Page 1

Operator’s Manual

PT6030 and PT8030

Pull-Type Planter

Model Serial No.

PT6030 U1069 and Later

PT8030 V1015 and Later

Manufacturing, Inc.

www .g reatplainsmfg.com

Read the operator’s manual entirely. When you see this symbol, the subsequent in-

!

structions and warnings are serious - follow without exception. Your life and the lives of

others depend on it!

© Copyright 1999 Printed

04/12/2005

17931

Cover illustration may show optional equipment not supplied with standard unit.

401-032M-B

Page 2

Table of Contents

Table of Contents

Great Plains Mfg., Inc.

Important Safety Information . . . . . . . . . . . . . . . . . 1

Personal Safety Equipment . . . . . . . . . . . . . . . . . 4

Safety Decals. . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Description of Unit . . . . . . . . . . . . . . . . . . . . . . . 10

Using This Manual . . . . . . . . . . . . . . . . . . . . . . . 10

Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Owner Assistance . . . . . . . . . . . . . . . . . . . . . . . 10

Section 1 Planter Preparation and Setup. . . . . . . 11

Prestart Checklist. . . . . . . . . . . . . . . . . . . . . . . . 11

Hitching Planter to Tractor . . . . . . . . . . . . . . . . . 11

Hydraulic Hose Hookup . . . . . . . . . . . . . . . . . . . 11

Leveling Planter . . . . . . . . . . . . . . . . . . . . . . . . . 12

Ridge Planting . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Liquid Fertilizer Option. . . . . . . . . . . . . . . . . . . . 13

Section 2 Operating Instructions . . . . . . . . . . . . . 14

Prestart Checklist. . . . . . . . . . . . . . . . . . . . . . . . 14

Field Operation. . . . . . . . . . . . . . . . . . . . . . . . . . 14

Meter Clutches . . . . . . . . . . . . . . . . . . . . . . 14

Row Unit Operation. . . . . . . . . . . . . . . . . . . 14

Chemical Hoppers. . . . . . . . . . . . . . . . . . . . 14

Marker Operation. . . . . . . . . . . . . . . . . . . . . 15

Liquid Fertilizer Operation . . . . . . . . . . . . . . 15

Squeeze Pump Hose Alignment . . . . . . . . . 16

Transporting . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Parking. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Section 3 Adjustments. . . . . . . . . . . . . . . . . . . . . . 17

Planting Rate . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Transmission Adjustment. . . . . . . . . . . . . . . 17

2-to-1 Drive Reduction. . . . . . . . . . . . . . . . . 17

Checking Planting Population . . . . . . . . . . . 17

Planting Rates for Finger Pickup Corn Meters. . 18

Planting Rates for Brush Meters . . . . . . . . . . . . 19

Brush Meters, Cotton Discs. . . . . . . . . . . . . 20

Granular Chemical Rates. . . . . . . . . . . . . . . . . . 21

Conversion from Broadcast to Row Coverage21

Recalibrating Granular Chemical Meters. . . 22

Granular Chemical Rate Charts. . . . . . . . . . . . . 23

Clay Granules, Herbicide . . . . . . . . . . . . . . .23

Clay Granules, Insecticide . . . . . . . . . . . . . .24

Sand Granules, Herbicide and Insecticide. .25

Liquid Fertilizer Attachment . . . . . . . . . . . . . . . . 26

Dry Fertilizer Attachment . . . . . . . . . . . . . . . . . . 26

Meter Drive Adjustments . . . . . . . . . . . . . . . . . .28

Row Unit Adjustments . . . . . . . . . . . . . . . . . . . .28

Down Pressure. . . . . . . . . . . . . . . . . . . . . . . 28

Down Pressure Charts. . . . . . . . . . . . . . . . .28

Coulter Depth. . . . . . . . . . . . . . . . . . . . . . . .29

Opener Seeding Depth. . . . . . . . . . . . . . . . .29

Side Gauge Wheels . . . . . . . . . . . . . . . . . . .29

1 x 12 Closing Wheel Option . . . . . . . . . . . . 30

Closing Disk Option . . . . . . . . . . . . . . . . . . . 31

Marker Adjustments . . . . . . . . . . . . . . . . . . . . . .31

Seed-Lok Lock Up . . . . . . . . . . . . . . . . . . . . . . . 32

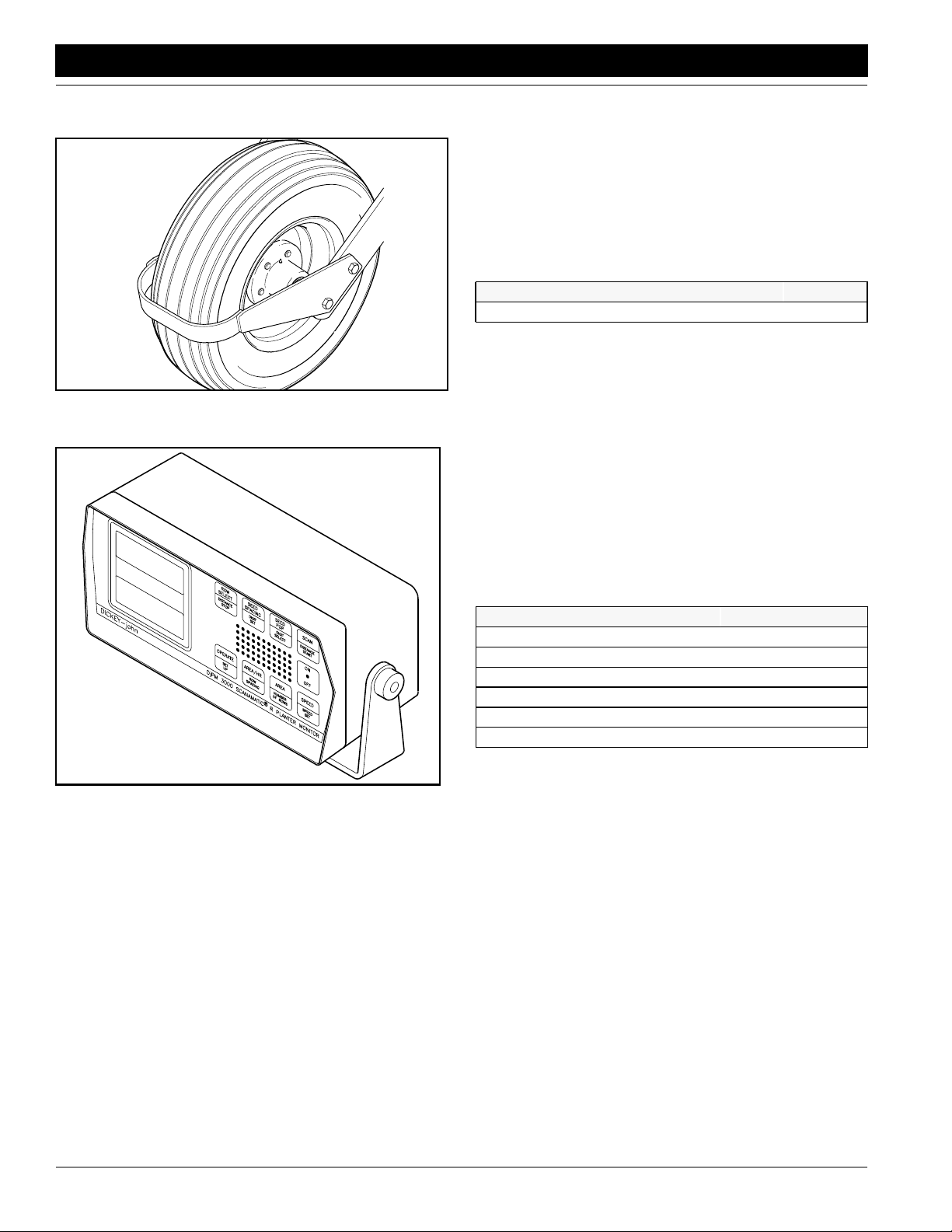

Tire Scraper . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Section 4 Troubleshooting . . . . . . . . . . . . . . . . . . .34

Section 5 Maintenance and Lubrication . . . . . . . . 37

Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

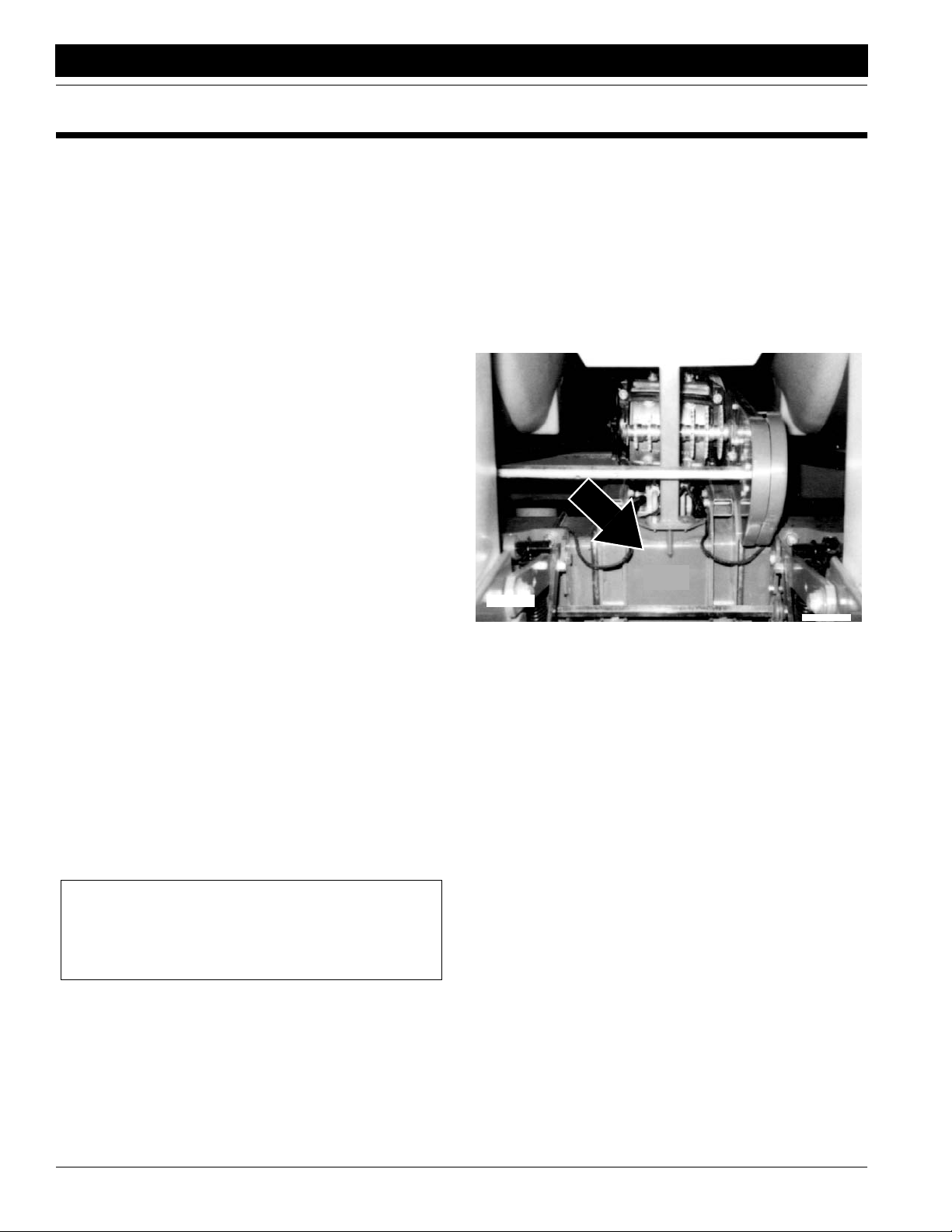

Replacing Shear Pins. . . . . . . . . . . . . . . . . . 37

Shaft Alignment . . . . . . . . . . . . . . . . . . . . . . 38

Ratchet Drive (8 Row Only) . . . . . . . . . . . . .38

Chain Tension. . . . . . . . . . . . . . . . . . . . . . . .39

Finger Pickup Meter. . . . . . . . . . . . . . . . . . .40

Brush-Type Meter. . . . . . . . . . . . . . . . . . . . . 41

Opener Disks, Scrapers and Gauge Wheels42

Liquid Fertilizer Option . . . . . . . . . . . . . . . . . . . .42

Squeeze Pumps. . . . . . . . . . . . . . . . . . . . . . 43

Marker Breakaway Protection. . . . . . . . . . . . . . .43

Storage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Section 6 Options . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Section 7 Specifications and Capacities . . . . . . . 53

Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Torque Values Chart for Common Bolt Sizes . . .55

Tire Inflation Chart . . . . . . . . . . . . . . . . . . . . . . . 56

Metric Conversion Chart. . . . . . . . . . . . . . . . . . . 56

© Copyright 1999 All rights Reserved

Great Plains Manufacturing, Inc. provides this publication “as is” without warr anty of any kind, either expressed or implied. W hile ev ery precaution has been taken in the preparation

of this manual, Great Plains Manufacturing, Inc. assumes no responsibility for errors or omissions . Neither is any liability assumed for damages resulting from the use of the inf ormation contained herein. Great Plains Manufacturing, Inc. reserves the right to revise and improve its products as it sees fit. This publication describes the state of this product at the

time of its publication, and may not reflect the product in the future.

The following are trademarks of Great Plains Mfg., Inc.: Application Systems, A usherman, Land Pride, Great Plains

All other brands and product names are trademarks or registered trademarks of their respective holders.

Great Plains Manufacturing, Incorporated Trademarks

Printed in the United States of America.

PT6030 and PT8030 Pull-Type Planter 401-032M-B 4/12/05Great Plains Mfg., Inc.

Page 3

Great Plains Mfg., Inc.

Important Safety Information

Important Safety Information

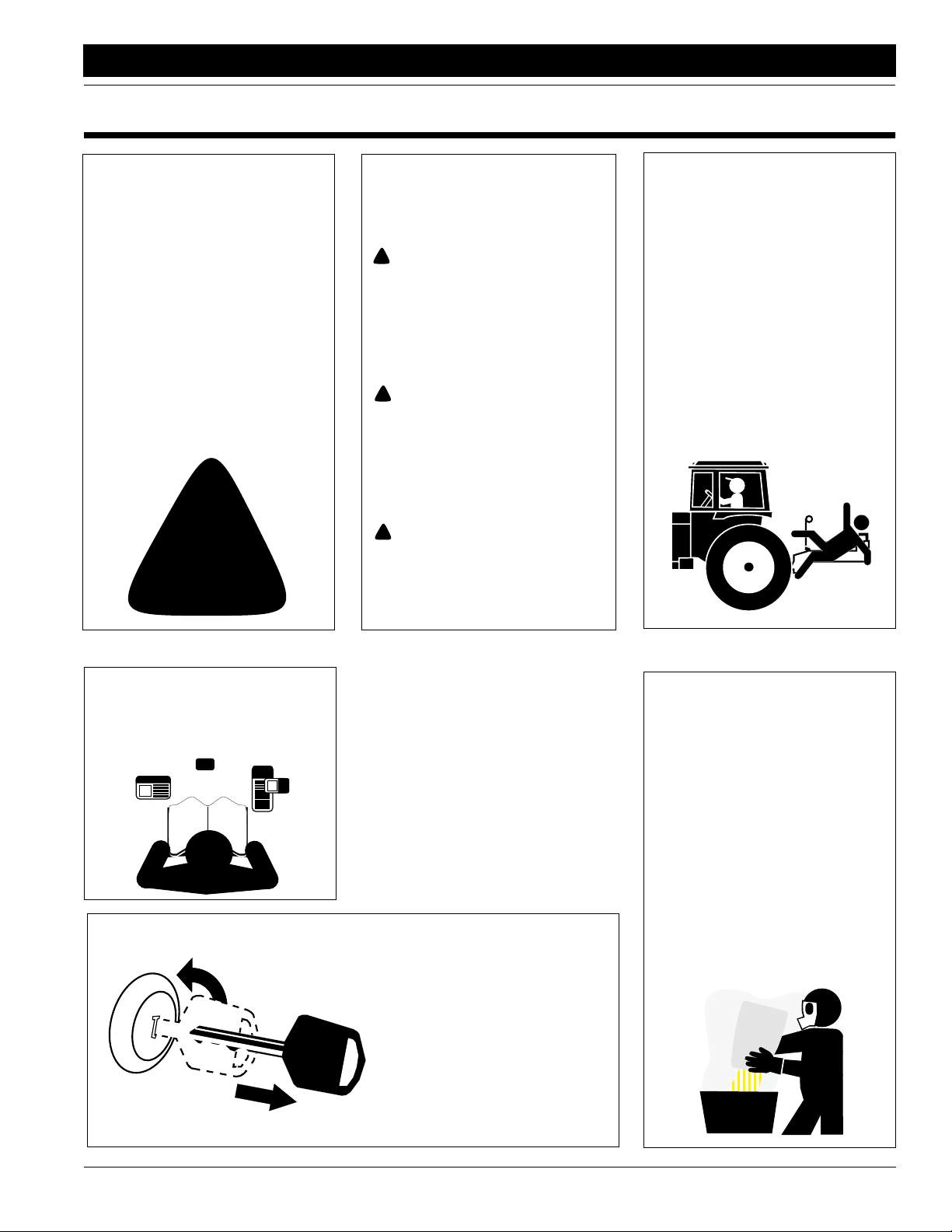

Look for Safety Symbol

The SAFETY ALERT SYMBOL indicates there is a potential hazard to

personal safety involved and extra

safety precaution must be taken.

When you see this symbol, be alert

and carefully read the message that

follows it. In addition to design and

configuration of equipment, hazard

control and accident prevention are

dependent upon the awareness, concern, prudence and proper training of

personnel involved in the operation,

transport, maintenance and storage

of equipment.

!

Be Aware of Signal Words

Signal words designate a degree or

level of hazard seriousness. The signal words are:

!

DANGER!

Indicates an imminently hazardous

situation which, if not avoided, will

result in death or serious injury. This

signal word is limited to the most

extreme situations, typically for

machine components that, for functional purposes, cannot be guarded.

!

WARNING!

Indicates a potentially hazardous situation which, if not avoided, could

result in death or serious injury, and

includes hazards that are exposed

when guards are removed. It may

also be used to alert against unsafe

practices.

!

CAUTION!

Indicates a potentially hazardous situation which, if not avoided, may

result in minor or moderate injury. It

may also be used to alert against

unsafe practices.

Keep Riders

Off Machinery

Riders obstruct the operator’s view.

Riders could be struck by foreign

objects or thrown from machine.

▲ Never allow riders on implement.

▲ Never allow children to operate

equipment.

For Your Protection

▲ Thoroughly read and understand

Safety Decals, page 5. Read all

instructions noted on decals.

OFF

Shutdown and Storage

▲ Lower machine to ground, put

tractor in park, turn off engine,

and remove key.

▲ Detach and store implement in an

area where children normally do

not play. Secure implement with

blocks and supports.

Handle

Chemicals Properly

Agricultural chemicals can be dangerous. Improper use can seriously

injure persons, animals, plants, soil

and property.

▲ Wear protective clothing.

▲ Handle all chemicals with care.

▲ Follow instructions on container

label.

▲ Avoid inhaling smoke from any

type of chemical fire.

▲ Store or dispose of unused chem-

icals as specified by chemical

manufacturer.

4/12/05

PT6030 and PT8030 Pull-Type Planter 401-032M-B

1

Page 4

Important Safety Information

Great Plains Mfg., Inc.

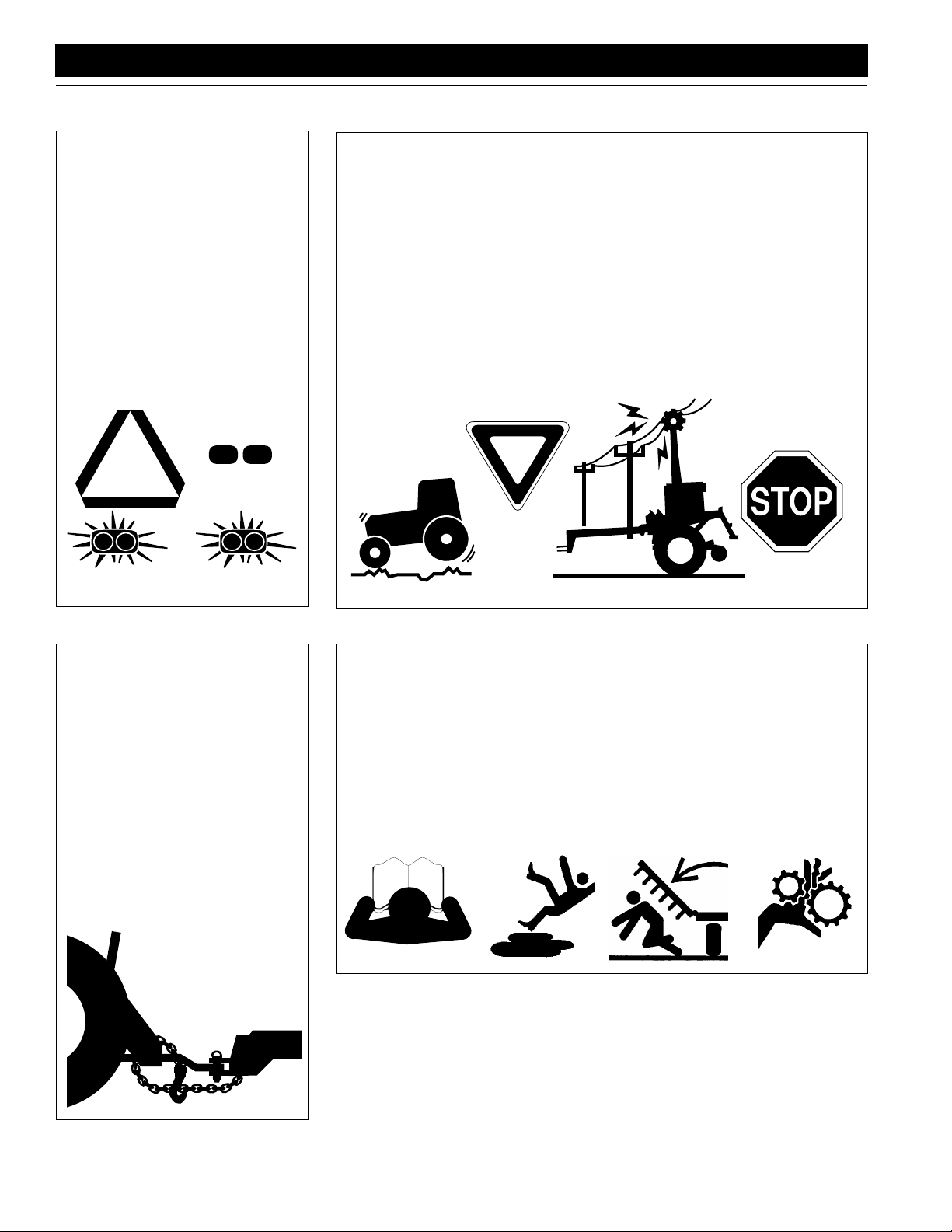

Use Safety

Lights and Devices

Slow-moving tractors, self-propelled

equipment and towed implements

can create a hazard when driven on

public roads. They are difficult to see,

especially at night.

▲ Use flashing warning lights and

turn signals whenever driving on

public roads.

▲ Use lights and devices provided

with implement.

Transport

Machinery Safely

Maximum transport speed for implement is 20 mph. Some rough terrains

require a slower speed. Sudden

braking can cause a towed load to

swerve and upset.

▲ Do not exceed 20 mph. Never

travel at a speed which does not

allow adequate control of steering

and stopping. Reduce speed if

towed load is not equipped with

brakes.

▲ Comply with state and local laws.

▲ Do not tow an implement that,

when fully loaded, weighs more

than 1.5 times the weight of towing vehicle.

Use A Safety Chain

▲ Use a safety chain to help con-

trol drawn machinery should it

separate from tractor drawbar.

▲ Use a chain with a strength rat-

ing equal to or greater than the

gross weight of towed machinery.

▲ Attach chain to tractor drawbar

support or other specified

anchor location. Allow only

enough slack in chain to permit

turning.

▲ Replace chain if any links or end

fittings are broken, stretched or

damaged.

▲ Do not use safety

chain for towing.

Practice Safe Maintenance

▲ Understand procedure before

doing work. Use proper tools and

equipment. Refer to this manual

for additional information.

▲ Work in a clean, dry area.

▲ Lower implement to ground, put

tractor in park, turn off engine,

and remove ke y before performing

maintenance.

▲ Allow implement to cool completely.

▲ Inspect all parts. Make sure parts

are in good condition and installed

properly.

▲ Remove buildup of grease, oil or

debris.

▲ Remove all tools and unused

parts from implement before operation.

PT6030 and PT8030 Pull-Type Planter 401-032M-B 4/12/05

2

Page 5

Great Plains Mfg., Inc.

Important Safety Information

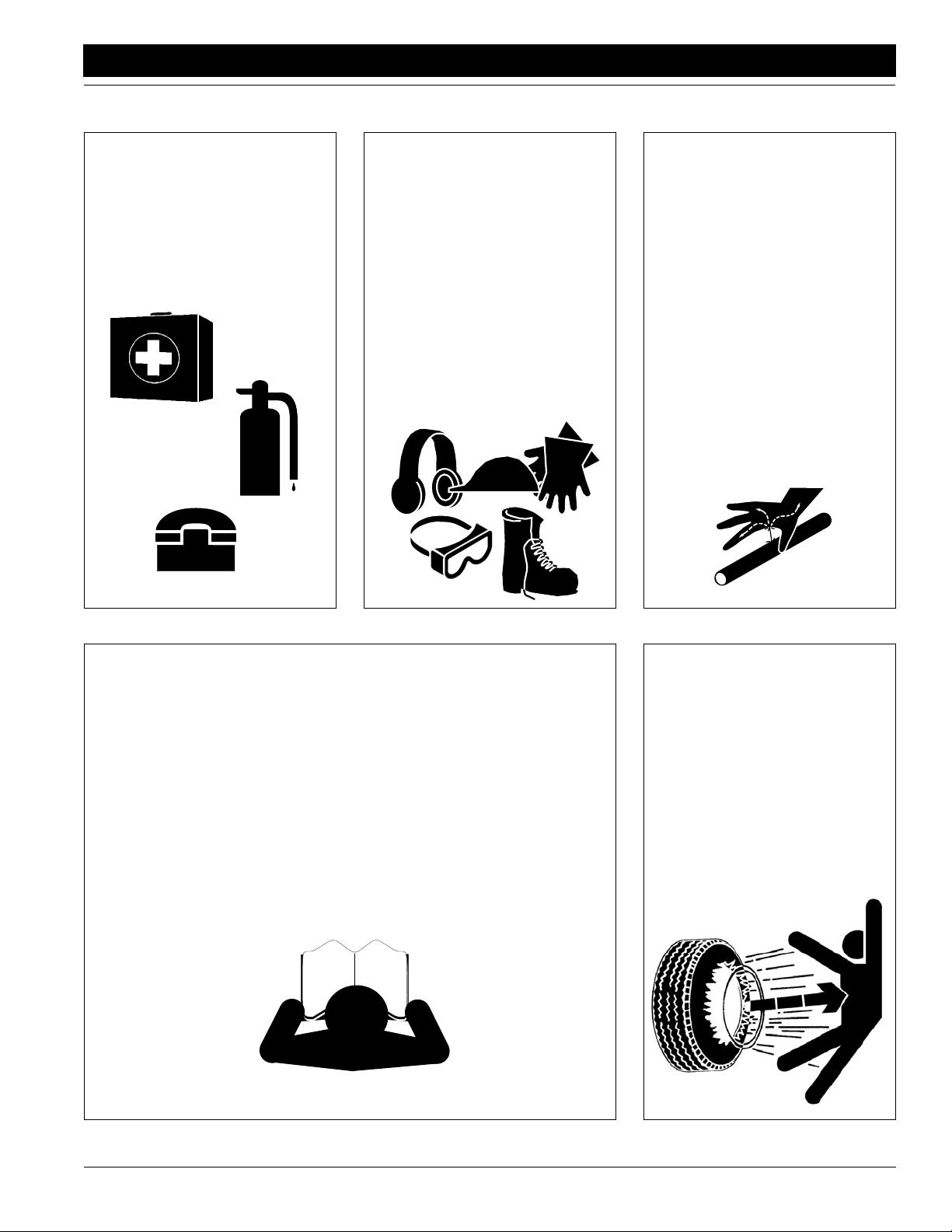

Prepare for Emergencies

▲ Be prepared if a fire starts.

▲ Keep a first aid kit and fire extin-

guisher handy.

▲ Keep emergency numbers for

doctor, ambulance, hospital and

fire department near phone.

911

Wear

Protective Equipment

▲ Wear protective clothing and

equipment.

▲ Wear clothing and equipment

appropriate for the job. Avoid

loose-fitting clothing.

▲ Because prolonged exposure to

loud noise can cause hearing

impairment or hearing loss, wear

suitable hearing protection such

as earmuffs or earplugs.

▲ Because operating equipment

safely requires your full attention,

avoid wearing radio headphones

while operating machinery.

Avoid High

Pressure Fluids Hazard

Escaping fluid under pressure can

penetrate skin, causing serious

injury.

▲ Avoid the hazard by relieving

pressure before disconnecting

hydraulic lines.

▲ Use a piece of paper or card-

board, NOT BODY PARTS, to

check for suspected leaks.

▲ Wear protective gloves and safety

glasses or goggles when working

with hydraulic systems.

▲ If an accident occurs, see a doc-

tor immediately. Any fluid injected

into the skin must be surgically

removed within a few hours or

gangrene may result.

Safety at All Times

Thoroughly read and understand this

manual before operating implement.

Refer to Safety Decals, page 5. Read

all instructions noted on decals.

▲ Be familiar with all implement

functions.

▲ Operate implement from driver’s

seat only.

▲ Do not leave tractor or implement

unattended with engine running.

▲ Do not dismount a moving tractor.

Dismounting a moving tractor could

cause serious injury or death.

▲ Do not stand between the tractor

and implement during hitching.

▲ Keep hands, feet and clothing

away from power-driven parts.

▲ Wear snug-fitting clothing to avoid

entanglement with moving parts.

▲ Watch out for wires, trees, etc.,

when raising implement. Make

sure all persons are clear of working area.

▲ Do not turn tractor too tight, caus-

ing implement to ride up on

wheels.

Tire Safety

Tire changing can be dangerous and

should be performed by trained personnel using correct tools and equipment.

▲ When inflating tires, use a clip-on

chuck and extension hose long

enough to allow you to stand to

one side–not in front of or over tire

assembly. Use a safety cage if

available.

▲ When removing and installing

wheels, use wheel-handling

equipment adequate for weight

involved.

4/12/05

PT6030 and PT8030 Pull-Type Planter 401-032M-B

3

Page 6

Important Safety Information

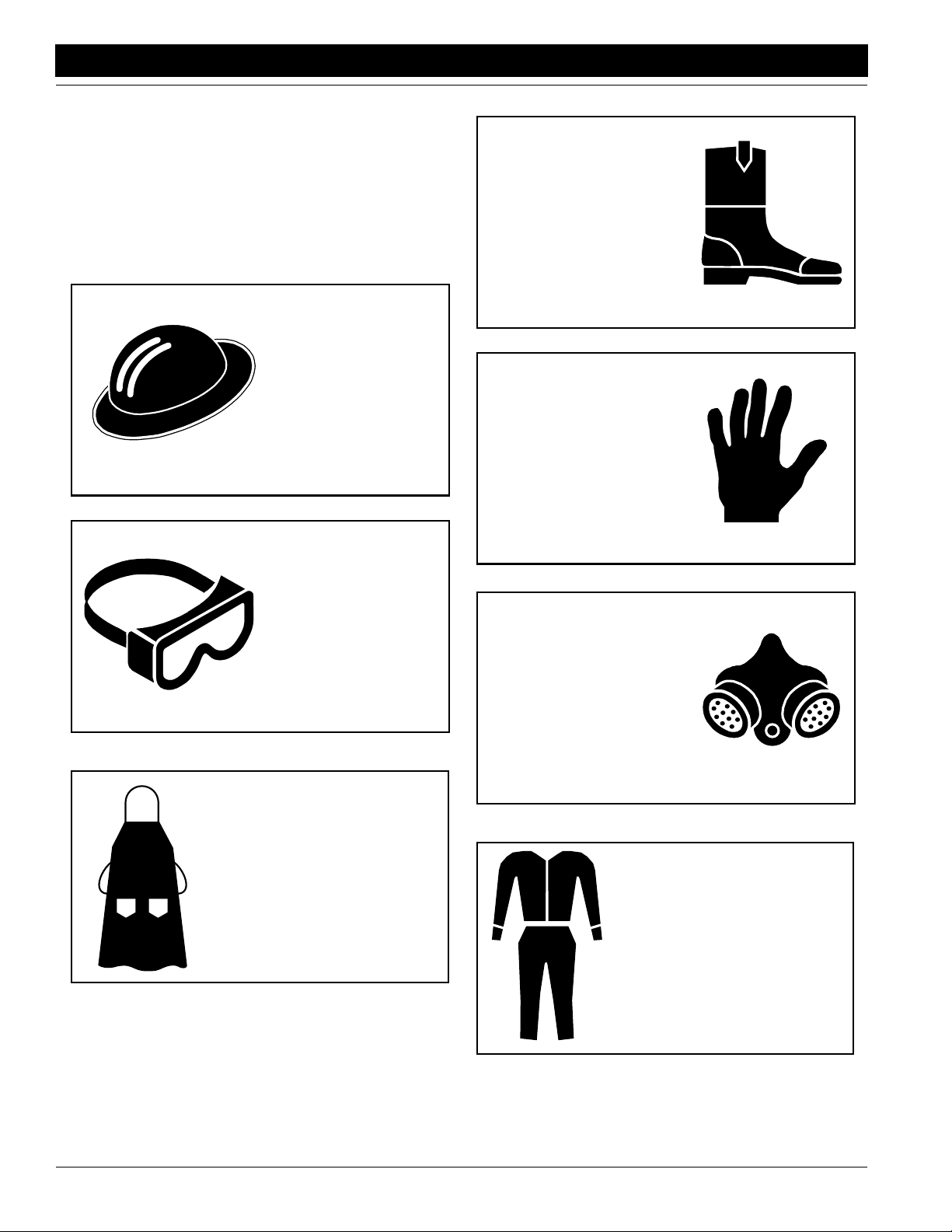

Personal Saf ety Equipment

Great Plains advises all users of chemical pesticides or herbicides to use the following personal safety equipment. Always follow the chemical label instructions, your safety and

the effectivity of the product depends upon your actions.

Waterproof, widebrimmed hat

Great Plains Mfg., Inc.

Waterproof boots or foot coverings

Waterproof, unlined gloves.

Neoprene gloves are recommended.

Face shield, goggles or full

face respirator. Goggles

with side shields or a full

face respirator is required if

handling or applying dusts,

wettable powders, or granules or if being exposed to

spray mist.

Waterproof apron

Cartridge-type respirator

approved for pesticide vapors unless label specifies

another type of respirator.

Cloth coveralls/outer clothing

changed daily; waterproof items

if there is a chance of becoming

wet with spray

PT6030 and PT8030 Pull-Type Planter 401-032M-B 4/12/05

4

Page 7

Great Plains Mfg., Inc.

Important Safety Information

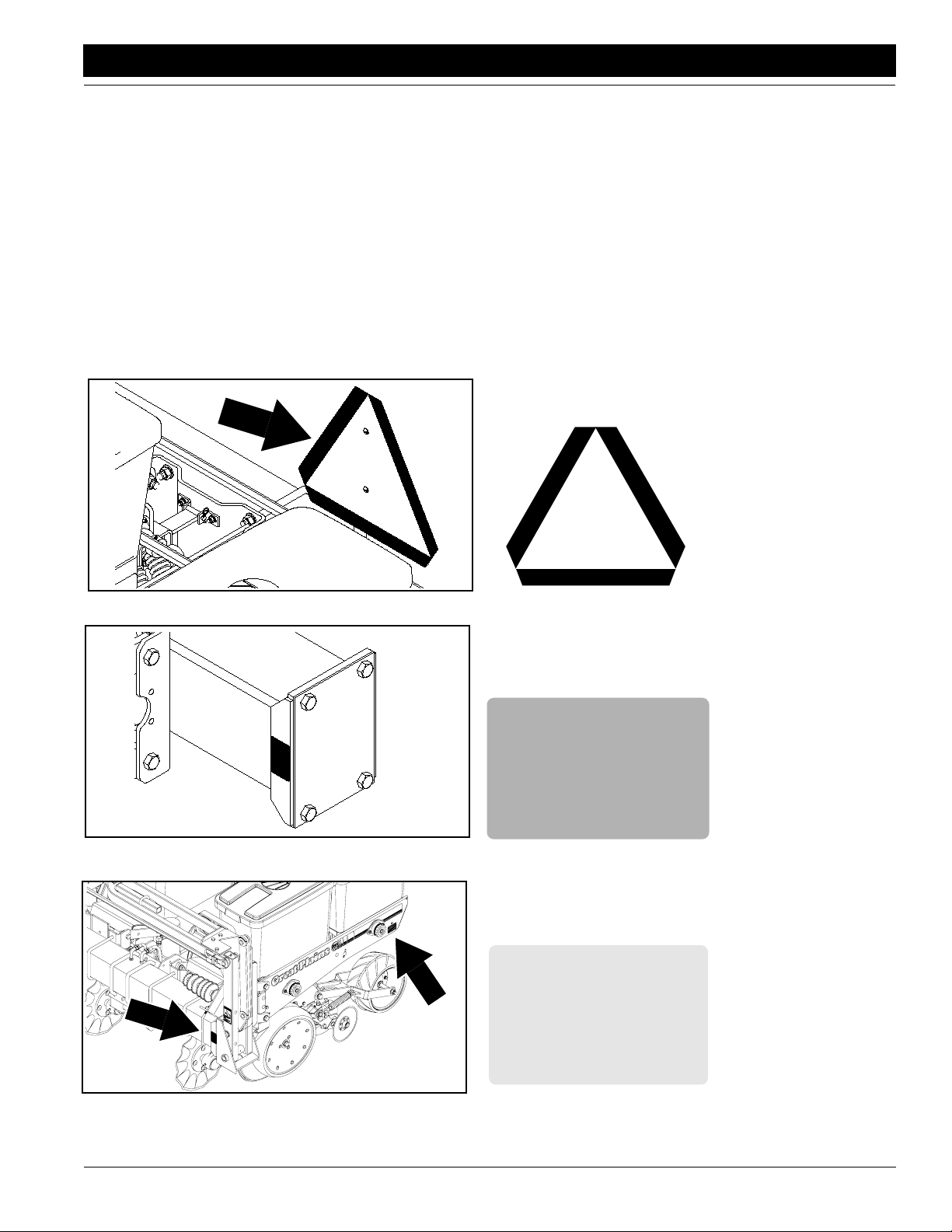

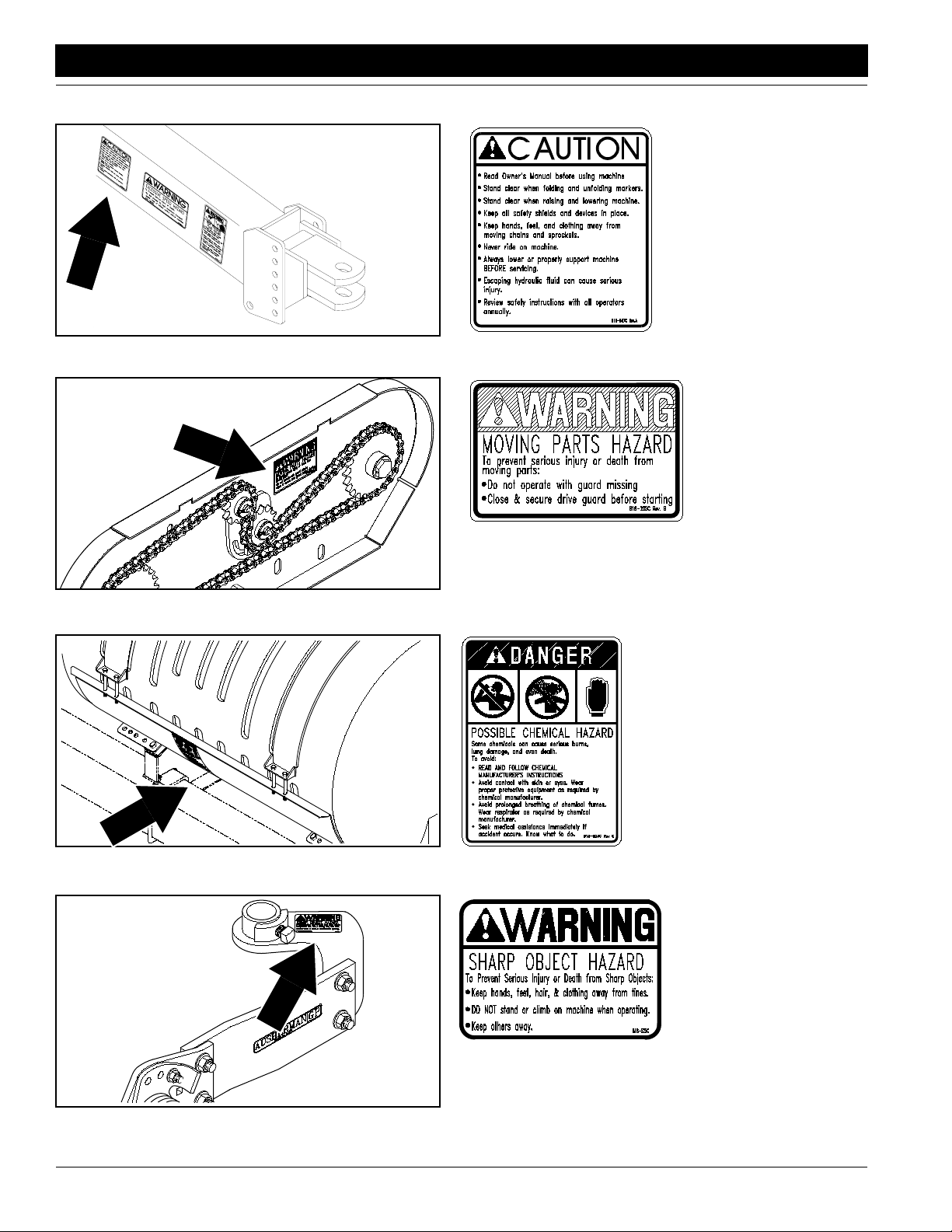

Safety Decals

Your implement comes equipped with all safety decals in place.

They were designed to help you safely operate your implement.

1. Read and follow decal directions.

2. Keep all safety decals clean and legible.

3. Replace all damaged or missing decals. Order new decals

from your Great Plains dealer. Refer to this section for

proper decal placement.

4. When ordering new parts or components, also request corresponding safety decals.

5. To install new decals:

a. Clean the area on which the decal is to be placed.

b. Peel backing from decal. Press firmly on surface,

being careful not to cause air bubbles under decal.

14945

12356

818-003C

Slow Moving Vehicle Label

818-230C

Red Reflector

4/12/05

17936

818-229C

Amber Reflectors

PT6030 and PT8030 Pull-Type Planter 401-032M-B

5

Page 8

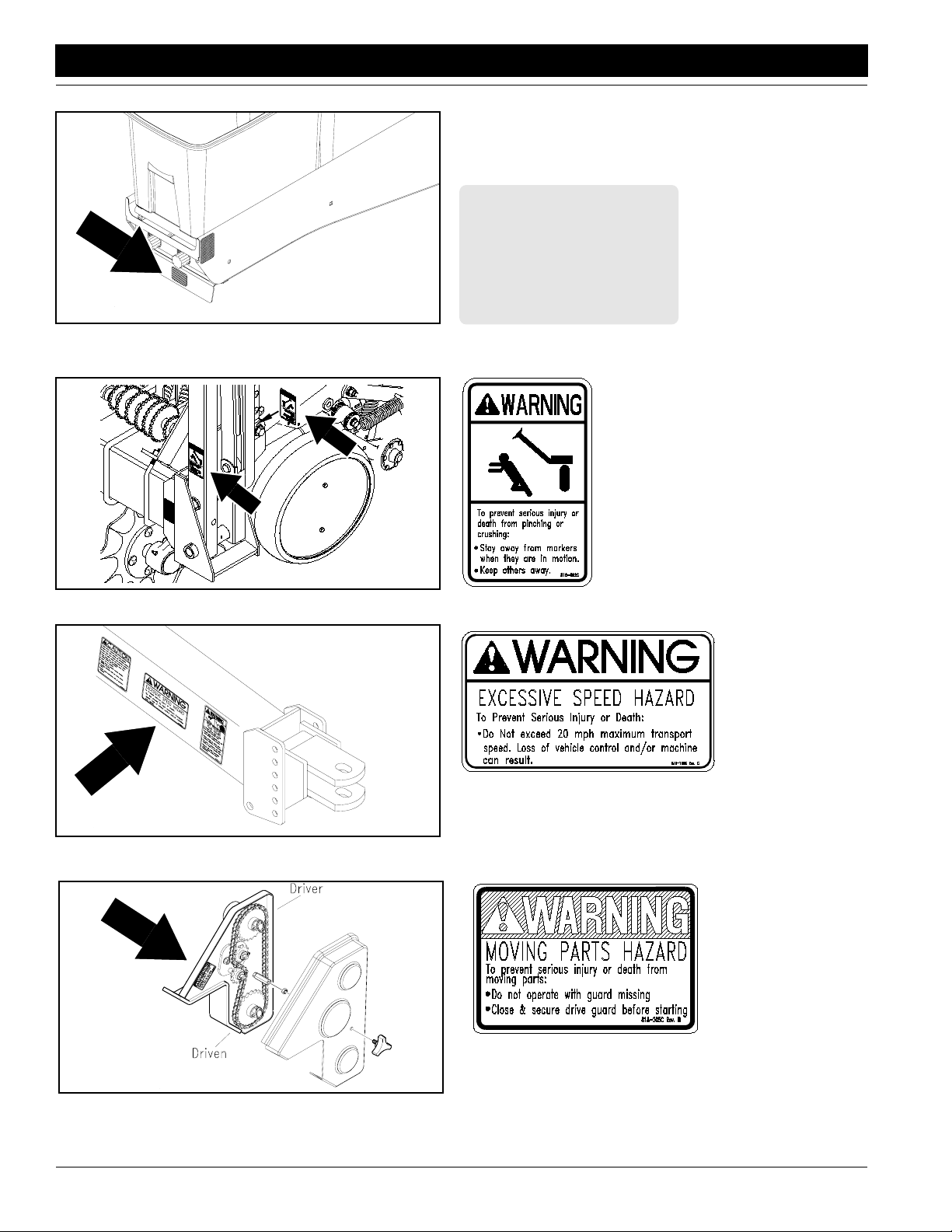

Important Safety Information

17920

Great Plains Mfg., Inc.

818-230C

Red Reflector

On outside row units;

two reflectors total

14919

17983

818-682C

Pinch/Crush Warning

818-188C

Transport Speed Warning

16861

PT6030 and PT8030 Pull-Type Planter 401-032M-B 4/12/05

6

Moving Parts Warning

818-205C

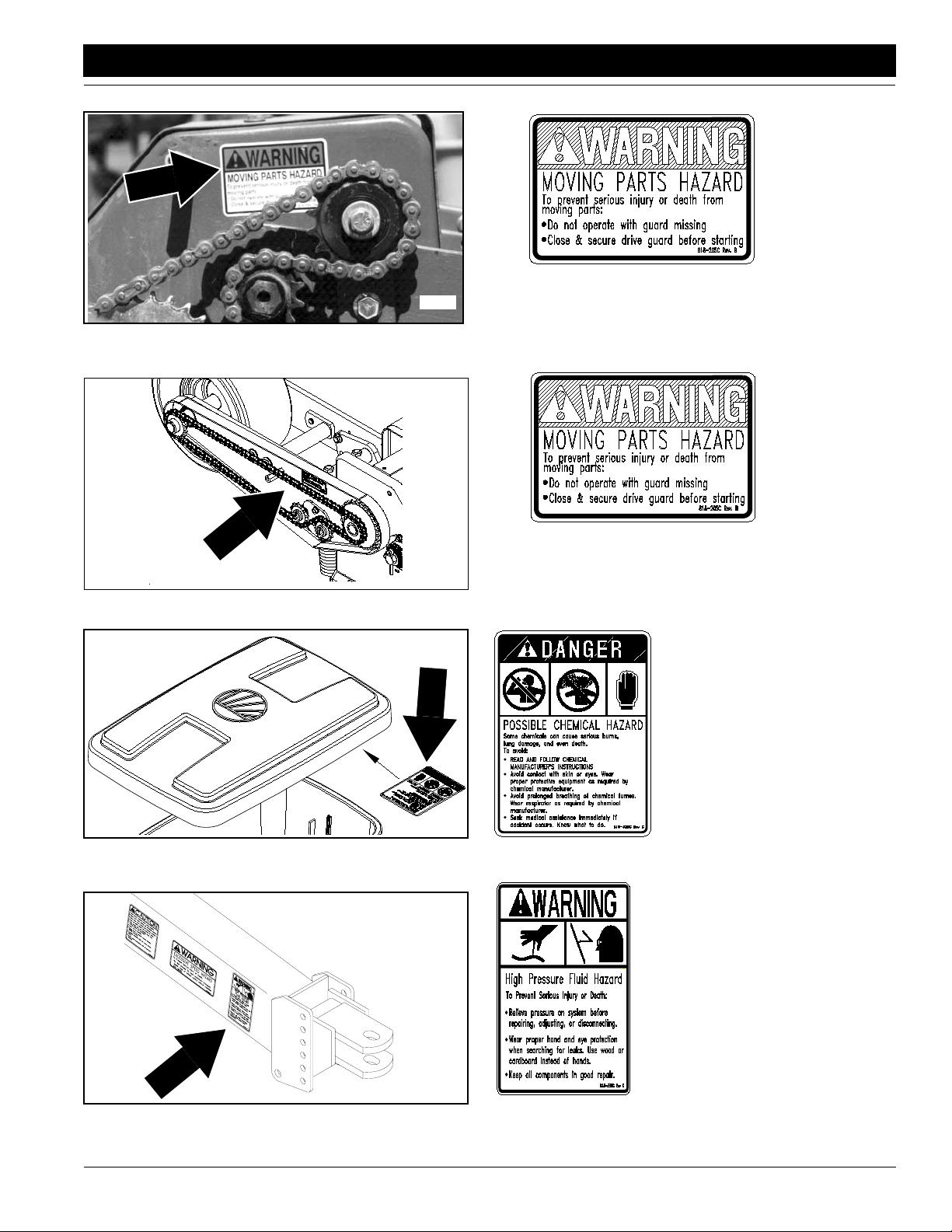

Page 9

Great Plains Mfg., Inc.

Important Safety Information

16863

15720

818-205C

Moving Parts Warning

818-205C

Moving Parts Warning

15726

4/12/05

17983

818-323C

Ag Chemicals Caution

Located inside chemical

lids

818-339C

Warning High Pressure

PT6030 and PT8030 Pull-Type Planter 401-032M-B

7

Page 10

Important Safety Information

17983

Great Plains Mfg., Inc.

818-587C

Operational Caution

16864

15723

818-205C

Moving Parts Warning

Liquid-Dry Fertilizer Option

818-323C

Chemical Hazard Warning

Liquid Fertilizer Option

818-525C

15732

PT6030 and PT8030 Pull-Type Planter 401-032M-B 4/12/05

8

Sharp Object Warning

Optional Terra-Tine

Page 11

Great Plains Mfg., Inc.

Important Safety Information

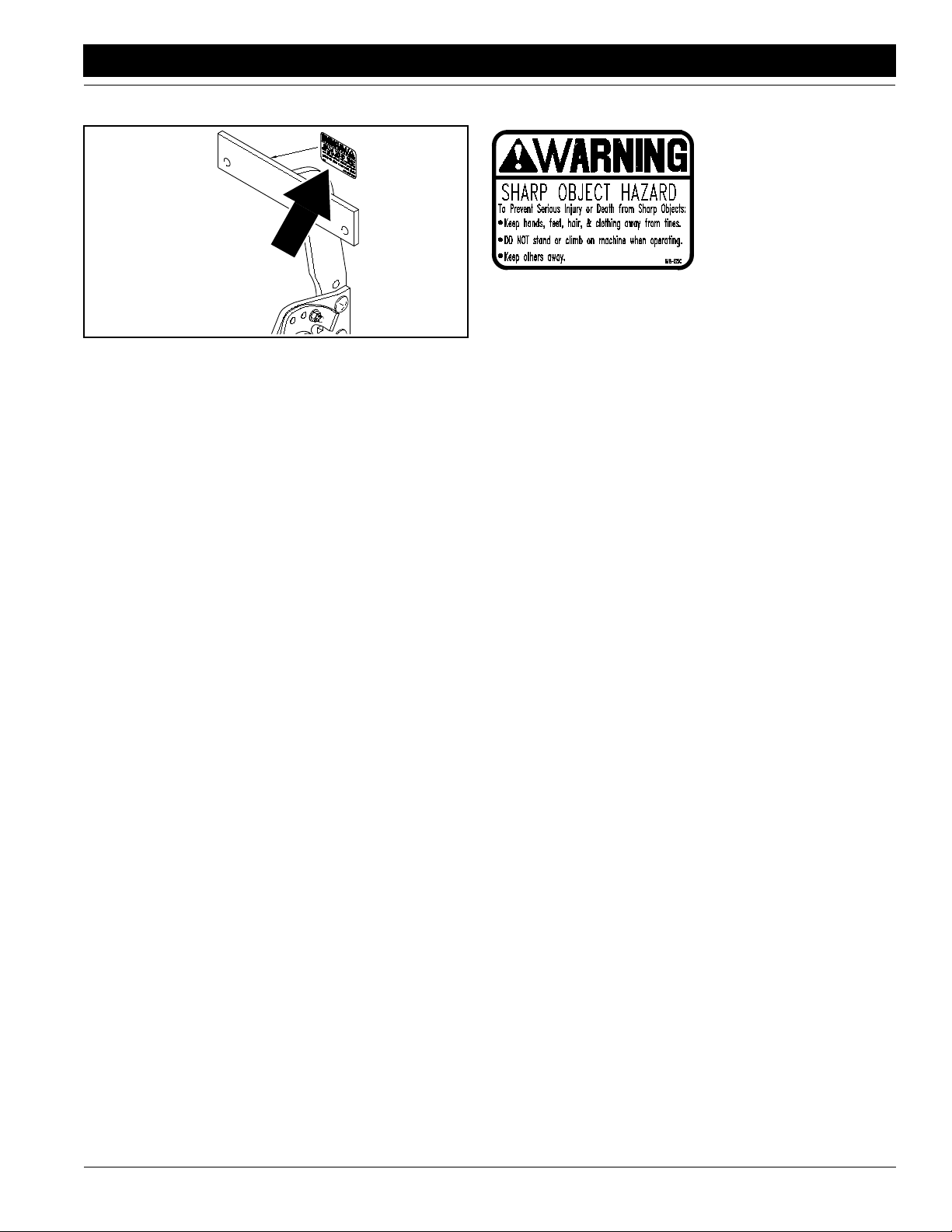

15733

818-525C

Sharp Object Warning

Optional Terra-Tine

4/12/05

PT6030 and PT8030 Pull-Type Planter 401-032M-B

9

Page 12

Introduction

Introduction

Great Plains Mfg., Inc.

Great Plains welcomes you to its growing family of new

product owners. This implement has been designed with

care and built by skilled workers using quality materials.

Proper setup, maintenance and safe oper ating pr actices

will help you get years of satisf actory use from the ma

-

chine.

Description of Unit

The 6- and 8-row , pull-type planter is a to wed planting implement. The frame consists of 7-by-7-inch tubing. Planting rates are adjustable by changing sproc k ets on the

planter transmission or contact drive. Row units are

mounted on the frame. Seed hoppers are standard on the

row units; chemical hoppers and granular-chemical appli

cators are available . Springs on each row unit provide

down pressure needed for the double-disk openers to

make a seed trench. Finger-pickup meters singulate and

dispense seed from the hopper and deliver it to the trench.

Seeding depth is controlled by side gauge wheels on the

openers. Closing wheels or disks close the trench. With an

optional 5-by-7-inch fertilizer bar , the planter can be outfit

ted with dry or liquid fertilizer application and tillage attachments.

Intended Usage

Use this implement for planting row crops in large fields.

T ow the implement behind an agricultural tractor at speeds

of less than 20 mph. The unit is designed for conv ention

ally tilled fields but can be used in no- or minimum-till conditions if outfitted with optional tillage attachments.

Using This Manual

This manual will familiarize you with safety, assembly, operation, adjustments, troubleshooting and maintenance.

Read this manual and follow the recommendations to help

ensure safe and efficient operation.

The information in this manual is current at printing. Some

parts may change to assure top performance.

Definitions

Right-hand and left-hand as used in this manual are determined by facing the direction the machine will tra v el while

in use unless otherwise stated.

IMPORTANT: A crucial point of information related to

the preceding topic. For safe and correct oper ation,

read and follow the directions provided before continuing.

NOTE: Useful inf ormation related to the preceding topic.

Owner Assistance

If you need customer service or repair parts, contact a

Great Plains dealer. The y ha ve trained personnel, repair

parts and equipment specially designed for Great Plains

products.

Your machine’s parts were specially designed and should

only be replaced with Great Plains parts. Always use the

serial and model number when ordering parts from your

Great Plains dealer. The serial-number plate is located on

the 7-by-7-inch, main frame tube on the left-hand side of

the planter as shown in Figure A.

-

-

Great Plains

MANUFACTURING INCORPORATED

ASSARIA, KANSAS 67416

MODEL NO.

PT 6030

SERIAL NO.

-

14921

Record your planter model and serial number here for quick

reference:

Model Number: _________________________________

Serial Number: _________________________________

Your Great Plains dealer wants you to be satisfied with

your new machine. If y ou do not understand an y part of

this manual or are not satisfied with the service received,

please take the following actions .

1. Discuss the matter with y our dealership service manager. Mak e sure the y are aw are of an y prob lems so

they can assist you.

2. If you are still not satisfied, seek out the owner or general manager of the dealership.

3. For further assistance write to:

Product Support

Great Plains Mfg. Inc., Service Department

Salina, KS 67402-5060

GP-U0000000

Figure A

Serial Number

PO Box 5060

PT6030 and PT8030 Pull-Type Planter 401-032M-B 4/12/05

10

Page 13

Great Plains Mfg., Inc.

Section 1 Planter Preparation and Setup

Section 1 Planter Preparation and Setup

This section will help you prepare your tractor and planter

for use. The planter must be hitched on a suitab le tr actor

and leveled.

Prestart Checklist

1. Read and understand “Important Safety Information,” beginning on page 1.

2. Check that all working parts are moving freely, bolts

are tight, and cotter pins are spread.

3. Check that all grease fittings are in place and lubricated. Refer to Lubrication, “Maintenance and Lubri-

cation,” page 44.

4. Check the chains for proper tension and alignment.

Lubricate chains thoroughly.

5. Check that all safety decals and reflectors are legib le.

Replace if damaged. Refer to Safety Decals , “Impor

tant Safety Information,” page 5.

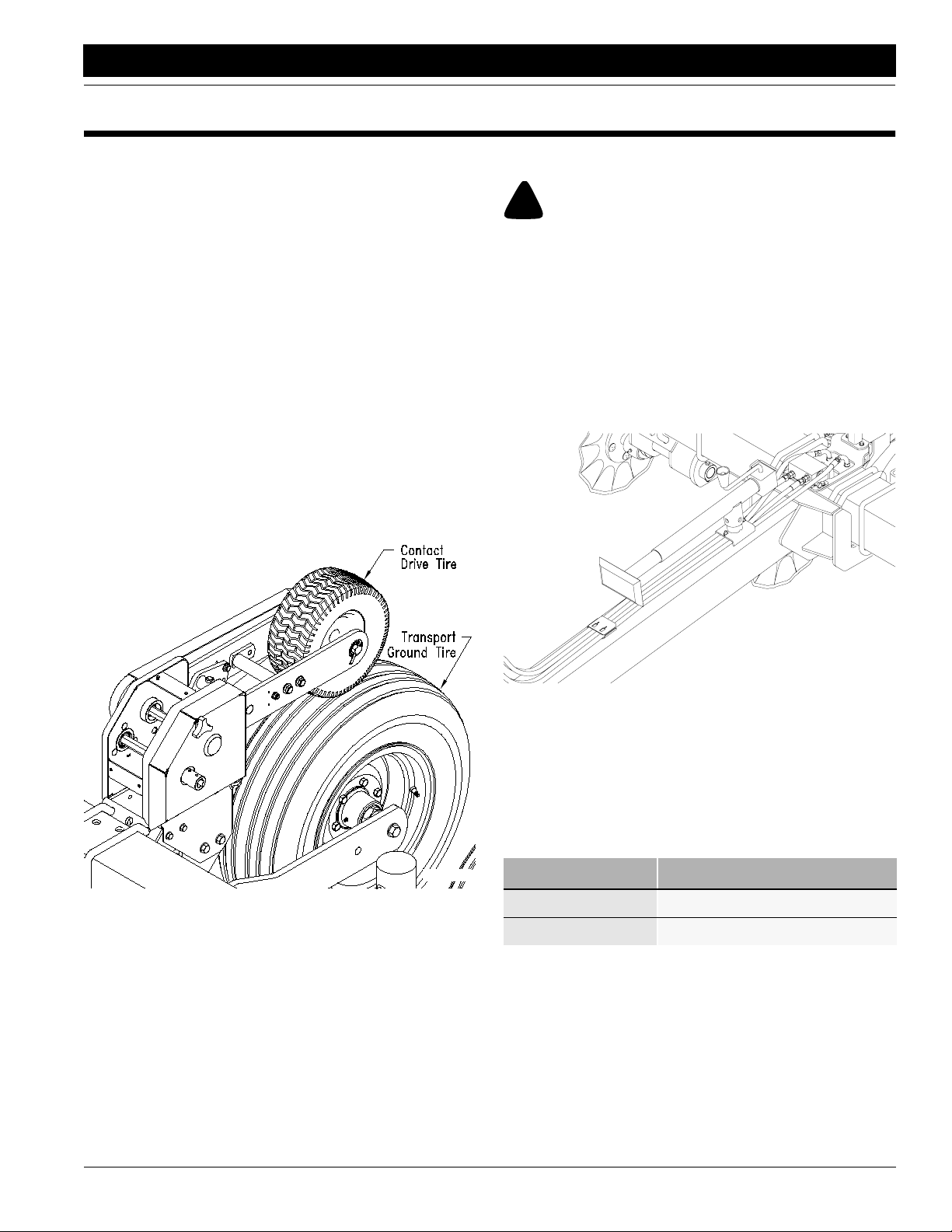

6. Inflate tires as recommended. Refer to Figure 1-1.

Transport/Ground Drive 9.5L X 15-8 ply . . . . . 44 psi

Contact Drive 13-5.0 X 6. . . . . . . . . . . . . . . . . 40 psi

Hitching Planter to Tractor

!

DANGER!

Y ou may be se ver ely injur ed or killed by being crushed between

the tractor and planter. Do not stand or place any part of your

body between planter and moving tractor. Stop tractor engine

and set park brake before installing hitch pin.

1. T o prev ent soil compaction on rows, set tractor wheels

at 60 inches center to center. For hillsides and steep

slopes, set tractor wheels as wide as possible f or max

imum stability.

2. Use jack to raise and lower planter tongue . After hitching tractor to planter, store jac k on storage tube on top

-

of planter tongue as shown in

Figure 1-2.

-

Figure 1-1

Contact Drive Transport/Ground Drive

15057

17930

Figure 1-2

Jack in Storage Position

3. Secure planter safety chain to an anchor on the tractor

capable of pulling the unit.

Hydraulic Hose Hookup

Great Plains hydraulic hoses are color coded to help you

hookup hoses to your tractor outlets. Hoses that go to the

same remote valve are marked with the same color.

Color Hydraulic Function

Orange Marker Cylinders

Blue Lift Cylinders

4/12/05

PT6030 and PT8030 Pull-Type Planter 401-032M-B

11

Page 14

Section 1 Planter Preparation and Setup

Great Plains Mfg., Inc.

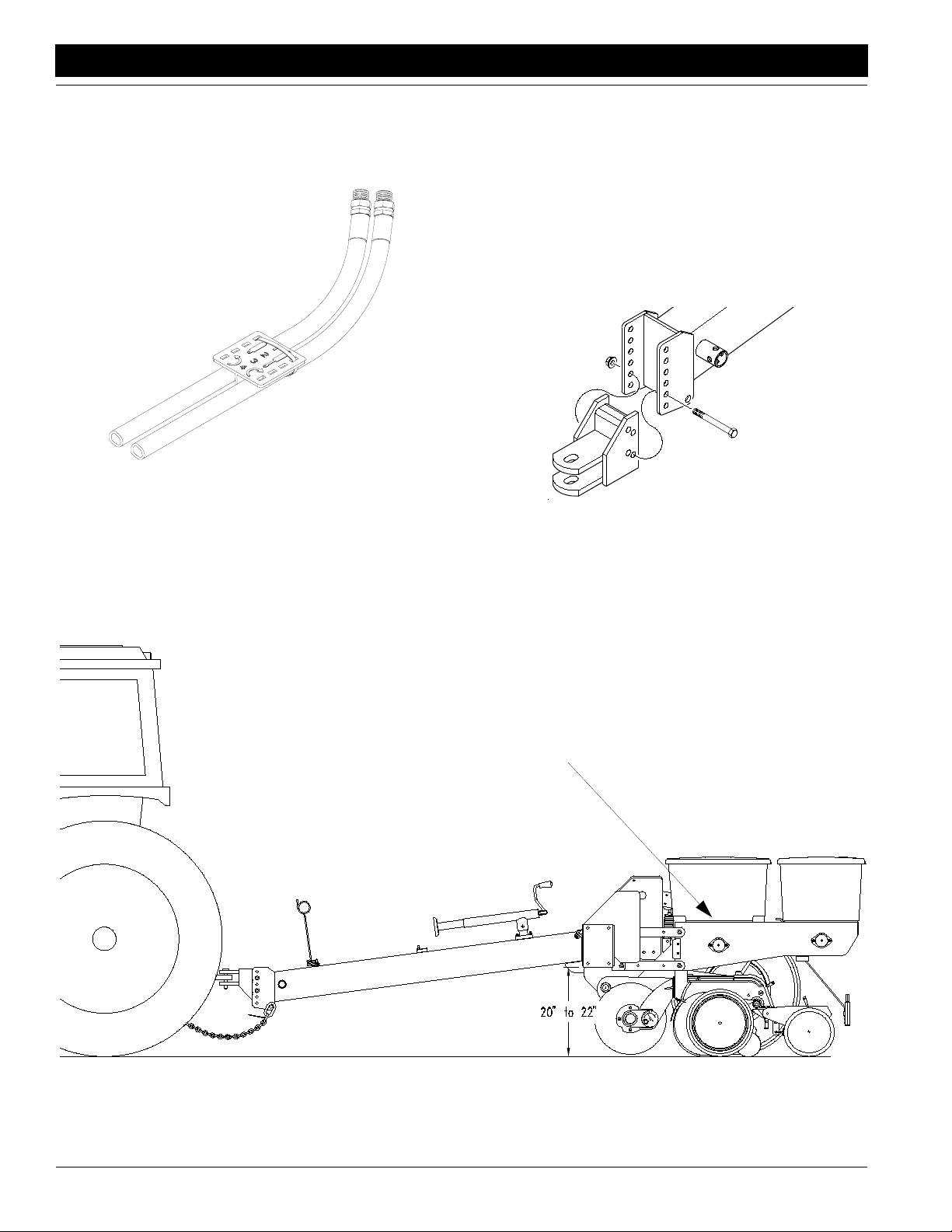

T o distinguish hoses on the same h ydraulic circuit, refer to

plastic hose holder. See

Figure 1-3. Hose under extended-cylinder symbol feeds cylinder base ends and raises

the planter. Hose under retracted-cylinder symbol feeds

cylinder rod ends and lowers planter .

17641

Figure 1-3

Hydraulic Hose Label

Leveling Planter

During initial setup and periodically throughout the season, check that the planter runs level. When planting, the

top of the hopper support panel should be parallel to the

ground as shown in

T o lev el the planter, the bottom of the mainframe tube must

run between 20 and 22 inches above ground when low

ered into planting position. See Figure 1-5.

T o obtain the correct height, reposition the planter hitch on

the tongue. The hitch can be turned over for different

heights. See Figure 1-4.

Figure 1-5.

-

Figure 1-4

Hitch Height Adjustment

Top of Hopper Support Level with Ground

Figure 1-5

Leveling the Planter

PT6030 and PT8030 Pull-Type Planter 401-032M-B 4/12/05

12

14956

Page 15

Great Plains Mfg., Inc.

Section 1 Planter Preparation and Setup

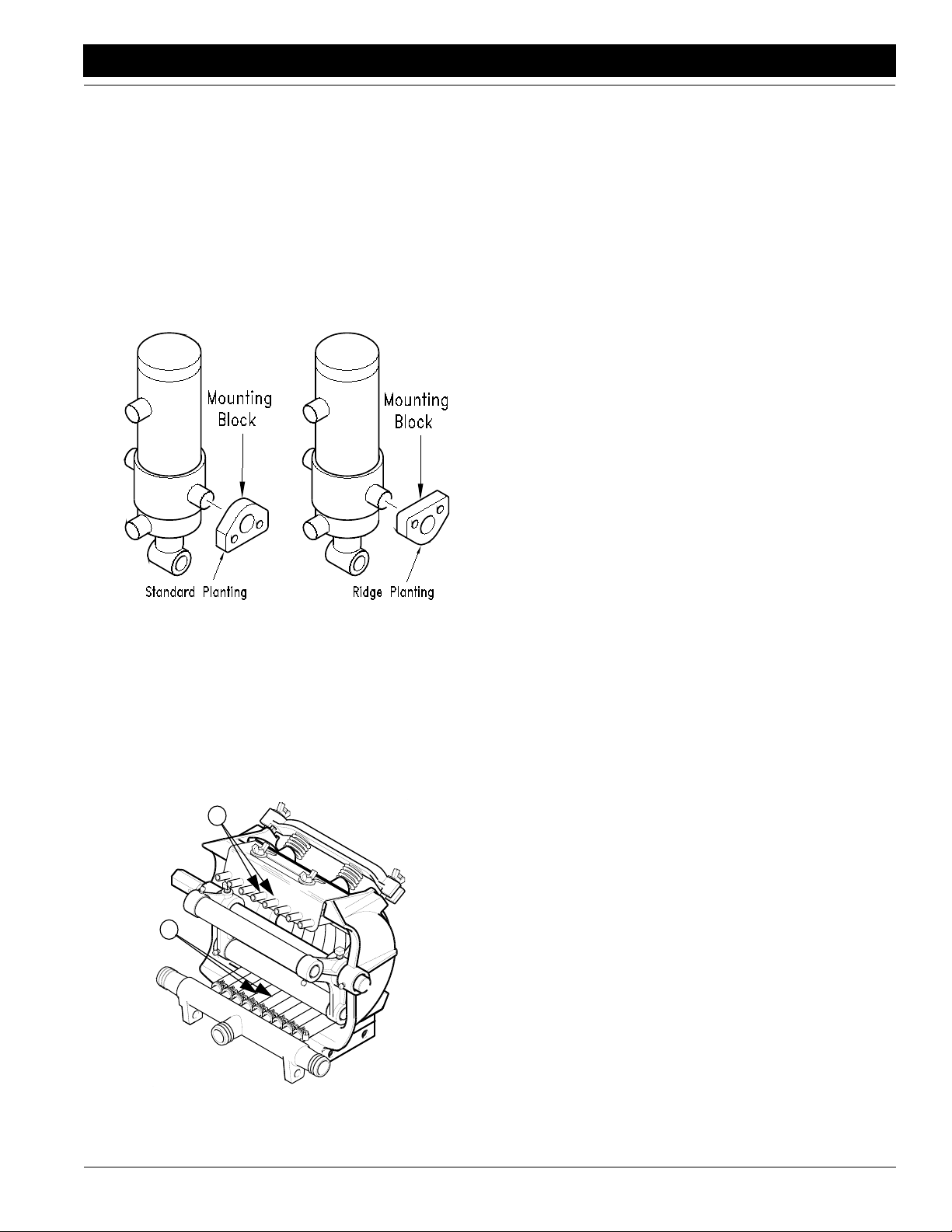

Ridge Planting

To prepare the planter for ridge planting, you must lower

the gauge wheels by inverting the cylinder mounting

blocks.

To invert, refer to Figure 1-6.

1. Block up the frame to remov e weight from tires.

2. Remove the f our 5/8-inch cap scre ws .

3. Invert mounting blocks and reinstall cap screws .

Torque to specification as listed on the Torque Values

Chart,

“Appendix” on page 55.

Figure 1-6

Ridge Planting Adjustment

14958

Liquid Fertilizer Option

The pump should always be mounted e ven with or lower

than the fertilizer tank.

Hose arrangement is important for efficient pump operation. If you will be using fe wer hoses than there are on the

pump, remov e pump hoses from near the center of the in

take manifold (1) and cap the intak e ports (2).

2

1

-

4/12/05

Figure 1-7

Removing Squeeze Pump Hoses

12409

PT6030 and PT8030 Pull-Type Planter 401-032M-B

13

Page 16

Section 2 Operating Instructions

Section 2 Operating Instructions

Great Plains Mfg., Inc.

This section covers general operating procedures . Experience, machine familiarity and the follo wing information will

lead to efficient operation and good working habits. Al

ways operate farm machinery with safety in mind.

-

Prestart Checklist

1. Carefully read “Important Safety Information,” beginning on page 1.

2. Clean any dirt or grease off chains and other moving

parts. Check chains for proper tension and alignment

as shown in Chain T ension, “Maintenance and Lubri

cation,” page 39.

3. Check that planter tires are the correct size and properly inflated as indicated on Tire Inflation Chart, “Ap-

pendix,” page 56.

4. Check all bolts, pins and fasteners. T orque as specified on Torque Values Chart, “Appendix,” page 55.

5. Lubricate planter as indicated under Lubrication,

“Maintenance and Lubrication,”

6. Check planter for worn or damaged parts. Repair or

replace before going to the field.

7. Check that hoppers are free of dirt and debris. Turn

meter-drive shaft by hand to be sure drive shaft and

seed meter turn freely .

page 44.

Field Operation

1. Perf orm all checks listed on Prestart Checklist, this

page.

2. Hitch planter to a tractor with sufficient horsepower.

Refer to Tractor Requirements, “Specifications and

Capacities,”

“Preparation and Setup,” page 11.

3. Set and calibrate planting rate as explained under

Planting Rate, “Adjustments,”

4. Load seed hoppers with clean seed. Add 1 teaspoon

of graphite to each seed hopper . Replace hopper lids.

5. Adjust down pressure on row units to match field conditions. Set row units to desired planting depth. Refer

to Row Unit Adjustments, “Adjustments,”

6. Check if planter is lev el. Refer to Leveling Planter ,

“Preparation and Setup,”

7. Lower planter , pull forward and begin planting.

8. Always raise planter for field turns. Meters will stop

automatically as you raise planters.

page 53, and Hitching Planter to T ractor ,

page 17.

page 28.

page 12.

Meter Clutches

To disengage seed- and chemical-hopper clutches, pull

and rotate knobs until meters are disengaged. See

2-1.

-

17887

Figure 2-1

Meter Clutch

To engage clutches, pull and rotate knobs until meters

reengage.

Row Unit Operation

Never back up with row units in ground. If you do , check all

openers to be sure none are clogged. Always lift planter

out of ground when turning at row ends and for other

short-radius turns.

For information on planting-depth and down-pressure

adjustments, refer to Row Unit Adjustments , “Adjust

ments,” beginning on page 28.

Chemical Hoppers

The optional chemical hopper comes in two versions: one

chemical meter or two chemical meters with a divider that

separates the hopper into two compartments.

Before filling chemical hoppers, clean any f oreign objects

out of hoppers. To remove hopper from row unit, disen

gage meter clutch and undo over-center latch at front of

hopper. See

Set and calibrate chemical-application rate as explained

under Granular Chemical Rates, “Adjustments,”

Fill chemical hoppers and replace hopper lids before operating planter.

Periodically clean dirt and foreign objects out of chemical

hoppers.

Figure 2-2.

Figure

-

-

page 21.

PT6030 and PT8030 Pull-Type Planter 401-032M-B 4/12/05

14

Page 17

Great Plains Mfg., Inc.

Section 2 Operating Instructions

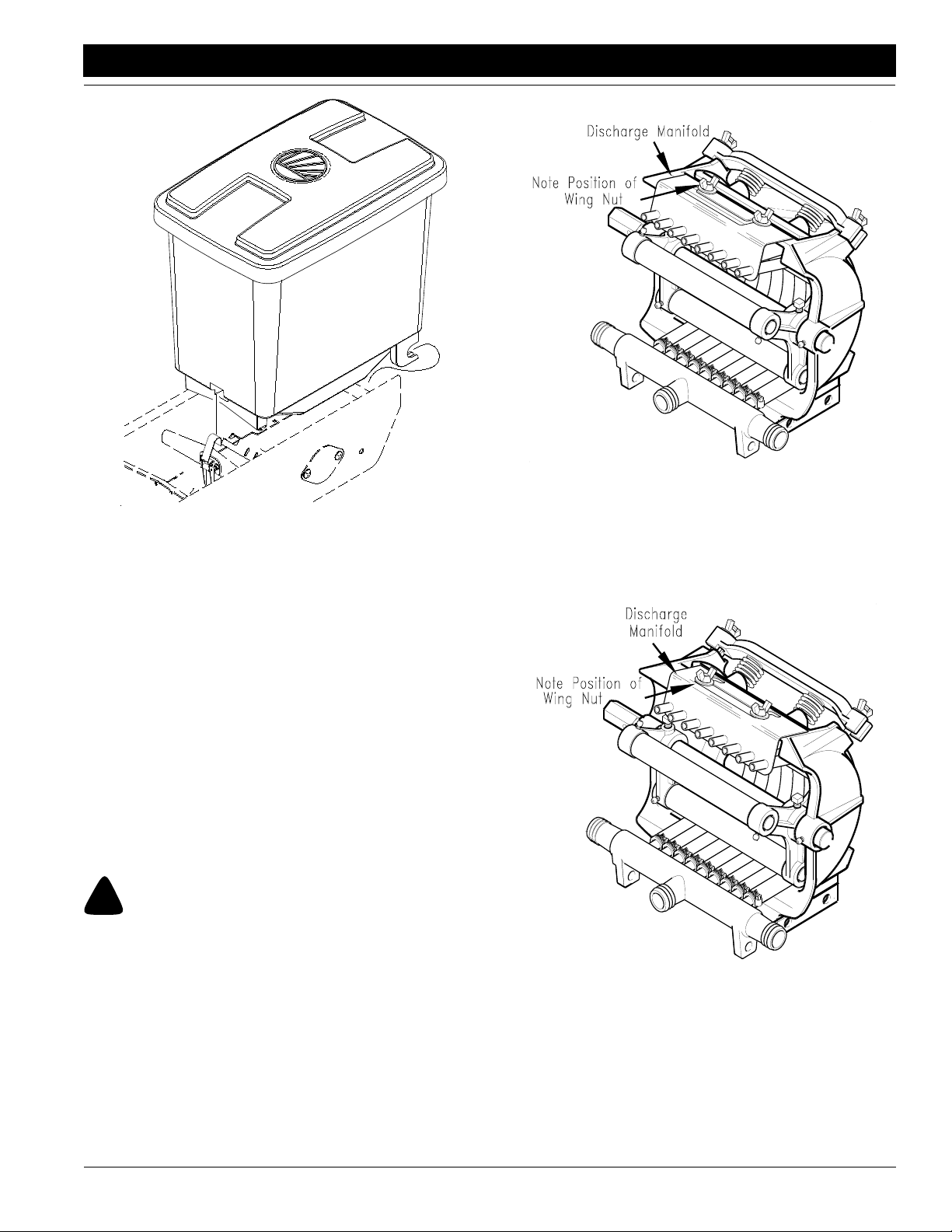

Secure wing nuts as shown in Figure 2-3.

14949

16866

Figure 2-2

Chemical Hopper

Marker Operation

Markers can be raised simultaneously but must be lo wered one at a time. If both markers are required down at

the same time, run one marker down, momentarily start to

raise it, reverse the h ydraulic le v er and lower the opposite

marker. Holding the lever down will force both markers

down.

On a tractor where the oil flow cannot be controlled, the

rate of flow of oil from the tractor may be g reater than the

rate at which the marker cylinder can accept it. The tractor

hydraulic control le ver will have to be held until the cylinder

reaches the end of its stroke. This occurs most often on

tractors with an open-center hydraulic system.

On tractors with a closed-center hydraulic system, the

tractor’s hydraulic flow control can be set so the tractor’s

detent will function properly.

Liquid Fertilizer Operation

!

WARNING!

Agricultural chemicals can be dangerous if not selected and

handled with care. Always read and follow directions supplied

by the chemical manufacturer.

For accurate metering, keep pump speed below 125 rpm.

To operate the pump, the discharge manif old must be in

the forward position as shown in

shipped in the rearward position.

To position the manifold forw ard for operation, loosen the

wing nuts on the manifold and pull the manif old forward.

Figure 2-3. Pumps are

Figure 2-3

Discharge Manifold Forward Position–In Use

When the pump is not in use, reposition the pump manifold

to prolong the life of the hoses in the squeeze pump . To re

position the discharge manifold to the rearward position,

loosen the wing nuts and push the manifold back as

shown in

For more information on preparing the squeeze pump for

parking and storage, refer to Squeeze Pumps , “Mainte

nance and Lubrication,” page 43 and the John Blue

manual provided with the pumps.

Figure 2-4.

14950

Figure 2-4

Discharge Manifold Rearward Position–Parking

-

-

4/12/05

PT6030 and PT8030 Pull-Type Planter 401-032M-B

15

Page 18

Section 2 Operating Instructions

Great Plains Mfg., Inc.

Squeeze Pump Hose Alignment

!

CAUTION!

Avoid pr essure when using the quic k-fill attachment. The rubber

plugs installed in the manifold may be forced out under pres

sure.

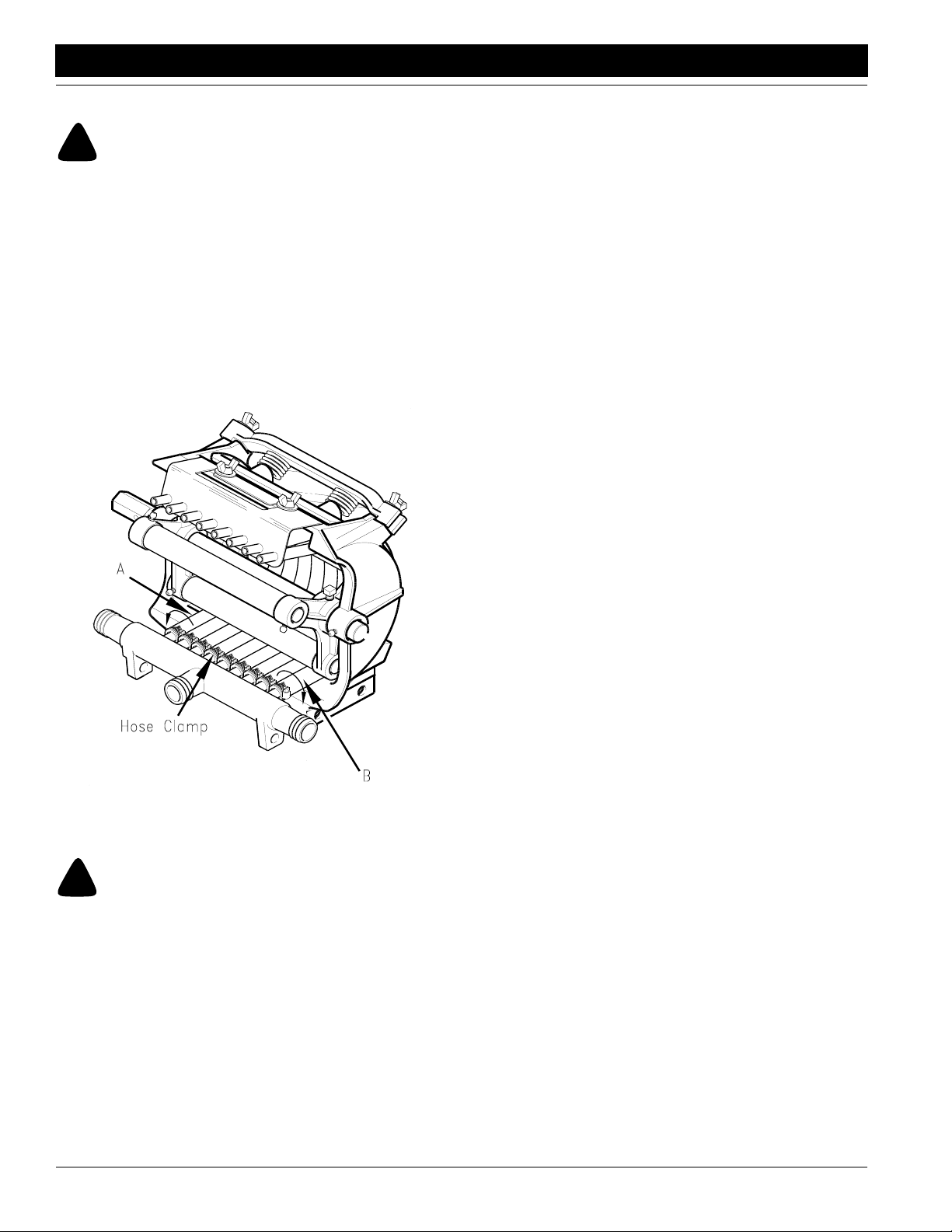

Refer to Figure 2-5.

If end hoses (A and B) should run off the back, realign hos-

es as follows:

1. On hose A, loosen hose clamps on intake manifold

and twist hose counterclockwise 1/4 turn.

2. On hose B, loosen hose clamp on intake manif old and

twist hose clockwise 1/4 turn.

3. Retighten hose clamp.

-

Tractor Requirements, “Specifications and Capaci-

ties,” page 53, and Hitching Planter to Tractor, “Prep-

aration and Setup,” page 11.

2. Unload hoppers before transporting if at all possible.

The planter can be transported with full hoppers, but

the added weight will increase stopping distance and

decrease maneuverability.

3. Check that tires are properly inflated. Refer to Tire

Inflation Chart, “Appendix,”

4. Comply with all federal, state and local laws when

traveling on pub lic roads .

5. Remember that the planter is wider than the tractor.

Allow safe clearance .

6. Transport slowly over uneven or rough terrain.

page 56.

Parking

See also Storage, “Maintenance and Lubrication,”

page 43, for information on long-term storage.

1. Park planter on a lev el, solid area.

2. Place jack on stob on the side of the planter tongue.

Lower jack until weight of planter is off of tractor dr aw

bar. Remove hitch pin and safety chain.

3. Disconnect any hydraulic hoses from tractor. Do not

let hose ends rest on the ground.

-

12402

Figure 2-5

Hose Alignment

Transporting

!

WARNING!

Towing the planter at high speeds can lead to loss of vehicle

control. Loss of vehicle control can lead to serious road acci

dents, injury and death. Do not exceed 20 mph.

Before transporting the planter, chec k and practice the following items.

1. Check that planter is securely hitched to a sufficient

tractor. Alw ays use a locking-style hitch pin sized to

match holes in hitch and drawbar (minimum 1-inch-di

ameter, heat-treated pin). Attach saf ety chain to tr actor with enough slack to permit turning. Refer to

PT6030 and PT8030 Pull-Type Planter 401-032M-B 4/12/05

16

-

-

Page 19

Great Plains Mfg., Inc.

Section 3 Adjustments

Section 3 Adjustments

Planting Rate

T ransmission Adjustment

To change the planting population, change the sprocket

combination on the transmission.

1. Refer to Planting Rates for Finger Pickup Corn

Meters,

page 19, for proper sprock et combination for your desired planting population.

2. Remove cov er from tr ansmission by loosening knob

on cover. See

3. Loosen carriage bolt and flange nut on idler plate. Rotate idler plate and move idlers out of chain.

4. Remove chain. Place correct sprock ets for desired

planting rate on shafts. Store all unused sprock ets on

storage bracket.

5. Reroute chain over idlers and sprock ets .

6. T urn idler plate counterclockwise to take up all b ut 1/4inch slack out of chain. Retighten carriage bolt and

flange nut on idler plate.

7. Replace transmission cover and hand tighten knob.

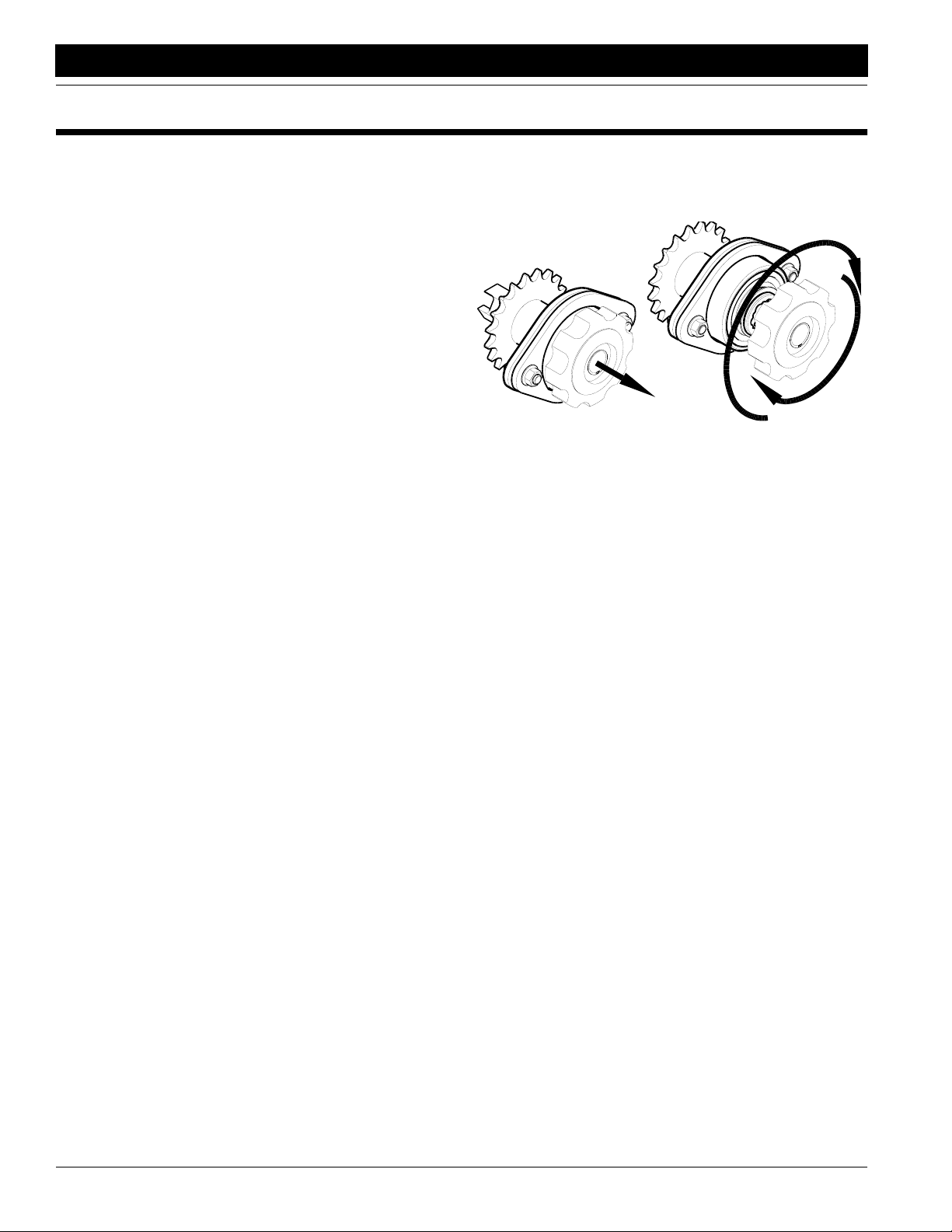

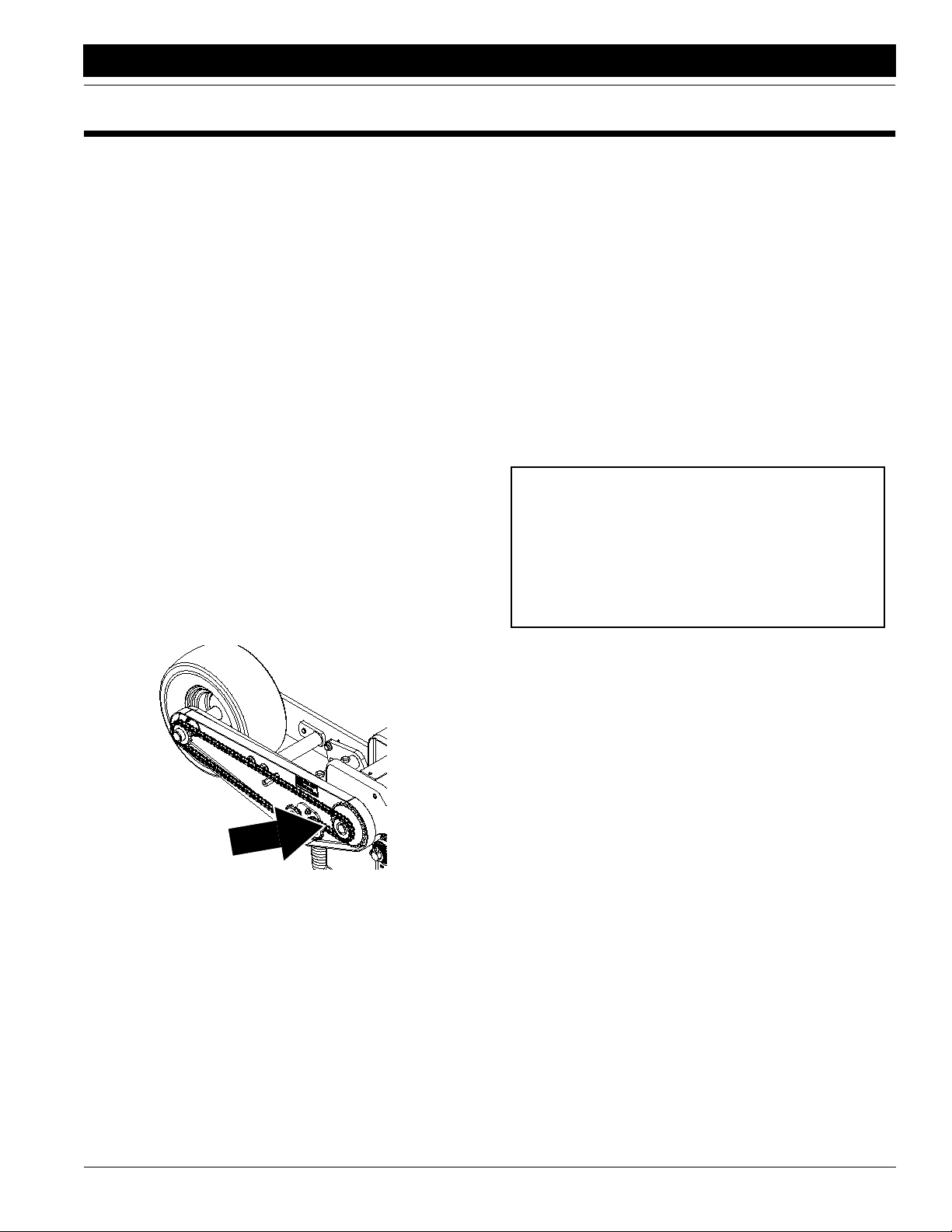

2-to-1 Drive Reduction

The charts on page 18 and page 19 are based on a 15tooth, driven sprocket in the contact-wheel drive . To reduce planting rates by one-half, s witch to 28-tooth sproc ket. See Figure 3-1.

page 18, or Planting Rates for Brush Meters,

Figure 3-2.

Checking Planting Population

After setting transmission, always field chec k planting

population as follows.

1. Release spring pressure on closing wheels or disks.

2. Tie up closing disks or wheels to hopper support using

a chain or heavy wire. Lock up optional Seed-Lok

wheels.

3. Adjust planting depth to a shallow setting.

4. Plant at a normal speed for a short distance.

5. For 30-inch rows, measure 17 f eet 6 inches (one-thousandth of an acre).

6. Count the number of seeds in one row over the measured distance.

7. Multiply the number of seeds counted by 1000. This

gives you total population.

Example

• 30-inch row spacing

• Measure 17 feet 6 inches

• 24 seeds over measured distance in one row

24 X1000 = 24,000 plant population per acre

If the planting population is significantly different than desired, make the following checks.

• Double check the sprocket combination in the transmission. Refer to Planting Rates for Corn Meters,

page 18, or Planting Rates for Brush Meters, page 19.

• Check air pressure in the gauge-wheel tires. Refer to

Tire Inflation Chart, “Appendix,”

• Check for meter malfunction or excessive contactdrive-wheel slippage. Refer to “Troubleshooting,”

page 34.

page 56.

4/12/05

Figure 3-1

2-to-1 Drive Reduction

16863

PT6030 and PT8030 Pull-Type Planter 401-032M-B

17

Page 20

Section 3 Adjustments

Planting Rates for Finger Pickup Corn Meters

Great Plains Mfg., Inc.

Drive

Driven

Figure 3-2

Planter Transmission Drive and Driven Sprockets

Planting Rates 30-Inch Row Width

Planting

Population/

Acre

16,074 17 28 4 to 8 13.0

16,668 17 27 4 to 8 12.5

17,313 17 26 4 to 8 12.1

17,971 19 28 4 to 8 11.6

13,228 17 25 4 to 8 15.8

16,674 19 27 4 to 8 12.5

18,739 17 24 4 to 8 11.2

19,323 19 26 4 to 8 10.8

19,550 17 23 4 to 8 10.7

20,093 19 25 4 to 8 10.4

20,922 19 24 4 to 8 10.0

21,692 23 28 4 to 8 9.6

21,828 19 23 4 to 8 9.6

22,493 23 27 4 to 8 9.3

22,632 24 28 4 to 8 9.2

23,355 23 26 4 to 8 9.0

23,467 24 27 4 to 8 8.9

23,565 25 28 4 to 8 8.9

Transmission

Sprockets

Drive Driven

Recom-

mended Speed

Range (mph)

Average Seed

Spacing

(inches)

16861

Planting Rates 30-Inch Row Width

Planting

Population/

Acre

23,630 17 19 4 to 7.5 8.8

24,286 23 25 4 to 7.5 8.6

24,367 24 26 4 to 7.5 8.6

24,435 25 27 4 to 7.5 8.6

24,504 26 28 4 to 7.5 8.5

25,288 23 24 4 to 7.5 8.3

25,338 24 25 4 to 7.5 8.3

25,372 25 26 4 to 7.5 8.2

25,409 26 27 4 to 7.5 8.2

25,444 27 28 4 to 7.5 8.2

26,383 23 23 4 to 7 7.9

27,357 28 27 4 to 7 7.6

27,394 27 26 4 to 7 7.6

27,471 25 24 4 to 7 7.6

27,525 24 23 4 to 7 7.6

28,406 28 26 4 to 6.5 7.4

28,486 27 25 4 to 6.5 7.3

28,661 25 23 4 to 6.5 7.3

29,457 19 17 4 to 6.5 7.1

29,538 28 25 4 to 6.5 7.1

29,661 27 24 4 to 6.5 7.0

29,803 26 23 4 to 6.5 7.0

30,756 28 24 3 to 6 6.8

30,945 27 23 3 to 6 6.8

31,889 23 19 3 to 5.5 6.6

32,088 28 23 3 to 5.5 6.5

33,270 24 19 3 to 5.5 6.3

34,642 25 19 3 to 5 6.0

35,604 23 17 3 to 5 5.9

36,023 26 19 3 to 5 5.8

37,146 24 17 3 to 5 5.6

37,403 27 19 3 to 5 5.6

38,678 25 17 3 to 4.5 5.4

38,784 28 19 3 to 4.5 5.4

40,219 26 17 3 to 4.5 5.2

41,761 27 17 3 to 4.5 5.0

43,303 28 17 3 to 4.5 4.8

Transmission

Sprockets

Drive Driven

Recom-

mended Speed

Range (mph)

Average Seed

Spacing

(inches)

PT6030 and PT8030 Pull-Type Planter 401-032M-B 4/12/05

18

Page 21

Great Plains Mfg., Inc.

Section 3 Adjustments

Planting Rates for Brush Meters

Planting Rates 30-Inch Row Width

60 Cell

Soybean or

High Rate Milo/

Speed

Sprockets

Transmission

Drive Driven

17 28 2 to 8 80,928 2.6 64,742 3.2 48,557 4.3 40,464 5.2

17 27 2 to 8 83,926 2.5 67,141 3.1 50,356 4.2 41,963 5.0

17 26 2 to 8 87,154 2.4 69,723 3.0 52,292 4.0 43,577 4.8

19 28 2 to 8 90,449 2.3 72,359 2.9 54,269 3.9 45,225 4.6

19 27 2 to 8 93,799 2.2 75,039 2.8 56,279 3.7 46,900 4.5

17 24 2 to 8 94,416 2.2 75,533 2.8 56,650 3.7 47,208 4.4

17 23 2 to 8 98,521 2.1 78,817 2.7 59,113 3.5 49,261 4.2

19 25 2 to 8 101,303 2.1 81,042 2.6 60,782 3.4 50,652 4.1

19 24 2 to 8 105,524 2.0 84,419 2.5 63,314 3.3 52,762 4.0

23 28 2 to 8 109,491 1.9 87,593 2.4 65,695 3.2 54,746 3.8

19 23 2 to 8 110,112 1.9 88,090 2.4 66,067 3.2 55,056 3.8

24 28 2 to 8 114,252 1.8 91,402 2.3 68,551 3.0 57,126 3.7

24 27 2 to 8 118,483 1.8 94,786 2.2 71,090 2.9 59,242 3.5

17 19 2 to 8 119,263 1.8 95,410 2.2 71,558 2.9 59,631 3.5

24 26 2 to 8 123,040 1.7 98,432 2.1 73,824 2.8 61,520 3.4

26 28 2 to 8 123,773 1.7 99,018 2.1 74,264 2.8 61,886 3.4

24 25 2 to 8 127,962 1.6 102,370 2.0 76,772 2.7 63,981 3.3

26 27 2 to 8 128,357 1.6 102,686 2.0 77,014 2.7 64,178 3.3

23 23 2 to 8 133,294 1.6 106,635 2.0 79,976 2.6 66,647 3.1

27 26 2 to 8 138,420 1.5 110,736 1.9 83,052 2.5 69,210 3.0

24 23 2 to 8 139,089 1.5 111,271 1.9 83,453 2.5 69,544 3.0

25 23 2 to 8 144,884 1.4 115,907 1.8 86,930 2.4 72,442 2.9

19 17 2 to 8 148,975 1.4 119,180 1.8 89,385 2.3 74,488 2.8

27 24 2 to 8 149,955 1.4 119,964 1.7 89,973 2.3 74,978 2.8

28 24 2 to 8 155,509 1.3 124,407 1.7 93,305 2.2 77,755 2.7

23 19 2 to 8 161,355 1.3 129,084 1.6 96,813 2.2 80,678 2.6

28 23 2 to 8 162,270 1.3 129,816 1.6 97,362 2.1 81,135 2.6

24 19 2 to 8 168,371 1.2 134,696 1.6 101,023 2.1 84,185 2.5

25 19 2 to 8 175,386 1.2 140,309 1.5 105,232 2.0 87,693 2.4

23 17 2 to 8 180,338 1.2 144,270 1.5 108,233 1.9 90,169 2.3

26 19 2 to 7 182,402 1.1 145,922 1.4 109,441 1.9 91,201 2.3

27 19 2 to 7 189,417 1.1 151,534 1.4 113,650 1.8 94,709 2.2

28 19 2 to 7 196,433 1.1 157,146 1.3 117,860 1.8 98,216 2.1

26 17 2 to 7 203,861 1.0 163,089 1.3 122,317 1.7 101,930 2.1

27 17 2 to 7 211,702 0.9 169,362 1.2 127,021 1.6 105,851 2.0

28 17 2 to 7 219,542 0.9 175,634 1.2 131,725 1.6 109,771 1.9

Range

(mph)

Grain Sorghum

Planting

Population/

Acre

Average Seed

Spacing

(inches)

Planting

Population/

48 Cell

Specialty Soybean or

High Rate

Acid-delinted Cotton

Average Seed

Acre

Spacing

(inches)

Acid-delinted

Large Cotton

Planting

Population/

Acre

36 Cell

Average Seed

Spacing

(inches)

30 Cell

Milo/Grain Sorghum or

Acid-delinted Cotton

Planting

Population/

Acre

Average Seed

Spacing

(inches)

4/12/05

PT6030 and PT8030 Pull-Type Planter 401-032M-B

19

Page 22

Section 3 Adjustments

Brush Meters, Cotton Discs

Great Plains Mfg., Inc.

Meters equipped with the 12 cell acid-delinted hill-drop

cotton discs will plant from 3 to 6 seeds per cell because of

variations in cotton seed size.

Determine which hill spacing is desired and select the

transmission ratio that is closest to that hill spacing on

chart.

To determine the average seeds per hill and hills per acre

do the following field check:

Planting Rates 30-Inch Row Width

Transmission

Sprockets

Drive Driven

17 28 2 to 8 16,186 12.9

17 27 2 to 8 16,785 12.5

17 26 2 to 8 17,431 12.0

19 28 2 to 8 18,090 11.6

19 27 2 to 8 18,760 11.1

17 24 2 to 8 18,883 11.1

17 23 2 to 8 19,704 10.6

19 25 2 to 8 20,261 10.3

19 24 2 to 8 21,105 9.9

23 28 2 to 8 21,898 9.5

19 23 2 to 8 22,022 9.5

24 28 2 to 8 22,850 9.2

24 27 2 to 8 23,697 8.8

17 19 2 to 8 23,853 8.8

24 26 2 to 8 24,608 8.5

26 28 2 to 8 24,755 8.4

24 25 2 to 8 25,592 8.2

26 27 2 to 8 25,671 8.1

23 23 2 to 8 26,659 7.8

Speed

Range

(mph)

Hill-drop Cotton, Acid-delinted

Hills/Acre

12 Cell

Average Hill

Spacing

(inches)

1. Measure 1/1000 of an acre. (1/1000 acre = length of

row 17’5” for 30” widths).

2. Multiply the average seed per hill b y hills per acre .

Example:

4 seeds per hill x (13 hills x 1000) = 52,000

Planting Rates 30-Inch Row Width

Transmission

Sprockets

Drive Driven

27 26 2 to 8 27,684 7.6

24 23 2 to 8 27,818 7.5

25 23 2 to 8 28,977 7.2

19 17 2 to 8 29,795 7.0

27 24 2 to 8 29,991 7.0

28 24 2 to 8 31,102 6.7

23 19 2 to 8 32,271 6.5

28 23 2 to 8 32,454 6.5

24 19 2 to 8 33,674 6.2

25 19 2 to 8 35,077 6.0

23 17 2 to 8 36,068 5.8

26 19 2 to 7 36,480 5.7

27 19 2 to 7 37,883 5.5

28 19 2 to 7 39,287 5.3

26 17 2 to 7 40,772 5.1

27 17 2 to 7 42,340 4.9

28 17 2 to 7 43,908 4.8

Speed

Range

(mph)

Hill-drop Cotton, Acid-delinted

Hills/Acre

12 Cell

Average Hill

Spacing

(inches)

PT6030 and PT8030 Pull-Type Planter 401-032M-B 4/12/05

20

Page 23

Great Plains Mfg., Inc.

Section 3 Adjustments

Granular Chemical Rates

The application rate is determined by:

• the size of the opening on the meter and

• travel speed.

Application rates will also vary with the consistency and

composition of the chemicals, air temperature, humidity

and ground speed. Because of the wide variability in ap

plication rates, you must field chec k the actual r ate of application for each meter .

-

!

WARNING!

Agricultural chemicals can be dangerous if not selected and

handled with care. Always read and follow directions supplied

by the chemical manufacturer.

To adjust the chemical rate:

1. Select a meter setting as a starting point.

• If the chemical manufacturer recommends ounces per

1000 linear row feet or pounds per acre for a given

band width and row spacing, use the recommended

meter setting as a starting point.

• If the chemical manufacturer recommends pounds

per acre for complete (broadcast) coverage, you must

calculate the pounds per acre for your band width and

row area. Refer to Conversion from Broadcast to Row

Coverage,

• If the meter setting is not available from the chemical

manufacturer, use Granular Chemical Rate Charts,

starting on

are based on a ground speed of 5 mph. Use these

charts as a starting point for setting the meter.

2. Turn meter knob until the display shows the correct

number. See

3. Fill the hoppers with chemical.

4. Attach a plastic bag to each chemical

diffuser.

5. Drive 500 feet at a normal planting speed.

6. Weigh the contents of the bag in ounces.

7. Multiply weight by 2.2 to determine the pounds

per acre.

8. If necessary , adjust the meter setting and repeat

steps.

page 21.

page 23. The charts are approximate and

Figure 3-3.

17929

Figure 3-3

Meter Knob

Conversion fr om Broadcast to Row Coverage

If the chemical manufacturer recommends pounds per

acre for complete (broadcast) cov erage, y ou must reduce

the pounds per acre rate to match for your band width and

row area. Use the following f ormula to find the pounds per

acre for your band width and row spacing.

A X B/C = Pounds per Acre Application Rate

Where:

A = Recommended rate in pounds per acre for complete

(broadcast) coverage

B = Band width in inches

C = Row spacing in inches

NOTE: Measure the actual band width applied in your con-

ditions and use this width in your calculations.

Example

The chemical manufacturer recommends 20 pounds

per acre for complete broadcast cov erage. The band

width is 14 inches. The row spacing is 30 inches.

A = 20

B = 14

C = 30

20 x 14/30 = 9.3 pounds per acre

Turn meter knob to setting recommended for 9.3

pounds per acre.

IMPORTANT: If a significant difference in rate is observed between rows, the meter may require recalibration. Refer to Recalibrating Chemical Meter , page

22.

4/12/05

PT6030 and PT8030 Pull-Type Planter 401-032M-B

21

Page 24

Section 3 Adjustments

Recalibrating Granular Chemical Meters

If the metering rate differs significantly between rows,

recalibrate the meters.

Refer to Figure 3-4.

1. Remove and empty hopper. Turn hopper upside

down.

2. Turn meter knob (1) to 10.

3. Loosen screws (2) in metering gate.

4. Insert calibration tool (3).

5. Readjust meter setting to 04.

6. Slide gate (4) to tool.

7. Retighten screws. Reinstall hoppers, refill and recheck chemical-application rate.

Great Plains Mfg., Inc.

Figure 3-4

15051

PT6030 and PT8030 Pull-Type Planter 401-032M-B 4/12/05

22

Recalibrating Meter

Page 25

Great Plains Mfg., Inc.

Section 3 Adjustments

Granular Chemical Rate Charts

Clay Granules, Herbicide

14914

Clay Granules Herbicide Rate Chart

30-Inch Row Width

Pounds per Acre Ounces per 1000 Row Ft.

Meter

Setting

10 0.9 0.6 0.5 0.87 0.58 0.43

11 1.1 0.7 0.6 1.03 0.69 0.51

12 1.3 0.9 0.7 1.22 0.82 0.61

13 1.6 1.1 0.8 1.45 0.97 0.72

14 1.9 1.2 0.9 1.70 1.13 0.85

15 2.1 1.4 1.1 1.97 1.32 0.99

16 2.5 1.6 1.2 2.27 1.51 1.14

17 2.8 1.9 1.4 2.59 1.72 1.29

18 3.2 2.1 1.6 2.92 1.94 1.46

19 3.6 2.4 1.8 3.26 2.17 1.63

20 3.9 2.6 2.0 3.62 2.41 1.81

21 4.3 2.9 2.2 3.99 2.66 1.99

22 4.8 3.2 2.4 4.37 2.91 2.18

23 5.2 3.4 2.6 4.75 3.17 2.37

24 5.6 3.7 2.8 5.14 3.43 2.57

25 6.0 4.0 3.0 5.53 3.69 2.77

26 6.5 4.3 3.2 5.93 3.95 2.96

27 6.9 4.6 3.4 6.33 4.22 3.16

28 7.3 4.9 3.7 6.72 4.48 3.36

29 7.8 5.2 3.9 7.12 4.75 3.56

30 8.2 5.5 4.1 7.52 5.01 3.76

31 8.6 5.7 4.3 7.92 5.28 3.96

32 9.1 6.0 4.5 8.31 5.54 4.16

33 9.5 6.3 4.7 8.71 5.80 4.35

34 9.9 6.6 5.0 9.10 6.06 4.55

35 10.3 6.9 5.2 9.48 6.32 4.74

36 10.7 7.2 5.4 9.87 6.58 4.93

37 11.2 7.4 5.6 10.25 6.83 5.12

38 11.6 7.7 5.8 10.62 7.08 5.31

39 12.0 8.0 6.0 11.00 7.33 5.50

40 12.4 8.3 6.2 11.37 7.58 5.69

41 12.8 8.5 6.4 11.74 7.83 5.87

42 13.2 8.8 6.6 12.11 8.07 6.05

43 13.6 9.1 6.8 12.47 8.32 6.24

44 14.0 9.3 7.0 12.84 8.56 6.42

45 14.4 9.6 7.2 13.20 8.80 6.60

46 14.8 9.8 7.4 13.56 9.04 6.78

47 15.2 10.1 7.6 13.92 9.28 6.96

48 15.6 10.4 7.8 14.28 9.52 7.14

49 16.0 10.6 8.0 14.65 9.76 7.32

50 16.3 10.9 8.2 15.01 10.01 7.51

miles per hour miles per hour

4 6 8468

Clay Granules Herbicide Rate Chart

30-Inch Row Width

Pounds per Acre Ounces per 1000 Row Ft.

Meter

Setting

51 16.7 11.2 8.4 15.38 10.25 7.69

52 17.2 11.4 8.6 15.75 10.50 7.87

53 17.6 11.7 8.8 16.12 10.75 8.06

54 18.0 12.0 9.0 16.50 11.00 8.25

55 18.4 12.3 9.2 16.88 11.26 8.44

56 18.8 12.5 9.4 17.27 11.52 8.64

57 19.2 12.8 9.6 17.67 11.78 8.83

58 19.7 13.1 9.8 18.07 12.05 9.04

59 20.1 13.4 10.1 18.48 12.32 9.24

60 20.6 13.7 10.3 18.90 12.60 9.45

61 21.1 14.0 10.5 19.33 12.89 9.67

62 21.5 14.4 10.8 19.77 13.18 9.89

63 22.0 14.7 11.0 20.22 13.48 10.11

64 22.5 15.0 11.3 20.68 13.79 10.34

65 23.0 15.4 11.5 21.16 14.10 10.58

66 23.6 15.7 11.8 21.64 14.43 10.82

67 24.1 16.1 12.1 22.14 14.76 11.07

68 24.7 16.4 12.3 22.65 15.10 11.33

69 25.2 16.8 12.6 23.18 15.45 11.59

70 25.8 17.2 12.9 23.72 15.81 11.86

71 26.4 17.6 13.2 24.27 16.18 12.13

72 27.0 18.0 13.5 24.84 16.56 12.42

73 27.7 18.5 13.8 25.42 16.95 12.71

74 28.3 18.9 14.2 26.02 17.34 13.01

75 29.0 19.3 14.5 26.63 17.75 13.31

76 29.7 19.8 14.8 27.25 18.17 13.63

77 30.4 20.3 15.2 27.90 18.60 13.95

78 31.1 20.7 15.5 28.55 19.03 14.28

79 31.8 21.2 15.9 29.22 19.48 14.61

80 32.6 21.7 16.3 29.90 19.94 14.95

81 33.3 22.2 16.7 30.60 20.40 15.30

82 34.1 22.7 17.0 31.31 20.87 15.65

83 34.9 23.3 17.4 32.03 21.35 16.01

84 35.7 23.8 17.8 32.76 21.84 16.38

85 36.5 24.3 18.2 33.50 22.33 16.75

86 37.3 24.9 18.6 34.25 22.83 17.12

87 38.1 25.4 19.1 35.00 23.33 17.50

88 38.9 26.0 19.5 35.76 23.84 17.88

89 39.8 26.5 19.9 36.53 24.35 18.27

90 40.6 27.1 20.3 37.30 24.87 18.65

miles per hour miles per hour

4 6 8468

4/12/05

PT6030 and PT8030 Pull-Type Planter 401-032M-B

23

Page 26

Section 3 Adjustments

Granular Chemical Rate Charts

Clay Granules, Insecticide

Great Plains Mfg., Inc.

14914

Clay Granules Insecticide Rate Chart

30-Inch Row Width

Pounds per Acre Ounces per 1000 Row Ft.

Meter

Setting

10 0.9 0.6 0.5 0.85 0.57 0.42

11 1.0 0.7 0.5 0.92 0.61 0.46

12 1.2 0.8 0.6 1.06 0.71 0.53

13 1.4 0.9 0.7 1.25 0.84 0.63

14 1.6 1.1 0.8 1.50 1.00 0.75

15 2.0 1.3 1.0 1.79 1.19 0.90

16 2.3 1.5 1.2 2.12 1.42 1.06

17 2.7 1.8 1.4 2.49 1.66 1.24

18 3.1 2.1 1.6 2.88 1.92 1.44

19 3.6 2.4 1.8 3.31 2.20 1.65

20 4.1 2.7 2.0 3.75 2.50 1.87

21 4.6 3.1 2.3 4.20 2.80 2.10

22 5.1 3.4 2.5 4.68 3.12 2.34

23 5.6 3.7 2.8 5.16 3.44 2.58

24 6.1 4.1 3.1 5.64 3.76 2.82

25 6.7 4.5 3.3 6.14 4.09 3.07

26 7.2 4.8 3.6 6.63 4.42 3.31

27 7.8 5.2 3.9 7.12 4.75 3.56

28 8.3 5.5 4.1 7.61 5.07 3.81

29 8.8 5.9 4.4 8.10 5.40 4.05

30 9.3 6.2 4.7 8.58 5.72 4.29

31 9.9 6.6 4.9 9.05 6.03 4.52

32 10.4 6.9 5.2 9.51 6.34 4.76

33 10.9 7.2 5.4 9.97 6.65 4.98

34 11.3 7.6 5.7 10.41 6.94 5.21

35 11.8 7.9 5.9 10.85 7.23 5.42

36 12.3 8.2 6.1 11.27 7.52 5.64

37 12.7 8.5 6.4 11.69 7.79 5.84

38 13.2 8.8 6.6 12.09 8.06 6.05

39 13.6 9.1 6.8 12.48 8.32 6.24

40 14.0 9.3 7.0 12.87 8.58 6.43

41 14.4 9.6 7.2 13.24 8.83 6.62

42 14.8 9.9 7.4 13.60 9.07 6.80

43 15.2 10.1 7.6 13.96 9.31 6.98

44 15.6 10.4 7.8 14.31 9.54 7.15

45 16.0 10.6 8.0 14.65 9.77 7.33

46 16.3 10.9 8.2 14.99 9.99 7.49

47 16.7 11.1 8.3 15.32 10.21 7.66

48 17.0 11.4 8.5 15.65 10.43 7.82

49 17.4 11.6 8.7 15.98 10.65 7.99

50 17.8 11.8 8.9 16.30 10.87 8.15

miles per hour miles per hour

4 6 8468

Clay Granules Insecticide Rate Chart

30-Inch Row Width

Pounds per Acre Ounces per 1000 Row Ft.

Meter

Setting

51 18.1 12.1 9.1 16.63 11.08 8.31

52 18.5 12.3 9.2 16.95 11.30 8.48

53 18.8 12.5 9.4 17.29 11.52 8.64

54 19.2 12.8 9.6 17.62 11.75 8.81

55 19.6 13.0 9.8 17.96 11.97 8.98

56 19.9 13.3 10.0 18.31 12.21 9.15

57 20.3 13.5 10.2 18.66 12.44 9.33

58 20.7 13.8 10.4 19.03 12.69 9.51

59 21.1 14.1 10.6 19.40 12.94 9.70

60 21.6 14.4 10.8 19.79 13.19 9.90

61 22.0 14.7 11.0 20.19 13.46 10.10

62 22.4 15.0 11.2 20.61 13.74 10.30

63 22.9 15.3 11.5 21.04 14.02 10.52

64 23.4 15.6 11.7 21.48 14.32 10.74

65 23.9 15.9 11.9 21.94 14.63 10.97

66 24.4 16.3 12.2 22.42 14.95 11.21

67 25.0 16.6 12.5 22.92 15.28 11.46

68 25.5 17.0 12.8 23.44 15.62 11.72

69 26.1 17.4 13.1 23.97 15.98 11.99

70 26.7 17.8 13.4 24.52 16.35 12.26

71 27.3 18.2 13.7 25.10 16.73 12.55

72 28.0 18.7 14.0 25.69 17.13 12.84

73 28.6 19.1 14.3 26.30 17.53 13.15

74 29.3 19.6 14.7 26.93 17.95 13.46

75 30.0 20.0 15.0 27.58 18.38 13.79

76 30.8 20.5 15.4 28.24 18.83 14.12

77 31.5 21.0 15.7 28.92 19.28 14.46

78 32.2 21.5 16.1 29.61 19.74 14.81

79 33.0 22.0 16.5 30.32 20.21 15.16

80 33.8 22.5 16.9 31.03 20.69 15.52

81 34.6 23.1 17.3 31.76 21.17 15.88

82 35.4 23.6 17.7 32.49 21.66 16.25

83 36.2 24.1 18.1 33.23 22.15 16.62

84 37.0 24.7 18.5 33.97 22.65 16.99

85 37.8 25.2 18.9 34.71 23.14 17.35

86 38.6 25.7 19.3 35.44 23.63 17.72

87 39.4 26.3 19.7 36.17 24.11 18.08

88 40.2 26.8 20.1 36.88 24.59 18.44

89 40.9 27.3 20.5 37.58 25.05 18.79

90 41.7 27.8 20.8 38.25 25.50 19.13

miles per hour miles per hour

4 6 8468

PT6030 and PT8030 Pull-Type Planter 401-032M-B 4/12/05

24

Page 27

Great Plains Mfg., Inc.

Section 3 Adjustments

Granular Chemical Rate Charts

Sand Granules, Herbicide and Insecticide

14914

Sand Granules Chemical Rate Chart

30-Inch Row Width

Pounds per Acre Ounces per 1000 Row Ft.

Meter

Setting

5 1.7 1.1 0.8 1.53 1.02 0.76

6 2.2 1.4 1.1 1.98 1.32 0.99

7 2.7 1.8 1.3 2.47 1.65 1.23

8 3.3 2.2 1.6 3.00 2.00 1.50

9 3.9 2.6 1.9 3.56 2.38 1.78

10 4.5 3.0 2.3 4.17 2.78 2.08

11 5.2 3.5 2.6 4.82 3.21 2.41

12 6.0 4.0 3.0 5.50 3.67 2.75

13 6.8 4.5 3.4 6.23 4.15 3.12

14 7.6 5.1 3.8 7.00 4.66 3.50

15 8.5 5.7 4.2 7.80 5.20 3.90

16 9.4 6.3 4.7 8.65 5.77 4.32

17 10.4 6.9 5.2 9.53 6.35 4.77

18 11.4 7.6 5.7 10.45 6.97 5.23

19 12.4 8.3 6.2 11.41 7.60 5.70

20 13.5 9.0 6.7 12.39 8.26 6.20

21 14.6 9.7 7.3 13.41 8.94 6.71

22 15.8 10.5 7.9 14.47 9.64 7.23

23 16.9 11.3 8.5 15.55 10.36 7.77

24 18.1 12.1 9.1 16.65 11.10 8.33

25 19.4 12.9 9.7 17.78 11.86 8.89

26 20.6 13.7 10.3 18.94 12.62 9.47

27 21.9 14.6 11.0 20.11 13.41 10.06

28 23.2 15.5 11.6 21.30 14.20 10.65

29 24.5 16.3 12.3 22.51 15.01 11.26

30 25.8 17.2 12.9 23.73 15.82 11.87

31 27.2 18.1 13.6 24.97 16.64 12.48

32 28.5 19.0 14.3 26.21 17.47 13.10

33 29.9 19.9 14.9 27.45 18.30 13.73

34 31.3 20.8 15.6 28.71 19.14 14.35

35 32.6 21.8 16.3 29.96 19.97 14.98

36 34.0 22.7 17.0 31.21 20.81 15.61

37 35.4 23.6 17.7 32.46 21.64 16.23

38 36.7 24.5 18.4 33.71 22.47 16.85

39 38.1 25.4 19.0 34.95 23.30 17.47

40 39.4 26.3 19.7 36.17 24.12 18.09

41 40.7 27.1 20.4 37.39 24.93 18.70

42 42.0 28.0 21.0 38.60 25.73 19.30

43 43.3 28.9 21.7 39.79 26.53 19.90

44 44.6 29.7 22.3 40.97 27.31 20.48

45 45.9 30.6 22.9 42.13 28.08 21.06

miles per hour miles per hour

4 6 8468

Sand Granules Chemical Rate Chart

30-Inch Row Width

Pounds per Acre Ounces per 1000 Row Ft.

Meter

Setting

46 47.1 31.4 23.6 43.27 28.85 21.63

47 48.3 32.2 24.2 44.39 29.59 22.20

48 49.5 33.0 24.8 45.49 30.33 22.75

49 50.7 33.8 25.4 46.58 31.05 23.29

50 51.9 34.6 25.9 47.64 31.76 23.82

51 53.0 35.3 26.5 48.68 32.45 24.34

52 54.1 36.1 27.1 49.70 33.13 24.85

53 55.2 36.8 27.6 50.70 33.80 25.35

54 56.3 37.5 28.1 51.68 34.45 25.84

55 57.3 38.2 28.7 52.64 35.09 26.32

56 58.3 38.9 29.2 53.58 35.72 26.79

57 59.4 39.6 29.7 54.50 36.34 27.25

58 60.3 40.2 30.2 55.42 36.94 27.71

59 61.3 40.9 30.7 56.32 37.54 28.16

60 62.3 41.5 31.1 57.21 38.14 28.60

61 63.3 42.2 31.6 58.09 38.73 29.05

62 64.2 42.8 32.1 58.97 39.31 29.48

63 65.2 43.5 32.6 59.85 39.90 29.92

64 66.1 44.1 33.1 60.73 40.49 30.37

65 67.1 44.7 33.6 61.62 41.08 30.81

66 68.1 45.4 34.0 62.53 41.69 31.26

67 69.1 46.1 34.5 63.45 42.30 31.73

68 70.1 46.8 35.1 64.40 42.93 32.20

69 71.2 47.5 35.6 65.38 43.58 32.69

70 72.3 48.2 36.2 66.39 44.26 33.20

71 73.5 49.0 36.7 67.45 44.97 33.72

72 74.7 49.8 37.3 68.56 45.71 34.28

73 75.9 50.6 38.0 69.73 46.49 34.86

74 77.3 51.5 38.6 70.96 47.31 35.48

75 78.7 52.5 39.4 72.28 48.19 36.14

76 80.2 53.5 40.1 73.68 49.12 36.84

77 81.9 54.6 40.9 75.18 50.12 37.59

78 83.6 55.7 41.8 76.78 51.19 38.39

79 85.5 57.0 42.7 78.51 52.34 39.25

80 87.5 58.3 43.8 80.36 53.58 40.18

81 89.7 59.8 44.8 82.36 54.91 41.18

82 92.0 61.4 46.0 84.52 56.35 42.26

83 94.6 63.1 47.3 86.85 57.90 43.42

84 97.3 64.9 48.7 89.36 59.57 44.68

85 100.3 66.8 50.1 92.07 61.38 46.03

miles per hour miles per hour

4 6 8468

4/12/05

PT6030 and PT8030 Pull-Type Planter 401-032M-B

25

Page 28

Section 3 Adjustments

Great Plains Mfg., Inc.

Liquid Fertilizer Attachment

!

WARNING!

Agricultural chemicals can be dangerous if not selected and

handled with care. Always read and follow directions supplied

by the chemical manufacturer.

On machines equipped with the squeeze pump option, the

rate of liquid fertilizer application is determined by the

combination of sprockets on the squeeze pump driven and

drive shafts. When changing sprocket combinations,

make sure sprockets are in alignment, sproc ket retaining

collars are tight and chain tension is sufficiently restored.

The chart on this page provides approximate application

rates. Actual rates will vary with temperature and the par

ticular fertilizer being used.

NOTE: If placed too close to the seed, certain analysis of

fertilizer may cause germination or seedling damage es

pecially if used in amounts in excess of fertilizer manuf acturer’s recommendations. Chec k with your f ertilizer dealer

or manufacturer f or the correct amount and placement.

Liquid Fertilizer Rate Chart

Transmission

Combination

Driver Driven Gallons/Acre Gallons/Acre

15 44 3.49 8.99

15 41 3.75 9.65

17 44 4.06 10.19

17 41 4.25 10.94

19 44 4.43 11.39

15 32 4.8 12.36

21 41 5.25 13.51

17 32 5.45 14.01

24 41 6.00 15.44

19 32 6.09 15.66

15 24 6.41 16.48

17 24 7.26 18.68

15 21 7.32 18.84

17 23 7.58 19.49

15 19 8.09 20.82

17 21 8.30 21.35

19 23 8.47 21.79

15 17 9.04 23.27

17 19 9.17 23.60

23 24 9.82 25.28

24 23 10.70 27.52

19 17 11.46 29.48

17 15 11.62 29.89

23 19 12.41 31.93

21 17 12.66 32.58

19 15 12.98 33.41

23 17 13.87 35.68

21 15 14.35 36.93

24 17 14.47 37.24

32 21 15.62 40.19

24 15 16.40 42.20

32 19 17.26 44.42

41 24 17.51 45.06

Hose Dia. at 5/16 Hose Dia. at 1/2

-

Dry Fertilizer Attachment

IMPORTANT: Fertilizer application rates can vary

from the weights in the charts. Make field checks to

assure you are applying fertilizer at the desired rate.

Use the following instructions to check the e xact n umber

of pounds your fertilizer attachment will actually deliver on

a 30-inch row spacing.

1. Remove a hose from one of the f ertilizer hoppers and

attach a container under the opening.

2. Engage the fertilizer attachment and drive forward f or

174 feet.

-

3. Weigh the amount of fertilizer caught in the container

and multiply that amount by 100. The result will be the

pounds of fertilizer delivered per acre when planting in

30-inch rows.

To assure proper application check the gauge tires and

contact drive tire for proper inflation, see Tire Inflation

Chart in

“Appendix” on page 55.

IMPORTANT: Before applying fertilizer make sure

that augers are rotating correctly and are positioned

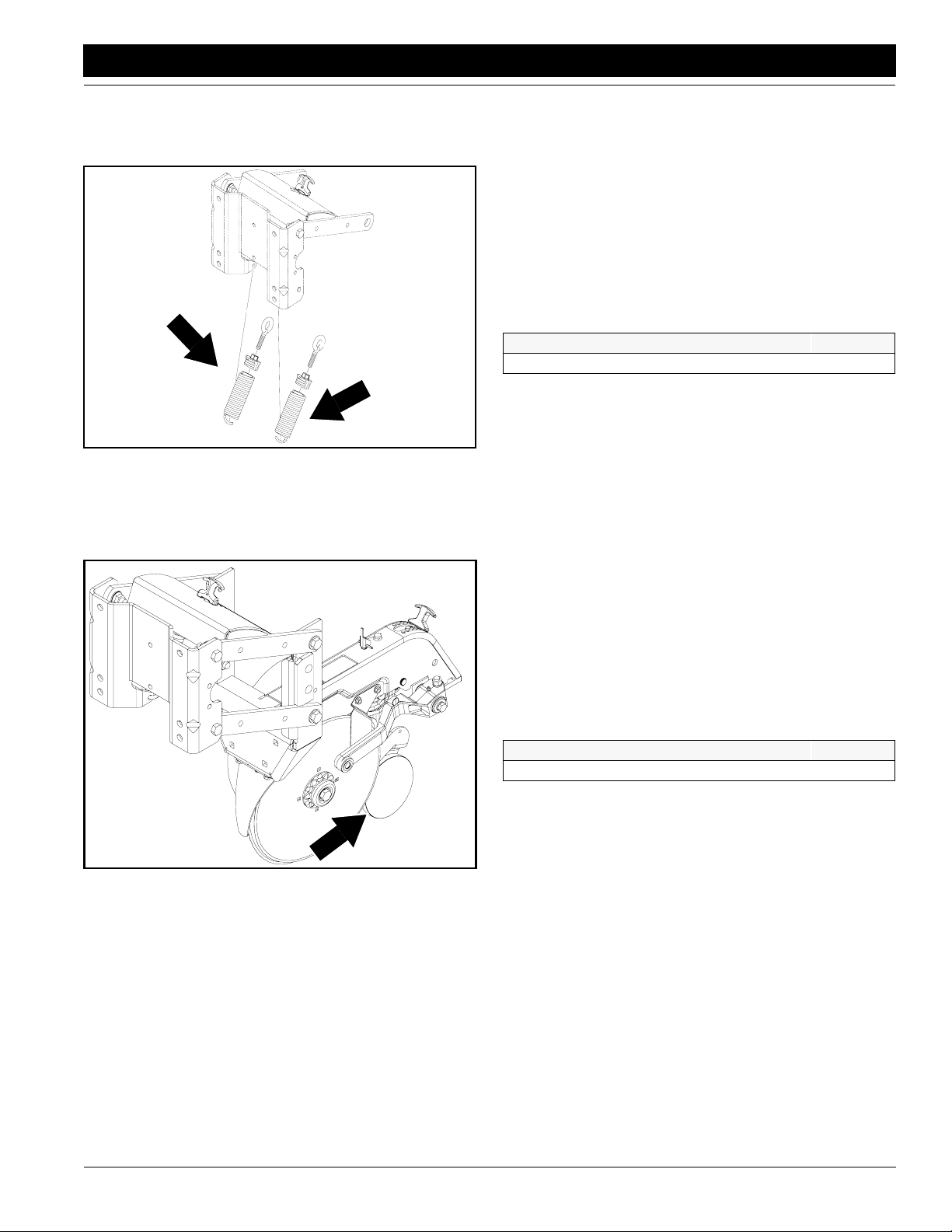

for your desired rate setting. See Figure 3-6 and Figure 3-7.

Driven

Figure 3-5

Fertilizer Transmission–Liquid and Dry

Drive

16864

PT6030 and PT8030 Pull-Type Planter 401-032M-B 4/12/05

26

Page 29

Great Plains Mfg., Inc.

Section 3 Adjustments

Dry Fertilizer Low Rate Setting

Approximate rate in pounds per acre

Drive 15 17 19 21 23 24 32 41 44

15 n/a 71 79 88 96 100 133 171 183

17 55 63 70 77 85 88 118 151 162

19 49 56 63 69 76 79 105 135 145

21 45 51 57 63 68 71 95 122 131

23 41 46 52 57 63 65 87 111 120

Driven

24 39 44 49 55 60 63 83 107 115

32 29 33 37 41 45 47 n/a 80 86

41 23 26 29 32 35 37 49 n/a 67

44 21 24 27 30 33 34 45 58 n/a

15699

Figure 3-6

Low Rate Setting

Dry Fertilizer High Rate Setting

Approximate rate in pounds per acre

Drive 15 17 19 21 23 24 32 41 44

15 n/a 212 237 262 286 299 399 511 548

17 165 187 209 231 253 264 352 451 484

19 148 167 187 207 226 236 315 403 433

21 133 151 169 187 205 214 285 365 391

23 122 138 154 171 187 195 260 333 357

Driven

24 117 132 148 163 179 187 249 319 343

32 88 99 111 123 134 140 n/a 239 257

41 68 77 87 96 105 109 146 n/a 201

44 64 72 81 89 98 102 136 174 n/a

NOTE: The application charts on this page were calculated with a bulk density of 65 pounds per cubic foot.

4/12/05

PT6030 and PT8030 Pull-Type Planter 401-032M-B

15696

Figure 3-7

High Rate Setting

27

Page 30

Section 3 Adjustments

Great Plains Mfg., Inc.

Meter Drive Adjustments

The meter clutch and meter-input shaft must be aligned.

Misalignment will cause meter malfunction and excessive

meter-housing wear. Periodically check vertical and hori

zontal alignment of meter clutch and meter-input shaft.

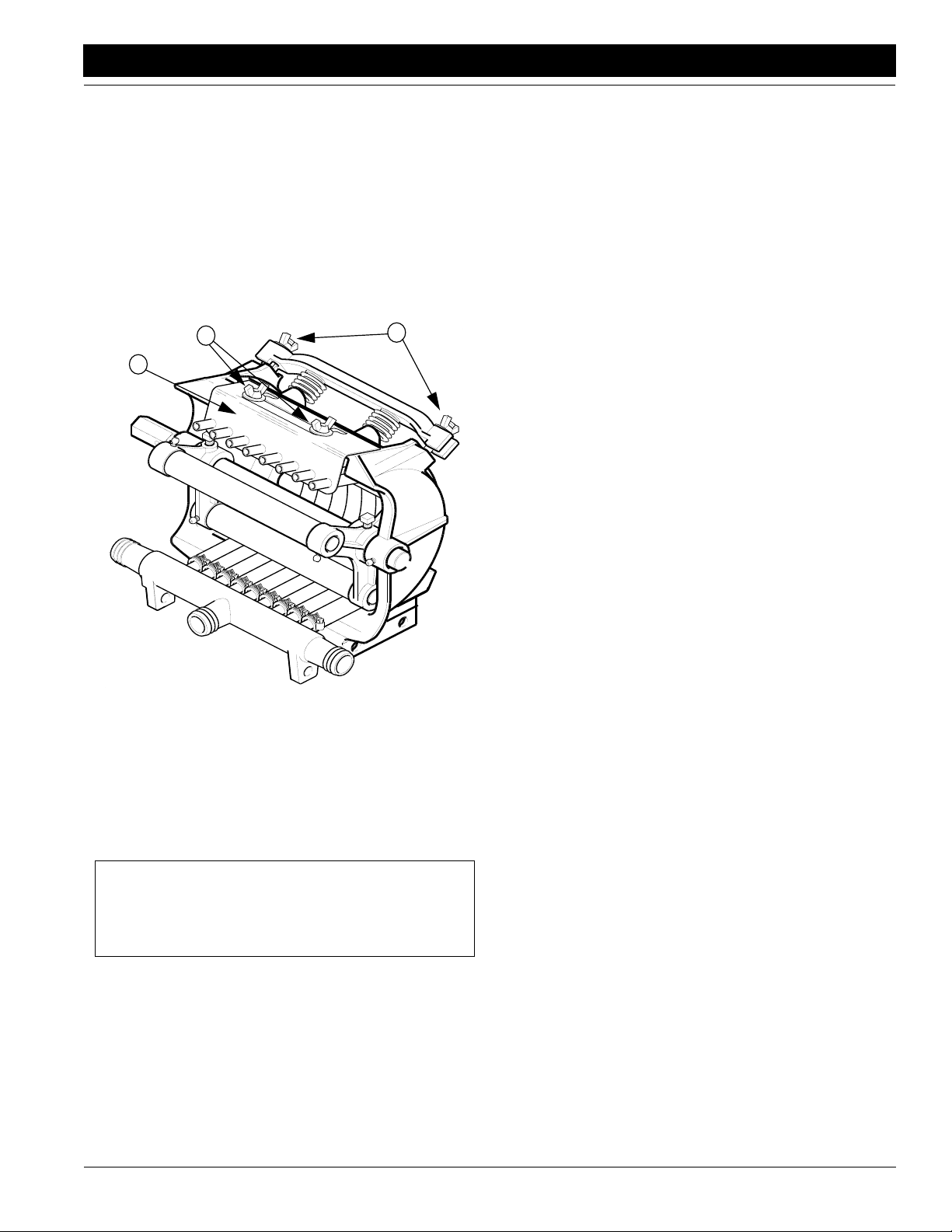

Refer to Figure 3-8.

1. Latch hopper onto hopper support.

2. Check that roll pin (1) in end of the meter-input shaft is

centered. When centered, equal amounts of the roll

pin will protrude from both sides of the shaft.

3. Rotate meter-input shaft so that roll pin is vertical.

4. Rotate the drive coupler (2) on meter clutch so that the

slots are vertical.

5. Release meter clutch to engage meter-input shaft.

6. If shafts are aligned vertically , the drive coupler will engage with meter-input shaft freely and the roll pin will

extend equally on each side of the drive coupler. Dis

engage the clutch and repeat steps, checking for horizontal alignment.

Row Unit Adjustments

Down Pressure

Springs provide the down pressure necessary for opener

-

disks to open a seed trench. The springs allow the row unit

to float down into depressions and up over obstructions.

You can adjust down pressure individually for each row

unit. Use only enough down pressure to cut the seed

trench and maintain proper soil-firming over seed. Exces

sive down pressure will lead to premature wear on rowunit components.

To adjust, lift T-handle shown in Figure 3-9.

• Move T-handle back to increase spring pressure.

• Move T-handle ahead toward tractor to decrease

spring pressure.

-

-

17891

Figure 3-8

Vertical Alignment

7. If drive coupler does not freely engage meter-input

shaft vertically or horizontally, loosen 5/16-inch nuts

(3) shown in

Figure 3-8. Engage meter clutch. Align

meter clutch with meter-input shaft.

8. Tighten 5/16-inch nuts to torque values listed on

Torque Values Chart, “Appendix,”

page 55.

17718

Figure 3-9

Row Unit Spring Adjustment

Refer to the charts below for the amount of spring pressure at the opener for each spring setting.

Down Pressure Charts

Medium-Duty Spring Package Pounds Pressure

First Holes (Closest to Tractor) 85

Second Holes 100

Third Holes 115

Fourth Holes 135

Fifth Holes (Closest to Hopper) 155

Heavy-Duty Spring Package Pounds Pressure

First Holes (Closest to Tractor) 155

Second Holes 175

Third Holes 205

Fourth Holes 225

Fifth Holes (Closest to Hopper) 245

PT6030 and PT8030 Pull-Type Planter 401-032M-B 4/12/05

28

Page 31

Great Plains Mfg., Inc.

Section 3 Adjustments

Coulter Depth

Optional coulters allow row unit to penetrate tough ground

conditions. Adjust coulters to run at the same depth as the

opener disks.

1. To adjust coulter depth, loosen 3/4-inch jam nut (1)

and 3/4-by-3-inch hex bolt (2). See

Figure 3-10.

2. By turning cam hex (3), rotate cam casting to the de-

sired height. Each notch represents about 1/4 inch of

depth.

3. Torque bolt and jam nut to values recommended on

Torque Values Chart, “Appendix,”

Figure 3-10

Row Unit Mounted Coulter

page 55.

15053

Side Gauge Wheels

The side gauge wheels have two, interrelated adjustments:

• angle of side gauge wheel, and

• distance between side gauge wheel and opener disk.

Opener

Disks

Side Gauge

Wheel

Incorrect Correct

Figure 3-12

Side Gauge Wheels

Side Gauge

Wheel

Adjust side-gauge-wheel angle so the wheels contact the

opener disks between 4 and 8 o’clock.

Opener Seeding Depth

Seeding depth is controlled by gauge wheels mounted on

the sides of the opener disks.

To adjust seeding depth:

1. Raise planter to remove weight from side gauge

wheels.

2. Raise and move T-handle sho wn in Figure 3-11.

• Move T-handle forward for deeper seeding depth.

• Move T-handle back for shallower seeding depth.

3. Move T-handles on all ro w units to the same location.

12345

Figure 3-11

Opener Depth Adjustment

8:00

Figure 3-13

Wheel-to-Disk Contact Area

4:00

17812

At the same time, keep the side gauge wheels close to the

opener disks so openers do not plug with soil or trash but

far enough out so the disks and wheels turn freely.

To adjust side gauge wheels:

1. Raise implement slightly to remove weight from side

gauge wheels.

2. Loosen hex-head bolt. Mov e wheel and arm out on oring bushing. See

Figure 3-14.

4/12/05

PT6030 and PT8030 Pull-Type Planter 401-032M-B

29

Page 32

Section 3 Adjustments

17916

Figure 3-14

Loosen Hex-Head Bolt

3. Loosen pivot bolt. Turn hex adjuster so roll pin (1) is at

1 o’clock. Use this as the starting point for adjustment.

Great Plains Mfg., Inc.

1 x 12 Closing Wheel Option

The closing wheels can be adjusted for down pressure,

alignment and offset.

Down Pressure. Adjust the closing wheels so they have

enough down force to close the seed trench without unnec

essary compaction.

Start with T-handle in first notch. See Figure 3-16. If the

seed trench does not close, move handle to next notch

and try again. Keep moving handle back just until the seed

trench closes.

-

Starting Point

17914

Figure 3-15

Turn Hex Adjuster

4. Move wheel arm in so side gauge wheel contacts

opener disk. Tighten hex-head bolt to clamp arm

around bushing and shank.

5. Check the wheel-to-disk contact. Lift wheel and arm.

When let go, the wheel should f all freely.

• If wheel does not contact disk from 4 to 8 o’clock,

move hex adjuster until wheel is angled for proper

contact with disk.

• If wheel does not fall freely, loosen hex-head bolt

and slide wheel arm out just until wheel and arm move

freely. Retighten hex-head bolt.

6. Keep turning hex adjuster and moving wheel arm until

the wheel is adjusted properly . When satisfied, tighten

pivot bolt to 110 foot-pounds .

17888

Figure 3-16

Closing Wheel Down Pressure

Alignment. If one closing wheel is running in the seed

trench or closing wheels are not centered over the seed

trench, adjust closing wheels as follows.

1. Raise planter slightly to remove weight from closing

wheels.

7. Loosen two 1/2-inch mounting bolts (1) shown in Figure 3-17.

8. T urn adjuster cam (2) left or right to center wheels over

the seed trench.

9. Torque 1/2-inch mounting bolts as recommended on

Torque Value Chart, “Appendix,”

page 55

.

Figure 3-17

Closing Wheel Alignment

PT6030 and PT8030 Pull-Type Planter 401-032M-B 4/12/05

30

17889

Page 33

Great Plains Mfg., Inc.

Section 3 Adjustments

Offset. The closing wheels can be offset to help prevent

trash from plugging the closing wheels.

To offset the closing wheels:

1. Raise planter slightly to remove weight from closing

wheels.

2. Remove 5/8-inch bolt attaching wheel to press-wheel

arm. See

3. Move closing wheel to rear mounting hole and reattach

with 5/8-inch bolt. Torque bolt as recommended on

Torque Values Chart, “Appendix,”

17893

If the closing wheels are not offset, mount wheels in the

front holes of press-wheel arm.

Closing Disk Option

For proper seed-to-soil contact, the closing disks must

have enough down pressure to close the seed trench with

out unnecessary soil compaction.

To adjust down pressure on closing disks, ratchet spring

cam to next cam height by turning head of support bolt (1)

clockwise. Refer to

Figure 3-18.

page 55.

Figure 3-18

Closing Wheel Offset

Figure 3-19.

Marker Adjustments

!

WARNING!

Pinching and crushing hazard. The moving markers could

pinch or crush bystanders. Never allow anyone near the planter

when cycling the markers. Reduce marker folding speed to a

safe speed.

!

WARNING!

Escaping fluid under pressure can have sufficient pressure to

penetrate the skin. Check all hydraulic lines and fittings before

applying pressur e. Fluid escaping fr om a very small hole can be

almost invisible. Use paper or cardboard, not body parts, and

wear heavy gloves to check for suspected leaks. If injur ed, seek

medical assistance from a doctor that is familiar with this type

of injury. For eign fluids in the tissue must be surgically r emoved

within a few hours or gangrene will result.

Folding Speed

The marker hydraulic system is equipped with needle

valves to control how f ast each marker operates . The nee

dle valves are b uilt into the sequence valve body . There

are two hex adjustment heads, one f or controlling marker

speed up and one for controlling marker speed down.

Excessive folding speeds can cause marker damage .

With the tractor engine at an operating rpm, loosen jam

nut and adjust the needle valve to limit the marker to a saf e

operating speed. Make sure all adjustments are made

with warm oil. Fold the marker up and down a few times

and recheck for pinching and kinking of hoses.

-

-

4/12/05

Figure 3-19

Closing Disk and Tube Holes

17890

15029

Figure 3-20

Flow Control Raise/Lower

IMPORTANT: JIC fittings do not require high torque.

JIC and O-ring fittings do not require sealant. Always

use liquid pipe sealant when adding or replacing

pipe-thread fittings. To avoid possible danger of

cracking hydr aulic fittings from over tightening, do not

use plastic sealant tape.

PT6030 and PT8030 Pull-Type Planter 401-032M-B

31

Page 34

Section 3 Adjustments

Marker Width

Refer to Figure 3-21.

To adjust marker width, loosen the marker tube u-bolt (1)

and slide marker tube in or out to dimension A. After ad

justing, retighten u-bolt.

Dimension A is measured from the center line of the planter to the marker disk. The dimensions provided are approximate. After adjusting, field check the actual

dimension.

For 6-row, 30 inch rows, A = 180 inches.

For 8-row, 30 inch rows, A = 240 inches.

-

Great Plains Mfg., Inc.

17928

Figure 3-22

Marker Disk Adjustments

Seed-Lok Lock Up

Optional Seed-Lok firming wheels provide additional

seed-to-soil contact. The wheels are spring loaded and do

not require adjusting. In some wet and sticky conditions

the wheels may accumulate soil.