Page 1

Page 2

Page 3

TABLE OF CONTENTS

Safety Notices ...................................................................................................... 1

Introduction .......................................................................................................... 3

System Overview ............................................................................................................... 3

Specifications..................................................................................................................... 5

Major Features ..................................................................................................... 7

Performance ...................................................................................................................... 7

Console/Display ................................................................................................................. 7

Compatibility ...................................................................................................................... 7

User Aid ............................................................................................................................. 7

Quick Start Guide................................................................................................. 9

Planter Configuration ......................................................................................................... 9

Number of Rows ............................................................................................................................... 9

Row Spacing ................................................................................................................................... 10

Ground Speed Configuration ........................................................................................... 11

Help Card......................................................................................................................... 12

Key Functions .................................................................................................... 15

On/Off Key ....................................................................................................................... 15

Alarm Cancel Key ............................................................................................................ 15

Enter Key ......................................................................................................................... 16

Escape Key...................................................................................................................... 16

Up and Down Arrow Keys................................................................................................ 16

Left and Right Arrow Keys ............................................................................................... 16

Operate Key..................................................................................................................... 16

Planter Setup Key............................................................................................................ 16

Ground Speed Setup Key ................................................................................................ 17

Limits Setup Key.............................................................................................................. 17

Display And Service Key ................................................................................................. 17

Accessory Setup Key....................................................................................................... 17

Seed Count Mode Key..................................................................................................... 17

Speed Area Mode Key..................................................................................................... 17

Editing Screen Fields Using Keys.................................................................................... 18

Highlighted Digit for Editing............................................................................................................. 18

Installation .......................................................................................................... 19

Standard Mounting Bracket ............................................................................................. 19

Optional Mounting 3D Adjustable Bracket ....................................................................... 20

Installing Console Harnesses .......................................................................................... 21

Installing Implement Harness and Sensors ..................................................................... 22

PM300, PM332, PM400 Planter Monitors

11001-1372-200606

i

Page 4

TABLE OF CONTENTS

Advanced SetUp................................................................................................ 23

Planter and Ground Speed............................................................................................... 23

Row SetUp (Auto Assigned)............................................................................................................ 23

Ground Speed Setup....................................................................................................................... 24

Manual Ground Speed Constant Entry............................................................................................ 25

Accessory Setup (Optional)............................................................................................. 26

Limits Setup (population) (Optional) ................................................................................ 28

Target Population ............................................................................................................................ 28

HI Population/Low Population ......................................................................................................... 29

Population Adjustment..................................................................................................................... 29

Population Response Rate .............................................................................................................. 29

Units of Measurement, Backlighting and Alarm Volume Control..................................... 30

Service Screen ................................................................................................................ 30

Security Screen ............................................................................................................... 31

Auxiliary Modes................................................................................................. 33

Speed Area Mode............................................................................................................ 33

Seed Count Mode............................................................................................................ 33

Monitoring Planting........................................................................................... 35

Operate Screen Setup..................................................................................................... 35

Customizing the Upper Parameter Window .................................................................... 35

Customizing the Lower Parameter Window .................................................................... 37

Available Planting Parameters ........................................................................................ 38

Average Population ......................................................................................................................... 38

Minimum/Average/Maximum Population......................................................................................... 39

Population Row Scan ...................................................................................................................... 39

Average Spacing ............................................................................................................................. 39

Minimum/Average/Maximum Spacing............................................................................................. 39

Spacing Row Scan .......................................................................................................................... 39

Seeds per Distance ......................................................................................................................... 39

Minimum/Average/Maximum Seeds per Distance........................................................................... 39

Seeds per Distance Row Scan........................................................................................................ 39

Field Area 1 ..................................................................................................................................... 40

Field Area 2 ..................................................................................................................................... 40

Total Area ........................................................................................................................................ 40

Speed .............................................................................................................................................. 40

Area per Hour .................................................................................................................................. 40

Fan .................................................................................................................................................. 40

Shaft ................................................................................................................................................ 40

Flow ................................................................................................................................................. 40

Alarms ................................................................................................................ 41

Hopper Level ................................................................................................................... 41

Row Failure ..................................................................................................................... 41

All Rows Failure............................................................................................................... 42

Hi/Low Population Warning ............................................................................................. 43

Fan Speed Low/Hi Limit Warning .................................................................................... 43

Shaft Speed Low/Hi Limit Warning.................................................................................. 44

Flow Low/Hi Limit Warning .............................................................................................. 44

Failed Ground Speed Sensor .......................................................................................... 45

Battery Hi/Low ................................................................................................................. 45

Self-Test Failure .............................................................................................................. 46

Hi Ground Speed Exceeded (Optional) ........................................................................... 46

ii

PM300, PM332, PM400 Planter Monitors

11001-1372-200606

Page 5

TABLE OF CONTENTS

Troubleshooting................................................................................................. 47

Monitor Will Not Power On .............................................................................................. 47

Row Failure or Hi/Low Alarm When Row is Planting Properly..........................................47

Hopper Alarm Does not Sound When Hopper is Empty ...................................................48

Hopper Alarm Does Not Sound When Hopper is Full.......................................................48

System Voltage Alarm ......................................................................................................48

Accessory Alarm Sounds When Shaft, Fan or Flow is Working .......................................49

Ground Speed Alarm Sounds When Forward Movement ................................................49

Ground Speed High Alarm Sounds ..................................................................................49

Self-Test Alarm .................................................................................................................50

Connector Pin-Outs ......................................................................................................... 51

Connector Pin-Outs ......................................................................................................... 52

PM300, PM332, PM400 Planter Monitors

11001-1372-200606

iii

Page 6

TABLE OF CONTENTS

iv

PM300, PM332, PM400 Planter Monitors

11001-1372-200606

Page 7

OPERATOR’S MANUAL

SAFETY NOTICES

Safety notices are one of the primary ways to call attention to potential

hazards.

This Safety Alert Symbol identifies important safety

messages in this manual. When you see this

!

Use of the word WARNING indicates a potentially hazardous

situation which, if not avoided, could result in death or serious

injury.

symbol, carefully read the message that follows. Be

alert to the possibility of personal injury or death.

Use of the word CAUTION with the Safety Alert Symbol indicates a

potentially hazardous situation which, if not avoided, may result in

minor or moderate injury.

Use of the word CAUTION without the safety alert symbol

indicates a potentially hazardous situation which, if not avoided,

may result in equipment damage.

PM300, PM332, PM400 Planter Monitors

11001-1372-200606

SAFETY NOTICES / 1

Page 8

OPERATOR’S MANUAL

2 / SAFETY NOTICES

PM300, PM332, PM400 Planter Monitors

11001-1372-200606

Page 9

OPERATOR’S MANUAL

INTRODUCTION

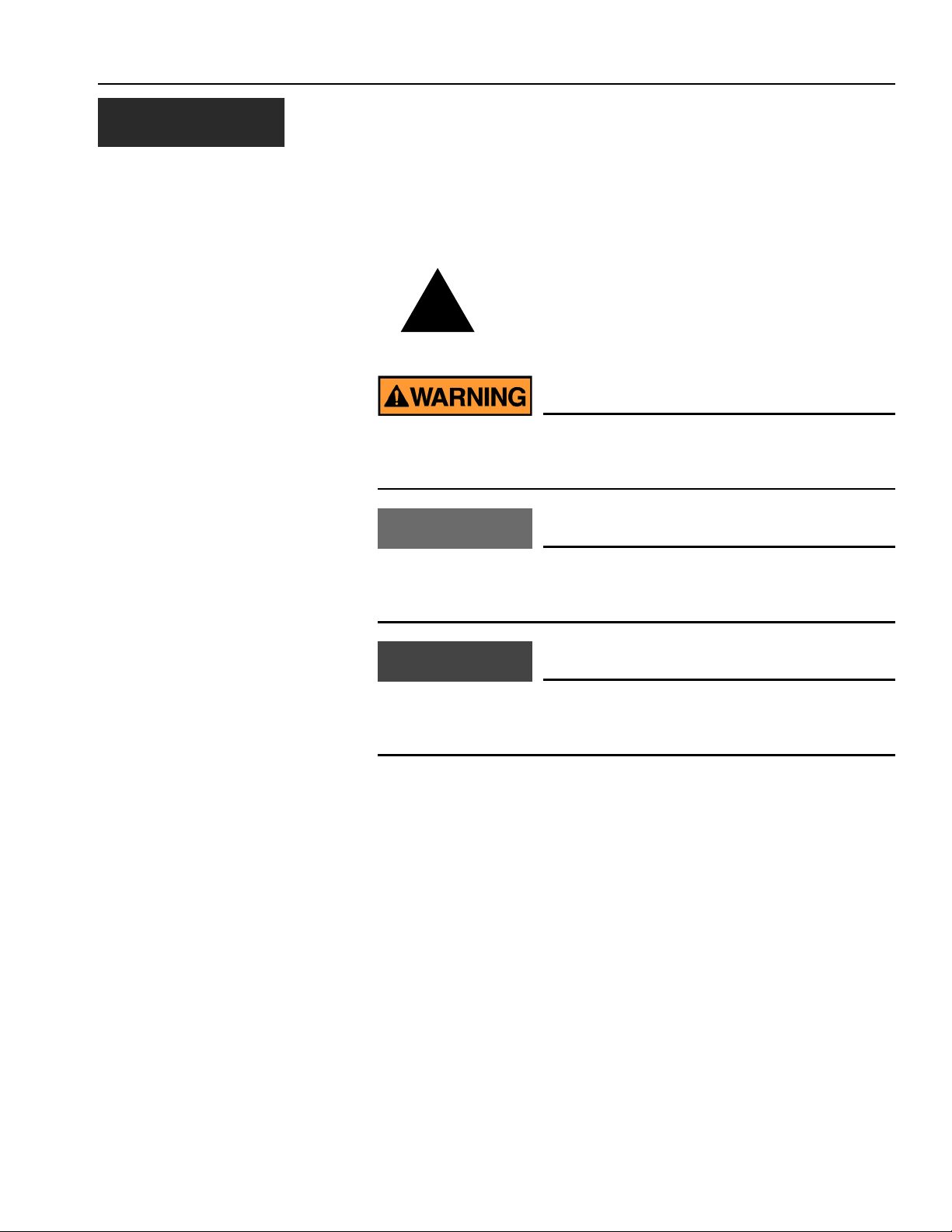

SYSTEM OVERVIEW

The DICKEY-john PM300, PM332, and PM400 Planter Monitors offer

features to monitor 16, 32, and 36 rows, respectively. The units monitor

seed or fertilizer rows, two hopper levels, and a frequency input (shaft, fan,

or flow). The monitors are compatible with DICKEY-john seed, flow, hopper

level, and gear sensors. The units store all configuration data in nonvolatile

memory, retaining information even when disconnected from power. Figure

1 provides an illustration of a generic console.

The PM300, PM332, and PM400 are designed to meet the custom needs of

individual users. The display may be configured to output a comprehensive

set of planter parameters. The user selects the type and number of

parameters to be monitored. Choices may be as simple as monitoring

population and field area or may be more complex. Similarly, blink or fail

mode information may be viewed as a bar graph, gauge, or symbol.

Information may be viewed in large format (for ease of viewing), or small

format (for entire planter view). Auto-scrolling and arrow key override are

used to maintain control of real-time information required by the user.

Figure 1

PM300, PM332, and PM400

GROUND

PLANTER

SPEED

SETUP

SETUP

ACCY

OPERATE

SETUP

LIMITS

SETUP

SEED

COUNT

MODE

DISPLAY

&

SERVICE

SPEED

AREA

MODE

ESCAPE

ENTER

PMXXX

PM300, PM332, PM400 Planter Monitors

11001-1372-200606

INTRODUCTION / 3

Page 10

OPERATOR’S MANUAL

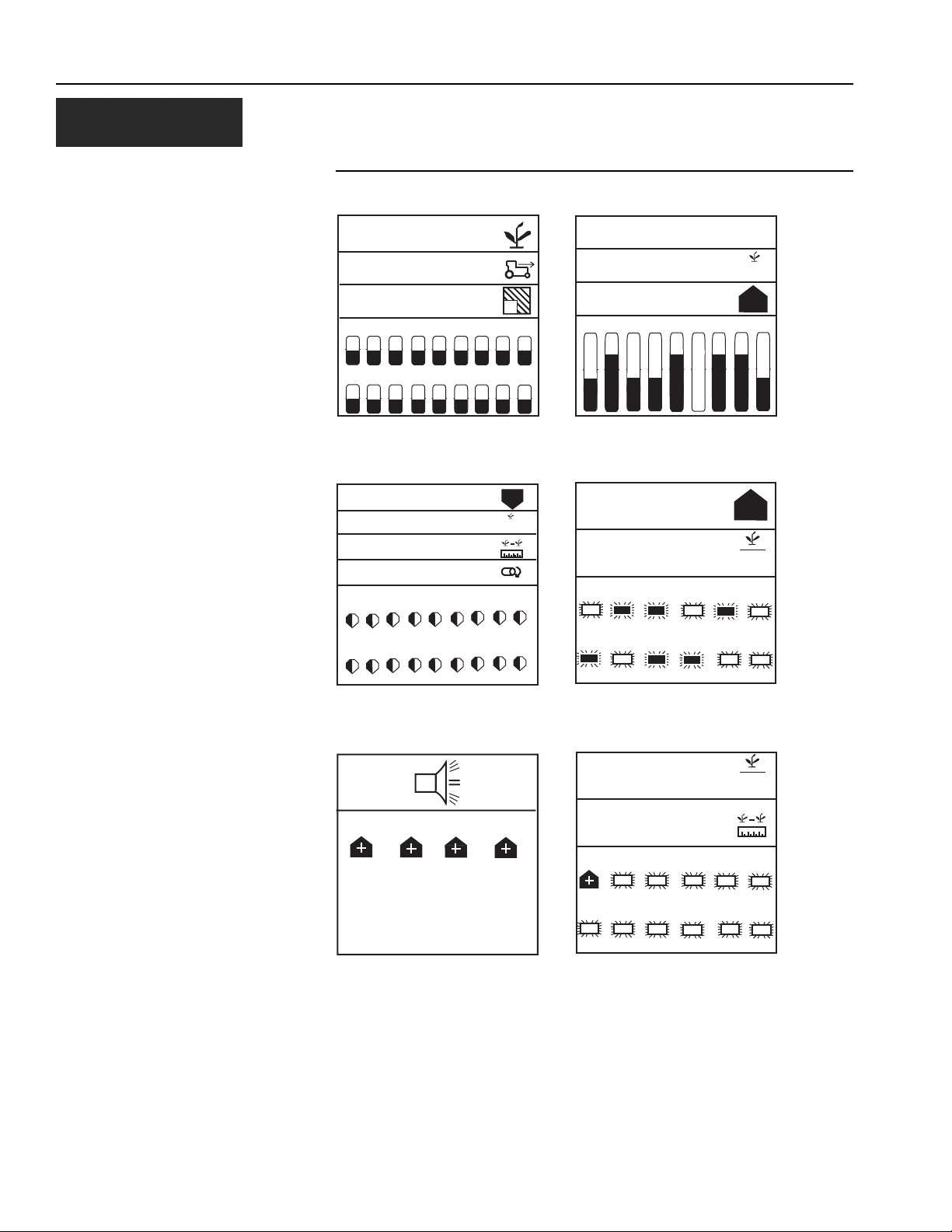

Figure 2

User-Definable Display Examples

527.3

5.2

4.5

1 2 3 4 5 6 7 8 9

10 11 12 13 14 15 16 17 18

Graphic mode: average population,

speed, and field 1 area output with bar

graphs

33.4

33.4

12.5

0.0

1 2 3 4 5 6 7 8 9

10 11 12 13 14 15 16 17 18

1

9

10

2.9

3.2

5.0

1 2 3 4 5 6 7 8 9

Text mode: average spacing, spacing

scan and min/max/avg spacing output

with bar graphs

37.2

33.5

1 2 3 4 5 6

7 8 9 10 11 12

in

6

6

10

10

Min/max/avg population, population

row scan, avg speed spacing, and shaft

speed with gauges

2 4 6 8

Rows 2, 4, 6, 8 (above limit) alarm

screen

Min/max/avg population and row scan

with blinking row symbols

33.3

2

12.5

1 2 3 4 5 6

7 8 9 10 11 12

Row scan and average spacing with

blinking symbols and row 1 hi alarm

(alarm cancel returns user to operate

screen)

4 / INTRODUCTION

PM300, PM332, PM400 Planter Monitors

11001-1372-200606

Page 11

OPERATOR’S MANUAL

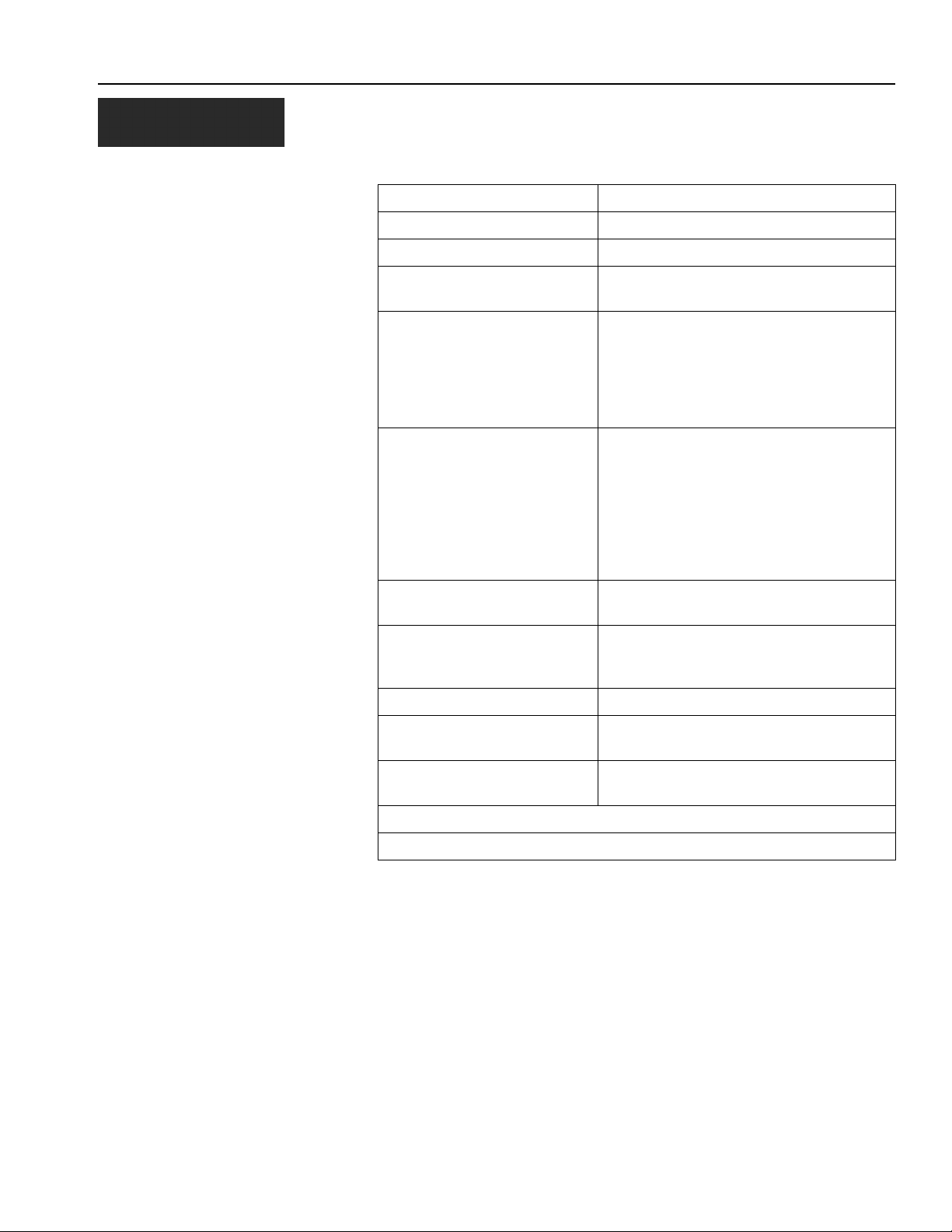

SPECIFICATIONS

Power 10–16 VDC, 5 A maximum

Operating temperature range -20°C to 70°C (-4°F to 158°F)

Storage temperature range -40°C to 85°C (-40°F to 185°F)

Size 18.4 cm W x 20.1 cm H x 4.3 cm D

(7.3" W x 7.9" H x 1.7" D)

Weight 4.4 lbs for 16-row PM300 system

4.8 lbs for 32-row PM332 system

6.4 lbs for 36-row PM400 system

*Weight includes console and attached

cables (battery power cable and signal

cable that extends to the drawbar).

Wire Harnesses The PM300, PM332, and PM400 include

integrated harnesses to supply the unit's

power (fused), ground speed input, and

sensor inputs (to drawbar). The connectors

are compatible with existing DICKEY-john

harnesses. DICKEY-john can supply

custom harnesses required for sensor

inputs.

Sensors Compatible with existing DICKEY-john

sensors

Standard mounting Rear attached horizontal or vertical

mounting bracket

Mounting bracket weighs 1.0 lb.

Optional mounting Three-axis adjustable mounting bracket

Contrast adjustment Automatic temperature compensation for

contrast

Backlight adjustment Three settings for full sun, daytime, or

nighttime use

CE certified

Dust and moisture resistant

PM300, PM332, PM400 Planter Monitors

11001-1372-200606

INTRODUCTION / 5

Page 12

OPERATOR’S MANUAL

6 / INTRODUCTION

PM300, PM332, PM400 Planter Monitors

11001-1372-200606

Page 13

OPERATOR’S MANUAL

MAJOR FEATURES

PERFORMANCE

• Planter monitoring of 16 row (PM300), 32 rows (PM332), or 36 rows

PM400

• Monitoring of ground speed, two hopper levels, one frequency function

(fan, shaft, or flow)

• Easy and flexible configuration

• User-definable view of two, three, or four functions (all are available):

– Average Population

– Average Seed Spacing

– Average Seeds Per Distance

– Population Row Scan

– Seed Spacing Row Scan

– Seed Per Distance Row Scan

– Minimum, Maximum, Average Row Population

– Minimum, Maximum, Average Row Spacing

– Minimum, Maximum, Average Spacing Per Distance

– Field Area 1

– Field Area 2

– Total Area 3

– Ground Speed

– Fan, Shaft, or Flow Frequency

• User-definable row information:

–Bar Graph

– Wiper Gauge

– Symbols (Failure mode)

– Symbols flashing proportional to seeding rates

PM300, PM332, PM400 Planter Monitors

11001-1372-200606

CONSOLE/DISPLAY

• Large, user friendly keys

• User-definable text size ease of viewing

• Graphic or text-based output labels

• Backlit graphic display for nighttime use

• Three-level backlight intensity adjustment

• Large, concise error messages displayed with audible alarm

• English or metric units

• Horizontal and vertical mounting (optional 3D adjustment bracket)

COMPATIBILITY

• Compatible with DICKEY-john sensors

• Plug-in replacement for other DICKEY-john monitors

• Optional support of RS-232 based data logging

USER AID

•Help card

MAJOR FEATURES / 7

Page 14

OPERATOR’S MANUAL

8 / MAJOR FEATURES

PM300, PM332, PM400 Planter Monitors

11001-1372-200606

Page 15

OPERATOR’S MANUAL

PLANTER

SETUP

QUICK START GUIDE

Three inputs are required for monitor operation.

• Number of rows

• Row spacing

• Ground speed constant

Selecting a pre-programmed planter configuration provides easy set-up of

planter row width, number of rows, implement width, and row types.

PLANTER CONFIGURATION

Planter Setup key

To program the planter configuration, select the Planter Setup key. The

Planter Configuration screen will be displayed.

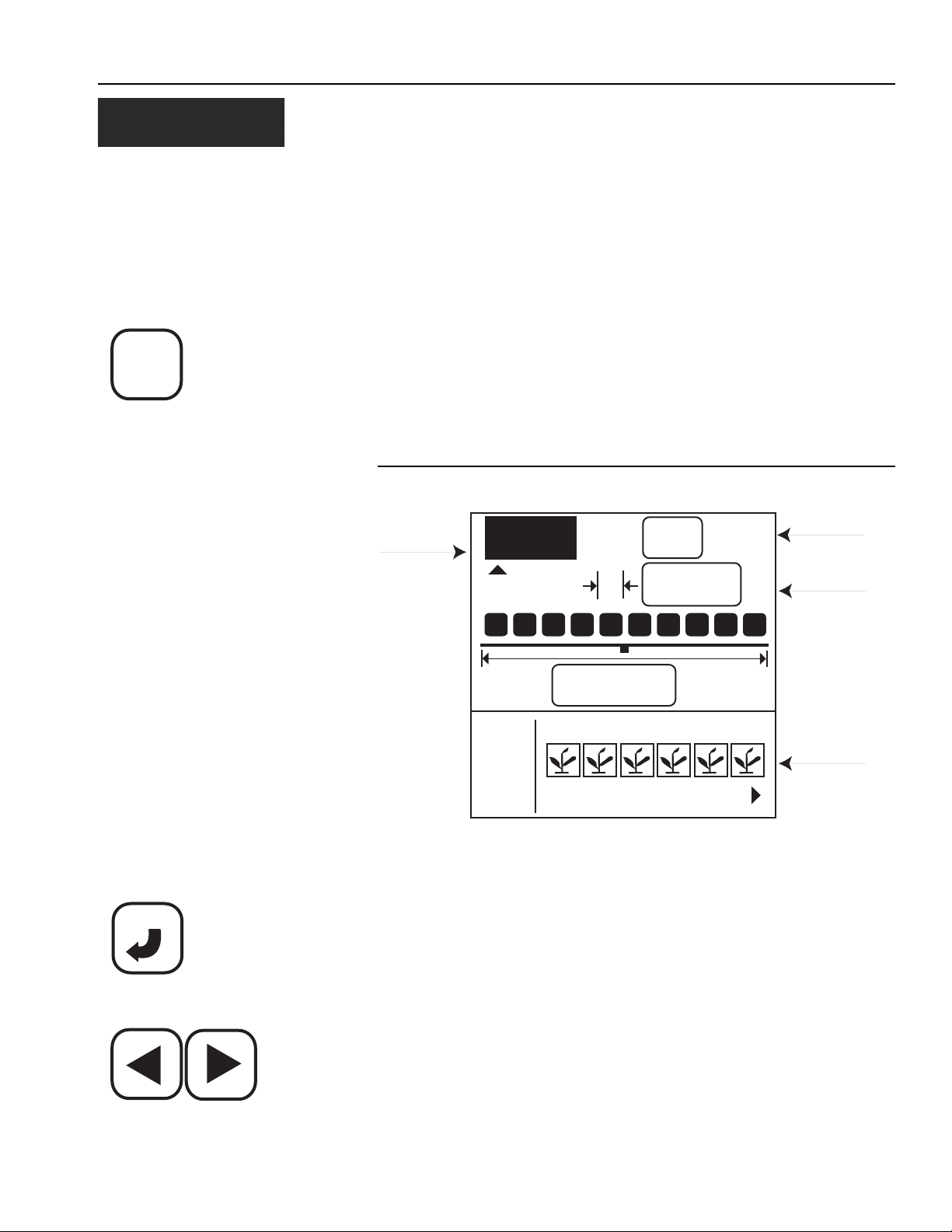

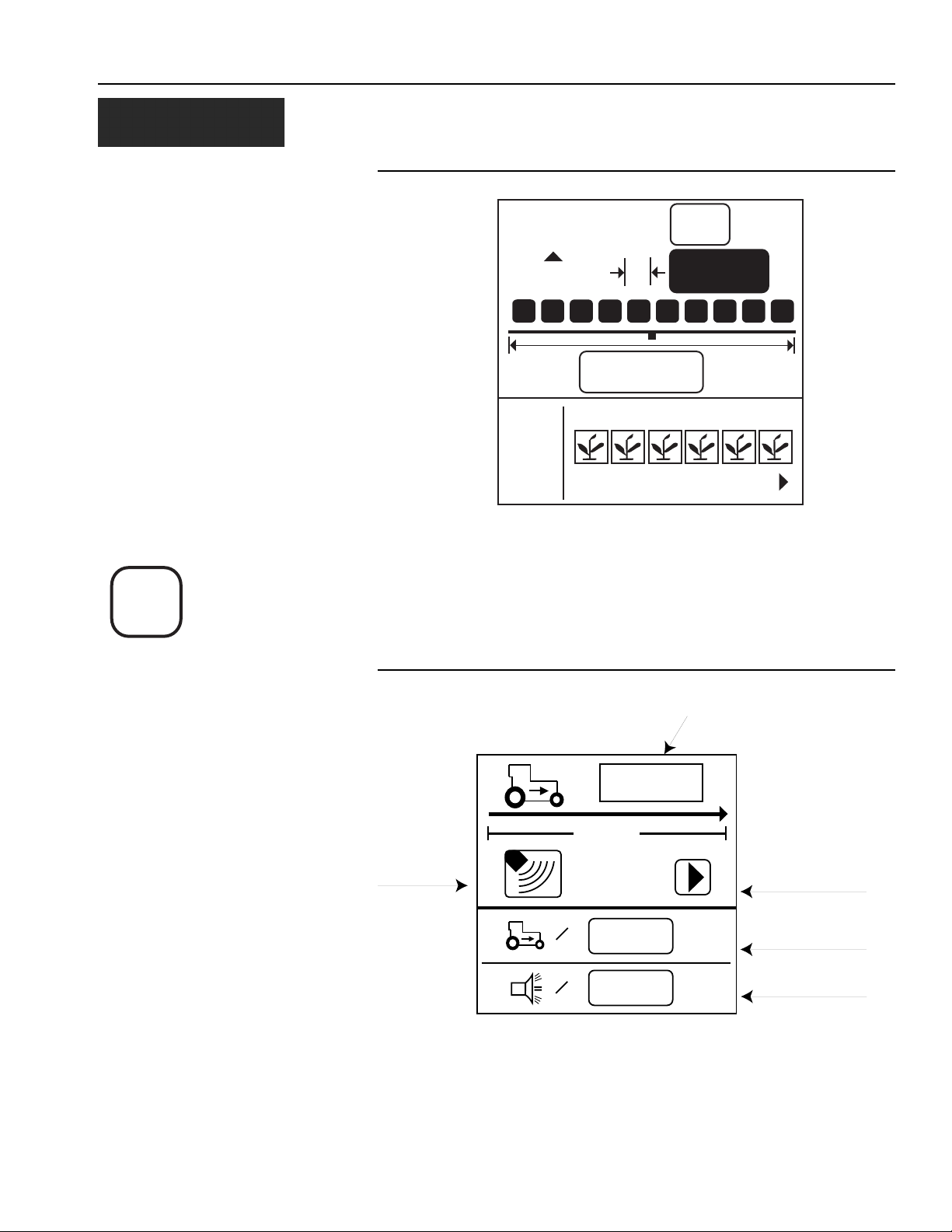

Figure 3

Planter Configuration Screen

Planter

Configuration

123

20.00

1 2 3 5 6

I/O

PLANTER CONFIG #

16

#

in

15.0

ft

4

# of Rows

Row Spacing

Row Setup

ENTER

Enter key

Left and Right Arrow keys

PM300, PM332, PM400 Planter Monitors

11001-1372-200606

The PM300, PM332, and PM400 can store three planter configurations for

users with split row planters or multiple planters and seeders, but many

users store only one configuration.

To select a planter configuration number (1, 2, or 3)

1. Press Enter to highlight arrow indicator ( S ) and move using the Left

and Right keys to make a selection.

2. Press Enter to confirm the selection.

NUMBER OF ROWS

To change number of rows:

1. Use the Left and Right Arrow keys to highlight the number of rows

field.

QUICK START GUIDE / 9

Page 16

OPERATOR’S MANUAL

ENTER

Enter

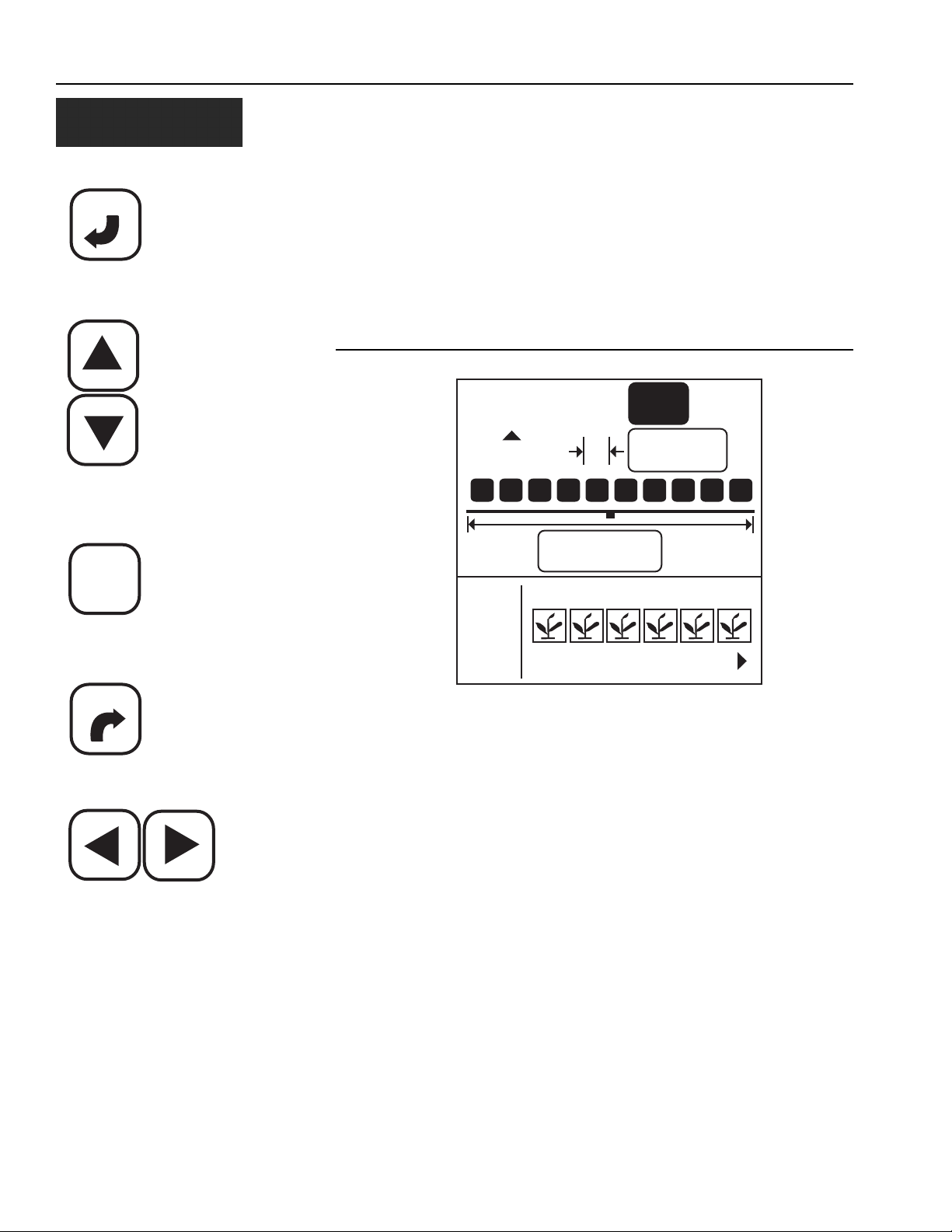

2. Press Enter to modify the number of rows as shown in Figure 4. Use

the Right and Left Arrow keys to select the digit to change. Use the

Up and Down Arrow keys to edit the selected digit. Use the Up Arrow

key to increase the value; use the Down Arrow key to decrease the

value.

3. Press the Enter key to confirm the selection. Enter the row spacing in

the same manner.

4. Once the new values are entered, select either the Escape or Operate

key to return to the Operate (main) screen.

Figure 4

Number of Rows Screen

Up and Down Arrow keys

OPERATE

Operate key

ESCAPE

Escape key

Left and Right Arrow keys

123

15.00

1 2 3 5 6

I/O

NUMBER OF ROWS

ROW SPACING

To change row spacing:

1. Press Planter Setup key.

2. Use the Down arrow to highlight the row spacing field (refer to Figure

5).

3. Press Enter to select the field.

4. Use the Left and Right Arrow keys to select a digit for editing.

5. When a digit is highlighted, use the Up and Down Arrow keys to edit

the value displayed. Use the Up Arrow key to increase the value; use

the Down Arrow key to decrease the value.

6. When the field shows the correct planter row spacing, press Enter to

confirm the selection.

7. Once the new values are entered, select either the Escape or Operate

key to return to the Operate (main) screen.

12

#

in

15.0

ft

4

10 / QUICK START GUIDE

PM300, PM332, PM400 Planter Monitors

11001-1372-200606

Page 17

OPERATOR’S MANUAL

Figure 5

Row Spacing Screen

GROUND

SPEED

SETUP

Ground Speed Setup key

123

in

10.00

1 2 3 5 6

I/O

ROW SPACING

#

8

15.0

ft

4

GROUND SPEED CONFIGURATION

To perform Ground Speed Configuration, select the Ground Speed Setup

key. The Ground Speed Setup screen will display (refer to Figure 6).

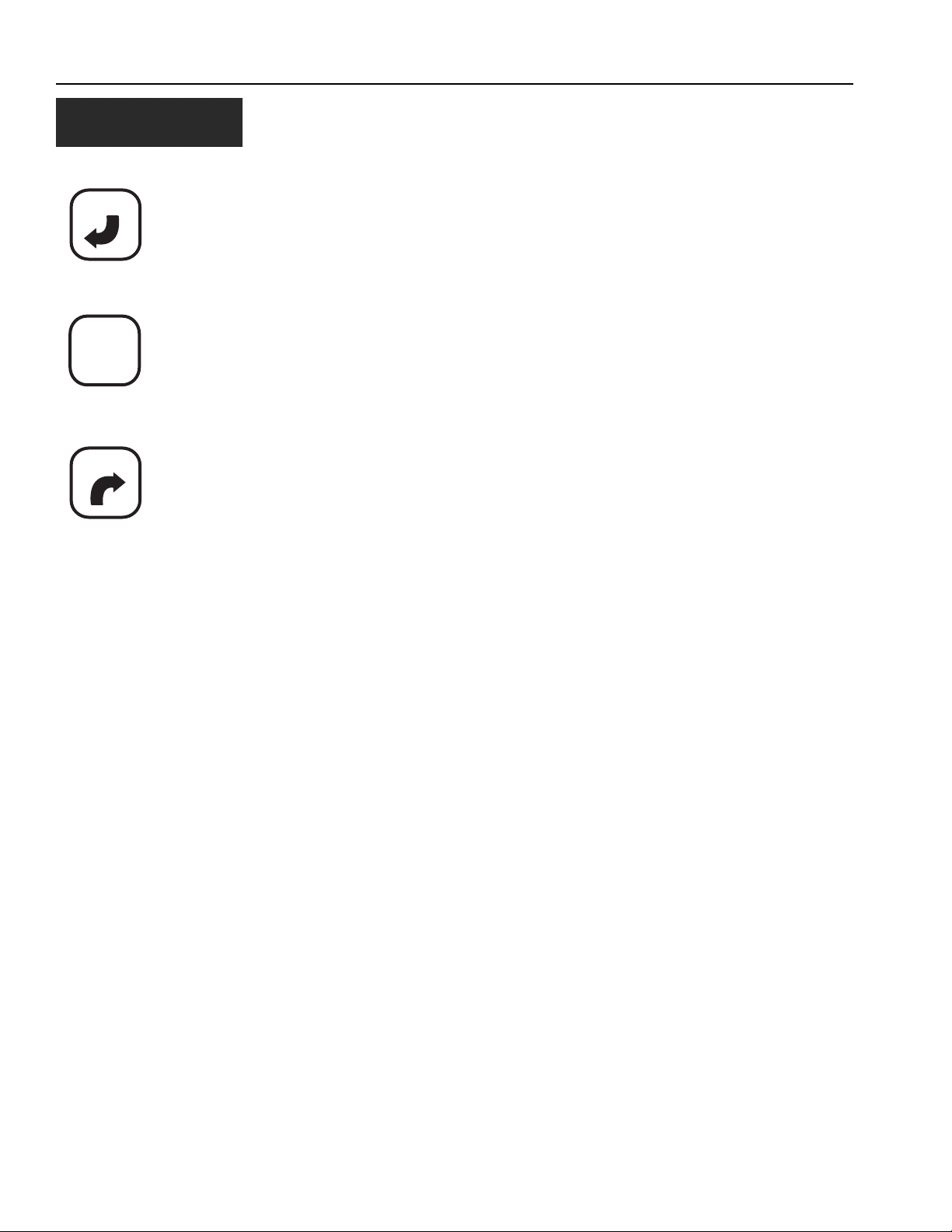

Figure 6

Ground Speed Setup Screen

Ground Speed

Source

(Radar or

Reluctance)

400 ft

=

=

# of pulses in 400 ft.

6096

0.0

0.0

mph

mph

Start symbol (will

change to

Stop symbol when

test begins

Manual ground

speed (optional)

Maximum speed

alarm (optional)

PM300, PM332, PM400 Planter Monitors

11001-1372-200606

QUICK START GUIDE / 11

Page 18

OPERATOR’S MANUAL

ENTER

Enter key

OPERATE

Operate key

ESCAPE

To perform a new calibration:

1. Measure a 400 foot (122 meter) course, clearly marking the beginning

and end.

2. Using the Arrow keys, highlight the Start softkey on the screen ( X ).

3. Begin moving the tractor forward at 2-5 mph.

4. When the tractor is even with the beginning marker, press the Enter

key to start the 400-foot calibration.

5. After the calibration has begun, the softkey on the screen will change

to a Stop ( ) softkey. Drive 400 feet and stop the vehicle.

6. Select the Enter key to stop the calibration. The new calibration factor

will be displayed on the window.

7. Once the Stop key is selected, the value will be saved upon screen

exit. Selecting the Escape key while the calibration is running will not

save the value.

8. Select either the Escape or Operate key to return to the Operate

(main) screen.

Escape key

HELP CARD

The help card (Figure 7) may be cut out to provide a compact reference for

definitions, set-up screens, and general operating information.

12 / QUICK START GUIDE

PM300, PM332, PM400 Planter Monitors

11001-1372-200606

Page 19

OPERATOR’S MANUAL

Figure 7

Help Card

123.4

10

#

123

in

12.50

1 23

I/O

789

Planter Setup

15.0

ft

456

10 11 12

400 ft

=

=

Ground Speed

33.3

16.8

16.9

123456789

Operate (main) Accessory Setup

1

6096

0.0

0.0

3,0

3,0

3,0

mph

mph

%

+

Limits Setup

1

9,521

2

9,521

3

9,521

4

9,521

5

9,521

6

9,521

7

8

9

9,521

9,521

9,521

Seed Count

3

%

0.0

0.0

0.0

0.0

%

0

+

10

9,521

11

9,521

12

9,521

13

9,521

14

9,521

15

9,521

16

9,521

17

9,521

18

9,521

43.8

1234

%

123

M

E

E

User Preference

Speed Area Distance

5.1

0.0

17.217.2

14.1

31.4

0.0

Use keys to select screen

Use (arrow keys) to select item

Use ENTER to modify highlighted item

Use (arrow keys) to change items/digits or to select digits

Use ENTER to accept data or OPERATE to accept data and return to the

OPERATE screen

Population

Average

Seed Spacing Seeds per Distance

...

Functions (top half )

1

2

12

123456789

Field Area 1

Display and Service Menus

123.4

43.8

1234

M: 0305022109

1

B: 0205030714

2

1

aA

123

Rows output

(bottom half )

1

3

10,910.0

1

Field Area 2 Total Area

2

H: 1

25.7

12.8

2

Service

0000

0000

ac

III.I

III.I

123

2

...

1,2,3

Population

Seed Spacing Seeds per Distance

Row

Scan

Minimum

Population

Seed Spacing Seeds per Distance

Maximum

Average

Warning Hi/Lo No flow

!

Start

Alarm

Stop

English/Metric

M

E

...

...

Reset

Back light

Speed

Area/hour Distance

Shaft

Hopper

All Rows Failed

Planter Lifted

Security Password Save Password

Graphic/Text Label

Population Adjust+Response Rate

aA

Fan Flow

No Speed Input

Configuration

PM300, PM332, PM400 Planter Monitors

11001-1372-200606

QUICK START GUIDE / 13

Page 20

OPERATOR’S MANUAL

14 / QUICK START GUIDE

PM300, PM332, PM400 Planter Monitors

11001-1372-200606

Page 21

OPERATOR’S MANUAL

KEY FUNCTIONS

Figure 8

Keys

ESCAPE

ENTER

On/Off key

Alarm Cancel key

PLANTER

SETUP

OPERATE

GROUND

SPEED

SETUP

ACCY

SETUP

LIMITS

SETUP

SEED

COUNT

MODE

DISPLAY

&

SERVICE

SPEED

AREA

MODE

PMXXX

ON/OFF KEY

The On/Off key activates the unit. During power up, the monitor performs

internal self-tests, illuminates the display, sounds the alarm, and determines

which sensors are connected to the system. Pressing and holding the key

for one second when the power is ON will turn the power OFF, independent

of the screen being displayed.

ALARM CANCEL KEY

During normal operation, selecting the Alarm Cancel key acknowledges

the alarm condition displayed on the screen. Active row alarms are reset

after an ALL ROWS FAILURE condition or a power down-up sequence

occurs. If the error condition continues, the key must be selected again to

cancel the alarm. When no alarms are active, the volume may be modified

by selecting and holding the Alarm Cancel key.

PM300, PM332, PM400 Planter Monitors

11001-1372-200606

KEY FUNCTIONS / 15

Page 22

OPERATOR’S MANUAL

ENTER

Enter key

ESCAPE

Escape key

Up and Down Arrow keys

ENTER KEY

TTe Enter key selects a highlighted item for data modification. After

changing the parameter values, Enter accepts the modified data.

ESCAPE KEY

On the Operate (main) screen, select and hold the Escape key for four

seconds to clear an area accumulator if it is located on the top line of the

display.

When navigating through sub-menus, the Escape key moves the user back

one selection. After changing parameter values, selecting Escape accepts

the modified data. The Escape key also serves as an alarm cancel key.

UP AND DOWN ARROW KEYS

On the Operate (main) screen, the Up and Down Arrow keys are used to

manually select the parameters viewed at the top of the display. They are

inactive if all parameters are already displayed (number of parameters are

equal to or less than number of lines).

On the Operate (main) screen, the arrows are used to navigate between

options. On set-up screens, the arrows are used to navigate between

options or to change a digit/option.

Left and Right Arrow keys

OPERATE

Operate key

PLANTER

SETUP

Planter Setup key

LEFT AND RIGHT ARROW KEYS

On the Operate (main) screen, the Left and Right Arrow keys are used to

manually select the rows viewed at the bottom of the display. They are

inactive if all rows are already displayed. On other screens, the arrows are

used to navigate between options.

OPERATE KEY

The Operate (home) key is used to return the user to the Operate (main)

screen.

If data is changed, it is saved when this key is selected.

PLANTER SETUP KEY

The Planter Setup key is used to navigate to the Planter Setup screen for

input of the number of rows, row spacing, implement width (optional), and

row type (population — default, blockage, skipped, or disabled).

If data on another screen is changed, it is saved when this key is selected.

16 / KEY FUNCTIONS

PM300, PM332, PM400 Planter Monitors

11001-1372-200606

Page 23

OPERATOR’S MANUAL

GROUND

SPEED

SETUP

Ground Speed Setup key

GROUND SPEED SETUP KEY

The Ground Speed Setup key is used to navigate to the Ground Speed

Setup screen for input of the ground speed calibration (or manual entry of

ground speed calibration number), manual ground speed (used if no ground

speed is available), and ground speed maximum limit (optional).

If data on another screen is changed, it is saved when this key is selected.

LIMITS SETUP KEY

LIMITS

SETUP

Limits Setup key

DISPLAY

&

SERVICE

Display and Service key

ACCY

SETUP

Accessory Setup key

The Limits Setup key is used to navigate to the Limits Setup screen for

input of the upper limit (optional), target population value (optional), lower

limit (optional), population adjustment factor (optional for sensors that count

less than 100% of all seeds), and response rate (optional to increase or

decrease the console’s response rate).

If data on another screen is changed, it is saved when this key is selected.

DISPLAY AND SERVICE KEY

The Display And Service key is used to navigate to the Display & Service

Setup screen for access to the function, row indicators, service, and

security sub-menus; English/Metric units selection; display backlight

intensity; and alarm volume.

If data on another screen is changed, it is saved when this key is selected.

ACCESSORY SETUP KEY

The Accessory Setup key is used to navigate to the Accessory Setup

screen for selection of a fan (RPM) / shaft (RPM) / or flow (G/MIN or L/min)

labels, upper and lower alarm limits, and calibration (or manual calibration

number entry).

If data on another screen is changed, it is saved when this key is selected.

SEED

COUNT

MODE

Seed Count Mode key

SPEED

AREA

MODE

Speed Area Mode key

PM300, PM332, PM400 Planter Monitors

11001-1372-200606

SEED COUNT MODE KEY

The Seed Count Mode key is used to navigate to the Seed Count screen.

This mode allows users to test planters for proper operation prior to field

use.

If data on another screen is changed, it is saved when this key is selected.

SPEED AREA MODE KEY

The Speed Area Mode key is used to navigate to the Speed Area

Distance screen. This mode allows use of the console for non-planting

operations. This mode is also used to start, stop, or clear the three

independent area accumulators (FIELD AREA 1, FIELD AREA 2, and

TOTAL AREA).

If data on another screen is changed, it is saved when this key is selected.

KEY FUNCTIONS / 17

Page 24

OPERATOR’S MANUAL

6096

00.0

mph

400ft

=

0.0

mph

=

GNDSPD CONSTANT

A highlighted digit can be edited by

using the Arrow keys on the Control

Panel. Press Enter to accept

and confirm the selection.

ENTER

ESCAPE

EDITING SCREEN FIELDS USING KEYS

The term “highlight” used throughout the manual refers to pressing a key to

activate and move the blinking cursor until the desired digit on the screen is

highlighted. Pressing Enter accepts and confirms the selection.

HIGHLIGHTED DIGIT FOR EDITING

18 / KEY FUNCTIONS

PM300, PM332, PM400 Planter Monitors

11001-1372-200606

Page 25

OPERATOR’S MANUAL

INSTALLATION

The monitor is tested and inspected before shipping to ensure the unit is

fully operational and meets measurement specifications. Inspect for

damage that may have occurred during transit. Save all packing materials

until the inspection is complete. If damage is found, immediately file a claim

with the carrier and notify your DICKEY-john Sales Representative.

STANDARD MOUNTING BRACKET

NOTE: When mounted to a vertical

surface, a tie-wrap may be

used to secure the cables to the

bottom of the bracket.

Install the mounting bracket at the desired location using locally acquired

hardware. Install the console to the bracket by aligning the console mating

grooves with the bracket and sliding the console onto the bracket until the

snap engages.

Figure 9

Standard Mounting Bracket

Slide console

until snap

engages

Mount on vehicle

with locally acquired

hardware

PM300, PM332, PM400 Planter Monitors

11001-1372-200606

The console must not obstruct the view of the operator or interfere

with the operation of the tractor.

To prevent damage to the console, be sure the snap fully engages

during installation.

INSTALLATION / 19

Page 26

OPERATOR’S MANUAL

OPTIONAL MOUNTING 3D ADJUSTABLE BRACKET

Separate the bracket halves from one another by loosening the wing bolt.

Install the upper bracket half into the console by sliding the bracket’s

rectangular section into the console mating grooves until the snap engages.

Install the bottom bracket half at the location of your choice using locally

acquired hardware.

Figure 10

Optional 3D Mounting Bracket

Slide console

until snap

engages

Wing bolts

Mount on vehicle

with locally acquired

hardware

The console must not obstruct the view of the operator or interfere

with the operation of the tractor.

To prevent damage to the console, be sure the snap fully engages

during installation.

20 / INSTALLATION

PM300, PM332, PM400 Planter Monitors

11001-1372-200606

Page 27

OPERATOR’S MANUAL

INSTALLING CONSOLE HARNESSES

Several harnesses are located at the bottom of the PM300, PM332, and

PM400. These include power, ground speed sensor, and sensor inputs

(rows, lift switch, two hopper levels, and one frequency function [shaft/fan/

flow]).

Figure 11

Console Harnesses

ESCAPE

ENTER

Battery

GROUND

DISPLAY

LIMITS

PLANTER

SPEED

&

SETUP

SETUP

SETUP

SERVICE

PMXXX

SPEED

SEED

ACCY

AREA

COUNT

OPERATE

SETUP

MODE

MODE

+

Ground

Implement

*

Speed

(rows and accessories)

*PM300 does not have a second cable

PM332 has a 9 pin accessory cable

PM400 has a 37-pin cable

1. Route the power harness to a +12 V source near the battery if

possible.

2. Route the ground speed sensor harness connection to the RADAR,

Hall Effect, or GPS ground speed sensor.

3. Route the implement harness to the location of choice, typically near

the drawbar.

PM300, PM332, PM400 Planter Monitors

11001-1372-200606

The harnesses must not obstruct movement of the operator or of

the moving parts of the tractor or implement. Take care when

routing harnesses to secure them at proper locations; provide

slack as needed to allow for movement.

Poor +12 V connections may cause intermittent console operation.

Be sure to connect the power harness to a clean, well-conditioned

source (direct battery connection is preferred).

INSTALLATION / 21

Page 28

OPERATOR’S MANUAL

INSTALLING IMPLEMENT HARNESS AND SENSORS

The implement harness provides custom fit and functions required by the

implement. Each harness branch is labeled for location (row 1, row 2, etc.)

or sensor (lift switch) for routed connection. Some sensors may require

special adapters for connection.

Figure 12

Implement Harness/Sensors

Implement connector(s)

rows and accessories

Row1Row2Row3Row4Row5Row

6

Row

Row

7

8

Seed sensors

1. Install sensors onto seed tubes using tie-wraps.

2. Route implement harness to the appropriate locations; provide slack

near moving parts to allow for movement. Attach harness to the

implement using tie-wraps.

3. Make sure the hitch connections will connect to the tractor connections

with the proper amount of slack for implement movement.

The harnesses must not obstruct moving parts of the tractor or

implement. Take care when routing harnesses to retain them at

proper locations with adequate slack for movement.

22 / INSTALLATION

PM300, PM332, PM400 Planter Monitors

11001-1372-200606

Page 29

OPERATOR’S MANUAL

PLANTER

SETUP

Planter Setup key

ADVANCED SETUP

The monitor is designed for ease of basic monitoring by new users while

supporting expanded features for advanced users. The user may decide

which features to configure.

PLANTER AND GROUND SPEED (REQUIRES DATA ENTRY)

The two setup screens that require input for the system to function as a

monitor are the Planter Setup screen (Figure 13) and the Ground Speed

Setup screen (Figure 14).

Figure 13

Planter Setup Screen

Planter

Configuration

123

20.00

1 2 3 5 6

I/O

PLANTER CONFIG #

ROW SETUP (AUTO ASSIGNED)

The console will automatically assign the number of rows defined on the

Planter Setup screen as ON (population rows).

Rows may be configured to ON (population), OFF (split row), FLOW

(blockage), or DISABLED.

• When ON is selected (plant), the row is active and the console

will detect sensors and seed flow.

16

#

in

15.0

ft

4

# of Rows

Row Spacing

Row Setup

PM300, PM332, PM400 Planter Monitors

11001-1372-200606

• When OFF is selected (blank), the row is removed and remaining

rows are re-numbered. This is used for split row systems where every

other row or sets of internal rows are not planting. Their corresponding

row number is ignored, allowing for true planting operations to be

displayed on the monitor.

ADVANCED SETUP / 23

Page 30

OPERATOR’S MANUAL

ENTER

Enter key

Left and Right Arrow keys

• When DISABLED is selected (circle with slash), the row input is

ignored. The row number will be displayed. This is used when a row or

sensor is malfunctioning and the operator wants to disable monitoring

on that row.

• When FLOW is selected (funnel), the row will not be included for

population calculations but will be monitored for flow. The flow rows will

be used to detect flow (fertilizer or seeds) and alarm if the flow falls

below two pulses per second.

The Planter Setup screen must include the number of rows and the row

spacing or implement width for the console to properly display population.

Up to three individual configurations can be programmed and supports split

row planters (CONFIGURATION 1 for NORMAL and 2 for SPLIT ROW) and

a separate seeder or drill (CONFIGURATION 3).

To configure row setup:

1. Highlight the 123 (refer to Figure 13) at the upper left corner of the

screen

2. Press the Enter key

3. Use the Left and Right Arrow keys to select the appropriate planter

configuration.

4. Press Enter to accept selection.

5. Press the Down Arrow key to highlight the I/O icon for row setup.

6. Press the Enter key to select the icon and highlight the first row unit.

7. Use the Up or Down Arrow key to toggle through the four possible

configurations: On, Off, Disabled or Flow.

8. Use the Left or Right Arrow key to highlight another row unit for

reconfiguring.

9. Press the Enter key to save the selection.

10. Press Enter key again to select another row to change and the Left or

Right Arrow key to move to other row units to reconfigure.

11. When finished, press Operate key to return to the Operate (main)

screen.

Up or Down Arrow keys

GROUND

SPEED

SETUP

Ground Speed Setup key

24 / ADVANCED SETUP

GROUND SPEED SETUP

The Ground Speed Setup screen must include a calibration factor for

proper calculation and display of ground speed. Also included on the

Ground Speed Setup screen are a calibration aid, a manual ground speed

value, and a maximum speed alarm. The calibration aid may be used to

measure the calibration factor, which is the number of pulses in 400 ft (122

m). The manual ground speed (optional) may be used when a ground

speed sensor is not installed or has failed in the field. The maximum speed

alarm (optional) provides the user with an over-speed alarm.

PM300, PM332, PM400 Planter Monitors

11001-1372-200606

Page 31

OPERATOR’S MANUAL

Figure 14

Ground Speed Setup Screen

# of pulses in 400 ft.

6096

NOTE: To verify that the correct

calibration number has been

obtained, move to the Speed

Area Mode screen. Verify that

the speed matches the

vehicle’s speedometer or

remeasure the 400-foot

distance.

Ground Speed

Source

(Radar or

Reluctance)

400 ft

=

=

0.0

0.0

mph

mph

Start symbol (will

change to

Stop symbol when

test begins

Manual ground

speed (optional)

Maximum speed

alarm (optional)

MANUAL GROUND SPEED CONSTANT ENTRY

A manual ground speed value should only be entered when the ground

speed sensor or tractor radar has failed and no ground speed input is

available.

IMPORTANT: Entering a manual ground speed value when the ground

speed sensor or tractor radar is working properly and

connected to the monitor will interfere with the proper

operation of the planter monitor. Accumulated acreage

will not be recorded.

To enter a manual ground speed value:

Up or Down Arrow keys

ENTER

Enter key

PM300, PM332, PM400 Planter Monitors

11001-1372-200606

1. Press the Ground Speed Setup key to access the ground speed setup

screen.

1. Use the Down Arrow key to highlight the manual ground speed value

(refer to Figure 6).

2. Select the Enter key to modify the constant.

3. Use the Arrow keys to select digits, increment, and decrement values.

4. Select the Enter key to accept the new number.

5. Once the new values have been entered, select either the Escape or

Operate key to return to the Operate (main) screen.

Any non-zero value will activate manual ground speed. Set manual ground

speed to zero to disable.

To verify that the correct calibration number has been obtained, move to the

Speed Area Mode screen.

1. Press the Speed Area Mode key.

ADVANCED SETUP / 25

Page 32

OPERATOR’S MANUAL

1

5.1

0.0

2

17.217.2

12

14.1

31.4

0.0

Field Area 1

Field Area 2

Total Area

Distance

Reset

Counter

Stop

Start

SPEED

AREA

MODE

2. Verify that the speed matches the vehicle’s speedometer or

re-measure the 400-foot distance.

Figure 15

Speed Area Mode Screen

ACCY

SETUP

ACCESSORY SETUP (OPTIONAL)

To add an auxiliary sensor and its performance characteristics (calibration

values, limits, etc.) to the monitoring inputs, it must be activated by entering

a calibration constant. If minimum or maximum alarms are desired, the

limits may be added to the calibrated sensors. A fan, shaft, or flow sensor

may be monitored with HI and/or LOW alarms or no alarm values. Refer to

Figure 16.

26 / ADVANCED SETUP

PM300, PM332, PM400 Planter Monitors

11001-1372-200606

Page 33

OPERATOR’S MANUAL

Figure 16

Accessory Screen

ACCY

SETUP

Left and Right Arrow keys

Fan

Shaft

Flow

3,0

3,0

3

3,0

To enter a calibration constant:

1. Press Accessory Setup key.

2. Use the Left and Right key to select fan, shaft or flow symbol.

3. Use the Down Arrow key to change high and low alarm values.

4. Press Enter to Highlight digit to change. If the calibration factor is

unknown, the monitor can determine the calibration factor by using the

built-in calibration mode.

ENTER

Enter key

Start symbol

Stop symbol

PM300, PM332, PM400 Planter Monitors

11001-1372-200606

Assure equipment is configured to be operated safely. Shaft/fan

calibration requires movement in associated equipment and

revolution counting. Flow calibration requires liquid dispensing,

catching, and measurement.

To perform a sensor calibration, highlight the Start symbol. Assure the

system is in a safe state. Start the monitor calibration by selecting the Enter

key. The Start symbol (triangle) will change to a Stop symbol (square).

Activate the shaft, fan, or flow. Count the revolutions (shaft/fan) or catch

liquid (flow) while the monitor measures pulses. Deactivate the shaft, fan, or

flow. Stop the monitor calibration by selecting the Enter key again. Highlight

the revolutions or liquid level window. Select the Enter key. Enter the

number of revolutions (shaft/fan) or gallons (flow).

ADVANCED SETUP / 27

Page 34

OPERATOR’S MANUAL

LIMITS

SETUP

LIMITS SETUP (POPULATION) (OPTIONAL)

The Limits Setup screen allows users to define several population features

(refer to Figure 17). Users may define a target population, a minimum or

under population alarm limit, a maximum or over population alarm limit, a

population adjustment factor, and a population response rate.

Figure 17

Limits Setup Screen

Up or Down Arrow keys

Left and Right Arrow keys

Hi Alarm

Target Population

33.0

%

30.0

27.0

%

%

+

HI POP ALARM

TARGET POPULATION

Target population is defined in 1000s of seeds per acre or hectare,

dependent on the unit of measurement selected. If no value is entered, the

monitor uses average population to calculate alarms or row population

indicators.

With the limits set up screen displayed as shown in Figure 17,

1. Use the Down Arrow key to highlight the target population field.

2. Press the Enter key to highlight field.

3. Use the Left or Right Arrow key to select a digit for editing.

4. When a digit is highlighted, use the Up or Down Arrow keys to edit

the value displayed.

5. When the field shows the desired target population, press the Enter

key to confirm the selection.

6. Select either the Escape or Operate key to return to the Operate

(main) screen.

0

%

+

Lo Alarm

Population Adjust

Population Filter

ENTER

Enter key

28 / ADVANCED SETUP

If no value is entered, the monitor uses average population to calculate

alarms or row population indicators.

PM300, PM332, PM400 Planter Monitors

11001-1372-200606

Page 35

OPERATOR’S MANUAL

OPERATE

Up or Down Arrow keys

ENTER

Enter key

HI POPULATION/LOW POPULATION

The Hi population and Low population values determine when an alarm or

row indicator displays to warn the operator about a population problem. If

the percentage (%) box is checked, the values are percentage based. For

example, 10% of 30,000 seeds/acre for the over population setting (33,000

seeds/acre) and for the under population setting (27,000 seeds/acre) (refer

to Figure 17). If the percentage (%) box is not checked, the values are

population based and expressed in 1000s of seeds per acre or hectare. The

over population and under population values are independent of each other

and do not have to be the same percentage value.

To change the percentage (%) box setting,

1. Use the Up or Down Arrow key to highlight the percentage (%) box.

2. Press the Enter key to toggle the setting from checked to unchecked.

To change the population value settings:

1. Use the Up or Down Arrow key to highlight the hi alarm or low alarm

field.

2. Press the Enter key to highlight the field for editing.

3. Use the Left or Right Arrow key to select a digit for editing.

4. When a digit is highlighted, use the Up or Down Arrow keys to edit

the value displayed.

5. Press Enter key to confirm the selection.

6. Press the Operate key to return to the Operate (main) screen.

Left and Right Arrow keys

POPULATION ADJUSTMENT

A population adjustment provides a means to display populations nearer

the actual versus the sensed seeding rates. This is useful when sensors do

not detect doubles, triples, etc.

To change the over population value setting:

1. Use the Up or Down Arrow key to highlight the field.

2. Press the Enter key to highlight the field for editing.

3. Use the Left or Right Arrow key to select a digit for editing.

4. When a digit is highlighted, use the Up or Down Arrow keys to edit

the value displayed.

5. Press Enter key to confirm the selection.

6. Press the Operate key to return to the Operate (main) screen.

POPULATION RESPONSE RATE

The population response rate is used to provide population display stability

for planters with few rows versus many or when the sensed application rate

does not match the actual application rate. Use the Population Filter to

stabilize population and alarm reporting.

To change population response rate:

1. Move the slide to the right when planting high seed rates and to the left

when planting low seed rates. (refer to Figure 17).

2. Press the Operate key to return to the Operate (main) screen.

PM300, PM332, PM400 Planter Monitors

11001-1372-200606

ADVANCED SETUP / 29

Page 36

OPERATOR’S MANUAL

DISPLAY

&

SERVICE

UNITS OF MEASUREMENT, BACKLIGHTING AND ALARM VOLUME CONTROL

The display screen can be customized by changing the units of

measurement to English or Metric, control backlight intensity and increase

or decrease alarm volume.

M

E

E

Units

Backlighting

Volume

Service icon

Figure 18

Display & Service Screen

123.4

M

E

123.4

43.8

43.8

1234

1 2 3

E

Service

Security

Units, Backlight, Alarm Volume

Upper

Setup

Lower

Setup

To change Units, Backlight, and Alarm Volume:

1. Press Display & Service key.

2. Press the Down Arrow key to highlight Units, Backlight or Alarm

Volume icon.

3. Press Enter to highlight the setting to change and the Up and Down

Arrow key to cycle through selection.

4. Press Enter to confirm the desired selection.

Up or Down Arrow keys

ENTER

Enter key

30 / ADVANCED SETUP

SERVICE SCREEN

The service screen provides information about the monitor’s software and

hardware versions, total hours of operation, total acres covered, battery

voltage, hopper level 1 and 2 sensor status, and lift switch status. (refer to

Figure 19).

To display the service screen:

1. Press the Display & Service key.

2. Highlight the Service icon and press Enter.

PM300, PM332, PM400 Planter Monitors

11001-1372-200606

Page 37

OPERATOR’S MANUAL

Figure 19

Service Screen

M: 0305022109

B: 0205030714

H: 1

25.7

910.0

ac

Hardware and

software versions

Total hours of

operation

Total acres

covered

Up or Down Arrow keys

Security icon

ENTER

Enter key

ESCAPE

Escape key

12.8

Battery voltage

1

Hopper Level 1 and 2

sensor status

SECURITY SCREEN

Security features allow password protection security levels to be activated

(refer to Figure 20). This prevents unauthorized personnel from modifying

key parameters in the field.

The password screen allows the operator to individually lock screens to

assure they are not modified.

To Lock and Unlock Screens:

1. Press the Display & Service key.

2. Using the Arrow keys, highlight the Security icon and press the Enter

key to enter a password.

3. Modify the digits and select the Enter key again to accept the

password.

4. Highlight the Configuration key and press Enter to navigate to the list

of screens.

5. Use the Up or Down Arrow key to highlight icon for editing.

6. Press Enter to select the Lock/Unlock icon.

7. Lock or unlock screens by pressing the Up or Down Arrow keys.

8. Press Enter key to accept Lock or Unlock.

9. Select the Escape key to return to the Password screen.

10. Highlight the padlock and select the Enter key to toggle the unlocked

state to locked. The selected screens will require input of the password

prior to modification.

2

Lift switch

status

PM300, PM332, PM400 Planter Monitors

11001-1372-200606

ADVANCED SETUP / 31

Page 38

OPERATOR’S MANUAL

Figure 20

Security Screen and Screens That May Be Locked

0000

Configuration softkey

0000

Configuration

III.I

III.I

+

-

l

...

1,2,3

Screens that may be locked

1 2 3

32 / ADVANCED SETUP

PM300, PM332, PM400 Planter Monitors

11001-1372-200606

Page 39

OPERATOR’S MANUAL

AUXILIARY MODES

NOTE: Alarms are disabled in these

modes.

NOTE: A lift switch may be used to

more accurately monitor acre

accumulators and is required

for acreage monitoring in

n o n - p l a n t i n g o p e r a t i o n s .

If a manual ground speed is

selected, the area and distance

will not accumulate in this

mode.

SPEED

AREA

MODE

U

The monitors provide modes for alternate monitor use and row unit testing.

SPEED AREA MODE

The SPEED AREA mode is used for cultivating (Figure 21). This mode

includes start/stop/reset for Field Area 1, Field Area 2, Total Area (hc3/ac3),

and distance.

Figure 21

Speed Area Mode

S

5.1

Accessory field

not supported

on this model

0.0

Stop

Start

Reset

Counter

17.217.2

14.1

31.4

0.0

1

2

1 2

Field Area 1

Field Area 2

Total Area

Distance

SEED

COUNT

MODE

PM300, PM332, PM400 Planter Monitors

11001-1372-200606

SEED COUNT MODE

The SEED COUNT mode is used to determine row unit performance when

operating in a stationary manner. A reset for all rows is included (refer to

Figure 22).

AUXILIARY MODES / 33

Page 40

OPERATOR’S MANUAL

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

9,521

9,521

9,521

9,521

9,521

9,521

9,521

9,521

9,521

9,521

9,521

9,521

9,521

9,521

9,521

9,521

9,521

9,521

Reset option

Figure 22

Seed Counting Mode

34 / AUXILIARY MODES

PM300, PM332, PM400 Planter Monitors

11001-1372-200606

Page 41

OPERATOR’S MANUAL

192103114125136147158

16

16.8

33.1

Upper

Lower

OPERATE

MONITORING PLANTING

OPERATE SCREEN SETUP

The Operate (main) screen provides many tools for monitoring planting.

This screen can be immediately accessed from any other screen or

sub-menu by pressing the Operate key.

The Operate screen is divided into the upper parameter window and the

lower parameter window. The operator can customize the layout and

content of both windows, but the size of the individual windows is fixed.

(refer to Figure 23).

Figure 23

Operate Screen

PM300, PM332, PM400 Planter Monitors

11001-1372-200606

CUSTOMIZING THE UPPER PARAMETER WINDOW

The Operate (Main) screen may be customized by changing the number of

parameter lines to display in the upper window, the icon selected as text or

graphic, and the planting parameter reported for each line.

An example of five parameters selected:

1 = Average population

2 = Speed

3 = Field area

4 = Total area

5 = Shaft RPM

MONITORING PLANTING / 35

Page 42

OPERATOR’S MANUAL

Figure 24

Upper Parameters Screen

1

DISPLAY

&

SERVICE

123.4

43.8

1234

Upper Parameter icon

ENTER

Parameter

Lines

Increases/Decreases

Parameter Lines

Graphics/Text Mode

2

3

1

aA

SET UPPER PARAMS

Changing Number of Parameters

The parameter lines display can be configured to show 2, 3, or 4

parameters at one time by changing the size of the parameters. The Up

and Down Arrow keys are used at the Operate screen to scroll down to

see all parameters being monitored.

To Change the Number of Parameter Lines:

1. Press the Display & Service key with the Upper Parameter icon

highlighted.

2. Press the Enter key.

3. Press the Down Arrow key to highlight the magnifying glass.

4. Press Enter key to select the icon. Use the Up or Down Arrow key to

toggle through the options for 2, 3 or 4 display lines.

5. Press Enter to confirm the selection.

Enter key

Up or Down Arrow key

36 / MONITORING PLANTING

Figure 25

Parameter Line Options

37.2

25

33.1

5.4

33.5

1 2 3 4 5 6 7 8 9

10 11 12 13 14 15 16 17 18

2 Parameter Functions 3 Parameter Functions 4 Parameter Functions

8

1 2 3 4 5 6 7 8 9

10 11 12 13 14 15 16 17 18

4.5

1

1 2 3 4 5 6 7 8 9

10 11 12 13 14 15 16 17 18

PM300, PM332, PM400 Planter Monitors

33.1

16.8

12.5

16.8

11001-1372-200606

9

13

...

Page 43

OPERATOR’S MANUAL

DISPLAY

&

SERVICE

ENTER

Enter key

Parameters may be selected to display in numerical order from the following

list. (refer to MONITORING FUNCTIONS p. 39 for additional information).

• Average Population

• Average Seed Spacing

• Average Seeds Per Distance

• Population Row Scan

• Seed Spacing Row Scan

• Seed Per Distance Row Scan

• Minimum, Maximum, Average Row Population

• Minimum, Maximum, Average Row Spacing

• Minimum, Maximum, Average Spacing Per Distance

• Field Area 1

• Field Area 2

• Total Area 3

• Ground Speed

• Fan, Shaft, or Flow Frequency

Changing Graphic or Text Icons

The planting parameters display can be configured for text or graphic icons

in the upper window.

To Change the Graphic/Text Settings:

1. Press the Display & Service key with the Upper parameter icon

highlighted.

2. Press the Enter key.

3. Use the Down Arrow key to highlight the Graphic/Text icon.

4. Press Enter key to select the icon. Use the Up or Down Arrow key to

toggle to desired setting.

5. Press Enter to confirm selection.

123

Lower Parameter icon

Up and Down Arrow keys

PM300, PM332, PM400 Planter Monitors

11001-1372-200606

CUSTOMIZING THE LOWER PARAMETER WINDOW

The lower setup screen parameters can be modified to change the row

indicator type and size. Row indicator types include blinking box (blink rate

proportional to seeding rate), solid box (indicating row failure), bar graph, or

wiper gauge.

To Change the Row Indicator Type and Row Indicator Size:

1. Press the Display & Service key with the Lower Parameter row

indicator icon highlighted.

2. Press Enter to display the lower setup screen.

3. Highlight the Row Indicator Type or Row Indicator Size icon to change.

4. Press the Up or Down Arrow key to cycle through desired setting.

5. Press Enter to accept selection.

MONITORING PLANTING / 37

Page 44

OPERATOR’S MANUAL

1 2 3 4 5 6 7 8

blinking box

solid box

bar graph

wiper gauge

SET LOWER TYPE

Row Indicator

Type

Row Indicator

Size

Left and Right Arrow keys

Figure 26

Lower Parameters Screen

Row indicator size determines the number of rows displayed on the bottom

half of the screen and may be displayed in a small, medium, or large size as

shown in Figure 27. Default setting is non-blinking box, medium size.

When more rows are configured ON than are viewable, the monitor

automatically scrolls through the rows at 5 second intervals (bar graph with

36-row machine). The operator may use the Right and Left Arrow keys to

manually select the desired rows. Automatic scrolling will restart 10

seconds after a manual selection.

Average Population

Figure 27

Row Indicator Size

33.1

16.8

1 2 3 4 5 6 7 8 9

10 11 12 13 14 15 16 17 18

Small Row Indicators Medium Row Indicators

33.1

16.8

1 2 3 4 5 6 7 8 9

33.1

16.8

1 2 3 4 5 6

Large Row Indicators

AVAILABLE PLANTING PARAMETERS

AVERAGE POPULATION

Average Population displays the average of the planter's rows that are

configured for population in thousands of seeds per acre (s/ac) or

thousands of seeds per hectare (s/ha). The population response rate and

population adjustment may be modified on the target set-up screen. This

function may be labeled with a symbol or text, depending on the text/

graphic setting.

38 / MONITORING PLANTING

PM300, PM332, PM400 Planter Monitors

11001-1372-200606

Page 45

OPERATOR’S MANUAL

Minimum/Average/Maximum Population

Population Row Scan

...

Average Spacing

...

Minimum/Average/Maximum Spacing

...

Spacing Row Scan

MINIMUM/AVERAGE/MAXIMUM POPULATION

Minimum/Average/Maximum Population alternates the display of the

minimum row, planter average, and maximum row every two seconds.

When a minimum or maximum row is displayed, the corresponding symbol

is shown with the row number.

POPULATION ROW SCAN

Population Row Scan displays the population of each of the planter’s

rows. The displayed row is incremented every two seconds. After the last

row is displayed, the scan will resequence beginning with the first active

row.

AVERAGE SPACING

Average Spacing displays the average seed spacing (inches or cm) of the

planter's rows that are configured for population. This function may be

labeled with a symbol or text, depending on the text/graphic setting.

MINIMUM/AVERAGE/MAXIMUM SPACING

Minimum/Average/Maximum Spacing alternates the display of the

minimum row, planter average, and maximum row every two seconds.

When a minimum or maximum row is displayed, the corresponding symbol

is shown with the row number.

SPACING ROW SCAN

Spacing Row Scan displays the spacing of each of the planter's rows. The

displayed row is incremented every two seconds. After the last row is

displayed, the scan will resequence beginning with the first active row.

SEEDS PER DISTANCE

Seeds Per Distance

Minimum/Average/Maximum Seeds Per Distance

Seeds Per Distance Row Scan

PM300, PM332, PM400 Planter Monitors

11001-1372-200606

Average Seeds Per Distance displays the average seeds per foot (s/ft) or

seeds per meter (s/m) of the planter's rows that are configured for

population. This function may be labeled with a symbol or text, depending

on the text/graphic setting.

MINIMUM/AVERAGE/MAXIMUM SEEDS PER DISTANCE

Minimum/Average/Maximum Seeds Per Distance alternates the display

of the minimum row, planter average, and maximum row every two

seconds. When a minimum or maximum row is being displayed, the

corresponding symbol is shown with the row number.

SEEDS PER DISTANCE ROW SCAN

Seeds Per Distance Row Scan displays the seeds per distance of each of

the planter's rows. The displayed row is incremented every two seconds.

After the last row is displayed, the scan will resequence beginning with the

first active row.

MONITORING PLANTING / 39

Page 46

OPERATOR’S MANUAL

1

Field Area 1

2

FIELD AREA 1

Field Area 1 (ac1/ha1) displays the area of Field 1 in acres (ac) or hectares

(ha) depending on the English/Metric setting. This function may be labeled

with a symbol or text, depending on the text/graphic setting.

FIELD AREA 2

Field Area 2 (ac2/ha2) displays the area of Field 2 in acres (ac) or hectares

(ha) depending on the English/Metric setting. This function may be labeled

with a symbol or text, depending on the text/graphic setting.

Field Area 2

Total A re a

Speed

Area Per Hour

TOTAL A REA

Tota l Area (ac3/ha3) displays the total field area in acres (ac) or hectares

(ha) depending on the English/Metric setting. This function may be labeled

with a symbol or text, depending on the text/graphic setting.

SPEED

Speed displays vehicle speed in miles per hour (MPH) or kilometers per

hour (km/h) depending on the English/Metric setting. This function may be

labeled with a symbol or text, depending on the text/graphic setting.

AREA PER HOUR

Area Per Hour displays the current rate of area per hour in acres per hour

(ac/hr) or hectares per hour (ha/hr) depending on the English/Metric setting.

FAN

Fan displays the fan's speed in revolutions per minute (RPM).

SHAFT

Shaft function displays the shaft's speed in revolutions per minute (RPM).

FLOW

Fan

Shaft

Flow

40 / MONITORING PLANTING

Flow displays the flow rate speed in gallons per acre (g/ac) or liters per

hectare (l/ha) depending on the English/Metric setting.

PM300, PM332, PM400 Planter Monitors

11001-1372-200606

Page 47

OPERATOR’S MANUAL

ALARMS

NOTE: An audible 2-chirp alarm is also

output during navigation or data

entry to indicate an illegal or

nonfunctional key selection.

Alarm Cancel key

Primary operating alarms are displayed on the entire screen and are

accompanied by an audible alarm.

All monitor alarms are set to a default of Zero (0) and will not activate unless

programmed per the Advanced Setup section.

HOPPER LEVEL

Hopper level alarms activate when the seed level drops below the sensor

mounting level (refer to figure 28). Alarm can be silenced by pressing the

Alarm Cancel key.

Figure 28

Hopper 1 And 2 Alarms

HOPPER 1 LOW HOPPER 2 LOW

1

2

PM300, PM332, PM400 Planter Monitors

11001-1372-200606

ROW FAILURE

A row failure alarm occurs when the console detects less than 2 seeds per

second through the seed tube. This may result from a poor or faulty

connection to the seed sensor harness. This is a solid on alarm indicating a

problem has been detected and is silenced by pressing the Alarm Cancel

key as shown in Figure 29.

Once the Alarm Cancel key is pressed, the alarm will not sound again

unless:

1. Planting condition returns to a normal state and falls again below 2

seeds per second.

2. Power on/off sequence occurs before problem is corrected.

3. An All Rows Failure alarm occurs then the console again detects less

than 2 seeds per second through the seed tube.

ALARMS / 41

Page 48

OPERATOR’S MANUAL

1 3 5 7

Row Failure

Figure 29

Row Failure Display

ALL ROWS FAILURE

An All Row Failure alarm is a unique alarm identifier (8 chirps) that

differentiates from all other alarms and triggers when no seed flow is

detected from any row unit when ground speed is detected (refer to Figure

30).

Typical scenarious to activate an All Row Failure alarm:

1. Tractor is stopped while planter is in the ground.

2. Tractor is operating with planter lifted.

3. Normal “end of run” turn around.

Figure 30

All Rows Failure Display

42 / ALARMS

PM300, PM332, PM400 Planter Monitors

11001-1372-200606

Page 49

OPERATOR’S MANUAL

HI/LOW POPULATION WARNING

The Hi and Low population alarm triggers when seed flow drops below the

population alarm limit set on the Limits Setup screen. The alarm display will

beep and flash on the screen briefly indicating row units are over or under

the desired population (refer to Figure 31). The Operate (Main) screen will

display the row unit over or under population symbol until recorrected, All

Rows Failure occurs, or sensor mechanical problems are fixed.

Figure 31

Population Limit Warning Display

2 4 6 8

2 4 6 8

FAN SPEED LO/HI LIMIT WARNING

Fan speed alarms are triggered with a solid-on alarm when any fan speed

exceeds or falls below the value entered for Fan Speed Lo/Hi Limits in the

Setup mode (Refer to Figure 32). Alarm can be silenced by pressing Alarm

Cancel key, but will re-activate if problem is not resolved.

Figure 32

Fan Speed Limit Warning Display (Optional)

LOW FAN SPEED

HIGH FAN SPEED

PM300, PM332, PM400 Planter Monitors

11001-1372-200606

ALARMS / 43

Page 50

OPERATOR’S MANUAL

SHAFT SPEED LOW/HI LIMIT WARNING

Alarm sounds when any shaft speed exceeds or falls below the value

entered for Shaft Speed Lo or Hi Limits in the Setup mode (Refer to Figure

33). Alarm can be silenced by pressing Alarm Cancel key, but will

re-activate if problem is not resolved.

Figure 33

Shaft Speed Limit Warning Display (Optional)

LOW SHAFT SPEED

HI SHAFT SPEED

FLOW LOW/HI LIMIT WARNING

An alarm will sound when flow inputs exceed or fall below the value entered

for the Flow Lo or Hi Limits in the Setup mode. (Refer to Figure 34). Alarm

can be silenced by pressing Alarm Cancel key, but will re-activate if

problem is not resolved.

Figure 34

Flow Low/ Hi Limit Warning Display (Optional)

LOW FLOW RATE

HIGH FLOW RATE

44 / ALARMS

PM300, PM332, PM400 Planter Monitors

11001-1372-200606

Page 51

OPERATOR’S MANUAL

FAILED GROUND SPEED SENSOR (PLANTING DETECTED WITHOUT GROUND SPEED)

The failed ground speed sensor alarm triggers when planting is detected

with no ground speed being reported. This may result from a poor or faulty

connection to the speed sensor or from a defective sensor. This is a 4-chirp

alarm which is acknowledged by pressing the Alarm Cancel key, but will

re-activate until the problem is corrected (refer to Figure 35).

Figure 35

Ground Speed Sensor Failure Display

GROUND SPD FAILED

=

00.0

BATTERY HI/LOW

The battery hi/low alarm triggers when battery voltage is out of range - over

voltage and under voltage. The correct power operating range is 10-16

VDC. Alarm indicates an electrical problem exists that must be corrected.

The alarm cannot be shut off and will continue to sound until corrective

action is taken (refer to Figure 36).

Figure 36

Battery Failure Display

HI BATTERY VOLTAGE

16.5

PM300, PM332, PM400 Planter Monitors

11001-1372-200606

ALARMS / 45

Page 52

OPERATOR’S MANUAL

SELF-TEST FAILURE

The Self Test Failure alarm activates at every power cycle comparing

configured number of rows to number of rows detected. Any sensor not

found during self-test or inaccurate configuration will sound alarm and

display on the Operate (main) screen. The alarm can be acknowledged by

pressing the Alarm Cancel key, but will re-activate until problem is

resolved.

Figure 37

Self Test Failure

SELF TEST FAILURE

2 4 5 6

7 8 9

11

12

10

HI GROUND SPEED EXCEEDED (OPTIONAL)