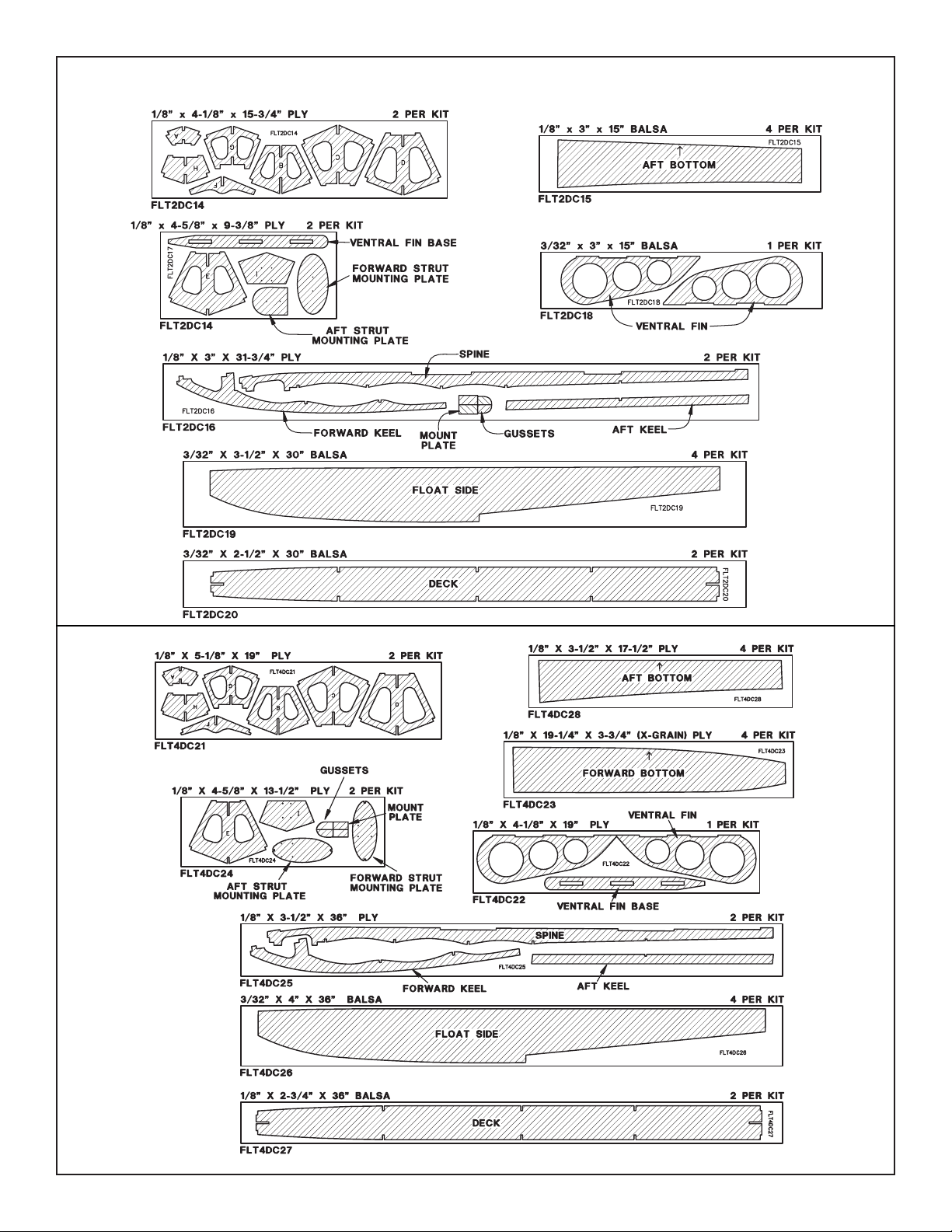

Remove all parts from the box. As you do, determine the

name of each part by comparing it with the instructions and

the parts list included with this kit. Using a ball point pen,

lightly write the part name on each piece to avoid confusion

later. Use the die-cut patterns shown on pages 4 and 5 to

identify the die-cut parts and mark them before removing

them from the sheet. Save all scraps. If any of the die-cut

parts are difficult to punch out, do not force them! Instead,

cut around the parts with a hobby knife. After punching out

the die-cut parts, use your T-Bar or sanding block to lightl y

sand the edges to remove any die-cutting irregularities.

Parts Identification

Get Ready to Build

Other Suggested Items

Suggested Tools & Building Supplies

Inch Scale

0" 1" 2" 3" 4" 5" 6" 7"

0 10 20 30 40 50 60 70 80 90 100 110 120 130 140 150 160 170 180

Metric Scale

Page 4

4

DIE-CUT PATTERNS

60 – SIZE

Page 5

5

DIE-CUT PATTERNS

20 – SIZE

40 – SIZE

Page 6

If you are building the 20 or 40 Sports Floats, skip to

“Construction of 20, 40, 60 Floats” in the next column

on this page.

❏ 1. On a flat surface covered with wax paper, laminate the

die-cut 1/8" plywood forward and aft spine to one 1/16" diecut plywood spine doubler with 6-minute epoxy.Use weights

to hold the pieces together. Hint: Before the epoxy fully

cures, use a #11 blade to remove excess epoxy that gets into

the notches or oozes out from between the laminated pieces.

With Great Planes 6-minute Pro™Epoxy, this can be done

about 10 to 15 minutes after the epoxy has been mix ed.

❏ 2. Glue the other doubler to the other side of the

assembly with 6-minute epoxy.

❏ 1. Since the par ts are smaller, both forward keel

doublers may be laminated to the forward keel at the same

time. Mix up some 6-minute epoxy and apply to one side of

both die-cut 1/16" plywood forward keel doublers. Then

position a doubler on each side of the die-cut 1/8" plywood

forward keel. Hold the pieces together with weights.

Remove the excess epoxy before it fully cures.

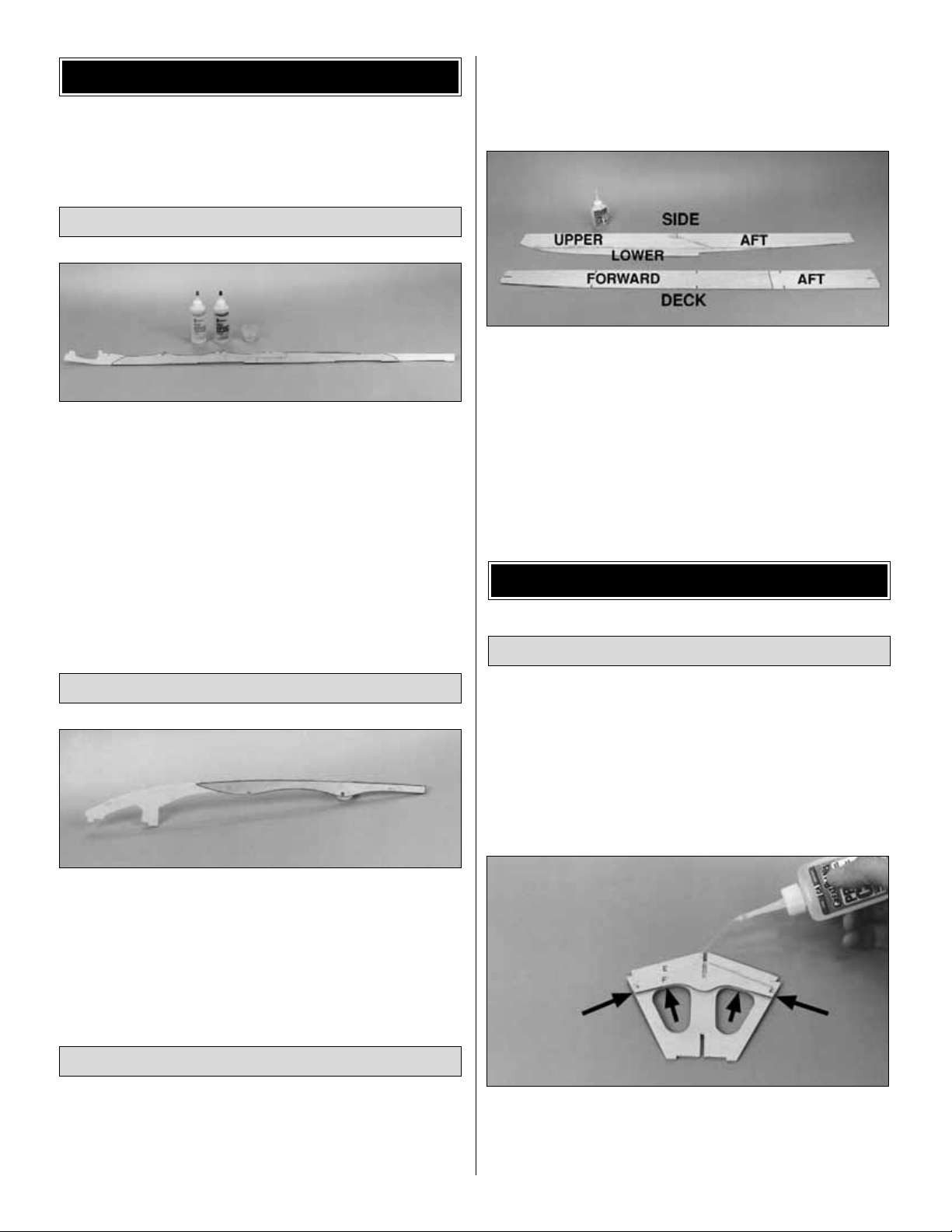

❏ 1. Trial fit the die-cut 3/32" balsa upper float side,

lower float side and aft float side. Make adjustments if

necessary. When satisfied with the fit, use thin CA to glue

the three pieces together over a building table covered with

waxed paper. After the CA has cured, use 150-grit

sandpaper and a sanding block to sand both sides of the

float side flat and smooth. Make another float side,

identical to the first.

❏ 2. Use thin CA to glue the die-cut balsa forward deck to

the aft deck. After the CA has cured, sand both sides of

the deck flat and smooth.

NOTE: If your float parts do not match each photo exactly,

it is because these instructions are written for all three

sizes. Regardless of which size Sport Float you are

building, the forward end of the float deck is the end

that tapers slightly.

❏ 1. Drill 1/8" holes through the punch mar ks in the die-cut

1/8" plywood forward and aft strut mounting plates.

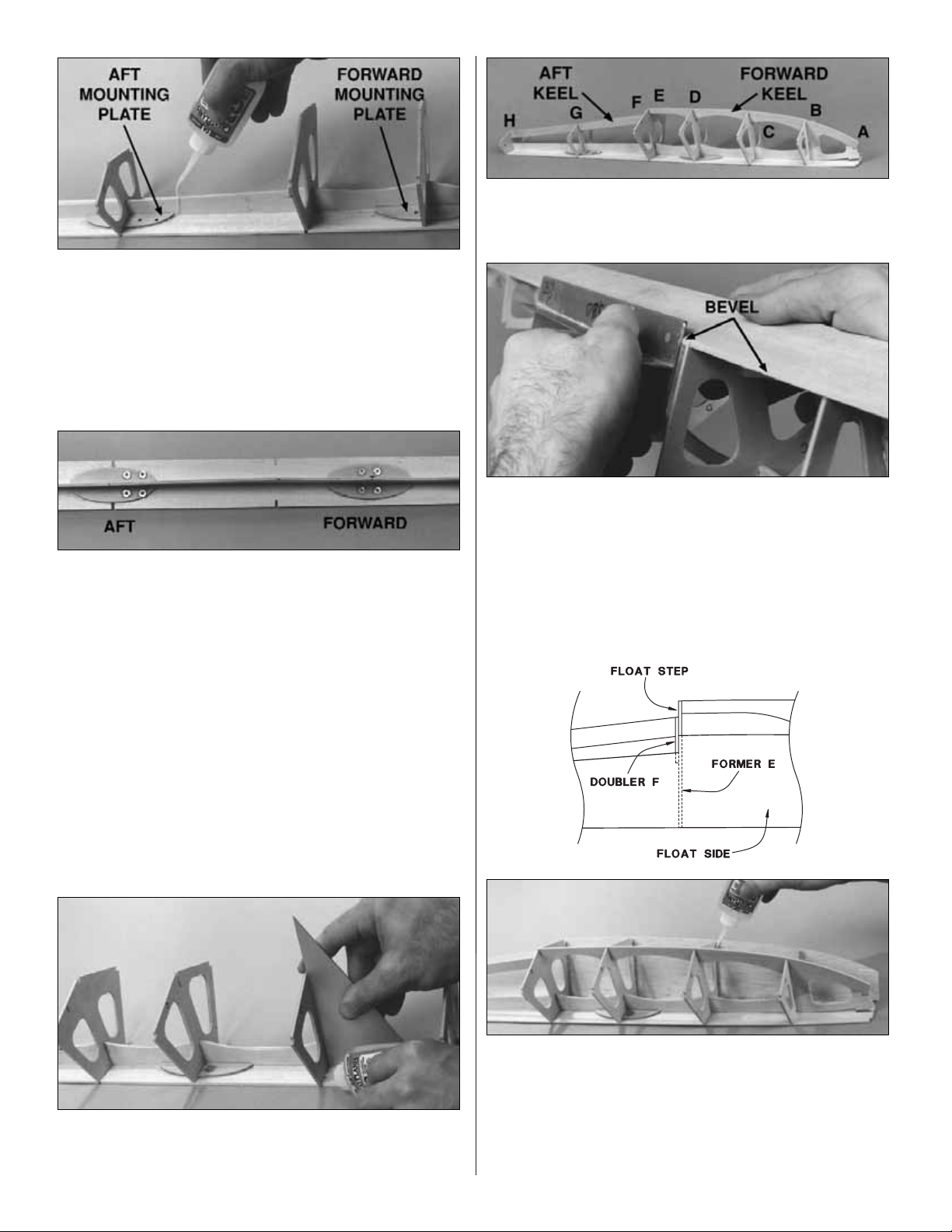

❏ 2. With the die-cut 1/8" plywood former doubler F

centered on the die-cut 1/8" plywood former E, align the

bottom edge of the doubler F with the lightening holes in

former E. Glue the pieces together with thin CA.

Framing

CONSTRUCTION OF 20, 40 & 60

Sides and Deck

Forward Keel

Spine

60 FLOATS PREASSEMBLY

6

Page 7

7

❏ 3. Tr ial fit the 1/8" plywood forward and aft strut mounting

plates, spine and formers C, D, E, and G to the balsa deck.

The formers are positioned in descending order with former A

in the front(see the photo to the right). NOTE: The aft str ut

mounting plate for the .40 and .60 Sport Float has the holes

towards the front. The aft strut mount plate for the .20 Sport

Float has a flat edge.Make sure all parts contact the deck, then

use thin CA to glue only the mounting plates to the deck.

❏ 4. Remove the formers and spine from the deck. Place a

scrap piece of wood under the deck, then using the holes in the

strut mounting plates as a guide, drill 1/8" holes through the

deck. Run a 4-40 x 1/2" bolt in and out of eight 4-40 blind nuts

to make sure the threads are “cleaned out.” Use a hammer to

lightly tap the 4-40 blind nuts into the plates, then add a few

drops of thin CA to the flange of each blind nut to secure them

in place. Do not get glue in the threads of the blind nuts.

Reinstall the spine and formers.Make sure all parts contact the

deck, then use thin CA to glue the spine to the deck.NOTE:Do

not glue the spine to the deck from former C forw ard.

❏ 5. Lay waxed paper over your flat building board and

position all the formers except A and I on the deck. Make

sure the notches in the formers fit all the way down to the

deck and make adjustments if necessary. Doubler F faces

the rear of the float.

❏ 6. Using a carpenter's square or a draftsman's triangle,

make sure each former is perpendicular to the deck and

use medium CA to glue them to the deck and spine.

❏ 7. Making sure the formers remain perpendicular to the

deck, trial fit, then use medium CA to glue the forward and

aft keel into the notches in the formers and the spine.

❏ 8.Remove the structure from the building board and use

a T-bar or flat sanding block with 150-grit sandpaper to

bevel the edges of the deck sheeting to match the formers.

❏ 9. Pin the assembly to your waxed paper-covered flat

building board.Trial fit, then sand a bevel to the top edge of

both die-cut balsa float sides to match the deck. Be sure

to make a

right

and a

left

side.

❏ 10. Align the step of one of the float sides with the aft

edge of former E. Use medium CA to glue the side to all

formers and the deck from former B to former H. Do not

glue the side to the deck forward of former B. Glue the

other side in the same manner. NOTE: The float side will

bow inward slightly at former G. This slight bow

is intentional.

Page 8

❏ 1. Cut the 3/16" x 3/16" aft stringers to length. Then

use thick CA to glue them to the formers only in the

notches of formers E, G, and H.

❏ 2. Remove the float from the building board once and for

all, then glue the sides to the aft stringers with thin CA.

Hint: hold the stringer to the sides with clothespins and

apply the thin CA from the

inside.

❏ 1.Install former A to the forward keel and spine, making

sure it is perpendicular. Then glue it in position with

medium CA.

❏ 2. Use medium CA to securely glue the deck to former

A, then the sides to the deck between formers A and B.

Inspect all glue joints and add CA where necessary. See

the following photo.

❏❏3. Cut a 3/16" x 3/16" forward stringer to fit in the

notches of formers E to A (do not attempt to bend the

stringer down to the notches in former A at this time). Use a

pen to make marks every 1/2" between formers C and A.

❏❏4.Take the stringer out of the notches in the float and

use a razor saw to cut a 1/16" deep notch at every mark

you just made. Hint: use a piece of 1/8" thick scrap

plywood as a gauge so the saw will cut every notch the

same depth.

❏❏5. With the notches in the forward stringer facing the

deck, first glue the stringer to the formers only with

medium CA. Then glue the side to the forward stringer in

the same manner that you glued the side to the

rear stringer.

❏ 6. Add the other forward stringer in the same manner.

The photo at step 2 (next page) shows the stringers glued

to the sides.

Forward Stringers

Aft Stringers

8

Page 9

❏ 1. To provide a good glue joint for the bottom sheeting,

use a sanding block and 150-grit sandpaper to trim the side

sheeting down to the side stringers and to bevel the

forward and aft keel to the same angle as the formers. Be

sure to maintain a smooth curve in the float sides when

sanding. Use the stringers as a guide.

❏ 2. It has been our experience that ballast is required in

order to move the center of gravity forward when the floats

are mounted on the airplane. This can easily be

accomplished by using 6-minute epoxy to glue the weight

inside the floats just behind the front former A. Spread

epoxy over and around the lead weights to prevent them

from coming loose. We suggest 1 oz. inside each 20 float,

1-1/2 oz. inside each 40 float and 2 oz. inside each 60 float.

❏ 1. Tr ial fit the die-cut 1/8" plywood aft bottom sheets.

Note: The 20 floats use die-cut 1/8" balsa aft bottom

sheets. The straight edge goes toward the center and

should be placed so it covers half of the keel. Make

adjustments if necessary and bevel the edges of the aft

bottom sheets that contact each other in the center.

Note: An embossed arrow is provided on the .40 and .60

aft float bottoms as an aid to alignment.

❏ 2. Working on your flat building board, use thick CA to

glue one aft bottom sheet to the aft side stringer and

formers only. Do not apply CA to the aft keel at this time.

❏ 3. Glue the other aft bottom sheet in position, applying

thick CA to the side stringers, formers and aft keel, gluing

both aft sheets to the keel and each other simultaneously.

❏ 1.To prepare the forward bottom sheets for one float,

cut ten 3-1/2" pieces from a 1/8" x 3" x 30" balsa sheet,

then make two cross-grain sheets by gluing 5 pieces

together.

Carefully

sand the sheets flat using a sanding

block and 150-grit sandpaper.

20 Floats Only

If you are building the 20 Sport Floats, follow these

steps first to make the bottom forward sheeting.

Otherwise, skip these three steps and add the

bottom forward sheeting now.

Forward Bottom Sheeting

Aft Bottom Sheeting

Prepare for Sheeting

9

Page 10

Add the forward bottom sheeting in the same manner as

the aft bottom sheeting:

❏ 1. On the 40 and 60 die-cut 1/8" plywood forward

bottom sheets, there is an arrow indicating the inboard

edge of each sheet (although one of the sheets on each

float will have to be flipped over).Trial fit the two sheets and

bevel the inboard edges that contact each other for a good

glue joint.

❏ 2. Use thick CA to glue one of the sheets to the side

stringer and formers only – do not apply CA to the

forward keel.

❏ 3. Apply thick CA to the side stringer, formers and keel

to glue the second sheet in position and both sheets to the

keel and each other simultaneously. Use the embossed

arrows to aid in final alignment.

❏ 4. Referring to the sketch, “rough sand” the entire float

with a sanding block and 150-grit sandpaper, blending the

sides to the deck and the bottoms to the side. Sand all

sheeting and stringers flush with formers A and H.

❏ 1.Glue the balsa nose block to former A with thick CA.

❏ 2.Carve the nose block to the approximate shape, then

use a sanding block and 150-grit sandpaper to blend the

block to the sides, deck and bottom.

❏ 3. Finish sand the nose block by rounding the front and

slightly

rounding the corners.

Nose Block and Finishing

❏ 3. Carefully cut the strips along the line. Mark the

inboard edge of each bottom sheet.

❏ 2. Accurately cut out the 20 float forward bottom

sheeting template from the center sheet in the manual,

then trace the outline on each sheet. Hint: Tape the

template to the sheet at the front and the rear.

10

Page 11

❏ 4. Use thick CA to glue on the die-cut 1/8" plywood

transom plate I so the punch marks are visible. Sand the

edges to blend with the sides, top and bottom.

❏ 5. Dr ill a 1/16" hole through each punch mark in the

transom plate on only one of the floats. This is now the

right float to which the rudder will be mounted.

❏ 6. Fill any nicks, scratches, or seams with HobbyLite

™

filler. After the filler has cured, final sand the entire float

with a sanding block and 220-grit, then 320-grit, then 400grit sandpaper.

There are two ways you can cover your floats.You can use

Top Flite®MonoKote®covering or fiberglass cloth and resin

with paint. “Glassing” seals the wood grain and is required

if you wish to paint the floats. This can be an involved,

messy project but yields a highly durable finish. MonoKote

covering is the quicker, easier method and provides a

surprisingly durable finish as well. In fact, our prototype 60

floats mounted on our Great Planes J-3 Cub 60 are

covered with MonoKote film and were really put to the test!

Following are instructions for both covering methods.

❏ 1. Seal all seams (except around the nose block) with

1/2" wide strips of MonoKote film. Iron these strips down

with a hot iron for a good seal.

❏ 2.Continue to cover the float, in the following sequence:

A.Transom

B.Deck

C.Sides

D. Aft bottom

E. Forward bottom

All pieces should overlap at the nose. Iron the large pieces

of covering down by starting in the center, pulling and

working out to the edges.

❏ 3. You can enhance realism by adding panel lines and

rivets with a fine-point indelible pen, creating a propeller

arc warning line (red) from MonoKote covering, and making

the flat black walkways (on right float only) from 400-grit

wet/dry sandpaper.

Apply the glass cloth in this order:

1.Transom

2. Deck and both sides in one piece

3. Aft bottom

4. Forward Bottom

❏ 1. Cut a piece of 3/4 oz. (Lightweight) glass cloth 1/2"

larger than the transom all the way around.

Glass Cloth and Resin

MonoKote®Covering

Covering Method

COVERING

11

Page 12

❏ 2. Mix up 1 oz. of finishing resin following the

instructions provided in the Great Planes Pro™Epoxy

Finishing Resin kit. Use an epoxy brush to liberally coat the

transom of the float.

❏ 3. Place the cloth on the resin-coated transom, then

brush the resin through the cloth, removing excess resin

from the center to the edges. Be sure to allow the excess

glass cloth to wrap around the top, sides and bottom of the

float. Some expert modelers squeegee the excess resin off

with a business card or expired plastic credit card. Let the

transom fully cure.Then with a sanding block and fresh 220

grit sandpaper, feather the glass cloth into the float top,

sides and bottom.

❏ 4.Apply glass cloth and resin to the deck and sides (one

piece).The cloth should wrap around the bottom 1/4". Hint:

If you cut and position the cloth with the weave running at

45 degrees to the float, the cloth will more readily go

around the sharp bottom corners.Try it!

Another Hint: Build a simple stand to hold the float while you

apply the resin and cloth to the deck and sides. Let the deck

and sides fully cure.Then with a sanding block and fresh 220

grit sandpaper, f eather the glass cloth into the bottoms .

❏ 5. Following the same procedure outlined above, apply

glass cloth to the bottoms and step. The cloth needs to

overlap the sides 1/4" as shown in the sketch.

❏ 6. Lightly sand the entire float with 320-grit sandpaper

being careful not to cut into the glass cloth. Mix up a

2 oz. batch of resin and use a regular camel hair or similar

1" wide paint brush to brush on another coat of resin over

the entire float. For ease of handling, you may do the top

and sides first, then the bottom. If you work quickly you can

save the paint brush by cleaning it with alcohol before the

resin begins to thicken.

❏ 7. Carefully sand the entire float with 360-grit sandpaper

and a sanding block, being careful not to sand through

to the cloth. Note: See step 2 under Pushrod Hookup on

page 17 and glue the 1/8" plywood mount block to the deck

after you apply the glass cloth. It is not necessary to cover

the mount block with glass cloth but you should apply resin

over the bare wood. The float is now ready for a coat of

primer.If you have sanded through the second coat of resin

into the cloth, you will have to apply a third coat of resin in

those areas.

❏ 8. Apply a coat of primer to the floats. Many expert

modelers have established their favorite brand of paint and

painting methods, but our recommendation is Top Flite

LustreKote Primer. Over glass cloth and resin, one coat of

primer may be sufficient but two coats may be required.You

may dry sand between coats of primer and paint but wet

sanding is preferred – be sure to plug the holes in the deck

for the strut mounts so water does not get inside and do

not sand through the glass cloth.

❏ 9 . Paint the floats. Again, our recommendation is Top

Flite LustreKote.If you have a good base coat of primer you

may need only one coat of color.

Before you continue, take a break from building and

study the following information to be sure you

understand the positioning of the floats in relation to

the wing and fuselage.

While the following instructions show the Sport Floats on

Great Planes Piper Cubs, there are general tips and

guidelines that apply to all models which will insure proper

handling characteristics in the water and good landing and

takeoff tendencies.

POSITIONING OF FLOATS

12

Page 13

The relationship between the “step” on the floats and the

center of gravity on the model is important. First, the floats

should be mounted on the model so the step is positioned

as detailed in the “Step Sketch” for your particular model.

Then, when the floats are mounted on the model, move the

C.G. slightly forward as listed below. Although you may

have added the recommended ballast inside the front of

the float, in some cases a little more ballast may be

required on the model.

For 60-size floats: Move the CG (Balance point) 1/2"

ahead of the manufacturers recommended CG.

For 40-size floats: Move the CG (Balance point) 3/8"

ahead of the manufacturers recommended CG.

For 20-size floats: Move the CG (Balance point) 9/32"

ahead of the manufacturers recommended CG.

Another important relationship between the wing and the

floats is the relative “angle of attack.’’ With a virtually flat

bottom wing such as a Piper Cub, the deck of the floats

should be parallel to the bottom of the wing. Since the Cub

does not have a truly flat wing, this yields a slight positive

wing incidence in relation to the floats, and the airplane will

tend to rise off the water at the correct time. If you have a

model with a symmetrical wing, the wing incidence in

relation to the float deck should be positive 1-1/2 degrees.

Finally, each float should be set so that it is parallel to the

centerline of the fuselage.

❏ 1. You must have a solid mounting location on the

fuselage bottom for the aft float strut. If you have not

previously built in the aft float mount plate to the bottom

of your fuselage, follow the instructions below.

A. For greatest strength, it is preferred that the 1/8”

plywood aft float mount plate (included with the float

kit) be positioned under a former.The location of the aft

float mount plate is determined by the aft strut (included

with the float kit) which can be custom bent. On the

Great Planes Cub 60 and Cub 20, the location of the aft

float mount plate is shown on the plan included with the

model. To locate the former, push a pin through the

bottom of the fuselage until you find it.

B. Remove a section of the bottom sheeting, centered

over the former, wide enough to accept the aft float

mount plate.

Prepare Your Airplane to Accept

the Floats

13

Page 14

❏ 2. Use the landing gear included with your airplane for

the front struts unless you are building a Great Planes

Cub 60. For the Cub 60, you will use the front landing gear

strut and cross brace provided with the floats. For some

models, the front landing gear mounting location on the

fuselage may have to be moved to allow the step in the

float to be placed according to the recommendations.

❏ 1. Remove any oily residue from the wire struts by

wiping them with alcohol. Roughen the area to be soldered

with 150-grit sandpaper.

❏ 2. Silver solder, such as Great Planes Silver Solder

(GPMR8070), is highly recommended.

❏ 3.For soldering the heavy gauge wire struts, higher heat

is required than for normal electrical soldering. A torch is

recommended but some heavy duty soldering irons may

work as well. The higher the temperature of the heating

source applied to the joint, the quicker the solder will flow

and the less time the wire will have to draw heat away from

the area.

❏ 4. Avoid a “cold” solder joint which will not have the

shiny appearance of a proper solder joint. A cold joint may

be caused by disturbing the pieces before the molten

solder has solidified or by a joint that never had enough

heat to let the solder flow.

❏ 5. Read the instr uctions provided by the manufacturer of

the solder.

❏ 1. Match the shor ter front strut with the front cross

brace and the taller rear strut with the rear cross-brace.

The matching struts and cross-braces are the ones that fit

together the best. Note: If you are mounting the floats on a

model other than the Great Planes Cub 60, you may use

the main landing gear included with your model to mount

the front of the floats, and the rear struts included with this

kit to mount the rear of the floats.You may have to relocate

your main landing gear in order to place the step on the

floats at the required position.

❏ 2. Wrap each joint neatly and tightly with the

reinforcement wire.

A. For ease of handling, apply thin CA to the joint to

temporarily hold the pieces together.

Solder the Cross-Braces

Notes about Soldering

60 FLO

ATS ONLY

This section pertains to the 60 Sport Floats only. If

you are building the 20 or 40 Sport Floats, skip to

the “20 And 40 Floats Only”section now.

60 FLOATS ONLY

C. Use 30-minute epoxy to glue the die-cut 1/8" plywood

float mount plate gussets to the fuselage side and

former. Note: The bottom of the gussets may have to be

beveled so they are flush with the bottom of the

fuselage side.

D. Tr ial fit the aft float mount plate, cut it to the correct

length, then use 30-minute epoxy to securely glue it in

position.When the epoxy has cured, use a sanding block

and 150-grit sandpaper to blend the aft float mount plate

to match the contour of the fuselage bottom. Cover the

bare wood to match you model.

14

Page 15

B. Cut a 26" piece of wire and make a sharp bend about

3/8" from the end.

C. Place the wire between the braces and begin tightly

wrapping the wire.

D. When complete, route the excess wire through the wire

wrap and pull it tight.Cut off the excess wire.

❏ 3. Heat the joint, apply a few drops of acid flux, then

feed in the silver solder. A proper solder joint looks like the

one in the photo – not a “dry” solder joint nor a big hideous

glob.Solder all four joints.

❏ 1. Cut the nylon bearing mounts into two pieces, then

enlarge them with a #12 (or 13/64") drill bit. Mount the

bearings to the floats with 4-40 x 1/2" screws.

❏ 2. Temporarily join the floats to the struts by inserting

them into the bearing mounts. Use a felt tip pen to mark the

location of the diagonal braces as indicated in the sketch.

❏ 3. Trial fit the floats and struts on your model before

soldering the diagonal braces.The spacing and angle of the

struts is determined by placement of the diagonal braces.

❏ 4. Wrap, then solder the diagonal braces to the struts.

Lay a damp cloth under each solder joint as you proceed to

avoid damaging your finish.Test fit the floats to your model

and make adjustments if necessary.

Mount the Struts to the Floats and

Solder the Diagonal Braces

15

Page 16

❏ 5.The completed struts may be painted. First remove all

residue with alcohol, thoroughly sand with 400-grit

sandpaper, then clean again with alcohol or thinner

before painting.

❏ 1. Mount the struts to the floats with 3/16" wheel

collars and 6-32 machine screws. Then turn the

fuselage upside-down and place the struts on the model

with the “step” in the floats positioned according to

the recommendations.

❏ 2. Place three 5/32" nylon hump straps, evenly spaced,

on each strut and mark the screw hole locations. Dr ill a

3/32" hole at each mark, then fasten the floats to the

fuselage with 12 #4 x 1/2" sheet metal screws.

If you are building the 60 floats, skip to “Build the water

rudder” on page 17.

❏ 1. Cut the nylon bearing mounts into two pieces and

mount them to the floats with 4-40 x 1/2" screws. If your

front landing gear is 3/16" diameter wire, you will have to

drill out the front bearing mounts with a 13/64" or #12 drill

bit. See the following photo for proper bearing

mount placement.

❏ 2.Temporarily join the floats to the str uts with the 5/32"

wheel collars.

The following instructions show the Great Planes J-3 Cub

20 and 40. Use the instructions, sketches and photographs

as a general guide if you are mounting the 20 or 40 Sport

Floats to a different model.

❏ 1. Turn the fuselage upside-down and place the front

struts in the torque blocks in the fuselage and the lay rear

struts on the aft strut mount plate.

❏ 2. Mount the front struts to the fuselage as they were

with the conventional landing gear, then place two nylon

5/32" hump straps on the rear strut 3/8" from the fuselage

side. Mark the strap locations. Note: The 40 Spor t Floats

require a third hump strap in the center of the rear strut.

❏ 3. Drill 1/16" holes at each mar k. Then fasten the float

struts to the fuselage with #2 x 3/8 sheet metal screws.

❏ 4.The completed struts may be painted. First remove all

residue with alcohol, thoroughly sand with 400-grit

sandpaper, then clean again with alcohol or thinner

before painting.

Mount the Floats to the Airplane

Mount the Struts to the Floats

20 AND 40 FLOATS ONLY

Mount the 60 Floats to the Airplane

16

Page 17

❏ 1. Install the wheel collar and the brass tube bearing

on the rudder shaft. Use the 4-40 x 1/4" socket head cap

screw and 4-40 lock nut to mount the rudder to the

rudder bracket, then silver solder the rudder bracket to the

rudder shaft. Do not solder the brass tube to the rudder

shaft. Note: The 60 and 40 floats require a brass tube,

wheel collar, then another brass tube. Refer to the sketch

for each assembly.

❏ 2. Lock the wheel collar so the rudder shaft cannot slide

up and down in the brass tube. Note: on the 60 and 40

rudder, lock the wheel collar so the rudder shaft cannot

slide up and down on the bottom brass tube.

❏ 3. Cut the threaded portion of the rudder shaft so 3/4" of

the thread remains, then screw on the nylon swivel 1/8"

past the end.

❏ 4. Loosely install the rudder on the right float with two flat

straps, two 1/8" hump straps and four #2 x 3/8" sheet metal

screws. Adjust the bottom of the r udder bracket so it is even

with the bottom of the transom, then tighten the screws.

Note: Do not overtighten the 4-40 screw and nut that secures

the rudder to the bracket. The rudder must be able to pivot

upward in case it hits a foreign object in the water – or

the shore.

❏ 1. With the floats mounted to the model, solder a

threaded coupler to one end of the braided cable, then

thread on the nylon swivel clevis. Slide the cable into the

pushrod guide tube.

❏ 2. Position a die-cut 1/8" mount plate on the deck of the

float 3" from the rear. Remove the covering from

underneath, then glue it in position. Hint: Cover the mount

plate to match your floats before you glue it in place.

Pushrod Hookup

Build the Water Rudder

ALL MODELS

17

Page 18

❏ 3. Drill 1/16" holes in the mount plate. Then use #2 x

3/8" sheet metal screws to fasten a 1/8" hump strap and

outer pushrod tube with pushrod. Connect the swivel clevis

to the swivel on the rudder shaft.

❏ 4.Mount an additional control horn (included with float

kit) on the right side of the rudder.

❏ 5. Cut off one side of the

base

from two 1/8" nylon hump

straps as shown in the sketch.

❏ 6 . Hold the outer pushrod tube and cable along the

bottom of the fuselage in a position that will provide a gentle

loop from the float to the rudder as shown in the photo.

Where the pushrod tube meets the fuselage, remove a

section of covering and install another die-cut plate.

❏ 7.Fasten the guide tube to the aft strut with a nylon tie.

❏ 8. Drill a 1/16" hole and secure the cable guide tube to

the mount plate with one of the cut-off hump straps and

#2 x 3/8" sheet metal screws.

20 - 40 Floats only

After performing steps A and B, continue with step 8.

A. Screw a threaded coupler to a nylon clevis. Then

temporarily fasten the clevis and coupler to the rudder

horn. Holding both the water rudder on the float and the

rudder on the model in a neutral position, determine the

length of the pushrod cable, remove it from the guide tube,

then cut it to length. Hint: A Great Planes cut-off wheel

(GPMR8200) works great for cutting cable like this without

fraying the end.Cut the guide tube to a length so that it will

not interfere with the threaded coupler when it is soldered

onto the cable. There must be enough clearance to allow

the cable to slide freely.

Connect the Rudder

18

Page 19

Note: Before reinstalling the cable into the guide, apply a

light coat of oil or petroleum jelly to the cable to prevent

future corrosion.

B.Remove the threaded coupler from the nylon clevis, slide

the cable back into the outer pushrod tube, then solder the

cable to the coupler. Thread the clevis back onto the

coupler. Then attach it to the rudder horn. Make final

adjustments by screwing or unscrewing the nylon clevis at

either end of the cable.

60 Floats Only

After performing steps A and B, continue with step 8.

A. Screw a nylon clevis to the .074" x 12" threaded rod.

Then temporarily fasten the clevis to the rudder horn.

Holding the water rudder on the float and the rudder on the

airplane in a neutral position, determine where the threaded

rod and the cable will be joined with the coupling sleeve.

Then cut the rod to length. Remove the cable from the guide

tube, and then cut the cable to length. Hint: A Great Planes

cut-off wheel (GPMR8200) works well for cutting cable like

this without fraying the end. Cut the guide tube to a length

that will not interfere with the split coupler when it is

soldered onto the cable and the cable moves in and out.

Note: Before reinstalling the cable into the guide, apply a

light coat of oil or petroleum jelly to the cable to prevent

future corrosion.

B. Slide the cable back into the guide tube. Then join the

threaded rod to the cable by soldering the coupling sleeve

to both pieces. Make final adjustments by screwing or

unscrewing the nylon clevis at either end of the cable.

❏ 8. Mount another 1/8" plywood mount plate and the

other cut hump strap near the rear of the guide tube.

❏ 9. Test the actuation of the water rudder on the floats.

The water rudder and the rudder on the model must both

be neutral and move in the same direction.

The purpose of the ventral fin is to increase yaw stability.

Some models may be flown successfully without the ventral

fin, but we strongly recommend that you add the ventral fin

to your airplane when flying with Great Planes Sport Floats.

❏ 1. Laminate the die-cut 3/32" balsa ventral fins with

6-minute epoxy. Note: The 60 ventral fin is two pieces of

die-cut 1/8" plywood. Hint: Clamp the ventral fins together

while the epoxy cures by laying weights on top of them over

a flat work surface covered with wax paper. After the glue

has cured, use a sanding block and 150-grit sandpaper to

sand the ventral fin flat, remove any excess glue, and round

the edges.Final sand with 320 to 400-grit sandpaper.

❏ 2. Making sure the ventral fin is perpendicular to the

die-cut 1/8" plywood ventral fin base, glue the pieces

together with medium CA.Then glue the 1/4" balsa triangle

stock to the fin and base.

❏ 3. Cover the assembled ventral fin to match your model.

Then mount it to the bottom of the fuselage right on the

centerline of the fuselage. The suggested mounting method

is double-sided foam mounting tape. An alternate mounting

method would be to use #2 x 3/8" sheet metal screws.If you

use screws, 1/8" plywood blocks should be glued to the

inside of the bottom sheeting where the screws are located.

❏ 4. Balance your airplane again, after adding the ventral fin.

VENTRAL FIN

19

Page 20

❏ 1. The set screws on the wheel collars should be

secured with liquid thread-locking compound. On the 60

floats, it is recommended that a small flat spot be filed on

each strut where the set screw locks.

❏ 2. Plastic “splash strips” that protrude below each inner

float side by 1/2" may be added if too much water gets

splashed up onto the propeller – you'll be surprised at the

damage water can do to the propeller. This is highly

recommended for the 20 floats and can be fastened directly

to the covering with double-sided foam tape or Pacer brand

ZAP-A-DAP-A-GOO cement. A template is provided in the

middle of the manual for the float splash strips.They may

be cut from .06" ABS, styrene or other plastic sheet.

Salt water flyers should pay special attention

to these instructions.

❏ 1. Where possible, seal pushrod exits and the receiver

switch or other openings with petroleum jelly or similar.

❏ 2. Seal screw holes with clear RTV silicone. This

includes screws on the floats that hold on the water rudder,

strut mount bearings, and hump straps, as well as the

screw holes that hold the straps on the fuselage, etc.

❏ 3. Lightly oil the moving parts of the r udder and the

cable inside the outer pushrod tube.

❏ 4. Make sure you have a good seal between the wing

and the fuselage. If not, make a “gasket” out of RTV

silicone or foam wing tape.

❏ 5.Enclose the receiver and battery in plastic bags, then

wrap with rubber bands.

Before setting the model in the water, be sure the water

rudder on the float is extended. A reliable, slow idle is a

must – unless you can swim well! First flight attempts with

floats should be reserved for relatively calm days when the

water is not so choppy. Practice taxiing around in the water

to learn the handling characteristics and see if you have

built in enough throw on the water rudder. Make

adjustments if required. During taxiing, hold “up”elevator to

keep the nose of the airplane high and the propeller out of

the water. Always takeoff into the wind. Gently add throttle

and gradually release some of the up elevator as the speed

increases. Just like the model takes off the ground, when it

has enough speed it will lift into the air – don't force it off.

Continue a gradual, conservative climbout until you are at

an altitude where you are comfortable making the

downwind turn.

Learn the flight characteristics of the model with the added

weight and drag of the floats. A model that was not

marginal on power to begin with will do fine – you'll

probably be surprised. Our Cub 60 with the O.S. 91

Surpass while not overpowered, does have plenty of

reserve and is perfectly capable of loops, rolls, stall turns

and inverted flight with the Sport Floats.

Landing approach is the same on water as it is on land.

Touch down slow to avoid bouncing the airplane off the

water back into the air.“Crabbing” is a great technique used

to bleed off airspeed during approach of “floater”models like

a Cub. This is done by applying a balance of rudder and

opposite aileron to make the airplane fly “sideways.” The

path of the model is “down the runway” while the nose is

pointing off to one side. Just before the floats contact the

water, release the rudder and opposite aileron.

Although it is difficult to do, the model can contact the water at

such an angle as to allow the tips of the floats to “catch,” thus

flipping the model immediately. Avoid letting the floats contact

the water at anything but a le v el or slightly positiv e attitude .

Be considerate to others at the lake and

enjoy your Great Planes Sport Floats!

FLYING

WATERPROOFING

BEFORE GOING TO THE LAKE

Page 21

Loading...

Loading...