Page 1

ElectriFly’s™BL-8 Brushless ESC is designed for powering small, brushless motors for 3D aerobats and flat-foam airplanes. The

BL-8 ESC is capable of delivering 8 amps of current continuously, or 9 amps of surge current, and has numerous programmable

features including battery type (NiCd/NiMH or Li-Po), soft-start, brake, timing and more.

INSTRUCTIONS

Input Voltage: 5 – 10 NiCd/NiMH cells, 2-3 Li-Po cells

(20V input w/o BEC)

Output current: 8A continuous max., 9A surge max.

BEC: 5V / 1.5A

Operating frequency: 8 or 16kHz programmable

On resistance: 0.013 ohms

Brake: on / off

Acceleration: soft, hard or automatic

Low voltage cutoff: programmable

Max. temp.cutoff: 230°F [110°C]

Dimensions: 0.87 x 0.16 x 0.83" [22 x 4 x 21mm]

Weight: 0.42oz. with wires [12g]

• Great for small, high-performance airplanes, from flat foams to

built-up 3D’s.

• Fully proportional forward with brake.

• Very smooth throttle response.

• Custom BEC circuit handles up to 1.5A – great for models

requiring up to three high-powered servos.

• Li-Po compatible, as well as NiCd and NiMH batteries.

• Other programmable features include:

• Brake Control: On/off.

• Safe-Start: On/off, prevents accidental motor spin at start-up.

• Switching frequency: 8kHz or 16kHz, to optimize battery runtime and cool operation.

• Low-V oltage Control:Reduce or cut motor power, but maintain

radio control.

• Timing: Soft (7 degrees), hard (30 degrees for outrunners),

or automatic.

• Reverse rotation.

• Includes over-temperature protection.

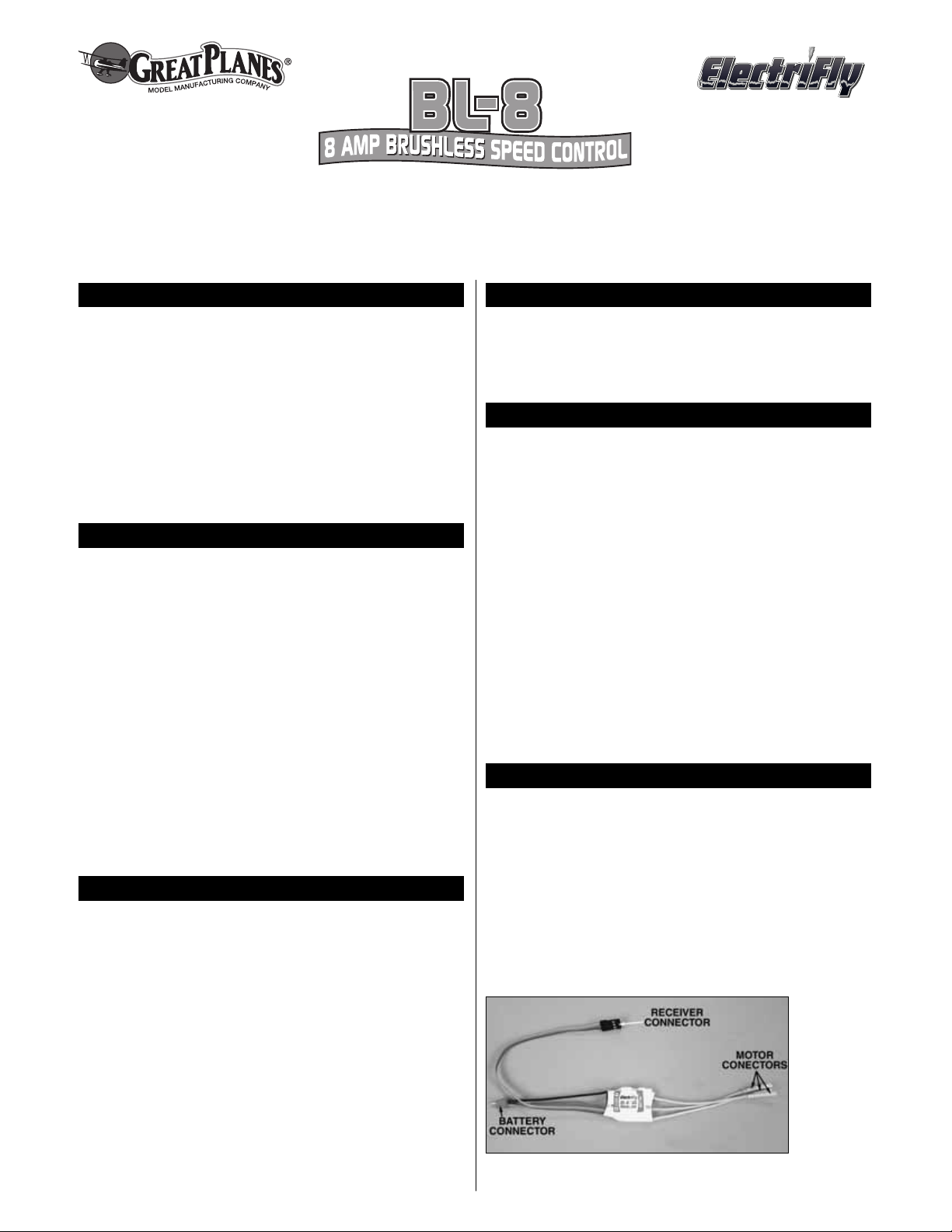

• Pre-installed universal radio connector, micro batter y connector,

and 2mm female bullet motor connectors.

Please read and follow these instructions carefully before using.

• Do NOT apply an input voltage that exceeds the maximum

specification above.

• Do NOT apply currents to the motor that exceeds the maximum

specifications above.

• Do NOT allow the input or output connectors to accidentally touch

each other while power is applied. Make sure all connections are

insulated electrically.

• Do NOT allow water or moisture to make contact with the ESC’s

circuitry as it can cause permanent damage.

• Do NOT place the ESC in a location inside the airplane where air

cannot flow. Always provide a path for external air to flow freely

across the ESC while in operation.

• Do NOT attempt to touch a rotating motor as personal injury can

result! If setting up the motor/ESC on the workbench, make sure

the motor is securely attached and that nothing is connected to the

output shaft BEFORE applying power.

• Always connect the power battery just before flight, and disconnect

the battery immediately after the flight has ended.

The BL-8 ESC is designed to work with brushless motors of all types –

except motors that include sensors. Its adjustable timing makes the

BL-8 a great choice for great operation with inner-rotating and outrunner

type brushless motors. Do NOT attempt to use the BL-8 ESC with

traditional brushed motors as permanent damage may result!

IMPORTANT!! The ESC should always be mounted in a location

which allows good airflow for proper cooling!! Failure to allow

good airflow over the ESC during operation can cause severe

overheating, resulting in thermal shutdown and/or permanent

damage to the ESC!

Determine the best location for the ESC on the fuselage. If the

location of the ESC is not vented or ducted to allow airflow inside and

out of the fuselage you will need to create one or more vents or ducts.

For some airplanes, mounting the ESC in front of the firewall or next

to the motor might be good options.Other airplanes only allow for the

ESC to be mounted behind the firewall, in which case air vent holes

will need to be cut in the firewall, and air exit holes may need to be

cut in the tail end of the fuselage.

Mount the ESC to the airplane in a way that minimizes the amount of

shock and vibration to the ESC.Attaching the body of the ESC to the

model with double-sided foam tape or Velcro

®

is recommended. It’s

also a good idea to try and locate the body of the ESC as far away

from the electric motor as possible, to help avoid any unwanted

electrical interference.

This ESC has a built-in “BEC” or “Battery Eliminator Circuit” which

takes power from the airplane’s main pow er battery and supplies it to

the receiver and servos. The BEC delivers this power through the

receiver connector. Therefore, it is not necessary to connect a

separate battery to the receiver. Always connect the ESC’s receiver

connector to the receiver’s throttle channel (see your radio’s

instruction manual for details). IMPORTANT!! The BL-8’s BEC

circuit is rated to handle up to 1.5A of current for short bursts –

NOT continuous 1.5 amps of current.If your application will use

higher powered servos it is very important to make sure to

mount the ESC so that a large amount of air can flow over the

ESC during operation.

The BL-8’s

receiver

connector is a

universal style

plug, and will

connect

directly to

most R/C

receivers

without need

for physical

modification or re-wiring.The orange “signal” wire on the ESC’s receiver

plug should be in the same position in the receiver slot as the white wire

STEP 2 – THE BEC CIRCUIT & RECEIVER CONNECTION

STEP 1 – MOUNTING THE SPEED CONTROL

COMPATIBLE MOTORS

IMPORTANT PRECAUTIONS

SPECIAL FEATURES

SPECIFICATIONS

™

Page 2

2

on Futaba®, the blue wire on the newer Airtronics “Z” connector, the

yellow wire on the Hitec “S” connector, or the orange wire on the JR

connector. WARNING: This connector is NOT directly compatible with

the old Airtronics connector style. Use an Air tronics Servo Adapter to

connect this ESC to the older style Airtronics radios.

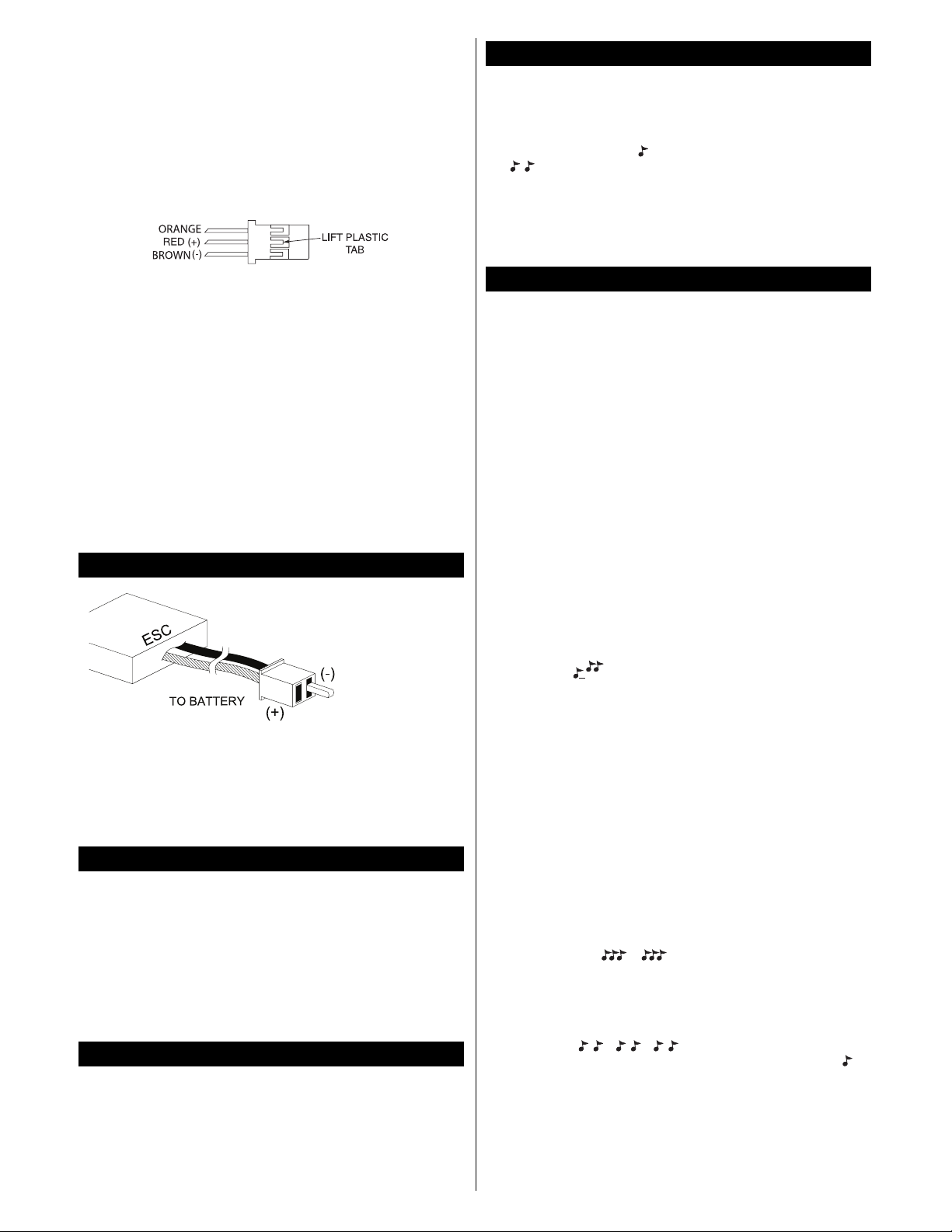

DISABLING THE BEC CIRCUIT

If using more than 10 NiCd/NiMH or 3 Li-Po cells, it will be necessary

to disable the speed control’s BEC circuit and connect a separate

battery to power the receiver and servos. Failure to do so will

permanently damage the BEC circuit. To disable the BEC circuit:

A. The red wire and its terminal should be removed from the plastic

shell. To do this use a small flat bladed screwdriver to slightly,

carefully raise the plastic tab holding the metal pin. Carefully pull

the red wire out of the receiver plug.Or, cut a small section of the

red wire out completely with wire cutters.

B. Always make sure to cov er the bare terminal or cut wire with electrical

tape or shrink tubing to avoid an unwanted short circuit condition.

C. Connect the ESC’s receiver connector to the receiver’s throttle

channel (see your radio’s instruction manual for details).

A separate battery will then need to be connected to the receiver.

When the BEC circuit is disabled, it will be important to remember not

to exceed the ESC’s maximum rated current!

WARNING: NEVER ALLOW THE BARE RED (+) AND BLACK (-)

WIRES TO TOUCH ON ANY RECEIVER OR ESC, AS

PERMANENT DAMAGE WILL RESULT TO BOTH ITEMS AND

VOID ALL WARRANTIES!

A polarized micro

connector is preinstalled for

connecting the ESC

to an external

battery pack. It’s a

good idea for the

length of wire

between the battery

and ESC to be no

longer than 6

inches. IMPORTANT! Make sure the polarity of the battery’s

wires/connector matches the polarity of the wires/connector on

the ESC, with the battery and ESC’s red (+) wires connected and

the black (-) wires connected together.NEVER allow the bare red

(+) and black (-) wires to touch as permanent damage will result

to both items and void all warranties.

The BL-8 has three output leads. Female 2mm bullet connectors are

pre-installed on each lead. These connections are not polarized, so

there is no need to match the color of the ESC’s wires to the motor’s

wires. Once connected to the motor, make sure all connections are

insulated electrically .Failure to do so could result in permanent damage

to the motor/ESC if the output leads touch each other while power is

applied to the ESC, thus voiding all warranties. If the motor operates in

the opposite direction desired, switch any two of the motor wires to

reverse the motor’ s rotation, or adjust the “re verse rotation”setting in the

BL-8’s programming (see page 3).

Proper adjustment of the transmitter’s controls is critical for proper

operation of the ESC.The transmitter’s throttle channel adjustments

should be set as follows:

A. Set the throttle travel adjustment (ATV, EPA or ATL) to maximum

(+/- 100% or the greatest value available).

B. Set the throttle trim and sub-trim to neutral, or zero.

C. For most radio types (including Futaba, Hitec and others) set the

throttle channel’s reversing option to “reverse.”

The BL-8’s normal start-up procedure is very simple, as follows:

A. Turn the transmitter’s power switch to “ON.”

B. Move the Tx throttle stick to MINIMUM position.

C. Connect the battery to the ESC.

D. You will hear one tone

“”if the brake is set to “ON,”or two tones

“”to indicate the brake is set to “OFF.”

E. If the brake setting is O.K.and no other programming adjustments

are needed, skip directly to Step 8 and get ready to fly. If you do

wish to change the brake setting or any other programmable

feature, disconnect the battery and go to Step 7 below.

The BL-8 has seven programmable features, and will automatically

step through each feature in order as shown below. It is not

necessary to wait for the ESC to step through all seven

programmable features unless you wish to change the setting of the

last feature. Each programmable feature has its own distinguishing

series of audible tones. Selecting/changing features is accomplished

by moving the Tx’s throttle stick in conjunction with certain tones that

are emitted by the ESC. Anytime a programmable feature has been

set the ESC will memorize the setting until it’s changed again

manually. Before entering the programming mode, remove the

propeller from the motor and make sure the battery is disconnected

from the ESC. It’s a good idea to read through all steps below

BEFORE attempting to program your ESC.

IMPORTANT!! It’s critical to remember that only ONE

programmable feature can be adjusted at a time. To change more

than one programmable feature, after changing the first feature you

must disconnect the battery from the ESC, reconnect the battery,

then re-start the programming mode below to change the next

programmable feature. It will be necessary to repeat this process for

each programming change that you wish to make.

A. Turn the transmitter’s power switch to “ON.”

B. Move the Tx’s throttle stick to FULL throttle.

C. Connect the battery to the ESC.After a 5 second delay two tones

will sound “ ” to indicate the programming mode has been

entered. The ESC will automatically begin scrolling through all of

the programmable features in this order: brake > battery type >

reverse rotation > soft start > low voltage indication > timing >

switching frequency > restore defaults > RPM control.Follow the

points below to change any of these features.

D. BRAKE: T o change the brak e setting, simply pull the throttle stic k

to minimum within five seconds of hearing the programming tones

noted in step C above. This will change the state of the brake

setting - if the brake was on this will turn it off, and vice-versa. You

can determine which setting is active by listening to the arming

tone. One tone indicates that the brake is enabled, and two tones

indicates that the brake is disabled. Skip to Step 8 if you do not

wish to make any other programming changes. To CHANGE

ANOTHER programmable feature disconnect the battery from the

ESC and return to Step B above.

E. BATTERY TYPE: The ESC will automatically sound three

different series of tones to indicate the three battery type settings

as shown below. If you do NOT wish to change the battery setting

wait after the “ ” tones sound and the ESC will

automatically skip to the reverse rotation feature below. To

CHANGE the battery type, move the throttle stick to minimum

when you hear the tones that match the setting you wish to have.

For example, to set for a “2-cell Li-Po” battery wait until the tones

for NiCd batteries have ended, then when 2 short tones sound

repeatedly “

” move the Tx throttle stick to

minimum position.The ESC will then sound a single tone

“”to

indicate the new setting was accepted, and the ESC is now armed

and ready for operation.Skip to Step 8 if you do not wish to make

any other programming changes. To CHANGE ANOTHER

programmable feature disconnect the battery from the ESC and

return to Step B above.

WARNING: Failure to set the proper

battery type will likely result in unwanted operation and/or

damage to your battery.

STEP 7 – PROGRAMMING MODE

STEP 6 – NORMAL START UP

STEP 5 – TRANSMITTER ADJUSTMENTS

STEP 4 – MOTOR CONNECTIONS

STEP 3 – BATTERY CONNECTION

Page 3

3

Battery type Series of tones

NiCd: (cuts at 50% of initial battery voltage)

2-cell Li-Po: (cuts at 5.6V)

3-cell Li-Po: (cuts at 8.4V, factory default)

F. REVERSE ROTATION: The ESC will sound a ser ies of tones

as shown below to indicate the direction of motor rotation can

be reversed. If you do NOT wish to change the direction of

rotation wait 5 seconds after these tones sound and skip to the

soft-start feature below. To CHANGE the direction of motor

rotation, move the throttle stick to minimum when you hear

these tones. The ESC will sound “ ” to indicate the new

setting was accepted, and the ESC is now armed and ready

for operation. Skip to Step 8 if you do not wish to make any

other programming changes. To CHANGE ANOTHER

programmable feature disconnect the battery from the ESC

and return to Step B above.

Note: It may be necessary to

reverse a motor’s rotation when using a gear drive.

Reverse Rotation:

G. SOFT-START: The ESC will sound two different series of

tones to indicate the two soft-start settings as shown below.If

you do NOT wish to change the soft-start setting wait 5

seconds after the “ ” tones sound and skip to the low

voltage indication feature below. To CHANGE the soft-start

setting, move the throttle stick to minimum when you hear the

tones which match the setting you wish to have. The ESC will

sound “ ” to indicate the new setting was accepted, and the

ESC is now armed and ready for operation. Skip to Step 8 if

you do not wish to make any other programming changes. To

CHANGE ANOTHER programmable feature disconnect the

battery from the ESC and return to Step B above.

Note: It’s

often recommended to enable the soft-start feature when

using the motor with a gear drive, to help prevent breakage of

the gears as the motor begins rotation (especially when a

large diameter prop is being used). Enabling the soft-start

feature is optional when not using a gear drive, but can be

used as a safety precaution.

Enable: (factory default)

Disable:

H. LOW VOLTAGE INDICATION: The ESC will sound three

different series of tones to indicate the three low voltage

indication settings as shown below. If you do NOT wish to

change the low voltage indicator setting wait 5 seconds after

the “ ” tones sound and skip to the timing feature below.

To CHANGE the low voltage indicator setting, move the

throttle stick to minimum when you hear the tones that match

the setting you wish to have. The ESC will sound “ ” to

indicate the new setting was accepted, and the ESC is now

armed and ready for operation. Skip to Step 8 if you do not

wish to make any other programming changes.To CHANGE

ANOTHER programmable feature disconnect the battery from

the ESC and return to Step B above.

This feature warns you that the battery’s voltage has dropped

to a dangerously low level. The ESC can be set to give a

warning by either reducing or totally cutting throttle.When the

throttle change is observed the airplane should be landed

quickly. This feature can also be set to “ignore” so that no

indication is given.When the low voltage indication is given the

ESC will still deliver power to the receiver and servos to

control the airplane, and regular throttle control can be

regained by cycling the throttle stick to full minimum and back

upward, but the airplane should be landed quickly before

all control is lost. The voltages at which the low voltage

indications will activate are as shown in the

“BA TTERY TYPE”

section above.

Ignore (no indication):

Reduce throttle power (factory default):

Cut motor power:

I. TIMING (rotor advancement timing): The ESC will sound

three different series of tones to indicate the three timing

advancement options as shown below. If you do NOT wish to

change the timing setting wait 5 seconds after the tones “ ”

sound and skip to the switching frequency setting below. To

CHANGE the timing setting, move the throttle stick to

minimum when you hear the tones that match the setting you

wish to have. The ESC will sound “ ” to indicate the new

setting was accepted, and the ESC is now armed and ready

for operation. Skip to Step 8 if you do not wish to make any

other programming changes. To CHANGE ANOTHER

programmable feature disconnect the battery from the ESC

and return to Step B above.

Selecting the proper timing will help to optimize the overall

efficiency of your power system. The “automatic” setting is

acceptable for all types of brushless motors.The “soft” setting

is for “multi-pole” or “inner-rotating” motors. The “hard” setting

is for outrunner type motors.

Automatic (7-30 degree advance,factory default):

Soft (7 degrees):

Hard (30 degrees):

:

J. SWITCHING FREQUENCY: The ESC will sound two different

series of tones to indicate the two switching frequency options as

shown below. If you do NOT wish to change the switching

frequency wait 5 seconds after the tones “ ” sound and skip

ahead to the restore factory default setting below. To CHANGE

the switching frequency, move the throttle stick to minimum when

you hear the tones that match the setting you wish to have. The

ESC will sound “ ” to indicate the new setting was accepted,

and the ESC is now armed and ready for operation.Skip to Step

8 if you do not wish to make any other programming changes.To

CHANGE ANOTHER programmable feature disconnect the

battery from the ESC and return to Step B above.

Note: The

8kHz frequency is good for all types of 2-pole and outrunner type

motors, and the 16kHz setting is good for “multi-pole” or “innerrotating” motors.

8kHz (factory default):

16kHz:

K. RESTORE FACTORY DEFAULT SETTINGS: The ESC will

sound a series of tones to indicate the function for restoring all

ESC settings back to the factory defaults.If you do NOT wish

to restore all settings back to factory defaults wait 5 seconds

after these tones stop and skip ahead to the active RPM

control setting below. To CHANGE all settings back to the

factory defaults, move the throttle stick to minimum when you

hear these tones. The ESC will sound a single tone “ ” to

indicate the new setting was accepted, and the ESC is now

Page 4

armed and ready for operation. Skip to Step 8 if you do not

wish to make any other programming changes.To CHANGE

ANOTHER programmable feature disconnect the battery from

the ESC and return to Step B above.

L. ACTIVE RPM CONTROL: The ESC will sound four different

series of tones to indicate the four RPM control options as

shown below. To CHANGE the RPM control setting, move the

throttle stick to minimum when you hear the tones that match

the setting you wish to have .The ESC will sound a single tone

“ ” to indicate the new setting was accepted. The ESC will

now be armed and ready for operation, and skip to Step 8. If

you do NOT wish to change the RPM setting do not move the

throttle stick, and after the last tones sound the ESC will sound

“ ” to indicate the programming mode has finished, the ESC

is now armed, and go to Step 8.

The active RPM control function is designed for use with small

electric helicopters. Selecting the proper RPM maximum

control value will help to prevent the ESC from overpowering

the model during flight. Refer to your helicopter’s instruction

manual for a recommended maximum RPM value. Leave this

setting “OFF” for model airplanes.

RPM control off (factory default):

first range (20,000 RPM max.):

second range (50,000 RPM max.):

third range (100,000 RPM max.):

Once all connections have been made and all programming has

been set it’s a good idea to perfor m a range test with your radio

before attempting a flight to ensure that a good Rf link exists

between the transmitter and the airplane. With the Tx antenna

collapsed and a helper holding the airplane, apply full throttle and

operate the other flight controls while walking away from the

airplane. Full control should be maintained at a range of up to

approximately 75 to 100 feet a wa y from the airplane.If the system

fails this range test it may be necessary to re-route the location of

the Rx and/or its antenna away from linkages or electronic

components in the airplane. Refer to the radio’s instruction

manual for further details.

ESC DOES NOT WORK

Problem: Motor and/or Rx or servos do not function.

1. Batter ies are dead. Recharge batteries.

2. Check for incorrect or faulty battery connections.

3. Check for a damaged connection between ESC and Rx.

4. Check for faulty motor connections.

5. Internal damage. Unit may require service. See

“Service

Procedures.”

6. Make sure the ON/OFF switch is set to “ON.”

Problem: Motor rotates in the wrong direction.

1. Motor wires attached incorrectly. See

“Step 4 – Motor

Connection.”

2. “Reverse rotation” setting in ESC must be changed. See

“Step 5 – Speed Control Setup.”

ESC WORKS BUT OTHER PROBLEMS EXIST

Problem: Rx glitches or stutters dur ing acceleration.

1. Rx mounted too close to ESC causing interference. Relocate

Rx away from ESC.

2. Check for faulty power connections.

Problem: Rx and servos function, but programming tones do not

function properly (does not emit setup tones).

1. ESC may need to be reset.Remove and re-apply power to the ESC.

2. Check the Tx throttle channel to see if it needs to be reversed.

3. Check ATV, EPA or ATL must be set to maximum or +/- 100%.

Problem: Model runs slowly or has no acceleration.

1. The ESC is not set up properly. Repeat

“Step 5 – Speed

Control Setup.”

2. Check for faulty battery and/or motor connections.

3. Tx is improperly adjusted. Repeat

“Step 4 – Transmitter

Adjustments.”

Problem: Rx and servos function, but motor does not rotate.

1. Tx is improperly adjusted. Repeat

“Step 4 – Transmitter

Adjustments.”

2. Check for faulty motor connections.

3. Motor is bad or hung up. Clean or replace motor.

Problem: Motor seems to function very inefficiently, has difficulty

in starting to rotate, or hesitates when trying to rotate.

1. The timing feature is set improperly for the selected motor.See

“Step 5 – Speed Control Setup.”

2. Check for faulty motor connection.

3. Problem with motor.Tr y a different motor.

Problem: Low voltage cutoff indicator activates at improper voltage.

1. Low voltage cutoff feature set improperly. See

“Step 5 –

Speed Control Setup.”

2. Bad cell or battery pack. Replace batter y.

ESCs that operate normally when received will be charged a

minimum service fee and return shipping charges.Before sending

your ESC in for service, it is important that you review the

“T roubleshooting Guide”

in this instruction sheet.The ESC may

appear to have failed when other problems exist in the system,

such as a defective Tx, Rx or servo, or incorrect

adjustments/installation.

• Hobby dealers are not authorized to replace ESCs thought to

be defective.

• Do not cut the input harness, switch harness, or power wires

of the ESC before sending it for service.A fee will be charged

for cut wires which must be replaced for testing.

Great Planes®warrants this product to be free from defects in materials and

workmanship for a period of 180 days from the date of purchase. During that

period, Great Planes will, at its option, repair or replace without service charge

any product deemed defective due to those causes. You will be required to

provide proof of purchase (invoice or receipt). This warranty does not cover

damage caused by abuse, misuse, alteration or accident. If there is damage

stemming from these causes within the stated warranty period, Great Planes

will, at its option, repair or replace it for a service charge not greater than 50%

of its then current retail list price. Be sure to include your daytime telephone

number in case we need to contact you about your repair. This warranty gives

you specific rights.You ma y also hav e other rights, which vary from state to state.

For service on your Great Planes product, warranty or non-warranty, send it

post-paid and insured to:

HOBBY SERVICES

3002 N. Apollo Drive, Suite 1

Champaign, IL 61822

(217) 398-0007

e-mail:

hobbyservices@hobbico.com

*For warranty and service information if purchased outside the USA or Canada,

see the additional warranty information insert (if applicable) or ask your retailer

for more information.

www.greatplanes.com

www.electrifly.com

180 DAY LIMITED WARRANTY – *U.S.A.AND CANADA ONLY

SERVICE PROCEDURES

TROUBLESHOOTING GUIDE

STEP 8 – RANGE TEST

GPMZ0307 for GPMM2070Made in China Entire Contents © Copyright 2005

Loading...

Loading...