Page 1

Operator’s Manual

Front Fold Boom Sprayer

Manufacturing, Inc.

www.greatplainsmfg.com

Read the operator’s manual entirely. When you see this symbol, the subsequent

instructions and warnings are serious - follow without exception. Your life and

!

the lives of others depend on it!

TSF660

23113

Cover illustration may show optional equipment not supplied with standard unit.

© Copyright 2009 Printed 08/31/2009

500-644M

Page 2

Table of Contents

Important Safety Information . . . . . . . . . . . . . . . . 1

Wear Protective Equipment . . . . . . . . . . . . . . . 5

Handle Chemicals Properly . . . . . . . . . . . . . . . 6

Safety Decals . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Description of Unit. . . . . . . . . . . . . . . . . . . . . . 13

Intended Usage . . . . . . . . . . . . . . . . . . . . 13

Models Covered . . . . . . . . . . . . . . . . . . . . 13

Using This Manual . . . . . . . . . . . . . . . . . . . . . 13

Definitions. . . . . . . . . . . . . . . . . . . . . . . . . 13

Owner Assistance . . . . . . . . . . . . . . . . . . . . . . 14

Preparation and Setup . . . . . . . . . . . . . . . . . . . . 15

Before You Start . . . . . . . . . . . . . . . . . . . . . . . 15

Hitching Tractor to Sprayer . . . . . . . . . . . . . . . 15

Hydraulic Pump Setup . . . . . . . . . . . . . . . . . . 17

Hydraulic Hook-Up . . . . . . . . . . . . . . . . . . . . . 18

Axle Wheel Spacing Adjustment. . . . . . . . . . . 19

Quad-Jet Agitators . . . . . . . . . . . . . . . . . . . . . 20

Raven SCS 440 . . . . . . . . . . . . . . . . . . . . . . . 20

Electrical Connections . . . . . . . . . . . . . . . . . . 20

Adjustments Before Going to the Field . . . . . . 21

Hydraulic Driven Pumps . . . . . . . . . . . . . . 21

Field Adjustments . . . . . . . . . . . . . . . . . . . . . . 22

Boom Height. . . . . . . . . . . . . . . . . . . . . . . 22

Agitation Adjustments. . . . . . . . . . . . . . . . 22

Tank Straps. . . . . . . . . . . . . . . . . . . . . . . . 22

Operating Instructions . . . . . . . . . . . . . . . . . . . . 23

Operating Checklist. . . . . . . . . . . . . . . . . . . . . 24

Plumbing Operations . . . . . . . . . . . . . . . . . . . 25

Boom Operations . . . . . . . . . . . . . . . . . . . . . . 27

Boom Folding Procedure . . . . . . . . . . . . . . . . 28

Boom Folding . . . . . . . . . . . . . . . . . . . . . . 28

Boom Unfolding . . . . . . . . . . . . . . . . . . . . 28

Locking System. . . . . . . . . . . . . . . . . . . . . . . . 29

Break Away Spring . . . . . . . . . . . . . . . . . . . . . 29

Leveling Boom . . . . . . . . . . . . . . . . . . . . . . . . 30

Filling Tank Procedures. . . . . . . . . . . . . . . . . . 31

Using Handwash Tank . . . . . . . . . . . . . . . . . . 31

Operating Whirlfilter® . . . . . . . . . . . . . . . . . . . 31

Transporting . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Parking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Tank Rinse and Flush System. . . . . . . . . . . . . 34

Inductor (Optional Equipment) . . . . . . . . . . . . 35

Raven G1 Autoboom (Optional Equipment) . . 35

Adjustments. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Boom Height . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Nozzle Pressure . . . . . . . . . . . . . . . . . . . . . . . 37

Tank Straps . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Manual Pressure Adjustment Valve . . . . . . . . 37

Agitation Adjustment . . . . . . . . . . . . . . . . . . . . 39

Operating Whirlfilter® . . . . . . . . . . . . . . . . . . . 39

Clean-out the solution Whirlfilter® . . . . . . 39

Elevator Slide Adjustment . . . . . . . . . . . . . . . . 40

Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . 41

Maintenance and Lubrication. . . . . . . . . . . . . . . 43

Sprayer/Boom Maintenance . . . . . . . . . . . . . . 43

Equipment Cleanup. . . . . . . . . . . . . . . . . . . . . 43

General Information . . . . . . . . . . . . . . . . . . . . 43

Pump Maintenance and Repair. . . . . . . . . . . . 43

Ace Pumps . . . . . . . . . . . . . . . . . . . . . . . . 43

Ace Hydraulic Pump Seal Replacement. . 44

Shear Bolt Replacement . . . . . . . . . . . . . . . . . 45

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Chemical Inductor . . . . . . . . . . . . . . . . . . . . . . 49

Foam Marker. . . . . . . . . . . . . . . . . . . . . . . . . . 49

Raven G1 Autoboom. . . . . . . . . . . . . . . . . . . . 49

Pumps. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Specifications and Capacities . . . . . . . . . . . . . . 51

Tire Inflation Chart . . . . . . . . . . . . . . . . . . . . . 51

Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Torque Values Chart . . . . . . . . . . . . . . . . . . . . 52

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

© Copyright 2009 All rights Reserved

Great Plains Manufacturing, Inc. provides this publication “as is” without warranty of any kind, either expressed or implied. While every precaution has been taken in the

preparation ofthis manual,Great PlainsManufacturing, Inc.assumes noresponsibility for errors or omissions.Neither is any liability assumed fordamages resultingfrom

the use of the information contained herein. GreatPlains Manufacturing, Inc. reserves theright to revise and improve its products as it sees fit. Thispublication describes

the state of this product at the time of its publication, and may not reflect the product in the future.

Great Plains Manufacturing, Incorporated Trademarks

The following are trademarks of Great Plains Mfg., Inc.: Application Systems, Ausherman, Land Pride, Great Plains

All other brands and product names are trademarks or registered trademarks of their respective holders.

Printed in the United States of America.

9/1/2009

500-644M

Page 3

Important Safety Information

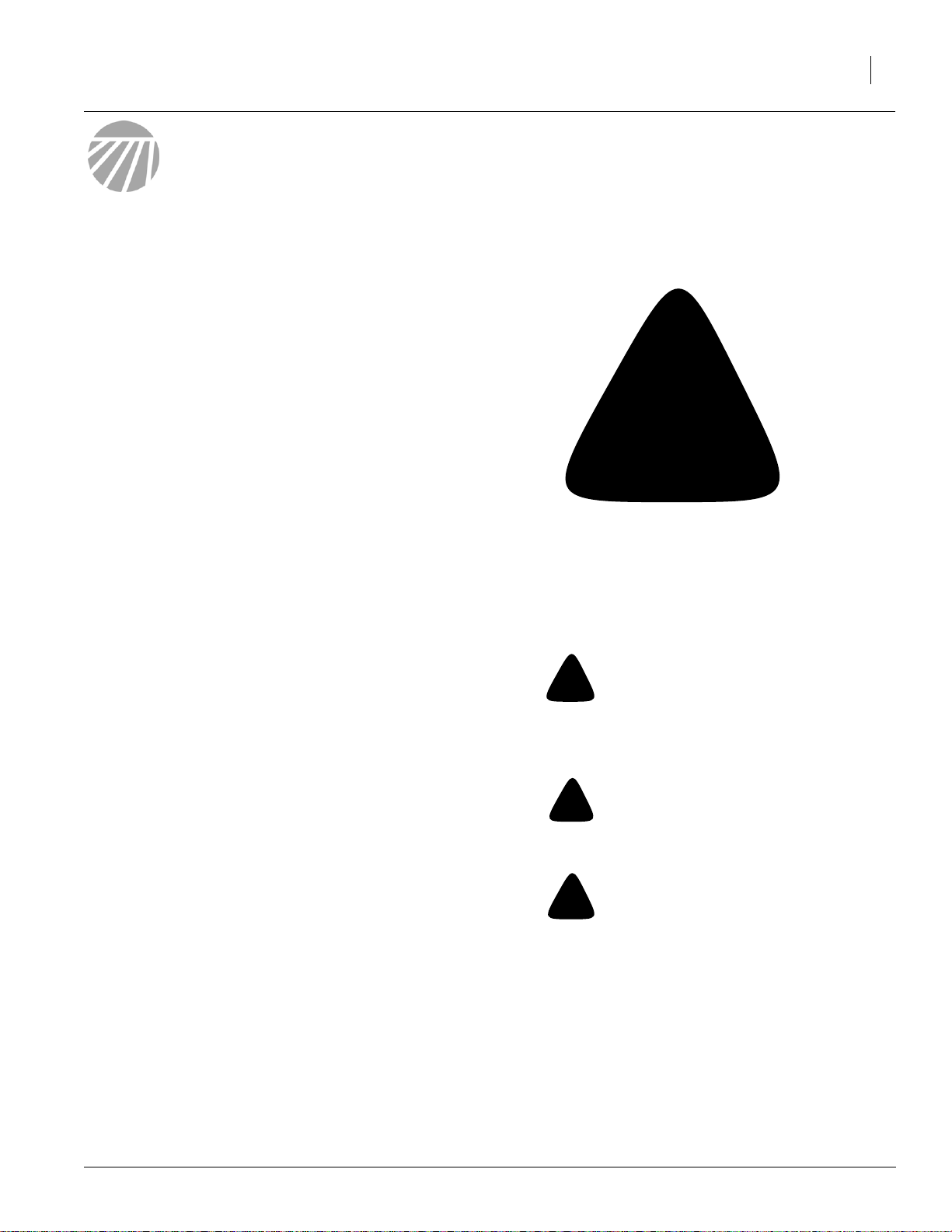

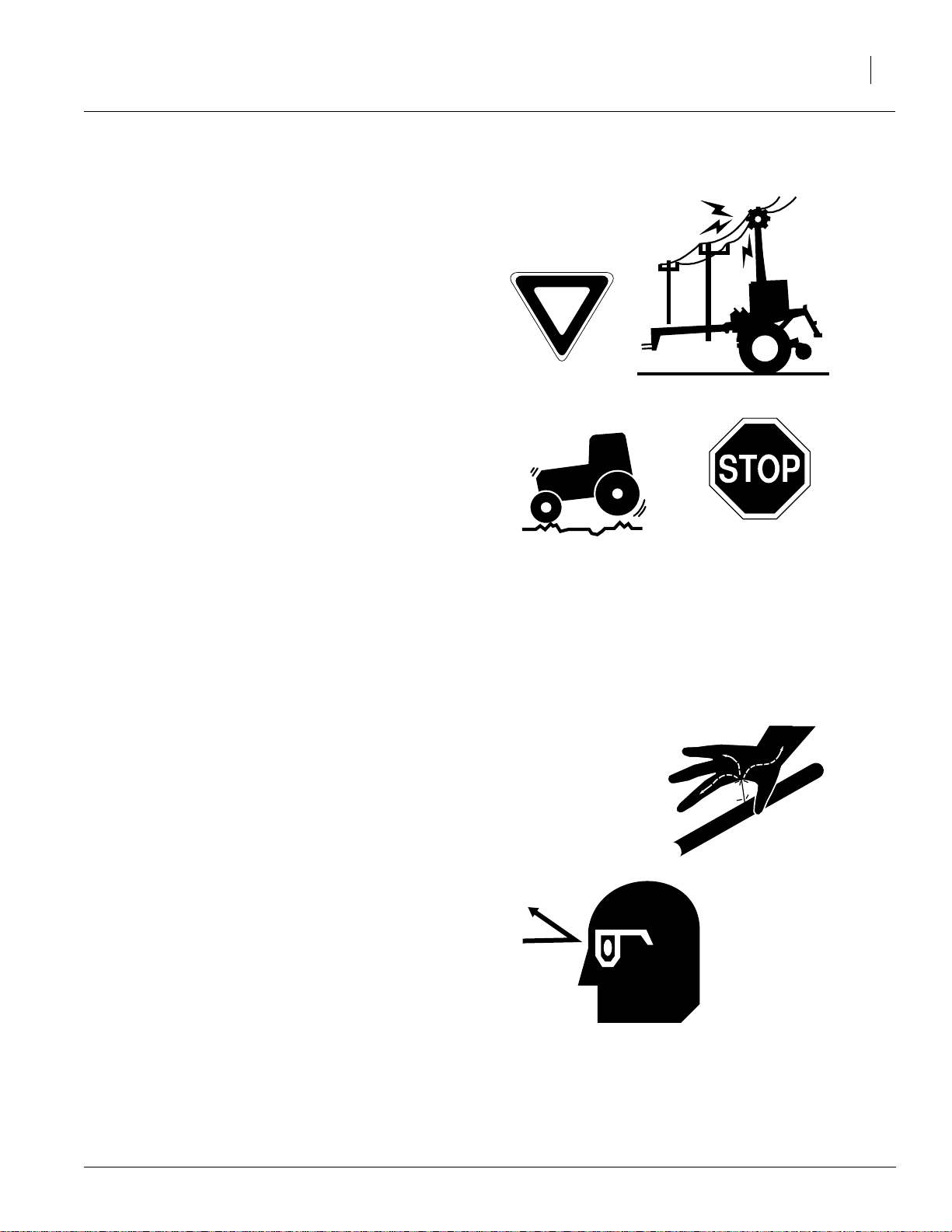

Look for Safety Symbol

The SAFETY ALERT SYMBOL indicates there is

a potential hazard to personal safety involved and

extra safety precaution must be taken. When you

see this symbol, be alert and carefully read the

message that follows it. In addition to design and

configuration of equipment, hazard control and

accident prevention are dependent upon the

awareness, concern, prudence and proper training of personnel involved in the operation,

transport, maintenance and storage of

equipment.

Important Safety Information

!

1

Be Aware of Signal Words

Signal words designate a degree or level of hazard seriousness.

DANGER indicates an imminently hazardous situation which, if not avoided, will result in death or

serious injury. This signal word is limited to the

most extreme situations, typically for machine

components that, for functional purposes, cannot

be guarded.

WARNING indicates a potentially hazardous situation which, if not avoided, could result in death or

serious injury, and includes hazards that are exposed when guards are removed. It may also be

used to alert against unsafe practices.

CAUTION indicates a potentially hazardous situation which, if not avoided, may result in minor or

moderate injury. It may also be used to alert

against unsafe practices.

DANGER

!

WARNING

!

CAUTION

!

9/1/2009

500-644M

Page 4

TSF660

2

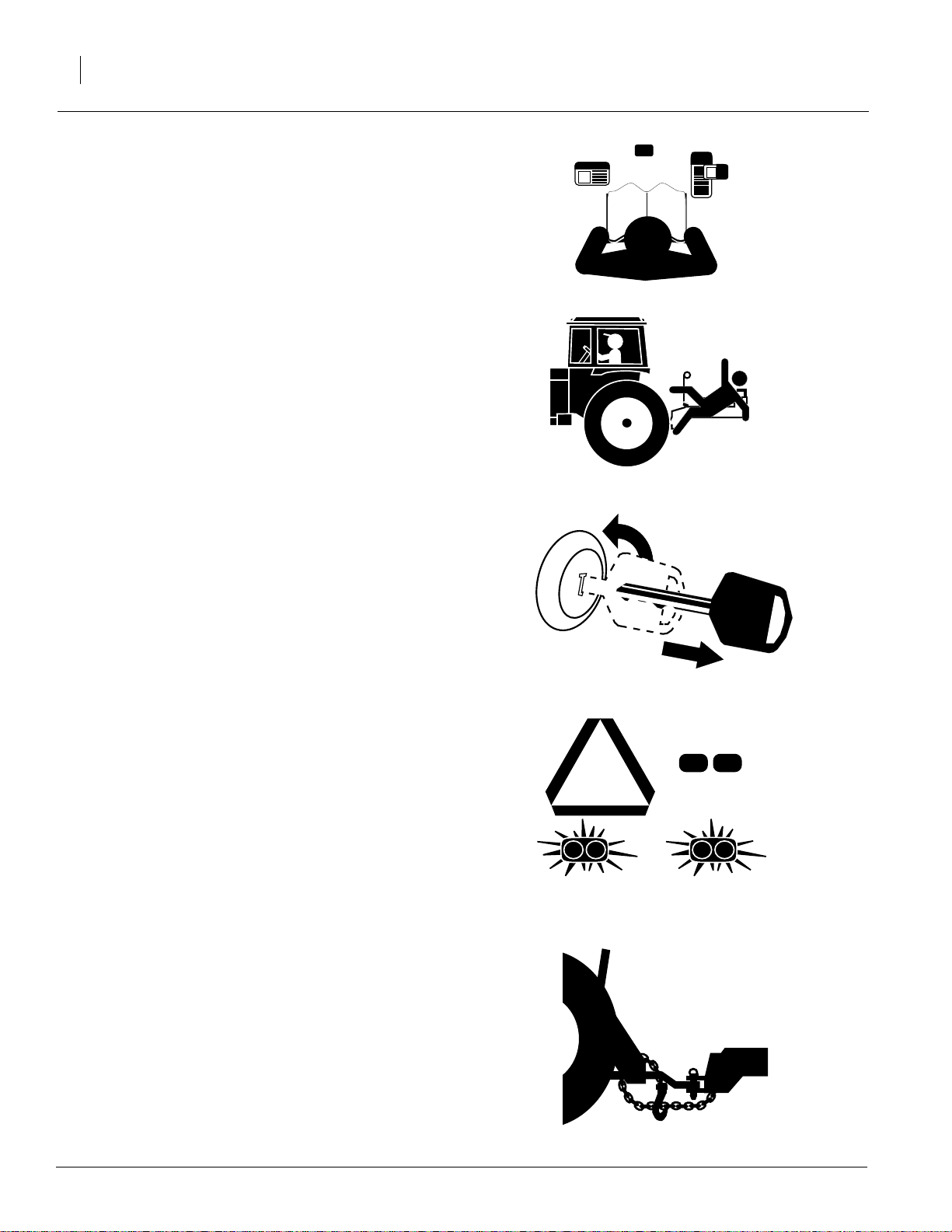

Be Familiar with Safety Decals

▲ Read and understand “Safety Decals,” page 8,

thoroughly.

▲ Read all instructions noted on the decals.

Keep Riders Off Machinery

Riders obstruct the operator’s view. Riders could

be struck by foreign objects or thrown from the

machine.

▲ Never allow children to operate equipment.

▲ Keep all bystanders away from machine dur-

ing operation.

Shutdown and Storage

▲ Fold Front Fold Boom Sprayer, put tractor in

park, turn off engine, and remove the key.

▲ Secure Front Fold Boom Sprayer using blocks

and supports provided.

OFF

▲ Detach and store Front Fold Boom Sprayer in

an area where children normally do not play.

Use Safety Lights and Devices

Slow-moving tractors and towed implements can

create a hazard when driven on public roads.

They are difficult to see, especially at night.

▲ Use flashing warning lights and turn signals

whenever driving on public roads.

▲ Use lights and devices provided with imple-

ment.

Use A Safety Chain

▲ Use a safety chain to help control drawn

machinery should it separate from tractor

drawbar.

▲ Use a chain with a strength rating equal to or

greater than the gross weight of towed

machinery.

▲ Attach chain to tractor drawbar support or

other specified anchor location. Allow only

enough slack in chain to permit turning.

▲ Replace chain if any links or end fittings are

broken, stretched or damaged.

▲ Do not use safety chain for towing.

500-644M

9/1/2009

Page 5

Transport Machinery Safely

Maximum transport speed for implement is 20

mph. Some rough terrains require a slower

speed. Sudden braking can cause a towed load to

swerve and upset.

▲ Do not exceed 20 mph. Never travel at a

speed which does not allow adequate control

of steering and stopping. Reduce speed if

towed load is not equipped with brakes.

▲ Comply with state and local laws.

▲ Do not tow an implement that, when fully

loaded, weighs more than 1.5 times the weight

of towing vehicle.

▲ Carry reflectors or flags to mark Front Fold

Boom Sprayer in case of breakdown on the

road.

Important Safety Information

3

▲ Keep clear of overhead power lines and other

obstructions when transporting. Refer to transport dimensions under “Specifications and

Capacities,” page 51.

▲ Do not fold or unfold the Front Fold Boom

Sprayer while the tractor is moving.

Avoid High Pressure Fluids

Escaping fluid under pressure can penetrate the

skin, causing serious injury.

▲ Avoid the hazard by relieving pressure before

disconnecting hydraulic lines.

▲ Use a piece of paper or cardboard, NOT

BODY PARTS, to check for suspected leaks.

▲ Wear protective gloves and safety glasses or

goggles when working with hydraulic systems.

▲ If an accident occurs, see a doctor immedi-

ately. Any fluid injected into the skin must be

surgically removed within a few hours or gangrene may result.

9/1/2009

500-644M

Page 6

TSF660

4

Practice Safe Maintenance

▲ Understand procedure before doing work. Use

proper tools and equipment. Refer to this manual for additional information.

▲ Work in a clean, dry area.

▲ Fold the Front Fold Boom Sprayer, put tractor

in park, turn off engine, and remove key before

performing maintenance.

▲ Make sure all moving parts have stopped and

all system pressure is relieved.

▲ Allow Front Fold Boom Sprayer to cool com-

pletely.

▲ Disconnect battery ground cable (-) before

servicing or adjusting electrical systems or

before welding on Front Fold Boom Sprayer.

▲ Inspect all parts. Make sure parts are in good

condition and installed properly.

▲ Remove buildup of grease, oil or debris.

▲ Remove all tools and unused parts from Front

Fold Boom Sprayer before operation.

Prepare for Emergencies

▲ Be prepared if a fire starts.

▲ Keep a first aid kit and fire extinguisher handy.

OFF

▲ Keep emergency numbers for doctor, ambu-

lance, hospital and fire department near

phone.

Tire Safety

Tire changing can be dangerous and should be

performed by trained personnel using correct

tools and equipment.

▲ When inflating tires, use a clip-on chuck and

extension hose long enough for you to stand

to one side–not in front of or over tire assembly. Use a safety cage if available.

▲ When removing and installing wheels, use

wheel-handling equipment adequate for

weight involved.

500-644M

911

9/1/2009

Page 7

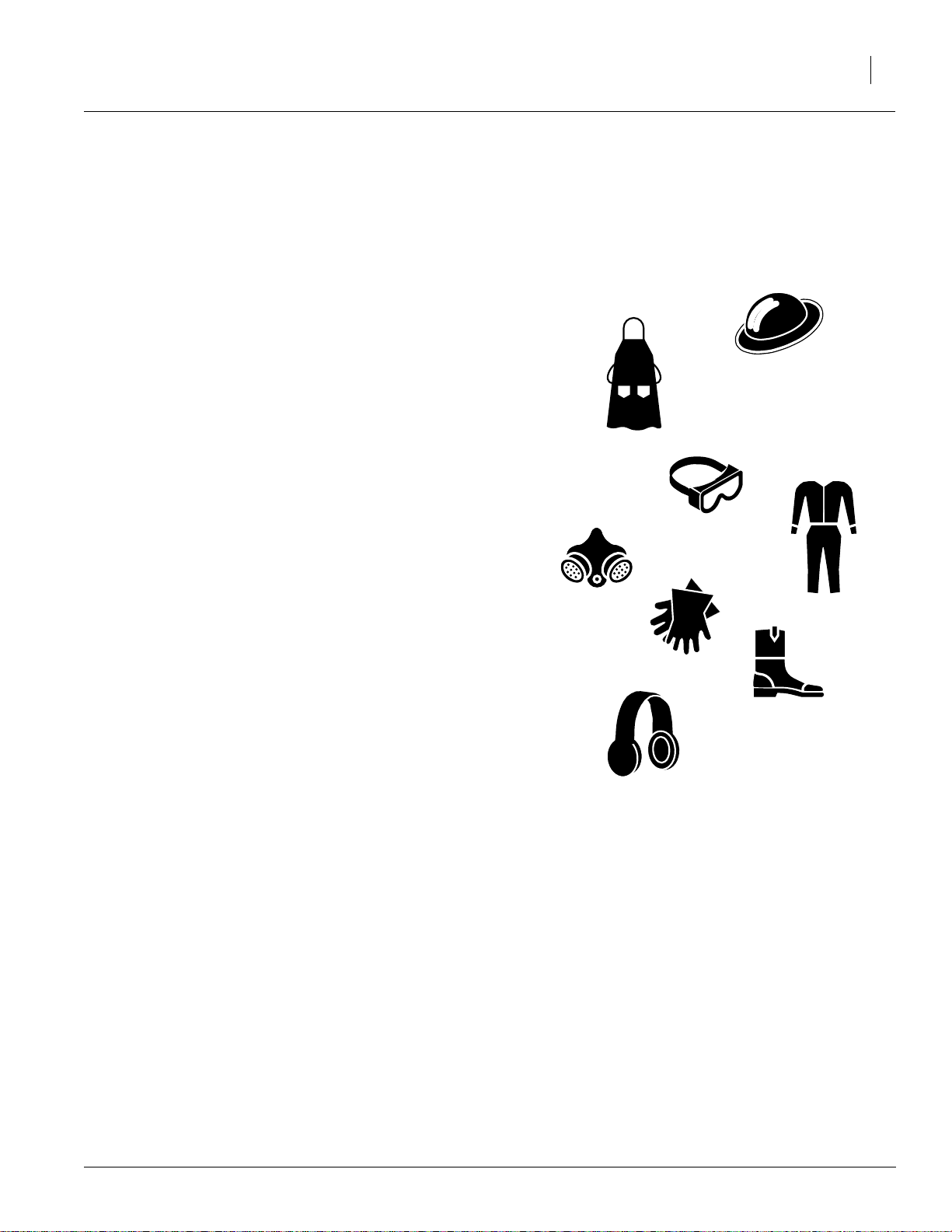

Wear Protective Equipment

Great Plains advises all users of chemical pesticides or

herbicides to use the following personal safety

equipment.

▲ Waterproof, wide-brimmed hat

▲ Waterproof apron.

▲ Face shield, goggles or full face respirator.

▲ Goggles with side shields or a full face respirator is

required if handling or applying dusts, wettable powders, or granules or if being exposed to spray mist.

▲ Cartridge-type respirator approved for pesticide

vapors unless label specifies another type of respirator.

▲ Waterproof, unlined gloves. Neoprene gloves are

recommended.

Important Safety Information

5

▲ Cloth coveralls/outer clothing changed daily; water-

proof items if there is a chance of becoming wet with

spray

▲ Waterproof boots or foot coverings

▲ Do not wear contaminated clothing. Wash protective

clothing and equipment with soap and water after

each use. Personal clothing must be laundered separately from household articles.

▲ Clothing contaminated with certain pesticides must

be destroyed according to state and local regulations. Read chemical label for specific instructions.

▲ Wear clothing and equipment appropriate for the job.

Avoid loose-fitting clothing.

▲ Prolonged exposure to loud noise can cause hear-

ing impairment or loss. Wear suitable hearing protection such as earmuffs or earplugs.

▲ Avoid wearing radio headphones while operating

machinery. Operating equipment safely requires the

full attention of the operator.

9/1/2009

500-644M

Page 8

TSF660

6

Handle Chemicals Properly

▲ Read and follow chemical manufacturer’s

instructions.

▲ Wear protective clothing.

▲ Handle all chemicals with care.

▲ Agricultural chemicals can be dangerous.

Improper use can seriously injure persons,

animals, plants, soil and property.

▲ Inhaling smoke from any type of chemical fire

is a serious health hazard.

▲ Store or dispose of unused chemicals as

specified by the chemical manufacturer.

▲ Before adding chemical to the tank, make

sure tank is at least half full. Do not pour concentrate into an empty tank.

▲ Spray only with acceptable wind conditions.

Wind speed must be below 5 mph. Make sure

wind drift of chemicals will not affect any surrounding land, people or animals.

▲ Never wash out the sprayer tank within 100

feet of any freshwater source or in a car wash.

▲ Rinse out the tank. Spray rinse water on last

field sprayed.

▲ Never leave fill hose attached to the sprayer

after filling tank. Chemicals in tank can siphon

out of tank and contaminate freshwater

source.

▲ Always keep hand-wash tank filled with clean

water and have soap available in case of an

emergency. Immediately and thoroughly flush

any area of the body that is contaminated by

chemicals.

▲ Do not touch sprayer components with mouth

or lips.

▲ If chemical is swallowed, carefully follow the

chemical manufacturer’s recommendations

and consult with a doctor.

▲ If persons are exposed to a chemical in a way

that could affect their health, consult a doctor

immediately with the chemical label or container in hand. Any delay could cause serious

illness or death.

▲ Dispose of empty chemical containers prop-

erly. By law rinsing of the used chemical container must be repeated three times. Puncture

the container to prevent future use. An alternative is to jet-rinse or pressure rinse the container.

▲ Wash hands and face before eating after

working with chemicals. Shower as soon as

spraying is completed for the day.

500-644M

9/1/2009

Page 9

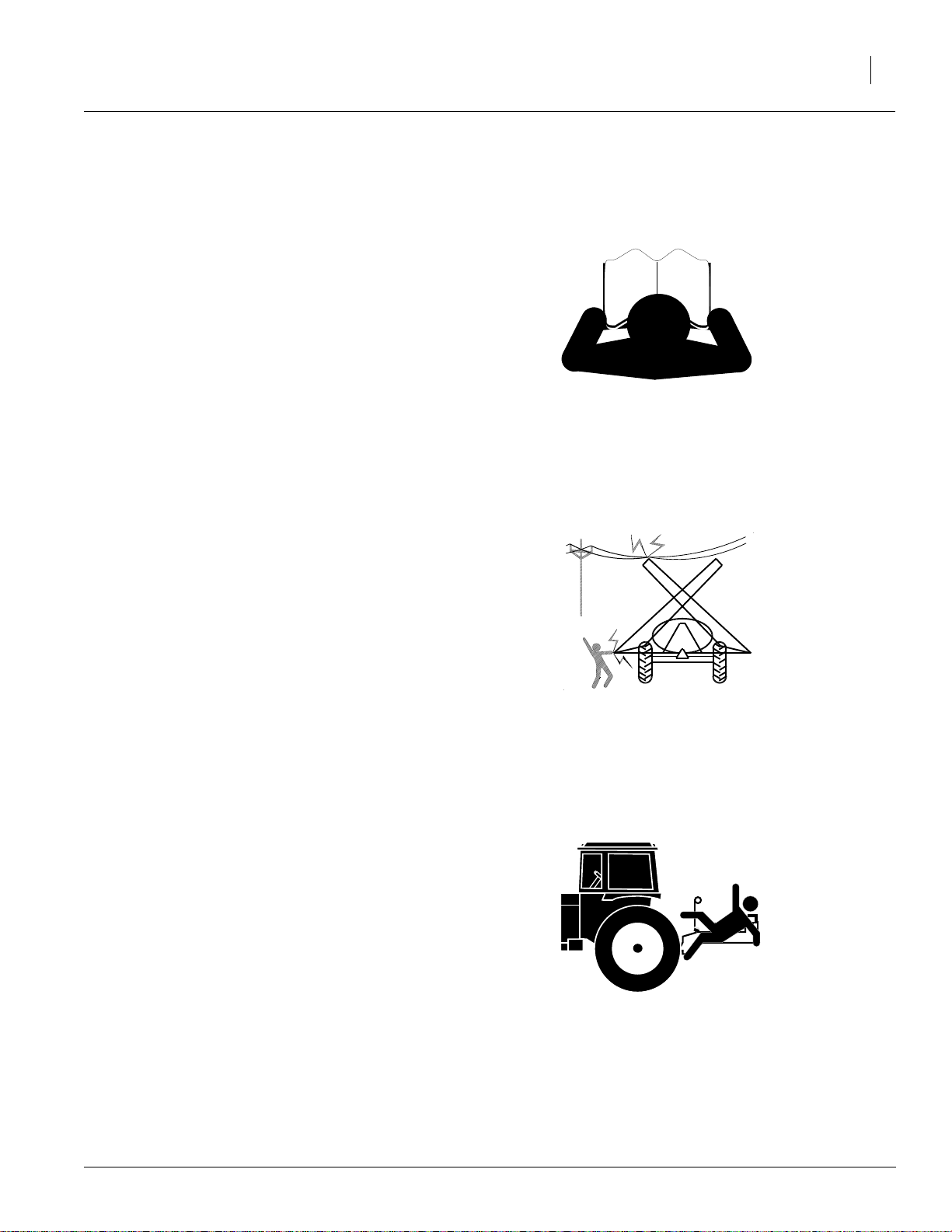

Safety At All Times

Thoroughly read and understand the instructions

in this manual before operation. Read all instructions noted on the safety decals.

▲ Be familiar with all Front Fold Boom Sprayer

functions.

▲ Operate machinery from the driver’s seat only.

▲ Do not leave Front Fold Boom Sprayer unat-

tended with tractor engine running.

▲ Do not dismount a moving tractor. Dismount-

ing a moving tractor could cause serious injury

or death.

▲ Do not stand between the tractor and Front

Fold Boom Sprayer during hitching.

▲ Keep hands, feet and clothing away from

power-driven parts.

Important Safety Information

7

▲ Wear snug-fitting clothing to avoid entangle-

ment with moving parts.

▲ Watch out for wires, trees, etc., when folding

and raising Front Fold Boom Sprayer. Make

sure all persons are clear of working area.

▲ Do not turn tractor too tightly, causing Front

Fold Boom Sprayer to ride up on wheels. This

could cause personal injury or equipment

damage.

▲ Use only water without pesticides added to

calibrate the sprayer.Do not exceed the calibrated sprayer speed and pressure when

operating.

▲ Spray with the boom in the unfolded position

only.

▲ The boom has many pinch points during field

operation and folding. Keep all bystanders

away.

9/1/2009

500-644M

Page 10

8

TSF660

Safety Decals

Your implement comes equipped with all safety

decals in place. They were designed to help you

safely operate your implement.

▲ Read and follow decal directions.

▲ Keep all safety decals clean and legible.

▲ Replace all damaged or missing decals. Order

new decals from your Great Plains dealer.

Refer to this section for proper decal placement.

▲ When ordering new parts or components, also

request corresponding safety decals.

▲ To install new decals:

1. Clean the area where the decal is to be

placed.

2. Peel backing from decal. Press firmly on

surface, being careful not to cause air

bubbles under decal.

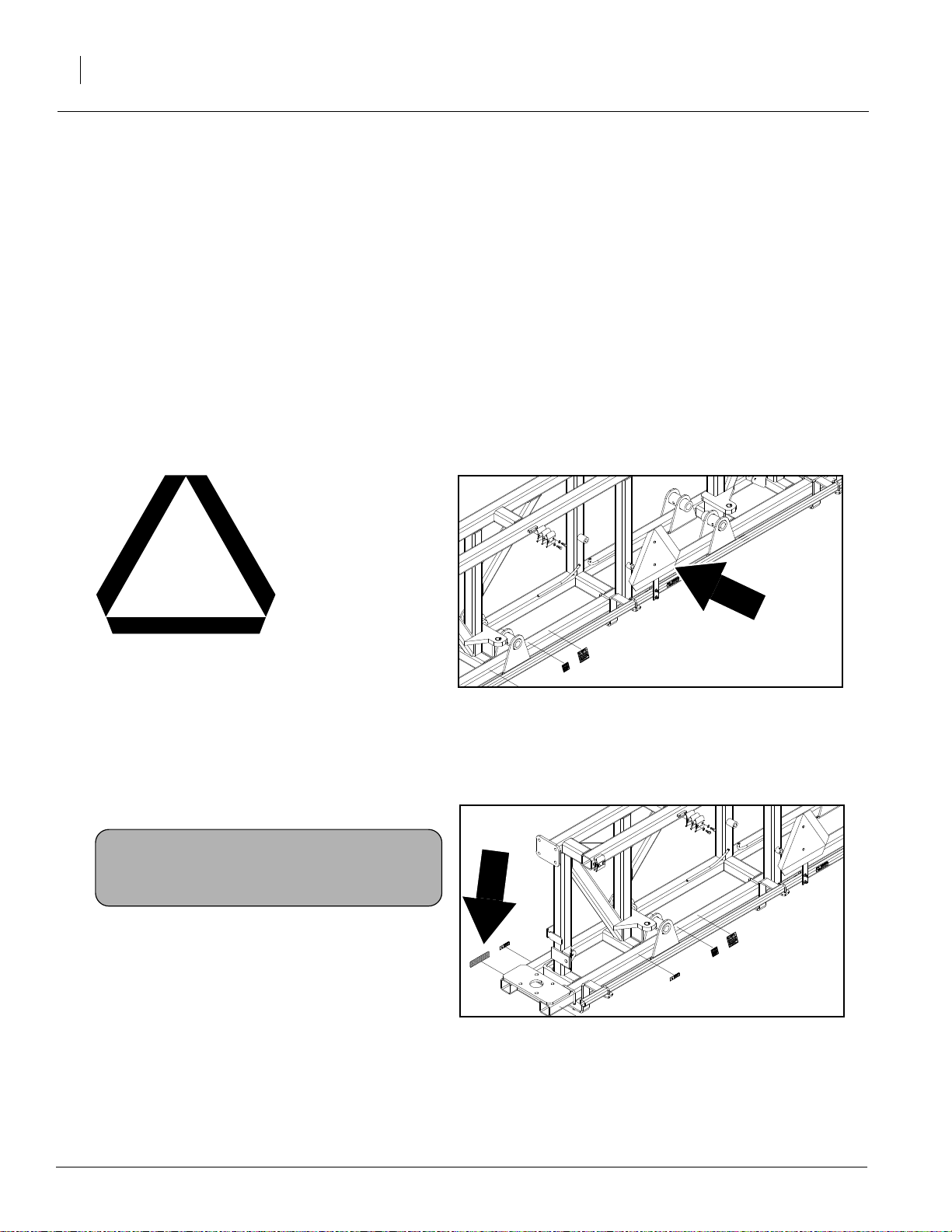

818-055C

Slow Moving Vehicle Label

Middle rear of center section, one total

838-265C

Amber Reflectors

Front of center section, both ends, two total

20410

20410

500-644M

9/1/2009

Page 11

13862

Important Safety Information

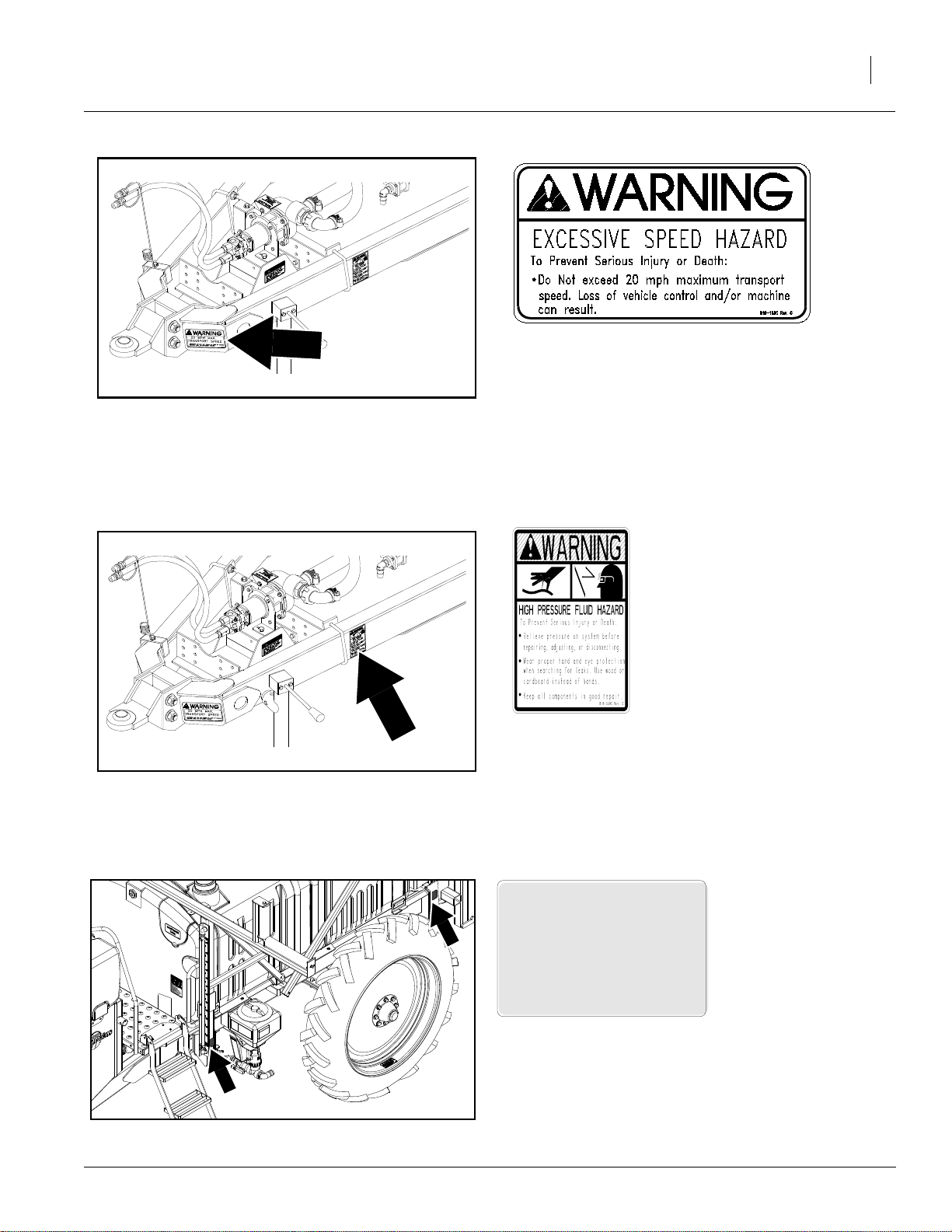

818-188C

Warning! Excessive Speed Hazard

Front of tongue, one total

9

13862

818-339C

Warning! High Pressure Fluid Hazard

Side of tank frame and rear center of

boom center section, two total

818-265C

Amber Reflector

Front and rear {both sides} four total

9/1/2009

500-644M

Page 12

10

TSF660

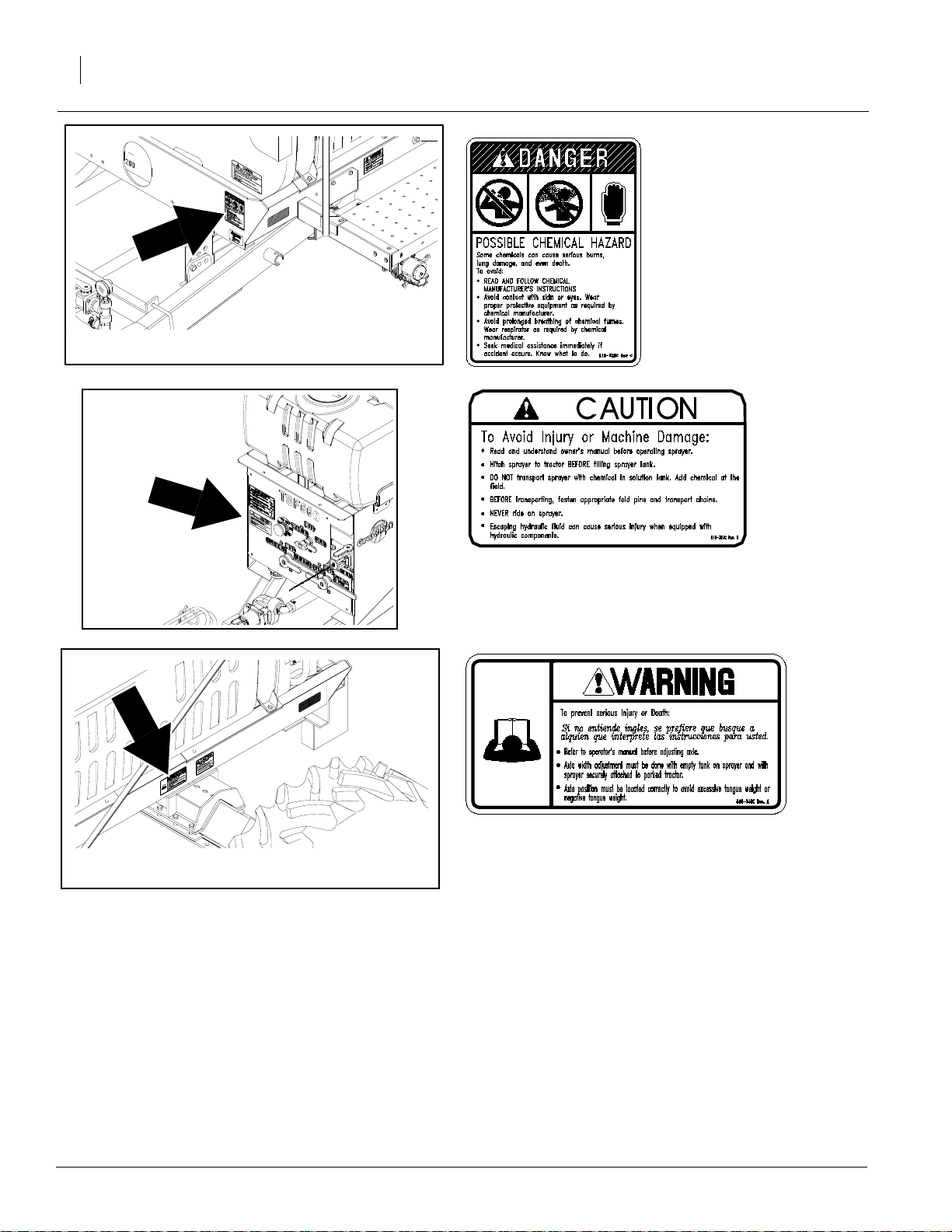

13863

818-323C

Danger! Possible Chemical Hazard

Front of tank frame and rear center

of boom center section, two total

24033

13864

818-324C

Caution! To Avoid Injury or Machine Damage

Front of tank frame, one total

818-548C

Warning! To Prevent Serious Injury or Death

On each side of tank frame, two total

500-644M

9/1/2009

Page 13

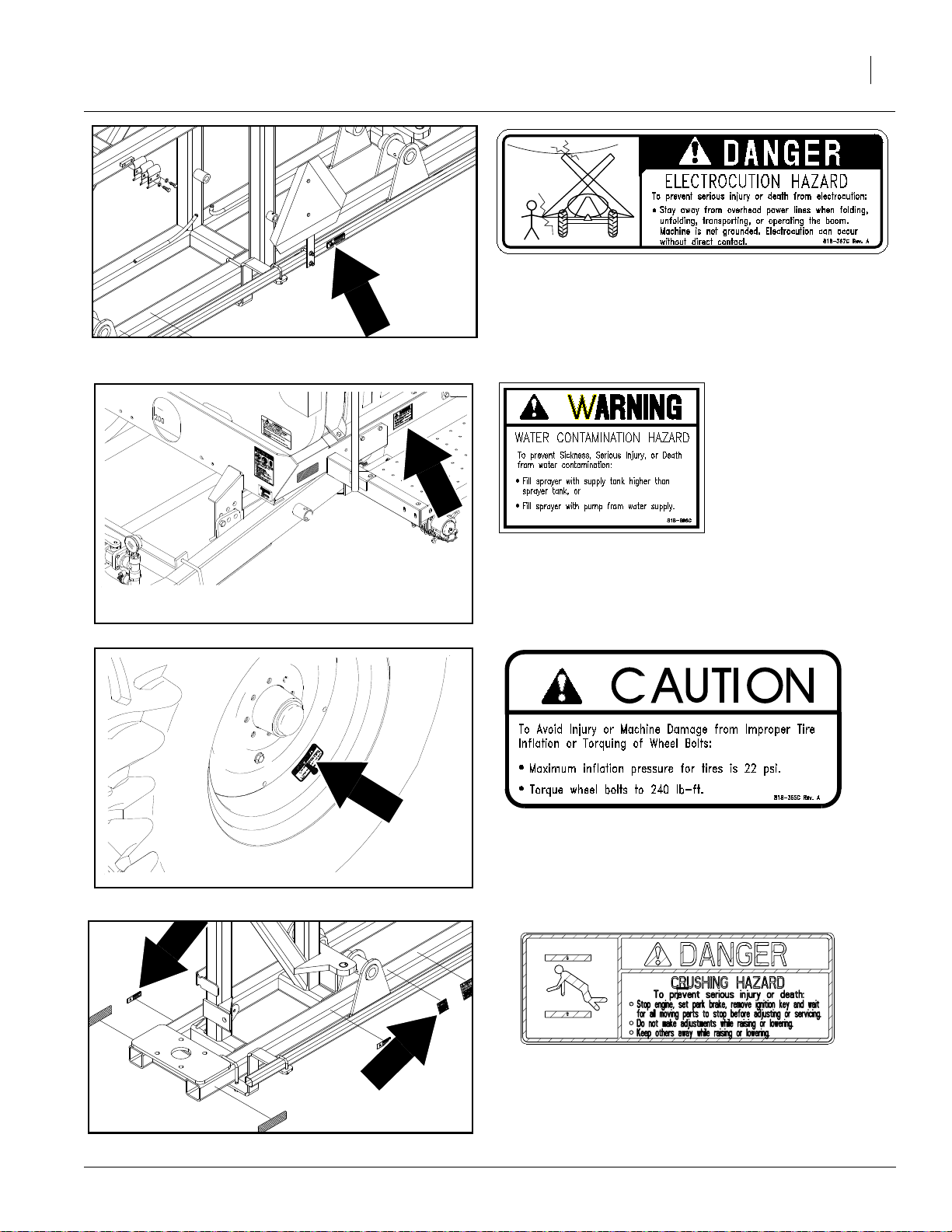

2041020410

Important Safety Information

818-367C

Danger! Electrocution Hazard

Middle rear of center section, one total

11

13863

13838

818-696C

Warning! Water Contamination Hazard

Side of tank frame, one total

818-365C (SN A1082N-)

848-347C (SN A1083N+)

Caution! Tire inflation & wheel bolt torquing information

(13.6 x 38 or 320/85R38 wheel rims), 0 or 2 total

9/1/2009

20410

818-864C

Danger! Crushing Hazard

Rear center and both ends front side of center section,

three total

500-644M

Page 14

12

TSF660

20278

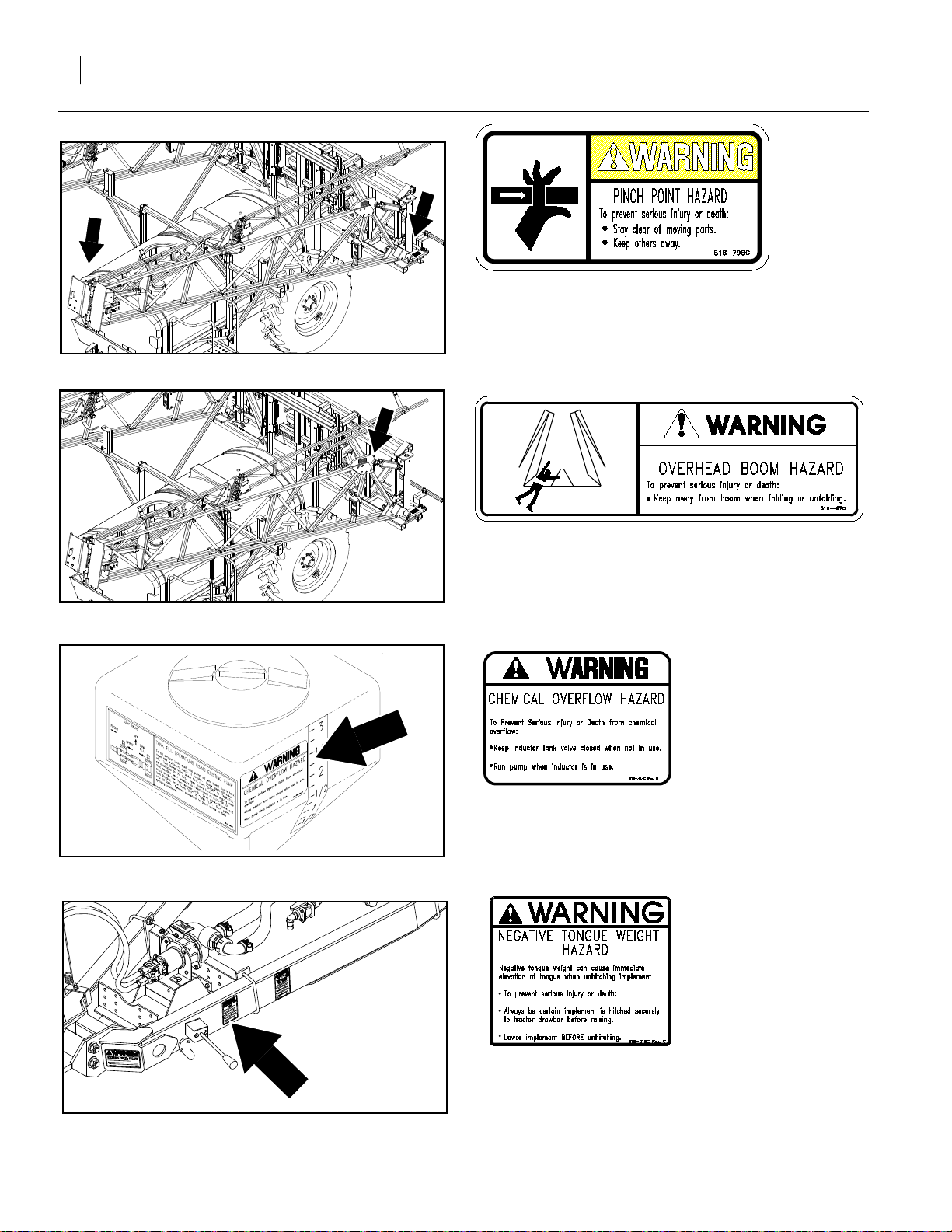

818-798C

Warning! Pinch Point

Decals at wing hinge points, front and back of booms, ten

total

20278

15763

818-467C

Warning! Overhead Boom

Left and right wings, two total

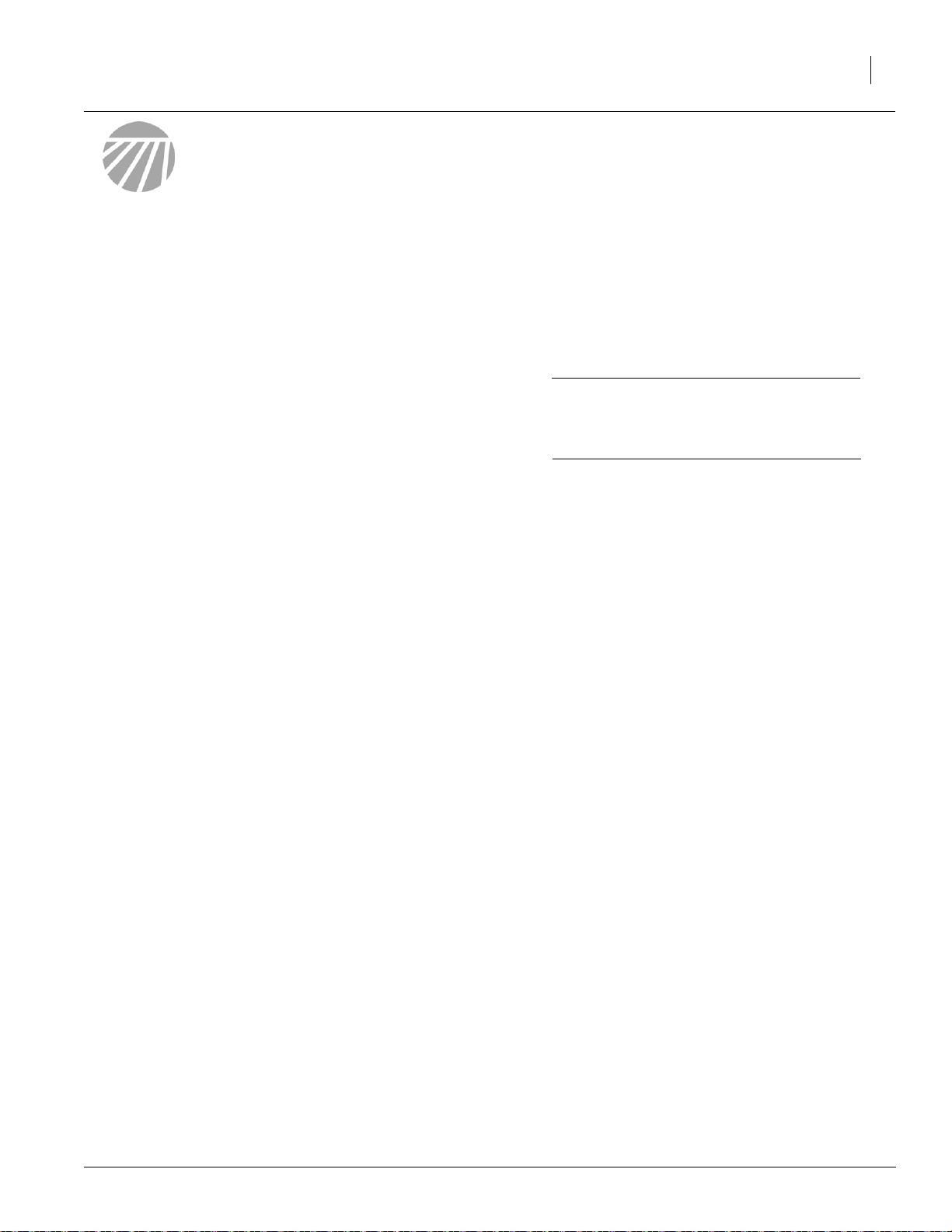

818-303C

Warning! Chemical Overflow

On chemical tank, one total

500-644M

20411

818-019C

Warning! Negative Tongue Weight

On tongue, one total

9/1/2009

Page 15

Introduction

Introduction

13

Great Plains welcomes you to its growing family of

new product owners. This Front Fold Boom Sprayer has been designed with care and builtby skilled

workers using quality materials. Proper setup,

maintenance and safe operating practices will

help you get years of satisfactory use from the

machine.

Description of Unit

The TSF660 sprayer is capable of spraying at

60’.The level float boom is fully suspended starting with vertical spring suspension in a 42”

hydraulic elevator which provides a wide range of

boom height adjustment along with gas shocks

that provide side-to-side stability.

Intended Usage

Use these booms as part of a pressurized sprayer

system to apply liquid pesticides, herbicides or

fertilizers to production-agriculture crops only. Do

not modify sprayer for use with attachments other

than those approved by Great Plains.

Models Covered

TSF660

Definitions

The following terms are used throughout this

manual.

Right-hand and left-hand as used in this manual

are determined by facing the direction the machine

will travel while in use unless otherwise stated.

IMPORTANT: A crucial point of information related to the preceding topic. For safe and correct operation, read and follow the directions

provided before continuing.

NOTE: Useful information related to the preceding

topic.

9/1/2009

Using This Manual

This manual will familiarize you with safety, assembly, operation, adjustments, troubleshooting

and maintenance. Read this manual and follow

the recommendations to help ensure safe and efficient operation.

The information in this manual is current at printing. Some parts may change to assure top

performance.

500-644M

Page 16

TSF660

14

Owner Assistance

If you need customer service or repair parts, contact a Great Plains dealer. They have trained

personnel, repair parts and equipment specially

designed for Front Fold Boom Sprayer products.

Refer to Figure 1

Your machine’s parts werespecially designed and

should only be replaced with Front Fold Boom

Sprayer parts. Always use the serial and model

number when ordering parts from your Great

Plains dealer. The serial-number plate is located

on the front of the tank frame as shown.

Record your drill model and serial number here for

quick reference:

Model Number:__________________________

Serial Number: ___________________________

Your Great Plains dealer wants you to be satisfied

with your new machine. If you do not understand

any part of this manual or are not satisfied with the

service received, please take the following

actions.

1. Discuss the matter with your dealership service manager. Make sure they are aware of

any problems so they can assist you.

2. If you are still unsatisfied, seek out the owner

or general manager of the dealership.

3. For further assistance write to:

Product Support

Great Plains Mfg. Inc., Service Department

PO Box 5060

Salina, KS 67402-5060

Figure 1

Serial Number Plate

23312

500-644M

9/1/2009

Page 17

Preparation and Setup

!

!

Before You Start

Read and understand the owners manual for your

sprayer. A basic understanding of how the sprayer

works will aid in the assembly, setup and operation of your sprayer.

Perform these checks before setting up your

cross-fold boom.

1. Read and understand “Important Safety Information,” beginning on page 1.

2. Check that all working parts are moving freely, bolts are tight, and cotter pins are spread.

3. Check that all grease fittings are in place and

lubricated. Refer to “Lubrication,” page 46.

4. Check that all safety decals and reflectors are

correctly located and legible. Replace if damaged. Refer to “Safety Decals,” page 8.

Preparation and Setup

15

Hitching Tractor to Sprayer

DANGER

You may be severely injured or killed by being crushed

between the tractor and Front Fold Boom Sprayer. Do

not stand or place any part of your body between Front

Fold Boom Sprayer and moving tractor. Stop tractor

engine and set park brake before installing the hitch

pin.

DANGER

Electrocution hazard. To prevent serious injury or

death from electric shock, keep clear of overhead power lines when transporting, folding or unfolding boom.

Boom is not grounded. Electrocution can occur without direct contact. Refer to transport dimensions under

“Specifications and Capacities”, page 51. Do not fold

or unfold boom while tractor is moving.

9/1/2009

500-644M

Page 18

TSF660

16

A clevis hitch is used. Park the sprayer in an open,

flat area with the jack in the park position. See figure

2.

Refer to Figure 2

1. Park the sprayer in an open, flat area with the

jack in the park position.

Refer to Figure 3

2. Back the tractorup to the sprayer. Secure tractor

to sprayer with bolt (1), flat washer (2), and hex

nut (3).

3. Now that the sprayer is attached to the tractor,

prepare to level the frame of the sprayer by securely supporting the front of the frame with a

hoist.

13811

4. Adjust theframe by moving the hitch up ordown.

Hitch may be turned over for further adjustment.

The frame should be sloping to the front by

about one degree. This will allow the fluid to

drain into the sump.

Figure 2

Jack In Parking Position

500-644M

24497

Figure 3

Hitching Tractor to Sprayer

9/1/2009

Page 19

Hydraulic Pump Setup

The hydraulic motor used on all liquid pumps isa7gpm

(23 liter/min.) motor. If the tractor used on the sprayer

does not have the capabilities to adjust the remotes down

to this flow, then a Hydraulic Flow Divider Kit must be installed so that flow can be controlled to prevent operating

the pump at excessive speeds. See a Great Plains dealer

for more information.

1. Connect the hydraulic pump to the tractor remotes.

See “Hydraulic Pump Hookup” on page 18 for

details. If no limiter is required, skip to step 7.

DO NOT move the hydraulic lever into the neutral position while the hydraulic pump is running. To do so may

cause damage to the hydraulic pump.

Preparation and Setup

Figure 4

Ace Pump Flow Limiter

17

23395

Ace Pump Flow Limiter (Option)

The flow limiter (Great Plains part number 829-125C) is

a hydraulic device designed to shut off the flow of

hydraulic oil when a specified flow is exceeded. On tractors with LOAD SENSING (LS) Closed Center hydraulic

systems, this device limits the flow of oil to the Ace motor

and prevents failures due to misapplication.

Newer Case-IH, John Deere, New Holland, and CAT

tractors, present a great potential to turn the motors

beyond their rated speeds. Flows out of the hydraulic

valves can exceed 20 gpm while the motors are rated at

4-11 gpm. The flow limiter protects the Ace motor by

shutting off when hydraulic flows exceed the motor’s

capacity.

The flow limiter should not be used on OPEN Center or

PRESSURE COMPENSATING Closed Center hydraulic

systems. The flow limiter should not be used with a

restrictor orifice.

Flow Limiter Installation

2. Install the flow limiter in the inlet port of the Ace

motor.

3. Shut off boom and agitation valves on the sprayer to

deadhead the sprayer pump flow.

4. Adjust the flow control on the tractor to the minimum

flow setting (typically a “turtle” icon).

5. Move the hydraulic lever to the “Lower/Retract” position.

6. Adjust the flow control on the tractor until the sprayer

system deadhead pressure is 80 psi.

Note: If the flow limiter stops the flow of oil to the motor:

6a) Move the hydraulic lever to the “Neutral” position. This removes the oil pressure from the flow

limiter and allows it to reset.

6b) Adjust the flow control to a lower flow position.

6c) Repeat step 5 and step 6.

Setting Pump Rate

7. To determine the correct setting of the flow rate, start

out with the hydraulic flow control valve at minimum

flow for the outlets that operate the pump.

8. With water in the sprayer tank and in the pump, place

the hydraulic lever in the float position.

9. Open up the sprayer flow control valve to its maximum setting.

10. Start the tractor and engage the pump by placing the

hydraulic lever in the down (forward) position.

11. Once the system builds pressure, close the agitation

valve, shut off the boom section switches, and close

the throttling valves (if applicable).

12. The pump is now at dead head pressure and the

hydraulic control valve must be adjusted so that the

spray pressure reaches 80 PSI maximum on the

nozzle pressure gauge. This process should be done

with the tractor throttle set at normal operating

speed. Mark this setting on the hydraulic control

valve for future reference.

13. Open up the agitation valve.

9/1/2009

500-644M

Page 20

TSF660

18

Hydraulic Hookup

The standard TSF660 sprayer has a single hydraulic connection at the hitch. Each cart hydraulic function is served

by an electro-hydraulic control valve at boom center.

If an optional hydraulic pump is installed, there is a second hydraulic connection for the pump, which is located

near the hitch.

Refer to Hose Label

Both hose sets have labels for flow conventions. These labels use cylinder Base/Extend and Rod/Retract icons.

Be sure to connect these to the matching tractor remotes,

so that when remote levers are activated as described in

this manual:

a. booms move in the described directions, and

b. pump flow is forward and not reversed.

Sprayer Control Hydraulic Hookup

If the sprayer has a hydraulic pump, and the tractor has

only one circuit capable of continuous flow or only one capable of adjustable continuous flow, reserve that circuit for

the pump, and use another for the main sprayer functions.

1. Connect the main sprayer hydraulic hoses to suitable

tractor remotes. They are easily identified, as they

pass behind the pump.

Hydraulic Pump Hookup

The hydraulic motor used on all liquid pumps is a 7 gpm

(23 liter/min.) motor. If the tractor used on the sprayer

does not have the capabilities to adjust the remotes down

to this flow, then a Hydraulic Flow Divider Kit must be installed so that flow can be controlled to prevent operating

the pump at excessive speeds. See a Great Plains dealer

for more information.

Outlet Port

Hose Label

27270

Inlet Port

Refer to Ace Pump Connections

2. The pressure hose coming out of the tractor remotes

must be connected to the motor inlet port (“I” on current pumps; “A” on older pumps, Base end on hose

label), and the return line connected to the motor

outlet (“O” on current pumps, “B” on older pumps,

Rod end on hose label).

3. Before operating, place a stop in the neutral position

for the tractor hydraulics so that the hydraulic lever

can only be moved to the float and down positions.

Refer to the tractor’s operator’s manual or tractor

dealer on information for the neutral stop.

Note: DO NOT move the hydraulic lever into the neutral

position while the hydraulic pump is running. To do

so may cause damage to the hydraulic pump.

4. See page 21 for setting flow rate.

500-644M

Motor Model (204N,206N,210N)

Ace Pump Connections

Date Code

27141

9/1/2009

Page 21

Axle Wheel Spacing Adjustment

!

!

CAUTION

Axle position must be located correctly to avoid excessive tongue weight or negative tongue weight which

could cause mechanical failure resulting in personal

injury.

Refer to Figure 5

The wheel spacing of the axle can also be adjusted for differing row spacings.

CAUTION

Do not adjust the wheel spacing wider than 120". To

do so may cause a falling axle hazard while the sprayer is in service.

24035

Figure 5

Sprayer Axle Assembly

Preparation and Setup

19

9/1/2009

500-644M

Page 22

20

TSF660

Quad-Jet Agitators

Refer to Figure 6

The Quad-Jet agitators are the two agitators in

the sprayer tank. Each agitator has four holes that

shoot jets of water out at a high velocity. The agitator head is oriented at 45 degrees, with

reference to the tank ends, so that the water jets

are aimed at the corners of the tank. Refer to Figure 22 to ensure proper agitation, make sure that

the agitator heads are always kept in the orientation shown.

Raven SCS 440

The Raven SCS 440 (Sprayer Control System) is

designed to improve the uniformity of spray applications. Its performance relies on the installation

and preventive maintenance of the complete

sprayer. An installation and service manual are

provided with this sprayer. It is important to read

and understand this manual before operating the

system.

Figure 6

Tank Top View

Quad-Jet Agitator Head Orientation

11585

Note: Refer to the Raven SCS 440 manual for

step-by-step instructions for installing and operating.

The SCS 440 system consists of a computerbased Control Console, a Speed Sensor, a turbine type Flow Meter and a motorized Control

Valve. The Console mounts directly in the cab of

the tractor for easy operator use. The Radar

Speed Sensor is mounted to the frame of the tractor or sprayer (wheel drive and speedometer

Drive Speed Sensors are also available.) The motorized Control Valve and Flow Meter mount to the

framework supporting the boom valves. Appropriate cabling is furnished for field installation.

The operator sets thetarget volume per area tobe

sprayedand the SCS440 automaticallymaintains

the flow regardless of vehicle speed or gear selection. A manual override switch allows the operator

to manually control flow for system check-out and

spot spraying. Actual volume per area being applied is displayed at all times. The SCS 440

additionally functions as an area monitor, speed

monitor and volume totalizer.

Electrical Connections

The following equipment must be connected to

the tractor’s battery: Raven 440 Controller, Fasse

Valve Hydraulic Control Box, and Optional Foam

Marker Control.

To connect the Raven 440 Controller to the tractor

battery, see pages 7 and 8 in the Raven Installation and Service Manual.

To connect the Fasse Valve Hydraulic Control Box

to the tractor battery, follow the steps below.

1. Use the 6 ft, two-wire red and black cable to

connect the hydraulic controls.

2. Connect the red wire from each cable to the

positive terminal and the black wire from each

cable to the negative terminal.

Use the 6 ft gray cable to connect the Optional

Foam Marker Control.

500-644M

9/1/2009

Page 23

Preparation and Setup

21

Adjustments Before Going to the

Field

1. Securely hitch the sprayer to the tractor and fasten

the safety chain. Make sure the hitch is adjusted

so that the front of sprayer is 1 1/2” lower than the

rear so that liquid in the tank will drain to the sump.

2. Fill sprayer 1/2 full with water for calibrating purposes.

3. Hook-up the pump to the tractor. Engage the

pump slowly and check for any leaks.

4. Set the deadhead pressure of the pump at 80

P.S.I. depending on how the pump is driven.

Hydraulic Driven Pumps

a. To determine the correct flow rate to the hy-

draulic motor, start out with the hydraulic control valve set at a minimum flow, and the

hydraulic lever in the float position.

b. Open up the sprayer control valve to its maxi-

mum setting. (On the Raven 440 monitor, with

the power switch on, the rate switch must be

placed in the manual position, and the increase/decrease switch must be pushed to increase for 10-12 seconds.)

c. Start the tractor and engage the pump by

placing the hydraulic lever in the down position. Once the system builds pressure on the

nozzle pressure gauge, speed up the tractor

throttle to normal operating speed. Shut off

the boom section switches and close the agitation valve.

d. The pump is now at deadhead pressure and

the hydraulic control valve must be adjusted

up until the spray pressure reaches 80 P.S.I.

maximum on the nozzle pressure gauge.

Mark this setting on the hydraulic control valve

for future reference.

e. Open up the agitation valve.

5. Calibrate sprayer. Sprayer calibration (1) prepares

your sprayer for operation, and (2) diagnoses nozzle wear. This will give you optimum performance

from your nozzles and ensure accuracy from your

sprayer.

Equipment Needed:

• Calibration Container

Step 1

Measure off a 200’ course in the area to be

sprayed or in an area with similar surface conditions. Select the engine throttle setting and gear

that will be used when spraying. The starting

post should be far enough away to permit your

tractor/sprayer to reach desired spraying speed.

Hold that speed as you approach the “start”

marker, and check the time required to travel

through the course to the “end” marker. Repeat

the above procedure, and average the times that

were recorded. Use the following equation to determine the exact ground speed.

Speed (MPH) = Distance (ft.) x 60

Time (seconds) x 88

Example: MPH = 200 x 60

27x88

MPH = 12000

2376

MPH = 5.05

Step 2

Determine the application rate at which your

chemical should be sprayed. In determining

which spray nozzles to use with your sprayer, you

must know:

a. Nominal application pressure ____P.S.I.

b. Target application rate ____GPA

c. Target speed ____MPH

d. Nozzle spacing ____W (in)

Using this information, calculate the volume per

minute, per nozzle as follows:

GPM = GPA x MPH x W (nozzle spacing)

5,940

Example:

a. Nominal application pressure 30 P.S.I.

b. Target application rate 20 GPA

c. Target speed 5.0 MPH

d. Nozzle spacing 20 W (in)

GPM=20GPAx5MPHx20W(in) = .34

5,940

• Calculator

• Stopwatch or wristwatch with second hand.

9/1/2009

Using GPM .34 and pressure 30 P.S.I., you

would select a nozzle from your nozzle chart that

comes closest to providing the desired output.

500-644M

Page 24

22

TSF660

Step 3

Turn on your sprayer and adjust the pressure. Operate the sprayer at desired pressure and catchthe

discharge in the calibration container for one

minute. Divide 128 into the number of ounces

caught to determine gallons per minute (GPM) per

nozzle. 128 fluid ounces equals one gallon.

Example:

OPM (ounces per minute) ÷ 128 = GPM (gallons

per minute)

44 OPM ÷ 128 =.34 GPM

Step 4

Determine your nozzle spacing in inches.

Example: 1 nozzle every 20 inches.

Solution:

GPA (gallons per acre) = 5,940 x GPM(per nozzle)

MPH x W (nozzle spacing)

Example: GPA = 5,940 x .34

5.05 x 20

GPA = 2020

101

GPA = 20

The above information will assure you of a check for

accurate application in the event there is an error in the

gauge, nozzle spacing, nozzle height, tractor speed or

nozzle wear. Since all tabulations are based on spraying water, conversion factors must be used when

spraying solutions which are heavier or lighter than

water.

Field Adjustments

Boom Height

After calibrating the sprayer for the specific nozzle

that will be used at a desired pressure and tractor

speed, the main field adjustment is the boom height.

Depending on which type of nozzle is being used,

set the boom height so that the correct overlap for

that specific nozzle is achieved. If the crop canopy is

taller in some fields than others, adjust the boom

height accordingly. Refer to the Nozzle Charts in the

Application Guide to determine the height of the

boom.

Agitation Adjustments

The agitation valve is used to adjust the pressure to

the agitation nozzles in the tank. Refer to the agitation gauge, and adjustthe pressure to a desired rate.

Different chemicals require different agitation pressures to keep the chemical in suspension. (See

chemical label)

Tank Straps

The tank straps that wrap around the sprayer tank

may become loose after the first few hours of operation. This occurs when the tank settles in the saddle.

Polyethylene tanks are especially susceptible to this.

Retighten the tank straps to secure the tank.

If sprayer is equipped with a Raven 440 Automatic

Rate Controller, this simple calibration procedure will

also work for verifying speed and proper nozzle output.

All Raven 440 Control Systems require either wheel

drive speed sensor magnets or a radar speed sensor.

Calibration procedures for the speed sensor magnets

can be found in the Raven 440 manual. Calculation

procedures for radar speed sensors are included with

each radar unit dependent on make and model. Make

sure to follow initial programming instructions (Step 3)

of the Raven manual to select either SP1-(wheel drive

sensor), or SP2-(radar sensor).

500-644M

9/1/2009

Page 25

!

Operating Instructions

Operating Instructions

23

Basic Sprayer

Operating Procedures

DANGER

Read and follow chemical manufacturer’s instructions. Some chemicals can cause serious burns, lung

damage and even death.

1. Securely hitch the sprayer to the tractor and

fasten the safety chain. Make sure the hitch is

adjusted so that the liquid in the tank will drain

to the sump of the tank. Refer to Tractor/

Sprayer Hook-Up in the “Preparation and

Set-up” section on page 15.

2. Check the tire pressure in each tire. Refer to

the Tire Inflation Chart in the “Appendix”

section on page 51.

3. Lubricate the sprayer as needed. Refer to the

Lubrication portion of the “Maintenance and

Lubrication” section starting on page 46.

4. Hook-Up the pump to the tractor. Refer to

“Preparation and Set-up” on page 15 and

follow the instructions

5. When transporting the sprayer, DO NOT exceed 20 mph and DO NOT transport with

chemical in the tank.

6. NEVER allow anyone to ride on the sprayer.

7. Make sure all tank shut off valves are turned

on.

8. Calibrate sprayer with water only, not chemical and water. Calibrate with the sprayer tank

half full of water. Refer to the calibration procedures in the Application Guide.

9. Adjust the boom height required for the nozzles and spacing to be used. (Refer to nozzle

tables in the Application Guide.)

10. Check and clean, if necessary, pump, nozzles

and Whirlfilter®.

11. Check the sprayer initially and periodically for

loose bolts, pins and hose clamps. Check the

hoses, pumps, valves and fittings for leaks.

12. Make sure that the hand wash tank is full of

clean water.

Make sure to read the label on the chemical

compound that is to be applied. It is the law.

13. Consider how the chemical will be stored and

how you will dispose of the chemical, according to the chemical label.

14. When calibrating, filling the tank, or working

around chemicals, wear protective clothing

that covers the body. Refer to “Personal Safe-

ty Equipment” on page 5. Have soap and

clean water available to wash any exposed areas. Never open a container with your bare

hands.

15. When filling the sprayer, it is better to mix the

chemical in the field where it is to be applied.

Position the sprayer 100 feet from any well or

other water source before mixing the chemi-

cal.

16. By law, you must repeat the rinsing of the

chemical container 3 times. The container

should then be punctured to prevent future

use. An alternative is to jet-rinse or pressure

rinse the container.

17. Check the condition of hoses and connections frequently. Release system pressure

before working on the sprayer by shutting off

the pump and flipping the individual boom

section switches on the control box. Always

wear rubber gloves when making repairs or

adjustments.

18. Apply spray when the wind is 5 m.p.h. or less.

Minimize drift by using nozzle tips with the

largest practical openings and by operating

the sprayer boom at the lowest practical

height and lowest practical pressure.

19. Drive at the same speed you used in your calibration. Refer to Application Guide. Keep

your sprayer calibrated.

20. If possible work crosswise to the wind, starting from the downwind side of the field. Do

this so you won’t ever be heading directly into

chemical fumes.

9/1/2009

500-644M

Page 26

24

O

TSF660

21. Take note of adjoining crops, houses, gardens, people, etc.

22. When you are finished spraying, empty the

tank and flush the sprayer with water, including the pump, the nozzles and the bypass line

from the throttling valves. Properly store the

chemical emptied from the tank or dispose of

it by the recommendations on its label.

23. When turning at the end of a field, make sure

you are correct on the rows so that the boom

will not overlap on crop previously sprayed.

perating Checklist

Each time the sprayer is used, check the following:

Check tire pressure, wear and overall condition.

Check the tractor’s brakes to make sure they operate

properly.

Make sure all lights and turn signals are working properly.

Lubricate sprayer as needed.

Booms must be locked in place before transporting.

Inspect tank. Make sure the hitch is adjusted so that

the solution drains to the sump.

Use safety equipment as listed on page 5.

Fill with water and calibrate sprayer BEFORE adding

chemical to the tank.

Check the position of the ball valves in the plumbing to

see if they are in the correct position.

Check hoses, pumps and valves for any leaks.

500-644M

Check nozzle pattern for streaks and non-uniformity.

Check the sprayer initially and periodically for loose

bolts and pins.

Follow “Important Safety Information” on page 4 of

this Manual.

Make sure the handwash tank is full of clean water.

9/1/2009

Page 27

Operating Instructions

25

Plumbing Operations

Refer to Figure 7

Figure 6 shows the basic plumbing diagram for the

sprayer. A basic knowledge of how the sprayer is

plumbed will help you to understand how to operate

your Great Plains Sprayer. Throughout this manual,

the components on this diagram will be described with

the terminology labeling these components.

Fluid is drawn out of the sump in the tank and passes

through the pump. From the pump it passes through

the solution whirlfilter

undissolved chemical and solid particles. The fluid

then passes through both the Flow Meter and the Bypass Control Butterfly Valve.

The Bypass Control Butterfly Valve controls how much

fluid goes to the boom. This is regulated by the Raven

SCS 440 controller. The fluid passes through the Flow

Meter and proceeds to the 3-Way Boom Manifold

valves. If a Boom Valve is on, the fluid passes to its per-

®

and filters out or grinds up all

spective Boom Section and is sprayed out the individual

nozzles. Refer to page 26 for a layout of the boom

plumbing.

The agitation can be set by adjusting the agitation pressure valve while the pump is at operating speed. Refer

to Application Guide to adjust the agitation.

There are tank shut off valves everywhere there is an

outlet from the tank so that if there is a leak, the source

can be shut off and the chemical spill reduced. These

valves need to be wide open when the sprayer is in use.

To operate the hydraulic pump, first make sure that the

hydraulic hoses are routed correctly so that the pump

turns in the correct direction. See the “Tractor/Hydraulic

Pump Hook-Up” on page 17,for more details. To run the

pump, push the hydraulic lever in the “down” position.

When you want to stop the pump, push the hydraulic lever in the “float” position.

IMPORTANT: Do not move the hydraulic lever to the

neutral position while the hydraulic pump is running.

To do so may cause damage to the hydraulic pump.

9/1/2009

24437

Figure 7

Plumbing Diagrams Polyethylene Tank

500-644M

Page 28

26

TSF660

500-644M

24438

Boom Plumbing Schematic

9/1/2009

Page 29

Boom Operations

2007+ Sprayer Hydraulics

On newer sprayers, the hydraulics use a “live” system.

The tractor hydraulic pump may be left on during sprayer

operations. This requires 5-to-8 gpm flow.

The console toggle switches move up and down from

center off, and are auto-return. They must be held up or

down until an operation is complete.

2006- Sprayer Hydraulics

The tractor circuit is engaged only during the operation,

and the tractor lever determines the direction of cylinder

movement.

The console switches move only up, are detented, and remain in the selected position until moved. The switch may

be operated before or after lever movement.

Refer to Figure 8

The “live” hydraulic controls come standard to operate

with “closed center” tractor hydraulics. To be used with an

“open center” system a conversion kit must be purchased

(part no. 833-427C). To install the conversion kit, remove

the plug from the end of the valve block (#14) located on

the top of the center boom section. Install the conversion

valve and coil into this location. Plug the electrical cable

into the open plug on the valve harness and the conversion is complete.

14

Operating Instructions

Figure 8

Fasse Valve Block

27

29639

Elevator Raising/Lowering

The elevator lifts and lowers the center section of the

boom, which raises and lowers the entire boom.

Refer to Figure 9

Lifting is performed by a hydraulic cylinder controlled by a

solenoid valve, which in turn is controlled by an up-down/

center-stop switch on the boom control panel in the

tractor cab.

The elevator is fully raised for folding.

Lowering is by gravity retraction of the cylinder. When the

switch is toggled down, the hydraulic circuit is put in float.

Lifting and lowering speeds may differ.

Boom Height

After calibrating the sprayer for the specific nozzle to be

used at a desired pressure and tractor speed, the main

field adjustment is the boom height.

Depending on which type of nozzle is being used, set the

boom height so that the correct overlap for that specific

nozzle is achieved. If the crop canopy is taller in some

1

1

Figure 9

Elevation Switches

fields than others, adjust the boom height accordingly.

Refer to the Nozzle Charts in the Application Guide to

determine the height of the boom.

In center-off, the elevator stays at the current position. In

normal field operations, the elevator is set to the desired

height, and left there for the field. Typically this is about

20in (51cm) above the crop canopy.

As necessary, wings are raised and lowered at turns by

the operator, and adjusted to accommodate uneven terrain. The optional Autoboom system is useful on irregular

terrain.

27276

9/1/2009

500-644M

Page 30

28

!

TSF660

Boom Folding Procedure

The Front Folding Boom is hydraulically operated,

and is controlled by a single valve block. There are

controls for the vertical elevation, left and right

boom tilt, left and right inner fold and left and right

outer fold.

Boom Folding

The following procedure should be used to fold

the boom.

1. Raise elevator to top position.

2. Fold left and right outer booms 180˚. Make

sure outer booms snap into locks.

3. Raise left and right tilt to uppermost position.

Make sure lock plunger moves up, locking

boom in place.

4. Fold left and right inner booms 90˚.

5. Lower left and right tilt so the booms rest on

the transport supports.

Note: Outer boomswill not lock if booms are tilted.

Boom Unfolding

WARNING

Negative tongue weight. Do Not unfold the booms if

the sprayer is unhooked from tractor with the sprayer

tank empty or low.

The following procedure should be used to unfold

the boom.

1. Raise left and right tilt to uppermost position.

2. Unfold left and right inner booms 90˚.

3. Lower left and right tilt to lowest position.

Make sure lock plunger lowers out of the way.

4. Unfold left and right outer booms 180˚.

5. Lower elevator to proper spraying height.

Normal boom use may shift the outer boom support locks along the inner section. When properly

adjusted, the outer arm plate will snap into the

gap between the lock plates, and the holes line

up. Loosen the U-bolts and reposition brackets as

necessary. Adjust cable tension so the plunger is

out of the way when boom is unfolded.

500-644M

Make sure outer boom cylinder pressure is released and lock plunger is free to move up and

down before unfolding boom.

9/1/2009

Page 31

Locking System

Refer to Figure 10

The TSF660 has a locking system for automatic

boom locking during folding and transport. For

proper folding, the boom-lock cable must be tight

enough that the lock arms just clear their stops

when unfolded and rest secure against the stop

when folded.

Refer to Figure 11

Lock Arms

Figure 10

Locking System

Operating Instructions

21760

29

To adjust the tension on the boom-lock cable,

loosen jam nut and turn clevis.

Break Away Spring

Refer to Figure 12

Periodically check that break-away springs are

compressed to 5 1/2 inches. Adjust spring by turning mounting nut under spring.

21761

Figure 11

Boom-Lock Cable

9/1/2009

22952

Figure 12

Break-Away Spring

500-644M

Page 32

TSF660

!

30

Leveling Boom

WARNING

Pinch point hazard. Your fingers, hands or arms could

be seriously injured or severed if caught in the folding

boom sections. Shut off tractor and remove key before

adjusting shims.

Note: The boom sections must be level across the

span for even spraying.

Refer to Figure 13

To adjust the inner arm place supports under

boom and loosen bolts holding plate (A) at the top

of the pivot. Add or remove shims as necessary

and retighten bolts.

Figure 13

Shims

21762

500-644M

9/1/2009

Page 33

Operating Instructions

!

!

!

31

Filling Tank Procedures

CAUTION

When filling the sprayer tank, use a check valve or

anti-siphon device to prevent the solution in the tank

from infiltrating into the fresh water source and contaminating it.

Your Great Plains Sprayer fills the tank from the

bottom of the tank and uses a standard 2 inch

Cam-Lock coupler to connect to the freshwater

hose. A 1 1/2 inch Cam-Lock coupler is also available as an accessory. Refer to "Quick Fill

Assembly" in the parts manual.

1. To fill the tank, hook up the freshwater hose

to the quick-fill Cam-Lock coupler with the

quick-fill ball valve in the closed position.

2. Turn the water on and open the quick-fill ball

valve for the freshwater to enter the tank.

When using a positive displacement pump to

fill the tank, open the quick fill ball valve first

and then pump water into the tank.

Using Handwash Tank

In the event when an accident occurs and chemical is spilled on your skin or in your eyes, use the

Handwash Tank to flush away the chemical.

1. Open thetank valve and use the hose to direct

the clean water on all contaminated areas.

Wash all areas of skin that has been contaminated with soap and water. To flush your

eyes, point thehose andwater stream upward

while you lower your eye into the stream of

flowing water.

2. Close the tank valve and refill the handwash

tank with fresh water when you are finished.

3. Periodically refill the handwash tank with

fresh water. Always keep the handwash tank

clean.

Operating Whirlfilter

There is one Whirlfilter®on your Great Plains

Sprayer. The Whirlfilter®filters the chemical solution being sprayed.

®

CAUTION

Do not add the chemical until you are at the field, just

prior to spraying. When you add the chemical, follow

the manufacturer’s instructions for mixing the spray

solution in order to achieve the desired application

rate.

CAUTION

Read the manufacturer’s label carefully before handling chemicals.

3. Before you add the chemical to the tank,

make sure the tank is at least one half full.

The concentrate should not be poured into an

empty tank.

4. Keep the spray solution away from all skin.

Wear protective clothing and goggles. If the

solutions comes in contact with the body,

wash off the contaminated area with soap

and water.

5. Keep chemical containers low when pouring.

To clean-out the solution Whirlfilter®, proceed with

the following:

1. Fill the sprayer tank with water and turn the

pump on.

2. With the pump running, slowly open the

clean-out valve and allow the grit to flow out

into a bucket. Clean out the solution Whirlfilter®only when the sprayer tank is filled with

water and no chemical has been added.

3. Close the clean-out valve and turn off the

pump.

4. Dispose of the grit and water in the same

manner described on the manufacturer’s label

of the latest chemical used in the sprayer.

6. Let the wind blow fumes and dust away from

you while pouring the chemical.

7. Do not smoke while handling chemicals.

9/1/2009

500-644M

Page 34

32

!

!

TSF660

Transporting

1. Park your sprayer in an open area where you

will not hit power lines, buildings, etc. when

the boom is folded.

2. Make sure the safety chain is securely fas-

tened to the tractor draw bar and the retaining

clip is fastened to the hitch pin.

3. Never allow riders when transporting the

sprayer.

4. When transporting your sprayer, be sure to

watch the height clearances of your folded

boom to prevent damage to the boom and

possible injury.

DANGER

Contact with electrical power lines can cause death by

electrocution.

5. Do not exceed 20 mph transporting your

sprayer.

6. Do not transport sprayer while filled with

chemical mixture.

Parking

WARNING

Negative tongue weight. Do Not unhook the sprayer

from tractor with the sprayer tank empty or low with

the booms unfolded.

The following list should be conducted when you

want to unhitch your sprayer. See “Storage”on

Page 45, for more information on long term storage of your sprayer.

500-644M

9/1/2009

Page 35

Refer to Figures 14 and 15

1. Remove the jack from the transport position

and move to the parking position.

2. If the ground is soft, place a board or plate under the jack to widen the ground contact area.

3. Extend the jack until the weight of the tongue

is off the tractor drawbar and is supported by

the jack.

4. Unplug the hydraulic lines from the hydraulic

pump.

5. Remove the hitch pin and safety chain from

the tractor drawbar.

Operating Instructions

33

NOTE: Refer to “Hitching Tractor to Sprayer,” on Page 15, when you are preparing to

hitch the sprayer to the tractor.

NOTE: If the sprayer is being hitched up and

operated for the first time, it is important to follow the safety, set up, adjustment, and operating information in the front of this manual

13811

Figure 14

Jack In Parking Position

23316

9/1/2009

Figure 15

Jack In Transport Position

500-644M

Page 36

TSF660

34

Tank Rinse and Flush System

The Tank Rinse and Flush is a factory installed

feature that compliments the Boom Flush option.The Tank Rinse and Flush feature will use the

fresh water in the 50 gallon flush tank to rinse out

the main sprayer tank in the field.

Refer to Figure 16

Before operation make sure the flush tank is filled

with fresh, clean water. To operate the Tank Rinse

and Flush, refer to the following instructions:

1. Completely empty the chemical in the main

sprayer tank by turning the agitation off the

last pass and spraying it out in the field.

2. Make sure all boom valves and pump are

turned off.

3. Turn the agitation valve #1 (in the control panel) to “FLUSH”, and rotate the tank valve #2

from “MAIN TANK” to “FLUSH TANK”.

4. Operate the pump with the sprayer stationary,

and rinse the tank until 1/3 of the flush tank

volume (17 gallons) is consumed and then

stop the pump.

24493

Figure 16

Control Panel

5. With the sprayer pump off, turn the agitation

valve #1 from “FLUSH” to “OFF”.

Refer to Figure 17

6. Rotate the tank valve #2 from “FLUSH TANK”

to “MAIN TANK”.

7. Operate the pump and spray out the full volume of liquid (deposited into the main sprayer

tank from the Flush Tank) in the field just finished.

8. Repeat steps two through seven twice more

until the flush tank is empty and the main

sprayer tank has been rinsed completely

three times.

9. Reset the agitation pressure before filling the

main sprayer tank again.

24494

Figure 17

Control Panel

500-644M

9/1/2009

Page 37

Inductor (Optional Equipment)

The Inductor option isused toinduct chemicalinto

the main sprayer tank so that the operator doesn’t

have to climb up the walk-board to do so.

To induct chemical into the tank refer to the following instructions:

Refer to Figure 18

1. Fill the main sprayer tank with the carrier

needed and transport the sprayer to the field

where the sprayer will be used.

2. Make sure the boom section switches are all

off and operate the pump.

3. Turn the agitation valve #1 to “AGITATION”,

the tank valve #2 to “MAIN TANK” and the operation valve #3 to “SPRAY”. Be sure the

valve to the tank is open.

Operating Instructions

35

4. Turn the product valve #4 from “OFF” to “INDUCT”.

5. Add chemical to inductor tank.

6. Turn inductor valve #5 from “INDUCTOR

OFF” to “INDUCTOR ON”.

Raven G1 Autoboom (Optional

Equipment)

The Raven Autoboom is a system that helps automatically adjust the height of the boom to

changing terrain. Although this option will allow

the sprayer to be driven faster most of the time,

take care to avoid large obstacles and large terraces as the autoboom will only sense terrain

changes at the point of the wheel sensor.

For information on installation, calibration, and

operation of the system, refer to the Raven manuals supplied.

14993

Figure 18

Product Valve and Inductor Valve

9/1/2009

500-644M

Page 38

TSF660

!

36

Tank Fill Using Existing Pump Operations (If

Equipped) (2006-)

The Tank Fill can be used to fill the main sprayer tank using the existing sprayer pump. To do so refer to the

following instructions:

1. Make sure sprayer pump is off and insert supply tank

hose into the main quick-fill coupler. Leave quick-fill

valve off.

Refer to Figure 19

2. Turn agitation valve #1 to “OFF”. Turn tank valve #2 to

“MAIN TANK”.

3. Open supply tank valve making sure that positive

head pressure is maintained at the quick-fill to prevent

back-flow from the sprayer tank.

WARNING

Make sure the supply tank is higher than the sprayer tank. Failure to do so can cause back-flow from the sprayer tank causing

sickness, serious injury or death from water contamination.

4. Open quick-fill valve under the main frame.

Refer to Figure 20

5. Turn product valve #4 from “OFF” to “TANK FILL”.

6. Make sure the boom section valve switches are all off,

start the pump and fill the tank.

7. When finished, follow this order:

a. Turn off pump.

b. Rotate product valve #4 from “TANK” to “OFF”.

c. Shut quick fill valve under walkboard.

d. Shut off supply tank valve.

e. Rotate operation valve #3 to “SPRAY”.

NOTE: Make sure there is positive head pressure from

supply tank during this procedure.

24494

Figure 19

Control Panel

500-644M

14993

Figure 20

Product Valve and Inductor Valve

9/1/2009

Page 39

Adjustments

Boom Height

After calibrating your sprayer for the specific nozzle you will use at a desired pressure, and tractor

speed, the main field adjustment is the boom

height. Depending on which type of nozzle you

are using, you need to set your boom height so

that you achieve the correct overlap for that specific nozzle. If the crop canopy is taller in some

fields than others, you will need to adjust the

boom height accordingly. Refer to the nozzle

charts located in this manual to determine the

height of the boom needed. Use the elevator

gauge as a height reference.

EXAMPLE: A 2.5 MeterCone nozzle at 20 inch

spacing is being used. From the nozzle chart {refer to section 4 of this manual or the Application

Guide}, a height of 19 to 21 inches above the top

of the crop is required. If the crop is 6 inches off

the ground, the boom height should be set to 25 to

27 inches off the ground.

Adjustments

37

Nozzle Pressure

Another area that will need some field adjustments is the nozzle pressure. As your tank level

decreases, you may have to adjust the boom

pressure to keep the pressure at the same magnitude for what the sprayer was calibrated for if

your sprayer is not equipped with a monitor.

Watch your pressure gauge and be aware of

changes in the pressure.

Tank Straps

The tank straps that wrap around the sprayer tank

may become loose after the first few hours of operation. This occurs when the tank settles in the

saddle. Polyethylene tanks are especially susceptible to this. Retighten the tank straps to secure

your tank.

9/1/2009

500-644M

Page 40

TSF660

!

38

Manual Pressure Adjustment Valve

Refer to Figure 21

The manual pressure adjustment valve allows the

operator to choke down the amount of fluid flowing to

the boom. When the valve is wide open and the application is at a low rate, a small amount of

adjustment on the butterfly valve makes a large difference in the flow rate. To dampen the sensitivity of

the system, adjust manual pressure adjustment

valve so that the pressure of the system is 20 psi

greater than the maximum flow you want to achieve.

To adjust the manual pressure adjustment valve,

open the butterfly valve until it is completely open.

Operate the pump at the same rpm you would when

spraying, and adjust the manual pressure adjustment valve until the system pressure is reading 20

psi greater than the maximum application pressure.

Butterfly Valve

Manual Pressure

Adjustment Valve

On the Raven Monitor control system, you will have

to adjust the manual pressure adjustment valve with

clean water coming out of the nozzles.Operate the

pump at the same rpm you would when spraying,

and adjust the manual pressure adjustment valve

until the system pressure is reading 20 psi greater

than the maximum application pressure.

A good time to do this would be during calibration of

the sprayer.

CAUTION

If equipped with a boom control valve without a bypass

(Raven Monitor Unit) adjust the boom flow throttle valve

when the sprayer is full of clean water (no chemical added). Never adjust the valve when you would be exposed to

chemical coming out of the boom.

With the manual pressure adjustment valve set correctly, the system pressure will be able to be

adjusted without large fluctuations in the pressure.

NOTE: When the pressure is increased at a later

date, the manual pressure adjustment valve will

need to be opened, and re-calibrated.

22939

Figure 21

Manual Pressure Adjustment

500-644M

9/1/2009

Page 41

Agitation Adjustment

!

Refer to Figure 22

The agitation valve is used to adjust the pressure

to the agitation nozzles in the tank. Refer to the

agitation gauge, and adjust the pressure to a desired rate. Different chemicals require different

agitation pressures to keep the chemical in

suspension.

CAUTION

If using liquid fertilizer or any other chemical that will

corrode brass, install a gauge protector under the

brass agitation gauge or plug the gauge hole. Failure

to do so will eventually cause the gauge to fail and

chemical to be expelled from the gauge.

Adjustments

39

Operating Whirlfilter

There is one Whirlfilter®on the Great Plains

Sprayer. The Whirlfilter®filters the chemical solution being sprayed.

Refer to Figure 23

Clean-out the solution Whirlfilter

1. Fill the sprayer tank with water and turn the

pump on.

2. With the pump running, slowly open the

clean-out valve and allow the grit to flow out

into a bucket. Clean out the solution Whirlfilter®only when the sprayer tank is filled with

water and no chemical has been added.

3. Close the clean-out valve and turn off the

pump.

4. Dispose of the grit and water in the same

manner described on the manufacturer’s label of the latest chemical used in the sprayer.

®

®

24495

Figure 22

Control Panel

24496

Figure 23

Quick-fill Ball Valve

9/1/2009

500-644M

Page 42

TSF660

40

Elevator Slide Adjustment

Refer to Figure 24

The polyethylene slides on the elevator can be adjusted to take out any side-to-side play.

Periodically check the slide pads (A) for wear. As

the pads wear, tighten 1/2-inch bolts (B) on both

sides of elevator frame (C) until pads just touch

frame.

Tighten the slides so that there is a minimal

amount of play in the elevator.

Important: When tightening the slides be sure

to keep the elevator slide centered in the elevator mount. If the elevator is adjusted to one

side there can be an interference.

Cycle the elevator a few times to ensure there is

no binding and that the slides are sufficiently

tightened.

500-644M

17000

Figure 24

Hydraulic Elevator

9/1/2009

Page 43

Troubleshooting

Problem Problem Area Specific Checks Solutions

Troubleshooting

41

Pressure

decreasing

Pressure

fluctuating

Pressure

increasing

Pressure cannot

increase

Between gauge

and liquid supply

Between pump

outlet and liquid

Between gauge

and nozzle

Pump or electric

ball valve

Pump wearing Rebuild or replace pump

Plugged suction or pump to pressure head hose

Plugged Whirlfilter Clean out Whirlfilter

Plugged gauge

Check suction hose & fittings for

air leaks. Air in system is indicated

by buffs of air at nozzles

Vortex in tank suction

Cracked pump housing

Nozzle screens clogged Clean screens

Nozzle orifices plugged

Boom hoses becoming clogged

Boom hoses pinched

From nozzle charts check liquid

demand against pump capacity

(nozzle requirement + agitation

requirement)

Electric ball valve or gauge not

functional

Clean hose and reduce cause of clogging

Remove the quick disconnect fitting and

flush gauge protector

Remove obstruction from clogged area

Align agitators properly

Replace pump housing

Remove material with soft brush or air

Remove obstruction from clogged area

Use cable ties to position hose so it will

not kink

Reduce swath width by nozzle reduction;

install smaller nozzles and drive at a lower

rate of speed

Replace or repair

No pressure

No pressure

Pressure cannot

decrease

Pressure adjust switch faulty Test switch & replace if faulty

Fuse is out in control box

Manual pressure adjustment valve

not all the way open

Plumbing Tank shut-off valves off Make sure all tank shut-off valves are open

Loose fittings

Collapsed suction hose to pump

Obstruction in suction hose or tank

Pump not primed

Pump Hydraulic pump running in the

Pump or electric

ball valve

wrong direction

PTO pump coupler loose Tighten PTO coupler

Tank agitation restricted Check that the agitator valve is open and

Replace fuse

Open the manual pressure valve all the

way and allow the electric ball valve to

govern the pressure

Tighten fittings so pump can prime

Replace hose

Remove obstruction

Turn off valve after Whirlfilter. Turn agitation/flush valve to “flush” or “off”. Turn off

chemical inductor valve. Open valve under

tank sump. Turn main valve to “main tank”.

Open Whirlfilter clean-out valve to prime

pump. When water comes out of valve,

pump is prime.

Switch hydraulic hoses in the tractor outlet

that the liquid is being agitated

9/1/2009

500-644M

Page 44

TSF660

42

Problem Problem Area Solutions

Liquid will not induct

Chemical

Inductor

Make sure the valve below the inductor tank is open

Make sure the pump is in operation and has prime

Make sure the venturi bypass valve is open

Inductor overflow

Boom will not fold

Chemical

Inductor

Hydraulic block

Close valve below inductor tank until pump is running, has pressure

and venturi valve is open