Page 1

Variable Pitch Prop Specifications:

Mechanical Design:

Push-Pull System

Blades (2):

Symmetrical Design, Fiber-Reinforced Nylon

Rotor Materials:

ABS Plastic and Aluminum

Control Rod Material:

Steel

Control Rod Dimensions:

0.04 x 6.02 in. (1 x 153mm)

Ball Bearings (5):

Shielded

Motor Specifications:

Input V oltage:

7.2 – 12V

kV Rating:

1000 rpm/volt

Max. Constant Current:

11A

Max. Surge Current:

15A

No Load Current:

0.65A

Internal Resistance:

235 milli-ohms

Ball Bearings (2):

Shielded

Motor Diameter/Length:

1.10 x 1.14 in. (28 x 29mm)

Shaft Diameter/Length:

0.16 x 1.73 in. (4 x 44mm)

Total Weight (VPP and Motor):

2.1 oz. (59.5 g)

The following hard ware is included in the V-Pitch System:

M3 x 16 bolts, hex (2, factory installed)

M3 nuts (2, factory installed)

M3 x 8 bolts, hex (2, factory installed)

M3 set screws (5, factory installed)

M3 x 5 round head bolts (3)

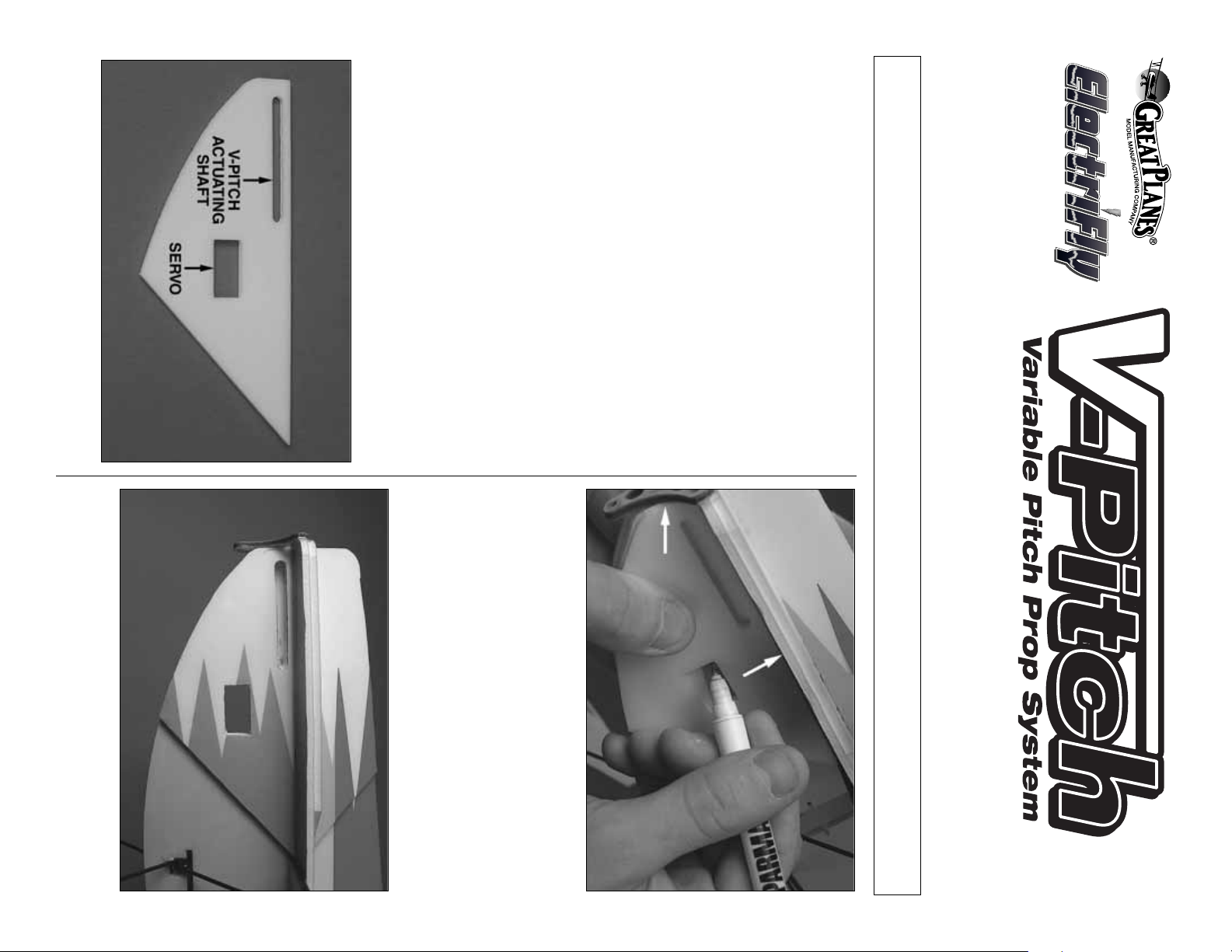

❏ 1.Locate the template f or marking the servo location and

the exit slot for the V-Pitch actuating shaft.

❏ 2. Place the template directly over the bottom fuselage

doubler that is required for the Firewall-Mounted installation.

Trace the template with a fine marker or pen accordingly.Only

trace the template on one side of the plane.

❏ 3. With a sharp hobby knife, cut the servo slot completely

through both sides of the fuselage as shown. Cut the slot for

the servo actuating shaft only on the side you traced as shown.

™

™

These installation instructions for the V-Pitch Variable Pitch Prop System are designed

specifically for use with all Great Planes FlatOut

™

models. Please follow the “Firewall-Mounted

Motor System” instructions in your FlatOut manual before proceeding any further.

Additional items you will need to upgrade your FlatOut with the V-Pitch system are: One 17 oz/in micro servo, a

brushless ESC with governor (ElectriFly’s BL-12, GPMM2075) and a 5-channel micro receiver.

Page 2

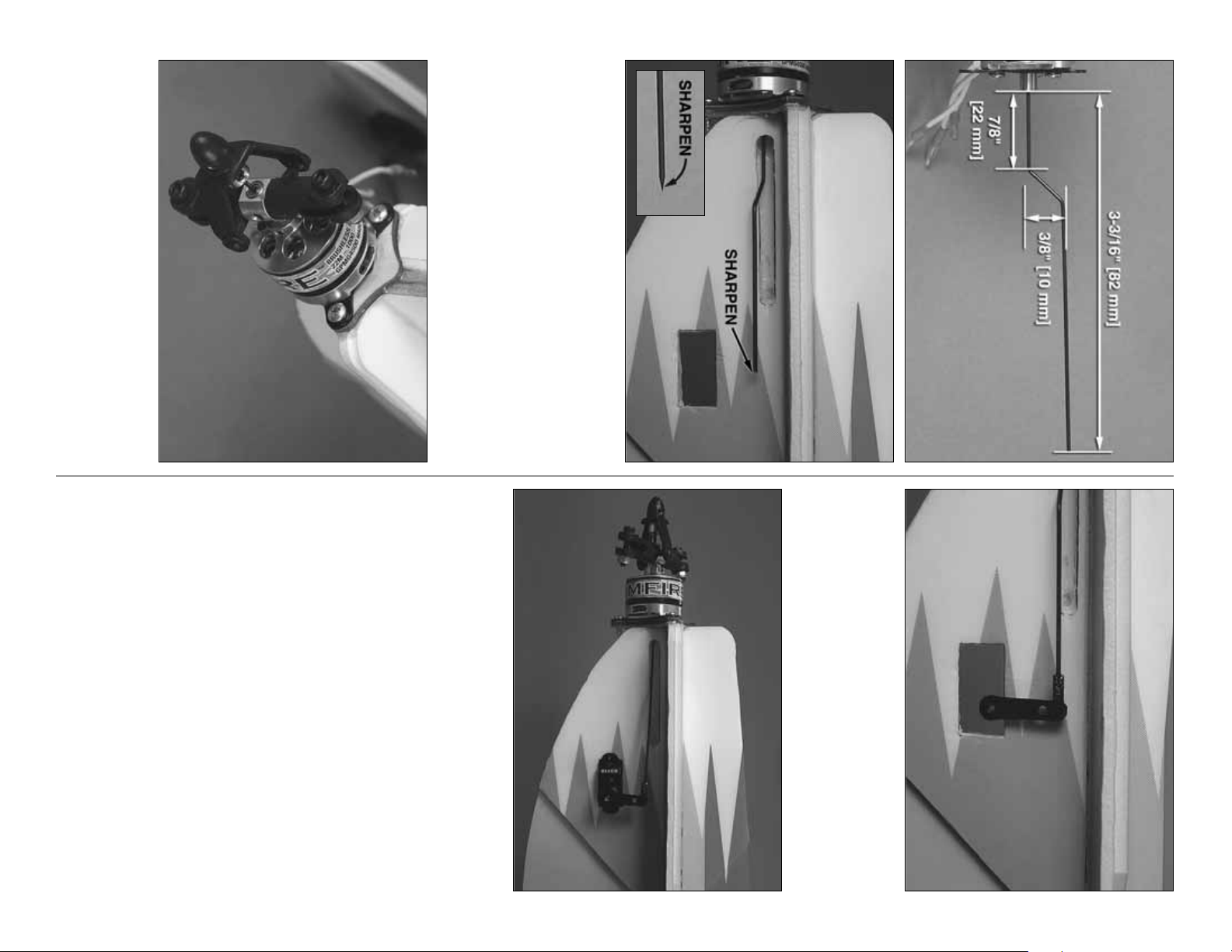

❏ 5. Install the V-Pitch and Rimfire motor onto the plywood

firewall using (3) #4 x 3/8" wood screws (not included).Make

sure the wire exits the slot correctly before tightening the

screws. Apply a drop of foam safe CA to the screws to

ensure they will not back out.

take a sanding bar or a piece of sandpaper and sharpen the

end of the shaft before you install the motor.

❏ 4.Cut the shaft to length as shown above , but be sure that

the blade holders are completely neutral (not pitching forw ard

or backward) when doing this step. Also, bend a slight angle

in the shaft to allow for it to exit the fuselage as shown.Next,

GPMG4490 ......Replacement Blades (2)

GPMG4491 ......Optional Carbon Fiber Blades (2)

GPMG4492 ......Replacement Shaft w/2 Ball Bearings

GPMG4493 ......Spinner/Collar

GPMG4494 ......Screw and Nut Set

GPMG4495 ......Blade Holder w/Ball Bearings

GPMG4496 ......Blade Holder Hub

V-PITCH REPLACEMENT PARTS:

For models other than the Great Planes FlatOuts,

similar mounting methods might apply to your model.

Refer to your model manufacturer for details.

The installation is now complete. Please precede with

the radio set-up instructions on the next page before

you attempt to fly the V-Pitch unit.

❏ 7. Install your servo into the slot as shown with a few

drops of foam safe CA.

❏ 6. Locate one servo arm and a z-bend from your FlatOut

parts tree. Clip the z-bend through the servo arm. Next,

press the shaft into the z-bend as shown. After you have

firmly pressed the shaft into the z-bend, apply a drop of

foam safe CA to keep the shaft from slipping out.

Page 3

Radio Set-Up for V-Pitch

1.When setting up your V-Pitch unit in your radio, be sure to

select the radio’s helicopter prog ram.This will allow y ou to

use pitch and throttle curves.

2. All of your channels will be as follows when using a

Futaba radio:

3. Be sure to set an “idle-up”and a “normal” flight mode in the

radio that can be changed with a switch that you prefer.

This will allow you to disable the V-Pitch with a switch.

“Normal” Mode: Acts just like any other conventional

fixed pitch aircraft.

“Idle-Up” Mode: Allows you to reverse the thrust of the

propeller. When you have your throttle stick in the center

position (0% throttle) you will not have any pitch. As you

push the stick forward (100% throttle) y ou get positiv e pitch

which allows the airplane to move forward. When you pull

the throttle stick back (–100% throttle) it applies negative

pitch to the blades and allows the plane to go in reverse.

4. Before you go any further, unplug all 3 motor wires from

the ESC so you can adjust the ATV (end point) on the

pitch channel in the radio.Set the pitch ATV to maximum

travel for positive and negative pitch.

5. Please see the illustrations for setting up your r adio’ s pitch

and throttle curves when using your V-Pitch with and

without governor mode. Keep in mind that these are just

starting points. You will need to fine tune each point per

your airplane and flying preferences.

• Channel 1: Aileron

• Channel 2: Elevator

• Channel 3:ESC/Throttle

• Channel 4: Rudder

• Channel 5: Pitch

0%

10%

20%

30%

40%

50%

60%

70%

80%

90%

100%

Low Throttle Stick

0%

10%

20%

Negative Pitch

Zero Pitch

30%

40%

50%

60%

70%

Zero Pitch

80%

Throttle (Idle Up) Pitch (Idle Up)

Full Throttle Stick

90%

100%

Low Throttle Stick

Negative Pitch

Zero Pitch

Throttle (Normal) Pitch (Normal)

With Governor Mode Set in the ESC:

Full Throttle Stick

0%

10%

20%

30%

40%

50%

60%

70%

80%

90%

Positive Pitch

100%

0%

10%

20%

30%

40%

50%

60%

70%

80%

90%

Positive Pitch

100%

Page 4

For replacement items or support on this or any other ElectriFly item, please contact:

Low Throttle Stick

Throttle (Idle Up) Pitch (Idle Up)

Low Throttle Stick

Throttle (Normal) Pitch (Normal)

Without Governor Mode Set in the ESC:

www.hobbyservices.com

217-398-0007

Printed in China

productsupport@greatplanes.com

217-398-8970

0%

10%

20%

30%

Low Throttle Stick

Zero Pitch

Full Throttle Stick

40%

50%

60%

70%

80%

90%

100%

0%

10%

20%

30%

40%

50%

60%

70%

80%

90%

Full Throttle Stick

100%

Negative Pitch

Zero Pitch

Full Throttle Stick

Positive Pitch

GPMZ0326 for GPMG4501Entire Contents © Copyright 2006

0%

10%

20%

30%

40%

50%

60%

70%

80%

90%

100%

0%

20%

30%

40%

50%

60%

70%

80%

90%

10%

100%

Loading...

Loading...