Great Plains SS0300 Operator Manual

Table of Contents Index

Operator Manual

SS0300

Sub-Soiler Inline Ripper

Manufacturing, Inc.

www.greatplainsmfg.com

Read the operator’s manual entirely. When you see this symbol, the

subsequent instructions and warnings are serious - follow without

exception. Your life and the lives of others depend on it!

Null4:

Null4:

41935

Illustrations may show optional equipment not supplied with standard unit.

Null4:

EN

© Copyright 2011 Printed 09/19/2011 596-224M

Table of Contents Index

Blank page for correct duplexing.

Table of Contents Index

Table of Contents Index

Great Plains Manufacturing, Inc. Cover Index iii

Table of Contents

Equipment Identification .............................................1

Machine Label ................................................................1

Machine Record ............................................................. 2

Machine Log...............................................................2

Machine Details..........................................................2

Dealer Information......................................................2

Great Plains Regional Agent ......................................2

Introduction.....................................................................3

Description of Unit ..........................................................3

Using This Manual..........................................................4

Document Family........................................................4

Definitions................................................................... 4

Owner Assistance ..........................................................4

Important Safety Information ...................................... 5

Safety Reflectors and Decals .........................................9

Preparation and Setup ...............................................13

Prior to Going to the Field Checklist.............................13

Machine Adjustments ...................................................15

Pre-Leveling of Machine........................................... 15

Front to Rear Leveling ..........................................15

Gauge Wheel Adjustment.....................................16

Coulter Adjustment ...............................................16

Coulter Alignment .................................................16

Operating Instructions...............................................18

Pre-Start Checklist .......................................................18

Field Operation ............................................................ 18

Transporting................................................................. 19

Check Tractor Capacity and Configuration .............. 19

Transport Checklist .................................................. 19

Parking ................................................................. 19

Troubleshooting......................................................... 20

Maintenance and Lubrication ................................... 21

Storage................................................................. 21

Lubrication ................................................................... 22

Appendix..................................................................... 24

SS0300 Specifications and Capacities ........................ 24

Tire Inflation Chart ....................................................... 25

Torque Values Chart.................................................... 26

SS0300-03-70cm Machine Layout............................... 27

SS0300-03-75cm Machine Layout............................... 28

SS0300-04-70cm Machine Layout............................... 29

SS0300-04-75cm Machine Layout............................... 30

SS0300-05-68cm Machine Layout............................... 31

SS0300-05-70cm Machine Layout............................... 32

SS0300-06-54cm Machine Layout............................... 33

SS0300-06-56cm Machine Layout............................... 34

Appendix R - Regulatory Data .................................. 36

EC Declaration of Conformity ...................................... 36

Environmental Information ........................................... 37

Index............................................................................ 39

© Copyright 2006, 2007, 2008, 2009, 2010, 2011 All rights Reserved

Great Plains Manufacturing, Inc. provides this publication “as is” without warranty of any kind, either expressed or implied. While every precaution has been

taken in the preparation of this manual, Great Plains Manufacturing, Inc. assumes no responsibility for errors or omissions. Neither is any liability assumed for

damages resulting from the use of the information contained herein. Great Plains Manufacturing, Inc. reserves the right to revise and improve its products as

it sees fit. This publication describes the state of this product at the time of its publication, and may not reflect the product in the future.

09/19/2011 Cover Index 596-224M

Trademarks of Great Plains Manufacturing, Inc. include: Singulator Plus, Swath Command, Terra-Tine.

Registered Trademarks of Great Plains Manufacturing, Inc. include:

Air-Pro, Clear-Shot, Great Plains, Land Pride, MeterCone, Nutri-Pro, Seed-Lok, Solid Stand, Whirlfilter, Yield-Pro.

Brand and Product Names that appear and are owned by others are trademarks of their respective owners.

Printed in the United States of America

iv SS0300 Table of Contents Index Great Plains Manufacturing, Inc.

596-224M Table of Contents Index 09/19/2011

Great Plains Manufacturing, Inc. Table of Contents Index 1

Equipment Identification

This Operator manual applies to the following Great

Plains pull-type secondary conventional tillage systems:

SS0300 70cm-centers, 3-shank, 1-section

SS0300 77cm-centers, 3-shank, 1-section

SS0300 70cm-centers, 4-shank, 1-section

SS0300 75cm-centers, 4-shank, 1-section

SS0300 68cm-centers, 5-shank, 1-section

SS0300 70cm-centers, 5-shank, 1-section

SS0300 54cm-centers, 6-shank, 1-section

SS0300 56cm-centers, 6-shank, 1-section

See “SS0300 Specifications and Capacities” on

page 24 for precise swath information.

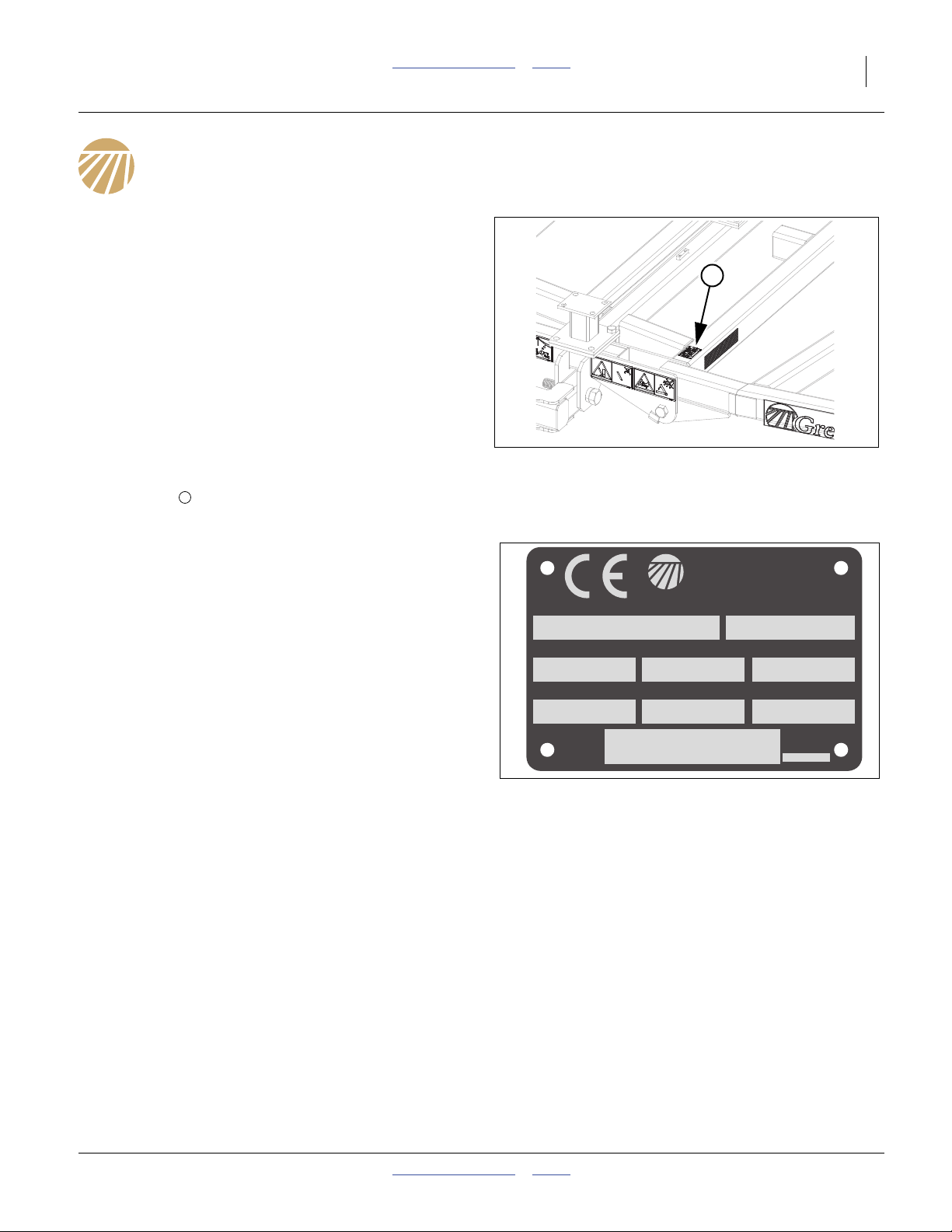

Refer to Figure 1

For positive equipment identification, consult the

machine label located on the top of the left hand hitch

1

truss, near the single point depth control.

Null4:

600 dpi

.tif

Label/Plate Location

Figure 1

1

41585

_55%

Machine Label

Models SS0300 can be built to European regulatory and

highway transport standards. See “EC Declaration of

Conformity” on page 36 for full details. The machine can

also be built to North American regulatory and highway

transport standards, depending on which light option

package is purchased.

Refer to Figure 2 (which is NOT from an actual machine)

The machine label provides data which is specific to your

machine as originally shipped from the factory.

If you, or the dealer, have added Options not originally

ordered with the machine, or removed Options that were

originally ordered, the weights and measurements no

longer are accurate for your machine. Update the Record

on the next page upon modifications.

See “SS0300 Specifications and Capacities” on

page 24 for additional weights and measurements.

Great Plains

Manufacturing, Inc.

P.O. Box 5060

Model Number: Serial Number:

Salina, KS 67401 USA

GP-1398YYSS0300

Working Width m: Transport Width m: Year of Manufacture:

Total Weight kg:

99999 Kg

Axle Load kg: Vertical Load kg:

N/A

*GP-1398YY*

A1196X

Null4:

.eps

100%

Figure 2:SS0300:

Example Machine Label

201199.9 m99.9 m

99999 Kg

819-000C

422283

09/19/2011 Table of Contents Index 596-224M

2 SS0300 Table of Contents Index Great Plains Manufacturing, Inc.

Machine Record

Machine Details

Record your machine details in the Log at right. If you

replace this manual, be sure to transfer this information

to the similar page of the new manual.

If you add or remove Options, update the Log. If the page

cannot be legibly updated, request or print a new Operator manual.

Dealer Information

My Customer

Number / ID

Dealer Name

Street

Place

Post Code

Country

Voice

Machine Log

Machine Model

Serial Number

Working Width

Transport Width

Maximum Gross Weight

Maximum Axle Load

Year of Manufacture

Date of Delivery

Date in Service

Options

Fax

Web

Email

Great Plains Regional Agent

(If different than those on page 4)

Agent Voice

Street Fax

Place Web

Post Code Email

Country

596-224M Table of Contents Index 09/19/2011

Great Plains Manufacturing, Inc. Table of Contents Index Equipment Identification 3

Introduction

Great Plains welcomes you to its growing family of new

product owners. Your Sub-Soiler SS0300 has been

designed with care and built by skilled workers using quality materials. Proper setup, maintenance, and safe operating practices will help you get years of satisfactory use

from the machine.

Before placing the machine into service for the first time,

read and understand this manual, in particular the

“Important Safety Information”, pages 5 to 8. Have all

operators read this manual before allowing them to work

with the machine.

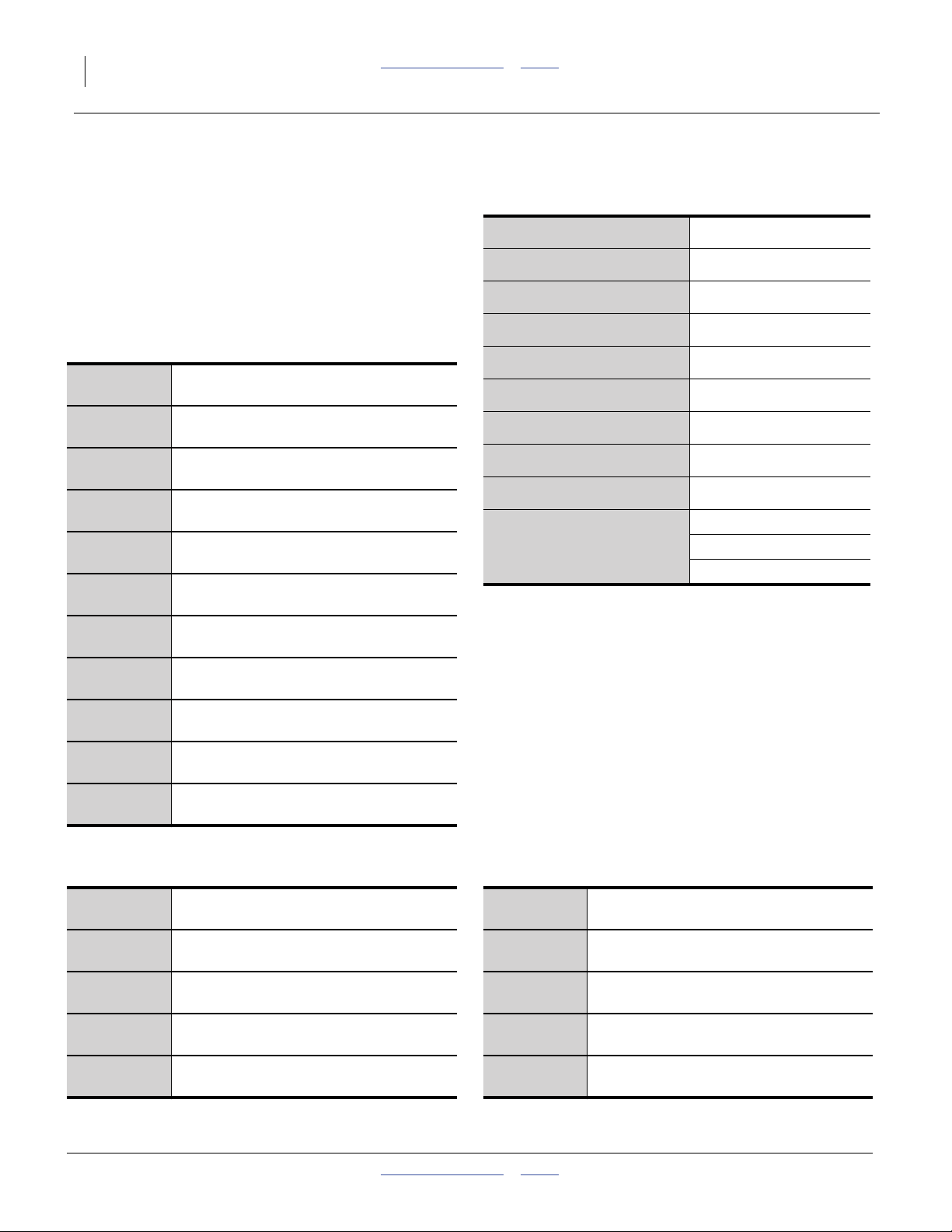

Description of Unit

The SS0300 Inline Ripper is a one-section machine. It is

designed to break up soil crust on hard dried fields while

eliminating compaction layers. An optional berm conditioner may be added to the rear of each shank.

Null4:

R

L

Figure 3

SS0300 Sub-Soiler

R

F

U

B

L

D

42286

09/19/2011 Table of Contents Index 596-224M

4 SS0300 Table of Contents Index Great Plains Manufacturing, Inc.

Using This Manual

This manual will familiarize you with safety, hitching,

operation, adjustments, troubleshooting, and maintenance. Read this manual and follow the recommendations to help ensure safe and efficient operation.

The information in this manual is current at printing.

Some parts may change to assure top performance.

Document Family

596-224M Operator Manual (this document)

596-224P Parts Manual

Definitions

Safety admonishment signal words are described on

page 5.

The following terms are used throughout this manual.

Identifies an Economic (not a Safety) Risk:

NOTICE provides a crucial point of information related to the

current topic. Read and follow the instructions to avoid damage

to equipment and ensure desired field results.

Note: This form sets off useful information related to the

current topic, or forestalls possible misunderstanding.

Right-hand and left-hand as used in

this manual are determined by facing

the direction the machine will travel

while in use unless otherwise stated.

An orientation rose in some line art

illustrations shows the directions of:

Up, Back, Left, Down, Front, Right.

R

F

U

B

L

D

Owner Assistance

parts and equipment specially designed for Great Plains

products.

Your machine’s parts were specially designed and

should only be replaced with Great Plains parts. Always

use the serial and model number (page 1) when ordering

parts from your Great Plains dealer.

Your Great Plains dealer wants you to be satisfied with

your new machine. If you do not understand any part of

this manual or are not satisfied with the service received,

please take the following actions.

Null4:

1. Discuss the matter with your dealership service

manager. Make sure they are aware of any problems

so they can assist you.

2. If you are still unsatisfied, seek out the owner or general manager of the dealership.

For further assistance contact Great Plains via the Agent

recorded on page 2, or at:

For U.K. and Europe

SIMBA Great Plains

Woodbridge Road Ind. East

Sleaford

Lincolnshire NG34 7EW England

Voice:+44 (0) 1529 304654

Fax:+44 (0) 1529 413468

Email:simba.international@simba.co.uk

For Other Regions

Great Plains Manufacturing, Inc.

PO Box 5060

Salina KS 67402-5060 USA

Voice:+(800)255-9215

Fax:+1 785-822-6722

Email:gp_web_cs@greatplainsmfg.com

If you need customer service or repair parts, contact a

Great Plains dealer. They have trained personnel, repair

596-224M Table of Contents Index 09/19/2011

Great Plains Manufacturing, Inc. Table of Contents Index 5

Important Safety Information

Look for Safety Symbol

The SAFETY ALERT SYMBOL1 indicates there is a

potential hazard to personal safety involved and extra

safety precaution must be taken. When you see this

symbol, be alert and carefully read the message that follows it. In addition to design and configuration of equipment, hazard control and accident prevention are

dependent upon the awareness, concern, prudence and

proper training of personnel involved in the operation,

transport, maintenance and storage of equipment.

Be Aware of Signal Words

Signal words designate a degree or level of hazard seriousness.

DANGER, and the colour Safety Red, indicate an

imminent hazard which, if not avoided, will result in death

or serious injury. This signal word is limited to the most

extreme situations, typically for machine components

that, for functional purposes, cannot be guarded.

WARNING, and the colour Safety Orange, indicate a

potential hazard which, if not avoided, could result in

death or serious injury, and includes hazards that are

exposed when guards are removed. It may also be used

to alert against unsafe practices.

CAUTION, and the colour Safety Yellow, indicate a

potential hazard which, if not avoided, may result in

minor or moderate injury. It may also be used to alert

against unsafe practices.

Prepare for Emergencies

▲ Be prepared if a fire starts

▲ Keep a first aid kit and fire extinguisher handy.

▲ Keep emergency numbers for doctor, ambulance, hospital

and fire department near phone.

Be Familiar with Safety Decals

▲ Read and understand “Safety Reflectors and Decals”on

page 9, thoroughly.

▲ Read all instructions noted on the decals.

▲ Keep decals clean. Replace damaged, faded and illegible

decals.

1. Symbols and colours in this manual, and on north american models, are based on ANSI standard Z535.

Decals on international models are based on ISO standard 3864.

09/19/2011 Table of Contents Index 596-224M

6 SS0300 Table of Contents Index Great Plains Manufacturing, Inc.

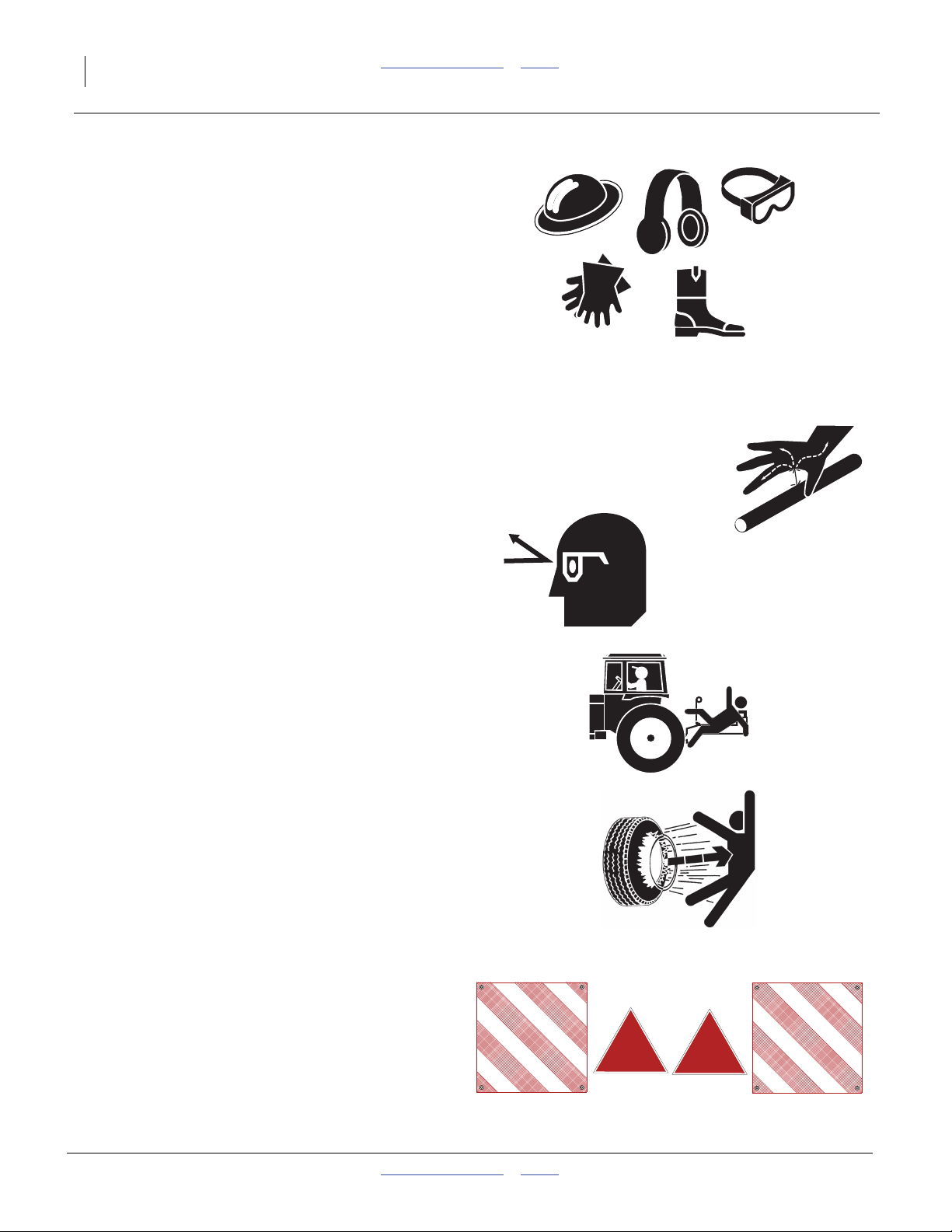

Wear Protective Equipment

▲ Wear protective clothing and equipment.

▲ Wear clothing and equipment appropriate for the job. Avoid

loose-fitting clothing.

▲ Because prolonged exposure to loud noise can cause hear-

ing impairment or hearing loss, wear suitable hearing protection such as earmuffs or earplugs.

▲ Because operating equipment safely requires your full

attention, avoid wearing entertainment headphones while

operating machinery.

Avoid High Pressure Fluids

Escaping fluid under pressure can penetrate the skin,

causing serious injury.

▲ Avoid the hazard by relieving pressure at other remote, and

shutting down tractor before connecting, disconnecting or

inspecting hydraulic lines.

▲ Use a piece of paper or cardboard, NOT BODY PARTS, to

check for suspected leaks.

▲ Wear protective gloves and safety glasses or goggles when

working with hydraulic systems.

▲ If an accident occurs, seek immediate medical assistance

from a physician familiar with this type of injury.

Keep Riders Off Machinery

Riders obstruct the operator’s view. Riders could be

struck by foreign objects or thrown from the machine.

▲ Never allow children to operate equipment.

▲ Keep all bystanders away from machine during operation.

Tire Safety

Tire changing can be dangerous. Employ trained personnel using correct tools and equipment.

▲ When inflating tires, use a clip-on chuck and extension hose

long enough for you to stand to one side–not in front of or

over tire assembly. Use a safety cage if available.

▲ When removing and installing wheels, use wheel-handling

equipment adequate for weight involved.

Use Safety Lights and Devices

Slow-moving tractors and towed implements can create

a hazard when driven on public roads. They are difficult

to see, especially at night.

▲ Use flashing warning lights and turn signals whenever driv-

ing on public roads.

▲ Use lights and devices provided with implement.

596-224M Table of Contents Index 09/19/2011

Great Plains Manufacturing, Inc. Table of Contents Index Important Safety Information 7

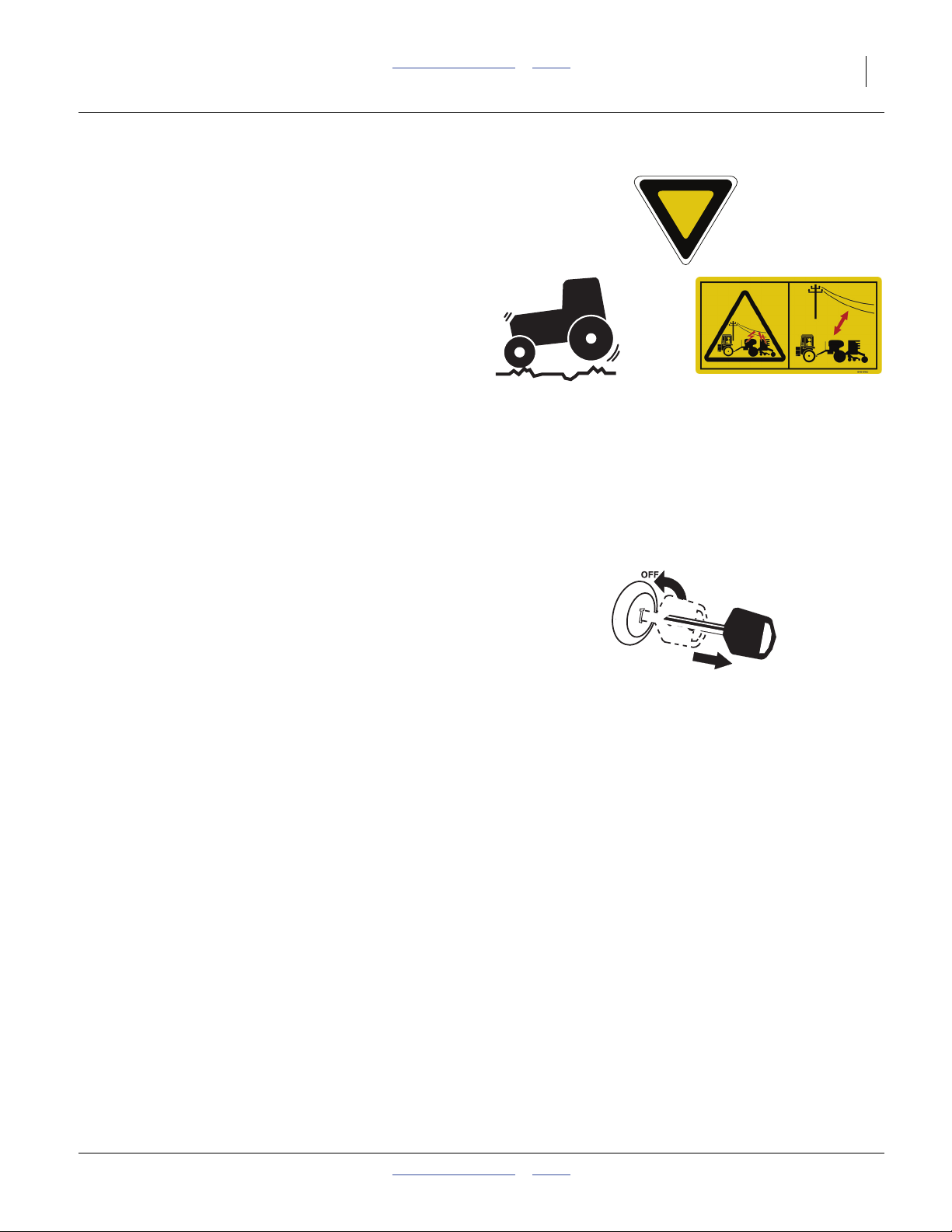

Transport Machinery Safely

Maximum transport speed for implement is 30 kph.

Some rough terrains require a slower speed. Sudden

braking can cause a towed load to swerve and upset.

▲ Do not exceed 30 kph or 20 mph. Never travel at a speed

which does not allow adequate control of steering and stopping. Reduce speed if towed load is not equipped with

brakes.

▲ Comply with national, regional and local laws.

▲ Do not tow an implement or nurse tank that weighs more

than 1.5 times the weight of towing vehicle.

▲ Carry reflectors or flags to mark Sub-Soiler in case of

breakdown on the road.

▲ Keep clear of overhead power lines and other obstructions

when transporting. Refer to transport dimensions under

“SS0300 Specifications and Capacities” on page 24.

▲ Reduce speed on rough roads.

▲ Do not fold or unfold the Sub-Soiler while the tractor is

moving.

Shutdown and Storage

▲ Lower Sub-Soiler, put tractor in park, turn off engine, and

remove the key.

▲ Secure Sub-Soiler using parking stands provided.

▲ Detach and store Sub-Soiler in an area where children nor-

mally do not play.

Null4:

09/19/2011 Table of Contents Index 596-224M

8 SS0300 Table of Contents Index Great Plains Manufacturing, Inc.

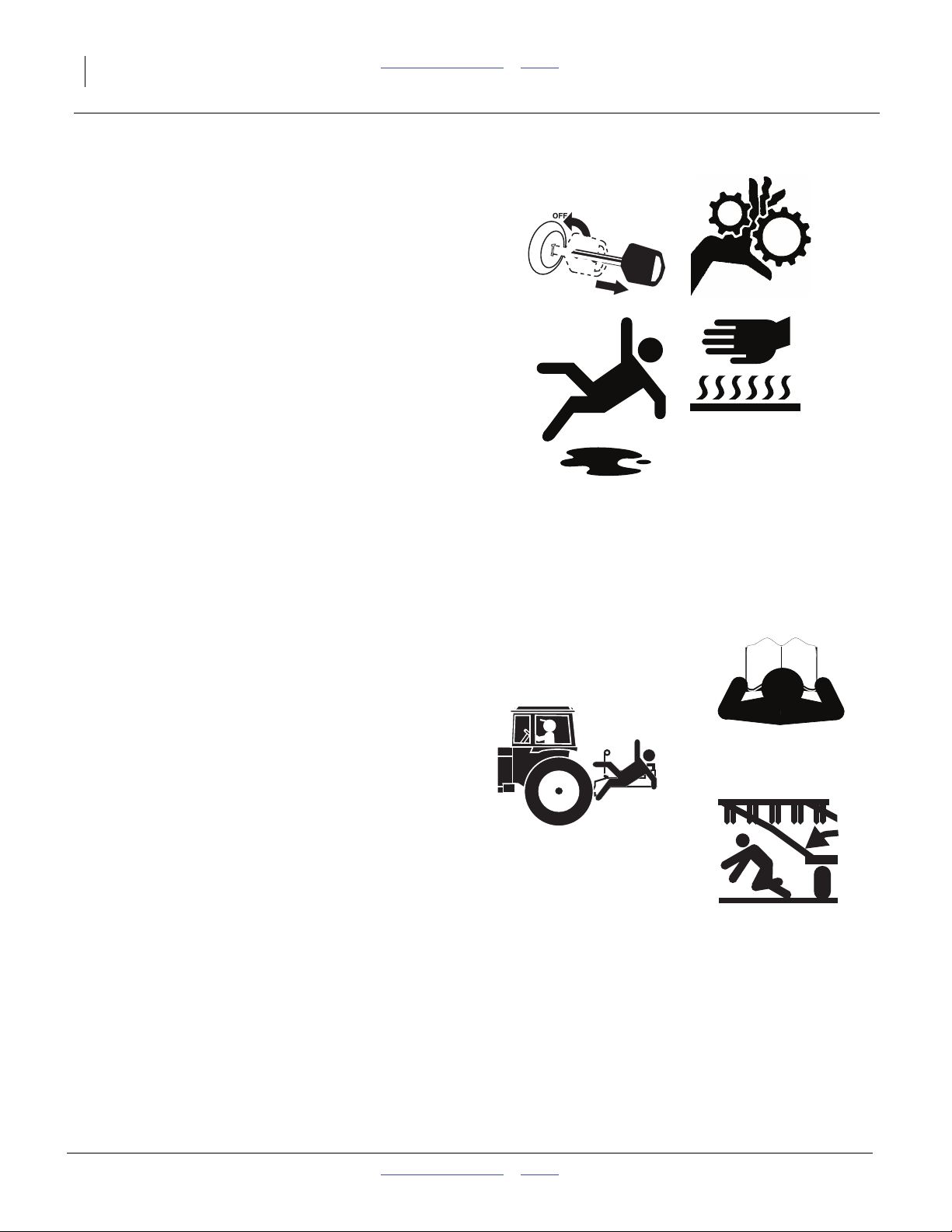

Practice Safe Maintenance

▲ Understand procedure before doing work. Use proper

tools and equipment.

▲ Work in a clean, dry area.

▲ Unfold and lower the implement, put tractor in park, turn

off engine, and remove key before performing maintenance. If work must be performed with implement raised,

use centre section lift lock and gauge lock channels provided.

▲ Make sure all moving parts have stopped and all system

pressure is relieved.

▲ Allow machine to cool completely.

▲ Disconnect battery ground cable (-) before servicing or

adjusting electrical systems.

▲ Welding: Disconnect battery ground. Protect hydraulic

lines. Avoid fumes from heated paint.

▲ Inspect all parts. Make sure parts are in good condition

and installed properly.

▲ Remove buildup of grease, oil or debris.

▲ Remove all tools and unused parts from Sub-Soiler before

operation.

Safety At All Times

Thoroughly read and understand the instructions in this

manual before operation. Read all instructions noted on

the safety decals.

▲ Be familiar with all Sub-Soiler functions.

▲ Operate machinery from the driver’s seat only.

▲ Do not leave Sub-Soiler unattended with tractor engine

running.

▲ Do not stand between the tractor and implement, or imple-

ment and nurse tank during hitching.

▲ Keep hands, feet and clothing away from power-driven

parts.

▲ Wear snug-fitting clothing to avoid entanglement with mov-

ing parts.

▲ Watch out for wires, trees, etc., when folding and raising

Sub-Soiler. Make sure all persons are clear of working

area.

Accident Prevention

▲ In addition to the Operating Instructions, it is important to

observe the accident prevention regulations specified by

agricultural trade associations. It is the Operator’s responsibility to ensure that all other persons are excluded from

danger zones surrounding or on the machine during its

operation.

596-224M Table of Contents Index 09/19/2011

Great Plains Manufacturing, Inc. Table of Contents Index Important Safety Information 9

It is the Owner’s Responsibility to Ensure;

▲ The Operator is trained and competent to use the machine

and tractor.

▲ The tractor is suitable for the machine.

▲ Adequate Risk and COSHH assessments have been under-

taken regarding the machine’s use, Specifically, these

include issues concerning contact with the soil, crop residues, chemicals, lubricants and other compounds during

operation, maintenance, and he possibility of stones being

ejected at high speed during work.

Beware of trapping hazards when manipulating the parking

jacks or other moving parts. Ensure any heavy components are

fully supported when removing pins/bolts. Safety Decals

Safety Reflectors and Decals

Your implement comes equipped with all lights, safety

reflectors and decals in place. They were designed to

help you safely operate your implement.

▲ Read and follow decal directions.

▲ Keep lights in operating condition.

▲ Keep all safety decals clean and legible.

▲ Replace all damaged or missing decals. Order new decals

from your Great Plains dealer. Refer to this section for

proper decal placement.

▲ When ordering new parts or components, also request cor-

responding safety decals.

To install new decals:

3. Clean the area on which the decal is to be placed.

4. Peel backing from decal. Press firmly on surface,

being careful not to cause air bubbles under decal.

41936

833-398C

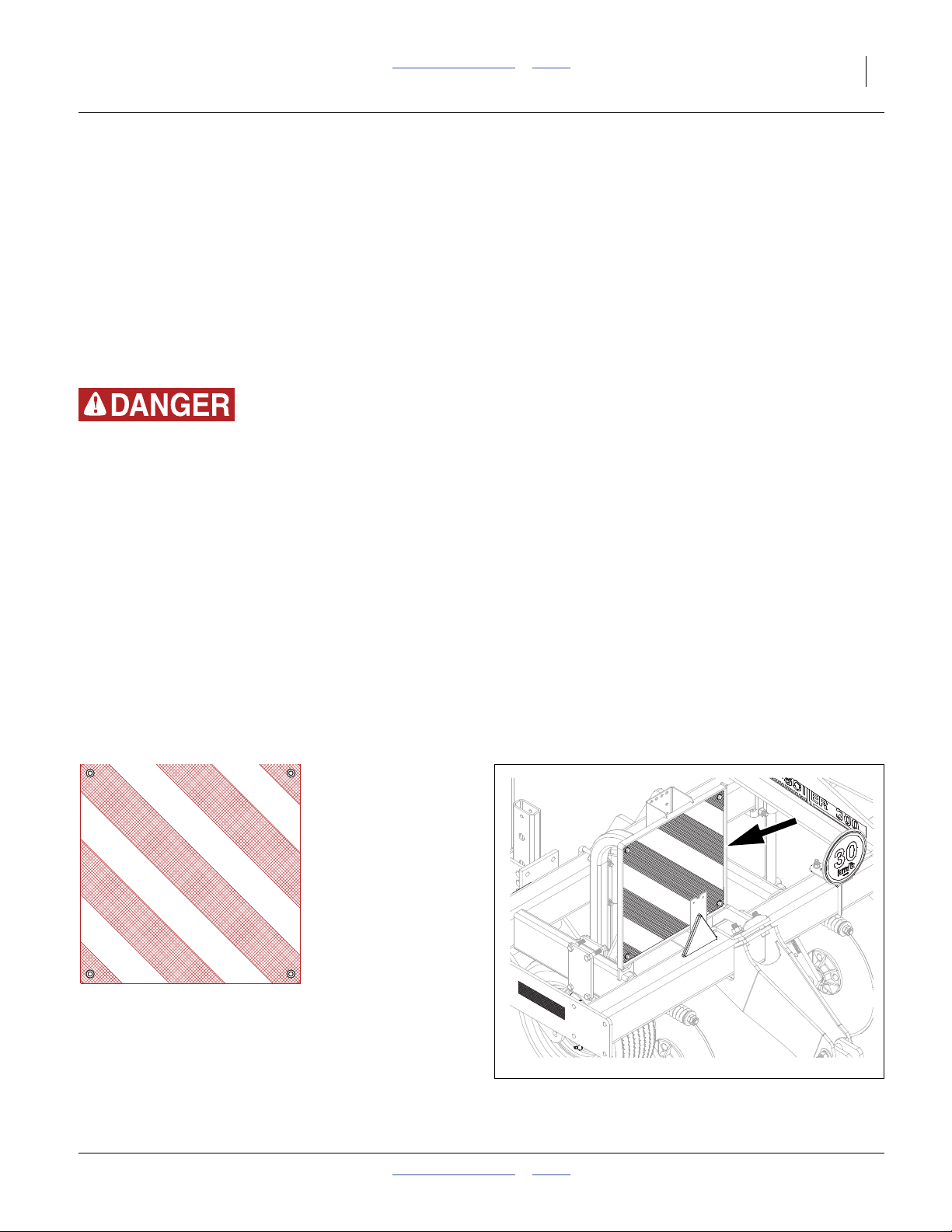

Fluorescent Reflector

On the back sign mount weldment both sides.

2 total

09/19/2011 Table of Contents Index 596-224M

10 SS0300 Table of Contents Index Great Plains Manufacturing, Inc.

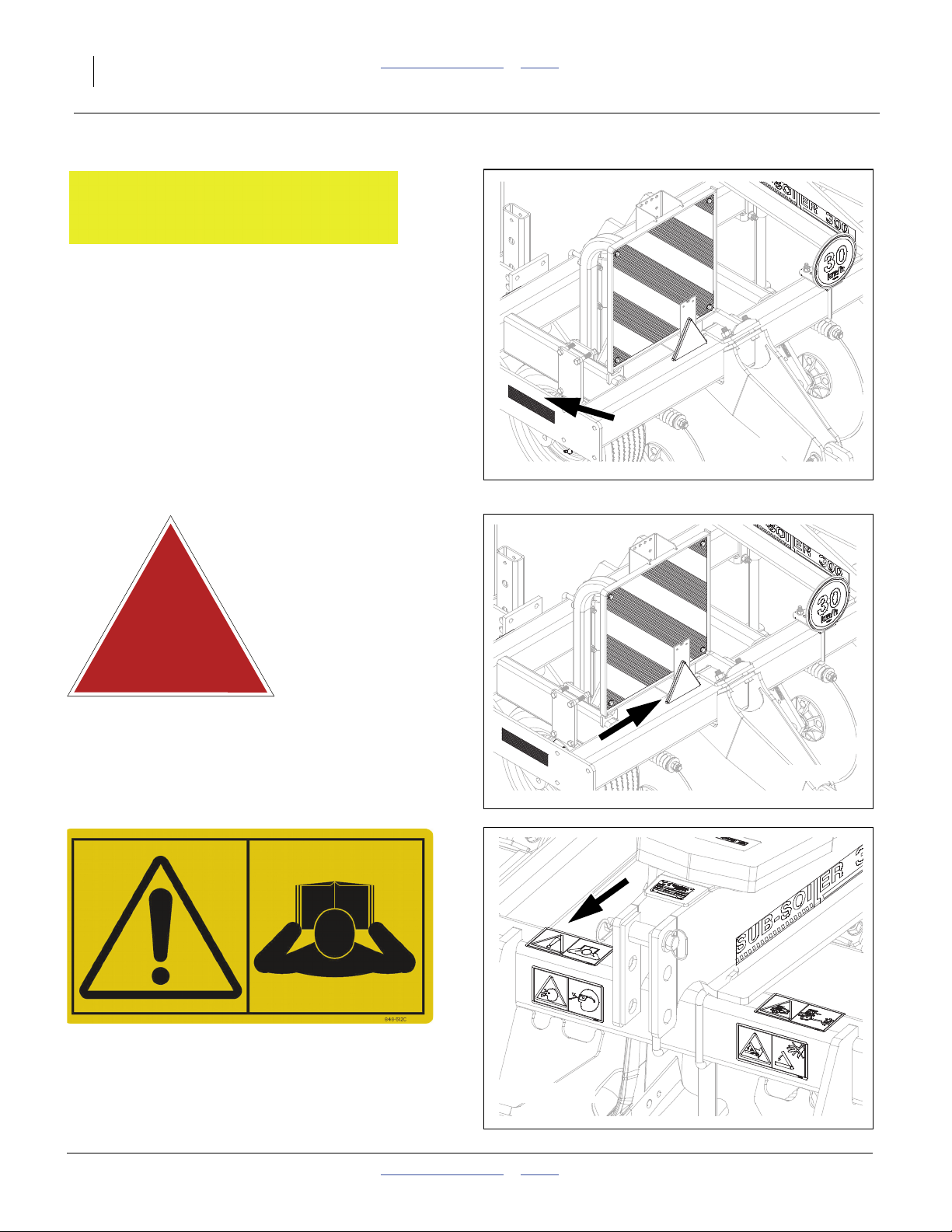

838-615C

Amber Reflectors

On outside of ripper frame, both sides.

2total

41936

833-399C

Red Triangle Reflector

On rear of speed limit bracket, both sides;

2 total

Null4:

Null4:

41936

848-512C Pic: Read Manual

On front, top of ripper frame.

1 total

596-224M Table of Contents Index 09/19/2011

41937

Loading...

Loading...