Page 1

Table of Contents Index

Installation and Reference

Swath Command™ Section Control

Manufacturing, Inc.

www.greatplainsmfg.com

Read the installation manual entirely. When you see this symbol, the

subsequent instructions and warnings are serious - follow without

exception. Your life and the lives of others depend on it!

31548

Illustrations may show optional equipment or components not supplied with your kit.

ORIGINAL INSTRUCTIONS

© Copyright 2012 Printed 2012-08-23 402-382M

Table of Contents Index

EN

Page 2

Table of Contents Index

Table of Contents Index

Page 3

Great Plains Manufacturing, Inc. Cover Index iii

Table of Contents

Important Safety Information ......................................1

General Information .....................................................3

Prerequisites ..................................................................3

Components ...................................................................3

Additional Components Always Required ......................3

Additional Components That May Be Required .............3

Related Documents........................................................5

Notations and Conventions ............................................5

Call-Outs ....................................................................5

Prepare Planter.............................................................6

Verify Compatibility.........................................................6

Tools Required ...............................................................7

Shaft Locator Tool ......................................................7

Other Tools Required .................................................7

Prepare Planter ..........................................................7

Replace Electric Clutches ...........................................8

Install Air Clutches.......................................................9

Install Center Air Clutches..............................................9

Assess The Center Shaft............................................9

Remove Center Shaft...............................................10

Remove Bearings (Conditional)............................10

Attach Locator Tools ................................................10

Install Center Air Clutches........................................11

Align Center Shaft ................................................11

Install Wing Air Clutches ..............................................12

Assess The Wing Shaft ............................................ 12

Remove Wing Shaft..................................................13

Remove Bearings (Conditional)............................13

Attach Locator Tools ................................................13

Install Wing Air Clutches...........................................14

Align Wing Shaft ...................................................14

Install Compressor.....................................................15

Hydraulic Tongue (H.T.) Compressor Installation ........15

Install H.T. Mount Bracket(s)....................................15

Prepare H.T. Hitch Weldment...............................15

Affix H.T. Bracket(s) .............................................15

Install Compressor Mount (H.T.) ..............................16

Install Compressor (H.T.) .........................................16

Install Compressor Covers (H.T.).............................16

Pull-Type 3-Point Compressor Installation ...................17

Install Compressor (3P)............................................ 17

Install Compressor Covers (3P) ...............................17

3PYP and 3PYPA Compressor Installation..................18

Install Compressor (3PYP).......................................18

Install Compressor Covers (3PYP) .......................... 18

Install Valve Blocks ................................................... 19

Install Air Tank(s)....................................................... 21

Install Air Lines .......................................................... 22

Install Row Air Lines .................................................... 22

Install Section Air Lines................................................ 23

Install Supply Air Lines................................................. 23

Fish Line Bind .......................................................... 23

Install Harness ........................................................... 24

Determine Connections ............................................... 24

Connect WSMB Harnesses ......................................... 24

Insert Left Wing WSMB Harness ............................. 24

Insert Right Wing WSMB Harness ........................... 24

Connect Valve Blocks .................................................. 25

Connect 1st Valve Block .......................................... 25

Connect 2nd Valve Block (if any) ............................. 25

Connect 3rd Valve Block (if any).............................. 25

Secure Tubing and Harnesses .................................... 25

System Set Up............................................................ 26

Implement Considerations ........................................... 26

Install Tractor Components.......................................... 26

Relocate Standard Compressor............................... 26

Inlet Air Hose Specification ..................................26

Mount Pressure Gauge ............................................ 27

Connect Compressor Air Lines ................................ 27

Install Satellite Receiver........................................... 28

Install Cab Components............................................... 28

Install Air Inlet Filter.................................................. 28

Install Control Terminal ............................................ 29

Planter Option 57 (AI120) Console ......................29

Field Kit (A5) Console ..........................................29

Connect Cab Harnesses .......................................... 29

Planter Option 57 (AI120) Harnesses ..................29

Field Kit (A5) Harnesses ......................................29

System Harness Diagram (Option 57) ......................... 30

System Harness Diagram (Kit) .................................... 31

IntelliAg® PDC Setup ................................................. 32

Appendix A - Reference Information........................ 33

Torque Values Chart.................................................... 33

Clutch Exploded Views ................................................ 34

823-327C Right Hand (RH) Air Clutch ..................... 34

823-328C Left hand (LH) Air Clutch......................... 35

402-273K Single-Row Left Hand.............................. 36

402-273K-ASY: 402-273K Installation Details ......... 37

© Copyright 2012 All rights Reserved

Great Plains Manufacturing, Inc. provides this publication “as is” without warranty of any kind, either expressed or implied. While every precaution has been

taken in the preparation of this manual, Great Plains Manufacturing, Inc. assumes no responsibility for errors or omissions. Neither is any liability assumed for

damages resulting from the use of the information contained herein. Great Plains Manufacturing, Inc. reserves the right to revise and improve its products as

it sees fit. This publication describes the state of this product at the time of its publication, and may not reflect the product in the future.

2012-08-23 Cover Index 402-382M

Trademarks of Great Plains Manufacturing, Inc. include: Singulator Plus, Swath Command, Terra-Tine.

Registered Trademarks of Great Plains Manufacturing, Inc. include:

Air-Pro, Clear-Shot, Discovator, Great Plains, Land Pride, MeterCone, Nutri-Pro, Seed-Lok, Solid Stand,

Terra-Guard, Turbo-Chisel, Turbo-Chopper, Turbo Max, Turbo-Till, Ultra-Till, Ver ti-Till, Whirlfilter, Yield-Pro.

Brand and Product Names that appear and are owned by others are trademarks of their respective owners.

Printed in the United States of America

Page 4

iv Swath Command™ Table of Contents Index Great Plains Manufacturing, Inc.

402-275K Two-Row RH 15-Inch .............................. 38

402-275K-ASY: 402-275K Installation Details ......... 39

402-276K Two-Row LH 15-Inch............................... 40

402-276K-ASY: 402-276K Installation Details ......... 41

402-279K Twin-Row (RH Clutch)............................. 42

402-279K-ASY: 402-279K Installation Details ......... 43

402-281K Twin-Row Reverse (LH Clutch)............... 44

402-281K-ASY: 402-281K Installation Details ......... 45

402-329K Single-Row Short Mount (RH Clutch)...... 46

402-329K-ASY: 402-329K Installation Details ......... 47

Swath Command™ Planter Clutch Layouts................. 48

Kit: 402-376A Clutch Layout: YP4025, 32 Twin Row...

50

Kit: 402-377A Clutch Layout: YP4025, 16 Row ....... 52

Kit: 402-378A Clutch Layout: YP4025, 32 Row ....... 54

Kit: 402-379A Clutch Layout: YP1625, 24 Twin Row

36-Inch ............................................................. 56

Kit: 402-380A Clutch Layout: YP1625, 16 Row ....... 58

Kit: 402-381A Clutch Layout: YP1625, 32 Twin Row...

60

Kit: 402-383A Clutch Layout: YP1625, 31 Row ....... 62

Kit: 402-384A Clutch Layout: YP4025/A, YP4425A, 24

Row .................................................................. 64

Kit: 402-385A Clutch Layout: YP2425/A, 48 Twin Row

66

Kit: 402-386A Clutch Layout: YP2425/A, 47 Row.... 68

Kit: 402-387A Clutch Layout: YP2425/A/F 24Row... 70

Kit: 402-388A Clutch Layout: YP2425/A 36 Row 20

Inch................................................................... 72

Kit: 402-389A Clutch Layout: 3PYP/A 32 Twin Row 30

Inch................................................................... 74

Kit: 402-390A Clutch Layout: 3PYP/A 24 Twin Row 36

Inch................................................................... 76

Kit: 402-391A Clutch Layout: 3PYP/A 24 Twin Row 38

Inch................................................................... 78

Kit: 402-392A Clutch Layout: 3PYP/A 24 Twin Row 40

Inch................................................................... 80

Kit: 402-392A Clutch Layout: 3PYP/A 12 Row ........ 82

Kit: 402-400A Clutch Layout: YP3025/A 24-Row Twin

84

Kit: 402-401A Clutch Layout: YP3025/A 23-Row..... 86

Kit: 402-402A Clutch Layout: YP3025/A 24-Row

15-Inch ............................................................. 88

Kit: 402-403A Clutch Layout: YP3025/A 12-Row..... 90

Kit: 402-404A Clutch Layout: YP3025/A 18-Row..... 92

Kit: 402-405A Clutch Layout: YP3025/A 16-Row Twin

94

Kit: 402-406A Clutch Layout: YP4025/A 24-Row Twin.

96

CANbus Module, Output and Row Assignments..........98

Models YP1225-1230, YP1225A-1230.....................98

Models YP1225-1820, YP1225A-1820.....................99

Models YP1225-16TR36, YP1225A-16TR36 .........100

Models YP1225-2315, YP1225A-2315...................101

Models YP1225-24TR, YP1225A-24TR .................102

Models YP1625-1236, YP1625A-1236...................103

Models YP1625-1630, YP1625A-1630, YP1625-1670,

YP1625A-1670................................................104

Models YP1625-2420, YP1625A-2420...................105

Models YP1625-24TR36, YP1625A-24TR36 .........106

Models YP1625-3115, YP1625A-3115...................107

Models YP1625-32TR, YP1625A-32TR .................108

Models YP2425-2430, YP2425A-2430, YP2425-2470,

YP2425A-2470................................................109

Model YP2425F-2470.............................................110

Models YP2425-3620, YP2425A-3620...................111

Models YP2425-4715, YP2425A-4715...................112

Models YP2425-48TR, YP2425A-48TR .................113

Models YP3025-1230, YP3025A-1230, YP3025-1270,

YP3025A-1270................................................114

Models YP3025-16TR36, YP3025A-16TR36 .........115

Models YP3025-1820, YP3025A-1820...................116

Models YP3025-2315, YP3025A-2315...................117

Models YP3025-2415, YP3025A-2415...................118

Models YP3025-24TR, YP3025A-24TR,

YP3025-24TR70, YP3025A-24TR70 ..............119

Models YP4025-1630, YP4025A-1630,

YP4025F-1630, YP4025-1670, YP4025A-1670,

YP4025A-1670, YP4025F-1670 .....................120

Models YP4025-2420, YP4025A-2420...................121

Models YP4025-24TR36, YP4025A-24TR36 .........122

Models YP4025-3115, YP4025A-3115...................123

Models YP4025-3215, YP4025A-3215...................124

Models YP4025-32TR, YP4025A-32TR,

YP4025-32TR70, YP4025A-32TR70 ..............125

Models 3PYP-1236, 3PYPA-1236, 3PYP-1238,

3PYPA-1238, 3PYP-1240, 3PYPA-1240 ........126

Models 3PYP-1630, 3PYPA-1630 ..........................127

Models 3PYP-24TR36, 3PYPA-24TR36 ................128

Models 3PYP-24TR38, 3PYPA-24TR38 ................129

Models 3PYP-24TR40, 3PYPA-24TR40 ................130

Models 3PYP-3115, 3PYPA-3115 ..........................131

Models 3PYP-32TR30, 3PYPA-32TR30 ................132

Abbreviations..............................................................133

Index ..........................................................................135

402-382M Table of Contents Index 2012-08-23

Page 5

Great Plains Manufacturing, Inc. Table of Contents Index 1

Important Safety Information

Look for Safety Symbol

The SAFETY ALERT SYMBOL indicates there is a

potential hazard to personal safety involved and extra

safety precaution must be taken. When you see this

symbol, be alert and carefully read the message that

follows it. In addition to design and configuration of

equipment, hazard control and accident prevention are

dependent upon the awareness, concern, prudence and

proper training of personnel involved in the operation,

transport, maintenance and storage of equipment.

Be Aware of Signal Words

Signal words designate a degree or level of hazard

seriousness.

DANGER indicates an imminently hazardous situation

which, if not avoided, will result in death or serious injury.

This signal word is limited to the most extreme situations,

typically for machine components that, for functional

purposes, cannot be guarded.

WARNING indicates a potentially hazardous situation

which, if not avoided, could result in death or serious

injury, and includes hazards that are exposed when

guards are removed. It may also be used to alert against

unsafe practices.

CAUTION indicates a potentially hazardous situation

which, if not avoided, may result in minor or moderate

injury. It may also be used to alert against unsafe

practices.

Prepare for Emergencies

▲ Be prepared if a fire starts

▲ Keep a first aid kit and fire extinguisher handy.

▲ Keep emergency numbers for doctor, ambulance, hospital

and fire department near phone.

Be Familiar with Safety Decals

▲ Read and understand “Safety Decals” in the Operator

manual.

▲ Read all instructions noted on the decals.

▲ Keep decals clean. Replace damaged, faded and illegible

decals.

2012-08-23 Table of Contents Index 402-382M

Page 6

2 Swath Command™ Table of Contents Index Great Plains Manufacturing, Inc.

Wear Protective Equipment

▲ Wear protective clothing and equipment.

▲ Because prolonged exposure to loud noise can cause

hearing impairment or hearing loss, wear suitable hearing

protection such as earmuffs or earplugs.

▲ Because working on equipment safely requires your full

attention, avoid wearing entertainment headphones while

perform the installation.

Avoid High Pressure Fluids

Observe normal precautions for hitch hydraulic

connections and disconnections. Escaping fluid under

pressure can penetrate the skin, causing serious injury.

▲ Avoid the hazard by relieving pressure before disconnecting

hydraulic lines.

▲ Wear protective gloves and safety glasses or goggles when

working with hydraulic systems.

▲ If an accident occurs, seek immediate medical assistance

from a physician familiar with this type of injury.

Practice Safe Maintenance

▲ Understand procedure before doing work. Use proper

tools and equipment. Refer to this manual for additional

information.

▲ Work in a clean, dry area.

▲ Lower the planter, put tractor in park, turn off engine, and

remove key before performing maintenance.

▲ Make sure all moving parts have stopped and all system

pressure is relieved.

▲ Allow planter to cool completely.

▲ Disconnect battery ground cable (-) before servicing or

adjusting electrical systems or before welding on planter.

▲ Inspect all parts. Make sure parts are in good condition

and installed properly.

▲ Remove buildup of grease, oil or debris.

▲ Remove all tools and unused parts from planter before

operation.

3PYP/3PYPA Fold Hazard

Unstable Heavy Overhead Object:

Under no circumstances ever leave the 3PYP/A planter in a

partially unfolded state. Wings could fall suddenly if a circuit

opens or fails. Wings may settle in any case. Working on fully

folded wings is not recommended due to the height.

402-382M Table of Contents Index 2012-08-23

Page 7

Great Plains Manufacturing, Inc. Table of Contents Index 3

General Information

These instructions explain how to install and set up the

Swath Command™ Section Control system.

This manual also provides reference information for a

factory-installed Swath Command™ Section Control

system.

With the optional Swath Command™ system, all row unit

final drive chains are clutch-controlled. Swath

Command™ can turn seed metering on and off for 6 to 8

sectionsa of rows. Using geolocationb information you

provide to the system, seeding can be disabled when

row units cross non-planting or previously-planted areas.

Prerequisites

For a field installation, verify this information before

opening cartons or beginning disassembly:

• Verify that you have the correct kit (step 1, page 6).

• Verify seed monitor compatibility (step 2, page 6).

• Verify that you have the tools required (page 7).

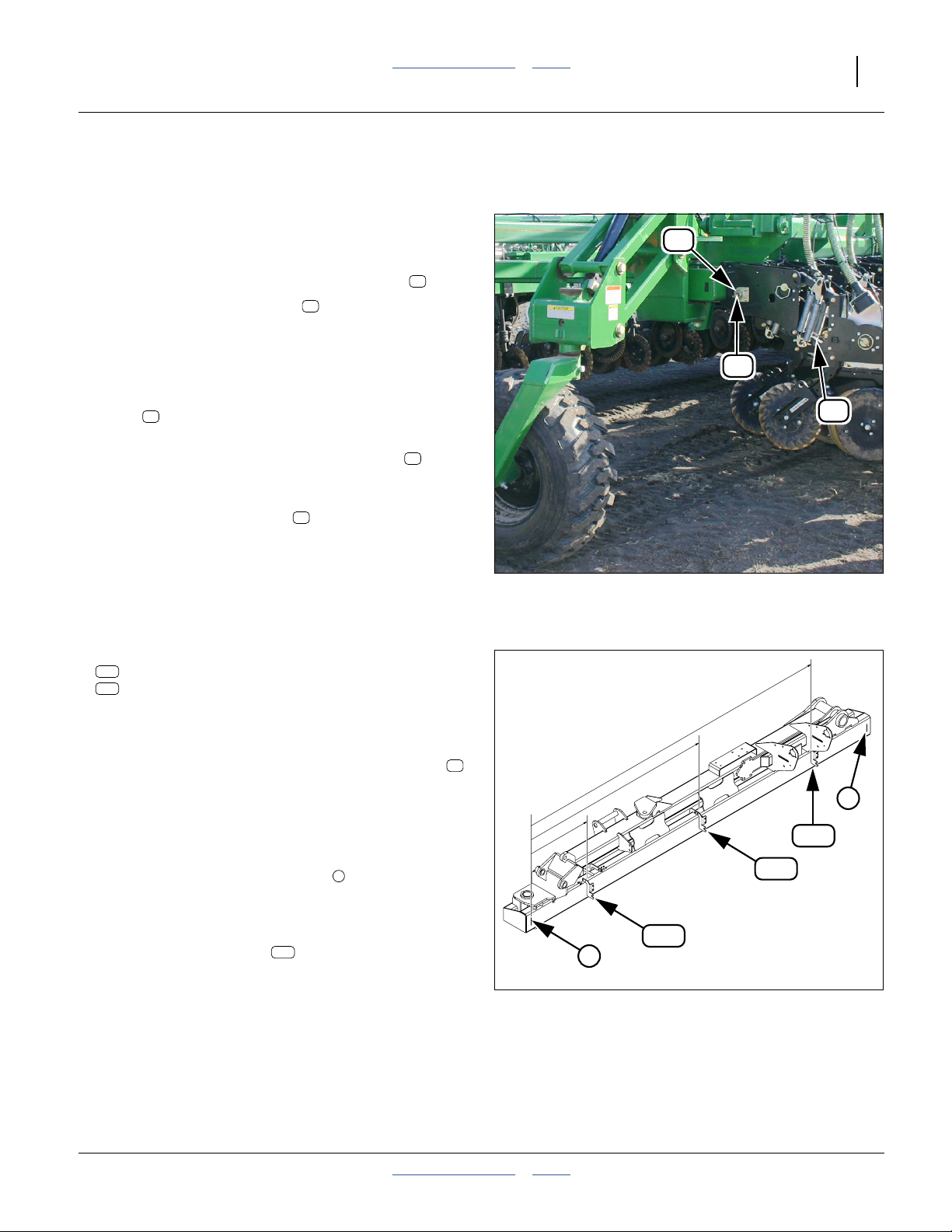

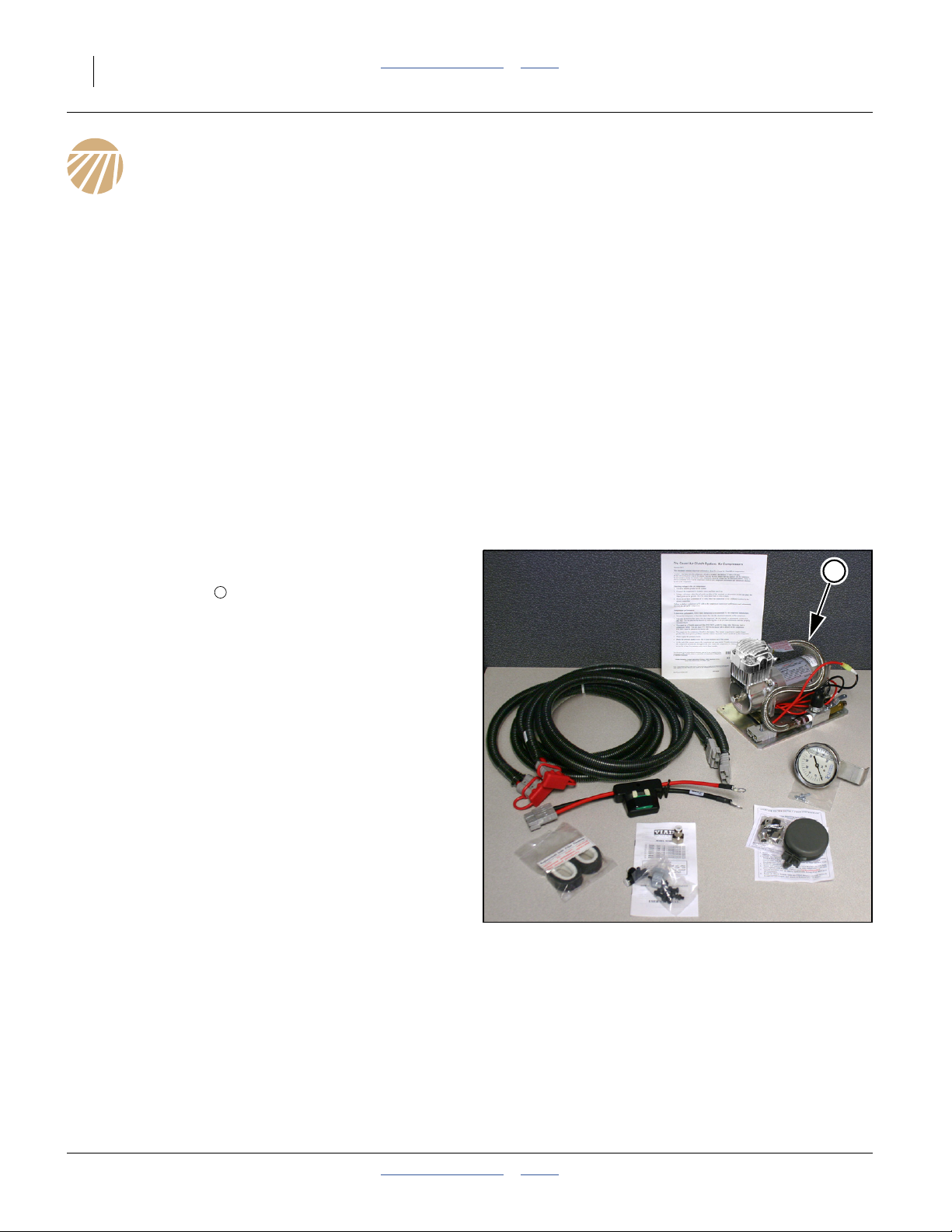

Figure 1

Swath Command™ Components

31548

Components

A field installation kit includes these new components:

• air-operated row unit clutches

• solenoid valves

• compressor, tank and air delivery tubing

• CANbus valve control module

• DICKEY-john® A5 section control console

(supplementing the existing A1or AI110)

These existing planter components are removed:

• electric section clutches (two or three)

• final meter drive input sprockets at rows

There will be fasteners left over.

Additional Components Always Required

Whether factory or field-installed, these optional

components are dealer- or user-installed, and must be

configured prior to use:

• geolocation receiver, such a Trimble® AgGPS®262

(available from Great Plains).

• coordinate augmentation data source, such as a

Trimble® AgGPS®900 RTK rover radio

(available from Great Plains)

Additional Components That May Be Required

Field installation:

• For a pull-type planter with a hydraulic tongue,

manufactured prior to 2012, order one or two sets of

404-228D component mounting brackets and

fasteners (see step 97 on page 15).

Note: See “Options” in Operator manual 403-857M for

component and accessory ordering information.

a. Controlling a larger number of sections requires field installation of additional solenoid valves and CANbus modules. It also requires

sub-inch precision geolocation augmentation data.

b. The system requires a source of sub-meter geolocation data, usually via differential satellite positioning system, such as DGPS.

The antenna, receiver and cable for this are not included in the system. Further, enhanced resolution geolocation data may require

additional receiver capability and may require subscription from an augmentation service provider.

2012-08-23 Table of Contents Index 402-382M

Page 8

4 Swath Command™ Table of Contents Index Great Plains Manufacturing, Inc.

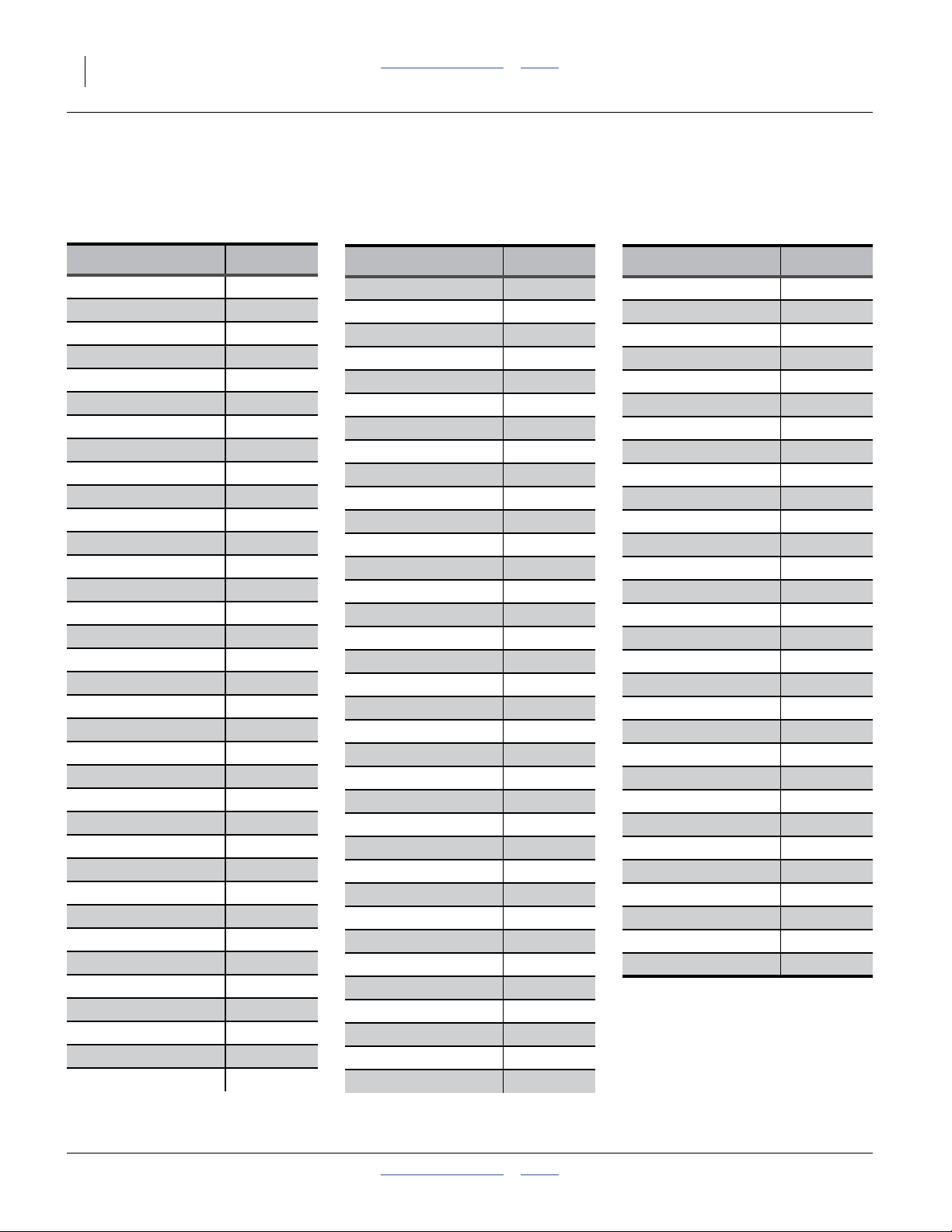

Models and Kits Covered

This manual provides information for Swath Command™

system on the following specific models of Yield-Pro

®

planters. Kit part numbers are for field-install kits.

Planter Model Kit

3PYP-1236 402-393A

3PYP-1238 402-393A

3PYP-1240 402-393A

3PYP-1630 402-394A

3PYP-2320 402-384A

3PYP-24TR36 402-390A

3PYP-24TR38 402-391A

3PYP-24TR40 402-392A

3PYP-3115 402-383A

3PYP-32TR30 402-389A

3PYPA-1236 402-393A

3PYPA-1238 402-393A

3PYPA-1240 402-393A

3PYPA-1630 402-394A

3PYPA-24TR36 402-390A

3PYPA-24TR38 402-391A

3PYPA-24TR40 402-392A

3PYPA-3115 402-383A

3PYPA-32TR30 402-389A

YP1225-1230 402-395A

YP1225-16TR36 402-398A

YP1225-1820 402-399A

YP1225-2315 402-397A

YP1225-24TR 402-396A

YP1225A-1230 402-395A

YP1225A-16TR36 402-398A

YP1225A-1820 402-399A

YP1225A-2315 402-397A

YP1225A-24TR 402-396A

YP1625-1236 402-393A

YP1625-1630 402-380A

YP1625-1670 402-380A

YP1625-2420 402-384A

YP1625-24TR36 402-379A

YP1625-3115 402-383A

Planter Model Kit

YP1625-32TR 402-381A

YP1625A-1236 402-393A

YP1625A-1630 402-380A

YP1625A-1670 402-380A

YP1625A-2420 402-384A

YP1625A-24TR36 402-379A

YP1625A-3115 402-383A

YP1625A-32TR 402-381A

YP2425-2430 402-387A

YP2425-2470 402-387A

YP2425-3620 402-388A

YP2425-4715 402-386A

YP2425-48TR 402-385A

YP2425A-2430 402-387A

YP2425A-2470 402-387A

YP2425A-3620 402-388A

YP2425A-4715 402-386A

YP2425A-48TR 402-385A

YP2425F-2470 402-387A

YP3025-1230 402-403A

YP3025-1270 402-403A

YP3025-16TR36 402-405A

YP3025-1820 402-404A

YP3025-2315 402-401A

YP3025-2335 N/A

YP3025-2415 402-402A

YP3025-24TR 402-400A

YP3025-24TR70 402-400A

YP3025-24TR75 402-400A

YP3025-3610 N/A

YP3025A-1230 402-403A

YP3025A-1270 402-403A

YP3025A-16TR36 402-405A

YP3025A-1820 402-404A

YP3025A-2315 402-401A

Planter Model Kit

YP3025A-2335 N/A

YP3025A-2415 402-402A

YP3025A-24TR 402-400A

YP3025A-24TR70 402-400A

YP3025A-24TR75 402-400A

YP3025A-3610 N/A

YP4025-1630 402-377A

YP4025-1670 402-377A

YP4025-2420 402-384A

YP4025-24TR36 402-406A

YP4025-3115 402-375A

YP4025-3135 N/A

YP4025-3215 402-378A

YP4025-32TR 402-376A

YP4025-32TR70 402-376A

YP4025-4810 N/A

YP4025A-1630 402-377A

YP4025A-1670 402-377A

YP4025A-2420 402-384A

YP4025A-24TR36 402-406A

YP4025A-3115 402-375A

YP4025-3135 N/A

YP4025A-3215 402-378A

YP4025A-32TR 402-376A

a

YP4025A-32TR70 402-376A

YP4025A-4810 N/A

YP4025AF-1670 402-377A

YP4025F-1630 402-377A

YP4025F-1670 402-377A

a

YP4425A-2422 402-384A

a. Not Available.

Swath Command™ is not

presently available for row

spacings at or below

13.8 inches (35 cm)

a

a

a

a

a

a

402-382M Table of Contents Index 2012-08-23

Page 9

Great Plains Manufacturing, Inc. Table of Contents Index General Information 5

Related Documents

Have your planter Operator and Parts manual available

during installation. Also have the following manuals

available:

403-857M

11001-1508

11001-1501

11001-1561A

56110-00

55565-00

-

Great Plains Planter Operator and Parts manuals are

available as PDF files on the Great Plains web site:

Manuals > Planters

The DICKEY-john®manuals above are available as PDF

files on the Great Plains web site:

Manuals > Planters > Service Information & Monitor Manuals

Swath Command operation manual

DICKEY-john® Planter/Drill Control User

Level 1 Operator’s Manual

DICKEY-john® Planter/Drill Control User

Level 2&3 Operator’s Manual

DICKEY-john® Auto Section Control

System Operator’s Manual

(or equivalent manual for a different brand

of swath controller)

Trimble® AgGPS®262 Satellite Receiver

User Guide

(or equivalent manual for a different

geolocation data receiver)

Trimble® AgGPS® 900 Radio

(or equivalent manual for a different

augmentation receiver)

Viair User’s Manual

for 35030-350C (or equivalent manual for

other compressor)

Notations and Conventions

U

F

L

D

Call-Outs

1 9

to

a z

to

11 28

to Two digit callouts represent the same existing

101 288

This manual fully describes a system based on Great

Plains-provisioned DICKEY-john®IntelliAg® seed

monitor (A1 / AI110), and the DICKEY-john®A5 terminal

and Great Plains Swath Command™ implement

components.

It is possible to use aftermarket or customer-provisioned

seed monitor, swath control terminal, geolocation

receiver and clutch control air system. This manual

provides only limited support for such installations,

primarily reference data concerning clutch placement,

clutch groupings and row geometry.

Single-digit or single-letter callouts identify

components in the currently referenced

Figure. These numbers may be reused for

different items from page to page.

(old) parts throughout this manual.

to Three digit callouts represent the same new

parts throughout this manual.

“Left”/LH and “Right”/RH are facing in

the direction of machine travel. An

R

orientation rose in the line art

illustrations shows the directions of

Left, Right, Front, Back, Up, Down.

B

2012-08-23 Table of Contents Index 402-382M

Page 10

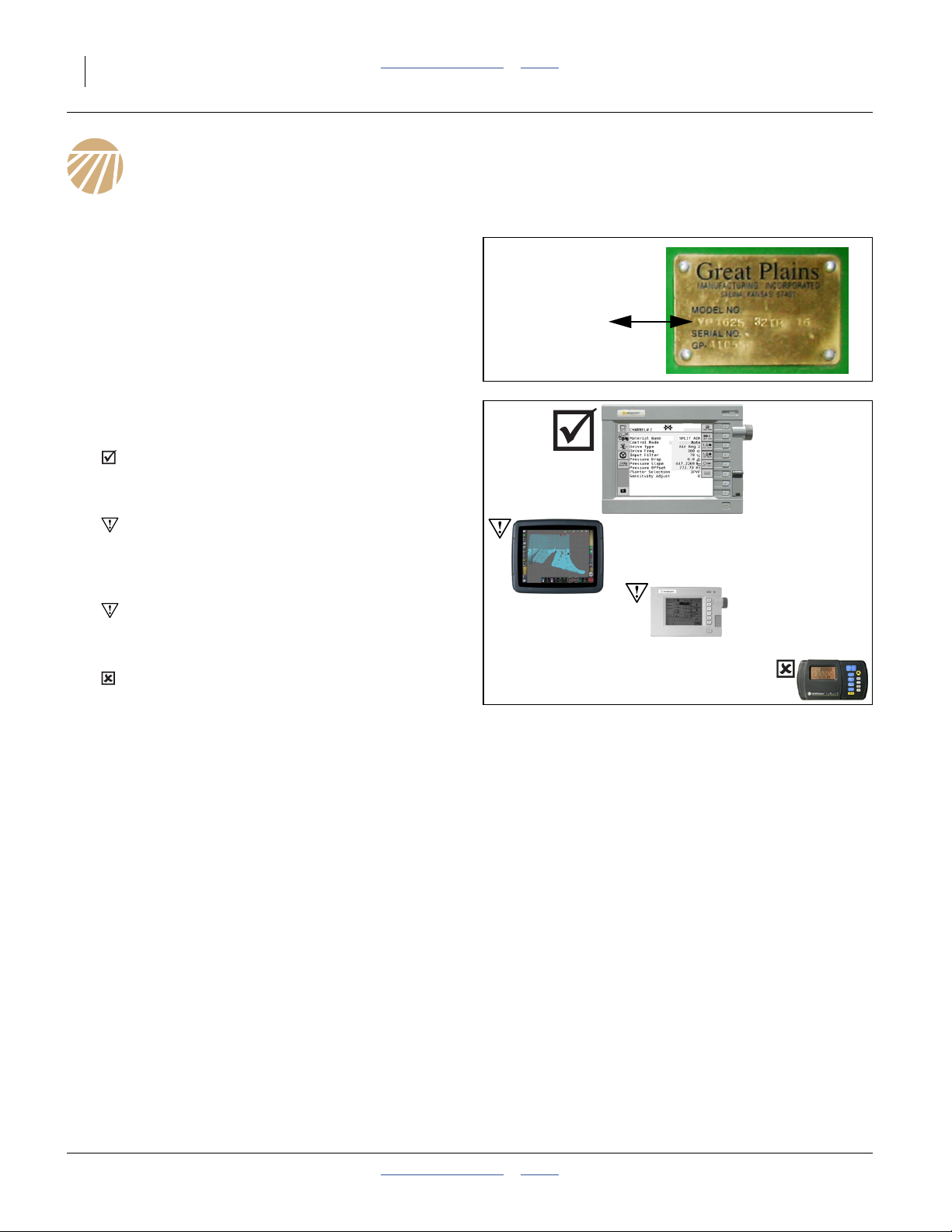

6 Swath Command™ Table of Contents Index Great Plains Manufacturing, Inc.

Prepare Planter

Verify Compatibility

1. Verify that you have the correct kit. Check your

planter model number (from the serial number

plate) against the kit part number table on page 4.

If your planter is not listed (or has an N/A), stop.

Contact your dealer.

If the kit you have is not for your planter, stop.

Contact your dealer.

2. Verify that the planter has a compatible seed

monitor.

Verify that the monitor console for your planter is

a DICKEY-john®IntelliAg® 10 inch color display,

Model A1, A1+ or AI100.

If you have a DICKEY-john®IntelliAg® 12 inch

color display, Model AI120, and Swath Command™

was not factory-installed, have your dealer contact

the factory.

If you have a 5 inch monochrome IntelliAg

console, a separate console upgrade is required.

Contact your dealer.

If you have a Seed Manager™ SE console, the

Swath Command™ Section Control kit is

completely incompatible. Contact your dealer for kit

return.

3. Plan the air clutch installation. Meter shafts run the

entire length of each section (center or wing).

Removal requires a clear path from at least one end

of the shaft, into the workspace, for that length.

Horizontal-Fold 2-Section Horizontal-Fold 3-Section Stack-Fold

In general, access to the drive shafts

is easiest from the wing ends. The

wings must be positioned such that

the wing-end casters swing clear of

the shaft path.

The wings must be partially or fully

folded for access to the center

section drive shaft.

In general, access to the drive shafts

is easiest from the wing ends. The

wings must be positioned such that

the wing-end casters swing clear of

the shaft path.

YP24 and YP44: Wing drive shafts

are in two segments with a coupler.

®

Kit: 402-381A

Updating the center section shaft

must be done with the planter fully

folded.

Updating the wing shafts must be

done with the planter fully unfolded.

402-382M Table of Contents Index 2012-08-23

Page 11

Great Plains Manufacturing, Inc. Table of Contents Index Prepare Planter 7

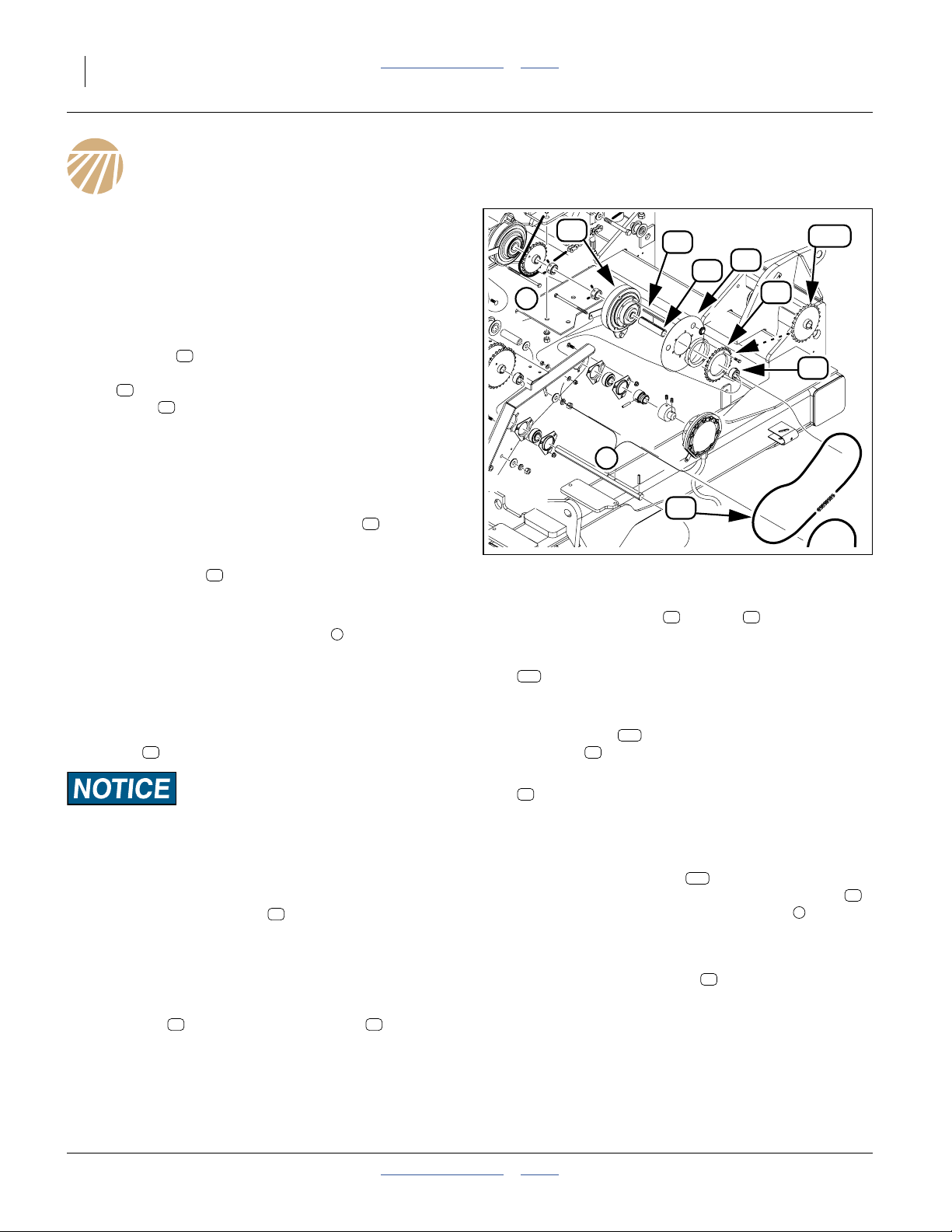

Tools Required

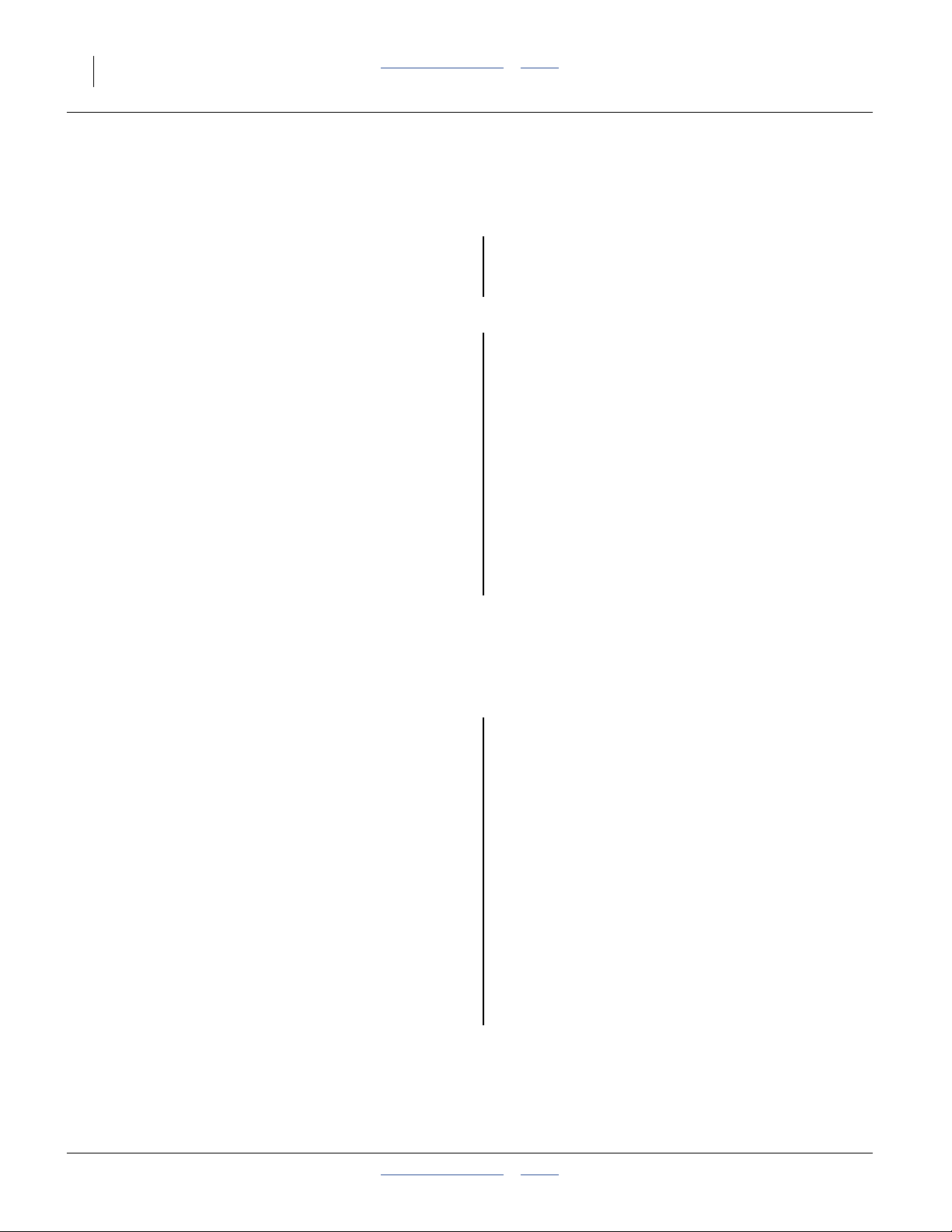

Shaft Locator Tool

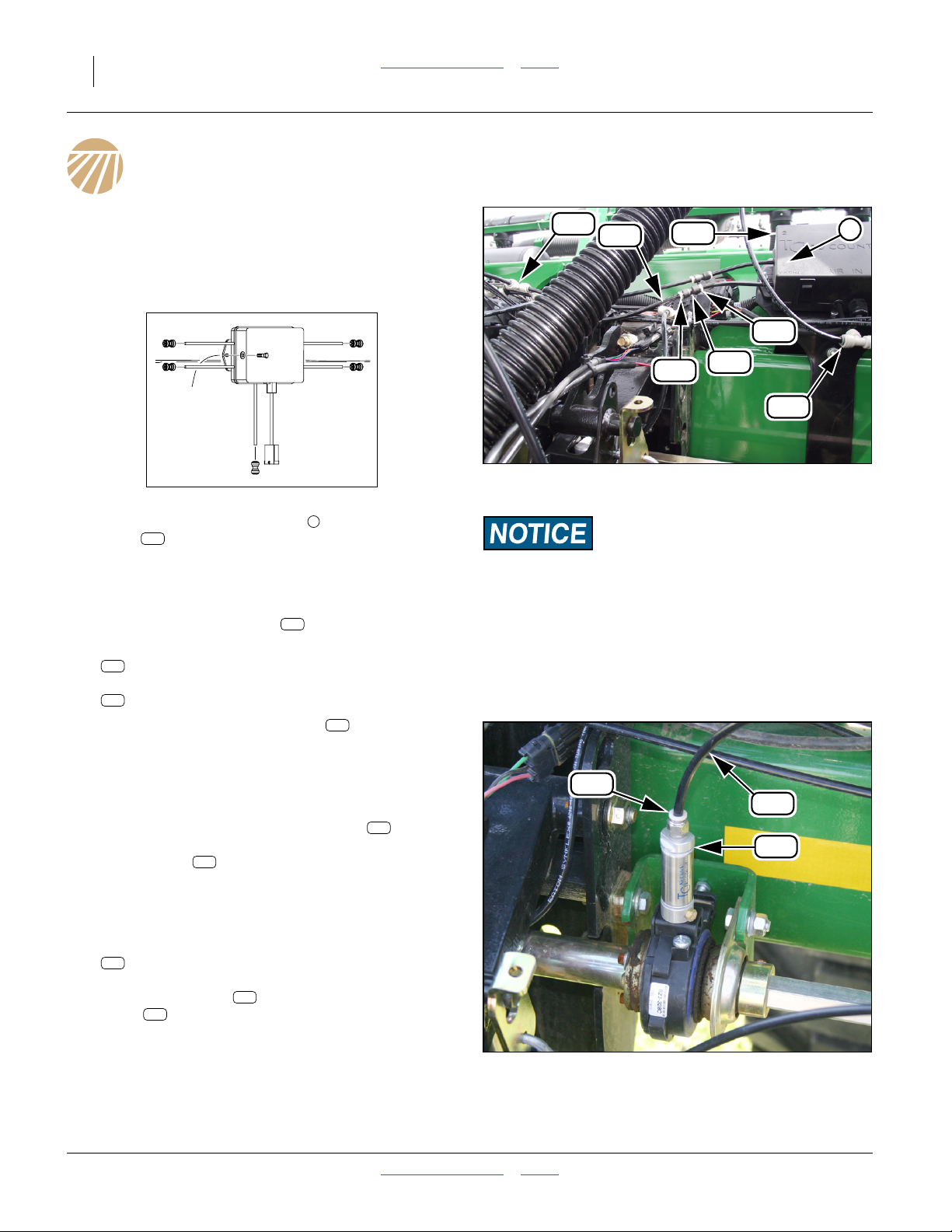

Refer to Figure 2

Kit installation requires removal and re-installation of

meter line shafts and their bearings. Bearing flanges

must be aligned during re-installation. Great Plains

offersa a tool kit to simplify this task, shown at right.

4. Check that alignment bolts are set correctly.

With the leading edge of the tool against a flat

surface, the bolt sets the face of the tool

perpendicular to that surface. Adjust jam nuts

as needed.

232

1

2

1

238

232

238

Other Tools Required

• The tractor to be used afield with the upgraded planter

must be present for spotting, unfolding, folding and

final setup.

• The work area must have sufficient area for a partially

unfolded planter (fully unfolded 3PYP/A), including

clearance at each wing end for complete removal of

wing-long meter drive shafts.

• Folding planter only: A fish wire or stiff fish tape may

be needed to pull the air tubing through the left wing

pull bar. If the fish line cannot easily be inserted

through the pull bar, it will be necessary to remove the

existing hoses and harnesses, and re-pull them with

the air tubing.

• 3PYP/A planter only: The work area must have

sufficient vertical clearance for a fully folded planter.

• The work area must be well illuminated, with a clear

surface beneath for recovery of any dropped parts.

• One or more adjustable stand are recommended for

supporting extended free shaft ends.

• The Operator and Parts manuals for the planter must

be present. Check the Great Plains web to ensure

they are current.

• Twin-Row only: The Seed Rate manual is needed if

sprocket index settings need to be restored after the

installation. For Air-Pro® models, have the 812-391C

timing tool on hand for restoring index settings.

• Pre-2012 Hydraulic Tongue only: a drill with a

17

⁄32inch (13.5 mm) bit and suitable pilot bit.

•A1⁄4inch (6.3 mm) flat-face punch is needed for

driving roll pins.

2

Figure 2

402-270A Locator Tool Kit

Machine Damage and Population Risks:

Use the locator tools or precision optical alignment. If a shaft

has sag, excess bearing wear results. In more severe cases of

bearing mis-alignment, a hard-to-turn shaft could cause

excess chain wear, or drive system slippage and low

populations on a ground-drive planter, and motor overheating

on a hydraulic-drive planter.

• A cleaning rag and fine point indelible marker are

recommended for identifying the location and

orientation of removed shafts.

• A note pad is recommended for recording locations of

some re-used and/or replaced components. A digital

camera may also be helpful.

• Only basic hand tools, including hex keys in fractional

sizes, are otherwise required.

• Cable ties.

Prepare Planter

5. Move the planter to the work space.

6. Unfold the wings.

7. Lower the row units.

8. Shut down the tractor.

9. Unplug all electrical connections at planter hitch.

34066

a. Great Plains dealers often have a locator kit on hand.

2012-08-23 Table of Contents Index 402-382M

Page 12

8 Swath Command™ Table of Contents Index Great Plains Manufacturing, Inc.

Replace Electric Clutches

Depending on planter model and drive type, there are

two or three electric clutch assemblies that are replaced

with a simple sprocket. Due to their electrical load, these

cannot be left connected to the system harness, and

without electrical control, would leave the drive system

disabled.

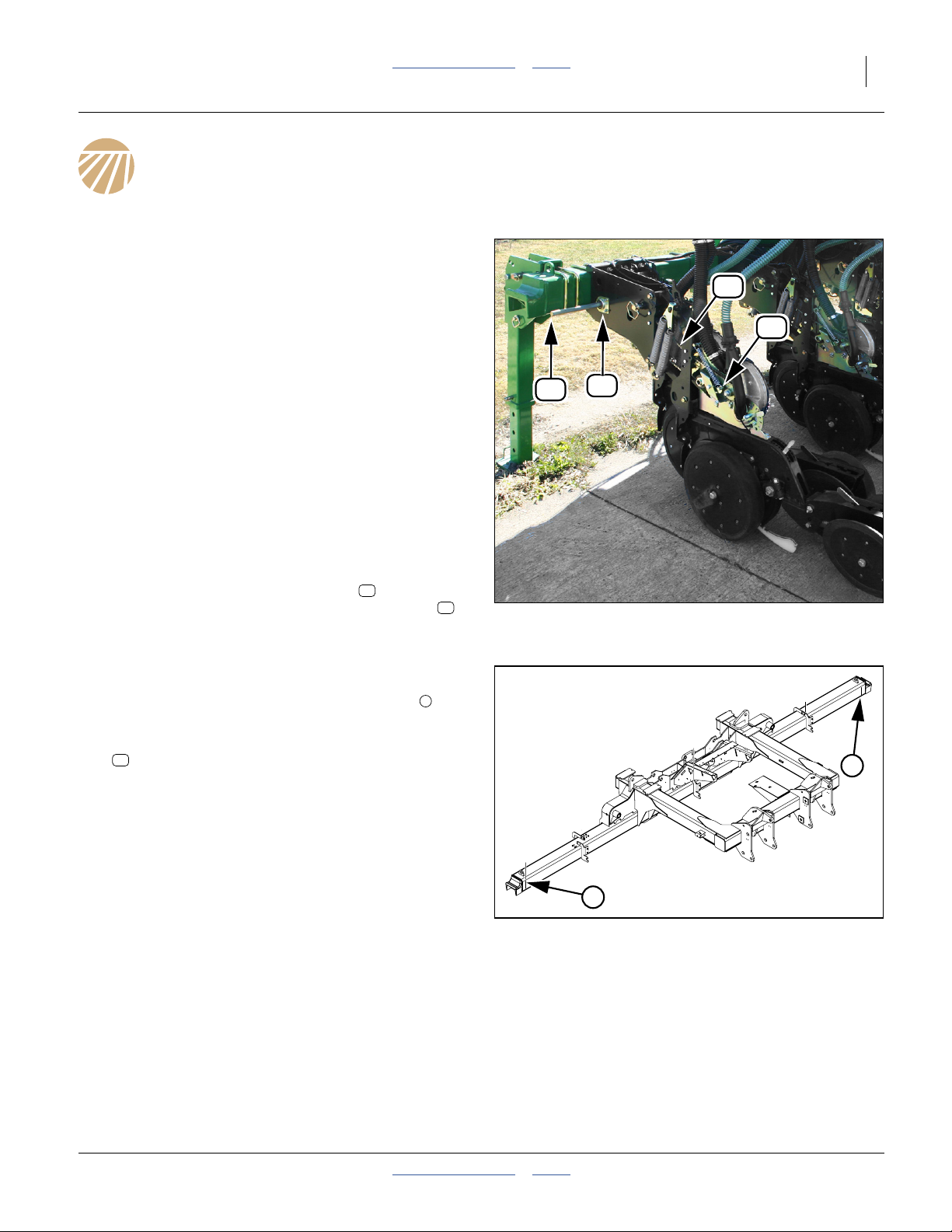

Refer to Figure 3

(which depicts a clutch on a hydraulic drive 3PYP planter)

These clutches are generally present at shaft ends,

27

and may be secured on their shaft by set screw lock

collars , roll pins, or both. Older assemblies may lack

the oil shield depicted at right.

15

16

10. Locate all the electric clutches on the planter.

11. Unplug the lead at each clutch.

Update one clutch at a time.

12. Measure from any convenient reference point to the

center-line of a clutch output sprocket (along the

24

shaft). Make a record of this location. The

replacement sprocket provided needs to align with

the drive chain , and must be at this same

12

position on the shaft (installed at step 18).

13. At the end of the shaft where you plan to remove a

clutch, examine any components mounted

1

between the clutch and shaft end (and there may be

none).

Note: Check your Parts manual to ensure that you know

how these go back together.

14. Loosen or release spring on idlers (not shown) on

12

chain .

Roll Pin Damage Risk:

If any roll pins need to be removed, drive them out carefully

and save them. The kits do not include replacement roll pins.

15. Remove and save all components (except bearings,

if possible), between shaft end, up to and including

the outside clutch collar or roll pin (not shown).

15

Loosen bearings and/or brackets as needed to free

shaft end. If may be necessary to free the other end

of the shaft and slide it clear of the clutch. Take note

of, and save, any removed components.

16. Lift chain off clutch output sprocket . Remove

12 24

the clutch assembly. It is not necessary to remove

the sprocket, spacer and oil shield from the clutch.

None of these parts are reused.

17. Remove the bushing and key . These are not

18. Select one new:

19. Slide sprocket loosely onto the drive shaft. Loop

20. Add one saved:

21. As needed, reposition the shaft, bearings and

22. Adjust the new sprocket to the position

23. Reinstall any end-of-shaft components removed at

24. Engage idlers to set chain to recommended

25. Repeat step 12 through step 24 for each clutch.

27

2

28

13

16

24

256

15

1

12

Figure 3

Typical Electric Clutch

13 28

reused.

256

808-309C SPKT 50C25 X 7/8 HEX BORE

This is a plain 25 tooth sprocket with a7⁄8inch

hexagonal bore. It is stamped “25” on each side.

256

the chain over the sprocket.

15

402-025S LOCK COLLAR, 7/8 HEX W/ SET SC

12

Slide it loosely onto the shaft.

brackets to its original placement.

256

recorded at step 12. Secure in place with collar

(or original roll pin) and the inside collar .

step 15.

12

slack. (See “Chain Maintenance” in the 403-857M

Operator manual).

25060

15

2

402-382M Table of Contents Index 2012-08-23

Page 13

Great Plains Manufacturing, Inc. Table of Contents Index 9

Install Air Clutches

Install Center Air Clutches

If the planter frame does not have a center section, for

example Models YP1225 and YP1625, continue at

“Install Wing Air Clutches” on page 12.

26. Connect the hitch hydraulics and harnesses at the

tractor.

27. a. For Model 3PYP and 3PYPA,

completely fold the wings.

b. For all other Models,

partially or completely fold the wings.

This provides access to center section shaft ends.

28. Lower the openers.

29. Shut down the tractor. Disconnect hydraulics and

harnesses at hitch.

14

26

11

17

Assess The Center Shaft

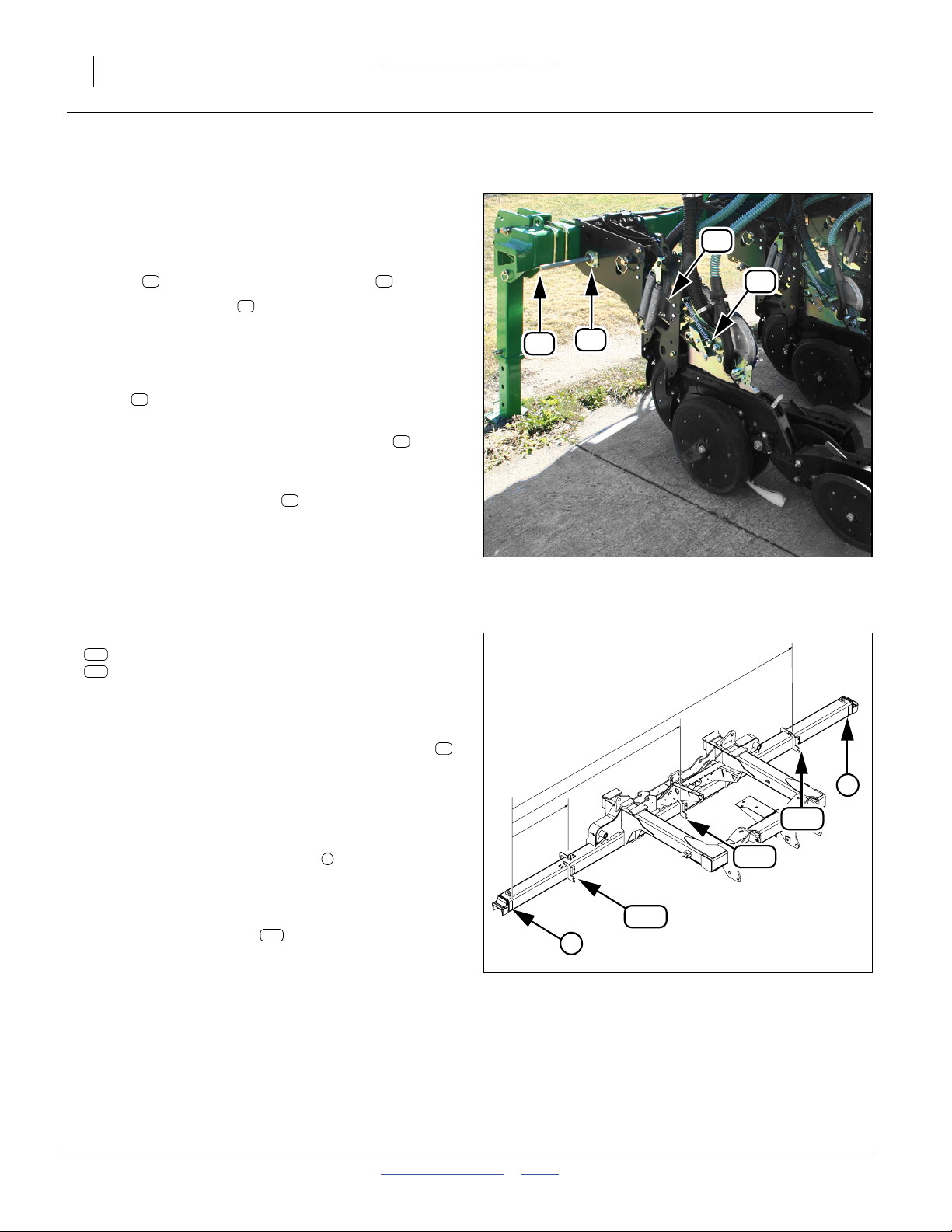

Refer to Figure 4

(which depicts a 3PYPA center section shaft)

30. At one end of the center section, measure the

length of exposed meter drive shaft , from tip of

shaft to row unit mount sidewall (not to bearing

face - the bearing may be relocated during this

installation). Record the dimension.

Refer to Figure 5

(which depicts a 3PYP/A center section)

31. Mark the approximate end-of-shaft locations on

the tool bar (needed for step 42).

32. Locate the 30T shaft input sprocket (not shown):

23

808-319C SPKT 50C30 X 7/8 HEX BORE

Measure the position of this sprocket with reference

to the row unit shanks on either side. Record these

dimensions, and whether the sprocket is secured in

place by no collars, one LH, one RH or two collars.

33. Along the entire length of the shaft, locate each pin

hole and roll pin (not shown, and there may be

none). Clean the shaft near each hole. Mark

occupied holes (for example “I”) and empty holes

(for example “o”).

34. Twin Row Only (Air-Pro® and finger meter only):

Check for deliberate stagger (consistent difference

sprocket tooth orientation at the meter sprocket).

For the front row, note the tooth number at top dead

center. Record that number and the T.D.C. tooth

number for the rear row.

Note: Lock collar (not shown) locations, other than for

shaft input sprocket, do not need to be recorded.

The clutch layout drawings show the final locations

of all collars.

14

26

1

Figure 4

Center Section Meter Shaft

1

Figure 5

Center Shaft End Points

34056

1

34067

2012-08-23 Table of Contents Index 402-382M

Page 14

10 Swath Command™ Table of Contents Index Great Plains Manufacturing, Inc.

Remove Center Shaft

Refer to Figure 6

(which depicts a 3PYPA center section shaft)

35. Relax the idlers on the chain driving the shaft input

sprocket.

36. At each center section row, relax the row unit

17 12

idlers to slacken the final drive chain .

37. Along the line shaft :

14

- loosen all lock collar set screws (not shown)

- loosen all sprocket set screws (not shown)

- carefully drive out and save roll pins (not shown)

38. Make arrangements to support the free shaft

14

end . From one end, for example the RH end,

begin driving the shaft toward the other end.

39. Use a rag to clean the free end of the shaft . Mark

14

it (for example) “CTR LH END”. Shafts are often

section-specific and not symmetrical end-to-end.

40. Continue driving the shaft out. As the shaft exits

14

each collar and sprocket, recover and save these

parts. Some are re-used.

Remove Bearings (Conditional)

41. Check the materials list on the opener layout

drawing for your kit, found in “Swath Command™

Planter Clutch Layouts”, pages 48 through 97.

If the kit contains, for the center section, any:

106

402-273K TRU-COUNT SINGLE ROW ASM or

144

402-329K TRU-COUNT SHORT ROW SINGLE ASM

do not remove the bearings at rows indicated by the

drawing reference number for either of those clutch

kits.

Otherwise, remove and save the bearing assembly

26

and its fasteners, at every row.

Attach Locator Tools

Refer to Figure 7

(which depicts a 3PYP/A center section)

42. In between the shaft-end marks made at step 31,

make additional marks at the positions:

1

⁄6(17%),1⁄2(50%) and5⁄6(83%)

in between the end marks.

43. Attach one locator tool as close as practical to

104

each marked location. Each locator equally

supports1⁄3 of the shaft length at these positions.

Make sure tool is perpendicular to tool bar, and

snug front-to-back.

1

14

17%

26

Figure 6

Center Section Line Shaft

50%

104

1

Figure 7

Attach Center Shaft Locators

12

17

34056

83.%

1

104

104

34067

402-382M Table of Contents Index 2012-08-23

Page 15

Great Plains Manufacturing, Inc. Table of Contents Index Install Air Clutches 11

Install Center Air Clutches

44. Consult the layout drawing for your kit (found in

pages 48 through page 97).

45. Note which types of clutch assemblies are supplied

in your kit (there are six different total assemblies,

and as many as four combinations per kit). Find the

detailed assembly drawing and instructions for each

in the Appendix, found on pages listed at right.

46. Working from left to right, install the specified

components ahead of, at and in between each row.

see the checklist at right for items to watch out for

during row installation.

Align Center Shaft

When the right-most row clutch has been installed, and

any final lock collar or roll pin installed, make final shaft

adjustments.

47. Check that all bearing flangettes are slightly loose.

Working from left to right:

48. Push the line shaft fully into the hex cut in a locator

tool.

49. Tighten flangette nuts on bearings immediately left

and right of the locator tool.

50. Repeat step 48 and step 49 for the remaining tools.

At the left end of the center section:

51. Being careful to not disturb the shaft position,

tighten the flangette nuts of the left end row.

At the right end of the center section:

52. Being careful to not disturb the shaft position,

tighten the flangette nuts of the right end row.

Working from left to right:

53. Being careful to not disturb the shaft position,

tighten the flangette nuts at each row.

At the left end of the shaft:

54. Adjust the left-right position of the shaft to match the

measurement taken at step 30.

Working from left to right:

55. Slide each lock collar into gentle contact with the

associated bearing shown in the layout drawing.

Secure the set screws.

56. Adjust the line shaft input sprocket so that the chain

is vertical. Secure the sprocket set screws.

57. Re-engage meter drive chain idlers. See special

instructions at right for twin-row chains.

58. Remove the locator tools. This completes the center

section clutch installation.

Clutch Assembly Installation Details

402-273K-ASY: page 37 402-279K-ASY: page 43

402-275K-ASY: page 39 402-281K-ASY: page 45

402-276K-ASY: page 41 402-329K-ASY: page 47

Row Item Checklist

• Route shaft through locator tools as encountered.

• Add lock collar left of clutch where specified.

• Install roll pins as marked on shaft.

• Loop meter chain(s) when installing clutch.

• Add lock collar right of clutch where specified.

• Add shaft input sprocket when chain encountered.

Be sure to re-install any lock collars as recorded at

step 32.

• Do not tighten any collar or sprocket set screws

during row installation.

• Do not remove any chain slack during row

installation.

Twin Row Chain Alignment

If the planter is only ever used:

• with Singulator Plus™ (green wheel) meters, or

• at seed spacings below 61⁄2inches (16.5 cm), or

• with Air-Pro® seed discs having more than 24

pockets,

then skip this alignment.

If no deliberate sprocket indexing was noted at step 34,

re-engage meter chains with both meter sprockets in

the same tooth orientation (for example, with both

sprockets having tooth 1 at top dead center).

Otherwise, engage the chain for the front meter as

noted at step 34, and engage or adjust the chain for the

rear meter as noted.

Engage both idlers. Recheck the tooth number

relationship.

2012-08-23 Table of Contents Index 402-382M

Page 16

12 Swath Command™ Table of Contents Index Great Plains Manufacturing, Inc.

Install Wing Air Clutches

59. Connect the hitch hydraulics and harnesses at the

tractor.

60. a. For Model 3PYP and 3PYPA,

completely unfold the wings.

b. For all other Models,

Refer to Figure 8: take note of the location of the

14

14

26

1

Figure 8

14

34069

Wing End Line Shaft

1

1

1

Figure 9

Wing Shaft End Points

Note: Lock collar (not shown) locations, other than for

line shaft input sprocket, do not need to be

recorded. The clutch layout drawings show the

final locations of all collars.

34070

outside end of the line shaft . Partially or

completely fold the wings, leaving the wing-end

casters oriented so that they do not obstruct shaft

1

removal.

61. Lower the openers.

62. Shut down the tractor. Disconnect hydraulics and

harnesses at hitch.

Start with the left wing.

Assess The Wing Shaft

Refer to Figure 8

(which depicts a YP24 left wing shaft)

63. At one end of the wing, measure the length of

exposed meter drive shaft , from tip of shaft to

row unit mount sidewall (not to bearing face - the

bearing may be relocated during this installation).

Record the dimension.

Refer to Figure 9

(which depicts a YP40 left wing)

64. Mark the approximate end-of-shaft locations on

the tool bar (needed for step 76).

65. Locate the 30T shaft input sprocket (not shown):

23

808-319C SPKT 50C30 X 7/8 HEX BORE

Measure the position of this sprocket with reference

to the row unit shanks on either side. Record these

dimensions, and whether the sprocket is secured in

place by no collars, one LH, one RH or two collars.

66. Locate any coupler on the shaft. Decide on a

removal/re-insertion strategy (both sections from

one end, or each section from each end).

67. Along the entire length of the shaft, locate each pin

hole and roll pin (not shown, and there may be

none, and there may be one coupler with two pins).

Clean the shaft near each hole. Mark occupied

holes (for example “I”) and empty holes (for example

“o”).

68. Twin Row Only (Air-Pro® and finger meter only):

Check for deliberate stagger (consistent difference

sprocket tooth orientation at the meter sprocket).

For the front row, note the tooth number at top dead

center. Record that number and the T.D.C. tooth

number for the rear row.

402-382M Table of Contents Index 2012-08-23

Page 17

Great Plains Manufacturing, Inc. Table of Contents Index Install Air Clutches 13

Remove Wing Shaft

Refer to Figure 10

(which depicts a YP24 wing shaft)

69. Relax the idlers on the chain driving the shaft input

sprocket.

26

70. At each center section row, relax the row unit idlers

(not shown) to slacken the final drive chain .

71. Along the meter drive shaft :

14

12

- loosen all lock collar set screws (not shown)

- loosen all sprocket set screws (not shown)

- carefully drive out and save roll pins (not shown)

- remove and save any coupler

14

72. Make arrangements to support the free shaft

14

end . From one end, for example the RH end,

12

begin driving the shaft toward the other end.

73. Use a rag to clean the free end of the shaft . Mark

14

it (for example) “LW LH END”. Shafts are often

section-specific and not symmetrical end-to-end.

74. Continue driving the shaft out. As the shaft exits

14

each collar and sprocket, recover and save these

parts. Some are re-used.

Remove Bearings (Conditional)

75. Check the materials list on the opener layout

drawing for your kit, found in “Swath Command™

Figure 10

Wing Line Shaft

34069

Planter Clutch Layouts”, pages 48 through 97.

If the kit contains, for the center section, any:

106

402-273K TRU-COUNT SINGLE ROW ASM or

144

402-329K TRU-COUNT SHORT ROW SINGLE ASM

do not remove the bearings at rows indicated by the

83.%

drawing reference number for either of those clutch

kits.

Otherwise, remove and save the bearing assembly

and its fasteners, at every row.

26

50%

1

Attach Locator Tools

Refer to Figure 11

(which depicts a YP40 wing)

76. In between the shaft-end marks made at step 31,

make additional marks at the positions:

1

⁄6(17%),1⁄2(50%) and5⁄6(83%)

1

in between the end marks.

77. Attach one locator tool as close as practical to

104

each marked location. Each locator equally

supports1⁄3 of the shaft length at these positions.

Make sure tool is perpendicular to tool bar, and

snug front-to-back.

17%

104

1

Figure 11

Attach Wing Shaft Locators

104

104

34070

2012-08-23 Table of Contents Index 402-382M

Page 18

14 Swath Command™ Table of Contents Index Great Plains Manufacturing, Inc.

Install Wing Air Clutches

78. Consult the layout drawing for your kit (found in

pages 48 through page 97).

79. Note which types of clutch assemblies are supplied

in your kit (there are six different total assemblies,

and as many as four combinations per kit). Find the

detailed assembly drawing and instructions for each

in the Appendix, found on pages listed at right.

80. Working from left to right, install the specified

components ahead of, at and in between each row.

see the checklist at right for items to watch out for

during row installation.

81. When all rows are updated, re-install any coupler.

Align Wing Shaft

When the right-most row clutch is installed, and any final

collar or roll pin installed, make final shaft adjustments.

82. Check that all bearing flangettes are slightly loose.

Working from left to right:

83. Push the shaft fully into the hex cut of a locator tool.

84. Tighten flangette nuts on bearings immediately left

and right of the locator tool.

85. Repeat step 83 and step 84 for the remaining tools.

At the left end of the center section:

86. Being careful to not disturb the shaft position,

tighten the flangette nuts of the left end row.

At the right end of the center section:

87. Being careful to not disturb the shaft position,

tighten the flangette nuts of the right end row.

Working from left to right:

88. Being careful to not disturb the shaft position,

tighten the flangette nuts at each row.

At the left end of the shaft:

89. Adjust the left-right position of the shaft to match the

measurement taken at step 63.

Working from left to right:

90. Slide each lock collar into gentle contact with the

associated bearing shown in the layout drawing.

Secure the set screws.

91. Adjust the line shaft input sprocket so that the chain

is vertical. Secure the sprocket set screws.

92. Re-engage meter drive chain idlers. See special

instructions at right for twin-row chains.

93. Remove the locator tools. This completes a wing

clutch installation.

94. Repeat step 63 through step 93 for the right wing.

Clutch Assembly Installation Details

402-273K-ASY: page 37 402-279K-ASY: page 43

402-275K-ASY: page 39 402-281K-ASY: page 45

402-276K-ASY: page 41 402-329K-ASY: page 47

Row Item Checklist

• Route shaft through locator tools as encountered.

• Add lock collar left of clutch where specified.

• Install roll pins as marked on shaft.

• Loop meter chain(s) when installing clutch.

• Add lock collar right of clutch where specified.

• Add shaft input sprocket when chain encountered.

Be sure to re-install any lock collars as recorded at

step 32.

• Do not tighten any collar or sprocket set screws

during row installation.

• Do not remove any chain slack during row

installation.

Twin Row Chain Alignment

If the planter is only ever used:

• with Singulator Plus™ (green wheel) meters, or

• at seed spacings below 61⁄2inches (16.5 cm), or

• with Air-Pro® seed discs having more than 24

pockets,

skip this alignment.

If no deliberate sprocket indexing was noted at step 34,

re-engage meter chains with both meter sprockets in

the same tooth orientation (for example, with both

sprockets having tooth 1 at top dead center).

Otherwise, engage the chain for the front meter as

noted at step 34, and engage or adjust the chain for the

rear meter as noted.

Engage both idlers. Recheck the tooth number

relationship.

402-382M Table of Contents Index 2012-08-23

Page 19

Great Plains Manufacturing, Inc. Table of Contents Index 15

Install Compressor

Compressor installation varies by hitch type:

Pull Type, Hydraulic Tongue: below

Pull Type, Three-Point: page 17

3PYP/A Three-Point: page 18

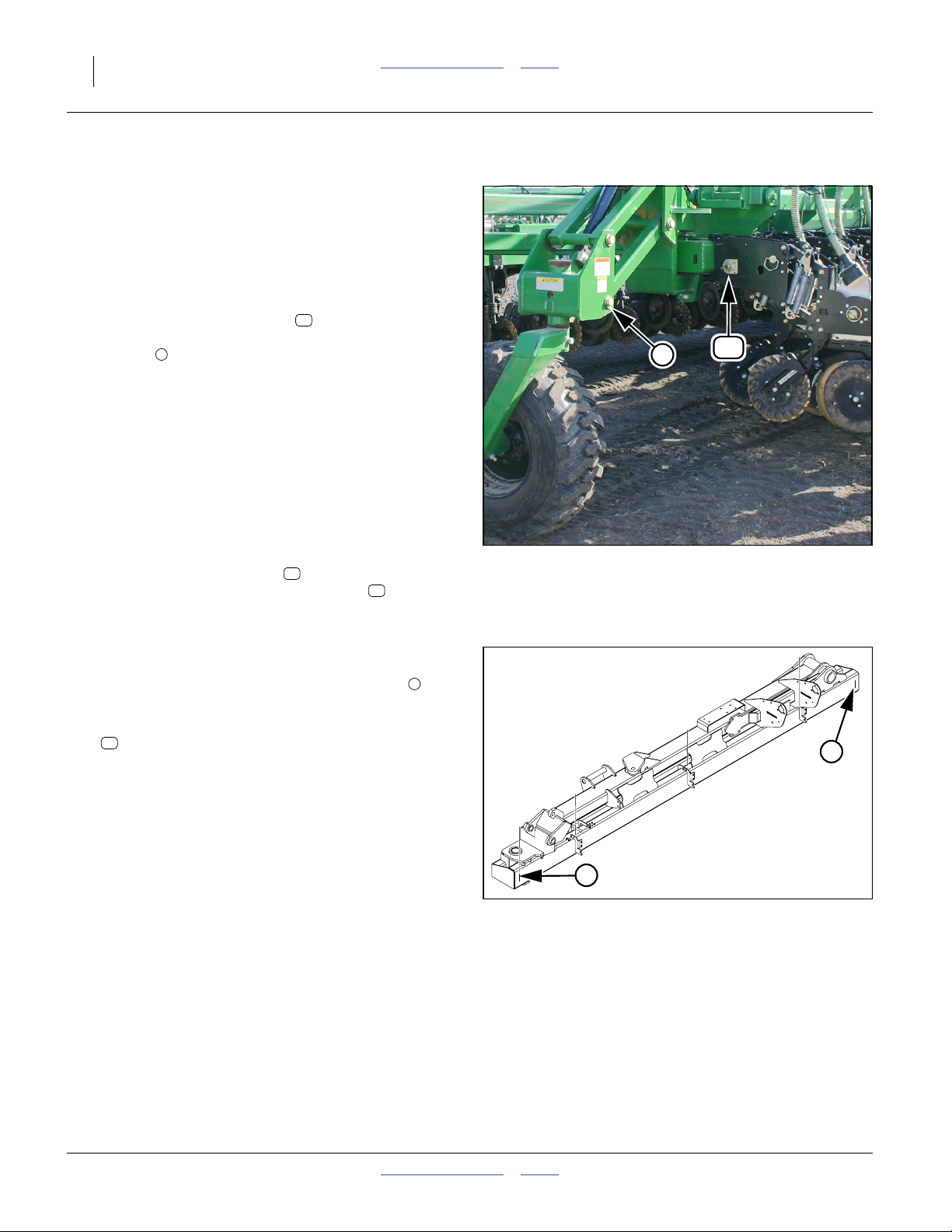

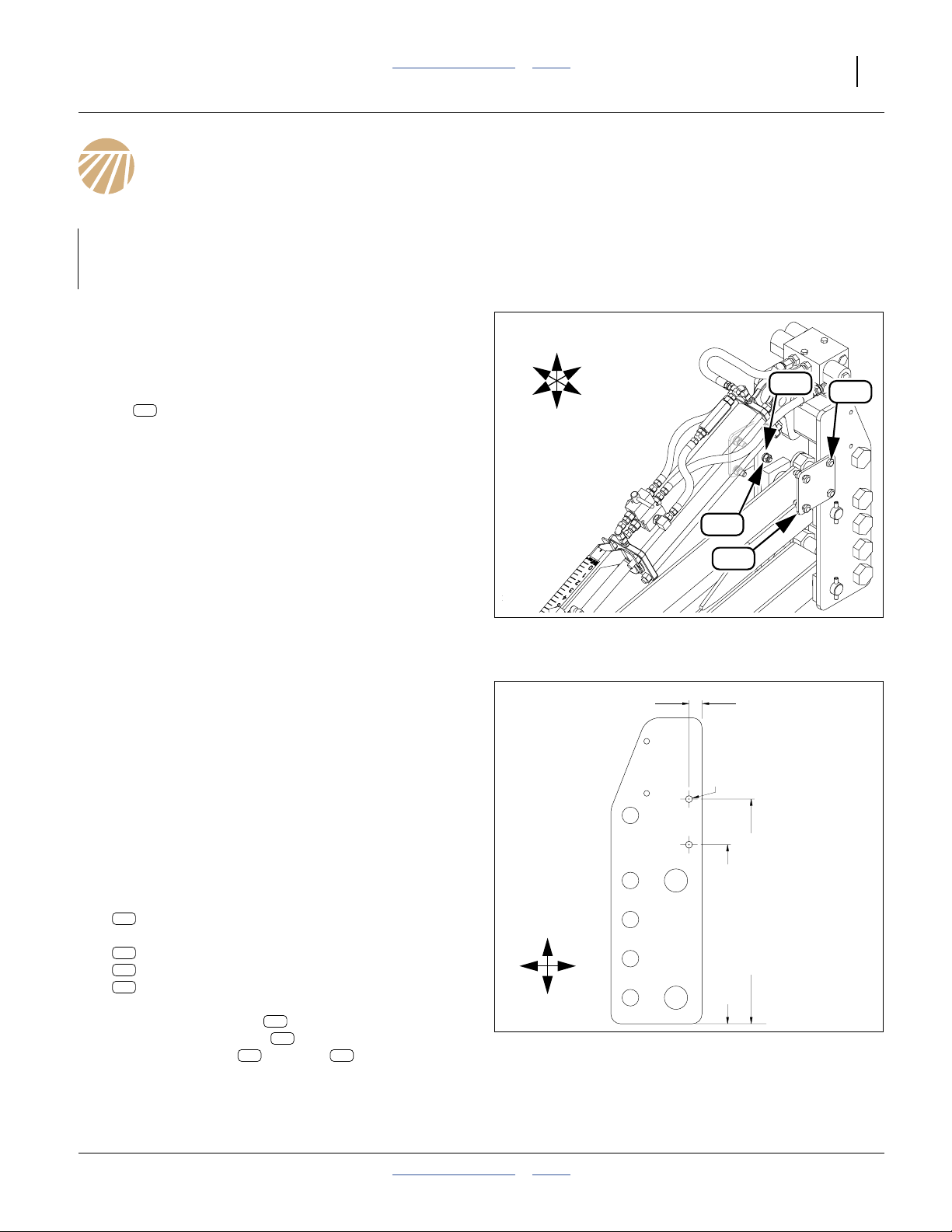

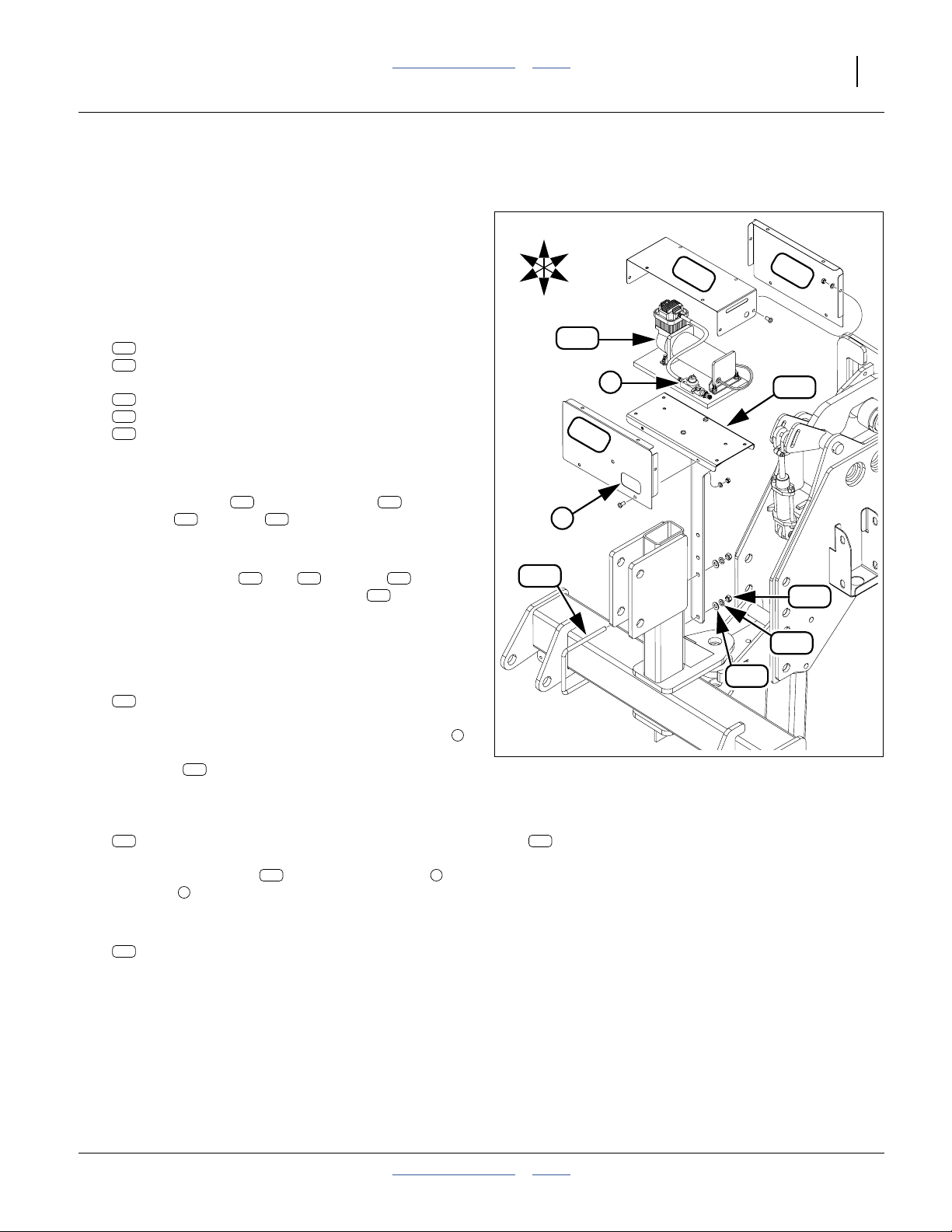

Hydraulic Tongue (H.T.) Compressor Installation

Refer to Figure 12

If the hydraulic tongue already has a compressor mount

bracket available, continue at “Install Compressor

Mount (H.T.)” on page 16.

Note: 2012 and later hydraulic tongues have these

Install H.T. Mount Bracket(s)

Swath Command™ kits do not include mount brackets.

The necessary parts are presumed to have been

separately ordered.

Prepare H.T. Hitch Weldment

Refer to Figure 13 (showing right side of hitch)

Note: By convention the Swath Command™ compressor

95. Mark and center-punch locations as shown near the

96. Use a pilot bit and a17⁄32inch (13.5 mm) bit to

Affix H.T. Bracket(s)

Refer to Figure 12 and Figure 13

97. Select one or two:

209

brackets. Earlier tongues do not, and must be

upgraded with parts purchased separately (see

parts list in step 97).

is installed on the right side of the hitch. The

second mount bracket, on the left side, would be

used for a Row-Pro™ compressor.

leading right edge of the hitch weldment. If two sets

of mount brackets are on hand, mark holes on the

left side as well (also near leading edge).

create two or four holes.

209

404-228D HYD HITCH COMP MOUNT BRACKET

and two or four sets:

227

802-091C HHCS 1/2-13X1 1/2 GR5

246

804-015C WASHER LOCK SPRING 1/2 PLT

239

803-020C NUT HEX 1/2-13 PLT

Position each bracket forward of the hitch

weldment. Insert a bolt from the outside. Secure

with lock washers and nuts .

209

227

246 239

U

R

F

B

L

D

H.T. Compressor Mount Check

1.0 in. (25.4 mm)

U

B

F

D

239

209

Figure 12

in.

32

⁄

17

∅

(13.5 mm)

in. (43.8 cm)

4

⁄

1

in. (34.9 cm)

17

4

⁄

3

13

Figure 13

H.T. Mount Hole Locations

246

227

34072

34073

2012-08-23 Table of Contents Index 402-382M

Page 20

16 Swath Command™ Table of Contents Index Great Plains Manufacturing, Inc.

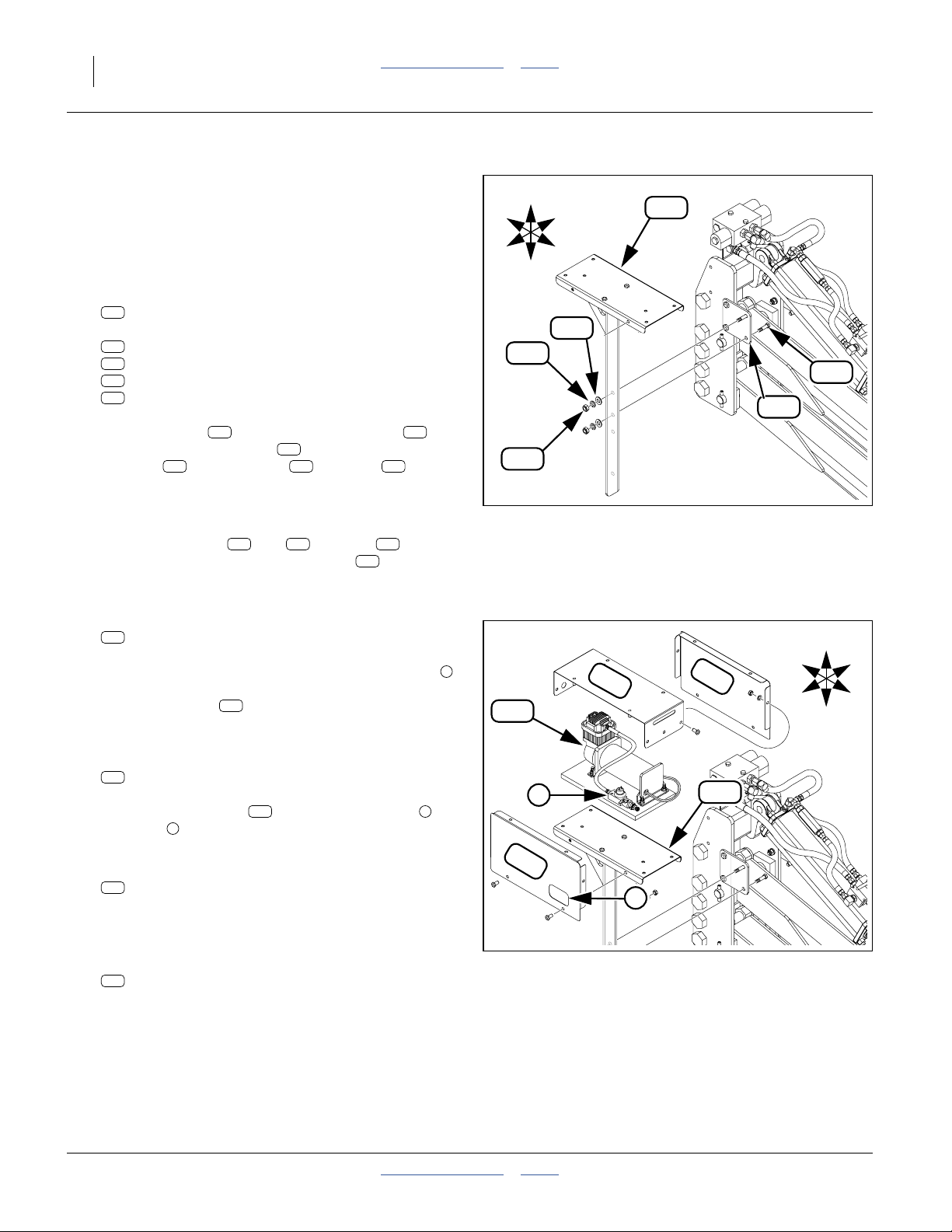

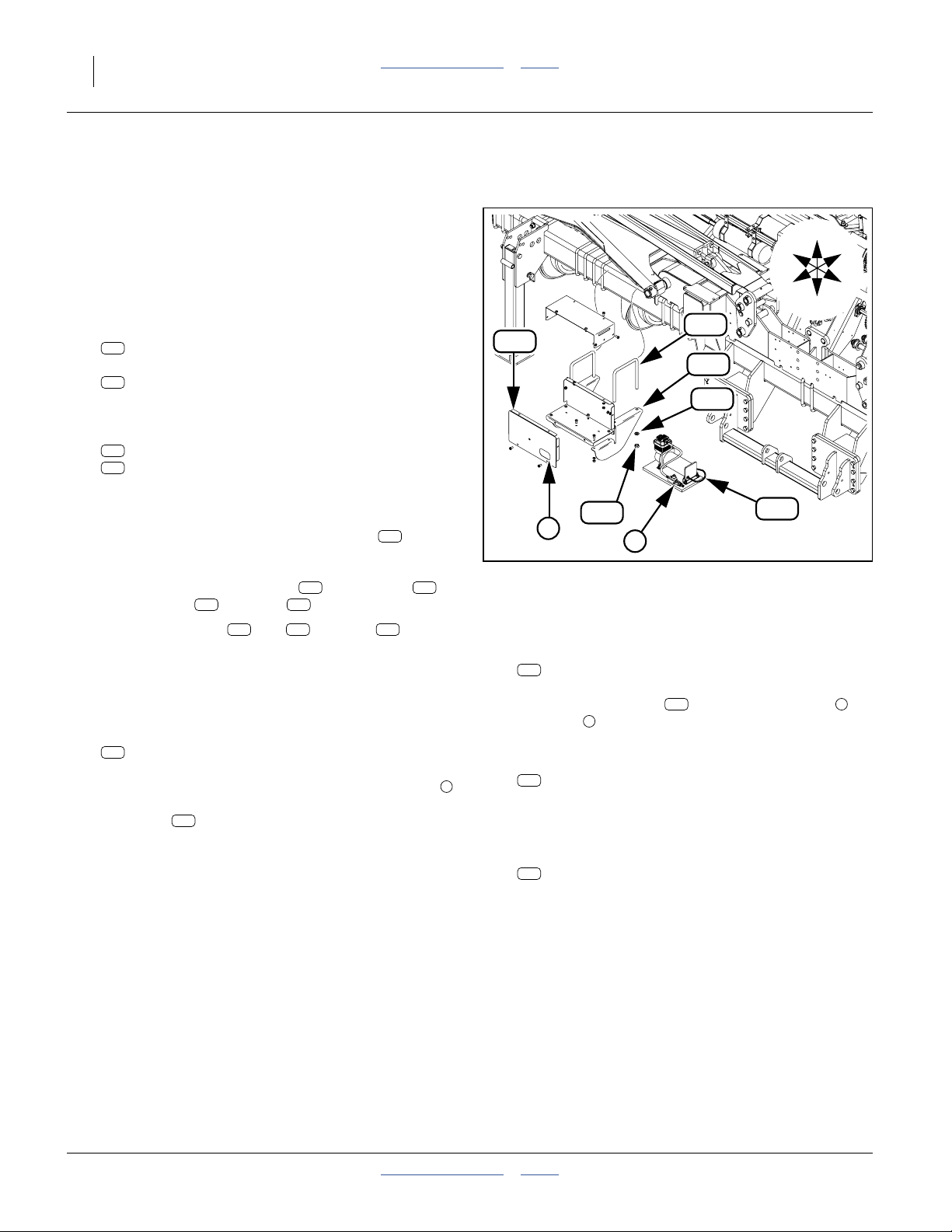

Install Compressor Mount (H.T.)

Note: By convention, the Swath Command™

compressor is installed on the right hand side of the

hitch. If a Row-Pro™ compressor is already

installed there, the Swath Command™

compressor may be installed on the left hand side.

Refer to Figure 14

98. Select one new:

211

404-861H 12V COMP MOUNT WELDMENT

and two sets:

227

802-091C HHCS 1/2-13X1 1/2 GR5

247

804-016C WASHER FLAT 1/2 SAE PLT

246

804-015C WASHER LOCK SPRING 1/2 PLT

239

803-020C NUT HEX 1/2-13 PLT

Insert the bolts from behind the bracket .

Add the mount weldment . Secure with flat

washers , lock washers and nuts .

227 209

211

247 246 239

B

R

U

D

246

239

L

F

247

211

227

209

Install Compressor (H.T.)

B

R

34075

U

L

F

D

Refer to Figure 15

99. If the side covers ( and ) and top are

pre-installed on the mount weldment , and the

compressor is not pre-installed, remove the covers,

saving the fasteners.

100. Select one:

263

823-330C TRU-COUNT COMPRESSOR ASSEMBLY

Orient the compressor assembly so that the valve

is to the outside. Secure it to the platform of the

mount weldment using the fasteners provided.

207 208 206

211

211

Figure 14

H.T. Compressor Mount

1

206

208

263

Install Compressor Covers (H.T.)

101. Select one:

207

404-226D TC COMPRESSOR COVER SIDE R

211

Orient the side cover with the access port at

the valve . Loosely secure cover to mount with

provided fasteners.

102. Select one:

208

1

404-227D TC COMPRESSOR COVER SIDE L

207 2

1

207

2

Loosely secure cover to mount with provided

fasteners.

103. Select one:

206

404-225D 12 COMPRESSOR COVER TOP

Figure 15

H.T. Compressor

34075

Completely secure top to side covers with provided

fasteners.

104. Continue at “Install Valve Blocks” on page 19.

402-382M Table of Contents Index 2012-08-23

Page 21

Great Plains Manufacturing, Inc. Table of Contents Index Install Compressor 17

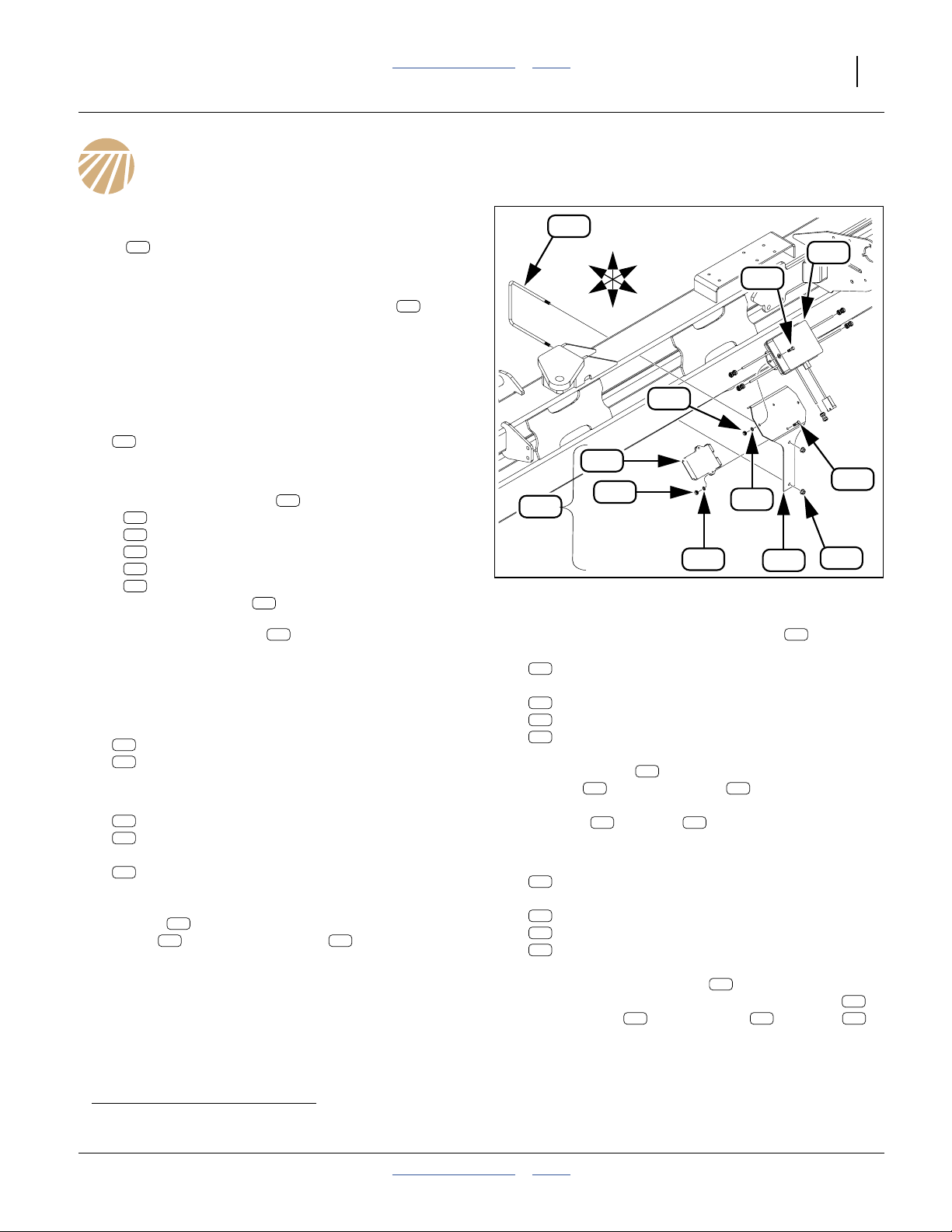

Pull-Type 3-Point Compressor Installation

Note: By convention, the Swath Command™

compressor is installed on the right hand side of the

hitch. If a Row-Pro™ compressor is already

installed there, the Swath Command™

compressor may be installed on the left hand side.

Refer to Figure 16

105. Select one each new:

211

404-861H 12V COMP MOUNT WELDMENT

254

806-060C U-BOLT 1/2-13 X 6 1/32 X 7 1/4

and two sets:

247

804-016C WASHER FLAT 1/2 SAE PLT

246

804-015C WASHER LOCK SPRING 1/2 PLT

239

803-020C NUT HEX 1/2-13 PLT

Place the U-bolt on the 3-point hitch cross-tube, to

the right of the center riser. Loosely secure the

mount weldment with flat washers , lock

washers and nuts . Adjust mount position so

that the left edge of the platform clears the riser by

approximately an inch (5 cm).

106. If the side covers ( and ) and top are

pre-installed on the mount weldment , and the

compressor is not pre-installed, remove the covers,

saving the fasteners.

246 239

211 247

207 208 206

211

Install Compressor (3P)

107. Select one:

263

823-330C TRU-COUNT COMPRESSOR ASSEMBLY

R

F

U

D

254

B

L

263

207

2

206

1

208

211

239

246

247

Orient the compressor assembly so that the valve

is to the front. Secure it to the platform of the mount

weldment using the fasteners provided.

211

1

Figure 16

Pull-Type 3-Point Mount

34076

Install Compressor Covers (3P)

108. Select one:

207

404-226D TC COMPRESSOR COVER SIDE R

Orient the side cover with the access port at

the valve . Loosely secure cover to mount with

provided fasteners.

109. Select one:

208

Loosely secure cover to mount with provided

fasteners.

2012-08-23 Table of Contents Index 402-382M

1

404-227D TC COMPRESSOR COVER SIDE L

207 2

110. Select one:

206

404-225D 12 COMPRESSOR COVER TOP

Completely secure top to side covers with provided

fasteners.

111. Continue at “Install Valve Blocks” on page 19.

Page 22

18 Swath Command™ Table of Contents Index Great Plains Manufacturing, Inc.

3PYP and 3PYPA Compressor Installation

Note: By convention, the Swath Command™

compressor is installed on the right hand side of the

hitch. If a Row-Pro™ compressor is already

installed there, the Swath Command™

compressor may be installed on the left hand side.

Refer to Figure 17

112. Select two each new:

253

806-052C U-BOLT 5/8-11 X 7 1/32 X 8 1/2

and two:

210

404-230D COMPRESSOR MOUNT BRACKET

(or the complete mount assembly, if pre-assembled)

and four sets:

248

804-022C WASHER LOCK SPRING 5/8 PLT

240

803-021C NUT HEX 5/8-11 PLT

Find a location on the opener tool bar, right of the

hitch, where the mount assembly clears other

machine parts in front, and the brackets seat

fully against the bottom of the tool bar.

Secure the mount weldment with U-bolts ,

lock washers and nuts .

113. If the side covers ( and ) and top are

pre-installed on the mount assembly, and the

compressor is not pre-installed, remove the covers,

saving the fasteners.

246 239

207 208 206

211 253

210

Install Compressor (3PYP)

114. Select one:

263

823-330C TRU-COUNT COMPRESSOR ASSEMBLY

Orient the compressor assembly so that the valve

is to the front. Secure it to the platform of the mount

weldment using the fasteners provided.

211

253

207

210

240

2

1

Figure 17

3PYP Compressor Mount

Install Compressor Covers (3PYP)

115. Select one:

207

404-226D TC COMPRESSOR COVER SIDE R

207 2

116. Select one:

1

117. Select one:

Orient the side cover with the access port at

the valve . Loosely secure cover to mount with

provided fasteners.

208

Loosely secure cover to mount with provided

fasteners.

206

1

404-227D TC COMPRESSOR COVER SIDE L

404-225D 12 COMPRESSOR COVER TOP

248

R

F

263

U

B

L

D

34077

Completely secure top to side covers with provided

fasteners.

402-382M Table of Contents Index 2012-08-23

Page 23

Great Plains Manufacturing, Inc. Table of Contents Index 19

Install Valve Blocks

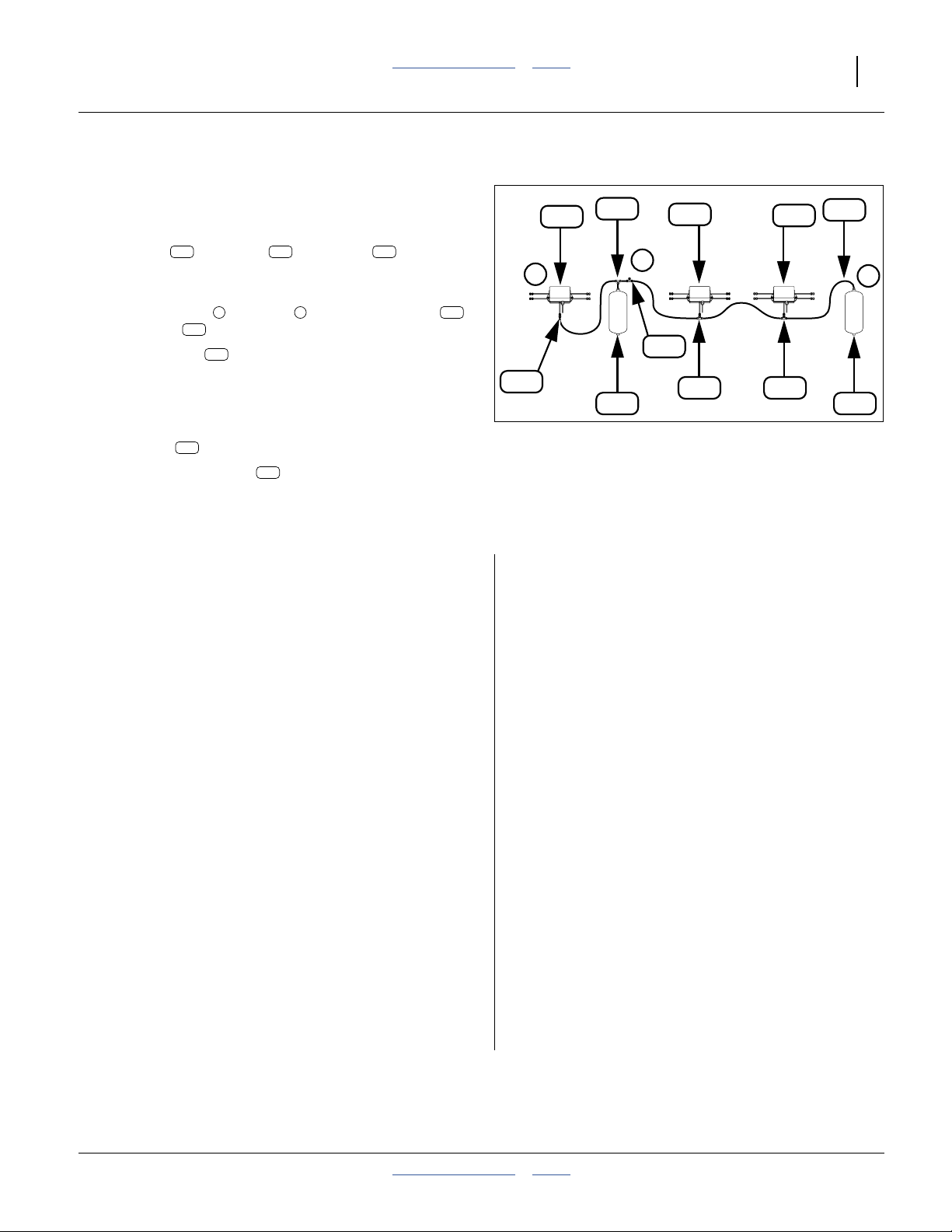

Refer to Figure 18

143

255

F

L

U

R

B

D

237

218

237

Figure 18

Valve Block Mount

242

221

242

1

2

195

272

3

4

AIR IN

231

241

34084

The air clutches now installed are controlled by solenoid

valves provided in blocks of 4 valves, each valve

272

controlling a number of rows. A Swath Command™ kit

includes 1, 2 or 3 valve blocks.

a

218

The valves are controlled by a WSMB-TCOM

. Each

TCOM controls up to eight valves. A Swath Command™

kit includes 1 or 2 WSMBs.

Start at the left side of the planter. Install the valve block

and/or TCOM for each section. A section may have both

components or only a valve block.

118. Select all included WSMB-TCOM bundles:

143

402-305K DJ 8 CHANNEL TRU-COUNT MOD ASM

If the kit has more than one, arrange them in serial

number order for installation.

Note: The 402-305K bundle includes:

218

467982000S1 PLNTR CNTRL OUTPUT MODULE(POM)

219

467983505 DJIA OUTPUT HARN 8-CH TRU-COUN

231

802-224C HHCS 1/4-20X1 1/4 GR5

242

804-006C WASHER LOCK SPRING 1/4 PLT

237

803-006C NUT HEX 1/4-20 PLT

Set each harness aside for later installation.

143

219

Note: Connecting WSMBs to the CANbus in serial

218

number order (page 24) causes them to be

correctly ordered by rows when the seed monitor

detects the configuration change.

119. Consult the clutch layout drawing for the kit

(page 48 through page 132). Note locations of any:

272

829-140C TRU-COUNT 75713-00 VALVE ASM

218

467982000S1

PLNTR CNTRL OUTPUT MODULE(POM)

If none, move to the next section.

120. Select one each new:

195

402-533D TRU-COUNT VALVE MODULE BRACKET

255

806-073C U-BOLT 3/8-16 X 7 1/32 X 7 7/8

and two new:

241

803-209C NUT FLANGE LOCK 3/8-16 PLT

At the location shown in the layout, secure the

bracket to the opener tool bar using the

U-bolt and flange lock nuts .

195

255 241

121. If the layout drawing shows a WSMB at the

218

current location, select the:

218

467982000S1 PLNTR CNTRL OUTPUT MODULE(POM)

with the lowest serial number, and two sets:

231

802-224C HHCS 1/4-20X1 1/4 GR5

242

804-006C WASHER LOCK SPRING 1/4 PLT

237

803-006C NUT HEX 1/4-20 PLT

Insert the bolts from the top rear of the

bracket . Add the WSMB , with connectors

195 218

231

toward implement center, and secure with lock

washers and nuts . Tighten nuts only to

242 237

Grade 2 torque specification.

122. Select one new:

272

829-140C TRU-COUNT 75713-00 VALVE ASM

and two sets new:

221

802-004C HHCS 1/4-20X3/4 GR5

242

804-006C WASHER LOCK SPRING 1/4 PLT

237

803-006C NUT HEX 1/4-20 PLT

Orient the valve assembly with the port lettering

272

upright. Secure the valve block to the bracket

with the bolts , lock washers and nuts .

221 242 237

Tighten nuts only to Grade 2 torque specification.

123. Repeat step 119 through step 122 for the next

bracket, if any.

195

a. Working Set MemBer - Planter Output Module

2012-08-23 Table of Contents Index 402-382M

Page 24

20 Swath Command™ Table of Contents Index Great Plains Manufacturing, Inc.

402-382M Table of Contents Index 2012-08-23

Page 25

Great Plains Manufacturing, Inc. Table of Contents Index 21

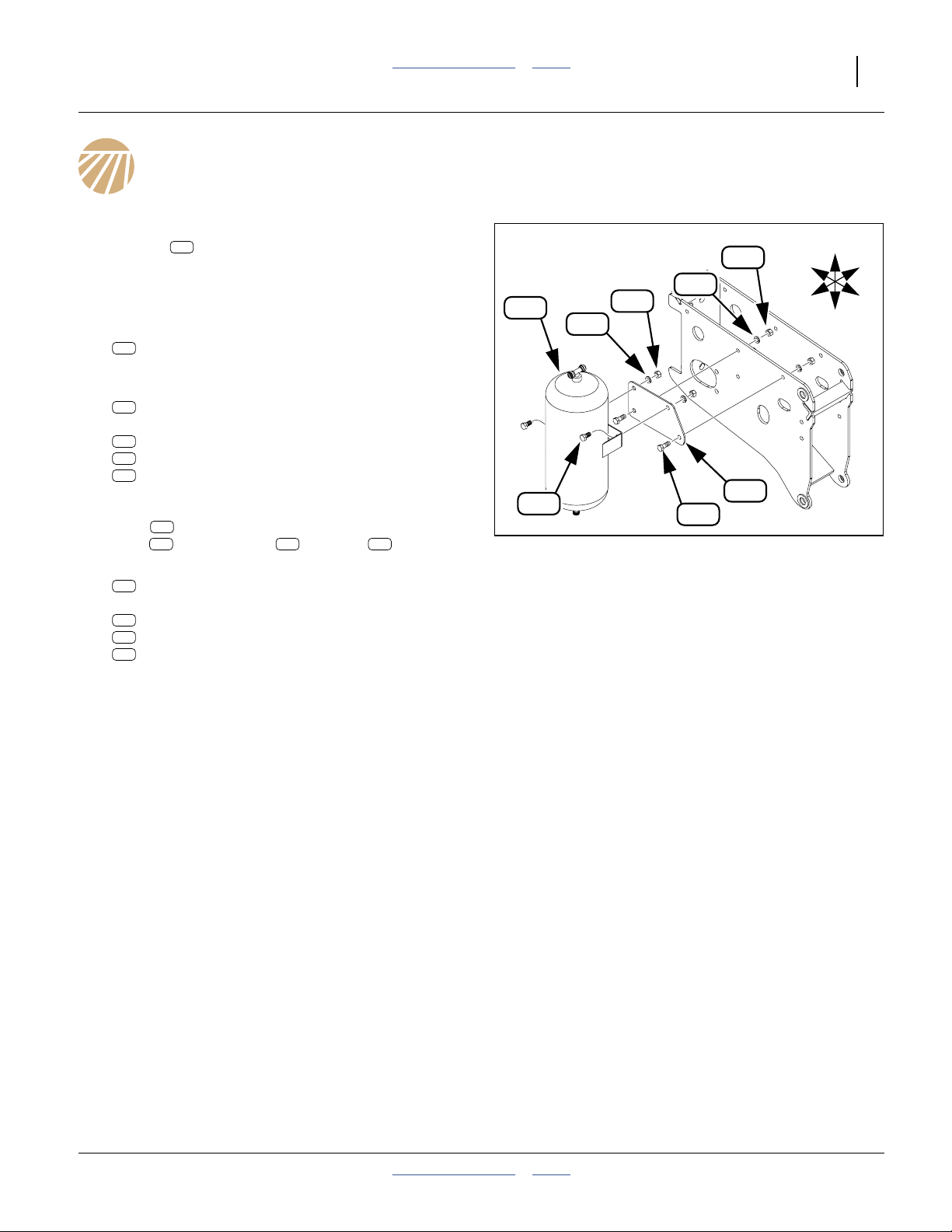

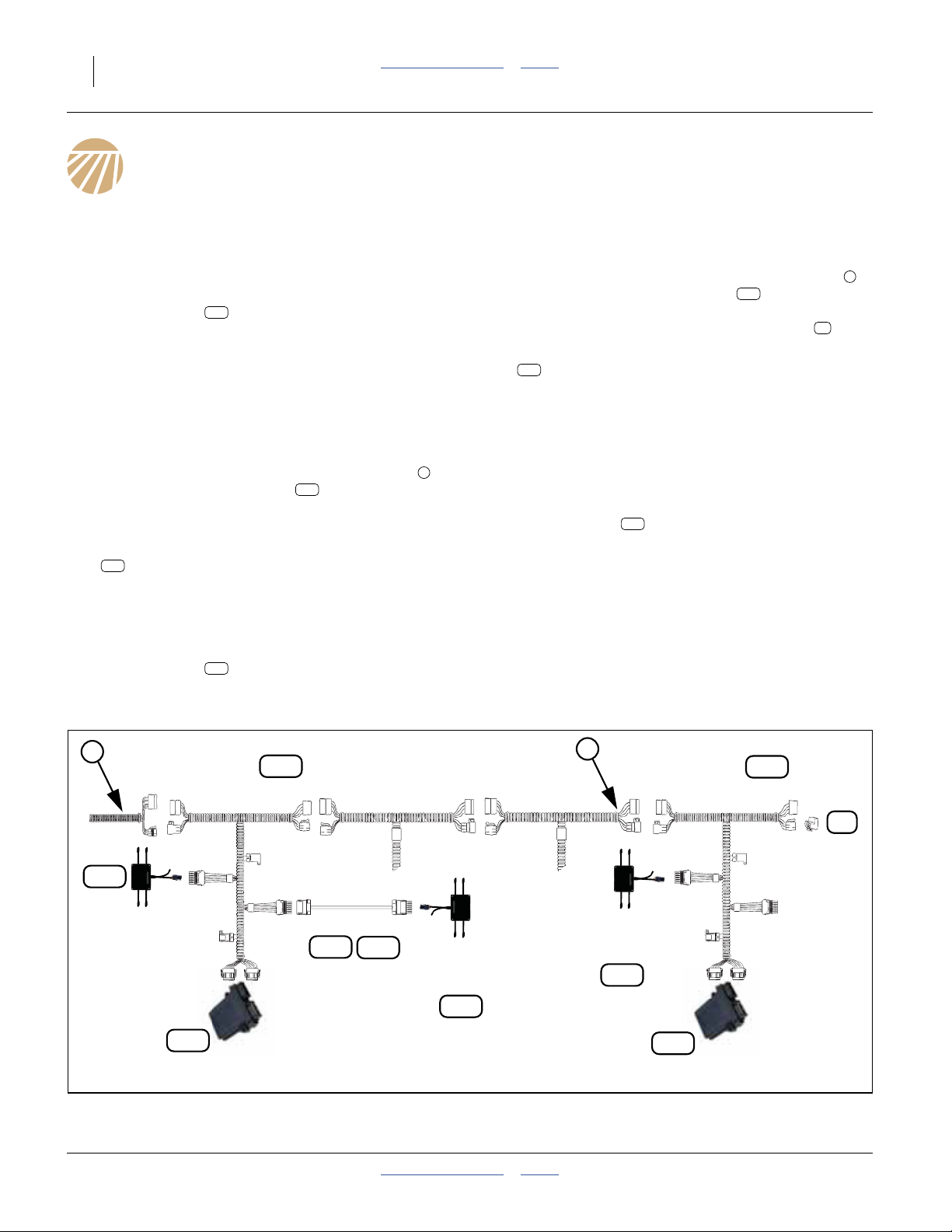

Install Air Tank(s)

Refer to Figure 19

The solenoid valves now installed are supplied by one or

two air tanks .

Start at the left side of the planter. A section may have

one tank or no tank.

124. Consult the clutch layout drawing for the kit

(page 48 through page 132). Note locations of any:

262

If none, move to the next section.

125. Select one each new:

197

and two sets new:

224

245

238

At the location shown in the layout, secure the

plate to the left side of the opener using the

bolts , lock washers and nuts .

126. Select one new:

262

and two sets new:

223

245

238

127. Repeat step 124 through step 126 for the next tank,

if any.

262

823-329C TRU-COUNT AIR TANK ASM

402-535D TRU-COUNT AIR TANK MOUNT PLATE

802-017C HHCS 3/8-16X1 GR5

804-013C WASHER LOCK SPRING 3/8 PLT

803-014C NUT HEX 3/8-16 PLT

197

224 245 238

823-329C TRU-COUNT AIR TANK ASM

802-014C HHCS 3/8-16X3/4 GR5

804-013C WASHER LOCK SPRING 3/8 PLT

803-014C NUT HEX 3/8-16 PLT

262

262

238

245

238

245

197

224

Figure 19

Air Tank Mount

U

F

L

R

B

D

34085

2012-08-23 Table of Contents Index 402-382M

Page 26

22 Swath Command™ Table of Contents Index Great Plains Manufacturing, Inc.

1

2

3

4

AIR IN

Install Air Lines

Install Row Air Lines

128. Find the Clutch Layout for your planter model (these

are on page 48 through page 132).

Start with the left wing, first clutch and valve Port 1. Valve

ports are numbered 1-4 on the top cover.

34084

Refer to Figure 20

129. Locate the next available port of the valve

272

block .

130. Identify which air clutches are served by that port,

and which clutch is the furthest from the port.

Refer to Figure 21

131. Locate the clutch cylinder to be connected.

132. Select a spool of:

275

990-109R TUBE NYLON 1/4OD X 062WL

and one:

273

830-383C CP 1/4 PUSH LOK POLY

133. Route the tubing from the clutch to the valve

port, passing near each served row clutch. Remain

clear of moving parts. allow enough slack to dress

the tubing against the rear top corner of the tool bar,

and avoid kinking at turns.

Pull the white polymer or metal collars away

from the fitting body. Insert the valve tubing and

clutch tubing . Push together. Re-seat collars.

273

134. At the clutch cylinder, cut the tubing to length. Pull

up collar. Insert tubing. Push together.

135. If the valve port serves more than one clutch, select

one tee for each additional served clutch:

274

830-405C TE POLY 1/4 PUSH LOCK

Cut the tubing just installed, directly above a served

clutch. Insert a tee . Cut a length of fresh

275

tubing to run from the tee to the clutch.

274

Make the connection.

136. Repeat step 129 through step 135 for all used valve

ports and row clutches.

1

278

278

283

273

275

272

1

283

283

273

274

Figure 20

Valve Block Tubing

Tubing Damage Risk:

At section divisions, route the tubing with the existing air hose

and harness bundle, as these pass through a pivot point,

eliminating pull-out risk and minimizing tubing flex. Routing

tubing directly across a wing gap will result in tubing damage

during operation.

34242

283

275

278

Figure 21

Clutch Cylinder Tubing

34242

402-382M Table of Contents Index 2012-08-23

Page 27

Great Plains Manufacturing, Inc. Table of Contents Index Install Air Lines 23

Install Section Air Lines

All of the tanks and valve inlets are interconnected,

forming a single shared reservoir system.

On a smaller planter, this topic is a simple connection of

a single tank and valve . Use a tee at the

inside end of the tubing, for the supply connection.

Refer to Figure 22

137. Locate the left and right extents of the tank

and valve set now installed.

138. Route tubing between these ends. Stay at the

upper rear edge of the tool bar, except at inboard

wing ends. At wing pivots, follow the existing seed

hose and harness bundles.

139. Make end connections using push-lock fittings or

couplers .

140. Select as many tees as needed to make

connections between ends. Select one additional

tee for use as supply line, inserted and connected in

the next topic.

262 272 274

1 3 262

272

275

273

274

272

1

273

274

272

272

2

274

274 274

262 262

Figure 22

Generalized Section Connections

275

3

34245

Install Supply Air Lines

The supply line from the hitch connects to the section

line:

• On a folding planter, the line is routed inside the left

pull bar, and connects to the section line on the left

wing.

• On a 3PYP/A planter, the line is routed from the hitch

and connects to the section line at machine center.

141. Use the final tee to splice into the section line at the

point where the supply line is expected to meet it.

142. Route the remaining tubing from the hitch to the

section connection point.

143. If the compressor is tractor-mounted, cut the supply

line near the hitch and insert a coupler.

144. Connect the end of the supply line to the pump

outlet.

145. Install and secure the compressor cover.

Fish Line Bind

If the wire or tape cannot be fished through the left pull

bar of a folding planter, it is necessary to re-pull the

entire hose/harness bundle, with the tubing added.

a. Connect each hydraulic hose at the hitch to a

hydraulic source that has a Float capability. Set the

circuit to Float to relieve pressure in the hose.

b. Identify each hose inside the left pull bar with tape

and marker. Determine which hose end is easier to

disconnect. Mark the other side of each connection.

c. Carefully crack each JIC connection to relieve any

unexpected residual pressure. Disconnect each

connection and drain it into a bucket.

d. Mark and disconnect any harness routed through

the pull bar.

e. Connect a fish line to the disconnected end of a

hose or harness.

f. Pull the hose and harness bundle out.

g. Add the supply tubing to the bundle.

h. Attach the bundle to the fish line. Pull the bundle

through the pull bar.

i. Re-establish all connections.

j. Perform a bleed before performing any hydraulic

lifts or folds.

2012-08-23 Table of Contents Index 402-382M

Page 28

24 Swath Command™ Table of Contents Index Great Plains Manufacturing, Inc.

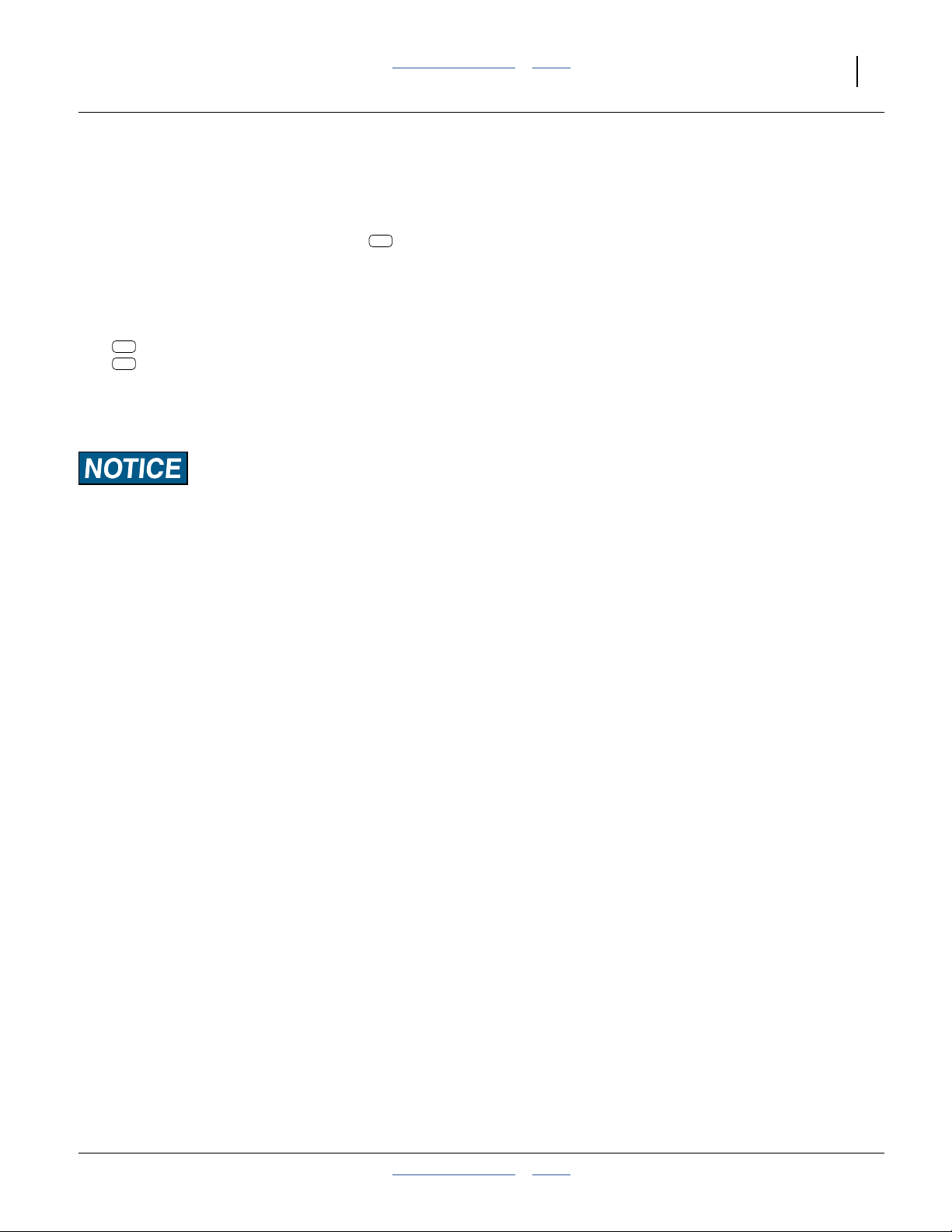

Install Harness

Determine Connections

146. Find the Clutch Layout for your planter model

(these are on page 48 through page 132).

Determine which valve is attached to which

WSMB-TCOM , and which outputs of the

WSMB.

Refer to Figure 23 (which is a generalized layout, and not

specific to any particular kit)

218

Connect WSMB Harnesses

Insert Left Wing WSMB Harness

147. On the left wing, locate a CANbus connection

near the first WSMB-TCOM . This connection

may be from the hitch lead, at the WSMT, or at an

existing WSMB.

148. Select one new:

219

467983505 DJIA OUTPUT HARN 8-CH TRU-COUN

Interconnect the four CANbus connectors into the

existing harness.

Connect the DEUTSCH connectors to the

WSMB-TCOM .

218

218

1

Insert Right Wing WSMB Harness

If your kit only had one WSMB, continue at “Connect

Valve Blocks” on page 25.

149. On the right wing, locate a CANbus connection

near the second WSMB-TCOM . This

connection may be at an existing WSMB, but is

more likely to be at the CANbus terminator .

150. Select one new:

219

467983505 DJIA OUTPUT HARN 8-CH TRU-COUN

Interconnect the four CANbus connectors into the

existing harness. In the case of a terminator

connection, one harness connector is left

unconnected, and the other on that side takes the

terminator.

Connect the DEUTSCH connectors to the

WSMB-TCOM .

218

218

18

1

1

Tru Count

Clutch Harness

467983505

219

2

Tru Count

Clutch Harness

467983505

219

18

CAN

Terminator

272

Tru Count

Solenoid

Module

WP6 Extension

264

265

Tru Count

Solenoid

Module

Tru Count

Solenoid

Module

272

272

218

WSMB

Tru Count

Output Module

Figure 23

Generalized Implement Harness Diagram

402-382M Table of Contents Index 2012-08-23

218

WSMB

Tru Count

Output Module

34246

Page 29

Great Plains Manufacturing, Inc. Table of Contents Index Install Harness 25

Connect Valve Blocks

Connect 1st Valve Block

151. Connect the 6-pin weatherpak connector marked for

outputs 1-4 to the first solenoid valve .

Connect 2nd Valve Block (if any)

152. Move to the next (second) valve. If the valve lead

cannot reach the WSMB to which it is assigned,

select one of:

264

823-336C EXTENSION HARNESS 25’6 PIN WP