Great Planes GPMA1166 User Manual

INSTRUCTION

:

5

[

]

i

2

]

o

z/f

t

2

0

/dm

2

]

]

W

[

136 0

]

s

CIRRUS® is a registered trademark of Cirrus Design Corporation and is in no way affiliated with Hobbico, Inc.

SPECIFICATIONS

SPECIFICATIONS

Wingspan: 50.5 in [1285mm]

Wingspan

Wing Area: 305 in

Wing Area:05

Wing Loading: 19-23 oz/ft

Wing Loading:-23

WARRANTY

WARRANTY

Great Planes® Model Manufacturing Co. guarantees this kit to

be free from defects in both material and workmanship at the

date of purchase. This warranty does not cover any component

parts damaged by use or modification. In no case shall Great

Planes’ liability exceed the original cost of the purchased kit.

Further, Great Planes reserves the right to change or modify this

warranty without notice.

In that Great Planes has no control over the final assembly or

material used for final assembly, no liability shall be assumed nor

accepted for any damage resulting from the use by the user of

the final user-assembled product. By the act of using the

user-assembled product, the user accepts all resulting liability.

If the buyer is not prepared to accept the liability associated

with the use of this product, the buyer is advised to return

0.5 in

2

2

[19.7 dm2]

19.7 dm

2

mm

[58-70 g/dm2]

-7

ength:6 in [915mm

Length: 36 in [915mm]

eight:2.5-3 lb

Weight: 2.5-3 lb [1130-1360 g]

Radio: 4-channel, 4-nano servos

Radio:4-channel, 4-nano servos

this kit immediately in new and unused condition to the

place of purchase.

To make a warranty claim send the defective part or item to

Hobby Services at the address below:

Include a letter stating your name, return shipping address, as

much contact information as possible (daytime telephone

number, fax number, e-mail address), a detailed description of

the problem and a photocopy of the purchase receipt. Upon

receipt of the package the problem will be evaluated as quickly

as possible.

MANUAL

-

g

Hobby Services

3002 N. Apollo Dr. Suite 1

Champaign IL 61822 USA

otor:

Motor: .10 (35-30-1250) Brushless

10 (35-30-1250) Brushles

Outrunner

utrunner

READ THROUGH THIS MANUAL BEFORE STARTING CONSTRUCTION. IT CONTAINS IMPORTANT

INSTRUCTIONS AND WARNINGS CONCERNING THE ASSEMBLY AND USE OF THIS MODEL.

Champaign, Illinois

(217) 398-8970, Ext 5

airsupport@greatplanes.com

© 2010 Hobbico®, Inc. GPMA1166 Mnl

TABLE OF CONTENTS

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

SAFETY PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . .2

DECISIONS YOU MUST MAKE. . . . . . . . . . . . . . . . . . . . .3

Radio Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Motor Recommendation. . . . . . . . . . . . . . . . . . . . . . . .3

Propeller. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Batteries and Charger . . . . . . . . . . . . . . . . . . . . . . . . .3

Pilot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

ADDITIONAL ITEMS REQUIRED . . . . . . . . . . . . . . . . . . .4

Adhesives and Building Supplies. . . . . . . . . . . . . . . . .4

Optional Supplies and Tools. . . . . . . . . . . . . . . . . . . . .4

Building Stand . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

IMPORTANT BUILDING NOTES. . . . . . . . . . . . . . . . . . . .4

KIT INSPECTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

ORDERING REPLACEMENT PARTS . . . . . . . . . . . . . . . .5

KIT CONTENTS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

BUILDING INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . .6

Preparations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Assemble the Wing Panels . . . . . . . . . . . . . . . . . . . . .6

Install the Tail Section . . . . . . . . . . . . . . . . . . . . . . . . .9

Install the Nose Gear, Motor and ESC. . . . . . . . . . . .12

Finish the Model. . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

APPLY THE DECALS . . . . . . . . . . . . . . . . . . . . . . . . . . .16

GET THE MODEL READY TO FLY . . . . . . . . . . . . . . . . .17

Check the Control Directions . . . . . . . . . . . . . . . . . . .17

Set the Control Throws. . . . . . . . . . . . . . . . . . . . . . . .17

Balance the Model (C.G.). . . . . . . . . . . . . . . . . . . . . .18

Balance the Model Laterally. . . . . . . . . . . . . . . . . . . .19

PREFLIGHT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Identify Your Model . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Charge the Batteries . . . . . . . . . . . . . . . . . . . . . . . . .19

Balance Propellers. . . . . . . . . . . . . . . . . . . . . . . . . . .19

Range Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

MOTOR SAFETY PRECAUTIONS . . . . . . . . . . . . . . . . .20

LITHIUM BATTERY HANDLING AND USAGE . . . . . . . .20

AMA SAFETY CODE. . . . . . . . . . . . . . . . . . . . . . . . . . . .20

CHECK LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

FLYING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Takeoff . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Flight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Landing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

INTRODUCTION

Congratulations on your purchase of the Great Planes

ElectriFly Cirrus SR22 ARF! With only an evening or two of

fi nal assembly, you will be rewarded with a beautiful scale

model that fl ies with inexpensive radio components and can

fi t in the backseat of a car without removing the wings. The

wings can be removed for storage by simply unscrewing the

knurled wing bolts and sliding the panels off of the lightweight

carbon wing tube. Battery changes are a snap with the self-

aligning magnetic hatch. A fi berglass fuselage and canopy

hatch ensure a smooth appearance that looks great in the

pits and in the air. A cockpit interior, which only requires the

addition of a pilot(s) of your choice, fi nishes off the realism.

For the latest technical updates or manual corrections to

the Cirrus SR22 ARF visit the Great Planes web site at

www.greatplanes.com. Open the “Airplanes” link, then

select the Cirrus SR22 ARF. If there is new technical

information or changes to this model a “tech notice” box will

appear in the upper left corner of the page.

AMA

If you are not already a member of the AMA, please join!

The AMA is the governing body of model aviation and

membership provides liability insurance coverage, protects

modelers’ rights and interests and is required to fl y at most

R/C sites.

ACADEMY OF MODEL AERONAUTICS

5151 East Memorial Drive

Muncie, IN 47302-9252

Tele. (800) 435-9262

Fax (765) 741-0057

Or via the Internet at:

www.modelaircraft.org

IMPORTANT!!!

Two of the most important things you can do to preserve the

radio controlled aircraft hobby are to avoid fl ying near fullscale aircraft and avoid fl ying near or over groups of people.

PROTECT YOUR MODEL, YOURSELF

& OTHERS… FOLLOW THESE

IMPORTANT SAFETY PRECAUTIONS

1. Your Cirrus SR22 ARF should not be considered a toy, but

rather a sophisticated, working model that functions very

much like a full-size airplane. Because of its performance

capabilities, the Cirrus SR22, if not assembled and operated

correctly, could possibly cause injury to yourself or spectators

and damage to property.

2. You must assemble the model according to the

instructions. Do not alter or modify the model, as doing so

may result in an unsafe or unfl yable model. In a few cases

the instructions may differ slightly from the photos. In those

instances the written instructions should be considered

as correct.

3. You must take time to build straight, true and strong.

4. You must use an R/C radio system that is in good condition,

a correctly sized motor, and other components as specifi ed

in this instruction manual. All components must be correctly

installed so that the model operates correctly on the ground

and in the air. You must check the operation of the model and

all components before every fl ight.

5. If you are not an experienced pilot or have not fl own

this type of model before, we recommend that you get

the assistance of an experienced pilot in your R/C club for

2

your fi rst fl ights. If you’re not a member of a club, your local

hobby shop has information about clubs in your area whose

membership includes experienced pilots.

6. While this kit has been fl ight tested to exceed normal use,

if the plane will be used for extremely high stress fl ying, such

as racing, or if a motor larger than one in the recommended

range is used, the modeler is responsible for taking steps to

reinforce the high stress points and/or substituting hardware

more suitable for the increased stress.

7. WARNING: The fuselage, wheel pants, and canopy hatch

included in this kit are made of fi berglass, the fi bers of which

may cause eye, skin and respiratory tract irritation. Never

blow into a part to remove fi berglass dust, as the dust will

blow back into your eyes. Always wear safety goggles, a

particle mask and rubber gloves when grinding, drilling and

sanding fi berglass parts. Vacuum the parts and the work

area thoroughly after working with fi berglass parts.

We, as the kit manufacturer, provide you with a top quality,

thoroughly tested kit and instructions, but ultimately the

quality and fl yability of your fi nished model depends

on how you build it; therefore, we cannot in any way

guarantee the performance of your completed model,

and no representations are expressed or implied as to the

performance or safety of your completed model.

Remember: Take your time and follow the instructions to

end up with a well-built model that is straight and true.

Propeller

If you are installing the recommended RimFire brushless

motor, we suggest a 10x7E APC propeller (APCQ4123).

Batteries and Charger

One 1500-3350mAh 11.1V Lithium Polymer battery pack

is recommended. Using a 2200mAh 11.1V LiPo, our SR22

balanced at the recommended C.G. without the need for

additional ballast.

Great Planes ElectriFly LiPo 3S 11.1V 1500mAh 25C

❏

(GPMP0511)

Great Planes ElectriFly LiPo 3S 11.1V 2200mAh 25C

❏

(GPMP0520)

FlightPower® EON-X™ Lite LiPo 3S 11.1V 2500mAh 25C

❏

(FPWP4238)

Great Planes ElectriFly LiPo 3S 11.1V 3350mAh 25C

❏

(GPMP0541)

A cell balancer is required for the LiPo battery packs listed

above:

Great Planes ElectriFly Equinox™ LiPo Cell Balancer 1-5

❏

(GPMM3160)

DECISIONS YOU MUST MAKE

This is a partial list of items required to fi nish the Cirrus SR22

ARF that may require planning or decision making before

starting to build. Order numbers are provided in parentheses.

Radio Equipment

The Cirrus SR22 ARF requires a minimum 4-channel radio

system with four nano servos such as the ElectriFly ES-50

nano servo. In addition, two 12" [305mm] servo extensions

and a dual servo extension are required for the aileron servos.

Great Planes ElectriFly ES50 Nano Servo J (GPMM1210)

❏

Hobbico® Extension 12" [152mm] Futaba J (HCAM2100)

❏

Futaba® Dual Servo Extension 6" J (FUTM4130)

❏

Motor Recommendation

The recommended motor for the Cirrus SR22 ARF is a

RimFire™ .10 (35-30-1250) brushless outrunner motor.

Great Planes RimFire .10 (35-30-1250) Outrunner

❏

Brushless (GPMG4595)

If using the recommended brushless motor, a 35A brushless

ESC is required:

Great Planes Silver Series 35A Brushless ESC 5V/2A

❏

(GPMM1830)

A suitable charger is also required. The Great Planes

PolyCharge4™ is designed for LiPo packs only. However, it

is able to charge four LiPo packs simultaneously. The Great

Planes Triton2™ charger will only charge one pack at a time,

but is capable of charging NiCd, NiMH, LiPo, and Pb acid

batteries. Order numbers for both are provided below:

Great Planes PolyCharge4 DC Only 4 Output LiPo

❏

Charger (GPMM3015) OR

Great Planes ElectriFly Triton2 DC Comp Peak Charger

❏

(GPMM3153)

Pilot

If you wish to use the same pilot that is shown in the building

instructions, purchase Williams Brothers 1/8 Pilot Bust Kit

Sportsman (WBRQ1130). This pilot fi gure requires fi nish

sanding and painting, and some additional modifi cation of

the pilot fi gure is described in the building instructions.

3

ADDITIONAL ITEMS REQUIRED

Adhesives and Building Supplies

This is the list of Adhesives and Building Supplies that are

required to fi nish the Cirrus SR22 ARF:

1/2 oz. [15g] Thin Pro™ CA (GPMR6001)

❏

1/2 oz. [15g] Thick Pro CA- (GPMR6013)

❏

Threadlocker thread locking cement (GPMR6060)

❏

Drill bits: 1/16" [1.6mm], 5/64" [2mm]

❏

Small metal fi le or rotary tool

❏

Revell® #1 Light Duty Aluminum Handle Knife w/Blade

❏

(RMXR6901)

Revell #11 Light Duty Blades (5) (RMXR6930)

❏

Medium T-pins (100, HCAR5150)

❏

Top Flite® MonoKote® sealing iron (TOPR2100)

❏

Top Flite Hot Sock™ iron cover (TOPR2175)

❏

220 grit sandpaper

❏

Panel Line Pen (TOPQ2510)

❏

Optional Supplies and Tools

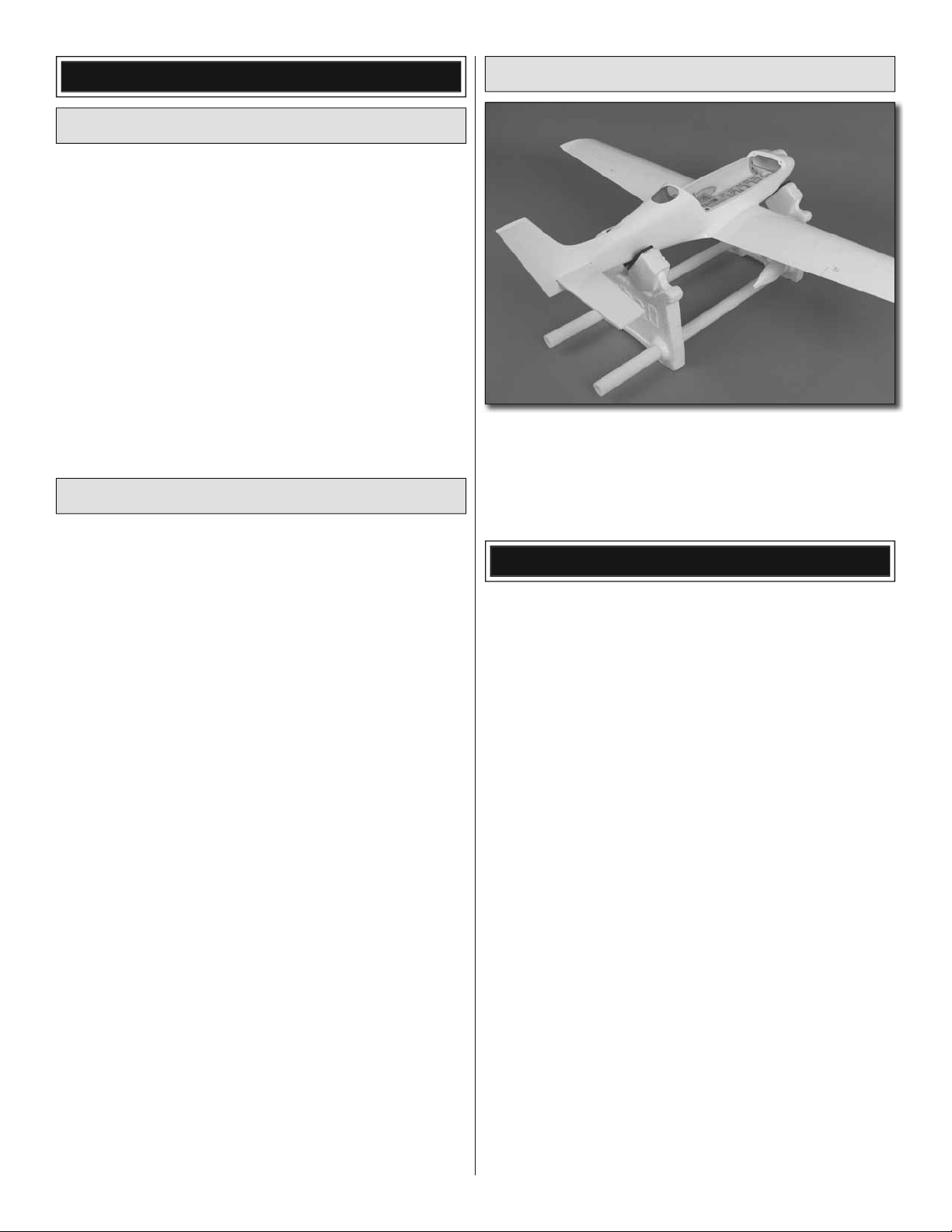

Building Stand

A building stand or cradle comes in handy during the build.

We use the Robart Super Stand II (ROBP1402) for all our

projects in R&D, and it can be seen in pictures throughout

this manual.

Here is a list of optional tools that will help you build the

Cirrus SR22 ARF:

1/2 oz. [15g] Medium Pro CA+ (GPMR6007)

❏

2 oz. [57g] spray CA activator (GPMR6035)

❏

4 oz. [113g] aerosol CA activator (GPMR6034)

❏

CA applicator tips (HCAR3780)

❏

CA debonder (GPMR6039)

❏

Pro 6-minute epoxy (GPMR6045)

❏

Pro 30-minute epoxy (GPMR6047)

❏

Epoxy brushes 6, (GPMR8060)

❏

Mixing sticks (GPMR8055)

❏

Mixing cups (GPMR8056)

❏

Pliers with wire cutter (HCAR0630)

❏

Rotary tool reinforced cut-off wheel (GPMR8020)

❏

Hobby Heat™ micro torch II (HCAR0755)

❏

Precision Magnetic Prop Balancer (TOPQ5700)

❏

AccuThrow™ Defl ection Gauge (GPMR2405)

❏

CG Machine™ (GPMR2400)

❏

Hobbico Flexible 18" Ruler Stainless Steel (HCAR0460)

❏

Top Flite MonoKote heat gun (TOPR2000)

❏

Hobbico Pin Vise 1/16 Collet w/6 Bits (HCAR0696)

❏

Great Planes Heat Shrink Tubing 3/8x3" (3) (GPMM1060)

❏

Woodland Scenics Low Temp Foam Glue Gun

❏

(WOOU1445)

Denatured alcohol (for epoxy clean up)

❏

IMPORTANT BUILDING NOTES

• When you see the term test fi t in the instructions, it means

that you should fi rst position the part on the assembly without

using any glue, then slightly modify or custom fi t the part as

necessary for the best fi t.

• Whenever the term “glue” is written, you should rely upon

your experience to decide what type of glue to use. When

a specifi c type of adhesive works best for that step, the

instructions will make a recommendation.

• Photos and sketches are placed before the step they refer

to. Frequently you can study photos in following steps to get

another view of the same parts.

• The Cirrus SR22 is factory-covered with Top Flite Jet White

MonoKote fi lm (TOPQ0204). Should repairs ever be required,

MonoKote can be patched with additional MonoKote

purchased separately. MonoKote is packaged in six-foot rolls,

but some hobby shops also sell it by the foot. If only a small

piece of MonoKote is needed for a minor patch, perhaps a

fellow modeler would give you some. MonoKote is applied

with a model airplane covering iron, but in an emergency a

regular iron could be used. A roll of MonoKote includes full

instructions for application.

• The stabilizer and wing incidences and engine thrust angles

have been factory-built into this model. However, some

technically-minded modelers may wish to check these

measurements anyway. To view this information visit the web

site at www.greatplanes.com and click on “Technical Data.”

Due to manufacturing tolerances which will have little or no

effect on the way your model will fl y, please expect slight

deviations between your model and the published values.

4

KIT INSPECTION

Before starting to build, inspect the parts to make sure they

are of acceptable quality. If any parts are missing or are not of

acceptable quality, or if you need assistance with assembly,

contact Product Support. When reporting defective or

missing parts, use the part names exactly as they are written

in the Kit Contents list.

Great Planes Product Support

3002 N. Apollo Drive, Suite 1

Champaign, IL 61822

Telephone: (217) 398-8970, ext. 5

Fax: (217) 398-7721

E-mail: airsupport@greatplanes.com

Mail parts orders and payments by personal check to:

Hobby Services

3002 N. Apollo Drive, Suite 1

Champaign, IL 61822

Be certain to specify the order number exactly as listed in

the Replacement Parts List. Payment by credit card or

personal check only; no C.O.D.

If additional assistance is required for any reason, contact

Product Support by telephone at (217) 398-8970, or by

e-mail at productsupport@greatplanes.com.

REPLACEMENT PARTS LIST

Order No. Description

ORDERING REPLACEMENT PARTS

Replacement parts for the Great Planes Cirrus SR22 ARF

are available using the order numbers in the Replacement

Parts List that follows. The fastest, most economical service

can be provided by your hobby dealer or mail-order company.

To locate a hobby dealer, visit the Great Planes web site

at www.greatplanes.com. Choose “Where to Buy” at the

bottom of the menu on the left side of the page. Follow the

instructions provided on the page to locate a U.S., Canadian

or International dealer.

Parts may also be ordered directly from Hobby Services

by calling (217) 398-0007, or fax at (217) 398-7721, but full

retail prices and shipping and handling charges will apply.

Illinois and Nevada residents will also be charged sales tax.

If ordering via fax, include a Visa® or MasterCard® number

and expiration date for payment.

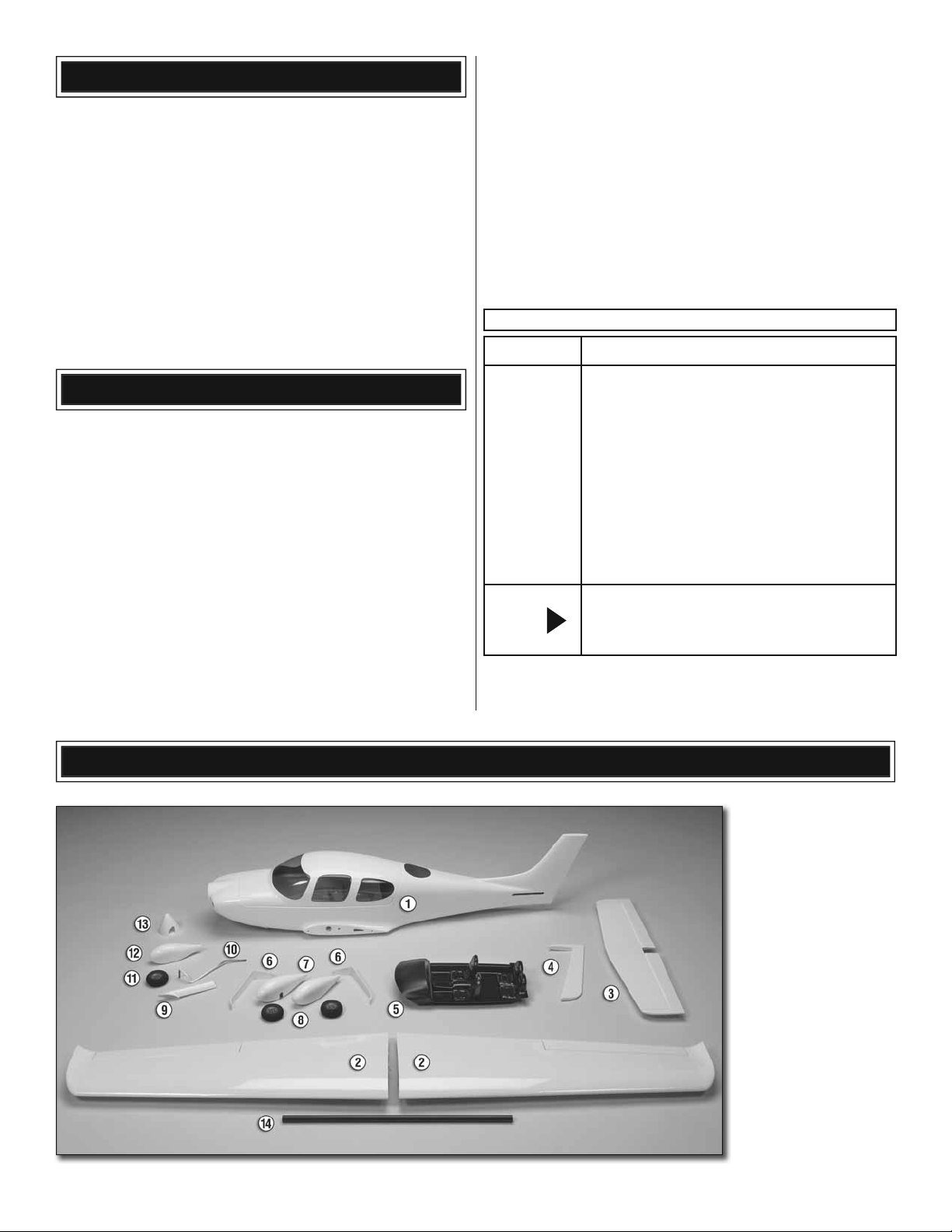

KIT CONTENTS

GPMA4035

GPMA4036

GPMA4037

GPMA4038

GPMA4039

GPMA4040

GPMA4041

GPMA4042

GPMA4043

GPMA4044

GPMA4045

NOTE

FUSELAGE

WING

TAIL SURFACES

HATCH

WHEELPANTS

NOSE GEAR FAIRING

MAIN GEAR SET

NOSE GEAR

DECALS

WING JOINER ROD

SPINNER

Full-size plans are not available.

You can download a copy of this

manual at www.greatplanes.com.

1. Fuselage, canopy hatch

2. Wing

3. Horizontal stabilizer

(stab) with elevators

4. Rudder

5. Cockpit interior

6. Main landing gear

7. Main gear wheel pants

8. Main wheels

9. Nose gear fairing

10. Nose gear

11. Nose wheel

12. Nose wheel pant

13. Spinner

14. Wing tube

5

BUILDING INSTRUCTIONS

Preparations

1. If you have not done so already, remove the major

❏

parts of the kit from the box and inspect for damage. If any

parts are damaged or missing, contact Product Support at

the address or telephone number listed in the “Kit Inspection”

section on page 5.

2. Carefully remove the tape and separate all the control

❏

surfaces. Use a covering iron with a covering sock on high

heat to tighten the covering if necessary. Apply pressure over

sheeted areas to thoroughly bond the covering to the wood.

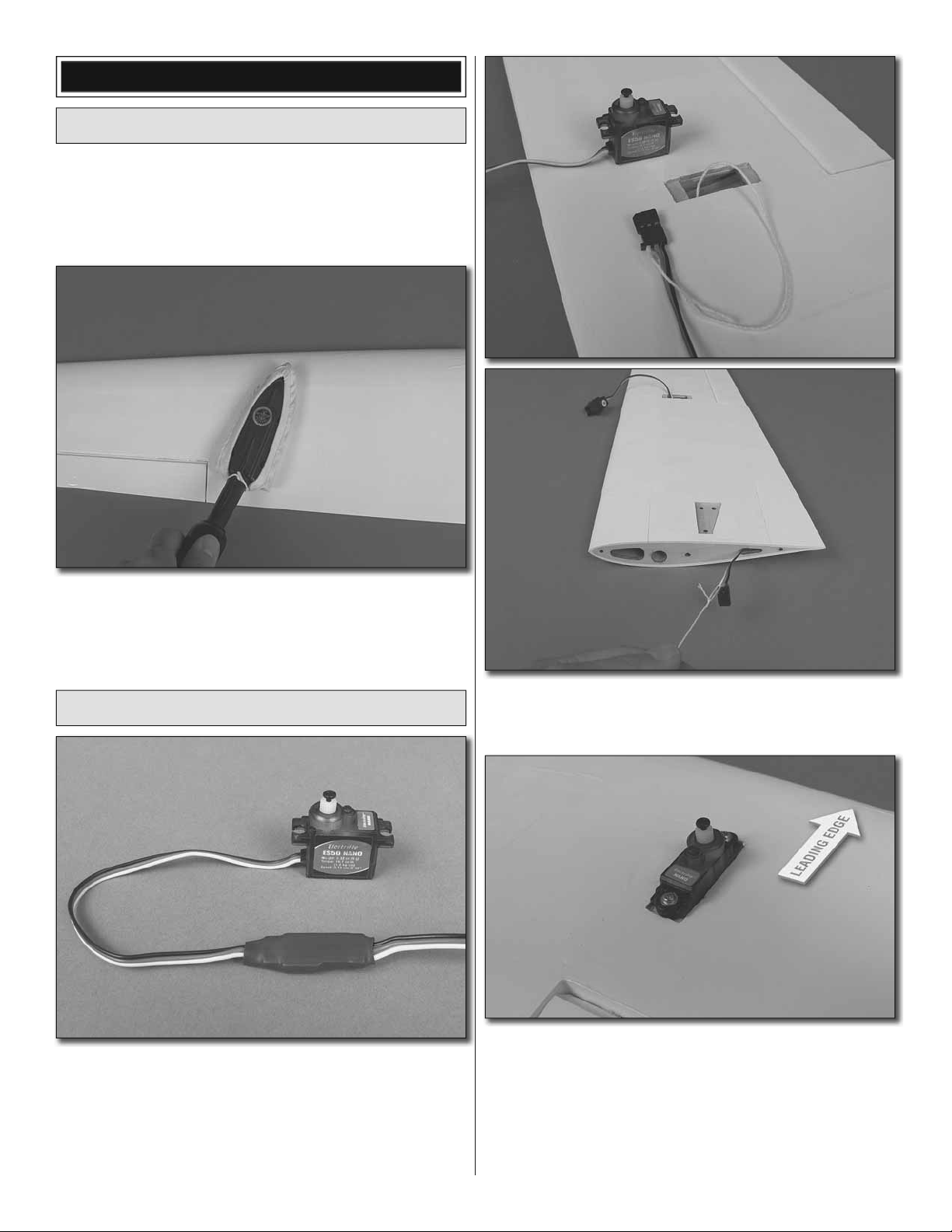

Assemble the Wing Panels

1. Attach a 12" [305mm] servo extension to each aileron

❏

servo. Secure the connections using tape, heat shrink tubing

(not included) or special clips designed for that purpose.

2. Locate the strings taped inside the aileron servo bays

❏

and tie the ends of the strings to the servo extensions. Use

the string to pull the servo leads through the wing ribs.

3. Install the rubber grommets and eyelets included with

❏

the servos. Position the servos in the aileron servo bays in

the orientation shown. Drill 1/16" [1.6mm] holes through

the servo mounting tabs. Thread a servo mounting screw

(included with the servos) into each hole and back it out.

Apply a drop of thin CA to each hole to harden the wood.

When the glue has dried, install the servos using the screws

included with the servos.

6

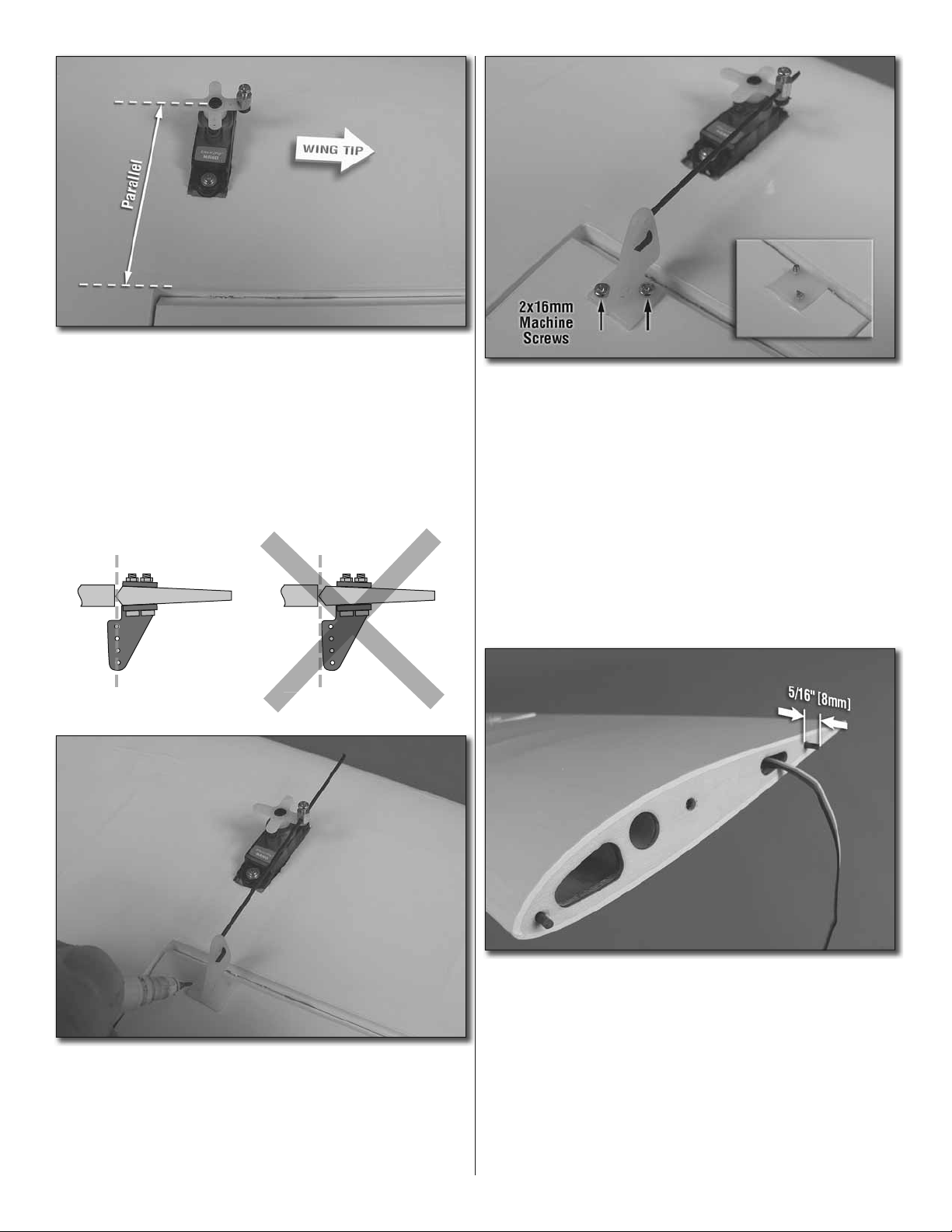

4. Install a screw lock pushrod connector into the outer

❏

hole of the long servo arm as shown with a nylon screw

lock retainer. Loosely thread a 2x4mm machine screw into

the connector. Center the servos with your radio system and

install the servo arm onto the servo parallel to the aileron

hinge line as shown with the connector toward the wing

tip. Be sure to reinstall the servo arm screw into the servo.

Repeat this step for the other aileron servo.

CORRECT INCORRECT

Hinge Line Hinge Line

6. Drill 5/64" [2mm] holes at the marks you made through

❏

the ailerons. Apply a couple drops of thin CA glue to each

hole to harden the wood surrounding the holes. When the

glue has dried, install the control horns onto the ailerons

using four 2x16mm machine screws and control horn

backplates. The ends of the screws can be cut off beyond

the control horns.

7. Position the aileron in the neutral position and tighten

❏

the screw in the screw lock pushrod connector against the

pushrod with threadlocking compound. The excess pushrod

beyond the pushrod connector can be cut off.

5. Connect the Z-bend end from a 90mm aileron pushrod

❏

into the second outer hole of a control horn. Insert the

other end into the screw lock pushrod connector. Align the

pushrod perpendicular to the hinge line and align the holes

in the control horns directly over the aileron hinge line. Mark

the location of the control horn mounting holes. Repeat this

step for the other aileron servo.

8. Use medium or thick CA to glue the carbon anti-rotation

❏

pins into the wing root ribs. The pins should protrude beyond

the ribs approximately 5/16" [8mm].

7

9. Install the axles onto the landing gear legs using the

❏

included landing gear nuts and threadlocking compound.

12. Thread a 2x6mm self-tapping screw into each hole in

❏

the wheel pants and back it out. Apply a drop of thin CA to

each hole and allow the glue to dry. Install the wheel pants

onto the landing gear with four 2x6mm self-tapping screws.

13. Bolt the landing gear legs to the wing panels using

❏

six 3x10mm machine screws and threadlocking compound.

10. Slide a 4mm wheel collar onto each axle followed

❏

by a main wheel and another 4mm wheel collar. Mark the

location of the screw holes in the wheel collars onto the

axles. Remove the wheel collars and wheels and use a fi le

or rotary tool to grind fl at spots onto the axles at the marks

you made.

11. Install the wheel collars and main wheels onto the

❏

axles. Secure the collars onto the axles with 3mm set screws

and threadlocking compound. Be sure that the wheels rotate

freely. Oil them if necessary.

8

Loading...

Loading...