Great Plains YP625PD User Manual

Table of Contents Appendix

Manufacturing, Inc.

www.greatplainsmfg.com

Seed and Fertilizer Rate Charts for the YP625PD (Pull-Type), and YP625TD and YP925TD (3-Point) 6- and 9-Row Yield-Pro® Air Planters with Air-Pro® seed meters

The following pages are to assist in the proper setting of seeding and

®

fertilizer rates for the 6- and 9-Row Yield-Pro

the most accurate seeding rates, Great Plains recommends checking

singulated seed rates, and calibrating for fertilizer application rate at the

time of planting.

Air Planters. To assure

Null4:

EN

© Copyright 2011 Printed 09/29/2011 401-754B

Great Plains Mfg., Inc. Cover ii

Table of Contents

Introduction ..................................................................1

Setting Planting Rate......................................................1

Setting Fertilizer Rate.....................................................1

Models Covered .............................................................1

Document Family........................................................1

Planting Rate Overview ...............................................3

Singulated Rate Setting Summary .................................3

Population Reference Information..................................3

Seeds per Unit............................................................ 3

Seed Spacing .............................................................3

Air-Pro® Meter Disk Selection ........................................4

Meter Pressurization ......................................................6

Initial Meter Pressurization: Milo.................................6

Initial Meter Pressurization: Soybeans .......................6

Initial Meter Pressurization: Round Corn.................... 6

Initial Meter Pressurization: Flat Corn ........................7

Checking Planting Rate..................................................8

Checking Singulated Rates ........................................8

Planting Rate ..............................................................10

1. Rate: Monitor configuration: .....................................10

2. Rate: Disk Selection: ................................................ 10

3. Rate: Range Sprockets ............................................11

4. Rate: Transmission Sprockets .................................11

5. Rate: Seed Inlet Shutter ........................................... 12

6. Rate: Meter Pressurization.......................................12

7. Rate: Checking.........................................................12

Seed Rate Charts........................................................13

How to Read a Chart....................................................13

Corn ............................................................................. 14

Single Row 65cm 40 Cell ......................................... 14

Twin Row 110cm 24 Cell ......................................... 15

Twin Row 110cm 40 Cell ......................................... 16

Milo .............................................................................. 17

Single Row 65cm, 130 Cell, Low Range.................. 17

Single Row 65cm, 130 Cell, High Range ................. 18

Twin Row 110cm, 65 Cell, Low Range .................... 19

Twin Row 110cm, 65 Cell, High Range ................... 20

Soybean....................................................................... 21

Single Row 65cm, 168 Cell ...................................... 21

Tri Row 110cm, 84 Cell............................................ 23

Sprocket Indexing (Stagger) ..................................... 24

Indexing Preparation.................................................... 25

Indexing Fine Adjustment ............................................ 27

Sprocket Indexing Charts............................................. 28

110cm Twin Row Sprocket Indexing........................ 28

110cm Triple Row Sprocket Indexing ...................... 30

Fertilizer Rate ............................................................. 33

Dry Fertilizer Rate ........................................................ 33

Setting Dry Fertilizer Rate............................................ 33

Fertilizer Density Adjustment ................................... 35

Dry Fertilizer Rate Check............................................. 35

Dry Fertilizer Rate Charts ............................................ 36

65cm Single Row ..................................................... 36

110cm Twin- & Triple-Row....................................... 37

Appendix..................................................................... 38

Seed Lubricants ........................................................... 38

© Copyright 2010, 2011 All rights Reserved

Great Plains Manufacturing, Inc. provides this publication “as is” without warranty of any kind, either expressed or implied. While every precaution has

been taken in the preparation of this manual, Great Plains Manufacturing, Inc. assumes no responsibility for errors or omissions. Neither is any liability

assumed for damages resulting from the use of the information contained herein. Great Plains Manufacturing, Inc. reserves the right to revise and

improve its products as it sees fit. This publication describes the state of this product at the time of its publication, and may not reflect the product in

the future.

09/29/2011 Cover 401-754B

Trademarks of Great Plains Manufacturing, Inc. include: Singulator Plus, Swath Command, Terra-Tine.

Registered Trademarks of Great Plains Manufacturing, Inc. include:

Air-Pro, Clear-Shot, Great Plains, Land Pride, MeterCone, Nutri-Pro, Seed-Lok, Solid Stand, Whirlfilter, Yield-Pro.

Brand and Product Names that appear and are owned by others are trademarks of their respective owners.

Printed in the United States of America

Great Plains Manufacturing, Inc. Table of Contents Introduction 1

Introduction

This manual covers the following tasks for both pull-type

and three-point 6- and 9-Row Yield-Pro® Air Planters

equipped with Air-Pro

• setting and checking seed rate for singulated crops

• applying fertilizer from the dry fertilizer system.

This manual is your guide to planter adjustments for

achieving specific seed population and fertilizer

application rate targets.

Although some setup/adjustment material herein is

repeated from the Operator’s Manual, you need to be

thoroughly familiar with planter operations and

adjustments before applying this Seed Rate manual and

its table data.

®

seed meters:

R

F

U

B

L

D

R

Setting Planting Rate

Begin at section:

“Planting Rate Overview” on page 3

and complete the setup using section:

“Seed Rate Charts” on page 13.

Setting Fertilizer Rate

This topic is covered beginning at:

“Fertilizer Rate” on page 33.

Null4:

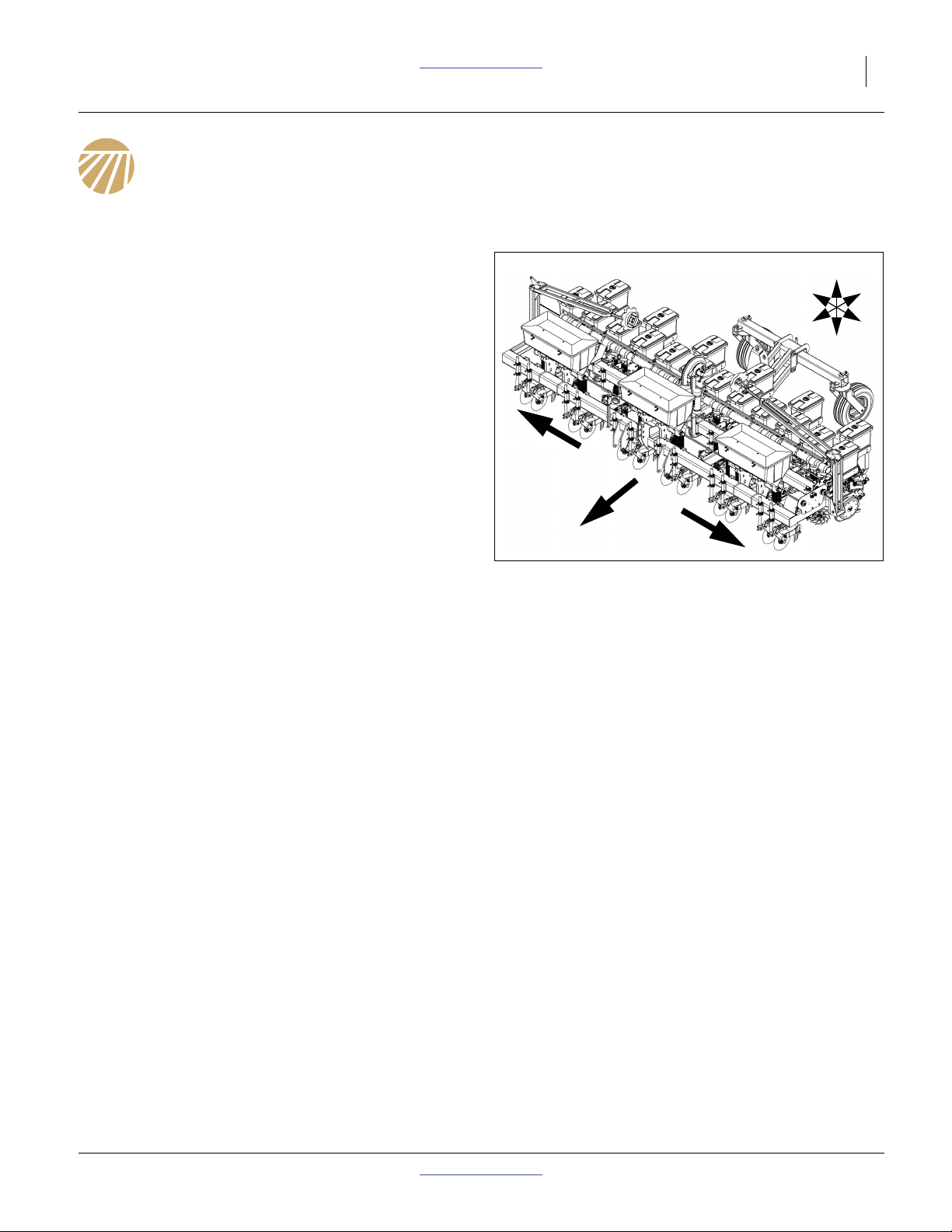

YP625TD Planter

L

Figure 1

31793

Models Covered

Pull-Type:

YP625PD18TP110

3-Point:

YP625TD12TR110

YP625TD18TP110

YP925TD0965

Null4:

Yield-Pro® Model 625, Pull-Type, Dry

Fertilizer, 18-Row (6 triplets), Triple-Row,

110 cm triplet row spacing

Yield-Pro® Model 625, 3-Point, Dry

Fertilizer, 12-Twin-Row (6 pair), 110 cm

pair-to-pair row spacing

Yield-Pro® Model 625, 3-Point, Dry

Fertilizer, 18-Row (6 triplets), Triple-Row,

110 cm triplet row spacing

Yield-Pro® Model 925, 3-Point, Dry

Fertilizer, 9-Row, 65 cm row spacing

Document Family

401-754M YP625PD Operator Manual

401-755M YP625TD/925TD Operator Manual

401-754B Seed Rate Manual (this document)

401-754P YP625PD Parts Manual

401-755P YP625TD/925TD Parts Manual

11001-1372 DICKEY-john® PM400 manual

MetaData: End of Introduction.

09/29/2011 Table of Contents 401-754B

2 YP625PD/TD, YP925TD Table of Contents Great Plains Manufacturing, Inc.

401-754B Table of Contents 09/29/2011

Great Plains Manufacturing, Inc. Table of Contents Planting Rate Overview 3

Planting Rate Overview

The information in this section covers important setup

and checking information that applies to the Air-Pro

®

meter in singulated planting.

Singulated Rate Setting Summary

1. For your crop, determine your intended population, in

seeds/hectare. If you know only the seed spacing or

population in kg/ha, consult the conversion formula

below.

2. For your crop, population and desired field speed,

select the correct seed disk:

“Air-Pro® Meter Disk Selection” on page 4

3. Set meter rate (page 11).

4. For staggered twin row, time row pairs using:

“Sprocket Indexing (Stagger)” on page 24

5. Set initial seed inlet shutter per seed rate chart.

6. Set initial meter pressurization per page 6, 7.

7. Verify your planting rate per the instructions at:

“Checking Planting Rate” on page 8. If the results

are consistent with your setup, plant the crop.

Population Reference Information

Seeds per Unit

If only population weight (kilograms/hectare) is known,

obtain the population count by multiplying the population

weight by the “Kernels per kg” value from the seed

container.

Null4:

Figure 2

Air-Pro® Seed Meter

Example: Corn

Target rate: 21.3 kg/ha

Seed density: 3500 seeds/kg

Population: = Rate x Density

= 21.3 x 3500, or:

74550 seeds/ha

29626

Seed Spacing

If only seed spacing is known, use the seed rate chart

(pages 14 to 23) to determine population.

Null4:

MetaData: End of Population Reference Information

09/29/2011 Table of Contents 401-754B

4 YP625PD/TD, YP925TD Table of Contents Great Plains Manufacturing, Inc.

817-841C

Air-Pro® Meter Disk Selection

Recommended Seed Disks (1 of 2)

Page 1 of 2

Air-Pro® Meter Disk Selection

NONE Air Meter Blank Disk

These disks are used in (Off Row Meters) when changing from

Tri Row 110cm to Twin Row 110cm Rows.

CORN 24 Cell Disk 40 Cell Disk

817-794C Corn Round Large 817-796C Corn Round Large

817-795C Corn Round Small 817-797C Corn Round Small

817-836C Corn Flat Large 817-838C Corn Flat Large

( Sweet Corn plants in Round Corn disks )

Seed Size Recommendations.

Corn Round Large Seeds per Kilogram:

3750 (or fewer)

Corn Round Small Seeds per Kilogram:

3640 (or more)

Corn Flat Large Seeds per Kilogram:

3640 (or fewer)

Corn Flat Small Seeds per Kilogram:

3640 (or more)

ATTENTION: This Corn is planted with the Corn Round Small Disks!!!!!!

(Recommended)

Twin Row 110cm Below 88 735 seeds/ha @ 8.9kph 24 Cell Disk

Above 88 735 seeds/ha @ 8.9kph 40 Cell Disk

65cm Rows Below 75 080 seeds/ha @ 8.9kph 24 Cell Disk

Above 75 080 seeds/ha @ 8.9kph 40 Cell Disk

31847A

Null4:

401-754B Table of Contents 09/29/2011

Great Plains Manufacturing, Inc. Table of Contents Planting Rate Overview 5

817-849C 817-800C

817-798C 403-551D

Recommended Seed Disks (2 of 2)

Page 2 of 2

Air-Pro® Meter Disk Selection

MILO 65 Cell Disk 130 Cell Disk

Seed Size Recommendations.

These disks should plant all seed sizes of Milo.

(Recommended)

Twin Row 110cm Below 220 300 seeds/ha @ 9.7kph 65 Cell Disk

Above 220 300 seeds/ha @ 9.7kph 130 Cell Disk

65cm Rows Below 186 400 seeds/ha @ 9.7kph 65 Cell Disk

Above 186 400 seeds/ha @ 9.7kph 130 Cell Disk

SOYBEAN 84 Cell Disk 168 Cell Disk

Seed Size Recommendations.

These disks should plant all seed sizes of Soybeans.

Small edible beans (navy, black jack, black eye peas, etc) will plant with this disk also.

(Recommended)

Tri Row 110cm Below 526 700 seeds/ha @ 9.7kph 84 Cell Disk

Above 526 700 seeds/ha @ 9.7kph 168 Cell Disk

Twin Row 110cm Below 351 200 seeds/ha @ 9.7kph 84 Cell Disk

Above 351 200 seeds/ha @ 9.7kph 168 Cell Disk

65cm Rows Below 297 100 seeds/ha @ 9.7kph 84 Cell Disk

Above 297 100 seeds/ha @ 9.7kph 168 Cell Disk

31847B

Null4:

09/29/2011 Table of Contents 401-754B

6 YP625PD/TD, YP925TD Table of Contents Great Plains Manufacturing, Inc.

(y)

g

)

Meter Pressurization

Refer to the Operator Manual for the procedure for fine

tuning meter pressurization.

Start with pressures from below and on page 7, which

are based on crop, and for corn, seed shape and density.

Note: These are suggested initial (starting) pressures.

Adjust them up or down per the procedure in the

Operator Manual.

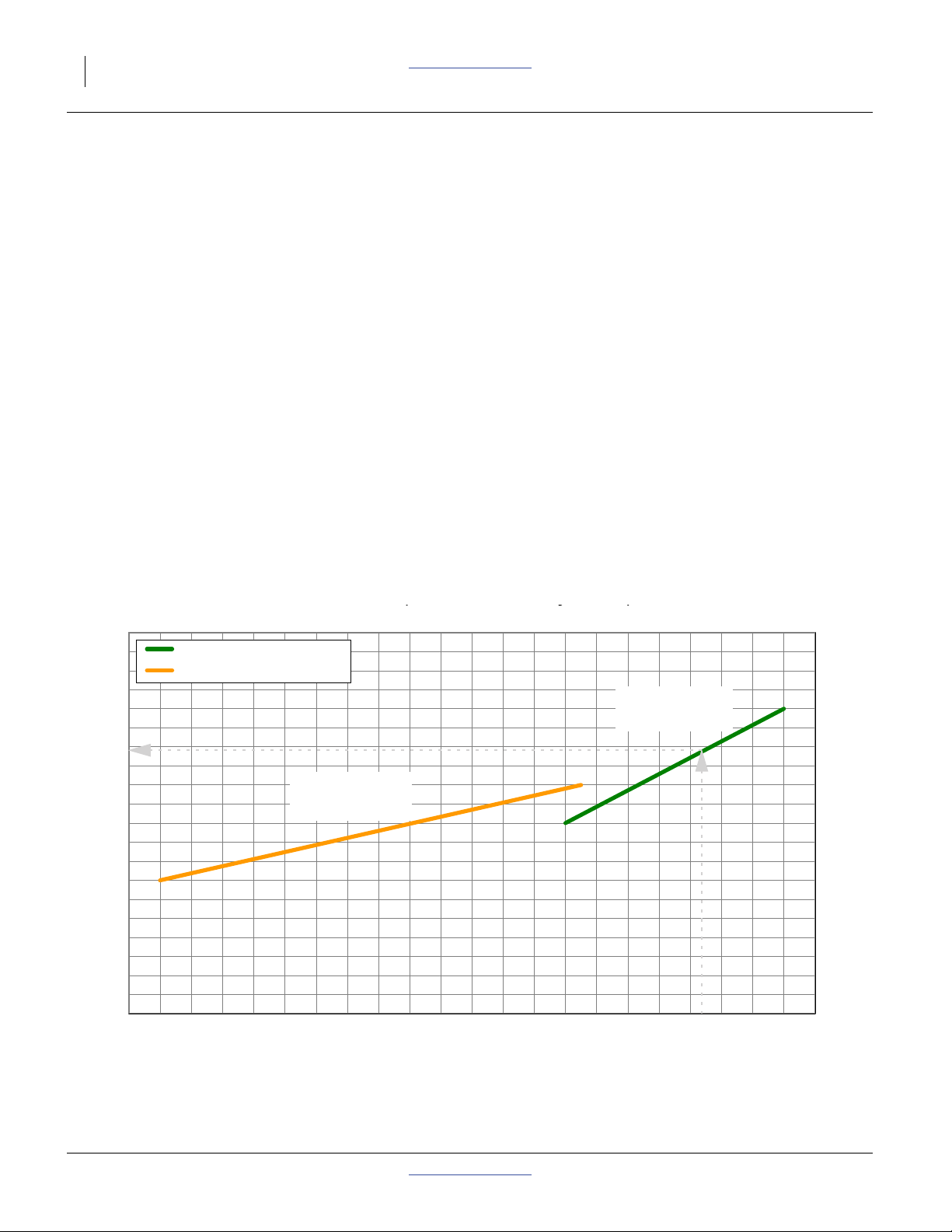

Corn: Reading a Pressure Chart (below, next page)

1. Pick the chart based on seed shape (flat, round).

Example: round corn

2. Pick a line based on seed size (large, small).

Example: large round corn, the right line below

3. Find the seed density on the bottom scale.

Example: 2800 seeds/kg

4. Read the suggested starting pressure on the left

scale, where the line (example shown as dotted

gray) intersects the density.

Example: 3.4 inches of water

Initial seed inlet Shutter for corn is: 3

Initial Meter Pressurization: Milo

1.5 inches of water (all disk, any seed density)

Initial seed inlet Shutter: 1

Initial Meter Pressurization: Soybeans

2.0 inches of water (84 cell disk, any seed density)

3.0 inches of water (168 cell disk, any seed density)

Initial seed inlet Shutter: 2

Initial Meter Pressurization: Round Corn

5

Linear (Round Corn Large)

4.5

4

3.5

3

2.5

2

Meter Pressure (in/water)

1.5

1

Null4:

Meter Pressurization in inches of Water

0.5

0

3100

6800 6400 6000 5500 5100 4600 4200 3700 3300 2900 2400 2000

25.8

Linear (Round Corn Small)

Example

817-795C & 817-797C

Round Corn-Small

27002900

29.627.6

Disks

31441 Seeds Per Kilogram 29725

Pressure/Seed Comparison

23002500

2100

Seeds Per Pound

Unit Wei

ht (80K

Disks

817-794C & 817-796C

Round Corn-Large

Example

150017001900

53.347.142.138.134.832.0

11001300

72.761.5

Overlay for

900

88.9

5

4.5

4

3.5

3

2.5

2

1.5

1

0.5

0

Meter Pressurization in inches of Water

Meter Pressure (in/water)

Null4:

401-754B Table of Contents 09/29/2011

Great Plains Manufacturing, Inc. Table of Contents Planting Rate Overview 7

(y)

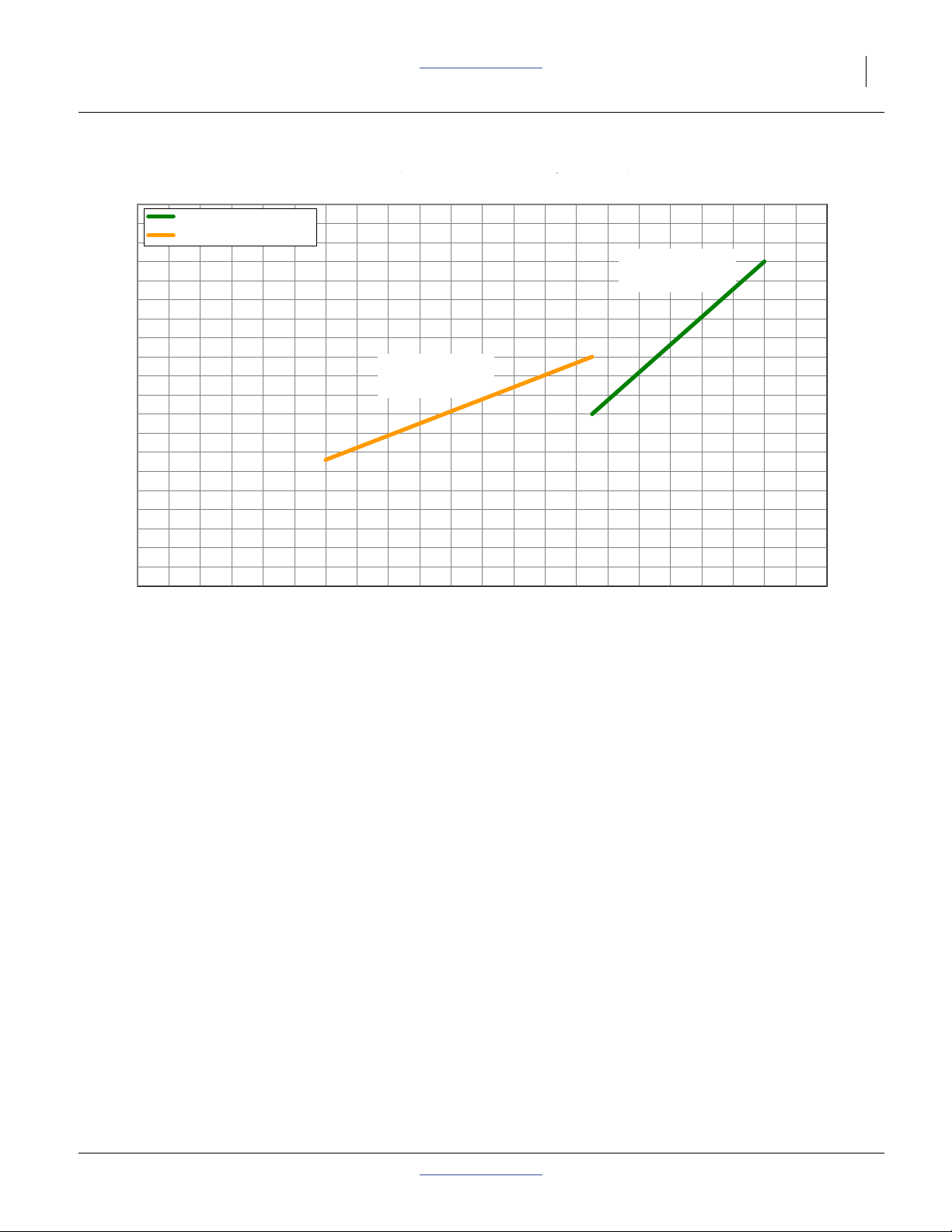

Initial Meter Pressurization: Flat Corn

Pressure/Seed Comparison

4.5

3.5

5

Linear (Flat Corn Large)

Linear (Flat Corn Small)

Disks

4

817-836C & 817-838C

Flat Corn-Large

5

4.5

4

3.5

Meter Pressurization in inches of Water

Meter Pressure (in/water)

Null4:

3

2.5

Disks

817-795C & 817-797C

Flat Corn-Small

2

Meter Pressure (in/water)

1.5

1

Null4:

Meter Pressurization in inches of Water

0.5

0

3100

6800 6400 6000 5500 5100 4600 4200 3700 3300 2900 2400 2000

2900

31441 Seeds Per Kilogram 29725

230025002700

2100

38.134.832.029.627.625.8

42.1

Seeds Per Pound

Unit Weight (80K)

47.1

53.3

61.5

Overlay for

3

2.5

2

1.5

1

0.5

0

90011001300150017001900

88.972.7

29726

MetaData: End of Meter Pressurization

09/29/2011 Table of Contents 401-754B

8 YP625PD/TD, YP925TD Table of Contents Great Plains Manufacturing, Inc.

Checking Planting Rate

Singulated seed charts are based on cleaned and sized

seed singulated with the recommended disk. Extreme

seed size variations, foreign material and tire pressure

can affect the planting rate.

Any material difference between chart and field rates

implies a mechanical malfunction, a planter setup error,

unsuitable planting conditions (such as excessive tire

slippage) or extremely worn planter components. You

can verify your setup and planter performance by

measuring seed placement and spacing over a relatively

short distance.

Null4:

The columns to the right provide example data for a rate

check.

Null4:

Figure 3

Furrow Check

Planter: YP625TD-12TR-110

Crop: Corn

Density: 3500 seeds/kg

Seed Disk: 817-797C, 40 cell

Target Population:

80 000 seeds/hectare

Range Sprockets:

DRIVING: 20T

DRIVEN: 30T

Transmission Sprockets:

DRIVING: 23T

DRIVEN: 19T

Maximum Planting Speed:

10.5 kph

Chart Seed Spacing:

22.6 cm

29247

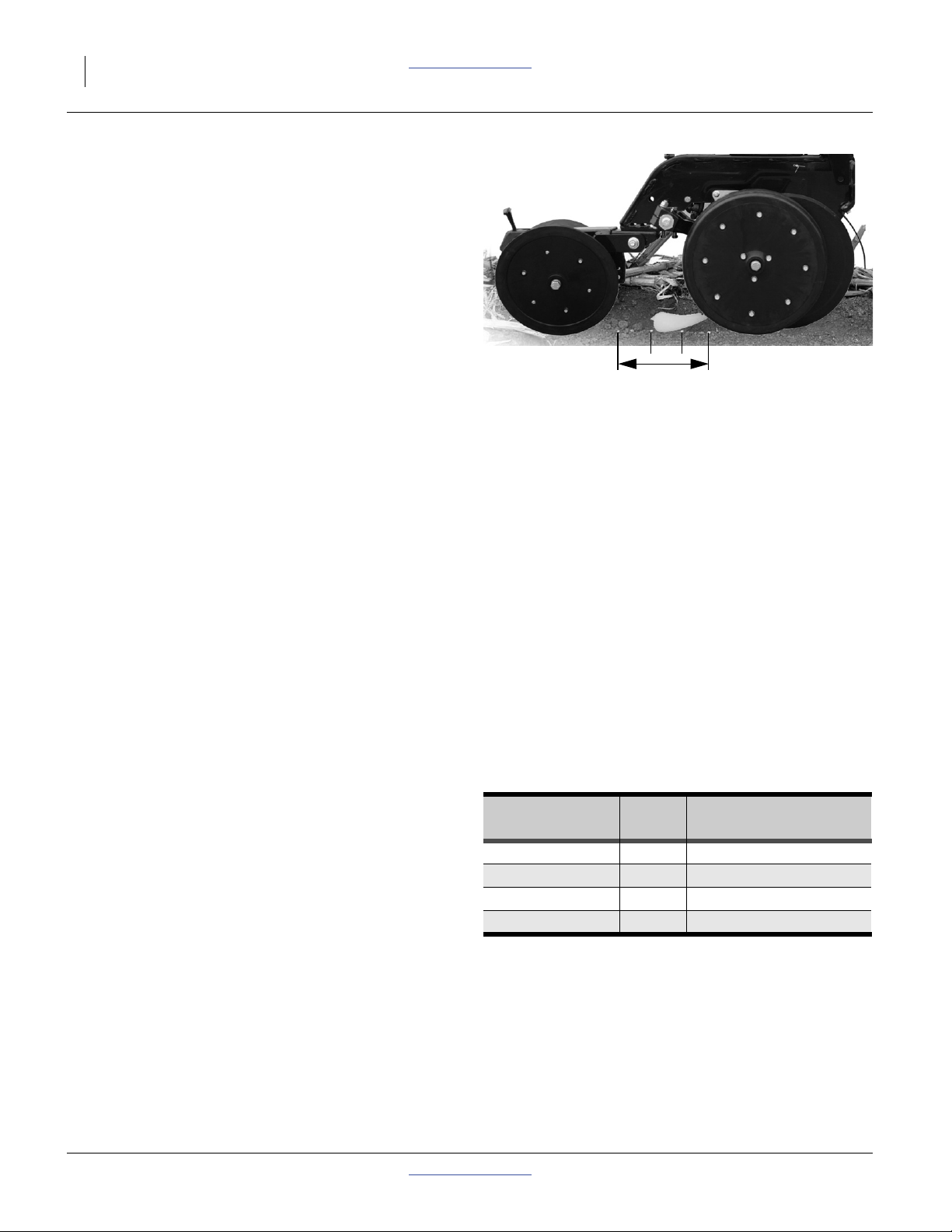

Checking Singulated Rates

1. Determine the sample distance to check. Find your

row spacing in the table at right.

2. Note the number of rows to sample. Adjust the

planting depth to a shallow setting on one or two

outside rows (per table). Tie up the press wheel

arms with wire or bungee to prevent furrow closure.

3. Configure the planter for the chart rate, using the

chart settings for sprockets.

401-754B Table of Contents 09/29/2011

Rows to Sample Row Length of Sample Run

Row Spacing* Count 1/1000th Hectare

65cm Single 2 7.69 m

110cm Single 1 9.09 m

110cm Twin 1 pair 9.09 m

110cm Triple 1 triplet 9.09 m

* Not all spacings may be offered on implements

covered by this manual.

31805

Great Plains Manufacturing, Inc. Table of Contents Planting Rate Overview 9

4. Plant at the desired planting speed for slightly more

than the computed sample run length.

5. Measure off the sample distance, balanced in

between where seeding started and stopped.

6. Count the number of seeds over the distance

measured. Also note the consistency of the seed

spacing.

7. Compute the rate for a full hectare.

For a 1/1000th sample, multiply the counted seeds

by 1000.

8. If the field and chart rates vary by more than a few

percent, re-check planter setup, including meter disk

or cell count, air system, tire size, tire pressures,

sprocket setup, chain slack, etc. If seed spacing is

irregular, this suggests a seed delivery problem, and

not a rate setup problem.

9. While planting, pay attention to the seed monitor. In

addition to confirming the single-row furrow check, it

will also provide field rate data on all the other rows,

and alert you to any irregularities or stoppages.

Sample size:

1/1000th ha

Plant for approximately:

10 meters

Measure the central:

4.55 meters

Seeds counted:

a

79

Computed for full hectare:

79 x 1000 = 79,000

This differs from chart by:

2%

a If the sample size is less than 100 seeds, you may want

to double or triple the number of rows sampled, so as to

increase the precision of the count.

MetaData: End of Planting Rate Overview.

09/29/2011 Table of Contents 401-754B

10 YP625PD/TD, YP925TD Table of Contents Great Plains Manufacturing, Inc.

Planting Rate

Setting the seeding rate requires the following steps:

1. monitor setup

2. seed disk selection,

3. drive speed Range sprockets,

4. Transmission sprockets,

5. inlet shutters

6. meter pressurization,

7. checking seeding rate.

All rate adjustments are performed at the left end of the

planter. There are no adjustments at the ground drive

assembly. Changes in seed rate do not affect fertilizer

rate.

1. Rate: Monitor configuration:

The seed monitor must be set up with the

• correct row count,

• correct row spacing,

• speed calibration and;

• expected population limits, in order to have accurate

rate reports and useful alarms.

See the DICKEY-john® Planter Monitor operator (PM)

manual.

If you only plant with the factory configuration of the

planter, you never need to update row count and

spacing. If any rows are unused, adjust the monitor

setup.

Speed calibration must be done prior to first use, and

re-calibration is recommended periodically, particularly if

soil conditions change.

Null4:

Figure 4

Monitor Setup Screen

31809

2. Rate: Disk Selection:

Select seed disks per page 4 and page 5. See Operator

manual for installation. Disks are specific to crops. Some

crops have multiple disks available, to cover both seed

varieties, and different populations within disk rpm limits.

Disks have a high and low rpm limit, which also

corresponds to a high and low field speed limit. The

charts account for these limits.

See “Air-Pro® Meter Disk Installation” in the Operator

manual.

If any rows are unused, install special blank disks. See

“Row Unit Shut-Off” in Operator manual.

401-754B Table of Contents 09/29/2011

Null4:

Figure 5

Air-Pro® Seed Disks

29594

Great Plains Manufacturing, Inc. Table of Contents Planting Rate 11

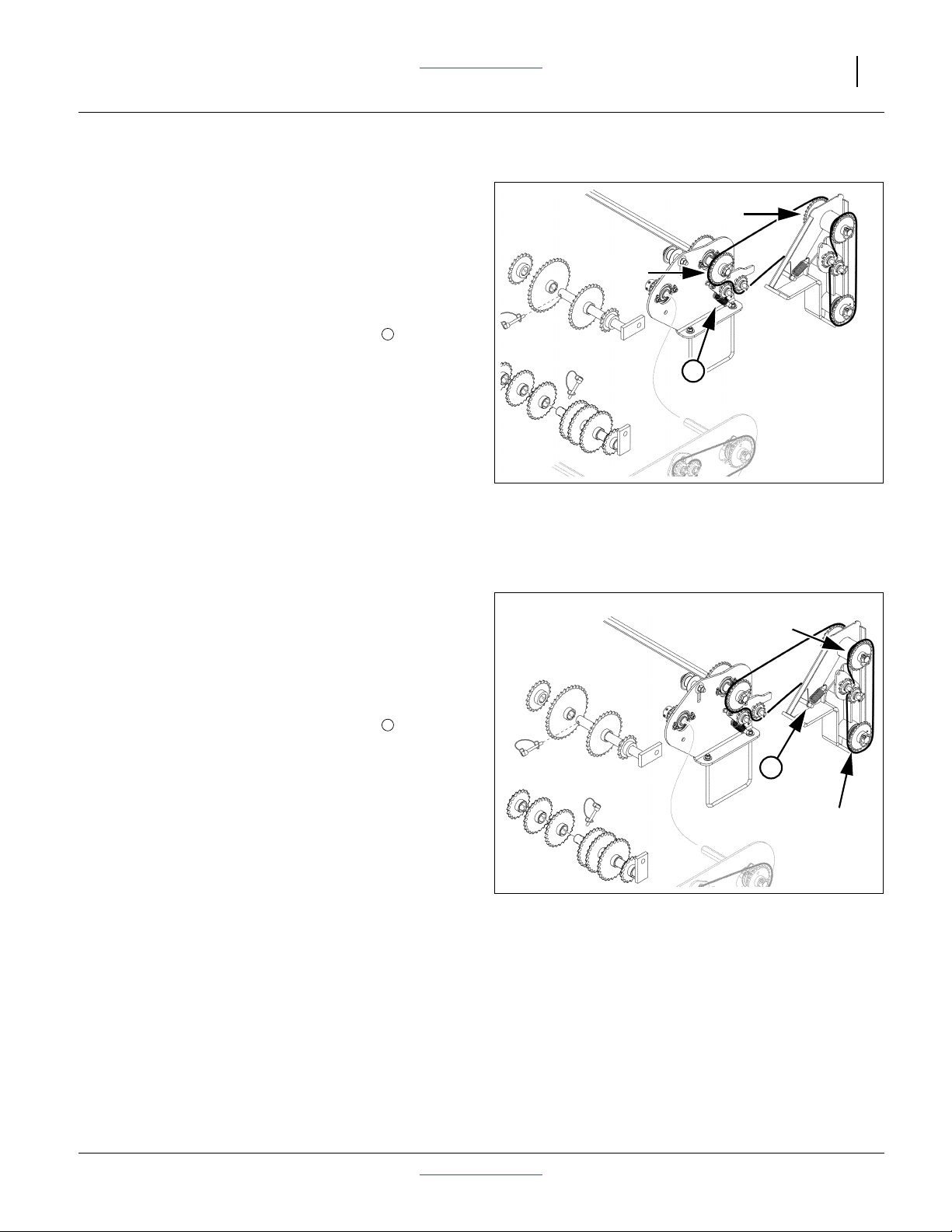

3. Rate: Range Sprockets

Range sprockets provide coarse control of seed rate.

Refer to Figure 6 and Figure 7

All Seed Rate charts specify a DRIVING and DRIVEN

sprocket combination for the Range. Crops with more

than one range are noted as “LOW RANGE” or

“HIGH RANGE” at the top of the chart.

To change Range:

a. Rotate the idler plate against the spring to

3

disengage the idler.

Remove the chain.

b. Remove pins from shaft ends at DRIVING and

DRIVEN sprockets, as well as at storage shaft.

c. Exchange sprockets so that new DRIVING and

DRIVEN sprocket tooth counts (stamped on sprocket

face) match chart. Re-pin all shafts.

d. Remount chain. Re-engage idler spring.

Null4:

Null4:

DRIVING

Null4:

Null4:

DRIVEN

3

Figure 6

Range Sprockets

31870

4. Rate: Transmission Sprockets

Transmission sprockets provide fine control of seed rate.

Each chart row provides a rate adjustment of 2 to 3%.

Refer to Figure 7

Each Seed Rate chart row has a unique pairing of

DRIVING and DRIVEN Transmission sprocket.

To change Transmission:

a. Rotate the idler plate against the spring to

disengage the idler.

Remove the chain.

b. Remove pins from shaft ends at DRIVING and

DRIVEN sprockets, as well as at storage shaft.

c. Exchange sprockets so that new DRIVING and

DRIVEN sprocket tooth counts (stamped on sprocket

face) match chart. Re-pin all shafts.

d. Remount chain. Re-engage idler spring.

4

Null4:

Null4:

DRIVING

Figure 7

Transmission Sprockets

4

Null4:

DRIVEN

31870

09/29/2011 Table of Contents 401-754B

Loading...

Loading...