Page 1

1 S3T & Reel Great Plains Manufacturing, Inc.

S3T & Reel Update

Using This Manual

This manual was written to help you assemble and prepare the new finishing attachment. The manual includes

instructions for assembly and setup. Read this manual

and follow the recommendations for safe, efficient and

proper assembly and setup.

The information in this manual is current at printing.

Some parts may change to assure top performance.

Definitions

The following terms are used throughout this manual.

A crucial point of information related to the preceding topic.

Read and follow the directions to remain safe, avoid serious

damage to equipment and ensure desired field results.

Note: Useful information related to the preceding topic.

Right-hand and left-hand as used in

this manual are determined by facing

the direction the machine will travel

while in use unless otherwise stated.

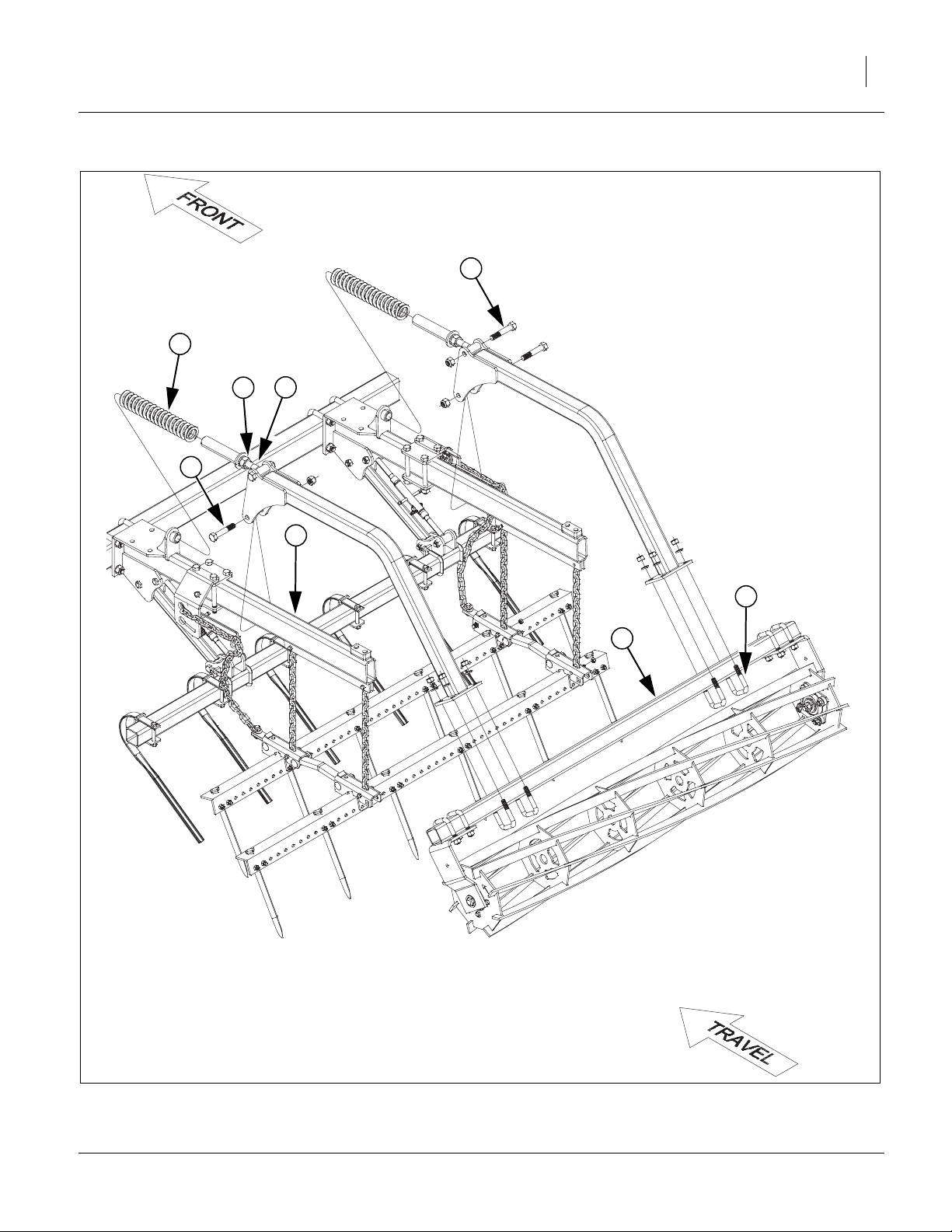

An orientation rose in some line art

illustrations shows the directions of: Up,

Back, Left, Down, Front, Right

R

F

U

B

L

D

R

FigureSpacer:

L

Figure 1

Right / Left

42091

550-487M 12/22/2011

Page 2

2 S3T & Reel Great Plains Manufacturing, Inc.

Models Covered

8318DVN 18-Foot 3-section

8324DVN 24-Foot 3-section

7548DV 48-Foot 5-section

8328DV 28-Foot 3-section

8537DV 37-Foot 5-section

8544DV 44-Foot 5-section

An operator’s and parts manual is also provided with the

machine or can be viewed on Great Plains web site.

Read and understand “Important Safety Information”

and “Operating Instructions” in the operator’s manual

before assembling the machine. Refer to the parts manual for proper part’s identification. As a reference, keep

the operator’s and part’s manual on hand while assembling.

Document Family

550-466M Operator Manual

550-466P Parts Manual

550-353M Operator Manual

550-353P Parts Manual

550-221M Operator Manual

550-221P Parts Manual

Tools Required

• Basic Hand Tools

• Torque Wrench

• Fork Truck, Overhead Hoist or Loader

Pre-assembly Checklist

1. Before assembling, read and understand “Important

Safety Information” in front part of operator’s manual.

2. Have at least two people on hand while assembling.

550-487M 12/22/2011

Page 3

Great Plains Manufacturing, Inc. S3T & Reel Update 3

12/22/2011 550-487M

Page 4

4 S3T & Reel Great Plains Manufacturing, Inc.

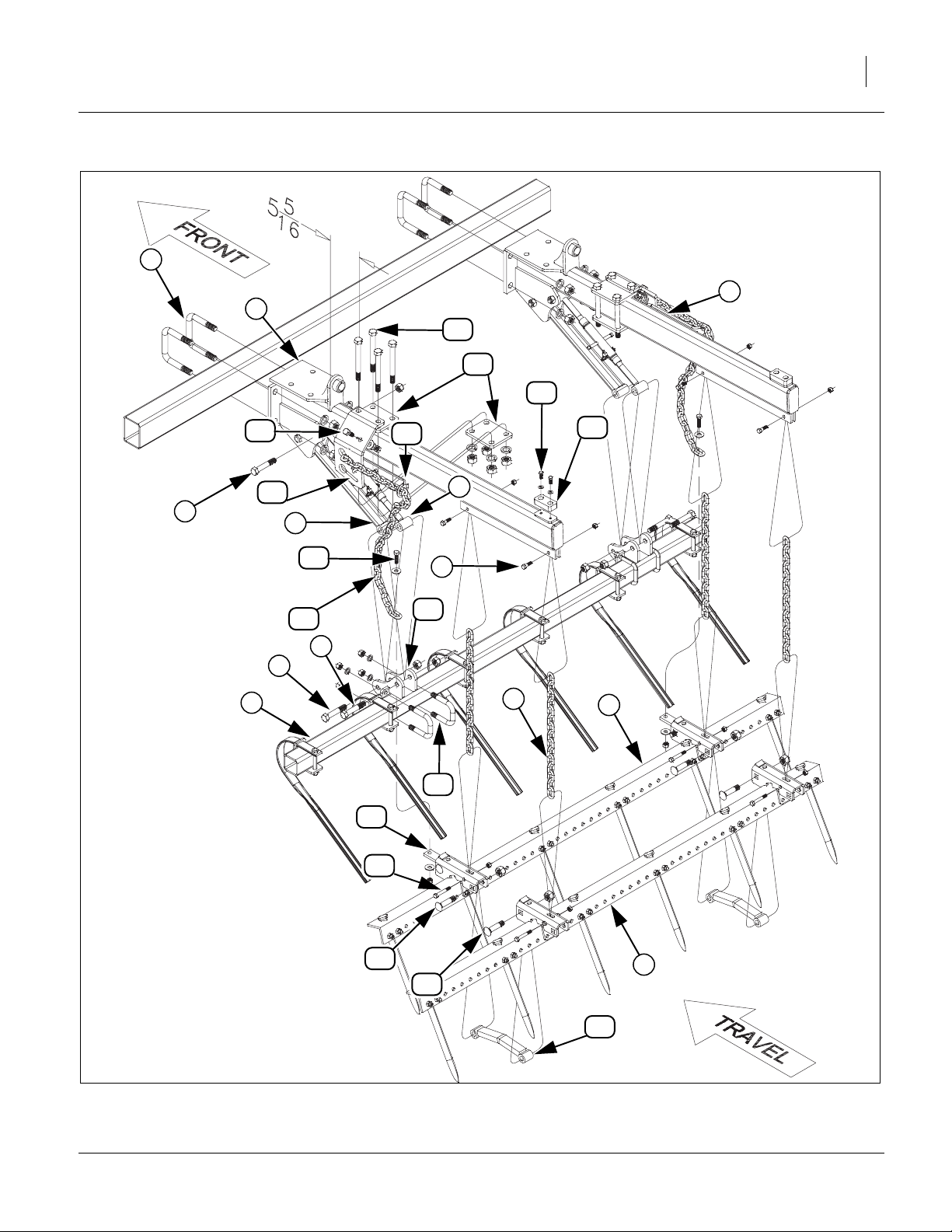

Assembly

S3T Bar & Spike Drag

Refer to Figure 2

1. Attach arm assemblies to rear bar of machine with

3/4 x 4 1/32 x 4 1/2 u-bolts , 3/4 lock washers and

1

2

nuts.

Note: See Layout drawings pages 8-16 for proper arm

placements.

2. Mount front bar assembly to rear of adjustable link

and link , with 5/8 x 3 1/2 hex bolts , 5/8 top

4 5 6

3

lock nuts.

3. Attach top of 15 link drag chains to bottom side of

arm assemblies with 3/8 x 1 1/4 hex bolts 3/8

1 8

7

lock washers and 3/8 nuts.

4. Slide lower link of 15 link drag chains into slot on

spike drag bar bracket , secure with 3/8 x 2 1/2 hex

bolt , and top lock nut.

10

5. Align holes in harrow link with holes in spike drag

bar bracket , secure with 5/8 x 2 7/8 special bolts

and 5/8 top lock nuts.

12

9

6. Attach two plates (one on top and one on bottom) of arm assembly . Note measurement of 5 5/

9

11

13

1

16” from rear of spring to front of plate . Attach key

7

13

hole plate to outside of plates key hole plates .

Secure with 5/8 x 6 hex botlts , 5/8 lock washers

14 13

15

and 5/8 nuts.

7. Attach safety chain spring loop to inside of key

hole plate with 1/2 x 1 1/2 hex bolt , 1/2 flat

14 17

16

washer, 1/2 lock washer and 1/2 nut.

8. Attach one end of 25 link pull chain to slotted hole

in key hole plate .

14

18

9. Attach other end of chain to front drag link assembly

with 7/16 x 1 1/2 hex bolt , 7/16 flat washers

19 20

(one on bolt and one under plate) and 7/16 nylock

nut.

10. Attach polyurethane bumper to top side of arm

assemblies with 5/16 x 1/2 hex bolts and 5/16

1

21

22

flat washers.

11. Attach front bar mount assembly with 1/2 x 2 1/2 x

3 1/2 u-bolts , 1/2 lock washers and 1/2 nuts.

24

23

12. All bolts may be tightened to specs, See “Torque

Values Chart” on page 22.

550-487M 12/22/2011

Page 5

Great Plains Manufacturing, Inc. Assembly 5

2

1

1

15

13

22

17

14

6

5

20

18

16

4

8

23

21

6

6

3

7

9

24

19

10

12

9

12

11

ull4:

S3T Bar & Spike Drag Assembly

12/22/2011 550-487M

Figure 2

42089

Page 6

6 S3T & Reel Great Plains Manufacturing, Inc.

Reel Following S3T

Refer to Figure 3

1. Slide spring over tube of reel arm assembly .

Align other end of spring to tube on front plate of

arm assembly and let the rest of the reel arm

assembly rest on the pad towards rear of arm

assembly .

2. Secure reel arm assembly to arm assembly with

3/4 x 4 hex bolt and 3/4 top lock nut. Tighten top

1 2

1

3

2

3

2 3

4

lock nut snug but do not torque as arm needs to

pivot.

Note: Adjust nut on reel arm assembly snug to hold

5

3

spring on round tube on front plate of arm assem-

bly . When rest of drag is installed, set the pre-

3

load pressure on spring, See “5-Section Fold

Catch Assembly” on page 8.

Note: See Layout drawings pages 8-16 for proper reel

placements.

3. Attach reel assemblies to rear plates of reel arm

assembly with 3/4 x 4 1/32 x 4 1/2 u-bolts , 3/4

2 7

6

lock washers and 3/4 nuts.

4. All u-bolts may be tightened to specs, See “Torque

Values Chart” on page 22.

550-487M 12/22/2011

Page 7

Great Plains Manufacturing, Inc. Assembly 7

4

1

2

5

4

3

7

6

ull4:

12/22/2011 550-487M

Figure 3

Reel Assembly

42090

Page 8

8 S3T & Reel Great Plains Manufacturing, Inc.

5-Section Fold Catch Assembly

Refer to Figure 3

Note: The catch assembly is only used on 5-section

outer wings. Be sure to mount the bent catch

towards center of machine on both sides.

1. Attach catch assembly to inside of arm assembly

with the mounting plates . Secure with 1/2 x 3 1/2

1

2

hex bolts in top holes and 1/2 x 3 hex bolts in

3 4

bottom holes, 1/2 lock washers and 1/2 nuts.

2. Align arm assembly 3 7/8” from rear of arm to rear of

rear angle iron as shown.

3. All bolts may be tightened to specs, See “Torque

Values Chart” on page 22.

550-487M 12/22/2011

Page 9

Great Plains Manufacturing, Inc. Assembly 9

2

3

4

1

ull4:

12/22/2011 550-487M

Figure 4

Fold Catch

42150

Page 10

10 S3T & Reel Great Plains Manufacturing, Inc.

Reel Spring Pre-Load

Refer to Figure 5

4. Adjust nut to where spring is just making contact with front plate .

5. Turn nut another 1” further on spring rod to set

pre-load on spring.

1 2

2

1 4

3

2

1

4

Null4:

Figure 5

Reel Spring Pre-Load

42094

550-487M 12/22/2011

Page 11

Great Plains Manufacturing, Inc. Assembly 11

12/22/2011 550-487M

Page 12

12 S3T & Reel Great Plains Manufacturing, Inc.

8318DVN

FigureSpacer:

42082

FigureSpacer:

550-487M 12/22/2011

Page 13

Great Plains Manufacturing, Inc. Assembly 13

8321DVN

FigureSpacer:

42409

FigureSpacer:

12/22/2011 550-487M

Page 14

14 S3T & Reel Great Plains Manufacturing, Inc.

8324DVN

FigureSpacer:

42083

FigureSpacer:

550-487M 12/22/2011

Page 15

Great Plains Manufacturing, Inc. Assembly 15

8328DV

FigureSpacer:

42084

FigureSpacer:

12/22/2011 550-487M

Page 16

16 S3T & Reel Great Plains Manufacturing, Inc.

8537DV

FigureSpacer:

42085

FigureSpacer:

550-487M 12/22/2011

Page 17

Great Plains Manufacturing, Inc. Assembly 17

8537DV

FigureSpacer:

42086

FigureSpacer:

12/22/2011 550-487M

Page 18

18 S3T & Reel Great Plains Manufacturing, Inc.

88544DV

FigureSpacer:

420887

FigureSpacer:

550-487M 12/22/2011

Page 19

Great Plains Manufacturing, Inc. Assembly 19

88544DV

FigureSpacer:

420888

FigureSpacer:

12/22/2011 550-487M

Page 20

20 S3T & Reel Great Plains Manufacturing, Inc.

7548DV

FigureSpacer:

42092

FigureSpacer:

550-487M 12/22/2011

Page 21

Great Plains Manufacturing, Inc. Assembly 21

7548DV

FigureSpacer:

42093

FigureSpacer:

12/22/2011 550-487M

Page 22

22 S3T & Reel Great Plains Manufacturing, Inc.

Torque Values Chart

Bolt

Size

in-tpi

1

⁄4-20

1

⁄4-28

5

⁄16-18

5

⁄16-24

3

⁄8-16

3

⁄8-24

7

⁄16-14

7

⁄16-20

1

⁄2-13

1

⁄2-20

9

⁄16-12

9

⁄16-18

5

⁄8-11

5

⁄8-18

3

⁄4-10

3

⁄4-16

7

⁄8-9

7

⁄8-14

1-8

1-12

1

1

⁄8-7

1

1

⁄8-12

1

⁄4-7

1

1

⁄4-12

1

3

⁄8-6

1

3

1

⁄8-12

1

1

⁄2-6

1

1

⁄2-12

Bolt Head Identification

Grade 2 Grade 5 Grade 8 Class 5.8 Class 8.8 Class 10.9

a

b

d

N-m

ft-lb

7.4 11 16

8.5 13 18

15 24 33

17 26 37

27 42 59

31 47 67

43 67 95

49 75 105

66 105 145

75 115 165

95 150 210

105 165 235

130 205 285

150 230 325

235 360 510

260 405 570

225 585 820

250 640 905

340 875 1230

370 955 1350

480 1080 1750

540 1210 1960

680 1520 2460

750 1680 2730

890 1990 3230

1010 2270 3680

1180 2640 4290

1330 2970 4820

N-m N-m

5.6 8 12

61014 5 811

11 17 25 12 19 27

13 19 27 13 21 29

20 31 44 24 39 53

22 35 49 29 45 62

32 49 70 42 67 93

36 55 78 44 70 97

49 76 105 66 77 105

55 85 120 68 105 150

70 110 155 73 115 160

79 120 170 105 165 230

97 150 210 115 180 245

110 170 240 145 230 300

170 265 375 165 260 355

190 295 420 205 325 450

165 430 605 230 480 665

185 475 670 355 560 780

250 645 910 390 610 845

275 705 995 705 1120 1550

355 795 1290 785 1240 1710

395 890 1440 1270 1950 2700

500 1120 1820 1380 2190 3220

555 1240 2010

655 1470 2380

745 1670 2710

870 1950 3160

980 2190 3560

Bolt Head Identification

Bolt

Size

ft-lb ft-lb ft-lb ft-lb ft-lb

mm x pitch

M 5 X 0.8

M 6 X 1

M 8 X 1.25

M 8 X 1

M10 X 1.5

M10 X 0.75

M12 X 1.75

M12 X 1.5

M12 X 1

M14 X 2

M14 X 1.5

M16 X 2

M16 X 1.5

M18 X 2.5

M18 X 1.5

M20 X 2.5

M20 X 1.5

M24 X 3

M24 X 2

M30 X 3.5

M30 X 2

M36 X 3.5

M36 X 2

a. in-tpi = nominal thread diameter in inches-threads per inch

b. N· m = newton-meters

c. mm x pitch = nominal thread diameter in mm x thread pitch

d. ft-lb = foot pounds

c

5.8 8.8 10.9

N-m N-m N-m

357

71115

17 26 36

18 28 39

33 52 72

39 61 85

58 91 125

60 95 130

90 105 145

92 145 200

99 155 215

145 225 315

155 240 335

195 310 405

220 350 485

280 440 610

310 650 900

480 760 1050

525 830 1150

960 1510 2100

1060 1680 2320

1730 2650 3660

1880 2960 4100

946

Torque tolerance + 0%, -15% of torquing values. Unless otherwise specified use torque values listed above.

25199m

25199

Disc or Coulter Gang Bolt Torque 1 1/2”-6 650-750 Foot-pounds (175 lbs on 4’ cheater).

550-487M 12/22/2011

Loading...

Loading...