Page 1

INSTRUCTION MANUAL

™

Wingspan: 30 in [760mm]

Wing Area: 332 sq in [21.4 dm2]

Weight: 7.5 – 8.0 oz. [215 – 225g]

Wing Loading: 3.3 – 3.4 oz/sq ft [10 – 11 g/dm2]

Length: 22 in [545mm]

Radio: 3-Channel with two micro servos

Motor: RimFire™ 250 (28-13-1750kV),

WARRANTY

Great Planes® Model Manufacturing Co. guarantees this kit to

be free from defects in both material and workmanship at the date

of purchase. This warranty does not cover any component parts

damaged by use or modifi cation. In no case shall Great Planes’

liability exceed the original cost of the purchased kit. Further,

Great Planes reserves the right to change or modify this warranty

without notice.

In that Great Planes has no control over the fi nal assembly or

material used for fi nal assembly, no liability shall be assumed nor

accepted for any damage resulting from the use by the user of

the fi nal user-assembled product. By the act of using the userassembled product, the user accepts all resulting liability.

If the buyer is not prepared to accept the liability associated

with the use of this product, the buyer is advised to return

7.4V (2S) LiPo 300mAh, SS-8 ESC

this kit immediately in new and unused condition to the place

of purchase.

To make a warranty claim send the defective part or item to Hobby

Services at the address below:

Hobby Services

3002 N. Apollo Dr., Suite 1

Champaign, IL 61822 USA

Include a letter stating your name, return shipping address, as

much contact information as possible (daytime telephone number,

fax number, e-mail address), a detailed description of the problem

and a photocopy of the purchase receipt. Upon receipt of the

package, the problem will be evaluated as quickly as possible.

READ THROUGH THIS MANUAL BEFORE STARTING CONSTRUCTION. IT CONTAINS IMPORTANT

INSTRUCTIONS AND WARNINGS CONCERNING THE ASSEMBLY AND USE OF THIS MODEL.

Entire Contents © Copyright 2008

Champaign, Illinois

(217) 398-8970, Ext 5

airsupport@greatplanes.com

GPMA1133Mnl1.0

Page 2

TABLE OF CONTENTS

AMA

INTRODUCTION ............................................................... 2

PRECAUTIONS ................................................................. 2

DECISIONS YOU MUST MAKE ........................................ 3

Motor, Battery, ESC Recommendations .................... 3

Radio Equipment ......................................................3

ADDITIONAL ITEMS REQUIRED .................................... 3

KIT INSPECTION .............................................................. 3

KIT CONTENTS ................................................................ 3

ASSEMBLY ....................................................................... 4

Join the Bottom Wing to the Fuselage ....................... 4

Join the Stab and Fin to the Fuselage ....................... 4

Hook up the Elevator and Rudder .............................. 6

Mount the Motor, ESC and Battery ............................ 6

Mount the Top Wing and Main Landing Gear ............. 7

Attach the Cowl and Add the Decals .........................8

OPTIONAL: Add the Flying Wires .............................. 9

GET THE MODEL READY TO FLY ................................. 10

Check the Control Directions ................................... 10

Set the Control Throws ............................................ 10

Balance the Model (C.G.).........................................11

PREFLIGHT .................................................................... 11

Charge the Batteries ................................................ 11

Balance Propellers ................................................... 11

MOTOR SAFETY PRECAUTIONS ...................Back Cover

FLYING ..............................................................Back Cover

Ground Check and Range Check ..............Back Cover

Flight ..........................................................Back Cover

If you are not already a member of the AMA, please join! The

AMA is the governing body of model aviation and membership

provides liability insurance coverage, protects modelers’ rights

and interests and is required to fl y at most R/C sites.

Academy of Model Aeronautics

5151 East Memorial Drive

Muncie, IN 47302

Tele: (800) 435-9262

Fax (765) 741-0057

Or via the Internet at:

http://www.modelaircraft.org

IMPORTANT!!! Two of the most important things you can do

to preserve the radio controlled aircraft hobby are to avoid

fl ying near full-scale aircraft and avoid fl ying near or over

groups of people.

PROTECT YOUR MODEL, YOURSELF

& OTHERS...FOLLOW THESE

IMPORTANT SAFETY PRECAUTIONS

1. Your Sopwith Pup should not be considered a toy, but rather

a sophisticated, working model that functions very much like a

full-size airplane. Because of its performance capabilities, the

Pup, if not assembled and operated correctly, could possibly

cause injury to yourself or spectators and damage to property.

INTRODUCTION

Thank you for purchasing the ElectriFly Sopwith Pup Slow

Flyer EP ARF. Obviously, the Pup was intended for indoor

fl ying, but is also fun to fl y outdoors on calm evenings or in

the morning when the winds are still calm.

For the latest technical updates or manual corrections

to the Sopwith Pup, visit the Great Planes web site at

www.greatplanes.com. Open the “Airplanes” link, then

select the ElectriFly Sopwith Pup ARF. If there is new technical

information or changes to this model a “tech notice” box will

appear in the upper left corner of the page.

2. You must assemble the model according to the instructions.

Do not alter or modify the model, as doing so may result in an

unsafe or unfl yable model. In a few cases the instructions may

differ slightly from the photos. In those instances the written

instructions should be considered as correct.

3. You must take time to build straight, true and strong.

4. You must use an R/C radio system that is in good condition,

a correctly sized engine, and other components as specifi ed

in this instruction manual. All components must be correctly

installed so that the model operates correctly on the ground

and in the air. You must check the operation of the model and

all components before every fl ight.

5. If you are not an experienced pilot or have not fl own

this type of model before, we recommend that you get the

assistance of an experienced pilot in your R/C club for

your fi rst fl ights. If you’re not a member of a club, your local

hobby shop has information about clubs in your area whose

membership includes experienced pilots.

6. While this kit has been fl ight tested to exceed normal use,

if the plane will be used for extremely high stress fl ying, such

as aggressive aerobatics, or if a motor larger than one in the

recommended range is used, the modeler is responsible

for taking steps to reinforce the high stress points and/or

substituting hardware more suitable for the increased stress.

2

Page 3

We, as the kit manufacturer, provide you with a top quality,

thoroughly tested kit and instructions, but ultimately the

quality and fl yability of your fi nished model depends

on how you build it; therefore, we cannot in any way

guarantee the performance of your completed model,

and no representations are expressed or implied as to

the performance or safety of your completed model.

Remember: Take your time and follow the instructions to

end up with a well-built model that is straight and true.

Radio Equipment

The ElectriFly Sopwith Pup is designed to fl y on three

channels—elevator, rudder and throttle. Two ES40 Pico

Micro Servos (GPMM1200) are recommended and are

featured in this manual. A minimum 3-channel receiver is

also required.

ADDITIONAL ITEMS REQUIRED

DECISIONS YOU MUST MAKE

This is a partial list of items required to fi nish the Sopwith Pup

that may require planning or decision making before starting to

build. Order numbers are provided in parentheses.

Motor, Battery and ESC

Recommendations

The ElectriFly Sopwith Pup was designed to fl y with a RimFire

250 (28-13-1750kV) Outrunner Motor (GPMG4502)

powered by either a 7.4V (2S) 300mAh ElectriFly Power

Series LiPo Battery (GPMP0594) or a 7.4V (2S) 300mAh

ElectriFly Competition BP LiPo Battery (GPMP0700). The

Power Series battery will allow the Pup to fl y longer, but the

Competition BP is lighter weight and will provide more power.

An ElectriFly SS-8 8 Amp Brushless ESC (electronic speed

control) is also required (GPMM1800).

Finally, a suitable propeller such as a Great Planes 8 x 6

Power Flow Slo-Flyer Electric Propeller (GPMQ6610, qty.

2) will also be required.

In addition to common hobby tools, this is the list of additional

accessories and building supplies required to fi nish the Pup.

Order numbers are provided in parentheses.

❏ Medium foam-safe CA (GPMR6069)

❏ J&Z R/C-56 white glue (or any household white glue)

❏ Optional: Black thread or string for fl ying wires (see page 8)

KIT INSPECTION

Before starting to build, take an inventory of this kit to make

sure it is complete, and inspect the parts to make sure they

are of acceptable quality. If any parts are missing or are not of

acceptable quality, or if you need assistance with assembly,

contact Product Support.

Great Planes Product Support

3002 N Apollo Drive, Suite 1

Champaign, IL 61822

Telephone: (217) 398-8970, ext. 5

Fax: (217) 398-7721

E-mail: airsupport@greatplanes.com

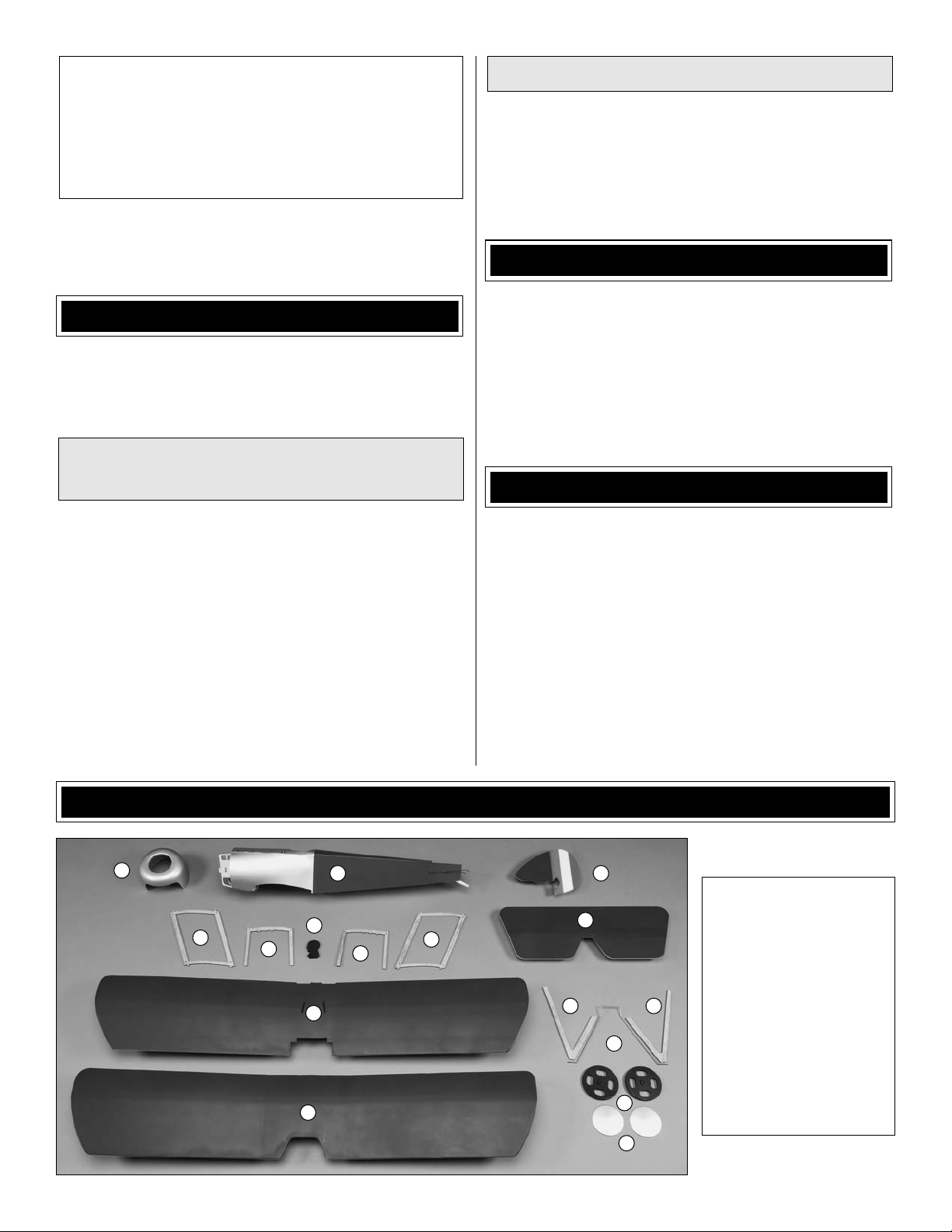

KIT CONTENTS

1

5

6

2 3

7

5

6

8

9

3

4

10 10

11

12

13

1. Cowl

2. Fuselage

3. Vertical Stabilizer

4. Horizontal Stabilizer

5. Struts (2)

6. Cabanes (2)

7. Pilot

8. Bottom Wing

9. Top Wing

10. Landing Gear Covers (2)

11. Landing Gear Wire

12. Wheels (2)

13. Wheel Covers (2)

Page 4

ASSEMBLY

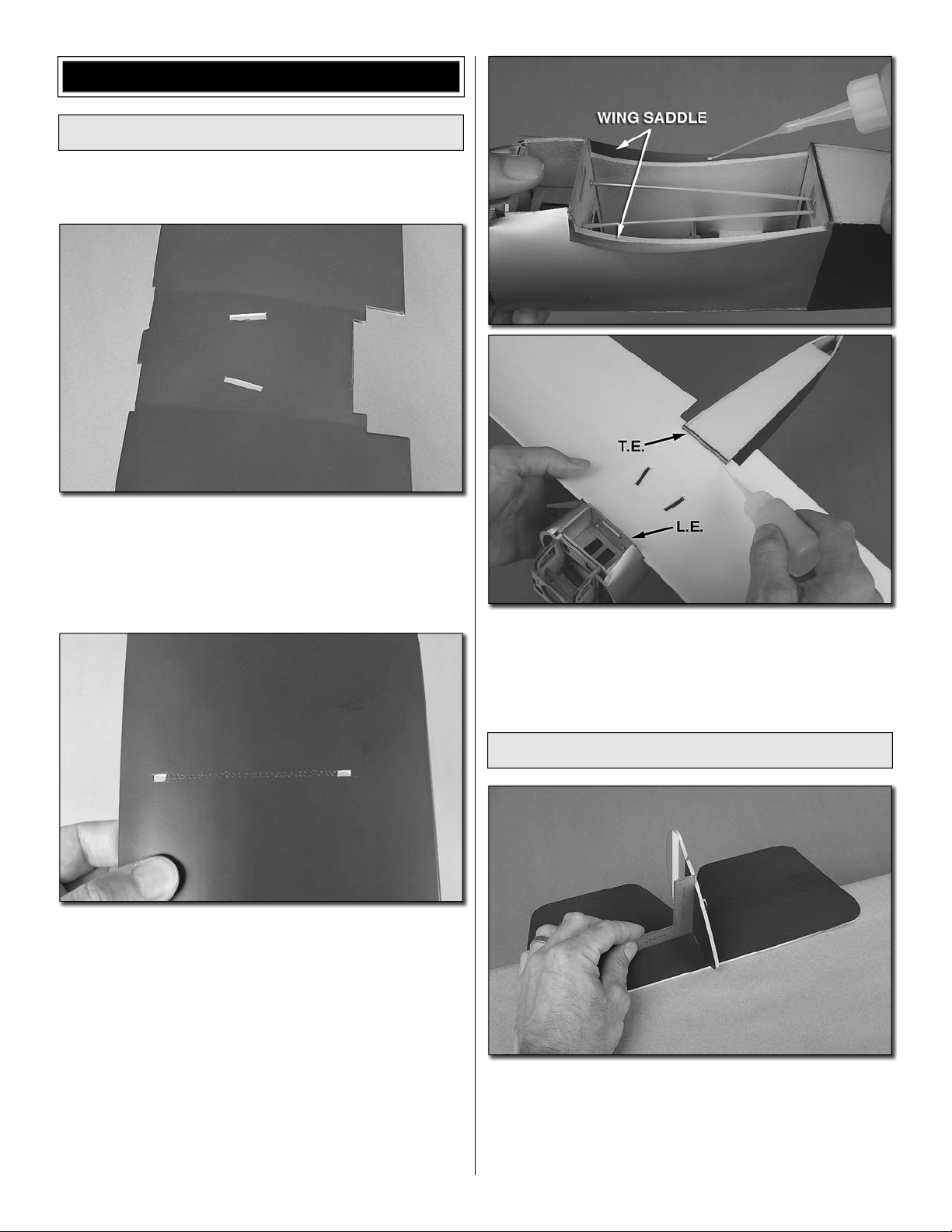

Join the Bottom Wing to the Fuselage

The bottom wing is done fi rst so it can be used as a reference

for aligning the horizontal stabilizer.

❏ 1. Use a sharp hobby knife to cut the skin from the top of

the bottom wing over the landing gear slots. Also cut the skin

from the slots near both ends of the wing for the struts.

❏ 2. Using a pin with a straightedge as a guide, perforate

the skin of the bottom wing between the outer strut slots

as shown, but don’t poke the holes all the way through to

the bottom. These perforations will strengthen the glue bond

between the struts and wing.

❏ 3. Test fi t the bottom wing to the fuselage. When satisfi ed

with the fi t, apply a generous bead of foam-safe CA to both

wing saddles on the fuselage, and then place the wing into

position. Also glue the leading and trailing edges of the wings

to the balsa formers.

Join the Stab and Fin to the Fuselage

❏ 1. Glue the vertical stabilizer (fi n) to the horizontal stabilizer

(stab) using a small builder’s square to make sure they are

perpendicular. Note: Don’t build up a large fi llet of CA. Later,

after the model has been completed, all of the glue joints

will be reinforced with white glue (such as R/C 56 or regular

white glue).

4

Page 5

AA'

A = A'

❏ 2. Hold the stab/fi n assembly into position on the fuselage.

View the alignment of the stab and wing from behind. If the

stab and wing are not parallel with each other, use a sharp

hobby knife to carefully trim the “high side” of the stab saddle

to achieve the alignment.

❏ 5. Use foam-safe CA to securely glue the horn into position.

❏ 6. Glue the plywood horn keeper to the other side of the

horn and to the top of the elevator.

❏ 3. Once the stab aligns with the wing, hold the assembly

to the fuselage. Center the LE of the fi n with the top of

the fuselage and the LE of the rudder with the back of the

fuselage. Securely glue the stab into position. Reinforce the

joint by gluing from the bottom up inside the fuselage.

❏ 4. As shown in the photo, fi t one of the plywood control

horns to the Z-bend on the end of the elevator pushrod

(already in the fuselage). Fit the horn into the slot in the

bottom of the elevator. Use a sharp #11 hobby knife to cut

the hinge tape from the slot on the top of the elevator so the

horn will go all the way through. Note: If the pushrod is too

long it may be bumping up against the former in the front of

the servo compartment—cut the pushrod if necessary, but

cut only enough to allow the horn to fi t—otherwise you may

inadvertently cut the wire too short.

❏ 7. Fit the other horn and keeper to the rudder pushrod and

glue them to the rudder the same way.

5

Page 6

Hook Up the Elevator and Rudder

K

Refer to this picture while hooking up

the elevator and rudder.

1/4"

[6.5mm]

5/16"

[8mm]

Mount the Motor, ESC and Battery

❏ 1. Cut a 1-1/4" x 1/2" [32 x 12mm] strip from the “rough”

side of the adhesive-backed hook-and-loop strip that

came with this kit. Stick the strip to the back of the fi rewall

brace just behind the fi rewall. This is where the battery will

be mounted.

ELEVATOR

RUDDER

❏ 1. In order to achieve the correct elevator and rudder throws

specifi ed on page 11, the pushrods need to be connected to

the servo arms as shown. If your servo arms don’t already

have holes that are the correct distance out, drill new holes in

the servo arms you will be using and cut off the unused arms.

❏ 2. Place the elevator and rudder servos in the servo tray in

the fuselage. Temporarily connect the servos to your receiver

with the battery and ESC so you can power the system up.

Note: With 3-channel models such as this (where there are

no ailerons), it is common to connect the rudder servo into

the “aileron” channel in the receiver. This way, the right stick

will still be used for turning the model. If it is your preference

however, you may connect the rudder servo into the rudder

channel instead.

SCREW-LOC

CONNECTOR

❏ 3. Turn on your

transmitter and plug in

the battery and center the

servos. Connect screwlock connectors to the

servo arms. Then fi t the

arms onto the servos.

SERVO ARM

NYLON

RETAINER

❏ 4. Connect the pushrods to the screw-lock connectors on

the servo arms, and center the elevator and rudder. Then,

with a drop of threadlocker on the screws, tighten the screws

in the screw-lock connectors to lock the pushrods down.

❏ 5. Use CA to glue the servos into position. Install the screws

that hold the servo arms onto the servo output shafts.

❏ 2. Mount the motor with the included (3) 2 x 5mm Phillips

wood screws. Use the included adhesive-backed hook-andloop strips, or double-sided foam tape (not included), to

mount the receiver and ESC. Guide excess wiring behind

each component inside the fuselage.

6

Page 7

❏ 3. If you’ve mounted a 2.4GHz receiver as shown in the

photo, guide one of the antennas back through the fuselage.

The other antenna will be looped around the inside of the

cowl when it is mounted later. If you've mounted a 72MHz

receiver, guide the antenna down and out the bottom of the

fuselage. Tape the antenna to the bottom of the fuselage in a

few places so it will not get caught in the wheels or propeller

or drag on the ground.

❏ 4. Test fi t the cowl to make sure none of the wiring or the

ESC or receiver interfere with the fi t.

Mount the Top Wing

and the Landing Gear

Refer to this picture while mounting the top wing.

from the bottom to make certain top wing is parallel with the

bottom wing by “eyeballing” the leading edges. If necessary,

trim the notches for the cabanes in the top wing to get it

parallel with the bottom wing.

❏ 3. Holding the top wing to the cabanes in alignment with the

bottom wing, glue the wing to the cabanes. Without adding

any twist to the wings, glue the wing struts into position.

TIGHTER CURVE

(FORWARD)

❏ 1. Test fi t the cabanes into the fuselage so they are facing

the correct direction as illustrated—the part with the “tighter

curve” on the top goes forward. If necessary, trim the cutouts

in the thin, plastic fuselage top so the cabanes fi t easily, then

glue them into position.

❏ 4. Wipe any residual oil or fi lm from the main landing gear

wire using a small paper towel scrap and denatured alcohol.

Roughen the gear with medium-grit sandpaper so glue will

adhere. Fit the gear into position. Note that it sweeps back.

Note: The gear could be permanently glued into position,

but it should fi t tight enough so that no glue is required.

❏ 2. Test fi t the top wing to the cabanes by fi tting the tabs

of the cabanes into the notches in the wing. View the model

❏ 5. Test fi t, then use CA to glue the plywood landing gear

covers onto the gear wire. If necessary, trim the slots in the

bottom wing to accommodate the braces.

7

Page 8

❏ 6. Fit the wheels onto the gear followed by the small, black

nylon wheel retainers.

Attach the Cowl and Add the Decals

❏ 1. Before attaching the cowl, connect your battery and turn

on the radio and momentarily power up the motor to make

sure it is turning the correct direction (counterclockwise when

viewed from the front). If the motor is turning backwards, switch

any two wires between the motor and ESC with each other.

❏ 2. Fit the cowl into position. If using a 2.4GHz receiver,

loop the second antenna (that is not inside the fuselage)

around the inside of the cowl. Use a few pieces of clear

tape to hold the cowl in place. Mount the propeller with the

propeller saver O-ring.

❏ 7. Glue the wheel covers to the wheels—it may be

necessary to cut a portion of the gear wire protruding from

the wheel retainers to accommodate the covers. An easy way

to glue on the hubs is to hold the plane in your lap with the

wings vertical and the fuselage across your legs. Hold the

cover in position with your thumb and your fi ngers around

the other side of the wheels, and then apply medium CA all

the way around.

❏ 8. Now that all the parts of the airframe have been glued

together, reinforce the joints between the wings and the

wood struts with J&Z Products RC-56 or white glue. Do the

same for the tail surfaces.

❏ 3. While we’re working on the front end, cut a small strip of

the softer “loop” side of the adhesive-backed hook-and-loop

material and attach it to the middle of the battery. Test mount

the battery in the fuselage.

❏ 4. Cut out the decals and carefully position on the model

where shown on the kit box cover.

❏ 9. Glue the pilot into position.

8

Page 9

OPTIONAL: Add the Flying Wires

The fl ying wires are not included and are optional, but are

one way to add realism and interest to your model. However,

a little dexterity will be required to “lace them up.” If you wish

to install the optional fl ying wires, use medium/heavy, black

sewing thread, black carpet thread or any other lightweight

line that seems appropriate. A wood toothpick or small wood

dowel will also be required to anchor the ends of the lines

down into the bottom wing at the fuselage.

❏ 3. Turn the fuselage over. Using care to keep the lines

just tight enough so they don’t sag, but not so tight as to

introduce any warp into the wings, tie the other end of each

line down to the holes in the bottom wing struts.

❏ 4. Cut four more 20” [500mm]

pieces of line. Cut a toothpick or

small wood dowel into four 3/8”

[10mm] pieces. Tie one end of each

string onto each dowel. Wrap each

string around the dowel a few times,

then set with a drop of thin CA.

❏ 1. If necessary, use a hobby knife or a pin vise with a small

drill to reopen any of the holes in the cabanes or wing struts

that may have been covered with glue.

1/4"

[6mm]

2-1/8"

[55mm]

❏ 5. Going down at an angle through the top of the bottom

wing, use a pin to poke four holes for the strings on both

sides of the fuselage where shown in the illustration.

❏ 2. Cut four 20” [500mm] pieces of line. Turn the model

upside-down and tie one end of each line to the cabanes.

After you tie each knot, add a drop of thin, foam-safe CA and

cut off any excess line.

❏ 6. Guide the strings up through the holes in the bottom

of the wing. Tie the other ends of the strings to the holes in

the tops of the wing struts. Add a few drops of thin CA to the

toothpicks in the bottom wing and to the knots on the ends of

the strings at the struts. Cut off any excess line.

9

Page 10

GET THE MODEL READY TO FLY

Check the Control Directions

❏ 1. Connect the motor battery and turn on the transmitter

and receiver and center the trims. Make sure the elevator and

rudder are centered. If necessary, adjust the pushrods in the

screw-lock connectors and center the elevator and rudder.

3-CHANNEL

RADIO SET UP

RUDDER

MOVES RIGHT

(STANDARD MODE 2)

FULL

THROTTLE

ELEVATOR

MOVES DOWN

❏ 2. Make certain that elevator, rudder and throttle respond

in the correct direction as shown in the diagram. If any of

the controls respond in the wrong direction, use the servo

reversing in the transmitter to reverse the servos connected

to those controls. Be certain the control surfaces have

remained centered. Adjust if necessary.

MOVE THE RULER

FORWARD

❏ 1. Prop up the rear of the fuselage on a box or something

so the horizontal stabilizer will be level. Holding a ruler

vertical, place it up against the trailing edge of the elevator

and note the measurement. Use the transmitter to defl ect

the elevator. Keeping the ruler vertical, move it forward until

it is touching the trailing edge of the elevator again. Note the

new measurement. The difference in the two measurements

is the control throw.

Set the Control Throws

To ensure a successful fi rst fl ight, fl y your Sopwith Pup

set up according only to the C.G. and control surface

throws specifi ed in this manual. The throws and C.G. are

not arbitrary, but have been determined through extensive

testing and accurate record-keeping. This provides you

with the best chance for success and enjoyable fi rst fl ights

that should be surprise-free. Additionally, the throws

and C.G. shown are true, real data which will allow the

model to perform in the manner in which it was intended

when fl own by a pilot of the skill level for which it was

intended. DO NOT OVERLOOK THESE IMPORTANT

PROCEDURES. A model that is not properly set up may

be unstable and possibly unfl yable.

❏ 2. If you mounted the screw-lock connectors the correct

distance (5/16" [8mm]) out on the servo arms, the throws

should be correct (or very close). If necessary, use your

endpoint adjustments in the transmitter to set the correct

high and low rate throws.

❏ 3. Measure the rudder throw at the widest part of the

rudder the same way.

10

Page 11

These are the recommended control surface throws:

HIGH RATE LOW RATE

Up

Down

Up

Down

model is “nose heavy” and weight must be added to the tail

to balance. If additional weight is required use segments of

Great Planes “stick-on” lead (GPMQ4485). If nose weight is

required, don’t attach it to the cowl. Attach any nose weight

required to the fi rewall.

ELEVATOR

RUDDER

5/8"

[16mm]

17°

Right

1-1/4"

[32mm]

25°

5/8"

[16mm]

17°

Left

1-1/4"

[32mm]

25°

3/8"

[10mm]

10°

Right

3/4"

[19mm]

15°

3/8"

[10mm]

10°

Left

3/4"

[19mm]

15°

Balance the Model (C.G.)

At this stage the model should be in ready-to-fl y condition

with all of the systems in place including the motor, complete

radio system, ESC, propeller and battery.

❏ 3. IMPORTANT: If you found it necessary to add any weight,

recheck the C.G. after the weight has been installed.

PREFLIGHT

Charge the Batteries

Follow the battery charging instructions that came with your

radio control system to charge the transmitter batteries.

You should always charge your transmitter and receiver

batteries the night before you go fl ying, and at other times as

recommended by the radio manufacturer.

CAUTION: Unless the instructions that came with your

radio system state differently, the initial charge on new

transmitter and receiver batteries should be done for 15

hours using the slow-charger that came with the radio

system. This will “condition” the batteries so that the

next charge may be done using the fast-charger of your

choice. If the initial charge is done with a fast-charger, the

batteries may not reach their full capacity and you may be

fl ying with batteries that are only partially charged.

❏ 1. Note the “balance spikes” under the top of the cabanes.

These indicate the forward, aft, and recommended (middle)

C.G. locations. For fi rst fl ights it is recommended to balance

the model at the middle location.

❏ 2. Lift the model with your fi ngers under the middle balance

spikes. If the tail drops, the model is “tail heavy” and weight

must be added to the nose to balance. If the nose drops, the

Balance Propellers

Take a few minutes to balance your propeller and a spare

propeller before you fl y. A balanced propeller will allow the

motor run smoothly and effi ciently. A severely unbalanced

propeller can cause enough vibration to stress glue joints

and cause screws to loosen.

If the propeller is unbalanced, use a single-edge razor blade

or a hobby knife to scrape material off the heavy blade until

you can get the propeller to balance.

11

Page 12

MOTOR SAFETY PRECAUTIONS

Flight

Failure to follow these safety precautions may result

in severe injury to yourself and others.

• Use safety glasses when starting or running motors.

• Do not run the motor in an area of loose gravel or sand; the

propeller may throw such material in your face or eyes.

• Keep your face and body as well as all spectators away

from the plane of rotation of the propeller as you start and

run the motor.

• Keep loose clothing, shirt sleeves, ties, scarfs, long hair or

loose objects such as pencils or screwdrivers that may fall

out of shirt or jacket pockets away from the prop.

FLYING

Ground Check and Range Check

When you get to your fl ying site ground check the operational

range of your radio before the fi rst fl ight following the

manufacturer’s instructions that came with your radio. This

should be done both with the motor off and with the motor

running at various speeds. If the motor or control surfaces do

not respond correctly or move erratically without command,

do not fl y! Find and correct the problem fi rst. Look for loose

servo connections or broken or loose motor or battery wires.

The SlowFly Sopwith Pup is capable of “ROG” (rise off

ground) takeoffs as long as the surface is smooth (as any

indoor venue would be), but if fl ying outdoors over grass

a hand-launch will be required. To hand-launch, hold the

model by the fuselage just behind the cockpit and advance

the throttle. Give the model a gentle push with a slightly

nose-up attitude and let go. Allow the model to momentarily

sink while it gains fl ying speed and work the controls to keep

the wings and fuselage level. Once, after just a second or

two, the model has gained suffi cient fl ying speed, establish

a gentle climb.

Once at “altitude” the fi rst priority will be to trim the elevator

and rudder so the model fl ies straight-and-level. Once the

model has been trimmed continue to fl y around for a few

minutes getting used to how the model responds. If using

dual rates, switch between the rates to see how the model

responds. At a safe altitude, cut the power and see how the

model reacts. Make sure there will be enough elevator to

make a landing fl air.

After fl ying around for a few minutes make a few landing

approaches. Once you have an approach you “like,” simply

allow the model to land, applying elevator to execute the fl air.

If there is enough battery power you could perform another

takeoff and continue to fl y around, or go back and change

the battery (or recharge the battery you are using).

One fi nal note about fl ying your model. Have a goal or fl ight

plan in mind for every fl ight. This can be learning a new

maneuver(s), improving a maneuver(s) you already know,

or learning how the model behaves in certain conditions

(such as on high or low rates). This is not necessarily to

improve your skills (though it is never a bad idea!), but more

importantly so you do not surprise yourself by impulsively

attempting a maneuver and suddenly fi nding that you’ve run

out of time, altitude or airspeed. Every maneuver should be

deliberate, not impulsive. For example, if you’re going to do a

loop, check your altitude, mind the wind direction (anticipating

rudder corrections that will be required to maintain heading),

remember to throttle back at the top, and make certain you

are on the desired rates (high/low rates). A fl ight plan greatly

reduces the chances of crashing your model just because of

poor planning and impulsive moves. Remember to think.

Please fi ll in this identifi cation tag

and place inside your model.

Have a ball! But always stay in control

and fl y in a safe manner

GOOD LUCK AND GREAT FLYING!

Loading...

Loading...