Page 1

Table of Contents Index

Semi-Mounted Fertilizer Carts

Operator Manual

SML-1000, SML-750, SML-500

Manufacturing, Inc.

www.greatplainsmfg.com

Read the Operator manual entirely. When you see this symbol, the

subsequent instructions and warnings are serious - follow without

exception. Your life and the lives of others depend on it!

Null4:

Null4:

31506

Illustrations may show optional equipment not supplied with standard unit, and may not

show your specific cart model where operation is identical.

Null4:

EN

© Copyright 2011 Printed 03/31/2011 407-451M

Table of Contents Index

Page 2

Blank page for correct duplexing.

Table of Contents Index

Table of Contents Index

Page 3

Great Plains Manufacturing, Inc. Cover Index iii

Table of Contents

Important Safety Information ......................................1

Safety Decals .................................................................5

Introduction ..................................................................7

Models Covered .............................................................7

Description of Unit ..........................................................7

Intended Usage ..........................................................7

Compatible Materials.................................................. 8

Serial Number Plates..................................................8

Document Family........................................................9

Using This Manual..........................................................9

Definitions................................................................... 9

Owner Assistance ..........................................................9

Preparation and Setup ............................................... 10

Initial Setup...................................................................10

Post-Delivery/Seasonal Setup......................................10

Pre-Planting Setup .......................................................10

Hitching Cart to Implement...........................................11

Shims .......................................................................11

Open Implement Hitches..........................................12

Hitch Cart and Implement......................................... 12

Double-Check Latch Plates......................................13

Make Fertilizer Connection...........................................13

Parking Stands ............................................................. 14

Raise Stand After Hitching .......................................14

Lower Stand for Unhitching ......................................14

Operating Instructions...............................................15

Pre-Start Checklist .......................................................15

Transporting the Cart ...................................................16

Transport Checklist...................................................16

Walkboard and Ladder ................................................. 17

Ladder Operation .....................................................17

Loading Materials ......................................................... 18

Filling by Either Method............................................18

Sight Gauge Scale Metric Equivalents ................. 18

Tank Quick-Fill..........................................................19

Tank Lid Fill ..............................................................19

Tank Field Operation....................................................20

Field Start-Up ...........................................................20

Planting .................................................................... 20

Material Run-Out...................................................... 20

Field Set-Up Checklists................................................ 21

Field Operation ............................................................ 21

Short-Term Stopping.................................................... 22

Short-Term Parking...................................................... 22

Long-Term Storage...................................................... 22

Troubleshooting......................................................... 23

Maintenance and Lubrication ................................... 25

Maintenance ................................................................ 25

Material Clean-Out....................................................... 26

Material Recovery .................................................... 26

Excess Application ................................................... 26

System Flush ........................................................... 26

Pump Preservation................................................... 26

Cart Inlet Strainer ..................................................... 27

Filter Removal ...................................................... 27

Filter Cleaning ...................................................... 27

Lubrication and Scheduled Maintenance..................... 28

Appendix A - Reference Information........................ 30

Specifications and Capacities ...................................... 30

SML-1000, SML-750, SML-500 Fertilizer Carts ....... 30

Tire Inflation Chart ....................................................... 30

Torque Values Chart.................................................... 31

Plumbing Diagrams...................................................... 32

SML-1000 Gallon Cart Plumbing ............................. 32

SML-750 Gallon Cart Plumbing ............................... 33

SML-500 Gallon Cart Plumbing ............................... 34

Appendix B - Pre-Delivery......................................... 35

Appendix C - Initial Setup ......................................... 40

Remove Pintle Hitch .................................................... 40

Install Quick Hitches .................................................... 40

Mount Boom Inlet ..................................................... 41

Install Hitch Latches ................................................. 41

Check Handrail Fill....................................................... 41

Index............................................................................ 43

© Copyright 2007, 2010, 2011. All rights Reserved

Great Plains Manufacturing, Inc. provides this publication “as is” without warranty of any kind, either expressed or implied. While every precaution has been

taken in the preparation of this manual, Great Plains Manufacturing, Inc. assumes no responsibility for errors or omissions. Neither is any liability assumed for

damages resulting from the use of the information contained herein. Great Plains Manufacturing, Inc. reserves the right to revise and improve its products as

it sees fit. This publication describes the state of this product at the time of its publication, and may not reflect the product in the future.

03/31/2011 Cover Index 407-451M

Trademarks of Great Plains Manufacturing, Inc. include: Singulator Plus, Swath Command, Terra-Tine.

Registered Trademarks of Great Plains Manufacturing, Inc. include:

Air-Pro, Clear-Shot, Great Plains, Land Pride, MeterCone, Nutri-Pro, Seed-Lok, Solid Stand, Whirlfilter, Yield-Pro.

Brand and Product Names that appear and are owned by others are trademarks of their respective owners.

Printed in the United States of America

Page 4

SML-1000, SML-750, SML-500 Table of Contents Index Great Plains Manufacturing, Inc.

407-451M Table of Contents Index 03/31/2011

Page 5

Great Plains Manufacturing, Inc. Table of Contents Index 1

Important Safety Information

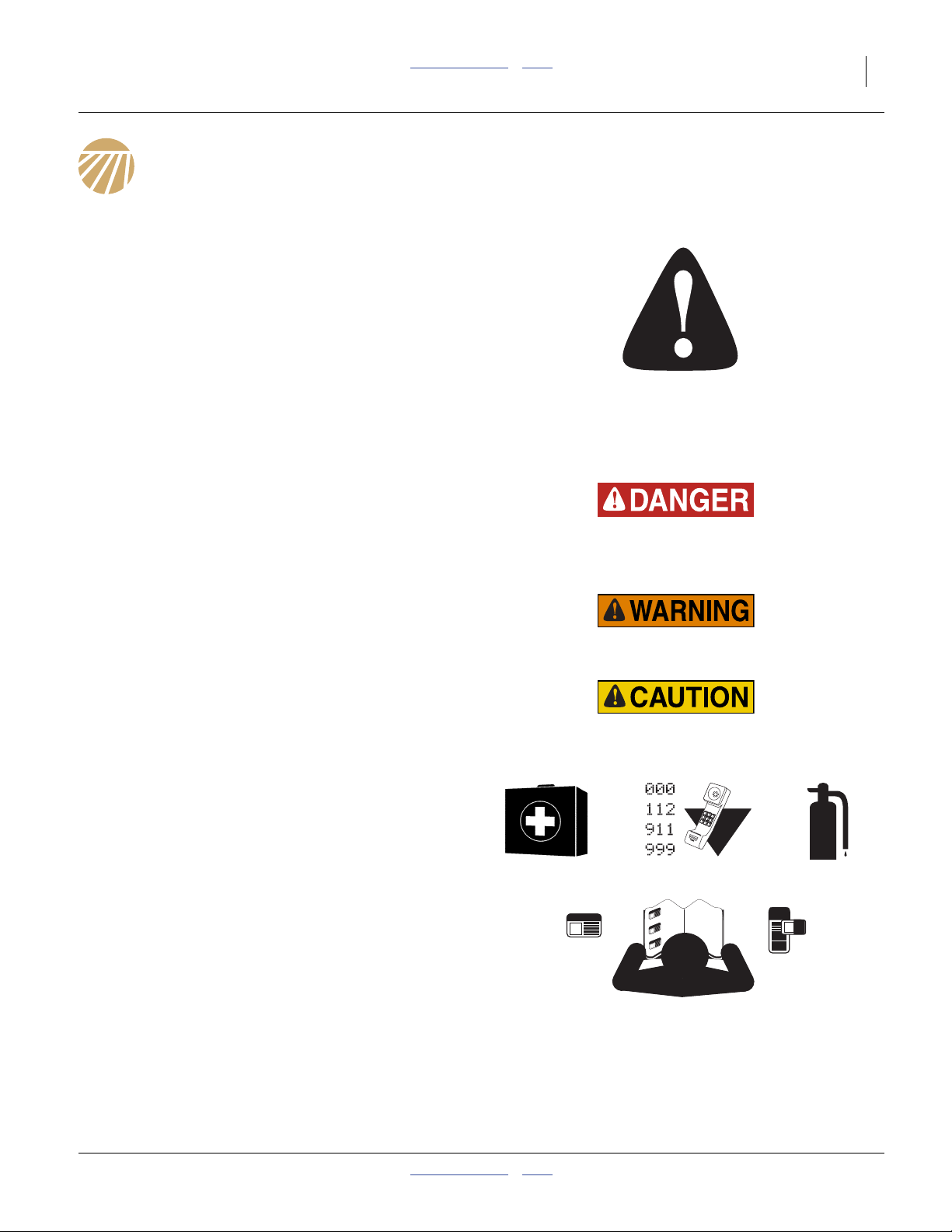

Look for Safety Symbol

The SAFETY ALERT SYMBOL indicates there is a

potential hazard to personal safety involved and extra

safety precaution must be taken. When you see this

symbol, be alert and carefully read the message that follows it. In addition to design and configuration of equipment, hazard control and accident prevention are

dependent upon the awareness, concern, prudence and

proper training of personnel involved in the operation,

transport, maintenance and storage of equipment.

Be Aware of Signal Words

Signal words designate a degree or level of hazard seriousness.

DANGER indicates an imminently hazardous situation

which, if not avoided, will result in death or serious injury.

This signal word is limited to the most extreme situations,

typically for machine components that, for functional purposes, cannot be guarded.

WARNING indicates a potentially hazardous situation

which, if not avoided, could result in death or serious

injury, and includes hazards that are exposed when

guards are removed. It may also be used to alert against

unsafe practices.

CAUTION indicates a potentially hazardous situation

which, if not avoided, may result in minor or moderate

injury. It may also be used to alert against unsafe practices.

Prepare for Emergencies

▲ Be prepared if a fire starts

▲ Keep a first aid kit and fire extinguisher handy.

▲ Keep emergency numbers for doctor, ambulance, hospital

and fire department near phone.

Be Familiar with Safety Decals

▲ Read and understand “Safety Decals” on page 5, thor-

oughly.

▲ Read all instructions noted on the decals.

▲ Keep decals clean. Replace damaged, faded and illegible

decals.17

03/31/2011 Table of Contents Index 407-451M

Page 6

2 SML-1000, SML-750, SML-500 Table of Contents Index Great Plains Manufacturing, Inc.

Wear Protective Equipment

▲ Wear Protective Equipment

▲ Wear protective clothing and equipment.

▲ Wear clothing and equipment appropriate for the job. Avoid

loose-fitting clothing.

▲ Because operating equipment safely requires your full

attention, avoid wearing entertainment headphones while

operating machinery.

Handle Chemicals Properly

Agricultural chemicals can be dangerous. Improper use

can seriously injure persons, animals, plants, soil and

property.

▲ Read and follow chemical supplier instructions. Obtain and

read the MSDSa for any material used.

▲ Wear protective clothing.

▲ Handle all chemicals with care.

▲ Agricultural chemicals can be dangerous. Improper use can

seriously injure persons, animals, plants, soil and property.

▲ Inhaling smoke from any type of chemical fire is a serious

health hazard.

▲ Store or dispose of unused chemicals as specified by the

chemical manufacturer.

▲ If chemical is swallowed, carefully follow the chemical

manufacturer’s recommendations and consult with a doctor.

▲ If persons are exposed to a chemical in a way that could

affect their health, consult a doctor immediately with the

chemical label or container in hand. Any delay could cause

serious illness or death.

▲ Dispose of empty chemical containers properly. By law

rinsing of the used chemical container must be repeated

three times. Puncture the container to prevent future use. An

alternative is to jet-rinse or pressure rinse the container.

▲ Wash hands and face before eating after working with

chemicals. Shower as soon as application is completed for

the day.

▲ Apply only with acceptable wind conditions. Make sure

wind drift of chemicals will not affect any surrounding land,

people or animals.

▲ Never wash out a hopper within 100 feet of any freshwater

source or in a car wash.

a. MSDS: Material Safety Data Sheet

407-451M Table of Contents Index 03/31/2011

Page 7

Great Plains Manufacturing, Inc. Table of Contents Index Important Safety Information 3

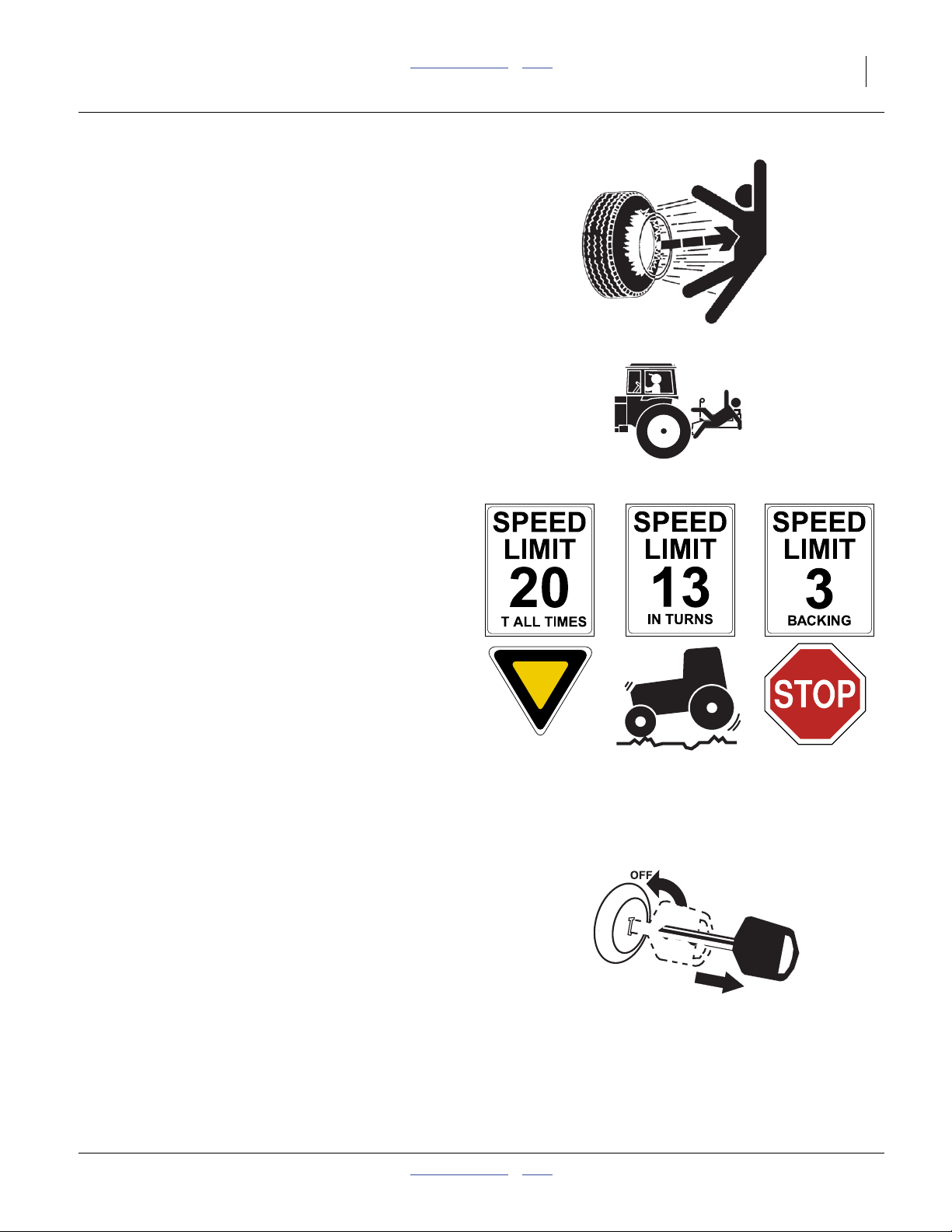

Tire Safety

Tire changing can be dangerous and should be performed by trained personnel using correct tools and

equipment.

▲ When inflating tires, use a clip-on chuck and extension hose

long enough for you to stand to one side–not in front of or

over tire assembly. Use a safety cage if available.

▲ When removing and installing wheels, use wheel-handling

equipment adequate for weight involved.

Keep Riders Off Machinery

Riders obstruct the operator’s view. Riders could be

struck by foreign objects or thrown from the machine.

▲ Never allow children to operate equipment.

▲ Keep all bystanders away from machine during operation.

Transport Machinery Safely

Maximum transport speed for implement is 20 mph (32

kph), 13 mph (22 kph) in turns. Some rough terrains

require a slower speed. Sudden braking can cause a

towed load to swerve and upset.

▲ Do not exceed 20 mph. Never travel at a speed which does

not allow adequate control of steering and stopping. Reduce

speed if towed load is not equipped with brakes.

▲ Comply with state and local laws.

▲ Do not tow an implement that, when fully loaded, weighs

more than 1.5 times the weight of towing vehicle.

▲ Carry reflectors or flags to mark cart in case of breakdown

on the road.

▲ Keep clear of overhead power lines and other obstructions

when transporting. Refer to transport dimensions under

“Specifications and Capacities” on page 30.

▲ Do not fold or unfold the cart while the tractor is moving

Shutdown and Storage

▲ Secure cart using supports provided. Block wheels.

▲ Detach and store cart on level ground in an area where

children normally do not play.

A

03/31/2011 Table of Contents Index 407-451M

Page 8

4 SML-1000, SML-750, SML-500 Table of Contents Index Great Plains Manufacturing, Inc.

Practice Safe Maintenance

▲ Understand procedure before doing work. Use proper

tools and equipment. Refer to this manual for additional

information.

▲ Work in a clean, dry area.

▲ Put tractor in park, turn off engine, and remove key before

performing maintenance while hitched.

▲ Inspect all parts. Make sure parts are in good condition

and installed properly.

▲ Remove buildup of grease, oil or debris.

▲ Remove all tools and unused parts from cart before opera-

tion.

Safety At All Times

Thoroughly read and understand the instructions in this

manual before operation. Read all instructions noted on

the safety decals.

▲ Be familiar with all cart functions.

▲ Operate machinery from the driver’s seat only.

▲ Do not leave cart unattended with tractor engine running.

▲ Do not stand between the tractor and cart during hitching.

▲ Watch out for wires, trees, etc., when folding and raising

cart. Make sure all persons are clear of working area.

MetaData: End of <Safety Topics>

407-451M Table of Contents Index 03/31/2011

Page 9

Great Plains Manufacturing, Inc. Table of Contents Index Important Safety Information 5

Safety Decals

Safety Reflectors and Decals

Your implement comes equipped with all safety reflectors

and decals in place. They were designed to help you

safely operate your implement.

▲ Read and follow decal directions.

▲ Keep lights in operating condition.

▲ Keep all safety decals clean and legible.

▲ Replace all damaged or missing decals. Order new decals

from your Great Plains dealer. Refer to this section for

proper decal placement.

▲ When ordering new parts or components, also request cor-

responding safety decals.

To install new decals:

1. Clean the area on which the decal is to be placed.

2. Peel backing from decal. Press firmly on surface,

being careful not to cause air bubbles under decal.

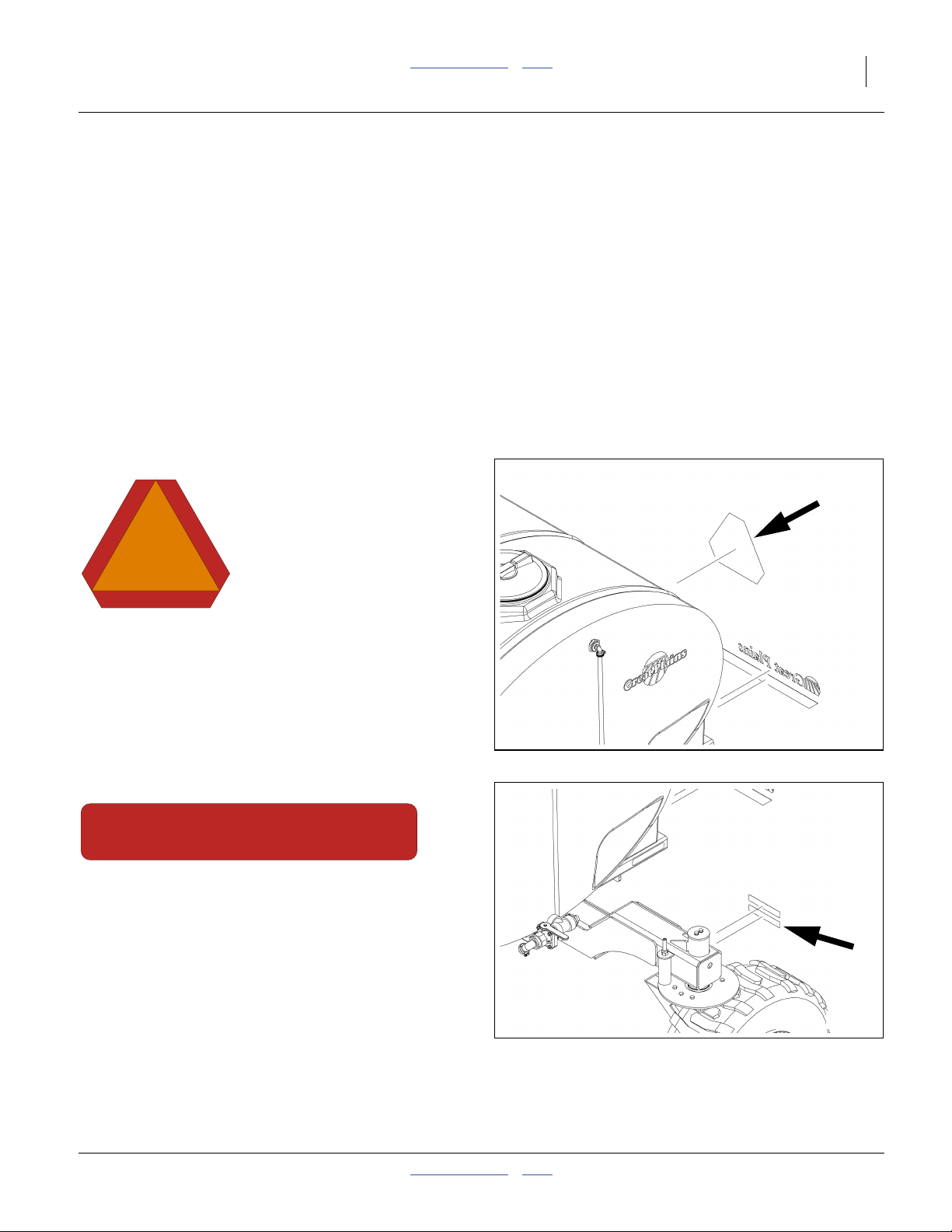

818-003C

Slow Moving Vehicle Reflector

On the back of the tank;

1 total

Null4:

838-266C

Red Reflectors

On rear face of axle (below Daytime reflectors);

two total

Null4:

31499

Null4:

31499

Null4:

03/31/2011 Table of Contents Index 407-451M

Page 10

6 SML-1000, SML-750, SML-500 Table of Contents Index Great Plains Manufacturing, Inc.

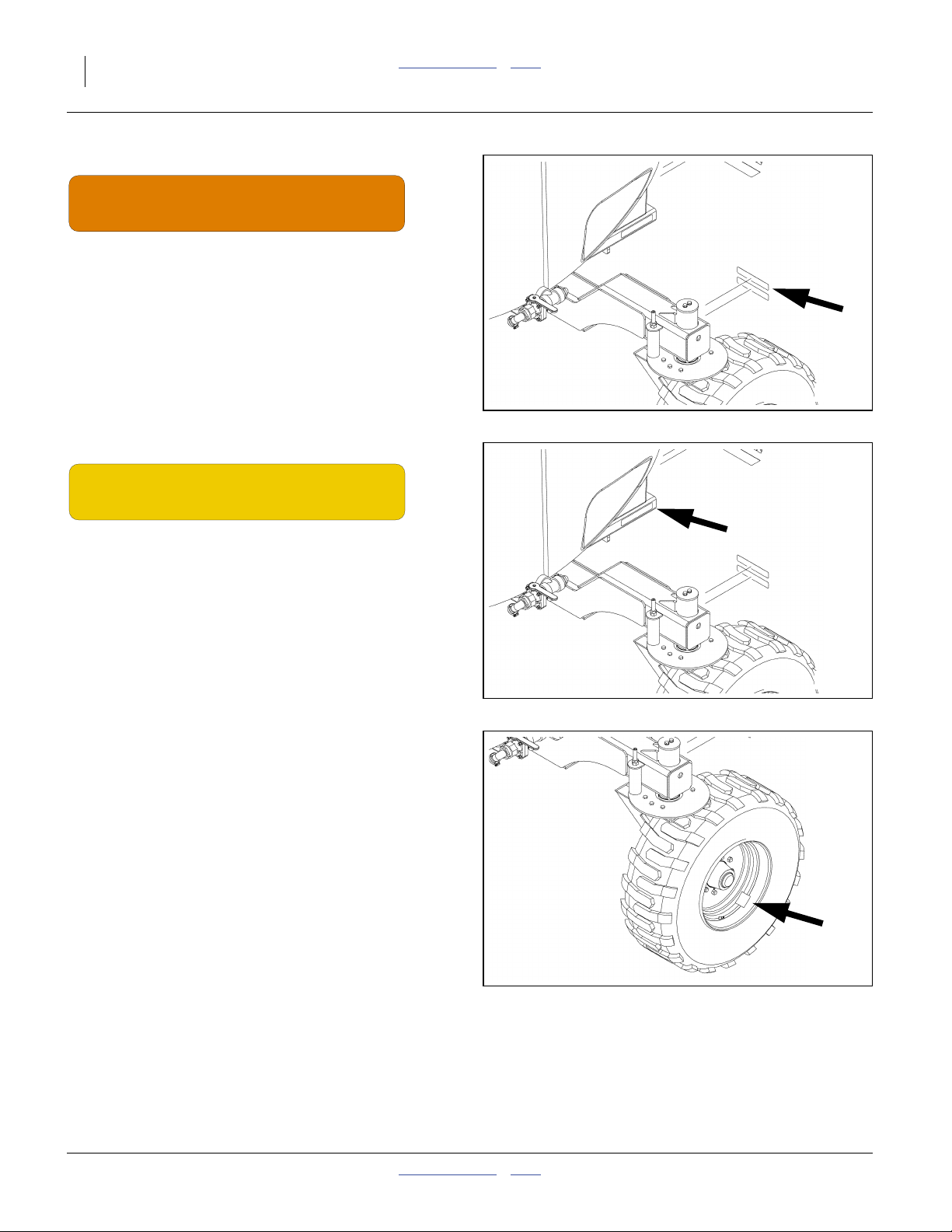

838-267C

Daytime Reflectors

On rear face of axle (above Red reflectors);

two total

Null4:

31499

Null4:

838-265C

Amber Reflectors

On the rear of the frame side channels;

two total.

Null4:

838-426C

Caution: Pressure and Torque

On outside rim each transport tire;

2 total

MetaData: End of “Safety Decals”.

MetaData: End of “Important Safety Information”.

Null4:

31499

Null4:

31499

407-451M Table of Contents Index 03/31/2011

Page 11

Great Plains Manufacturing, Inc. Table of Contents Index 7

Introduction

Great Plains welcomes you to its growing family of new

product owners. The 1000 or 735 Gallon Semi-Mounted

Fertilizer Cart has been designed with care and built by

skilled workers using quality materials. Proper setup,

maintenance, and safe operating practices will help you

get years of satisfactory use from the cart.

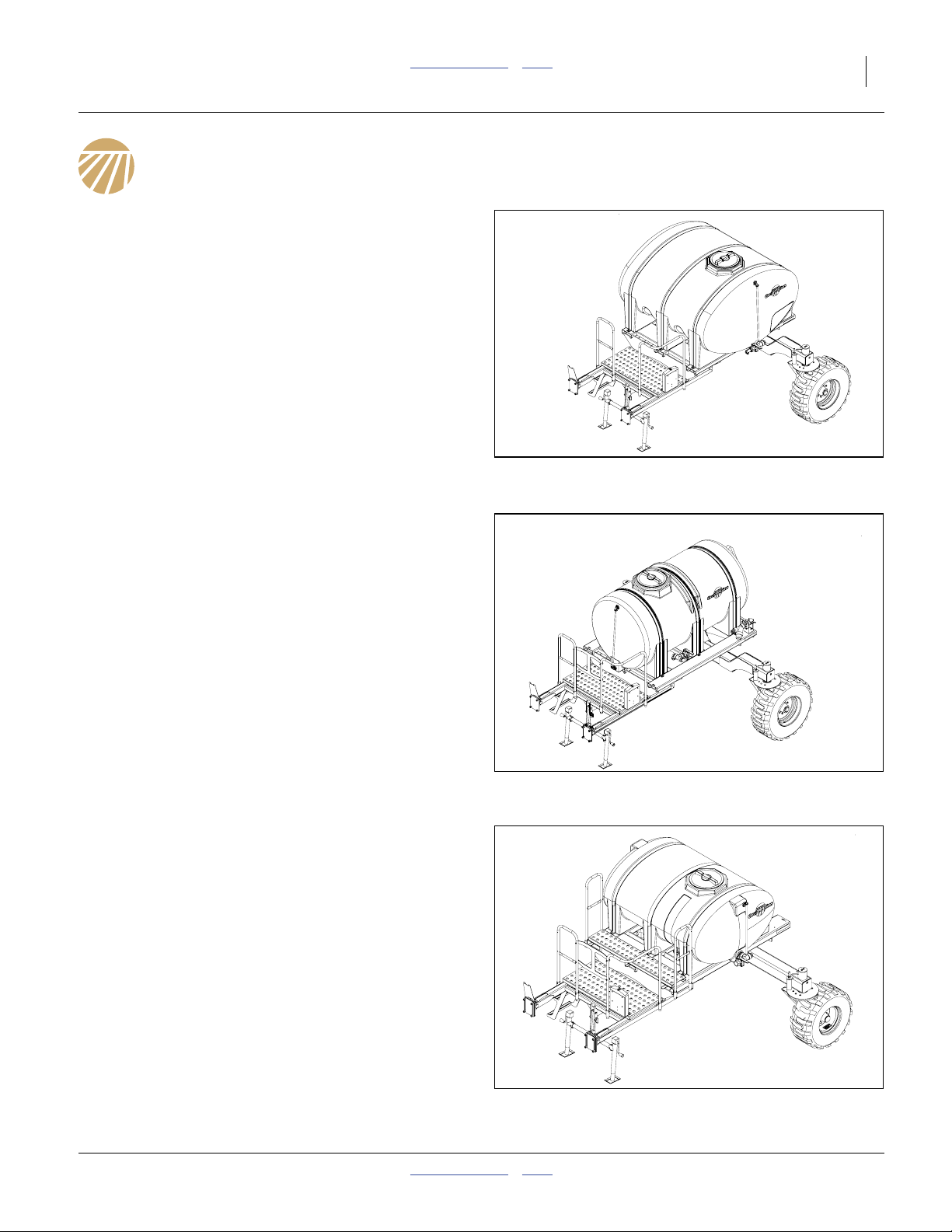

Models Covered

This manual applies only to the cart models shown and

listed in the figures at right.

Description of Unit

The SML-1000, SML-750, SML-500 carts are semimounted trailing tank carts intended for use with specific

models of Great Plains planters and drills.

Use with any implement requires:

• a “Type 2” fertilizer manifold, plumbed to...

• an implement-mounted pump, with a single inlet

routed to the implement rear hitch, and

• mounting of the quick-connect hitch hardware provided with the cart (which requires removing the rear

pintle hitch, if present on the implement).

Intended Usage

Use the 1000 or 735 Gallon Semi-Mounted Fertilizer

Cart to supply compatible agricultural chemicals to the

implement pump and boom system. Do not modify the

cart for use with attachments other than Great Plains

options and accessories specified for use with the cart.

Null4:

Null4: Null4:

Null4:

Null4: Null4:

Figure 1

SML-1000 Gallon Cart

Figure 2

SML-750 Gallon Cart

Null4:

Null4:

31487

31487

Null4:

Null4: Null4:

Figure 3

Null4:

32014

SML-500 Gallon Cart

03/31/2011 Table of Contents Index 407-451M

Page 12

8 SML-1000, SML-750, SML-500 Table of Contents Index Great Plains Manufacturing, Inc.

Null4:

Compatible Materials

Null4:

Null4:

Carts are intended for pre-mixed liquid fertilizers

• Use stable mixtures. The carts do not include agitators

to prevent rapid settling, stratification, coagulation or

precipitation of components not fully dissolved or suspended in the base liquid.

• The specific gravity (density relative to water) of the

mixture must be 1.7 or lower.

• If the mixture contains any particulates, the largest

must be no larger than the smallest of:

screen size of the cart inlet filter,

screen size of the pump strainer and the

orifice size of the boom nozzle plates.

• All materials must be compatible with: high density

polyethylene (HDPE), nylon, polypropylene (PP)

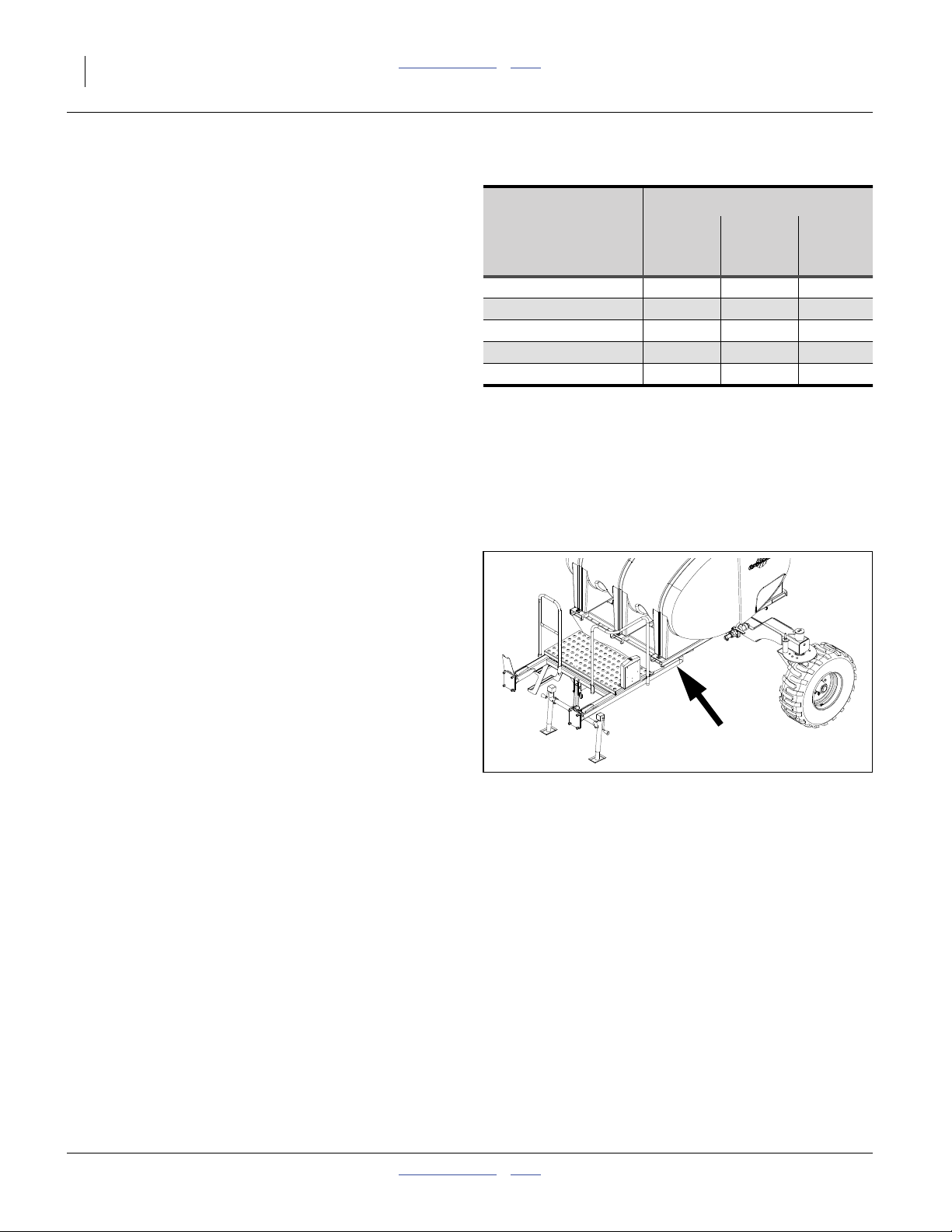

Compatible

Implement Models

SML-1000

Gallon

AD4010HD No Yes Yes

YP2425, YP2425A Ye s Ye s Ye s

YP4010HDP No Yes Yes

YP4020P No Ye s Ye s

YP4025, YP4025A No Yes Yes

Note: The 500, 750 and 1000 gallon carts are not sup-

ported with 30-foot (9m) implement models

AD3010HD, YP3010HDP, YP3020P or YP3025/A.

Cart Models

Cart

SML-750

Gallon

Cart

SML-500

Gallon

Cart

polyvinyl chloride (PVC) and Teflon®(PTFE) plastics,

EPDM and Viton® rubber, stainless steel; and temporary contact with cast iron.

Null4:

Serial Number Plates

The serial number plate is located on the side face of the

left front frame tank support plate.

Note: The SML-1000, SML-750 and SML-500 were for-

merly sold as the 407-451A, 407-452A and 407643A and did not have serial number plates.

Null4:

Figure 4

Serial Number Plate

31487

407-451M Table of Contents Index 03/31/2011

Page 13

Great Plains Manufacturing, Inc. Table of Contents Index Introduction 9

Document Family

407-451M Cart Operator Manual (this document)

407-451P Cart Parts Manual

Material Rate Manuals

167-085B AD4010HD

401-406B YP2425

401-626B YP2425A

401-571B YP4010HDP, YP4020P, YP4025

401-627B YP4025A

Null4:

Using This Manual

This manual will familiarize you with safety, assembly,

operation, adjustments, troubleshooting, and maintenance. Read this manual and follow the recommendations to help ensure safe and efficient operation.

The information in this manual is current at printing.

Some parts may change to assure top performance.

Definitions

The following terms are used throughout this manual.

Owner Assistance

If you need customer service or repair parts, contact a

Great Plains dealer. They have trained personnel, repair

parts and equipment specially designed for Great Plains

products.

Your machine’s parts were specially designed and

should only be replaced with Great Plains parts.

These carts do not have serial number plates. Use the

illustrations on page 7 for model identification.

Your Great Plains dealer wants you to be satisfied with

your new machine. If you do not understand any part of

this manual or are not satisfied with the service received,

please take the following actions.

1. Discuss the matter with your dealership service

manager. Make sure they are aware of any problems

so they can assist you.

2. If you are still unsatisfied, seek out the owner or general manager of the dealership.

For further assistance write to:

Product Support

Great Plains Mfg. Inc., Service Department

PO Box 5060

Salina, KS 67402-5060

A crucial point of information related to the preceding topic.

Read and follow the directions to remain safe, avoid serious

damage to equipment and ensure desired field results.

Note: Useful information related to the preceding topic.

Right-hand and left-hand as used in

this manual are determined by facing

the direction the machine will travel

while in use unless otherwise stated.

An orientation rose in some line art

illustrations shows the directions of:

Up, Back, Left, Down, Front, Right.

MetaData: End of “Introduction”

R

F

U

B

L

D

785-823-3276

03/31/2011 Table of Contents Index 407-451M

Page 14

10 SML-1000, SML-750, SML-500 Table of Contents Index Great Plains Manufacturing, Inc.

Preparation and Setup

This section helps you prepare your cart for use, and

covers tasks that need to be done seasonally, or when

the tractor/implement/cart configuration changes.

Before using the cart in the field, you must hitch it to a

compatible planter or drill, and inspect and pre-set systems.

Initial Setup

See “Appendix C - Initial Setup” on page 40 for tasks

that must be completed prior to initial use, including:

• Dismount implement rear pintle hitch (if any).

• Install implement quick hitches for cart.

Post-Delivery/Seasonal Setup

On initial delivery, use with a new tractor, and seasonally,

check and as necessary, complete these items before

continuing to the routine setup items:

• Flush tank and lines (page 26).

• Clean inlet filter (page 27).

Pre-Planting Setup

Complete this cart checklist before routine setup:

❑ Read and understand “Important Safety Informa-

tion” on page 1.

❑ Check that all working parts are moving freely, bolts

are tight, and cotter pins are spread.

❑ Check that all grease fittings are in place and lubri-

cated. See “Lubrication and Scheduled Mainte-

nance” on page 28.

❑ Check that all safety decals and reflectors are cor-

rectly located and legible. Replace if damaged. See

“Safety Decals” on page 5.

❑ Inflate tires to pressure recommended and tighten

wheel bolts as specified. See “Tire Inflation Chart”

on page 30.

❑ Check winds. For application via fertilizer coulter or

high rate dribbler, high wind may disperse or displace material. Wind is normally not a factor for lowrate “starter” application via the tube between the

opener discs, or via Keeton seed firmer.

Loss of Time Risk:

Perform any planter seed cart changes before hitching fertilizer cart, for example, if switching from bulk box to hopper.

Once hitched, the fertilizer cart obstructs forklift access to the

rear of the planter. Forklifts may still approach the planter

from the side, but hopper and seed box lifting takes more time

and care from the side.

407-451M Table of Contents Index 03/31/2011

Page 15

Great Plains Manufacturing, Inc. Table of Contents Index Preparation and Setup 11

Hitching Cart to Implement

There are two main methods of bringing the cart arms

into alignment with the quick hitches installed on the

implement (planter or drill):

A. Hitch the implement to a tractor, and carefully back

1

the implement up to the cart. These instructions presume the use of this approach.

B. Lift the cart from behind with a forklift (forks under

frame), and move it into alignment with implement.

3

Crushing Hazard:

Do not stand or place any body part between cart and moving

implement. You may be severely injured or killed by being

crushed between the cart arm and implement. Stop tractor

engine and set parking brake before securing quick hitches.

Null4:

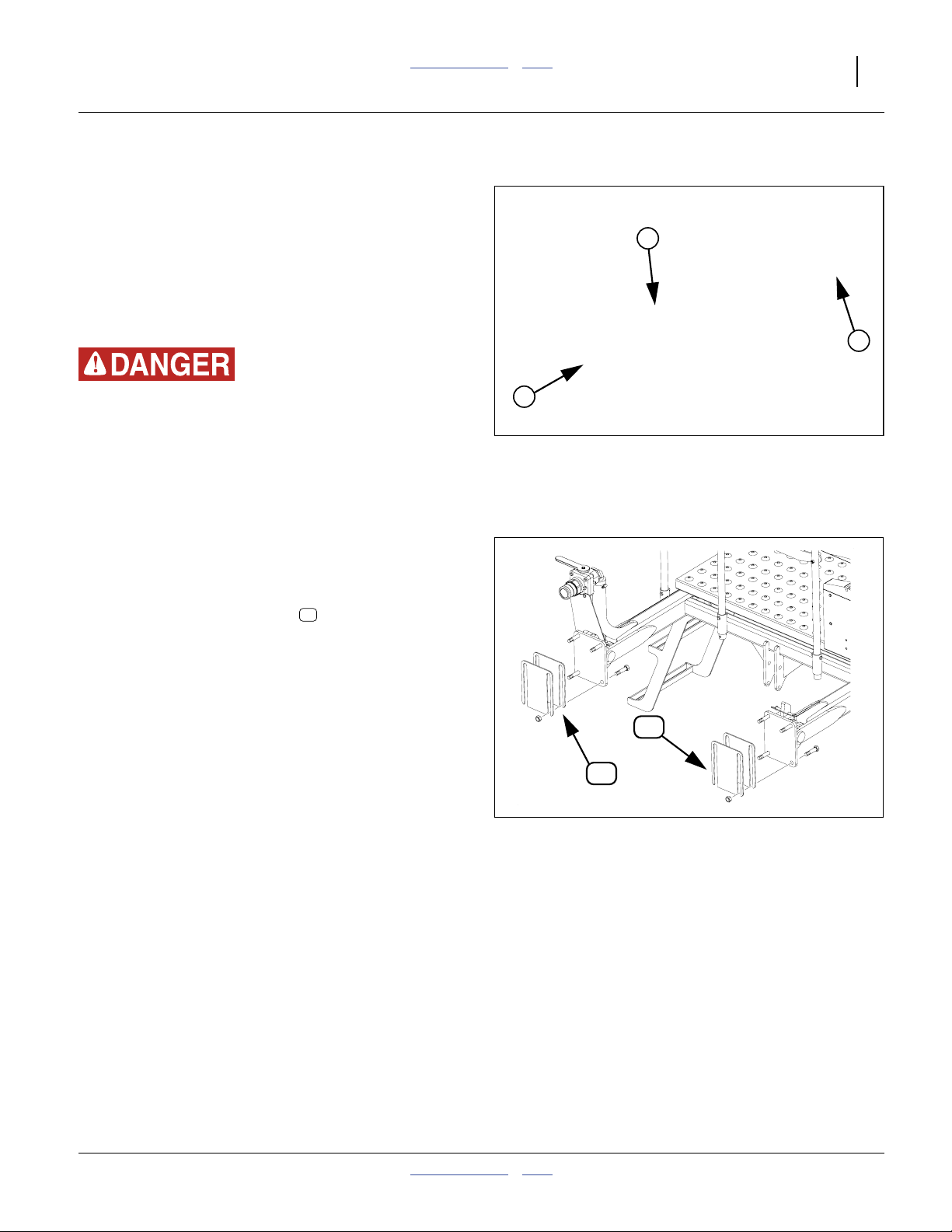

Shims

Refer to Figure 6

Four shims are supplied with each model of cart. The

shims fit between the cart hitch and the implement. It is

recommended to use two shims on each right and left

quick hitch.

Removing one shim will result in a1⁄2in move of the casters in the direction of the side the shim was removed

from.

Moving one of the shims from its present position and

inserting it on the opposite side results in the casters

trailing one inch in the direction of the side the shim was

originally removed from.

26

Null4:

Null4:

2

Figure 5

Quick Hitch Closed and Open

31484

26

26

Figure 6

Shims

32016

03/31/2011 Table of Contents Index 407-451M

Page 16

12 SML-1000, SML-750, SML-500 Table of Contents Index Great Plains Manufacturing, Inc.

Crushing / Loss of Control Hazards:

Do not move the cart by hand. Even when empty, the cart is too

heavy for safe hand movement. Wheel castering can also cause

sudden changes in tongue weight. Attempting hand moves

could result in serious injury or equipment damage. Use a

powered hoist or lift if the cart must be moved for alignment

with towing implement.

4

Open Implement Hitches

At the implement, if the hitches are closed, latch them

both open.

Refer to Figure 5

1. Remove the snap lock wire pin .

2. Flip the latch plate fully up.

3. Re-insert the pin in the plate only.

2

3

Hitch Cart and Implement

4. Bring implement and cart into close alignment.

Refer to Figure 5 and Figure 7

5. Use the parking stand jacks (page 14) to raise the

cart arms above the quick hitch hooks .

6. Move the implement and/or cart into contact.

7. Use the parking jacks to lower the cart arms into the

quick hitch hooks.

8. Remove the snap lock wire pins , allow the latch

plates to fall.

9. Insert pins through both hook risers and latch plates.

Pull up on plates to verify pinning. Secure the pins

with the wire bails.

2

1

Null4:

Null4:

Null4:

Figure 7:

Cart Hitched to Implement

31485

Roll-Away Hazard:

4

Prior to hitching cart, ensure implement cannot move. If

implement is hitched to a tractor, set tractor brakes or put tractor in Park. Block tires if no tractor is hitched. Once weight is

off the cart parking stand, the cart can roll freely. If the ground

is unlevel, the cart could cause the implement to move. The

1

parking stand of an unhitched implement may not prevent rollaway. A roll-away accident could result in equipment damage,

serious injury or death.

407-451M Table of Contents Index 03/31/2011

Page 17

Great Plains Manufacturing, Inc. Table of Contents Index Preparation and Setup 13

Double-Check Latch Plates

Null4.aac:

Accident Hazard:

Ensure the latch plates are pinned down. The pins must be

through both the hook risers and the plates, and not just one

or the other. If a plate is merely resting on a pin, or a pin is

only through a plate, or pin is not secured, one or both cart

arms may come loose in transport. Equipment damage is

likely. An accident could result in serious injury or death.

See Figure 5 (left) and Figure 7 on page 11 for correct

latch plate configurations.

Refer to Figure 8 for

Problems to watch for:

a. Pin behind latch plate:

This is a dangerous configuration. The cart is not

hitched. The latch plate cannot prevent an unhitch

accident while in motion.

b. Pin through latch plate only:

This is a hazardous configuration. It causes excess

wear on the hitch and latch, which may fail, and fail

to prevent an unhitch accident while in motion.

c. No pin:

This is a hazardous configuration. The latch plate

can bounce out of engagement, and fail to prevent

an unhitch accident while in motion. It also causes

excess wear on the hitch and latch.

d. Pin not secured by wire bail:

This is a hazardous configuration. The pin will work

loose, causing the same hazard as configuration c.

Null4:

a

c

Figure 8

Incorrect Latch Plates

56

b

d

31500

6

Make Fertilizer Connection

Make and secure mechanical hitch connections

(page 11) before making the fertilizer line connection.

Refer to Figure 9

(which depicts inlet valve open and outlet valve closed)

10. Close shut-off valves on both cart outlet and

planter inlet .

6

56

11. Remove plug (not shown) from inlet.

12. Inspect, and as needed, clean outlet.

13. Mate connectors. Fold cam levers forward to lock.

Leave valves closed.

Material Loss Risk:

Open hose and inlet valves only when ready to begin planting.

Close them when not in use. Damage to hoses when not applying material can result in rapid tank depletion.

03/31/2011 Table of Contents Index 407-451M

Null4:

Null4:

Figure 9

Fertilizer Cart Connection

31495

Note: These carts require a “Type 2” boom on the planter,

with a single 2in quick-connect inlet at the rear of

the planter.

If there is a boom but no quick connect, the planter

is probably plumbed for on-board dual 200 gallon

tanks, and not a cart.

If there are four quick connects, the planter has a

“Type 3” boom and is not compatible.

If there are five quick-connects, only the inlet for the

Type 2 boom is served by a pump and may be connected to the cart. The Type 3 boom is unused.

Page 18

14 SML-1000, SML-750, SML-500 Table of Contents Index Great Plains Manufacturing, Inc.

Parking Stands

Refer to Figure 10

The parking stands support the front of the cart when

unhitched, and also provide height control during hitching and unhitching.

Crushing Hazard:

Never remove the parking stand pin when the cart is sup-

7

ported solely by the stands. Unless the cart is otherwise immobilized against any movement, the front of the cart may move

forward or backward when the pin is removed, and the arms

will fall to the ground. Anyone in the path of the arms could

suffer serious injury or death.

Raise Stand After Hitching

1. Verify that the cart arms are fully seated in the implement quick hitch, and that the hitch arms are correctly latched and pinned (page 12).

2. Operate the jack stand cranks in the counterclockwise direction to raise the feet off the ground. It

is not necessary to fully retract the leg extensions.

3. When all weight is off the stand assembly, remove

the lock pin .

7

Refer to Figure 11

4. Swing the stand to the rear, until the lock pin hole

aligns with holes . Insert pin.

9

5. To continue setup, skip to topic “Make Fertilizer

Connection” on page 13.

8

7

Null4:

Figure 10:

Cart Parked on Stands

9

9

8

31488

Lower Stand for Unhitching

1. Verify that cart is positioned on firm, dry level

ground. See advisories in the topic “Short-Term

Parking” on page 22.

2. Support the weight of the stand assembly.

3. Remove pin holding stand under walkboard. Swing

stand to vertical. If ground is uneven, it may be necessary to crank up the leg extensions a bit.

4. When stand pin hole aligns with lock hole, insert pin.

5. Operate cranks in the clockwise direction until they

just begin to lift the arms in the quick hitch.

Verify that each jack is supporting a share of the

weight. Operate each until it performs some lifting of

the cart arms at the quick hitch.

6. To continue unhitching, skip to topic “Short-Term

Parking” on page 22.

MetaData: End of “Preparation and Setup”

407-451M Table of Contents Index 03/31/2011

Null4:

Figure 11:

Stand Raised

31491

Page 19

Great Plains Manufacturing, Inc. Table of Contents Index 15

Operating Instructions

This section covers general operating procedures. Experience, machine familiarity, and the following information

will lead to efficient operation and good working habits.

Always operate farm machinery with safety in mind.

Pre-Start Checklist

Perform the following steps before transporting the fertilizer cart cart to the field.

❑ Carefully read “Important Safety Information” on

page 1.

❑ Inspect all hoses, tubing and fittings for holes,

cracks, excess wear and any other signs of possible

leaks.

❑ Lubricate cart as indicated under “Lubrication and

Scheduled Maintenance” on page 28.

❑ Check all tires for proper inflation. See “Tire Infla-

tion Chart” on page 30.

❑ Check all bolts, pins, and fasteners. Torque as

shown in “Torque Values Chart” on page 31.

❑ Check cart for other worn or damaged parts. Repair

or replace parts before going to the field.

❑ Review inlet filter cleaning history. Clean filter if due

(page 27).

❑ Ensure that the implement is set up for the material

and application rate desired. See the Seed Rate

manual for the implement. Setup items commonly

include:

• boom drop line orifice plates

• pump rate setting

• pump strainer check

• relief valve check and set

❑ Determine how long (in time or area) it will take to

exhaust the material in the tank at the desired rate.

This information is important both to ensure correct

application rate, and to avoid running a dry pump at

material run-out.

03/31/2011 Table of Contents Index 407-451M

Page 20

16 SML-1000, SML-750, SML-500 Table of Contents Index Great Plains Manufacturing, Inc.

Transporting the Cart

Loss of Control Hazard:

Ensure that the towing vehicle is adequate for the task. Using

an inadequate tow vehicle is extremely unsafe, and can result

in loss of control, serious injury and death.

A full cart adds up to 18,000 pounds (8100 kg) to the weight

of the implement. An empty cart cart adds up to 3,300 pounds

(1500 kg) to the weight of the implement. The tractor unit

MUST be rated for the load.

Do not tow if the weight of implement plus cart exceeds the

load rating of the vehicle.

Check Bridge Loads: A loaded implement with cart in tow,

can exceed the load ratings of bridges you must cross.

A

Braking and Loss of Control Hazard:

Do not exceed 20 mph (32 kph) when driving straight.

Loss of Control Hazard:

Do not exceed 13 mph (21 kph) in turns. The cart wheels and

rear implement wheel freely caster and provide no resistance

to side sway. The combination of implement and cart (particularly if the cart is loaded) is extremely heavy, and can cause

“over-steer” with most tractors.

Reduction of Control Risk:

Material may be loaded prior to travel, but increases stopping

distance, increases the need for caution in turns and braking,

and increases tire wear.

Never exceed 3 mph (5 kph) in reverse.

Transport Checklist

❑ Plan the route so that no reverse movements will be

necessary. Avoid steep hills.

❑ Check the hitch. See “Hitching Cart to Implement”

on page 11.

❑ Complete implement transport checklist.

❑ Check that tank lid and breather plug are secure.

❑ Close all valves (cart inlet, tank discharge and cart

outlet). See page 32 or page 33 for valve locations

by cart model

❑ Fold up and latch ladder. See page 17.

❑ Always have lights on for highway operation.

❑ Comply with all national, regional and local safety

laws when traveling on public roads.

❑ Travel with caution.

407-451M Table of Contents Index 03/31/2011

Page 21

Great Plains Manufacturing, Inc. Table of Contents Index Operating Instructions 17

Walkboard and Ladder

The cart walkboard is used for:

• access to the tank lid for clean-out,

• access to the tank lid for top-loading, and;

• access to the planter ladder (model YP2425 only) for

planter operations.

No Riders:

Allow no one on the ladder or walkboard during cart movement. The railings are designed to act as guards only when

parked. The cart is subject to sudden and unpredictable jolts

and sways, and the railings may fail to protect a rider. If material is loaded in the tank, there is also some risk of small

amounts escaping the lid vent and reaching the walkboard

during braking and in rough conditions.

Ladder Operation

Refer to Figure 12

To lower the ladder, pull the spring-loaded pin to cart

1

rear and pull the top of the free end of the ladder away

(right) from the cart.

To raise the ladder, merely swing it up. The pin automatically engages as the ladder is fully raised.

1

Equipment Damage Risk:

Ladder must be locked up before transport or field operations

or machine damage may occur if the ladder strikes obstructions.

Null4:

Null4:

Figure 12

Walkboard Ladder Pinned Up

31503

03/31/2011 Table of Contents Index 407-451M

Page 22

18 SML-1000, SML-750, SML-500 Table of Contents Index Great Plains Manufacturing, Inc.

Loading Materials

The cart tank may be loaded from the quick-fill inlet, or

from the lid. Filling the tank from the top is not recommended, unless the supply line has a filter with capability

equivalent to the inlet filter at the cart quick-fill.

Load only pre-mixed liquid fertilizer solutions. The cart is

not designed for dry fertilizer mixing.

If the fertilizer solution has any tendency to settle, sediment, gel, coagulate, precipitate or stratify, load material

Agricultural Chemical Hazards:

Avoid contact with skin or eyes. Wear proper protective equipment as required by chemical manufacturer. Avoid prolonged

breathing of chemical fumes. Wear respirator as required by

chemical manufacturer. Some chemicals will cause serious

burns, lung damage and death. Seek medical assistance immediately if accident occurs. Know what to do in case of an accident.

immediately prior to application. The cart has no agitators for sustaining suspensions.

Material Loss Risk:

If loading before transport, note that a combination of a tank

over half full, and rough roads, steep hills or heavy braking

can slosh material to the cap, and some can escape through

the breather tubes.

System Plugging Risk:

Do not allow fertilizer to remain in the tanks for extended periods or settling of material and system plugging will occur.

Filling by Either Method

1. Hitch the cart to the implement. Filling an unhitched

cart is not recommended, as it can increase parking

stand loads above the bearing capacity of the soil. A

loaded cart is also substantially more difficult to move during hitching.

2. Inspect the tank from the lid.

3. Drain excess condensation from the tank, so that this

water does not dilute the material to be loaded. See

“Material Clean-Out” on page 26 for the procedure.

Flush the tank if there is other residue present.

Refer to Figure 13

4. Inspect the sight gauge . If you can’t see your

1

hand behind the tube, clean or replace the tube.

5. Close the cart inlet and outlet valves. See

51

56

page 32 or page 33 for valve locations by cart model.

6. Set the discharge valve (see page 32 or 33):

55

On the SML-1000 Gallon Cart,

close the discharge valve.

On the SML-750 Gallon Cart,

open the discharge valve

On the SML-500 Gallon Cart,

close the discharge valve

Null4:

Sight Gauge Scale Metric Equivalents

Capacity 1,035 gal. 735 gal. 510 gal.

—1000—

—900—

—800—

—700—

—600—

—500—

—400—

—300—

—200—

—100—

55

1

Figure 13

31505

Sight Gauge (1000 Gallon Tank)

Cart SML-1000 SML-750 SML-500

Full

3920 liters 2780 liters 1930 liters

3790 liters

3410 liters

3030 liters

2650 liters 2650 liters

2270 liters 2270 liters

1890 liters 1890 liters 1890 liters

1510 liters 1510 liters 1510 liters

1140 liters 1140 liters 1140 liters

760 liters 760 liters 760 liters

380 liters 380 liters

407-451M Table of Contents Index 03/31/2011

Page 23

Great Plains Manufacturing, Inc. Table of Contents Index Operating Instructions 19

Tank Quick-Fill

The quick-fill inlet is a 2in quick-connect coupling.

Refer to Figure 13

These steps presume completion of step 1 through

step 6 on page 18.

7. Connect nurse-tank/supply hose to quick-fill

coupler . Lock hose in place with cam-lock levers.

51

This inlet is located at the rear of the 1000 gallon

cart, and at the left side of the 735 gallon cart.

8. Close valve (not shown) going to the in-line filter

located just before the pump.

9. Open cart inlet valve .

10. Open supply outlet valve (not shown), and moni-

52

56

tor fill level in sight gauge.

11. Close supply outlet valve when tank fill reaches

desired level.

12. Close cart inlet valve .

52

13. Disconnect the source at the quick fill inlet. Insert

and secure the inlet plug.

Tank Lid Fill

Filling the tank from the top is not recommended, unless

the supply line has a filter with capability equivalent to

the inlet filter at the cart quick-fill.

Employ two persons for top fill; one to secure the hose at

the tank, the other to monitor the sight gauge. One of

these persons must also control a supply line shut-off

valve.

These steps presume completion of step 1 through

step 6 on page 18.

Refer to Figure 15

5. Open the tank lid:

Note: The cart has no pump. The implement boom

pump cannot load the tank. The supply source

must provide, via pump or gravity, the pressure for

tank filling. A pressure of at least 10 psi (46 kPa),

or a water column of at least 60in, at the inlet, is

required for a reasonable fill rate.

Null4:

Null4:

Null4:

52

Quick-Fill Coupler (1000 Gal.)

51

Figure 14

31504

Chemical Hazard - Tank Lid:

For top loading, wear gloves and any other protective equipment indicated for any materials that have ever been used in

the tank (not just the material presently being loaded). Normal

operations splash material on the underside of the lid. It is

likely to be coated with residues that could be highly concentrated, whether dry, damp or wet. Remove the lid slowly to

avoid throwing off material toward yourself.

The breather plug in the center of the lid removes,

providing 4.5in (11.4 cm) opening. Turn it about 30°

2

2

counter-clockwise to release the bayonet lugs. This

opening is sufficient for most fill hoses.

The tank lid completely unscrews for a larger

16in (40.6 cm) opening. The lid has twin threads.

Make sure that both are evenly engaged when tightening the lid, and that the lid is fully seated.

6. Insert the supply hose.

7. Open the supply line valve. Monitor sight gauge. Fill

to desired level. Close supply valve.

Null4:

Figure 15

Tank Lid Breather Plug

31509

8. Remove hose. Close and secure the tank lid.

Null4.aac:

03/31/2011 Table of Contents Index 407-451M

Page 24

20 SML-1000, SML-750, SML-500 Table of Contents Index Great Plains Manufacturing, Inc.

Tank Field Operation

Field Start-Up

These steps presume that all implement and cart setup

items are completed.

1. Position implement at start of field to be planted.

Raise and unfold the implement.

2. Open the inlet valve on the implement.

3. Open the outlet valve on the cart.

4. Open the discharge valve on the cart.

5. Check for leaks.

6. Prime the pumpa:

Rotate the ground drive wheel (top forward) to operate the pump until material appears at the row drop

lines.

7. If using an electrically activated pump integrated with

the seed monitor, set the “Fert.Pump” switch (on the

switch under the console) to “ON”.

No other actions are usually required. Using a grounddrive pump on the implement, material application starts

automatically when the implement is lowered and in

motion.

Note: Pump Priming:

The standard Great Plains ground-drive piston

pump is lower than the tank when the implement

is lowered for planting. Any amount of air in the

fertilizer lines is quickly pumped out.

If you are using another pump, such as a tractormounted pump, or a pump that does not have positive displacement. The pump may have some difficulty with air in the lines. Refilling the tank to

pump installation height usually aids in priming.

Planting

Liquid fertilizer systems on Great Plains implements are

generally not integrated with seed monitor electronics.

The tractor operator must visually monitor and periodically check tank condition.

Mind the boom manifold gauge. Investigate any periods

when the gauge is reading zero. Generally, the tank sight

gauge will not be visible from the tractor cab. The manifold gauge may be the only indication of a material issue.

Check the material level in the tank at every opportunity.

Refill as needed to avoid pumping dry.

Material Run-Out

If the entire supply of material is consumed before planting is complete, disconnect the ground drive pump (see

implement Operator and/or Seed Rate manuals for

steps to disable a pump, typically removing a sprocket or

chain).

Null4:

Equipment Damage Risk:

Avoid dry pumping. Pumps, such as the CDS-John Blue pump

supplied by Great Plains, can be damaged if operated without

working fluid to pump.

a. For a pump other than a Great Plains ground drive, consult the pump or system documentation for stationary operation.

407-451M Table of Contents Index 03/31/2011

Page 25

Great Plains Manufacturing, Inc. Table of Contents Index Operating Instructions 21

Field Set-Up Checklists

Use the following tables, and the checklists in your implement Operator

final checklist for your tractor/implement/cart configuration. Additional or fewer steps may be necessary

depending on tractor features, implement options and

planting accessories.

Null4:

Implement Checklist Page

Basic implement checklist completed a

Boom system checklist completed a

Null4:

Mechanical Checklist Page

Cart hitched. Hitch latch plates pinned 11

Tank lid and breather insert secure 19

Ladder raised and pinned 17

Null4:

Plumbing Checklist Page

Inspect hoses and fittings for leaks

Cart inlet valve - CLOSED 18

Tank discharge valve - OPEN 18

Implement inlet valve - OPEN a

Cart outlet valve - OPEN 18

Prime pump 20

Null4:

Treatments Checklist Page

Material depletion rate estimated

a

and Seed Rateb manual to develop a

Field Operation

Perform all steps in “Pre-Start Checklist” on page 15

and “Field Set-Up Checklists” on page 21.

Null4:

First Pass Operation Checklist Page

1. Complete implement pass 1 checklist a

2. If cart has a fertilizer system integrated

with the DICKEY-john seed monitor,

set the “Fert.Pump” switch on the

Clutch Folding Module to ON.

3. Pull forward, lower implement, and

begin planting.

4. Check boom manifold pressure gauge b

Null4:

Suspending Planting Checklist Page

1. Stop tractor. Set brakes.

2. Complete implement Suspend Planting checklist

3. If cart has a fertilizer system integrated

with the DICKEY-john seed monitor,

set the “Fert.Pump” switch on the

Clutch Folding Module to OFF.

4. Cart outlet valve CLOSED. 32 or 33

Material Re-Load Checklist Page

1. Perform Suspending checklist. above

2. Check fertilizer level whenever re-loading seed.

3. Check fertilizer level prior to expected

time or distance of fertilizer depletion.

4. When reloading seed and fertilizer,

check consumption against anticipated

use to that point.

Null4:

Null4:

Ending Planting Checklist Page

a

a

a

a

1. Suspend operations as above, then

2. Implement inlet valve CLOSED a

3. Tank discharge valve CLOSED 32 or 33

4. Perform a material clean-out to preserve pump as soon as possible.

Null4:

a. See planter or air drill implement Operator manual.

b. Topic covered in Seed Rate manual. See “Document Family” on page 9 for a list of Rate manuals.

03/31/2011 Table of Contents Index 407-451M

26

Page 26

22 SML-1000, SML-750, SML-500 Table of Contents Index Great Plains Manufacturing, Inc.

Short-Term Stopping

These steps presume that the cart remains hitched to

the implement during stopping.

1. Complete implement stopping or parking steps.

2. If cart has a fertilizer system integrated with the

DICKEY-john seed monitor, set the “Fert.Pump”

switch on the Clutch Folding Module to OFF.

3. Ensure implement cannot move. Block tires if tractor

is unhitched.

4. Set cart outlet valve to CLOSED.

Equipment Damage Risk:

Do not leave the implement stopped for an extended period of

time with fertilizer in the pump. Most fertilizers are corrosive

and may damage a pump in a few hours. If extended stopping

is required, perform a “Material Clean-Out” (see page 26).

Short-Term Parking

These steps presume that the cart is unhitched from the

implement during parking.

1. Spot cart on level pavement or firm level ground. If

there is any doubt about the ability of the surface to

support the weight on the parking stands, provide

stout plates for use under the stands.

2. Complete implement parking steps.

3. Complete “Short-Term Stopping” steps on this

page, including blocking tires if ground is unlevel.

4. Set implement inlet valve to CLOSED.

5. Set tank discharge valve to CLOSED.

6. Disconnect cart hose at implement quick-fill.

7. Swing cart parking stand up and pin.

8. Un-pin cart hitch latches. Swing up. Pin up.

9. Crank stand feet down. Raise stands equally until

cart arms are above hitch hooks.

10. Pull implement away.

Long-Term Storage

1. Perform a “Material Clean-Out” (see page 26):

Recover or dispose of remaining material.

Flush tank, then partly fill with clean water.

Pump water through boom system.

Empty and clean cart inlet filter.

2. Store the cart indoors if possible.

3. Complete “Short-Term Parking” steps, but set

valves to these positions:

Cart inlet - CLOSED

Tank discharge - OPEN

Cart Outlet - CLOSED

4. Breather plug - CLOSED.

5. Tank lid - CLOSED TIGHTLY.

6. Ladder - raised and pinned up.

7. Lubricate all points listed in Maintenance to prevent

rust.

8. Clean cart of mud, dirt, excess oil and grease. Rinse

the cart generally. Fertilizers are corrosive to

unpainted metal surfaces of the cart.

9. Inspect for worn or damaged parts. Make repairs

and service during off season.

10. Use spray paint to cover scratches, chips, and worn

areas on the cart to protect the metal.

11. Cover fertilizer cart with a tarp if stored outside.

Equipment Damage Risk:

Do not leave the implement parked for an extended period of

time with fertilizer in the pump (see Notice above). Do not

leave the cart parked for an extended period of time with fertilizer in the tank. Fertilizer may evaporate, gel, settle, sediment,

stratify, precipitate or coagulate, and clog the lines. If

extended parking is required, perform a “Material Clean-

Out” (see page 26).

MetaData: End of “Operating Instructions”

407-451M Table of Contents Index 03/31/2011

Page 27

Great Plains Manufacturing, Inc. Table of Contents Index 23

Troubleshooting

See also the Troubleshooting sections of the implement Operator manual, and the Seed Rate manual.

Fertilizer Cart Troubleshooting

Problem Cause Solution Page(s)

No Load

Slow Load

Tank Level

Lower at

Field

No Flow in

Field

Inlet valve and/or 735 gallon

tank discharge valve closed

Insufficient pressure at

source

Inlet filter completely clogged Clean filter. 27

In cold weather, inlet plumbing may be frozen

Inlet filter partially clogged Clean filter. 27

Insufficient pressure at

source

Solids in mix too large for

inlet filter

Material sloshed out breather

vent in transport

Leak due to damaged or

loose hose/fitting

Pump not yet primed Prime the pump. Otherwise, at low application rates, it

One or more valves closed Check that tank discharge, cart outlet and implement

Material depletion Stop and check sight gauge 18

Pump strainer completely

clogged

Pump inoperative Check pump sprockets, chain, range and scale setting.

Cold weather: material too

viscous for strainer and/or

orifice plates. Material might

be entirely frozen.

All material dumping at relief

valve

Open valve(s).

Elevate source or use pump.

Move cart to warm space or wait for warmer weather.

Elevate source or use pump.

Reconsider using this material. Although you could topload it, or replace the 12 mesh filter with a 6 mesh, no

standard orifice plate sizes are apt to be large enough

to pass this material at the row drops.

Fill tank at field, or to less than half full prior to transport,

and/or drive slower, brake more gently or chose a

smoother route.

Inspect entire cart plumbing system for leaks. Repair as

needed.

may take some time/distance to clear the air from a

completely dry implement inlet and boom system.

inlet valves are all open.

Clean pump strainer. Also check mesh size vs. material

requirements.

Check for internal pump failure. For a pump other than

Great Plains ground drive, also check monitor settings,

cable harness, fuses, clutches, etc.

Wait for warmer weather. Increasing pump strainer

mesh and orifice plate sizes to compensate for cold gelling may produce uneven application rates.

Check and adjust the relief valve. If not set too low, orifice size is likely to small for material viscosity or solids.

32 or 33

19

19

20

20

27

a

a

03/31/2011 Table of Contents Index 407-451M

Page 28

24 SML-1000, SML-750, SML-500 Table of Contents Index Great Plains Manufacturing, Inc.

Fertilizer Cart Troubleshooting

Problem Cause Solution Page(s)

Material

Dumping

Low Flow

Erratic

Gauge

Reading

High Flow

a. See Seed Rate manual for relief valve pressure range and adjustment.

MetaData: End of “Troubleshooting”

Orifice size too small for

material or rate

Speed too high Gallons/acre or liters/ha is correct, but speed is too high

Relief valve set too low Check and adjust the relief valve. If not set too low, ori-

Pump strainer clogged or

mesh size too fine for material

But no material is dumping...

Pump drive in Low Range Exchange sprockets a

Valve not fully open Check tank discharge, cart outlet and implement inlet

Ground drive wheel slipping Wait for dryer conditions

Rate setting calculation (or

pump range/scale setting)

incorrect

Pump wearing This check for positive displacement pumps only:

Air in lines Prime pump or wait for pump to clear air. 20

Failed gauge Replace gauge.

Cold weather: material too

viscous for accurate reading

Pump drive in High Range Exchange sprockets a

Rate setting calculation (or

pump range/scale setting)

incorrect

Re-check orifice plates against Seed Rate manual

guidelines.

for orifice plate size. Slow down or recalculate for speed

actually used.

fice size is likely to small for material viscosity or solids.

Inspect pump strainer. Clean filter mesh. Check size

against material requirements.

valves. Align handles with hose.

Re-check field size, swath, speed, pump setup and orifice plate sizing. a

With implement lowered and stopped, and tank over

half full, disconnect fitting at pump outlet. Once fluid

already present in fitting drains off, flow should stop.

If material continues to flow, even at a very low rate,

it indicates bypass in the pump. Repair or replace the

pump.

Wait for warmer weather.

Re-check field size, swath, speed, pump setup and orifice plate sizing. a

a

a

a

a

32 or 33

407-451M Table of Contents Index 03/31/2011

Page 29

Great Plains Manufacturing, Inc. Table of Contents Index 25

Maintenance and Lubrication

Maintenance

Proper servicing and maintenance is the key to long

implement life. With careful and systematic inspection,

you can avoid costly maintenance, downtime, and repair.

Always turn off and remove the tractor key before making

any adjustments or performing any maintenance.

Crushing Hazard:

Always have transport locks in place and frame sufficiently

blocked up when working on implement. You may be severely

injured or killed by being crushed under the falling implement.

1. After using your cart for several hours, check all bolts

to be sure they are tight.

2. Maintain proper air pressure in cart tires.

3. Clean cart on a regular basis. Fertilizers are generally corrosive to unprotected carbon steel. Regular

and thorough cleaning will lengthen equipment life

and reduce maintenance and repair.

4. Lubricate areas listed under “Lubrication and

Scheduled Maintenance” on page 28.

5. Replace any worn, damaged, or illegible safety

labels by obtaining new labels from your Great

Plains dealer.

03/31/2011 Table of Contents Index 407-451M

Page 30

26 SML-1000, SML-750, SML-500 Table of Contents Index Great Plains Manufacturing, Inc.

Material Clean-Out

When planting is completed, it is commonly the case that

some fertilizer remains. Do not allow left over material to

remain in the tank, pump or boom for more than a few

hours. It will corrode the pump and can clog strainer, orifice plates, valves and lines.

Material Recovery

The tank may be gravity-drained out either the inlet or

outlet lines (there is no dump line at the tank).

If draining via the inlet line, this reverses the flow at the

inlet strainer. This can cause filtered solids to be

returned to the source supply. It can also cause some

build-up on the downstream face of the strainer screen.

Plan to clean the strainer (page 27) after a drain-back

recovery.

Excess Application

If excess material in the tank cannot be recovered, apply

it to the field just planted.

• To avoid over-fertilizing, dilute the remaining material

with water, or reduce the application rate.

• To minimize seed disturbance, lock-up row units or set

their down-force to minimum (cam setting zero; out of

notch). Set press wheels for zero or minimum opener

disc depth.

System Flush

• Once the tank is empty, fill it with enough clean water

to flush the cart hoses, implement hoses, pump system, boom system and drop lines. If possible, fill from

the lid and wash the side walls of the tank.

• Apply this water to the planted field as for “Excess

Application”.

Pump Preservation

When the weather is expected to remain above freezing,

a cast iron pump is protected by the flush water. If the

period of storage is of unknown duration, take freezing

precautions. Water freezing in hoses, fittings and tubing

generally does no harm, but water freezing in a pump

can easily fracture the case.

When the temperature may sink below freezing, either

remove the pump to warm storage, or fill it with RV antifreeze (propylene glycol [PG] with corrosion inhibitors). It

is not necessary to introduce anti-freeze to the cart tank,

nor fill the entire hose and boom system with anti-freeze.

Check the product MSDS for the actual concentration of

PG in the product (often omitted on the packaging). Calculate the dilution for protection temperature based on

independent sources (as product names and package

claims are often optimistic).

Confined Space Hazard:

Never enter the tank for any reason.

▲ You can be overcome by hazardous fumes very quickly even

in an empty tank with the lid open.

▲ Even if the fumes are not hazardous, oxygen levels may be

insufficient for breathing.

▲ A partially full tank is a drowning risk.

Possible Chemical Hazard:

Wear proper protective equipment as required by chemical

manufacturer. Avoid prolonged breathing of chemical fumes.

Wear respirator as required by chemical manufacturer. Some

chemicals will cause serious burns, lung damage, and death.

Avoid contact with skin or eyes. Seek medical assistance immediately if accident occurs. Know what to do in case of an accident.

Equipment Damage Risk:

Do not leave fertilizer or fertilizer residue in pump. Do not

allow air to enter pump. Even for short periods of storage, the

entrance of air into the pump causes RAPID and SEVERE

CORROSION.

Note: Dispose of residual materials as specified by the

material supplier.

Note: Removal of the tank discharge fitting requires spe-

cial procedures or special tools. When working

with external fittings, avoid loosening the tank fitting.

Null4:

407-451M Table of Contents Index 03/31/2011

Page 31

Great Plains Manufacturing, Inc. Table of Contents Index Maintenance and Lubrication 27

Cart Inlet Strainer

Refer to Figure 16

The cart uses an in-line strainer to keep damaging particulates out of the system, and reduce the workload of

the strainer at the pump (which has a smaller screen

size).

The inlet strainer becomes clogged over time, reducing

material loading rate. Plan to clean the strainer several

times per season. Don’t wait for loading problems to

arise. Higher quality liquid fertilizers may require less frequent cleaning.

Disassemble and clean the strainer prior to storage to

prevent caking.

Filter Removal

1. For the SML-1000 Gallon Cart or the SML-500 Gallon Cart, the tank must be empty for inlet filter

removal. The tank discharge valve only protects

55

the cart outlet line and not the inlet line.

1. For the SML-750 Gallon Cart, close the discharge

55

valve . The tank does not need to be empty.

2. Place a pail or bucket under the filter. It will be full of

fluid. The hose line from inlet shut-out valve to tank

may also contain fluid.

3. Unscrew and remove the canister cap . Drain the

1

fluid. Be careful to preserve the small gasket.

4. Unscrew and remove the canister body . Be careful

to preserve the filter screen screen gaskets and

48

2

large canister gasket.

Filter Cleaning

Replacement parts for the 831-040C are available

53

from Banjo Corporation and their authorized resellers.

The filter screen is available from banjo or Great Plains.

The Great Plains part is:

48

LS212 BANJO SCREEN FOR 831-040C

5. Inspect O-ring gaskets. Replace gaskets if torn or

excessively worn.

6. Inspect filter cartridge (which also has O-ring

48

gaskets) Wash the filter cartridge with water, or

replace with new cartridge if necessary. Replace if

screen is separated, torn, punctured, or build-up

cannot be removed.

7. Reinstall the cartridge, canister, and plug cap.

MetaData: End of <Maintenance Topics>

Possible Chemical Hazard:

Wear gloves and proper protective equipment as required by

chemical manufacturer. Filter cleaning will result in hand contact with fertilizer. Avoid prolonged breathing of chemical

fumes. Wear respirator as required by chemical manufacturer.

Some chemicals will cause serious burns, lung damage, and

death. Avoid contact with skin or eyes. Seek medical assistance

immediately if accident occurs. Know what to do in case of an

accident.

53

2

1

48

Null4:

Figure 16

831-040C Inlet Filter

Replacement parts:

http://www.banjocorp.com/

31508

03/31/2011 Table of Contents Index 407-451M

Page 32

28 SML-1000, SML-750, SML-500 Table of Contents Index Great Plains Manufacturing, Inc.

Lubrication and Scheduled Maintenance

Intervals

Multipurpose

spray lube

Multipurpose

grease lube

Multipurpose

oil lube

Inspection

required

(service hours)

50

at which lubrication

is required

Axle Pivot

8

One zerk

Type of Lubrication: Grease

Quantity: Until grease emerges

Null4:

Rear Caster Wheel Pivot

1 zerk each of 2 casters; 2 total

Type of Lubrication: Grease

Quantity: Until grease emerges

Null4:

Tire Pressures

20

8

Null4:

31481

Null4:

31483

2 cart tires

Check tire pressures more frequently on a new drill, and

with new tires. Check tire pressures whenever there are

planting problems.

Null4:

407-451M Table of Contents Index 03/31/2011

Page 33

Great Plains Manufacturing, Inc. Table of Contents Index Maintenance and Lubrication 29

Walkboard Hinges

As Required

2 pivot points,

1 spring-load pin

Type of Lubrication: Spray lube

Quantity: Coat thoroughly

Null4:

Caster Stabilizers

Seasonal

One UHMW brake piston each caster;

2 total.

Replace UHMW piston if its length is less than 3.2cm

(11⁄4in). Also replace piston if missing, damaged, tilted,

or top of piston is visible.

To set spring tension with a new piston:

a. Loosen jam nut and back out set screw .

b. Drive screw in (down) until it contacts spring plate .

c. Drive screw in another 1 inch (2.5cm).

d. Tighten jam nut.

Use more tension as needed to eliminate caster vibration

during highway transport.

Null4:

17

39 27

16

Null4:

31479

Null4:

31483

Null4:

27

39

16

17

Wing Casters: Wheel Hubs

Seasonal

4 bearings; 2 each wing

Type of Lubrication: Grease

Quantity: Re-pack

MetaData: End of “Lubrication and Scheduled Maintenance”

MetaData: End of “Maintenance and Lubrication”

Null4:

31483

03/31/2011 Table of Contents Index 407-451M

Page 34

30 SML-1000, SML-750, SML-500 Table of Contents Index Great Plains Manufacturing, Inc.

Appendix A - Reference Information

Specifications and Capacities

SML-1000, SML-750, SML-500 Fertilizer Carts

Cart Model SML-1000 SML-750 SML-500

Tank Capacity

Track

Width (maximum)

Width (nominal)

Height

Length

Tire Size

Weight, empty cart

Weight, full water load

Weight, maximum fertilizer load

1,035 gal. (3,900 liters) 735 gal. (2,800 liters) 510 gal. (1,900 liters)

120 in. (305 cm) 120 in. (305 cm) 120 in. (305 cm)

184 in. (467 cm) 184 in. (467 cm) 180 in. (457 cm)

142 in. (361 cm) 142 in. (361 cm) 141 in. (358 cm)

112 in. (284 cm) 112 in. (284 cm) 102 in. (259 cm)

149 in. (378 cm) 149 in. (378 cm) 147 in. (373 cm)

15-19.5 NHS 12 Ply Skid

Steer 9190 lbs load

3,300 lbs (1,500 kg) 3,200 lbs (1,500 kg) 3,100 lbs (1,400 kg)

11,921 lbs (5,400 kg) 9,322 lbs (4,200 kg) 7,348 lbs (3,300 kg)

17,955 lbs (8,100 kg) 13,607 lbs (6,200 kg) 10,321 lbs (4,700 kg)

15-19.5 NHS 12 Ply Skid

Steer 9190 lbs load

15.5-16.5 14 Ply Skid

Steer 7480 lbs load

Tire Inflation Chart

Tire Inflation Chart

Wheel Tire Size Inflation

Transport

Transport

15-19.5 NHS 12 Ply

Skid Steer

15.5-16.5 NHS 14 Ply

Skid Steer

60 psi

(414 kPa)

60 psi

(414 kPa)

Tire Warranty Information

All tires are warranted by the original manufacturer of the tire.

Tire warranty information is found in the brochures included with

your Operator’s and Parts Manuals or online at the manufacturer’s web sites listed below. For assistance or information, contact your nearest Authorized Farm Tire Retailer.

Manufacturer Web site

Firestone www.firestoneag.com

Gleason www.gleasonwheel.com

Titan www.titan-intl.com

407-451M Table of Contents Index 03/31/2011

Page 35

Great Plains Manufacturing, Inc. Table of Contents Index Appendix A - Reference Information 31

Torque Values Chart

Null4:

Bolt

Size

in-tpi

1

⁄4-20

1

⁄4-28

5

⁄16-18

5

⁄16-24

3

⁄8-16

3

⁄8-24

7

⁄16-14

7

⁄16-20

1

⁄2-13

1

⁄2-20

9

⁄16-12

9

⁄16-18

5

⁄8-11

5

⁄8-18

3

⁄4-10

3

⁄4-16

7

⁄8-9

7

⁄8-14

1-8

1-12

11⁄8-7

11⁄8-12

11⁄4-7

11⁄4-12

13⁄8-6

13⁄8-12

11⁄2-6

11⁄2-12

Bolt Head Identification

Bolt Head Identification

Bolt

Size

Grade 2 Grade 5 Grade 8 Class 5.8 Class 8.8 Class 10.9

1

N-m2ft-lb

7.4 5.6 11 8 16 12

8.5 6 13 10 18 14

15 11 24 17 33 25

17 13 26 19 37 27

27 20 42 31 59 44

31 22 47 35 67 49

43 32 67 49 95 70

49 36 75 55 105 78

66 49 105 76 145 105

75 55 115 85 165 120

95 70 150 110 210 155

105 79 165 120 235 170

130 97 205 150 285 210

150 110 230 170 325 240

235 170 360 265 510 375

260 190 405 295 570 420

225 165 585 430 820 605

250 185 640 475 905 670

340 250 875 645 1230 910

370 275 955 705 1350 995

480 355 1080 795 1750 1290

540 395 1210 890 1960 1440

680 500 1520 1120 2460 1820

750 555 1680 1240 2730 2010

890 655 1990 1470 3230 2380

1010 745 2270 1670 3680 2710

1180 870 2640 1950 4290 3160

1330 980 2970 2190 4820 3560

Torque tolerance + 0%, -15% of torquing values. Unless otherwise specified use torque values listed above.

3

N-m ft-lb N-m ft-lb

mm x pitch

M 5 X 0.8

M 6 X 1

M 8 X 1.25

M 8 X 1

M10 X 1.5

M10 X 0.75

M12 X 1.75

M12 X 1.5

M12 X 1

M14 X 2

M14 X 1.5

M16 X 2

M16 X 1.5

M18 X 2.5

M18 X 1.5

M20 X 2.5

M20 X 1.5

M24 X 3

M24 X 2

M30 X 3.5

M30 X 2

M36 X 3.5

M36 X 2

1. in-tpi = nominal thread diameter in inches-threads per inch

2. N· m = newton-meters

3. ft-lb = foot pounds

4. mm x pitch = nominal thread diameter in millimeters x thread

pitch

4

5.8 8.8 10.9

N-m ft-lb N-m ft-lb N-m ft-lb

43659 7

7 5 11 8 15 11

17 12 26 19 36 27

18 13 28 21 39 29

33 24 52 39 72 53

39 29 61 45 85 62

58 42 91 67 125 93

60 44 95 70 130 97

90 66 105 77 145 105

92 68 145 105 200 150

99 73 155 115 215 160

145 105 225 165 315 230

155 115 240 180 335 245

195 145 310 230 405 300

220 165 350 260 485 355

280 205 440 325 610 450

310 230 650 480 900 665

480 355 760 560 1050 780

525 390 830 610 1150 845

960 705 1510 1120 2100 1550

1060 785 1680 1240 2320 1710

1730 1270 2650 1950 3660 2700

1880 1380 2960 2190 4100 3220

03/31/2011 Table of Contents Index 407-451M

Page 36

32 SML-1000, SML-750, SML-500 Table of Contents Index Great Plains Manufacturing, Inc.

Plumbing Diagrams

SML-1000 Gallon Cart Plumbing

51 Quick-fill inlet

52 Quick-fill shut-off valve

53 Quick-fill strainer

54 Tank tee

55 Tank discharge line valve

56 Cart outlet shut-off valve

57 Quick-fill outlet

57

56

53

52

51

54

Null4:

Null4:

2in

57 56

55

Tank

55 54 53

Figure 17

SML-1000 Gallon Cart Plumbing

52 51

31510

407-451M Table of Contents Index 03/31/2011

Page 37

Great Plains Manufacturing, Inc. Table of Contents Index Appendix A - Reference Information 33

SML-750 Gallon Cart Plumbing

51 Quick-fill inlet

52 Quick-fill shut-off valve

53 Quick-fill strainer

56

57

54 Tank tee

55 Tank discharge line valve

56 Cart outlet shut-off valve

57 Quick-fill outlet

52

55

51

54

53

2in

57

Null4:

MetaData: End of “Appendix A - Reference Information”

56

Tank

55

54 53 52 51

Figure 18

SML-750 Gallon Cart Plumbing

31511

03/31/2011 Table of Contents Index 407-451M

Page 38

34 SML-1000, SML-750, SML-500 Table of Contents Index Great Plains Manufacturing, Inc.

SML-500 Gallon Cart Plumbing

51 Quick-fill inlet

52 Quick-fill shut-off valve

53 Quick-fill strainer

56

57

53 52

54 Tank tee

55 Tank discharge line valve

56 Cart outlet shut-off valve

57 Quick-fill outlet

51

54

Null4:

2in

57 56

55

Tank

55 54 53

Figure 19

SML-500 Gallon Cart Plumbing

52 51

32015

407-451M Table of Contents Index 03/31/2011

Page 39