Page 1

Table of Contents Index

Operator Manual

Turbo-Chisel TCN

5107, 5309, 5311 & 5313

Manufacturing, Inc.

www.greatplainsmfg.com

Read the operator’s manual entirely. When you see this symbol, the

subsequent instructions and warnings are serious - follow without

exception. Your life and the lives of others depend on it!

Illustrations may show optional equipment not supplied with standard unit.

41967

ORIGINAL INSTRUCTIONS

© Copyright 2014 Printed 2014-03-17 566-170M

Table of Contents Index

EN

Page 2

Table of Contents Index

Plains International

Plains International

Plains International

Great Plains International

(166-372M-CZE)

Great Plains International

(166-372M-FRA)

Great Plains International

(166-372M-BUL)

(166-372M-ENG)

Great

(166-372M-HUN)

Great

(166-372M-LIT)

Great

Great Plains International

Plains International

(166-372M-RUS)

Great Plains International

Table of Contents Index

(166-372M-RUM)

Great

(166-372M-GER)

Page 3

Great Plains Manufacturing, Inc. iii

Table of Contents

Equipment Identification .............................................1

Export Models 5107-5313 .............................................. 1

Machine Record ............................................................. 2

Machine Log...............................................................2

Machine Details..........................................................2

Dealer Information......................................................2

Great Plains Regional Agent ......................................2

Introduction.....................................................................3

Description of Unit ..........................................................3

Using This Manual..........................................................4

Document Family........................................................4

Definitions................................................................... 4

Owner Assistance ..........................................................4

Important Safety Information ...................................... 5

Safety Reflectors and Decals ...................................10

Preparation and Setup ...............................................17

Initial Setup...................................................................17

Seasonal Setup ............................................................17

Pre-Tilling Setup...........................................................17

Hitching Tractor to Turbo-Chisel ..................................18

Clevis Hitch...............................................................19

Category III Hitch...................................................... 19

Electrical Hookup......................................................20

Hydraulic Hose Hookup............................................ 21

Brake Hook-up (Option) ...............................................22

Operating Instructions...............................................24

Pre-Start Checklist .......................................................24

Unfolding and Folding ..................................................25

Folding...................................................................... 26

Unfolding ..................................................................27

Lowering and Raising Turbo-Chisel ............................. 28

Lowering...................................................................29

Raising .....................................................................30

Transporting the Turbo-Chisel......................................31

Tractor Requirements............................................... 32

Transport Checklist...................................................32

Brake Operation (option) ..............................................33

Service Brake Operation ..........................................33

Transport ......................................................................35

Transport Steps........................................................ 35

Hitching a Trailing Implement (Optional)..................36

Final Field Checklists ............................................... 36

Field Operation ............................................................ 36

First Time Field Adjustments ....................................... 37

Pre-Leveling of Machine .......................................... 37

Front to Rear Leveling.............................................. 37

Wing Adjustment (3-Section Wings) ........................ 38

General Operation and In-Field Adjustments............... 38

Rear Attachment Settings ............................................ 40

Rear Chopper Reel .................................................. 40

Buster Bar ................................................................ 41

Parking......................................................................... 42

Storage ........................................................................ 43

Unfolded Storage ..................................................... 43

Troubleshooting......................................................... 44

Brake Troubleshooting (Option)................................... 44

Maintenance and Lubrication ................................... 46

Maintenance Lift Lock .................................................. 47

Maintenance Lift Unlock...........................................47

Lubrication and Scheduled Maintenance..................... 48

Brake Maintenance (Option) ........................................ 48

Brake Line Charge and Bleed .................................. 48

Air Brake Maintenance.............................................50

Brake Drum and Liner Maintenance ........................ 51

Brake Shoe Replacement ........................................ 53

Brake Drum Maintenance ........................................ 58

Mounting Wheels ..................................................... 59

Test and Adjust Brakes ............................................ 59

Appendix..................................................................... 60

TCN Specifications and Capacities.............................. 60

Tire Inflation Chart ....................................................... 61

Hydraulic Connectors and Torque ............................... 62

Torque Values Chart.................................................... 63

Dimensions (Transport) TCN5107 .............................. 64

Dimensions (Transport) TCN5309 ............................... 65

Dimensions (Transport) TCN5311 ............................... 66

Dimensions (Transport) TCN5313 ............................... 67

Index............................................................................ 69

© Copyright 2006, 2007, 2008, 2009, 2010, 2011, 2012, 2013, 2014 All rights Reserved

Great Plains Manufacturing, Inc. provides this publication “as is” without warranty of any kind, either expressed or implied. While every precaution has been

taken in the preparation of this manual, Great Plains Manufacturing, Inc. assumes no responsibility for errors or omissions. Neither is any liability assumed for

damages resulting from the use of the information contained herein. Great Plains Manufacturing, Inc. reserves the right to revise and improve its products as

it sees fit. This publication describes the state of this product at the time of its publication, and may not reflect the product in the future.

03/17/2014 566-170M

Trademarks of Great Plains Manufacturing, Inc. include: Singulator Plus, Swath Command, Terra-Tine.

Registered Trademarks of Great Plains Manufacturing, Inc. include:

Air-Pro, Clear-Shot, Discovator, Great Plains, Land Pride, MeterCone, Nutri-Pro, Seed-Lok, Solid Stand,

Terra-Guard, Turbo-Chisel, Turbo-Chopper, Turbo Max, Turbo-Till, Ultra-Till, Verti-Till, Whirlfilter, Yield-Pro.

Brand and Product Names that appear and are owned by others are trademarks of their respective owners.

Printed in the United States of America

Page 4

iv TCN5107-5313 Great Plains Manufacturing, Inc.

566-170M 03/17/2014

Page 5

Great Plains Manufacturing, Inc. 1

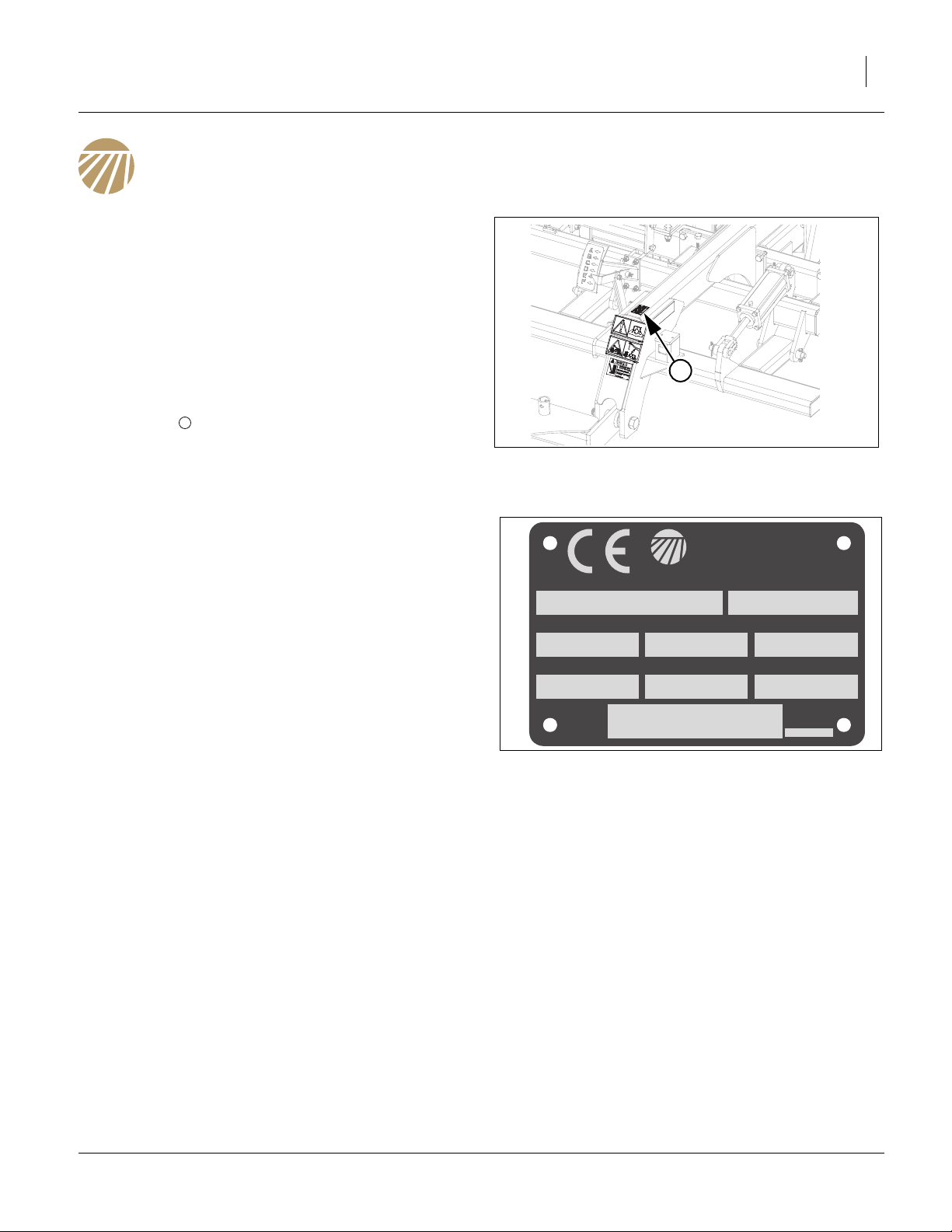

Equipment Identification

This Operator manual applies to the following Great

Plains pull-type primary vertical tillage chisels:

TCN5107 2.7m, 7-shank

TCN5309 3.43m, 9-shank

TCN5311 4.19m, 11-shank

TCN5313 4.95m, 13-shank

See “TCN Specifications and Capacities” on page 60

for precise swath information.

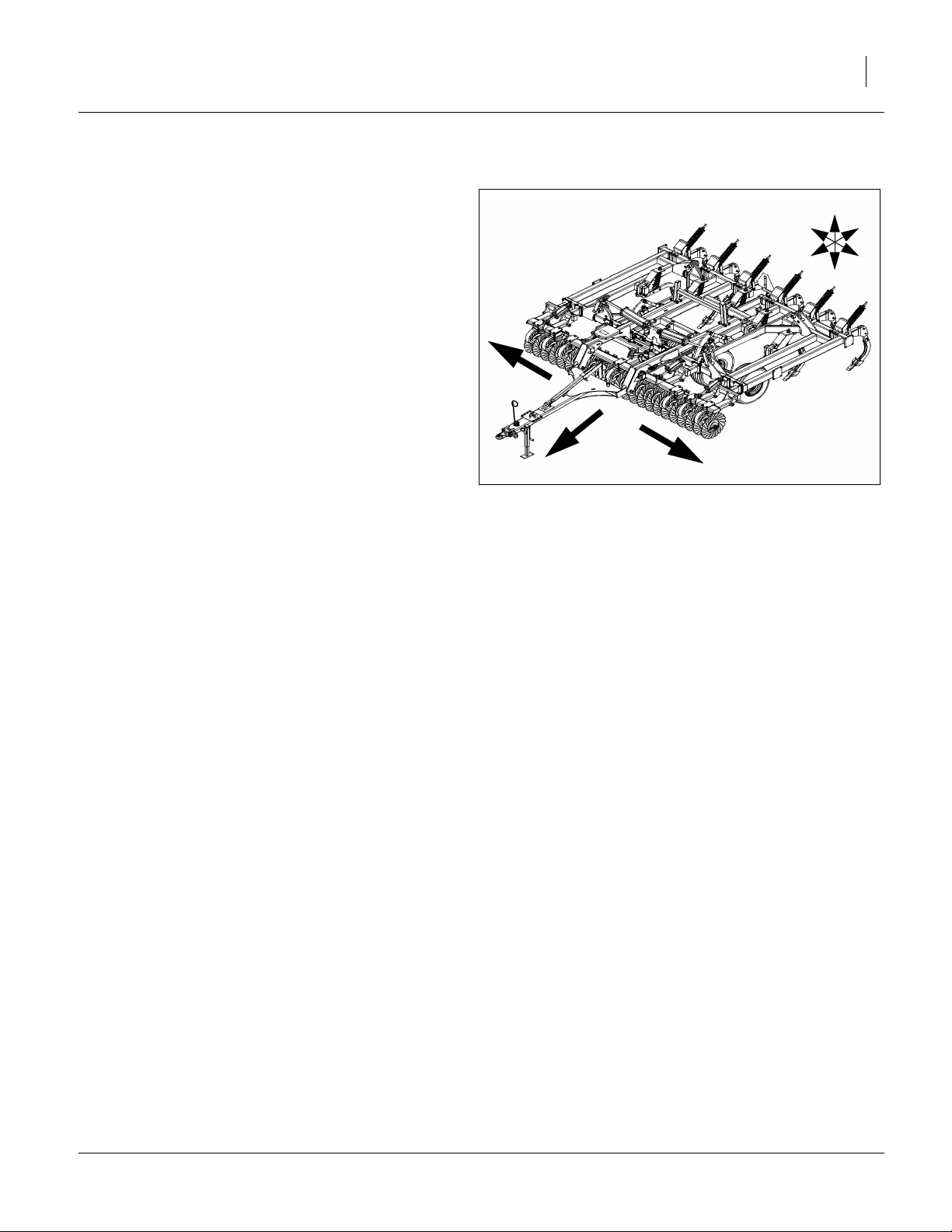

Refer to Figure 1

For positive equipment identification, consult the

machine label located on the top of the left hand hitch

1

truss, near the single point depth control.

Label/Plate Location

1

Figure 1

41978

Export Models 5107-5313

Models TCN5107, TCN5309, TCN5311 and TCN5313

can be built to European regulatory and highway transport standards. The machine can also be built to North

American regulatory and highway transport standards,

depending on which light option package is purchased.

Refer to Figure 2 (which is NOT from an actual machine)

The machine label provides data which is specific to your

machine as originally shipped from the factory.

If you, or the dealer, have added Options not originally

ordered with the machine, or removed Options that were

originally ordered, the weights and measurements no

longer are accurate for your machine. Update the Record

on the next page upon modifications.

See “Transporting the Turbo-Chisel” on page 31 and

“TCN Specifications and Capacities” on page 60 for

additional weights and measurements.

Great Plains

Manufacturing, Inc.

P.O. Box 5060

Model Number: Serial Number:

Salina, KS 67401 USA

A1196XTCN5107

Working Width m: Transport Width m: Year of Manufacture:

201199.9 m99.9 m

Total Weight kg:

99999 Kg

Axle Load kg: Drawbar Vertical Load kg:

99999 Kg

*GP-1196X*

99999 Kg

A1196X

Figure 2:TCN5107:

Example Machine Label

819-197C

42160

03/17/2014 566-170M

Page 6

2 TCN5107-5313 Great Plains Manufacturing, Inc.

Machine Record

Machine Details

Record your machine details in the Log at right. If you

replace this manual, be sure to transfer this information

to the similar page of the new manual.

If you add or remove Options, update the Log. If the page

cannot be legibly updated, request or print a new Operator manual.

Dealer Information

My Customer

Number / ID

Dealer Name

Street

Place

Post Code

Country

Voice

Machine Log

Machine Model

Serial Number

Working Width

Transport Width

Maximum Gross Weight

Maximum Axle Load

Year of Manufacture

Date of Delivery

Date in Service

Options

Fax

Web

Email

Great Plains Regional Agent

(If different than those on page 4)

Agent Voice

Street Fax

Place Web

Post Code Email

Country

566-170M 03/17/2014

Page 7

Great Plains Manufacturing, Inc. Equipment Identification 3

Introduction

Great Plains welcomes you to its growing family of new

product owners. Your Turbo-Chisel TCN5107-5313 has

been designed with care and built by skilled workers using

quality materials. Proper setup, maintenance, and safe

operating practices will help you get years of satisfactory

use from the machine..

Before placing the machine into service for the first time,

read and understand this manual, in particular the

“Important Safety Information”, pages 5 to 9. Have all

operators read this manual before allowing them to work

with the machine.

Description of Unit

The TCN5107, TCN5309, TCN5311 and TCN5313 are

pull-type primary vertical tillage chisels. The TCN 5107 is

a one section machine for narrow (3m) transport. The

TCN5309, TCN5311 and TCN5313 are three section

machines that fold for narrow (3m) transport.

A row of hydraulic-adjustable Turbo coulters fractures the

ground 7-15 cm directly ahead of the shanks.

Two rows of shanks on 76.2 cm centers allows for residue

to flow through the machine. The effective spacing of the

two rows of shanks is 38.1 cm. The shanks can fracture

the ground up to 30.5 cm deep.

The TCN models offer optional shank configurations. The

configurations can have heavy duty parabolic shanks,

medium duty parabolic shanks and/or chisels shanks.

The chopper wheel or buster bar are the two optional TCN

finishing attachments. Finishing attachments are placed

behind the last row of shanks to level the soil.

An optional rear hitch is available for pulling implement/

tanks that do not impose high vertical loads on the hitch,

e.g., vertical load < 350kg.

Brakes are optional on TCN models. Service brakes are

operated by air or hydraulic lines to the tractor. Chock

blocks are provided in both brake options to prevent

movement of the machine while not connected to the tractor. Chock blocks are manually placed.

Do not modify the TCN except as instructed by Great

Plains. Do not use attachments other than as provided by

or authorized by Great Plains.

R

L

Figure 3

TCN5311 Turbo-Chisel

R

F

U

B

L

D

41977

03/17/2014 566-170M

Page 8

4 TCN5107-5313 Great Plains Manufacturing, Inc.

Using This Manual

This manual will familiarize you with safety, hitching,

operation, adjustments, troubleshooting, and maintenance. Read this manual and follow the recommendations to help ensure safe and efficient operation.

The information in this manual is current at printing.

Some parts may change to assure top performance.

Document Family

566-170Q-ENG Assembly Manual

566-170Q Pre-Delivery Manual

566-170M Operator Manual (this document)

566-170P Parts Manual

Definitions

Safety admonishment signal words are described on

page 5.

The following terms are used throughout this manual.

Identifies an Economic (not a Safety) Risk:

NOTICE provides a crucial point of information related to the

current topic. Read and follow the instructions to avoid damage

to equipment and ensure desired field results.

Note: This form sets off useful information related to the

current topic, or forestalls possible misunderstanding.

Right-hand and left-hand as used in

this manual are determined by facing

the direction the machine will travel

while in use unless otherwise stated.

An orientation rose in some line art

illustrations shows the directions of:

Up, Back, Left, Down, Front, Right.

R

F

U

B

L

D

Owner Assistance

If you need customer service or repair parts, contact a

Great Plains dealer. They have trained personnel, repair

parts and equipment specially designed for Great Plains

products.

Your machine’s parts were specially designed and

should only be replaced with Great Plains parts. Always

use the serial and model number (page 1) when ordering

parts from your Great Plains dealer.

Your Great Plains dealer wants you to be satisfied with

your new machine. If you do not understand any part of

this manual or are not satisfied with the service received,

please take the following actions.

1. Discuss the matter with your dealership service

manager. Make sure they are aware of any problems

so they can assist you.

2. If you are still unsatisfied, seek out the owner or general manager of the dealership.

For further assistance contact Great Plains via the Agent

recorded on page 2, or at:

For U.K. and Europe

SIMBA Great Plains

Woodbridge Road Ind. East

Sleaford

Lincolnshire NG34 7EW England

Voice: +44 (0) 1529 304654

Fax: +44 (0) 1529 413468

Email: simba.international@simba.co.uk

For Other Regions

Great Plains Manufacturing, Inc.

PO Box 5060

Salina KS 67402-5060 USA

Voice:+(800)255-9215

Fax:+1 785-822-6722

Email:gp_web_cs@greatplainsmfg.com

566-170M 03/17/2014

Page 9

Great Plains Manufacturing, Inc. 5

Important Safety Information

Look for Safety Symbol

The SAFETY ALERT SYMBOL1 indicates there is a

potential hazard to personal safety involved and extra

safety precaution must be taken. When you see this

symbol, be alert and carefully read the message that follows it. In addition to design and configuration of equipment, hazard control and accident prevention are

dependent upon the awareness, concern, prudence and

proper training of personnel involved in the operation,

transport, maintenance and storage of equipment.

Be Aware of Signal Words

Signal words designate a degree or level of hazard seriousness.

DANGER, and the colour Safety Red, indicate an

imminent hazard which, if not avoided, will result in death

or serious injury. This signal word is limited to the most

extreme situations, typically for machine components

that, for functional purposes, cannot be guarded.

WARNING, and the colour Safety Orange, indicate a

potential hazard which, if not avoided, could result in

death or serious injury, and includes hazards that are

exposed when guards are removed. It may also be used

to alert against unsafe practices.

CAUTION, and the colour Safety Yellow, indicate a

potential hazard which, if not avoided, may result in

minor or moderate injury. It may also be used to alert

against unsafe practices.

Prepare for Emergencies

▲ Be prepared if a fire starts

▲ Keep a first aid kit and fire extinguisher handy.

▲ Keep emergency numbers for doctor, ambulance, hospital

and fire department near phone.

Be Familiar with Safety Decals

▲ Read and understand “Safety Decals” on page 10, thor-

oughly.

▲ Read all instructions noted on the decals.

▲ Keep decals clean. Replace damaged, faded and illegible

decals.

1. Symbols and colours in this manual, and on north american models, are based on ANSI standard Z535.

Decals on international models are based on ISO standard 3864.

03/17/2014 566-170M

Page 10

6 TCN5107-5313 Great Plains Manufacturing, Inc.

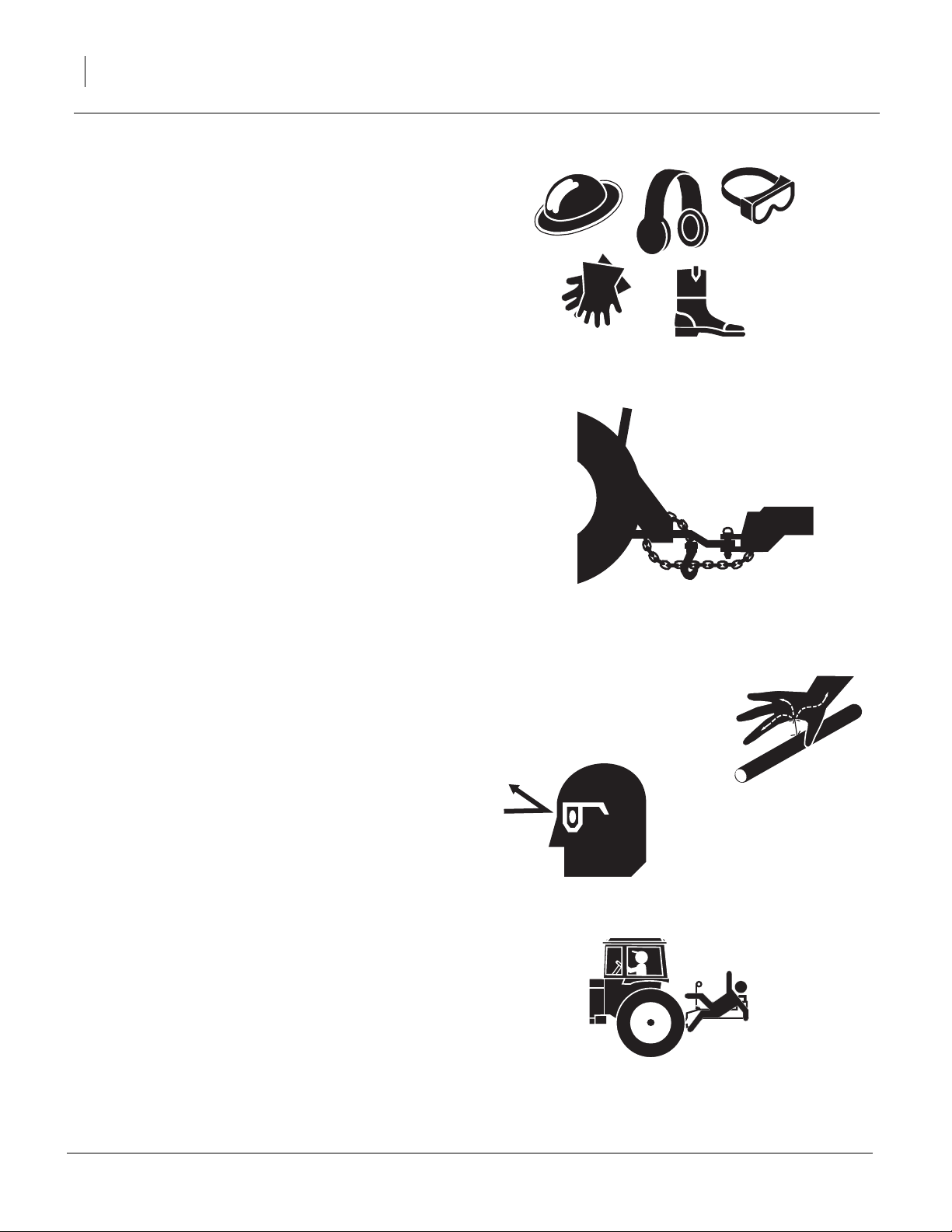

Wear Protective Equipment

▲ Wear protective clothing and equipment.

▲ Wear clothing and equipment appropriate for the job. Avoid

loose-fitting clothing.

▲ Because prolonged exposure to loud noise can cause hear-

ing impairment or hearing loss, wear suitable hearing protection such as earmuffs or earplugs.

▲ Because operating equipment safely requires your full

attention, avoid wearing entertainment headphones while

operating machinery.

Use Safety Chains

▲ Use safety chains to help control drawn machinery should it

separate from tractor draw-bar or trailing nurse tank hitch.

▲ Use chain with a strength rating equal to or greater than

the gross weight of towed machinery.

▲ Attach implement chain to tractor draw-bar support or

specified anchor location. Allow only enough slack in chain

for turns.

▲ Replace chain if any links or end fittings are broken,

stretched or damaged.

▲ Do not use safety chain for towing.

Avoid High Pressure Fluids

Escaping fluid under pressure can penetrate the skin,

causing serious injury. This Turbo-Chisel requires a

Power-Beyond port, which is always under pressure

when the tractor is running.

▲ Avoid the hazard by relieving pressure at other remote, and

shutting down tractor before connecting, disconnecting or

inspecting hydraulic lines.

▲ Use a piece of paper or cardboard, NOT BODY PARTS, to

check for suspected leaks.

▲ Wear protective gloves and safety glasses or goggles when

working with hydraulic systems.

▲ If an accident occurs, seek immediate medical assistance

from a physician familiar with this type of injury.

Keep Riders Off Machinery

Riders obstruct the operator’s view. Riders could be

struck by foreign objects or thrown from the machine.

▲ Never allow children to operate equipment.

▲ Keep all bystanders away from machine during operation.

566-170M 03/17/2014

Page 11

Great Plains Manufacturing, Inc. Important Safety Information 7

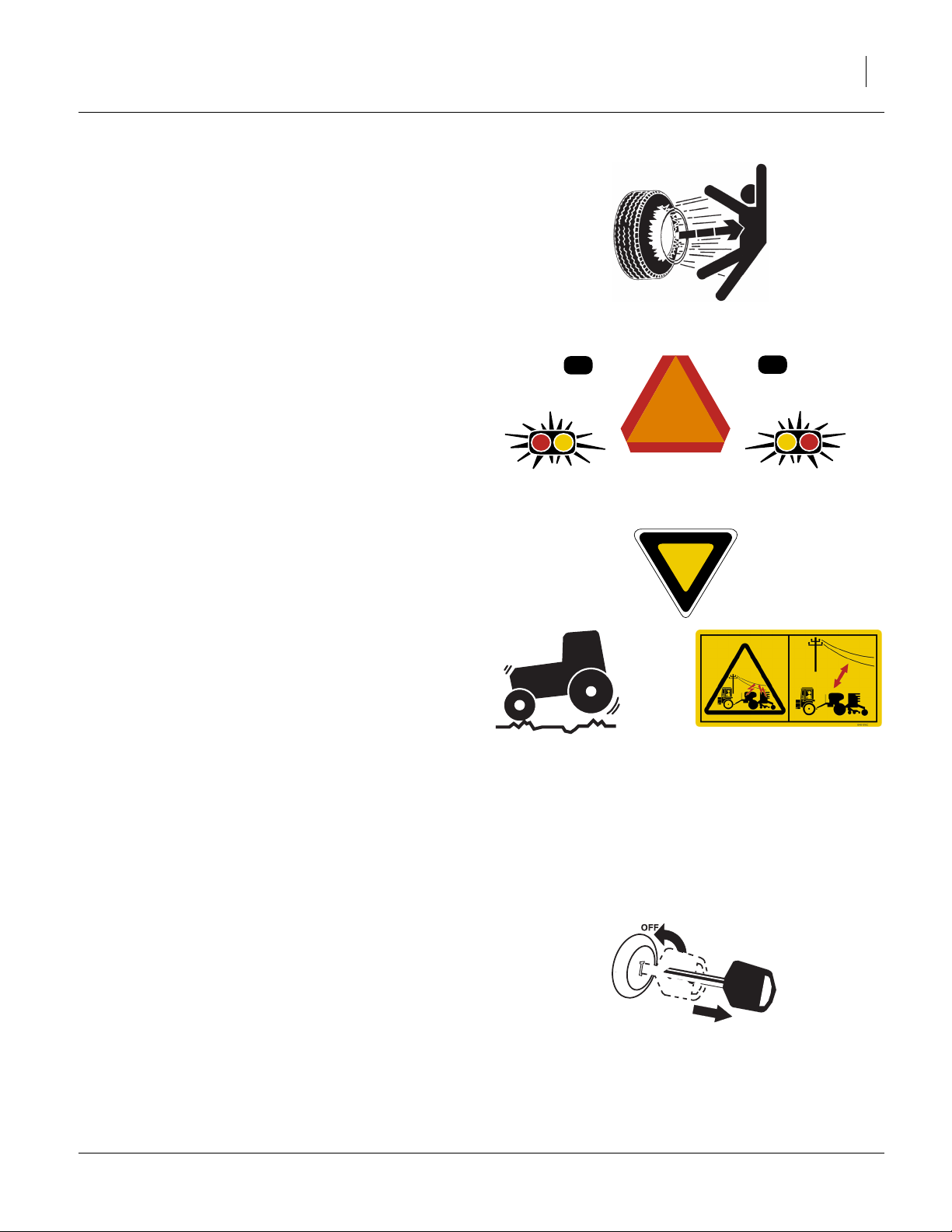

Tire Safety

Tire changing can be dangerous. Employ trained personnel using correct tools and equipment.

▲ When inflating tires, use a clip-on chuck and extension hose

long enough for you to stand to one side–not in front of or

over tire assembly. Use a safety cage if available.

▲ When removing and installing wheels, use wheel-handling

equipment adequate for weight involved.

Use Safety Lights and Devices

Slow-moving tractors and towed implements can create

a hazard when driven on public roads. They are difficult

to see, especially at night.

▲ Use flashing warning lights and turn signals whenever driv-

ing on public roads.

▲ Use lights and devices provided with implement.

Transport Machinery Safely

Maximum transport speed for implement is 30 kph.

Some rough terrains require a slower speed. Sudden

braking can cause a towed load to swerve and upset.

▲ Do not exceed 30 kph or 20 mph. Never travel at a speed

which does not allow adequate control of steering and stopping. Reduce speed if towed load is not equipped with

brakes.

▲ Comply with national, regional and local laws.

▲ Do not tow an implement or nurse tank that weighs more

than 1.5 times the weight of towing vehicle.

▲ Carry reflectors or flags to mark Turbo-Chisel in case of

breakdown on the road.

▲ Keep clear of overhead power lines and other obstructions

when transporting. Refer to transport dimensions under

“TCN Specifications and Capacities” on page 60.

▲ Reduce speed on rough roads.

▲ Do not fold or unfold the Turbo-Chisel while the tractor is

moving.

Shutdown and Storage

▲ Lower Turbo-Chisel, put tractor in park, turn off engine,

and remove the key.

▲ Secure Turbo-Chisel using parking jack provided.

▲ Detach and store Turbo-Chisel in an area where children

normally do not play.

03/17/2014 566-170M

Page 12

8 TCN5107-5313 Great Plains Manufacturing, Inc.

Practice Safe Maintenance

▲ Understand procedure before doing work. Use proper

tools and equipment. Refer to this manual. For brake

work, see specific safety information beginning on

page 48.

▲ Work in a clean, dry area.

▲ Unfold and lower the implement, put tractor in park, turn

off engine, and remove key before performing maintenance. If work must be performed with implement raised,

use centre section lift lock and gauge lock channels provided.

▲ Make sure all moving parts have stopped and all system

pressure is relieved.

▲ Allow machine to cool completely.

▲ Disconnect battery ground cable (-) before servicing or

adjusting electrical systems.

▲ Welding: Disconnect battery ground. Protect hydraulic

lines. Avoid fumes from heated paint.

▲ Inspect all parts. Make sure parts are in good condition

and installed properly.

▲ Remove buildup of grease, oil or debris.

▲ Remove all tools and unused parts from Turbo-Chisel

before operation.

566-170M 03/17/2014

Page 13

Great Plains Manufacturing, Inc. Important Safety Information 9

Safety At All Times

Thoroughly read and understand the instructions in this

manual before operation. Read all instructions noted on

the safety decals.

▲ Be familiar with all Turbo-Chisel functions.

▲ Operate machinery from the driver’s seat only.

▲ Do not leave Turbo-Chisel unattended with tractor engine

running.

▲ Do not stand between the tractor and implement, or imple-

ment and nurse tank during hitching.

▲ Keep hands, feet and clothing away from power-driven

parts.

▲ Wear snug-fitting clothing to avoid entanglement with mov-

ing parts.

▲ Watch out for wires, trees, etc., when folding and raising

Turbo-Chisel. Make sure all persons are clear of working

area.

Accident Prevention

▲ In addition to the Operating Instructions, it is important to

observe the accident prevention regulations specified by

agricultural trade associations. It is the Operator’s responsibility to ensure that all other persons are excluded from

danger zones surrounding or on the machine during its

operation.

It is the Owner’s Responsibility to Ensure;

▲ The Operator is trained and competent to use the machine

and tractor.

▲ The tractor is suitable for the machine.

▲ Adequate Risk and COSHH assessments have been under-

taken regarding the machine’s use, Specifically, these

include issues concerning contact with the soil, crop residues, chemicals, lubricants and other compounds during

operation, maintenance, and rhe possibility of stones being

ejected at high speed during work.

Beware of trapping hazards when manipulating the parking

jacks, shut-off valves, wheel chocks, or other moving parts.

Ensure any heavy components are fully supported when removing pins/bolts.

03/17/2014 566-170M

Page 14

10 TCN5107-5313 Great Plains Manufacturing, Inc.

Safety Decals

Safety Reflectors and Decals

Your implement comes equipped with all lights, safety

reflectors and decals in place. They were designed to

help you safely operate your implement.

▲ Read and follow decal directions.

▲ Keep lights in operating condition.

▲ Keep all safety decals clean and legible.

▲ Replace all damaged or missing decals. Order new decals

from your Great Plains dealer. Refer to this section for

proper decal placement.

▲ When ordering new parts or components, also request cor-

responding safety decals.

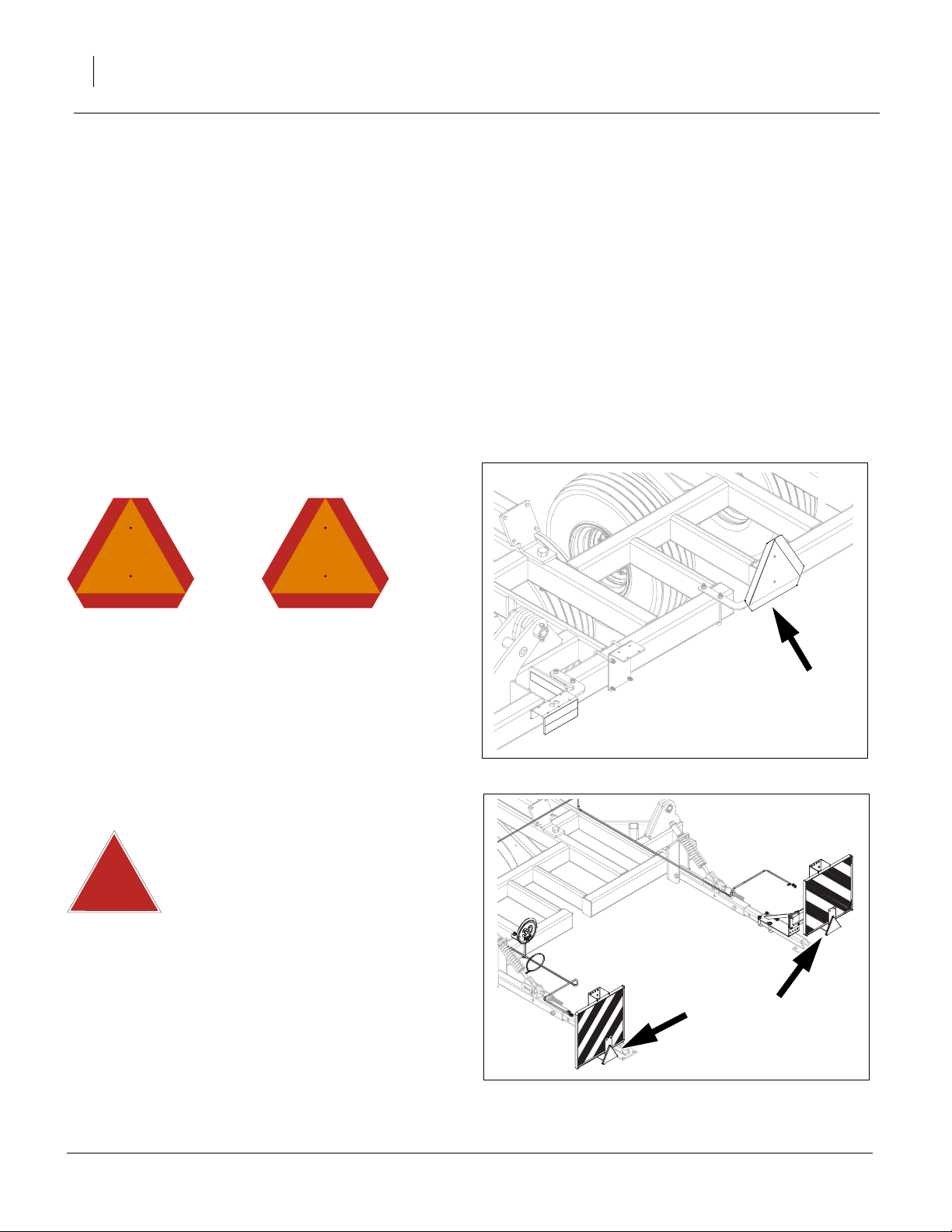

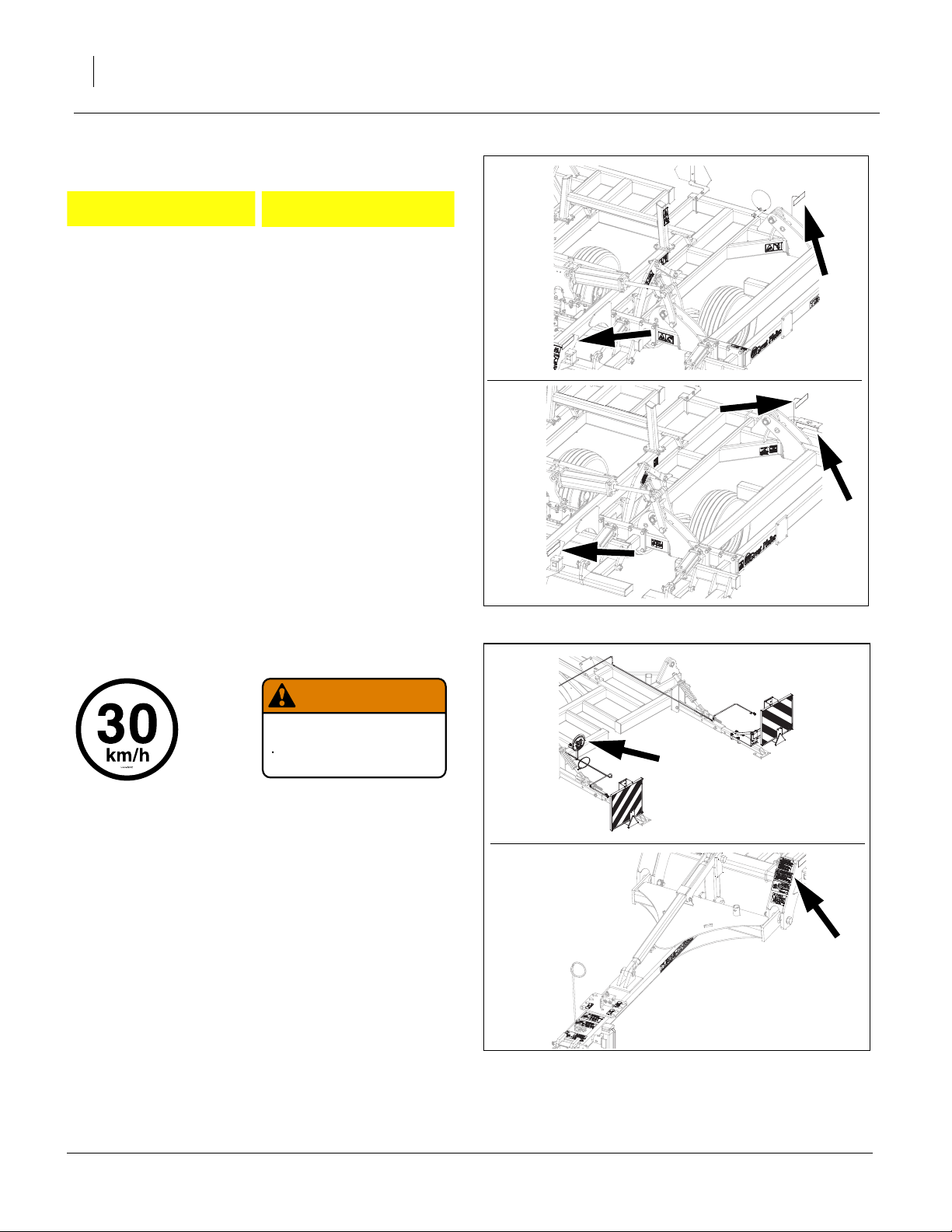

Reflector: Slow Moving Vehicle (SMV)

International: 818-055C North America: 818-055C

To install new decals:

1. Clean the area on which the decal is to be placed.

2. Peel backing from decal. Press firmly on surface,

being careful not to cause air bubbles under decal.

On the back of smv post;

1 total

.

Reflectors: Red Triangles

International: 833-399C North America: n/a

(North American models

use

818-055C SMV reflectors,

838-614C red reflectors &

838-615C amber reflectors.)

One each rear fluorescent panel;

2 total

.

41973

42154

566-170M 03/17/2014

Page 15

Great Plains Manufacturing, Inc. Important Safety Information 11

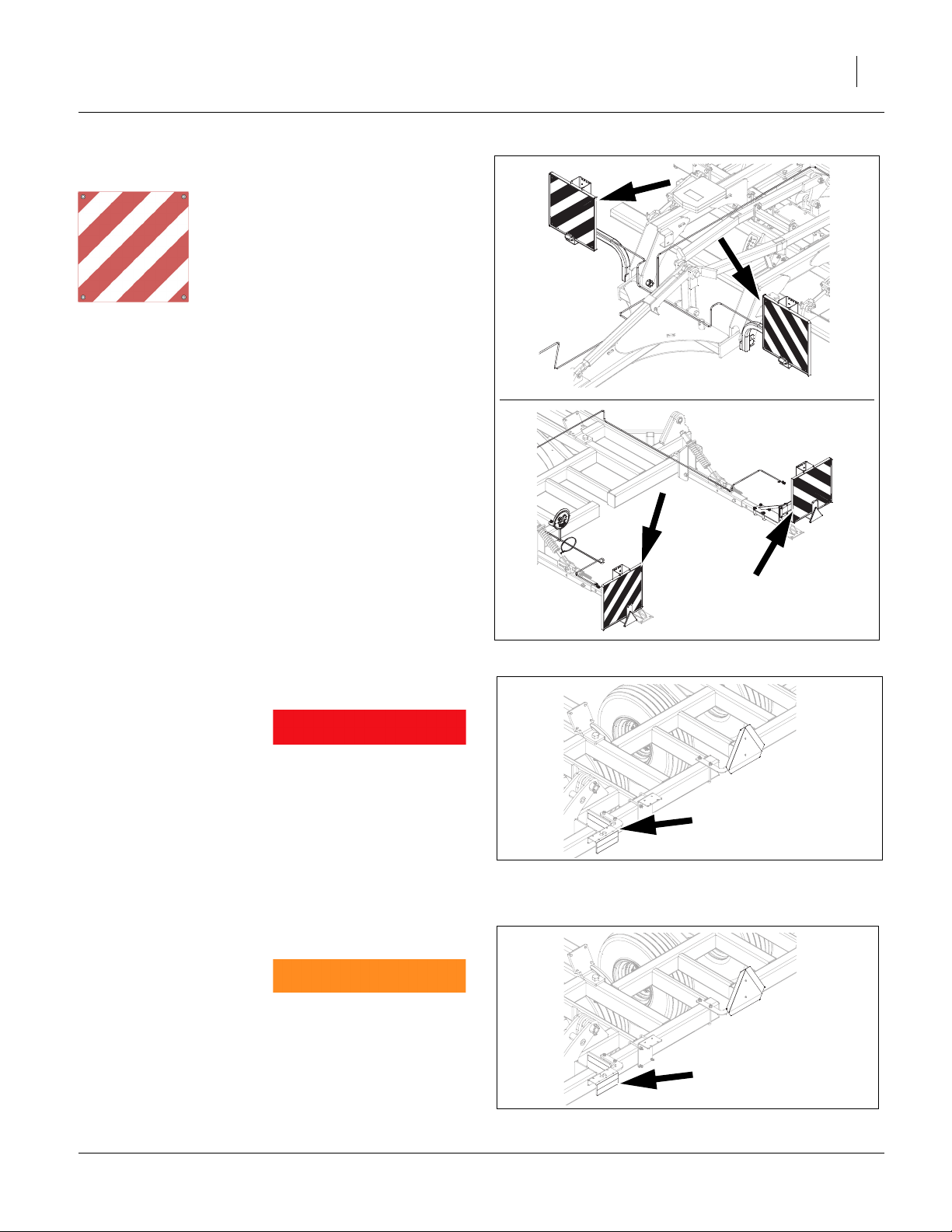

Reflectors: Fluorescent Panels

International: 833-398C

One each side, front frame,

one each side, rear;

4 panels total

North America: n/a

42155

Reflectors: Red

International: n/a North America: 838-614C

On rear of light bracelets

both sides (above Orange);

2 total

Reflectors: Orange

International: n/a North America: 838-603C

On rear of light brackets,

both sides

(below Reds);

2 total

42154

41973

41973

03/17/2014 566-170M

Page 16

12 TCN5107-5313 Great Plains Manufacturing, Inc.

Reflectors: Amber

International: 838-615C

North America: 838-615C

One on outside of center

frame plate (rear), one on

outside of trusses (front)

(both sides), two on optional

rear finishing attachment

(not shown, visible from side

while folded for transport;

6 total

Transport: Speed

International: 848-398C

One on front of light bracket,

one on outside of center

frame plate (rear), one on

outside of trusses (front)

(both sides), two on optional

rear finishing attachment

(not shown, visible from side

while folded for transport;

8 total

North America: 818-188C

42325

41972

On speed limit braced, rear

of center frame;

1 total

WARNING

EXCESSIVE SPEED HAZARD

To Prevent Serious Injury or Death:

Do Not exceed 20 mph maximum transport

speed. Loss of vehicle control and/or machine

can result.

On front of left truss (2nd

from top);

1 total

818-188C Rev. C

42154

41971

566-170M 03/17/2014

Page 17

Great Plains Manufacturing, Inc. Important Safety Information 13

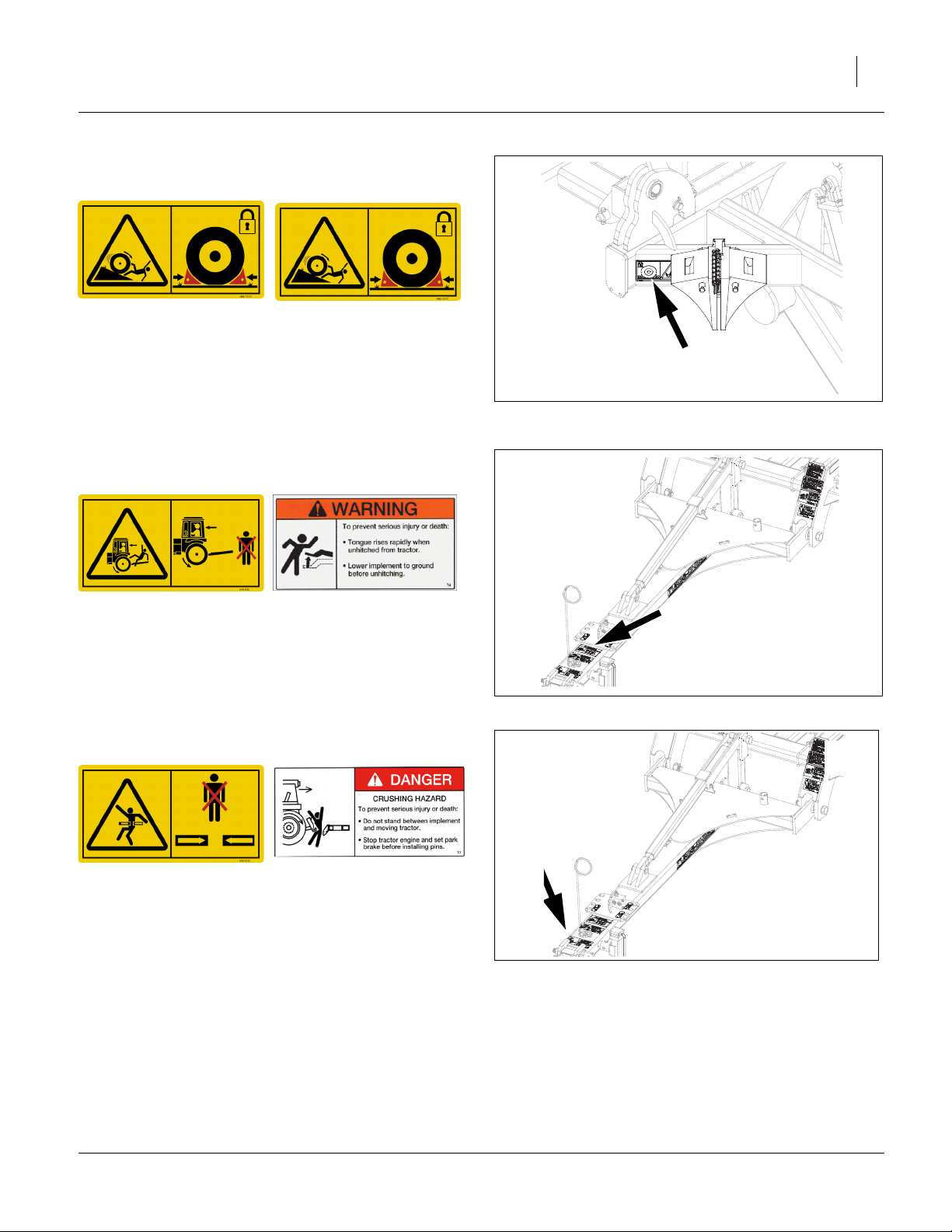

Transport: Wheel Chock (Option)

International: 848-757C North America: 848-757C

Front angled tube of center frame, near wheel chocks

(both sides);

2 total

41979

Warning: Tongue Rising

International: 848-511C North America: 838-606C

Front of hitch (rear);

1 total

Danger: Crush

International: 848-513C North America: 838-600C

Front of hitch (front);

1 total

41971

41971

03/17/2014 566-170M

Page 18

14 TCN5107-5313 Great Plains Manufacturing, Inc.

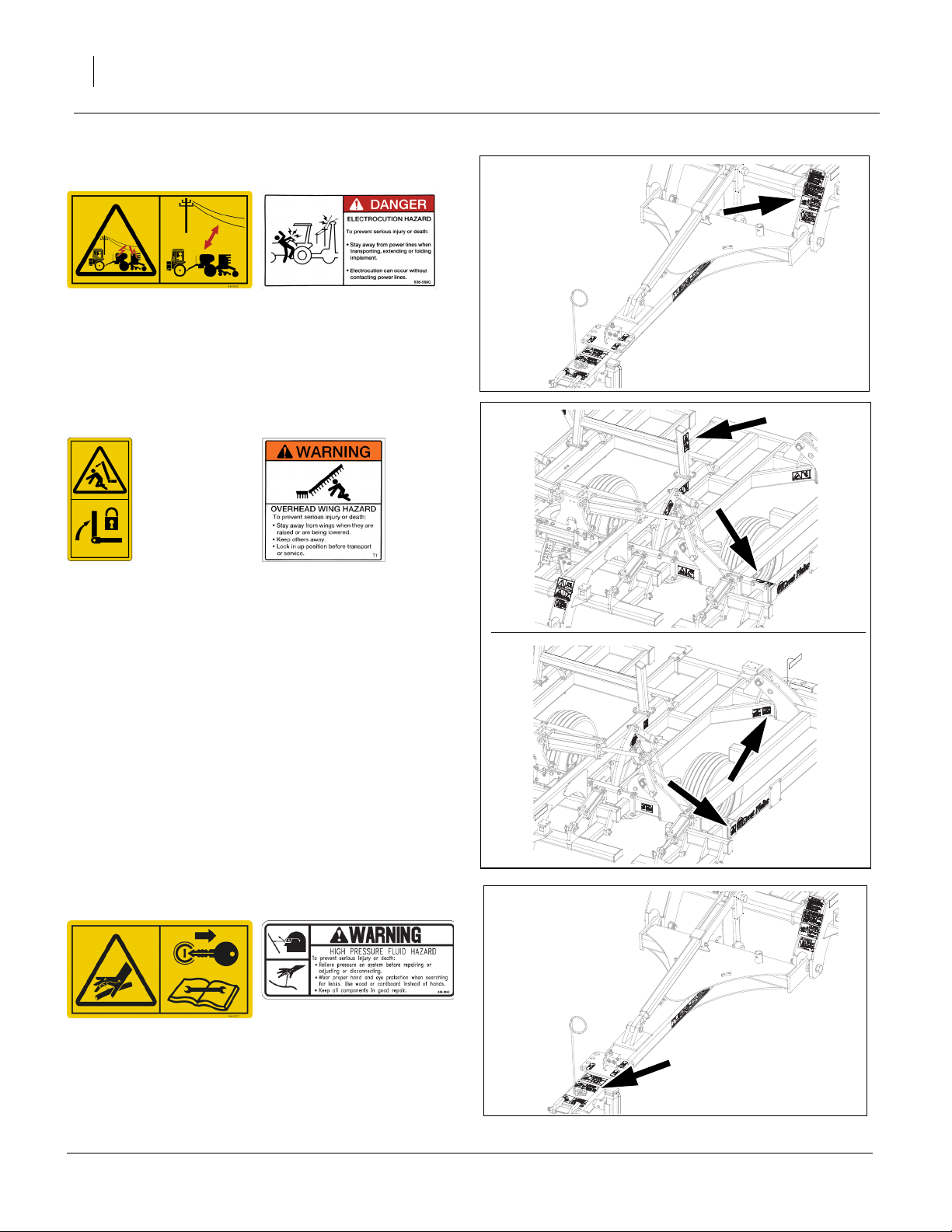

Danger: Electrocution

International: 848-516C North America: 838-599C

On front of left truss (3rd from top);

1 total

41971

Warning: Wing Crushing

International: 848-530C

North America: 838-602C

848-530C REV A

Outside of wing stop tube

(both sides);

4 total

Outside center frame angle

tube, front (both sides);

4 total

Warning: High Pressure Fluid

International: 848-517C North America: 838-094C

42157

41972

41971

Front of hitch (middle);

1 total

566-170M 03/17/2014

Page 19

Great Plains Manufacturing, Inc. Important Safety Information 15

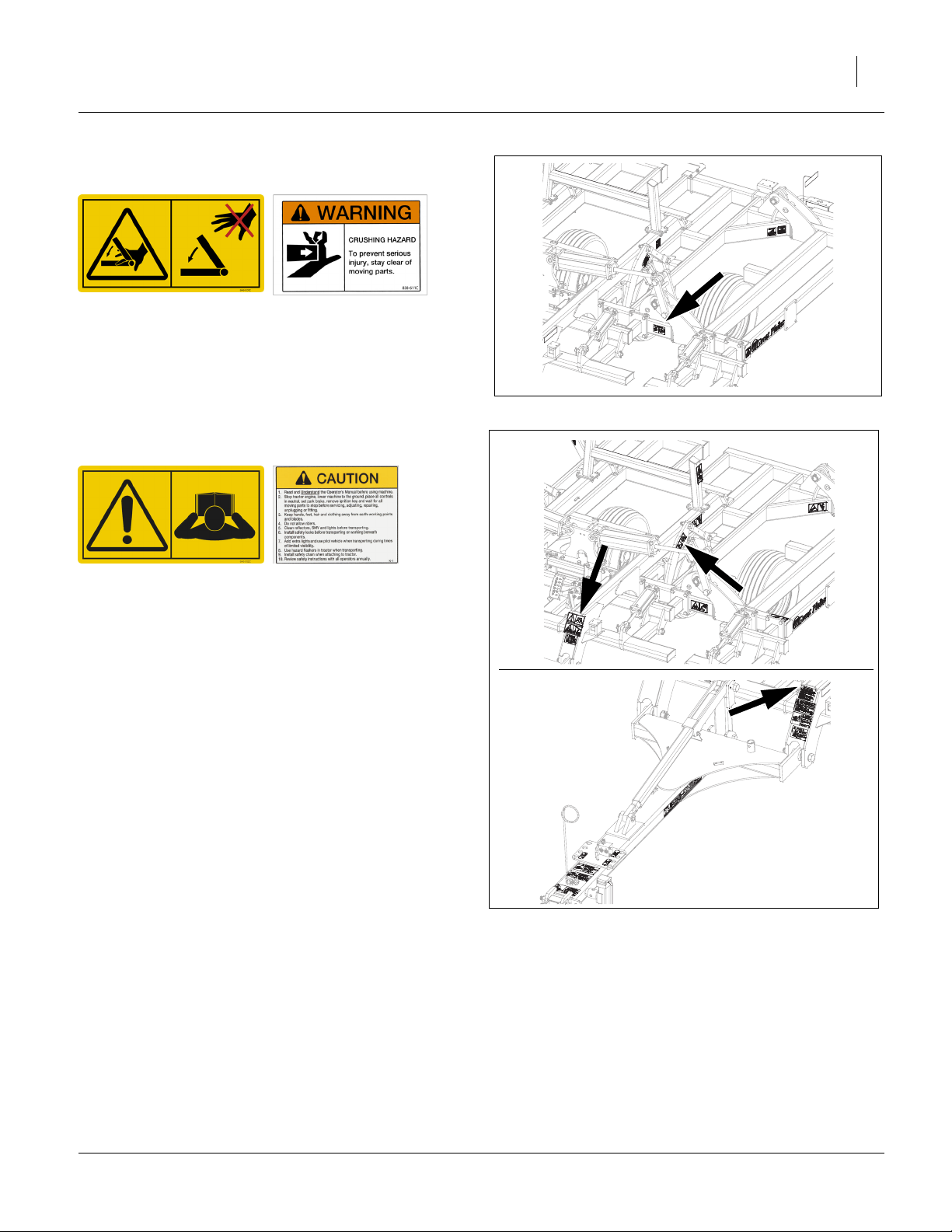

Warning: Hand Pinch

International: 848-531C North America: 838-611C

Front side of center frame (left & right side);

2 total

41972

Caution: Read Operator Manual

International: 848-512C

On front of left truss (top),

outside cylinder mount bar

(both sides;

3 total

North America: 838-598C

On front of left truss (top);

1 total

42157

41971

03/17/2014 566-170M

Page 20

16 TCN5107-5313 Great Plains Manufacturing, Inc.

Caution: Tires Not A Step

International: 848-507C North America: 818-398C

41972

On outside of truss, and center frame angled tube (both

sides);

4 total

Notice: Transport Lock

International: 848-512C North America: 838-613C

Outside of cylinder mount bar (both sides);

2 total

Danger: Cutting of Foot

International: 848-781C North America: 848-271C

On front of left truss (bottom);

1 total

41972

41971

566-170M 03/17/2014

Page 21

Great Plains Manufacturing, Inc. 17

Preparation and Setup

This section helps you prepare your tractor and

TCN5107, TCN5309, TCN5311, or TCN5313for use, and

covers seasonal tasks, and tasks when the tractor/TurboChisel configuration changes.

Before using the TCN5107, TCN5309, TCN5311, or

TCN5313 in the field, you must hitch the Turbo-Chisel to

a suitable tractor, inspect systems and level the TurboChisel. Before using the Turbo-Chisel for the first time,

and periodically thereafter, certain adjustments and calibrations are required.

Initial Setup

See “First Time Field Adjustments” on page 37 and

“Hitching a Trailing Implement (Optional)” on page 36

for pre-delivery items (normally completed by dealer),

and first-time/infrequent setup tasks, including:

❑ Remove protective film from large highway reflec-

tors.

Seasonal Setup

On initial delivery, use with a new tractor, and seasonally,

check and as necessary, complete these items before

continuing to the routine setup items:

❑ Bleed hydraulic system (page 30).

❑ Wing levelling and alignment (page 38).

❑ De-grease exposed cylinder rods if so protected at

last storage.

Pre-Tilling Setup

Complete this checklist before routine setup:

❑ Read and understand “Important Safety Informa-

tion” on page 5.

❑ Check that all working parts are moving freely, bolts

are tight, and cotter pins are spread.

❑ Make sure your tractor horsepower matches the

implement you are pulling. This is important so the

implement can do the best possible job.

❑ Clean all hydraulic couplings and connect to tractor

as shown on page “Hydraulic Hose Hookup” on

page 21.

❑ If machine is folded, open the two, lock valves on rod

end of fold cylinders and slowly untold the unit. Make

sure no one is under the wings during the unfolding

process.

❑ Check again for hydraulic leaks and watch that

hoses do not get pinched in hinges, wing stops, etc.

❑ After the machine is completely unfolded, remove

both transport locks from lift cylinders, raise and

lower the Turbo-Chisel several times to purge air

from the hydraulic system. Again check for hydraulic

leaks and tighten or replace if necessary.

❑ Check safety chain hookup. Make sure all warning

lights are hooked up and functioning correctly.

❑ Check that all grease fittings are in place and lubri-

cated. See “Lubrication and Scheduled Mainte-

nance” on page 48. The hubs will come pre-greased

and will not need greased at this time.

❑ Check that all safety decals and reflectors are cor-

rectly located and legible. Replace if damaged. See

“Safety Decals” on page 10.

❑ Inflate tires to pressure recommended and tighten

wheel bolts as specified. See “Tire Inflation Chart”

on page 61.

❑ Put transport locks back in place on lift cylinders and

re-fold the machine slowly. Close the two lock valves

on rod end of fold cylinders. Always use the transport

locks and close lock valves when moving from field

to field. You are now ready to go to the field.

03/17/2014 566-170M

Page 22

18 TCN5107-5313 Great Plains Manufacturing, Inc.

Hitching Tractor to Turbo-Chisel

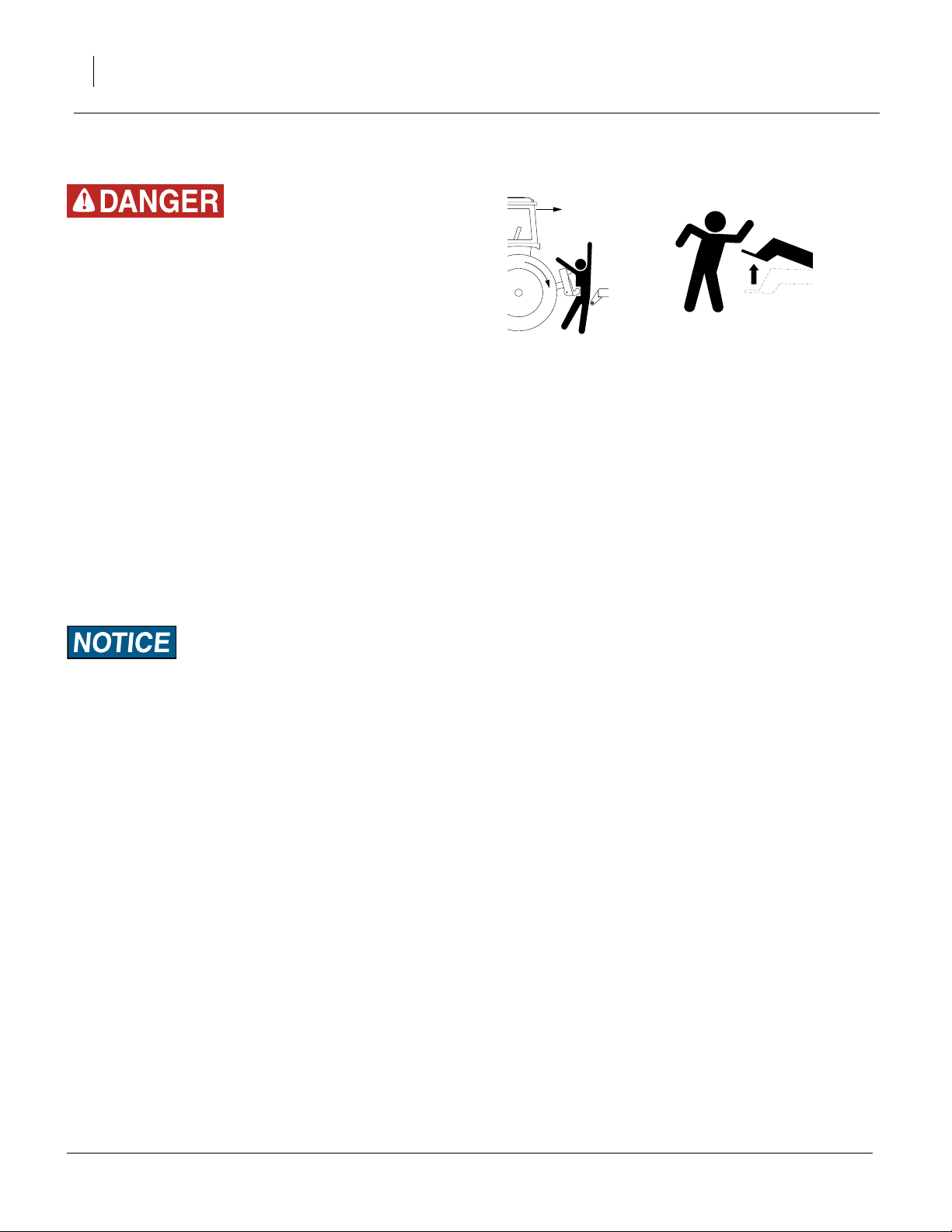

Crushing Hazard:

You may be severely injured or killed by being crushed between

the tractor and implement. Do not stand or place any part of

your body between implement and moving tractor. Stop tractor

engine and set tractor parking brake before attaching cables

and hoses.

Improper Pull Hazard:

Severe injury or death may result if improper transport vehicle

is used. Hitch to tractor for highway transport or field operations. Hitch to a leading implement only for field operations.

Do not transport behind another implement.

Before hitching, check the compatibility of the towing tractor

or implement.

For hillsides and steep slopes, set tractor wheels as wide as

possible for maximum stability.

Negative Tongue Weight Hazard:

If the rear parking jack is not set, an unhitched Turbo-Chisel

can tip over backwards during hitching and unhitching resulting in severe injury or death. If the Turbo-Chisel has a rear

attachment make sure the rear parking jack is in the parking

position, before attempting to hitch or unhitch from the tractor.

Hitch Failure Risk:

The TCN5107-5313 Turbo-Chisel’s are pull-type implements

equipped with standard Category IV single tang hitch. It may

be converted to a Category III or clevis hitch using supplied

accessory parts. Always have two (2) bolts in two holes of both

tongue and hitch.

Tractor Oil Flow Adjustment Risk:

As a general rule the tractor oil flow rate should be set to the

lower setting before starting. Oil flow can be increased to

allow the desired rate of operation as applicable. Performing

the adjustment will minimise excessive oil flow and consequent

power usage and heat generation.

Extended Parking Risk:

When the TCN5107-5313 Turbo-Chisel’s are parked for

extended periods of time, it should ideally be left in the

unfolded, i.e work position for stability, safety and ease of

access for maintenance. However, parking the TCN5107-5313

Turbo-Chisel’s in the fold position (ensuring transport locks

are engaged) is acceptable in the normal course of operation.

Drawbar Sway Risk:

Lock drawbar swing to center position to minimize any sideto-side sway to assure proper tracking in the field, and safe

road travel. See “Transport” on page 35, for safe trans-

porting.

566-170M 03/17/2014

Page 23

Great Plains Manufacturing, Inc. Preparation and Setup 19

To prevent soil compaction on rows, set tractor wheels

between rows.Raise tractor three-point arms (if equipped)

clear up to clear Turbo-Chisel.

1. For TWO-WHEEL DRIVE and MFWD tractors, pin

drawbar in fixed center position for field and transport. For FOUR-WHEEL DRIVE and TRAC-DRIVE

tractors, leave one hole clearance on each side of

drawbar for field position, hitch damage may occur if

pinned solid. Pin in center position for transport to

maintain maximum steering control.

Clevis Hitch

Refer to Figure 4

The base hitch must be upright (with the recessed notch

on the bottom) for this configuration. This places the

tongue weight on the base hitch, and not the clevis.

1. Select one each:

82

890-798C HITCH CLEVIS

802-487C HHCS 3/4-10X6 GR8

48

803-367C NUT HEX TOP LOCK 3/4-10 PLT

62

2. With the square-shouldered end of the clevis up,

fully seat the clevis in the upright base hitch .

Insert the Grade 8 bolt from below. Secure with

lock nut .1

62

48

82

83

62

82

3.

48

Hitch Failure Hazard:

Install the hitch base and assemble the clevis parts as shown.

Incorrect installation or assembly may result in failure of the

clevis bolt, leading to hitch failure. This could result in a serious highway accident or severe machine damage.

Category III Hitch

The base hitch must be inverted (with the recessed notch

on the top) for this configuration. Set the V-block to

allow some vertical articulation of the draw bar pin.

Always use at least one cushion .

88

1. Select one each:

PPI-302V TOP PLATE - CAT 3

89

PPI-203VR V-BLOCK

87

802-383C HHCS 3/4-10X3 GR5

47

and two:

PPI-205H CUSHION

88

2. Set the cushions inside the hitch recess , just forward of the vertical bolt hole. Position the V-block

forward of the cushions and check the size of the

resulting pinning hole. Remove a cushion if needed.

3. Add the top plate . Secure from below with

Grade 5 bolt .

89

47

87

88

87

83

88

87

89

47

Figure 4

Configure Hitch

31740

42326

31741

03/17/2014 566-170M

Page 24

20 TCN5107-5313 Great Plains Manufacturing, Inc.

Refer to Figure 5

4. Rear jack should be lowered to ground when

1

machine is in parking position to keep machine from

tipping over backwards. Adjust rear jack up off

ground to allow for front jack to be adjusted.

5. Use front jack to raise and lower turbo-chisel

2

2

tongue.

3

2

6

6. Remove hitch pin from tractor draw-bar.

7. Back tractor draw-bar into alignment with hitch . Set

3

tractor parking break.

4

1

8. Secure with a locking hitch pin.

9. Secure safety chain to an anchor on the tractor .

4

Figure 5

Front & Rear Jack (Parking)

41993

42162

Refer to Figure 6

10. Retract jack foot.

11. After hitching tractor to turbo-chisel, store front jack

on storage stob on Turbo-Chisel tongue.

12. Remove pin from rear jack (Figure 5), move to front

5

1

outside tube of center frame storage stob (Figure 6)

and re-install pin.

13. Remove pin in jack stand tube (Figure 5) and raise

tube up to top hole, re-install pin.

6

2

1

Figure 6

42178

Jacks in Storage

Electrical Hookup

Refer to Figure 7

Make sure tractor is shut down with accessory power off

before making connections.

14. Mate lighting connector to tractor outlet.

15. Mate any optional or after-market electrical connectors.

16. Make connections prior to TCN5107-5313 move-

Lighting Connector European

Figure 7

(North American)

ment.

566-170M 03/17/2014

41995

36051

Page 25

Great Plains Manufacturing, Inc. Preparation and Setup 21

Hydraulic Hose Hookup

Great Plains hydraulic hoses are color coded to help you

hookup hoses to your tractor outlets. Hoses that go to the

same remote valve are marked with the same color.

High Pressure Fluid Hazard:

Shut down tractor before making hydraulic connections.

Only trained personnel should work on system hydraulics!

Escaping fluid under pressure can have sufficient pressure to

penetrate the skin causing serious injury. Avoid the hazard by

relieving pressure before disconnecting hydraulic lines. Use a

piece of paper or cardboard, NOT BODY PARTS, to check for

leaks. Wear protective gloves and safety glasses or goggles

when working with hydraulic systems. If an accident occurs,

seek immediate medical assistance from a physician familiar

with this type of injury.

Refer to Figure 8

To distinguish hoses on the same hydraulic circuit, refer

to handle symbols.

• The hose with an extended-cylinder symbol feeds a

cylinder base end.

• The hose with a retracted-cylinder symbol feeds a cylinder rod end.

Secure hoses and cables so that they have sufficient

slack for hitch movements, but cannot get caught

between moving parts of tractor, implement or hitch. Failure to safely route and secure hoses and cables could

result in damage requiring component repair/replacement, and lost field time.

Clean all hydraulic couplings and hook hoses to tractor.

Figure 8

Hose Handles

Colour Hydraulic Function

Black Lift (2 hoses)

Green Fold (2 hoses)

Red Gang (2 hoses)

“BRAKES” Hydraulic trailer brakes (Option)

31733

03/17/2014 566-170M

Page 26

22 TCN5107-5313 Great Plains Manufacturing, Inc.

Brake Hook-up (Option)

Two TCN5107-5313 braking (trailer braking) systems are

available:

• Dual-line air system (Figure 9) with wheel chocks

(Figure 11) for parking and

• Single-line hydraulic (Figure 10) with wheel chocks

(Figure 11).

In both systems, the tractor’s trailer brake remote port(s)

operate a hydraulic slave cylinder on the Turbo-Chisel.

Tractor trailer braking systems are normally integrated

with the tractor brakes, and operate the trailer brakes

when tractor brakes are used during tractor movement.

The trailer braking system may or may not be integrated

with the tractor parking brake system.

Trailer brakes typically are not automatically engaged

when the tractor transmission is in Park, and may not be

engaged by any tractor Emergency Brake.

Both brake systems include four chock blocks to be manually installed for parking the TCN5107-5313. The tractor

cannot set the implement wheel chocks.

Figure 9

Air Brake System

41999

Braking Hazards:

Make sure the operator understands when Turbo-Chisel

brakes are engaged and when they are released (make a record

of tractor behaviour on page 33).

Also understand and comply with tractor operational restrictions when trailer brakes are used. For example, it is generally

necessary to inter-tie split brakes, and avoid differential

(steering braking) if trailer brakes are used.

Figure 10

Hydraulic Brake System

Figure 11

Machine Parking Brake System

42000

42167

566-170M 03/17/2014

Page 27

Great Plains Manufacturing, Inc. Preparation and Setup 23

Air Brake Hook-up

Refer to Figure 12

17. Open petcock at reservoir tank. Drain any water

from tank. Close petcock.

Refer to Figure 13

18. Inspect gladhands before connecting. Clean elastomer seal surfaces . Blow debris out of inlet ports.

Check screen condition.

19. Connect the “Brake”, “Service” or “Control” line first.

This line is Blue-coded.

This line operates the Turbo-Chisel brakes.

1

1

1

20. Connect the “Provision” or “Supply” line. This line is

Red-coded.

The Provision line charges a reservoir tank on the

implement. The Brake line operates a valve system

which meters tank air to the master cylinder on the

implement.

Braking Hazard:

Do not use the TCN5107-5313 with a “single-line” air brake

system. This Turbo-Chisel is designed for transport speeds

that require an air brake system to be “dual-line”. A singleline tractor system cannot charge the tank that powers the

Turbo-Chisel brakes.

Roll-Away Hazard:

When unhitching, disconnect the red (control) line first. This

sets the brakes on the implement.

RED

Figure 12

Air Brake Reservoir

Figure 13

Air Brake Connectors

41998

BLU

2

29646

Hydraulic Brake Hook-up

Refer to Figure 14

This is a single hydraulic line, connected to the tractor

“Brake” outlet.

The factory default connector is a 19 mm poppet-style

QD (Quick Disconnect). If this is incompatible with your

tractor, it may be replaced by a connector that mates to,

or can be adapted to:

19 mm male ORB (O-Ring Boss), or

19 mm female JIC (Joint Industry Conference, 37°

flare).

Figure 14

Hydraulic Brake Connector

03/17/2014 566-170M

29647

Page 28

24 TCN5107-5313 Great Plains Manufacturing, Inc.

-

Operating Instructions

This section covers general operating procedures. Experience, machine familiarity, and the following information

will lead to efficient operation and good working habits.

Always operate farm machinery with safety in mind.

Pre-Start Checklist

Perform the following steps before transporting the

TCN5107-5313 Turbo-Chisel to the field.

❑ Carefully read “Important Safety Information” on

page 5.

❑ Lubricate Turbo-Chisel as indicated under “Lubrica-

tion and Scheduled Maintenance” on page 48.

❑ Check all tires for proper inflation, “Tire Inflation

Chart” on page 61.

❑ Check all bolts, pins, and fasteners. Torque as shown

in “Torque Values Chart” on page 63.

❑ Check Turbo-Chisel for worn or damaged parts.

Repair or replace parts before going to the field.

❑ Check hydraulic hoses, fittings, and cylinders for

leaks. Repair or replace before going to the field.

High Pressure Fluid Hazard:

Relieve pressure and shut down tractor before connecting, dis

connecting or checking hydraulic lines. Use a piece of paper

or cardboard, NOT BODY PARTS, to check for leaks. Wear

protective gloves and safety glasses or goggles when working

with hydraulic systems. Escaping fluid under pressure can

have sufficient pressure to penetrate the skin causing serious

injury. If an accident occurs, seek immediate medical assistance from a physician familiar with this type of injury.

566-170M 03/17/2014

Page 29

Great Plains Manufacturing, Inc. Operating Instructions 25

Unfolding and Folding

Unfold/Fold: Safety Information

Electrocution Hazard:

Keep clear of overhead power lines when unfolding, operating, folding or transporting the machine. Machine is not. At

higher voltages, electrocution can occur without direct contact. Any line voltage present on implement, implement or

tractor can cause severe injury or death.

Overhead crushing hazard:

Unfold and fold implement only if fold hydraulics are bled free

of air and fully charged with hydraulic oil. Keep away and

keep others away when unfolding or folding.

Danger crushing hazard:

An energized hydraulic circuit can activate the fold cylinder

causing serious injury or death. Avoid the hazard by relieving

pressure before shutting down the tractor and removing the

key. Once the hydraulic circuit is de-energized, the shut-off

valve may be opened. If an accident occurs, seek immediate

medical assistance from a physician familiar with this type of

injury.

Pinch Point and Crushing Hazards:

Keep people away from the implement and tractor during folding. Risks include pinching or crushing at pivot points and at

multiple sites in pivoting assemblies.

Use wing fold locks. If a hydraulic failure occurs, or hydraulic

levers are moved, unlocked wings could fall suddenly causing

a major road accident, or crushing anything near the wings,

resulting in death or serious injury, and property damage.

Falling Hazard - Tires Not a Step:

Do not use tires as steps or platforms. All tires can be in light

ground contact, or free to spin, when implement is lowered.

Equipment Damage Risk:

Raise implement before unfolding or folding. Folding with

implement lowered causes wing ground engaging components

to dig or drag sideways. Damage is likely.

Wing Tilt Risk:

Fold only while parked on hard level ground. If unfolding

across a slope or while moving, implement may become unstable and damage to implement components and surrounding

property. Damage is likely.

03/17/2014 566-170M

Page 30

26 TCN5107-5313 Great Plains Manufacturing, Inc.

Folding

Fold the Turbo-Chisel for moves between fields, transport

over public roads, parking and storage.

Refer to Figure 15

Fold: Move to Level Ground

1. Move the implement to level ground with adequate

overhead and lateral clearances for the fold

operation. Park the tractor.

2. Ensure locking valves on both fold cylinders are

open (parallel with side of cylinder), as shown.

1 2

2

1

Refer to Figure 16

Fold: Raise Implement (page 30)

3. Extend the lift cylinders to full raise implement. Hold

at raised for a few seconds. Set circuit to Neutral.

Do not install transport locks.

Fold: Fold Wings (page 26)

4. Activate the circuit to retract the fold cylinders.

Note: One wing may reach the stop before the other. A

slight asymmetry is not uncommon in folding.

5. When both wings are in contact with their stops. Set

fold circuit to Neutral (not Float) to hold at folded.

Fold: Close Locking Valves (page 26)

Refer to Figure 17

6. At each wing, ensure the lock valves are in the

closed position (90 degrees from side of cylinder )

as shown.

1

2

Figure 15

Wing Lock Valve (Open)

Figure 16

Wing Fold Progression

42169

42174

2

1

Figure 17

Wing Lock Valve (Closed)

566-170M 03/17/2014

42170

Page 31

Great Plains Manufacturing, Inc. Operating Instructions 27

Unfolding

These steps presume a implement raised and folded for

transport, such as at initial delivery. Follow the detailed

instructions in step 7 through step 15, beginning on this

page, until this is a familiar operation.

Refer to Figure 18

Locking valves are on the wing cylinders to prevent wing

movement during transport. Note the open and closed position of the valves.

7. Move the implement to level ground with adequate

overhead and lateral clearances for the fold operation.

Remove Transport Locks

Refer to Figure 19

8. Extend lift circuit to lift implement off the transport locks

1

.

9. Park tractor and implement. Ensure the tractor hydraulics are depressurized and in the locked or closed (not

float) setting,

10. Shut down tractor and remove the key.

11. Inspect fold/lift cylinders linkages and hoses for wear. If

parts are worn, the operator should have a qualified

technician replace worn parts.

12. If parts are in good working order, move transport locks

2

to the working position on lift mechanism link.

13. Move locking valve lever to the open position slowly on

both fold cylinders.

14. Ensure all personal, e.g., children are out of the danger

zones.

15. Insert key into tractor and restart the tractor.

2

Figure 18

Wing Lock Valve (Closed)

1

Figure 19

Transport Locks

2

42170

2

42172

Equipment Damage Risk:

Raise before unfolding. If this operation is not performed, the

wing shanks contact the ground, drag, and may be damaged.

Unfolding: Unfold Wings (page 25)

16. Unfold the wings by extending the fold cylinders.

Note: One wing may reach the ground before the other. It

is not uncommon for the folding to be slightly -nonsymmetrical.

Refer to Figure 20

Hold the circuit at extended for several seconds after the

wings engage wing stops on center frame.

Figure 20

Wing Unfold Progression

03/17/2014 566-170M

42175

Page 32

28 TCN5107-5313 Great Plains Manufacturing, Inc.

Lift: Verify Transport Lock

Refer to Figure 21

1

Crush/Pinch Hazards:

Make sure the transport locks are engaged. Lift and re-lower if

it is not. If the transport locks are not installed, install transport locks, in the transport position the implement will slowly

lower after hydraulic power is removed. If anyone is working

on or under the implement, this could result in serious injury

or death.

Figure 21

Lift Lock Engaged

41981

Lowering and Raising Turbo-Chisel

Lowering/Raising Safety Information

Crushing Hazard During Lowering:

Stay clear of wings, coulters, shanks, and attachments during

lowering and raising. Wings are extremely heavy and are

driven down with hydraulic pressure. Coulter disk and chisel

points are sharp. During lowering, coulters and chisel points

will cut or crush anything beneath them, and can cause serious

injury or death.

Crushing Hazard While Raised:

Use transport locks (page 28) when working on implement.

Without transport locks, center section and wings are held up

only by hydraulic pressure, and slowly lower over time. They

may lower more rapidly if the hydraulic system is damaged.

They lower rapidly if the hydraulics fail, or the Lift circuit is set

to Float or Retract.

Shoving Hazard:

Chisel length changes during raising and lowering. Injury is

possible.

Implement wheels move forward during raising, and backward

during lowering. Tractor may move in some circumstances.

Set brakes / use park to avoid tractor movement. Remain clear

of all tires and row units during raise and lower.

Equipment Damage Risk:

Do not lower while any folding or unfolding operations are

under way or partially complete. Coulter disks and chisel

points can dig in or drag on ground and be damaged.

566-170M 03/17/2014

Page 33

Great Plains Manufacturing, Inc. Operating Instructions 29

Lowering

Refer to Figure 22

17. Check that the transport locks are not on lift cylinders

and installed in storage position.

18. Unfold implement before lowering (page 27).

19. Make sure all persons are clear of danger zones,

e.g., coulters and chisel points.

Refer to Figure 23

Falling Hazard:

Do not stand on tires when implement is lowered as they may

have little or no weight on them, and may turn suddenly and

without warning if used as a step, resulting in serious injury.

Figure 22

Lift Lock Disengaged

Figure 23

Implement Raised / Lowered

41997

42176

03/17/2014 566-170M

Page 34

30 TCN5107-5313 Great Plains Manufacturing, Inc.

Raising

Equipment Damage Risk:

Raise the implement for folding and unfolding. If lowered,

inside wing coulter disks and chisel points drag or dig sideways during fold/unfold, and damage is likely.

Equipment Damage Risk:

Always raise the implement for tight turns and reverse/backing

operations. Backing with implement lowered causes implement

plugging and damage to implement ground engaging components. Tight turns with implement lowered may damage ground

engaging implement components.

20. Make sure all persons are safely clear of implement

sections.

21. Activate dedicated Lift circuit (normally Extend).

Refer to Figure 24

22. Extend cylinders until all sections are raised. Hold for

a few seconds to re-phase cylinders.

23. Set circuit to Neutral to temporarily hold sections at

raised.

.Equipment Damage Risk:

On tractors with electronic timer controls for hydraulic circuits, lift timers must be set to no more than 2 seconds longer

than needed to fully raise Turbo-Chisel. To reduce oil heating

and system wear, Do Not Set for Continuous Mode.

Figure 24

42177

Implement Lowered / Raised

Refer to Figure 25

Note: Transport locks are provided to hold a fold/unfold

implement at fully raised position for transport,

maintenance, or storage.

Figure 25

41981

Lift Lock Engaged

Unfolded Transport Locks: Wing Pinch and Crushing Hazards:

The transport locks prevents the center section from lowering,

Use transport locks to hold implement raised for extended

periods. See page 27.

566-170M 03/17/2014

Page 35

Great Plains Manufacturing, Inc. Operating Instructions 31

Transporting the Turbo-Chisel

Transport Safety Information

Inadequate Tractor Hazard:

Tractor must weight at least 67% of the implement as towed.

Ensure that the towing vehicle is adequate for the task. Using

an inadequate tow vehicle is extremely unsafe, and can result

in loss of control, serious injury and death. See table on next

page. Do not tow if Turbo-Chisel exceeds the load rating of the

vehicle.

Loss of Control Hazard:

Do not tow the turbo-chisel behind another implement on public roads. Tow the turbo-chisel to the field with a separate vehicle. The leading implement may not provide sufficient lateral

control of a trailing implement at highway speeds. The total

weight of the train can also exceed the steering and/or braking

capability of the tractor. The resulting accident could cause

serious injury or death

Excessive Speed Hazard:

Maximum transport speed is 30 kph at all times, and lower

with a lighter tractor. Excess speed can result in loss of control

or inability to stop. Reduce speeds if road conditions are less

than ideal.

Collision Hazard:

Check lights and reflector regularly. Replace bulbs and faded/

worn/missing decals as required. Use lights in transport.

These features are critical to visibility, particularly with other

drivers unfamiliar with farm equipment or not expecting to

encounter a slow-moving vehicle.

Note: An installation of optional brakes on the implement

does not reduce tractor capability requirements or

increase allowed maximum transport speed.

Unexpected Wing Tilt-Down and Lowering Hazards:

Use wing locking valves (page 26). Check that implement centre section lift lock is engaged (page 27). Failure to use these

safety features can cause a major accident resulting in death,

injury and equipment damage. If locks are not engaged, and a

hydraulic failure occurs, or a circuit is unintentionally set to

Float, wings can unfold to ground contact, or implement can

settle into ground contact.

Loss of Control Hazard, Tires:

Inflate tires to factory specifications. Tighten wheel nuts to

specifications. Under-inflated tires or loose nuts can cause loss

of control. Over-inflated tires or overt-tightened nuts can fail

suddenly and cause loss of control. Loss of control can cause a

major accident resulting in death, injury and equipment damage.

03/17/2014 566-170M

Page 36

32 TCN5107-5313 Great Plains Manufacturing, Inc.

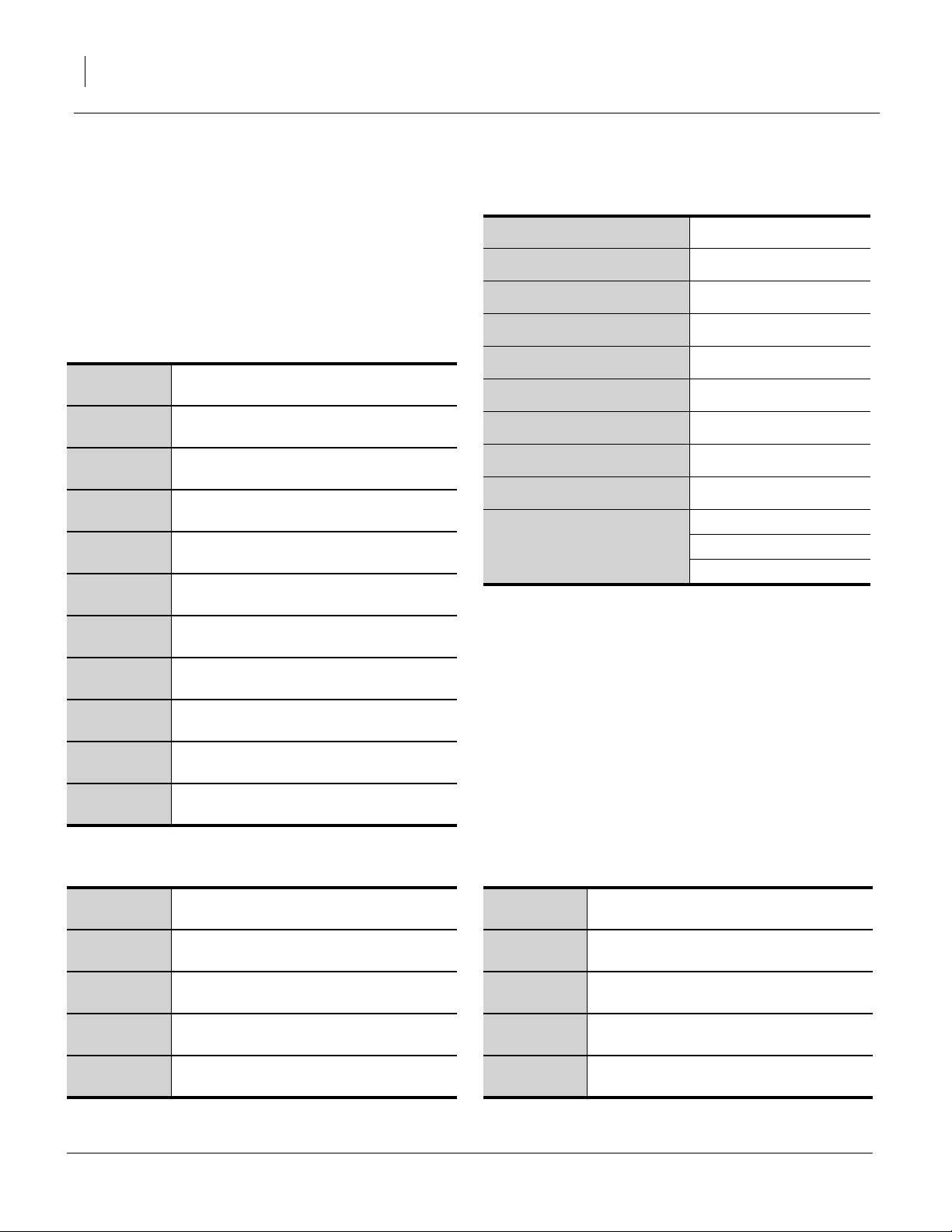

Tractor Requirements

The figures in the table below represent a limited number

of configurations. The weight of your Turbo-Chisel can

vary by hundreds of kilograms, even if it is the same base

model, due to installed options and/or after-market

equipment.

If your tractor weight or capability is in question, take

your Turbo-Chisel to a scale and get a precise weight.

Transport Checklist

❑ Plan the route. Avoid steep hills. Keep clearances in

mind. Folded, your TCN5107-5313 is nearly

3.12m high and is 3m wide.

❑ Hitch.

Check that implement is securely hitched to a sufficient tractor (page 18). Always use a locking-style

hitch pin sized to match holes in hitch and draw-bar,

and rated for the load.

❑ Check that tires are properly inflated. Remember

that the implement may be wider than the towing

vehicle. Allow safe clearance.

❑ If implement is equipped with optional brakes:

With tractor in Park, and with tractor parking brake

set, place chock blocks in transport position

(page 22).

❑ Always have lights on for highway operation.

❑ Comply with all national, regional and local safety

laws when travelling on public roads.

❑ Release all brakes and travel with caution.

Conguration TCN5107 TCN5309 TCN5311 TCN5313

Medium Chisel Auto Reset, no attachment 3589kg (7905lbs) 4733kg (10,425lbs) 5205kg (11,465lbs) 5496kg (12,105lbs)

Medium Chisel Auto Reset, Chopper wheel 4140kg (9120lbs) 5505kg (12,125lbs) 5648kg (13,590lbs) 5648kg (12,505lbs)

Medium Chisel Auto Reset, Buster Bar 3739kg (8235lbs) 4980kg (10,970lbs) 5677kg (12,235lbs) 5677kg (12,505lbs)

HEAVY/MEDIUM CHISEL AUTO REST, NO ATTACHMENT 3752kg (8265lbs) 5005kg (11,025lbs) 5478kg (12,065lbs) 5877kg (12,945lbs)

HEAVY/MEDIUM CHISEL AUTO REST, CHOPPER WHEEL 4304kg (9480lbs) 5777kg (12,725lbs) 6442kg (14,190lbs) 6955kg (15,320lbs)

HEAVY/MEDIUM CHISEL AUTO REST, BUSTER BAR 3902kg (8595lbs) 5253kg (11,570lbs) 5827kg (12,835lbs) 6236kg (13,735lbs)

MEDIUM PARABOLIC AUTO RESET, NO ATTACHMENT 3700kg (8150lbs) 4876kg (10,740lbs) 5380kg (11,850lbs) 5702kg (12,560lbs)

MEDIUM PARABOLIC AUTO RESET, CHOPPER WHEEL 4252kg (9365lbs) 5648kg (12,440lbs) 6345kg (13,975lbs) 6780kg (14,935lbs)

MEDIUM PARABOLIC AUTO RESET, BUSTER BAR 3850kg (8480lbs) 5123kg (11,285lbs) 5729kg (12,620lbs) 6061kg (13,350lbs)

HEAVY/MEDIUM PARABOLIC, NO ATTACHMENT 3816kg (8405lbs) 5069kg (11,165lbs) 5573kg (12,275lbs) 5972kg (13,155lbs)

HEAVY/MEDIUM PARABOLIC, CHOPPER WHEEL 4367kg (9620lbs) 5841kg (12,865lbs) 6538kg (14,400lbs) 7051kg (15,530lbs)

HEAVY/MEDIUM PARABOLIC, BUSTER BAR 3966kg (8735lbs) 5316kg (11,710lbs) 5922kg (13,045lbs) 6331kg (13,945lbs)

HEAVY SHANK AUTORESET, NO ATTACHMENT 3975kg (8755lbs) 5228kg (11,515lbs) 5809kg (12,795lbs) 6211kg (13,680lbs)

HEAVY SHANK AUTORESET, CHOPPER WHEEL 4526kg (9970lbs) 6000kg (13,215lbs) 6774kg (14,920lbs) 7289kg (16,055lbs)

HEAVY SHANK AUTORESET, BUSTER BAR 4125kg (9085lbs) 5475kg (12,060lbs) 6159kg (13,565lbs) 6569kg (14,470lbs)

566-170M 03/17/2014

Weights with air brakes and EU light kit installed.

Page 37

Great Plains Manufacturing, Inc. Operating Instructions 33

Brake Operation (option)

Implement wheel brakes are optional. There are brake

shoe pairs on each of the outside transport wheels. The

shoe pairs are operated by two independent systems:

1. The “service” or “trailer brake” system is controlled

by the tractor. It is connected to the tractor with a

single hydraulic line or two air lines.

2. The implement can be parked by manually placing

chock blocks on either side of the transport tires.

See also:

page 22 - “Brake Hook-up (Option)”

page 44 - “Brake Troubleshooting (Option)”

page 48 - “Brake Maintenance (Option)”

Brake Roll-Away Hazard:

Set manual chock blocks before unhitching implement. Block

tires if brakes are not installed, and for extra safety in case

brake system is tampered with or is not in working order.

Parking jack is not sufficient restraint for a implement parked

on un-level ground. An unsecured implement. could roll away,

causing an accident resulting in death, injury and substantial

property damage.

Both versions of the trailer brake system to the tractor are

spring-release on the implement. Unless the chock blocks are

set, implement service braking is released shortly after

unhitching the implement.

Note: The wheel chock system is not a true emergency

brake system, as there is no safe way to set the

chock blocks when the implement id in motion.

This manual therefore refers to it only for parking.

Machine Damage Risk:

Make the implement chock block removal part of your transport check-list. The tractor cannot place the chock blocks in

the transport position. Transporting with chock blocks in the

park position will result in tire or chock block damage.

1

Figure 26

Parking Brake (Chock Blocks)

29589

Service Brake Operation

If optional brakes are installed and connected, the

hydraulic/hydraulic or air/hydraulic systems automatically

work in conjunction with the tractor’s own brakes.

Application and release of tractor brakes during tractor

motion applies and releases the service brake system on

the implement.

Know Your Tractor Systems:

Application of tractor Parking and/or Emergency brakes may

or may not operate the implement service brake system,

depending on the design of the tractor systems.

Consult your tractor manual for details on when remote

brake ports are engaged and released. Note any variance from general behaviour in the table at right. Make

sure the tractor operator knows when implement brakes

are engaged and released.

03/17/2014 566-170M

Tractor

Braking-

Related Event

Normal tractor

braking

Differential tractor braking

Tractor Parking

Brake

Tractor Emergency Brake

Tractor transmission to Park

Typical Trailer

Brake Port

Response

Activates trailer

brakes

Reduced trailer

braking

Activates trailer

brakes

No effect on

trailer brakes

Record How

Your Tractor

Operates

Page 38

34 TCN5107-5313 Great Plains Manufacturing, Inc.

Single-Line Hydraulic Brake Operation

In this system, a single hydraulic line from the tractor

operates a de-intensifier cylinder on the implement,

which is coupled to the implement master cylinder .

The implement brake hydraulic lines are separate from

the tractor’s line.

With the hydraulic/hydraulic system, braking is immediately available when the tractor hydraulic system is

active.

Dual-Line Air/Hydraulic Brake Operation

In this system, the “supply” (yellow or blue coded) line

charges a reservoir air tank on the implement. The

“service” (red coded) line meters air from the

reservoir to a booster cylinder , which operates the

implement’s hydraulic brake lines .

5 7

2

5

6

1

3

2

3

1

4

Figure 27

Hydraulic/Hydraulic Brakes

8

42173

Service Air Brakes Not Instantly Available:

Prior to movement, wait for the tractor air system to reach full

charge after implement hook-up. Tractor and implement reservoir tanks must be pressurized. implement service braking may

not be immediately available upon tractor hook-up with the

air/hydraulic system.

4

5

6

7

8

Figure 28

Air/Hydraulic Brakes

42168

566-170M 03/17/2014

Page 39

Great Plains Manufacturing, Inc. Operating Instructions 35

Transport

Loss of Control Hazard:

Do not tow the turbo-chisel behind another implement on public roads. Tow the turbo-chisel to the field with a separate vehicle. The leading implement may not provide sufficient lateral

control of a trailing implement at highway speeds. The total

weight of the train can also exceed the steering and/or braking

capability of the tractor. The resulting accident could cause

serious injury or death.

Loss of Control Hazard:

Use an adequate towing vehicle. Never tow an implement that

weighs more than 150% of the towing vehicle (transport vehicle must weigh at least 67% of implement). Ensure that the

towing vehicle is adequate for the task. Using an inadequate

tow vehicle is extremely unsafe, and can result in loss of control, serious injury and death.

Braking and Loss of Control Hazard:

Do not exceed 20 mph (32 kph). Slow down on rough roads.

Transport Steps

Know your implement weight. If tractor capabilities are

marginal, check actual weight of implement at a scale.

1. Check that implement is securely hitched to a sufficient tractor (page 18).

2. Always use a locking-style hitch pin sized to match

holes in hitch and draw-bar, and rated for the load.

3. Attach safety chain to tractor with enough slack to

permit turning (page 18).

4. Verify correct operation of lights.

5. Instal transport locks (page 28).

6. Check that tires are properly inflated (page 61).

7. Plan the route. Avoid steep hills.

8. Always have lights on for highway operation.

9. Do not exceed 32 kph (20 mph). Comply with all

national, regional and local laws when traveling on

public roads.

10. Remember that the implement may be wider than the

towing vehicle. Allow safe clearance.

03/17/2014 566-170M

Page 40

36 TCN5107-5313 Great Plains Manufacturing, Inc.

Hitching a Trailing Implement (Optional)

Note: Maximum rear drawbar vertical loading-350kg.

Ensure the TCN ia unfolded.

1. Raise machine to attain a suitable height to attach

the trailing implement.

2. Reverse the TCN up to the implement, ensuring that

the drawbars are correctly aligned allowing a slight

clearance to enable the machines to be coupled

together.

3. Attach the hydraulic hoses between the TCN and the

implement.

4. Reverse the TCN and couple the two machines

together.

5. Fully raise both machines into the road transport

position. Fold the machine(s) if necessary.

Final Field Checklists

Use the following tables to develop a final checklist for

your tractor/Turbo-Chisel configuration.

Mechanical Checklist Page

❑ Turbo-Chisel hitched 18

❑ Hitch pin locked

❑ Safety chain secured to tractor or leading

implement

❑ Parking jack stowed 18

❑ Check all tire pressures 61

❑ Transport locks and locking valves are in

the field position

❑ Implement unfolded 27

18

27

Ensure that no fouling occurs between the TCN and the towed

machine.

Note: Any tineson the towed machine should be adjusted

so that they do not engage the soil (or should be removed altogether).

Field Operation

This implement is designed to be pulled in the field with

the chisel engaged (including wide turns). Pulling for

extended distances with sections lifted, or routine lifting

for turns, is not recommended. Lifting for short distances

to clear residue clogs is acceptable. Lifting for tight turns

or reverse moves is required.

Equipment Damage Risk:

Do not pull for extended distances when partially raised.

Do not routinely raise for wide turns. Such practices cause

premature wear of cylinders, pins and frame components. Such

wear is not covered by the warranty.

Equipment Damage Risk:

Lift for tight turns and reverse moves. Tight turns can result in

a section moving backward. Never back up with chisels on the

ground. If the inside tire stops or rolls backward, the turn is

tight and requires lift

Hydraulic System Checklist Page

❑ Check tractor hydraulic reservoir full -

❑ Make hydraulic connections 21

❑ Inspect connections for leaks -

❑ Unfold Implement 27

❑ Perform a raise and lower operation 25

Electrical Checklist Page

❑ Verify electrical hookups solid, or connec-

tor securely stowed if not using lights in

field.

20

566-170M 03/17/2014

Page 41

Great Plains Manufacturing, Inc. Operating Instructions 37

Perform all steps in “Pre-Start Checklist” on page 24

and “Final Field Checklists” on page 36.

First Pass Operation Checklist Page

1. Implement unfolded and aligned for first

pass, with coulter disks about 3m before

field edge.

2. Pull forward, lower Turbo-Chisel, and

begin tilling for a short distance.

3. Stop. Assess:

• coulter depth

• shank depth

• finishing attachment operation

4. Make necessary adjustments 37

Sharp Field Turns Checklist Page

1. Raise Turbo-Chisel 30

2. Make turn

3. Lower Turbo-Chisel 3m before field edge 29

4. Resume tilling.

25

Do not make short radius turns with the implement in the

ground.

Note: If you stop in the middle of a pass, raise the imple-

ment and back up 3m (10 ft) before resumption of

tilling.

Ending Tilling Checklist Page

1. Suspend operations as above, then

2. Lift implement

3. Set tractor for fold 26

4. Fold wings 26

5. Place locking valves in transport position 29

6. Place transport locks in transport position

7. Lower implement on to transport locks

8. Lights ON for transport

First Time Field Adjustments

Pre-Leveling of Machine

Note: Pre-leveling of machine should be done on a good

level surface.

Front to Rear Leveling

Refer to Figure 29

1. Lower the machine until the front row of shanks are 1 to

2” above the surface. At this point, remove the snap

wire pin from the turnbuckle lock , swing lock off

turnbuckle and adjust the hitch turnbuckle to adjust

the fore and aft. The front corner of the main frame

should be 1/2 to 1” lower than the rear corner.

2. Now the turnbuckle lock may be swung back onto

hitch turnbuckle and the snap wire pin may be reinstalled.

3. If machine needs leveled from front to rear when running in field, remove the snap wire pin from the turnbuckle lock , swing lock off turnbuckle and adjust the

hitch turnbuckle . When done adjusting, be sure and

swing turnbuckle lock back down and secure with snap

wire pin.

1 2

3

2

3 1

1

2

3

2

3

1

Figure 29

Hitch Turnbuckle Adjustment

41805

03/17/2014 566-170M

Page 42

38 TCN5107-5313 Great Plains Manufacturing, Inc.

Wing Adjustment (3-Section Wings)

Refer to Figure 30

4. Once the machine is level fore to aft, the wings may be

leveled (Models 5309-5313). Start by unfolding the

wings to a rigid position.

5. Completely extend the wing fold cylinders and check

the wings for levelness. If machine is not level, fold

wings back up, close the locking valves, and install

shims as needed to level.

Note: Extra shims are stored in manual pak. The extra

shims may be needed in the future if the hinge holes or

bolts begin to wear. There are two different thickness

of shims, you may use multiple shims to level wings.

6. Remove the two 3/8 x 1 1/4 bolts and either add more