Great Plains Industries GPRO PRO25-012PO, GPRO PRO25-012 Series, GPRO PRO25-024PO, GPRO PRO25-024 Series, GPRO PRO25-012PO/XTS Owner's Manual

OWNER'S MANUAL

SAVE THESE INSTRUCTIONS

PRO25-012 PRO25-024

12-Volt DC 24-Volt DC

PRO25-012PO Pump Only PRO25-024PO Pump Only

PRO25-012PO/XTS Pump Only - Extreme

Temperature Series

DO NOT RETURN THIS PRODUCT

TO THE STORE!

Please contact Great Plains Industries before returning any product.

If you are missing parts or experience problems with your installation,

our Customer

Support Department will be happy

800-835-0113 or 316-686-7361

to assist you:

TABLE OF CONTENTS

General Information .................................................... 2

Safety Instructions ...................................................... 2

Installation .................................................................. 3

Operation .................................................................... 4

Maintenance ............................................................... 4

Repair ......................................................................... 4

Troubleshooting .......................................................... 5

Specications ............................................................. 6

Illustrated Parts Drawing ............................................ 7

Parts and Service ....................................................... 8

Warranty .......................................................See Insert

To the owner...

Congratulations on receiving your GPRO® Fuel Transfer

Pump. We are pleased to provide you with a system designed

to give you maximum reliability and efciency.

Your fuel pump is designed, tested, and approved for use with

gasoline blends, diesel fuel blends and kerosene. Please take

all due precautions when handling these ammable liquids.

Your safety is important to us.

Also, to assure the longest possible service life, it is important

that you follow the operation and maintenance procedures

outlined in this manual. We are proud to provide you with a

quality product and dedicated support. Together with your

conscientious use, we are sure that you will obtain years of

safe, dependable service.

02/2017

Victor Lukic, President

Great Plains Industries, Inc.

922106-01 Rev D

GENERAL INFORMATION

The purpose of this manual is to assist you in installing, operating and maintaining your

manual covers models PRO25-012 (12-Volt DC) and

PRO25-024 (24-Volt DC).

GPRO® pump. This

Model Components

PRO25-024PO / PRO25-012PO: Includes pump only.

PRO25-012PO/XTS: Includes pump only and compo-

nents to assemble to unit before use.

NOTE: Sufxes PO and PO/XTS are for ordering purposes

only. Constructions described above are covered as

alternate constructions under the Part No. PRO25

UL Listing.

An automatic bypass valve prevents pressure build

up when the pump is on with the nozzle closed. To

avoid damage, do not run the pump more than 10

minutes with the nozzle closed.

The duty cycle of this pump is 30 minutes ON and 30

minutes OFF. Allow the pump to cool for 30 minutes.

This pump is designed for use only with gasoline (up

to 15% alcohol blends such as E-15), diesel fuel (up to

20% biodiesel blends such as B20) and kerosene. Do

not use this pump for dispensing any uids other than

those for which it was designed. To do so may damage

pump components and will void the warranty.

This pump is designed to operate on a typical DC automotive electrical system. The pump is designed to operate

with the appropriate DC voltage at the motor leads and

the ratings are determined at this voltage. Performance

may vary due to length of power cord, battery condition

or output from the vehicle charging system that will affect

system voltage.

Do not leave the system running with uids. “Dry running”

can damage the pump.

Do not pump the tank completely dry, as contaminants

from the bottom of the tank may enter the pump.

SAFETY INSTRUCTIONS

The following safety alert symbols are used in

this manual. Obey all safety messages that follow

this symbol to avoid possible injury or death.

DANGER

WARNING

DANGER indicates an

imminently hazardous

situation which, if not avoided, will result in death or

serious injury.

WARNING indicates

a potentially hazardous

situation which, if not avoided, could result in death or

serious injury.

CAUTION

There are inherent dangers wherever ammable fuel and

AC electrical sources are in close proximity.

Static electricity as a source of sparking is always a

concern and requires extreme care in the installation and

operation of your entire fuel transfer system.

Additional components such as meters, automatic nozzles

and lters must be listed for use with fuel transfer systems.

The ow of fuel through a hose and nozzle can generate

static electrical charges and dangerous sparking can

result in re or explosion. Hoses and nozzles must be

electrically conductive and bonded to ground.

It is your responsibility to:

• Know and follow applicable national, state and local

safety codes pertaining to installing and operating

electrical equipment for use with ammable liquids.

• Know and follow all safety precautions when handling

petroleum fuels.

• Ensure that all equipment operators have access to

adequate instructions concerning safe operating and

maintenance procedures.

Observe all safety precautions concerning safe handling

of petroleum fuels.

To ensure safe operation, all fuel transfer systems must

be properly grounded. Proper grounding means a continuous metal-to-metal contact from one component to the

next, including tank, bung, pump, meter, lter, hose and

nozzle. Care should be taken to ensure proper grounding

during initial installation and after any service or repair

procedures. For your safety, please take a moment to

review the warnings below.

To prevent physical injury, observe precautions against

re or explosion when dispensing fuel. Do not operate

the system in the presence of any source of ignition

including running or hot engines, lighted cigarettes, or

gas or electric heaters.

Observe precautions against electrical shock when operating the system. Serious or fatal shock can result from

operating electrical equipment in damp or wet locations.

Inspect external pump wiring regularly to make sure it is

correctly attached to the battery. To avoid electrical shock,

use extra care when connecting the pump to power.

Avoid prolonged skin contact with petroleum fuels. Use

protective goggles, gloves and aprons in case of splashing or spills. Change saturated clothing and wash skin

promptly with soap and water.

Observe precautions against electrical shock when

servicing the pump. Always disconnect power before

repairing or servicing. Never apply electrical power to

the system when any of the coverplates are removed.

If using solvent to clean pump components or tank, observe the solvent manufacturer’s recommendations for

safe use and disposal.

CAUTION indicates

a potentially hazardous

situation which, if not avoided, may result in minor or

moderate injury.

2

INSTALLATION

Install Suction Pipe

Your pump is designed to mount directly to a standard

2 in. NPT tank tting. For the suction pipe, a 1 inch

galvanized steel pipe cut to length and threaded on one

end may be used. Suction pipe should extend to within

3 inches of tank bottom. Apply thread tape to the suction

pipe thread and securely tighten the suction pipe to the

pump inlet port.

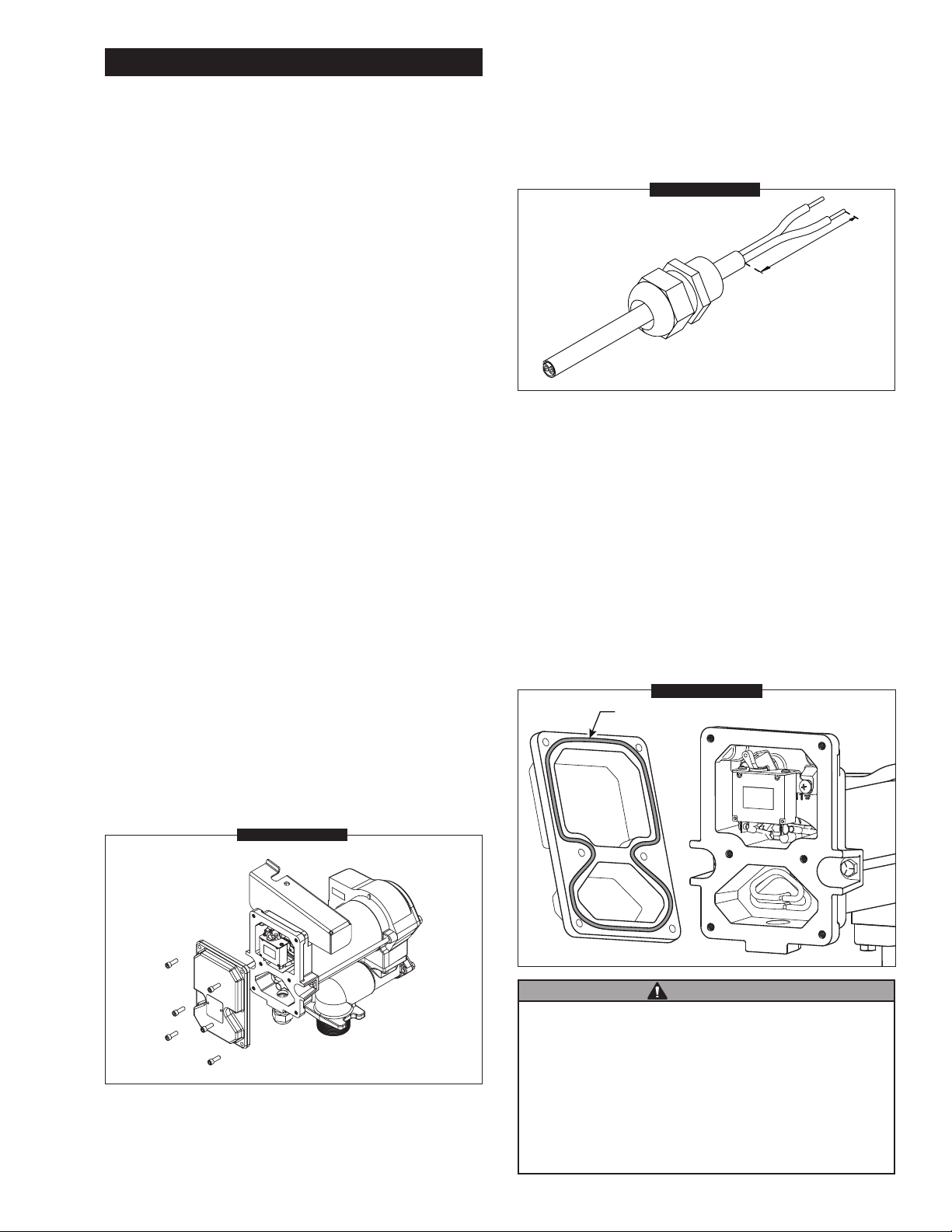

Trim the power cord to the desired length. If your power

cord is not pre-stripped, strip 3 inches of outer insulation

from the power cord end. Then strip 1/2 inch of insulation

from the power cord wires. Slide the strain relief grip onto

the power cord so that the threaded end of the strain relief

grip faces the stripped power wires. (Figure 2)

FIGURE 2

Make sure any check valve or foot valves used are

equipped with proper pressure relief valves.

Install Pump on Tank

• Clean the tank interior of all dirt and foreign material.

• Place the pump with suction pipe installed on the tank

tting and tighten securely. Make sure the pump is not

cross-threaded.

• To prevent pressure build-up and possible fuel leaks

through the nozzle, make sure the tank is vented. A

vent cap rated at 3 psi or less is recommended.

Install Electrical Connections

A grounding connection is provided. It is identied as a green

colored binding head screw in the electrical cavity.

PRO25-012 models must be connected to a 12-volt DC

power source only.

PRO25-024 models must be connected to a 24-volt DC

power source only.

DO NOT attempt to connect these pumps to a 115-volt

AC or 230-volt AC power source.

For installation in unclassied areas, the supplied power

cord, fuse and strain relief grip may be used.

NOTE: These components have not been evaluated as

part of the UL Listed Equipment and are not intended

for use in a Hazardous (Classied) Location.

3 in. Ref.

Insert the power cord through the 3/4 in. NPT connection

on the bottom of the pump.

Using wire nuts, connect the black wire to the black wire

and the white (or red) wire to the white (or red) wire in

the pump’s electrical cavity. Position the wires inside the

electrical cavity and tighten the strain relief grip securely.

Inspect the mating surfaces of the electrical coverplate

and electrical cavity for debris. Clean any debris with

an alcohol wipe. If needed, re-apply a light coating of

Lubriplate® 1242 (or equivalent) white lithium grease

to coverplate perimeter, as shown in Figure 3. Reinstall

electrical coverplate and tighten screws securely to 95105 in•lbs (10.7-11.8 N•m).

Apply grease around

perimeter, as shown

FIGURE 3

To install the power cord, remove the electrical coverplate.

(Figure 1)

FIGURE 1

WARNING

Carefully route the power cord to the battery, protecting the power

cord from hot surfaces, sharp edges or anything that could damage

the power cord, resulting in a short circuit.

A fuse is provided to protect the power cord and motor. Install fuse

in the white (or red) wire of the power cord as close as possible

to the battery. Connect the red wire of the fuse to the positive

(ungrounded) side of battery. Connect black wire to the negative

(grounded) side of the battery.

Failure to follow these instruction could result in death, serious

injury or loss of equipment due to short circuit, re or explosion.

3

Loading...

Loading...