Page 1

PINK

Predelivery Instructions

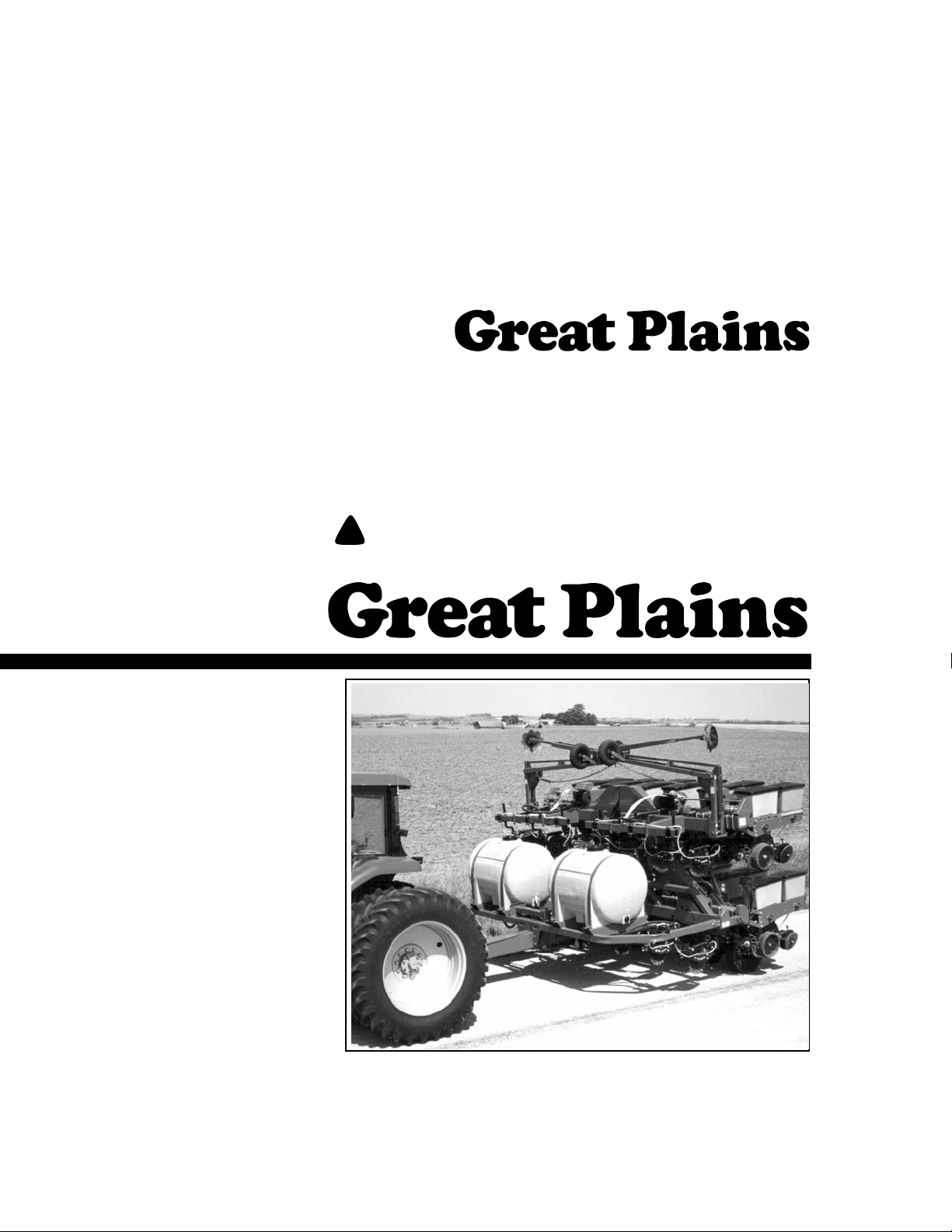

PT1230

Folding Pull-Type Planter

Manufacturing, Inc.

P.O. Box 5060 ● Salina, Kansas 67402-5060

Read this manual entirely . When y ou see this symbol, the subsequent instructions and

!

warnings are serious - follow without exception. Your life and the lives of others depend

on it!

© Copyright 1999 Printed

10/14/08

15788

Cover illustration may show optional equipment not supplied with standard unit.

401-072M

Page 2

Table of Contents

Table of Contents

Important Safety Information . . . . . . . . . . . . . . . . . 1

Safety Notations . . . . . . . . . . . . . . . . . . . . . . . . . 1

Safety Rules . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Description of Unit. . . . . . . . . . . . . . . . . . . . . . . . 2

Intended Usage. . . . . . . . . . . . . . . . . . . . . . . 2

Using This Manual. . . . . . . . . . . . . . . . . . . . . . . . 2

Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Assembly and Setup Assistance. . . . . . . . . . . . . 2

Section 1 Assembly. . . . . . . . . . . . . . . . . . . . . . . . . 3

Tools Required. . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Pre-Assembly Checklist. . . . . . . . . . . . . . . . . . . . 3

Planter Assembly. . . . . . . . . . . . . . . . . . . . . . . . . 3

Row Unit Assembly. . . . . . . . . . . . . . . . . . . . 4

Marker Installation. . . . . . . . . . . . . . . . . . . . . 4

U-Joint Assembly . . . . . . . . . . . . . . . . . . . . . 6

Point Row Clutch. . . . . . . . . . . . . . . . . . . . . . 6

Liquid Fertilizer Assembly . . . . . . . . . . . . . . . . . . 7

Section 2 Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Hitching Planter to Tractor . . . . . . . . . . . . . . . . . 10

Hydraulic Hose Hookup. . . . . . . . . . . . . . . . . . . 10

Row Unit Setup and Adjustment . . . . . . . . . . . . 11

Appendix. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Tire Inflation Chart. . . . . . . . . . . . . . . . . . . . . . . 12

Torque Values Chart for Common Bolt Sizes . . 12

Great Plains Mfg., Inc.

© Copyright 1999 All rights Reserved

Great Plains Manufacturing, Inc. provides this publication “as is” without warr anty of any kind, either expressed or implied. W hile ev ery precaution has been taken in the preparation

of this manual, Great Plains Manufacturing, Inc. assumes no responsibility for errors or omissions . Neither is any liability assumed for damages resulting from the use of the inf ormation contained herein. Great Plains Manufacturing, Inc. reserves the right to revise and improve its products as it sees fit. This publication describes the state of this product at the

time of its publication, and may not reflect the product in the future.

The following are trademarks of Great Plains Mfg., Inc.: Application Systems, A usherman, Land Pride, Great Plains

All other brands and product names are trademarks or registered trademarks of their respective holders.

PT1230 Folding Pull-Type Planter 401-072M 10/14/08

Great Plains Manufacturing, Incorporated Trademarks

Printed in the United States of America.

Page 3

Important Safety Information

Important Safety Information

For your safety, thoroughly read “Important Safety Information” and “Operating Instructions” in the operator’s manual

before proceeding.

Safety Notations

The SAFETY ALERT SYMBOL indicates that there is a potential hazard to personal safety involved and extra safety precautions must be taken. When you see this symbol, be alert and

carefully read the message that follows it. In addition to design

and configuration of equipment, hazard control and accident

prevention are dependent upon the awareness, concern, prudence and proper training of personnel involved in the operation, transport, maintenance and storage of equipment.

Watch for the following safety notations throughout your operator’s manual.

!

DANGER!

Indicates an imminently hazardous situation which, if not

avoided, will result in death or serious injury. This signal word

is limited to the most extreme situations.

!

Great Plains Mfg., Inc.

!

WARNING!

Indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury.

!

CAUTION!

Indicates a potentially hazardous situation which, if not avoided, may result in minor or moder ate injury. It may also be used

to alert against unsafe practices.

Safety Rules

Most accidents are the result of negligence, carelessness or

failure to follow safety precautions. Though your implement is

designed with many built-in safety features, safety precautions

are mandatory to prevent accidents.

PT1230 Folding Pull-Type Planter 401-072M 10/14/08

0

Page 4

Great Plains Mfg., Inc.

Introduction

Introduction

Great Plains Manufacturing wants y ou to be satisfied with

any new machine delivered b y the Great Plains Trucking

network. To ease the assembly task and produce a prop

erly working machine, read this entire manual before assembling or setting up new equipment.

Description of Unit

The 12-row , 30-inch spacing, pull-type planter has six rigid

center rows and 3 rows on each end which float indepen

dently in field operation. The outer 3 rows on each end lift

and fold abov e the center rows for transporting. Field turns

can be completed in a relatively small radius due to the lift

wheels and short tongue.

The PL1230 allows application of liquid fertilizer .The complete system allows you to band liquid fertilizer on 12 rows

with two, 230-gallon liquid tanks and an optional squeeze

pump.

Intended Usage

This machine is intended for planting row crops in conv entional as well as no-till conditions.

Using This Manual

This manual was written to help you assemble and prepare the new machine for the customer. The manual includes instructions for assembly and setup . Read this

manual and follow the recommendations f or safe, efficient

and proper assembly and setup.

An operator’s man ual is also pro vided with the ne w machine. Read and understand “Important Safety Informa-

tion” and “Operating Instructions” in the operator’ s

manual before assembling the machine . As a reference,

keep the operator’ s man ual on hand while assembling.

The information in this manual is current at printing. Some

parts may change to assure top performance.

-

Definitions

The following terms are used throughout this manual.

Right and left as used in this manual are determined by

facing the direction the machine will trav el while in use un

less otherwise stated.

NOTE: Useful inf ormation about the preceding topic.

IMPORTANT: A crucial point of information about the

preceding topic. For safe and correct oper ation, read

and follow the directions provided before continuing.

Assembly and Setup Assistance

To order additional copies of predelivery instructions or

operator’s and parts manuals, write to the follo wing ad

dress. Include model numbers in all correspondence.

If you do not understand any part of this manual or have

other assembly or setup questions, assistance is av ail

able. Contact

Product Support

Great Plains Mfg. Inc., Service Department

P.O . Box 5060

Salina, KS 67402-5060

-

-

-

10/14/08

PT1230 Folding Pull-Type Planter 401-072M

1

Page 5

Section 1 Assembly

Section 1 Assembly

Great Plains Mfg., Inc.

The following headings are step-by-step instructions for

assembling the planter. Begin with Tools Required and

Pre-Assembly Checklist to make sure y ou ha v e all neces

sary parts and equipment. Then proceed with Planter As-

sembly. Follow each step to make the job as quick and

safe as possible and produce a properly working machine.

The planter is shipped via flat bed truck. It is the dealer’s

responsibility to unload the new machine. Unload all

equipment before beginning assembly . Do not attempt any

assembly work while the planter is on the truck.

Tools Required

• Forklift with 3,000 pound capacity

• Lifting chains

• General hand tools

Pre-Assembly Checklist

1. Read and understand “Important Safety Information” on page 0 before assemb ling.

2. Have at least two people on hand while assemb ling.

3. Make sure the assembly area is le vel and free of obstructions (preferably an open concrete area).

4. Have all major components.

5. Have all f asteners and pins shipped with the planter

Planter Assembly

-

.

!

WARNING!

The fertilizer-tank weldment weighs more than 300 pounds and

could cause serious injury if it falls. Make sure the weldment is

securely attached to an adequate lifting device. Keep people

away while the weldment is being lifted. Do not place any body

parts under the weldment at any time.

1. If the planter has liquid fertilizer, remo ve fertilizer-tank

weldment from the planter frame. Secure adequate

lifting device to the weldment. Unstrap the weldment

from the planter frame. Loosen and remove the bolts

that hold the weldment on the planter. Sa ve bolts,

washers and nuts. Lift the weldment off the planter

frame and lower weldment to the ground.

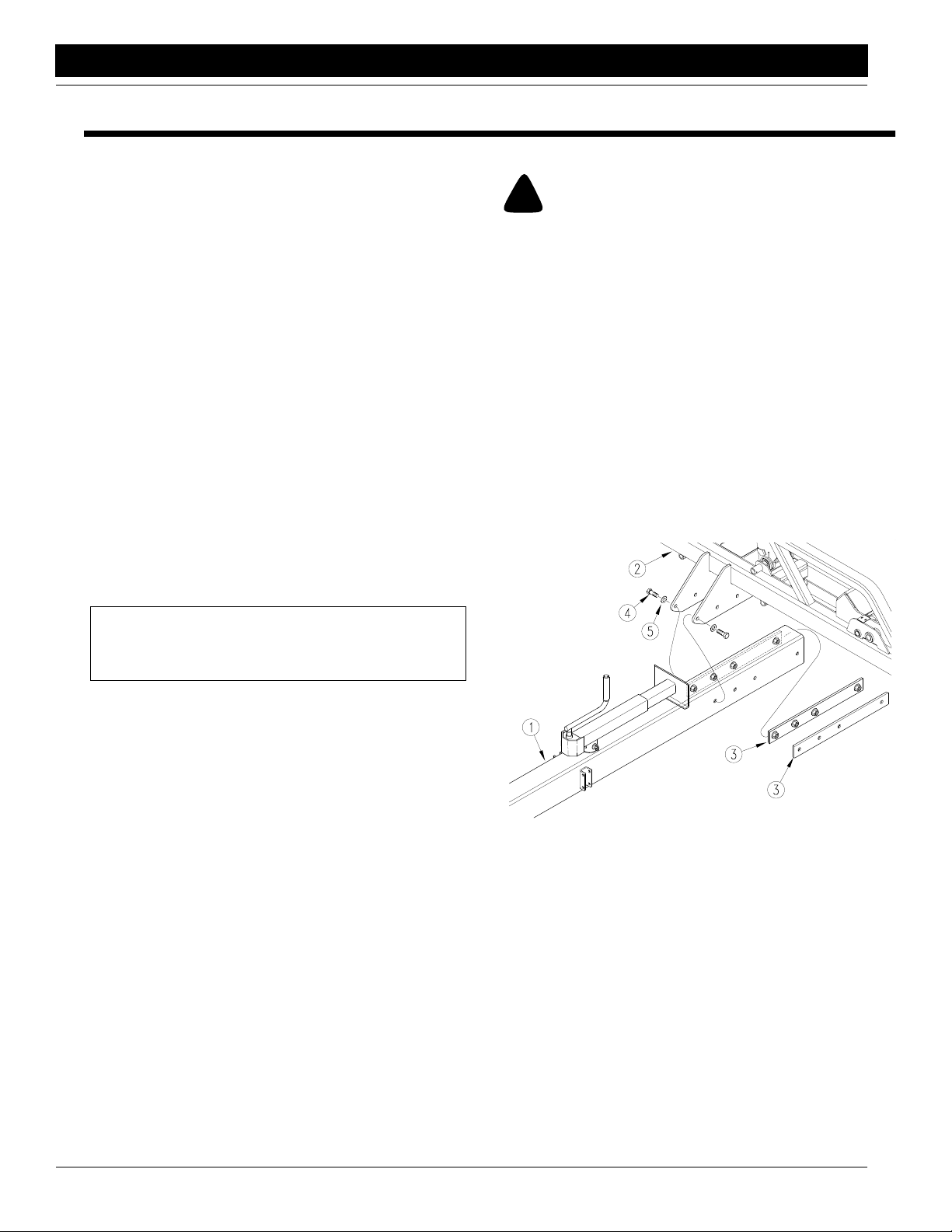

2. Refer to Figure 1-1. Attach tongue assembly (1) to

frame assembly (2) by installing nut str aps (3) with 1by-2 1/2-inch hex bolts (4) and USS flat washers (5).

Install front bolts first. T orque bolts as listed on Torque

V alues Chart, “Appendix,”

page 11.

IMPORTANT: If a pre-assembled part or fastener is

temporarily removed, remember where it goes. Keep

the parts separated.

6. Have a cop y of the parts manual on hand. If unsure of

proper placement or use of any part or fastener, ref er

to the parts manual.

7. Check that all working parts are moving freely, bolts

are tight, and cotter pins are spread.

8. Check for proper tension and alignment on all drive

chains.

9. Check that all safety labels and reflectors are correctly

located and legible. Replace if improperly located or

damaged. Refer to Safety Labels , “Important Safety

Information” in the operator’ s man ual.

10. Inflate tires to recommended pressure as listed on the

Tire Inflation Chart on the “Appendix” on

Tighten wheel bolts as specified on Torque Values

Chart on the “Appendix” on

page 11.

page 11.

15898

Figure 1-1

Tongue and Frame Assembly

PT1230 Folding Pull-Type Planter 401-072M 10/14/08

2

Page 6

Great Plains Mfg., Inc.

Section 1 Assembly

3. Pull hoses and electrical wires through tongue by

pushing a wire in through the hole near the valve

mounting (see

Figure 1-2) and pulling the hoses and

selector through the tongue.

4. Refer to Figure 1-2. Attach selector valv e (1) to mounting bracket on tongue with 5/16-b y-3/4-inch hex flange

cap screws (2).

15899

Figure 1-2

Selector Valve Mounting

5. Hitch tractor to planter. Refer to Hitching Planter to

Tractor, “Setup,”

page 9.

6. Connect hydraulic hoses. See Hydraulic Hose Hook-

up, “Setup,” page 9.

7. Remove the seed and chemical hoppers on rows f our

and nine to prevent damage to hoppers .

8. Unfold the planter as explained in the oper ator’ s manual. Be certain wing arms are locked and cylinder

stops are installed.

9. Install slow-moving vehicle sign as sho wn in Figure 1-

3. Bolt sign (1) to bracket (2) and slide bracket into

keeper on frame (3).

Row Unit Assembly

Refer to Figure 1-4.

1. Disassemble row-unit springs (1) from mounting shaft

(2) by removing cotter pins and washers.

2. Hook springs into row-unit mount (3).

3. T urn ey e-bolts (4) so they are just below the mounting

shaft (2), then turn eye-bolts back just enough so you

can assemble eye-bolts on mounting shaft (2).

4. Secure springs to mounting shaft using washers and

cotter pins

.

16878

Figure 1-3

Slow Moving Vehicle Sign Installation

10/14/08

17790

Figure 1-4

Row Unit Assembly

Marker Installation

Before assembling markers , hitch the planter to the tractor

and hookup the planter hydraulic hoses. Ref er to “Setup,”

page 9 and “Planter Operation” in the operator’s man ual.

Have ample space to assemble and install mark ers. Overall width with the markers unfolded is 60 feet.

PT1230 Folding Pull-Type Planter 401-072M

3

Page 7

Section 1 Assembly

Great Plains Mfg., Inc.

Refer to Figure 1-5.

1. Lower planter into planting position.

2. Attach first-stage arm (1) to marker mount (2) using

the 1-by-9-inch pin (3) and roll pin.

3. Move h ydraulic selector valve to field position and extend marker cylinder 6 inches.

4. Attach marker cylinder (4) to first-stage arm using a

cylinder pivot pin (5) and cotter pin.

Refer to Figure 1-7.

8. Assemble the third stage arm (1) to the second stage

pivot (2) using a 1-by-9-inch pin (3) and roll pin (4). As

semble marker so shear protection (5) faces the direction of marker travel

Third Stage Arm to Second Stage Arm

.

15902

Figure 1-7

-

15900

Figure 1-5

First Stage Arm to Marker Mount

5. Start tractor and fully extend cylinder. Shut off tractor.

Refer to Figure 1-6.

6. Connect second stage arm (1) to first stage arm (2)

with a 1-by-9-inch pin (3) and roll pin (4).

7. Attach the transfer link (5) to the second-stage arm

using a pivot pin (6) and cotter pin (7).

Refer to Figure 1-8.

9. Attach the link control (1) to the first-stage arm (2) using 1/2-by-1 1/2-inch carriage bolts (3), 13/16-inch

bushings (4) and flange lock nuts (5). Attach the link

control to the second-stage arm (6) with a 1/2-by-2inch bolt (7), 13/16-inch bushing and flange lock nut

(5).

10. Attach the other end of the link control to the thirdstage arm (8) using a 1/2-by-2 1/4-inch bolt (9), a

13/16-inch bushing and flange lock nut.

15901

Figure 1-6

Second Stage Arm to First Stage Arm

PT1230 Folding Pull-Type Planter 401-072M 10/14/08

4

15904

Figure 1-8

Link Control Assembly

Page 8

Great Plains Mfg., Inc.

Section 1 Assembly

11. Mount marker gauge wheel on second-stage arm

near the joint with the third-stage arm. U-bolt the

wheel to the front marker tube as shown.

IMPORTANT: Mount the marker gauge wheel so it is

square with the ground–not square with the marker

tube.

!

DANGER!

Never allow anyone near the planter when cycling the markers.

Excessive travel speed of the markers can be danger ous and/or

damage the marker assembly.The flow controls should be prop

erly adjusted before the marker assembly is first put into use.

Refer to Figure 1-11.

16. Adjust marker speed. The markers have needle

valves in the body of the sequence v alves to control

how fast each marker operates . There are two adjust

ment heads–one for controlling marker speed up and

one for controlling marker speed down.

With oil warm and the tractor engine at an operating

speed, adjust the needle valve to limit the marker to a

safe operating speed. T o adjust, loosen jam n ut, screw

the needle valve cloc kwise to a low setting. Excessive

folding speeds can cause marker damage.

-

-

Figure 1-9

Mount Marker Gauge Wheel

12. Lubricate all grease points.

13. Adjust width marker. Measure 30 f eet from the center

line of the planter to the marker blade.

14. Slowly fold markers and observe the link control (1).

When properly adjusted, the link will have the angle

shown in

link is improperly adjusted, the third-stage arm will not

rest on the marker stop or the folded markers will not

clear each other when the planter is folded.

15. If necessary, adjust the link. To adjust, remo ve the

connecting pin (see

bolt to shorten or lengthen the link.

Figure 1-10. The link should not sag. If the

1

Figure 1-10

Link Control Properly Adjusted

Figure 1-8, 9) and turn the eye

16879

15780

Figure 1-11

Flow Control Raise and Lower

IMPORT ANT : JIC fittings do not require high torque.

JIC and O-Ring fittings do not require sealant. To

avoid possible danger of cracking hydraulic fittings

from over tightening, do not use plastic sealant

tape.

17. Fold the marker up and down a f ew times and recheck

for pinching and kinking of hoses.

U-Joint Assembly

Connect drive shaft by removing keeper pin on one end of

the drive shaft. Slide drive shaft together and reinstall

keeper pin.

Point Row Clutch

Refer to operator’ s manual to install the control bo x for the

point row clutches.

15029

10/14/08

PT1230 Folding Pull-Type Planter 401-072M

5

Page 9

Section 1 Assembly

Great Plains Mfg., Inc.

Liquid Fertilizer Assembly

!

WARNING!

The fertilizer-tank weldment weighs more than 300 pounds and

could cause serious injury if it falls. Make sure the weldment is

securely attached to an adequate lifting device. Keep people

away while the weldment is being lifted. Do not place any body

parts under the weldment at any time.

1. Unstrap the fertilizer bars (1) from the fertilizer-tank

weldment (2).

16774

Figure 1-12

Remove Fertilizer Bars

2. Install fertilizer-tank weldment (1). Use forklift or other

mechanical lifting device to position the weldment

over the planter tongue. Use 5/8-b y-1 3/4-inch bolts ,

flat washers and flange nuts to bolt the weldment on

the frame tube (2) and tongue (3).

3. Install coulter bars (1) on the wing sections. Bolt the

extension brack ets (2) to the front fr ame tube using

5/8-by-7 1/32-inch u-bolts (3) and flange nuts (4). Bolt

the coulter bars to the extension brack ets using 5/8by-4 1/32-inch u-bolts (5) and flange nuts (4).

15908

Figure 1-14

Install Fertilizer Bars

4. Mount coulters on coulter bar. Ref er to your coulter

manual for specific instructions to achiev e your tillage

and fertilizer-application objectives.

5. Mount the left-hand squeeze pump (1) on the lefthand wing section. Mount the pump on the rear frame

tube just inside of the contact-drive tower (2). Mount

the pump ahead of the row unit (3) as shown in illus

tration. Use two 5/8-by-7 1/32-inch u-bolts and flange

nuts to secure pump.

6. Couple transmission shaft (4) to contact-drive shaft

with coupler sleeve (5). Secure slee ve to transmission

shaft with cotter key.

7. Repeat steps for the right-hand pump on the righthand wing section.

-

16771

Figure 1-13

Install Fertilizer Tank Weldment

PT1230 Folding Pull-Type Planter 401-072M 10/14/08

6

16770

Figure 1-15

Install Squeeze Pumps

Page 10

Great Plains Mfg., Inc.

Section 1 Assembly

8. Mount tanks. Unstrap the tanks from the shipping pallet. Use two people to position each tank (1) on the

weldment (2). Position each tank so the dr ain plug (3)

is toward the inside. Strap tanks to weldment using

tank straps (4) and 1/2-by-4-inch bolts (5).

16772

Figure 1-16

Install Tanks

9. Plumb tanks. Assemble fittings as shown in Figure 1-

17.

From the roll of 1 1/2-inch hose, cut hoses to connect

fittings. As a guide, use the approximate hose lengths

(in inches) on the illustration. Hose lengths will vary

from unit to unit.

Route hoses through holders (1) on fertilizer tank

weldment. Use worm clamps to secure hoses on fit

tings.

1

1

16898

Figure 1-18

Tanks Plumbed

10. Plumb squeeze pumps.

a. From the roll of 1-inch hose cut two hoses that are

each about 13 feet 6 inches long. Check the dis

tance between the T-fitting (1) and squeeze

pumps on your planter before cutting hose.

b. Route hoses over planter frame as shown in illus -

tration. Route hoses through wing housings (2)

when planter is folded.

c. Use hose clamps (3) to secure fertilizer hoses to

the planter frame in six location–four on the center

section and one on each wing. Use hose ties to

bundle the hoses together and to the planter

frame. Assemble clamps as shown in insert.

-

-

10/14/08

79 1/2

15

15

Figure 1-17

Plumb Tanks

58

16777

16897

Figure 1-19

T-Fitting to Squeeze Pump

PT1230 Folding Pull-Type Planter 401-072M

7

Page 11

Section 1 Assembly

d. Use worm clamps to secure hose to the squeeze

pump inlet (1) and T-fitting.

1

16894

Figure 1-20

Squeeze Pumps Plumped

11. Plumb coulters. F rom the roll of 3/8-inch hose cut hoses to connect squeeze pumps and coulters. Hose

lengths will vary with coulter positioning. Use hose

ties (1) to secure hoses to coulter arms.

Great Plains Mfg., Inc.

1

1

Figure 1-21

Plumb Coulters

1

12. Use worm clamps to secure 3/8-inch hoses to

squeeze-pump outlets. Use hose ties to secure hoses

to planter frame. Make sure hoses will not be pinched

or snagged during planter operation.

16890

PT1230 Folding Pull-Type Planter 401-072M 10/14/08

8

Page 12

Great Plains Mfg., Inc.

Section 2 Setup

Hitching the Planter to Tractor

!

DANGER!

Y ou may be se ver ely injur ed or killed by being crushed between

the tractor and planter. Do not stand or place any part of your

body between planter and moving tractor. Stop tractor engine

and set park brake before installing pins.

When hitching to the tractor, use the jac k as shown in Figure 2-1 to raise and lower the planter.

When hitching the planter to the tractor, alw ays secure the

safety chain to an anchor on the tractor capable of pulling

the planter.

15817

Figure 2-1

Jack Stand in Parking Position

After hitching the planter and tractor, store the jac k on the

stob on top the tongue as shown in

Figure 2-2.

15818

Figure 2-2

Jack in Storage Position

Hydraulic Hose Hookup

Great Plains hydraulic hoses are color coded to help you

hookup hoses to your tractor outlets. Hoses that go to the

same remote valve are marked with the same color.

Color Hydraulic Function

White Fold/Marker Cylinders

Blue Lift Cylinders

T o distinguish hoses on the same h ydraulic circuit, ref er to

plastic hose holder. See

cylinder symbol feeds cylinder base ends and raises the

planter. Hose under retracted-cylinder symbol f eeds cylin

der rod ends and lowers planter .

Figure 2-3. Hose under extended-

-

10/14/08

17641

Figure 2-3

Hydraulic Hose Label

PT1230 Folding Pull-Type Planter 401-072M

9

Page 13

Row Unit Setup and Adjustment

The meter clutch and meter-input shaft must be aligned.

Misalignment will cause meter malfunction and excessive

meter-housing wear. Periodically check vertical and hori

zontal alignment of meter clutch and meter-input shaft.

Refer to Figure 2-4.

1. Latch hopper onto hopper support.

2. Check that roll pin (1) in end of the meter-input shaft is

centered. When centered, equal amounts of the roll

pin will protrude from both sides of the shaft.

3. Rotate meter-input shaft so that roll pin is vertical.

4. Rotate the drive coupler (2) on meter clutch so that the

slots are vertical.

5. Release meter clutch to engage meter-input shaft.

6. If shafts are aligned vertically , the drive coupler will en-

gage with meter-input shaft freely and the roll pin will

extend equally on each side of the drive coupler. Dis

engage the clutch and repeat steps, checking for horizontal alignment.

Great Plains Mfg., Inc.

-

-

17891

Figure 2-4

Vertical Alignment

7. If drive coupler does not freely engage meter-input

shaft vertically or horizontally, loosen 5/16-inch nuts

(3) shown in

Figure 2-4. Engage meter clutch. Align

meter clutch with meter-input shaft.

8. Tighten 5/16-inch nuts to torque values listed on

Torque Values Chart, “Appendix,”

PT1230 Folding Pull-Type Planter 401-072M 10/14/08

10

page 11.

Page 14

Great Plains Mfg., Inc.

Appendix

Appendix

Torque Values Chart for Common Bolt Sizes

Bolt Head Identification

Bolt Size

(Inches)

1

in-tpi

1/4" - 20 7.4 5.6 11 8 16 12 M 5 X 0.8 4 3 6 5 9 7

1/4" - 28 8.5 6 13 10 18 14 M 6 X 1 7 5 11 8 15 11

5/16 - 18 15 11 24 17 33 25 M 8 X 1.25 17 12 26 19 36 27

5/16" - 24 17 13 26 19 37 27 M 8 X 1 18 13 28 21 39 29

3/8" - 16 27 20 42 31 59 44 M10 X 1.5 33 24 52 39 72 53

3/8" - 24 31 22 47 35 67 49 M10 X 0.75 39 29 61 45 85 62

7/16" - 14 43 32 67 49 95 70 M12 X 1.75 58 42 91 67 125 93

7/16" - 20 49 36 75 55 105 78 M12 X 1.5 60 44 95 70 130 97

1/2" - 13 66 49 105 76 145 105 M12 X 1 90 66 105 77 145 105

1/2" - 20 75 55 115 85 165 120 M14 X 2 92 68 145 105 200 150

9/16" - 12 95 70 150 110 210 155 M14 X 1.5 99 73 155 115 215 160

9/16" - 18 105 79 165 120 235 170 M16 X 2 145 105 225 165 315 230

5/8" - 11 130 97 205 150 285 210 M16 X 1.5 155 115 240 180 335 245

5/8" - 18 150 110 230 170 325 240 M18 X 2.5 195 145 310 230 405 300

3/4" - 10 235 170 360 265 510 375 M18 X 1.5 220 165 350 260 485 355

3/4" - 16 260 190 405 295 570 420 M20 X 2.5 280 205 440 325 610 450

7/8" - 9 225 165 585 430 820 605 M20 X 1.5 310 230 650 480 900 665

7/8" - 14 250 185 640 475 905 670 M24 X 3 480 355 760 560 1050 780

1" - 8 340 250 875 645 1230 910 M24 X 2 525 390 830 610 1150 845

1" - 12 370 275 955 705 1350 995 M30 X 3.5 960 705 1510 1120 2100 1550

1-1/8" - 7 480 355 1080 795 1750 1290 M30 X 2 1060 785 1680 1240 2320 1710

1 1/8" - 12 540 395 1210 890 1960 1440 M36 X 3.5 1730 1270 2650 1950 3660 2700

1 1/4" - 7 680 500 1520 1120 2460 1820 M36 X 2 1880 1380 2960 2190 4100 3220

1 1/4" - 12 750 555 1680 1240 2730 2010

1 3/8" - 6 890 655 1990 1470 3230 2380

1 3/8" - 12 1010 745 2270 1670 3680 2710

1 1/2" - 6 1180 870 2640 1950 4290 3160

1 1/2" - 12 1330 980 2970 2190 4820 3560

Torque tolerance + 0%, -15% of torquing values. Unless otherwise specified use torque values listed above.

Grade 2 Grade 5

N · m2ft-lb3N · m ft-lb N · m ft-lb mm x pitch

Grade 8

Bolt Size

(Metric)

4

N · m ft-lb N · m ft-lb N · m ft-lb

1

in-tpi = nominal thread dia.in inches-threads per inch

2

N· m = newton-meters

3

ft-lb= foot pounds

4

mm x pitch = nominal thread dia. in millimeters x thread pitch

Bolt Head Identification

5.8 8.8 10.9

Class 5.8 Class 8.8 Class 10.9

Tire Inflation Chart

Tire Size Inflation PSI Tire Size Inflation PSI

7.50 x 20" 4-Ply Rib 28 11L x 15" 6-Ply Rib Implement 28

9.0 x 22.5 10-Ply Highway Service 70 70 11L x 15" 12-Ply Rib Implement 52

9.0 x 24" 8-Ply Rib Implement 40 12.5L x 15" 8-Ply Rib Implement 36

9.5L x 15" 6-Ply Rib Implement 32 12.5L x 15" 10-Ply Rib Implement 44

9.5L x 15" 8-Ply Rib Implement 44 16.5L x 16.1" 10-Ply Rib Implement 36

9.5L x 15" 12-Ply Rib Implement 60 21.5 x 16.1” SC 10-Ply Rib Implement 28

10/14/08

PT1230 Folding Pull-Type Planter 401-072M

11

Page 15

Great Plains Manufacturing, Inc.

Corporate Office: PO. Box 5060

Salina, Kansas 67402-5060 USA

Loading...

Loading...