Great Planes GPMA1117 User Manual

WARRANTY

Great Planes

®

Model Manufacturing Co. guarantees this kit to be free from defects in both material and workmanship at the date of

purchase.This warranty does not cover any component parts damaged by use or modification. In no case shall Great Planes’ liability

exceed the original cost of the purchased kit. Further, Great Planes reserves the right to change or modify this warranty without notice.

In that Great Planes has no control over the final assembly or material used for final assembly, no liability shall be assumed nor

accepted for any damage resulting from the use by the user of the final user-assemb led product.By the act of using the user-assembled

product, the user accepts all resulting liability.

If the buyer is not prepared to accept the liability associated with the use of this product, the buyer is advised to return this

kit immediately in new and unused condition to the place of purchase.

To make a warranty claim send the defective part or item to Hobby Services at the address below:

Hobby Services

3002 N. Apollo Dr., Suite 1

Champaign, IL 61822 USA

Include a letter stating your name, return shipping address, as much contact information as possible (daytime telephone number, fax

number, e-mail address), a detailed description of the problem and a photocopy of the purchase receipt. Upon receipt of the package

the problem will be evaluated as quickly as possible.

READ THROUGH THIS MANUAL BEFORE STARTING

CONSTRUCTION. IT CONTAINS IMPORTANT WARNINGS

AND INSTRUCTIONS CONCERNING THE ASSEMBLY

AND USE OF THIS MODEL.

GPMZ0183 for GPMA1117 V1.1Entire Contents © Copyright 2006

Champaign, Illinois

(217) 398-8970, Ext 5

airsupport@greatplanes.com

INSTRUCTION MANUAL

Wingspan: 31 in [780 mm]

Wing Area: 420 sq in [27dm2]

Weight: 10 – 12 oz [285 – 340g]

Wing Loading: 3.9 oz/sq ft [10 – 12g/dm2]

Length: 34 in [850 mm]

Radio: 4-channel w/3 micro servos and 8-Amp Brushless ESC

Power System: Direct-drive RimFire™Brushless motor (not included)

By Great Planes

2

INTRODUCTION ...............................................................2

SAFETY PRECAUTIONS..................................................2

LITHIUM BATTERY HANDLING & USAGE.....................3

DECISIONS YOU MUST MAKE........................................3

Motor ...........................................................................3

Transmitter...................................................................3

Servos .........................................................................3

Receiver ......................................................................4

Battery.........................................................................4

Speed Control .............................................................4

Charger .......................................................................4

Battery Charging Leads ..............................................4

Propeller Selection......................................................4

Glue.............................................................................4

ADDITIONAL ITEMS REQUIRED.....................................4

Adhesives & Building Supplies....................................4

ORDERING REPLACEMENT PARTS ..............................5

COMMON ABBREVIATIONS............................................5

METRIC CONVERSIONS .................................................5

KIT INSPECTION..............................................................6

KIT CONTENTS ................................................................6

BUILDING INSTRUCTIONS..............................................7

Assemble the Horizontal Tail .......................................7

Assemble the Fuselage...............................................8

Finish the Fuselage...................................................10

Assemble the Wing....................................................11

Connect the Rod Struts .............................................12

Finish the Wings........................................................13

Assemble the Landing Gear......................................14

Install the Servos.......................................................15

Install the Motor System............................................16

GET THE MODEL READY TO FLY .................................17

Check the Control Directions ....................................17

Set the Control Throws..............................................18

Balance the Model (C.G.)..........................................18

Balance the Model Laterally ......................................19

PREFLIGHT.....................................................................19

Identify Your Model....................................................19

Charge the Batteries .................................................19

Balance the Propellers..............................................19

Range Check.............................................................19

MOTOR SAFETY PRECAUTIONS .................................19

AMA SAFETY CODE (excerpts)....................................20

General......................................................................20

Radio Control ............................................................20

CHECK LIST ...................................................................20

FLYING ............................................................................20

Hand Launch.............................................................20

Rise-Off-Ground (ROG) Takeoffs ..............................21

Flight..........................................................................21

Landing......................................................................21

ANGLE TEMPLA TES......................................................23

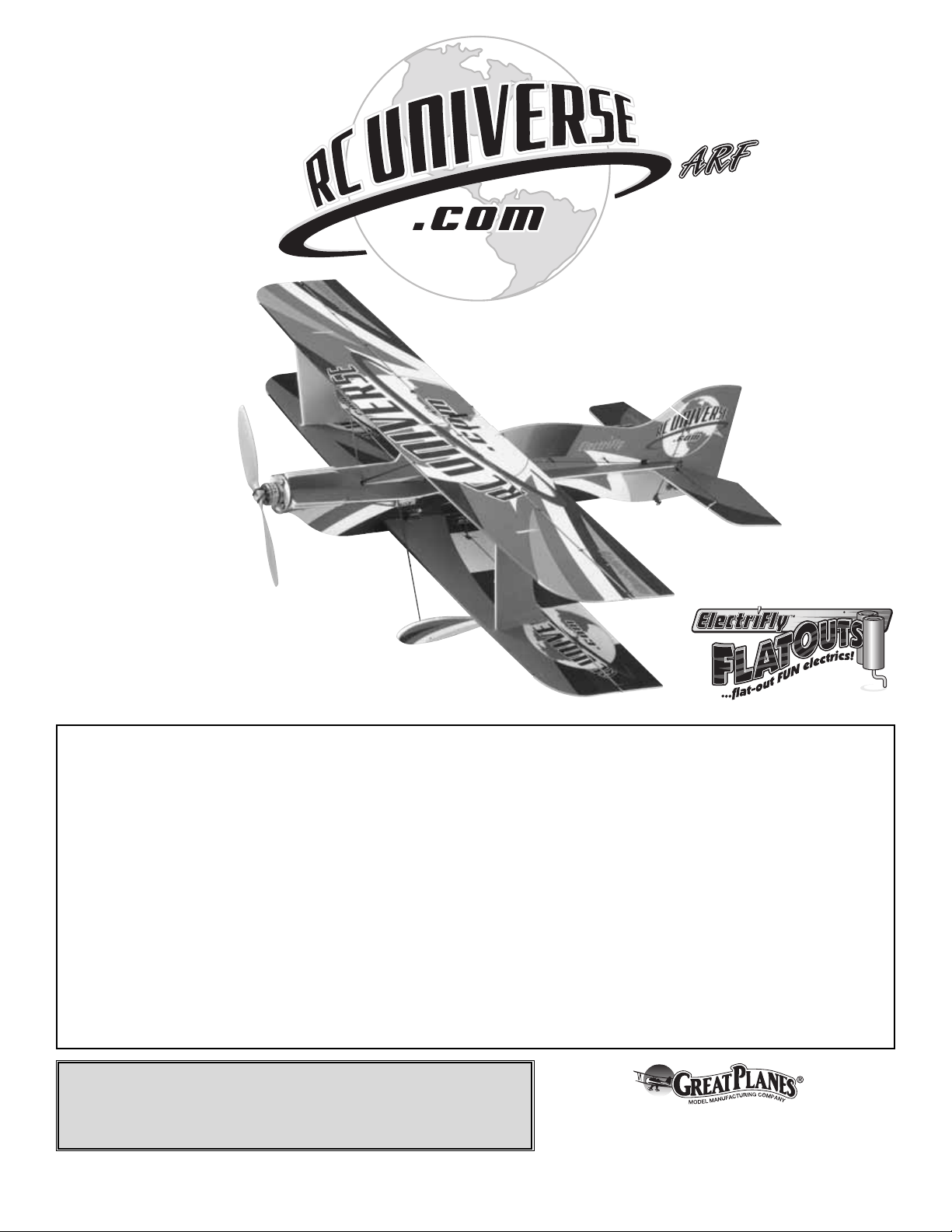

The ElectriFly

™

by Great Planes FlatOuts R/C Universe Bipe

is an excellent way to enjoy 3D aerobatics without the cost

and headaches of giant-scale gasoline-powered models.

Four to six hours on the workbench, and your R/C Universe

Bipe will be ready to tackle torque rolls, walls, harriers, highalpha rolling circles and more! An excellent indoor or calmday outdoor performer, this airplane is a virtually unlimited

3D aerobat, but flying it involves only connecting the battery,

throttling up, and letting go!

Take care to build straight and true.Misaligned parts will hurt

the airplane’s ability to perform the extreme aerobatics it is

designed for.

For the latest technical updates or manual corrections to the

FlatOuts R/C Universe Bipe, visit the Great Planes web site

at www.greatplanes.com. Open the “Airplanes” link, and

then select the FlatOuts R/C Universe Bipe ARF. If there is

new technical information or changes to this model, a “tech

notice” box will appear in the upper left corner of the page.

Attention:The product you have purchased is

powered by a rechargeable battery. At the end

of its useful life, under various state and local

laws, it may be illegal to dispose of this battery

into the municipal waste system. Check with

your local solid waste officials for details in your area for

recycling options or proper disposal.

This product contains a chemical known to the state of

California to cause cancer and birth defects or other

reproductive harm.

1. Even though the FlatOuts R/C Universe Bipe is small,

lightweight and flies slowly, if it is not assembled and

operated correctly it could possibly cause injury to yourself

or spectators and damage property.

PRO TECT YOUR MODEL,Y OURSELF

& OTHERS...FOLLOW THESE

IMPORTANT SAFETY PRECAUTIONS

CAUTION: Be aware that the FlatOuts R/C Universe Bipe is

operated on the same frequency band as larger, “regular”

R/C models.If flying your R/C Universe Bipe within five miles

of an R/C site, there is a real possibility that you could be

operating your model on the same frequency (channel) as

another R/C pilot.If this happens a crash will result–with the

person flying the more expensive model suffering the

greater loss (and having greater potential for property

damage or injury).The best thing to do is to join an R/C club

and fly at the site where frequency control measures will be

in effect.If you insist on flying elsewhere, always be aware

of your proximity to R/C flying sites.

INTRODUCTIONTABLE OF CONTENTS

2. Build the plane according to the instructions. Do not

alter or modify the model, as doing so may result in an

unsafe or unflyable model.

3.Use an R/C radio system and components that are in firstclass condition. The FlatOuts R/C Universe Bipe requires

specialized radio gear. Refer to

“DECISIONS YOU MUST

MAKE”

to get an accurate description of the specialized

gear required.

4.You must properly install all R/C and other components so

that the model operates correctly on the ground and in the air .

5. You must test the operation of the model before every

flight to insure that all equipment is operating, and that the

model has remained structurally sound. Be sure to check

connectors often and replace them if they show signs of

wear or fatigue.

Remember:Take your time and follow directions to end

up with a well-built model that is straight and true.

If you’re not already an AMA (Academy of Model

Aeronautics) member, we highly recommend that you join.

In addition to providing liability protection while operating

under the AMA Safety Code, the AMA is the governing body

of model aeronautics in the United States and fights for your

rights as member of the modeling community.You must also

be an AMA member to fly at R/C clubs chartered by the

AMA–most of which are.Contact the AMA at the address or

toll-free phone number below.

WARNING!! Failure to follow all instructions could cause

permanent damage to the battery and its surroundings, and

cause bodily harm!

• ONLY use a LiPo approved charger. NEVER use a

NiCd/NiMH peak charger!

• NEVER charge in excess of 4.20V per cell.

• ONLY charge through the “charge” lead. NEVER charge

through the “discharge” lead.

• NEVER charge at currents greater than 1C.

• ALWAYS set charger’ s output v olts to match battery volts.

• ALWAYS charge in a fireproof location.

• NEVER trickle charge.

• NEVER allow the battery temperature to exceed

50°F (65°C).

• NEVER disassemble or modify pack wiring in any way or

puncture cells.

• NEVER discharge below 2.5V per cell.

• NEVER place on combustible materials or leave

unattended during charge or discharge.

• ALWAYS KEEP OUT OF REACH OF CHILDREN.

In the hands of a capable pilot, the FlatOuts R/C Universe

Bipe is an impressive 3D performer .But for the R/C Universe

Bipe to perform to its full potential, it must be properly

equipped with all the right gear (servos, batteries, receiver,

speed control).There may be more than one type and brand

of radio equipment that can be used, but based on extensiv e

testing, following is the equipment we recommend so you

can get the most performance out of your R/C Universe Bipe

and assemble it as shown in this instruction manual.

The FlatOuts R/C Universe Bipe performs extremely well

with the Great Planes RimFire™22M-1000 Brushless Motor

(GPMG4500) and it is the recommended motor for this

airplane. This manual covers the installation of the RimFire

motor and the plywood firewall included is designed

specifically for use with the RimFire. Other motors can be

used, however modification may be required for installation.

With a standard, four-channel radio, the FlatOuts R/C

Universe Bipe is capable of all the basic 3D maneuvers.

However, some advanced pilots who are already familiar

with handling “flat foamies” may prefer to fly this FlatOuts

with a computer radio capable of endpoint adjustments (for

fine-tuning control throws), exponentials (for “softening” the

throws near the center of the travel), and various mixing

functions (such as rudder-to-elevator mixing for extended

knife-edge flight).

The FlatOuts R/C Universe Bipe requires three

micro

servos

with a maximum weight of 9g [.3 oz] each and a minimum

torque rating of 15 oz-in. Futaba®S3108 servos

Servos

Transmitter

Motor

DECISIONS YOU MUST MAKE

LITHIUM BATTERY HANDLING & USAGE

Academy of Model Aeronautics

5151 East Memorial Drive

Muncie, IN 47302

Tele: (800) 435-9262

Fax (765) 741-0057

Or via the Internet at:

http://www.modelaircraft.org

Note: We, as the kit manufacturer, provide you with a top

quality kit and great instructions, but ultimately the quality

and flyability of your finished model depends on how you

build it; therefore, we cannot in any way guarantee the

performance of your completed model, and no

representations are expressed or implied as to the

performance or safety of your completed model.

3

(FUTM0042) are ideal because they meet the torque and

weight requirements. Although there may be other servos

that will physically fit in the model, those outside the

recommended weight and torque specifications will

adversely affect flight performance and are not

recommended. Note: During assembly when it’s time to

mount the servos, you will be instructed to glue them in. Do

not be alarmed as this is a common practice with this type

of lightweight, high-performance model. Should servo

removal ever be necessary for repair, replacement or

transfer to another model, this can be done by prying them

out with a hobby knife or a small screwdriver.

A light, four-channel receiver is recommended and must be

compatible with whatever servos will be used (not all servos

are compatible with all receivers–even servos and receivers

within the same brand).The Futaba R-114F

Micro

receiver is

recommended and is compatible with the S3108 servos

recommended. Note: Futaba receivers are sold on high and

low bands and come without crystals. Following are the order

numbers for the R-114F receiver and compatible crystals:

Low Band High Band

(Channels 11-35) (Channels 36-60)

R124F Receiver FUTL0438 FUTL0439

Crystal FUTL62** FUTL63**

**Replace the “**” in the order number for the crystals with

the preferred channel number .For example, if you w ant to fly

on channel 33, order a low band receiver and crystal

number FUTL6233.

The FlatOuts R/C Universe Bipe requires a 3-cell (11.1V),

350–700mAh lithium-polymer (LiPo) battery capable of

providing 7A continuous discharge current. The ElectriFly

3-cell,

3-Series

640mAh battery pack is recommended

(GPMP0805). Note: The ElectriFly 720mAh battery is not

recommended for this model as it is not capable of

delivering the current required by this system. For optimum

performance, battery weight should not exceed 54g [2 oz.].

An electronic speed control capable of handling a minimum

of 8A continuous current is required. Additionally, the speed

control should be as light as possible. The ElectriFly BL-8

Micro Brushless ESC w/BEC (GPMM2070) or the Electrifly

Silver Series 8A Brushless ESC w/BEC (GPMM1800) are

suitable. NEVER use speed controllers intended for

brushed motors on brushless motors.

A charger capable of charging 3-cell (11.1V) LiPo batteries

such as the ElectriFly PolyCharge 1 to 3-cell LiPo charger

(GPMM3010) must be used. If using another charger, it

must be a LiPo charger or have a LiPo charge mode. Never

charge LiPo batteries with chargers not intended for LiPo

batteries or chargers on NiMH or NiCd settings.

Overcharging or explosion may result. In addition to the

PolyCharge, the ElectriFly Triton™(GPMM3150) or AccuCycle Elite™(HCAP0280) are also suitable chargers.

Many chargers (including the Triton and Accu-Cycle Elite

listed above) do not include charging leads, but rather have

banana jacks to plug the leads into. If this is the case with

your charger, you will need to purchase a charge lead to

match your battery. For the recommended 640mAh pack,

the correct lead is GPMM3105.

The Great Planes 9x3.5S (GPMQ6625) propeller offers very

good performance with the Great Planes RimFire motor system.

A Great Planes 10x3.5 (GPMQ6655) propeller will also offer

good performance.

Though there may be a few different types of adhesives that

the FlatOuts R/C Universe Bipe could be assembled with, we

have had the best success with and exclusively recommend,

foam-safe CA such as Great Planes 1 oz.thick, foam-safe CA

(GPMR6072).Thin, foam-safe CA such as Hot Stuff UFO thin

CA (HOTR1040) is also used in the construction of this model.

Regular CA is not recommended as it will aggressively attack

the foam used in this model. In addition to being foamcompatible, foam-saf e CA is also suitable f or gluing together all

of the rest of the materials (balsa, carbon) included in this kit.

No other adhesive is required to build the FlatOuts R/C

Universe Bipe.

In addition to common household tools and hobby tools, this

is the “short list”of the most important items required to build

the FlatOuts R/C Universe Bipe:

❏ Great Planes Aerosol Activator (GPMR6034)

❏ Hobbico

®

CA Applicator tips (HCAR3780)

❏ Hobby knife with #11 blade (HCAR0100)

Adhesives & Building Supplies

ADDITIONAL ITEMS REQUIRED

Glue

Propeller Selection

Battery Charging Leads

Charger

Speed Control

Battery

Receiver

4

❏ #11 blades (5-pack – HCAR0211)

❏ 1-meter metric ruler (for identifying tubes and rods)

❏ 5-1/2" [140 mm] Easy-Touch

™

bar sander (GPMR6169)

with 220-grit sandpaper (GPMR6185)

❏ Drill bits: 1/16" [1.5 mm], 3/32" [2.5 mm]

❏ Double-sided foam tape (GPMQ4400)

❏ Stick-on weight (GPMQ4485)

❏ Great Planes Plan Protector

™

(GPMR6167) or wax paper

Replacement parts for the Great Planes FlatOuts R/C

Universe Bipe ARF are av ailab le using the order n umbers in

the Replacement Parts List that follows.The fastest, most

economical service can be provided by your hobby dealer or

mail-order company.

To locate a hobby dealer, visit the Hobbico web site at

www.hobbico.com. Choose “Where to Buy” at the bottom of

the menu on the left side of the page. Follow the instructions

provided on the page to locate a U.S ., Canadian or International

dealer.If a hobby shop is not av ailable, replacement parts may also

be ordered from Tower Hobbies®at www.towerhobbies.com,

or by calling toll free (800) 637-6050.

Parts may also be ordered directly from Hobby Services by

calling (217) 398-0007, or via facsimile at (217) 398-7721,

but full retail prices and shipping and handling charges will

apply. Illinois and Nevada residents will also be charged

sales tax. If order ing via fax, include a Visa®or MasterCard

®

number and expiration date for payment.

Mail parts orders and payments by personal check to:

Hobby Services

3002 N. Apollo Drive, Suite 1

Champaign, IL 61822

Be certain to specify the order number exactly as listed in

the Replacement Parts List. Payment by credit card or

personal check only; no C.O.D.

If additional assistance is required for any reason contact Product

Support by e-mail at productsupport@greatplanes.com, or

by telephone at (217) 398-8970.

Replacement Parts List

Order Number Description How to Purchase

Missing pieces Contact Product Support

Instruction manual Contact Product Support

Full-size plans Not available

GPMQ6625 9x3.5S Propeller Contact Hobby Supplier

GPMQ4618 Prop Saver O-ring Contact Hobby Supplier

GPMQ4620 Prop Saver Contact Hobby Supplier

Fuse = Fuselage

Stab = Horizontal Stabilizer

Fin = Ver tical Fin

LE = Leading Edge

TE = Trailing Edge

LG = Landing Gear

Ply = Plywood

" = Inches

mm = Millimeters

SHCS = Socket Head Cap Screw

1" = 25.4 mm (conversion factor)

METRIC CONVERSIONS

COMMON ABBREVIATIONS

ORDERING REPLACEMENT PARTS

5

1/64" = .4 mm

1/32" = .8 mm

1/16" = 1.6 mm

3/32" = 2.4 mm

1/8" = 3.2 mm

5/32" = 4.0 mm

3/16" = 4.8 mm

1/4" = 6.4 mm

3/8" = 9.5 mm

1/2" = 12.7 mm

5/8" = 15.9 mm

3/4" = 19.0 mm

1" = 25.4 mm

2" = 50.8 mm

3" = 76.2 mm

6" = 152.4 mm

12" = 304.8 mm

18" = 457.2 mm

21" = 533.4 mm

24" = 609.6 mm

30" = 762.0 mm

36" = 914.4 mm

6

Before starting to build, take an inventory of this kit to make sure it is complete, and inspect the parts to make sure they

are of acceptable quality. If any parts are missing or are not of acceptable quality, or if you need assistance with assembly,

contact Product Support. When repor ting defective or missing parts, use the part names exactly as they are written in

the Kit Contents list.

Great Planes Product Support:

3002 N. Apollo Drive, Suite 1

Champaign, IL 61822

Telephone: (217) 398-8970, ext. 5

Fax: (217) 398-7721

E-mail:

airsupport@greatplanes.com

KIT INSPECTION

Plastic Tree Parts

A1 Z-Bend Clevis (10)

A2 Offset Z-Bend Clevis (4)

B1 Stand-Alone Control Horn (5)

B2 Stand-Alone Control Horn Retainer (5)

C1 Clip Hinge Control Horn (5)

C2 Clip Hinge (26)

C3 Hinge Retainer Ring (10)

C4 Aileron Link Horn (4)

D1 Axle Support (2)

D2 Rod Support (12)

D4 Tailwheel Bracket (1)

D5 Tailwheel (1)

D6 Wheel Collar (2)

E1 Control Surface Brace (4)

E2 Fuselage Joiner (3)

E3 Pushrod Suppor t (4)

F1 Wire Clip (4)

F2 Aileron Servo Mounting Tray (1)

F3 Fuselage Servo Mount (2)

F4 Fuselage Aileron Servo Mount (1)

G1 Double-Sided Offset Arm, Size B (2)

G2 Double-Sided Arm, Size B (2)

G3 Single-Sided Arm, Size B (4)

G4 Double-Sided Arm, Size A (2)

G5 Double-Sided Offset Arm, Size A (2)

G6 Single-Sided Arm, Size A (4)

G7 Double-Sided Arm, Size C (2)

G8 Double-Sided Offset Arm, Size C (2)

G9 Single-Aided Arm, Size C (4)

Carbon Rods & Tubes

Fuselage Doubler Tube 5.5 x 295 mm

Elevator Joiner Tube 3 x 216 mm

Rudder Post Tube 3 x 145 mm

Fuselage Main Tube 3 x 684 mm

Leading Edge Tube 3 x 650 mm (2)

Trailing Edge Tube 3 x 370 mm (4)

Landing Gear Rods 2 x 190 mm (2)

Wheel Axles 2 x 17 mm (2)

Rudder Pushrod 1 x 340 mm

Elevator Pushrod 1 x 370 mm

Aileron Pushrod 1 x 80 mm (2)

Aileron Link Pushrod 1 x 165 mm (2)

Other Parts

Firewall

O-rings

Top Wing Braces 2 x 115 mm (4)

Bottom Wing Braces 2 x 85 mm (2)

Kit Contents (Not Photographed)

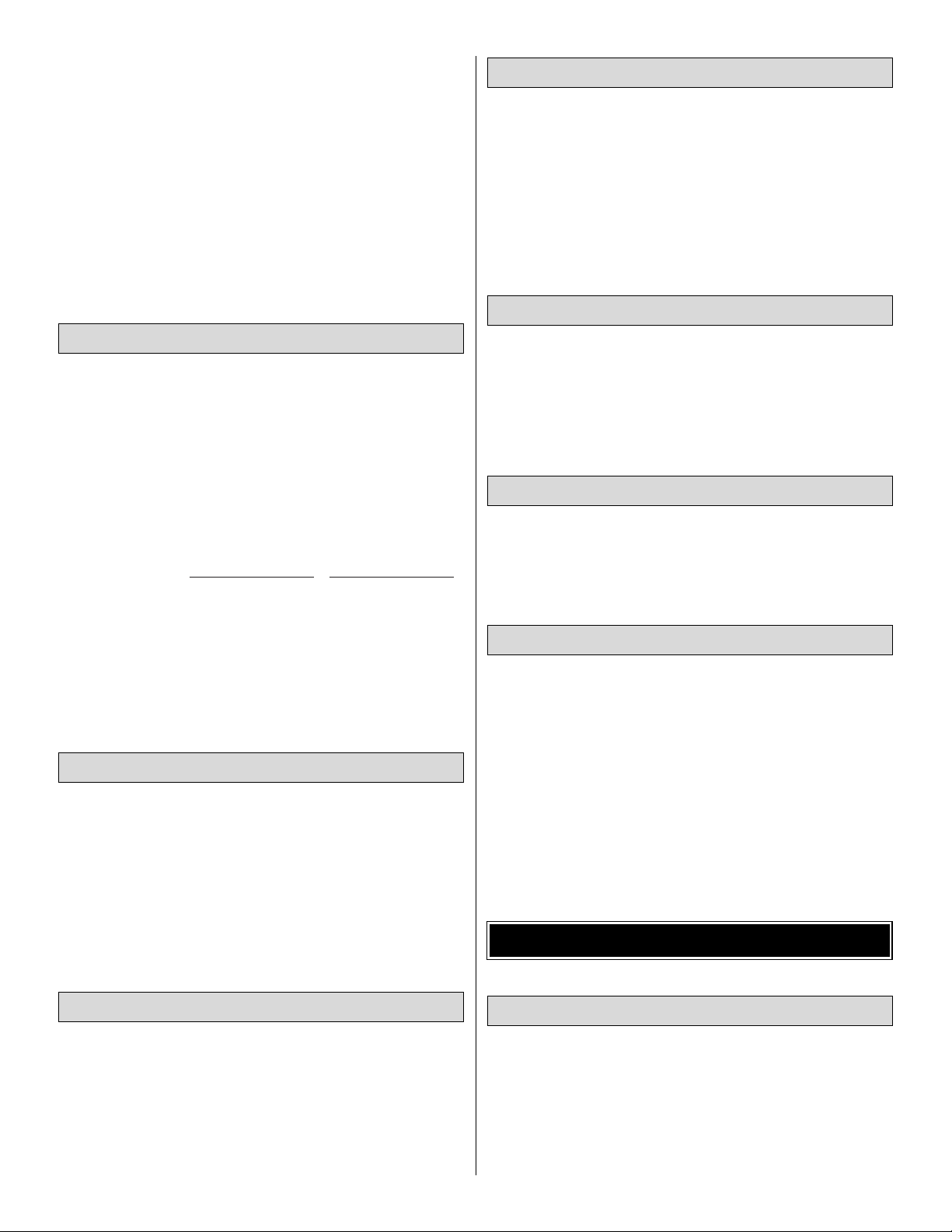

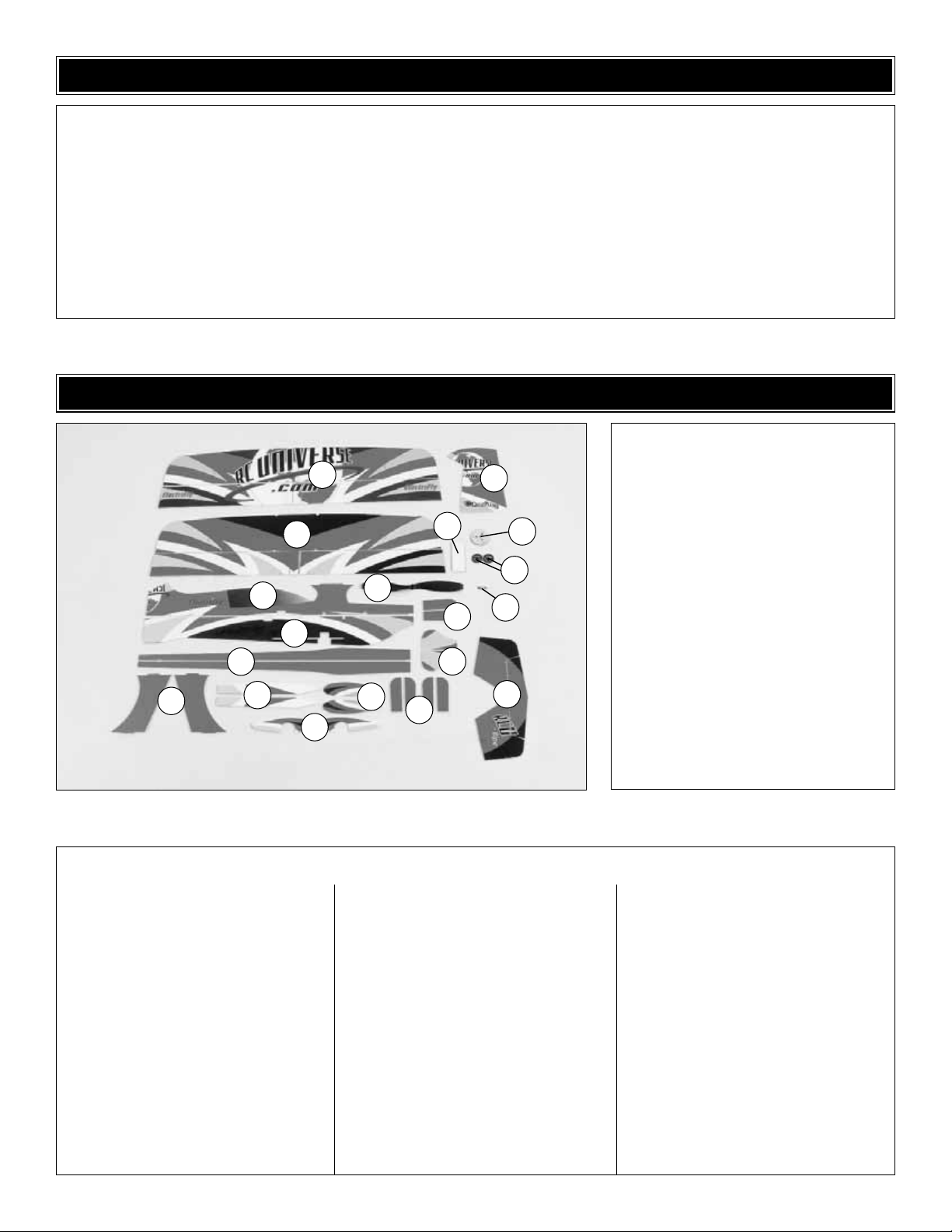

KIT CONTENTS

Kit Contents

1. Top Wing & Ailerons

2. Bottom Wing & Ailerons

3. Rudder

4. Plywood Firewall

5. Main Wheels

6. Hook and Loop Material

7. Upper Ver tical Fuselage Half

8. Lower Vertical Fuselage Half

9. Propeller

10. Small Vertical Nose Doublers (2)

11. Prop Saver

12. Horizontal Fuselage Halves (L&R)

13. Interplane Struts (L&R)

14. Fuselage Braces (L&R)

15. Inner Wheel Pants (L&R)

16. Outer Wheel Pants (L&R)

17. Horizontal Nose Doublers (4)

18. Large Vertical Nose Doublers (2)

19. Horizontal Stabilizer w/Elevators

1

3

7

8

9

10

2

5

4

6

11

12

13

14

16

17

19

18

15

Please note that all of the plastic parts used when building

the FlatOuts R/C Universe Bipe are identified by name and

part number, for example: Z-bend clevis (A1). The part

numbers are molded next to each part on the parts trees for

easy identification.

The carbon tube diameters referenced throughout this

manual may be difficult to measure without calipers. The

dimensions provided consist of 1 mm, 2 mm, 3 mm, and 5.5

mm.These four sizes can be identified by comparing all the

tubes next to each other. Once the diameters are

determined, it is advisable to group the tubes together by

size for quick reference.

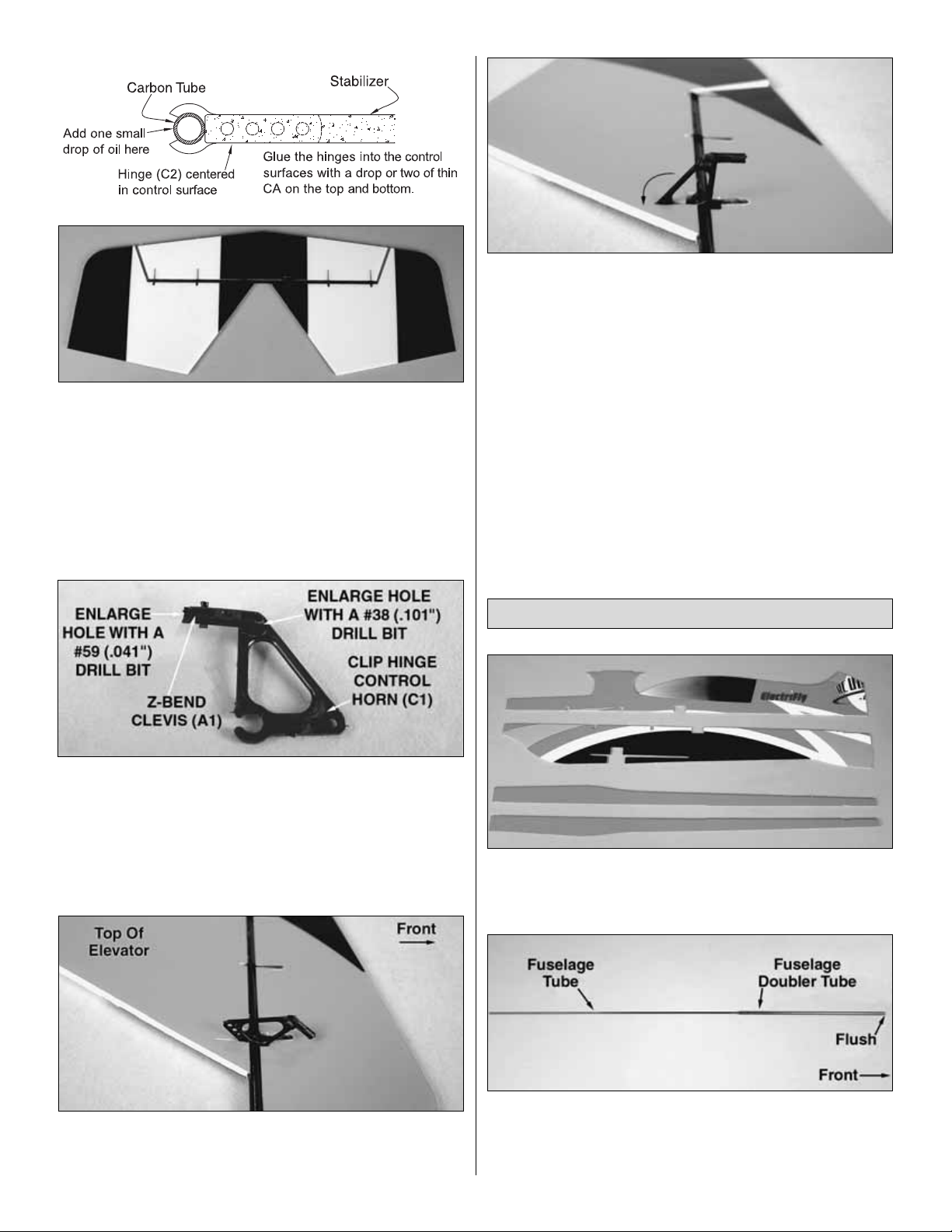

❏ 1. Cut the horizontal stabilizer free from the foam sheet

using a hobby knife with a sharp #11 blade.DO NOT cut the

elevator halves free at this time.

❏ 2. Without removing the elevator halves from the foam

sheet, slide two hinge retainer rings (C3) onto the elevator

joiner tube.Align the rings with the cutout in the left elevator

half.The ring on the right should be in line with the edge of

the cutout and there should be a 1.5 mm [1/16"] gap

between the two rings. Secure both rings to the tube with a

drop of glue on the outside of the gap.

❏ 3. Using the

Expert Tip

that follows, permanently join the

elevator halves by gluing in the 3 x 216 mm [1/8" x 8-1/2"]

elevator joiner tube.

❏ 4. Now the elevator halves may be cut from the sheet.

❏ 5.To avoid broken clip hinges (C2) and control horns (C1)

during assembly, tr im them as shown before installing onto

the 3mm carbon tubes.

HOW T O GLUE THE TUBES TO

THE CONTROL SURFACES

Note: You may want to protect your work surface from

excess glue.We recommend the use of Great Planes Plan

Protector™(GPMR6167) for this purpose.

A. Cut several 40 mm [1-1/2"] pieces of cellophane tape.Fold

the last 5 mm [1/4"] over to make a tab for easy removal.

B. Lightly coat the leading edges of the elevators with

foam-safe CA–do not use an excessive amount. Hint: A

CA applicator tip is recommended to accurately control

the bead of glue.

C. Tape the tube to the leading edge of the elevators.

Weight the assembly down on a flat surface to prevent

warping and allow the glue to harden without accelerator.

D. Once the glue has hardened, remove the tape.

E. Add a fillet of glue to the bottom of the joiner tube

and elevators.

Assemble the Horizontal Tail

BUILDING INSTRUCTIONS

7

❏ 6.Snap all the clip hinges to the carbon tube already glued

to the elevators .Push the hinges into the slots in the stabilizer.

Make sure the hinges are centered in the stabilizer .Add a drop

of oil to each hinge. Glue the hinges into the stabilizer with a

drop or two of foam-safe thin CA (Hot Stuff UFO Thin FoamSafe 1 oz, HOTR1040) where shown.

❏ 7. Enlarge the hole in the Z-bend clevis (A1) with a #59

(.041") drill bit. Enlarge the hole in a clip-hinge control horn

(C1) with a #38 (.101") drill bit. Insert the Z-bend clevis (A1)

into the clip-hinge control horn (C1) as shown.

❏ 8. Clip the control horn onto the joiner tube aligned with

the precut slot.The control horn must extend above the top

of the elevator.

❏ 9. Coat the gluing area on the control horn with thick,

foam-safe CA glue and rotate it down into the precut slot.

❏ 1. Cut the upper and lower vertical fuselage halves

and the left and right horizontal fuselage halves free from

their foam sheets.

❏ 2. Glue the 3 x 684 mm [1/8" x 26-15/16"] fuselage tube

into the 5.5 x 295 mm [7/32" x 11-5/8"] fuselage tube

doubler. One end should be flush. From now on, this

assembly will be referred to as the fuselage tube.

Assemble the Fuselage

8

Loading...

Loading...