Page 1

Table of Contents Index

Feature Supplement Manual

YP2425F-2470, YP4025F-1630 and YP4025F-1670

YP2425F and YP4025F Dry Fertilizer/Seeder

Manufacturing, Inc.

www.greatplainsmfg.com

Read the operator manual entirely. When you see this symbol, the

subsequent instructions and warnings are serious - follow without

exception. Your life and the lives of others depend on it!

31088

Illustrations may show optional equipment not supplied with standard unit or may

depict similar models where a topic is identical.

ORIGINAL INSTRUCTIONS

© Copyright 2013 Printed 2013-03-25 403-362M

Table of Contents Index

EN

Page 2

Table of Contents Index

Table of Contents Index

Page 3

Great Plains Manufacturing, Inc. Cover Index iii

Table of Contents

Important Safety Information ......................................1

Safety Decals .................................................................4

Introduction ..................................................................6

Description of Unit ..........................................................6

Intended Usage ..........................................................6

Models Covered .............................................................6

Document Family........................................................7

Using This Manual..........................................................7

Definitions................................................................... 7

Preparation and Setup .................................................8

Initial Setup.....................................................................8

Post-Delivery/Seasonal Setup........................................8

Hitching and Leveling .....................................................8

Operating Instructions.................................................9

Pre-Start Checklist .........................................................9

Planter Folding and Raising ...........................................9

Transport ......................................................................10

Typical YP2425F Weights ........................................ 10

Typical YP4025F Weights ........................................ 10

Loading Materials .........................................................11

Loading Seed ...........................................................11

Loading Fertilizer......................................................12

Changing Seed Box or Hopper ....................................13

Air Systems Operation .................................................14

Seeding System Overview .......................................15

Fertilizer System Overview....................................... 17

Fan Circuit Operation ...........................................18

Fan General Operating Information......................19

Butterfly Valves.....................................................19

Butterfly Valve Operation:.....................................19

Symptoms of Insufficient Air Flow ........................19

Symptoms of Excessive Air Flow .........................19

Monitor Operation.........................................................20

Marker Operation .........................................................20

Field Set-Up Checklists ................................................21

Field Operation.............................................................21

Short-Term Parking ......................................................21

Long-Term Storage ......................................................21

Adjustments................................................................22

Setting Material Rates ..................................................23

Setting Seed Rate ....................................................23

Setting Dry Fertilizer Rate ........................................23

Seed Meter Final Drive Range ................................. 23

Setting Variable Rate Gearbox ................................ 24

Meter Calibration......................................................25

Revolutions for Sample Size ................................ 25

Calibration Procedure .......................................... 25

Initial Calibration Steps ........................................ 25

Row Sample Calibration....................................... 26

Meter Sample Calibration..................................... 27

Calibration Adjustment ............................................. 28

Calibration: Rate Calculation................................ 28

Calibration: Gearbox Adjustment .........................28

Coulter Adjustment ...................................................... 29

Coulter Height Adjustment ....................................... 29

Coulter Applicator Adjustment.................................. 29

Frame-Mounted Coulter Force................................. 30

Troubleshooting......................................................... 31

Maintenance ............................................................... 34

Maintenance ................................................................ 34

No-Change Maintenance Items ................................... 34

Material Clean-Out....................................................... 35

Seeding System Clean-Out...................................... 35

Fertilizer System Clean-Out ..................................... 35

Meter Flute Replacement......................................... 36

Problem Fertilizer Clean-Outs.................................. 36

Removing Meter Box............................................ 37

Hopper Entry ............................................................ 37

Chain Maintenance ...................................................... 39

Fertilizer Meter Drive Chain ..................................... 39

Maintenance Schedule ................................................ 40

Seed Lubricants ....................................................... 45

Options ....................................................................... 46

Compatible Options ..................................................... 46

Options Not Recommended......................................... 46

Incompatible Options ................................................... 46

Appendix A - Reference Information........................ 47

Specifications and Capacities YP4025F ...................... 47

Tire Inflation Chart ....................................................... 47

Specifications and Capacities YP2425F ...................... 48

Torque Values Chart.................................................... 49

Hydraulic Diagrams...................................................... 49

Chain Routing YP2425F .............................................. 50

Chain Routing YP4025F .............................................. 51

Appendix B - Monitor Setup...................................... 53

Seed Monitor Console Setup ....................................... 53

Pre-Programming Preparation: ................................ 53

© Copyright 2012, 2013 All rights Reserved

Great Plains Manufacturing, Inc. provides this publication “as is” without warranty of any kind, either expressed or implied. While every precaution has been

taken in the preparation of this manual, Great Plains Manufacturing, Inc. assumes no responsibility for errors or omissions. Neither is any liability assumed for

damages resulting from the use of the information contained herein. Great Plains Manufacturing, Inc. reserves the right to revise and improve its products as

it sees fit. This publication describes the state of this product at the time of its publication, and may not reflect the product in the future.

2013-03-25 Cover Index 403-362M

Trademarks of Great Plains Manufacturing, Inc. include: Singulator Plus, Swath Command, Terra-Tine.

Registered Trademarks of Great Plains Manufacturing, Inc. include:

Air-Pro, Clear-Shot, Discovator, Great Plains, Land Pride, MeterCone, Nutri-Pro, Seed-Lok, Solid Stand,

Terra-Guard, Turbo-Chisel, Turbo-Chopper, Turbo Max, Turbo-Till, Ultra-Till, Ver ti-Till, Whirlfilter, Yield-Pro.

Brand and Product Names that appear and are owned by others are trademarks of their respective owners.

Printed in the United States of America

Page 4

iv YP2425F/YP4025F Table of Contents Index Great Plains Manufacturing, Inc.

Change User Level to Dealer Level ......................... 53

Auto Configuration ................................................... 54

To Run Auto Config:............................................. 54

Row Status/Row Width Setup.................................. 54

Material Configuration Setup

(Controlled Hydraulic Drive) ............................. 55

Planter Control Channel Setup ................................ 56

Valve Calibration...................................................... 57

Row Monitor Setup .................................................. 57

Speed Set Calibration Setup.................................... 58

Accessory Sensor Setup.......................................... 59

Hopper Assignment.............................................. 59

RPM Assignment ................................................. 59

Clutch Folding Module (CFM) Setup ........................60

Clutch Folding Module Operation .............................60

5 Revolution Test......................................................60

Summary Screen ......................................................61

Appendix C - Fertilizer Rate Charts ..........................62

Reading the Fertilizer Rate Chart .................................62

Fertilizer Rates .............................................................63

Fertilizer Rates, 70cm Row Spacing.........................64

Fertilizer Rates, 30 inch Row Spacing......................65

Density Adjustment.......................................................66

Index ............................................................................67

403-362M Table of Contents Index 2013-03-25

Page 5

Great Plains Manufacturing, Inc. Table of Contents Index 1

Important Safety Information

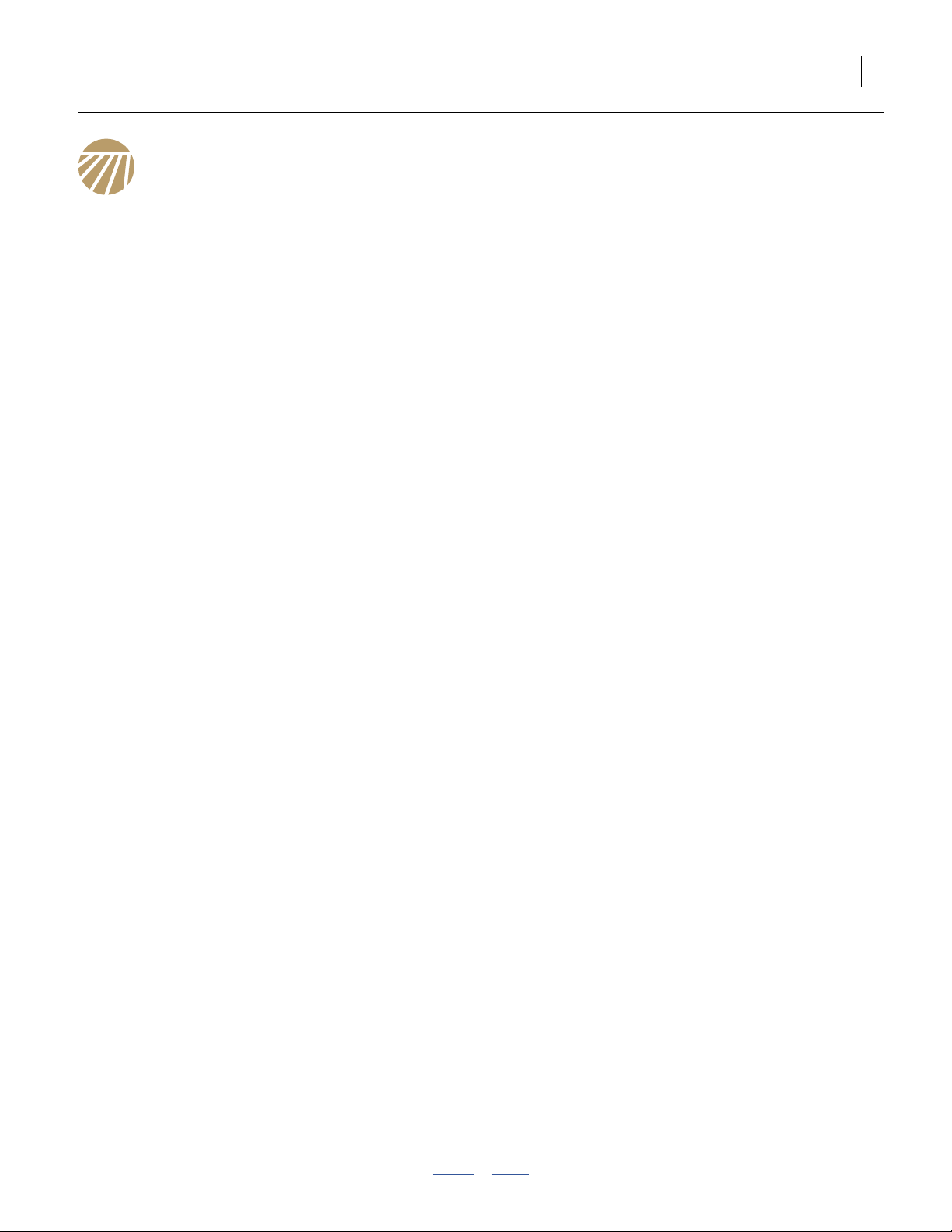

Look for Safety Symbol

The SAFETY ALERT SYMBOL indicates there is a

potential hazard to personal safety involved and extra

safety precaution must be taken. When you see this

symbol, be alert and carefully read the message that

follows it. In addition to design and configuration of

equipment, hazard control and accident prevention are

dependent upon the awareness, concern, prudence and

proper training of personnel involved in the operation,

transport, maintenance and storage of equipment.

Be Aware of Signal Words

Signal words designate a degree or level of hazard

seriousness.

DANGER indicates an imminently hazardous situation

which, if not avoided, will result in death or serious injury.

This signal word is limited to the most extreme situations,

typically for machine components that, for functional

purposes, cannot be guarded.

WARNING indicates a potentially hazardous situation

which, if not avoided, could result in death or serious

injury, and includes hazards that are exposed when

guards are removed. It may also be used to alert against

unsafe practices.

CAUTION indicates a potentially hazardous situation

which, if not avoided, may result in minor or moderate

injury. It may also be used to alert against unsafe

practices.

Prepare for Emergencies

▲ Be prepared if a fire starts.

▲ Keep a first aid kit and fire extinguisher handy.

▲ Keep emergency numbers for doctor, ambulance, hospital

and fire department near phone.

Be Familiar with Safety Decals

▲ Read and understand “Safety Decals” on page 4,

thoroughly.

▲ Read all instructions noted on the decals.

▲ Keep decals clean. Replace damaged, faded and illegible

decals.

2013-03-25 Table of Contents Index 403-362M

Page 6

2 YP2425F/YP4025F Table of Contents Index Great Plains Manufacturing, Inc.

Wear Protective Equipment

Great Plains advises use of the following personal safety

equipment.

▲ Hearing protection, such as earmuffs or earplugs, for

making planter adjustments with the hydraulic fan

running.Prolonged exposure to loud noise can cause

hearing impairment or loss.

Avoid wearing entertainment headphones while operating

machinery. Operating equipment safely requires the full

attention of the operator.

▲ Face shield, goggles or full face respirator when handling

treated seed, seed lubricants or seed treatment.

▲ Gloves for working near sharp objects, and for handing

lubricants or treatments.

Handle Chemicals Properly

Agricultural chemicals can be dangerous. Improper use

can seriously injure persons, animals, plants, soil and

property.

▲ Read and follow chemical supplier instructions.

▲ Wear protective clothing.

▲ Handle all chemicals with care.

▲ Agricultural chemicals can be dangerous. Improper use can

seriously injure persons, animals, plants, soil and property.

▲ Inhaling smoke from any type of chemical fire is a serious

health hazard.

▲ Store or dispose of unused chemicals as specified by the

chemical manufacturer.

▲ If chemical is swallowed, carefully follow the chemical

manufacturer’s recommendations and consult with a doctor.

▲ If persons are exposed to a chemical in a way that could

affect their health, consult a doctor immediately with the

chemical label or container in hand. Any delay could cause

serious illness or death.

▲ Dispose of empty chemical containers properly. By law

rinsing of the used chemical container must be repeated

three times. Puncture the container to prevent future use. An

alternative is to jet-rinse or pressure rinse the container.

▲ Wash hands and face before eating after working with

chemicals. Shower as soon as application is completed for

the day.

▲ Apply only with acceptable wind conditions. Wind speed

must be below 8 kph (5 mph). Make sure wind drift of

chemicals will not affect any surrounding land, people or

animals.

▲ Never wash out a hopper within 30m (100 feet) of any

freshwater source or in a car wash.

403-362M Table of Contents Index 2013-03-25

Page 7

Great Plains Manufacturing, Inc. Table of Contents Index Important Safety Information 3

Confined Space

With materials loaded, or once used for hazardous

fertilizers, or seeds with hazardous treatments, your

fertilizer hopper may become a

“permit-required confined space”

under applicable statutes, regulations, insurance rules or

business policy. The vent tube structure in the hopper

has features to assist escape, and is not for routine entry.

▲ A hopper that is full or merely appears full can be an

entrapment hazard. You can sink entirely into the material,

or into an oxygen-deficient void, and suffocate in a matter of

seconds. Fertilizer bridges and crusts are especially

dangerous.

▲ When hazardous fumes are present, you can be quickly

overcome even with the hopper lid open.

▲ Do not enter a hopper for material loading, material

unloading, hopper cleaning or meter maintenance.

▲ Clean hopper by power washing from outside hopper top.

▲ Perform meter maintenance by removing meter from bottom

of empty hopper.

▲ If obstruction removal or repair requires hopper entry, have

the work performed by a team trained in confined space

procedures. See “Hopper Entry” on page 37.

Practice Safe Maintenance

▲ Understand procedure before doing work. Use proper

tools and equipment. Refer to this manual for additional

information.

▲ Work in a clean, dry area.

▲ Lower the planter, put tractor in park, turn off engine, and

remove key before performing maintenance.

▲ Make sure all moving parts have stopped and all system

pressure is relieved.

▲ Allow planter to cool completely.

▲ Disconnect battery ground cable (-) before servicing or

adjusting electrical systems or before welding on planter.

▲ Inspect all parts. Make sure parts are in good condition

and installed properly.

▲ Remove buildup of grease, oil or debris.

▲ Remove all tools and unused parts from planter before

operation.

2013-03-25 Table of Contents Index 403-362M

Page 8

4 YP2425F/YP4025F Table of Contents Index Great Plains Manufacturing, Inc.

Safety At All Times

Thoroughly read and understand the instructions in this

manual before operation. Read all instructions noted on

the safety decals.

▲ Be familiar with all planter functions.

▲ Operate machinery from the driver’s seat only.

▲ Do not leave planter unattended with tractor engine

running.

▲ Do not stand between the tractor and planter during

hitching.

▲ Keep hands, feet and clothing away from power-driven

parts.

▲ Wear snug-fitting clothing to avoid entanglement with

moving parts.

▲ Watch out for wires, trees, etc., when folding and raising

planter. Make sure all persons are clear of working area.

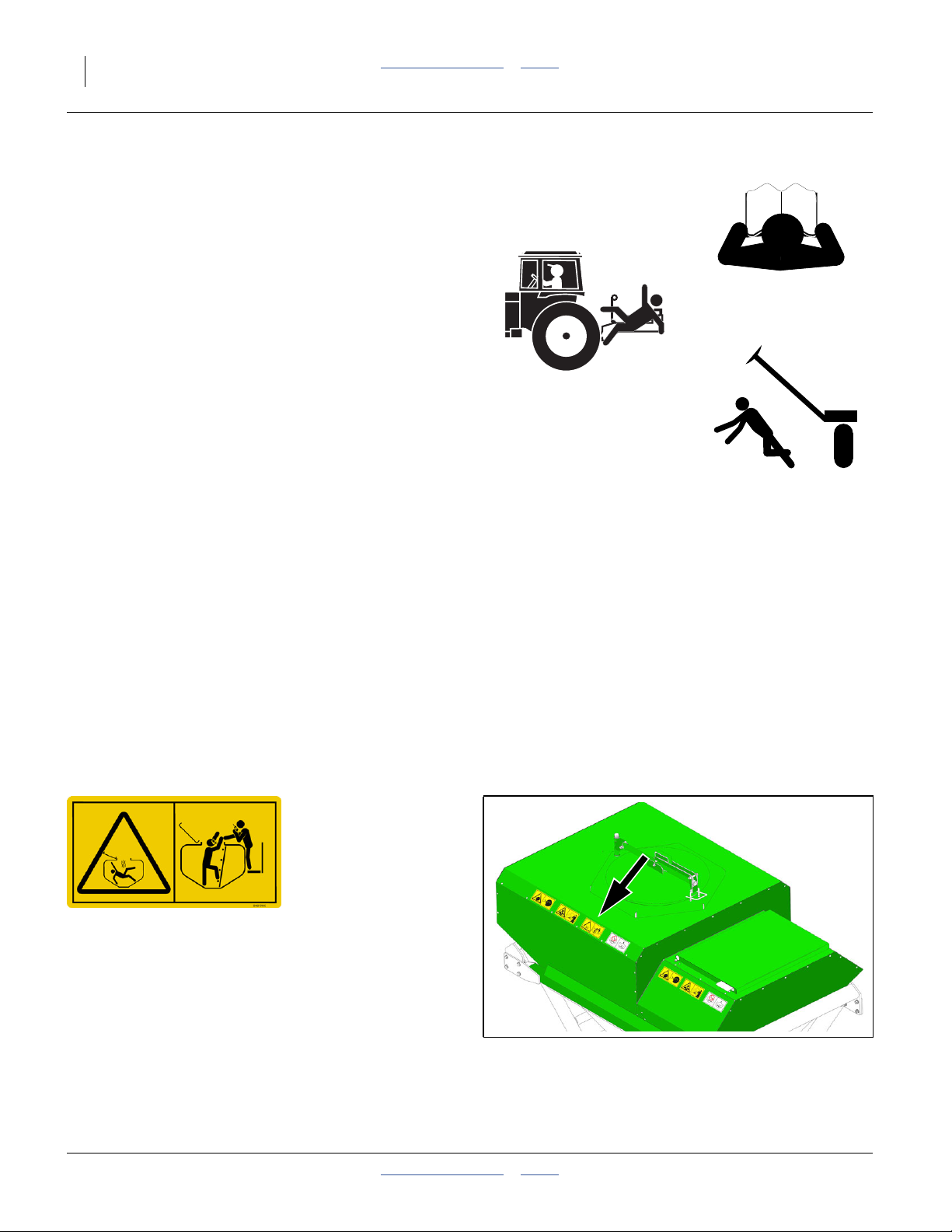

Safety Reflectors and Decals

Your YP2425F and YP4025F Dry Fertilizer/Seeder

comes equipped with decals in place. They were

designed to help you safely operate your implement.

▲ Read and follow decal directions.

▲ Keep all safety decals clean and legible.

▲ Replace all damaged or missing decals. Order new decals

from your Great Plains dealer. Refer to this section for

proper decal placement.

▲ When ordering new parts or components, also request

corresponding safety decals.

To install new decals:

848-519C

Warning: Confined Space Hazard

On upper left facet of fertilizer hopper;

1 total

See page 12 and page 35 through page 37 for further

information.

Safety Decals

1. Clean the area on which the decal is to be placed.

2. Peel backing from decal. Press firmly on surface,

being careful not to cause air bubbles under decal.

Note: This page describes only the option decals. See

your planter Operator manual for additional

decals.

31165

403-362M Table of Contents Index 2013-03-25

Page 9

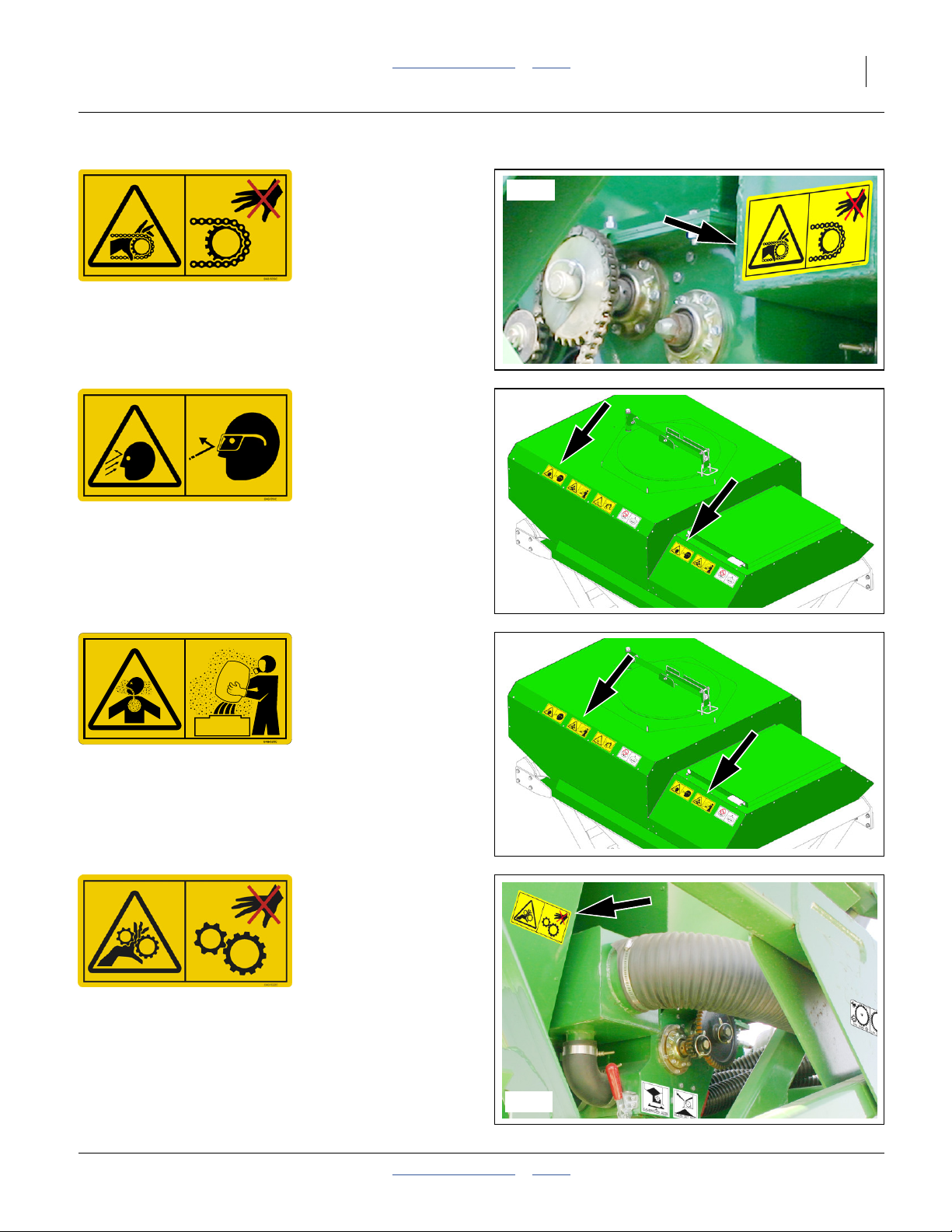

Great Plains Manufacturing, Inc. Table of Contents Index Important Safety Information 5

31165

848-509C Caution: Entanglement and Crushing

On left end of fertilizer air inlet manifold;

1 total

.eps

100%

848-510C Caution: Wear Eye Protection

On upper left facet of fertilizer and seed hoppers;

2 total

See page 11 for further information.

848-520C Caution: Possible Chemical Hazard

On upper left facet of fertilizer and seed hoppers;

2 total

See page 11 for further information.

31164

31165

848-522C Caution: Entanglement and Crushing

On right face of seed hopper near final range gears;

1 total

See page 23 for further information.

31166

2013-03-25 Table of Contents Index 403-362M

Page 10

6 YP2425F/YP4025F Table of Contents Index Great Plains Manufacturing, Inc.

Introduction

This feature operator manual (403-362M) is a

supplement to your planter Operator manual (401-406M:

YP2425F) or (401-571M: YP4025F), and covers only the

additional information required to setup, operate and

maintain a YP24 or YP40 planter equipped with the dry

fertilizer/seeder.

Your planter relies on these material rate references:

Pages

62 to 66

Manual

401-406B

Manual

401-571B

Dry Fertilizer Rate

Only the fertilizer rates of this manual

(403-362M) apply to the YP2425F-2470,

YP4025F-1630 and YP4025F-1670. Use of

the granular system for seeding is not

recommended.

YP2425 Seed Rate

Only the seed rates of manual 401-406B

usually apply to the YP2425F-2470.

Fertilizer rates in manual 401-406B apply

only if the YP24F is also equipped for liquid

fertilizer application.

YP4025 Seed Rate

Only the seed rates of manual 401-571B

usually apply to the YP4025-1670F or

YP4025F-1630. Fertilizer rates in manual

401-571B apply only if the YP40F is also

equipped for liquid fertilizer application.

5

2

3

4

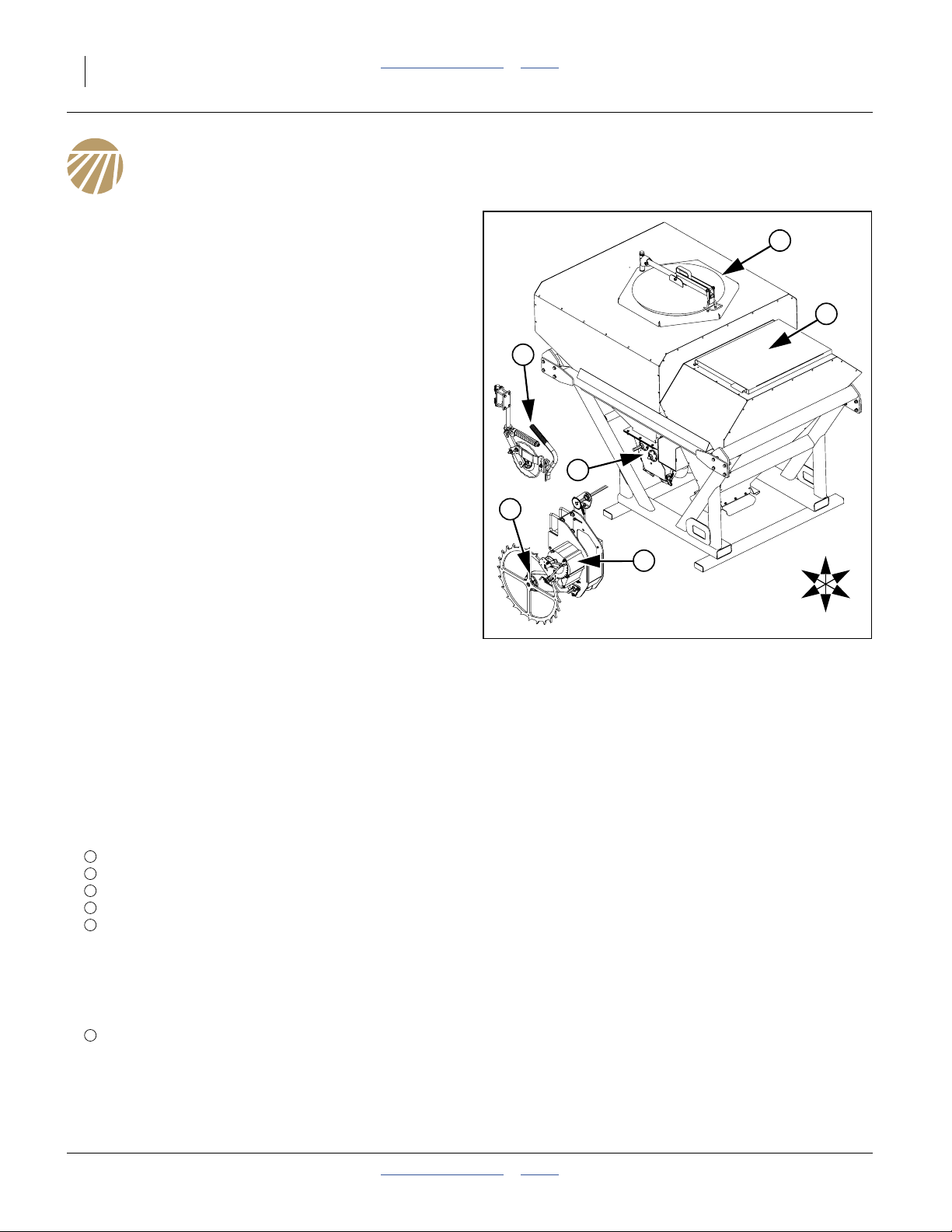

Figure 1

YP2425 and YP4025 DF Seeder

1

6

U

F

L

R

B

D

31088

Description of Unit

Refer to Figure 1

The YP2425F-2470, YP4025F-1630 and YP4025F-1670

Planter is a dry fertilizer/seeder version of the YP2425 or

YP4025. The standard seed-only hopper or bulk-box

capability is replaced by a dual-function hopper (one for

the YP4025F and two for the YP2425F).

• The dry fertilizer function includes:

a 1440 liter (41 bu) hopper compartment with

1

integrated volumetric meter;

2

ground drive;

3

gear box; and,

4

frame-mounted fertilizer zone counters.

5

Fertilizer is applied whenever the planter is lowered

and in forward motion. Rate is controlled by range

gears and a crank adjuster on the gearbox.

• The seeder function is a:

670 liter (19 bu) compartment

6

that delivers seed to the standard YP24/YP40 airbox

and row unit seed meters (not shown).

Seed rate is controlled by the standard DICKEY-john

IntelliAg® seed monitor and hydraulic meter drive.

Intended Usage

Use the YP2425F and YP4025F Dry Fertilizer/Seeder

only to apply dry granular fertilizer and/or plant seeds

compatible with Singulator Plus®or finger pickup meters.

Do not modify the planter for use with attachments other

than Great Plains options and accessories specified for

use with the YP2425F-2470, YP4025F-1630 and

YP4025F-1670.

Models Covered

This feature operator manual (403-362M) applies only to

these specific planter models equipped with the dry

fertilizer/seeder features:

YP2425F-2470 25-Series, Dry Fertilizer, 24-row, 70cm

YP4025F-1630 25-Series, Dry Fertilizer, 16-row, 30in

YP4025F-1670 25-Series, Dry Fertilizer, 16-row, 70cm

®

403-362M Table of Contents Index 2013-03-25

Page 11

Great Plains Manufacturing, Inc. Table of Contents Index Introduction 7

Document Family

403-362M Feature Supplement Manual (this manual)

YP2425F:

401-406M Planter Operator Manual

401-406P Planter Parts Manual

401-406B Planter Seed Rate manual

YP4025F:

401-571M Planter Operator Manual

401-571P Planter Parts Manual

401-571B Planter Seed Rate manual

DICKEY-john® manuals:

110011508 Seed Monitor Manual Level 1

110011501 Seed Monitor Manual Level 2 and 3

Using This Manual

This manual will familiarize you with

safety, assembly, operation,

adjustments, troubleshooting, and

maintenance. Read this manual and

follow the recommendations to help

ensure safe and efficient operation.

The information in this manual is current at printing.

Some parts may change to assure top performance.

Definitions

The following terms are used throughout this manual.

A crucial point of information related to the preceding topic.

Read and follow the directions to remain safe, avoid serious

damage to equipment and ensure desired field results.

Note: Useful information related to the preceding topic.

Right-hand and left-hand as used in

this manual are determined by facing

the direction the machine will travel

while in use unless otherwise stated.

An orientation rose in some line art

illustrations shows the directions of:

Up, Back, Left, Down, Front, Right.

R

F

U

B

L

D

2013-03-25 Table of Contents Index 403-362M

Page 12

8 YP2425F/YP4025F Table of Contents Index Great Plains Manufacturing, Inc.

Preparation and Setup

This section helps you prepare the dry fertilizer feature of

your YP2425F-2470, YP4025F-1630 and YP4025F-1670

planter for use, and covers tasks that need to be done

seasonally, or when the tractor/planter configuration

changes.

Before using the planter in the field, you must hitch it to a

suitable tractor, inspect systems and level the planter,

per the instructions in the 401-406M (YP2425) or

401-571M (YP4025) Operator manual. Before using the

planter for the first time, and periodically thereafter,

certain adjustments and calibrations are required. See

the Operator manual for these procedures.

Initial Setup

See the Operator manual, Appendix B, for pre-delivery

and first-time setup items for the basic planter.

First-time/infrequent setup tasks for the

YP24/YP40 DF/seeder feature include:

• Verify monitor setup (page 53 in this manual).

Post-Delivery/Seasonal Setup

On initial delivery, use with a new tractor, and seasonally,

check and as necessary, complete these items before

continuing to the routine setup items:

• Inspect fertilizer meter door seals for leaks or wear.

• Inspect fertilizer meter flutes for damage or wear.

Hitching and Leveling

The YP24/YP40 DF/seeder feature causes no changes

to the hitching procedures described in the planter

Operator manual.

403-362M Table of Contents Index 2013-03-25

Page 13

Great Plains Manufacturing, Inc. Table of Contents Index 9

Operating Instructions

This section covers general operating procedures.

Experience, machine familiarity, and the following

information will lead to efficient operation and good

working habits. Always operate farm machinery with

safety in mind.

Pre-Start Checklist

Perform the planter pre-start checklist, and the following

steps before transporting the YP24/YP40 DF/seeder

planter to the field. Add this item:

❑ Check for air system leaks at the fertilizer hopper lid,

meter, inlet and outlet manifolds.

Planter Folding and Raising

The YP24/YP40 DF/seeder feature does not affect

raising/lowering, folding/unfolding or tongue operations.

Material Loss Risk

The fertilizer ground drive operates whenever the planter is

lowered and in forward motion. If fertilizer application is not

desired (for example, during speed calibration or row unit

adjustment testing), take any of these steps to prevent fertilizer

metering:

▲ Tie ground drive wheel up out of ground contact.

▲ Remove a chain in the ground drive.

▲ Set meter gearbox adjuster to zero. Do this only on a

temporary basis, such as speed calibration.

▲ Defer loading of fertilizer until after speed calibration or

other non-application lowered movement.

2013-03-25 Table of Contents Index 403-362M

Page 14

10 YP2425F/YP4025F Table of Contents Index Great Plains Manufacturing, Inc.

Transport

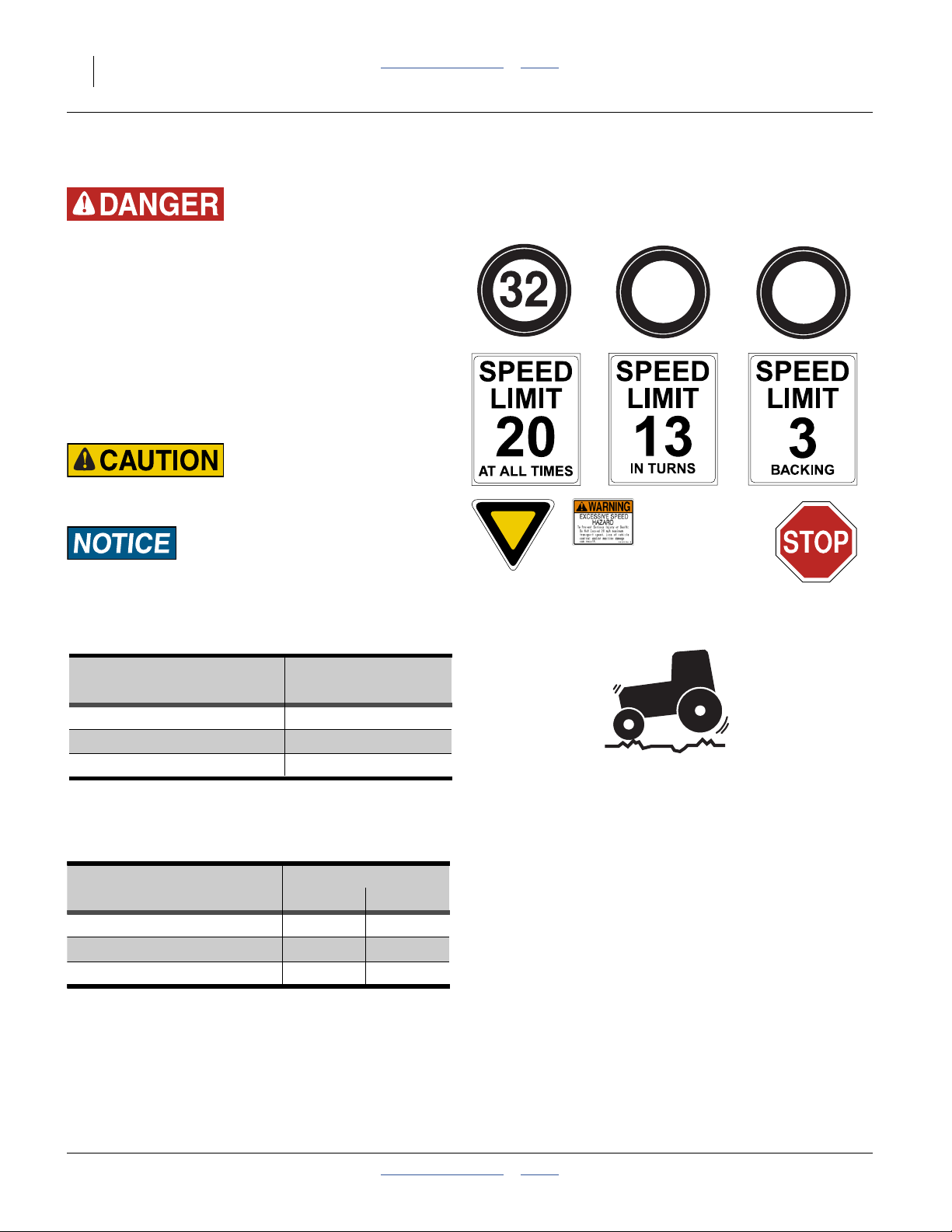

Loss of Control Hazard:

Ensure that the towing vehicle is adequate for the task. Using

an inadequate tow vehicle is extremely unsafe, and can result

in loss of control, serious injury and death.

21

The planter can weigh over 15 000 kg (33,500 pounds),

depending on configuration and material load. The tractor

unit MUST be rated for the load. If the tractor is not rated for

at least 15 000 kg, calculate or obtain a scale weight of the

planter.

Do not tow if planter exceeds the load rating of the vehicle.

Braking and Loss of Control Hazard:

Do not exceed 20 mph (32 kph).

5

Reduction of Control Risk:

Material loaded prior to travel increases stopping distance,

and increases the need for caution in turns and braking.

Typical YP2425F Weights

Configuration YP2425-2470

Standard¹ Model, Empty

Std. Model, Full Hoppers 13000 kg

Maximum² Configuration, Full

¹ Includes: Markers and Frame-Mounted Coulters

² Adds: Unit-Mounted Coulters & Dual Row Cleaners

9200 kg

13900 kg

Typical YP4025F Weights

YP4025F-

Configuration -1670 -1630

Standard¹ Model, Empty

Std. Model, Full Hoppers 14700 kg 32300 lbs

Maximum² Configuration, Full

¹ Includes: Markers and Frame-Mounted Coulters

² Adds: Unit-Mounted Coulters & Dual Row Cleaners

Other than considerations of planter weight, the

YP2425F-2470, YP4025F-1630 and YP4025F-1670

requires no changes to transport compared to the

standard YP24/YP40. See the 401-406M or 401-571M

Operator manual for transport instructions.

12800 kg 28200 lbs

15200 kg 33500 lbs

403-362M Table of Contents Index 2013-03-25

Page 15

Great Plains Manufacturing, Inc. Table of Contents Index Operating Instructions 11

Loading Materials

Seed and fertilizer may be loaded manually or via auger.

Walkboard/ladder details, and auger height requirements

are shown in the Operator manual. Before ascending the

ladder for loading or auger outlet control:

• Check that the walkboard is closed and latched.

Although the YP40F walkboard has a side extension,

the latching is identical to the standard walkboard.

• Swing down and latch the lower ladder section.

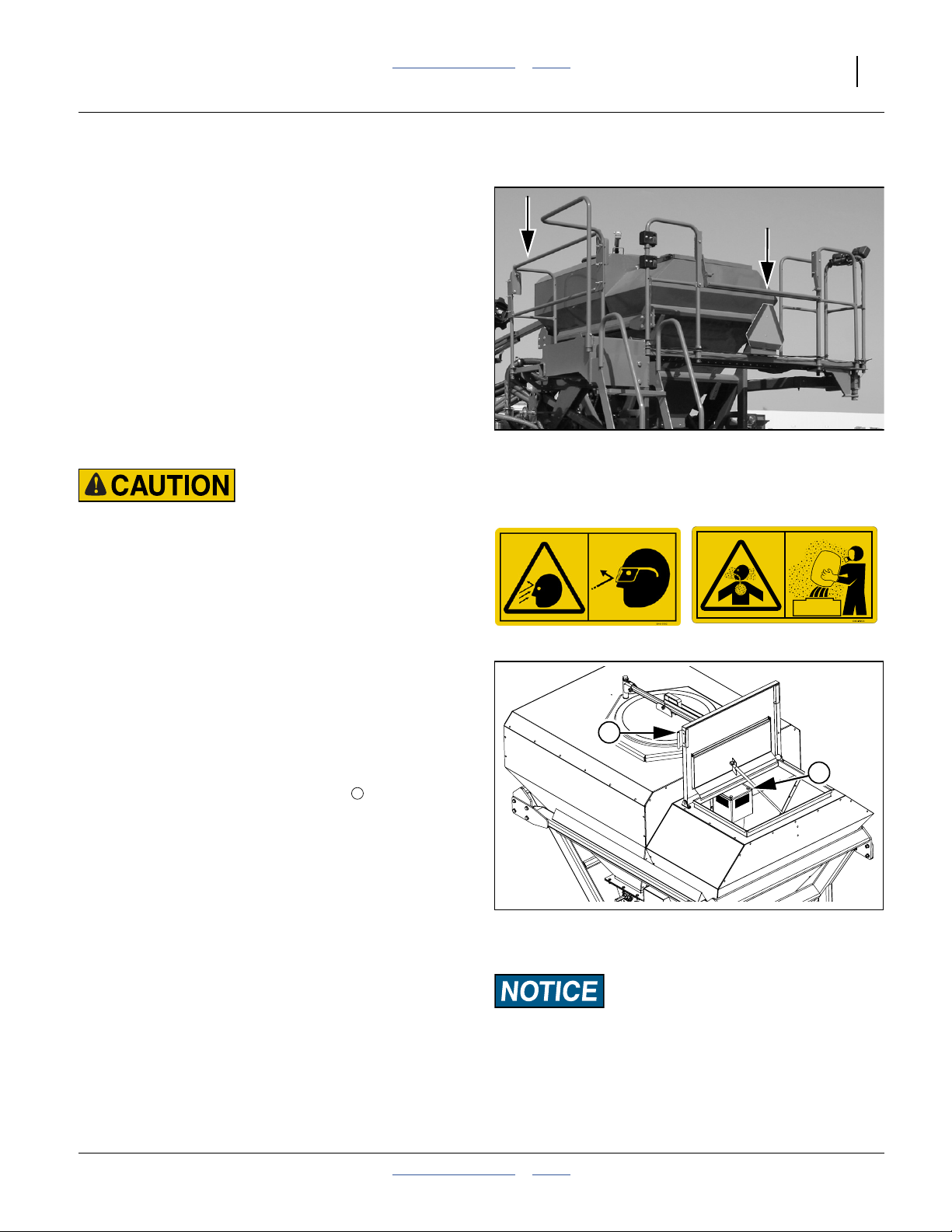

Refer to Figure 2

(depicting the side railing closed, and rear railing open)

If loading via auger, the side and rear top railings may be

swung down for clearance.

• Shut off hydraulic fan. Both hopper bins are

pressurized when the fan is running.

Figure 2

Walkboard Railings

31092

Blowing Debris and Possible Chemical Hazards:

Do not open hopper lids with fan running. Hopper contents

may blow into your face, possibly causing eye injury, and

exposing you to dust and possible chemical hazards.

Dust and Possible Chemical Hazards:

Seed may present a dust inhalation hazard. Treated seed may

present a chemical exposure hazard. Wear eye protection.

Wear a dust mask or respirator. Wear other protective

equipment specified by the seed and treatment suppliers.

Loading Seed

The seed hopper is the smaller rear hopper.

1. Close the slide gate at the base of the seed hopper.

Refer to Figure 3

2. To open the lid, lift up on the handle . The handle is

also a spring-loaded latch, and tilts up to release.

3. Inspect the hopper for leftover seed and debris.

Clean out anything other than the seed to be

planted. See “Material Clean-Out” on page 35

4. At first use, and seasonally, add seed lubricant to the

empty hopper, and then add a seed/lubricant mix to

the empty hopper per the Operator manual. Mix

lubricant with remaining seed per Operator manual.

5. See Caution at right. Load seed and seed lubricant

no higher than the top cap of the vent structure.

6. Close lid. Check that the latch snaps to horizontal

and is holding lid closed.

7. Swing up and latch railing if lowered for auger

operations.

1

1

Figure 3

Seed Hopper Lid

Sudden Lid Motion:

Open rear (seed) lid carefully. It is supported by a

spring-loaded piston, and may swing up rapidly.

2

31091

2013-03-25 Table of Contents Index 403-362M

Page 16

12 YP2425F/YP4025F Table of Contents Index Great Plains Manufacturing, Inc.

Loading Fertilizer

Check that calibration and clean-out doors are closed at

meter (page 35).

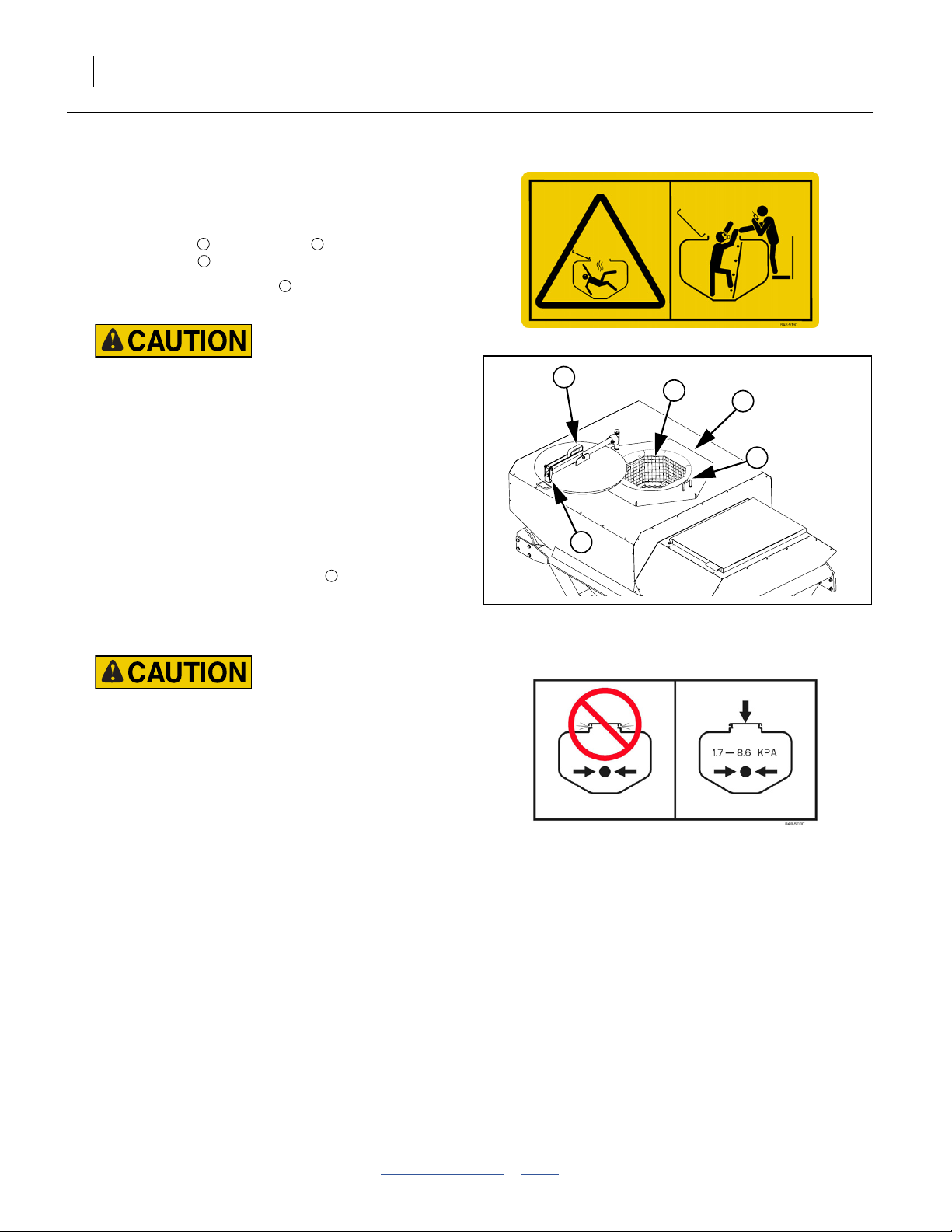

Refer to Figure 4

1. Lift the handle until the hook releases from the

U-bolt shackle .

2. Inspect the strainer basket for debris. Remove and

clean as necessary.

3 4

5

6

Confined Space Hazards:

Leave strainer in place for all routine operations. Do not

enter hopper for routine operations. Risk of entrapment

and rapid suffocation. See “Material Clean-Out” on

page 35 for further information.

3. Inspect the hopper for leftover fertilizer and debris.

Clean out anything other than the fertilizer to be

applied. See “Material Clean-Out” on page 35.

4. Re-install strainer.

5. Inspect the seal under the lid. It must make air-tight

seal against the hopper top plate when the lid is

closed and latched. Replace seal if crushed, worn or

missing.

6. Load fertilizer through strainer.

Dust and Possible Chemical Hazards:

Dry fertilizer may present a dust inhalation hazard and

may present a chemical exposure hazard. Wear eye

protection. Wear a dust mask or respirator. Wear any

other protective equipment specified by the material

supplier.

7

3

6

7

5

4

Figure 4

Fertilizer Hopper Lid

31090

7. Swing lid closed. Lift handle. Engage shackle with

hook. Close handle.

8. Swing up and latch railing if lowered for auger

operations.

Close lid handle for operations or short-term parking. For

long-term storage, do not engage hook or latch handle,

to avoid deforming the seal.

For storage, particularly unlatched, a padlock through

both U-bolts deters unauthorized entry by persons

unaware of possible confined space risks, and prevents

entry of pests, debris and precipitation.

403-362M Table of Contents Index 2013-03-25

Page 17

Great Plains Manufacturing, Inc. Table of Contents Index Operating Instructions 13

Changing Seed Box or Hopper

This topic in the Operator manual does not generally

apply to the YP2425F-2470, YP4025F-1630 and

YP4025F-1670. Using a standard 82bu hopper requires

substantial disassembly of the planter seed cart

structure, and modifications to the air system. Using a

150bu hopper or dual 200 gallon liquid fertilizer system

further requires removal of the entire fertilizer ground

drive. Such conversions are not documented or

recommended.

2013-03-25 Table of Contents Index 403-362M

Page 18

14 YP2425F/YP4025F Table of Contents Index Great Plains Manufacturing, Inc.

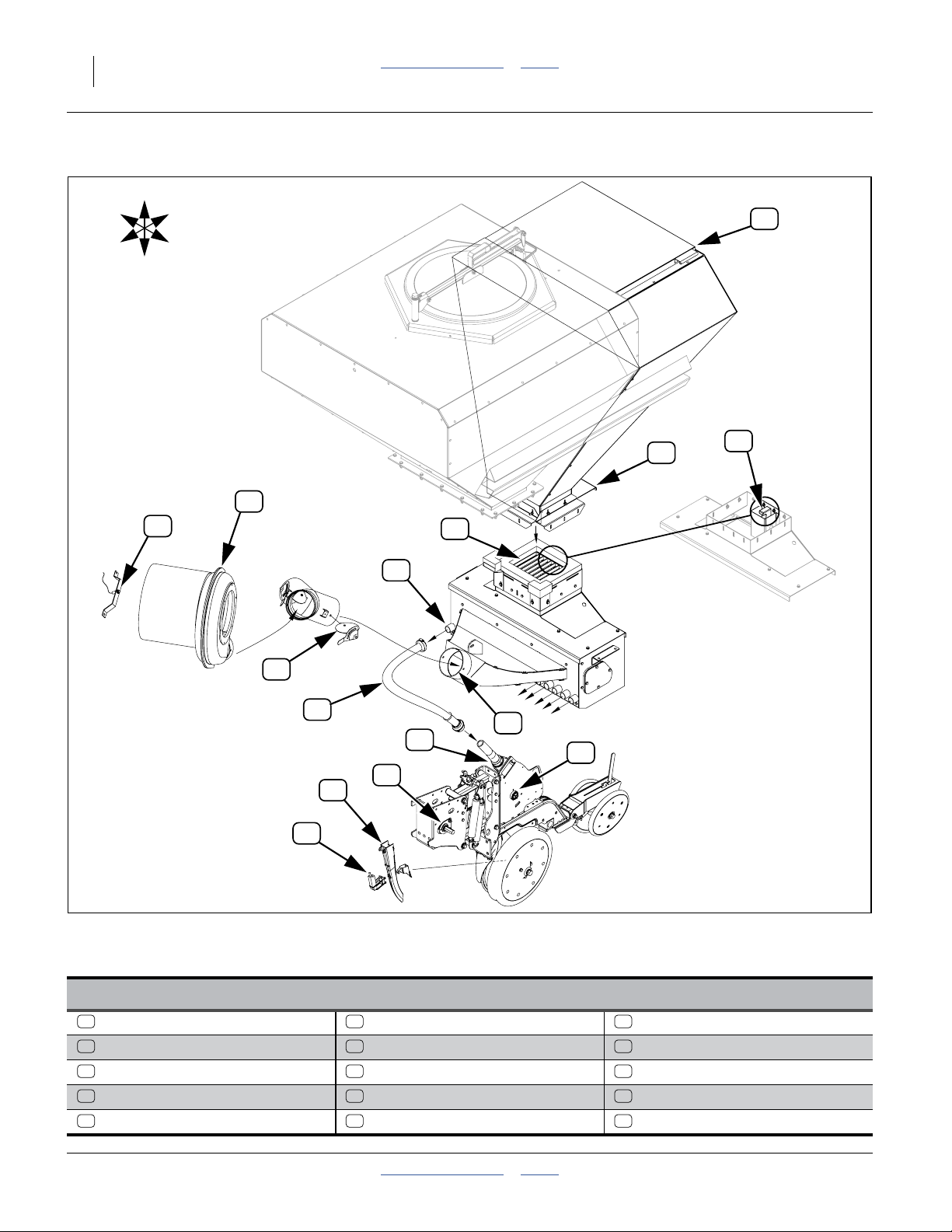

Air Systems Operation

U

R

B

5

F

L

D

6

8

1

2

7

9

3

10

4

11

12

13

14

15

Figure 5

Planter Air System for Seed Metering

Seeding System Elements (Excluding Drive)

1 6 11

Hydraulic Fan Slide Gate Meter Inlet Vent

2 7 12

Fan RPM Sensor Air Box Seed Inlet Seed Meter

3 8 13

Butterfly Valve (Seed Leg) Seed Level Sensor Meter Drive

4 9 14

Manifold Air Inlet Air Box Manifold Outlet Seed Tube

5 10 15

Seed Hopper Seed Delivery Hose Seed Sensor

31094

403-362M Table of Contents Index 2013-03-25

Page 19

Great Plains Manufacturing, Inc. Table of Contents Index Operating Instructions 15

Seeding System Overview

Refer to Figure 5 on page 14

1. Hydraulic Fan:

The hydraulic fan supplies air for both seed and

fertilizer delivery. Fan rpm is operator-adjusted via

the tractor circuit’s hydraulic flow control.

2. Fan RPM Sensor:

Fan rpm is measured by a sensor mounted inside

the fan cage, and reported on the seed monitor

console.

3. Butterfly Valve (Seed Leg):

Manually-adjusted butterfly valves are provided on

the splitter at the fan outlet. The valve on the left leg

controls air for the seeding system. See page 19 for

valve adjustment.

4. Air Box Air Inlet:

Fan air enters the air box at the manifold inlet and is

mixed with seed.

5. Seed Hopper:

The rear hopper is the seed hopper. See “Loading

Seed” on page 11. The hopper contains a

pressure-balancing system (not shown) to help

prevent seed bridging.

6. Slide Gate:

There is a slide gate at the base of the seed hopper,

used to shut off seed flow during transport,

maintenance and storage.

7. Air Box Seed Inlet:

Seed enters the air box manifold at the top.

8. Seed Level Sensor:

The inlet contains a level sensor. When this sensor is

exposed (seed level below sensor), there may be

less than a hectare of seed remaining.

9. Seed Manifold Outlets:

The fan airflow entrains seed inside the air box, and

exits at the manifold outlets. On this model planter,

there is one outlet port per row.

10. Seed Hoses:

Seed hoses deliver seed to the rows. On this model

planter, there is one hose per row, and no Y-tube

splitters.

11. Air Release Vents:

The meter inlets contain a venting system to exhaust

the delivery air. When seed backs up above the vent,

seed flow to that row stops until the meter has

consumed enough seed to re-expose the vent.

12. Seed Meter:

The Singulator Plus®or finger pickup meter contains

a seed wheel or finger-set that capture seeds at a

precise rate.

13. Seed Meter Drive:

Meter rotation is coupled to the drive system, which

is powered by a hydraulic motor (not shown) under

control of the seed monitor. Clutches control drive

shafts for entire planter sections. See planter

Operator manual for clutch operation.

Note: Seeding rate is independent of air system

operation, if the air system is set to provide

enough bulk seed flow to keep the meters full, but

not so much flow that system plugging occurs.

See page 19 for fan operation.

Note: A coupler at the meter may be disengaged to shut

off seeding at that row. See planter Operator

manual for row shut off. Fertilizer application

cannot be shut off at individual rows.

14. Seed Tube:

The seed wheel or finger set deposits seed in the

row’s seed tube, for delivery to the furrow.

15. Seed Sensor:

In the seed tube, the seed sensor detects passage of

seeds. Medium size and large seeds are counted

individually. With smaller seeds, most are detected,

allowing the monitor to detect stoppages.

2013-03-25 Table of Contents Index 403-362M

Page 20

16 YP2425F/YP4025F Table of Contents Index Great Plains Manufacturing, Inc.

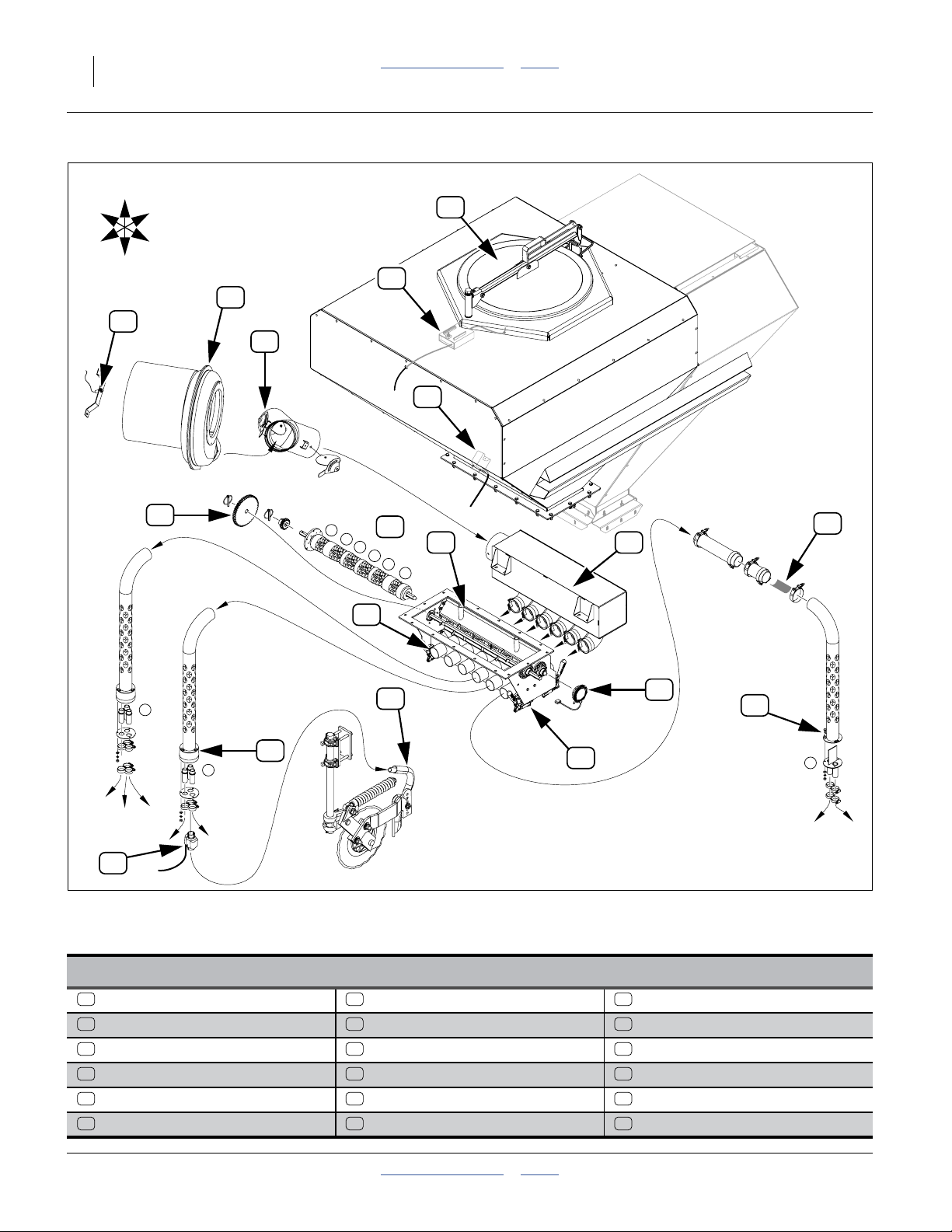

U

R

B

5

F

L

D

6

1

2

3

7

11

2

12

3

3

3

3

8

}

2

4

16

13

3

18

10

15

14

3

9

2

17

Figure 6

Planter Air System for Fertilizer Metering

Fertilizer System Elements (Excluding Drive)

1 7 13

Hydraulic Fan Level Sensor Manifold Outlets and Hoses

2 8 14

Fan RPM Sensor Fertilizer Meter 3-Way Tower

3 9 15

Butterfly Valve (Fertilizer Leg) Calibration/Clean-Out Doors 2-Way Tower

4 10 16

Air Inlet Manifold Meter Shaft RPM Sensor 2-Way Air Vent

5 12 17

Seed Hopper Flute Stars Blockage Detector

6 11 18

Pressure Sensor Range Gears Coulter Applicator

403-362M Table of Contents Index 2013-03-25

31093

Page 21

Great Plains Manufacturing, Inc. Table of Contents Index Operating Instructions 17

Fertilizer System Overview

Refer to Figure 6 on page 16

1. Hydraulic Fan:

The fan supplies air for both fertilizer and seed

delivery. Fan rpm is operator-adjusted via the tractor

circuit’s hydraulic flow control.

2. Fan RPM Sensor:

Fan rpm is measured by a sensor mounted inside

the fan cage, and reported on the seed monitor

console.

3. Butterfly Valve (Fertilizer Leg):

Manually-adjusted butterfly valves are provided on

the splitter at the fan outlet. The valve on the right leg

controls air for the fertilizer system. See page 19 for

valve adjustment.

4. Fertilizer Air Inlet Manifold:

Fan air is divided into six equal flows at the inlet

manifold.

5. Fertilizer Hopper:

The front hopper is the fertilizer hopper. See

“Loading Fertilizer” on page 12. The hopper

contains a ladder-style pressure-balancing system

(not shown) to help prevent fertilizer bridging.

6. Pressure Sensor:

A sensor in the fertilizer hopper reports air pressure

to the seed monitor, and is reported on the console.

7. Fertilizer Level Sensor:

The fertilizer hopper contains a level sensor. When

this sensor is exposed (fertilizer level below sensor),

approximately 78 liters (2.2 bu) of fertilizer remains.

8. Fertilizer Meter:

The fertilizer meter is at base of the fertilizer hopper.

There is no slide gate. The meter is always open to

the fertilizer hopper.

9. Meter Doors:

The meter box has doors at the bottom for clean-out

(front) and calibration (rear). See page 27 or

page 35. These doors are closed for field operations.

10. Fertilizer RPM Sensor (shaft monitor):

A sensor on the meter flute shaft reports shaft rate to

the seed monitor. The seed monitor does not report

material rate from this data, but can generate alarms

on shaft stoppages or rpm out-of-limits.

11. Range Gears:

Interchangeable Final Range Gears set the coarse

rate of the flute shaft. The meter system is powered

by a ground drive (not shown), which has a variable

rate gearbox for fine adjustment. See page 23.

Fertilizer metering occurs whenever the planter is

lowered and in forward motion.

12. Flute Stars:

Fertilizer is metered into the manifold air stream by

flutes on the final shaft. The four inside

compartments have three flutes (six halves) and feed

3-way towers. The two outside compartments have

two flutes and feed 2-way towers.

Material Mis-Application Risk:

If it is ever necessary to disconnect delivery hoses at the

manifold, it is essential that the hoses to the wing-end

(2-way) towers be connected to the outside ports

(#1 and #6) at the manifold.

13. Fertilizer Manifold Outlets:

The fan airflow from the inlet manifold entrains

metered fertilizer in the chambers below the flutes,

and exits at the manifold outlets. Each outlet serves

a single hose to a single distribution tower, and

multiple rows.

The center four outlets serve 3-way towers.

The outside two outlets serve 2-way towers.

14. 3-way Tower:

Four of the six towers divide the air/fertilizer flow

3ways.

15. 2-Way Tower:

Two of the six towers (the two serving wing end

rows) divide the air/fertilizer flow 2 ways.

16. Vent for 2-Way Towers:

To balance the airflow at all manifold ports, the 2-way

towers vent some of the air at the tower inlet. See

page 43 for maintenance.

17. Blockage Detectors:

Each tower divider outlet is equipped with a material

sensor, connected to the seed monitor and

configured for “Blockage” mode. These report any

flow failure at the rows. See page 54.

18. Coulter Applicators:

Coulters are factory configured for side-dress

fertilizer application, at 5cm (2in) off-row, and a

depth of 5cm (2in), “zone” application. The coulter

has adjustments for depth and the height of the

applicator exit tube.

2013-03-25 Table of Contents Index 403-362M

Page 22

18 YP2425F/YP4025F Table of Contents Index Great Plains Manufacturing, Inc.

Fan Circuit Operation

Refer to Figure 7

Three hydraulic hoses serve the fan, and must be

properly connected for the fan to operate in the correct

direction , at recommended speeds, and without

damage. See “Hydraulic Hose Hookup” in the

401-406M (YP24) or 401-571M (YP40) Operator

manual.

1. Always connect the case drain line first.

1

3

2

2

4

5

This line protects the outer shaft seal of the hydraulic

motor. The case drain is a small line to the hitch,

provisioned with a specialized low-seep flat-face

case drain Quick Disconnect. Pressure spikes during

motor operation, and pressure cycles due to

temperature change are bled off by the case drain.

1

Motor Seal Damage Hazard

Do not apply pressure to the case drain line. Do not change the

special QD connector. A restricted or sealed case drain line

will promptly result in motor seal damage.

2. Connect the motor return line second, to sump.

3

Figure 7

Hydraulics at Fan

31095

The planter includes a 11⁄16in low back-pressure QD

coupler set. Install the receptacle on a tractor sump

port, and not at a normal remote return port. The

unusual size aids in ensuring correct connection, so

that the motor return line handles high volume at low

back-pressure, ensuring full motor performance.

3. Connect the motor inlet line to a tractor remote

4

capable of 95 liters per minute (25 gpm). If a priority

remote is available, use it for the fan.

4. The fan hydraulic circuit includes a check valve ,

5

which provides a relief path for oil at motor shutoff.

If the fan is connected in reverse, flow through this

valve results in low fan rpm, providing strong

indication reversed connection.

Correct fan direction is shown at . If reversed fan is

1

suspected, observe it during shutoff, as the direction

of motion is easier to see at lower rpms as it slows to

a stop (initial startup is virtually instantaneous,

making observation at start difficult).

Fan speed is controlled by the tractor circuit and butterfly

valves (and not the seed monitor).

You may stop the fan by setting the circuit to neutral or

float. The check valve slows the blades to a stop by

locally recirculating the oil.

If the fan is connected in reverse, it may not run at all

(due to no oil source at the return connection). If oil is

present, oil bypass at the check valve prevents the

5

fan from reaching high rpm. A reversed fan may send

some air to the delivery systems, but is incapable of

providing reliable air flow for planting.

Fan speed can change as oil heats to operating

temperature. Re-check fan rpm and hopper pressure

more often during early operations.

403-362M Table of Contents Index 2013-03-25

Page 23

Great Plains Manufacturing, Inc. Table of Contents Index Operating Instructions 19

Fan General Operating Information

Adjust the fan rpm and butterfly valves to provide

sufficient air flow for consistent transport of seed and dry

fertilizer. Suggested values are shown at right.

Fan rpm is controlled by the tractor circuit, and reported

by the seed monitor. Always start the fan with a low flow

setting. Gradually bring fan up to the target rpm.

Fan air pressure is measured by a sensor in the fertilizer

hopper, and reported by the seed monitor. Air pressure is

controlled by fan rpm, butterfly valve settings, material

density and rates. System settings may vary with

material mix, material density and rates.

Recommend initial butterfly valve setting is 0° (wide

open) at both valves (assuming material application from

both hoppers). If one hopper is unused, set the valve for

that hopper to 30° to simulate the normal back-pressure

of material flow from that hopper.

Butterfly Valves

Use tractor remote hydraulic valve flow control to set fan

speed and butterfly valves to balance flow. Precise

technique depends on tractor capabilities:

• For any setup adjustment, operate the tractor engine

at typical field rpms, and not at idle.

• Preset the butterfly valves. Use any settings that you

previously developed for the material mix and rates,

otherwise:

70°

45°

2

20°

If the tractor has fine control of remote flow rates, and

consistent flow at varying tractor engine rpm, initially

set the butterfly valves to 0°.

If the tractor has only coarse control of flow, initially set

the butterfly valves to 45°.

• Set the fan circuit flow to bring the pressure sensor to

near the recommended value.

• If the tractor has marginal flow available, or the list

circuit has priority, you may need to experiment with

combinations of fan flow and butterfly valve settings.

At excessive rpm, too much air flow can cause:

Symptoms of Insufficient Air Flow

• Excessive skips (low seed population) at seed meters.

• Blockage reported at fertilizer applicators.

• Plugging of delivery hoses at low spots.

Symptoms of Excessive Air Flow

• Blockage reported at openers or coulters.

• Plugging of delivery hoses near air boxes.

• oil heating

• slow lift times

1

Figure 8

Fan Butterfly Valve Handle

Butterfly Valve Operation:

To adjust, loosen bolt and rotate the handle .

Re-tighten bolt.

0° is wide open - maximum air flow.

90° is closed - minimum air flow.

The valve provides the most effect at settings between

20° and 70°.

Starting at 30° reduces the fan workload.

Starting at 45° provides the most adjustment range up or

Note: If desired pressure cannot be reached, or requires

unusually high oil flow at low butterfly valve

settings, chances are the fan is running

backwards. Reverse the inlet/return lines at the

hitch.

1 2

25137

2013-03-25 Table of Contents Index 403-362M

Page 24

20 YP2425F/YP4025F Table of Contents Index Great Plains Manufacturing, Inc.

Monitor Operation

The YP2425F-2470, YP4025F-1630 and YP4025F-1670

includes the standard DICKEY-john

operating in Planter/Drill Control mode. There are setup

differences vs. other YP40 planters, generally:

• Row delivery tubes are equipped with blockage

sensors. These rows are treated as “seed” rows

numbered from

®

IntelliAg® monitor,

YP24 YP40

25 (actual seed row 1) to 17 (actual seed row 1) to

48 (actual seed row 24) 32 (actual seed row 16)

• Seed tubes are monitored in Population mode.

Fertilizer applicators are monitored in Blockage mode.

Note: Fertilizer is not set up as a separate Material or

Channel. The monitor’s “GRAN FERT” air drill

mode is not used. The seed monitor is not

engaged for fertilizer calibration, and no

“CAL CONST” is required.

• There are two hopper level sensors in use:

1. Seed air box

2. Fertilizer hopper level

Note: There is no optional level sensor for the seed

hopper.

• There is one air pressure sensor in use, installed in

the fertilizer hopper.

• There is a second

end of the fertilizer meter shaft. Although the seed

monitor can report the rpm, the main use is as a shaft

monitor.

Set upper and lower rpm limits based on the fertilizer

rate chart, and your planned field speed. The chart

shows expected meter rpm for various gearbox

settings, in High and Low range, at 9.7 kph (6 mph). If

using a different field speed, adjust the expected rpm

proportionately.

a

rpm sensor, installed on the left

Marker Operation

The YP24/YP40 DF/seeder feature does not affect

marker operations.

a. The first rpm sensor is on the hydraulic motor for the seed meters.

403-362M Table of Contents Index 2013-03-25

Page 25

Great Plains Manufacturing, Inc. Table of Contents Index Operating Instructions 21

Field Set-Up Checklists

Add the following items to the basic planter checklists, or

any customer checklist you have developed.

Mechanical Checklist (Hitching) Page

No changes

Electrical Checklist Page

No changes

Hydraulic System Checklist Page

No changes

Mechanical Checklist (post-Hitching) Page

No changes

Planter Meter Drive Checklist Page

Check fertilizer ground drive and gearbox

output chain lubrication and slack

Check final Range gears set for desired

High or Low range

Check setting of variable rate gear box

against chart or calibrated rate.

No changes for seeding

Air System Checklist Page

Fan butterfly valves set for fertilizer 19

Fertilizer loaded. Lid closed. 12

No air leaks in fertilizer system

Hoses and tubing - no sags, no pinches

Hoses fully connected to applicators

Row Units Checklist Page

Check frame-mounted coulter:

offset

angle

depth

Check applicator height. 29

39

23

24

29

Field Operation

The YP24 DF/seeder feature requires no changes to the

checklists in the 401-406M Operator manual, the YP40

DF/seeder requires no changes to the checklists in the

401-571M Operator manual.

When the fan is running, and the planter is lowered and

in forward motion, material is applied from the fertilizer

hopper at the currently set rate.

Consult seed monitor for blockage alarms.

When reloading fertilizer, check consumption against

anticipated use to that point.

Short-Term Parking

The YP24 or YP40 DF/seeder feature requires no

changes to the Parking steps in the 401-406M or

401-571M Operator manual.

Long-Term Storage

The YP24 or YP40 DF/seeder feature adds the following

steps to the storage recommendations of the 401-406M

or 401-571M Operator manual:

• Perform a seeding system clean-out (page 35)

• Close the lid of the seed hopper firmly, making sure it

is fully latched (page 11).

• Clean-out the fertilizer air system and hopper

(page 35).

• Tie the clean-out and calibration doors partly open

(page 35).

• Close, but do not tightly seal the fertilizer hopper lid

(page 12).

Equipment Damage Risk:

Perform a fertilizer clean-out when the planter is left unused

for more than 36 hours. Fertilizer is generally very corrosive.

If fertilizer or residue is allowed to remain in the hopper or

meter, exposed metal surfaces will be attacked. See “Material

Clean-Out” on page 35.

2013-03-25 Table of Contents Index 403-362M

Page 26

22 YP2425F/YP4025F Table of Contents Index Great Plains Manufacturing, Inc.

Adjustments

This table provides a cross-reference to all adjustment

items unique to the YP2425F-2470, YP4025F-1630 and

YP4025F-1670 planter.

For adjustments not listed, see the 401-406M (YP24) or

401-571M (YP40) Operator manual.

Adjustment Page The Adjustment Affects

Air Systems 14

Fan Speed 19 Optimal seed distribution

Butterfly Valve (Seed Leg) 19 Consistent seed flow and disk singulation

Butterfly Valve (Fertilizer Leg) 19

Material Rates

Seed Rate

Seed Rate

Fertilizer Rate 62

Monitor Adjustments

Alarms 20

Restore factory settings 53

Frame-Mounted Coulter Adjustments

Coulter Depth 29

Applicator Depth 29

401-406B

401-571B

(Same as for standard YP24 planters.

Refer to that Seed Rate manual.)

(Same as for standard YP40 planters.

Refer to that Seed Rate manual.)

403-362M Table of Contents Index 2013-03-25

Page 27

Great Plains Manufacturing, Inc. Table of Contents Index Adjustments 23

Setting Material Rates

Setting Seed Rate

Seed rate setting for the YP2425F-2470, YP4025F-1630

and YP4025F-1670 planter is identical to the standard

YP24 or YP40 planter. Refer to the Operator and Seed

Rate manuals for details:

YP2425F-2470 401-406M Operator manual

401-406B Seed Rate manual

YP4025F-1630 or

YP4025F-1670

401-571M Operator manual

401-571B Seed Rate manual

Setting Dry Fertilizer Rate

There are three steps to obtaining the target fertilizer

kilograms per hectare (or pounds per acre):

1. Set Final Drive Range on fertilizer meter (below)

2. Set Variable Rate Gearbox (page 24)

3. Calibrate (page 25).

2

DRIVING

3

Seed Meter Final Drive Range

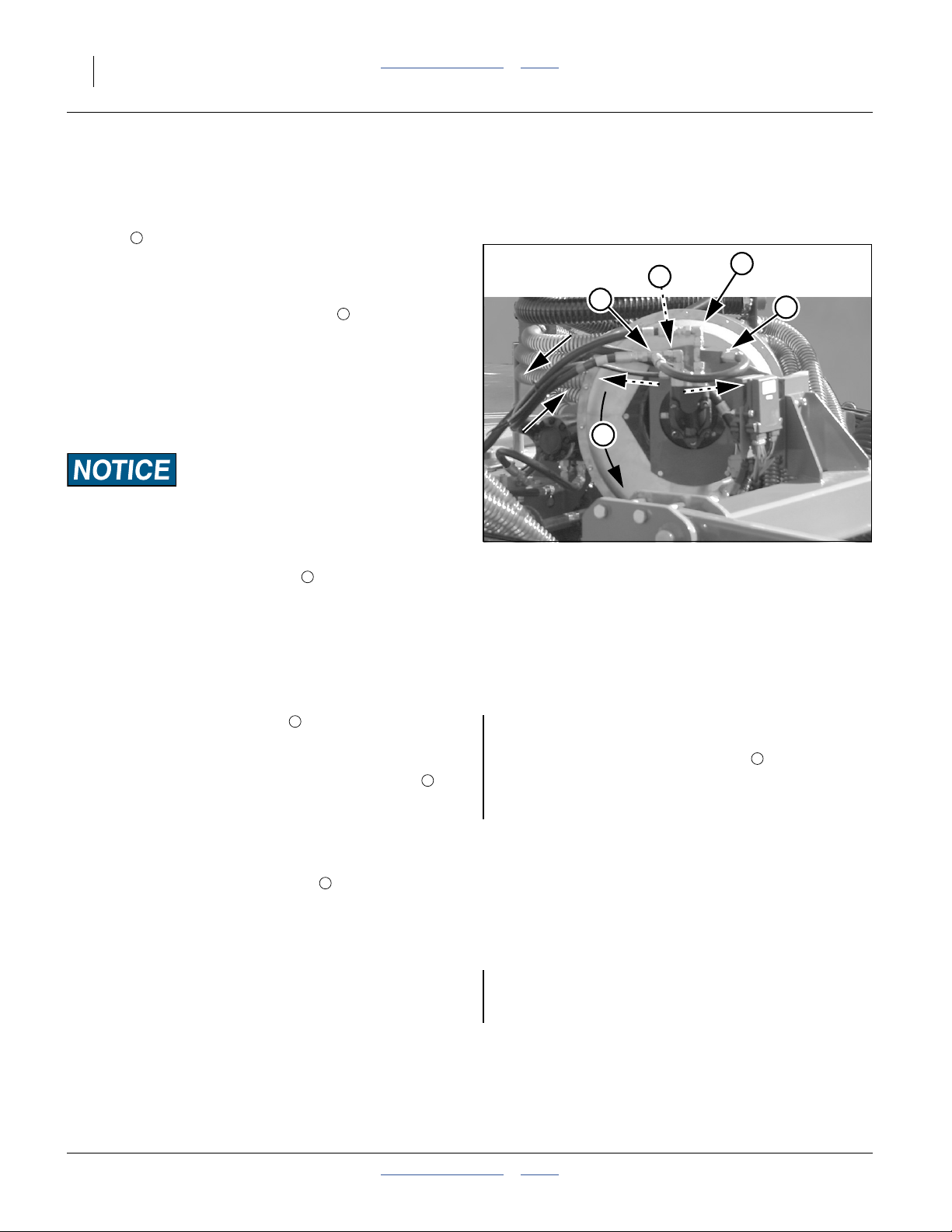

Refer to Figure 9

The meter flute shaft is driven by the agitator shaft

through a pair of interchangeable gears , . The

positioning of these gears creates two final drive ranges.

The rate chart has two page columns, each based on a

specific Final Drive Range. The Ranges are:

• “High” range, which is used for higher fertilizer rates

• “Low” range, which is used for lower fertilizer rates

The two meter shafts are labeled “DRIVING” and

“DRIVEN”.

The “DRIVING” shaft is the upper shaft.

The “DRIVEN” shaft is the lower shaft.

Refer to the Fertilizer Rate chart (page 63), the table at

right, and Figure 9 for setting the meter final drive range.

1. Remove the lynch pins from the ends of both shafts.

2. Remove and position the gears as shown in the table

above.

3. Secure with lynch pins.

1 2

3 4

DRIVEN

1

Figure 9

High Final Drive Range

FINAL DRIVE

RANGE

LOW RANGE 17 Tooth Small 54 Tooth Large

HIGH RANGE 54 Tooth Large 17 Tooth Small

DRIVING DRIVEN

4

91097

2013-03-25 Table of Contents Index 403-362M

Page 28

24 YP2425F/YP4025F Table of Contents Index Great Plains Manufacturing, Inc.

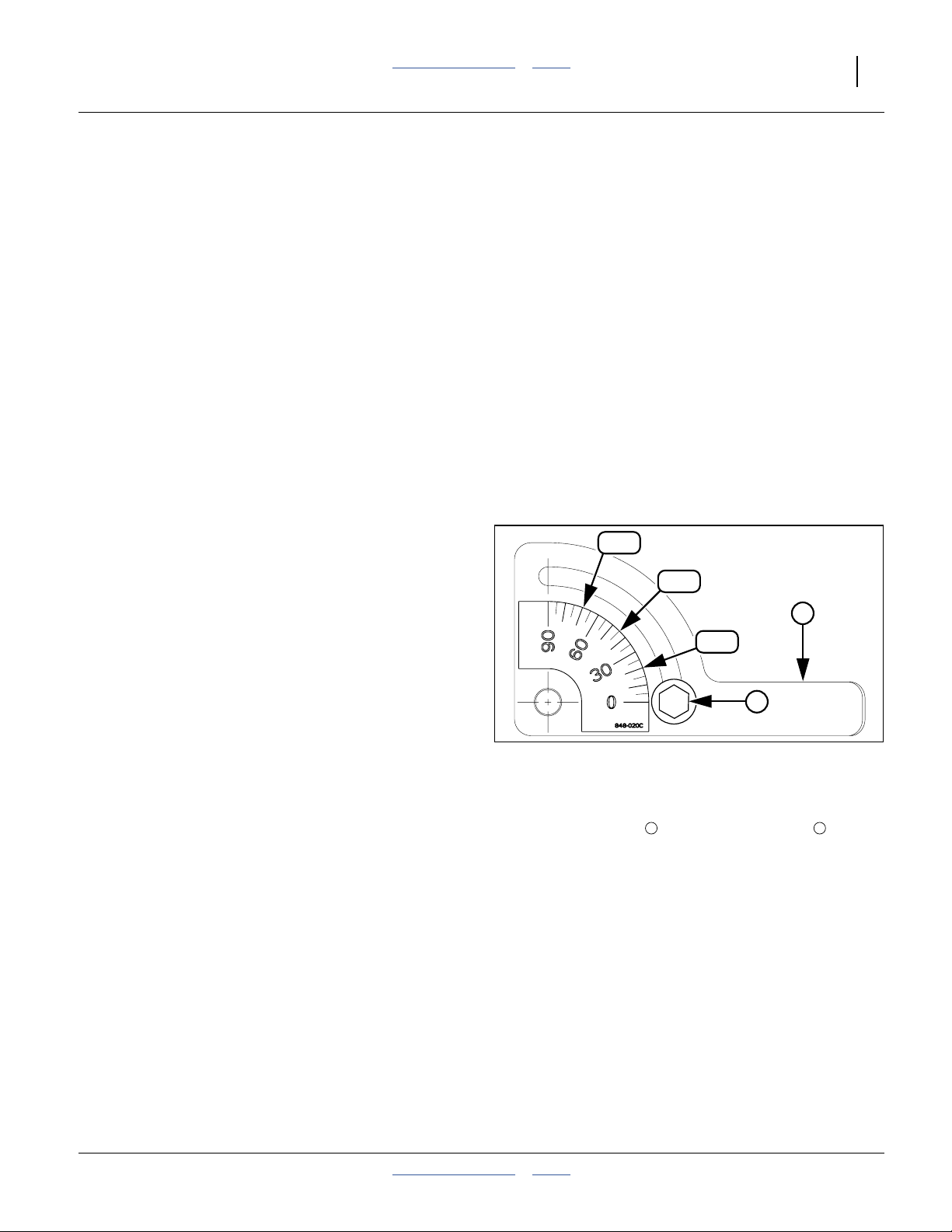

Setting Variable Rate Gearbox

The variable rate gearbox allows an infinitely variable

meter drive speed to attain a wide range of application

rates. The ratio of gearbox input speed to output speed is

controlled by the position of a gearbox control arm. The

control arm has an indicator that points to a scale

marked in degrees. The Fertilizer Rate chart shows the

rate for each five degrees of arm rotation.

Refer to the rate chart and set the variable rate gearbox

control arm to its scale setting for the target fertilizer rate

To adjust the Variable Rate Gearbox:

Refer to Figure 10

1. Remove the hairpin cotter securing the gearbox

adjustment crank .

2. Rotate crank until the control arm indicator

points to the scale setting that matches the rate from

the rate chart or as determined by calibration.

3. Reinsert the hairpin cotter.

Note: The variable rate gearbox operates optimally

between 30 and 70. If the target fertilizer rate

appears on both the Low and High Range charts,

the most consistent results are obtained when the

gearbox control arm is set between 30 and 70.

Settings below 20 degrees are not recommended.

When the control arm is set above 70 degrees,

large movements of the arm result in small

changes in seeding rate.

2

2 3

1

1

3

2

Figure 10

Variable Rate Gearbox

31099

403-362M Table of Contents Index 2013-03-25

Page 29

Great Plains Manufacturing, Inc. Table of Contents Index Adjustments 25

Meter Calibration

The fertilizer rate charts are based on a representative

11-52-0 dry granular fertilizer. Many factors affect meter

rates including fertilizer density, granularity, texture,

adhesion, humidity and field conditions.

Great Plains recommends calibrating for the exact

material being applied. Calibration determines the kg/ha

(or lbs/ac) of the meter at the current variable rate

gearbox setting for your particular fertilizer.

Calibration Procedure

Calibration consists of:

• metering material for a simulated distance (area), by

manually cranking the ground drive system,

• measuring the sample weight generated, computing

the rate, and, if not the rate desired,

• adjusting the gearbox setting to produce a rate closer

to the target rate, then;

• re-sampling to verify the adjustment.

There are two ways to collect the sample:

a. Fan On / Row Sample (page 26)

Place collection containers under each fertilizer row

applicator (calibration door closed).

b. Fan Off / Meter Sample (page 27)

Place a tarp under the fertilizer meter with the

calibration door open.

Either method relies on manual operation of the fertilizer

ground drive system and meter. You may operate the

drive by turning the ground drive wheel itself, or use the

supplied 403-414H crank to turn the jackshaft at the

ground drive arm pivot.

Initial Calibration Steps

1. Set the final gear Range and variable rate gearbox

adjuster (from the charts on page 64 or 65, or

previous calibrations of similar material).

2. Hitch planter to tractor capable of operating the

planter. (See 401-406M or 401-571M Operator

manual.)

3. Close the slide gate on the seed hopper (page 14).

4. Raise the planter. Install transport locks. (See

401-406M or 401-571M Operator manual.)

5. Load enough fertilizer for at least1⁄10hectare (or

1

⁄10acre) plus an extra 35 to 45 kg (75 to 100 lbs)

(page 12).

Refer to Figure 11

6. Attach the 403-414H calibration crank to the left

1

end of the fertilizer ground drive arm pivot. You can

use the hairpin cotter from the gearbox adjuster

2

crank to secure the calibration crank to the shaft.

Sampling Error Risk:

Do not leave fertilizer hopper lid open. Low pressure above

fertilizer skews results. Perform calibration with lid tightly

closed, as for normal field operations.

Revolutions for Sample Size

Sample Revolutions of:

Size Crank Wheel

1/10th Hectare 4.52 5.24

1/10th Acre 11.16 12.95

1 Hectare 45.2 52.4

1 Acre 111.6 129.5

Note: A cranking speed of 1 revolution per second

(60 rpm) simulates a field speed of 9 kph.

Note: For a more accurate calibration, crank for a full

hectare or acre. Make sure there is enough

material in the hopper.

Material Rate Risk:

Check consumption rates in the field. One variable factor that

calibration cannot compensate for is the effective rolling

radius of the ground wheel in unusually soft or hard ground.

2

Figure 11

Calibration Cranking

1

31000

31104

2013-03-25 Table of Contents Index 403-362M

Page 30

26 YP2425F/YP4025F Table of Contents Index Great Plains Manufacturing, Inc.

Row Sample Calibration

This method requires 16 or 24 containers each with a

capacity of about 1% of a hectare or acre, and a scale

capable of precisely weighing the heaviest empty

container plus the sample size (or all the containers at

once).

7. Turn on the seed monitor system. Although not used

for calibration, you need the monitor to display fan

rpm.

8. Weigh the empty sample containers (the “tare”).

Refer to Figure 12

9. Place the collection containers under each coulter

applicator.

Refer to Figure 13

10. Start the hydraulic fan. Adjust the rpm to normal field

Figure 12

Row Sample Collection

31102

values.

Machine Damage Risk:

Do NOT turn the crank clockwise, or the gearbox may be

damaged. Turn the crank only counter-clockwise (as seen from

planter left, facing planter right).

11. Turn the crank counter-clockwise until material is

consistently appearing in the collection containers.

Stop cranking.

12. Empty the collection containers.

13. Turn the crank for the number of revolutions

necessary to simulate the area to sample, as shown

in chart on page 25.

14. Calculate the material rate per the instructions and

examples on page 28.

15. If the results differ from your target by more than a

few percent, adjust the gearbox setting per the

instructions on page 28.

Then measure another sample starting at step 13.

Row Sample Close-Out

16. Pin the gearbox adjuster in position

3

17. Remove the calibration crank.

3

Figure 13

Calibration Crank (Row)

31000

403-362M Table of Contents Index 2013-03-25

Page 31

Great Plains Manufacturing, Inc. Table of Contents Index Adjustments 27

Meter Sample Calibration

18. Weigh any container(s) required to hold the sample

on the scale.

Refer to Figure 14

19. Place a tarp under the fertilizer meter. Support the

corners or edges so that no material can spill.

Refer to Figure 15

20. Open the meter calibration door. The calibration door

is the rear door, furthest from the DRIVING gear.

Material Loss Risk:

Do not open the (forward) door under the DRIVING gear.

This is the clean-out door. Opening this door drains the

hopper. Once the clean-out door is open it is difficult to stop

Figure 14

Meter Sample Collection

31105

seed flow until the hopper is empty.

21. Wipe all material off the flanges around the meter

door.

Machine Damage Risk:

Do NOT turn the crank clockwise, or the gearbox may be

damaged. Turn the crank only counter-clockwise (as seen from

planter left, facing planter right).

Refer to Figure 16

22. Turn the crank counter-clockwise until material is

consistently appearing in the collection containers.

Stop cranking.

23. Empty the tarp and return it to the collection position.

24. Turn the crank for the number of revolutions

necessary to simulate the area to sample, as shown

in chart on page 25.

25. Weigh the collected sample. Subtract the weight of

any container required at the scale.

26. Calculate the material rate per the instructions and

examples on page 28.

27. If the results differ from your target by more than a

few percent, adjust the gearbox setting per the

instructions on page 27.

Then measure another sample starting at step 23.

Meter Sample Close-Out

28. Pin the gearbox adjuster in position

3

29. Remove the calibration crank.

Figure 15

Calibration Door Handles

3

Figure 16

Calibration Crank (Meter)

31101

31000

2013-03-25 Table of Contents Index 403-362M

Page 32

28 YP2425F/YP4025F Table of Contents Index Great Plains Manufacturing, Inc.

Calibration Adjustment

Once a sample has been taken, two steps remain:

a. Calculate the current rate.

b. If needed, calculate and apply an adjustment to the

gearbox setting.

Calibration: Rate Calculation

30. If not already done, weigh the metered sample. This

is the gross weight.

31. Subtract the weight of the empty containers (the

tare) from the gross weight.

Net_Weight Gross_Weight Tare–=

If your sample size was based on cranking for a full

hectare or acre, no further rate calculation is necessary.

The net weight is the per-hectare or per-acre rate. Skip

to step 33.

32. If the sample size was1⁄

rate for the full area.

th

ha (or ac), calculate the

10

Area_Rate Net_Weight 10×=

Calibration: Gearbox Adjustment

33. If the calculated rate is within about 2% of your

target, there may be no benefit in attempting further

calibration. Resume at “Row Sample Close-Out”on

page 26 or “Meter Sample Close-Out” on page 27.

34. Calculate a gearbox scale adjustment. Divide the

targeta rate by the sampled rate.

Factor

Target_Rate

---------------------------- -

=

Area_Rate

Example based on YP4025-1670:

The example in this column is based on a target rate:

120 kg/ha

a gearbox setting of:

80

and a row sample, using 16 containers.

When empty the collection of 16 containers weighs:

1.1 kg

Example:

The sample and all containers weighs a total of:

12.6 kg

The net weight of the sample is:

12.6 - 1.1, or:

11.5 kg

Example:

Area rate for the sample is:

11.5 x 10, or:

115 kg/ha

This is just approximately 4% under the desired rate,

and is probably worth adjusting for.

Example:

120 ÷ 115 is:

1.043 or 104.3%

35. Use this factor to determine the next gearbox setting.

Next_Setting Previous_Setting Factor×=

36. Reset the gearbox adjuster to the “Next_Setting”

value.

For corrections of 5% or more, re-calibration is

recommended.

If a Low range correction puts the “Next_Setting” above

90, start settings development over in High range.

If a High Range correction puts the “Next_Setting” below

20, start settings development over in Low range.

a. Use the desired field application rate. Do not use any “adjusted” rate used to determine the initial gearbox setting.

403-362M Table of Contents Index 2013-03-25

Example:

80 x 1.043 is:

83.5

Note: The gearbox adjustment has a near-linear effect

on rates only near mid-scale or for small

adjustment changes. For corrections of 10% or

more, or near the ends of the scale, recalibration

is essential, as further adjustment is likely.

Page 33

Great Plains Manufacturing, Inc. Table of Contents Index Adjustments 29

Coulter Adjustment

The frame-mounted coulters standard on the

YP2425F-2470, YP4025F-1630 and YP4025F-1670 are

configured for “zone” application: 5cm offset from seed

furrow, and

5cm depth, or “2x2”in.

As blades wear, or under unusual field conditions, you

may need to adjust the coulter depth. If the depth is

adjusted, the applicator needs to be adjusted as well.

Coulter Height Adjustment

Refer to Figure 17

1. Raise the planter. Install transport locks.

2. Move the planter to a flat level surface. A paved area

is ideal.

3. At each coulter, measure the raised tool bar height

(“Bar_Height”) .

4. For a 2.5cm (2in) coulter depth, compute the ideal

raised height of the disk edge.

1

2

1

4

Metric:

Edge_Height Bar_Height 66– 5–=

Inch:

Edge_Height Bar_Height 26– 2.5–=

5. Reset the coulter shank to the new “Edge_Height”.

Coulter Applicator Adjustment

Normally, the coulter tine tip is set to exactly ground

level, although you may set it higher or lower for unusual

conditions. To change the height, loosen the mounting

bolt and move the applicator weldment up or down.

4

If you are adjusting the tine height, to ground level, with

the planter raised, use:

Metric (cm):

3

Tine_Height Edge_Height 5+=

or, U.S. customary (inches):

Tine_Height Edge_Height 2.5+=

2

Figure 17

Dry Fertilizer Coulter

3

31109

2013-03-25 Table of Contents Index 403-362M

Page 34

30 YP2425F/YP4025F Table of Contents Index Great Plains Manufacturing, Inc.

Frame-Mounted Coulter Force

In normal operation at target running depth, the spring is

at full extension or only slightly compressed. It

compresses briefly as obstructions and denser soil are

encountered.

Coulter springs are set to 181 kg (400 lbs). In normal

operation at target running depth, the spring is at full

extension. It compresses briefly as obstructions are

encountered.

• In heavy no-till conditions, you may observe the

springs in compression most of the time. This means

that the blades are not reaching the desired coulter

depth. If implement weight is sufficient, you can

increase the spring down-force to compensate.

• In light but rocky conditions, the factory spring setting

may be higher than needed. You can extend blade life

by reducing the force at which the blades ride up over

obstructions.

To adjust the coulter spring:

Refer to Figure 18

1. Raise the planter and install transport locks.

2. Determine the new spring length desired. See the

1

table at right.

3. Measure the current length of the spring(s) to be

changed. If already shorter than 24.8cm (9

longer than 26cm (10

1

⁄

in), do not further adjust

4

3

⁄

4

in), or

them.

4. Loosen the jam nut .

5. Rotate the adjuster nut until the spring is at the

2

3

new length. Tighten the jam nut.

Note: If all springs are continuously in compression, the

coulters can lift the wing frames off the ground (at

the gauge wheels), resulting in uneven coulter

depth and/or uneven seed depth. If the planter is

already operating at maximum down-pressure,

reduce coulter depth.

Figure 18

Frame-Mounted Coulter Spring

Spring Length Force at Blade

1

26.0 cm (10.25 in) 136 kg (300 lbs)

25.4 cm (10.00 in) 181 kg (400 lbs)

24.8 cm (9.75 in) 238 kg (525 lbs)

Machine Damage Risk:

Do not use spring lengths shorter than 24.8 cm (9.75 in). It

may contribute to premature parts failure which will not be

covered by warranty.

27139

403-362M Table of Contents Index 2013-03-25

Page 35

Great Plains Manufacturing, Inc. Table of Contents Index 31

Troubleshooting

The tables of this section cover possible issues specific

to the YP24/YP40 DF/seeder feature.

See also the Troubleshooting section of the 401-406M or

401-571M Operator manual.

Dry Fertilizer Troubleshooting

Problem Cause Solution

Delivery Hoses

Plugging

No Fertilizer Flow

(all rows)

No Fertilizer Flow

(some rows)

Insufficient airflow to operate both

fertilizer and seed delivery systems.

Fan circuit running in reverse Check and re-connect circuit hoses (see

Fan won’t run fast enough at

maximum tractor circuit setting

Fan speed low on capable tractor.

Hydraulic fan check valve is installed

backwards

Air leaks Check:

False-positive blockage detection.

Some fine materials and/or low rates,

may cause the monitor to report

blockage.

Gearbox set to zero Set and calibrate gearbox (page 24).

Gearbox at zero, even though not set

to zero.

Drive chain broken or skipping Check chain condition and slack (page 39).

Material run-out. Re-load fertilizer. Re-check rate setting and

Bridging in fertilizer hopper due to air

leak

Bridging in fertilizer hopper due to

material consistency

Meter box completely plugged. Clean-out hopper and meter. See page 36.

Butterfly valve closed at fertilizer leg Check setting of valve. Tighten bolt.

Blockage inside tower. Remove cap. Clear blockage.

Increase fan speed (page 19).

If already at 3800 rpm, open fertilizer-leg

butterfly valve (page 19).

401-406M or 401-571M Operator manual).

Check butterfly valves. Notes that tractor must

be able to supply 18 gallons/minute at 200 psi.

Reverse installation of check valve (see

401-406M or 401-571M Operator manual).

hopper lid,

hopper base to airbox seal,

clean-out and calibration door seals and

delivery hoses.

Shut off monitoring for fertilizer rows.

Check that gearbox indicator arm is pinned to

adjuster shaft.

level sensor function if run-out was

unexpected.

Inspect seal under lid. Replace as necessary.

Check that hook and shackle have not become

mis-adjusted.

Clean-out and replace material. See page 35.

2013-03-25 Table of Contents Index 403-362M

Page 36

32 YP2425F/YP4025F Table of Contents Index Great Plains Manufacturing, Inc.

Dry Fertilizer Troubleshooting

Problem Cause Solution

No Fertilizer Flow

(single row)

Application Rate Low

(all rows)

Application Rate Low

(some rows)

Application Rate Low

(single row)

Bridging at inlet of applicator tube Remove hose. Clear bridge. Check material for

oversize content. Also check meter flutes for

damage. Generally, anything that passes an