Press Wheel Mount Update Kit

25 and 25AP Series Implements

General Information

These instructions explain how to install a Press Wheel

Mount Update Kit. One kit updates one opener.

These instructions apply to an installation of:

Kit Kit Description

199-146A 25P LONG PW MOUNT KIT

199-147A 25P MID PW MOUNT KIT

Related Documents

Also available as a reference see the Parts Manual for

the particular implement being updated.

118-231P 2025 & 2525P (2007+)

118-232P 2025F & 2525F 3PT

118-949P 1525P

118-999P 2025A & 2525A

196-286P 3N-4025P

401-226P YP1225/1625

401-312P 3PYP

401-406P YP2425

401-571P YP40

401-625P YP1225A/1625A

401-626P YP2425A

401-627P YP4025A

401-651P YP425A/625A/825A

401-652P YP425A/625A/825A 3PT

401-647P 3PYPA

Part Lists Great Plains Manufacturing, Inc. 1

When you see this symbol, the subsequent instructions

and warnings are serious - follow without exception.

Your life and the lives of others depend on it!

U

F

L

R

B

D

Figure 1

Press Wheel Mount Kit

31489

Notations and Conventions

U

F

L

D

Call-Outs

1 9

to

11

to

51 64

to

© Copyright 2010 Printed 08/19/2010 Part Lists 199-146M

Single-digit callouts identify components in

the currently referenced Figure. These numbers may be reused for different items from

page to page.

22

Two-digit callouts in the range 11 to 22 reference new parts from the list on page 5.

Two-digit callouts in the range 51 to 64 reference existing parts from the list on page 5.

“Left” and “Right” are facing in the

direction of machine travel. An orienta-

R

tion rose in the line art illustrations

shows the directions of Left, Right,

Front, Back, Up, Down.

B

2 Great Plains Manufacturing, Inc. Front Page Part Lists Press Wheel Mount Update

Pre-Assembly Preparation

Tools Required

• suitable tractor for raising implement

• basic hand tools

• dead blow hammer or press

Work Location

1. Move the implement to a location with:

• flat, smooth surface

• adequate illumination

• clear surface beneath for recovery of any falling or

dropped parts

Prepare Implement

2. Raise implement with tractor.

3. Secure for safety.

Crushing and Sharp Object Hazards:

Be careful working near openers. Discs and other parts may

be sharp.

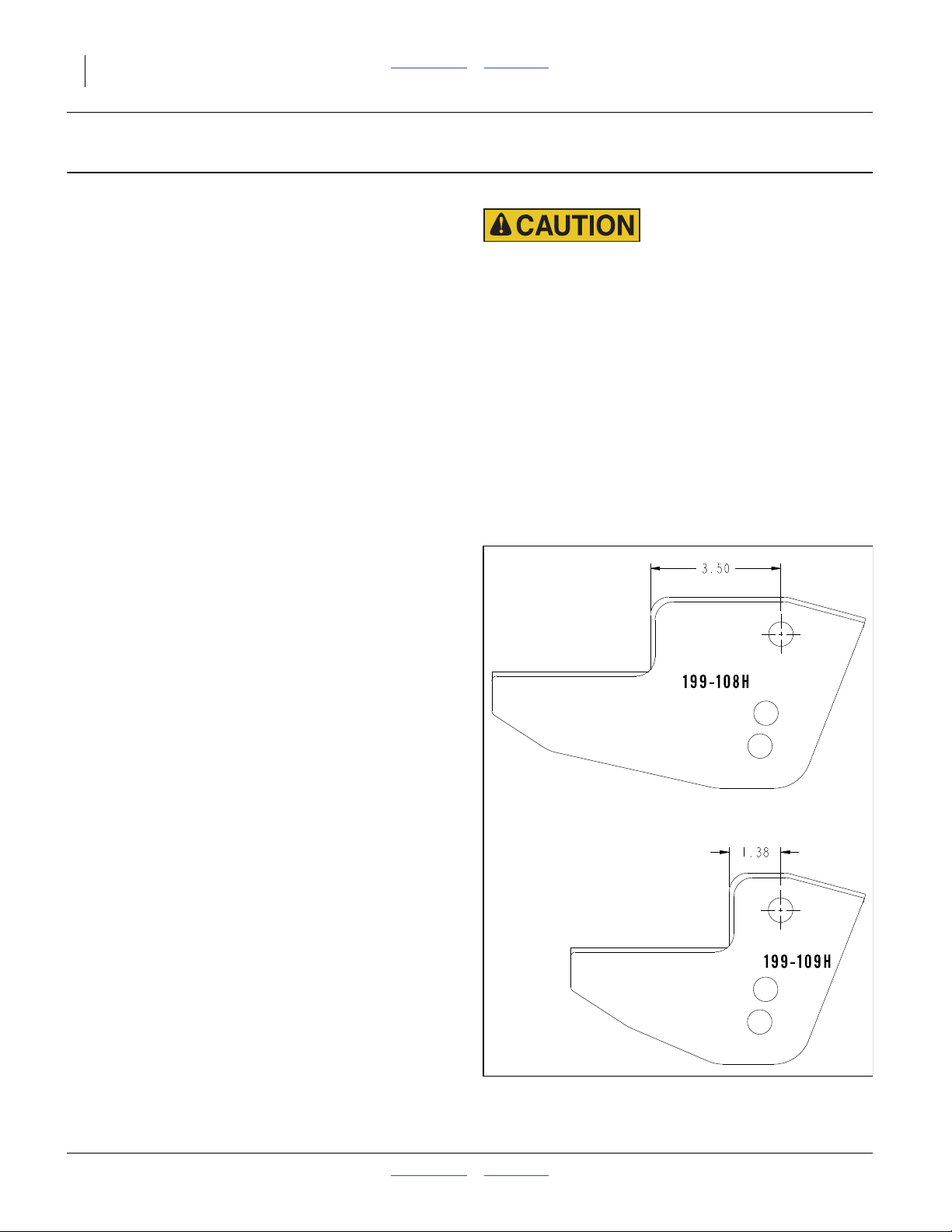

How to Identify Mount Length

To avoid confusion, if implement uses a combination of

both long and short press wheel mounts it may be easier

to remove and replace all the longs then all the shorts or

change out one complete arm at a time.

199-108H 25P LONG PW MOUNT

199-109H 25P MID PW MOUNT

Figure 2

Press Wheel Mount Lengths

199-146M Front Page Part Lists 08/19/2010

31507

Remove Old PW Mount Front Page Part Lists Great Plains Manufacturing, Inc. 3

Remove Old PW Mount

Refer to Figure 3

With openers slightly off ground spring tension is

released.

4. To detach press wheel assembly from opener

2

body remove two vertical bolts, washers, and nuts

from underside of press wheel mount:

56

802-091C HHCS 1/2-13X1 1/2 GR5

57

802-258C HHCS 1/2-13X1 GR5

61

804-015C WASHER LOCK SPRING 1/2 PLT

55

405-032D 1X12 PW ADJUSTER

64

51

2

52

63

53

58

54

Save hardware for reuse.

5. Detach old press wheel mount and/or from

press wheel arm by removing bolt, bushings, pin

clevis and other hardware.

58

802-616C HHCS 3/8-16X5 1/2 GR5

60

804-011C WASHER FLAT 3/8 USS PLT

59

803-209C NUT FLANGE LOCK 3/8-16 PLT

51

199-106D PW ANCHOR MOUNT TUBE

54

199-113D SPRING ALIGNMENT BUSHING

63

805-417C PIN CLEVIS 5/8 X 3 49/64 USBL

62

805-109C PIN COTTER 1/8 X 1 1/4 PLT

64

817-083C PW ARM PIVOT BUSHING

This hardware is not reused

6. Discard press wheel mount (it will not be reused):

Note: The opener assemblies can have all long or all

short mounts or a combination of the two.

52

199-108H 25P LONG PW MOUNT

53

199-109H 25P MID PW MOUNT

1

52 53

55

61

56

62

61

57

Figure 3

Remove PW Mount

59

60

60

1

31490

08/19/2010 Front Page Part Lists 199-146M

4 Great Plains Manufacturing, Inc. Front Page Part Lists Press Wheel Mount Update

Install New PW Mount

Refer to Figure 4

7. With press or dead blow hammer insert one bushing

12

16

2

13

14

17

Figure 4

21

18

22

20

15

18

16

3

17

1

31494

22 3 1

in hole on each side of the press wheel arm .

Install one pivot spacer into each bushing.

22

890-598C BUSHING 3/4OD X 5/8ID X 1/2

21

890-524C 20 SER PW ARM PIVOT SPACER

8. Select one new press wheel mount or :

Note: The press wheel assemblies can have either

all long or all short mounts or a combination of the

two.

13

199-148H 25P LONG PW MOUNT UPDATE

14

199-149H 25P MID PW MOUNT UPDATE

9. Slide new press wheel mount or into press

wheel arm . Insert 2 new carriage bolts in press

wheel mount (make sure head is on inside of pw

mount with end facing to the outside).

15

802-030C RHSNB 7/16-14X1 3/4 GR5

Select one each and install on end of each bolt:

18

804-041C WASHER FLAT 7/16 SAE PLT

17

804-014C WASHER LOCK 7/16 PLT

16

803-229C NUT HEX FLANGE LOC 7/16-14

10. Attach the spring on the underside of the press

wheel arm and insert top ring of spring between

the 2 spring alignment bushings .

115

1

21

13 14

13 14

12

22

21

55

61

19

56

57

Install New PW Mount Kit

Attach the spring to the lower holes of the mount

with the clevis pin and spacer bushings .

Secure with cotter pin .

12

199-113D SPRING ALIGNMENT BUSHING

20

805-417C PIN CLEVIS 5/8 X 3 49/64 USBL

19

805-109C PIN COTTER 1/8 X 1 1/4 PLT

11. Reinstall press wheel assembly to opener body

reusing hardware from prior disassembling.

56

802-091C HHCS 1/2-13X1 1/2 GR5

57

802-258C HHCS 1/2-13X1 GR5

61

804-015C WASHER LOCK SPRING 1/2 PLT

55

405-032D 1X12 PW ADJUSTER

20 12

19

13

2

199-146M Front Page Part Lists 08/19/2010

Appendix Front Page Part Lists Great Plains Manufacturing, Inc. 5

Appendix

Part Lists

New Parts

The part call-out numbers in this list match all Figures in

these installation instructions. Part descriptions match

those in your updated Parts Manual.

Quantities are units (“ea”).

Kit Contents

199-146A 25P LONG PW MOUNT KIT

199-147A 25P MID PW MOUNT KIT

Quantity in Kit:

Callout 199-146A 199-147A Part Number Part Description

11 1 1 199-146M MANUAL PW MOUNT KIT UPDATE

12 2 2 199-113D SPRING ALIGNMENT BUSHING

13 1 0 199-148H 25P LONG PW MOUNT UPDATE

14 0 1 199-149H 25P MID PW MOUNT UPDATE

15 2 2 802-030C RHSNB 7/16-14X1 3/4 GR5

16 2 2 803-229C NUT HEX FLANGE LOC 7/16-14

17 2 2 804-014C WASHER LOCK 7/16 PLT

18 2 2 804-041C WASHER FLAT 7/16 SAE PLT

19 1 1 805-067C PIN COTTER 1/8 X 3/4

20 1 1 805-417C PIN CLEVIS 5/8 X 3 49/64 US

21 2 2 890-524C 20 SER PW ARM PIVOT SPACER

22 2 2 890-598C BUSHING 3/4OD X 5/8ID X 1/2

Existing Parts Affected

The following existing parts are involved in the kit installation. The Disposition column indicates whether the part

is left in place, moved or not re-used.

The part call-out numbers in the list matches all Figures

in the installation instructions. The descriptions match

those in your implement Parts manual.

Callout Part No. Part Description Part Disposition

51 199-106D PW ANCHOR MOUNT TUBE Removed. Not reused.

52 199-108H 25P LONG PW MOUNT Removed. Not reused.

53 199-109H 25P MID PW MOUNT Removed. Not reused.

54 199-113D SPRING ALIGNMENT BUSHING Remove. Not reused.

55 405-032D 1X12 PW ADJUSTER Removed and re-installed.

56 802-091C HHCS 1/2-13X1 1/2 GR5 Removed and re-installed.

57 802-258C HHCS 1/2-13X1 GR5 Removed and re-installed.

58 802-616C HHCS 3/8-16X5 1/2 GR5 Removed. Not reused.

59 803-209C NUT FLANGE LOCK 3/8-16 PLT Removed. Not reused.

60 804-011C WASHER FLAT 3/8 USS PLT Removed. Not reused.

61 804-015C WASHER LOCK SPRING 1/2 PLT Removed and re-installed.

62 805-109C PIN COTTER 1/8 X 1 1/4 PLT Removed. Not reused.

63 805-417C PIN CLEVIS 5/8 X 3 49/64 USBL Removed. Not reused.

64 817-083C PW ARM PIVOT BUSHING Removed. Not reused.

08/19/2010 Front Page Part Lists 199-146M

6 Front Page Part Lists

Abbreviations

3PT 3 Point PW Press Wheel

A Air-Pro RHSNB Round Head Shank Neck Bolt

F Fluted SAE Society of Automotive Engineers

GR5 Grade 5 SER Series

HHCS Hex Head Cap Screw W/ With

OD Outside Diameter X By

PLT Plated

Great Plains Manufacturing, Inc.

Corporate Office P.O. Box 5060

Salina, Kansas 67402-5060 USA

199-146M Front Page Part Lists 08/19/2010

Loading...

Loading...