Great Plains YP825AR User Manual

Table of Contents Metric Charts

Manufacturing, Inc.

www.greatplainsmfg.com

Seed and Fertilizer Rate Charts for the

YP825AR 8-Row Rotating Yield-Pro

Planter

with Air-Pro® seed meters

The following pages are to assist in the proper setting of seeding and

®

®

fertilizer rates for the 8-Row Rotating Yield-Pro

most accurate seeding rates, Great Plains recommends checking

singulated seed rates, and calibrating for fertilizer application rate at the

time of planting.

Planter. To assure the

ORIGINAL INSTRUCTIONS

© Copyright 2013 Printed 2013-11-11 401-923B

EN

Table of Contents Metric Charts

Table of Contents Metric Charts

Great Plains Mfg., Inc. Cover Metric Charts iii

Table of Contents

Introduction ..................................................................1

Models Covered .............................................................1

Document Family ...........................................................1

Setting Planting Rate......................................................1

Setting Fertilizer Rate.....................................................1

Planting Rate Overview ...............................................2

Kernels Per Pound .................................................2

Singulated Rate Setting Summary .................................2

Population Reference Information..................................2

Seeds per Unit............................................................ 2

Seed Spacing .............................................................2

Seed Spacing (U.S. Customary units, page 1 of 2) 3

Seed Spacing (U.S. Customary units, page 2 of 2) 4

Air-Pro

®

Meter Disk Selection ........................................5

Air-Pro® Meter Disk Selection ........................................6

Meter Pressurization ......................................................8

Initial Meter Pressurization: Cotton.............................8

Initial Meter Pressurization: Milo.................................8

Initial Meter Pressurization: Soybeans .......................8

Initial Meter Pressurization: Sunflower .......................8

Initial Meter Pressurization: Round Corn.................... 8

Initial Meter Pressurization: Flat Corn ........................9

Checking Planting Rate................................................10

Checking Singulated Rates ......................................10

Planting Rate ..............................................................12

1. Rate: Monitor configuration: .....................................12

2. Rate: Disk Selection: ................................................ 12

3. Rate: Range Sprockets ............................................13

4. Rate: Transmission Sprockets .................................13

5. Rate: Seed Inlet Shutter ........................................... 14

6. Rate: Meter Pressurization.......................................14

7. Rate: Checking.........................................................14

Sprocket Indexing (Stagger) .....................................15

Indexing Preparation ....................................................16

Basic Indexing .............................................................. 16

Indexing Fine Adjustment.............................................18

Sprocket Indexing Charts ............................................. 19

Seed Rate Charts........................................................22

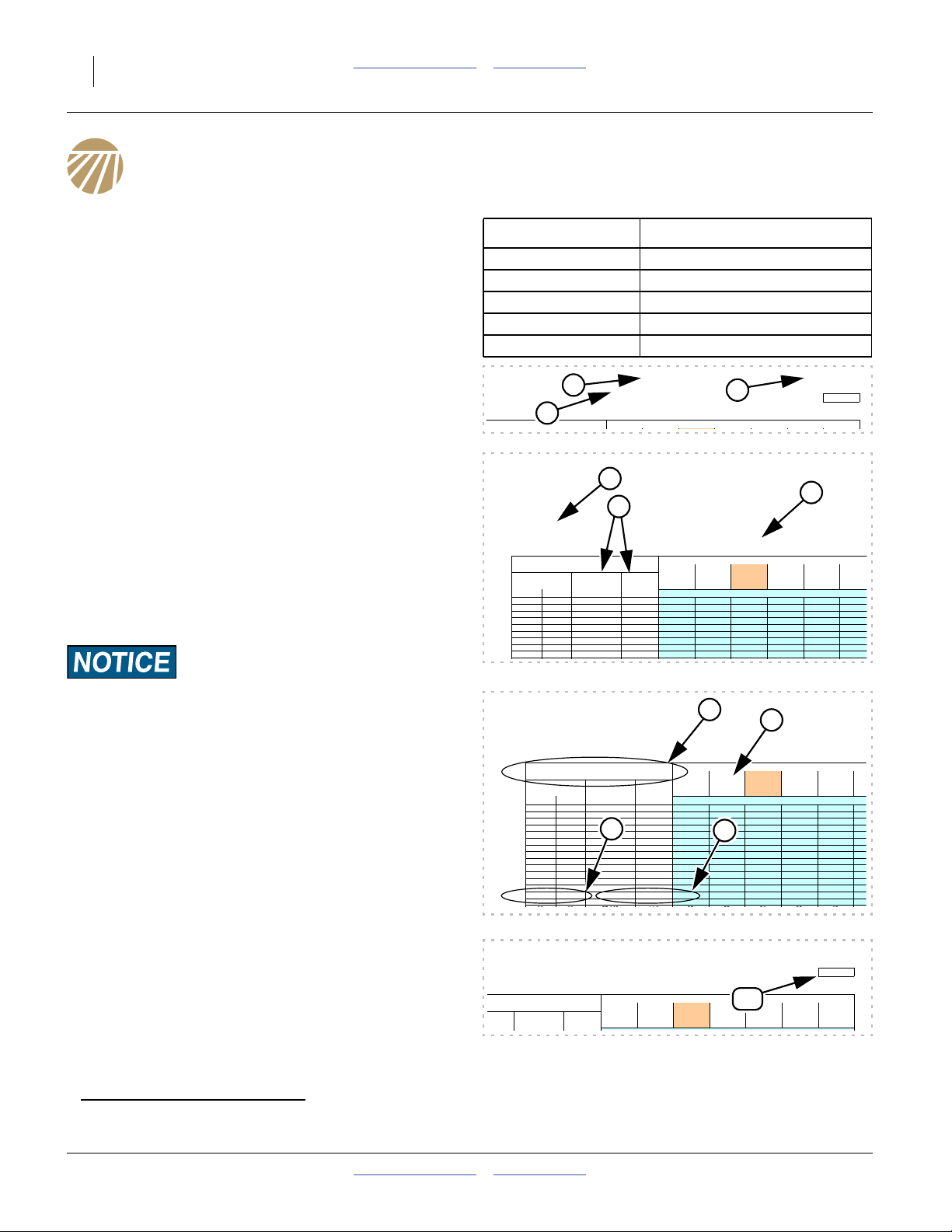

How to Read a Chart....................................................22

Corn..............................................................................23

22 inch Rows, 24 Cell, Low Range...........................23

22 inch Rows, 24 Cell, High Range.......................... 24

22 inch Rows, 40 Cell, High Range.......................... 25

30 inch Twin Row, 24 Cell, Low Range ................... 26

30 inch Twin Row, 24 Cell, High Range................... 27

30 inch Rows, 24 Cell .............................................. 28

30 inch Rows, 40 Cell, Low Range .......................... 29

30 inch Rows, 40 Cell, High Range ......................... 30

Cotton .......................................................................... 31

60 Cell, Low Range.................................................. 31

60 Cell, High Range ................................................. 32

Milo .............................................................................. 33

65 Cell, Low Range.................................................. 33

65 Cell, High Range ................................................. 34

130 Cell, Low Range................................................ 35

Soybean....................................................................... 36

84 Cell ...................................................................... 36

168 Cell .................................................................... 37

Sunflower, 24 Cell........................................................ 38

Canola Seeding .......................................................... 39

General Information ..................................................... 39

Pre-Requisites ............................................................. 39

Prepare Meters ............................................................ 39

Loading Seed............................................................... 39

Configure PM300 Monitor (Canola) ............................. 40

Canola Ground Drive Rates (USc)....................... 41

Canola Ground Drive Rates (metric).................... 42

Configure IntelliAg® Monitor (Canola).......................... 43

Related Documents.................................................. 43

Material Setup .......................................................... 43

Material Setup: Hydraulic Drive............................ 43

Air-Pro® Meter RPM Limits: Canola ..................... 44

Material Setup: Ground Drive............................... 45

Channel Setup: Hydraulic Drive ............................... 46

Row Monitor Setup (either drive) ............................. 46

Canola Field Update .................................................... 47

Tools Required......................................................... 47

Update Brushes ....................................................... 47

Loosen Meter ........................................................... 47

Update Seed Tube ................................................... 48

Dry Fertilizer Rate ...................................................... 50

Determine Your Rate ................................................... 50

Fertilizer Density Adjustment ................................... 50

Reading a Fertilizer Rate Chart ................................... 51

Set Auger Rate Range ............................................. 51

Set Transmission ......................................................... 52

Calibrate Dry Fertilizer Rate......................................... 52

© Copyright 2010, 2011, 2012, 2013 All rights Reserved

Great Plains Manufacturing, Inc. provides this publication “as is” without warranty of any kind, either expressed or implied. While every precaution has

been taken in the preparation of this manual, Great Plains Manufacturing, Inc. assumes no responsibility for errors or omissions. Neither is any liability

assumed for damages resulting from the use of the information contained herein. Great Plains Manufacturing, Inc. reserves the right to revise and improve its products as it sees fit. This publication describes the state of this product at the time of its publication, and may not reflect the product in the

future.

2013-11-11 Cover Metric Charts 401-923B

Trademarks of Great Plains Manufacturing, Inc. include: Singulator Plus, Swath Command, Terra-Tine.

Registered Trademarks of Great Plains Manufacturing, Inc. include:

Air-Pro, Clear-Shot, Discovator, Great Plains, Land Pride, MeterCone, Nutri-Pro, Seed-Lok, Solid Stand,

Terra-Guard, Turbo-Chisel, Turbo-Chopper, Turbo Max, Turbo-Till, Ultra-Till, Ver ti-Till, Whirlfilter, Yield-Pro.

Brand and Product Names that appear and are owned by others are trademarks of their respective owners.

Printed in the United States of America

Great Plains Mfg., Inc. Table of Contents Metric Charts iv

Dry Fertilizer Rate Charts: U.S. Customary Units ........ 54

22 inch Rows, Ground (Seed) Drive......................... 54

22 inch Rows, Hydraulic (Tire) Drive,.......................55

30 inch Rows, Ground (Seed) Drive......................... 56

30 inch Rows, Hydraulic (Tire) Drive........................57

70 cm Rows, Ground (Seed) Drive...........................58

70 cm Rows, Hydraulic (Tire) Drive.......................... 59

75 cm Rows, Ground (Seed) Drive...........................60

75 cm Rows, Hydraulic (Tire) Drive.......................... 61

Twin Row 30 inch, Ground (Seed) Drive..................62

Twin Row 30 inch, Hydraulic (Tire) Drive .................63

Twin Row 75 cm, Ground (Seed) Drive.................... 64

Twin Row 75 cm, Hydraulic (Tire) Drive ...................65

Liquid Fertilizer Rate..................................................66

Liquid Rate Setting Steps.............................................66

Set Rate Range........................................................66

Set Pump Adjuster ...................................................67

Determine Orifice Size..............................................67

Install Orifice Plates.................................................. 68

Row Shutoff..............................................................68

Strainer.....................................................................69

Setting Relief Valve ..................................................69

Web - Liquid Fertilizer Rate......................................70

Liquid Fertilizer Rate Charts.....................................71

22 inch Rows............................................................71

30 inch Rows............................................................72

70 cm Rows.............................................................. 73

75 cm Rows.............................................................. 74

Twin Row 30 inch .....................................................75

Twin Row 75 cm.......................................................76

Slide Chart - Liquid Fertilizer Rate............................77

Appendix A .................................................................78

Seed Lubricants ...........................................................78

Appendix B - Metric Charts .......................................79

Air-Pro® Meter Disk Selection - Metric .........................79

Seed Spacing Chart - Metric (1 of 2)............................82

Meter Pressurization - Metric .......................................84

Initial Meter Pressurization: Cotton...........................84

Initial Meter Pressurization: Milo...............................84

Initial Meter Pressurization: Soybeans..................... 84

Initial Meter Pressurization: Sunflower..................... 84

Initial Meter Pressurization: Round Corn ................. 85

Initial Meter Pressurization: Flat Corn ...................... 86

Sprocket Indexing Charts - Metric................................ 87

Furrow Check - Metric.................................................. 90

Seed Rate Charts Metric.............................................. 91

Corn (Metric) ................................................................ 91

56 cm Rows, 24 Cell, Low Range ............................ 91

56 cm Rows, 24 Cell, High Range ........................... 92

56 cm Rows, 40 Cell, High Range ........................... 93

75 cm Twin Row, 24 Cell, Low Range ..................... 94

75 cm Twin Row, 24 Cell, High Range .................... 95

70 cm Rows, 24 Cell ................................................ 96

70 cm Rows, 40 Cell, Low Range ............................ 97

70 cm Rows, 40 Cell, High Range ........................... 98

Cotton (Metric) ............................................................. 99

60 Cell, Low Range.................................................. 99

60 Cell, High Range ............................................... 100

Milo (Metric) ............................................................... 101

65 Cell, Low Range................................................ 101

65 Cell, High Range ............................................... 102

130 Cell, Low Range.............................................. 103

Soybean (Metric)........................................................ 104

84 Cell .................................................................... 104

168 Cell .................................................................. 105

Sunflower, 24 Cell (Metric)......................................... 106

Dry Fertilizer Rate Charts: Metric Units ..................... 108

70 cm Rows, Ground (Seed) Drive ........................ 108

70 cm Rows, Hydraulic (Tire) Drive ....................... 109

75 cm Rows, Ground (Seed) Drive ........................ 110

75 cm Rows, Hydraulic (Tire) Drive ....................... 111

30 inch (76.2 cm) Rows, Ground (Seed) Drive ...... 112

30 inch (76.2) cm Rows, Hydraulic (Tire) Drive ..... 113

Twin Row 75 cm, Ground (Seed) Drive ................. 114

Twin Row 75 cm, Hydraulic (Tire) Drive................. 115

Twin Row 30 inch (76.2 cm), Ground (Seed) Drive 116

Twin Row 30 inch (76.2), Hydraulic (Tire) Drive .... 117

Liquid Fertilizer Orifice Plate Selection, Metric .......... 118

2013-11-11 Table of Contents Metric Charts 401-923B

Great Plains Manufacturing, Inc. Table of Contents Metric Charts Introduction 1

Introduction

This manual covers the following tasks for the 8-Row

Rotating Yield-Pro®Planter equipped with Air-Pro®seed

meters:

• setting and checking seed rate for singulated crops

• applying fertilizer from an optional dry or liquid system

• applying fertilizer from an optional dry fertilizer system.

This manual is your guide to planter adjustments for

achieving specific seed population and fertilizer

application rate targets.

Although some setup/adjustment topics are repeated

from the Operator Manual, you need to be thoroughly

familiar with planter operations and adjustments before

applying this Seed Rate manual and its table data.

ModelsaCovered

YP825AR-0822 8 Single Row 22 Inch (55.9 cm) Spacing

YP825AR-0830 8 Single Row 30 Inch (76.2 cm) Spacing

YP825AR-0870 8 Single Row 70 cm (27.6 Inch) Spacing

YP825AR-0875 8 Single Row 75 cm (29.5 Inch) Spacing

YP825AR-16TR30 8 Twin Row 30 Inch (76.2 cm) Spacing

YP825AR-16TR75 8 Twin Row 75 cm (29.5 Inch) Spacing

U

R

F

D

R

L

Figure 1

YP825AR Planter

Setting Planting Rate

Begin at section: “Planting Rate Overview” on page 2

and complete the setup using section: “Indexing

Preparation” on page 16.

Setting Fertilizer Rate

This topic is covered beginning at:

“Liquid Fertilizer Rate” on page 66.

34722

B

L

Document Family

401-923M YP825AR Operator Manual

401-923M-QSG YP825AR Monitor Quick-Start Guide

401-923B Seed Rate Manual (this document)

401-923P YP825AR Parts Manual

11001-1333 DICKEY-john® PM300 manual

110011508 DICKEY-john®IntelliAg® Planter/Drill

Control, User Level 1

110011501 DICKEY-john®IntelliAg®Planter/Drill

Control, User Level 2&3

12-M-15 CDS-John Blue LM-1250 & LM-1255

Parts and Instruction manual (Option)

112718-01 CDS-John Blue Pump setting Chart

a. YP825A and YP825A3P models have a separate Rate manual (401-651B).

2013-11-11 Table of Contents Metric Charts 401-923B

2 YP825AR Table of Contents Metric Charts Great Plains Manufacturing, Inc.

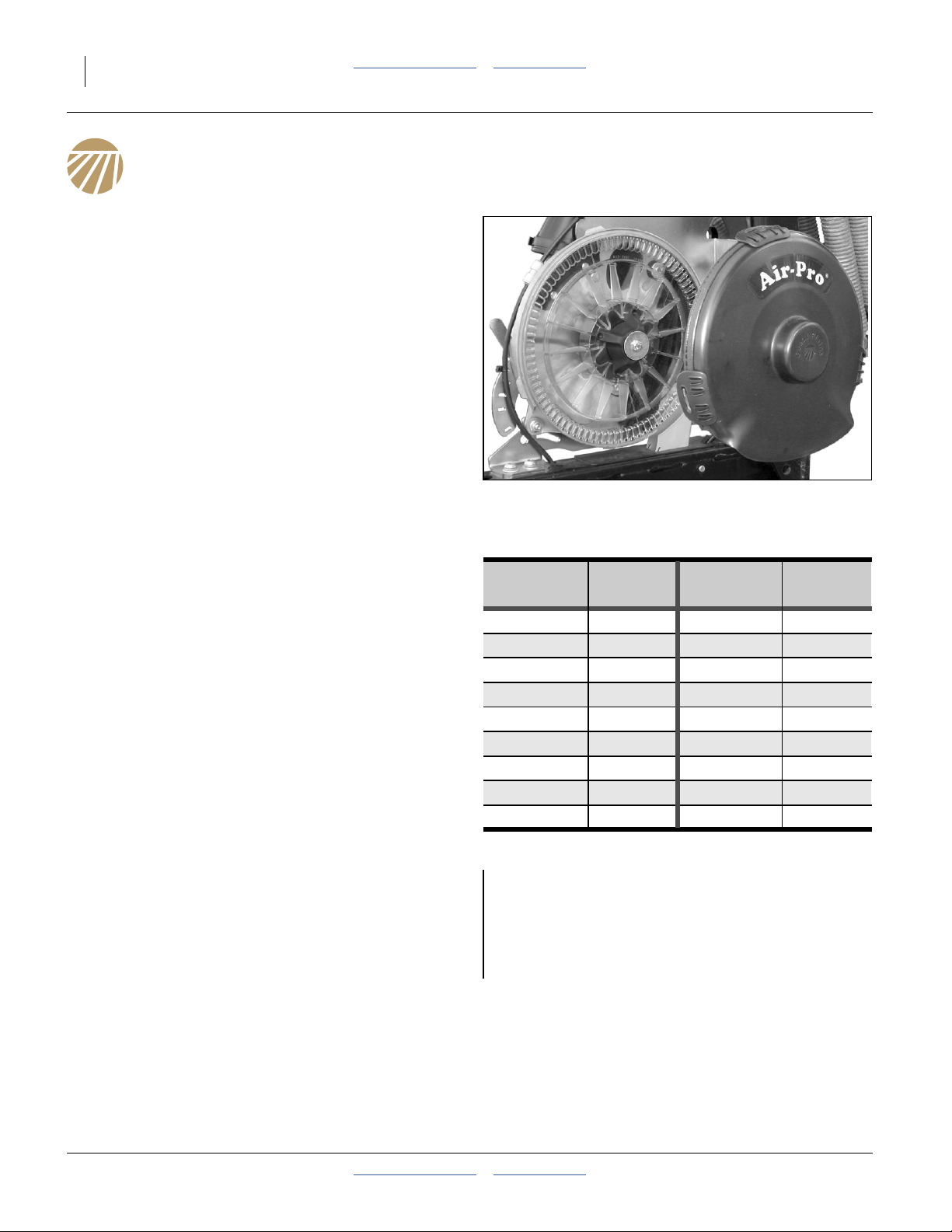

Planting Rate Overview

The information in this section covers important setup

and checking information that applies to the Air-Pro

meter in singulated planting.

®

Singulated Rate Setting Summary

1. For your crop, determine your intended population, in

seeds/acre or seeds/hectare. If you know only the

seed spacing or population in pounds/acre or kg/ha,

consult the charts on page 2 through page 4.

2. For your crop, population and desired field speed,

select the correct seed disk:

“Air-Pro® Meter Disk Selection” on page 5

3. Set meter rate (page 14).

4. For staggered twin row, time row pairs using:

“Sprocket Indexing (Stagger)” on page 15

5. Set initial seed inlet shutter per seed rate chart.

6. Set initial meter pressurization per page 8, 9.

7. Verify your planting rate per the instructions at:

“Checking Planting Rate” on page 10. If the results

are consistent with your setup, plant the crop.

Population Reference Information

Seeds per Unit

If only population weight (pounds/acre or kilograms/

hectare) is known, obtain the population count by

multiplying the population weight by the “Kernels per

pound” value from the seed container.

Seed Spacing

If only seed spacing is known, use the tables on the next

two pages to determine population.

Figure 2

Air-Pro® Seed Meter

Kernels Per Pound

80,000 Seed Kernels 80,000 Seed Kernels

Bag Weight per Pound Bag Weight per Pound

67.5 lbs 1,185 45.0 lbs 1,778

65.0 lbs 1,231 42.5 lbs 1,882

62.5 lbs 1,280 40.0 lbs 2,000

60.0 lbs 1,333 37.5 lbs 2,133

57.5 lbs 1,391 35.0 lbs 2,286

55.0 lbs 1,455 32.5 lbs 2,462

52.5 lbs 1,524 30.0 lbs 2,667

50.0 lbs 1,600 27.5 lbs 2,909

47.5 lbs 1,684 25.0 lbs 3,200

29626

29649

Example: Milo

Target rate: 4.5 pounds/acre

Seed density: 14500 seeds/pound

Population: = Rate x Density

= 4.5 x 14500, or:

65250 seeds/acre

401-923B Table of Contents Metric Charts 2013-11-11

Great Plains Manufacturing, Inc. Table of Contents Metric Charts Planting Rate Overview 3

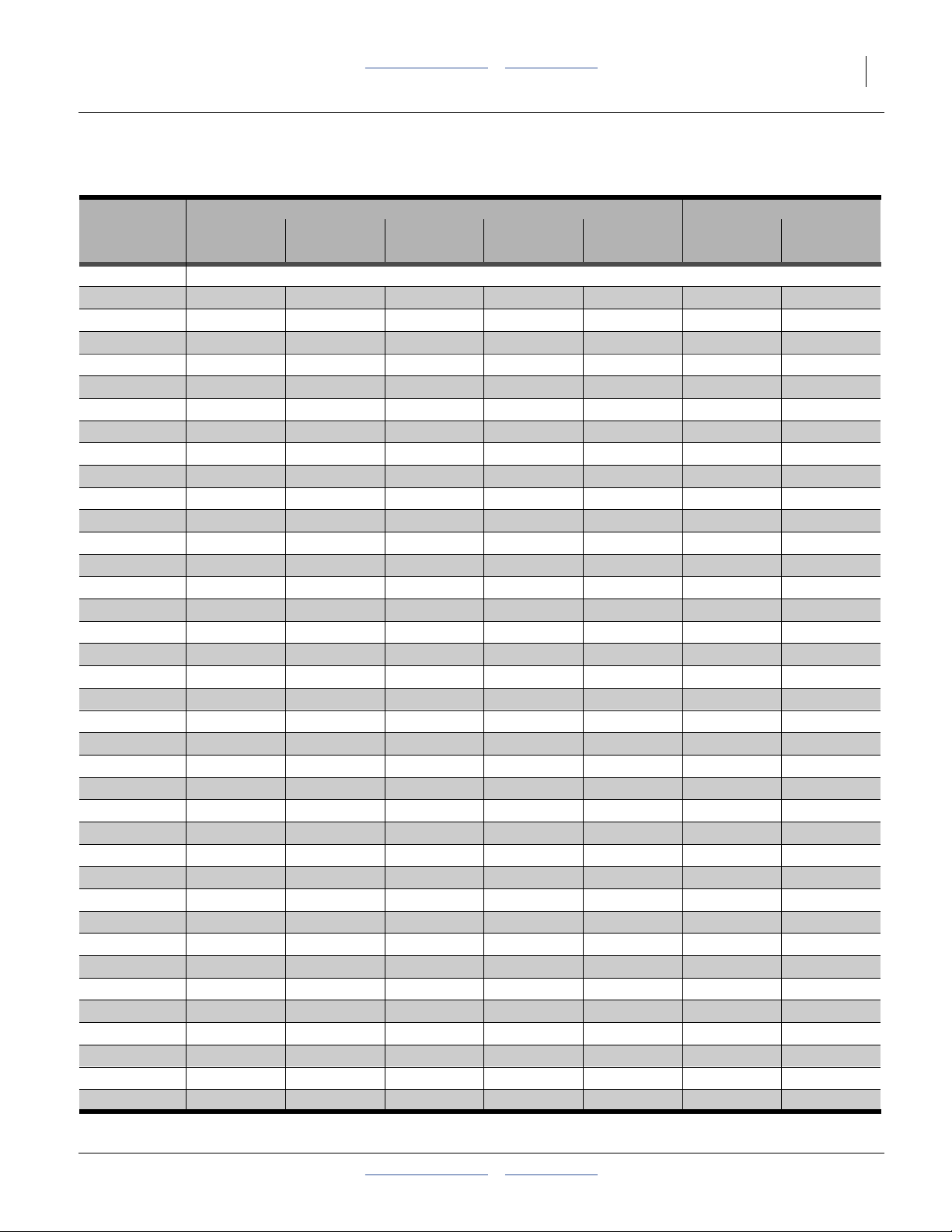

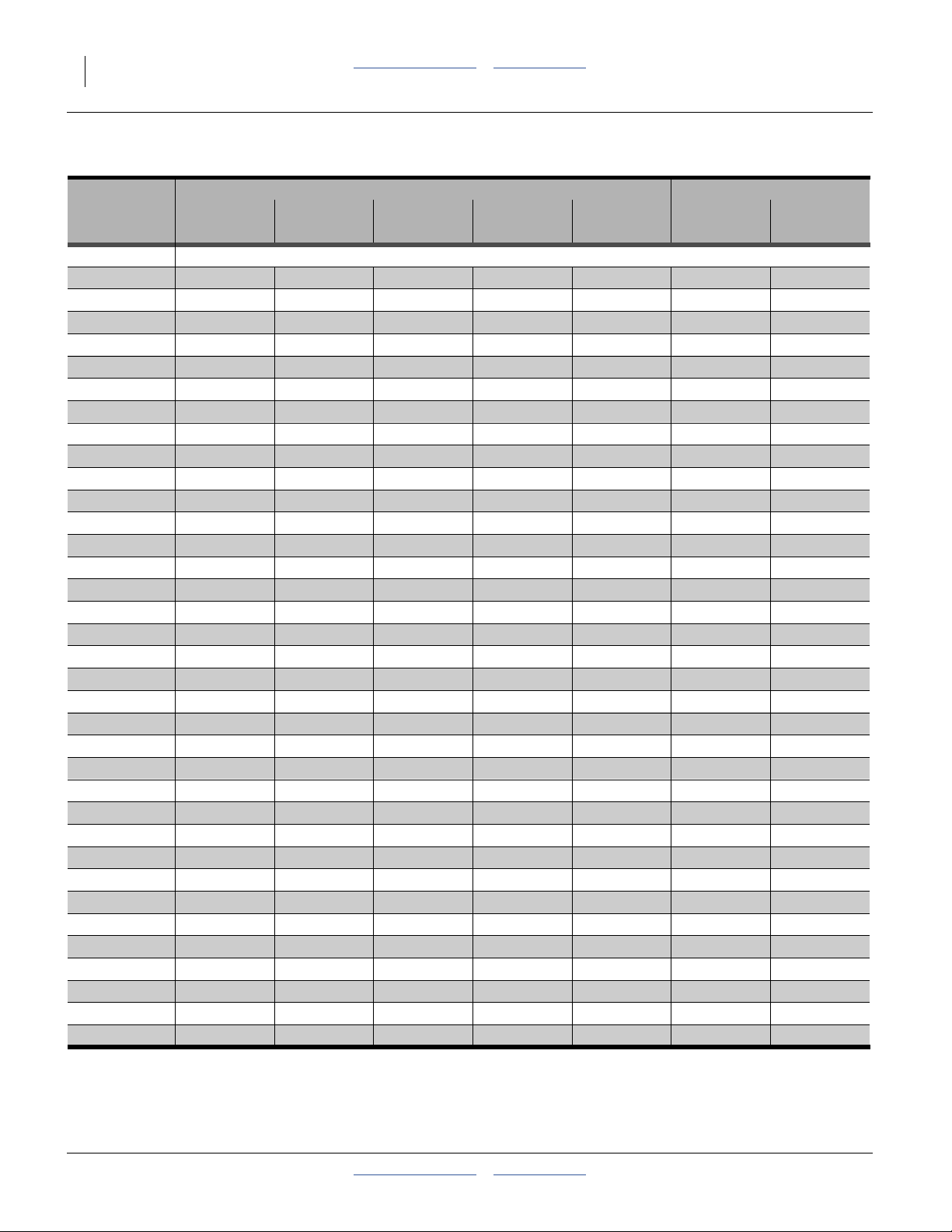

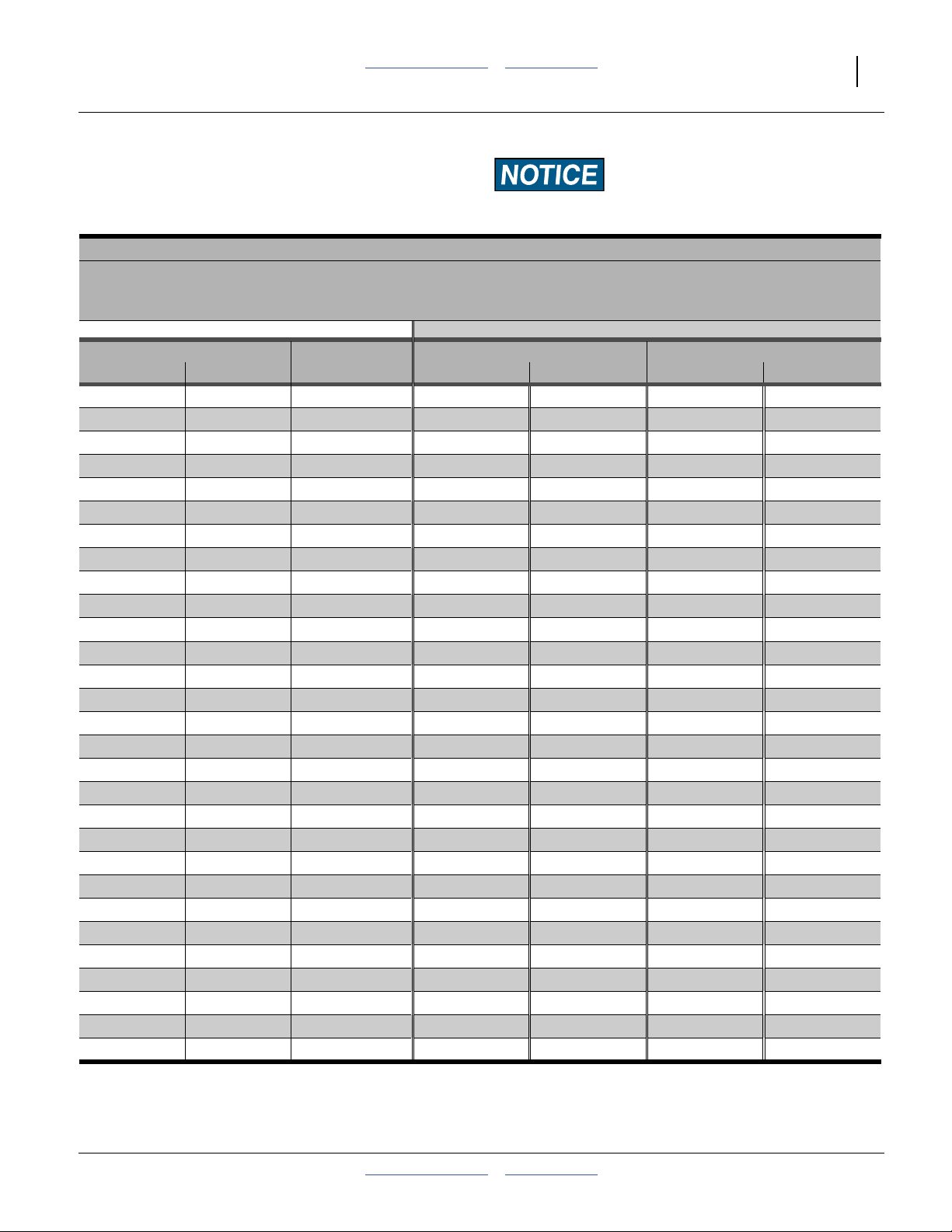

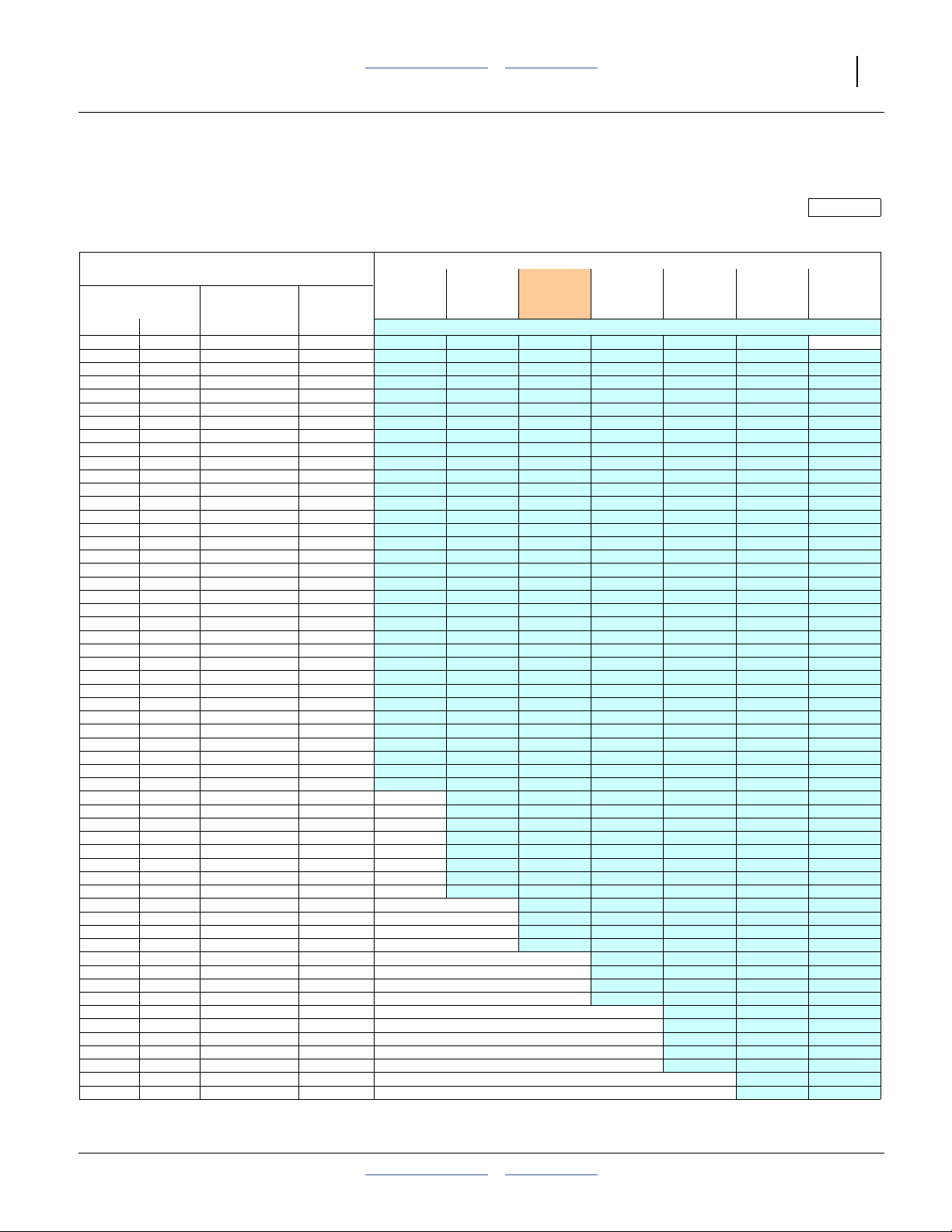

Seed Spacing (U.S. Customary units, page 1 of 2)

Metric seed spacing charts begin on page 82.

Plant

Population

22 inch 56 cm 70 cm 75 cm 30 inch Twin Row Twin Row

Single Row Spacings Twin Row Spacings

(seeds/acre) (55.9 cm) (22.05 in.) (27.6 in.) (29.5 in.) (76.2 cm) (29.5 in.) (76.2 cm)

Seed-to-Seed Spacing (Inches)

14 000

15 000

16 000

17 000

18 000

19 000

20 000

21 000

22 000

23 000

24 000

25 000

26 000

27 000

28 000

29 000

30 000

31 000

32 000

33 000

34 000

35 000

36 000

37 000

38 000

39 000

40 000

41 000

42 000

43 000

44 000

45 000

46 000

47 000

48 000

49 000

50 000

20.4 20.3 16.3 15.2 14.9 30.3 29.9

19.0 19.0 15.2 14.2 13.9 28.3 27.9

17.8 17.8 14.2 13.3 13.1 26.6 26.1

16.8 16.7 13.4 12.5 12.3 25.0 24.6

15.8 15.8 12.6 11.8 11.6 23.6 23.2

15.0 15.0 12.0 11.2 11.0 22.4 22.0

14.3 14.2 11.4 10.6 10.5 21.2 20.9

13.6 13.5 10.8 10.1 10.0 20.2 19.9

13.0 12.9 10.3 9.7 9.5 19.3 19.0

12.4 12.4 9.9 9.2 9.1 18.5 18.2

11.9 11.9 9.5 8.9 8.7 17.7 17.4

11.4 11.4 9.1 8.5 8.4 17.0 16.7

11.0 10.9 8.8 8.2 8.0 16.3 16.1

10.6 10.5 8.4 7.9 7.7 15.7 15.5

10.2 10.2 8.1 7.6 7.5 15.2 14.9

9.8 9.8 7.8 7.3 7.2 14.7 14.4

9.5 9.5 7.6 7.1 7.0 14.2 13.9

9.2 9.2 7.3 6.9 6.7 13.7 13.5

8.9 8.9 7.1 6.6 6.5 13.3 13.1

8.6 8.6 6.9 6.4 6.3 12.9 12.7

8.4 8.4 6.7 6.2 6.1 12.5 12.3

8.1 8.1 6.5 6.1 6.0 12.1 11.9

7.9 7.9 6.3 5.9 5.8 11.8 11.6

7.7 7.7 6.2 5.7 5.7 11.5 11.3

7.5 7.5 6.0 5.6 5.5 11.2 11.0

7.3 7.3 5.8 5.4 5.4 10.9 10.7

7.1 7.1 5.7 5.3 5.2 10.6 10.5

7.0 6.9 5.6 5.2 5.1 10.4 10.2

6.8 6.8 5.4 5.1 5.0 10.1 10.0

6.6 6.6 5.3 4.9 4.9 9.9 9.7

6.5 6.5 5.2 4.8 4.8 9.7 9.5

6.3 6.3 5.1 4.7 4.6 9.4 9.3

6.2 6.2 4.9 4.6 4.5 9.2 9.1

6.1 6.1 4.8 4.5 4.4 9.0 8.9

5.9 5.9 4.7 4.4 4.4 8.9 8.7

5.8 5.8 4.6 4.3 4.3 8.7 8.5

5.7 5.7 4.6 4.2 4.2 8.5 8.4

2013-11-11 Table of Contents Metric Charts 401-923B

4 YP825AR Table of Contents Metric Charts Great Plains Manufacturing, Inc.

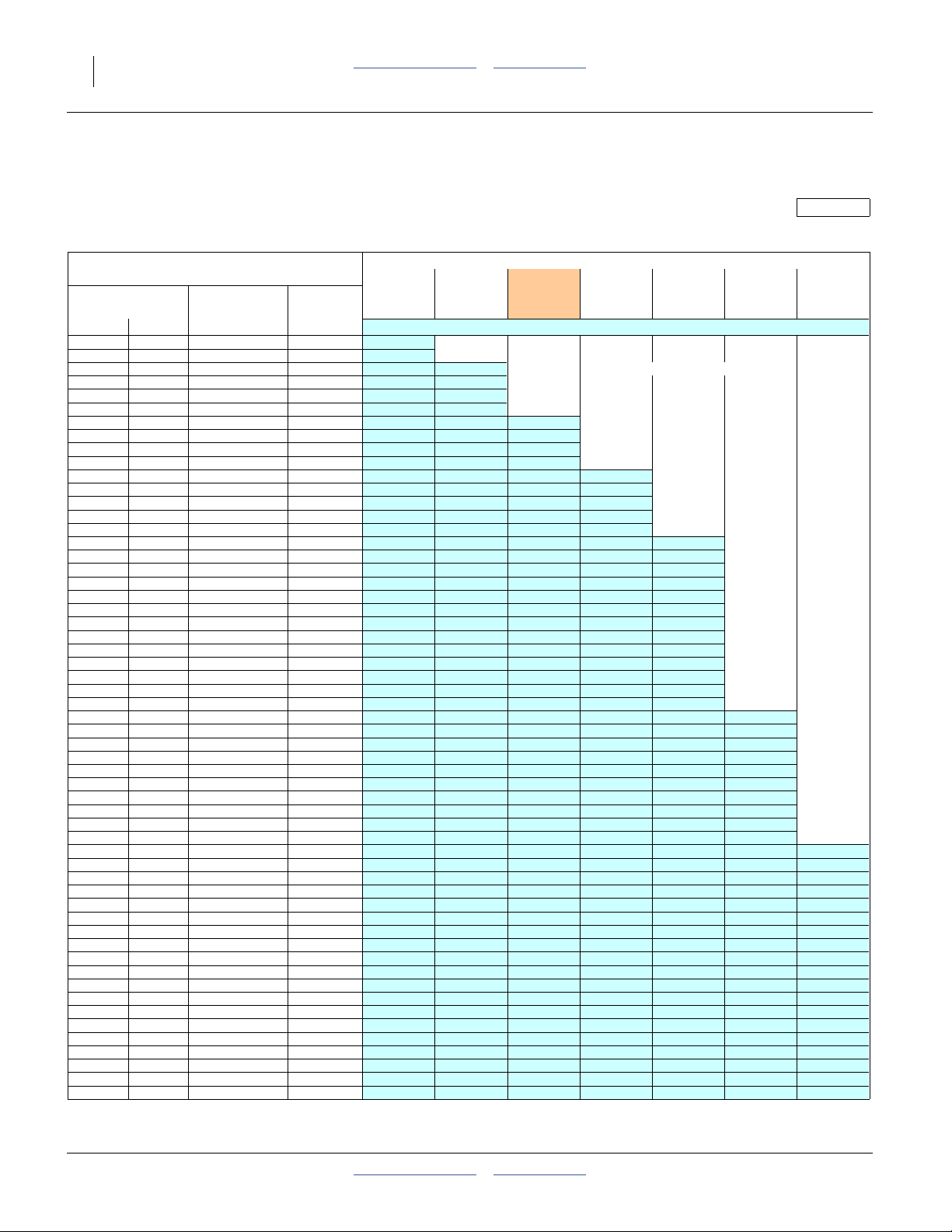

Seed Spacing (U.S. Customary units, page 2 of 2)

Plant

Population

22in 56 cm 70 cm 75 cm 30in Twin Row Twin Row

Single Row Spacings Twin Row Spacings

(seeds/acre) (55.9 cm) (22.05 in.) (27.6 in.) (29.5 in.) (76.2 cm) (29.5 in.) (76.2 cm)

Seed-to-Seed Spacing (Inches)

50 000

55 000

60 000

65 000

70 000

75 000

80 000

85 000

90 000

95 000

100 000

105 000

110 000

115 000

120 000

125 000

130 000

135 000

140 000

145 000

150 000

155 000

160 000

165 000

170 000

175 000

180 000

185 000

190 000

195 000

200 000

225 000

250 000

275 000

300 000

5.7 5.7 4.6 4.2 4.2 8.5 8.4

5.2 5.2 4.1 3.9 3.8 7.7 7.6

4.8 4.7 3.8 3.5 3.5 7.1 7.0

4.4 4.4 3.5 3.3 3.2 6.5 6.4

4.1 4.1 3.3 3.0 3.0 6.1 6.0

3.8 3.8 3.0 2.8 2.8 5.7 5.6

3.6 3.6 2.8 2.7 2.6 5.3 5.2

3.4 3.3 2.7 2.5 2.5 5.0 4.9

3.2 3.2 2.5 2.4 2.3 4.7 4.6

3.0 3.0 2.4 2.2 2.2 4.5 4.4

2.9 2.8 2.3 2.1 2.1 4.2 4.2

2.7 2.7 2.2 2.0 2.0 4.0 4.0

2.6 2.6 2.1 1.9 1.9 3.9 3.8

2.5 2.5 2.0 1.8 1.8 3.7 3.6

2.4 2.4 1.9 1.8 1.7 3.5 3.5

2.3 2.3 1.8 1.7 1.7 3.4 3.3

2.2 2.2 1.8 1.6 1.6 3.3 3.2

2.1 2.1 1.7 1.6 1.5 3.1 3.1

2.0 2.0 1.6 1.5 1.5 3.0 3.0

2.0 2.0 1.6 1.5 1.4 2.9 2.9

1.9 1.9 1.5 1.4 1.4 2.8 2.8

1.8 1.8 1.5 1.4 1.3 2.7 2.7

1.8 1.8 1.4 1.3 1.3 2.7 2.6

1.7 1.7 1.4 1.3 1.3 2.6 2.5

1.7 1.7 1.3 1.2 1.2 2.5 2.5

1.6 1.6 1.3 1.2 1.2 2.4 2.4

1.6 1.6 1.3 1.2 1.2 2.4 2.3

1.5 1.5 1.2 1.1 1.1 2.3 2.3

1.5 1.5 1.2 1.1 1.1 2.2 2.2

1.5 1.5 1.2 1.1 1.1 2.2 2.1

1.4 1.4 1.1 1.1 1.0 2.1 2.1

1.3 1.3 1.0 0.9 0.9 1.9 1.9

1.1 1.1 0.9 0.8 0.8 1.7 1.7

1.0 1.0 0.8 0.8 0.8 1.5 1.5

1.0 0.9 0.8 0.7 0.7 1.4 1.4

401-923B Table of Contents Metric Charts 2013-11-11

Great Plains Manufacturing, Inc. Table of Contents Metric Charts Planting Rate Overview 5

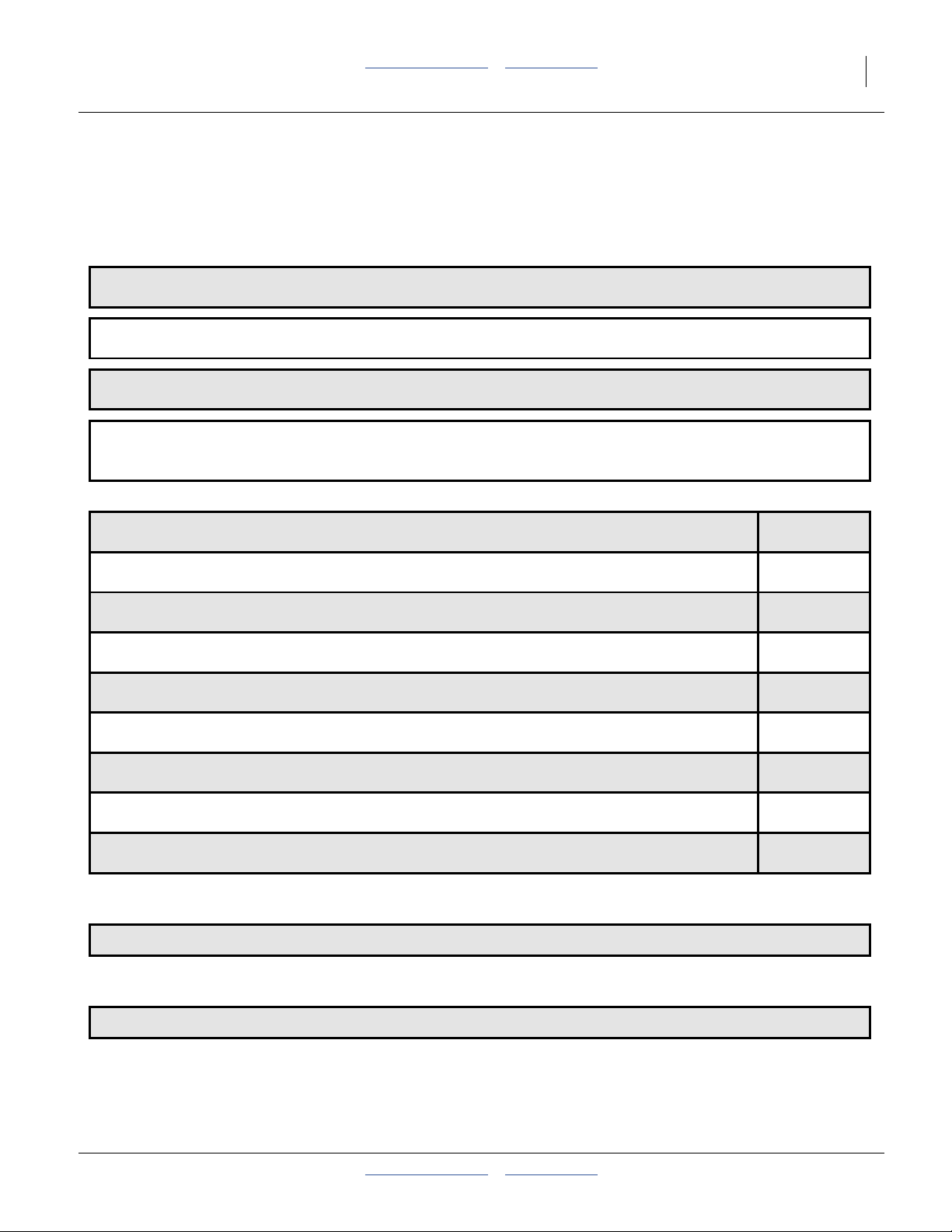

Air-Pro® Meter Disk Selection

U.S. customary units (metric charts begin on page 79).

817 - 836C Corn Flat Large 817 - 838C Corn Flat Large

( Sweet Corn plants in Round Corn disks )

Seed Size Recommendations.

Corn Round Large Seeds per Pound

(Page 1 of 3)

1700 (or fewer)

Unit Weight (or heavier)

47 pounds

Corn Round Small Seeds per Pound

1650 (or more)

Corn Flat Large Seeds per Pound

1650 (or fewer)

Corn Flat Small Seeds per Pound

1650 (or more)

ATTENTION: This Corn is planted with the Corn Round Small Disks!!!!!!

40 in. Rows

38 in. Rows

36 in. Rows

30 in. Rows

22 in. Rows

Twin Row 40 in.

20 in. Rows

Twin Row 38 in.

Twin Row 36 in.

Twin Row 30 in.

15 in. Rows

Below 19 400 Population @ 5.5 MPH 24 Cell Disk

Above 19 400 Population @ 5.5 MPH 40 Cell Disk

Below 20 500 Population @ 5.5 MPH 24 Cell Disk

Above 20 500 Population @ 5.5 MPH 40 Cell Disk

Below 21 600 Population @ 5.5 MPH 24 Cell Disk

Above 21 600 Population @ 5.5 MPH 40 Cell Disk

Below 25 900 Population @ 5.5 MPH 24 Cell Disk

Above 25 900 Population @ 5.5 MPH 40 Cell Disk

Below 35 300 Population @ 5.5 MPH 24 Cell Disk

Above 35 300 Population @ 5.5 MPH 40 Cell Disk

Below 38 900 Population @ 5.5 MPH 24 Cell Disk

Above 38 900 Population @ 5.5 MPH 40 Cell Disk

Below 40 900 Population @ 5.5 MPH 24 Cell Disk

Above 40 900 Population @ 5.5 MPH 40 Cell Disk

Below 43 200 Population @ 5.5 MPH 24 Cell Disk

Above 43 200 Population @ 5.5 MPH 40 Cell Disk

Below 51 800 Population @ 5.5 MPH 24 Cell Disk

Above 51 800 Population @ 5.5 MPH 40 Cell Disk

Unit Weight (or lighter)

48.5 pounds

Unit Weight (or lighter)

48.5 pounds

Unit Weight (or lighter)

48.5 pounds

(Recommended)

CANOLA

Seed Size Recommendations. 817 - 991C 250 Cell Disk

This disk should plant all seed sizes and row spacings for Canola & Mustard

COTTON

Seed Size Recommendations. 817 - 857C 60 Cell Disk

This disk should plant all seed sizes and row spacings for Cotton.

36049K

2013-11-11 Table of Contents Metric Charts 401-923B

6 YP825AR Table of Contents Metric Charts Great Plains Manufacturing, Inc.

)

)

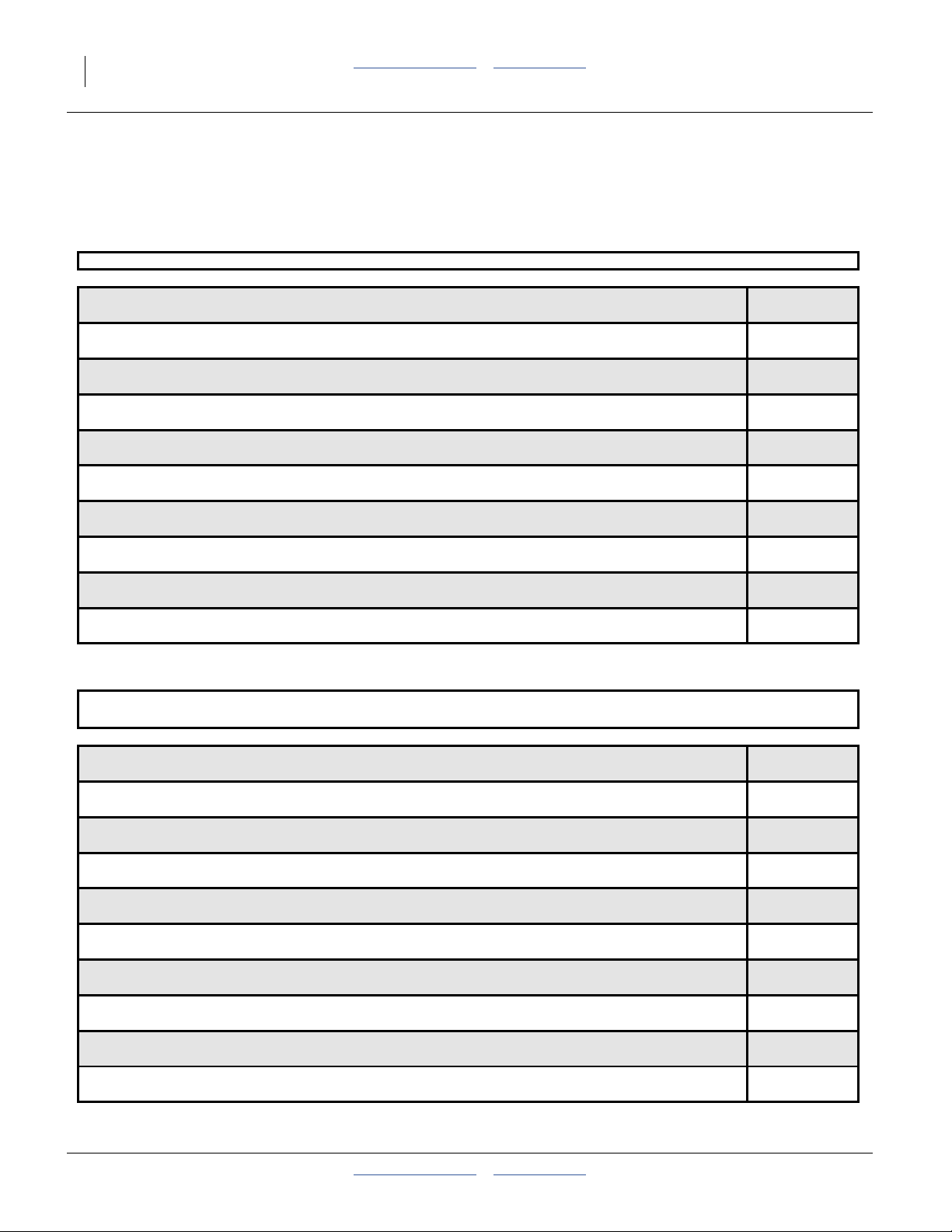

AIR-PRO® METER DISK SELECTION

Air-Pro®Meter Disk Selection

MILO / PELLETIZED SUGAR BEET MILO / PELLETIZED SUGAR BEET

(Page 2 of 3)

817 - 849C 65 Cell Disk 817 - 800C 130 Cell Disk

Seed Size Recommendations.

These disks should plant all seed sizes of Milo, Pelletized Sugar Beets & Tillage Radish

(Recommended

40 in. Rows

38 in. Rows

36 in. Rows

30 in. Rows

22 in. Rows

Twin Row 40 in.

20 in. Rows

Twin Row 38 in.

Twin Row 36 in.

Twin Row 30 in.

15 in. Rows

10 in. Rows

Below 48 300 Population @ 6 MPH 65 Cell Disk

Above 48 300 Population @ 6 MPH 130 Cell Disk

Below 50 800 Population @ 6 MPH 65 Cell Disk

Above 50 800 Population @ 6 MPH 130 Cell Disk

Below 53 600 Population @ 6 MPH 65 Cell Disk

Above 53 600 Population @ 6 MPH 130 Cell Disk

Below 64 300 Population @ 6 MPH 65 Cell Disk

Above 64 300 Population @ 6 MPH 130 Cell Disk

Below 87 700 Population @ 6 MPH 65 Cell Disk

Above 87 700 Population @ 6 MPH 130 Cell Disk

Below 96 500 Population @ 6 MPH 65 Cell Disk

Above 96 500 Population @ 6 MPH 130 Cell Disk

Below 101 600 Population @ 6 MPH 65 Cell Disk

Above 101 600 Population @ 6 MPH 130 Cell Disk

Below 107 200 Population @ 6 MPH 65 Cell Disk

Above 107 200 Population @ 6 MPH 130 Cell Disk

Below 128 700 Population @ 6 MPH 65 Cell Disk

Above 128 700 Population @ 6 MPH 130 Cell Disk

Below 193 000 Population @ 6 MPH 65 Cell Disk

Above 193 000 Population @ 6 MPH 130 Cell Disk

817 - 798C 84 Cell Disk SOYBEAN 403 - 551D 168 Cell Disk

Seed Size Recommendations. ( Small Edible Beans)

These disks should plant all seed sizes of Soybeans.

Small edible beans (navy, black jack, black eye peas, etc) will plant with this disk also.

(Recommended

40 in. Rows

38 in. Rows

36 in. Rows

30 in. Rows

22 in. Rows

Twin Row 40 in.

20 in. Rows

Twin Row 38 in.

Twin Row 36 in.

Twin Row 30 in.

15 in. Rows

10 in. Rows

Below 76 900 Population @ 6 MPH 84 Cell Disk

Above 76 900 Population @ 6 MPH 168 Cell Disk

Below 81 000 Population @ 6 MPH 84 Cell Disk

Above 81 000 Population @ 6 MPH 168 Cell Disk

Below 85 500 Population @ 6 MPH 84 Cell Disk

Above 85 500 Population @ 6 MPH 168 Cell Disk

Below 102 500 Population @ 6 MPH 84 Cell Disk

Above 102 500 Population @ 6 MPH 168 Cell Disk

Below 139 800 Population @ 6 MPH 84 Cell Disk

Above 139 800 Population @ 6 MPH 168 Cell Disk

Below 153 800 Population @ 6 MPH 84 Cell Disk

Above 153 800 Population @ 6 MPH 168 Cell Disk

Below 161 900 Population @ 6 MPH 84 Cell Disk

Above 161 900 Population @ 6 MPH 168 Cell Disk

Below 170 900 Population @ 6 MPH 84 Cell Disk

Above 170 900 Population @ 6 MPH 168 Cell Disk

Below 205 100 Population @ 6 MPH 84 Cell Disk

Above 205 100 Population @ 6 MPH 168 Cell Disk

Below 307 700 Population @ 6 MPH 84 Cell Disk

Above 307 700 Population @ 6 MPH 168 Cell Disk

36049L

401-923B Table of Contents Metric Charts 2013-11-11

Great Plains Manufacturing, Inc. Table of Contents Metric Charts Planting Rate Overview 7

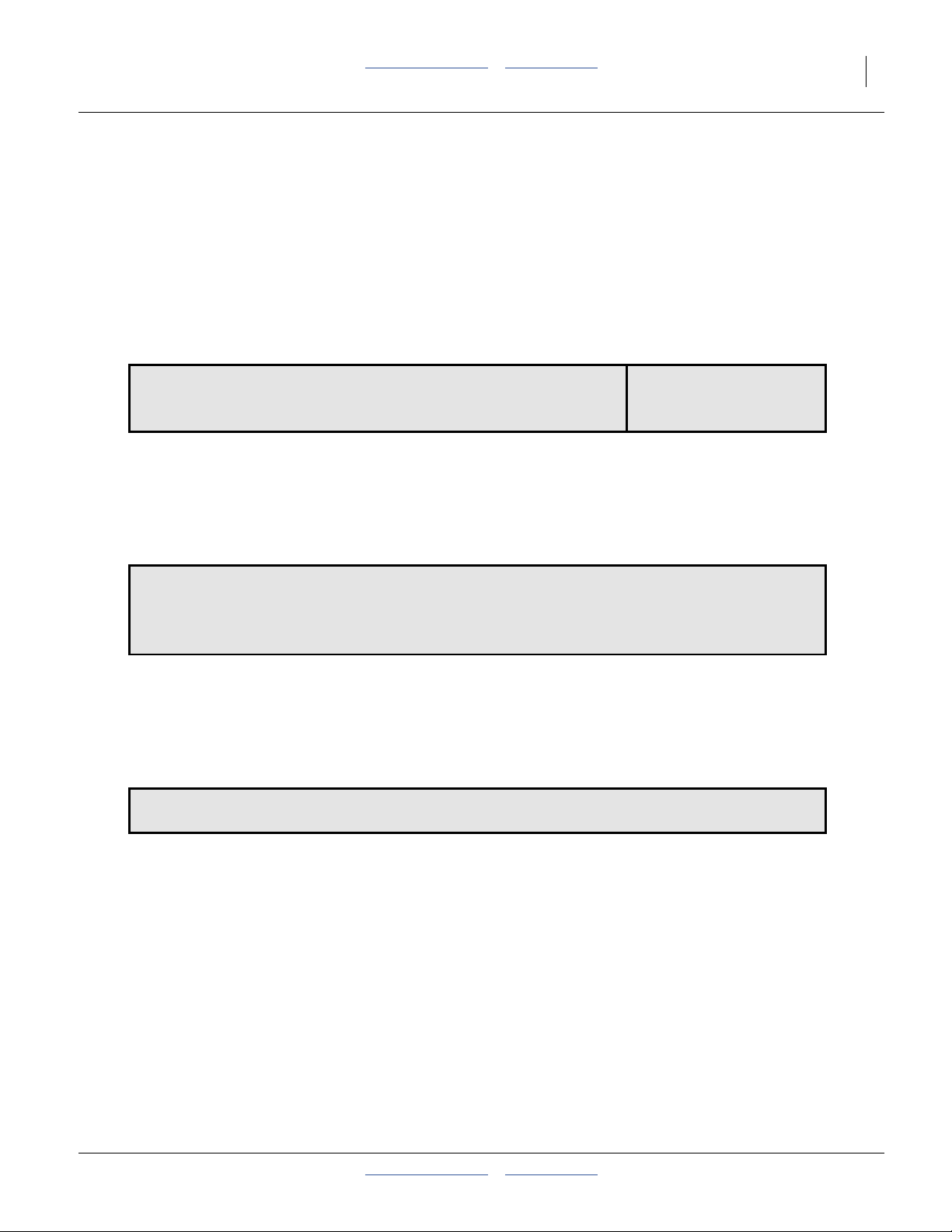

AIR-PRO® METER DISK SELECTION

Air-Pro® Meter Disk Selection

(Page 3 of 3)

SUNFLOWER OIL LARGE / POPCORN

24 Cell Disk

817 - 851C

Seed Size Recommendations.

Sunflower Oil Large Sunflower Seeds per Pound Popcorn

2's - most 3's 8500 (or fewer) This disk should plant all

And a few of the larger 4's seed sizes of Popcorn.

Volumetric No.1 84 Cell Disk

817 - 867C

Available for:

Wheat

Rice

Rice takes a special hardened meter.

Only available on 2525A on 9.5 in. rows, and YP30AR or YP40AR on 10 in. rows.

Air Meter Blank Disk

817 - 841C

These disks are used in (Off Row Meters) when changing from 15" to 30" Rows.

Twin Row 30" to 30" Rows. (etc)

36049M

2013-11-11 Table of Contents Metric Charts 401-923B

8 YP825AR Table of Contents Metric Charts Great Plains Manufacturing, Inc.

(y)

Meter Pressurization

Refer to the Operator Manual for the procedure for fine

tuning meter pressurization. See page 84 for metric.

Start with pressures from below and on page 9, which

are based on crop, and for corn, seed shape and density.

Note: These are suggested initial (starting) pressures.

Adjust them up or down per the procedure in the

Operator Manual.

Initial Meter Pressurization: Cotton

1.5 inches of water (any seed density)

Initial seed inlet Shutter: 2

Initial Meter Pressurization: Milo

1.5 inches of water (all disk, any seed density)

Initial seed inlet Shutter: 2

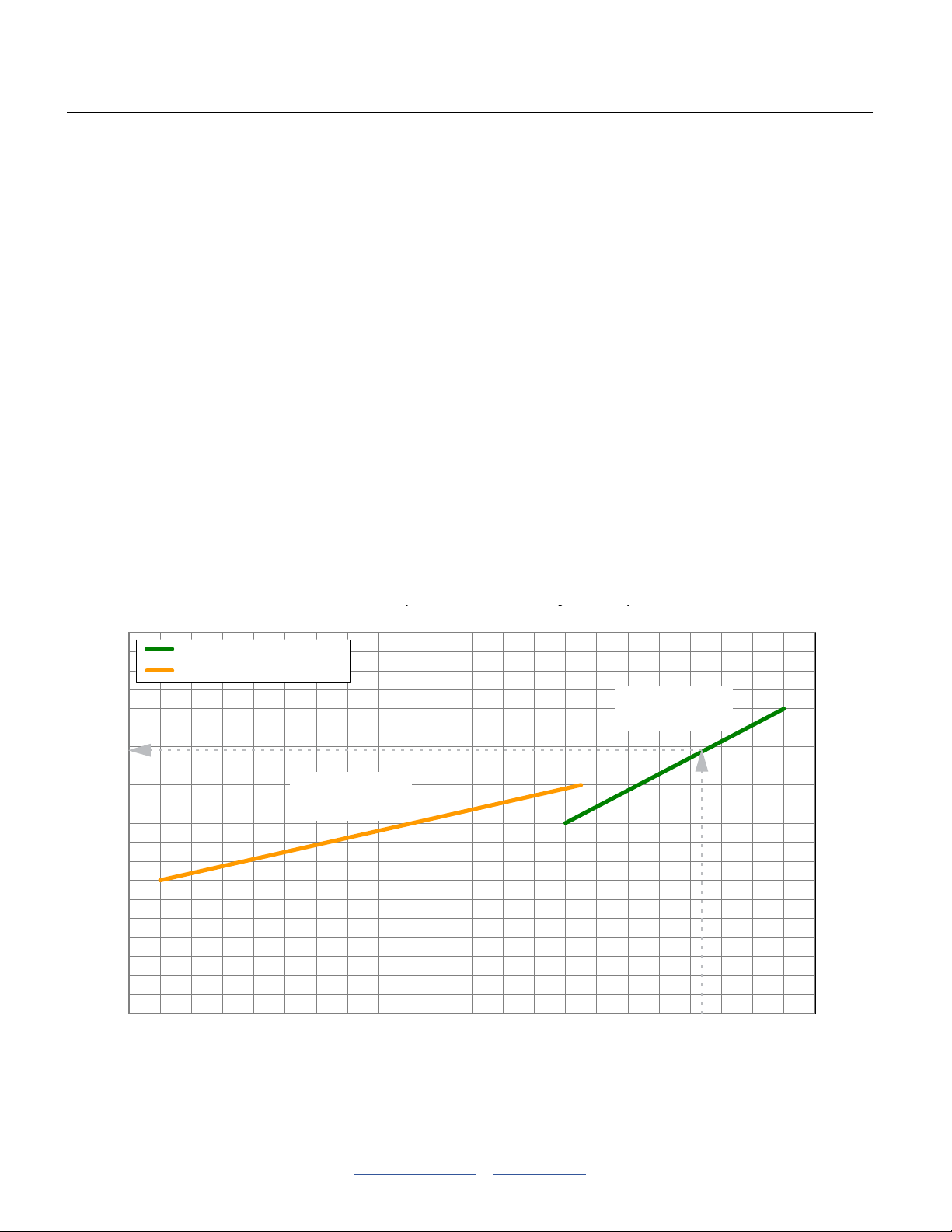

Corn: Reading a Pressure Chart (below, next page)

1. Pick the chart based on seed shape (flat, round).

Example: large round corn

2. Pick a line based on seed size (large, small).

Example: the right line below

3. Find the seed density on the bottom scale.

Example: 1260 seeds/pound

4. Read the suggested starting pressure on the left

scale, where the line (example shown as dotted

gray) intersects the density.

Example: 3.4 inches of water

Initial seed inlet Shutter for corn is: 3

Initial Meter Pressurization: Round Corn

Pressure/Seed Comparison

4.5

5

Linear (Round Corn Large)

Linear (Round Corn Small)

4

3.5

3

2.5

2

Example

Disks

817-795C & 817-797C

Round Corn-Small

Initial Meter Pressurization: Soybeans

2.0 inches of water (84 cell disk, any seed density)

3.0 inches of water (168 cell disk, any seed density)

Initial seed inlet Shutter: 2

Initial Meter Pressurization: Sunflower

Disk: 817-851C SUNFLOWER OIL LARGE

8500 seeds/pound (or fewer)

8500 - 7000 s/lb 1.25 inches of water

7000 - 5500 s/lb 1.75 inches of water

5500 s/lb and fewer 2.25 inches of water

Adjust pressure as needed for desired population.

Initial seed inlet Shutter: 2

5

4.5

Disks

817-794C & 817-796C

Round Corn-Large

Example

4

3.5

3

2.5

2

Meter Pressurization in inches of Water

Meter Pressure (in/water)

Meter Pressure (in/water)

1.5

1

1.5

1

Meter Pressurization in inches of Water

90011001300150017001900210023002500270029003100

88.9

29725

0.5

0

29725

0.5

0

25.8

401-923B Table of Contents Metric Charts 2013-11-11

29.627.6

Seeds Per Pound

Unit Weight (80K)

53.347.142.138.134.832.0

72.761.5

Great Plains Manufacturing, Inc. Table of Contents Metric Charts Planting Rate Overview 9

(y)

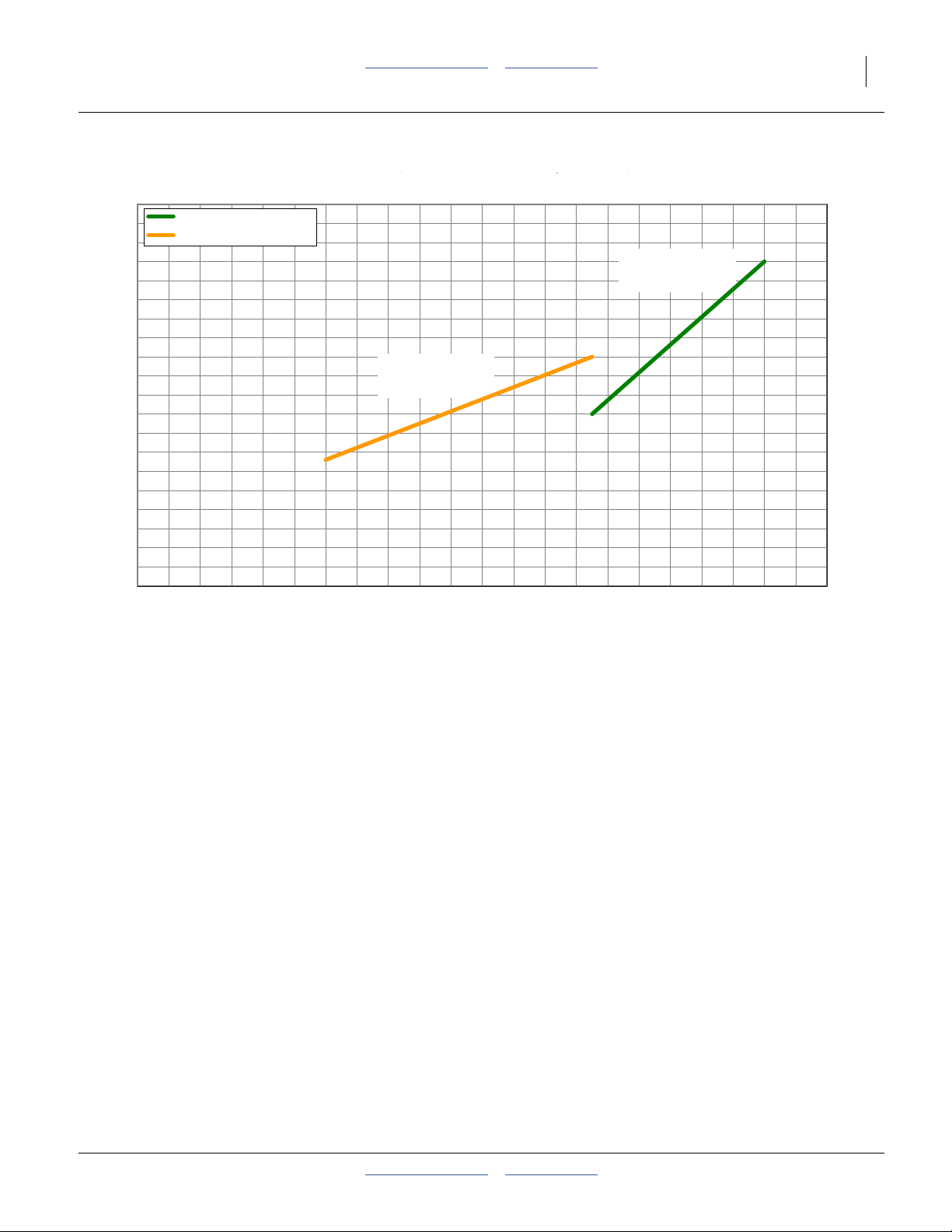

Initial Meter Pressurization: Flat Corn

Pressure/Seed Comparison

4.5

3.5

5

Linear (Flat Corn Large)

Linear (Flat Corn Small)

Disks

4

817-836C & 817-838C

Flat Corn-Large

5

4.5

4

3.5

Meter Pressurization in inches of Water

Meter Pressure (in/water)

Meter Pressure (in/water)

Meter Pressurization in inches of Water

2.5

1.5

0.5

3

2

1

0

Disks

817-795C & 817-797C

Flat Corn-Small

38.134.832.029.627.625.8

47.142.1

53.3

61.5

3

2.5

2

1.5

1

0.5

0

90011001300150017001900210023002500270029003100

88.972.7

Seeds Per Pound

Unit Weight (80K)

29726

29726

2013-11-11 Table of Contents Metric Charts 401-923B

10 YP825AR Table of Contents Metric Charts Great Plains Manufacturing, Inc.

Checking Planting Rate

Singulated seed charts are based on cleaned and sized

seed singulated with the recommended disk. Extreme

seed size variations, foreign material and, on ground

driver planters, tire pressure can affect the planting rate.

Any material difference between chart and field rates

implies a mechanical malfunction, a planter setup error,

unsuitable planting conditions (such as excessive tire

slippage) or extremely worn planter components. You

can verify your setup and planter performance by

measuring seed placement and spacing over a relatively

short distance.

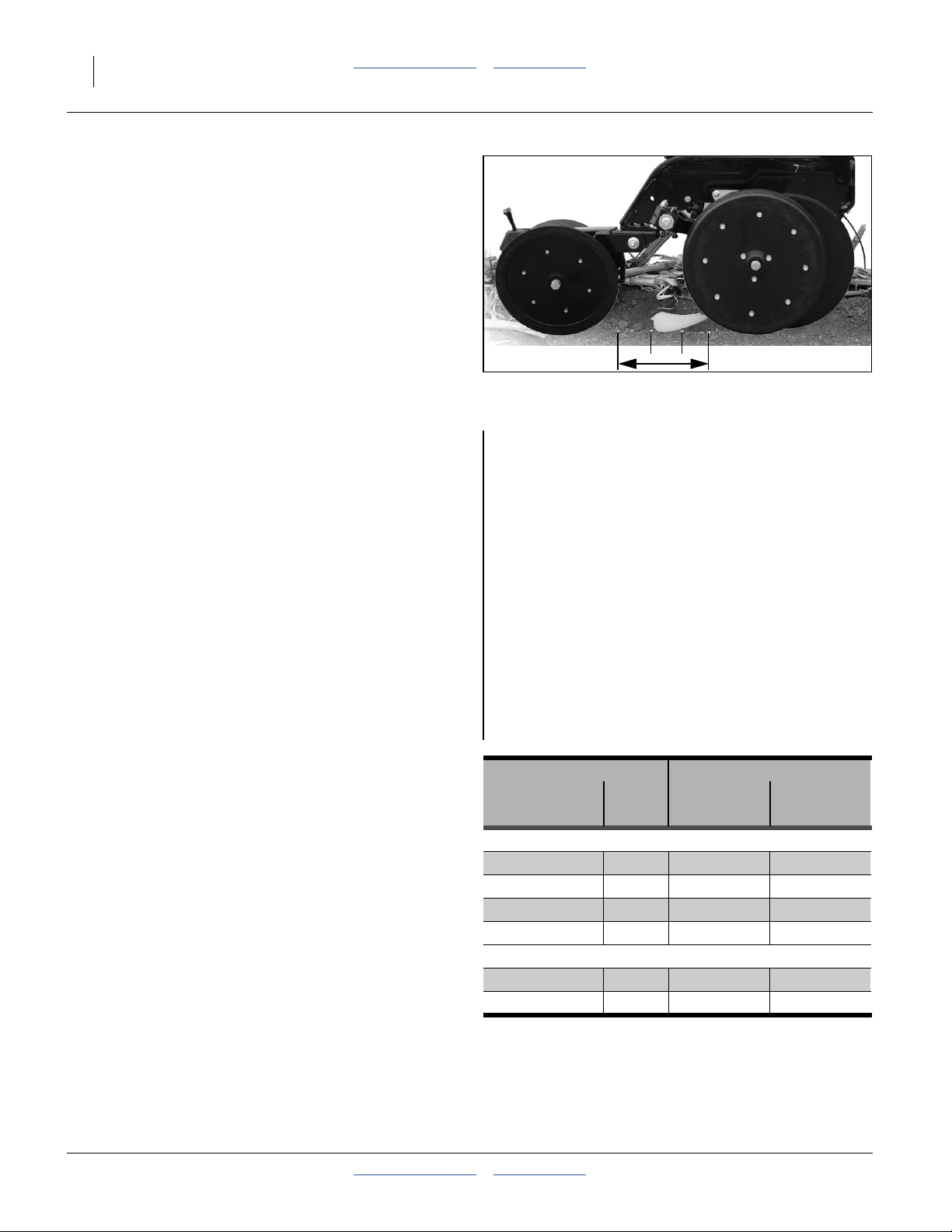

Figure 3

Furrow Check

29247

The columns to the right provide example data for a rate

check, in U.S. customary units and a similar example

metric units.

Checking Singulated Rates

1. Determine the sample distance to check. Find your

row spacing in the table at right (metric chart is on

page 90).

2. Note the number of rows to sample. Adjust the

planting depth to a shallow setting on one or two

outside rows (per table). Tie up the press wheel

arms with wire or bungee to prevent furrow closure.

3. For populations above 100 000 seeds/acre, use a

sample size of 1/1000th acre.

For populations below 100 000 seeds/acre, use a

sample size of 1/200th acre.

4. Configure the planter for the chart rate, either using

the chart settings for sprockets, or, with hydraulic

drive, selecting the rate on the seed monitor.

USc Example:

Planter: YP825AR-0830

Crop: Soybeans

Density: 3000 seeds/lb

Seed Disk: 403-551D

Target Population:

150,000 seeds/acre

Range Sprockets:

DRIVING: 25

DRIVEN: 15

Transmission Sprockets:

DRIVING: 17

DRIVEN: 23

Maximum Planting Speed:

8 mph

Chart Seed Spacing:

1.4 in

Rows to Sample Length of Sample Run

Row Row 1/1000th 1/200th

Spacing Count Acre Acre

Single Rows

22 in. (56 cm)

27.6 in. (70 cm)

29.5 in. (75 cm)

30 in. (76.2 cm)

Twin Rows

29.5 in. (75 cm)

30 in. (76.2 cm)

1 23 ft. 9 in.

1 18 ft. 12 in.

1 17 ft. 8 in.

1 17 ft. 5 in. 87 ft. 1 in.

1 pair 17 ft. 8 in. 88 ft. 6 in.

1 pair 17 ft. 5 in. 87 ft. 1 in.

Metric Example:

Planter: YP825AR-0830

Crop: Soybeans

Density: 6614 seeds/kg

Seed Disk: 403-551D

Target Population:

370 657 seeds/hectare

Range Sprockets:

DRIVER: 25

DRIVEN: 15

Transmission Sprockets:

DRIVER: 17

DRIVEN: 23

Maximum Planting Speed:

12.8 kph

Chart Seed Spacing:

3.6 cm

401-923B Table of Contents Metric Charts 2013-11-11

Great Plains Manufacturing, Inc. Table of Contents Metric Charts Planting Rate Overview 11

5. Plant at the desired planting speed for slightly more

than the computed sample run length.

6. Measure off the sample distance, balanced in

between where seeding started and stopped.

7. Count the number of seeds over the distance

measured. Also note the consistency of the seed

spacing.

8. Compute the rate for a full acre or hectare.

For a 1/1000th sample, multiply the counted seeds

by 1000.

For a 1/200th sample, multiply the counted seeds by

200.

9. If the field and chart rates vary by more than a few

percent, re-check planter setup, including meter disk

or cell count, air system, tire size, tire pressures,

sprocket setup, chain slack, etc. If seed spacing is

irregular, this suggests a seed delivery problem, and

not a rate setup problem.

10. While planting, pay attention to the seed monitor. In

addition to confirming the single-row furrow check, it

will also provide field rate data on all the other rows,

and alert you to any irregularities or stoppages.

USc Example:

Sample size:

1/1000th ac

Plant for approximately:

25 feet

Measure the central:

17 feet 5 inches

USc Example:

Seeds counted:

152

Computed for full acre:

152 x 1000 = 152,000

This differs from chart by:

1%G

Metric Example:

Sample size:

1/1000th ha

Plant for approximately:

20 meters

Measure the central:

13.12 meters

Metric Example:

Seeds counted:

300

Computed for full hectare:

300 x 1000 = 300,000

This differs from chart by:

0.6%

2013-11-11 Table of Contents Metric Charts 401-923B

12 YP825AR Table of Contents Metric Charts Great Plains Manufacturing, Inc.

Planting Rate

Setting the seeding rate requires the following steps:

1. monitor setup

2. seed disk selection,

3. drive speed Range sprockets,

4. Transmission sprockets,

5. inlet shutters

6. meter pressurization,

7. checking seeding rate.

All rate adjustments are performed at the left end of the

planter. There are no adjustments at the ground drive

assembly. Changes in seed rate do not affect fertilizer

rate.

1. Rate: Monitor configuration:

The seed monitor must be set up with the

• correct row count,

• correct row spacing,

• speed calibration and;

• expected population limits, in order to have accurate

rate reports and useful alarms.

See the DICKEY-john®Planter Monitor operator manual.

If you only plant with the factory configuration of the

planter, you never need to update row count and

spacing. If any rows are unused, adjust the monitor

setup.

Speed calibration must be done prior to first use, and

re-calibration is recommended periodically, particularly if

soil conditions change.

Figure 4

PM300 Monitor Setup Screen

29978

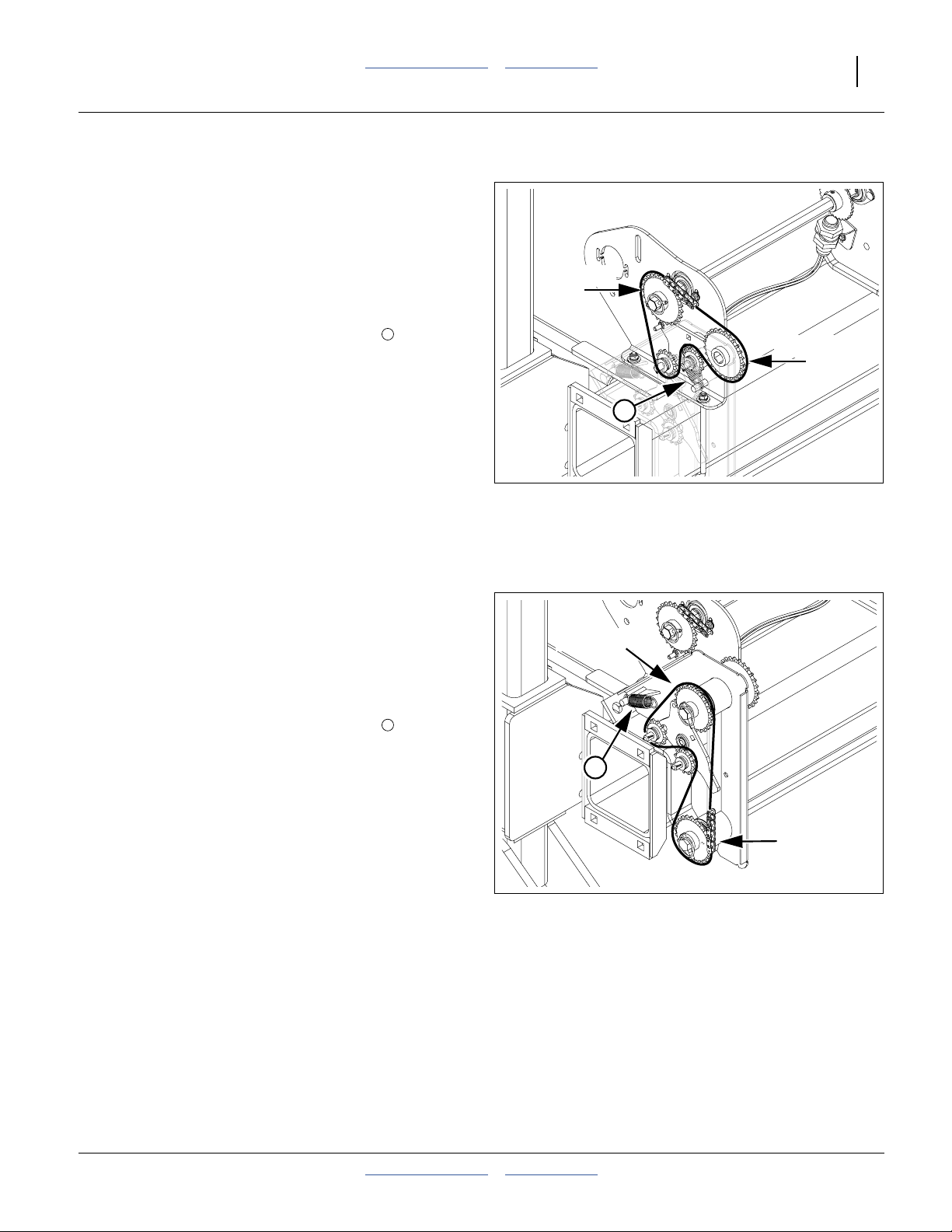

2. Rate: Disk Selection:

Select seed disks per page 5 through page 7. See

Operator manual for installation. Disks are specific to

crops. Some crops have multiple disks available, to cover

both seed varieties, and different populations within disk

rpm limits. Disks have a high and low rpm limit, which

also corresponds to a high and low field speed limit. The

charts account for these limits.

See “Air-Pro® Meter Disk Installation” in the Operator

manual.

If any rows are unused, install special blank disks. See

“Row Unit Shut-Off” in Operator manual.

401-923B Table of Contents Metric Charts 2013-11-11

Figure 5

Air-Pro® Seed Disks

29594

Great Plains Manufacturing, Inc. Table of Contents Metric Charts Planting Rate 13

3. Rate: Range Sprockets

Range sprockets provide coarse control of seed rate.

Refer to Figure 6 and Figure 7

All Seed Rate charts specify a DRIVING and DRIVEN

sprocket combination for the Range. Crops with more

than one range are noted as “LOW RANGE” or

“HIGH RANGE” at the top of the chart.

To change Range:

a. Rotate the idler plate against the spring to

disengage the idler.

Remove the chain.

b. Remove pins from shaft ends at DRIVING and

DRIVEN sprockets, as well as at storage shaft.

c. Exchange sprockets so that new DRIVING and

DRIVEN sprocket tooth counts (stamped on sprocket

face) match chart. Re-pin all shafts.

d. Remount chain. Re-engage spring idler.

3

DRIVING

3

Figure 6

Range Sprockets

DRIVEN

34807

4. Rate: Transmission Sprockets

Transmission sprockets provide fine control of seed rate.

Each chart row provides a rate adjustment of 2 to 3%.

Refer to Figure 7

Each Seed Rate chart row has a unique pairing of

DRIVING and DRIVEN Transmission sprocket.

To change Transmission:

a. Rotate the idler plate against the spring to

disengage the idler.

Remove the chain.

b. Remove pins from shaft ends at DRIVING and

DRIVEN sprockets, as well as at storage shaft.

c. Exchange sprockets so that new DRIVING and

DRIVEN sprocket tooth counts (stamped on sprocket

face) match chart. Re-pin all shafts.

d. Remount chain. Re-engage spring idler.

4

DRIVING

4

Figure 7

Transmission Sprockets

DRIVEN

34808

2013-11-11 Table of Contents Metric Charts 401-923B

14 YP825AR Table of Contents Metric Charts Great Plains Manufacturing, Inc.

5. Rate: Seed Inlet Shutter

A consistent seed rate requires: a consistent number of

seeds (usually one) in each pocket of the seed disk;

avoiding “skips” (fewer seeds per pocket); and, avoiding

“doubles” (excess seed per pocket).

Refer to Figure 8

One of the factors that affects seed pickup at the disk is

having an optimal seed pool (see Operator manual). The

depth of the seed pool is controlled by the seed inlet

shutter .

Each Seed Rate chart specifies a suggested initial

shutter setting. See “Seed Inlet Shutter Adjustment”in

Operator manual for setting details, and further

adjustment.

At unused rows, set the shutter to zero/closed to prevent

loss of meter pressurization air, and install a blank seed

disk. See the “Row Unit Shut Off” topic in the Operator

manual.

5

Figure 8

Seed Inlet Shutter: Setting III

5

29607

6. Rate: Meter Pressurization

Refer to Figure 9

(which depicts a typical reading for some densities of corn)

A major factor that affects seed pickup at the disk is

optimal meter pressurization. Fan air holds the seed in

the disk pockets until they pass the drop brush.

The Seed Rate manual has a section with suggested

initial meter pressures, which may be a single value, or a

graph based on seed density.

Meter pressure is set by a combination of tractor circuit

lever and fan butterfly valve. See “Air System

Operation” in Operator manual.

7. Rate: Checking

Although the seed monitor reports a computed

population based on seeds sensed, only an actual furrow

check provides certainty about the actual seeding rate.

See “Checking Planting Rate” on page 10.

Figure 9

Meter Pressure Gauge

29842

401-923B Table of Contents Metric Charts 2013-11-11

Great Plains Manufacturing, Inc. Table of Contents Metric Charts Sprocket Indexing (Stagger) 15

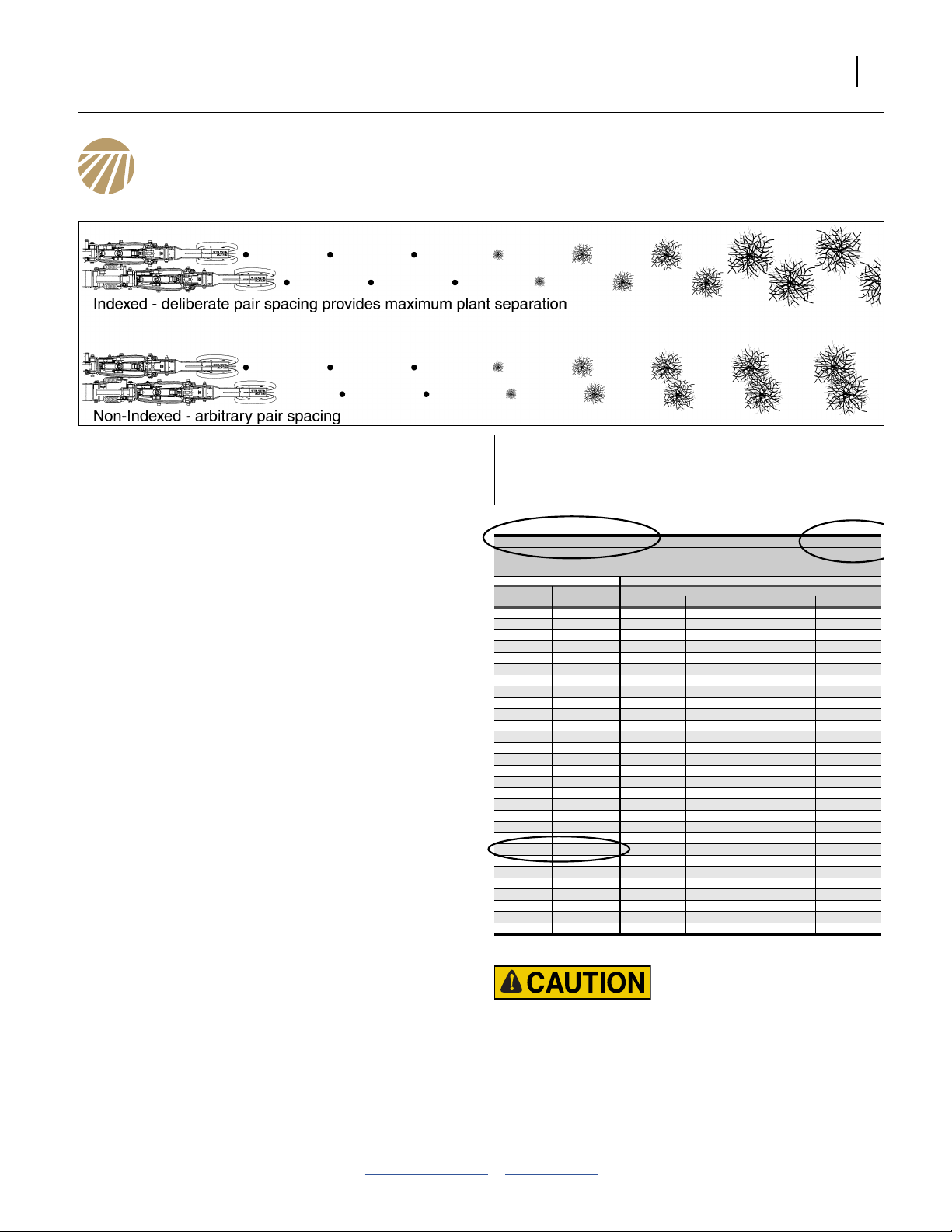

Sprocket Indexing (Stagger)

28420

.tif

600 dpi

If you are planting:

• with a seed disc having 24 cells or less,

• twin-row crops,

• at seed populations below 45,000 seeds/ac

(111 000 seeds/ha),

you can synchronize each pair of adjacent meters in a

twin row so that you achieve the maximum seed-to-seed

spacing between the units of the pair.

If the initial indexing does not provide equal spacing, see

“Indexing Fine Adjustment” on page 18.

If you are planting:

- single-row,

- or with seed discs or 25 cells or more,

- or a volumetric crop,

this section of the manual, and the sprocket indexing

charts, do not apply to your operations.

Due to limitations on the number of sprocket teeth and

Source:

Dated:

wheel cell count, it may not be possible to obtain perfect

Provider

stagger. Charts and fine adjustment provide the optimal

File:

Sheet:

available stagger.

Rendered:

Export As:

Import As:

Air-Pro® Meter Stagger Timing Chart

Set front meter to tooth “1”. Page 1 of 2

Set rear meter to indicated Initial tooth number.

Advance or Retard to adjust - see instructions in Seed Rate Manual.

Population Initial Rear 20% Rear Seed Drop Adjust 40% Rear Seed Drop Adjust

Seeds/Acre Tooth Number Retard Advance Retard Advance

Thumbnail view. Actual charts begin on page 19.

/files/manual/docs/gp/401-625b/charts/ods/reference/air_pro_meter_timing.ods

2009-08-11T11:49

GWA

/files/iso/text/29500/29715.ods

29715

2010-04-27T11:55

/files/iso/text/29500/29715A.pdf

/files/iso/text/29500/29715A.eps

These Columns are for Fine Adjustment Only

17000 7 3 4 6 16

17500 19 10 16 13 16

18000 19 10 16 13 16

18500 3 7 19 10 16

19000 4 6 19 9 12

19500 4 1 15 17 12

20000 18 11 15 14 12

20500 8 2 15 5 8

21000 8 5 11 5 8

21500 14 15 11 18 8

22000 14 15 11 18 4

22500 12 9 7 1 4

23000 10 19 7 3 4

23500 10 19 7 3 4

24000 16 13 3 10 19

24500 6 13 3 10 19

25000 6 4 3 7 19

25500 1 17 18 14 15

26000 2 17 18 14 15

26500 2 8 18 11 15

27000 5 5 18 18 11

27500 5 2 14 18 11

28000 17 12 14 15 11

28500 9 1 14 3 7

29000 9 6 10 3 7

29500 13 16 10 19 7

30000 13 16 10 19 3

30500 13 10 6 7 3

31000 9 10 6 4 3

RJN

By:

Twin Row 30in

29715A

Crushing Hazard:

Install transport locks. Do not rely on hydraulics to hold the

planter at raised. This adjustment takes some time.

2013-11-11 Table of Contents Metric Charts 401-923B

16 YP825AR Table of Contents Metric Charts Great Plains Manufacturing, Inc.

Indexing Preparation

Tools required:

•7⁄8inch (23 mm) open end wrench

•3⁄8inch socket wrench, or any socket wrench with

3

⁄8inch (9.5 mm) square drive

• 812-391C timing tool (located under walkboard)

1. Find (in page 19-55) the sprocket indexing chart for

your row spacing, cell count and desired seed

population. Note the “Initial Rear Tooth Number”

value in the second column.

2. Raise the planter. Chain geometry changes slightly

when lowered. The indexing charts account for this

change, and assume the planter is raised. Also,

raising the planter disengages the drive clutches,

allowing you to turn the drive shaft with a hand tool.

3. Clean out meters. Leave seed discs out.

See Operator Manual for procedure.

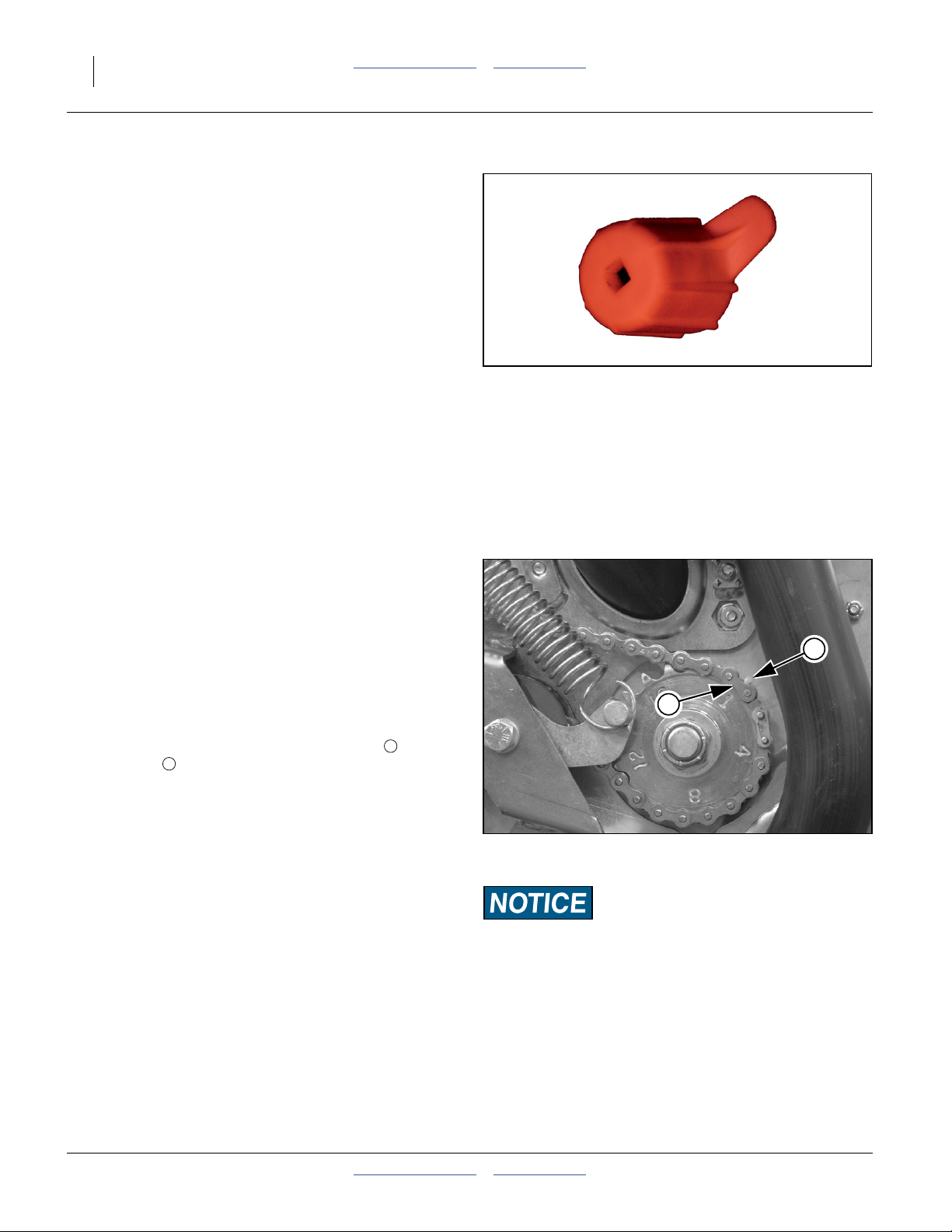

Figure 10

812-391C Timing Tool

Note: Sprocket indexing may be performed with seed

present and discs installed, but if so, you must

perform step 9 (chain taut check) by rotating the

drive shaft forward to remove slack. Reverse meter

rotation, with seed present, is not recommended.

31445

Basic Indexing

Refer to Figure 11 (which depicts tooth 1 slightly ahead of the

index rib at 2:00)

4. Use drive shaft to set front row unit to index 1.

Observe the meter drive sprocket at a front (short

mount) row unit on each wing. Use the wrench, from

the rear of the shaft, to rotate the shaft forward

(wrench up and forward).

Stop rotation with tip of tooth stamped “1” aligned

with a rib cast into the meter housing. In general,

the rib at the 2:00 position is the easiest to use, as it

is visible from the side and from behind the meter.

5. Check front sprocket synchronization.

Inspect all meter drive sprockets on front row units.

Check that all springs are taut, and no chains have

slack. All sprockets should be at “1”. If not, use

step 6 through step 10 to set them to 1. Although

front sprockets machine-wide may be at 1 after this

check, sprockets do not remain in sync wing-to-wing,

due to clutch operation.

When equipped with swath control clutches the front

sprockets will not be synchronized. When swath

control clutches are in place each front sprocket

must be checked when timing its mating rear

sprocket. The front row can be advanced by

manually turning the tandem sprocket forward until

the front sprocket is at 1. Then set the rear sprocket.

Check that the front sprocket has not moved.

2

1

2

1

Figure 11

Sprocket Indexing Reference

Equipment Damage Risk:

Do not apply significant force to meter disk, or drive hub may

be damaged.

Note: In the future, finding front sprockets out of sync on

a wing suggests idler/spring problems, and/or worn

chain. Row drive systems must be in reliable

working order for effective sprocket indexing.

29630

401-923B Table of Contents Metric Charts 2013-11-11

Great Plains Manufacturing, Inc. Table of Contents Metric Charts Sprocket Indexing (Stagger) 17

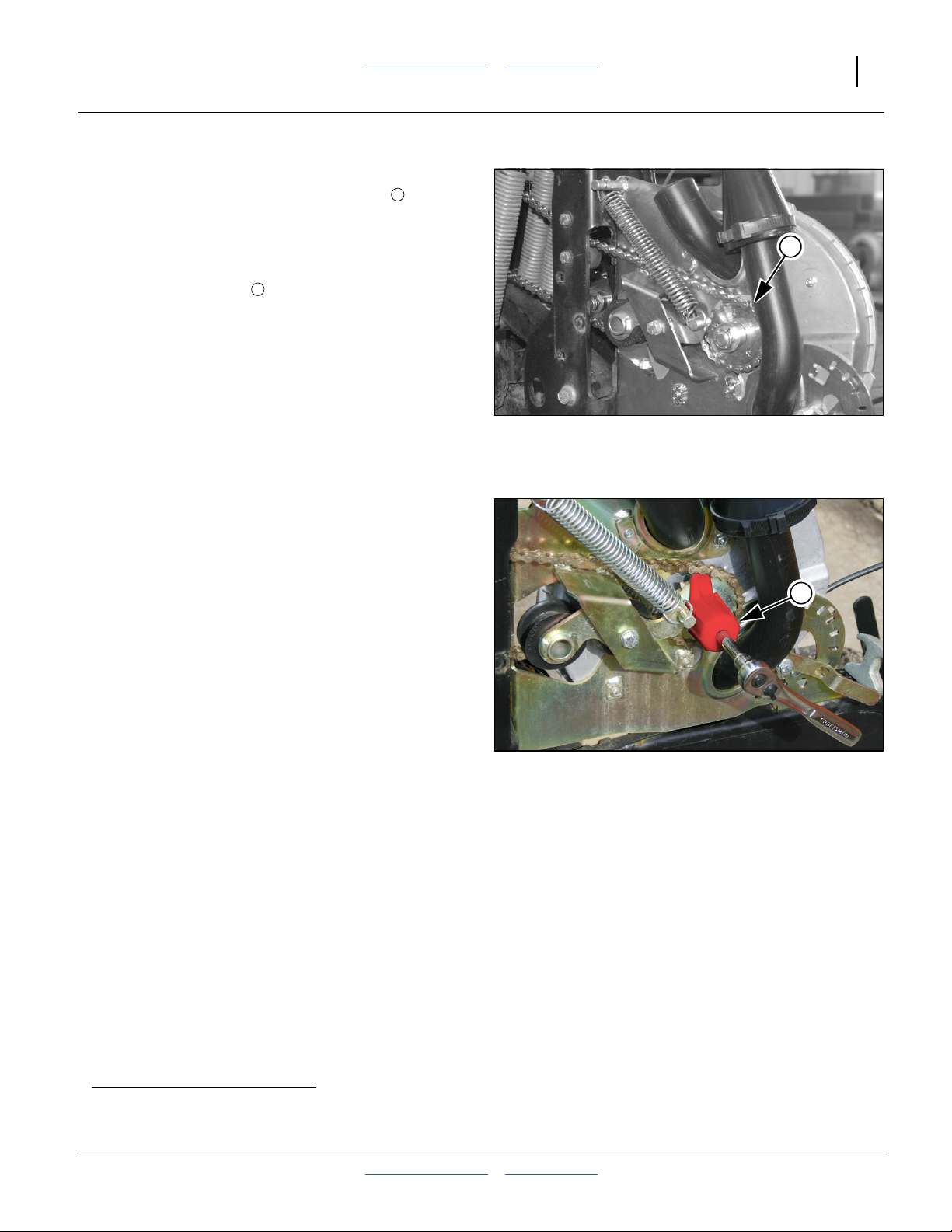

Refer to Figure 12

6. At the rear (long mount) row unit of each pair, note

which sprocket tooth is at the index mark . If the

2

sprocket is already at the chart value, skip to step 2.

Otherwise, complete step 7 through step 10 for that

row.

2

Refer to Figure 13

7. Place the timing tool over the meter shaft. Attach

3

a3⁄8inch socket wrench to aid in rotation.

Sweep the toolatooth under the chain, rotating in the

direction opposite of that desired for sprocket

adjustment.

Each clockwise rotation of the timing tool advances

the sprocket by one tooth.

Figure 12

29628

Sprocket Index Check

Each counter-clockwise rotation of the timing tool

retards the sprocket by one tooth.

8. Advance or retard the sprocket until the desired tooth

number is at the index mark. Hold the sprocket

stationary, and re-mount the chain, making sure the

chain is taut in the top loop.

9. Rotate meter shaft backward, or rotate wing drive

shaft forward to tension chain. Re-check that front

3

row sprocket is still at “1”.

10. Check the position of the rear row sprocket. The

tooth tip at, or just ahead of the index mark must be

the tooth called for by the chart. If not, release spring

and re-mount chain.

11. Repeat step 4 through step 10 for each row pair.

12. Re-install seed discs and meter covers. No particular

disc orientation is required during seed disc

installation. The disc is symmetrical about all four

seat lobes.

Figure 13

Adjusting Sprocket Index

31444

a. If the timing tool is not available, remove the idler tensioning spring to adjust the sprocket position. Rotate meter shaft backward (if

meter empty, otherwise forward one full rotation), and re-check indexing with normal tension on chain.

2013-11-11 Table of Contents Metric Charts 401-923B

18 YP825AR Table of Contents Metric Charts Great Plains Manufacturing, Inc.

Ad

Indexing Fine Adjustment

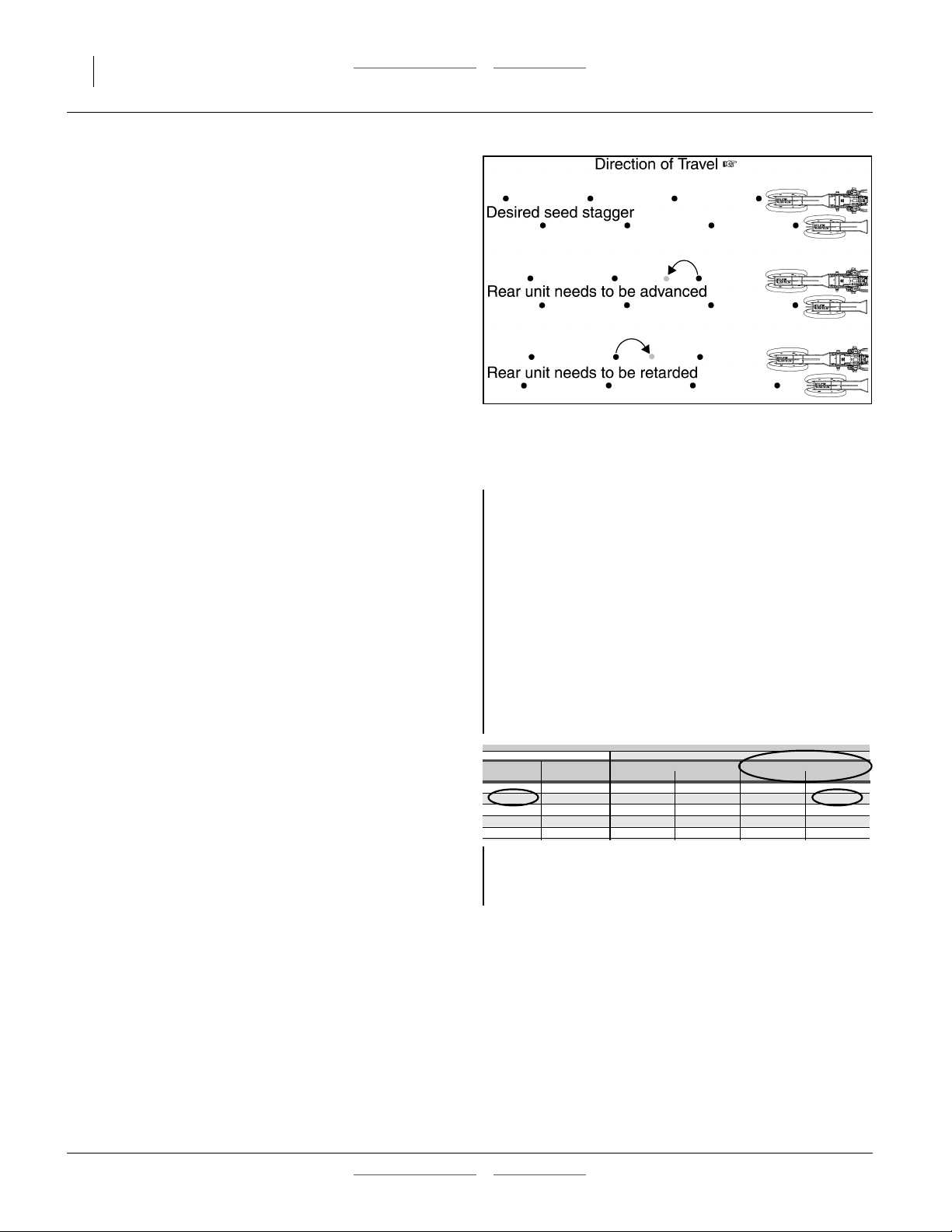

If, after indexing, the twin-row side-to-side seed stagger

is substantially imbalanced, it is possible to make small

adjustments that may correct it. Imbalance can occur

over time as row unit chains wear and stretch.

The Indexing charts on page 19 and 55 provide columns

for alternate rear row sprocket alignments. These

settings move the placement of the rear seed drop. The

amount of movement is given as a percentage (±20% or

±40%) of the in-row seed spacing.

Refer to Figure 14

Adjustments are made only to the rear row timing.

• Advancing the timing (dropping the seed sooner,

moves the seed position back).

• Retarding the timing moves the seed position forward.

If an adjustment is made, test it on one row pair before

adjusting the entire planter.

Indexing Adjustment Steps

1. Make sure the current front sprocket index is 1, and

the current rear sprocket index number matches the

“Initial” number in the indexing chart for the

population being planted.

2. Measure the actual stagger at the rear row seeds.

3. Determine by how many inches (or cm) the rear

seed placement needs to move in order to be

centered between the front seed placements.

4. Determine the percent of seed spacing, and whether

advance or retard, required to adjust the rear seed

drop to the desired spot.

5. In the tables (thumbnail view of one shown at right),

find the new rear sprocket tooth setting for the

percent retard or advance desired.

Figure 14

40% Rear Timing Adjustments

Example:

The front sprocket is “1”. At a target population of

31,500 seeds/ac, the rear sprocket is at tooth “17”.

At this population, spacing in a single row is:

13.3 inches

The rear row seeds would be ideally at:

6.6 inches

ahead or behind the front row seeds.

We find that the rear seeds are being placed:

1.5 inches behind the front seeds.

We need to move the rear seeds back another 5.1 in.

A 40% advance is 5.3 inches at this seed spacing.

vance or Retard to adjust - see instructions in Seed Rate Manual.

Population Initial Rear 20% Rear Seed Drop Adjust 40% Rear Seed Drop Adjust

Seeds/Acre Tooth Number Retard Advance Retard Advance

31000 9 10 6 4 3

31500 17 14 1 4 18

32000 17 14 2 11 18

32500 5 14 2 8 18

33000 5 18 5 8 14

33500 2 18 17 15 14

34000 1 18 17 12 14

Example:

34500 1 3 9 12 14

35000 6 3 9 19 10

Moving the rear sprocket from tooth 17 to tooth 18

35500 6 3 13 19 10

provides a 40% advance.

36000 10 7 13 16 10

36500 10 7 13 4 6

These Columns are for Fine Adjustment Only

29717

401-923B Table of Contents Metric Charts 2013-11-11

Great Plains Manufacturing, Inc. Table of Contents Metric Charts Sprocket Indexing (Stagger) 19

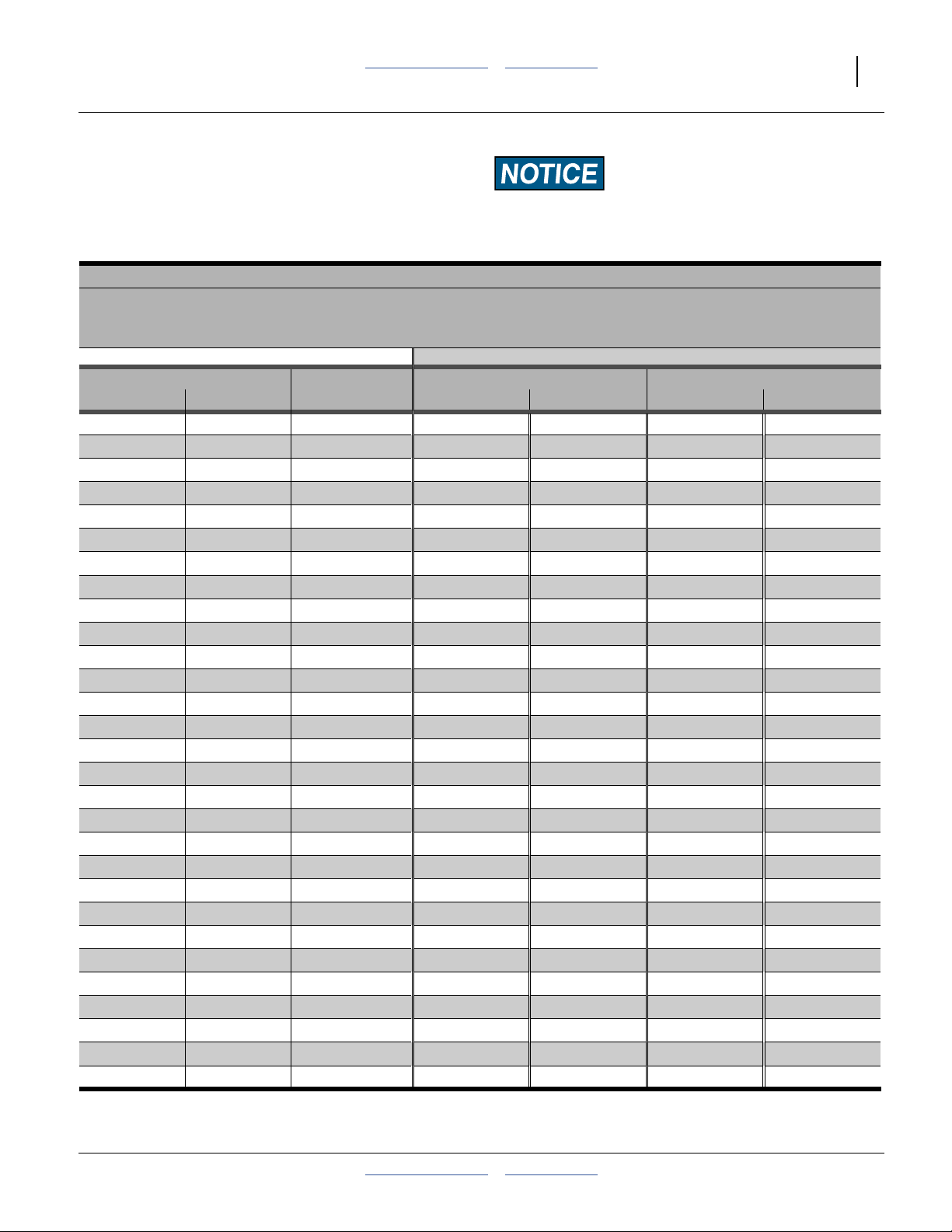

Sprocket Indexing Charts

Twin Row Sprocket Indexing

Note: This is NOT a seed rate chart.

This is a chart for staggering seed spacing

between rows of a twin-row planter.

Air-Pro® Meter Stagger Timing Chart (U.S. customary units)

Set front meter to tooth “1”. Page 1 of 3

Set rear meter to indicated Initial tooth number.

Advance or Retard to adjust - see instructions in Seed Rate Manual.

Population Seeds/Acre Initial Rear 20% Rear Seed Drop Adjust 40% Rear Seed Drop Adjust

30 in. 75 cm Tooth Number Retard Advance Retard Advance

17000 17272 7 3 4 6 16

17500 17780 19 10 16 13 16

18000 18288 19 10 16 13 16

18500 18796 3 7 19 10 16

19000 19304 4 6 19 9 12

19500 19812 4 1 15 17 12

20000 20320 18 11 15 14 12

20500 20828 8 2 15 5 8

21000 21336 8 5 11 5 8

21500 21844 14 15 11 18 8

22000 22352 14 15 11 18 4

22500 22860 12 9714

23000 23368 10 19 7 3 4

23500 23876 10 19 7 3 4

24000 24384 16 13 3 10 19

24500 24892 6 13 3 10 19

25000 25400 6 4 3 7 19

25500 25908 1 17 18 14 15

26000 26416 2 17 18 14 15

26500 26924 2 8 18 11 15

27000 27432 5 5 18 18 11

27500 27940 5 2 14 18 11

28000 28448 17 12 14 15 11

28500 28956 9 1 14 3 7

29000 29464 9 6 10 3 7

29500 29972 13 16 10 19 7

30000 30480 13 16 10 19 3

30500 30988 13 10 6 7 3

31000 31496 9 10 6 4 3

Verify sprocket tooth position with the top length of chain taut.

Metric charts begin on page 87.

Twin Row

These Columns are for Fine Adjustment Only

36076R

2013-11-11 Table of Contents Metric Charts 401-923B

20 YP825AR Table of Contents Metric Charts Great Plains Manufacturing, Inc.

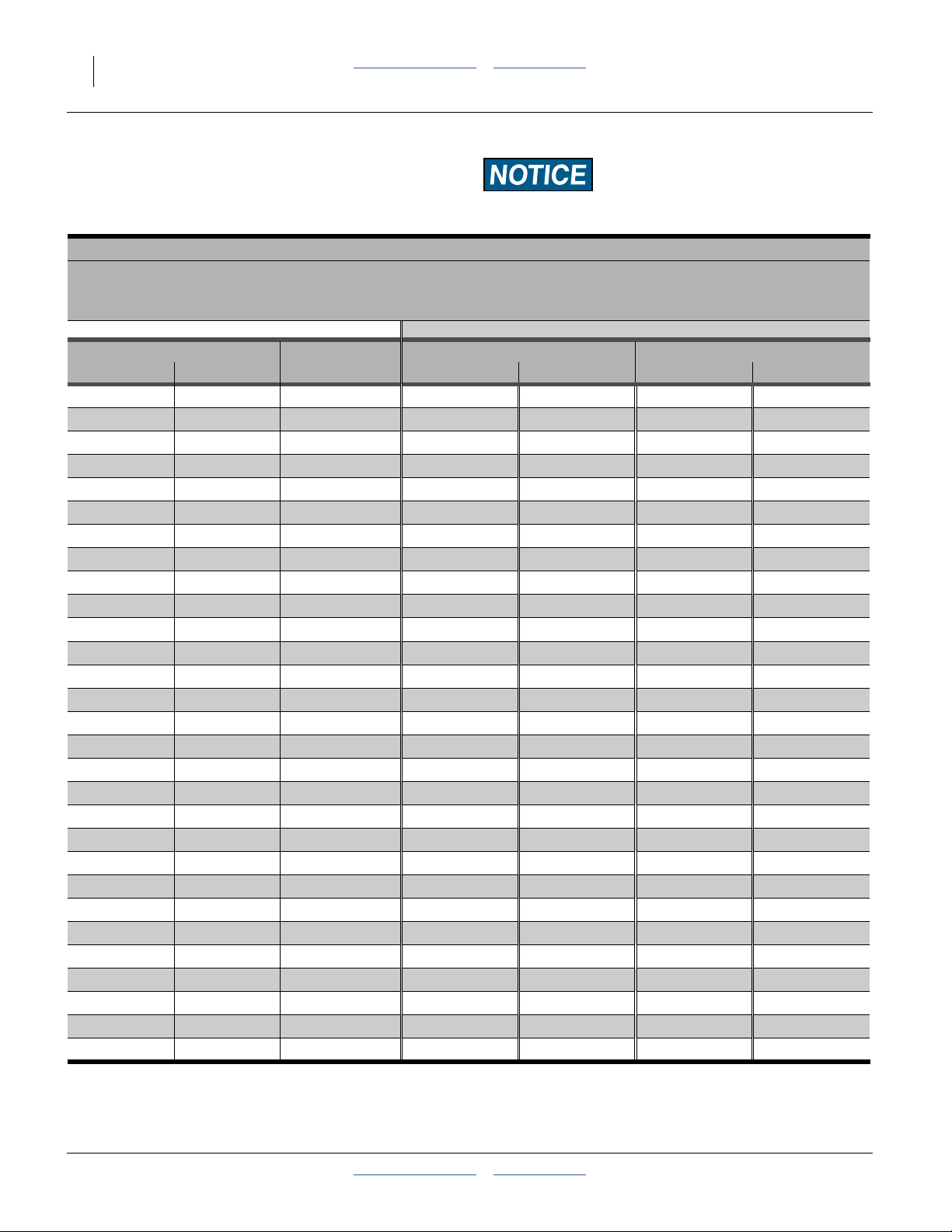

Twin Row Sprocket Indexing (cont.)

Note: This is NOT a seed rate chart.

This is a chart for staggering seed spacing

between rows of a twin-row planter.

Verify sprocket tooth position with the top length of chain taut.

Air-Pro® Meter Stagger Timing Chart (U.S. customary units)

Set front meter to tooth “1”. Page 2 of 3

Set rear meter to indicated Initial tooth number.

Advance or Retard to adjust - see instructions in Seed Rate Manual.

These Columns are for Fine Adjustment Only

Population Seeds/Acre Initial Rear 20% Rear Seed Drop Adjust 40% Rear Seed Drop Adjust

30 in. 75 cm Tooth Number Retard Advance Retard Advance

Twin Row

31500 32004 17 14 1 4 18

32000 32512 17 14 2 11 18

32500 33020 5 14 2 8 18

33000 33528 5 18 5 8 14

33500 34036 2 18 17 15 14

34000 34544 1 18 17 12 14

34500 35052 1 3 9 12 14

35000 35560 6 3 9 19 10

35500 36068 6 3 13 19 10

36000 36576 10 7 13 16 10

36500 37084 10 7 13 4 6

37000 37592 10 7946

37500 38100 14 11 17 4 1

38000 38608 14 11 17 8 2

38500 39116 14 11 5 8 2

39000 39624 18 11 2 8 5

39500 40132 18 15 2 12 17

40000 40640 18 15 1 12 17

40500 41148 3 15 1 12 9

41000 41656 3 19 6 16 9

41500 42164 3 19 6 16 13

42000 42672 7 19 10 16 13

42500 43180 7 4 10 16 13

43000 43688 7 4 10 16 9

43500 44196 11 4 14 16 17

44000 44704 11 8 14 16 17

44500 45212 11 8 14 16 5

45000 45720 15 8 18 16 2

45500 46228 15 12 18 16 2

36076S

401-923B Table of Contents Metric Charts 2013-11-11

Great Plains Manufacturing, Inc. Table of Contents Metric Charts Sprocket Indexing (Stagger) 21

Twin Row Sprocket Indexing (cont.)

Note: This is NOT a seed rate chart.

This is a chart for staggering seed spacing

between rows of a twin-row planter.

Verify sprocket tooth position with the top length of chain taut.

Air-Pro® Meter Stagger Timing Chart (U.S. customary units)

Set front meter to tooth “1”. Page 3 of 3

Set rear meter to indicated Initial tooth number.

Advance or Retard to adjust - see instructions in Seed Rate Manual.

These Columns are for Fine Adjustment Only

Population Seeds/Acre Initial Rear 20% Rear Seed Drop Adjust 40% Rear Seed Drop Adjust

30 in. 75 cm Tooth Number Retard Advance Retard Advance

Twin Row

46000 46736 15 12 18 16 1

46500 47244 15 12 3 16 1

47000 47752 19 16 3 16 6

47500 48260 19 16 3 16 6

48000 48768 19 16 7 16 10

48500 49276 4 16 7 16 10

49000 49784 4 16 7 16 10

49500 50292 4 16 11 16 14

50000 50800 8 16 11 16 14

50500 51308 8 16 11 16 14

51000 51816 8 16 15 16 18

51500 52324 12 16 15 16 18

52000 52832 12 16 15 16 18

52500 53340 12 16 15 16 3

53000 53848 16 16 19 16 3

53500 54356 16 16 19 16 3

54000 54864 16 16 19 16 7

54500 55372 16 16 4 16 7

55000 55880 16 16 4 16 7

55500 56388 16 16 4 16 11

56000 56896 16 16 8 16 11

56500 57404 16 16 8 16 11

57000 57912 16 16 8 16 15

57500 58420 16 16 12 16 15

58000 58928 16 16 12 16 15

58500 59436 16 16 12 16 15

59000 59944 16 16 16 16 19

59500 60452 16 16 16 16 19

60000 60960 16 16 16 16 19

36076T

2013-11-11 Table of Contents Metric Charts 401-923B

22 YP825AR Table of Contents Metric Charts Great Plains Manufacturing, Inc.

)

Source: YP825AR-US.ods

i

)

Export as: /files/manual/docs/gp/401-923b/charts/pdf/YP825AR_Rates_USc_TR30in24cellH.pdf

)

M

r

)

Seed Rate Charts

How to Read a Chart

Consult the chart for your crop, row spacing, disk cell

count, and population. Some charts have two pages.

1. Find the charts for your crop.

2. If there are separate charts based on row spacing,

find the charts for that spacing.

3. If there are separate charts by population range, find

the chart that cover the rate or seed spacing you

intend.

Note: If planting with every other row shut off, the actual

population is half the Twin Row chart rate.

4. Check what disk cell count, and which disk part

numbers are required for/covered by that chart.

5. Note that Ezee Glide Plus seed lubricant is required.

Seed Disk Chart Page Range

Corn Disks 23 - 30 (metric: 91 - 98)

Cotton Disks 31 - 32 (metric: 99 - 100)

Milo Disks 33 - 35 (metric: 101 - 103)

Soybean Disks 36 - 37 (metric: 104 - 105)

Sunflower Disks 38 (metric: 106)

AR

Disk Twin Row 30 inch (27.6 cm

C Round Corn Large Air-Pro® Meter 3

C Round Corn Small

C Flat Corn Large

nge Driving = 30 Ground Speed

Dated: 2013-02-20T0700 Provider: BWN

Sheet: TR30in24cellH

Edition: 2013-03-07T15:28 By: RJN

Export as: /files/manual/docs/gp/401-923b/charts/pdf/YP825AR_Rates_USc_TR30in24cellH.pdf

Import as: /files/manual/docs/gp/401-923b/charts/eps/YP825AR_Rates_USc_TR30in24cellH.eps

YP825AR

24 Cell Disk Twin Row 30 inch (27.6 cm

817-794C Round Corn Large Air-Pro® Meter

817-795C Round Corn Small

817-836C Flat Corn Large

Driving Driven (seeds/acre) (inches)

1

2

Range Driving = 30 Ground Speed

Sprockets Driven = 25 6.5 mph 6 mph 5.5 mph 5 mph 4.5 mph 4 mph

Transmission Seed Seed Meter Meter Meter Meter Meter Meter

Combinations Population Spacing (rpm) (rpm) (rpm) (rpm) (rpm) (rpm)

17 28

17 27

17 26

19 28

17 25

19 27

17 24

19 26

17 23

25 490

26 434

27 451

28 489

28 549

29 544

29 739

30 681

31 032

CORN

Ezee Glide Plus Required

4

3

Ezee Glide Plus Required

16.4

15.8

15.2

14.7

14.6

14.2

14.1

13.6

13.5

3

CORN

17 16 15 13 12 11

18 17 15 14 13 11

19 17 16 14 13 12

19 18 16 15 13 12

20 18 17 15 14 12

20 19 17 16 14 12

20 19 17 16 14 13

21 19 18 16 15 13

21 20 18 16 15 13

Recommended Meter RPM

High Range

Seed Inlet Shutter Setting:

5

Seed Inlet Shu

H

Skip/Double/Blockage Risk:

Ezee Glide Plus seed lubricant is required for all operations

with Air-Pro® meters. See “Seed Lubricants” on page 78 for

seed lubricant information.

6. Find the desired seed population range (or seed

spacing).

7. Note the maximum ground speed for that population.

This is based on the maximum disk rpmafor that disk

and crop.

8. The Range sprockets are at the top left of the

single-spacing charts, and at the top of the columns

for charts covering multiple row spacings.

9. The Transmission sprockets are in the table rows,

found to the left of the Population.

10. Note the suggested initial setting for the seed inlet

shutter.

Import as: /files/manual/docs/gp/401-923b/charts/eps/YP825AR_Rates_USc_TR30in24cellH.eps

YP825AR

24 Cell Disk Twin Row 30 inch (27.6 cm

817-794C Round Corn Large Air-Pro® Meter

817-795C Round Corn Small

817-836C Flat Corn Large

Range Driving = 30 Ground Speed

Sprockets Driven = 25 6.5 mph 6 mph 5.5 mph 5 mph 4.5 mph 4

Transmission Seed Seed Meter Meter Meter Meter Meter

Combinations Population Spacing (rpm) (rpm) (rpm) (rpm) (rpm) (

Driving Driven (seeds/acre) (inches)

17 28

17 27

17 26

19 28

17 25

19 27

17 24

19 26

17 23

19 25

19 24

23 28

19 23

23 27

24 28

R

isk Twin Row 30 inch (27.6 cm

Round Corn Large Air-Pro® Meter 3

Round Corn Small

Flat Corn Large

eDriving =30 Ground Speed

ets Driven = 25 6.5 mph 6 mph 5.5 mph 5 mph 4.5 mph 4 mph 3.5 mph

ssion Seed Seed Meter Meter Meter Meter Meter Meter Meter

tions Population Spacing (rpm) (rpm) (rpm) (rpm) (rpm) (rpm) (rpm)

25 490

26 434

27 451

28 489

28 549

29 544

29 739

30 681

31 032

31 908

33 237

34 487

34 682

35 764

35 986

16.4

15.8

15.2

14.7

9

14.6

14.2

14.1

13.6

13.5

13.1

12.6

12.1

12.1

11.7

11.6

CORN

Ezee Glide Plus Required

8

CORN

Ezee Glide Plus Required

17 16 15 13 12

18 17 15 14 13

19 17 16 14 13

19 18 16 15 13

20 18 17 15 14

6

20 19 17 16 14

20 19 17 16 14

21 19 18 16 15

21 20 18 16 15

22 20 18 17 15

23 21 19 17 16

24 22 20 18 16

24 22 20 18 16

24 23 21 19 17

25 23 21 19 17

10

a. The rpm information is for hydraulic drive planters. This information is not required for Air-Pro® ground drive planter operations.

7

Recommended Meter RPM

Seed Inlet Shutter Setting:

Seed Inlet

High Range

401-923B Table of Contents Metric Charts 2013-11-11

Great Plains Manufacturing, Inc. Table of Contents Metric Charts Seed Rate Charts 23

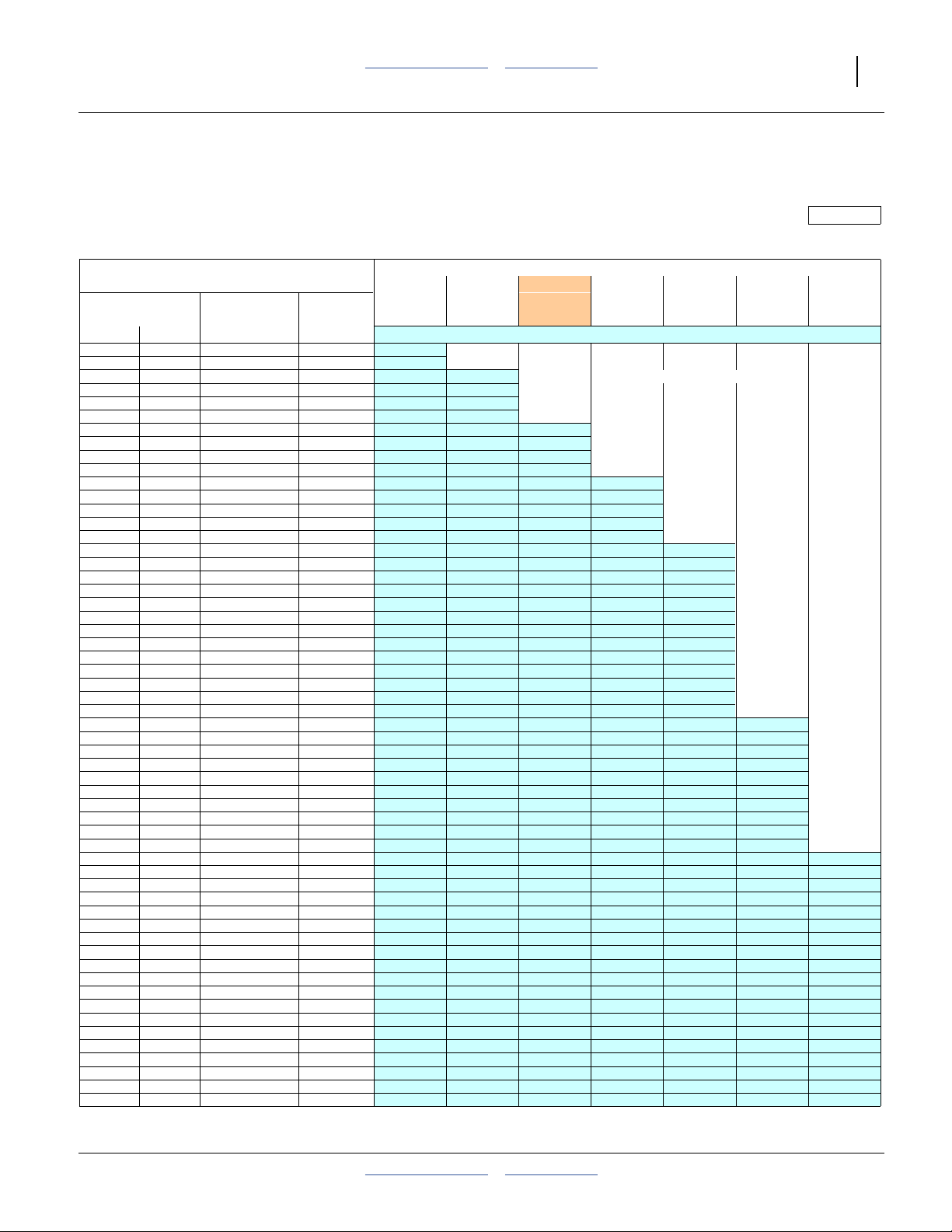

YP825AR

CORN

Low Range

24 Cell Disk 22 inch (55.9 cm) Rows Seed Inlet Shutter Setting:

817-794C Round Corn Large Air-Pro® Meter 3

817-795C Round Corn Small

Ezee Glide Plus Required

817-836C Flat Corn Large

Range Driving = 20 Ground Speed

Sprockets Driven = 30 6.5 mph 6 mph 5.5 mph 5 mph 4.5 mph 4 mph 3.5 mph

Transmission

Combinations Population Spacing (rpm) (rpm) (rpm) (rpm) (rpm) (rpm) (rpm)

Driving Driven (seeds/acre) (inches)

17 28

17 27

17 26

19 28

17 25

19 27

17 24

19 26

17 23

19 25

19 24

23 28

19 23

23 27

24 28

23 26

24 27

25 28

17 19

23 25

24 26

25 27

26 28

23 24

24 25

25 26

26 27

27 28

23 23

28 27

27 26

26 25

25 24

24 23

28 26

27 25

26 24

25 23

19 17

28 25

27 24

26 23

28 24

27 23

23 19

28 23

24 19

25 19

23 17

26 19

24 17

27 19

25 17

28 19

26 17

27 17

28 17

Seed Seed Meter Meter Meter Meter Meter Meter Meter

Recommended Meter RPM

9 655

10 013

10 398

10 791

10 814

11 191

11 265

11 621

11 754

12 086

12 590

13 063

13 137

13 547

13 631

14 068

14 136

14 199

14 229

14 631

14 680

14 725

14 767

15 240

15 267

15 291

15 314

15 335

15 903

16 492

16 515

16 539

16 566

16 594

17 126

17 175

17 228

17 286

17 774

17 811

17 891

17 977

18 553

18 669

19 251

19 360

20 088

20 925

21 516

21 762

22 451

22 599

23 387

23 436

24 322

25 258

26 193

29.5

28.5

27.4

26.4

26.4

25.5

25.3

24.5

24.3

23.6

22.6

21.8

21.7

21.0

20.9

20.3

20.2

20.1

20.0

19.5

19.4

19.4

19.3

18.7

18.7

18.

18.6

18.6

17.9

17.3

17.3

17.2

17.2

17.2

16.6

16.6

16.5

16.5

16.0

16.0

15.9

15.9

15.4

15.3

14.8

14.7

14.2

13.6

13.3

13.1

12.7

12.6

12.2

12.2

11.7

11.3

10.9

10

10

10 10 Not Recommended

11 10

11 10

11 10

11 10 10

12 11 10

12 11 10

12 11 10

13 12 11 10

13 12 11 10

13 12 11 10

14 13 11 10

14 13 12 11

14 13 12 11 10

14 13 12 11 10

14 13 12 11 10

14 13 12 11 10

15 14 12 11 10

15 14 12 11 10

15 14 12 11 10

15 14 13 11 10

15 14 13 12 11

6

15 14 13 12 11

15 14 13 12 11

15 14 13 12 11

15 14 13 12 11

16 15 13 12 11 10

17 15 14 13 11 10

17 15 14 13 11 10

17 15 14 13 11 10

17 15 14 13 12 10

17 15 14 13 12 10

17 16 15 13 12 11

17 16 15 13 12 11

17 16 15 13 12 11

17 16 15 13 12 11

18 16 15 14 12 11 10

18 16 15 14 12 11 10

18 17 15 14 12 11 10

18 17 15 14 12 11 10

19 17 16 14 13 11 10

19 17 16 14 13 12 10

19 18 16 15 13 12 10

19 18 16 15 13 12 10

20 19 17 15 14 12 11

21 19 18 16 15 13 11

22 20 18 17 15 13 12

22 20 18 17 15 13 12

23

23 21 19 17 16 14 12

23 22 20 18 16 14 13

24 22 20 18 16 14 13

24 23 21 19 17 15 13

25 23 21 19 18 16 14

26 24 22 20 18 16 14

21 19 17 16 14 12

2013-11-11 Table of Contents Metric Charts 401-923B

24 YP825AR Table of Contents Metric Charts Great Plains Manufacturing, Inc.

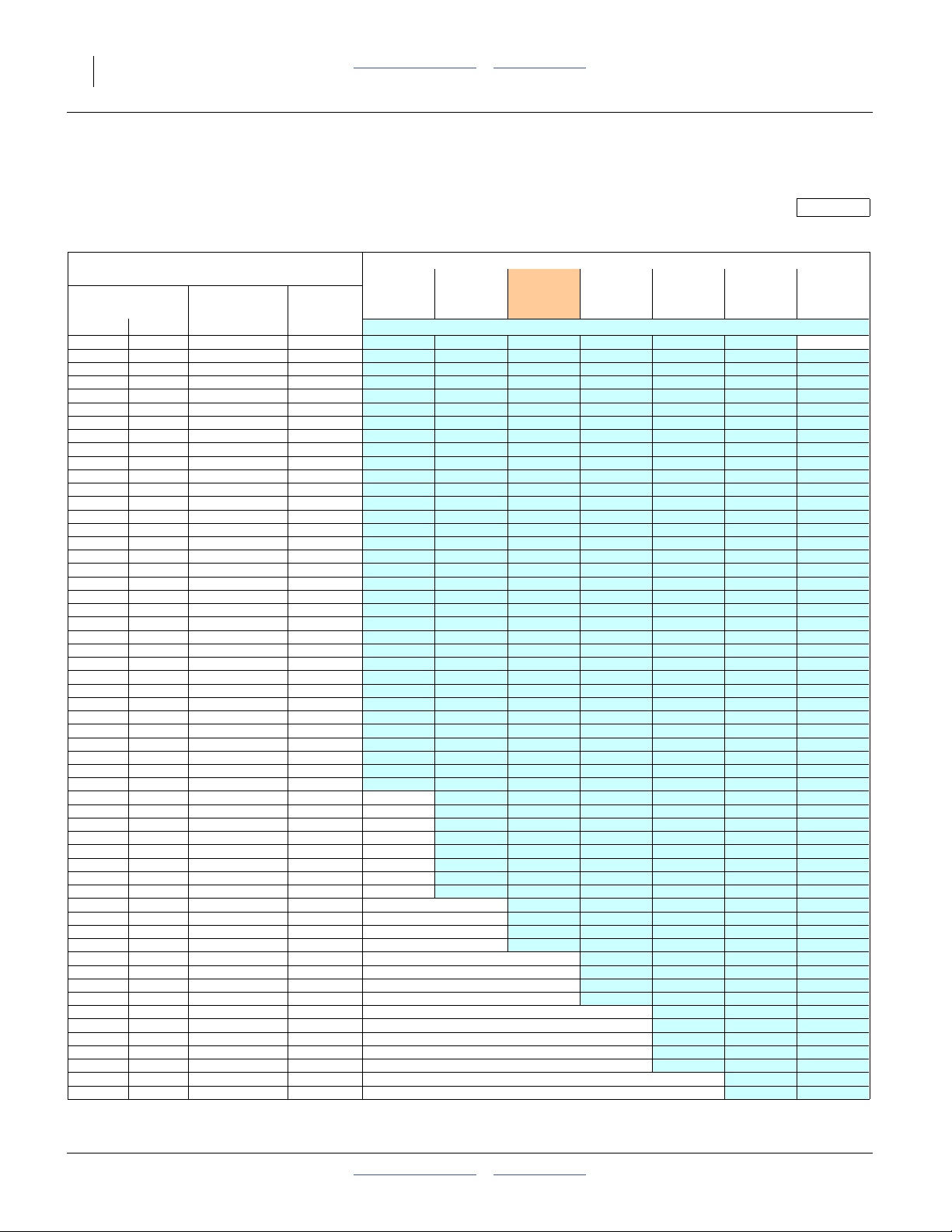

YP825AR

24 Cell Disk

CORN

22 inch (55.9 cm) Rows

Seed Inlet Shutter Setting:

High Range

817-794C Round Corn Large Air-Pro® Meter 3

817-795C Round Corn Small

Ezee Glide Plus Required

817-836C Flat Corn Large

Range Driving = 30 Ground Speed

Sprockets Driven = 25 6.5 mph 6 mph 5.5 mph 5 mph 4.5 mph 4 mph 3.5 mph

Transmission

Combinations Population Spacing (rpm) (rpm) (rpm) (rpm) (rpm) (rpm) (rpm)

Driving Driven (seeds/acre) (inches)

17 28

17 27

17 26

19 28

17 25

19 27

17 24

19 26

17 23

19 25

19 24

23 28

19 23

23 27

24 28

23 26

24 27

25 28

17 19

23 25

24 26

25 27

26 28

23 24

24 25

25 26

26 27

27 28

23 23

28 27

27 26

26 25

25 24

24 23

28 26

27 25

26 24

25 23

19 17

28 25

27 24

26 23

28 24

27 23

23 19

28 23

24 19

25 19

23 17

26 19

24 17

27 19

25 17

28 19

26 17

27 17

28 17

Seed Seed Meter Meter Meter Meter Meter Meter Meter

Recommended Meter RPM

17 380

18 023

18 717

19 424

19 465

20 144

20 276

20 919

21 158

21 755

22 662

23 514

23 647

24 385

24 536

25 322

25 445

25 558

25 612

26 335

26 423

26 505

26 581

27 433

27 480

27 524

27 565

27 603

28 625

29 686

29 726

29 770

29 818

29 870

30 827

30 915

31 011

31 115

31 993

32 060

32 204

32 359

33 396

33 604

34 652

34 848

36 158

37 665

38 728

39 172

40 412

40 678

42 096

42 185

43 780

45 464

47 148

16.4

15.8

15.2

14.7

14.6

14.2

14.1

13.6

13.5

13.1

12.6

12.1

12.1

11.7

11.6

11.3

11.2

11.2

11.1

10.8

10.8

10.8

10.7

10.4

10.4

10.

10.3

10.3

10.0

9.6

9.6

9.6

9.6

9.5

9.2

9.2

9.2

9.2

8.9

8.9

8.9

8.8

8.5

8.5

8.2

8.2

7.9

7.6

7.4

7.3

7.1

7.0

6.8

6.8

6.5

6.3

6.0

17 16 15 13 12 11

18 17 15 14 13 11 10

19 17 16 14 13 12 10

19 18 16 15 13 12 10

20 18 17 15 14 12 11

20 19 17 16 14 12 11

20 19 17 16 14 13 11

21 19 18 16 15 13 11

21 20 18 16 15 13 11

22 20 18 17 15 13 12

23 21 19 17 16 14 12

24 22 20 18 16 15 13

24 22 20 18 16 15 13

24 23 21 19 17 15 13

25 23 21 19 17 15 13

25 23 21 20 18 16 14

26 24 22 20 18 16 14

26 24 22 20 18 16 14

26 24 22 20 18 16 14

26 24 22 20 18 16 14

27 24 22 20 18 16 14

27 25 22 20 18 16 14

27 25 23 21 18 16 14

28 25 23 21 19 17 15

4

28 25 23 21 19 17 15

28 25 23 21 19 17 15

28 26 23 21 19 17 15

28 26 23 21 19 17 15

29 27 24 22 20 18 15

30 27 25 23 21 18 16

30 28 25 23 21 18 16

30 28 25 23 21 18 16

30 28 25 23 21 18 16

30 28 25 23 21 18 16

29 26 24 21 19 17

29 26 24 21 19 17

29 26 24 22 19 17

29 26 24 22 19 17

30 27 25 22 20 17

30 27 25 22 20 17

30 27 25 22 20 17

30 27 25 22 20 17

Not Recommended 30 27 24 21

28 26 23 21 18

29 26 23 21 18

29 27 24 21 19

30 27 24 22 19

28 25 22 20

29 26 23 20

30 27 24 21

28

28 25 22

29 26 23

29 26 23

30 27 24

25 22

28 25

29 25

401-923B Table of Contents Metric Charts 2013-11-11

Great Plains Manufacturing, Inc. Table of Contents Metric Charts Seed Rate Charts 25

YP825AR

CORN

High Range

40 Cell Disk 22 inch (55.9 cm) Rows Seed Inlet Shutter Setting:

817-796C Round Corn Large Air-Pro® Meter 3

817-797C Round Corn Small

Ezee Glide Plus Required

817-838C Flat Corn Large

Range Driving = 30 Ground Speed

Sprockets Driven = 25 6.5 mph 6 mph 5.5 mph 5 mph 4.5 mph 4 mph 3.5 mph

Transmission

Combinations Population Spacing (rpm) (rpm) (rpm) (rpm) (rpm) (rpm) (rpm)

Driving Driven (seeds/acre) (inches)

17 28

17 27

17 26

19 28

17 25

19 27

17 24

19 26

17 23

19 25

19 24

23 28

19 23

23 27

24 28

23 26

24 27

25 28

17 19

23 25

24 26

25 27

26 28

23 24

24 25

25 26

26 27

27 28

23 23

28 27

27 26

26 25

25 24

24 23

28 26

27 25

26 24

25 23

19 17

28 25

27 24

26 23

28 24

27 23

23 19

28 23

24 19

25 19

23 17

26 19

24 17

27 19

25 17

28 19

26 17

27 17

28 17

Seed Seed Meter Meter Meter Meter Meter Meter Meter

Recommended Meter RPM

28 966

30 039

31 194

32 374

32 442

33 573

33 794

34 864

35 263

36 259

37 770

39 190

39 412

40 641

40 893

42 204

42 408

42 597

42 687

43 892

44 039

44 175

44 301

45 721

45 801

45 874

45 942

46 005

47 709

49 476

49 544

49 617

49 697

49 783

51 379

51 526

51 685

51 858

53 322

53 434

53 673

53 932

55 660

56 006

57 753

58 080

60 264

62 775

64 547

65 286

67 354

67 797

70 160

70 308

72 967

75 773

78 579

9.8

9.5

9.1

8.8

8.8

8.5

8.4

8.2

8.1

7.9

7.5

7.3

7.2

7.0

7.0

6.8

6.7

6.7

6.7

6.5

6.5

6.5

6.4

6.2

6.2

6.

6.2

6.2

6.0

5.8

5.8

5.7

5.7

5.7

5.5

5.5

5.5

5.5

5.3

5.3

5.3

5.3

5.1

5.1

4.9

4.9

4.7

4.5

4.4

4.4

4.2

4.2

4.1

4.1

3.9

3.8

3.6

17 16 15 13 12 11

18 17 15 14 13 11 10

19 17 16 14 13 12 10

19 18 16 15 13 12 10

20 18 17 15 14 12 11

20 19 17 16 14 12 11

20 19 17 16 14 13 11

21 19 18 16 15 13 11

21 20 18 16 15 13 11