Page 1

Great Plains Mfg., Inc.

Installation Instructions 1

Smartbox® Mount Kit

Yield Pro Planters

Used with:

• 2005+ Yield Pro

® 1225/1625

• Yield Pro® YP2425

General Information

These instructions explain how to install the Smartbox®

Mount Kit. This kit provides the components necessary

to support mounting Smartbox® units on your Great

Plains planter. The kit does not include the Smartbox®

system itself, nor does it include the speed sensor (typically radar) required by the Smartbox monitor.

These instructions apply to:

Planter Model Uses Kit Kit Description

YP1225-1230

YP1225-16TR

YP1225-1820

YP1225-2315

YP1225-24TR

YP1625-1630

YP1625-2420

YP1625-24TR

YP1625-3115

YP1625-32TR

YP2425-2430

YP2425-3620

YP2425-4715

YP2425-48TR

403-196A

403-197A

403-196A

403-198A

403-199A

403-200A

403-201A

403-201A

403-218A

403-219A

403-218A

403-220A

YP30’ 15-30IN SMARTBOX MNT

(no kit presently available)

YP30’ 20IN SMARTBOX MNT KIT

YP30’ 30TR SMARTBOX MNT KIT

YP30’ 30TR SMARTBOX MNT KIT

YP40’ 15-30IN SMARTBOX MNT

YP40’ 20IN SMARTBOX MNT KIT

(no kit presently available)

YP40’ 30TR SMARTBOX MNT KIT

YP40’ 30TR SMARTBOX MNT KIT

YP60’ 15-30IN SMARTBOX MNT

YP60’ 20IN SMARTBOX MNT KIT

YP60’ 30TR SMARTBOX MNT KIT

YP60’ 30TR SMARTBOX MNT KIT

When you see this symbol, the subsequent instructions

and warnings are serious - follow without exception.

!

Your life and the lives of others depend on it!

25324

Before You Start

Each kit converts an entire planter. Inventory the contents per the “Kit Parts List” on page 18.

Although this kit can be installed before you have the

Smartboxes, Great Plains advises not undertaking this

upgrade until all components are at hand.

Review these instructions, and note which steps apply to

your planter model. For example, the Center Section

steps apply only to the YP2425.

Smartbox® is a registered trademark of AMVAC Chemical Corporation.

©Copyright 2005 Printed 12/12/2006 403-206M

Review the instructions provided by AMVAC, taking note

of where to merge those instructions with these. You may

want to make notations in these instructions for steps

required by AMVAC and not anticipated herein.

“Left” and “Right” are facing in the direction of machine

travel. An orientation rose in the line art illustrations

shows Left, Right, Front, Back, Up, Down.

Tools Required

• basic hand tools

Note: Assembly requires at least two people for the

longer and heavier parts.

Page 2

2 Smartbox® Mount Kit

Assembly Instructions

Great Plains Mfg., Inc.

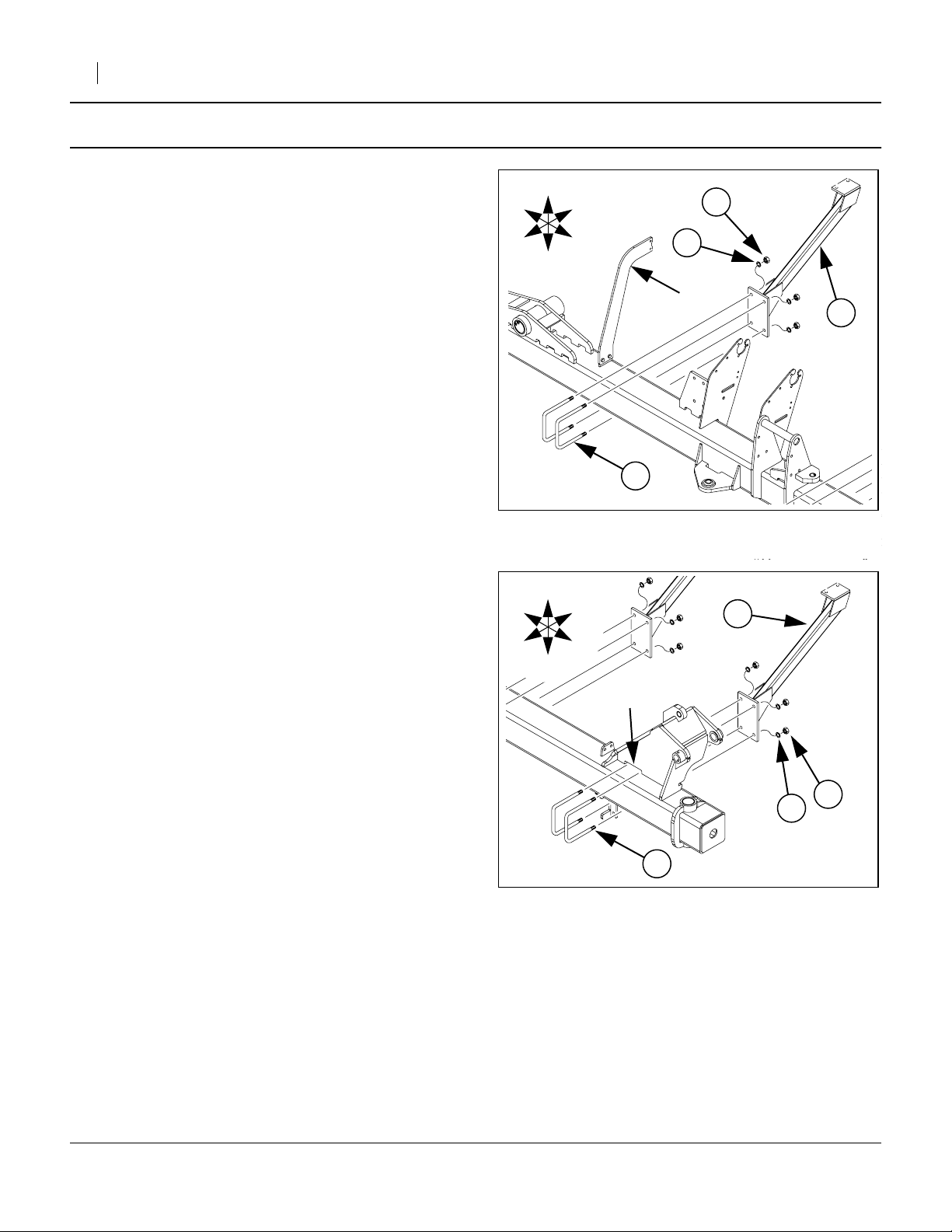

Wing Support Brackets

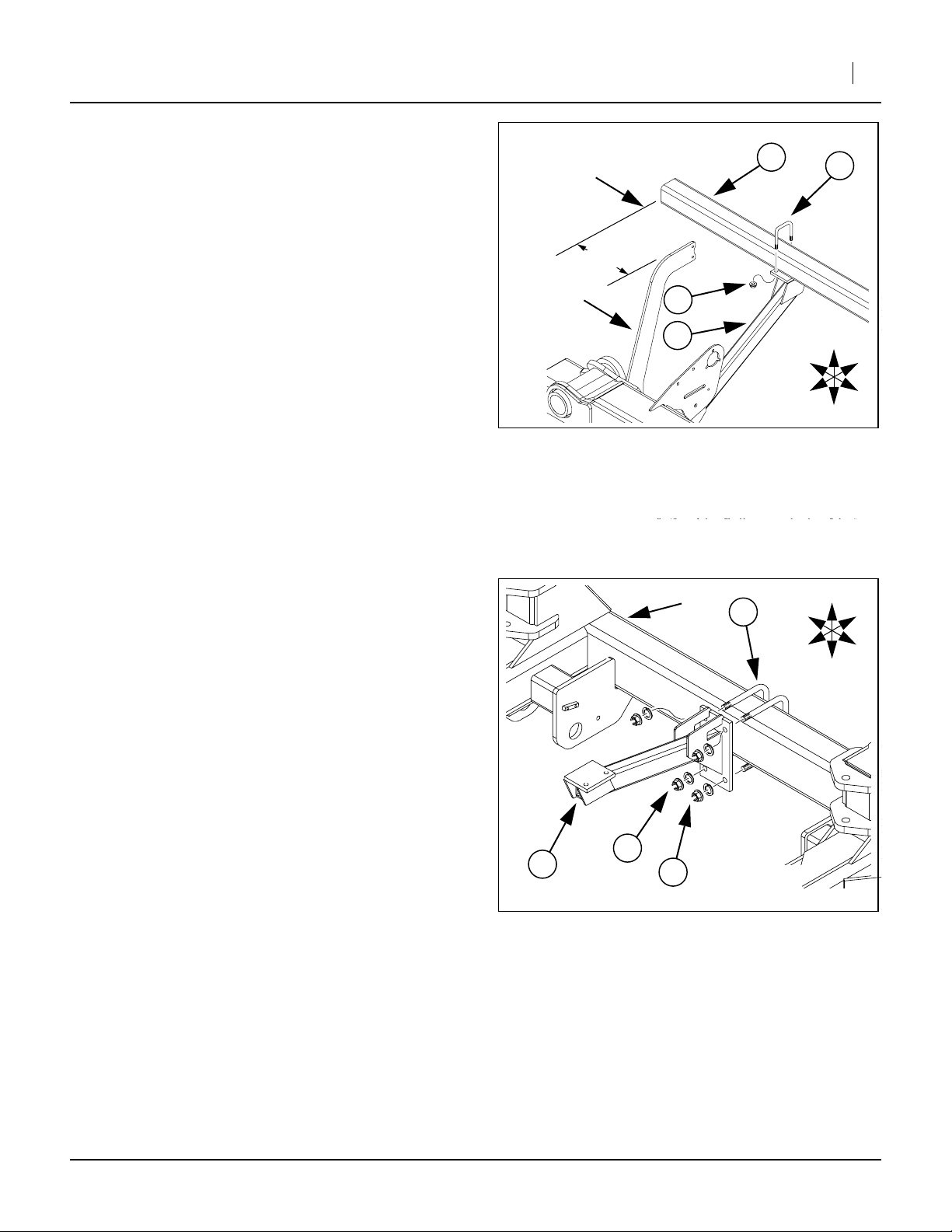

Outer End Wing Support Bracket (all Models)

Refer to Figure 1

1. Select:

one (14) 403-191H,

(SMARTBOX STANDOFF SUPPORT BKT)

two (35) 806-052C,

(U-BOLT 5/8-11 X 7 1/32 X 8 1/2)

four (33) 804-022C,

(WASHER LOCK SPRING 5/8 PLT),

and four (28) 803-021C,

(NUT HEX 5/8-11 PLT).

Attach the standoff support bracket (14) to Back of

toolbar of right-hand planter wing. Mount bracket

(14) as close to air pipe support ➀ as possible.

Note: It may be necessary to relocate hydraulic hose

support stand. Do not relocate row units.

Secure support bracket (14) to wing with U-bolts

(35), lock washers (33) and hex nuts (28).

Pivot End Wing Support Bracket (all Models)

Refer to Figure 2

2. Select:

one (14) 403-191H,

(SMARTBOX STANDOFF SUPPORT BKT)

two (35) 806-052C,

(U-BOLT 5/8-11 X 7 1/32 X 8 1/2)

four (33) 804-022C,

(WASHER LOCK SPRING 5/8 PLT),

and four (28) 803-021C,

(NUT HEX 5/8-11 PLT).

Attach the standoff support bracket (14) to Back of

toolbar of right-hand planter wing. Mount bracket

(14) in slot ➀ below sequence valve.

If this toolbar slot is occupied by a row unit (for

example, on 15in row spacing), position the standoff support bracket at the first available position

inboard of that.

Secure support bracket (14) to wing with U-bolts

(35), lock washers (33) and hex nuts (28).

R

F

R

F

U

D

U

D

B

L

33

➀

35

Figure 1

Wing Outer End Bracket

B

L

➀

35

Figure 2

Wing Pivot End Bracket

28

14

24167

14

28

33

24167

403-206M 12/12/2006

Page 3

Great Plains Mfg., Inc.

Installation Instructions 3

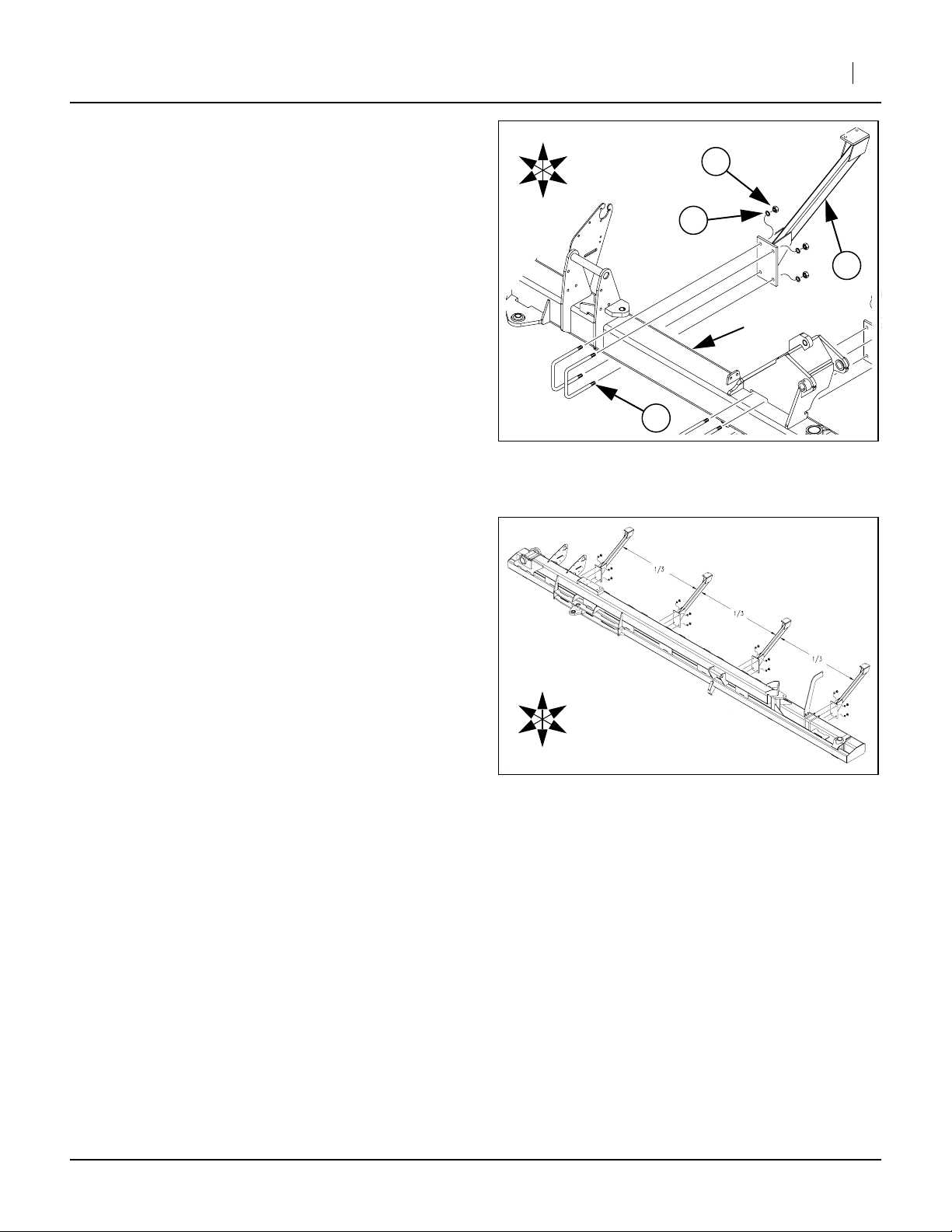

Inner Wing Support Bracket (Models YP1225 & YP1625 only)

Refer to Figure 3

3. Select:

one (14) 403-191H,

(SMARTBOX STANDOFF SUPPORT BKT)

two (35) 806-052C,

(U-BOLT 5/8-11 X 7 1/32 X 8 1/2)

four (33) 804-022C,

(WASHER LOCK SPRING 5/8 PLT),

and four (28) 803-021C,

(NUT HEX 5/8-11 PLT).

Attach the standoff support bracket (14) to Back of

toolbar of right-hand planter wing. Center bracket

(14) as best will fit approximately halfway between

the end brackets already installed. Do not relocate

row units.

Secure support bracket (14) to wing with U-bolts

(35), lock washers (33) and hex nuts (28).

Inner Wing Support Brackets (Model YP2425 only)

Refer to Figure 4

3. Select:

two (14) 403-191H,

(SMARTBOX STANDOFF SUPPORT BKT)

four (35) 806-052C,

(U-BOLT 5/8-11 X 7 1/32 X 8 1/2)

eight (33) 804-022C,

(WASHER LOCK SPRING 5/8 PLT),

and eight (28) 803-021C,

(NUT HEX 5/8-11 PLT).

Measure between the two brackets already

installed and find two locations approximately

the distance from each of them.

Attach a standoff support bracket (14) to Back of

toolbar of right-hand planter wing at each of those

locations. Do not relocate row units.

Secure support bracket (14) to wing with U-bolts

(35), lock washers (33) and hex nuts (28).

U

D

B

L

28

33

R

F

14

➀

35

Figure 3

Wing Inner Bracket

U

R

F

1

⁄

3

B

L

D

Figure 4

Wing Inner Brackets

24167

25232

Mount Brackets on Opposite Wing (All Models)

4. Repeat Step 1 through Step 3 on left-hand wing of planter.

12/12/2006 403-206M

Page 4

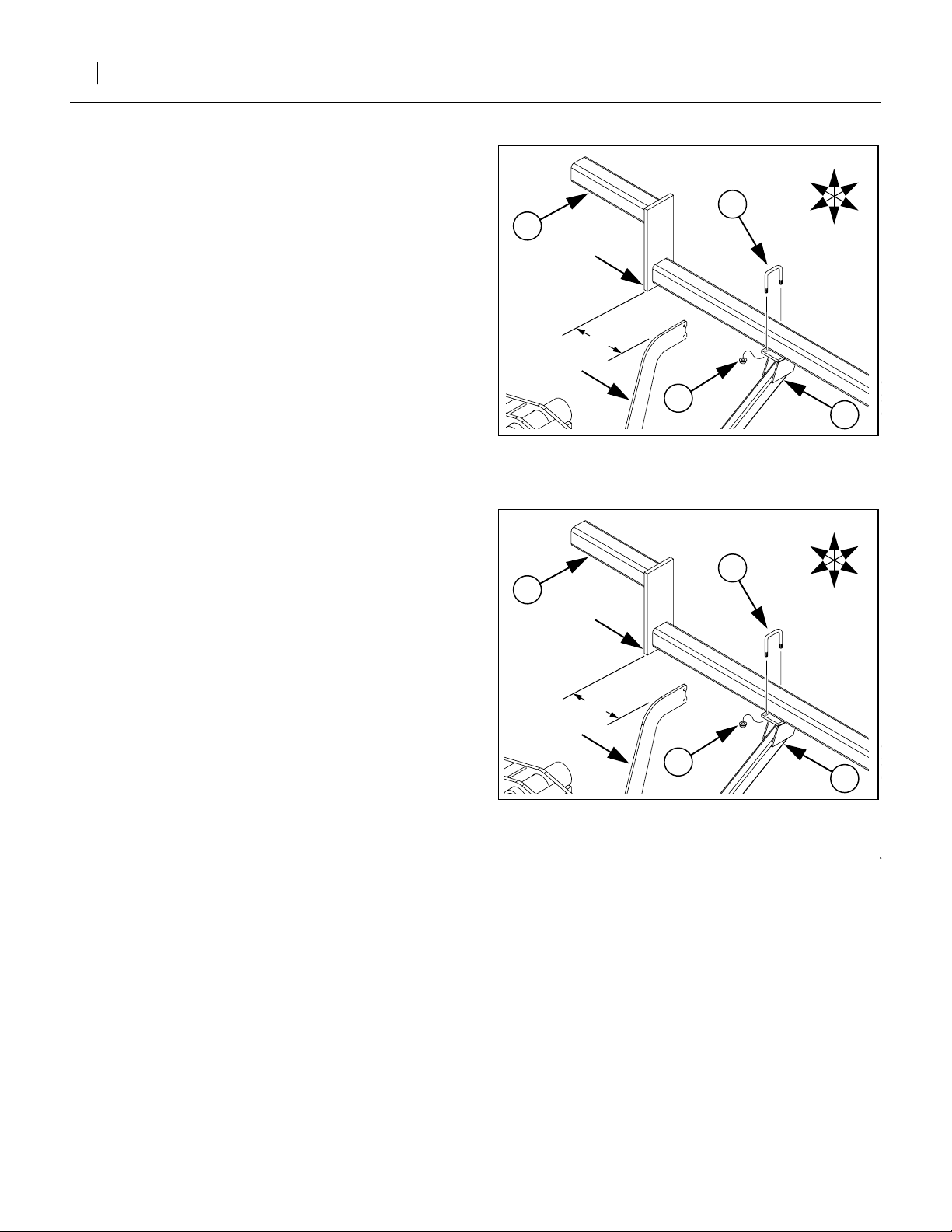

4 Smartbox® Mount Kit

Wing Support Tubes

Mount Tubes (Model YP1225 only)

Refer to Figure 5

5. Select:

one (15) 403-192H,

(SUPPORT TUBE WLDMNT - 12 ROW)

three (37) 806-066C,

(U-BOLT 1/2-13 X 3 1/32 X 4)

and six (30) 803-169C,

(NUT HEX FLG. LOCK 1/2-13 PLT.).

Align support tube (15) so a distance of 6 inches

exists between the planes defined by the end of air

pipe support ➀ and the support tube jog plate ➁.

Using U-bolts (37), attach support tube (15) to

standoff support brackets (14) with elevated end ➀

of support tube towards implement center.

Secure support tube (15) to each of three support

brackets (14) with hex lock nuts (30).

15

➀

6in

➁

30

Figure 5

YP1225 Wing Support Tube

Great Plains Mfg., Inc.

R

37

F

U

B

L

D

14

25325

Mount Tubes (Model YP1625 only)

Refer to Figure 6

5. Select:

one (13) 403-190H,

(SUPPORT TUBE WLDMNT)

three (37) 806-066C,

(U-BOLT 1/2-13 X 3 1/32 X 4)

and six (30) 803-169C,

(NUT HEX FLG. LOCK 1/2-13 PLT.).

Align support tube (13) so a distance of 6 inches

exists between end of air pipe support ➀ and support tube jog plate ➁.

Using U-bolts (37), attach support tube (13) to

standoff support brackets (14) with elevated end ➀

of support tube towards implement center.

Secure support tube (13) to each of three support

brackets (14) with hex lock nuts (30).

13

➀

6in

➁

30

Figure 6

YP1625 Wing Support Tube

37

R

F

U

B

L

D

14

25325

403-206M 12/12/2006

Page 5

Great Plains Mfg., Inc.

Mount Wing Tubes (Model YP2425 only)

Refer to Figure 7

5. Select:

one (19) 403-363D,

(TUBE SQ. 3.0X.25X260)

four (37) 806-066C,

(U-BOLT 1/2-13 X 3 1/32 X 4)

and eight (30) 803-169C,

(NUT HEX FLG. LOCK 1/2-13 PLT.).

Align support tube (19) so a distance of 20

exists between the planes defined by the air pipe

support ➀ and the support tube ➁.

Installation Instructions 5

19

➁

5

20

⁄

in

8

➀

5

⁄

in

8

30

14

R

37

U

B

Using U-bolts (37), attach support tube (19) to

standoff support brackets (14).

Secure support tube (19) to each of four support

brackets (14) with hex lock nuts (30).

(All Models)

6. Repeat Step 5 on opposite wing of planter.

(Models YP1225 & YP1625 only)

Skip to Step 16.

(Model YP2425 only)

Continue with Step 7.

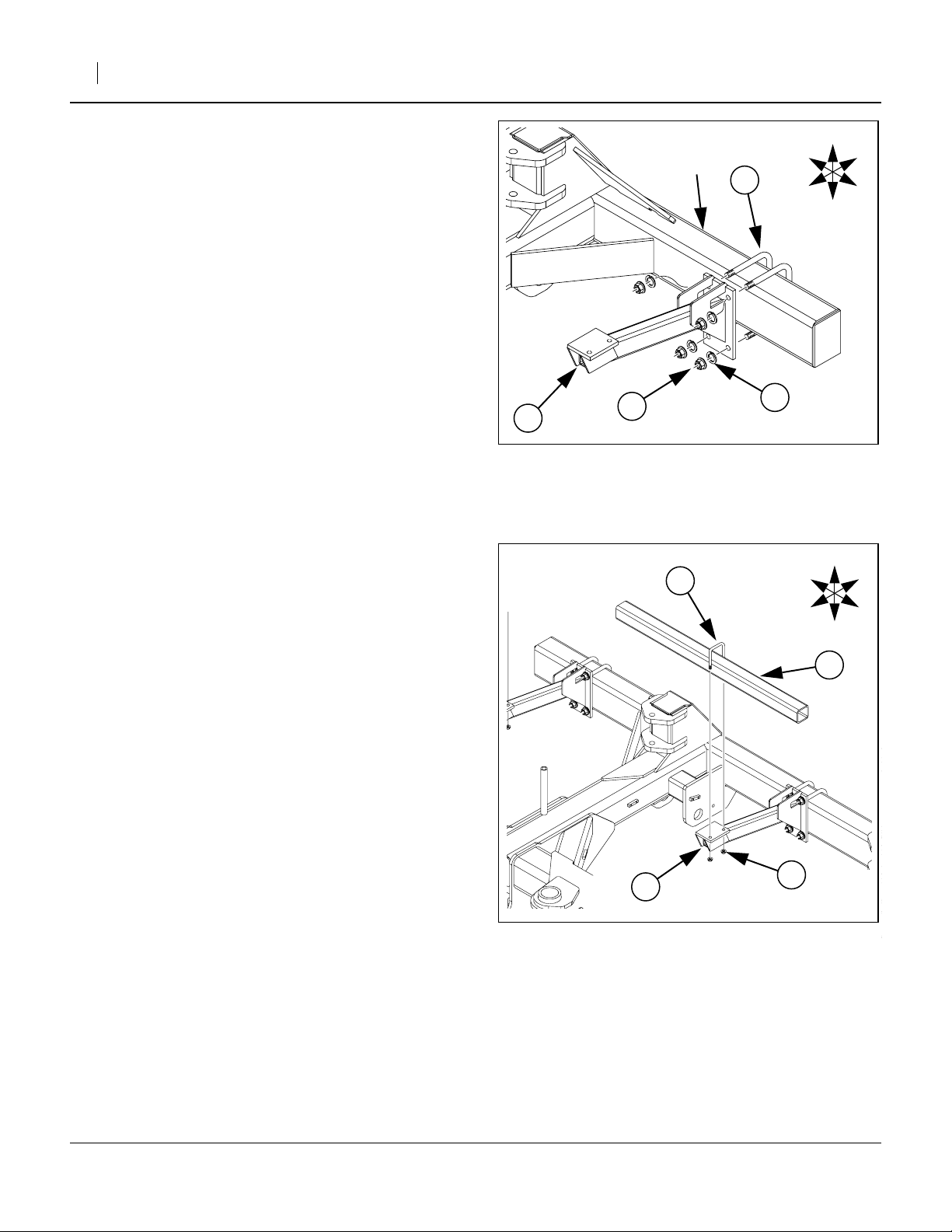

Center Support Brackets (Model YP2425 only)

Center Support Arm

Refer to Figure 8

7. Select:

one (17) 403-225H,

(SMARTBOX SUPPORT ARM SHORT)

two (36) 806-053C,

(U-BOLT 5/8-11 X 7 1/32 X 6 1/2),

eight (33) 804-022C,

(WASHER LOCK SPRING 5/8 PLT) and

(28) 803-021C,

(NUT HEX 5/8-11 PLT).

Mount the support arm (17) on the rear-most

cross-tube ➀ of the center frame, at machine center, arm facing forward.

Loosely secure it with U-bolts (36), lock washers

(33) and nuts (28).

17

Figure 7

YP2425 Wing Support Tube

➀

36

28

33

Figure 8

Center Support Arm

F

R

F

L

D

24168

U

B

L

D

25202

12/12/2006 403-206M

Page 6

6 Smartbox® Mount Kit

Great Plains Mfg., Inc.

Center Section, Right/Left Support Arms (YP2425 only)

Refer to Figure 9

8. Select:

one (17) 403-225H,

(SMARTBOX SUPPORT ARM SHORT)

two (36) 806-053C,

(U-BOLT 5/8-11 X 7 1/32 X 6 1/2),

eight (33) 804-022C,

(WASHER LOCK SPRING 5/8 PLT) and

(28) 803-021C,

(NUT HEX 5/8-11 PLT).

Mount the support arm (17) on the right end of the

rear-most cross-tube ➀ of the center frame, arm

facing forward. Position it approximately 11 inches

from the tube end.

Secure it tightly with U-bolts (36), lock washers

(33) and nuts (28).

9. Repeat Step 8 for the left center.

Center Section, Center Support Tube (YP2425 only)

Refer to Figure 10

10. Select:

one (20) 403-364D,

(TUBE SQ. 3.0X.25X48.00)

one (37) 806-066C,

(U-BOLT 1/2-13 X 3 1/32 X 4), and

two (30) 803-169C,

(NUT HEX FLG. LOCK 1/2-13 PLT.).

Mount the support tube (20), at tube center. on the

center support arm (17) installed in Step 7.

Loosely secure it with U-bolt (37) and nut (30).

17

➀

28

Figure 9

Left/Right Center Section Arms

36

33

37

R

F

R

F

U

B

L

D

25202

U

B

L

D

20

17

Figure 10

Left/Right Center Section Arms

403-206M 12/12/2006

30

25202

Page 7

Great Plains Mfg., Inc.

Installation Instructions 7

Center Section, Right/Left Support Tubes (YP2425 only)

Refer to Figure 11

11. Select:

one (20) 403-364D,

(TUBE SQ. 3.0X.25X48.00)

one (37) 806-066C,

(U-BOLT 1/2-13 X 3 1/32 X 4), and

two (30) 803-169C,

(NUT HEX FLG. LOCK 1/2-13 PLT.).

Mount the support tube (20), at tube center. on the

right support arm (17) installed in Step 8.

Loosely secure it with U-bolt (37) and nuts (30).

12. Repeat Step 11 for the left arm installed in Step 9.

Right/Left Stiffener Bars (YP2425 only)

Refer to Figure 12

The stiffener bars connect the center and right/left support tubes. In doing so, the bars pass between the fold

cylinders.

13. Select:

one (21) 403-365D,

(STIFFENER BAR)

two (37) 806-066C,

(U-BOLT 1/2-13 X 3 1/32 X 4), and

four (30) 803-169C,

(NUT HEX FLG. LOCK 1/2-13 PLT.).

Mount the stiffener bar (21) so that it joins the center and right tubes installed in Step 10 and Step

11. Align the end of each tube with first bend in the

bar.

Note: The bar mounts on top of the tubes, and the bend

in the bar is down, to maintain clearance from

cylinders during planter operations.

Secure the bar to the tubes with the U-bolt (37)

and nuts (30).

14. Adjust the location of the outer support arm to

keep it centered under the tube. Tighten the nuts at

the arm base.

15. Repeat Step 13 and Step 14 for the left tube.

37

17

Figure 11

Left/Right Center Tubes

30

37

Figure 12

Center Section Tube Stiffener

21

30

R

F

R

F

U

B

L

D

20

25203

U

B

L

D

25204

12/12/2006 403-206M

Page 8

8 Smartbox® Mount Kit

Prepare Smartboxes for Installation

Depending on planter configuration, some or all rows

may require installation of meter splitters before mounting

the Smartbox units on the new toolbar tubes.

| Machine Right

SP

Mount and Row Unit Assignments

Individual Row Units

|

Machine Left

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24

1

0

1

0

1

0

SP

BB

1

0

SP

BB

1

0

SP

BB

1

1

B

1

B

1

B

1

B

1

L

1

L

1

R

1

R

1

B

1

B

1

B

1

B

0

LL

SP

1

1

L

0

1

1

R

0

SP

RR

1

0

SP

BB

1

0

SP

BB

1

0

SP

BB

1

BB

B

SP

BB

B

SP

BB

B

SP

BB

B

-

LL

SP

L

-

LL

SP

L

SP

RR

R

SP

RR

R

SP

BB

B

SP

BB

B

SP

BB

B

SP

BB

B

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32

SP

BB

SP

BB

SP

BB

SP

BB

1

B

LL

SP

1

B

1

B

LL

SP

1

B

1

B

SP

1

1

1

1

1

1

1

1

1

1

1

RR

B

L

SP

RR

L

R

SP

BB

R

B

SP

BB

B

B

SP

BB

B

B

SP

BB

B

Great Plains Mfg., Inc.

Find your planter in the following table and note where

splitters (if any) are used. Note also meter pointing bias

near pivots and cylinder interruption points.

SP

1

0

1

0

1

0

1

0

1

0

1

0

SP

BB

1

0

SP

BB

1

B

SP

1

B

-

0

1

0

1

0

1

0

1

0

1

0

1

0

1

0

1

0

1

0

1

0

1

0

1

0

1

0

1

0

1

B

SP

B

B

SP

B

-

SP

BB

B

-

SP

B

-

SP

B

-

SP

L

-

SP

L

-

SP

R

-

SP

R

-

SP

B

-

SP

B

-

SP

B

-

SP

B

-

SP

B

-

SP

B

BB

BB

LL

LL

RR

RR

BB

BB

BB

BB

BB

BB

1

B

1

B

1

B

1

B

1

B

1

B

1

B

1

B

1

B

1

B

1

B

1

B

1

B

1

B

1

B

1

B

1

B

1

B

1

B

1

B

1

B

1

B

1

B

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48

1

B

0

SP

BB

1

0

SP

BB

1

0

SP

BB

1

0

SP

BB

1

0

SP

BB

1

0

SP

BB

1

0

SP

BR

1

0

LB

SP

1

0

SP

BB

1

0

SP

BB

1

0

SP

BB

1

0

SP

BB

1

0

SP

BB

1

0

SP

BB

1

0

SP

BB

1

0

SP

BB

1

BB

B

SP

BB

B

SP

BB

B

SP

BB

B

SP

BB

B

SP

BB

B

SP

BB

B

SP

BB

B

SP

BB

B

SP

BB

B

SP

BB

B

SP

BB

B

SP

BB

B

SP

BB

B

SP

BB

B

SP

BB

B

SP

BB

B

SP

BB

B

SP

BB

B

SP

BB

B

SP

BB

B

SP

BB

B

-

B

-

B

SP

BB

SP

BB

Row Unit Number (from machine left to right)1Unitary: One Smartbox connected to one row unit (no splitter)SPSplitter: One Smartbox connected to two row units via splitter0Null: No connection to this row unit

49

Meter Pointing: Some boxes cannot be mounted directly over the row unit(s) they serve.

Mount meter so that its exit port faces primarily Right(R), Left(L) or Back(B).

RLB

Pivot: Division point between wings, or between wings and center section

Cylinder: Division point in YP2425 center section where tube is interrupted by cylinders

Model

Planter

Tabl e

Legend

Kit

403-206M 12/12/2006

-196A -1230

403- YP1225

-197A -1820

-196A -2315

-198A -24TR

-199A -1630

403- YP1625

-200A -2420

-199A -3115

-201A -32TR

-218A -2430

403- YP2425

-219A -3620

-218A -4715

-220A -48TR

Page 9

Great Plains Mfg., Inc.

Preparing Mounts

Installation Instructions 9

Items for these steps supplied by AMVAC:

➀ Smartbox frames

➁ Smartbox base containers & fasteners

➂ Meters

➃ Gaskets

Preparing Unitary (no Splitter) Mounts

Refer to Figure 13 (base container shown with Smartbox frame - do

not assemble to frame at this time).

For each mount point which has no splitter, the meter is

attached to the Smartbox base container. Orient meter

exit ports per the table on page 8.

16. Select:

four (25) 802-004C,

(HHCS 1/4-20X3/4 GR5),

four (32) 804-007C,

(WASHER FLAT 1/4 SAE PLT), and

four (29) 803-088C (not shown),

(NUT HEX LOCK 1/4-20 FLG).

Position gasket ➃ between Smartbox base container ➁ and meter ➂. Insert bolt (25) through flat

washer (32). Attach meter ➂ to base container ➁

using nut (29) (not shown). Do not mount base

container on frame ➀ at this time.

17. Repeat Step 16 for each unitary Smartbox.

Preparing Split Mounts

Refer to Figure 14 (base container shown with Smartbox frame - do

not assemble to frame at this time)

For each mount point which has a splitter, the splitter is

attached to the Smartbox base container and two

meters are attached to the splitter.

18. Select:

one (16) 403-202H,

(SMARTBOX METER SPLITTER WLDMNT),

twelve (25) 802-004C,

(HHCS 1/4-20X3/4 GR5),

twelve (32) 804-007C,

(WASHER FLAT 1/4 SAE PLT), and

twelve (23) 800-163C,

(CLIP U-TYPE NUT 1/4-20 SLF-RET).

19. Insert all bolts (25) through flat washers (32).

20. Insert a clip nut (23) at each of the fastener openings in the top of the splitter (16). Insert the clip

with the flat side Up.

➁

➀

➃

➂

U

F

L

R

B

D

Figure 13

Unitary Pre-Assembly

U

D

B

R

➁

➀

F

L

23

16

32

25

25326

➃

23

23

➃

➂

32

➂

25

Figure 14

Split-Mount Pre-Assembly

25327

21. Insert a clip nut (23) at each of the fastener openings in the bottom of the splitter (16). Insert the clip

with the flat side Down.

22. Position a gasket ➃ between Smartbox base container ➁ and splitter (16). Using four bolts and

washers, attach splitter (16) to base container.

12/12/2006 403-206M

23. Position a gasket ➃ between a meter ➂ and the

splitter (16). Attach meter to splitter with four bolts

and washers. Repeat for second meter.

24. Repeat Step 18 through for Step 23 each splitter.

Page 10

10 Smartbox® Mount Kit

Mount Smartbox Frames

Refer to Figure 15 (which illustrates normal back-of-tube mounting)

The Smartbox frames ➀ mount to the new tubes ➁ with

3

⁄

a pair of clamps (18),

bolts (26), and flange lock nuts (31) provided in the

mount kit.

Most of the clamps are placed on the Back side of the

tube, but on the YP1225 and YP1625, two (pair) must

be placed on the Front side of the tube.

For model YP2425, skip to Step 40.

in long bolts (27),

8

3

⁄

in short

8

Great Plains Mfg., Inc.

27

➁

26

➀

18

U

L

F

18

YP1225 and 1625 Near-Pivot Mounting

Refer to Figure 16

Due to clearance from other components, the four

inner-most Smartboxes cannot be placed directly over

the row units they serve, and must be to the outside,

with meter hoses canted inward.

Identify the four Smartbox assemblies with meter exit

ports biased Left or Right and set them aside from the

assemblies with ports pointing Back. If you didn’t build

four assemblies with biased ports, pick four assemblies

and re-point the meters.

B

D

R

Figure 15

Typical Frame Mount

31

25328

Figure 16

YP1225/1625 Inner Mounts

403-206M 12/12/2006

24169

Page 11

Great Plains Mfg., Inc.

Installation Instructions 11

Mount Left Inner-Most YP1225/1625 Smartbox

Refer to Figure 17 and Figure 20

25. Select:

one ➀ Smartbox frame,

two (18) 403-319D,

(SMART BOX HOLD DOWN CLAMP),

two (27) 802-223C,

(HHCS 3/8-16X4 GR5),

two (26) 802-079C,

(HHCS 3/8-16X1 1/4 GR5), and

four (31) 803-209C,

(NUT FLANGE LOCK 3/8-16 PLT).

If the base container is already installed on the

SmartBox frame, it may be necessary to remove it

to gain access to the mounting holes.

26. Insert a 1

mounting hole

the shorter end of a clamp (18) over the bolt (26)

and add a flange lock nut (31). Put only a few turns

on the nut.

27. Position the frame ➀ about 4in from the end of the

inner-most end of the new tube ➂, or directly next

to the air pipe support plate.

28. Insert a 4in bolt (27) in the slotted hole ➃ just forward of center on each side of the frame ➀, and

then down through the hole in the clamp (18), and

add a flange lock nut (31). Put only a few turns on

the nut.

29. Alternately tighten the lock nuts (31), keeping the

Smartbox frame ➀ and the base of the clamp (18)

parallel to the tube ➂ top and bottom, and the front

of the clamp snug against the front of the tube.

30. Repeat Step 26 through Step 29 for the other side

of the frame ➀.

31. Position Smartbox base container/meter or

container/splitter/meter assembly ➄ in the frame

1

⁄

in bolt (26) in the forward slotted

4

➁ on one side of the frame ➀. Slip

➀, having the meter ports biased to the Right, and

secure with fasteners provided by AMVAC.

Mount Right Inner-Most YP1225/1625 Smartbox

32. Repeat Step 25 through Step 31 for the innermost

Smartbox on the right side of the machine, using a

Smartbox base container/meter or container/

splitter/meter assembly with the meter exit port(s)

biased to the Left.

➀

➀

➄

27

➁

➃

31

Figure 17

Near-Pivot Mounting

26

31

Figure 18

YP1225/1625 Inner-Most

18

➃

➂

➂

26

18

L

B

U

F

R

D

25329

➁

31

26

18

24176

12/12/2006 403-206M

Page 12

12 Smartbox® Mount Kit

Mount Second Inner YP1225/1625 Smartboxes

Refer to Figure 19 and Figure 20

The components for this step are identical to those of

Step 25 through Step 32. There are two procedural differences from mounting the inner-most frames:

33. Insert a 1

just forward of center ➁ on one side of the frame

1

⁄

in bolt (26) in the slotted mounting hole

4

➀. Slip the shorter end of a clamp (18) over the

bolt (26) and add a flange lock nut (31). Put only a

few turns on the nut.

34. Position the frame ➀ on the tube ➂ and against

the jog plate ➃.

35. Insert a 4in bolt (27) in the forward slotted hole ➄

of the frame ➀, and then down through the hole in

the clamp (18), and add a flange lock nut (31). Put

only a few turns on the nut.

36. Repeat Step 33 through Step 35 for the other side

of the frame ➀.

37. Position Smartbox base container/meter or

container/splitter/meter assembly ➅ in the frame

➀, having the meter ports biased to the Right, and

secure with fasteners provided by AMVAC.

B

Great Plains Mfg., Inc.

27

➂

➄

26

➀

➁

18

U

D

F

R

YP1225/1625 2nd Mount

18

31

Figure 19

25328

L

38. Slide the complete assembly fully forward and

against the jog plate ➃, and the tube ➂, before

final tightening.

39. Repeat Step 33 through Step 38 for the second

innermost Smartbox on the right side of the

machine, using a Smartbox base container/meter

or container/splitter/meter assembly with the meter

exit port(s) biased to the Left.

➂

➃

➅

Figure 20

YP1225/1625 2nd Inner

24169

403-206M 12/12/2006

Page 13

Great Plains Mfg., Inc.

Installation Instructions 13

YP2425 Center Section Smartbox Frames

For ease of access, mount the two inner-most center

section Smartbox frames first.

Note: Whether the entire center section will have four or

six Smartboxes total, the tube between the cylinders always has two.

Note: Meters may need to have one or both exit ports

biased Left or Right. Consult the table on page 8

before installing base container/[splitter]/meter

assemblies.

YP2425 Center Section Box Frames

Refer to Figure 21 and Figure 22

40. Select:

one ➀ Smartbox frame,

two (18) 403-319D,

(SMART BOX HOLD DOWN CLAMP),

two (27) 802-223C,

(HHCS 3/8-16X4 GR5),

two (26) 802-079C,

(HHCS 3/8-16X1 1/4 GR5), and

four (31) 803-209C,

(NUT FLANGE LOCK 3/8-16 PLT)

41. Insert a 1

near center ➁ on one side of the frame ➀. Slip the

shorter end of a clamp (18) over the bolt (26) and

add a flange lock nut (31). Put only a few turns on

the nut.

42. Position the frame ➀ Left of center on the tube ➂

per in Figure 21, clamp (18) to machine front.

43. Insert a 4in bolt (27) in the forward slotted hole ➄

of the frame ➀, and then down through the hole in

the clamp (18), and add a flange lock nut (31). Put

only a few turns on the nut.

44. Repeat Step 33 through Step 35 for the other side

of the frame ➀.

1

⁄

in bolt (26) in the slotted mounting hole

4

➈

Figure 21

Center Section Box Frames

27

➂

26

➄

➁

18

R

F

U

B

L

D

25207

➀

45. Position Smartbox base container/meter or

container/splitter/meter assembly ➅ in the frame

➀, having the meter ports biased per the table on

page 8, and secure with fasteners provided by

AMVAC.

46. Repeat Step 41 through Step 45 for the inner-most

center section box just Right of center.

47. Repeat Step 41 through Step 46 for the two box

frames to the outside of the center tube of the center section.

48. Repeat Step 41 through Step 45 for the box frames on the outside tubes of the center section.

Note: If the outer tubes have only one box, mount it to the outside, as shown at ➈ in Figure 21.

12/12/2006 403-206M

F

R

U

D

B

L

YP2425 Center Mount

18

31

Figure 22

25328

Page 14

14 Smartbox® Mount Kit

Mount Wing Box Frames

(all Models)

Mounting wing box frames does not have the same considerations as for frames near or at center. There is

some additional flexibility in placement on the tubes, so

review where each is to go. it might be useful to mark

the centerline of each proposed position with masking

or painting tape.

For unitary mounts, position as close as possible to

directly above the row unit to be served. For split

mounts, position as close as possible to halfway

between the row units to be served.

Repeat Step 49 through Step 54 until all frames are

mounted:

Refer to Figure 23

49. Select:

one ➀ Smartbox frame,

two (18) 403-319D,

(SMART BOX HOLD DOWN CLAMP),

two (27) 802-223C,

(HHCS 3/8-16X4 GR5),

two (26) 802-079C,

(HHCS 3/8-16X1 1/4 GR5), and

four (31) 803-209C,

(NUT FLANGE LOCK 3/8-16 PLT)

50. Insert a 1

just forward of center ➁ on one side of the frame

➀. Slip the shorter end of a clamp (18) over the

bolt (26) and add a flange lock nut (31). Put only a

few turns on the nut.

1

⁄

in bolt (26) in the slotted mounting hole

4

B

Great Plains Mfg., Inc.

27

➂

➄

26

➀

➁

18

U

D

F

18

R

Figure 23

Outboard Wing Mount

31

25328

L

51. Position the frame ➀.

52. Insert a 4in bolt (27) in the forward slotted hole ➄

of the frame ➀, and then down through the hole in

the clamp (18), and add a flange lock nut (31). Put

only a few turns on the nut.

53. Repeat Step 33 through Step 35 for the other side

of the frame ➀.

54. Position Smartbox base container/meter or

container/splitter/meter assembly ➅ in the frame

➀, having the meter ports biased per the table on

page 8, and secure with fasteners provided by

AMVAC.

403-206M 12/12/2006

Page 15

Great Plains Mfg., Inc.

Install T-Banders

Refer to Figure 24, which depicts two variations of T-bander

The T-Bander (39) is the distribution nozzle for the

Smartbox system. It mounts under the row unit, through

a dedicated pair of holes ➀ at the hinge point between

the opener and the press wheel assembly.

The T-Bander assembly consists of four parts:

(39) 817-655C (T-BANDER)

(12) 116-001D (T-BANDER TUBE)

(22) 800-126C (CLAMP WRM DRV #5 SS (.44-.70))

(34) 805-185C (PIN COTTER .186 WIRE DIA)

If your application requires a longer nozzle on the Tbander, an extension boot is available as Great Plains

part number 816-511C.

Repeat Step 55 through Step 58 for each row unit

served by a Smartbox meter.

Refer to Figure 24 and Figure 25

55. Attach T-Bander tube (12) to T-Bander (39).

Slide either end of tube fully down over neck of TBander.

25330

Installation Instructions 15

➀

12

22

➃

39

Figure 24

T-Bander w/Tube Attached

➀

34

24178

Note grooves ➃ for cotter pin, but do not attach

cotter pin at this time.

56. Place clamp (22) over neck of T-Bander, and position above groove ➃. Tighten clamp.

57. Insert T-Bander assembly ➀ through holes ➁ from

beneath row unit. Align it so that the exit port is

side-to-side.

Refer to Figure 26

58. Insert cotter pin (34) in slot ➂ so that it engages

grooves ➃ on T-Bander. If your T-bander has multi-

ple grooves for the cotter pin, consult AMVAC for a

height recommendation.

34

➂

Figure 25

Insert T-Bander

➁

34

24180

➀

Figure 26

T-Bander w/Cotter Pin

12/12/2006 403-206M

24181

Page 16

16 Smartbox® Mount Kit

Attach Delivery Hoses

Delivery hoses connect the exit ports of the Smartbox

meters to the T-Banders.

Although your kit includes one hose (38) for each meter/

T-Bander, these hoses are a common length which is

long enough for side-shifted mounts near machine center. This makes them too long for most outboard row

units. It will be necessary to trim some length from most

hoses. Do this after attaching them to the meters, at

Step 63.

Attach Hoses To Meters

Great Plains Mfg., Inc.

➀

22

38

Repeat Step 57 through Step 62 for each meter.

Refer to Figure 27

59. Select:

one (38) 816-358C,

(SGS HOSE 122 RIBS), and

one (22) 800-126C,

(CLAMP WRM DRV #5 SS (.44-.70))

60. Slide a clamp (22) over the end of a hose (38).

Unscrew the worm drive if the clamp does not fit

loosely on the hose.

61. Slide one end of the hose (38) fully onto the exit

port of the meter ➀.

62. Adjust the position of the clamp to be

end of the hose, and tighten worm drive. Do not

overtighten.

3

⁄

in from the

8

Trim Hoses to Length

Before beginning these steps, determine which hoses

go to which row units. This is particularly important for

15in planters, where only the “corn row” units are

served by a Smartbox.

63. Temporarily place the lower end of each hose over

its T-Bander tube at the row unit. Start with the

outer-most rows. At the inner-most rows, the hoses

are likely to cant inward as they descend.

64. Raise the planter.

The row units need to be at their lowest position in

order to determine the shortest hose length.

For each row unit, repeat Step 65 through Step 62:

65. Lift the hose off the T-Bander tube.

66. Determine the shortest length that allows the hose

to reach the meter.

67. Add 1

68. Cut the hose at that point.

1

⁄

inches.

2

Figure 27

Hose Attachment at Meter

24172

403-206M 12/12/2006

Page 17

Great Plains Mfg., Inc.

Attach Hoses to T-Banders

Refer to Figure 28

For each row unit, repeat Step 65 through Step 62:

69. Select:

one (24) 800-321C,

(HOSE CLAMP NO.12 3/4 ID)

70. Place the hose clamp (24) over the T-Bander tube

(12).

71. Slide the cut hose (38) by at least 1

1

⁄

in.

2

72. Using hose clamp pliers, open the hose clamp (24)

and lift it up about

3

⁄

in onto the hose. Release to

4

clamp hose in position.

Install Other Smartbox Components

Refer to AMVAC documentation for instructions regarding Controller, MTU, wiring harness and radar connection.

Installation Instructions 17

24

Figure 28

Hose Attach at T-bander

38

12

24181

Installation Reference Information

Torque Values

Fastener/Fitting Ft-Lbs N-m

1

⁄4-20 GR5

3

⁄8-16 GR5

1

⁄2-13 U-bolt

5

⁄8-11 U-bolt

811

31 42

105 76

205 150

12/12/2006 403-206M

Page 18

Great Plains Mfg., Inc.

18 Smartbox® Mount Kit

Kit Parts List

Smartbox® Mount Kits

The part call-out numbers in this list match all Figures in the installation instructions. Your kit includes:

(Callout)

Part No.

(11) 403-206M 1 1 1 1 11111

(12) 116-001D 12 18 24 16 24 32 24 36 48

(13) 403-190H 0 0 02220 0 0

(14) 403-191H 6 6 6 6 66888

(15) 403-192H 2 2 2 0 0 0 0 0 0

(16) 403-202H 08120121601824

(17) 403-225H 0 0 0 0 0 0333

(18) 403-319D 24 20 24 32 24 32 48 36 48

(19) 403-363D 0 0 0 0 0 0222

(20) 403-364D 0 0 0 0 0 0333

(21) 403-365D 0 0 0 0 0 0222

(22) 800-126C 24 18 24 32 48 64 48 72 96

(23) 800-163C 0 96 144 0 144 192 07296

(24) 800-321C 12 18 24 16 24 32 24 36 48

(25) 802-004C 48 104 144 64 144 192 07296

(26) 802-079C 24 20 24 32 24 32 48 36 48

(27) 802-223C 24 20 24 32 24 32 48 36 48

(28) 803-021C 24 24 24 24 24 24 44 44 44

(29) 803-088C 48 0 0640 0 0 0 0

(30) 803-169C 12 12 12 12 12 12 30 30 30

(31) 803-209C 48 40 48 64 48 64 96 72 96

(32) 804-007C 48 104 144 64 144 192 07296

(33) 804-022C 24 24 24 24 24 24 44 44 44

(34) 805-185C 12 18 24 16 24 32 24 36 48

(35) 806-052C 12 12 12 12 12 12 16 16 16

(36) 806-053C 0 0 0 0 0 0666

(37) 806-066C 6 6 6 6 6 6 15 15 15

(38) 816-358C 12 18 24 16 24 32 24 36 48

(39) 817-655C 12 18 24 16 24 32 24 36 48

-196A -197A -198A -199A -200A -201A -218A -219A -220A

Quantity per 403-

(Callout) Part Description

(11) This manual

(12) T-BANDER TUBE

(13) SUPPORT TUBE WLDMNT

(14) SMARTBOX STANDOFF SUPPORT BKT

(15) SUPPORT TUBE WLDMNT - 12 ROW

(16) SMARTBOX METER SPLITTER WLDMNT

(17) SMARTBOX SUPPORT ARM SHORT

(18) SMART BOX HOLD DOWN CLAMP

(19) TUBE SQ. 3.0X.25X260

(20) TUBE SQ. 3.0X.25X48.00

(21) STIFFENER BAR

(22) CLAMP WRM DRV #5 SS (.44-.70)

(23) CLIP U-TYPE NUT 1/4-20 SLF-RET

(24) HOSE CLAMP NO.12 3/4 ID

(25) HHCS 1/4-20X3/4 GR5

(26) HHCS 3/8-16X1 1/4 GR5

(27) HHCS 3/8-16X4 GR5

(28) NUT HEX 5/8-11 PLT

(29) NUT HEX LOCK 1/4-20 FLG

(30) NUT HEX FLG. LOCK 1/2-13 PLT.

(31) NUT FLANGE LOCK 3/8-16 PLT

(32) WASHER FLAT 1/4 SAE PLT

(33) WASHER LOCK SPRING 5/8 PLT

(34) PIN COTTER .186 WIRE DIA

(35) U-BOLT 5/8-11 X 7 1/32 X 8 1/2

(36) U-BOLT 5/8-11 X 7 1/32 X 6 1/2

(37) U-BOLT 1/2-13 X 3 1/32 X 4

(38) SGS HOSE 122 RIBS

(39) T-BANDER

Great Plains Manufacturing, Inc.

Corporate Office P.O. Box 5060

Salina, Kansas 67402-5060 USA

403-206M 12/12/2006

Loading...

Loading...