Great Plains SR5030 Operator Manual

PINK

Operator’s Manual

SR5030

Split-Row Planter

Model Serial No.

SR5030 KK1000, KK1005,

Manufacturing, Inc.

www .g reatplainsmfg.com

KK1006, KK1010 and

Later

Read the operator’s manual entirely. When you see this symbol, the subsequent in-

!

structions and warnings are serious - follow without exception. Your life and the lives of

others depend on it!

17732

© Copyright 1999 Printed

4/12/2005

Cover illustration may show optional equipment not supplied with standard unit.

401-140M-A

Table of Contents

Table of Contents

Great Plains Mfg., Inc.

Important Safety Information . . . . . . . . . . . . . . . . . 1

Safety Decals. . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Description of Unit. . . . . . . . . . . . . . . . . . . . . . . . 6

Intended Usage. . . . . . . . . . . . . . . . . . . . . . . 6

Using This Manual. . . . . . . . . . . . . . . . . . . . . . . . 6

Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Owner Assistance . . . . . . . . . . . . . . . . . . . . . . . . 6

Section 1 Preparation and Setup . . . . . . . . . . . . . . 7

Prestart Checklist . . . . . . . . . . . . . . . . . . . . . . . . 7

Hitching Planters to Tractor . . . . . . . . . . . . . . . . . 7

Leveling Planter. . . . . . . . . . . . . . . . . . . . . . . . . . 8

Section 2 Operating Instructions . . . . . . . . . . . . . . 9

Prestart Checklist . . . . . . . . . . . . . . . . . . . . . . . . 9

Field Operation . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Meter Clutches . . . . . . . . . . . . . . . . . . . . . . . 9

Row Unit Operation. . . . . . . . . . . . . . . . . . . . 9

Transporting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Parking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Section 3 Adjustments . . . . . . . . . . . . . . . . . . . . . 11

Row Unit Adjustments. . . . . . . . . . . . . . . . . . . . 11

Down Pressure . . . . . . . . . . . . . . . . . . . . . . 11

Down Pressure Charts . . . . . . . . . . . . . . . . 11

Coulter Depth . . . . . . . . . . . . . . . . . . . . . . . 11

Opener Seeding Depth . . . . . . . . . . . . . . . . 11

Side Gauge Wheels . . . . . . . . . . . . . . . . . . 12

1 x 12 Closing Wheel Option. . . . . . . . . . . . 13

Closing Disk Option. . . . . . . . . . . . . . . . . . . 13

Planting Rate. . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Transmission Adjustment . . . . . . . . . . . . . . 14

Checking Planting Population . . . . . . . . . . . 14

Planting Rate Charts . . . . . . . . . . . . . . . . . . . . . 15

Finger Pickup Meters for Corn . . . . . . . . . . 15

Brush Meters . . . . . . . . . . . . . . . . . . . . . . . . 16

Meter Drive Adjustments . . . . . . . . . . . . . . . . . . 17

Seed-Lok Lock Up . . . . . . . . . . . . . . . . . . . . . . . 17

Section 4 Troubleshooting. . . . . . . . . . . . . . . . . . . 18

Section 5 Maintenance and Lubrication. . . . . . . . 20

Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Finger Pickup Meter. . . . . . . . . . . . . . . . . . . 20

Opener Disks, Scrapers and Gauge Wheels21

Chain Tension . . . . . . . . . . . . . . . . . . . . . . . 22

Storage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Gauge Wheel Module . . . . . . . . . . . . . . . . . 24

Gauge Wheel Chain . . . . . . . . . . . . . . . . . . 24

Side Gauge Wheel Arms. . . . . . . . . . . . . . . 25

Counter Shaft Chain . . . . . . . . . . . . . . . . . . 25

Transmission Chain . . . . . . . . . . . . . . . . . . . 25

Meter Drive Chain . . . . . . . . . . . . . . . . . . . . 25

Finger Pickup Meter. . . . . . . . . . . . . . . . . . . 26

Section 6 Options. . . . . . . . . . . . . . . . . . . . . . . . . . 28

Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Coulter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Terra Tine. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Seed-Lok Firming Wheels . . . . . . . . . . . . . . . . . 29

Heavy Duty Spring Package. . . . . . . . . . . . . . . . 29

Section 7 Specifications and Capacities . . . . . . . 30

Tire Inflation Chart . . . . . . . . . . . . . . . . . . . . . . . 30

Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Torque Values Chart for Common Bolt Sizes. . . 31

© Copyright 1999 All rights Reserved

Great Plains Manufacturing, Inc. provides this publication “as is” without warr anty of any kind, either expressed or implied. W hile ev ery precaution has been taken in the preparation

of this manual, Great Plains Manufacturing, Inc. assumes no responsibility for errors or omissions . Neither is any liability assumed for damages resulting from the use of the inf ormation contained herein. Great Plains Manufacturing, Inc. reserves the right to revise and improve its products as it sees fit. This publication describes the state of this product at the

time of its publication, and may not reflect the product in the future.

The following are trademarks of Great Plains Mfg., Inc.: Application Systems, Ausherman, Land Pride, Great Plains, Seed-Lok

All other brands and product names are trademarks or registered trademarks of their respective holders.

SR5030 Split-Row Planter 401-140M-A 4/12/05

Great Plains Manufacturing, Incorporated Trademarks

Printed in the United States of America.

Great Plains Mfg., Inc.

Important Safety Information

Important Safety Information

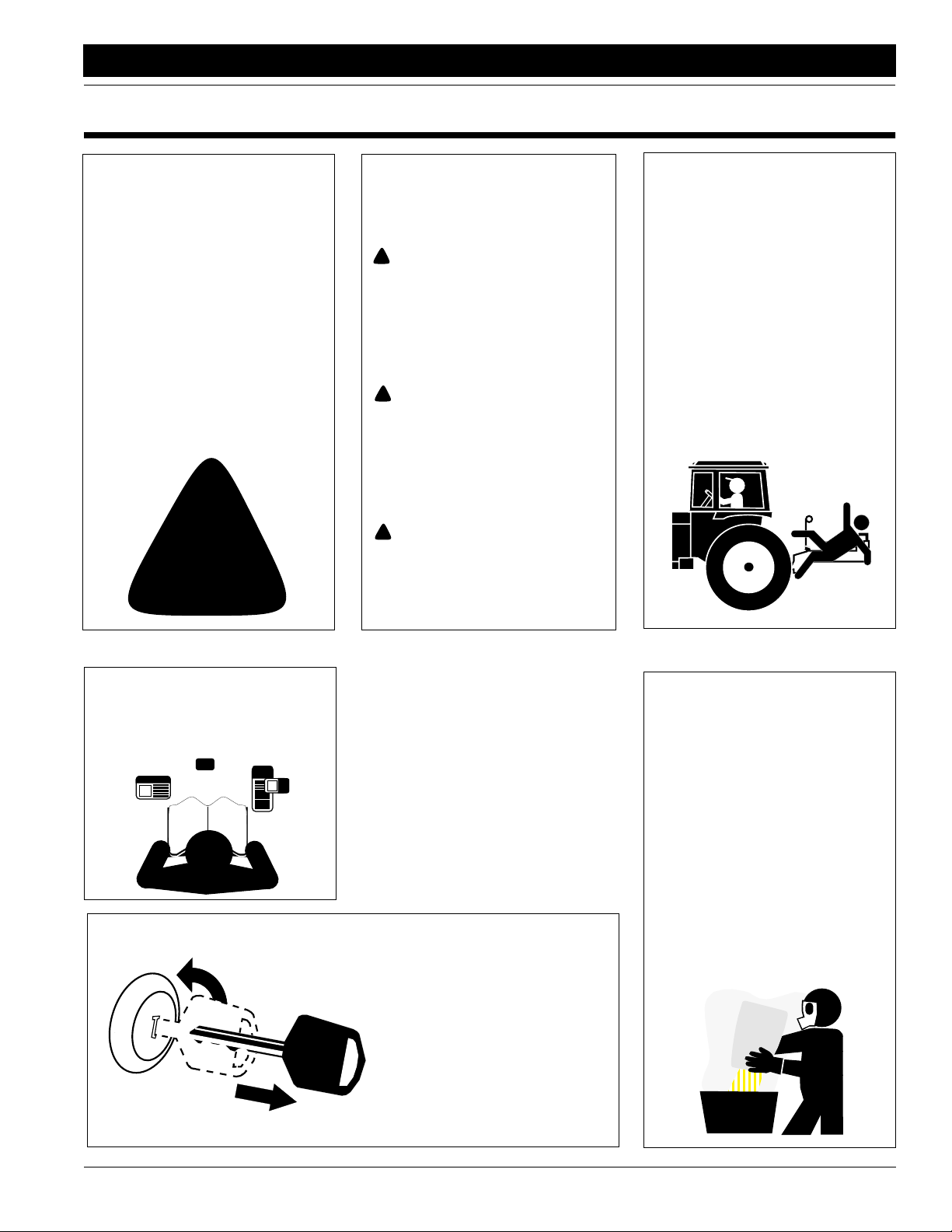

Look for Safety Symbol

The SAFETY ALERT SYMBOL indicates there is a potential hazard to

personal safety involved and extra

safety precaution must be taken.

When you see this symbol, be alert

and carefully read the message that

follows it. In addition to design and

configuration of equipment, hazard

control and accident prevention are

dependent upon the awareness, concern, prudence and proper training of

personnel involved in the operation,

transport, maintenance and storage

of equipment.

!

Be Aware of Signal Words

Signal words designate a degree or

level of hazard seriousness. The signal words are:

!

DANGER!

Indicates an imminently hazardous

situation which, if not avoided, will

result in death or serious injury. This

signal word is limited to the most

extreme situations, typically for

machine components that, for functional purposes, cannot be guarded.

!

WARNING!

Indicates a potentially hazardous situation which, if not avoided, could

result in death or serious injury, and

includes hazards that are exposed

when guards are removed. It may

also be used to alert against unsafe

practices.

!

CAUTION!

Indicates a potentially hazardous situation which, if not avoided, may

result in minor or moderate injury. It

may also be used to alert against

unsafe practices.

Keep Riders

Off Machinery

Riders obstruct the operator’s view.

Riders could be struck by foreign

objects or thrown from machine.

▲ Never allow riders on implement.

▲ Never allow children to operate

equipment.

For Your Protection

▲ Thoroughly read and understand

Safety Decals, page 4. Read all

instructions noted on decals.

OFF

Shutdown and Storage

▲ Lower machine to ground, put

tractor in park, turn off engine,

and remove key.

▲ Detach and store implement in an

area where children normally do

not play. Secure implement with

blocks and supports.

Handle

Chemicals Properly

Agricultural chemicals can be dangerous. Improper use can seriously

injure persons, animals, plants, soil

and property.

▲ Wear protective clothing.

▲ Handle all chemicals with care.

▲ Follow instructions on container

label.

▲ Avoid inhaling smoke from any

type of chemical fire.

▲ Store or dispose of unused chem-

icals as specified by chemical

manufacturer.

4/12/05

SR5030 Split-Row Planter 401-140M-A

1

Important Safety Information

Great Plains Mfg., Inc.

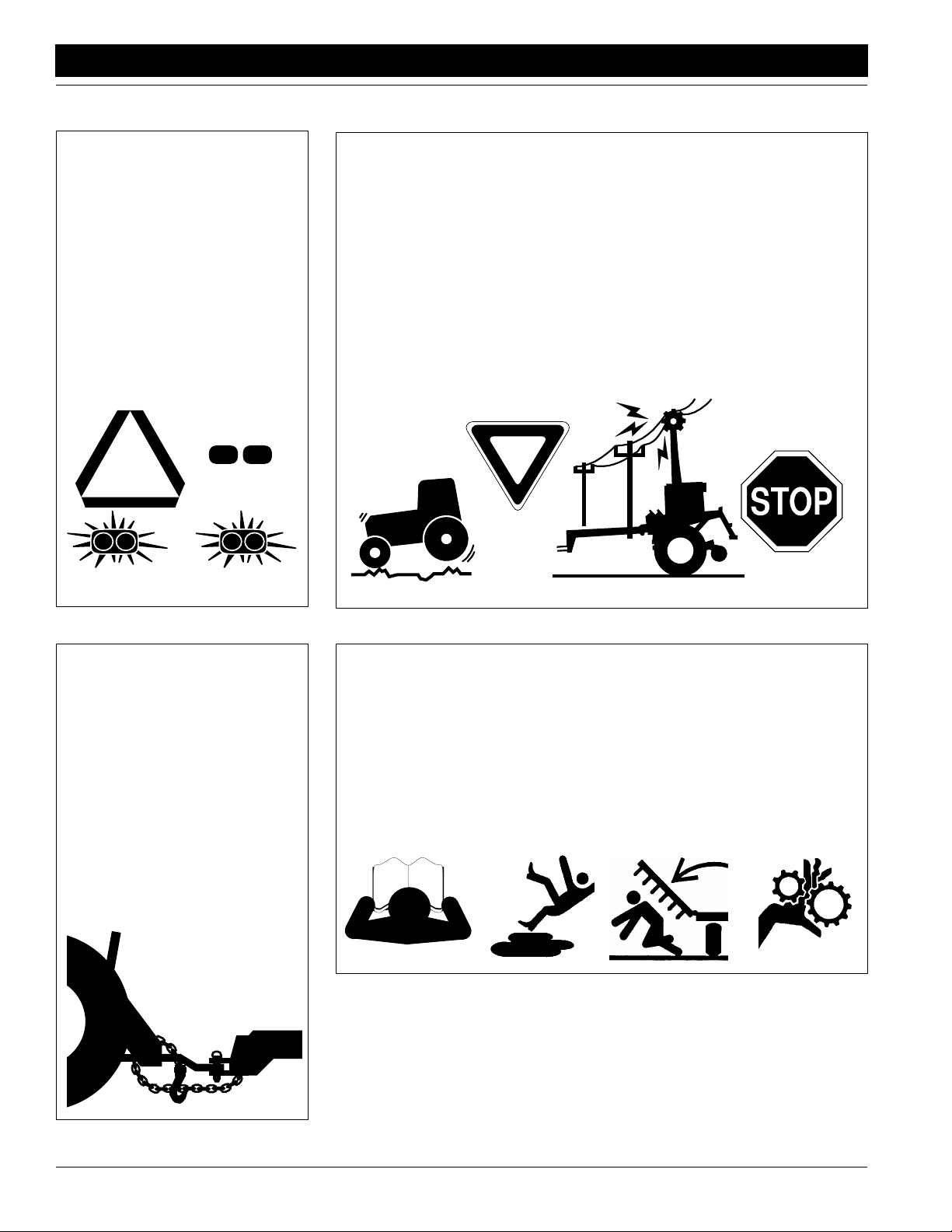

Use Safety

Lights and Devices

Slow-moving tractors, self-propelled

equipment and towed implements

can create a hazard when driven on

public roads. They are difficult to see,

especially at night.

▲ Use flashing warning lights and

turn signals whenever driving on

public roads.

▲ Use lights and devices provided

with implement.

Transport

Machinery Safely

Maximum transport speed for implement is 20 mph. Some rough terrains

require a slower speed. Sudden

braking can cause a towed load to

swerve and upset.

▲ Do not exceed 20 mph. Never

travel at a speed which does not

allow adequate control of steering

and stopping. Reduce speed if

towed load is not equipped with

brakes.

▲ Comply with state and local laws.

▲ Do not tow an implement that,

when fully loaded, weighs more

than 1.5 times the weight of towing vehicle.

Use A Safety Chain

▲ Use a safety chain to help con-

trol drawn machinery should it

separate from tractor drawbar.

▲ Use a chain with a strength rat-

ing equal to or greater than the

gross weight of towed machinery.

▲ Attach chain to tractor drawbar

support or other specified

anchor location. Allow only

enough slack in chain to permit

turning.

▲ Replace chain if any links or end

fittings are broken, stretched or

damaged.

▲ Do not use safety

chain for towing.

Practice Safe Maintenance

▲ Understand procedure before

doing work. Use proper tools and

equipment. Refer to this manual

for additional information.

▲ Work in a clean, dry area.

▲ Lower implement to ground, put

tractor in park, turn off engine,

and remove ke y before performing

maintenance.

▲ Allow implement to cool completely.

▲ Inspect all parts. Make sure parts

are in good condition and installed

properly.

▲ Remove buildup of grease, oil or

debris.

▲ Remove all tools and unused

parts from implement before operation.

SR5030 Split-Row Planter 401-140M-A 4/12/05

2

Great Plains Mfg., Inc.

Important Safety Information

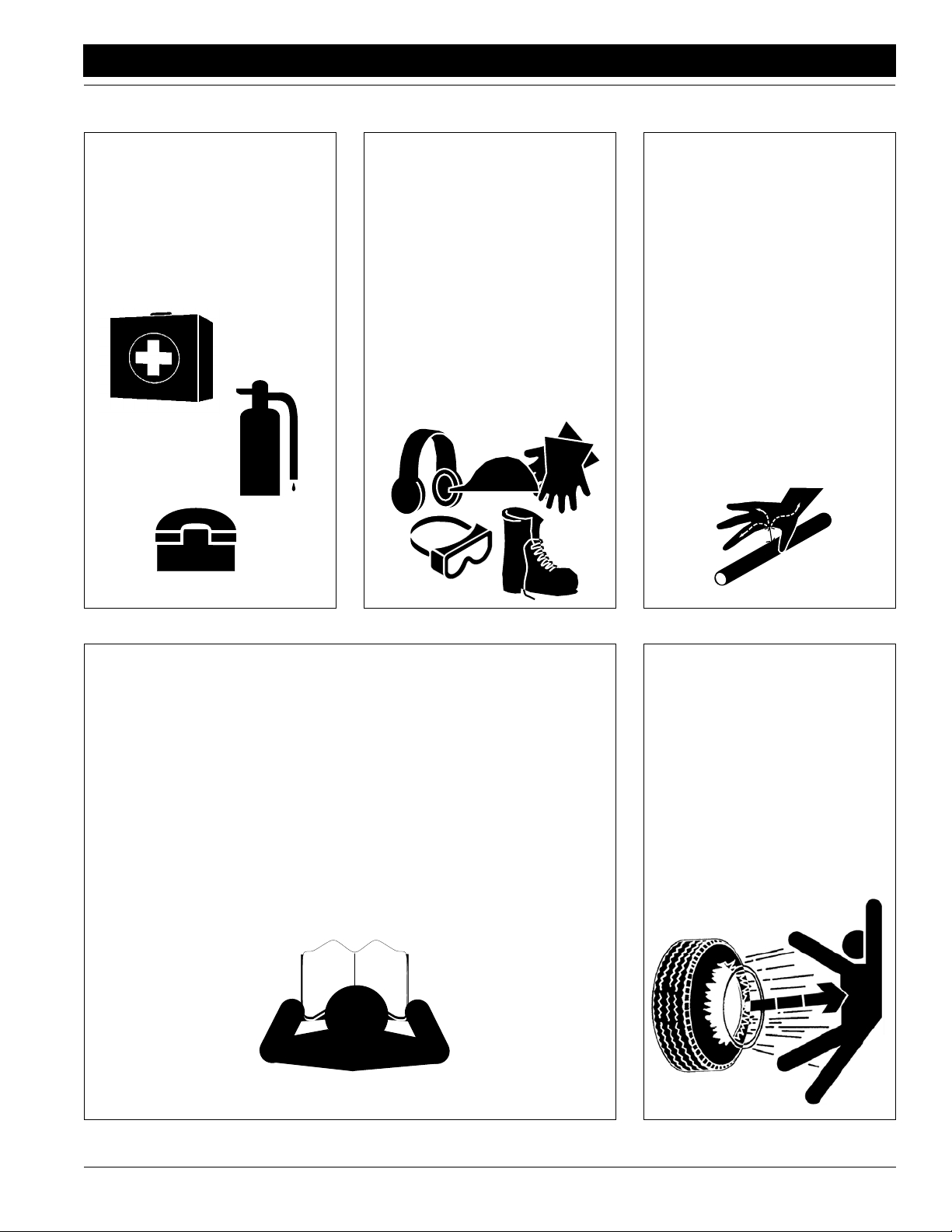

Prepare for Emergencies

▲ Be prepared if a fire starts.

▲ Keep a first aid kit and fire extin-

guisher handy.

▲ Keep emergency numbers for

doctor, ambulance, hospital and

fire department near phone.

911

Wear

Protective Equipment

▲ Wear protective clothing and

equipment.

▲ Wear clothing and equipment

appropriate for the job. Avoid

loose-fitting clothing.

▲ Because prolonged exposure to

loud noise can cause hearing

impairment or hearing loss, wear

suitable hearing protection such

as earmuffs or earplugs.

▲ Because operating equipment

safely requires your full attention,

avoid wearing radio headphones

while operating machinery.

Avoid High

Pressure Fluids Hazard

Escaping fluid under pressure can

penetrate skin, causing serious

injury.

▲ Avoid the hazard by relieving

pressure before disconnecting

hydraulic lines.

▲ Use a piece of paper or card-

board, NOT BODY PARTS, to

check for suspected leaks.

▲ Wear protective gloves and safety

glasses or goggles when working

with hydraulic systems.

▲ If an accident occurs, see a doc-

tor immediately. Any fluid injected

into the skin must be surgically

removed within a few hours or

gangrene may result.

Safety at All Times

Thoroughly read and understand this

manual before operating implement.

Refer to Safety Decals, page 4. Read

all instructions noted on decals.

▲ Be familiar with all implement

functions.

▲ Operate implement from driver’s

seat only.

▲ Do not leave tractor or implement

unattended with engine running.

▲ Do not dismount a moving tractor.

Dismounting a moving tractor could

cause serious injury or death.

▲ Do not stand between the tractor

and implement during hitching.

▲ Keep hands, feet and clothing

away from power-driven parts.

▲ Wear snug-fitting clothing to avoid

entanglement with moving parts.

▲ Watch out for wires, trees, etc.,

when raising implement. Make

sure all persons are clear of working area.

▲ Do not turn tractor too tight, caus-

ing implement to ride up on

wheels.

Tire Safety

Tire changing can be dangerous and

should be performed by trained personnel using correct tools and equipment.

▲ When inflating tires, use a clip-on

chuck and extension hose long

enough to allow you to stand to

one side–not in front of or over tire

assembly. Use a safety cage if

available.

▲ When removing and installing

wheels, use wheel-handling

equipment adequate for weight

involved.

4/12/05

SR5030 Split-Row Planter 401-140M-A

3

Important Safety Information

Safety Decals

Your implement comes equipped with all safety decals in place.

They were designed to help you safely operate your implement.

1. Read and follow decal directions.

2. Keep all safety decals clean and legible.

3. Replace all damaged or missing decals. Order new decals

from your Great Plains dealer. Refer to this section for

proper decal placement.

Great Plains Mfg., Inc.

4. When ordering new parts or components, also request corresponding safety decals.

5. To install new decals:

a. Clean the area on which the decal is to be placed.

b. Peel backing from decal. Press firmly on surface,

being careful not to cause air bubbles under decal.

17725

17725

17725

818-055C

Slow Moving Vehicle Sign

818-230C

Red Reflector

Reflectors on both ends

of planter frame; two decals total

818-229C

Amber Reflector

Reflectors on both ends

of planter frame; two decals total

SR5030 Split-Row Planter 401-140M-A 4/12/05

4

Great Plains Mfg., Inc.

Important Safety Information

17724

818-229C

Amber Reflector

Reflectors on outside row

units; two reflectors total

17725

17725

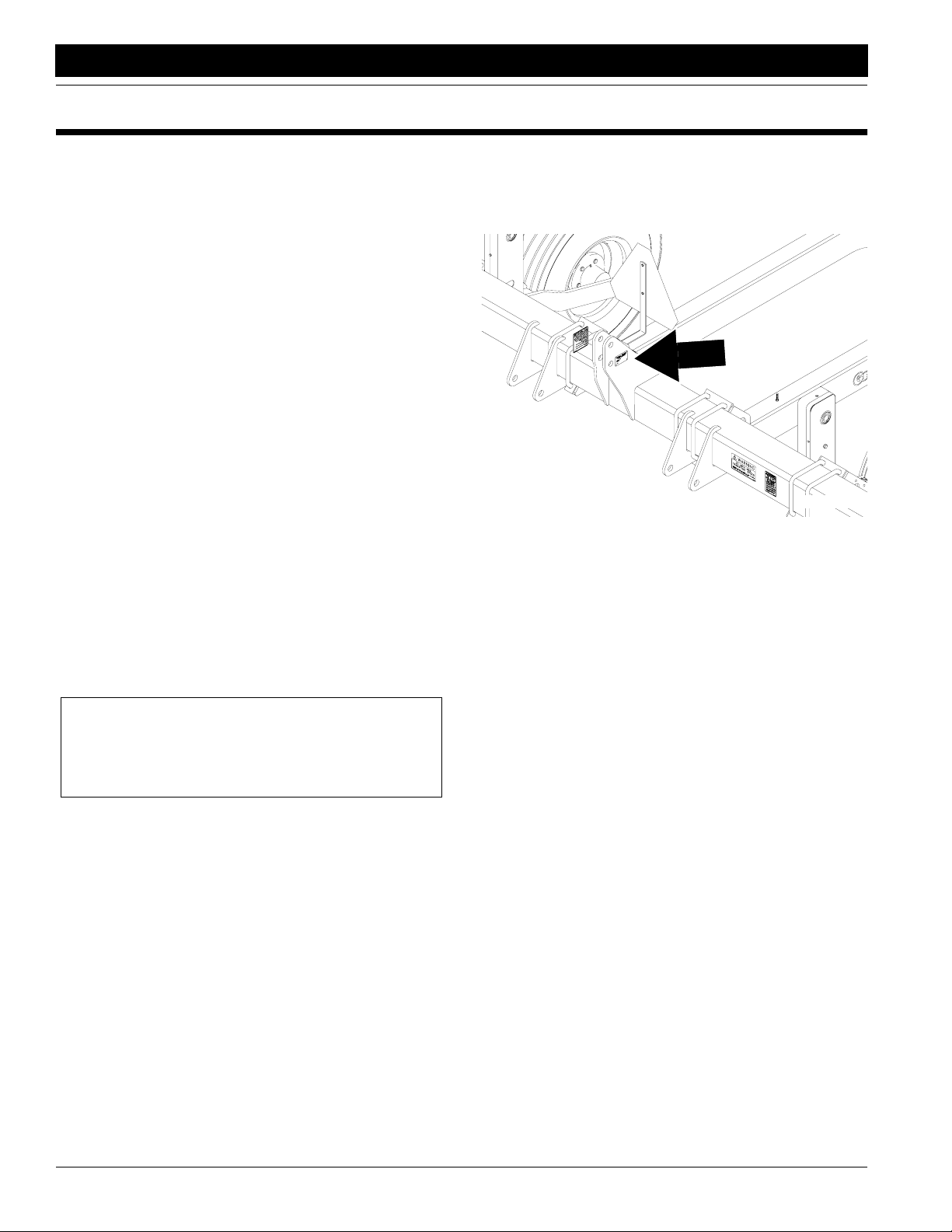

818-188C

Warning 20 MPH Trans

818-587C

Caution Operational

17725

4/12/05

818-339C

Warning High Pressure

SR5030 Split-Row Planter 401-140M-A

5

Introduction

Introduction

Great Plains Mfg., Inc.

Great Plains welcomes you to its growing family of new

product owners. This implement has been designed with

care and built by skilled workers using quality materials.

Proper setup, maintenance and safe oper ating pr actices

will help you get years of satisf actory use from the ma

chine.

-

Description of Unit

The SR5030 is a three-point-mounted planting implement.

The SR5030 has five row units spaced 30 inches apart.

The SR5030 is designed to pull a six-row , pull-type plant

er, splitting row width in half and planting 11 ro ws a pass .

Intended Usage

Use this unit with a six-row , pull-type planter to plant production-agriculture crops. Do not modify the planter for

use with attachments other than those specified by Great

Plains.

Using This Manual

This manual will familiarize you with safety, assembly, operation, adjustments, troubleshooting and maintenance.

Read this manual and follow the recommendations to help

ensure safe and efficient operation.

The information in this manual is current at printing. Some

parts may change to assure top performance.

Definitions

The following terms are used throughout this manual.

Right-hand and left-hand as used in this manual are deter-

mined by facing the direction the machine will tra v el while

in use unless otherwise stated.

IMPORTANT: A crucial point of information related to

the preceding topic. For safe and correct oper ation,

read and follow the directions provided before continuing.

NOTE: Useful inf ormation related to the preceding topic.

Owner Assistance

If you need customer service or repair parts, contact a

Great Plains dealer. The y ha ve trained personnel, repair

parts and equipment specially designed for Great Plains

products.

Your machine’s parts were specially designed and should

only be replaced with Great Plains parts. Always use the

serial and model number when ordering parts from your

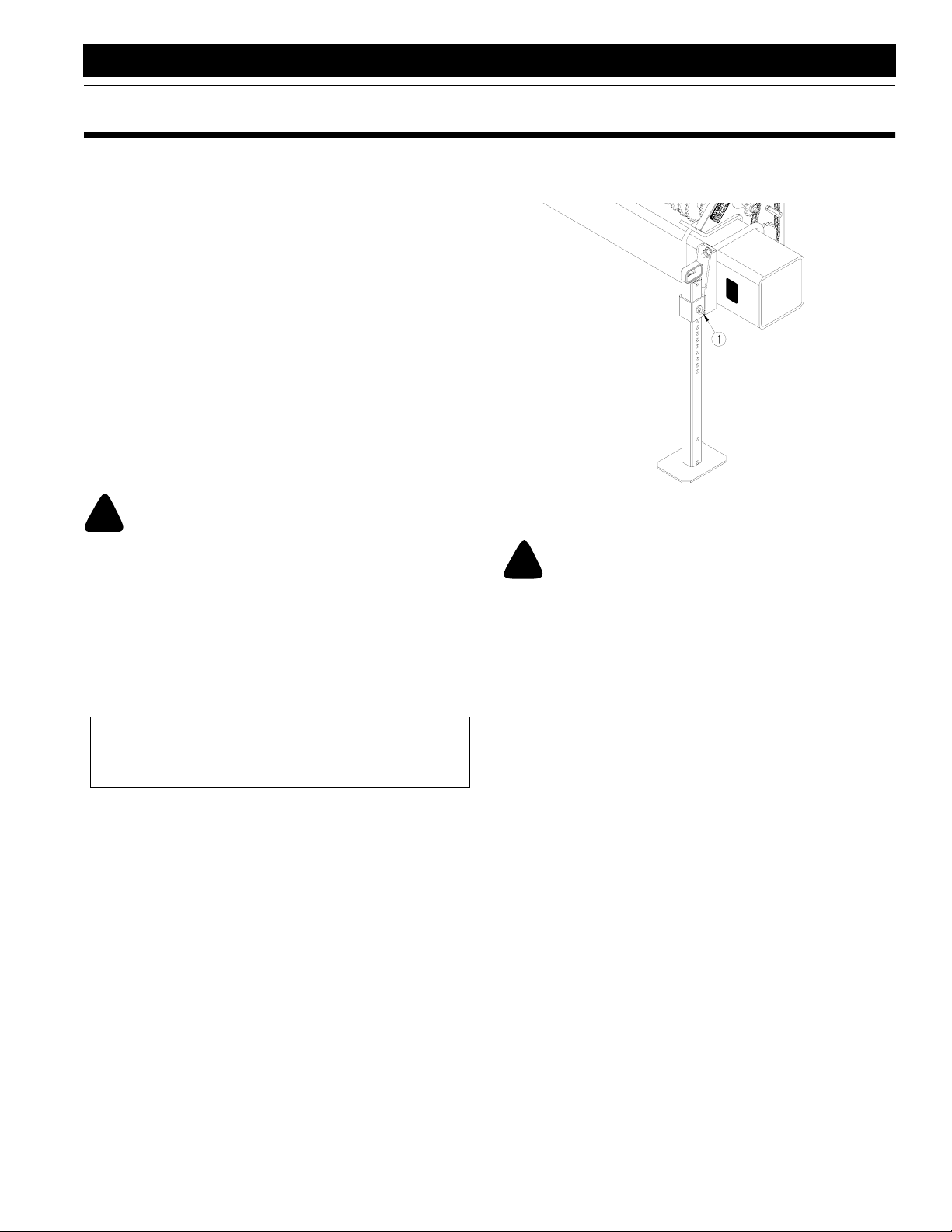

Great Plains dealer. The serial-number plate is located on

the upper-link clevis as shown in Figure A.

-

17725

Figure A

Serial Number

Record your planter model and serial number here for quick

reference:

Model Number: _________________________________

Serial Number: _________________________________

Your Great Plains dealer wants you to be satisfied with

your new machine. If y ou do not understand an y part of

this manual or are not satisfied with the service received,

please take the following actions .

1. Discuss the matter with y our dealership service man-

ager. Mak e sure the y are aw are of an y prob lems so

they can assist you.

2. If you are still unsatisfied, seek out the owner or gen-

eral manager of the dealership.

3. For further assistance write to:

Product Support

Great Plains Mfg. Inc., Service Department

PO Box 5060

Salina, KS 67402-5060

SR5030 Split-Row Planter 401-140M-A 4/12/05

6

Great Plains Mfg., Inc.

Section 1 Preparation and Setup

Section 1 Preparation and Setup

This section will help you prepare your tractor and planter

for use. The planter must be hitched to a suitab le tr actor

and leveled before using it in the field.

Prestart Checklist

1. Read and understand “Important Safety Information” beginning on page 1.

2. Check that all working parts are moving freely, bolts

are tight, and cotter pins are spread.

3. Check that all grease fittings are in place and lubricated. Refer to Lubrication, “Maintenance and Lubri-

cation,” page 24.

4. Check that all safety decals and reflectors are legib le.

Replace if damaged. Refer to Safety Decals , “Impor

tant Safety Information,” page 4.

5. Inflate tires and tighten bolts as recommended in the

“Appendix,”

page 31.

Hitching Planters to Tractor

!

DANGER!

Y ou may be se ver ely injur ed or killed by being crushed between

the tractor and planter. Do not stand or place any part of your

body between planter and moving tractor. Stop tractor engine

and set park brake before installing hitch pins.

1. To prevent soil compaction on rows, set tractor

wheels at 75 inches center to center. For hillsides and

steep slopes, set tractor wheels as wide as possible

for maximum stability.

2. Adjust tractor lower links to maximize lifting height.

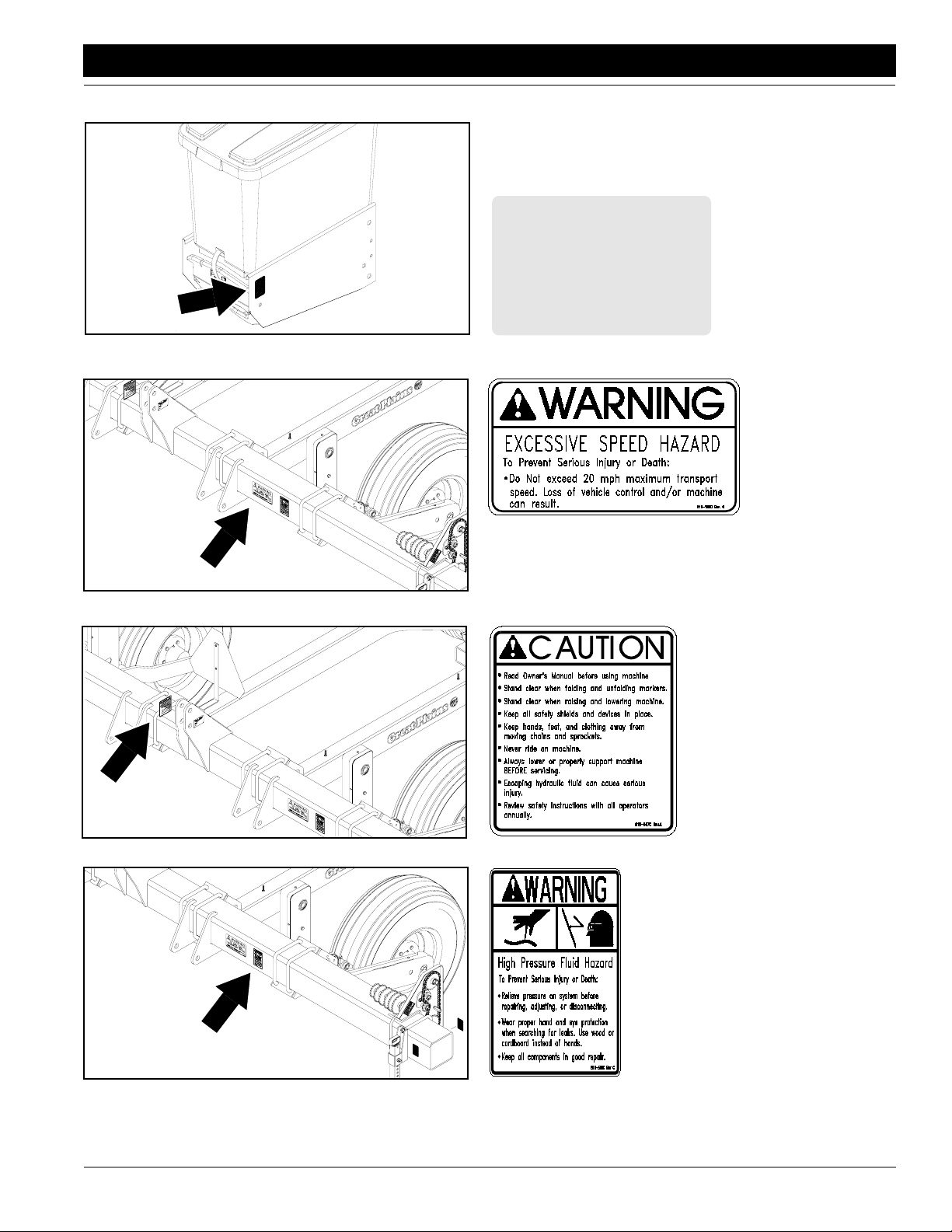

5. Raise planter. Remove pins (1) holding parking

stands and raise stands. Replace pins in lowest hole

of each stand.

-

Figure 1-1

Parking Stand

!

WARNING!

Escaping fluid under pressure can have sufficient pressure to

penetrate the skin. Check all hydraulic lines and fittings before

applying pressur e. Fluid escaping fr om a very small hole can be

almost invisible. Use paper or cardboard, not body parts, and

wear heavy gloves to check for suspected leaks. If injur ed, seek

medical assistance from a doctor that is familiar with this type

of injury. For eign fluids in the tissue must be surgically r emoved

within a few hours or gangrene will result.

17723

IMPORTANT: To keep the planter level make sure

the lower links are adjusted evenly.

Set tractor sway blocks to minimize side sway. Position tractor lift control in float position.

3. Back tractor up to planter. Align lower links with the

lower hitch holes on planter. Insert hitch pins and

spacers supplied with planter according to the catego

ry of your tractor. Lock pins in place.

4. Attach tractor top link in the lower hole for Category II

tractors. Attach tractor top link in the upper hole for

Category III tractors.

4/12/05

6. Hitch SR5030 to pull-type planter.

7. Connect hydraulic hoses f or pull-type planter to couplers on rear of SR5030. Connect hydraulic hoses f or

SR5030 to tractor outlets.

8. Connect planter electrical harness to SR5030 harness. Plug lead from SR5030 harness to the tractor

receptacle.

-

SR5030 Split-Row Planter 401-140M-A

7

Section 1 Preparation and Setup

Great Plains Mfg., Inc.

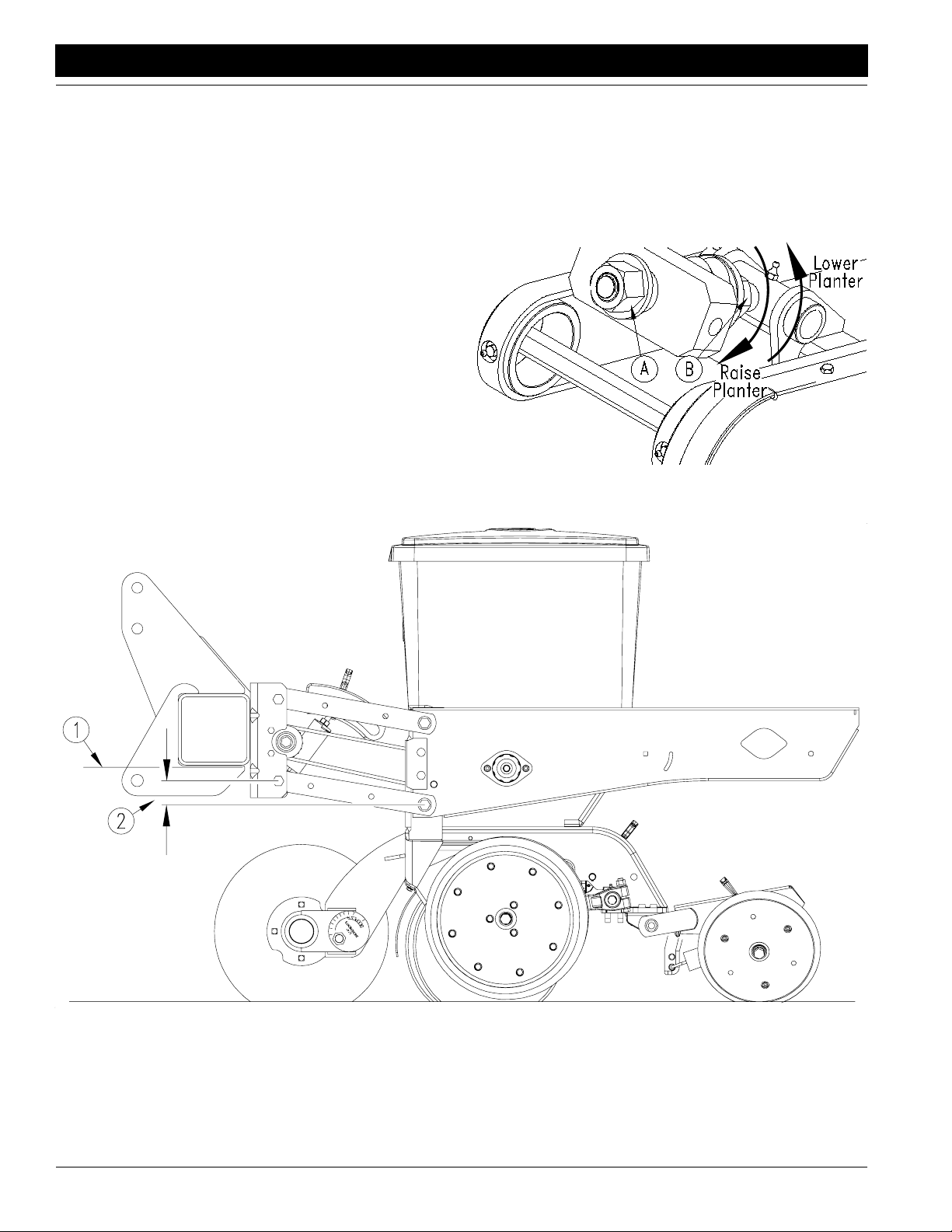

Leveling Planter

The planter must be level for the row units to function correctly. Before leveling the planter check tire pressures as

specified on Tire Inflation Chart, “Appendix,”

1. Check that planter is lev el from side to side. If not, adjust lower links of tractor three point to level planter.

2. After setting row units to the proper planting depth,

park tractor and planter on level ground in the field.

Lower planter . If planter is lev el from front to back, the

bottom of the frame tube will be parallel to the ground

(1). See

Figure 1-2. If planter is not level, adjust upper

link on tractor three point to level planter.

3. Check that row-unit arms are parallel to the ground. If

row-unit arms are not parallel, adjust gauge-wheel

modules.

To find the amount of adjustment needed, measure

the vertical distance between the front and rear pivot

on the row-unit arms (2). See

Figure 1-2. Adjust both

gauge-wheel modules this amount.

page 30.

To adjust the gauge-wheel modules, see Figure 1-3.

Raise planter and loosen jam nut (A) on wheel module.

• To lower the planter, turn the nut (B) at the opposite

end of link counter-clockwise.

• To raise planter, turn nut (B) clockwise.

When finished adjusting, tighten jam nut.

10495

Figure 1-3

Adjusting Gauge-Wheel Modules

17886

Figure 1-2

Level Planter Front to Rear

SR5030 Split-Row Planter 401-140M-A 4/12/05

8

Great Plains Mfg., Inc.

Section 2 Operating Instructions

Section 2 Operating Instructions

This section covers general operating procedures . Experience, machine familiarity and the follo wing information will

lead to efficient operation and good working habits. Al

ways operate farm machinery with safety in mind.

-

Prestart Checklist

1. Carefully read “Important Safety Information,” beginning on page 1.

2. Lubricate planter as indicated under Lubrication,

“Maintenance and Lubrication,”

3. Check that planter tires are the correct size and properly inflated as indicated on Tire Inflation Chart, “Ap-

pendix,” page 30.

4. Check all bolts, pins and fasteners. T orque as specified on Torque Values Chart, “Appendix,” page 31.

5. Check the chains for proper tension and alignment as

shown in Maintenance, “Maintenance and Lubrica

tion,” page 20.

6. Check planter for worn or damaged parts. Repair or

replace them before going to the field.

page 24.

Field Operation

1. Perf orm all checks listed on Prestart Checklist, this

page.

2. Hitch planters to a tractor with sufficient weight and

horsepower . Ref er to Tractor Requirements , “Specifi

cations and Capacities,” page 30, and Hitching

Planters to T ractor , “Preparation and Setup ,” page 7.

3. Set and calibrate planting rate as explained under

Planting Rate, “Adjustments,”

4. Clear seed hoppers of foreign objects. Load seed

hoppers with clean seed. Add 1 teaspoon of graphite

to each seed hopper. Replace hopper lids.

5. Adjust down pressure on row units to match field conditions. Set row units to desired planting depth. Refer

to Row Unit Adjustments, “Adjustments,”

6. Check if planters are lev el. Refer to Leveling Planter ,

“Preparation and Setup,”

7. Lower planters, pull f orw ard and begin planting.

8. Always raise planters for field turns. Meters will stop

automatically as you raise planters.

page 14.

page 11.

page 8.

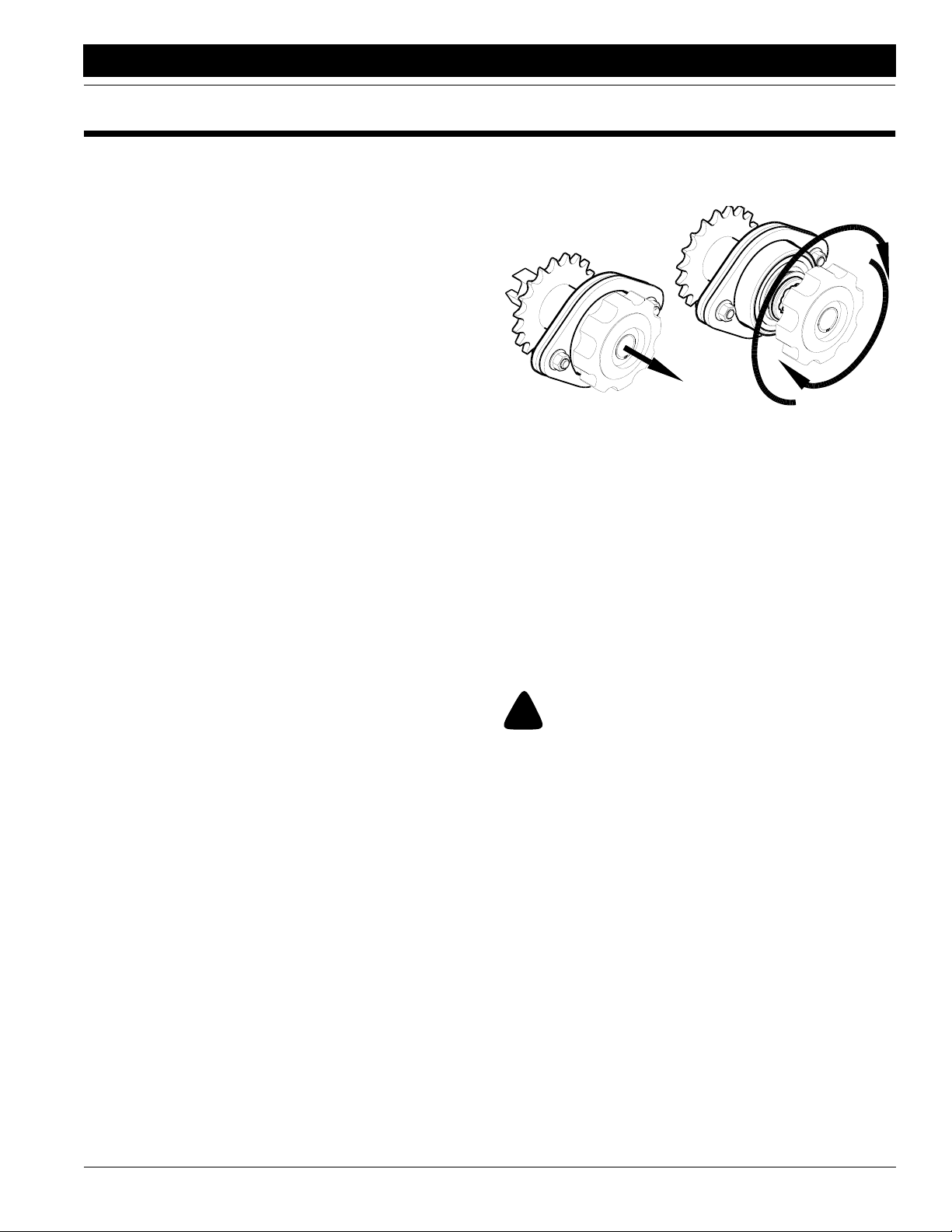

Meter Clutches

To disengage seed-hopper clutches, pull and rotate knobs

until meters are disengaged. See

17887

Figure 2-1

-

To engage clutches, pull and rotate knobs until meters

reengage.

Row Unit Operation

Never back up with row units in ground. If y ou do, check all

openers to be sure none are clogged. Always lift planter

out of ground when turning at ends of field rows and for

other short-radius turns.

For information on planting-depth and down-pressure

-

adjustments, refer to Row Unit Adjustments , “Adjust

ments,” beginning on page 11.

Meter Clutch

Figure 2-1.

Transporting

!

WARNING!

Towing the planter at high speeds can lead to loss of vehicle

control. Loss of vehicle control can lead to serious road acci

dents, injury and death. Do not exceed 20 mph. To maintain

steering control, ballast may need to be added to tractor front

end. To determine the amount of ballast required refer to your

tractor’s operator manual.

Before transporting the planter, chec k and practice the following items.

1. Check that planters are securely hitched to a sufficient

tractor. Refer to Tractor Requirements, “Specifica

tions and Capacities,” page 30 and Hitching Planters

to Tractor, “Preparation and Setup,” page 7.

-

-

-

4/12/05

SR5030 Split-Row Planter 401-140M-A

9

Loading...

Loading...