Page 1

ELECTRIC DUCTED FAN INSTRUCTION MANUAL

™

Technical Data

Fan Swept Area: 2.71 in2 [17.5cm2]

Maximum rpm: 50,000 rpm

Housing Inner Diameter: 2.14 in [54.5mm]

Outer Diameter: 2.23 in [56mm]

Complete Assembly Weight (no motor): 1.3 oz [37g]

Welcome to the exciting world of Electric Ducted Fans (EDF)! The HyperFlow is a new EDF design created by Great Planes

using the latest technology to fi t onto smaller EDF airplanes. The HyperFlow was created with ease of use in mind, as well as superior

performance using either a brushed or brushless motor. Great Planes offers several different motors that you can use to tailor the fan’s

performance to meet your needs. This EDF can fl y airplanes as small as 10oz [280g] to airplanes as big as 35oz [990g] depending on

the chosen motor. Flying speeds have been measured to be from 55mph [88km/h] to 110mph [185km/h]. You can now fl y modern jets

and fl y them in a realistic manner–fast.

Great Planes

®

Model Manufacturing Co. guarantees this product to be free from defects in both material and workmanship at the date of

purchase. This warranty does not cover any component parts damaged by use or modifi cation. In no case shall Great Planes’ liability exceed

the original cost of the purchased product. Further, Great Planes reserves the right to change or modify this warranty without notice.

In that Great Planes has no control over the fi nal assembly or material used for fi nal assembly, no liability shall be assumed nor

accepted for any damage resulting from the use by the user of the fi nal user-assembled product. By the act of using the user-assembled

product, the user accepts all resulting liability.

If the buyer is not prepared to accept the liability associated with the use of this product, the buyer is advised to return this product

immediately in new and unused condition to the place of purchase.

To make a warranty claim send the defective part or item to Hobby Services at the address below:

Include a letter stating your name, return shipping address, as much contact information as possible (daytime telephone number, fax

number, e-mail address), a detailed description of the problem and a photocopy of the purchase receipt. Upon receipt of the package

the problem will be evaluated as quickly as possible.

Entire Contents © Copyright 2007

WARRANTY

Hobby Services

3002 N. Apollo Dr. Suite 1

Champaign IL 61822 USA

GPMZ0194 for GPMG3910/3911 V1.1

Page 2

PERFORMANCE

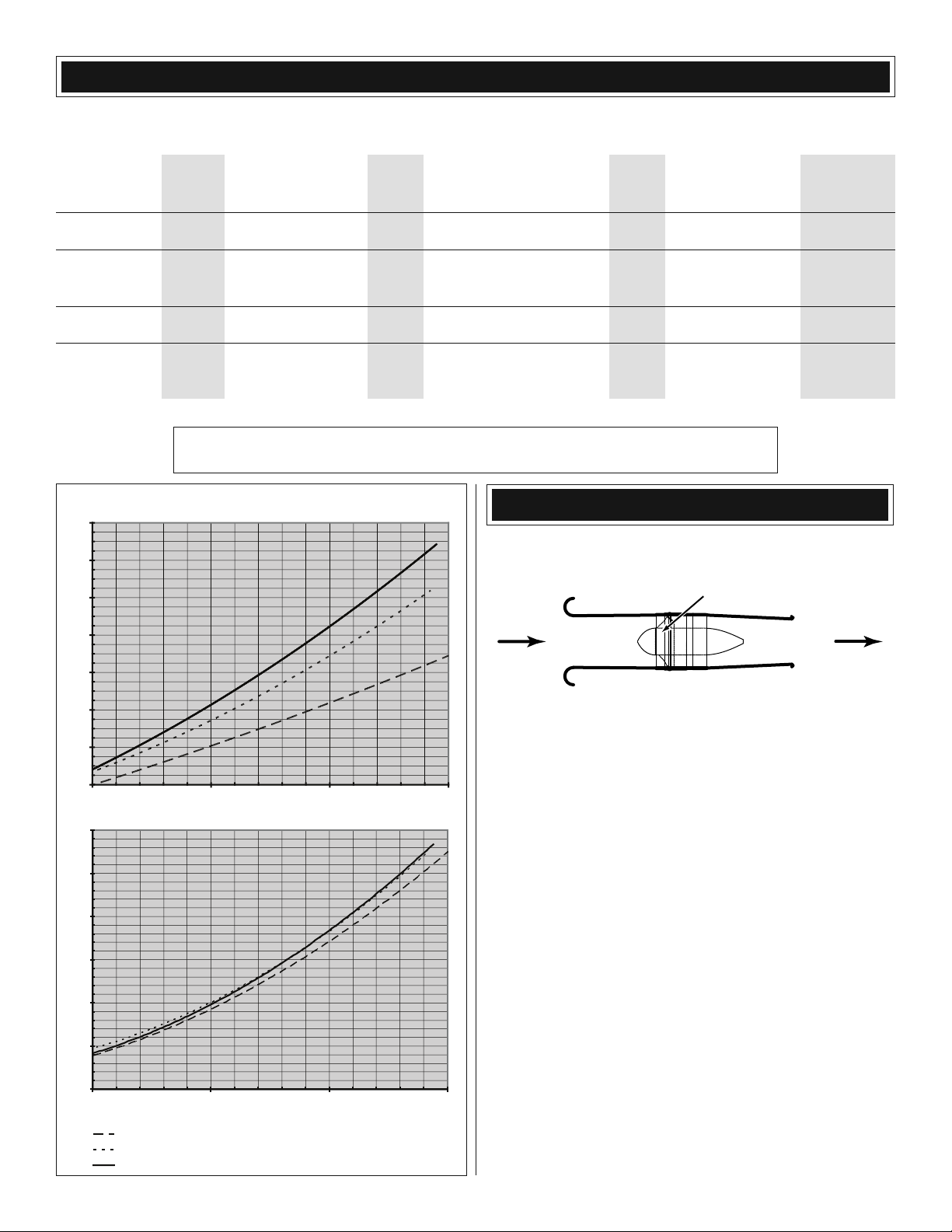

The following measured performance data has been achieved using the stock intake lip and 90% FSA exhaust duct.

# LiPo Cells Voltage Current Power Static Thrust RPM Effl ux Effl ux

Speed Speed

Motor: Brushed Speed 370BB (GPMG3910)

3 11.1V 10.3A 114W 240g (8.5oz) 29,000 32 m/s 72 mph

Motor: Brushless 20-40-3500 (GPMG5140)

2 7.4V 8.7A 64W 215g (7.6oz) 27,000 28 m/s 63 mph

3 11.1V 15.7A 174W 400g (14.2oz) 35,800 46 m/s 103 mph

Motor: Brushless 24-33-4875 (GPMG5170)

2 7.4V 17.2A 127W 330g (11.6oz) 32,300 41 m/s 92 mph

Motor: Brushless 24-45-3790 (GPMG5185)

2 7.4V 9.7A 72W 230g (8.0oz) 27,120 28 m/s 63 mph

3 11.1V 19.9A 221W 485g (17.1oz) 38,600 53 m/s 118 mph

4 14.8V 32.6A 482W 820g (28.9oz) 48,000 74 m/s 165 mph

Effl ux Speed: Air Speed Exiting at the Exhaust

Please visit the Great Planes website (www.greatplanes.com) for performance

data on recently released motors or any other technical updates.

(meters/second) (miles/hour)

Hyperflow 56mm Measured Performance

180

160

140

120

100

Efflux Speed (mph)

80

60

40

20000 30000 40000 50000

30

25

20

15

Thrust (oz)

10

5

0

20000 30000 40000 50000

134% FSA

99% FSA

90% FSA

RPM

RPM

The data in these charts was obtained using

a stock intake lip. The motor was an Ammo

24-45-3790 and the ESC was an SS-35.

TECHNICAL INFORMATION

Fan Swept Area

INTAKE

Duct Cross-Section

The way a ducted fan works is simple: As the fan rotates

and draws air, the surrounding duct causes the airfl ow to

accelerate through the fan and exit out of the exhaust tube.

With this in mind, fans are designed with a particular duct

profi le in mind and a particular fl ying speed. The HyperFlow

has been designed to be most effi cient while fl ying at 56 mph

[90 km/h]. This was done so that the fan would perform well

with an inexpensive brushed motor, but would still operate

at effi cient levels with a brushless motor. This is proven by

the maximum measured thrust of 28.9oz and 165mph effl ux

speed at 48,000rpm.

The duct profi le is extremely important for the fan to perform

well. The intake needs to be large enough to supply the

required air to the fan at both low and high speeds and

at different rpm, but if the duct profi le is too large, it may

increase the airplane's drag coeffi cient. Of course, the intake

and exhaust should be as short as possible to minimize

losses. The duct profi le must be smooth and absolutely free

of obstacles. It is also recommended that the intake has a

smooth, rounded lip which helps maximize static thrust and

smooth airfl ow into the intake.

2

EXHAUST

Page 3

2

The fan swept area (FSA) is 2.74in

[17.68cm2]. The minimum

intake area for this fan is 3.67in2 [23.6cm2]. This represents

134% of the FSA. This area can easily be achieved by using

a straight tube intake. Whenever possible, however, make

the intake as large as the model will aesthetically allow.

Exhaust area is equally important for the fan to perform well.

Using a straight-tube exhaust (134% FSA) will simplify the

construction of your duct, but at the cost of thrust and speed.

The optimum exhaust area for this fan is between 90 and

99% FSA (see graphs on the previous page). 99% FSA is

2

2.71in

[17.5cm2] while 90% FSA is 2.46in2 [15.9cm2]. The

Hyperfl ow will deliver slightly more thrust at slower rpms

with 99% FSA, but in all other fl ight regimes, the 90% FSA

exhaust will deliver more thrust and speed.

Useful Conversions:

134% FSA 3.67in2 [23.6cm2] = 2.162in [54.9mm] circle

99% FSA 2.71in2 [17.5cm2] = 1.857in [47.2mm] circle

90% FSA 2.46in2 [15.9cm2] = 1.769in [44.9mm] circle

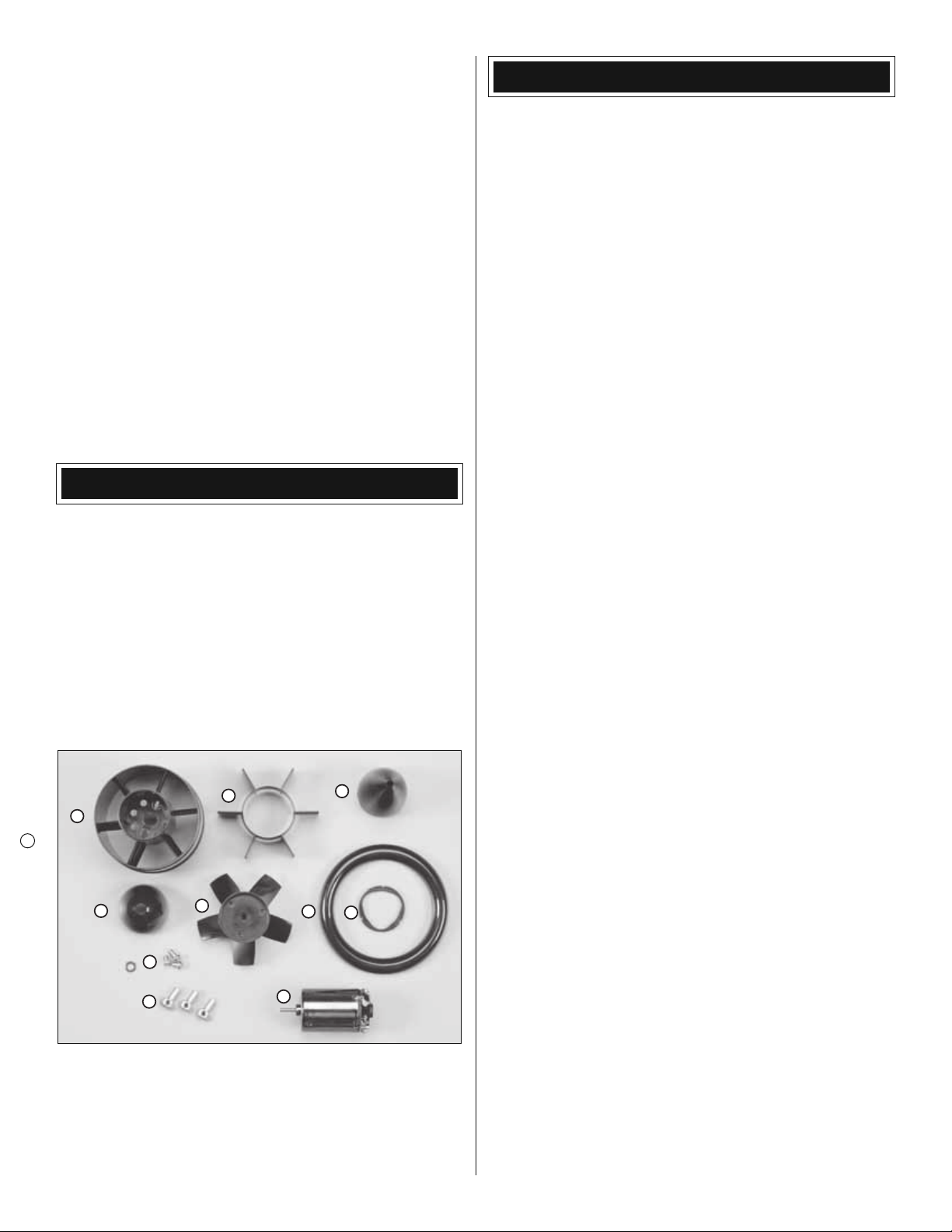

KIT INSPECTION

Before starting to assemble, take an inventory of this kit

to make sure it is complete, and inspect the parts to make

sure they are of acceptable quality. If any parts are missing

or are not of acceptable quality, or if you need assistance

with assembly, contact Product Support. When reporting

defective or missing parts, use the part names exactly as

they are written in the Kit Contents list.

ORDERING REPLACEMENT PARTS

Replacement parts for the Great Planes HyperFlow EDF are

available using the order numbers in the Replacement Parts

List that follows. The fastest, most economical service can

be provided by your hobby dealer or mail-order company.

To locate a hobby dealer, visit the Great Planes web site at

www.greatplanes.com. Choose “Where to Buy” at the top of

the page on the right side. Follow the instructions provided on

the page to locate a U.S., Canadian or International dealer.

Parts may also be ordered directly from Hobby Services by

calling (217) 398-0007, or via facsimile at (217) 398-7721,

but full retail prices and shipping and handling charges will

apply. Illinois and Nevada residents will also be charged

sales tax. If ordering via fax, include a Visa

number and expiration date for payment.

Mail parts orders and payments by personal check to:

Hobby Services

3002 N Apollo Drive, Suite 1

Champaign IL 61822

Be certain to specify the order number exactly as listed

in the Replacement Parts List. Payment by credit card or

personal check only; no C.O.D.

If additional assistance is required for any reason contact

Product Support by telephone at (217) 398-8970 or by

e-mail at productsupport@greatplanes.com

Replacement Parts List

®

or MasterCard®

Great Planes Product Support

3002 N Apollo Drive, Suite 1 Champaign, IL 61822

Telephone: (217) 398-8970, ext. 5 Fax: (217) 398-7721

E-mail: airsupport@greatplanes.com

2

1

4

8

9

5

10

3

6

7

NOTE: Motor is only included in GPMG3911.

1. Ducted Fan Housing 6. Front Housing Flange

2. Stator Extension 7. 20mm Brushless Motor Adapter

3. Aft Cone 8. Mounting Screws and Washer

4. Rotor Cone 9. Fan Rotor Adapters (2, 2.3, 3mm)

5. Fan Rotor Blade 10. Motor

Order Number Description

GPMG3940 Fan Rotor Blade

GPMG3941 Miscellaneous Parts

GPMG3942 Outer Duct

GPMG3943 Rotor Adapter

33

3

Page 4

DECISIONS YOU MUST MAKE

ASSEMBLY

At this point, based on the performance table from page 2

and the airplane you will install the HyperFlow ducted fan

into, you will need to decide which motor, ESC, and batteries

to use with the fan. Remember that once a motor is chosen

based on the power output, a speed controller and battery

must be used that are capable of delivering the current

drawn by the motor. Several power systems are available

from Great Planes at the time of this printing. Please check

www.electrifl y.com for the most up-to-date information.

Brushed Power System:

Speed 370 BB Brushed Motor (GPMG0311)

ElectriFly C-25 ESC (GPMM2025)

ElectriFly 3-cell 910mAh LiPo (GPMP0605)

ElectriFly 3-cell 1250mAh LiPo (GPMP0609)

Brushless Power System:

ElectriFly Ammo 20-40-3500 Brushless Motor (GPMG5140)

ElectriFly Ammo 24-33-4875 Brushless Motor (GPMG5170)

ElectriFly Ammo 24-45-3790 Brushless Motor (GPMG5185)

ElectriFly SS 12A Brushless ESC (GPMM1810)

ElectriFly SS 25A Brushless ESC (GPMM1820)

ElectriFly SS 35A Brushless ESC (GPMM1830)

ElectriFly SS 45A Brushless ESC (GPMM1840)

ElectriFly 2-cell 910mAh LiPo (GPMP0604)

ElectriFly 3-cell 910mAh LiPo (GPMP0605)

ElectriFly 2-cell 1250mAh LiPo (GPMP0608)

ElectriFly 3-cell 1250mAh LiPo (GPMP0609)

ElectriFly 2-cell 1500mAh LiPo (GPMP0612)

ElectriFly 3-cell 1500mAh LiPo (GPMP0613)

ElectriFly 2-cell 2100mAh LiPo (GPMP0616)

ElectriFly 3-cell 2100mAh LiPo (GPMP0617)

ElectriFly 2-cell 3200mAh LiPo (GPMP0622)

ElectriFly 3-cell 3200mAh LiPo (GPMP0623)

ADDITIONAL ITEMS REQUIRED

Installing a Brushed Motor

❏ 1. If installing a Great Planes T-370 brushed motor, slide

the motor into the ducted fan housing up to the mounting

plate. Align the slotted motor mounting holes in the housing

with the screw holes at the top of the motor.

❏ Threadlocking compound (GPMR6060)

❏ Phillips screwdriver (HCAR1024)

❏ 1.5mm hex wrench (GPMR8010)

❏ Medium CA+ glue (GPMR6008)

The EP Ducted Fan Unit will work with 370 sized brushed

motors, 20mm brushless motors, and 24mm brushless

motors. All necessary parts are included for these motor

installations, plus 2mm, 2.3mm, and 3mm adapters.

Note: The aft cone might not be installed when using longer

brushless motors.

If your motor does not already have leads attached, do so

prior to the motor installation into the ducted fan unit.

NOTE: If the ducted fan application requires the fan housing

to be installed into an existing duct tube that provides properly

distributed airfl ow into the fan rotor, then the optional rotor cone

should not be installed. If the ducted fan is to be installed in a

nacelle or into a duct tube that does not properly direct airfl ow

into the fan rotor, the optional rotor cone should be installed.

❏ 2. Secure the motor to the fan housing using two 3 x 5mm

fl at head screws with threadlocking compound.

4

Page 5

❏ 4A. Fit the fan rotor over the brass fan adapter and push

it down so it is fully seated. If you will not be installing the

optional rotor cone, thread a 3 x 8mm Phillips screw with

a 3mm washer through the fan adapter. Be sure to use

threadlocking compound.

❏ 4B. If you are installing the optional rotor cone, press it

onto the fan rotor as shown. Insert a 3 x 8mm Phillips screw

and 3mm washer (with threadlocking compound) into the

hole in the rotor cone and tighten the screw into the brass

fan adapter.

❏ 3. Press the 2mm fan rotor adapter onto the motor. Using

threadlocking compound, tighten the set screws against the

motor shaft. Allow a small amount of clearance (1/8" [3mm])

between the base of the adapter and the motor to prevent

binding. A 3/32" [2.4mm] hole can be drilled into the side of

the fan housing 9/16" [14.3mm] from the front edge to insert

an allen wrench for the fan adapter set screws.

❏ 5. Cut a portion of the aft cone away for motor cooling and

to allow the motor leads to pass through. For most motor

applications, the aft cone should be approximately 1-1/4"

[32mm] long after cutting it.

5

Page 6

❏ 6. Attach the aft cone to the fan housing with a couple

drops of CA glue or tape. Excess glue will make it diffi cult to

remove the motor from the housing should it be necessary

in the future.

Installing a Brushless Motor

IF INSTALLING A 24mm MOTOR (ONLY)

If installing a 24mm brushless motor, the three alignment

guides inside the fan housing must be trimmed prior to

inserting the motor (a hobby knife works; however, a rotary

tool such as a Dremel makes the job much easier). Slide

the motor into the housing, positioning the screw holes in

the motor with the slots in the mounting plate.

❏ 1. If installing a 20mm brushless motor, press the motor

adapter onto the rear of the motor can prior to sliding it into

the fan housing. The motor adapter is keyed to fi t over the

three alignment guides inside the fan housing. Push the motor

up against the mounting plate, aligning the motor mounting

holes with the slots. Depending on the model motor being

used, you may need to cut away a part of the fan housing

in order for the motor to sit fl ush against the mounting plate.

Use the molded recess as a cutting guide.

❏ 2. Secure the motor to the fan housing using two 3 x 5mm

fl at head screws with threadlocking compound.

❏ 3. There are brass fan rotor adapters provided for 2mm,

2.3mm, and 3mm motor shafts. Select the adapter that

fi ts your motor shaft and install the 3mm set screws with a

1.5mm wrench into the hexagonal base.

6

Page 7

❏ 4. Press the fan rotor adapter onto the motor and tighten

the set screws against the shaft. Allow a small amount of

clearance (1/8" [3mm]) between the base of the adapter and

the motor to prevent binding. A 3/32" [2.4mm] hole can be

drilled into the side of the fan housing 9/16" [14.3mm] from

the front edge to insert an allen wrench for the fan adapter

set screws.

❏ 5B. If you are installing the optional rotor cone, press it onto

the fan rotor as shown. Insert a 3 x 8mm Phillips screw and

3mm washer (with threadlocking compound) into the hole in the

rotor cone and tighten the screw into the brass fan adapter.

❏ 6. Slide the stator extension onto the back of the ducted fan

housing. There are small notches on the stator extension that

fi t around the fan housing. Be sure that the extension blades

are aligned with the stator blades inside the motor housing.

Secure the extension with a couple drops of CA glue.

❏ 5A. Fit the fan rotor over the brass fan adapter and push

it down so it is fully seated. If you will not be installing the

optional rotor cone, thread a 3 x 8mm Phillips screw with

a 3mm washer through the fan adapter. Be sure to use

threadlocking compound.

❏ 7. Cut a portion of the aft cone away for motor cooling and

to allow the motor leads to pass through. For most motor

applications, the aft cone should be approximately 1-1/4"

[32mm] long after cutting it. If using a long brushless motor,

the aft cone may not fi t and can be omitted. If you are going to

run a high power set-up, you can omit the aft cone to improve

motor cooling.

7

Page 8

❏ 8. Attach the aft cone to the fan housing with a few drops

of CA glue. Excess glue will make it diffi cult to remove the

motor from the housing should it be necessary in the future.

Install the Front Housing Flange

(Optional)

• Ensure all persons in the immediate area are using eye

protection while the fan is in operation.

• NEVER point the fan in the direction of anyone.

• Make sure you inspect the fan and all its parts before

each run.

• Never use motors larger than those recommended.

• Never run a fan that is damaged in any way.

• Never run the fan while holding it in your hands.

• NEVER run the fan above 50,000 rpm!

• Never run the fan rotor on any motor outside of the housing.

This is a device that runs at very high rpm and as such it

needs to be handled carefully. There is a very short “breakin” period that needs to be followed to ensure that all parts

fi t well, everything is tight, and that no excessive vibration

is present when running the fan. Also, if the power system

chosen has a large power output, the fan blades will expand

as rpm are increased to the point of possibly touching the

housing. This is expected and it is within the “break-in”

procedures. The blades will get shortened slightly to fi t the

fan housing as they wear on the sides.

The procedure below must be followed carefully:

1. If the fan is properly installed on an airframe and everything

is ready to be tested, arm the speed controller and advance

the throttle slowly to approximately 1/4 power for three

minutes. Check for vibration and/or unusual noises. If there

is vibration or unusual noise present during the test, do not

proceed to step 2 until the problem is resolved. Inspect all

moving parts, being sure that motor screws and the rotor

adapter screws are tight. Confi rm that the fan blades rotate

smoothly within the housing and the rotor is not rubbing on

the mounting plate (Be sure to unplug the battery from the

ESC before handling the fan!).

❏ For a nacelle installation, secure the front housing fl ange

to the fan housing using a couple drops of thin CA. The front

housing fl ange is not used on most internal fan installations

PREPARE TO RUN THE FAN

Before you run the fan make sure that:

• The motor selected is one of the recommended motors.

• An appropriate ESC is being used.

• An appropriate LiPo battery is being used.

• All the screws and set screws are secured with

threadlocking compound.

• All the fan parts are properly attached to the fan and to

the airframe.

• If any part of this fan should become damaged, replace all

parts. Never attempt to repair damaged parts.

• Keep the fan away from objects as it will try to suck them in,

which can cause damage to the fan and/or bodily injury.

• Always use eye protection when operating the fan unit.

• NEVER look into the fan as it is running.

2. If the fan operates smoothly, move the stick to 1/2 throttle

and repeat the test as described in step 1.

3. Slowly advance the throttle to 3/4 power. When using highpower systems, the fan blades may rub a bit on the fan housing.

You can see this by powering down the system and checking

for marks or grooves in the housing. If this is the case, return

to 1/2 throttle and cycle between 1/2 throttle and 3/4 throttle

for three to four minutes. Doing so will adjust the length of the

fan blades as they slowly wear on the fan housing.

4. Repeat the procedure described in step 3 between 3/4

throttle and full throttle.

5. Unplug the battery from the ESC and check the fan for

rubbing, cracks, or missing parts.

If your fan appears damaged, vibrates excessively, or

makes unexpected noises, please return it to Hobby

Services for inspection.

Happy fl ying!

Loading...

Loading...