Page 1

Table of Contents Index

Operating, Maintenance

and Installation Instructions

401-845A, 401-846A, 401-847A, 401-848A, 401-849A, 401-879A,

401-956A, 411-016A, 411-035A, 411-036A, 411-037A, 411-038A,

411-163A, 411-164A, 411-165A, 411-166A, 411-167A and 411-168A

PTO Pump Accessory for Single-Section

Air-Pro

®

Planters and Fan Update Kit

Manufacturing, Inc.

www.greatplainsmfg.com

Read the installation manual entirely. When you see this symbol, the

subsequent instructions and warnings are serious - follow without exception.

Your life and the lives of others depend on it!

CAUTION

818-130C Rev. B

To avoid Injury or

Machine Damage:

*Operate only with

540 rpm PTO

34617

Cover illustration shows only selected components for one kit. Manual illustrations may

show various Yield-Pro

are identical for the immediate topic.

®

planter models and configurations where installation details

ORIGINAL INSTRUCTIONS

© Copyright 2014 Printed 2014-06-16 401-885M

EN

Table of Contents Index

Page 2

Table of Contents Index

Table of Contents Index

Page 3

Great Plains Manufacturing, Inc. Cover Index iii

Table of Contents

Important Safety Information ......................................1

PTO-Specific Hazards....................................................1

Using PTO Safely...........................................................2

Safety Decals .................................................................4

Introduction ..................................................................6

Description of Unit .......................................................... 6

Suitable Applications ..................................................6

Kits Covered...................................................................6

Related Documents........................................................6

Related Parts..................................................................6

20-Spline Coupler...................................................6

21-Spline Coupler...................................................6

Using This Manual..........................................................7

Definitions................................................................... 7

Call-Outs ....................................................................7

Owner Assistance ..........................................................7

PTO Operation .............................................................. 8

Tractor Requirements.....................................................8

540 rpm Tractor Requirements...................................8

540 rpm PTO Clearance.........................................8

1000 rpm Tractor Requirements.................................9

1000 rpm Type 2 PTO Clearance...........................9

1000 rpm Type 3 PTO Clearance.........................10

Hitching with PTO.........................................................11

Hitching with 540 rpm PTO.......................................11

Prepare Tractor ....................................................11

Mount Pump .........................................................11

Secure Pump........................................................11

Hitching with 1000 rpm PTO.....................................12

Install Coupler.......................................................12

Prepare Tractor ....................................................13

Mount Pump .........................................................13

Check Hydraulics .........................................................14

Check Oil Level ........................................................14

Inspect Hoses and Fittings .......................................14

Starting the Pump.........................................................15

About the Flow Control Valve.......................................16

Setting Meter Pressurization ........................................17

General Steps for all Kits.......................................... 17

Ground Drive Meter Pressure...................................18

Hydraulic Drive Meter Pressure................................19

PTO Unhitching ............................................................ 20

Dismount 540 rpm Pump.......................................... 20

Dismount 1000 rpm Pump........................................ 20

PTO Troubleshooting ................................................ 21

PTO Maintenance....................................................... 22

Oil and Filter Change ................................................... 22

Oil Fill ....................................................................... 22

Oil Specification ................................................... 22

Oil and Filter Change ............................................... 22

Lubrication and Scheduled Maintenance..................... 23

Appendix A - Installation........................................... 25

Before You Start .......................................................... 25

Compatible Planters..................................................... 25

One PTO pump kit is always required. Older planters

may also require a fan update kit. Each kit

updates one planter.......................................... 25

Fan Motor Compatibility ........................................... 25

Configuration Compatibility ...................................... 26

2025A/2525A Compatible Kits ................................. 26

YP425A Compatible Kits.......................................... 26

YP625A Compatible Kits.......................................... 26

YP825A/AR Compatible Kits.................................... 26

Other Single-Section Air-Pro® Implements .............. 26

Tools Required............................................................. 27

Call-Outs .................................................................. 27

Pre-Delivery and Other Options................................... 27

Prepare Planter............................................................ 27

Prepare Fan ................................................................. 28

Disconnect Existing Fan Hoses ............................... 28

Disconnect 2-Port Fan ......................................... 28

Disconnect 3-Port Fan ......................................... 29

Open Fan Screen..................................................... 29

Dismount or Relocate Sensor Bracket ..................... 30

Update Fan Motor .................................................... 31

Recover Motor Fittings ......................................... 31

Release Impeller ..................................................31

Dismount Fan....................................................... 32

Remove 3-Port Hydraulic Motor........................... 32

Mount 2-Port Hydraulic Motor ..............................33

Re-Mount Fan ......................................................33

Install New Impeller Bushing................................ 34

Install Motor Fittings and Loop ............................. 35

Re-Mount Fan Inlet Screen .................................. 35

Re-Install RPM Sensor Bracket ........................... 36

Install Fan Cooler......................................................... 37

Install Fan Cooler ..................................................... 37

Break Down Cooler Assembly ............................. 37

Install Cooler Shroud............................................ 37

© Copyright 2013, 2014 All rights Reserved

Great Plains Manufacturing, Inc. provides this publication “as is” without warranty of any kind, either expressed or implied. While every precaution has been

taken in the preparation of this manual, Great Plains Manufacturing, Inc. assumes no responsibility for errors or omissions. Neither is any liability assumed for

damages resulting from the use of the information contained herein. Great Plains Manufacturing, Inc. reserves the right to revise and improve its products as

it sees fit. This publication describes the state of this product at the time of its publication, and may not reflect the product in the future.

2014-06-16 Cover Index 401-885M

Trademarks of Great Plains Manufacturing, Inc. include: Singulator Plus, Swath Command, Terra-Tine.

Registered Trademarks of Great Plains Manufacturing, Inc. include:

Air-Pro, Clear-Shot, Discovator, Great Plains, Land Pride, MeterCone, Nutri-Pro, Seed-Lok, Solid Stand,

Terra-Guard, Turbo-Chisel, Turbo-Chopper, Turbo Max, Turbo-Till, Ultra-Till, Ver ti-Till, Whirlfilter, Yield-Pro.

Brand and Product Names that appear and are owned by others are trademarks of their respective owners.

Printed in the United States of America

Page 4

iv Single-Section PTO Pumps Table of Contents Index Great Plains Manufacturing, Inc.

Orient Cooler Elbows ........................................... 38

Re-Assemble Fan Cooler..................................... 38

Modify Fan Cage.................................................. 38

Attach Cooler Hoses & Close............................... 39

Reconnect Hitch Hoses ............................................... 40

Install Oil Reservoir...................................................... 41

Determine Reservoir Location.................................. 41

Reservoir on Row Unit Tool Bar............................... 42

Identify Row Location........................................... 42

Support Row Unit ................................................. 43

Mount Row Unit Reservoir ................................... 43

Reservoir on Fertilizer Sub-Frame........................... 44

Reservoir on Mainframe Truss................................. 45

Reservoir Under Main Seed Box.............................. 46

Reservoir on Tongue at Hitch .................................. 47

Install Flow Control Valve ............................................ 48

Determine Control Location ..................................... 48

Install Controls on Fan Mast .................................... 49

Install Controls on Fertilizer Frame .......................... 50

Install Controls on Upper Frame Tube..................... 51

Install Controls on Forward Tool Bar........................ 52

Install Hoses ................................................................ 54

General Hose Installation......................................... 54

401-845A and 411-163A Flow Control Hydraulics... 54

401-846A and 411-164A Flow Control Hydraulics....55

401-847A and 411-165A Flow Control Hydraulics....56

401-848A and 411-166A Flow Control Hydraulics....57

401-849A and 411-167A Flow Control Hydraulics....58

401-879A and 411-168A Flow Control Hydraulics....59

411-016A Flow Control Hydraulics ...........................60

Connect Hoses .....................................................60

411-035A and 411-036A Flow Control Hydraulics....61

411-037A and 411-038A Flow Control Hydraulics....62

Replace/Add Fittings.............................................63

Connect Remaining Hoses ...................................63

Charge and Test...........................................................64

Close-Out .....................................................................64

Appendix R - Reference .............................................65

Torque Values ..............................................................65

Hydraulic Fitting Torque............................................66

Connector Identification ........................................66

Abbreviations................................................................67

Parts Lists.....................................................................68

Kits and This Manual ................................................68

New Parts in Kits ......................................................68

Existing Parts Affected..............................................70

Index ............................................................................73

401-885M Table of Contents Index 2014-06-16

Page 5

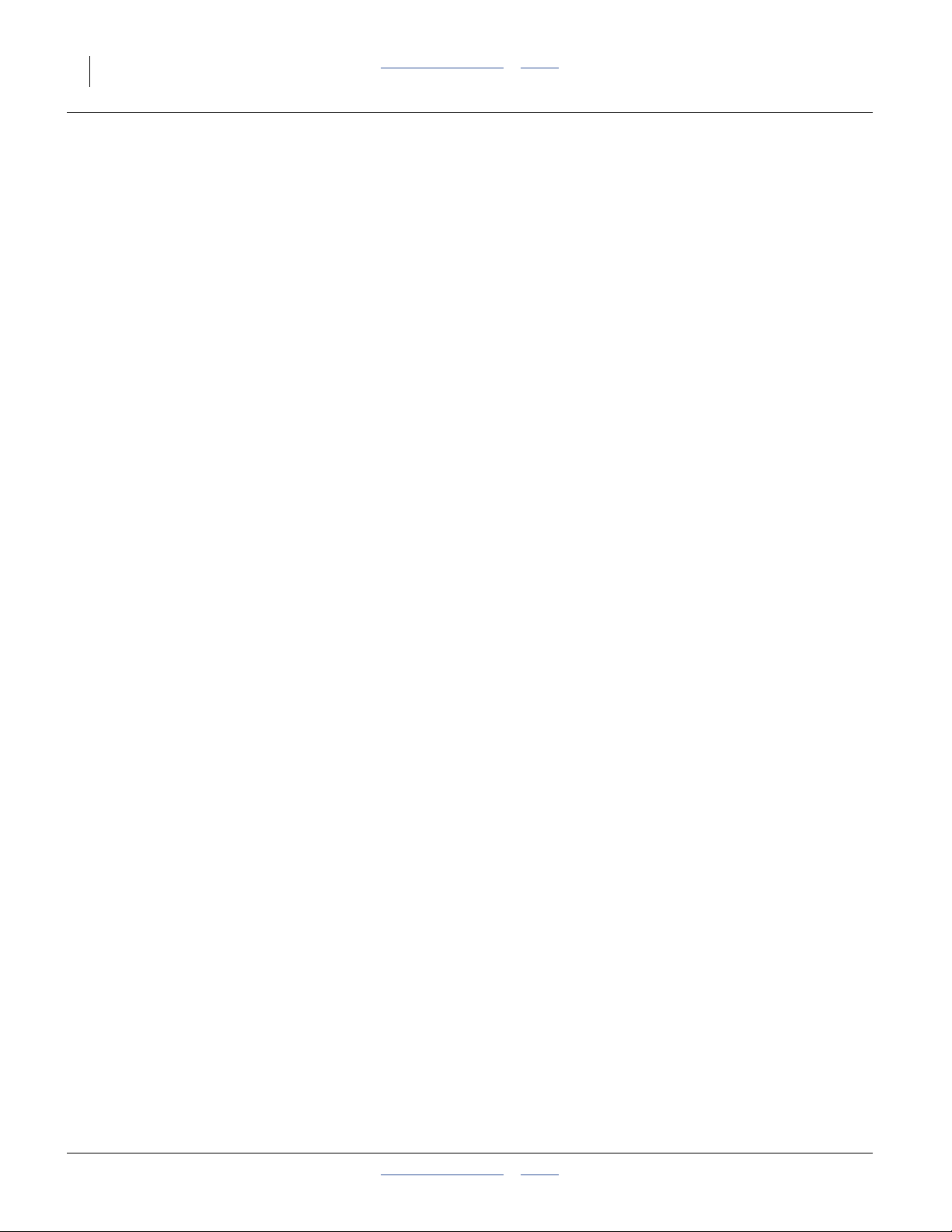

Great Plains Manufacturing, Inc. Table of Contents Index 1

Important Safety Information

PTO-Specific Hazards

Even if you are experienced in PTO operations, review

the “Using PTO Safely” topic on page 2. Topics in this

manual dealing with PTO hazards include this PTO alert

symbol and the standard alert symbol below.

PTO hazards include:

▲ Entanglement:

resulting in abrasions, lacerations, crushing,

dismemberment or death. Loose clothing, cuffs, frays, laces,

coattails, drawstrings, hair or scarves are taken up by a

PTO faster than you can react, and with overpowering

torque.

▲ Flailing machinery:

resulting from an unsecured torque arm, resulting in serious

injury or death.

▲ High pressure fluid sprays:

due to hydraulic hose failure, resulting from PTO shaft

over-speed or damaged hoses.

Look for Safety Symbol

The SAFETY ALERT SYMBOL indicates there is a

potential hazard to personal safety involved and extra

safety precaution must be taken. When you see this

symbol, be alert and carefully read the message that

follows it. In addition to design and configuration of

equipment, hazard control and accident prevention are

dependent upon the awareness, concern, prudence and

proper training of personnel involved in the operation,

transport, maintenance and storage of equipment.

Be Aware of Signal Words

Signal words designate a degree or level of hazard

seriousness.

DANGER indicates an imminently hazardous situation

which, if not avoided, will result in death or serious injury.

This signal word is limited to the most extreme situations,

typically for machine components that, for functional

purposes, cannot be guarded.

WARNING indicates a potentially hazardous situation

which, if not avoided, could result in death or serious

injury, and includes hazards that are exposed when

guards are removed. It may also be used to alert against

unsafe practices.

CAUTION indicates a potentially hazardous situation

which, if not avoided, may result in minor or moderate

injury. It may also be used to alert against unsafe

practices.

2014-06-16 Table of Contents Index 401-885M

Page 6

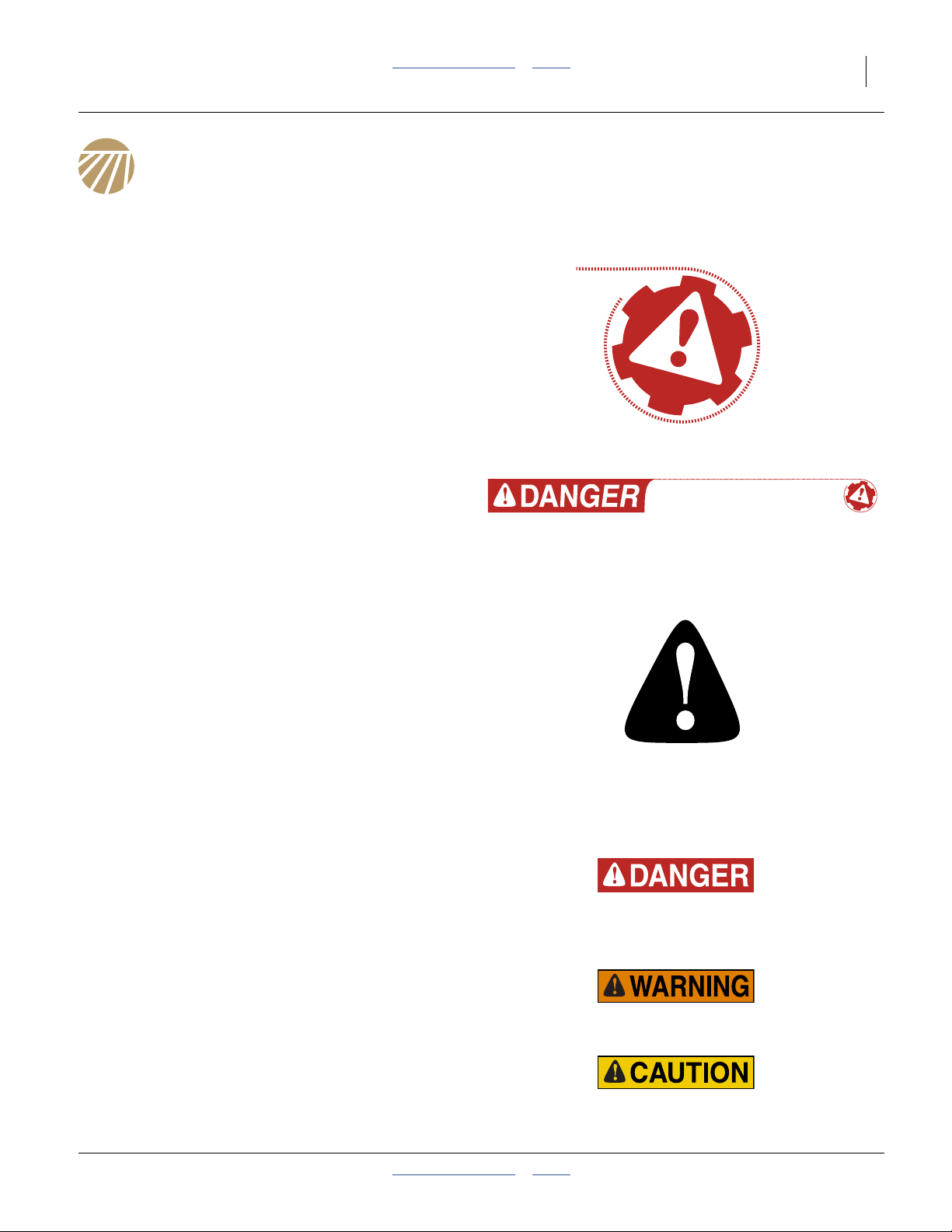

2 Single-Section PTO Pumps Table of Contents Index Great Plains Manufacturing, Inc.

Using PTO Safely

The accessories covered by this manual rely on PTO power to

operate, and require an adjustment at the planter while the

PTO is running. The PTO pump is designed to work on a stub

shaft PTO, and leaves no exposed shaft in use.

▲ Use only a tractor with an approved master shield for the

PTO.

▲ Use all guards provided for the tractor PTO. Have minimal

or NO shaft exposed after connecting the PTO pump.

▲ Use only a rear-facing PTO. The provided hoses and torque

arms are not designed for use with a tractor-front or

tractor-side PTO.

▲ Use only the correct (540 or 1000) rpm PTO, or an

adjustable PTO set to the correct rpm (maximum).

Running at a higher speed could result in equipment failure,

and serious injury.

▲ Use only a PTO with the correct shaft, and for 1000 rpm,

matching Great Plains coupler:

3

1

⁄8inch (35 mm) 6-spline

13⁄4inch (44.5 mm) 20-spline and 826-777C coupler

13⁄8inch (35 mm) 21-spline and 826-778C coupler

▲ Do not use any other adaptor, coupler, driveline, extender

or external gearbox.

▲ Use only a “live” or “independent” PTO. If the PTO only

operates when the tractor is in motion, there is no safe way

to set the fan speed.

▲ Ensure that all involved personnel are trained on PTO

operations and hazards. Always know where all team

members are before, during and after PTO operations.

▲ Allow only essential personnel near the PTO during setup,

adjustment, operation and disconnection.

▲ Prior to PTO setup, remove any stray wire, rope or twine

found nearby. Should a loose end encounter the PTO stub, it

is taken up at up to 14 feet per second, and could wrap

around someone and pull them in.

▲ Wear only snug-fitting clothes, with no scarves, loose

strings, cords, ties, and no frays, when working near a PTO.

▲ Tie long hair back or gather it up under a well-secured hat.

▲ Shut the tractor off for PTO connections or disconnections.

Do not trust your life to clutches and throw-outs.

▲ A PTO shaft is a hazard at any speed, even when well below

rated shaft rpm, coasting to a stop, or idling.

▲ Never step on or over the master shield or installed PTO

pump.

▲ Be extra vigilant if any tractor PTO controls are external,

and in proximity to the PTO.

▲ Elevate pump hose slack so that ground contact is not

possible during transport or field operations.

▲ Keep all PTO safety decals clean and legible. Replace any

that are faded or damaged.

CAUTION

To avoid Injury or

Machine Damage:

*Operate only with

540 rpm PTO

818-130C Rev. B

✔

6

CAUTION

To avoid Injury or

Machine Damage:

·Operate only with

1000 rpm PTO

✔

826-777C

818-240C Rev. A

20

✔

CAUTION

To avoid Injury or

Machine Damage:

·Operate only with

1000 rpm PTO

826-778C

818-240C Rev. A

✔

21

401-885M Table of Contents Index 2014-06-16

Page 7

Great Plains Manufacturing, Inc. Table of Contents Index Important Safety Information 3

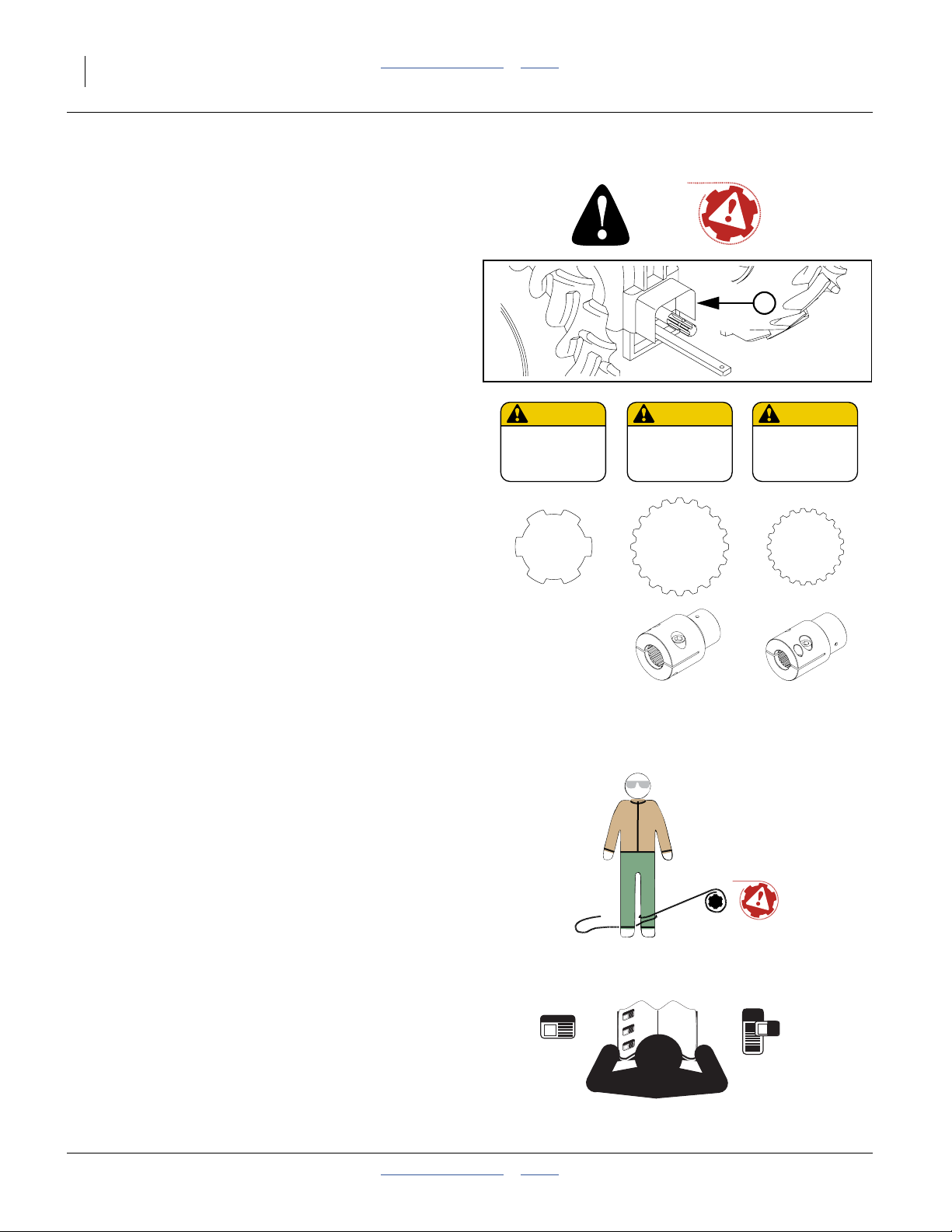

Prepare for Emergencies

▲ Be prepared if a fire starts.

▲ Keep a first aid kit and fire extinguisher handy.

▲ Keep emergency numbers for doctor, ambulance, hospital

and fire department near phone.

Be Familiar with Safety Decals

▲ Read and understand “Safety Decals” in the Operator

manual.

▲ Read all instructions noted on the decals.

▲ Keep decals clean. Replace damaged, faded and illegible

decals.

Avoid High Pressure Fluids

Observe normal precautions for hitch hydraulic

connections and disconnections. Escaping fluid under

pressure can penetrate the skin, causing serious injury.

▲ Avoid the hazard by relieving pressure before disconnecting

hydraulic lines.

▲ Wear protective gloves and safety glasses or goggles when

working with hydraulic systems.

▲ If an accident occurs, seek immediate medical assistance

from a physician familiar with this type of injury.

Practice Safe Maintenance

▲ Understand procedure before doing work. Use proper

tools and equipment. Refer to this manual for additional

information.

▲ Work in a clean, dry area.

▲ Lower the planter, put tractor in park, turn off engine, and

remove key before performing maintenance.

▲ Make sure all moving parts have stopped and all system

pressure is relieved.

▲ Inspect all parts. Make sure parts are in good condition

and installed properly.

▲ Remove buildup of grease, oil or debris.

▲ Remove all tools and unused parts from planter before

operation.

2014-06-16 Table of Contents Index 401-885M

Page 8

4 Single-Section PTO Pumps Table of Contents Index Great Plains Manufacturing, Inc.

Safety At All Times

▲ Thoroughly read and understand the instructions in this

manual before operation. Read all instructions noted on the

safety decals.

▲ Be familiar with all implement functions.

▲ Operate machinery from the driver’s seat only.

▲ Do not leave implement unattended with tractor engine

running.

▲ Wear snug-fitting clothing to avoid entanglement with

moving parts.

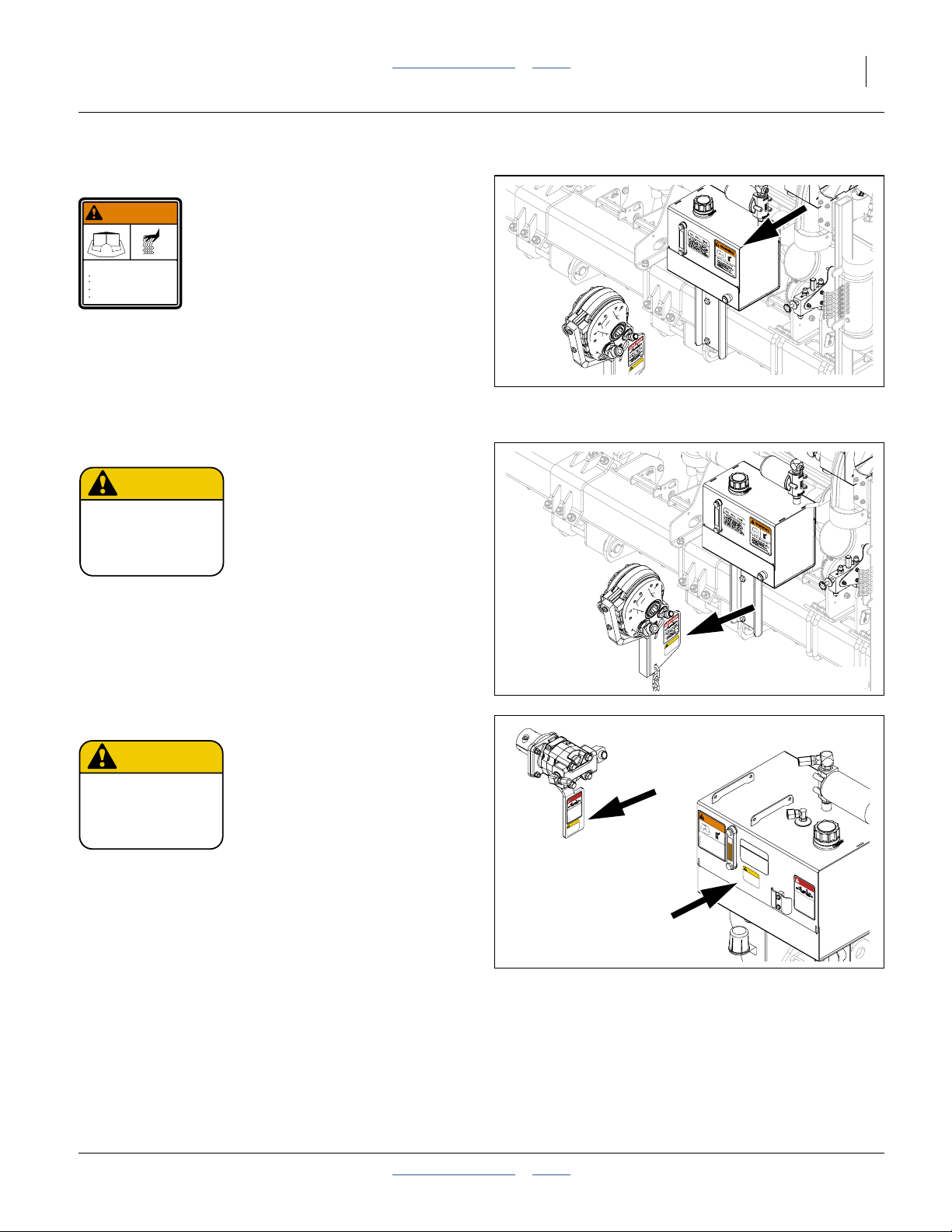

Safety Decals

Safety Decals

Kit components are shipped with all safety decals in

place. They are intended to help you safely operate your

implement.

▲ Read and follow decal directions.

▲ Keep all safety decals clean and legible.

▲ Replace all damaged or missing decals. Order new decals

from your Great Plains dealer. Refer to this section for

proper decal placement.

▲ When ordering new parts or components, also request

corresponding safety decals.

To install new decals:

1. Clean the area on which the decal is to be placed.

2. Peel backing from decal. Press firmly on surface,

being careful not to cause air bubbles under decal.

Danger Decals

858-005C

DANGER

ROTATING DRIVELINE -

CONTACT CAN CAUSE DEATH

KEEP AWAY!

DO NOT OPERATE WITHOUT-

All driveline guards, tractor

and equipment shields in place

PTO pump assembly securely

attached with torque arm and chain

Danger: Rotating Driveline

On chain plate of torque arm at pump, for pumps

with wide plates, otherwise on front face of oil

reservoir;

1 total

858-005C

ROTATING DRIVELINE -

CONTACT CAN CAUSE DEATH

DO NOT OPERATE WITHOUT-

To avoid Injury or

Machine Damage:

·Operate only with

1000 rpm PTO

DANGER

KEEP AWAY!

All driveline guards, tractor

and equipment shields in place

PTO pump assembly securely

attached with torque arm and chain

CAUTION

818-240C Rev. A

858-005C

CAUTION

818-130C Rev. B

To avoid Injury or

Machine Damage:

*Operate only with

540 rpm PTO

36313

34617

34843

WARNING

HOT FLUID HAZARD

Read Owner’s Manual BEFORE operating machine.

Keep tractor at IDLING SPEED and slowly engage PTO

to prevent damage to Hydraulic Motor

Keep Radiator clean and free of foreign matter to

prevent overheating.

Do NOT operate with hydraulic oil at or above 180°F.

OIL FILL LINE

CAPACITY = 13.5 U.S. GALS

USE ANY HIGH QUALITY MINERAL BASED

HYDRAULIC FLUID WITH A VISCOSITY RATING

OF 10W-30. OIL MUST BE CLEAN AND FREE

FROM DIRT OR CONTAMINANT PARTICLES TO

PREVENT DAMAGE TO PUMP AND MOTOR.

REPLACE FILTER ELEMENT AFTER EVERY

858-004C

150 OPERATING HOURS OR 2 YEARS SERVICE.

LEVEL TOOLBAR BEFORE CHEKING OIL LEVEL

CAUTION

To avoid Injury or

858-029C

Machine Damage:

·Operate only with

1000 rpm PTO

DANGER

818-240C Rev. A

ROTATING DRIVELINE -

CONTACT CAN CAUSE DEATH

KEEP AWAY!

DO NOT OPERATE WITHOUT-

All driveline guards, tractor

and equipment shields in place

PTO pump assembly securely

attached with torque arm and clamp

bolts properly torqued

858-030C

401-885M Table of Contents Index 2014-06-16

Page 9

Great Plains Manufacturing, Inc. Table of Contents Index Important Safety Information 5

Warning Decals

858-004C

WARNING

HOT FLUID HAZARD

Read Owner’s Manual BEFORE operating machine.

Keep tractor at IDLING SPEED and slowly engage PTO

to prevent damage to Hydraulic Motor

Keep Radiator clean and free of foreign matter to

prevent overheating.

Do NOT operate with hydraulic oil at or above 180°F.

858-004C

Warning: Hot Fluid

On front face of oil reservoir;

1 total

34617

To avoid Injury or

Machine Damage:

CAUTION

818-130C Rev. B

m PTO

erate only with

Caution Decals

818-130C

CAUTION

To avoid Injury or

Machine Damage:

*Operate only with

540 rpm PTO

818-130C Rev. B

Caution: 540 RPM PTO

On chain plate of torque arm at 540 rpm pump;

1 total (540 rpm kits only)

818-240C

CAUTION

To avoid Injury or

Machine Damage:

·Operate only with

1000 rpm PTO

Caution: 1000 RPM PTO

On chain plate of torque arm at pump, for pumps

with wide plates, otherwise on front face of oil

reservoir;

1 total (1000 rpm kits only)

818-240C Rev. A

ROTATING DRIVELINE -

CONTACT CAN CAUSE DEATH

DO NOT OPERATE WITHOUT-

To avoid Injury or

Machine Damage:

·Operate only with

1000 rpm PTO

DANGER

KEEP AWAY!

All driveline guards, tractor

and equipment shields in place

PTO pump assembly securely

attached with torque arm and chain

CAUTION

818-240C Rev. A

858-005C

36313

34843

To avoid Injury or

Machine Damage:

*Operate only with

540 rpm PTO

CAUTION

818-130C Rev. B

34617

WARNING

HOT FLUID HAZARD

Read Owner’s Manual BEFORE operating machine.

Keep tractor at IDLING SPEED and slowly engage PTO

to prevent damage to Hydraulic Motor

Keep Radiator clean and free of foreign matter to

prevent overheating.

OIL FILL LINE

Do NOT operate with hydraulic oil at or above 180°F.

CAPACITY = 13.5 U.S. GALS

USE ANY HIGH QUALITY MINERAL BASED

HYDRAULIC FLUID WITH A VISCOSITY RATING

OF 10W-30. OIL MUST BE CLEAN AND FREE

FROM DIRT OR CONTAMINANT PARTICLES TO

PREVENT DAMAGE TO PUMP AND MOTOR.

REPLACE FILTER ELEMENT AFTER EVERY

858-004C

150 OPERATING HOURS OR 2 YEARS SERVICE.

LEVEL TOOLBAR BEFORE CHEKING OIL LEVEL

CAUTION

To avoid Injury or

858-029C

Machine Damage:

·Operate only with

1000 rpm PTO

DANGER

818-240C Rev. A

ROTATING DRIVELINE -

CONTACT CAN CAUSE DEATH

KEEP AWAY!

DO NOT OPERATE WITHOUT-

All driveline guards, tractor

and equipment shields in place

PTO pump assembly securely

attached with torque arm and clamp

bolts properly torqued

858-030C

2014-06-16 Table of Contents Index 401-885M

Page 10

6 Single-Section PTO Pumps Table of Contents Index Great Plains Manufacturing, Inc.

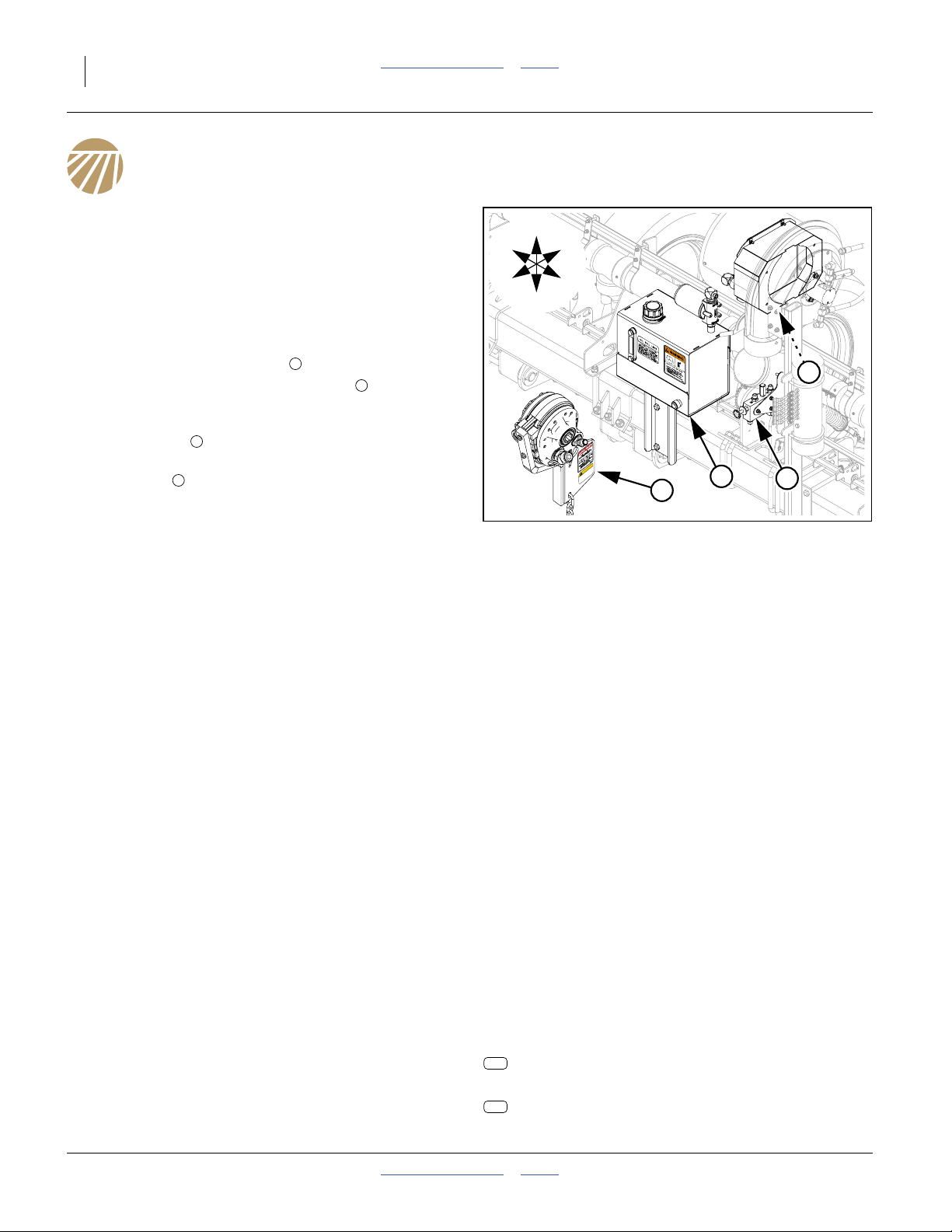

Introduction

Description of Unit

One of 17 dealer- or field-installed kits convert the

hydraulic fan power source from tractor hydraulic remote

to tractor Power Take-Off (PTO). An additional kit

updates older fan motors for PTO compatibility.

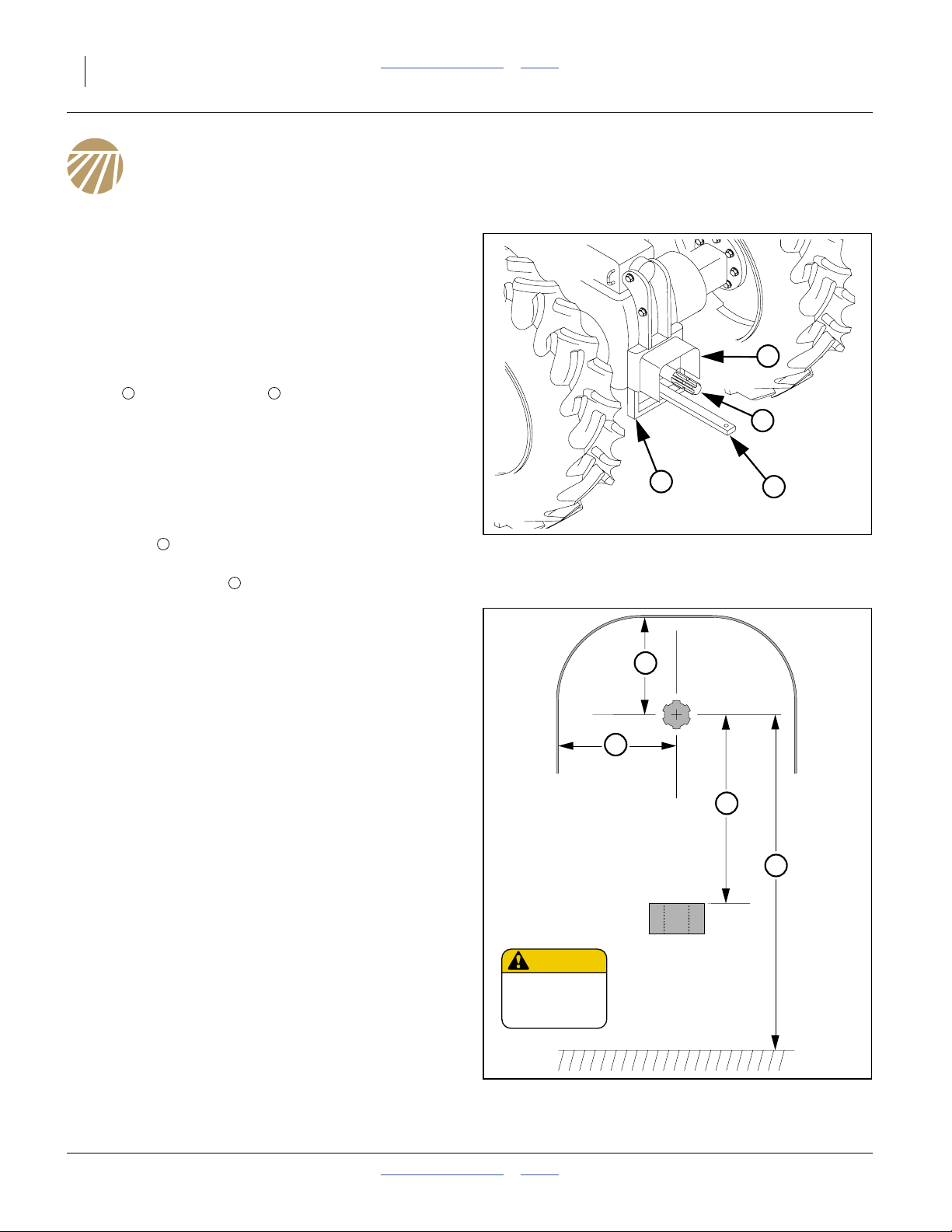

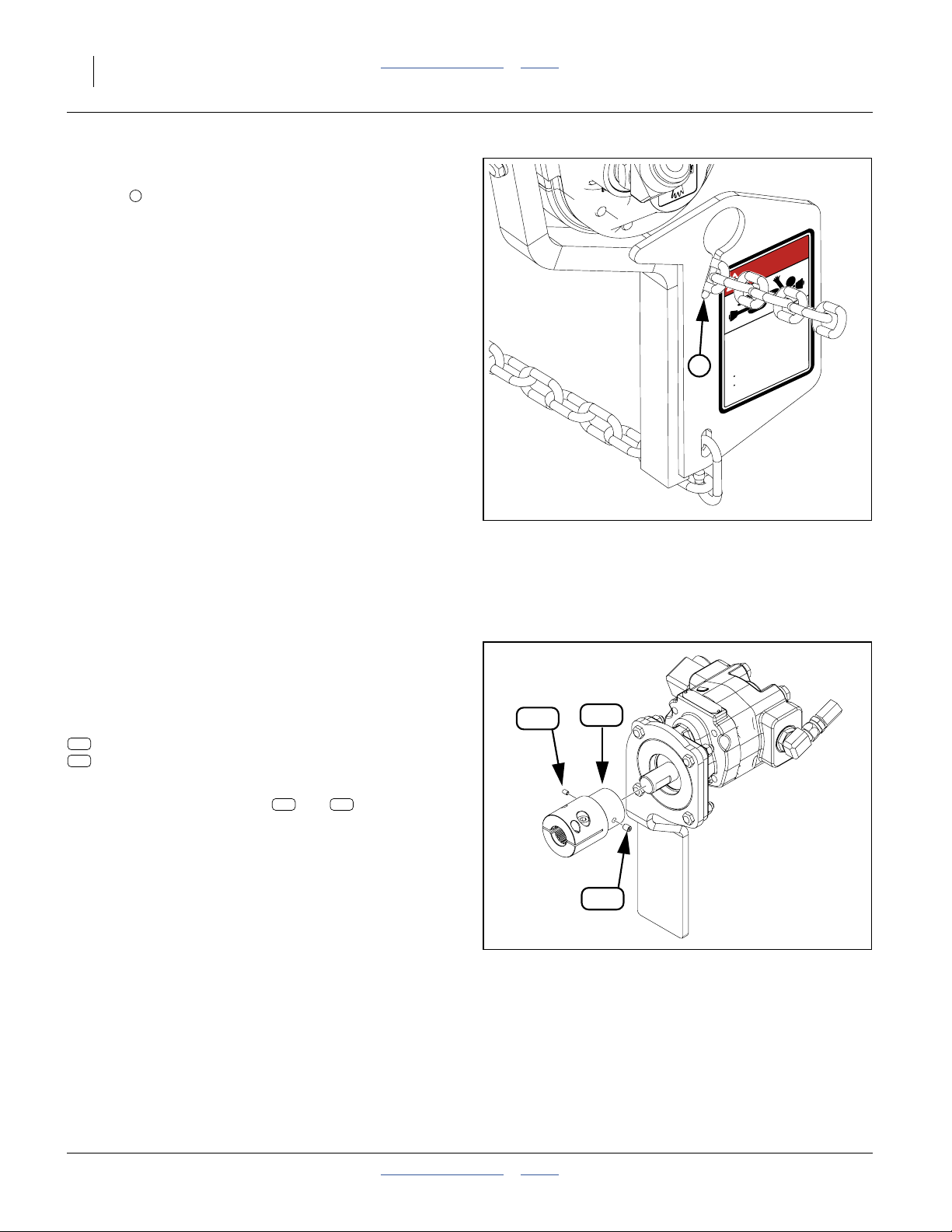

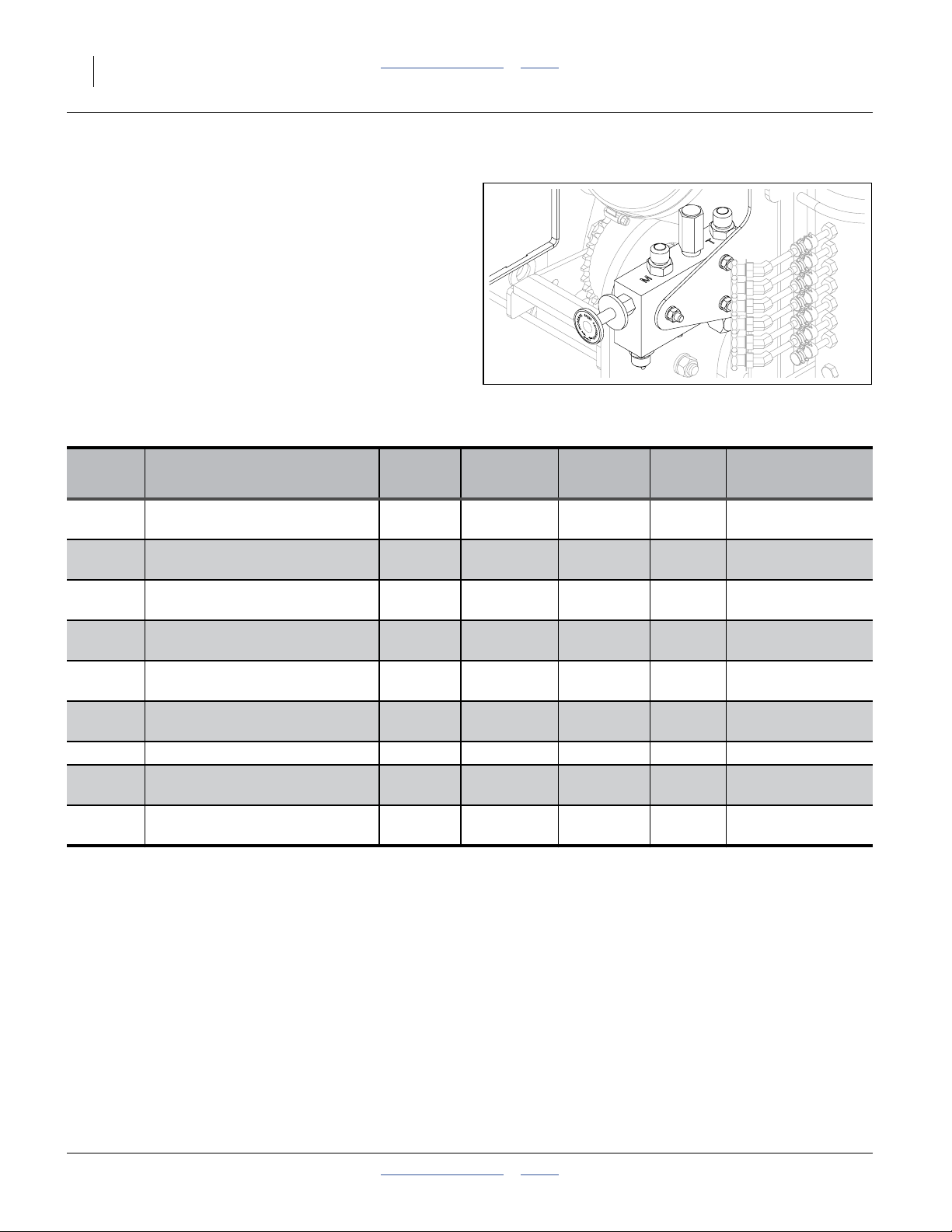

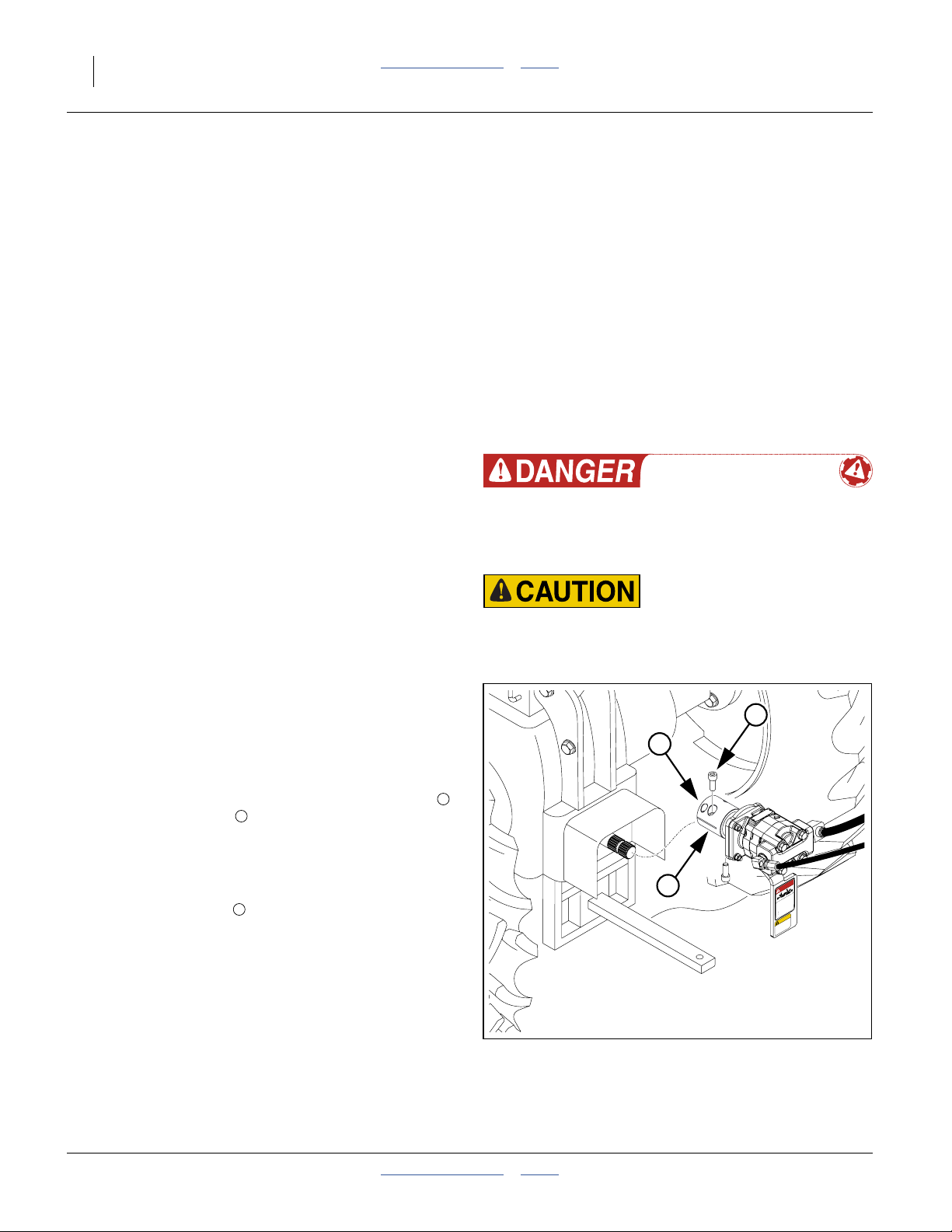

Refer to Figure 1

Each Single-Section PTO Pumps kit includes:

• a flow control valve assembly for setting fan rpm,

• a tethered 540 or 1000 rpm PTO pump , with torque

1

2

arm and safety chain (no gearbox is required; a

coupler is required for the 1000 rpm pump),

• an oil reservoir , with sight gauge, line filter and

3

6.5 gallon capacity (5.5 gallons/21 liters, used),

• an oil cooler , mounted inside the fan, and;

4

• all interconnecting hoses (not shown).

There are separate kits for rigid and rotating planters,

pull-type and 3-point planters, planters with and without

fertilizer capability and ground drive vs. hydraulic drive.

Suitable Applications

A PTO kit may be needed where:

• the tractor has an Open Center hydraulic system;

• the tractor has no remote port for the fan; or,

• the tractor is Closed Center, but the remotes offer

insufficient oil flow to reliably operate the fan.

Kits Covered

401-845A YP4-6-8 PTO 540 3PT ASSY

401-846A YP4-6-8 PTO 540 NO FERT PULL

401-847A YP4-6-8 PTO 540 DRY FERT ASSY

401-848A YP4 PTO 540 LIQ FERT ASSY

401-849A YP6-8 PTO 540 LIQ FERT ASSY

401-879A

401-956A

411-016A

411-035A

411-036A

411-037A

411-038A

411-163A

411-164A

411-165A

411-166A

411-167A

411-168A

See “Compatible Planters” starting on page 25 for more

details. Kits for 2- and 3-section planters are covered in

separate manual 411-015M.

YP8RW 3PT PTO 540 ASSY

YP4,6,8 FAN UPDATE

20A,25A PTO PUMP KIT

YP825R PTO HYD PUMP GND DV 540

YP825R PTO HYD PUMP GND DV1000

YP825R PTO HYD PUMP HYD DV 540

YP825R PTO HYD PUMP HYD DV1000

YP4-6-8 PTO 1000 3PT ASSY

YP4-6-8 PTO 1000 NO FERT PULL

YP4-6-8 PTO 1000 DRY FERT ASSY

YP4 PTO 1000 LIQ FERT ASSY

YP6-8 PTO 1000 LIQ FERT ASSY

YP8RW 3PT PTO 1000 ASSY

U

R

F

B

L

D

4

CAUTION

818-130C Rev. B

To avoid Injury or

Machine Damage:

*Operate only with

540 rpm PTO

2

Figure 1:

3

1

34617

PTO Kit Major Components

Related Documents

401-885M

118-999B

118-999M

118-999P

401-651M

401-651B

401-652P

401-652M

401-652P

401-923M

401-923B

401-923P

PTO Operation, Maintenance and Installation

(this document)

Material Rate manual, 2025A and 2525A

Operator manual, 2025A and 2525A

Parts manual, 2025A and 2525A

Operator manual, YP425A, YP625A and

YP825A pull-type models

Material Rate manual, YP4/6/825A/3P

Parts manual, YP4/6/825A pull-type

Operator manual, YP425A3P, YP625A3P

and YP825A3P three-point models

Parts manual, YP4/6/825A 3-point

Operator manual, YP825AR rotating

Material Rate manual, YP825AR

Parts manual, YP825AR

Related Parts

The 1000 rpm PTO kits require one of two

tractor-specific couplers, not included with the PTO kit.

20-Spline Coupler

210

826-777C 1 3/4-20 PTO COUPLER

21-Spline Coupler

211

826-778C 1 3/8-21 PTO COUPLER

401-885M Table of Contents Index 2014-06-16

Page 11

Great Plains Manufacturing, Inc. Table of Contents Index Introduction 7

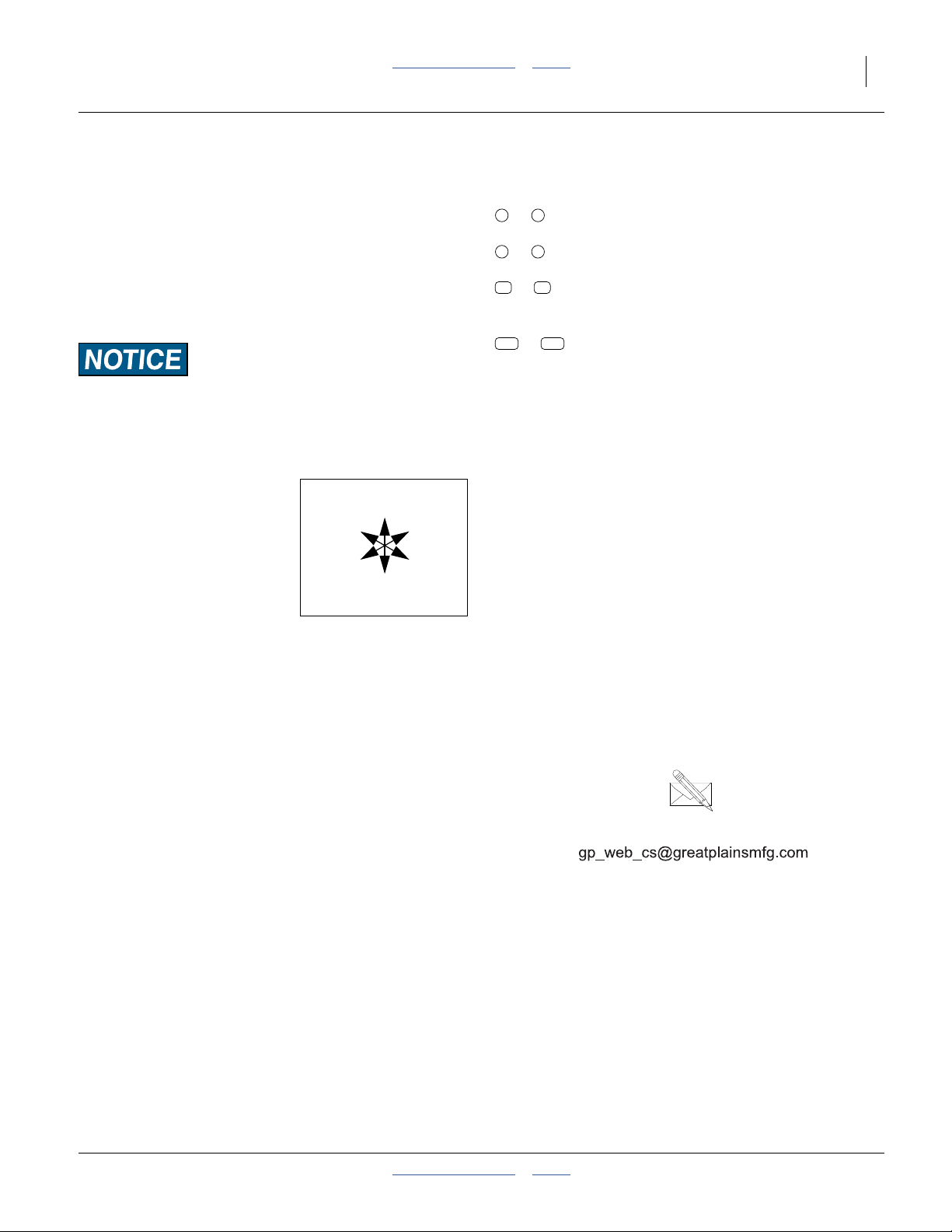

Using This Manual

This manual familiarizes you with safety, operation,

adjustments, maintenance and assembly. Follow the

recommendations to ensure safe and efficient operation.

Definitions

The following terms are used throughout this manual.

Note: Paragraphs in this format provide useful

information related to the current topic.

Liability, Economic and Results Risks:

Paragraphs in this format present a crucial point of information

related to the current topic. Read and follow the directions to:

remain safe, avoid serious damage to equipment and ensure

desired field results.

Right-hand and left-hand as

used in this manual are

determined by facing the

direction the machine will

travel while in use unless

otherwise stated.

An orientation rose (shown at

right) depicts Up, Right, Back,

Down, Left and Front.

U

F

L

R

B

D

Call-Outs

1 9

to

and

a z

to

11

to

101 244

to

The information in this manual is current at printing.

Some parts may change to assure top performance.

Single-character callouts identify

components in the currently referenced

Figure or Figures. Numbers and letters may

be reused for different items on other pages.

53

Two-digit callouts identify the same existing

parts throughout this manual. See page 70

for a list of these parts and their disposition.

Three-digit callouts identify the same new

parts throughout this manual. See page 68

for a list of these parts.

Owner Assistance

If you need customer service or repair parts, contact a

Great Plains dealer. They have trained personnel, repair

parts and equipment specially designed for Great Plains

products. Your machine’s parts were specially designed

and should only be replaced with Great Plains parts.

Record your Air-Pro® PTO pump kit model number here

for quick reference:

Model Number:__________________________

Date Purchased: __________________________

Your Great Plains dealer wants you to be satisfied with

your updated machine. If you do not understand any part

of this manual or are not satisfied with the service

received, please take the following actions.

1. Discuss the matter with your dealership service

manager. Make sure they are aware of any

problems so they can assist you.

2. If you are still unsatisfied, seek out the owner or

general manager of the dealership.

For further assistance write to:

Product Support

Great Plains Mfg. Inc., Service Department

PO Box 5060 Salina, KS 67402-5060

785-823-3276

2014-06-16 Table of Contents Index 401-885M

Page 12

8 Single-Section PTO Pumps Table of Contents Index Great Plains Manufacturing, Inc.

PTO Operation

Tractor Requirements

Tractor requirements are different for 540 rpm pumps

(below) and 1000 rpm pumps (page 9).

540 rpm Tractor Requirements

The 540 rpm Air-Pro® PTO pump accessories require a

tractor with:

Refer to Figure 2

• a rear-facing ASABE or ASAE Type 1 PTO stub

5 6

shaft with master shield

shaft: 1

clockwise rotation (as viewed from tractor rear, facing

forward),

• a “live” or “independent” PTO drive system, that can

be operated with the tractor stationary,

• a fixed or available shaft speed of 540 rpm, and an

available PTO power output of 5 hp (3.7 kW),

• a drawbar that engages the torque arm of the PTO

pump assembly, and

• a chain anchor point - a stable, non-moving

component of the tractor, within reach of the pump’s

torque arm chain.

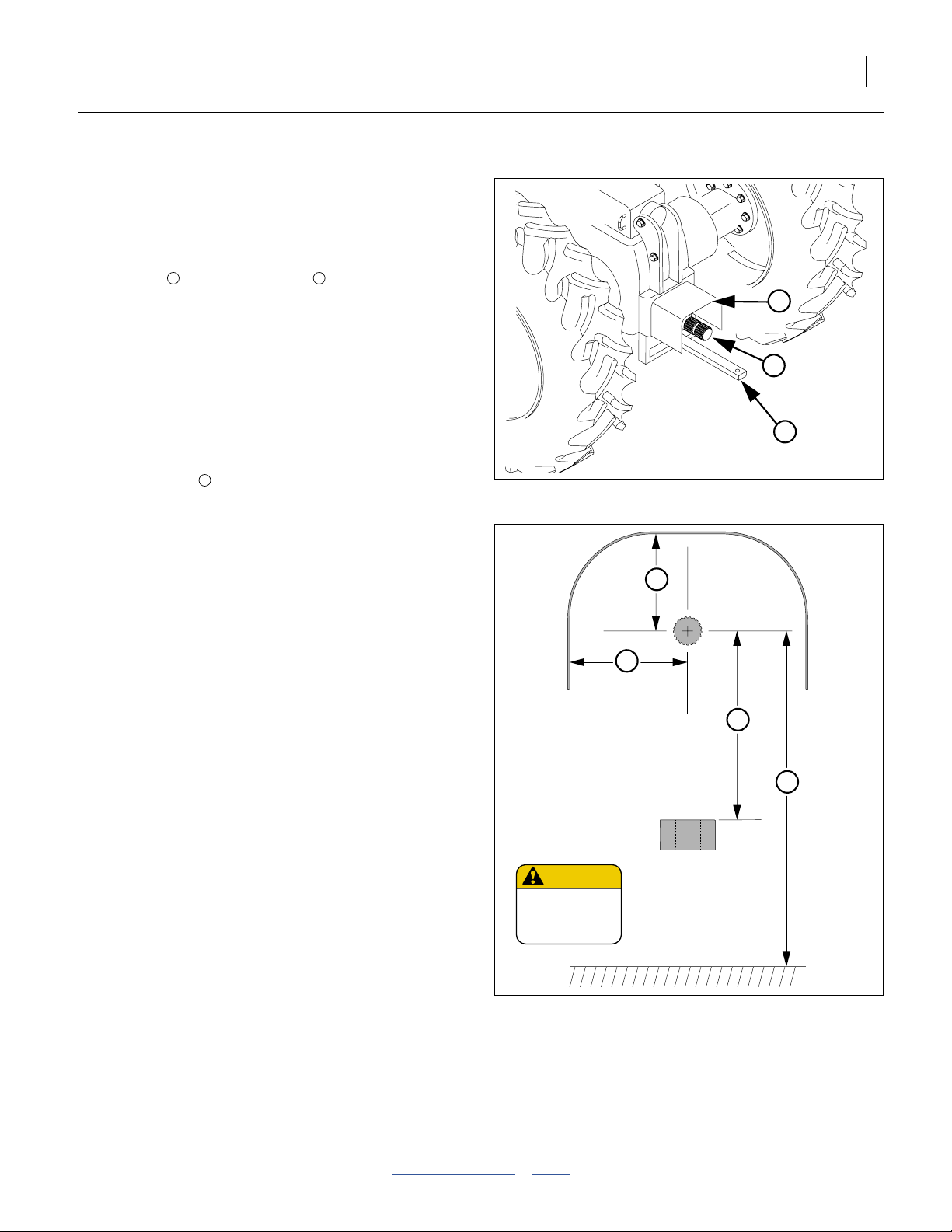

540 rpm PTO Clearance

If the tractor PTO is not known to conform to Type 1

specifications, check the following pump-specific

clearance dimensions:

Refer to Figure 3

a. Shaft to master shield top:

b. Shaft to master shield sides:

c. Shaft to drawbar top:

d. Shaft to ground:

3

⁄8inch (35 mm) 6-spline,

7

8

3.5 inches (8.9 cm) minimum

or hinged lid

5.0 inches (12.7 cm) minimum

9 inches (22.8 cm) minimum

15 inches (38.1 cm) maximum

It may be necessary to invert an offset drawbar, or

relocate or remove any clevis installed on the

drawbar.

16 inches (40.6 cm) minimum

CAUTION

To avoid Injury or

Machine Damage:

*Operate only with

540 rpm PTO

818-130C Rev. B

8

Figure 2:

Tractor PTO

a

b

6

5

7

34618

c

d

Figure 3:

Tractor PTO Clearances

401-885M Table of Contents Index 2014-06-16

34623

Page 13

Great Plains Manufacturing, Inc. Table of Contents Index PTO Operation 9

1000 rpm Tractor Requirements

540 rpm tractor requirements are on page 8. The

1000 rpm Air-Pro

tractor with:

Refer to Figure 2

• a rear-facing ASABE or ASAE Type 2 or Type 3 PTO

stub shaft with master shield

3

1

⁄4inch (44.5 mm) 20-spline

13⁄8inch (35 mm) 21-spline

clockwise rotation (as viewed from tractor rear, facing

forward),

• a “live” or “independent” PTO drive system, that can

be operated with the tractor stationary,

• a fixed or available shaft speed of 1000 rpm, and an

available PTO power output of:

20 hp (15 kW): Air-Pro® with ground drive meters

40 hp (30 kW): Air-Pro® with hydraulic drive meters

• and a drawbar that engages the torque arm of the

PTO pump assembly.

®

PTO pump accessories require a

5 6

7

Figure 4:

Tractor PTO

6

5

7

34842

1000 rpm Type 2 PTO Clearance

If the tractor PTO is not known to conform to Type 2

specifications, check the following pump-specific

clearance dimensions:

Refer to Figure 3

a. Shaft to master shield top:

3.5 inches (8.9 cm) minimum

or hinged lid

b. Shaft to master shield sides:

5.0 inches (12.7 cm) minimum

c. Shaft to drawbar top:

9 inches (22.8 cm) minimum

15 inches (38.1 cm) maximum

It may be necessary to invert an offset drawbar, or

relocate or remove any clevis installed on the

drawbar.

d. Shaft to ground:

16 inches (40.6 cm) minimum

CAUTION

To avoid Injury or

Machine Damage:

·Operate only with

1000 rpm PTO

818-240C Rev. A

a

b

c

d

Figure 5:

Type 2 PTO Clearances

2014-06-16 Table of Contents Index 401-885M

34844

Page 14

10 Single-Section PTO Pumps Table of Contents Index Great Plains Manufacturing, Inc.

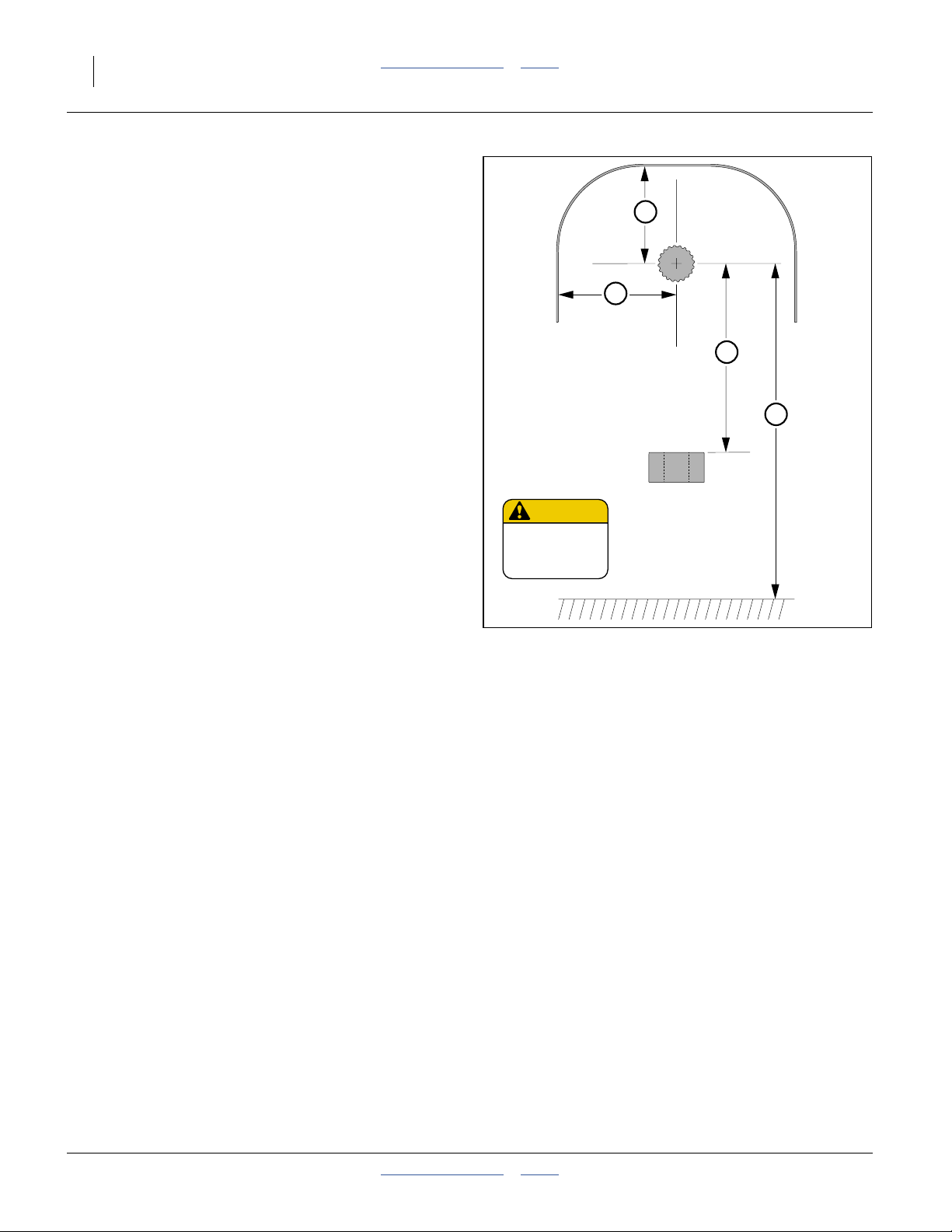

1000 rpm Type 3 PTO Clearance

If the tractor PTO is not known to conform to Type 3

specifications, check the following pump-specific

clearance dimensions:

Refer to Figure 3

a. Shaft to master shield top:

5.9 inches (15.0 cm) minimum

or hinged lid

b. Shaft to master shield sides:

7.0 inches (17.8 cm) minimum

c. Shaft to drawbar top:

8.6 inches (22.0 cm) minimum

13.75 inches (35.0 cm) maximum

It may be necessary to invert an offset drawbar, or

relocate or remove any clevis installed on the

drawbar.

d. Shaft to ground:

16 inches (40.6 cm) minimum

a

b

c

d

CAUTION

To avoid Injury or

Machine Damage:

·Operate only with

1000 rpm PTO

818-240C Rev. A

Type 3 PTO Clearances

Figure 6:

34845

401-885M Table of Contents Index 2014-06-16

Page 15

Great Plains Manufacturing, Inc. Table of Contents Index PTO Operation 11

Hitching with PTO

Hitching procedures are different for 540 rpm pumps

(below) and 1000 rpm pumps (page 12).

Hitching with 540 rpm PTO

The pump may be installed before or after hitching the

planter to the tractor. With a 3-point planter, installing the

pump first may be easier.

Prepare Tractor

1. Back the tractor into close proximity to the planter

(within pump hose reach of the PTO shaft).

2. Shut down the tractor and remove the key.

Entanglement and Crushing Hazard:

Never perform any mechanical adjustment, PTO setup or

hitching with the tractor running. Take no chances that the

PTO might become active. Entanglement or flailing equipment

can cause serious injury or death faster than you can react.

Refer to Figure 7

3. Make any necessary adjustment to the tractor

drawbar . This might include:

inverting an offset drawbar, and/or

relocating a clevis assembly (not shown).

1

Mount PTO Pump

2

1

Figure 7:

3

34620

Entanglement and Flailing Equipment Hazards:

Do not use a driveline, shaft extension, adaptor or external

gearbox with the PTO pump. Use only a native 540 rpm

6-spline stub shaft. Extra fittings create entanglement hazards.

Fittings also destabilize the shaft, and may make it impossible

to adequately secure the pump against torque and shaft slip.

Mount Pump

4. Clear the PTO shaft of any pins or wires that

might prevent the pump from fully seating on the

shaft.

5. With hydraulic hoses to rear, and torque arm to

right of drawbar, slide the pump assembly fully onto

the PTO shaft.

Secure Pump

Refer to Figure 8 (shown with pump off for clarity)

6. With the torque arm firmly against the drawbar:

loop the chain once around the drawbar,

then through the anchor point ,

then around the drawbar at least once more,

then through the keyhole slot in the torque plate.

The drawbar loops prevent pump rotation.

The anchor loop retains the pump on the PTO shaft.

2

3

4

5

1

7

5

4

Figure 8:

Route Pump Chain

6

7

34622

2014-06-16 Table of Contents Index 401-885M

Page 16

12 Single-Section PTO Pumps Table of Contents Index Great Plains Manufacturing, Inc.

Refer to Figure 9

7. At least one full chain link must be exposed at the

7

slot on the decal side of the torque arm plate.

If there are more than a few chain loops left at the

plate keyhole, route any excess chain through the

anchor point and/or around the drawbar.

8. Do NOT use any pins, cross-bolts or wires to secure

DANGER

the pump to the PTO shaft. Such fasteners are not

required for safe pump operation, and would add a

needless entanglement hazard.

9. Pull and twist the pump assembly to verify that the

chain is sufficiently taut to prevent excess pump

ROTATING DRIVELINE -

CONTACT CAN CAUSE DEATH

7

DO NOT OPERATE WITHOUT-

KEEP AWAY!

All driveline guards, tractor

and equipment shields in place

PTO pump assembly securely

attached with torque arm and chain

858-005C

rotation or sliding along the PTO shaft.

10. Complete normal planter hitching.

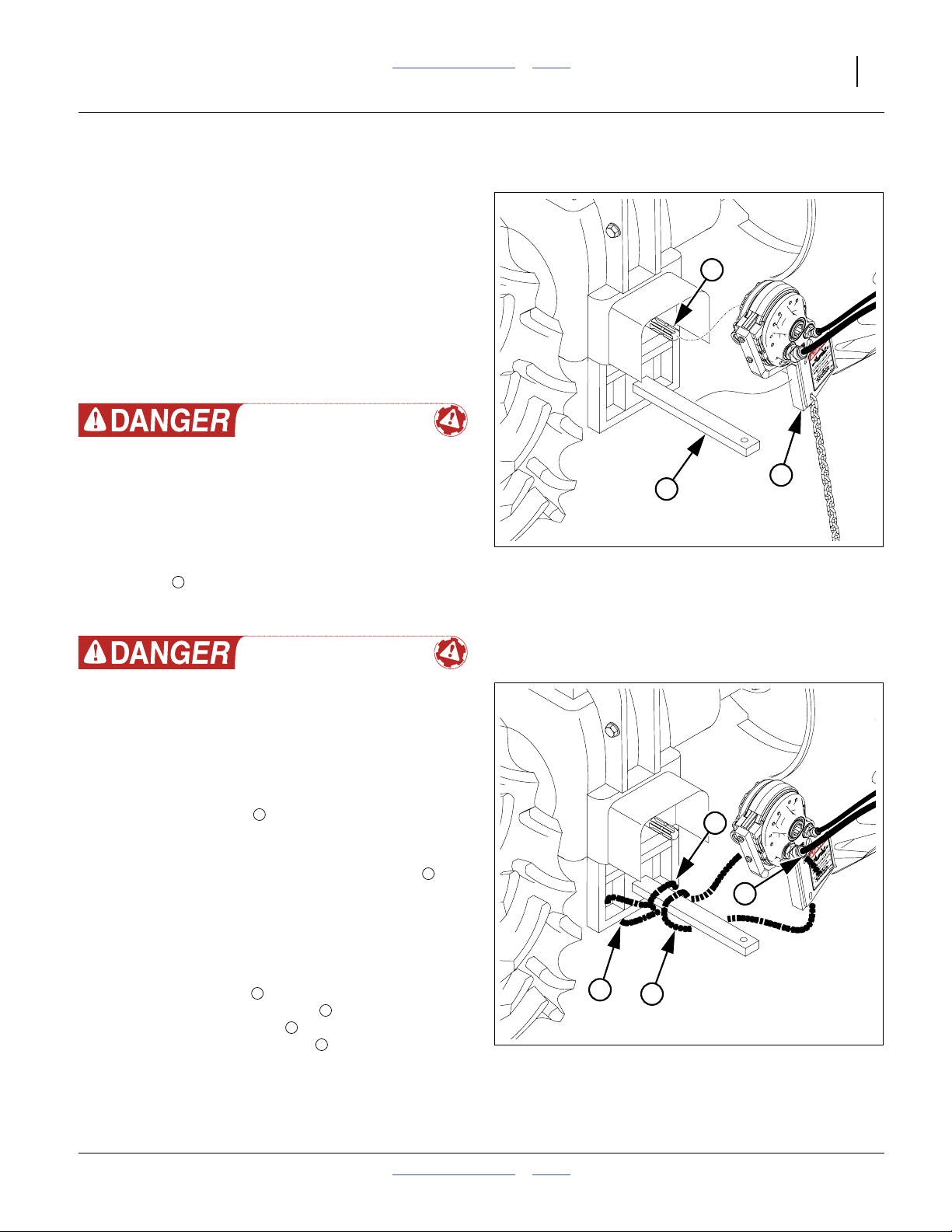

Hitching with 1000 rpm PTO

540 rpm hitching begins on page 11.

The 1000 rpm pump may be installed before or after

hitching the planter to the tractor.

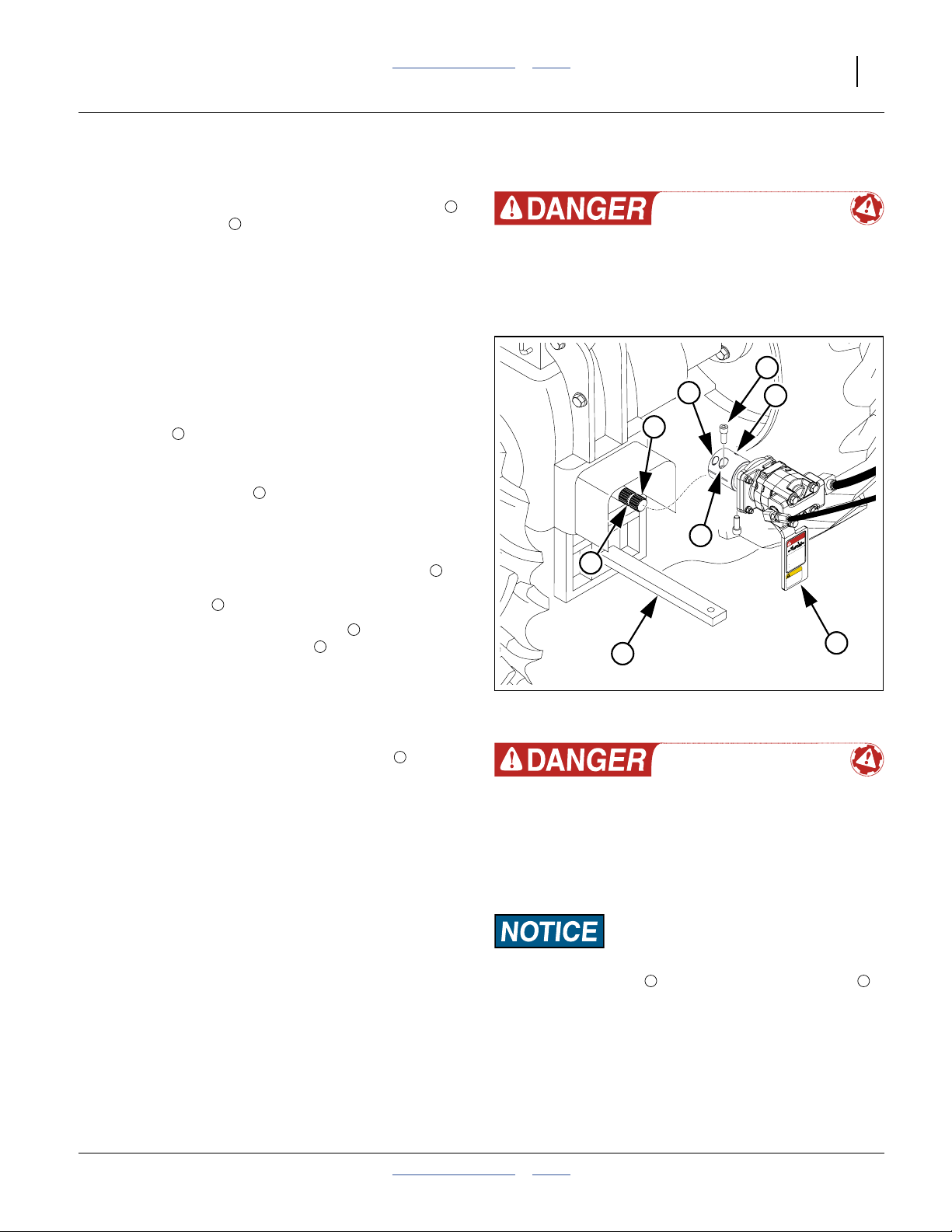

Install Coupler

The 1000 rpm PTO kits require one of two

tractor-specific couplers, not included with the PTO kit:

210

826-777C 1 3/4-20 PTO COUPLER

211

826-778C 1 3/8-21 PTO COUPLER

Refer to Figure 10 (showing coupler 826-778C)

1. Loosen both set screws ( and ) at the narrow

end of the coupler. Note that they are different sizes.

2. Rotate the coupler until the internal keyway aligns

with the key on the pump shaft. Slide the coupler

onto the pump shaft.

3. Tighten both set screws to the Grade 5 torque

specification for each thread size.

To remove or exchange a coupler at a later time, first

dismount the pump assembly from the tractor PTO shaft,

then loosen both set screws.

243 244

243

Figure 9:

Secure Pump Chain

211

244

Figure 10:

Secure Coupler to Pump

34627

36316

401-885M Table of Contents Index 2014-06-16

Page 17

Great Plains Manufacturing, Inc. Table of Contents Index PTO Operation 13

Prepare Tractor

Refer to Figure 11

4. Completely remove the socket head cap screws

from the coupler .

2

Note: If the coupler is not mounted, or you need to

change to a different coupler, see page 12.

5. If space is constrained inside the tractor PTO shield,

rotate the coupler to an orientation that eases later

1

Entanglement and Crushing Hazard:

Never perform any mechanical adjustment, PTO setup or

hitching with the tractor running. Take no chances that the

PTO might become active. Entanglement or flailing equipment

can cause serious injury or death faster than you can react.

inserting and tightening of the cap screws.

6. Back the tractor into close proximity to the planter

(within pump hose reach of the PTO shaft).

7. Shut down the tractor and remove the key.

8

1

2

8. Make any necessary adjustment to the tractor

drawbar . This might include:

3

4

inverting an offset drawbar, and/or

relocating a clevis assembly (not shown).

9. Clear the PTO shaft of any pins or wires that

4

might prevent the pump from fully seating on the

shaft.

Mount Pump

10. With hydraulics hoses to rear, and torque arm to

5

right of drawbar, slide the pump assembly fully onto

the PTO shaft .

11. Insert one socket head cap screw into the larger

counter-sunk clamping holes in the aft end of the

4

1

7

coupler. The screw head fully seat, below the

6

3

7

DANGER

ROTATING DRIVELINE -

CONTACT CAN CAUSE DEATH

KEEP AWAY!

DO NOT OPERATE WITHOUT-

All driveline guards, tractor

and equipment shields in place

PTO pump assembly securely

attached with torque arm and clamp

bolts properly torqued

CAUTION

To avoid Injury or

Machine Damage:

·Operate only with

1000 rpm PTO

858-030C

818-240C Rev. A

5

surface of the coupler, in these holes.

See NOTICE at right.

Figure 11:

Mount PTO Pump

36317

12. Adjust the position of the coupler on the shaft until

the screw threads are in the shaft groove . Thread

6

screw in until finger tight.

13. Insert the other socket head cap screw in the other

side of the coupler. Thread it until finger tight.

14. Pull and twist the pump assembly to verify that both

retention screws have engaged the PTO shaft grove

and prevent the pump from sliding along the PTO

shaft.

Entanglement and Flailing Equipment Hazards:

Do not use a driveline, shaft extension, adaptor or external

gearbox with the PTO pump. Use the pump, with a Great

Plains coupler, only on a native 1000 rpm 20- or 21-spline

stub shaft. Extra fittings create entanglement hazards. Fittings

also destabilize the shaft, and may make it impossible to

adequately secure the pump against torque and shaft slip.

15. Tighten both cap screws to1⁄2-13 Grade 8 torque

specification (105 foot-pounds, 145 N-m).

16. Complete normal planter hitching.

Equipment Damage Risk:

Use the clamping holes . Do not use the drive-out holes

7 8

(the smaller forward holes that are threaded to the surface).

Drive-out holes are used only during dismount. The screws

only partially thread into these holes. These holes do not

adequately secure the pump to the shaft. The screws are likely

to fall out if these holes are used for pump mounting.

2014-06-16 Table of Contents Index 401-885M

Page 18

14 Single-Section PTO Pumps Table of Contents Index Great Plains Manufacturing, Inc.

Check Hydraulics

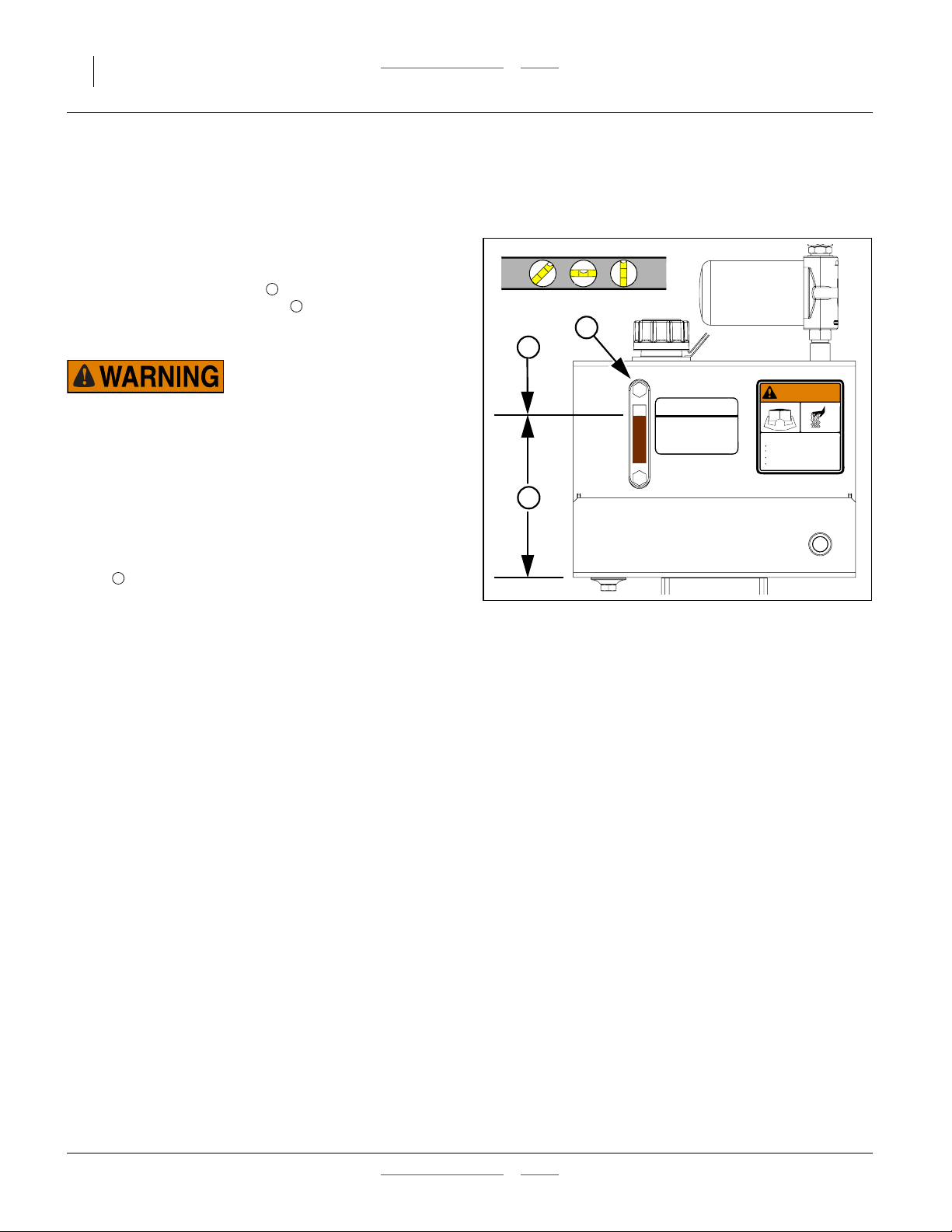

Check Oil Level

Refer to Figure 12

1. Verify that the planter is level front to back and side

to side.

2. Inspect the sight gauge on the pump system

reservoir tank. The oil level must be aligned with

the center border of the OIL FILL LINE decal

(858-003C).

8

9

8

9

Hot Surface and Hot Fluid Hazards:

Assess the tank temperature before adjusting oil level.

Draining excess hot oil could result in a severe burn. If the

PTO has been operated recently, the oil temperature could be

as high as 180°F (82°C).

3. Add or drain oil as needed to obtain the correct

amount. Some adjustment is normally required with

a new system, or after a filter change.

Note: The fill level dimension from tank bottom is:

a

9.15 inches (23.2 cm)

If the

858-003C decal requires replacement, adjust

the center border line to this height.

Inspect Hoses and Fittings

4. Check that all hydraulic fittings are tight and dry.

Inspect all hoses for damage, wear and fatigue.

Because the PTO pump system is closed, any

visible fluid may be an indication of a leak.

OIL FILL LINE

CAPACITY = 5.5 U.S. GALS

USE ANY HIGH QUALITY MINERAL BASED

HYDRAULIC FLUID WITH A VISCOSITY RATING

OF 10W-30. OIL MUST BE CLEAN AND FREE

FROM DIRT OR CONTAMINANT PARTICLES TO

PREVENT DAMAGE TO PUMP AND MOTOR.

REPLACE FILTER ELEMENT AFTER EVERY

150 OPERATING HOURS OR 2 YEARS SERVICE.

LEVEL TOOLBAR BEFORE CHECKING OIL LEVEL

858-003C

HOT FLUID HAZARD

Read Owner’s Manual BEFORE operating machine.

Keep tractor at IDLING SPEED and slowly engage PTO

to prevent damage to Hydraulic Motor

Keep Radiator clean and free of foreign matter to

prevent overheating.

Do NOT operate with hydraulic oil at or above 180°F.

858-004C

a

WARNING

Figure 12:

Check Oil Level

34625

401-885M Table of Contents Index 2014-06-16

Page 19

Great Plains Manufacturing, Inc. Table of Contents Index PTO Operation 15

Starting the Pump

While the planter is stationary, it may be necessary to

briefly operate the pump for any of several reasons:

• verify system installation or PTO operation.

• verify oil level with system fully charged.

• set initial meter pressurization.

Refer to Figure 13

1. If the system is adjusted, leave the flow control

valve as-is.

If the system is not yet adjusted, close the flow

control valve to prevent fan motion. Turn the lock

1 2

disc counter-clockwise to release the knob .

Turn the knob fully clockwise to close the valve.

2. Clear the hitch area of non-essential persons.

Check essential personnel for long hair, scarfs,

cords, frays, loose flaps and anything else that

might get entangled. Clear the area of dangling or

loose wires, straps, cord and other lines that might

become entangled and pull someone in.

3. It is not necessary to run the PTO at the full 540 or

1000 rpm. You may run it any lower speed that

provides sufficient meter pressurization (page 17).

Entanglement and Crushing Hazard:

Use extreme caution in the hitch area when the PTO is

operating.

1

2

Figure 13:

Flow Control Valve

34626

Equipment Damage Risk:

Do not START the pump and fan suddenly at high PTO power.

Engage the PTO clutch slowly (if possible) and/or at low

engine rpm, and gradually increase PTO rpm. The hydraulic

fan can be damaged by sudden acceleration.

4. • Check that tractor is in Park or Neutral.

• Check parking brake set.

• Set the tractor PTO controls for

540 or 1000arpm gearing (if multi-speed) and

clockwise rotation (if bidirectional).

• Start tractor engine and set throttle to idle.

• Engage the PTO.

• Bring the tractor engine and PTO up to intended

field rpms.

5. Check for hydraulic fluid leaks.

6. Verify fluid level in tank (page 14).

High Pressure Fluid Hazard:

Watch for signs of fluid leaks. Escaping fluid under pressure

can have sufficient pressure to penetrate the skin causing

serious injury. Use a piece of paper or cardboard, NOT BODY

PARTS, to check for leaks. Wear protective gloves and safety

glasses or goggles when working with hydraulic systems. If an

accident occurs, seek immediate medical attention from a

physician familiar with this type of injury.

a. Operate above 540 rpm only with a 1000 rpm pump.

2014-06-16 Table of Contents Index 401-885M

Page 20

16 Single-Section PTO Pumps Table of Contents Index Great Plains Manufacturing, Inc.

About the Flow Control Valve

The flow control valve adjusts the percent of PTO pump

output that is supplied to the planter hydraulic motors.

The total pump flow, in gpm or liters/min, is also directly

proportional to PTO shaft rpm.

Adjustment typically requires two persons. Pump oil flow

is ideally adjusted with all motors active under simulated

field workload, relying on Magnehelic® pressure gauge

readout, and in some cases seed monitor rpm readout.

On Great Plains Yield-Pro® single section planters, the

PTO pump supplies one or two hydraulic motors.

The table below summarizes the motor count/use and

readout resource available for the covered planters.

Figure 14:

Flow Control Valve (YP825A)

34626

PTO

Kit

401-845A

411-163A

401-846A

411-164A

401-847A

411-165A

401-848A

411-166A

401-849A

411-167A

401-879A

411-168A

411-016A 2025A, 2525A Ground Meter Fan - in. H

411-035A

411-036A

411-037A

411-038A

a. See page 25 for detailed compatibility information.

b. Fan rpm is reported by the monitor console on this configuration, and can be used as a reference.

YP425A3P, YP625A3P,

YP825A3P Narrow

Seed-only YP425A, YP625A,

YP825A

Dry fertilizer YP425A, YP625A,

YP825A

Liquid fertilizer YP425A

Liquid fertilizer YP625A,

YP825A

YP825A3P Wide

YP825AR ground drive

YP825AR hydraulic drive

Planter

Model(s)

a

a

Seed

Drive

First

Motor

Second

Motor

Fan

Adjust

Ground Meter Fan - in. H2O Fan mast

Ground Meter Fan - in. H2O Fan mast

Ground Meter Fan - in. H2O Fan mast

Ground Meter Fan - in. H2O Fan mast

Ground Meter Fan - in. H2O Fan mast

Ground Meter Fan - in. H2O Fan mast

Ground Meter Fan - in. H2O Mainframe front

Hydraulic Meter Fan Seed Drive in. H2O

Valve

Location

O Upper Frame Tube

2

b

Mainframe front

401-885M Table of Contents Index 2014-06-16

Page 21

Great Plains Manufacturing, Inc. Table of Contents Index PTO Operation 17

Setting Meter Pressurization

General Steps for all Kits

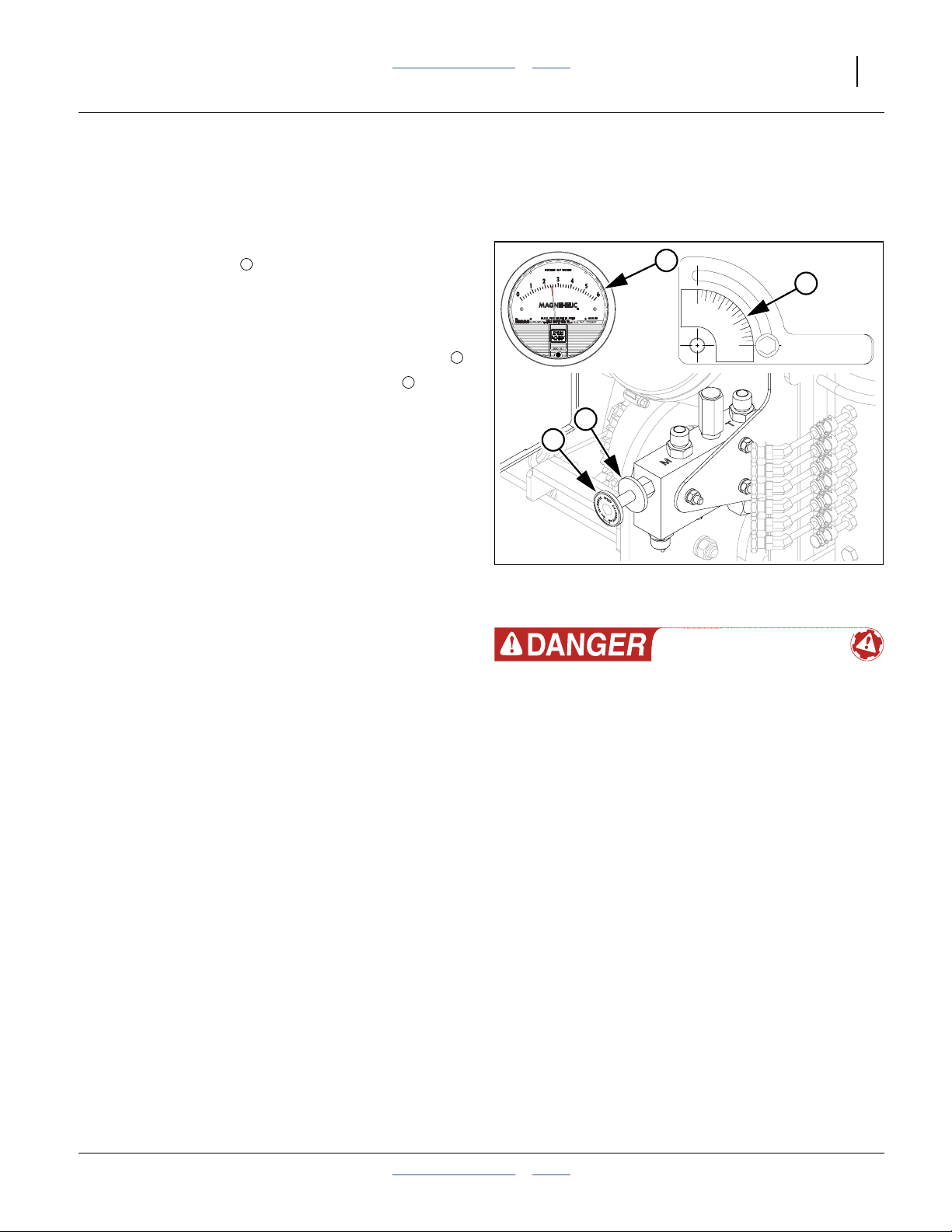

Refer to Figure 15

Meter pressurization is set as for a standard planter,

using the PTO kit valve rather than a lever for a tractor

1

hydraulic remote. This adjustment is normally made with

the seed meters full of seed.

Consult your planter Seed Rate manual for the correct

seed disk, meter inlet shutter setting, and recommended

initial pressure as reported by the Magnehelic

1. Check that the Inlet Butterfly valve handle is set

®

gauge .

3

to 30°. If not, loosen the pivot bolt, reset handle, and

Re-secure bolt.

2. Mount the PTO pump (page 11).

3. Shut off the tractor and remove the key.

4. Consult your planter Seed Rate manual for the

intended crop, noting:

• Range and Transmission sprockets required,

• correct Air-Pro

®

seed disk (not shown),

• initial inlet shutter setting (not shown), and

• initial meter pressurization.

5. Install seed disks. Leave rain covers off meters.

6. Set meter inlet shutters per the Seed Rate manual.

7. Open any slide gates under hoppers.

8. Load enough seed to completely fill the meter inlet

tubes, and at least partially fill every hopper.

9. Set out containers, under row unit seed tubes, to

collect seed metered during setup.

10. Clear the hitch area of non-essential persons.

Check essential personnel for long hair, scarves,

cords, frays, loose flaps and anything else that

might get entangled. Clear the area of dangling or

loose wires, straps, cord and other lines that might

become entangled and pull someone in.

2

4

1

Meter Pressure Adjustment

Entanglement and Crushing Hazard:

Use extreme caution in the hitch area when the PTO is

operating.

2

90

60

30

0

848-020C

Figure 15: YP625A

3

29842

25137

34626

2014-06-16 Table of Contents Index 401-885M

Page 22

18 Single-Section PTO Pumps Table of Contents Index Great Plains Manufacturing, Inc.

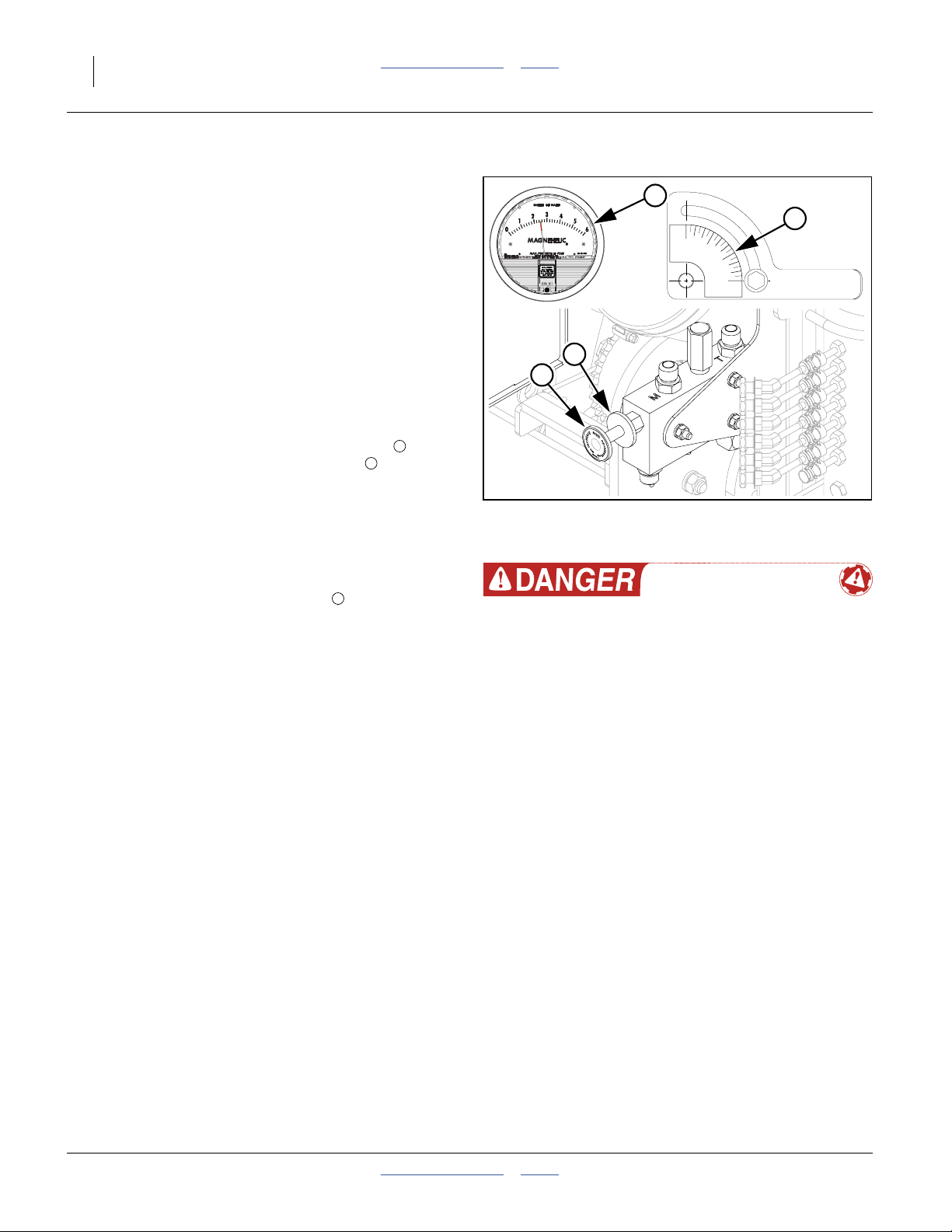

Ground Drive Meter Pressure

1. Configure the meter drive system sprockets for the

rate desired (see Seed Rate Manual).

2. Per your planter Operator manual, hitch the planter.

Raise the planter. Install lift locks. This is to free the

meter ground drive wheel.

3. • Check that tractor is in Park or Neutral.

• Check parking brake set.

• Set the tractor PTO controls for

540 or 1000 rpm gearing (if multi-speed) and

clockwise rotation (if bidirectional).

• Start tractor engine and set throttle to idle.

• Engage the PTO.

• Bring the tractor engine and PTO up to intended

field rpms.

4. At the flow control valve, turn the lock disc

counter-clockwise to release the knob . Slowly

4

1

turn the knob counter-clockwise to start the fan.

Bring the fan speed up until the Magnehelic®gauge

displays the suggested pressure for this crop.

5. Turn the meter ground drive wheel forward several

turns, until all exposed cells in all seed disks contain

seed.

6. Recheck the Magnehelic® gauge . The reported

2

pressure is likely to have increased. Adjust the flow

control knob to bring the pressure reading back to

the recommended value. Tighten the lock disc.

7. Shut down the PTO, and as desired, the tractor.

8. Install rain covers on seed meters.

The PTO pump is now ready for field work. Some

adjustment of meter pressure and inlet shutters may be

required, depending on seed and planting conditions.

Use the flow control valve, and not the butterfly valve, to

make pressure adjustments.

4

1

Meter Pressure Adjustment

Entanglement and Crushing Hazard:

Use extreme caution in the hitch area when the PTO is

operating.

2

90

60

30

0

848-020C

Figure 16: YP625A

3

29842

25137

34626

401-885M Table of Contents Index 2014-06-16

Page 23

Great Plains Manufacturing, Inc. Table of Contents Index PTO Operation 19

Hydraulic Drive Meter Pressure

On these models, the PTO system drives two motors,

plumbed in parallel.

Adjustment Steps:

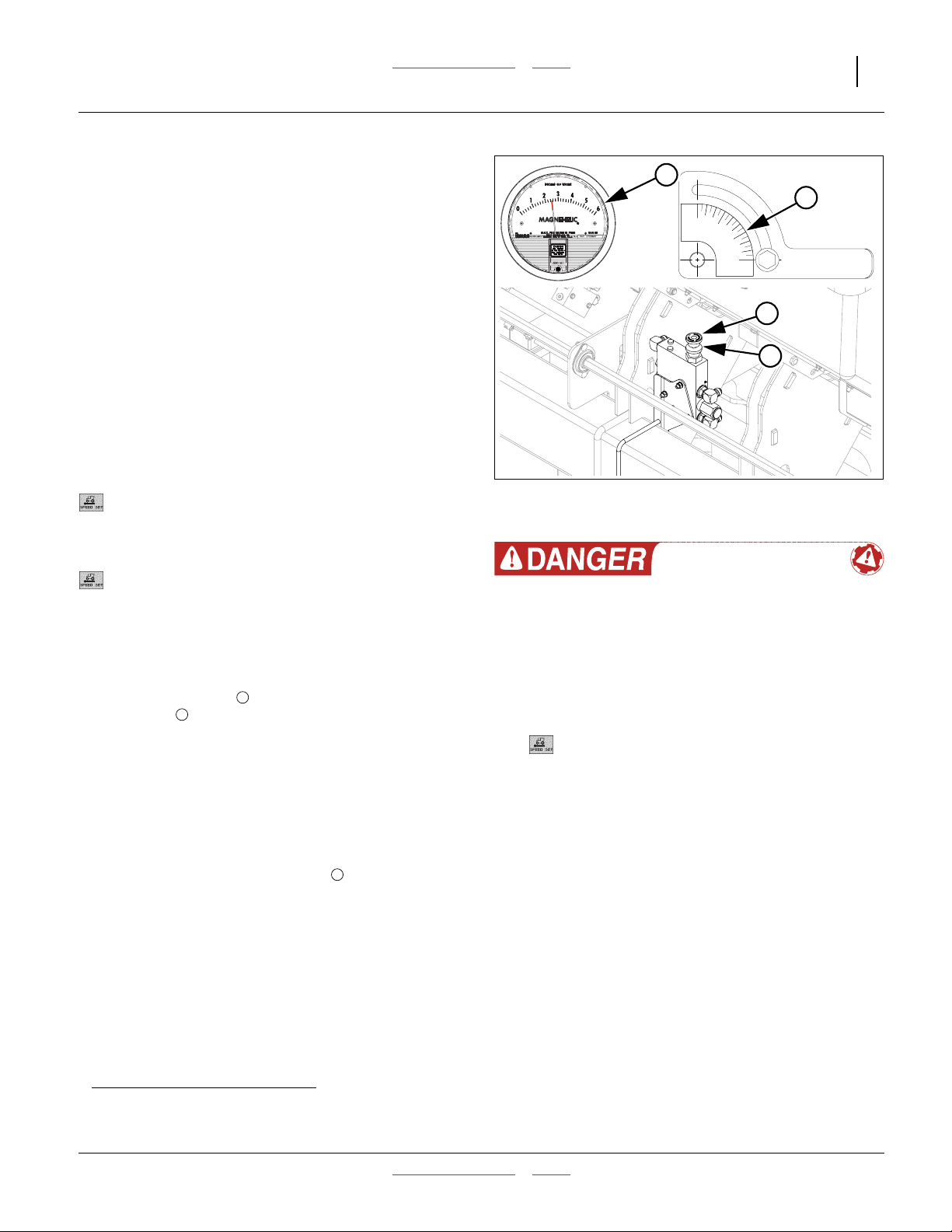

Refer to Figure 17

1. Have the DICKEY-john

Level 2&3 manual at hand. Making changes to the

GROUND SPEED SETUP configuration requires

the Level 2 password.

2. Have the Operator and Seed Rate manuals at hand,

so that meter setting and fan rpm targets are known

for the seed to be planted.

3. Turn the IntelliAg® monitor system on.

Turn the Master switch off.

On the console, navigate to the

GROUND SPEED SETUP screen.

Record the ground speed constant:

Source

Gspd Constant

4. Set:

Source

Manual Gnd Spd

Implement Lift

®

Planter/Drill Control User

Digital Freq.

12345 (actual value varies)

Manual

5.0 MPH (or as desired)

Disabled

2

3

90

60

30

0

848-020C

1

4

Figure 17: YP825AR

Meter Pressure Adjustment

Entanglement and Crushing Hazard:

Use extreme caution in the hitch area when the PTO is

operating.

29842

25137

36291

5. Hitch the tractor to be used, and install the PTO

pump. Raise the planter.

6. Turn the lock disc counter-clockwise to release

the knob . Turn the knob fully clockwise to shut off

1

4

flow to the motors.

7. Start the tractor, and seed monitor. Bring the PTO

up to expected field rpm (which is often not the full

1000 rpm).

8. Turn the IntelliAg

®

Master switch on to engage the

hydraulic seed meter drive.

9. With one person observing the Magnehelic

pressure gaugea, turn the knob

1

®

counter-clockwise to obtain the pressure

recommended for this planter configuration, crop,

population and intended field speed.

Secure the knob at this setting with the lock disc.

10. Shut down the PTO. Set Master switch off.

11. On the console, navigate to the

GROUND SPEED SETUP screen.

Restore the original settings:

Source

Gspd Constant

Implement Lift

Digital Freq.

12345 (actual value varies)

Enabled

12. If the planter has hydraulic drive, engage it for a

“FIVE REV TEST” or similar operation to create a

hydraulic motor load. Adjust PTO oil flow for target

fan speed plus 50 rpm.

Monitor meter pressurization when planting. If it is

different than during flow setup, perform the setup steps

again, and adjust the flow control valve for the

recommended pressure.

a. The monitor console also reports fan rpm. If you make a note of the fan rpm at the recommended pressure, you can use the console to

check air system status in the field.

2014-06-16 Table of Contents Index 401-885M

Page 24

20 Single-Section PTO Pumps Table of Contents Index Great Plains Manufacturing, Inc.

PTO Unhitching

The pump may be dismounted before or after unhitching

the planter and tractor. With a 3-point planter,

dismounting the pump last may be easier, which is the

order shown on this page. For safety, have the tractor

completely shut down during PTO dismounting.

1. At the tractor, shut down the PTO.

Note: The PTO may be shut down suddenly or gradually.

The fan circuit includes a bypass to recirculate

excess pressure during deceleration. The fan is

only sensitive to sudden acceleration.

2. Do not approach the hitch area until the PTO shaft,

and the fan, have slowed to a complete stop.

3. Mechanically unhitch the planter per the Operator

manual. Leave the PTO pump mounted at this time.

4. Pull the tractor forward enough to allow access to

the PTO pump. Put the tractor in Park or Neutral.

Engage the parking brake. Shut the tractor down.

Remove the key.

Dismount 540 rpm Pump

Refer to Figure 9 on page 12

5. Pass the free end of the pump chain forward

through the torque arm keyhole.

6. Unwrap the chain from the anchor point and

drawbar.

7. Slide the PTO pump off the PTO shaft. Store the

pump on the planter. Use the chain to secure it to

any available structure.

Entanglement Hazard:

Remain clear of a rotating PTO shaft. Even when coasting to a

stop, a PTO shaft can have enough residual torque to inflict

serious or fatal injury.

Hot Surface Hazard:

Remain clear of the pump reservoir during unhitching.

The oil may be hot enough to inflict a painful burn.

1

Dismount 1000 rpm Pump

3

Refer to Figure 18

5. Loosen and remove the socket head cap screws

at the PTO coupler .

2

1

6. Slide the PTO pump off the PTO shaft.

If, after removing the cap screws, the coupler is still

grasping the PTO shaft too tightly to remove, use

the drive-out holes to pry the clamping halves

3

apart. Insert the cap screws in the forward drive-out

2

DANGER

ROTATING DRIVELINE -

CONTACT CAN CAUSE DEATH

KEEP AWAY!

DO NOT OPERATE WITHOUT-

All driveline guards, tractor

and equipment shields in place

PTO pump assembly securely

attached with torque arm and clamp

bolts properly torqued

CAUTION

To avoid Injury or

Machine Damage:

·Operate only with

1000 rpm PTO

858-030C

818-240C Rev. A

holes. Tighten them alternately until the coupler is

free.

Figure 18:

36317

Dismount 1000 rpm PTO Pump

401-885M Table of Contents Index 2014-06-16

Page 25

Great Plains Manufacturing, Inc. Table of Contents Index 21

PTO Troubleshooting

Symptom Cause Remedy

Seed meter pressure

too low

Pressure correct on

®

Magnehelic

, but

skips or doubles

Oil overheating

Fan running in

reverse

Fan doesn’t run at all

Flow control adjusted too low. Increase flow control (page 17).

Fan butterfly valve closed or set at too high

an angle.

PTO rpm too low. Bring up PTO rpm, but do not exceed

Fan running in reverse (multiple possible

causes).

Pump cavitating. Check oil level (page 14).

No blank disks in unused seed meters. Install blank disks to balance pressure.

Seed inlet shutters open too wide. Verify setting vs., rate charts. Adjust as

Oil filter clogged. Replace oil filter and oil (page 22).

Magnehelic® gauge disconnected or

sample line(s) leaking.

Magnehelic® gauge uncalibrated. Re-zero (see Operator manual).

Flow control valve failure or malfunction. Repair or replace valve.

Fan seals damaged. Repair or replace fan motor.

PTO rotation and fan or valve hoses

reversed (highly unlikely).

Fan cooler plugged. Clean or replace fan cooler.

Pressure gauge disconnected or sample

line(s) leaking.

Magnehelic® gauge uncalibrated. Re-zero (see Operator manual).

Seed variety may require adjustment. Check all other possible pressure errors,

Oil filter clogged. Replace oil filter and oil (page 22).

PTO rpm too high. Adjust system for ideal pressure at lower

Fan butterfly valve angle too high. Reduce to 30° (page 17).

PTO shaft turning counter-clockwise. Set tractor controls for clockwise PTO.

Hoses reversed. Check hose routing from pump to valve, to

Low oil level in tank. Top off tank. Check system for leaks.

Flow control valve closed. Adjust valve (page 17).

Hoses misconnected. Review installation (page 54).

Reduce to 30° (page 17).

540 rpm.

See “Fan running in reverse” below.

need for actual seed pool.

Check air gauging system.

Set tractor controls for clockwise PTO.

Reconnect hoses.

Check air gauging system.

then fine tune pressure for one seed per

disk cell.

PTO rpm.

tank and fan per Parts manual.

2014-06-16 Table of Contents Index 401-885M

Page 26

22 Single-Section PTO Pumps Table of Contents Index Great Plains Manufacturing, Inc.

PTO Maintenance

Oil and Filter Change

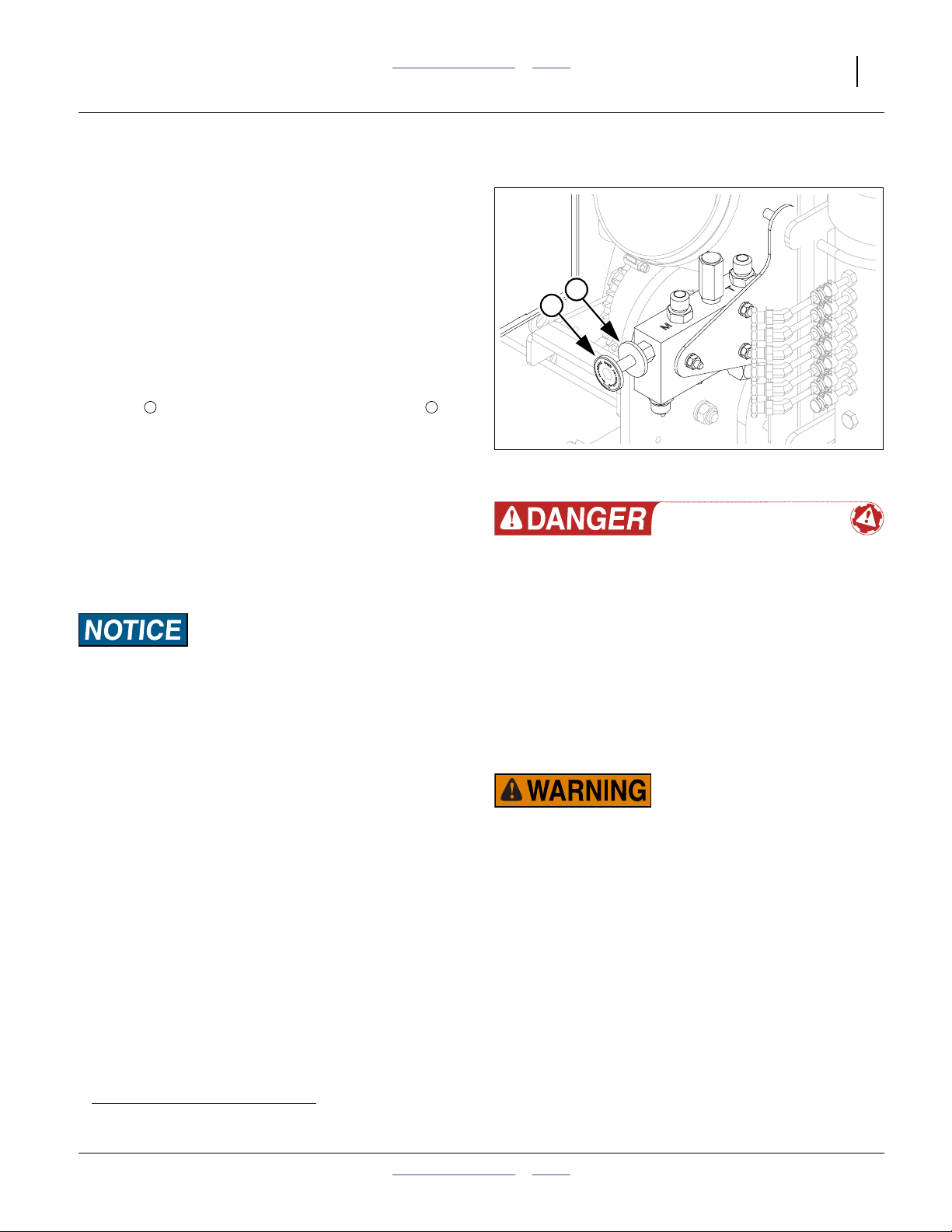

Oil Fill

Refer to Figure 19 and Figure 20

A dry or fully drained system may require as much as

6.5 gallons (25 liters) of oil to charge the cooler, pump,

motor, hoses, filter and valve, and leave 5.5 gallons

(21 liters) in the reservoir.

Before adding oil, check that the drain plug is secure,

1

and that there are no signs of leaks in hoses or at any

system fittings.

Oil Specification

10W-30 good quality mineral base hydraulic fluid,

viscosity 70 to 250 SUS at 210°F (100°C).

Remove the filler cap . Add oil until the oil level in the

tank, as observed on the sight gauge , reaches the fill

2

3

line on the decal (the horizontal mid-border of the decal).

The fill line is:

9.15 inches (23.2 cm)

above the tank bottom. If the 858-003C decal requires

replacement, adjust the center border line to this height.

Operate the PTO system briefly, or until the tank level

stops changing. See “PTO Operation” on page 8 for

operations.

Recheck the sight gauge. As necessary, add oil to fill

line.

Oil and Filter Change

At a regularly scheduled oil change, also change the

filter. At initial system flush, no filter change is required.

Refer to Figure 19 and Figure 20

1. Wait for the oil to cool before changing the oil.

2. Place a container under the drain plug of the

reservoir, with at least a capacity of:

7 gallons (26 liters)

3. Carefully remove the drain plug.

4. Allow several minutes for oil in the filter to drain into

and out of the reservoir. Change filter as required.

See page 23 for filter size. Seat filter per

instructions on filter.

5. Thread the plug back into the tank. Seating torque

is 27 to 43 foot-pounds (37 to 58 N-m).

1

Hot Surface and Hot Fluid Hazards:

Assess the tank temperature before adjusting oil level.

Draining excess hot oil could result in a severe burn. If the

PTO has been operated recently, the oil temperature could be

as high as 180°F (82°C).

2

3

CAUTION

818-130C Rev. B

To avoid Injury or

Machine Damage:

*Operate only with

540 rpm PTO

Figure 19:

34617

Oil Filler Cap and Filter

OIL FILL LINE

CAPACITY = 5.5 U.S. GALS

USE ANY HIGH QUALITY MINERAL BASED

HYDRAULIC FLUID WITH A VISCOSITY RATING

OF 10W-30. OIL MUST BE CLEAN AND FREE

FROM DIRT OR CONTAMINANT PARTICLES TO

PREVENT DAMAGE TO PUMP AND MOTOR.

REPLACE FILTER ELEMENT AFTER EVERY

150 OPERATING HOURS OR 2 YEARS SERVICE.

LEVEL TOOLBAR BEFORE CHECKING OIL LEVEL

858-003C

WARN ING

HOT FLUID HAZARD

Read Owner’s Manual BEFORE operating machine.

Keep tractor at IDLING SPEED and slowly engage PTO

to prevent damage to Hydraulic Motor

Keep Radiator clean and free of foreign matter to

prevent overheating.

Do NOT operate with hydraulic oil at or above 180°F.

858-004C

1

Figure 20:

34688

Oil Drain Plug

401-885M Table of Contents Index 2014-06-16

Page 27

Great Plains Manufacturing, Inc. Table of Contents Index PTO Maintenance 23

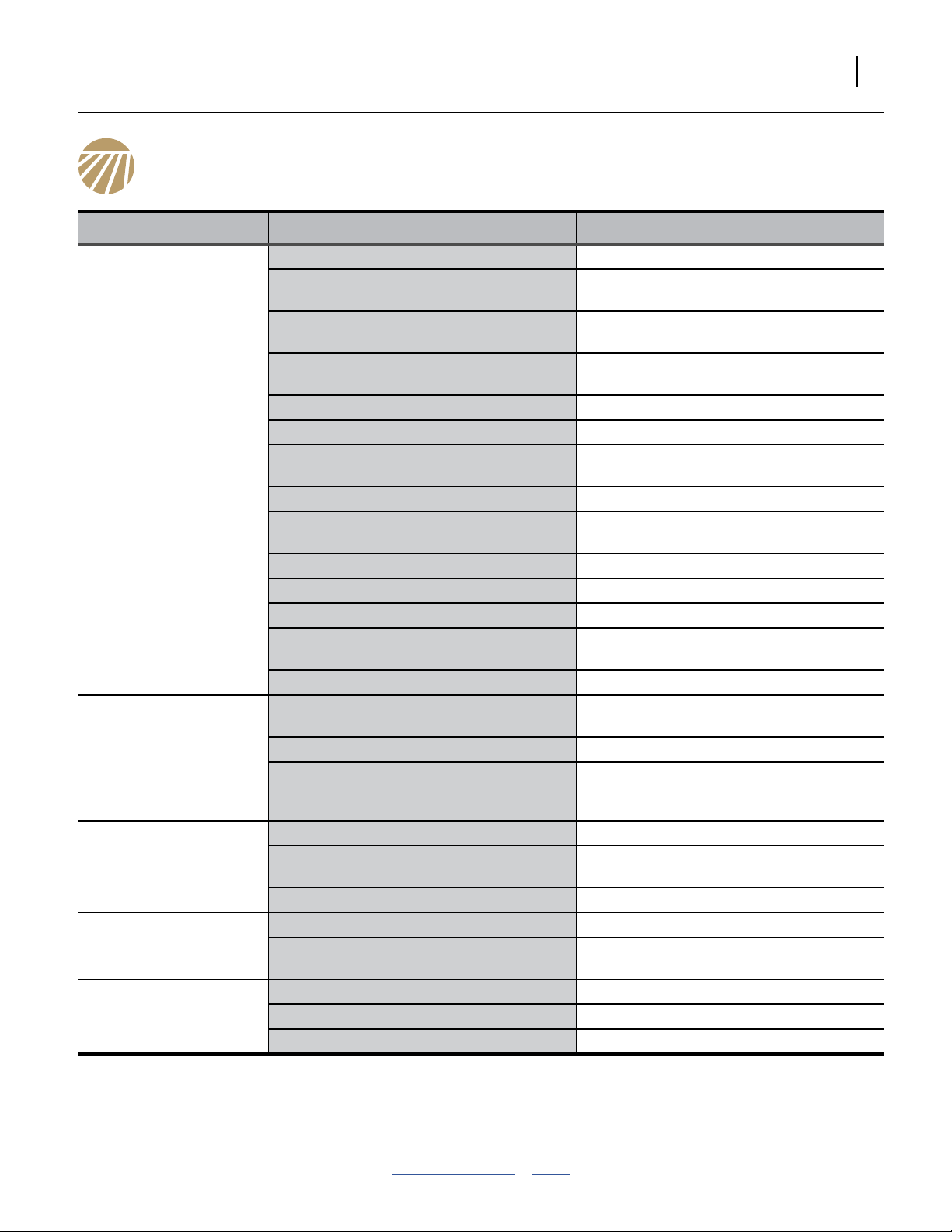

Lubrication and Scheduled Maintenance

Intervals

Multi-purpose

spray lubricant

Oil Filter

Multi-purpose

grease lubricant

Multi-purpose

oil lubricant

Inspection

34208

(operating hours)

50

at which service

is required

25 / 150

1 filter per planter

Type: Great Plains 891-110C

Fleetguard HF6610

Pall HC 9540S UJ4H

Zinga HE-10

Change filter after first 25 hours, and then every 2 years

or 150 hours.

N

34617

Pump/Fan Oil

300 or 4 Years

1 tank per planter

Type: 10W-30 Mineral-Based Oil

70 to 250 SUS at 210°F (100°C)

Quantity: 5.5 U.S. gallons (21 liters)

Change filter when changing oil, except at initial system

flush.

540 rpm Seal Kit

600 or as needed

1 kit per planter

Type: Great Plains 810-904C

Prince PMCK-PTO-1A

Consult the PTO Series Pump Parts Manual, available

from Prince Manufacturing Corp:

www.princehyd.com

N

34617

34634

2014-06-16 Table of Contents Index 401-885M

Page 28

24 Single-Section PTO Pumps Table of Contents Index Great Plains Manufacturing, Inc.

1000 rpm Seal Kit

600 or as needed

1 kit per planter, includes snap ring and all seals

Type: 810-901C for Parker 350C pumps

Consult the

Service Manual

PGP/PGM315, 330, 350, 365

HY09-SM300/US,

available from Parker Hannifin Corporation:

www.parker.com

34852

401-885M Table of Contents Index 2014-06-16

Page 29

Great Plains Manufacturing, Inc. Table of Contents Index 25

Appendix A - Installation

Before You Start

Most accidents are the result of negligence and

carelessness, usually caused by failure of the installer to

follow simple but necessary safety precautions. Allow no

one to install the Air-Pro® PTO pump before carefully

reading this manual.

Fasteners may be loosely assembled. Remove them

before mounting the component. Due to evolving

manufacturing practices, sub-assemblies may already be

completely pre-assembled. If so, check that fasteners are

tight, and skip the unneeded assembly steps.

Compatible Planters

One PTO pump kit is always required. Older planters may also require a fan update kit. Each kit updates one planter.

Fan Motor Compatibility

The YP425/625/825A/3P Single-Section PTO Pumps

kits require a 2-port fan hydraulic motor (having no case

drain). Older planters, having 3-port fan hydraulic motors

(with a case drain) cannot install a PTO kit unless the fan

is updated.

Check the planter serial number, or inspect the fan.

Planters manufactured with 3-port fans are:

Planter Model Serial Number or Lower

2025A (fan update never required)

2525A (fan update never required)

YP425A B1008N

YP425A3P B1004M

YP625A B1043Q

YP625A3P B1006P

YP825A B1014S

YP825A3P B1007R

YP825AR (fan update never required)

a. PTO kit for this model is compatible with a 3-port fan.

If the planter has a 3-port/case-drain fan motor, order

one fan update kit:

a

a

3

A Port

2

B Port

Kit Part Number

YP4,6,8 FAN UPDATE 401-956A

Instructions for installing this kit are merged with the

instructions for the Single-Section PTO Pumps kits.

2014-06-16 Table of Contents Index 401-885M

Top: Older 3-Port Fan Motor

Bottom: Current 2-Port Motor

Figure 21:

29781

31754

Page 30

26 Single-Section PTO Pumps Table of Contents Index Great Plains Manufacturing, Inc.

Configuration Compatibility

Refer to Figure 22 to distinguish between the liquid and dry

fertilizer options.

Before installing any kit, inspect the planter configuration

and serial number plate (for precise model number).

Refer to the Operator manual for plate location.

2025A/2525A Compatible Kits

Air-Pro® Precision Drills

PTO Pump Kit

540 rpm 1000 rpm

2025A n/a 411-016A

2525A n/a 411-016A

YP425A Compatible Kits

YP425A Planters

YP425A (PT) Dry Fertilizer

s/n B1005M+

YP425A (PT) Liquid Fertilizer 401-848A 411-166A

YP425A (PT) without Fertilizer 401-846A 411-164A

YP425A3P 401-845A 411-163A

PTO Pump Kit

540 rpm 1000 rpm

401-847A 411-165A

YP625A Compatible Kits

YP625A Planters

YP625A (PT) Dry Fertilizer 401-847A 411-165A

YP625A (PT) Liquid Fertilizer 401-849A 411-167A

YP625A (PT) without Fertilizer 401-846A 411-164A

YP625A3P 401-845A 411-163A

PTO Pump Kit

540 rpm 1000 rpm

Figure 22:

Top: Liquid Fertilizer Planter

Bottom: Dry Fertilizer Planter

®

Other Single-Section Air-Pro

Implements

Planter Model PTO Pump Kit

YP625PD n/a

YP625TD n/a

YP925TD n/a

YPE-825A n/a

29909

31794

YP825A/AR Compatible Kits

YP825A Planters

YP825A (PT) Dry Fertilizer 401-847A 411-165A

YP825A (PT) Liquid Fertilizer 401-849A 411-167A

YP825A (PT) without Fertilizer 401-846A 411-164A

YP825A3P, row spacings:

30 inch (76.2 cm) or less

36 inch (91.4 cm) or more

YP825AR ground drive 411-035A 411-036A

YP825AR hydraulic drive 411-037A 411-038A

401-885M Table of Contents Index 2014-06-16

PTO Pump Kit

540 rpm 1000 rpm

401-845A

401-879A

411-163A

411-168A

Page 31

Great Plains Manufacturing, Inc. Table of Contents Index Appendix A - Installation 27

Tools Required

• a lift or hoist with a 100 pound \ 45 kg capacity

(600 pound \ 272 kg capacity for kits 401-845A,

401-847A, 401-847A and 401-848A)

• basic hand tools

• 6 to 12 gallons of good quality 10-W30 mineral base

hydraulic fluid, viscosity from 70-250 SUS range at

210°F (100°C).

• bucket for collecting oil

• hose marker, such as white electrical tape and

indelible marker

• power equipment with a compatible PTO for flushing

and charging the system

• the planter Operator and Parts manuals (see page 6)

• protective footwear if the planter has coulters or row

cleaners installed

Torque values for fasteners are shown on page 65.

Call-Outs

1 9

to

and

a z

to

11 53

to

101 241

to

Single-character callouts identify

components in the currently referenced

Figure or Figures. Numbers and letters may

be reused for different items on other pages.

Two-digit callouts in the range 11 to 53

reference existing parts removed and

reused. They are listed on page 70.

Three-digit callouts in the range 101 to 241

reference new parts from the new parts list

beginning on page 68. The descriptions

match those on the parts, cartons, bags or

item tags, as well as descriptions your

updated Parts Manual.

Pre-Delivery and Other Options

If you are installing the Air-Pro® PTO Pump on a

newly-shipped planter, it may be more convenient to

install the PTO pump system during the pre-delivery

setup:

• Install the PTO pump system after installing the

tongue (pull-type only). The tongue must be in place

for hose re-routing.

• Install the PTO pump system after mounting a fertilizer

sub-frame (option, pull-type only). This sub-frame

must be in place for flow control valve mounting, and in

some cases, reservoir mounting.

• Install the PTO pump system before installing

frame-mounted row options. This improves foot room

and reduces sharp object hazards while working near