Page 1

ElectriFly’s™RimFire™22M-1000 brushless motors are designed and produced with high quality , po wer, precision and efficiency

in mind. Designed to be power upgrades for smaller 3D aerobats and flat-foamies, the “outrunner” design eliminates the need

for an external gear drive for many applications. And, RimFire’s prop-saver design eliminates the need for a prop adapter for

many applications – simply strap the prop onto the motor with a rubber O-ring and that’s it!

INSTRUCTIONS

Input Voltage: 7.2 – 12V DC

kV Rating: 1000 RPM/volt

Max. Constant Current: 11A

Max. Surge Current: 15A

No Load Current: 0.65A

Internal Resistance: 235 milli-ohms

Dimensions: 1.10 x 1.14 in. [28 x 29mm]

Weight: 1.48 oz. [42g]

Recommended Props: 10x3.8, 10x4.7, 11x3.8 for 2-cell Li-P o,

8x3.8, 8x6, 9x3.8 for 3-cell Li-Po

• Great for small high performance airplanes, from flat foams to

built-up 3D’s.

• RimFire’s prop mounting system eliminates the need f or a prop

adapter for many applications.

• Outrunner design often eliminates the need for using external

gear drives for many applications.

• Very reliable and virtually maintenance free. No brushes to

wear out.Dual ball-bearings are shielded on both sides to keep

out dirt and debris.

• Exceptionally high power to weight ratio.

• Very durable machined aluminum and iron can.

• Maximum rated efficiency of 77%.

• Extremely strong neodymium “rare earth”magnets for high output

torque, with one of the highest temperature ratings in R/C at

150°C [302°F] which won’t breakdown like lower quality magnets .

• Magnet wires with a maximum 160°C [320°F] temperature rating.

• Gold plated 2mm bullet connectors pre-installed (3 per motor).

• Each motor includes:

• 3 x 5mm, standard thread, round head mounting bolts –

3 each.

• 2.6 x 10mm, standard thread, flat head hex key bolts –

2 each.

• Small #10 rubber O-rings – 6 each.

• Stainless steel output shaft diameter and length: 3 x 12mm.

• Do NOT apply an input voltage that exceeds the maximum

voltage listed in the specifications above.

• Do NOT apply currents to the motor that exceed the maximum

specifications above.

• Do NOT allow the input connectors to accidentally touch each

other while power is applied to the motor. Make sure all input

connections are insulated electrically.

• Do NOT allow water or moisture to enter the motor, as it can

cause permanent damage to the motor and possibly short out

the attached ESC.

• Allow the motor to adequately cool if it becomes hot

during operation.

• The output shaft will rotate at very high RPMs.Do NOT attempt

to touch the shaft while it is rotating. If setting up the

motor/ESC on the workbench, make sure the motor is securely

attached and that nothing is connected to the output shaft

BEFORE applying power.

• Never attempt to use a damaged motor (having mechanical or

electrical defects).

RimFire brushless motors must be controlled with a brushless

electronic speed control. And, RimFire motors are sensorless so

the ESC must be of sensorless design as well. Do NOT attempt

to use RimFire motors with ESCs that are designed for traditional

brushed motors as permanent damage will result!

The BL-8 Brushless ESC from ElectriFly (GPMM2070) is a

perfect match for the RimFire 22M-1000 brushless motor for

small 3D flat-foam airplanes. ESCs with more power may be

better suited when using the RimFire motor in slightly larger

airplanes which require more current/torque. Check your local

hobby retailer for details on different ESC options.

There are two options for mounting the RimFire motor to your

airplane, either in-front or behind the firewall.

The entire motor can be mounted in front of the firewall. This is

the most common method for mounting a motor to a

flat-foam airplane (refer to the airplane’s instruction manual for

details).To mount the motor to the front of the firewall:

❏ 1. Secure the mounting plate to the motor with the three

included 3 x 5mm machine screws.

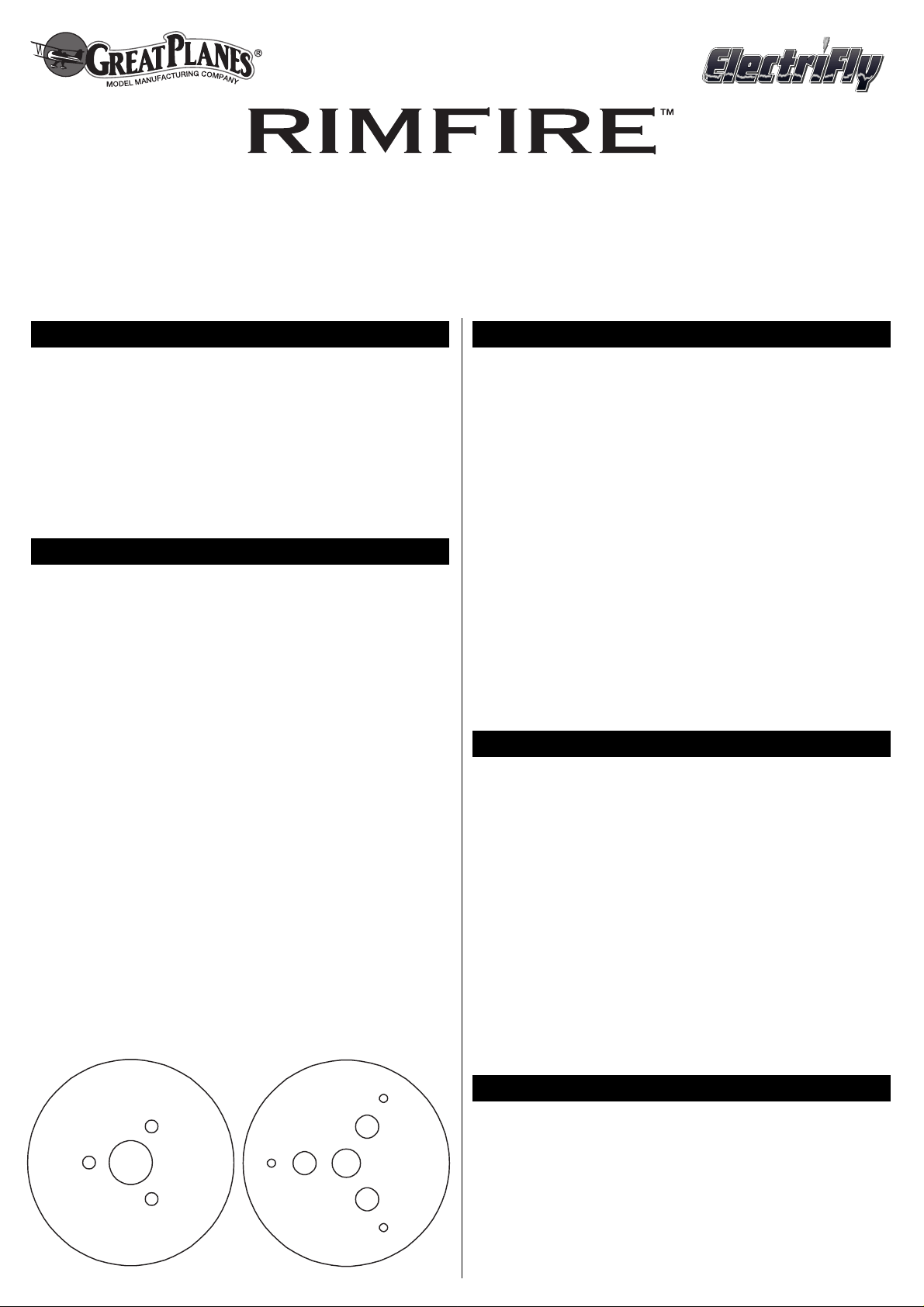

❏2. Use the printed template shown at left to mark the locations

of the mounting holes in the firewall.

MOUNTING THE MOTOR IN FRONT OF THE FIREWALL

COMPATIBLE ESCs

IMPORTANT PRECAUTIONS

SPECIAL FEATURES

SPECIFICATIONS

™

22M-1000 Brushless Motor

MOTOR BEHIND THE

FIREWALL TEMPLATE

MOTOR IN FRONT OF

FIREWALL TEMPLATE

Page 2

❏ 3. Drill four 5.5mm

holes to clear the three

machine screws and

motor shaft through the

firewall, and drill three

pilot holes for mounting

the motor to the firewall

with wood screws as

shown here.

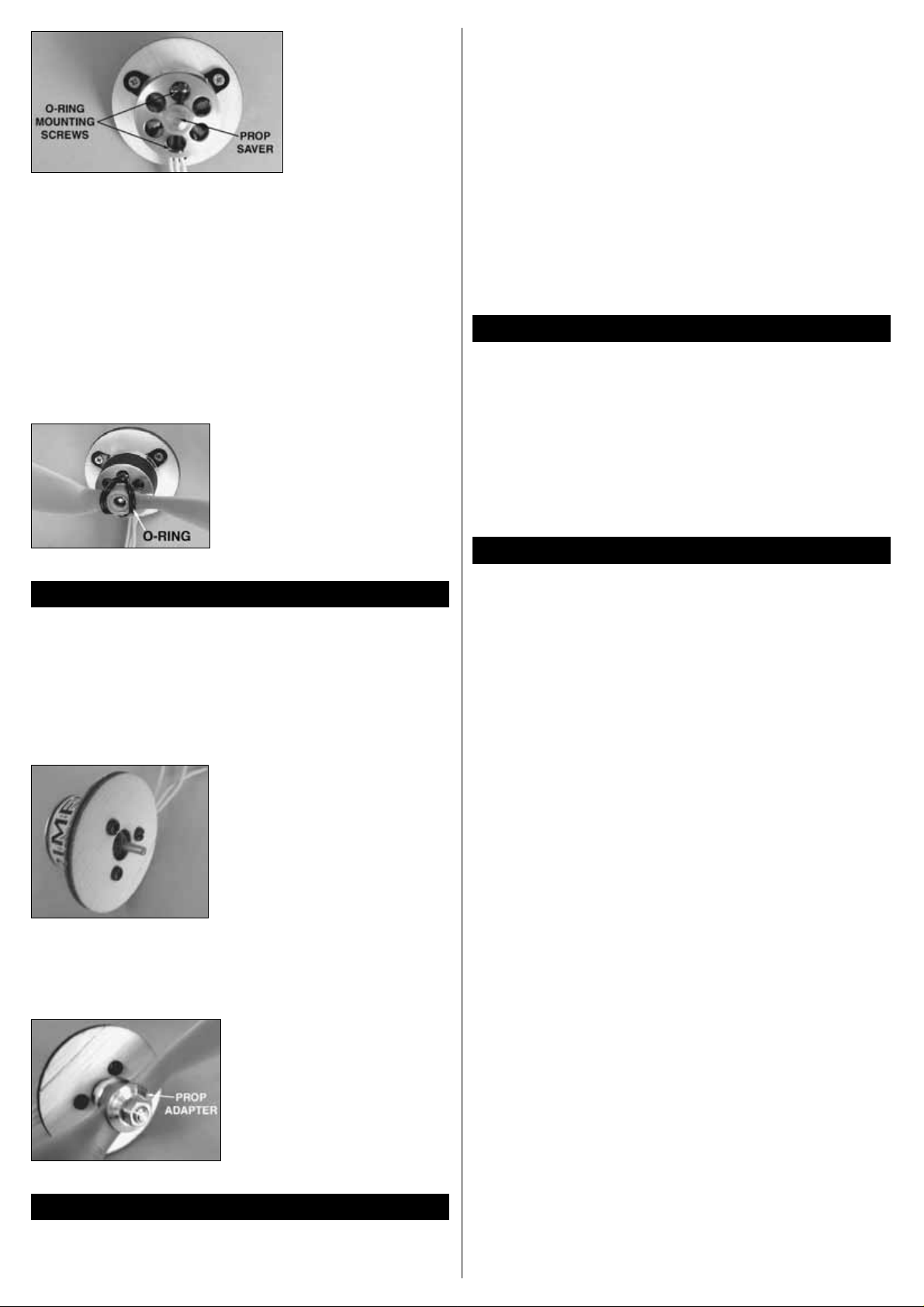

❏ 4. The prop will be installed on the motor’s built-in prop-saver

on the rotating section of the can. It will not be necessary to use

the included prop-adapter for this application. Install the two

included 2.6 x 10mm machine screws into the two holes on the

side of the motor’s built-in prop-saver. Make sure the screws are

tight, but do not overtighten the screws as they could strip the

threads inside the prop-saver!

❏ 5. The prop-saver is designed for use with APC Slo-Flyer

props. Press the larger of the two adapter rings included with the

propeller into the ACP Slo-Flyer prop hub and press the prop onto

the prop-saver.

❏6.Use one of the included rubber

O-rings to secure the propeller to

the screws on the prop saver. For

high-power applications, use two

O-rings for a stronger mount.

The motor can be installed behind a firewall.To do so:

❏1. Use the printed template shown on the rev erse page to mark

the mounting holes on the firewall.

❏ 2. Following the template, drill three 3mm holes (for the

mounting screws) and one 10mm hole (for the output shaft)

through the firewall.

❏3.Secure the motor to the firewall

using the three included 3 x 5mm

machine screws. If the firewall is

very thick it may be necessary to

use longer screws (not provided).

Here, the long end of the motor’s

shaft will protrude forward through

the firewall.

❏ 4. The included prop adapter will need to be installed onto the

motor’s long shaft as it protrudes through the firewall.There is no

need to install the 2.6 x 10mm machine screws into the two holes

on the side of the motor’s built-in prop-saver for these installations.

❏ 5. Remove the prop nut and

prop washer from the prop

adapter and slip the prop adapter

onto the shaft. Install the propeller

on the prop adapter.Re-install the

prop washer and prop nut.Tighten

the prop nut. This will cause the

collet to tighten down and grip the

motor’s shaft.

IMPORTANT! Always make sure the motor is mounted firmly to

the aircraft to prevent it from accidentally coming loose when

power is applied to the system!

When all motor/ESC connections are complete, make sure the

motor connections are not touching each other while power is

applied, as permanent damage to the motor/ESC could result.

Make sure all input connections are insulated electrically.

Installing heat-shrink tubing over each connection is

recommended. Do not attempt to cut or remove any of the input

wires from the motor as it will likely damage the motor beyond

feasible repair.

RimFire motors have three input connectors, each with 2mm

male bullet connectors pre-installed. Connect all three of the

motor’s input wires to the output wires on the ESC. It is not

necessary to match up the colors of the wires on the ESC to the

wires on the motor.If the motor operates in the opposite direction

as required, switch any two of the wires from the ESC to the

motor to reverse the motor’s rotation.

RimFire brushless motors require virtually no maintenance.There

aren’t any brushes to wear out and replace. The ball-bearings

have a very long service life and should maintain good operating

condition for a very long period of time. Blowing pressurized air

into the motor can help to remove dirt and debris, and improve

overall efficiency. The output wires should not require

replacement. If used with a gear drive, the gear drive itself might

require addition of lubricating grease after a certain period of

time. See the instructions which came with your gear drive for

detailed information.

Great Planes®warrants this product to be free from defects in materials

and workmanship for a period of one (1) year from the date of purchase.

During that period, Great Planes will, at its option, repair or replace

without service charge any product deemed defective due to those

causes. You will be required to provide proof of purchase (invoice or

receipt).This warranty does not cover damage caused by abuse, misuse,

alteration or accident. If there is damage stemming from these causes

within the stated warranty period, Great Planes will, at its option, repair

or replace it for a service charge not greater than 50% of its then current

retail list price.Be sure to include your daytime telephone number in case

we need to contact you about your repair .This warranty gives you specific

rights.You may also have other rights, which vary from state to state.

For service on your Great Planes product, warranty or non-warranty,

send it post-paid and insured to:

HOBBY SERVICES

3002 N. Apollo Drive, Suite 1

Champaign, IL 61822

(217) 398-0007

E-mail:

hobbyservices@hobbico.com

*For warranty and service information if purchased outside the USA or

Canada, see the additional warranty information insert (if applicable) or

ask your retailer for more information.

www.greatplanes.com

www.electrifly.com

1-YEAR LIMITED WARRANTY – *U.S.A.AND CANADA ONLY

MAINTENANCE

MOTOR CONNECTIONS

MOUNTING THE MOTOR BEHIND THE FIREW ALL

GPMZ0306 for GPMG4500Made in China Entire Contents © Copyright 2005

Loading...

Loading...