Page 1

WARRANTY

Great Planes

®

Model Manufacturing Co. guarantees this kit to be free from defects in both material and workmanship at the date of

purchase.This warranty does not cover any component parts damaged by use or modification. In no case shall Great Planes’liability

exceed the original cost of the purchased kit. Further, Great Planes reserves the right to change or modify this warranty without notice.

In that Great Planes has no control over the final assembly or material used for final assembly, no liability shall be assumed nor

accepted for any damage resulting from the use by the user of the final user-assemb led product.By the act of using the user-assembled

product, the user accepts all resulting liability.

If the buyer is not prepared to accept the liability associated with the use of this product, the buyer is advised to return this

kit immediately in new and unused condition to the place of purchase.

To make a warranty claim send the defective part or item to Hobby Services at the address below:

Hobby Services

3002 N. Apollo Dr. Suite 1

Champaign IL 61822 USA

Include a letter stating your name, return shipping address, as much contact information as possible (daytime telephone number, fax

number, e-mail address), a detailed description of the problem and a photocopy of the purchase receipt. Upon receipt of the package

the problem will be evaluated as quickly as possible.

READ THROUGH THIS MANUAL BEFORE STARTING

CONSTRUCTION. IT CONTAINS IMPORTANT WARNINGS

AND INSTRUCTIONS CONCERNING THE ASSEMBLY

AND USE OF THIS MODEL.

GPMZ0204 for GPMA1049 V1.0© Copyright 2005

Champaign, Illinois

(217) 398-8970, Ext 5

airsupport@greatplanes.com

INSTRUCTION MANUAL

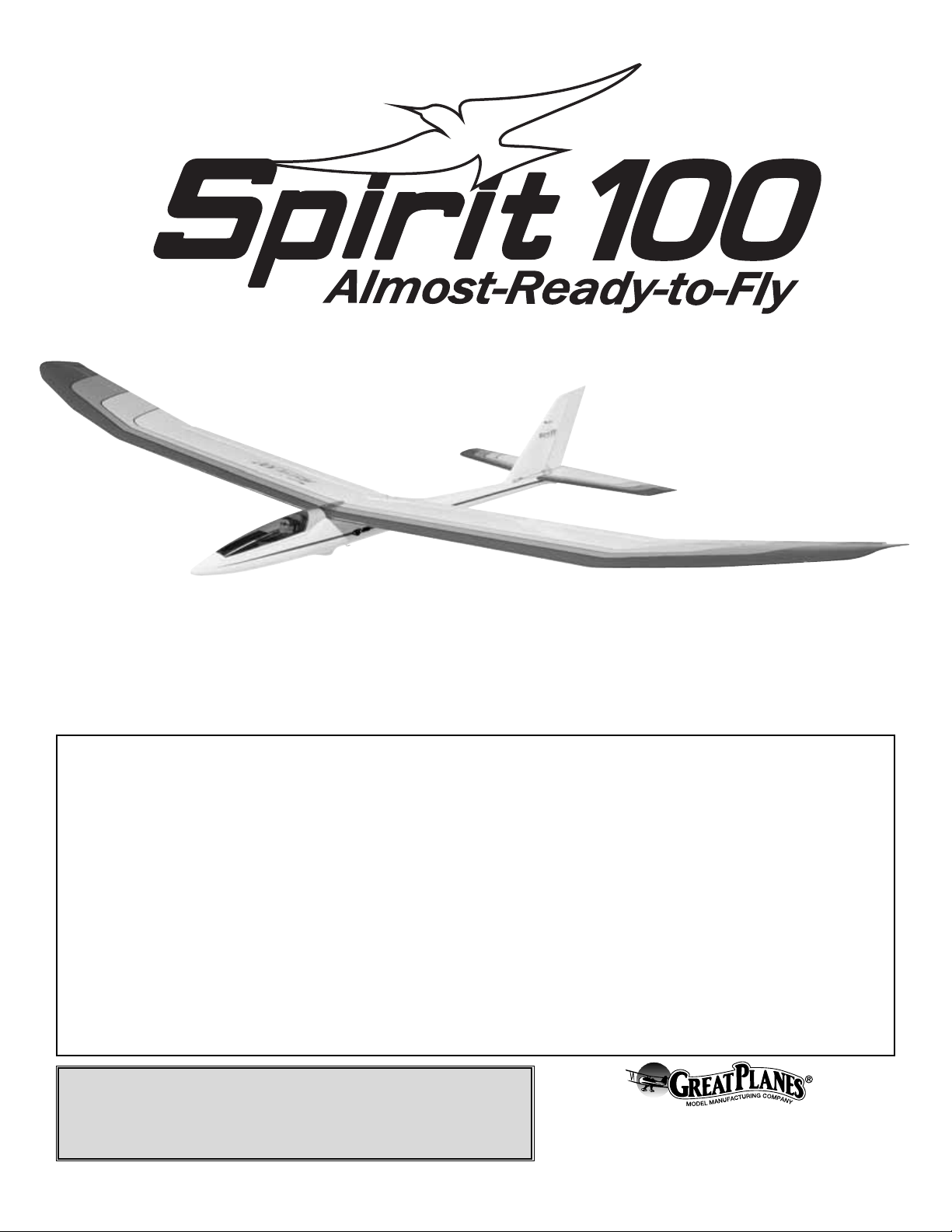

Wingspan: 100 in [2540mm]

Wing Area: 943 sq in [60.8 sq dm]

Weight: 4-4.5 lb [1800-2000g]

Wing Loading: 9.8-11 oz/sq ft [30-34 g/dm

2

]

Length: 54 in [1370 mm]

Radio: 5 Channel minimum, 7-9 channel with

sailplane mixing, 7 servos

™

Page 2

INTRODUCTION ...............................................................2

SAFETY PRECAUTIONS..................................................2

AMA...................................................................................3

DECISIONS YOU MUST MAKE........................................3

Radio Equipment .........................................................3

Spoilers .......................................................................3

ADDITIONAL ITEMS REQUIRED.....................................3

Adhesives & Building Supplies....................................3

Optional Items.............................................................4

IMPORTANT BUILDING NOTES......................................4

COMMON ABBREVIATIONS............................................4

KIT INSPECTION..............................................................5

KIT CONTENTS ................................................................5

ORDERING REPLACEMENT PARTS ..............................6

ASSEMBLE THE WING ....................................................7

Spoiler Option..............................................................7

Install the Aileron and Flap Servos.............................8

Finish the Wing..........................................................10

ASSEMBLE THE FUSE ..................................................11

Attach the Tail............................................................11

Install the Fuselage Servos .......................................12

Final Radio Installation..............................................14

Set the C.G................................................................14

Mount the Canopy and Tow Hook.............................15

Apply the Decals .......................................................16

GET THE MODEL READY TO FLY .................................16

Check the Control Directions ....................................16

Set the Control Throws..............................................16

Balance the Model Laterally ......................................17

PREFLIGHT.....................................................................17

Identify Your Model ....................................................17

Charge the Batteries .................................................17

Range Check.............................................................17

AMA SAFETY CODE (

EXCERPTS)....................................17

General......................................................................17

Radio Control ............................................................17

CHECK LIST ...................................................................18

THERMAL FLYING..........................................................18

Trimming Flights ........................................................18

Hi-Start Launch .........................................................18

First Flights ................................................................19

ADVANCED FEATURES.................................................19

FACTS ABOUT THERMALS...........................................19

THERMAL SOARING.......................................Back Cover

SLOPE SOARING.............................................Back Cover

BALLAST..........................................................Back Cover

Thank you for purchasing the Great Planes SPIRIT 100

ARF sailplane. Soaring offers a freedom that no other type

of flying can provide! With a little practice and some help

from mother nature, you will be able to defy gravity and

enjoy flights that can last for hours. The advanced wing

design incorporates flaps, spoilers and ailerons to provide

the ultimate in control when using computer radio mixing

functions.Take your time and follow directions to end up

with a well-built model that is straight and true.

For the latest technical updates or manual corrections to the

Great Planes Spirit 100 ARF, visit the Great Planes web site

at www.greatplanes.com. Open the “Airplanes” link, then

select the Spirit 100 ARF. If there is new technical

information or changes to this model, a “tech notice”box will

appear in the upper left corner of the page.

1. Your Spirit 100 ARF should not be considered a toy, but

rather a sophisticated, working model that functions very

much like a full-size airplane. Because of its performance

capabilities, the Spirit 100 ARF, if not assembled and

operated correctly, could possibly cause injury to yourself or

spectators and damage to property.

2. You must assemble the model according to the

instructions. Do not alter or modify the model, as doing so

may result in an unsafe or unflyable model. In a few cases

the instructions may differ slightly from the photos.In those

instances the written instructions should be considered

as correct.

3.You must take time to build straight, true and strong.

4.You must correctly install all R/C and other components so

that the model operates correctly on the ground and in the air .

5.You must check the operation of the model before every

flight to insure that all equipment is operating and that the

model has remained structurally sound. Be sure to check

clevises or other connectors often and replace them if they

show any signs of wear or fatigue.

6. If you are not an experienced pilot or have not flown this

type of model before, we recommend that you get the

assistance of an experienced pilot in your R/C club for your

first flights.If you’re not a member of a club, your local hobb y

shop has information about clubs in your area whose

membership includes experienced pilots.

PRO TECT YOUR MODEL,Y OURSELF

& OTHERS...FOLLOW THESE

IMPORTANT SAFETY PRECAUTIONS

INTRODUCTION

TABLE OF CONTENTS

2

Page 3

7. WARNING: The fuselage in this kit is made of fiberglass,

the fibers of which may cause ey e , skin and respiratory tract

irritation. Never blow into the fuse to remove fiberglass dust,

as the dust will blow back into y our e y es .Always w ear saf ety

goggles, a particle mask and rubber gloves when grinding,

drilling and sanding fiberglass parts. Vacuum the parts and

the work area thoroughly after working with fiberglass parts.

Remember:Take your time and f ollo w the instructions to

end up with a well-built model that is straight and true.

We urge you to join the AMA (Academy of Model

Aeronautics) and a local R/C club.The AMA is the governing

body of model aviation and membership is required to fly at

AMA clubs.Though joining the AMA provides many benefits,

one of the primary reasons to join is liability protection.

Coverage is not limited to flying at contests or on the club

field. It even applies to flying at public demonstrations and

air shows. Failure to comply with the Safety Code (excerpts

printed in the back of the manual) may endanger insurance

coverage.Additionally, training programs and instructors are

available at AMA club sites to help you get started the right

way. There are over 2,500 AMA chartered clubs across the

country. Contact the AMA at the address or toll-free phone

number below:

Academy of Model Aeronautics

5151 East Memorial Drive

Muncie, IN 47302-9252

Tele. (800) 435-9262

Fax (765) 741-0057

Or via the Internet at:

http://www.modelaircraft.org

IMPORTANT!!! T w o of the most important things you can do

to preserve the radio controlled aircraft hobby are to avoid

flying near full-scale aircraft and avoid flying near or over

groups of people.

This is a partial list of items required to finish the Spirit 100

ARF that may require planning or decision making before

starting to build.Order numbers are provided in parentheses.

❏ 5 channel radio with standard size receiver and battery

OR

❏ 7-9 channel radio with standard size receiver and battery

is recommended for maximum flight performance

❏ (2) Y-harnesses (FUTM4130) or (4) 9" extensions

(FUTM3910) utilizing a radio with flaperon mixing

❏ (4) Futaba

®

S3101 micro servos (FUTM0033) for ailerons

and flaps

❏ (2) Futaba S3004 standard size servos (FUTM0004)

The spoilers are highly recommended as they make it much

easier to land in smaller spaces or to lose altitude in a safe,

controlled manner.Y ou need an additional standard siz e servo

to operate the spoilers.

❏ (1) Futaba S3004 standard size servo (FUTM0004)

In addition to common household tools and hobby tools, this

is the “short list” of the most important items required to build

the Spirit 100 ARF.

Great Planes Pro™ CA and Epoxy glue

are recommended.

❏ 1/4" [6mm] R/C Foam Rubber (HCAQ1000)

❏ Velcro

®

Hook & Loop (GPMQ4480)

❏ 1/2 oz. [15g] Thin Pro CA (GPMR6001)

❏ Pro 30-Minute Epoxy (GPMR6047)

❏ Pro 6-Minute Epoxy (GPMR6045)

❏ Plan Protector (GPMR6167) or wax paper

❏ #1 Hobby Knife (HCAR0105)

❏ #11 Blades (5-pack, HCAR0211)

❏ 2 oz. [57g] Spray CA Activator (GPMR6035)

❏ Top Flite

®

MonoKote®Sealing Iron (TOPR2100)

❏ Mixing Cups (GPMR8056)

❏ Epoxy Brushes (6, GPMR8060)

❏ Silicone Glue (DEVR2500)

❏ Steel Shot

❏ Masking Tape (TOPR8018)

❏ Builder’s Triangle Set (HCAR0480)

❏ Drill bits: 1/16" [1.6mm], 5/64" [2mm]

Adhesives and Building Supplies

ADDITIONAL ITEMS REQUIRED

Spoilers

Radio Equipment

DECISIONS YOU MUST MAKE

AMA

We, as the kit manuf acturer, provide you with a top quality ,

thoroughly tested kit and instructions, but ultimately the

quality and flyability of your finished model depends on

how you build it; therefore, we cannot in any way

guarantee the performance of your completed model, and

no representations are expressed or implied as to the

performance or safety of your completed model.

3

Page 4

Here is a list of optional tools mentioned in the manual that

will help you build the Spirit 100 ARF.

❏ CA Debonder (GPMR6039)

❏ 36" Metal Ruler (HCAR0475)

❏ Hobbico

®

Duster™Can of Compressed Air (HCAR5500)

❏ Servo Horn Drill (HCAR0698)

❏ AccuThrow

™

Deflection Gauge (GPMR2405)

❏ CG Machine

™

(GPMR2400)

❏ Cover Sock (COVR2702)

• Whenever the term

glue

is written you should rely upon

your experience to decide what type of glue to use.When

a specific type of adhesive works best for that step, the

instructions will make a recommendation.

• Whenever just epoxy is specified you may use

either

30minute (or 45-minute) epoxy or6-minute epoxy. When 30minute epoxy is specified it is highly recommended that

you use only 30-minute (or 45-minute) epo xy, because you

will need the working time and/or the additional strength.

• Photos and sketches are placed before the step they

refer to .Frequently you can study photos in following steps

to get another view of the same parts.

• The Spirit 100 ARF is factory-covered with Top Flite

MonoKote film.Should repairs ever be required, MonoKote

can be patched with additional MonoKote purchased

separately. MonoKote is packaged in six-foot rolls, but

some hobby shops also sell it by the foot. If only a small

piece of MonoKote is needed for a minor patch, perhaps a

fellow modeler would give you some.MonoKote is applied

with a model airplane covering iron, but in an emergency a

regular iron could be used. A roll of MonoKote includes full

instructions for application. Following are the colors used

on this model and order numbers for six foot rolls.

True Red TOPQ0227

Cub Yellow TOPQ0220

Black TOPQ0208

Orange TOPQ0202

White TOPQ0204

Fuse = Fuselage

Stab = Horizontal Stabilizer

Fin = Ver tical Fin

LE = Leading Edge

TE = Trailing Edge

LG = Landing Gear

Ply = Plywood

" = Inches

mm = Millimeters

SHCS = Socket Head Cap Screw

COMMON ABBREVIATIONSIMPORTANT BUILDING NOTES

Optional Supplies and Tools

4

To convert inches to millimeters, multiply inches by 25.4

Inch Scale

0" 1" 2" 3" 4" 5" 6" 7"

0 10 20 30 40 50 60 70 80 90 100 110 120 130 140 150 160 170 180

Metric Scale

Page 5

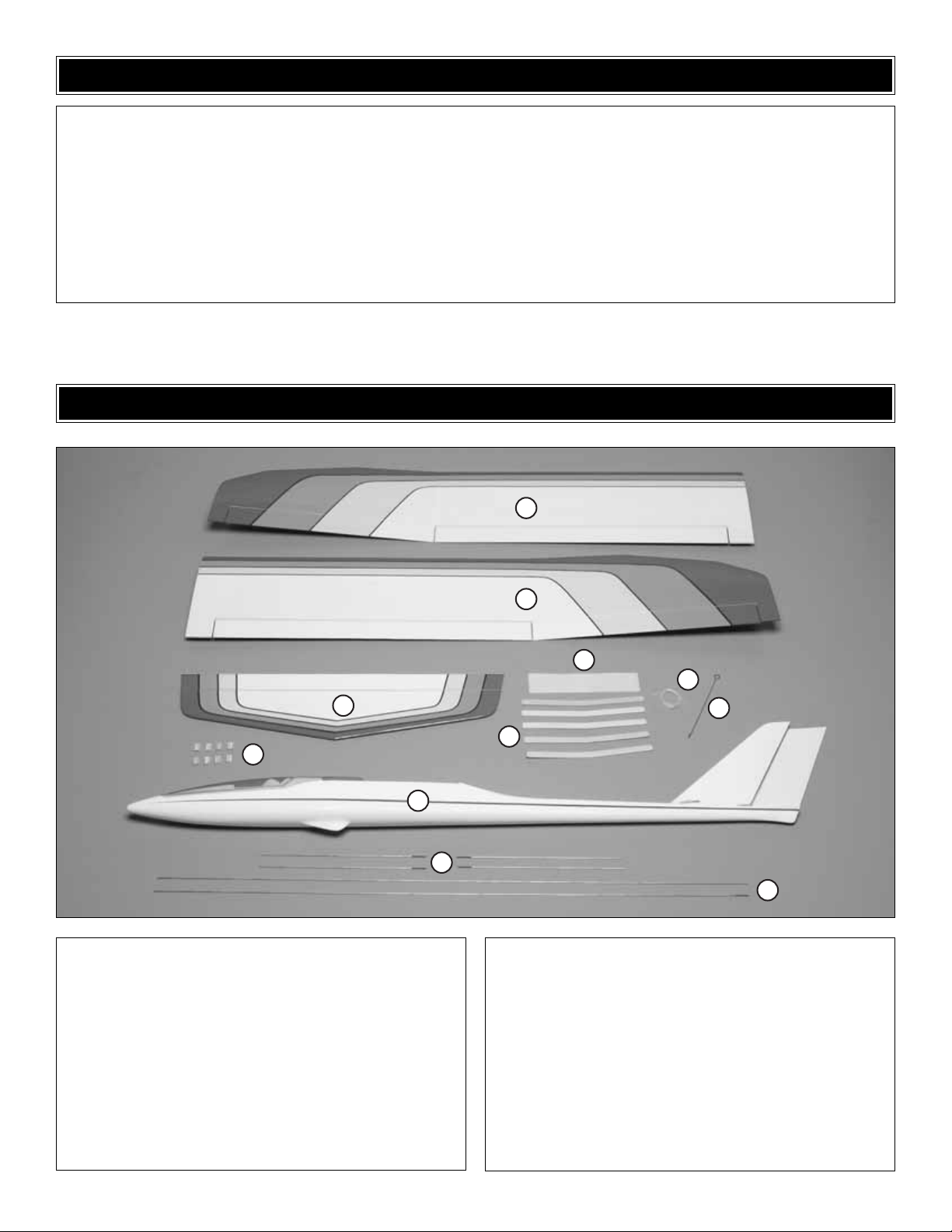

5

1 Left Wing

2 Right Wing

3 Horizontal Stabilizer

4 Hinge Strip

5 Wing Joiners (4–Wood, 1–Aluminum)

6 Spoiler String

7 Spoiler Activation Rod

8 Fuse and Canopy

9 12" Pushrods (4)

10 42" Pushrods (2)

11 Servo Blocks (8)

Kit Contents (Photographed)

Nylon Clevis (6)

Nylon Faslink Pushrod Keeper (6)

Nylon Small Control Horn (4)

Silicone Clevis Keeper (6)

6-32 x 3/4" Socket Head Cap Screw (5)

6-32 Nylon Lock Nut (1)

#6 Flat Washer (5)

2 x 3/8" Sheet Metal Screw (18)

2-56 x 1/2" Screw (6)

2-56 x 3/4" Socket Head Cap Screw (2)

Kit Contents (Not Photographed)

KIT CONTENTS

Before starting to build, take an inventory of this kit to make sure it is complete and inspect the parts to make sure they

are of acceptable quality. If any parts are missing or are not of acceptable quality , or if y ou need assistance with assemb ly,

contact Product Support. When repor ting defective or missing parts, use the part names exactly as they are written in

the Kit Contents list.

Great Planes Product Support:

3002 N Apollo Drive, Suite 1

Champaign, IL 61822

Telephone: (217) 398-8970, ext. 5

Fax: (217) 398-7721

E-mail:

airsupport@greatplanes.com

KIT INSPECTION

1

11

2

4

6

3

5

8

9

7

10

Page 6

6

ORDERING REPLACEMENT PARTS

Replacement parts for the Great Planes Spirit 100 ARF are available using the order numbers in the Replacement Parts

List that follows.The fastest, most economical service can be provided by your hobby dealer or mail-order company.

To locate a hobby dealer, visit the Great Planes web site at

www.greatplanes.com

.Choose “Where to Buy” from the menu

on the left side of the page.Follow the instructions provided on the page to locate a U.S., Canadian or International dealer.

If a hobby shop is not available, replacement parts may also be ordered from Tower Hobbies at

www.towerhobbies.com

,

or by calling toll free (800) 637-6050.

Parts may also be ordered directly from Hobby Services by calling (217) 398-0007, or via facsimile at (217) 398-7721, but

full retail prices and shipping and handling charges will apply. Illinois and Nevada residents will also be charged sales tax.

If ordering via fax, include a Visa®or MasterCard®number and expiration date for payment.

Mail parts orders and payments by personal check to:

Hobby Services

3002 N Apollo Drive, Suite 1

Champaign IL 61822

Be certain to specify the order number exactly as listed in the Replacement Parts List.Payment by credit card or personal

check only; no C.O.D.

If additional assistance is required, contact Product Support by e-mail at

productsupport@greatplanes.com

, or by telephone

at (217) 398-8970.

Replacement Parts List

Or

der Number Description How to Purchase

Missing pieces ................................................Contact Product Support

Instruction manual...........................................Contact Product Support

Full-size plans.................................................Not available

Kit parts listed below .......................................Hobby Supplier

GPMA1989............Fuselage Set

GPMA1987............Wing Set

GPMA1988............Tail Set

GPMA1989............Wing Joiner Set

GPMA1990............Canopy and Pilot

GPMA1991............Tow Hook Set

GPMA1992............Decal Set

Page 7

Spoilers are optional and can be made functional even

after you have flown the plane.

❏❏1. Use a sealing iron to securely attach the covering

to the spoiler and the wood surrounding it.

❏❏2. Trim the covering around the ends and TE of the

spoiler.DO NOT cut the along the LE

❏❏3. Trim covering from the spoiler string tube on the

bottom of the wing.

❏❏4.Insert the spoiler string in the string tube.Tie the end

to the spoiler control horn and secure with a drop of thin CA.

❏❏5. Cut a #64 rubber band in half. Clean the rubber

band with alcohol. Glue one end of the rubber band to the

front sheer web with a drop of medium CA.

❏❏6. Pull the rubber band up the spoiler and glue near

the TE with a drop of medium CA. NOTE: There should be

just enough tension to close the spoiler.

❏❏7. Cut the rubber band just behind the glue joint.

❏❏8.Pull the slack out of the spoiler string without opening

the spoiler and tie the spoiler hook to the string so that the

rear of the hook lines up with the front of the string opening.

Spoiler Option

ASSEMBLE THE WING

7

Page 8

❏❏9.Trim the excess string from the spoiler hook.

❏ 10. Repeat steps 1-9 for the second spoiler.

❏ 1.Cut a 3/16" x 1/2" [4 x 13mm] slot in the bottom of each

wing panel aligned with the hole in the root rib and 3/16"

[4mm] from the wing center.

❏ 2. Pull the servo leads up through the 3/16" x 1/2"

[4 x 13mm] slot.

❏ 3. Locate the openings for the flap and aileron servos in

the bottom of each wing panel. Trim out the covering and

seal the edges using a sealing iron.

❏ 4. Locate the four servo hatch covers and trim out the

servo arm openings. Seal the edges using a sealing iron.

❏ 5. Trial fit your servos on the covers and mark the

locations of the servo blocks. Using epoxy, glue the servo

blocks to the hatch cov ers.NOTE: The flap servos should be

oriented the same for both wing panels.

Install the Aileron and Flap Servos

8

Page 9

❏ 6.Attach the servos to the bloc ks using the hardware that

comes with your radio system. HINT: Dr ill a 1/16" [1.6mm]

pilot hole for the servo screws and strengthen the holes with

a drop of thin CA.

❏ 7. Attach the ser vo lead to the extension. Fit the servo

hatch to the wing. Use the holes in the cover as a guide and

drill four 1/16" [1.6mm] holes through the plywood servo

hatch mounts.

❏ 8. Temporarily mount the ser vo hatch cover to the wing

with four #2 x 3/8" [9.5mm] screws.Remove the screws and

hatch.Then, harden the holes in the wing with thin CA. Allow

the glue to dry and remount the servo hatch cover.

❏❏9. Align the aileron control hor n with the servo arm.

Glue the control horn to the aileron with a small drop of CA.

❏❏10. Drill two 1/16" [1.6mm] holes through the aileron.

Secure the control horns with two 2-56 x 1/2" [13mm]

screws and the nylon control horn back.

❏❏11.Screw a nylon clevis 15 turns onto each of the four

12" [305mm] pushrods. Slide a silicone retainer on each of

the nylon clevis.

9

Page 10

❏❏12. Attach the aileron clevis to the outer hole on the

control horn. With the ser vo and aileron centered mark the

location the pushrod crosses the servo arm. Bend a right

angle in the pushrod at the mark.

❏❏13. Cut the pushrod 1/4" [6mm] past the bend. Push

the pushrod through the servo arm. Retain the pushrod with

the nylon faslink.

❏❏14. Harden the control horn with thin CA and drill out

the second hole with a 1/16" drill.Attach the flap clevis to the

second hole on the control horn.

❏❏15. Plug the flap servo to the flap channel on your

radio. Make sure the servo arm is in the position shown in

the sketch. Align the flap with the wing TE and mark the

location the pushrod crosses the servo arm. Bend a right

angle in the pushrod at the mark.

❏❏16. Cut the pushrod 1/4" [6mm] past the bend. Push

the pushrod through the servo arm. Retain the pushrod with

the nylon faslink.

❏ 17. Repeat steps 7-14 for the other wing half.

❏ 1. Make a sandwich of the wing joiners as shown in the

sketch.Glue the wing joiners together with 6-minute epoxy and

clamp together. Use a paper towel dampened with alcohol to

remove the e xcess epoxy that has squeez ed out of the joiners.

Finish the Wing

10

SERVO

HORN

FASLINK

2-56 (.074")

PUSHROD WIRE

Plywood Joiners

Aluminum Joiner

Page 11

❏ 2. Remove the covering from the top and bottom of the

four wing bolt holes on the wing.

❏ 3. After the epoxy on the wing joiner has fully cured fit the

joiner in the wing.It might be necessary sand the joiner so it

will fit in the wing. The fit needs to be tight so sand small

amounts and take your time.

❏ 1. Trim the covering on the horizontal stabilizer from the

LE slot and the bolt hole.Apply thin CA to the exposed wood

in the LE slot.

❏ 2. Mount the stabilizer to the fuse with a 6-32 x 3/4"

[19mm] socket head cap screw and #6 washer.

❏ 3. Cut three 3/4" x 1" [19 x 25mm] CA hinges from the

supplied 2" x 9" [50 x 230mm] CA hinge strip. Snip off the

corners so they go into the rudder/fin easier.

Attach the Tail

ASSEMBLE THE FUSE

11

3/4" [19mm]

1" [25mm]

Page 12

❏ 4.Fit the rudder to the fin with the hinges.Glue both sides

of each hinge with 3 drops of thin CA.

❏ 5. Screw a nylon clevis 15 turns onto both of the 42"

[1067mm] pushrods. Slide a silicone retainer on each of the

nylon clevises.

❏ 6. If necessary , bend a slight angle in one of the pushrods

6" [150mm] from the end of the clevis.Slide this pushrod into

the rudder pushrod tube.

❏ 7. Align the r udder control horn with the rudder pushrod.

Glue the control horn to the rudder with a small drop of CA.

❏ 8. Drill two 1/16" [1.6mm] holes through the rudder.

Secure the control horn with two 2-56 x 3/4" [19mm] SHCS

and the nylon control horn back. Attach the clevis to the

outer hole on the control horn.

❏ 9. Slide the second 42" [1067mm] pushrod into the

elevator pushrod tube from the rear.

❏ 10. Mount the elevator control horn with two 2-56 x 5/8"

[15.9mm] screws. Attach the clevis to the second from the

outer hole.

❏ 1. Make two single sided servo arms that have the outer

hole 1/2" [13mm] from the servo mounting hole. Enlarge the

outer hole with a 5/64" drill bit.

Install the Fuselage Servos

12

5/64" [2mm]

1/2" [13mm]

Page 13

❏ 2. If you will be using the spoiler option make a servo arm

that has the outer hole at least 5/8" [16mm] from the servo

mounting hole. Enlarge the outer hole with a 5/64" dr ill bit.

❏ 3.Mount the rudder and elevator servos with the hardware

provided with the servos. If you will be using spoilers install

the spoiler servo also.NOTE:The spoiler servo mounts as far

right as it will go in the servo tray.

❏ 4.Plug the servos and batter y into your receiver.Turn on

the transmitter to center the servos. Attach the ser vo arms

to the servos as shown in the sketch.

❏ 5. Center the elevator and mark the pushrod where it

crosses the hole in the servo arm.

❏ 6.Bend the pushrod 90° up at the mark you made.

❏ 7. Attach the pushrod to the servo arm with a Faslink.

Trim the excess pushrod from flush with the Faslink.

❏ 8. Attach the rudder pushrod in the same manner you did

the elevator.

❏ 9. If you will be using spoilers slide the spoiler activation

rod forward through the hole in the former at the front of the

wing opening.

5/64" [2mm]

13

5/8" [16mm]

Spoiler

Rudder

FUTABA

S9001

Elevator

FUTABA

S9001

(Optional)

S9001

FUTABA

Page 14

❏ 10. Attach the Z-bend end of the spoiler activation rod to

the spoiler servo.

❏ 1. Attach the switch, charge jack, servos and servo

extensions to the receiver. Wrap the receiver in foam.

❏ 2. Push the receiver into the bottom of the fuse and retain

it with a small piece of Velcro®.

❏ 3.Drill a 1/16" [1.6mm] hole through the fuse side for the

antenna.Take a cut-off piece of servo arm with at least two

holes in it, and feed the antenna through two of the holes,

making a strain relief which protects the antenna from

accidentally being torn out of the receiver.P osition the strain

relief so that there is a small amount of slack between the

receiver and the when the strain relief is positioned against

the inside of the fuse.

❏ 4. Mount your switch in the canop y area with silicone glue ,

making sure it does not interfere with the pushrods or canopy.

❏ 1. Wrap the receiver battery in foam and tape. Tape the

battery to the outside of the fuse. NOTE: The batter y will be

installed after the CG is set.

Set the C.G.

Final Radio Installation

14

Page 15

❏ 2. Connect the wing servos and, if used, the spoiler hooks

to the loop end of the spoiler activation rod.The spoiler cables

will need to be pulled slightly to reach the loop on the wire.Be

careful no to over-extend the spoilers by pulling too hard on

the cable. Mount the wing with the four 6-32 x 3/4" [19mm]

SHCS and washers.

❏ 3. Tape the canopy to the opposite side of the fuse from

the battery.

❏ 4. Accurately mark the balance point on the bottom of the

wing on both sides of the fuselage. Use thin str ips of tape or

a felt-tip pen to make the marks.The balance point (CG) is

located 4-1/2" [115mm] back from the LE where the wing

meets the fuse. This is the balance point at which the model

should balance for your first flights.After initial trim flights you

may wish to experiment by shifting the balance up to 1/4"

[6mm] forward or back to change the flying characteristics.

❏ 5. Mix small amounts of the steel shot with epoxy and

pour it into the nose of the plane to set the CG.

❏ 6. After the epoxy has cured and the CG is confirmed

install the battery in the fuse.

❏ 1. Use needle nose pliers to open up the canopy hook so

there is a 1/16" [1.6mm] gap.

❏ 2. Drill a 3/64" [1.2mm] hole through the back of the

canopy. Screw the canopy hook into the canopy and secure

it with thin CA.

❏ 3. Attach a small rubber band to the fiberglass support at

the end of the hatch.

❏ 4. Loop the r ubber band over the canopy hook. Slide the

canopy in place.

Mount the Canopy and Tow Hook

15

4-1/2" [115mm]

Page 16

❏ 5. Mount the 6-32 tow hook to the fuse with the 6-32 nut

to lock it in place.

1.Use scissors or a sharp hobby knife to cut the decals from

the sheet.

2.Be certain the model is clean and free from oily fingerprints

and dust.Prepare a dishpan or small bucket with a mixture of

liquid dish soap and warm water–about one teaspoon of

soap per gallon of water.Submerse the decal in the soap and

water and peel off the paper backing. NOTE: Even though

the decals have a “stic ky-bac k”and are not the water transfer

type, submersing them in soap and water allows accurate

positioning and reduces air bubbles underneath.

3. Position decal on the model where desired. Holding the

decal down, use a paper towel to wipe most of the water a way.

4. Use a piece of soft balsa or something similar to squeegee

remaining water from under the decal. Apply the rest of the

decals the same way.

❏ 1. Tur n on the transmitter and receiver and center the

trims. If necessary, remove the servo arms from the servos

and reposition them so they are centered. Reinstall the

screws that hold on the servo arms.

❏ 2. With the transmitter and receiver still on, check all the

control surfaces to see if they are centered.If necessary, adjust

the clevises on the pushrods to center the control surfaces.

❏ 3. Make certain that the control surfaces respond in the

correct direction as shown in the diagram. If any of the

controls respond in the wrong direction, use the servo

reversing in the transmitter to reverse the servos connected

to those controls. Be certain the control surfaces have

remained centered. Adjust if necessary.

Use a Great Planes AccuThrow (or ruler) to accurately measure

and set the control throw of each control surface as indicated in

the chart that follows.If your radio does not have dual rates, we

recommend setting the throws at the high rate setting.

IMPORTANT: The Spirit 100 ARF has been extensively

flown and tested to arrive at the throws at which it flies

best. Flying your model at these throws will provide you

with the greatest chance for successful first flights.If, after

you have become accustomed to the way the Spirit 100

ARF flies, you would like to change the throws to suit your

taste, that is fine. However, too much control throw could

make the model difficult to control, so remember, “more is

not always better.”

These are the recommended control surface throws:

High Rate Low Rate

ELEVATOR: 5/8" [16mm] up 1/2" [13mm] up

5/8" [16mm] down 1/2" [13mm] down

RUDDER: 1-1/2" [38mm] right 1" [25mm] right

1-1/2" [38mm] left 1" [25mm] left

AILERONS: 3/4" [19mm] up 3/8" [9.5mm] up

3/4" [19mm] down 3/8" [9.5mm] down

Full Half

FLAPS: 2" [50mm] 1" [25mm]

SPOILERS: 2-1/4" [57mm] 1" [25mm]

Set the Control Throws

4-CHANNEL RADIO SETUP

Check the Control Directions

GET THE MODEL READY TO FLY

Apply the Decals

16

(STANDARD MODE 2)

4-CHANNEL

TRANSMITTER

ELEVATOR MOVES UP

4-CHANNEL

TRANSMITTER

RIGHT AILERON MOVES UP

LEFT AILERON MOVES DOWN

RUDDER MOVES RIGHT

FLAPS NEUTRAL

(STICK DOWN, FULL FLAPS)

4-CHANNEL

TRANSMITTER

4-CHANNEL

TRANSMITTER

Page 17

❏ 1. With the wing level, have an assistant help you lift the

model by the tip of the fuse and the bottom of the fin.Do this

several times.

❏ 2.If one wing always drops when you lift the model, it means

that side is heavy. Balance the airplane by adding weight to the

other wing tip. An airplane that has been laterally balanced

will track better in loops and other maneuvers.

No matter if you fly at an AMA sanctioned R/C club site or if you

fly somewhere on your own, you should always have your

name, address, telephone number and AMA number on or

inside your model.It is required at all AMA R/C club flying sites

and AMA sanctioned flying events. Fill out the identification tag

on the decal sheet and place it on or inside your model.

Follow the battery charging instructions that came with

your radio control system to charge the batteries. You

should always charge your tr ansmitter and receiver batteries

the night before you go flying, and at other times as

recommended by the radio manufacturer.

Ground check the operational range of your radio before the

first flight of the day. With the transmitter antenna collapsed

and the receiver and transmitter on, you should be ab le to walk

at least 100 feet away from the model and still have control.

Have an assistant stand by y our model and, while you work the

controls, tell you what the control surfaces are doing. If the

control surfaces do not respond correctly, do not fly! Find and

correct the problem first. Look for loose servo connections or

broken wires, corroded wires on old servo connectors, poor

solder joints in your battery pack or a defective cell, or a

damaged receiver crystal from a previous crash.

Read and abide by the following excerpts from the Academy

of Model Aeronautics Safety Code.For the complete Safety

Code refer to

Model Aviation

magazine, the AMA web site or

the Code that came with your AMA license.

1) I will not fly my model aircraft in sanctioned events , air shows,

or model flying demonstrations until it has been proven to be

airworthy by having been pre viously , successfully flight tested.

2) I will not fly my model aircraft higher than approximately

400 feet within 3 miles of an airport without notifying the

airpor t operator. I will give right-of-way and avoid flying in

the proximity of full-scale aircraft. Where necessary, an

observer shall be utilized to supervise flying to avoid

having models fly in the proximity of full-scale aircraft.

3) Where established, I will abide by the safety rules for the

flying site I use, and I will not willfully and deliberately fly my

models in a careless, reckless and/or dangerous manner.

5) I will not fly my model unless it is identified with my name

and address or AMA number, on or in the model. Note:

This does not apply to models while being flown indoors.

7) I will not operate models with pyrotechnics (any device

that explodes, burns, or propels a projectile of any kind).

1) I will have completed a successful radio equipment ground

check before the first flight of a new or repaired model.

2) I will not fly my model aircraft in the presence of

spectators until I become a qualified flier, unless assisted

by an experienced helper.

3) At all flying sites a straight or curved line(s) must be

established in front of which all flying takes place with the

other side for spectators. Only personnel involved with

flying the aircraft are allowed at or in the front of the flight

line. Intentional flying behind the flight line is prohibited.

4) I will operate my model using only radio control

frequencies currently allowed by the Federal

Communications Commission.

5) I will not knowingly operate my model within three

miles of any pre-existing flying site except in

accordance with the frequency sharing agreement

listed [in the complete AMA Safety Code].

Radio Control

General

AMA SAFETY CODE (

EXCERPTS

)

Range Check

CAUTION: Unless the instructions that came with your

radio system state differently, the initial charge on new

transmitter and receiver batteries should be done for 15

hours using the slow-charger that came with the radio

system.This will “condition” the batteries so that the next

charge may be done using the fast-charger of y our choice.

If the initial charge is done with a fast-charger, the

batteries may not reach their full capacity and you may be

flying with batteries that are only partially charged.

Charge the Batteries

Identify Y our Model

PREFLIGHT

Balance the Model Laterally

17

Page 18

❏ 1. Check the C.G. according to the measurements

provided in the manual.

❏ 2. Extend your receiver antenna and make sure it has a

strain relief inside the fuselage to keep tension off the

solder joint inside the receiver.

❏ 3.Balance your model

laterally

as explained in

the instructions.

❏ 4. Make sure all hinges are securely glued in place.

❏ 5. Confirm that all controls operate in the correct direction

and the throws are set up according to the manual.

❏ 6. Make sure any servo extension cords you may have

used do not interfere with other systems (servo arms,

pushrods, etc.).

❏ 7.Place your name, address, AMA number and

telephone number on or inside your model.

❏ 8. Cycle your receiver battery pack (if necessary) and

make sure it is fully charged.

❏ 9. If you wish to photograph your model, do so before

your first flight.

❏ 10. Range check your radio when you get to the flying field.

If you are not thoroughly familiar with the operation of R/C

models, ask an experienced modeler to check to see you

have the radio installed correctly and all the control surfaces

do what they are supposed to.

It is a good idea to do a couple of trim flights before each

flying session to make sure the plane is still in trim and the

radio is working properly.

Hold the Spirit 100 ARF under the wing with the nose

pointed slightly down and directly into the wind. Launch the

model with the wings level and the nose pointing at a spot

on the ground about 50 feet in front of you.If the sailplane is

launched with the nose up or launched too hard it will climb

a few feet, stall and fall nose first straight down. With the

nose pointed down slightly the sailplane will accelerate

down until it picks up enough flying speed, then level off and

glide forward.Adjust the trims on your transmitter to get the

plane to fly straight ahead in a smooth glide path.

A hi-start is the most common way to launch your Spirit 100

ARF. Follow the directions that came with the hi-start and lay

it out directly into the wind. Place the stake at the far upwind

edge of the flying field so the parachute will blow back onto

the flying field.

Hook the parachute up to the tow hook. Pull the plane back

approximately twice as far as the rubber is long or whatever

the hi-start instructions recommend.

Hold the plane above your head with the wings level and the

nose pointed slightly up and directly into the wind.Give the plane

a gentle push forward to get it flying and it will climb up like a kite .

You should not have to touch the elev ator during the launch.Use

the rudder stick to keep it going straight up. You will find the

ailerons are not very responsive during the first part of the

launch. As the rubber relaxes the plane will fly off the hi-start.

The wing and airframe of ANY sailplane—even those ha ving

composite structures—can be destroyed by excessive

stress if a winch is not used properly.Sailplanes with a builtup balsa/ply wing and thin airfoil are especially vulnerable.

Proper winch operation is the responsibility of its user.Without

appropriate restraint, wing failure can result.Therefore:

• Do NOT attempt full pedal launches with the Spirit

100 ARF.

• Understand that you minimize the risk of wing failure

by launching with a Hi-Start.

• If you must launch with a winch, please use the winch

pedal responsibly!

Great Planes subjects all new airplane kit and ARF models

to rigorous stress-testing.Tests showed no weakness in the

Spirit 100 ARF wing during hi-start or winch launching.

Winch launches were conducted in a reasonable manner,

knowing that overzealous use could fold the wings.

Hi-Start Launch

Trimming Flights

FLYING

During the last few moments of preparation your mind may

be elsewhere anticipating the excitement of the first flight.

Because of this, you may be more likely to overlook certain

checks and procedures that should be performed before the

model is flown.To help avoid this, a check list is provided to

make sure these important areas are not overlooked. Many

are covered in the instruction manual, so where appropriate,

refer to the manual for complete instructions. Be sure to

check the items off as they are completed.

CHECK LIST

18

Page 19

Use these flights to get the “feel”of the controls and the Spirit

100 ARF’s flying characteristics. Adjust the trims on your

transmitter (a little at a time) until the plane will fly straight and

level with the transmitter sticks in their neutral positions.

The Spirit 100 ARF is a very gentle plane that flies well in

light to moderate winds. Practice coordinating ailerons and

rudder until you can get a tight turn that is relatively flat.

Bank the sailplane with rudder and ailerons first, then add

elevator to pull it around.When setting up to land, point the

nose into the wind just downwind of where you want to land.

Line up with your landing spot and slowly feed in flaps (or

Crow). Add more or less flaps to control your descent angle

and speed so you end up hitting the spot.

There are several types of mixing the Spirit 100 ARF can

take advantage of if you have a “computer radio”.

Launch Camber: Lowering the flaps and ailerons during the

launch will produce a steeper climb, giving you better altitude.

A good place to start is about 15 degrees of flap and 5 degrees

of aileron drop (the flaps will drop about three times more than

the ailerons).This automatically puts some washout in the wing

which adds stability for arrow straight launches. If you don’t

have a switch for launch camber, just use the flaps for launch.

Crow:This is used to lose altitude quickly and to control your

glide for spot landings. This mixing is tied to the flap stick

(throttle)and allows the ailerons to come up as the flaps drop.

Be sure to use plenty of aileron differential when using

CROW mixing because the ailerons become less effective at

very high angles of deflection. Also use maximum rudder

coupling at full CROW. If you don’t have CROW capabilities

just use flaps and make sure you hav e full rudder throw when

the flaps start coming down. It is a good idea to get lined up

on the spot before dropping the flaps very much because

the rudder will become sluggish with the flaps down at slow

speeds. Note: You will need to mix in a little down elevator

with the flaps to keep the plane tracking straight.

Aileron/Rudder Coupling: This is used to allow the

sailplane to make efficient, non-slipping, non-skidding turns.

You will need to experiment to find the proper amount of

throw required to do this but 1"[25mm] of rudder throw at full

aileron is probably a good place to start.

Elevator/Camber Coupling - This is a neat type of mixing

that allows the TE (ailerons and flaps) to respond to the

elevator. When properly set up, this can be very useful when

floating around in light air or when trying to thermal very

tightly. This mixing can change the flying characteristics of

the plane so start off small and get used it. A good place to

start would be 1/8" [3mm] of TE drop at full up elevator.

Controlling the Wing Trailing Edge (Camber): The wing

camber is usually controlled by a 3-position switch. The

traditional way of setting this switch is to have: the middle

position set to neutral camber, one direction for reflex (the

entire TE raises about 1/16" [1.5mm]) and the other direction

for positive camber (the entire TE drops about 3/32" [2.5mm]).

This way of programming the s witch is g reat f or good thermaldays or days with a lot of wind where you might need the

reflex capability for zooming up wind. The other way we set

this switch is to have the “back” position for neutral camber,

the middle position for a slight amount of positive camber

[1/32" [1mm] - 1/16" [2mm]) and the forward position f or more

positive camber [3/32" [2.5mm] - 1/8" [3mm]). The middle

position can be used once good air is located or when trying

to gain a few extra seconds of air time. Nor mally the L/D will

not be as great as neutral camber but the sailplane will float

better.The forward position is when the sailplane is low and

encounters lift, don’t panic, just hit the switch. The SPIRIT

ELITE will really slow up and will thermal “on a dime”.This setup is great for duration type flying without a lot of wind.

Thermals are a natural phenomenon that happen outside,

by the millions, every single day of the year. Thermals are

responsible for many things including forming several types

of clouds, creating breezes and distributing plant seeds and

pollen. If you have ever seen a dust devil (which is nothing

more than a thermal that has picked up dust), you hav e seen

a thermal in action.Their swirling action is very similar to that

of a tornado but much gentler.Most thermals have updrafts

rising 200-700 feet per minute but have been known to

produce updrafts of over 5,000 f eet per min ute These strong

thermals can rip a plane apart or carry the plane out of sight

before the pilot can get out of the updraft.

Thermals are formed by the uneven heating of the earth and

buildings, etc.by the sun.The darker colored surfaces absorb

heat faster than the lighter colors which reflect a great deal of

the sun’s energy bac k into space .These darker areas (plowed

fields, asphalt parking lots, tar roofs, etc.) get warmer than the

lighter areas (lakes, grassy fields, forests, etc.). This causes

FACTS ABOUT THERMALS

ADVANCED FEATURES

First Flights

19

Page 20

the air above the darker areas to be warmer than the air over

the lighter areas and the more buoyant warm air rises as the

cooler, denser air f orces its wa y underneath the warmer air .As

this warm air is forced upward it contacts the cooler air of the

higher altitudes and this larger temperature difference makes

the thermal rise quicker.The thermal is gradually cooled by the

surrounding cooler air and its strength diminishes. Eventually

the thermal stops rising and any moisture contained in the

once warm air condenses and forms a puffy cumulus cloud.

These clouds, which mark the tops of thermals, are usually

between 2000 and 5000 feet high.

As the glider approaches a thermal, the wing tip that reaches

the rising air first will be lifted before the opposite wing tip.This

causes the plane to “bank”and turn away from where we would

like the plane to go.The best way to get back in is to continue

the bank and turn 270 degrees straight into the thermal.

When you are thermal soaring, try to fly as smoothly and

straight as possible.Trim the plane to fly in a straight line and

only touch the controls when you have to. Watch the

sailplane carefully and it will tell you what it is encountering.

When the sailplane flies directly into a thermal it will either start

rising or stop sinking. Either case is reason enough to start

circling.Fly straight until you feel lik e you are in the strongest lift,

then fly a couple of seconds farther so your circle will be

centered in the strongest lift.Thermals travel with the wind, so

be careful that you don’t get too far downwind that y ou can’t get

back.If you find yourself getting too high, don’t div e the plane to

get out of the lift. Sailplanes are very efficient aircraft and they

will build up a lot of speed and could “blow up” in the rough air

of a thermal. The easiest way to lose altitude is to apply full

rudder and full up elevator. This will put the plane into a tight

spin that will not over stress the airframe but it will enable it to

lose altitude very quickly. This is especially helpful if the

sailplane gets sucked into a cloud or it gets too high to see.

As you might expect, with all this air rising, there is also air

sinking. This air is the sailplane pilot’s nightmare that can

really make soaring challenging. “Sink” is usually not as

strong as the thermals in the same area but sometimes can

be. Because of this, it is important you do not let the

sailplane get too far downwind.

Watch the birds! - Thermals suck up small insects many

birds love to eat. A bunch of swallows flying around in one

area may indicate a thermal.Soaring birds (hawks, vultures,

eagles etc.) are the best thermal indicators. They not only

show you where the thermal is but they also show you

where the center is.These “Masters of the sky” will often fly

right along with sailplanes.

Practice those landings! Most thermal contests are won or

lost during the landing. Establish a particular landing patter n

and try to stick to it for all landings.Lear n to shift your pattern

to account for the wind and particular flying field

characteristics. Flaps can be very useful during contest

landings.They allow you to bring the sailplane in for a landing

higher or faster than normal to guard against any last minute

sink or gusts and dump the extra altitude and speed at the last

second.They can also be used to help control your skid.Flaps

will stop the plane from sliding a little quicker. You can also

“steer” the plane while it is sliding along the ground. Don’t

expect to be able to “horse it around”but you can gain v aluable

inches by using the rudder to guide it towards the spot as it

slides to a stop.Be very careful not to “ground loop” the plane

since you will lose your landing points if the plane flips over.

To be able to slope soar, you need a slope with a smooth

piece of land (or water) out in front of it and a breeze blowing

pretty close to straight up the slope.The higher and steeper

the hill or cliff the better. Also the larger and smoother the

land out in front the better.The air flowing towards the hill, is

forced up and can generate a very large area of lift. Behind

the hill is a large area of turbulent air that can be very

dangerous to try to fly in. The faster the wind is blowing the

stronger the lift and turbulence will be.

To fly off a slope, stand near the edge and throw the sailplane

(nose down) into the wind. As the sailplane flies out into the

“band” of lift it will begin to gain altitude.Turn and fly parallel to

the slope and make all of your turns into the wind (especially

when you are close to the slope).You will be surpr ised at the

altitude you can gain just from slope lift.Thermals will often be

“popped loose” by these slopes. If you catch a thermal and

follow it downwind, be v ery careful to stay high enough to mak e

it back to the slope without flying through the turbulent air.

Landings can be very tricky on some slopes. On gentle slopes

you can often fly very close to the top of the slope and “slide”

into the top of the slope without encountering any turbulent air.

On steeper slopes you may ha ve to be a little more aggressive

to get the plane out of the lift. In any case it is a good idea to

plan your landing before you launch your plane.

In strong wind conditions, you may want to add ballast

(weight) to the sailplane to increase its wing loading which

increases its normal flying speed. Increasing the weight of

your sailplane does not change its “glide ratio” but it does

make it fly faster which makes it sink a proportional amount

faster. Because of this faster sink rate, you need to be very

cautious when ballasting for a thermal contest. In duration

type contests only use ballast on very windy days that also

have a lot of thermal activity. Center the weight directly on

the center of gravity of the plane so you can add ballast

without having to re-balance the plane. When learning to

ballast your plane, start out small and work your way up.

HAVE FUN AND GOOD LIFT!!

BALLAST

SLOPE SOARING

THERMAL SOARING

Loading...

Loading...