Page 1

200 POWER

SYSTEM

Thank you for purchasing the RimFire 200 brushless outrunner

motor! You’ll be pleased with the performance of this micro

motor. We’ve carefully designed this motor to give you the

best performance while using the most popular propellers and

batteries. To get the most out of your RimFire 200, please use

only a 7.4V (2S) LiPo battery. The following instructions will

help you mount your motor and select the right components

to complete your power system.

MOTOR SPECIFICATION

1

Model Stock #

RimFire 200 (18-19-2400) GPMG4455

The RimFire motors are labeled to provide the most information

at a glance. For example: the RimFire 200 (18-19-2400) is

18mm in diameter, 19mm long, and has a kV (rpm-per-1volt)

of 2400 rpm.

18 mm

19 mm

Motor

0.71 in

Diameter

Overall

Length

Diameter

Length

Length

2

An ESC is basically the device that controls your motor through

your radio system. Never run any RimFire motors with a brushed

ESC. It will not work and you may damage both the motor and

the ESC. Always use a brushless ESC. When choosing an ESC,

choose one that is rated to handle at least the maximum current

your power system will draw during full-throttle operation.

ElectriFly offers Brushless ESCs that will work with the RimFire

200 motor.

Shaft

Shaft

Lead

(18mm)

0.74 in

(18.8mm)

0.079 in

(2.0mm)

0.20 in

(5mm)

1.57 in

(40 mm)

Max. Constant Current 4.9 A

Max. Surge Current 6.3 A

Max. Constant Watts 36W

Weight

0.38 oz (10.7g) 0.44 oz (12.4g)

ELECTRONIC SPEED CONTROL (ESC)

For the RimFire 200 we recommend this high quality,

lightweight ESC:

Connectors 3-pin micro

Burst Watts 47W

No Load Current 0.35A

Input Voltage 7.4V

motor

only

FlightPower

6A Brushless ESC w/BEC

(FPWM0206)

Weight = 0.20oz [5.7g]

motor, mount,

& prop adapter

®

(2S LiPo)

BATTERIES

3

Cells can be connected in series or in parallel. Usually batteries are

labeled by their number of cells, such as a 2-cell LiPo. This means

the cells are connected in SERIES (S). Arranging batteries in series

gives you more power (higher voltage).

Each LiPo battery has 3.7V, so a 2-cell LiPo

•

battery has 3.7 x 2 = 7.4V

When selecting batteries, please consider weight. Because of this,

we recommend the following batteries:

Great Planes® ElectriFly

300mAh 7.4V 2S 20C LiPo

(GPMP0700)

Weight = 0.7oz [19.6g]

FlightPower EON-X Lite

350mAh 7.4V 2S 25C LiPo

(FPWP4014)

Weight = 0.8oz [23g]

Due to the constantly changing battery technology, check out the

ElectriFly web site at www.electrifl y.com for the most up-to-date

listing of the ElectriFly battery line.

PROPELLER

4

For any given voltage, an electric motor’s load is determined by

the propeller chosen. A propeller that is too small will not take

advantage of the power that the motor can produce. A propeller

that is too large will cause current draw to exceed the maximum

allowed continuous current. This can catastrophically damage the

motor and/or ESC.

The fi rst number in a propeller designation is the diameter in inches.

The second number refers to the theoretic pitch in inches traveled

for one complete rotation of the prop. So, a 6x3 propeller measures

6" [152mm] in diameter and travels 3" [76mm] forward for one

complete revolution (360°). Generally, when sizing up a prop, going

up in diameter gains more thrust (immediate punch-out power).

Going up in pitch results in a higher top speed.

For the RimFire 200 we recommend the following propellers.

™

Best all-around performance

GWS 7x3.5 Propeller (GWSQ2008), 4.9A @ 7.4V, 8760rpm

Sport performance

GWS 6x3 Propeller (GWSQ2007), 4.0A @ 7.4V, 10620rpm

DETERMINE WHAT YOU NEED to BUILD YOUR POWER SYSTEM

5

Now that you have one component for your power system, there

are several different ways to select the rest. In time, experience will

help you to determine what works best for you, but an easy way to

determine what you need now is the following.

Procedure #1: If you know the size of the propeller you want to

turn and the rpm, then:

1. Find the combination that delivers the closest performance to what

❏

you want (refer to the ElectriFly web site for typical combinations),

or refer to the airplane manufacturer’s recommendations.

2. Note the recommended battery voltage.

❏

3. Determine the battery capacity needed based on the current

❏

draw of your system and your desired fl ight time.

4. Determine the ESC you need based on the system current

❏

draw. See the ESC section.

Procedure #2: If you know the approximate weight of your

airplane, including the motor and battery, and the performance

you want from it, answer the questions below to determine the

correct power system for your plane. You may need to make

more than one calculation using different motors and battery

combinations. See the battery section for some of the battery

weights for the suggested batteries.

1. Perform the following calculation to determine the wattage

❏

required:

If you expect trainer-like performance then multiply

•

75 x Airplane Weight (lbs).

If you expect aerobatic or high speed-like

•

performance then multiply 100 x Airplane

Weight (lbs).

If you expect 3D or extreme performance multiply

•

150 x Airplane Weight (lbs).

Note: To conver t gr ams to lbs, divide by 454. To conver t ounces

to lbs, divide by 28.

2. The number you get is the minimum wattage you will need

❏

for your plane to perform as you wish. Watts = current (A) ×

voltage (V). Using suggested power system combinations

for reference, determine what combination gives you the

performance you want based on wattage and maximum

propeller size that will fi t on the plane.

3. Note the recommended battery voltage.

❏

4. Determine the battery capacity needed based on the

❏

current draw of your system and your desired fl ight time.

5. Determine the ESC you need based on the system current

❏

draw. In addition to these two procedures, you can also

visit the Great Planes ElectriFly web site for descriptions

of the power systems recommended for our line of

electric airplanes as well as more detailed explanation

on the subject.

Essentially when using this rule, the maximum weight of

your model (fully equipped w/ battery, radio, etc.) should

be as follows when using this motor.

Trainer 7.7oz [219g ]

Sport 5.8oz [165g]

3D 3.9oz [110g]

To help you plan your power system requirements for your

project, use the following table to come up with a total weight.

Keep in mind that weight is critical in this size range.

RimFire 200

12.4 grams

Prop

Battery

Servos

Receiver

ESC

WEIGHT TABLE

Airframe

Total Weight

Page 2

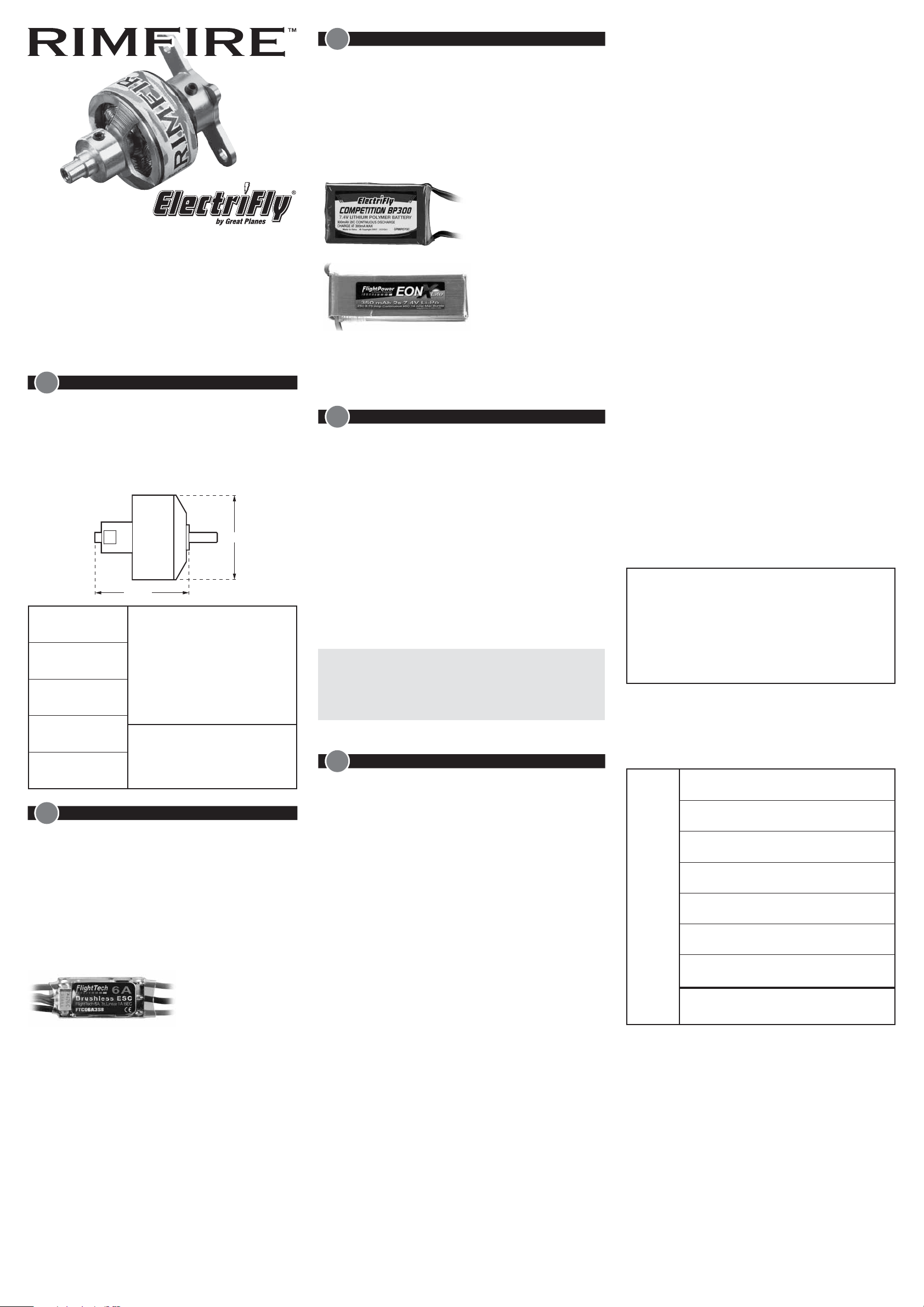

MOTOR INSTALLATION

6

1. Cut out the mounting template at the end of this manual. Line

up the crosshair alignment marks on the template with the

marks on the fi rewall of your model. Stick the template in place.

Drill two mounting screw holes in the fi rewall using a 1/16"

[1.6mm] drill.

2. Install the mount

onto the fi rewall using

two #2 x 3/16" [4.8mm]

sheetmetal screws (not

included). Remove the

screws and harden the

screw hole with thin

foam-safe CA. Reinstall

the mount.

3. Fit the motor to the

mount. Rotate the

motor so that the motor

wires can be routed in

the desired direction.

Install the two set

screws using thread

locking compound on

the screw threads. With

the motor in position,

tighten the set screws securely.

4. The prop adapter

is stepped to fi t 3mm

and 4mm prop hubs.

We have also included

a 5mm and a 6mm

bushing.

5. You have two options

when installing the

propeller. To install the

propeller using the

standard method,

install the two set

screws in the prop

adapter hub. Fit the

prop and bushing (if

needed) and install the

prop washer and screw. Use thread locking compound on all

screw threads.

6. If you choose to

use the “prop saver”

attachment method,

install the two M2 x

6mm countersunk

machine screws in the

prop adapter hub. Fit

the prop and bushing

(if needed) and fi t the

prop. Hook the rubber O-ring to one of the countersunk screws.

Stretch it across the hub of the prop and hook it onto the other

countersunk screw to retain the propeller. Use thread locking

compound on all screw threads.

If mounting space is a

concern, you can fl ip the

motor mount around and

decrease the amount of

space you need to mount

the motor. If you want to

do this, use the template

in this manual to help you

grind away a hole to allow

the motor mount to drop in.

22.8mm

9.5mm

17.8mm

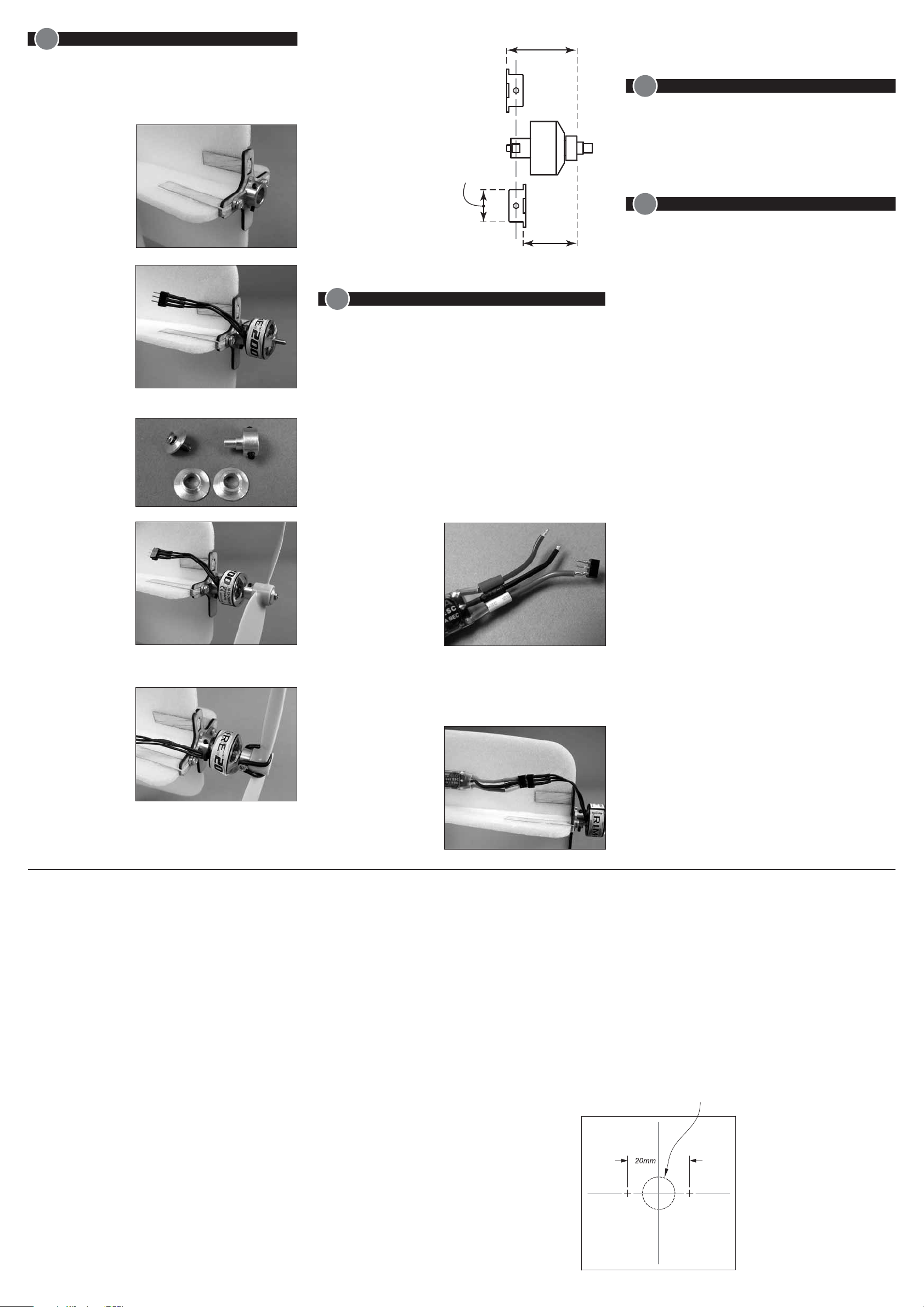

ESC INSTALLATION

7

We recommend that you use a variable temperature soldering iron

with a very fi ne tip. We suggest using the Team Checkpoint® TC-950

Soldering Station (TCPR0950) with the 1mm pencil tip. A set of

“helping hands” is also useful for soldering (XACR4214).

1. Strip off about 1/8" [3.2mm] of insulation from the end of each

motor wire on the ESC. Apply some soldering fl ux to the bare wires

and twist the end of each wire to neatly tighten the strands. Do this for

each individual wire. Tin the tips of each wire using electrical solder.

2. Cut three pieces of heat shrink tubing to a length that completely

covers each bare wire. Generally, you’ll need about 5/16" [7.9mm]

of heat shrink to cover each wire, but enough material is provided

for you if you need more. Apply fl ux and tin each pin of the female

connector as well.

3. Fit the heat shrink tubing

to each wire and slide it as

far away from the tip of the

wire as you can. Solder

each ESC lead to each pin of

the included female 3-pole

micro connector. Slide the

pieces of he at shrink tubing

into position and use heat

to shrink the tubing. Note:

Any wire can be connected to any pin.

4. Mount the ESC to your model using double-sided tape or hook

and loop material. Make sure that you choose a place that will allow

all of the wires to reach. Plug the ESC signal lead into your receiver.

5. Connect the male motor

connector to the female ESC

connector. Energize your

radio system. Connect a

2-cell LiPo battery to the

ESC. Using the throttle,

test the direction of motor

rotation. The motor should

rotate counter-clockwise as

viewed from the front of the

motor. If it does not rotate correctly, unplug the micro 3-pole

connector and rotate it 180°. This will reverse the motor rotation.

Note: Do not install the prop for this step.

RIMFIRE MOTOR MAINTENANCE

8

RimFire brushless motors require virtually no maintenance.

There are no brushes to wear out and replace. The precision

bearings have a very long service life and should last a very

long time. The internal parts of the motor should not require

any cleaning. The only thing that needs to be checked is to make

sure all the screws and set screws remain tight.

IMPORTANT PRECAUTIONS

9

Once the battery is connected to the ESC, stay clear of the

motor and prop.

DO NOT apply an input voltage that exceeds the maximum

•

specifi cation of each motor.

DO NOT apply currents to the motor that exceed the maximum

•

specifi cations of each motor.

DO NOT allow the input connectors to accidentally touch

•

each other while power is applied to the motor. Make sure

all input connections are insulated electrically.

DO NOT allow water or moisture to enter the motor, as it can

•

cause permanent damage to the motor and possibly short

out the attached ESC.

DO NOT cut the coated wires from the motor. If you must

•

remove the connector, please unsolder it.

Allow the motor to cool after each fl ight.

•

The shaft of the motor will rotate at very high rpm. DO NOT

•

attempt to touch the shaft while it is rotating. If setting up

the motor/ESC on the workbench, make sure the motor is

securely attached and that nothing is attached to the motor

shaft BEFORE applying power.

NEVER attempt to use a damaged motor (having mechanical

•

or electrical defects).

ElectriFly carries a complete line of Ammo™ (in-runner style)

•

and RimFire (out-runner style) brushless motors, gear drives,

motor mounts, prop adapters and speed controls. For a

complete list of these products, check out our web site at:

www.greatplanes.com, www.electrifl y.com or visit your

nearest hobby shop that carries the full line of Great Planes

and ElectriFly products.

© 2010 Hobbico,® Inc. GPMG4455

If you need to reduce the mounting space, flip over the motor mount and cut out this hole.

Loading...

Loading...