Great Plains YP925TD Assembly Instructions

Great Plains Mfg., Inc. Appendix Installation Instructions 1

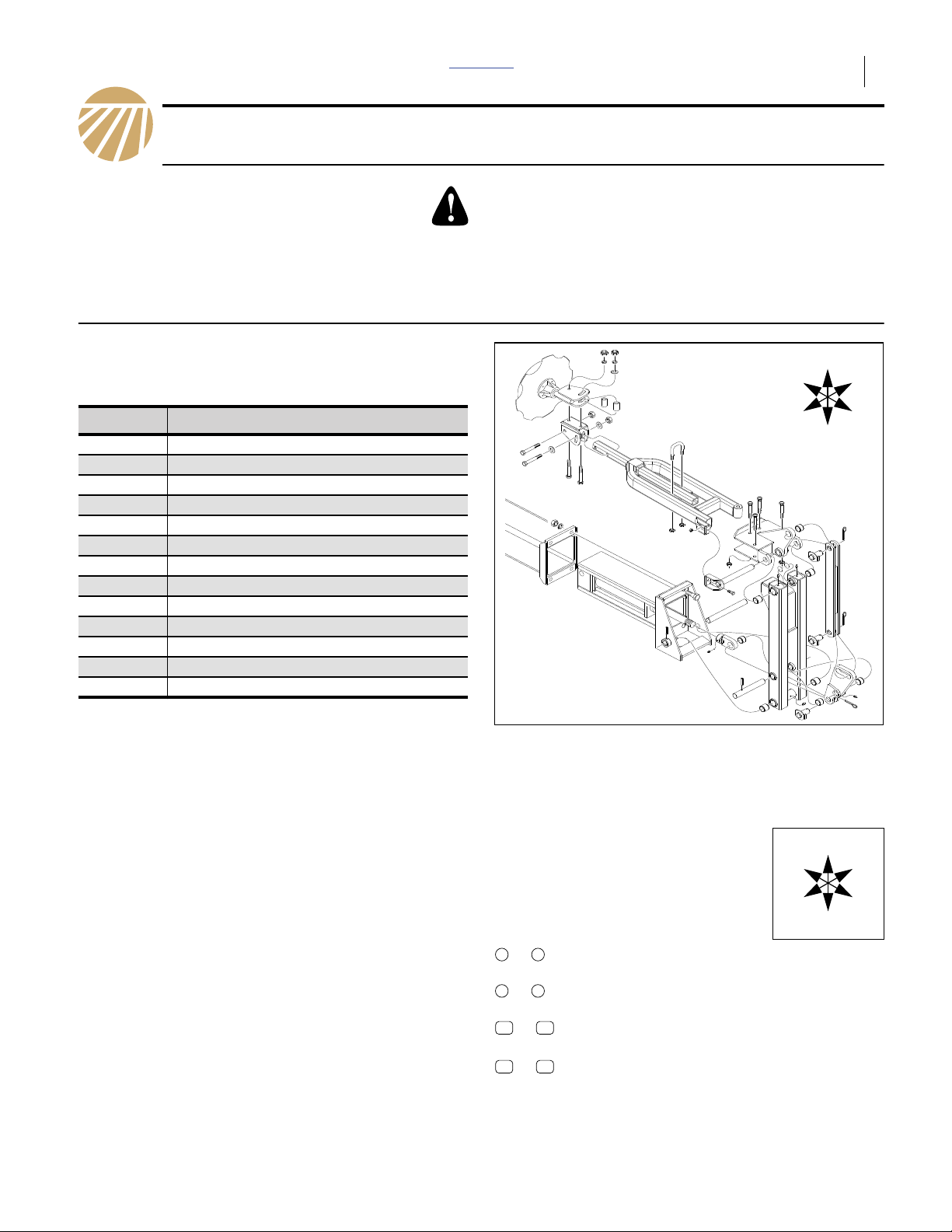

Flat Fold Marker

Single Section YP Planters

Used with: When you see this symbol, the subsequent instructions and

• YP425A, YP425A3P

• YP625A, YP625A3P, YP625PD/TD

• YP825A, YP825A3P

• YP925TD

General Information

warnings are serious - follow without exception.

Your life and the lives of others depend on it!

These instructions explain how to install field markers on

a compatible planter.

These instructions apply to an installation of:

Kit Kit Description

113-836A 4-30 3P PLTR FLAT FOLD MKR

113-837A 4-30 PT PLTR FLAT FOLD MKR

113-838A 6-30 PT PLTR FLAT FOLD MKR

113-839A 6-38-40 8-30 PT PLTR FOLD MKR

113-854A 4-38-40 PT PLTR FLAT FOLD MKR

113-855A 4-38-40 3P PLTR FLAT FOLD MKR

113-857A 4-36 PT PLTR FLAT FOLD MKR

113-858A 4-36 3P PLTR FLAT FOLD MKR

113-859A 6-36 3P PLTR FLAT FOLD MKR

113-860A 6-36 PT PLTR FLAT FOLD MKR

113-861A 6-110 3P PLTR FLAT FOLD MKR

113-862A 6-110 PT PLTR FLAT FOLD MKR

113-863A 9-65 3P PLTR FLAT FOLD MKR

One kit includes two markers (left and right), an

automatic sequence valve, all hydraulic hoses and

fittings, and all necessary mounting hardware.

One kit updates one planter.

Figure 1

Flat Fold Marker Kit

R

F

U

B

L

D

29872

Related Documents

Have the Operator Manual at hand for planter

movements.

401-651M YP425/625/825A3P Operator Manual

401-652M YP425/625/825A Operator Manual

401-754M YP625PD Operator Manual

401-755M YP625TD/925TD Operator Manual

Have the current Parts Manual at hand for parts

identification.

401-651P YP425/625/825A3P Parts Manual

401-652P YP425/625/825A Parts Manual

401-754P YP625PD Parts Manual

401-755P YP625TD/925TD Parts Manual

2012-22-03 ©Copyright 2012 113-870M

Notations and Conventions

“Left” and “Right” are facing in the

direction of machine travel. An

orientation rose in the line art

illustrations shows the directions of

Left, Right, Front, Back, Up, Down.

Call-Outs

1 9

to

and

a z

to

11 22

to

31 91

to

Single-character callouts identify

components in the currently referenced

Figure or Figures. These callouts may be

reused for different items from page to page.

Two-digit callouts in the range 11 to 22

reference affected existing parts.

Two-digit callouts in the range 31 to 91

reference new parts.

R

F

U

B

L

D

2 Flat Fold Marker Front Appendix Great Plains Mfg., Inc.

Before You Start

Parts and Tools Required

• You need a suitable tractor for positioning the planter,

and having sufficient hydraulic circuits, with adequate

capacity to operate the markers (installing markers

increases the required circuits by one).

• You need a hoist with 136 kg (300 pound) capacity.

• Have safety goggles and gloves for inspecting

hydraulic connections and handling sharp marker

discs.

• Other than the hoist, only basic hand tools are

required.

• 5 liters (1.2 gallons) of hydraulic fluid is needed to

charge the marker system.

• General purpose grease lubricant and grease gun.

• Liquid PTFE pipe sealant, if the kit includes QD

couplers. See page 20 for more information.

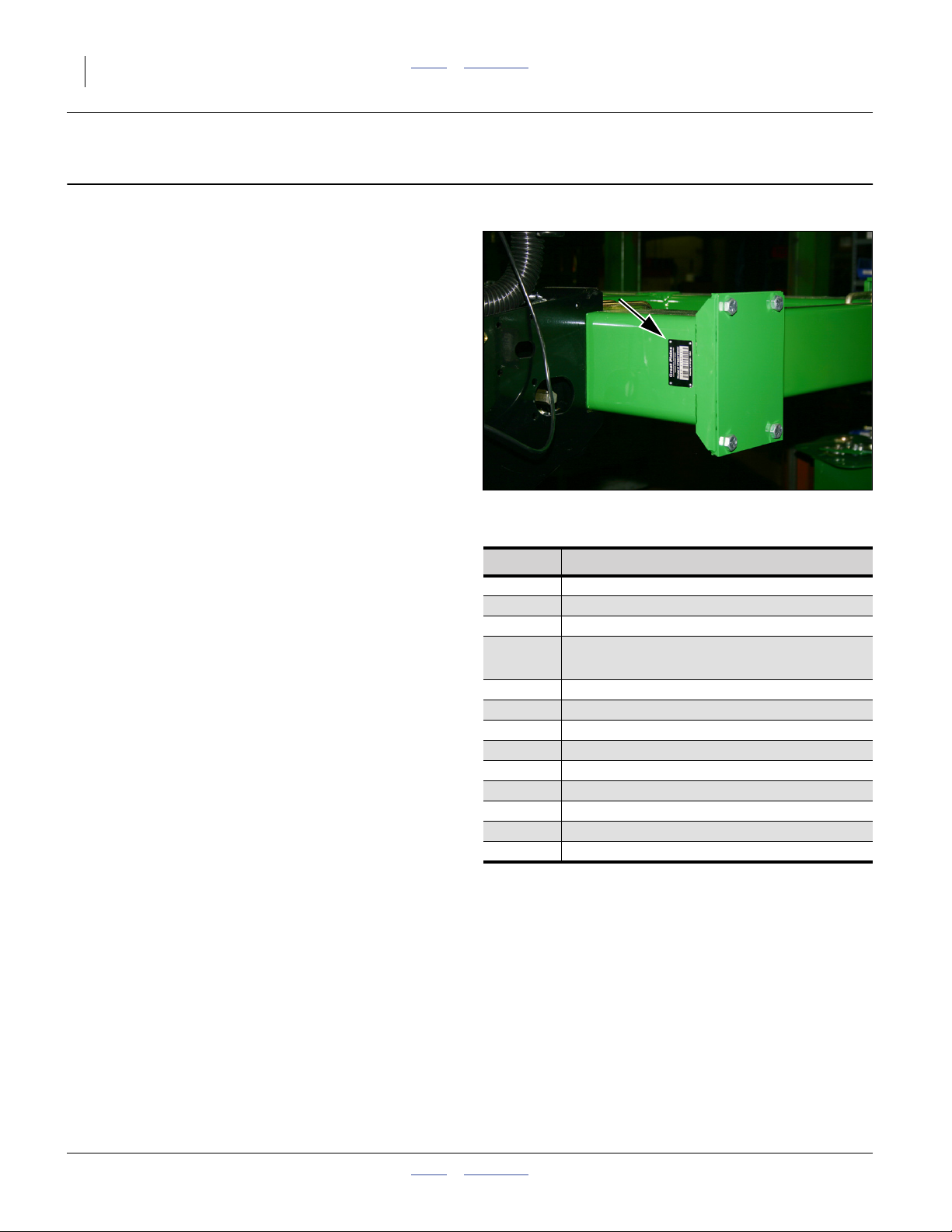

Figure 2

YP925 Serial Number Plate

31980

Compatibility

Refer to Figure 2 (consult planter Operator manual for serial

number plate location)

1. Check the model number of the planter against the

table at right to ensure you have the correct kit.

Sequence

If installing the markers as part of export pre-delivery,

perform the installation at the point called for in the

pre-delivery manual:

401-754Q YP625/925 Export Pre-Delivery Manual

Comprehension

2. Review these instructions. Make sure the installers

understand where each part or assembly is

installed, and what tools are required for the task.

Kit Compatible Planters

113-836A YP425A3P, spacings up to 30 in. (76 cm)

113-837A YP425A, spacings up to 30 in. (76 cm)

113-838A YP625A3P, spacings up to 30 in. (76 cm)

113-839A

113-854A YP425A, spacings 38 in. or 40 in

113-855A YP425A3P, spacings 38 in. or 40 in

113-857A YP425A, spacing 36 in.

113-858A YP425A3P, spacing 36 in.

113-859A YP625A3P, spacing 36 in.

113-860A YP625A, spacing 36 in.

113-861A YP625TD, spacing 110 cm

113-862A YP625PD, spacing 110 cm

113-863A YP925TD, spacing 65 cm

YP625A, spacings 38 in. or 40 in.,

YP825A, spacings up to 30 in. (76 cm)

113-870M Front Appendix 2012-22-03

Great Plains Mfg., Inc. Front Appendix Installation Instructions 3

Pre-Assembly Preparation

Work Location

3. Move the planter to a location with:

• access to tractor or hydraulic power;

• adequate illumination; and,

• clear surface beneath for recovery of any falling

or dropped parts - if the surface is not clear, have

a tarp or drop cloth available.

4. Raise planter. Install lift cylinder locks and/or

parking stands, as provided. Lower planter onto

locks. This minimizes planter movement during

exercising of markers on a planter with a shared lift/

marker circuit.

5. Set all hydraulic remote circuits to Float (to ensure

that pressure is relieved). Shut off tractor or

hydraulic source.

High Pressure Fluid Hazard:

Ensure lift circuit pressure is zero at step 5. Wear gloves and

safety eyewear when working on hydraulics. Some planter

configurations require disconnecting hydraulic fittings in the

lift circuit. Dangerous releases of hydraulic fluid may occur if

pressure remains in the circuit. This could lead to serious

personal injury. If hydraulic fluid penetrates the skin, seek

immediate medical attention from a physician familiar with

this type of injury.

2012-22-03 Front Appendix 113-870M

4 Flat Fold Marker Front Appendix Great Plains Mfg., Inc.

Install Sequence Valve Mount

Attach Valve to Mount

If the sequence valve is already attached to the

mount , continue at “Identify Mount Style”.

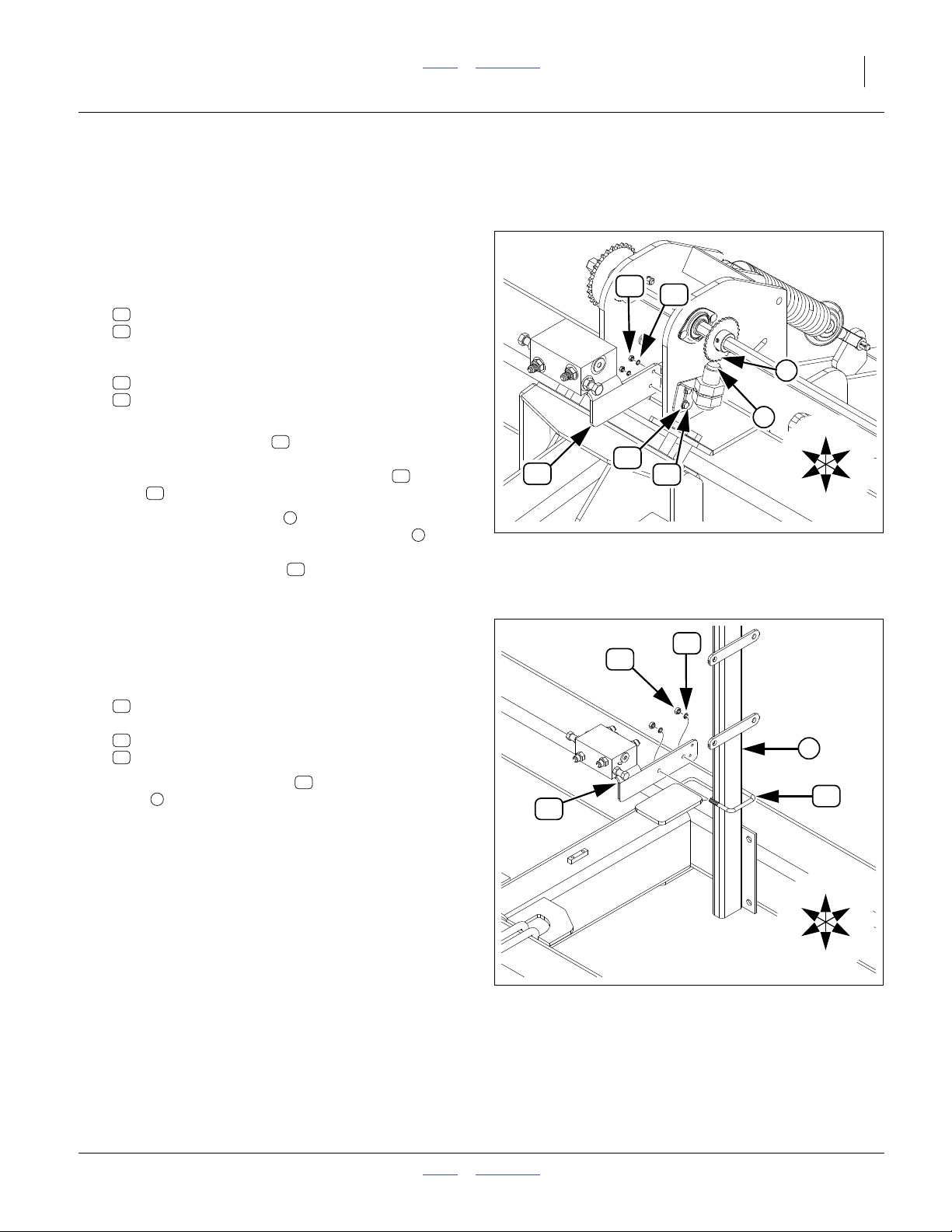

Refer to Figure 3 and Figure 4

6. Select one:

7. Select one:

48

71

810-197C VALVE,SEQUENCE SHOEMAKER

Examine the valve body to establish which faces are

front, rear and bottom.

The front (supply/return) face has two FORB ports

adapted to9⁄16MJIC. They are stamped “1” and “2”.

The rear (cylinder) face has four MORB ports

adapted to9⁄16MJIC. They are stamped “C1”, “C2”,

“R1” and “R2”. The “C” ports connect to cylinder rod

(retract) ends. The “R” ports connect to cylinder

base (extend) ends.

The bottom face has two3⁄8-16 threaded holes for

mounting (not shown).

48

411-642D MOUNT, SEQUENCE VALVE

and two sets:

53

802-017C HHCS 3/8-16X1 GR5

63

804-013C WASHER LOCK SPRING 3/8 PLT

Orient the valve on the top break of the

mount , with the valve rear (4-port) face toward

the mount side break. Secure the valve to the mount

with two bolts and lock washers .

48

Identify Mount Style

There are two styles of sequence valve mount:

• North American Models YP425/625/825 use a ground

drive mount, based on bundle:

113-841S SEQUENCE VALVE MOUNT ASSY

This style mounts to the ground drive weldment using

existing planter fasteners and the smaller 7 mm

148

holes in the side of the mount .

• Export Models YP625PD/TD and YP925 use a fan

mast mount based on bundle:

113-867S SEQUENCE VALVE MOUNT ASY FAN

This style mounts to the existing fan post using a new

U-bolt ( , not shown) through the large 11 mm

holes in the side of the mount .

69

248

71

71 3

53 63

U

L

B

71

F

R

D

48

3

2

1

63

53

Figure 3

Sequence Valve Mount

Note: Leave protective plastic caps on ports until

instructed to remove them at later steps.

Note: See table on page 11 for sequence valve port

assignments.

31986

71

Figure 4

Sequence Valve Front and Rear

31981

113-870M Front Appendix 2012-22-03

Great Plains Mfg., Inc. Front Appendix Installation Instructions 5

Install Mounted Valve

Ground Drive Mount

For a mast mount, continue at step 11.

The sequence valve mount uses the existing fasteners

for the ground drive speed sensor.

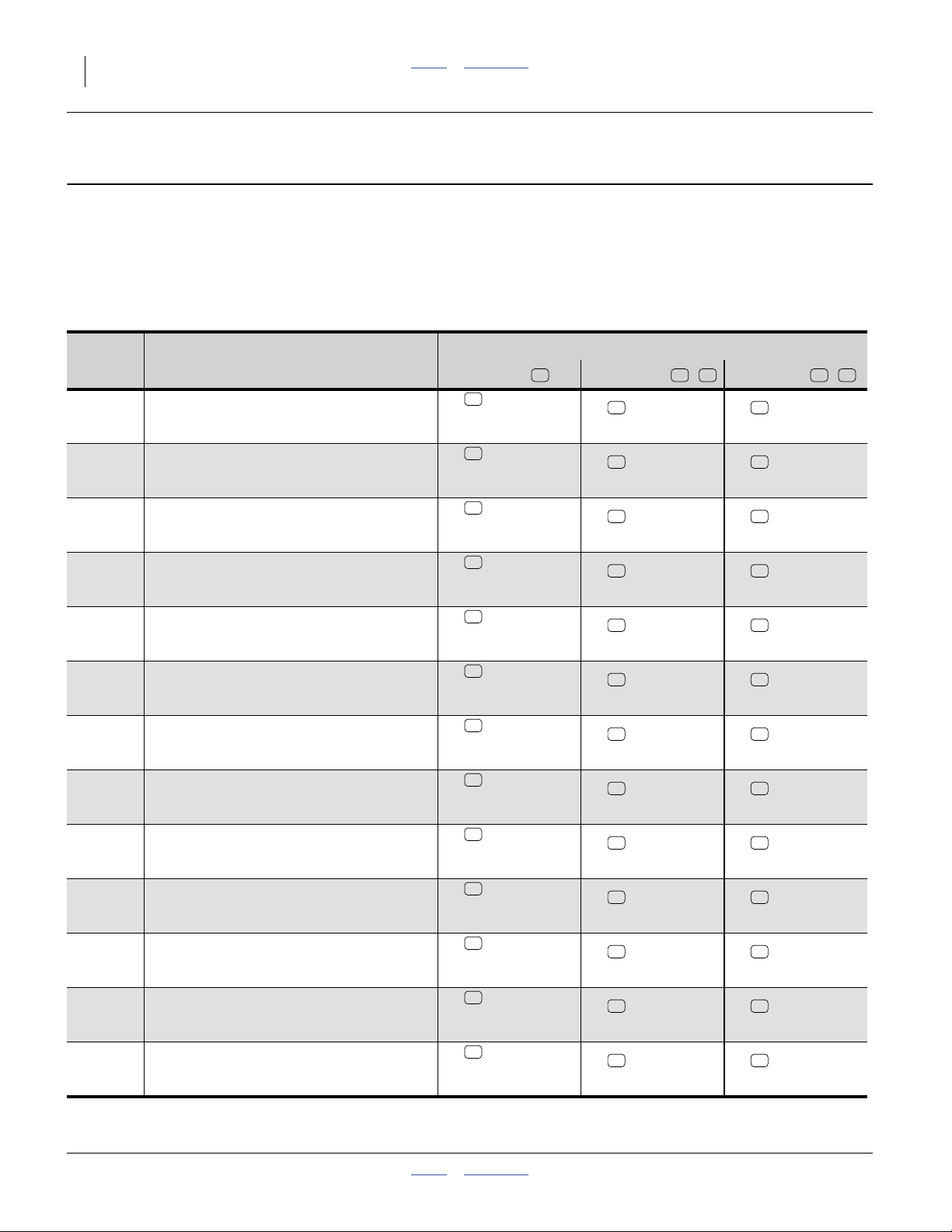

Refer to Figure 5

8. Remove and save two sets existing:

15

803-006C NUT HEX 1/4-20 PLT

17

804-006C WASHER LOCK SPRING 1/4 PLT

If possible leave the following existing parts in place,

to ease re-assembly:

18

804-007C WASHER FLAT 1/4 SAE PLT

14

802-224C HHCS 1/4-20X1 1/4 GR5

9. Align the smaller 7 mm mounting holes of the

sequence valve mount with the speed sensor

mounting holes in the ground drive weldment.

Loosely secure with saved lock washers and

15

nuts .

10. Adjust the speed sensor for a 1.6 mm gap

between its top face and the toothed wheel . See

Operator manual for further details regarding this

adjustment. Tighten nuts .

Continue at “Install Hydraulics” on page 6.

48

17

5

15

48

6

15

17

5

18

14

Figure 5

Ground Drive-Mounted Valve

6

U

R

F

B

L

D

31988

Mast Mount

For a ground drive mount, begin at step 8 above.

Refer to Figure 6

11. Select one new:

69

806-132C U-BOLT 3/8-16 X 3 1/32 X 2 3/4

and two sets new:

63

804-013C WASHER LOCK SPRING 3/8 PLT

59

803-014C NUT HEX 3/8-16 PLT

12. Loosely secure the mount near the base of the

7

mast .

48

48

63

59

Figure 6

Mast-Mounted Valve

R

F

7

69

U

B

L

D

31989

2012-22-03 Front Appendix 113-870M

6 Flat Fold Marker Front Appendix Great Plains Mfg., Inc.

Install Hydraulics

Identify Hoses

There are two or three sets of hoses in the system.

There are either three pairs, or one pair and one set of

four. See table below for hose part numbers by kit.

See “Hydraulic Connector Identification” on page 20

for descriptions of hydraulic connections, as well as

fitting torque recommendation, and sealant information.

Note: Do not remove plastic caps or plugs on hoses or

fittings until just before making connections.

Kit

113-836A

113-837A

113-838A

113-839A

113-854A

113-855A

113-857A

113-858A

113-859A

113-860A

113-861A

113-862A

113-863A

Kit Description

Planter Models

4-30 3P PLTR FLAT FOLD MKR

YP425A3P, spacings up to 30 in. (76 cm)

4-30 PT PLTR FLAT FOLD MKR

YP425A, spacings up to 30 in. (76 cm)

6-30 PT PLTR FLAT FOLD MKR

YP625A3P, spacings up to 30 in. (76 cm)

6-38-40 8-30 PT PLTR FOLD MKR

YP625A, spacings 38 in. or 40 in.,

YP825A, spacings up to 30 in. (76 cm)

4-38-40 PT PLTR FLAT FOLD MKR

YP425A, spacings 38 in. or 40 in

4-38-40 3P PLTR FLAT FOLD MKR

YP425A3P, spacings 38 in. or 40 in

4-36 PT PLTR FLAT FOLD MKR

YP425A, spacing 36 in.

4-36 3P PLTR FLAT FOLD MKR

YP425A3P, spacing 36 in.

6-36 3P PLTR FLAT FOLD MKR

YP625A3P, spacing 36 in.

6-36 PT PLTR FLAT FOLD MKR

YP625A, spacing 36 in.

6-110 3P PLTR FLAT FOLD MKR

YP625TD, spacing 110 cm

6-110 PT PLTR FLAT FOLD MKR

YP625PD, spacing 110 cm

9-65 3P PLTR FLAT FOLD MKR

YP925TD, spacing 65 cm

Hose Part Numbers, Length and Connectors

Supply Base End , Rod End ,

78

811-395C

183cm FJIC-MNPT

Dedicated

77

811-287C

76cm FJIC-FJIC

Shared, 2-Cylinder

77

811-287C

76cm FJIC-FJIC

Shared, 4-Cylinder

77

811-287C

76cm FJIC-FJIC

Shared, 4-Cylinder

77

811-287C

76cm FJIC-FJIC

Shared, 2-Cylinder

78

811-395C

183cm FJIC-MNPT

Dedicated

77

811-287C

76cm FJIC-FJIC

Shared, 2-Cylinder

78

811-395C

183cm FJIC-MNPT

Dedicated

78

811-395C

183cm FJIC-MNPT

Dedicated

77

811-287C

76cm FJIC-FJIC

Shared, 4-Cylinder

78

811-395C

183cm FJIC-MNPT

Dedicated

79

811-436C

396cm FJIC-MNPT

Dedicated

78

811-395C

183cm FJIC-MNPT

Dedicated

S R1 R2 C1 C2

88 88

841-397C

292cm FJIC-FJIC

86 87

841-171C

181cm FJIC-FJIC

89 88

841-469C

259cm FJIC-FJIC

85 84

841-125C

325cm FJIC-FJIC

89 88

841-469C

259cm FJIC-FJIC

91 91

841-477C

356cm FJIC-FJIC

89 88

841-469C

259cm FJIC-FJIC

91 91

841-477C

356cm FJIC-FJIC

81 81

811-637C

422cm FJIC-FJIC

85 84

841-125C

325cm FJIC-FJIC

81 81

811-637C

422cm FJIC-FJIC

81 81

811-637C

422cm FJIC-FJIC

84 84

841-124C

358cm FJIC-FJIC

292cm FJIC-FJIC

216cm FJIC-FJIC

292cm FJIC-FJIC

358cm FJIC-FJIC

292cm FJIC-FJIC

356cm FJIC-FJIC

292cm FJIC-FJIC

356cm FJIC-FJIC

422cm FJIC-FJIC

358cm FJIC-FJIC

422cm FJIC-FJIC

422cm FJIC-FJIC

358cm FJIC-FJIC

841-397C

841-374C

841-397C

841-124C

841-397C

841-477C

841-397C

841-477C

811-637C

841-124C

811-637C

811-637C

841-124C

113-870M Front Appendix 2012-22-03

Great Plains Mfg., Inc. Front Appendix Installation Instructions 7

Prepare Supply Hoses

Hose Part Numbers

This table has a complete list of hose callouts, part

numbers and descriptions. Your kit contains at most

three different part numbers.

Call

-out

77

78

79

80

81

84

85

86

87

88

89

91

Part

Number

Description

811-287C HH3/8R2 030 3/4FJIC 9/16FJIC

811-395C HH1/4R1 072 9/16FJIC 1/2MNPT

811-436C HH1/4R1 156 9/16FJIC 1/2MNPT

811-494C HH1/4R1 190 9/16FJIC

811-637C HH1/4R2 166 9/16FJIC

841-124C HH 1/4 R2 141 9/16FJIC

841-125C HH 1/4 R2 128 9/16FJIC

841-171C HH1/4R2 075 9/16FJIC

841-374C HH1/4R2 085 9/16FJIC

841-397C HH1/4R2 115 9/16FJIC

841-469C HH1/4R2 102 9/16FJIC

841-477C HH1/4R2 140 9/16FJIC

Note: Supply hoses are FJIC-to-FJIC where the markers

are on the lift circuit (North America pull-type

planters only). One FJIC end is connected into the

existing lift circuit.

In a shared 2-cylinder circuit (Model YP425

pull-type only), the marker kit includes tees, which

replace existing elbows.

In a shared 4-cylinder circuit, the marker kit

includes a cross, which replaces existing tees.

Note: Supply hoses are FJIC-to-MNPT where the

markers are on a dedicated hydraulic circuit. The

MNPT end of the hose is connected to a QD

coupler.

Note: A hose clamp and label (see step 17) are provided

in all kits. Their use on hoses shorter than 80 cm

is optional, and is not documented in this manual.

Dedicated Supply Circuit Hose

If the supply hoses rely on a shared circuit, continue at

“Two-Cylinder Shared Supply Circuit” on page 8 or

“Four-Cylinder Shared Supply Circuit” on page 9.

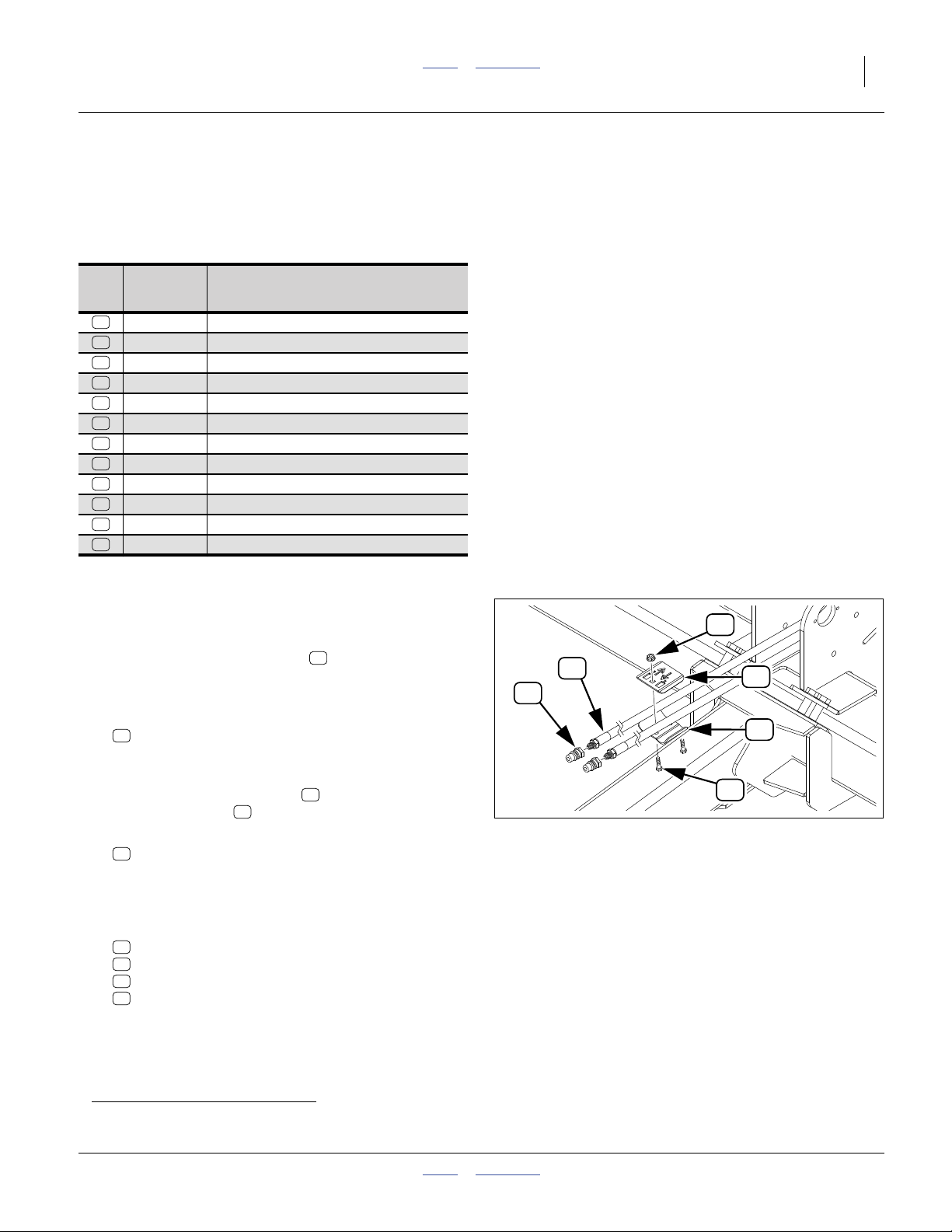

13. Select the two supply hoses . See the table on

page 6 for the correct part number for the planter.

Refer to Figure 7

14. Select two new:

82

811-856C CP 1/2FNPT MALE QD

and a quantity of PTFEa pipe thread sealant.

15. Apply sealant to the MNPT threads of the hose

fittings. Attach the couplers to the MNPT ends of

the supply hoses .

S

16. Select two new:

51

800-300C CABLE TIE 2 DIA MIN - ORG

Not shown in figure. Secure one tie to the QD end of

each hose. Wrap it around the hose body at the

crimp. Pull snug. Cut off excess tie.

17. Select one set new:

49

502-067D HYD HOSE CLAMP LABEL

50

502-068D HYD HOSE CLAMP BRACKET

52

802-009C RHSNB 5/16-18X1 1/4 GR5

62

803-199C NUT HEX FLANGE 5/16-18 PLT

Assemble the clamp near the QD end of the hoses.

The orientation of the arrows does not matter, and

the label side does not need to be up.

S

82

82

S

62

49

50

52

Figure 7

QD Couplers, Clamp

29937

a. See page 20 for pipe sealant information and NPT torque values.

2012-22-03 Front Appendix 113-870M

Loading...

Loading...