Great Planes GPMM2055 User Manual

™

C-25, C-35 and C-55 High-Power High-Frequency

Electronic Speed Controls w/BEC

INTRODUCING THE ELECTRIFLY LINE OF

HIGH-POWER BRUSHED ESC’s

The ElectriFly™ line of High-Power ESC’s feature the

“Safe Start” system to prevent accidental motor starts by

disabling the motor circuitry until the throttle stick is

moved to full throttle, then to the “off” position.

Other features include BEC (Battery Elimination Circuitry)

which allows the motor battery to power the receiver and

servos. When the motor battery voltage is reduced to a

set voltage per cell, the low-voltage cut-off circuitry stops

the motor while continuing to supply power to the

receiver and servos. This eliminates the need for and

weight of a separate receiver battery. The ElectriFly line

of ESC’s comes with thermal protection that reduces the

throttle to 70% when the maximum temperature is

reached. These ESC’s can easily be adjusted for use

with NiCd/NiMH or Li-Po batteries. These ESC’s function

with brushed motors only!

SPECIFICATIONS

C-25

Dimensions: 0.98" x 0.43" x 0.71"

[25 x 11 x 18mm]

Weight: 0.85oz. [24g]

Input Voltage: 6-10 cells NiCd/NiMH

2-3 cells Li-Po

Continuous Current: 25 amps

Max Rated Current: 35 amps

BEC Voltage: 5V / 1.5A

Low-Voltage Cutoff: 0.8 volts per cell NiCd/NiMH

2.75 volts per cell Li-Po

Battery Plug: Star

®

Plug

Switching Frequency: 1.3 kHz

C-35

Dimensions: 1.30" x 0.43" x 0.71"

[33 x 11 x 18mm]

Weight: 1.08oz. [31g]

Input Voltage: 6-12 cells NiCd/NiMH

2-4 cells Li-Po

Continuous Current: 35 amps

Max Rated Current: 45 amps

BEC Voltage: 5V / 1.5A

Low-Voltage Cutoff: 0.8 volts per cell NiCd/NiMH

2.75 volts per cell Li-Po

Battery Plug: Star

®

Plug

Switching Frequency: 1.3 kHz

C-55

Dimensions: 1.42" x 0.43" x 0.71"

[33 x 11 x 18mm]

Weight: 1.22oz. [35g]

Input Voltage: 6-12 cells NiCd/NiMH

2-4 cells Li-Po

Continuous Current: 50 amps

Max Rated Current: 65 amps

BEC Voltage: 5V / 1.5A

Low-Voltage Cutoff: 0.8 volts per cell NiCd/NiMH

2.75 volts per cell Li-Po

Battery Plug: Star

®

Plug

Switching Frequency: 1.3 kHz

IMPORTANT PRECAUTIONS

Read and follow these instructions carefully before

using.

• Do not operate the airplane on or near water. Never

allow water, moisture or any foreign material onto the

ESC’s PC board.

• Never use more cells then specified for the main

battery pack.

• The ceramic capacitors must be properly installed on

the motor to prevent radio interference.

• Always disconnect the motor battery from the ESC

when not in use.

• Always switch on the transmitter before switching on

the ESC.

• Use heat-shrink tubing to insulate any bare wires from

the motor battery to the ESC and from the ESC to the

motor to prevent a short circuit.

• Allow the ESC to cool before touching.

STEP 1 THE RECEIVER PLUG

The receiver plug attached to the

TRIM OFF

speed control plugs directly into a

Futaba

®

“J” receiver. However, if you

are using an Airtronics “Z,” Hitec “S” or

JR receiver, you will need to slightly

modify the receiver plug on the ESC. To modify the plug,

use a hobby knife or wire cutter to carefully cut off the

alignment tab on the side of the receiver plug as shown.

The white “signal wire” on the ESC receiver plug should be

in the same position in the receiver slot as the white wire

on Futaba, the blue wire on the new Airtronics “Z”

connector, the yellow wire on the Hitec “S” connector or the

orange wire on the JR connector. WARNING: This

connector is NOT directly compatible with the old Airtronics

connector style. Use an Airtronics Servo Adapter to

connect this ESC to the older style Airtronics radios.

NEVER ALLOW THE BARE RED (+) AND BLACK (-)

WIRES TO TOUCH ON ANY RECEIVER OR ESC, AS

PERMANENT DAMAGE WILL RESULT TO BOTH

ITEMS AND VOID ALL WARRANTIES.

STEP 2 MOUNTING THE SPEED CONTROL

Determine the best location for the ESC inside the

fuselage. The ESC should be in a position which allows

good airflow for proper cooling, and close enough so the

wires reach the motor. It is highly recommended to put

cooling air intake holes in the front of the fuselage and

exit holes towards the aft end.

IMPORTANT: When using the ESC’s with the maximum

number of cells and at the maximum current draw, the

ESC must have good air flow over it to keep it cool.

The best method to mount the ESC in the fuselage is

with Velcro

saturate the wood with thin CA and

1/4" x 1"

®

. If the ESC will be mounted on wood, first

allow to dry. Cut a

piece of Velcro (both hook and loop)

. Attach the

hook (hard) material to the inside of the fuselage. Clean

the side of the ESC with rubbing alcohol and attach the

loop (soft) material. The ESC on/off button should be

positioned in the battery compartment. Do not apply

Velcro to the top or bottom of the ESC’s. These are the

locations of the heat sinks and must not be covered.

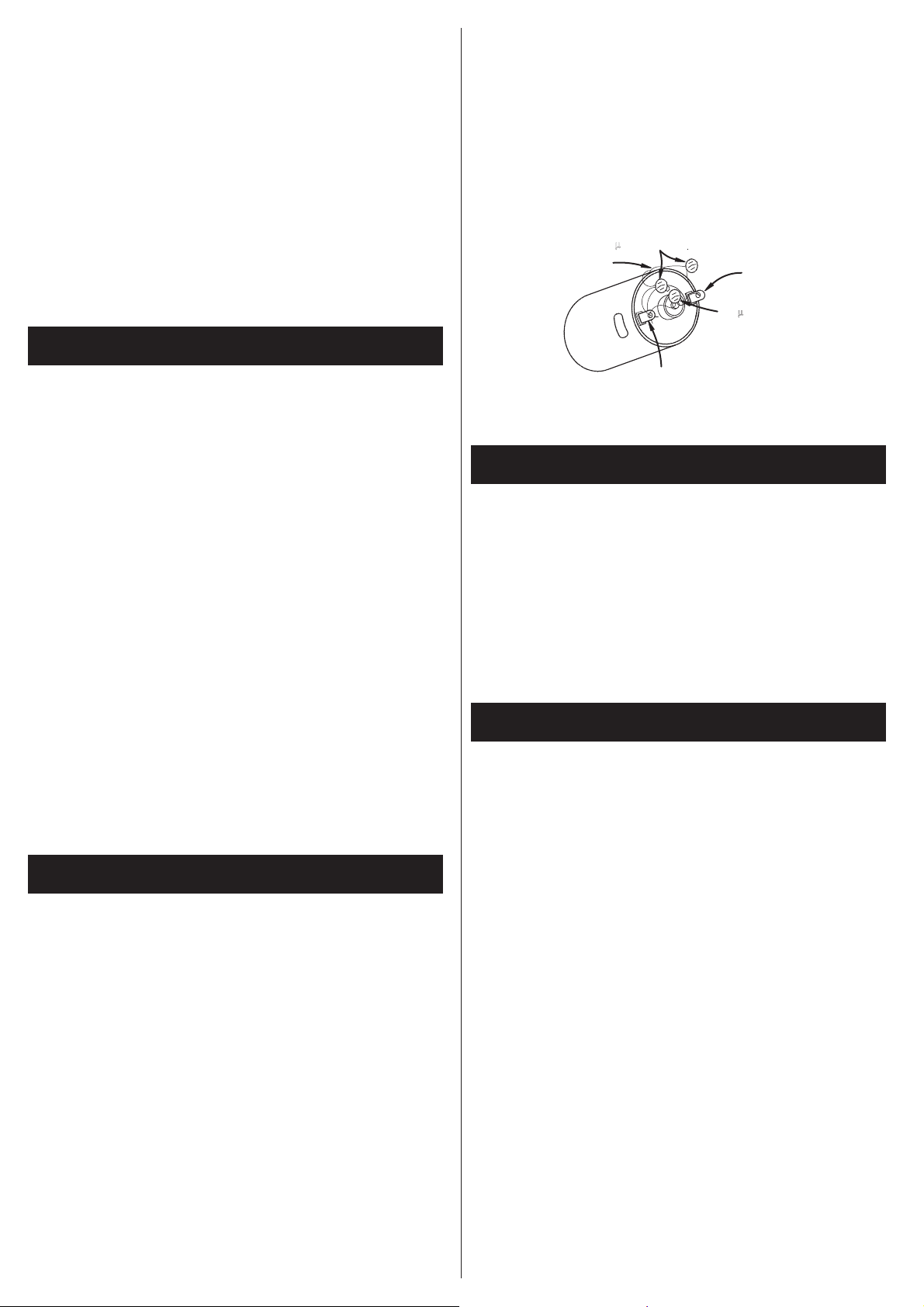

• Solder the remaining leads from both capacitors to the

side of the motor

case.

• Cut two pieces of heat-shrink tubing long enough to

cover both leads on the .047µF capacitor, leaving

approximately 1/4" of the lead exposed at the bottom.

• Solder one of the leads to the positive brush terminal

and the other lead to the negative brush terminal.

• Solder the positive (+) lead from the ESC to the

positive brush terminal on the motor and the negative

(-) lead to the negative brush terminal on the motor.

.10μF CAPACITOR (104)

SOLDER TO SIDE

OF MOTOR

NEGATIVE (–)

BRUSH TERMINAL

POSITIVE (+)

BRUSH TERMINAL

F CAPACITOR (473)

.047μ

STEP 4 TRANSMITTER ADJUSTMENTS

Adjusting the transmitter is critical for proper ESC

operation. The transmitter throttle adjustments should be

set as follows:

1. Set the travel adjustment, ATV, EPA or ATL to 100%.

2. Set the throttle trim and sub trim to neutral or zero.

3. Set the throttle reversing switch to reverse on Futaba

transmitters and to normal on most other transmitters.

STEP 5 SPEED CONTROL SETUP

Before you begin this setup, remove the propeller from

the motor. Then plug the ESC into the throttle channel on

the receiver and adjust the transmitter.

STEP 3 INSTALL THE MOTOR CAPACITORS

Motors generate radio noise which can interfere with

your receiver and cause problems. Your ESC includes

two .10µF (104) and one .047µF (473) non-polarized,

ceramic capacitors. These capacitors must be used at all

times, and on every motor to help reduce the radio noise

generated by the motor and prevent possible damage to

the ESC.

• Cut a piece of heat-shrink tubing long enough to cover

one of the leads on both of the .10µF capacitors,

leaving approximately 1/4" of the lead exposed at

the bottom.

• Solder the 1/4" of exposed lead from one of the

capacitors to the positive brush terminal on the motor

end cap.

• Solder the 1/4" of exposed lead from the second

capacitor to the negative brush terminal on the motor

end cap.

BATTERY SETUP MODE

1. Switch on the transmitter. With the ESC off, press and

hold the on/off button for 4-5 seconds until the red

LED goes off. Then, release the button.

2. Pressing the button again will cause the blue light to

stay on or start flashing. To change settings, press the

button until the correct setting is obtained.

NiCd/NiMH: The blue light will be on.

2-cell Li-Po: The blue light will blink 2 times.

3-cell Li-Po: The blue light will blink 3 times.

4-cell Li-Po: The blue light will blink 4 times.

3. Once the battery type is set, press and hold the button

for 2-3 seconds until the red light comes on.

BRAKE SETUP

1. The factory brake default setting is “brake on.” To turn

the brake off, switch the transmitter on and set the

throttle stick to the brake position. Press the on/off

button on the ESC. The red and blue light should be on

or flashing for Li-Po and the motor should beep

3 times.

2

Loading...

Loading...